Canon DU7-1175-000 User Manual

SERVICE

MANUAL

Professional

Puncher-A1

COPYRIGHT ©2005 CANON INC. CANON Professional Puncher-A1 REV. 0 PRINTED IN U.S.A.

DU7-1175-000

NOVEMBER 2005

REV. 0

TABLE OF CONTENTS

1. INTRODUCTION............................................................................... 3

1.1 INTRODUCTION .................................... ........................................................ 3

1.2 PROFESSIONAL PUNCHER-A1 FAQ’S ....................................................... 3

2. INSTALLATION................................................................................ 5

2.1 UNPACKING...................................................................................................5

2.2 UNIT SET-UP .................................................................................................5

2.3 UNIT OPERATION .........................................................................................5

3. MAINTENANCE................................................................................ 7

3.1 INSPECTION, CLEANING AND LUBRICATION ........................................... 7

3.2 DIE SET MAINTENANCE...............................................................................8

3.3 PREVENTATIVE MAINTENANCE SCHEDULE............................................9

3.4 SETTING THE RIGHT EXPECTATIONS.......................................................9

4. ADJUSTMENTS AND SPECIAL PROCEDURES ......................... 10

4.1 TOOL RECOMMENDATIONS .....................................................................10

4.2 DIE SET POSITION CRADLE ADJUSTMENT, CENTERING PUNCHED

HOLES................................................................................................................10

4.3 REMOVAL OF PUNCH MODULE................................................................13

4.4 GREEN BELT REPLACEMENT, ALIGNER PANEL REMOVAL,

EXPLANATION...................................................................................................14

4.5 GREEN BELT REPLACEMENT, PAPER ENTRANCE SIDE......................15

4.6 GREEN BELT REPLACEMENT, PAPER EXIT SIDE.................................. 21

4.7 BACK GAGE ASSEMBLY............................................................................28

4.8 INSTALLATION STEPS ...............................................................................28

4.9 TO CLEAR A PAPER JAM...........................................................................30

4.10 SOFTWARE UPDATE PROCEDURE........................................................31

5. TECHNICAL TROUBLESHOOTING.............................................. 32

5.1 THEORY OF OPERATION ..........................................................................32

5.2 TROUBLESHOOTING GUIDE CHART........................................................34

5.3 ELECTRICAL SCHEMATIC .........................................................................37

6. OPERATING CONTROLS.............................................................. 37

6.1 PUNCHING PATTERNS ..............................................................................37

6.2 CHANGING THE PUNCH DIE SETS........................................................... 37

6.3 PAPER CHIP DRAWER...............................................................................38

6.4 SERVICE......................................................................................................38

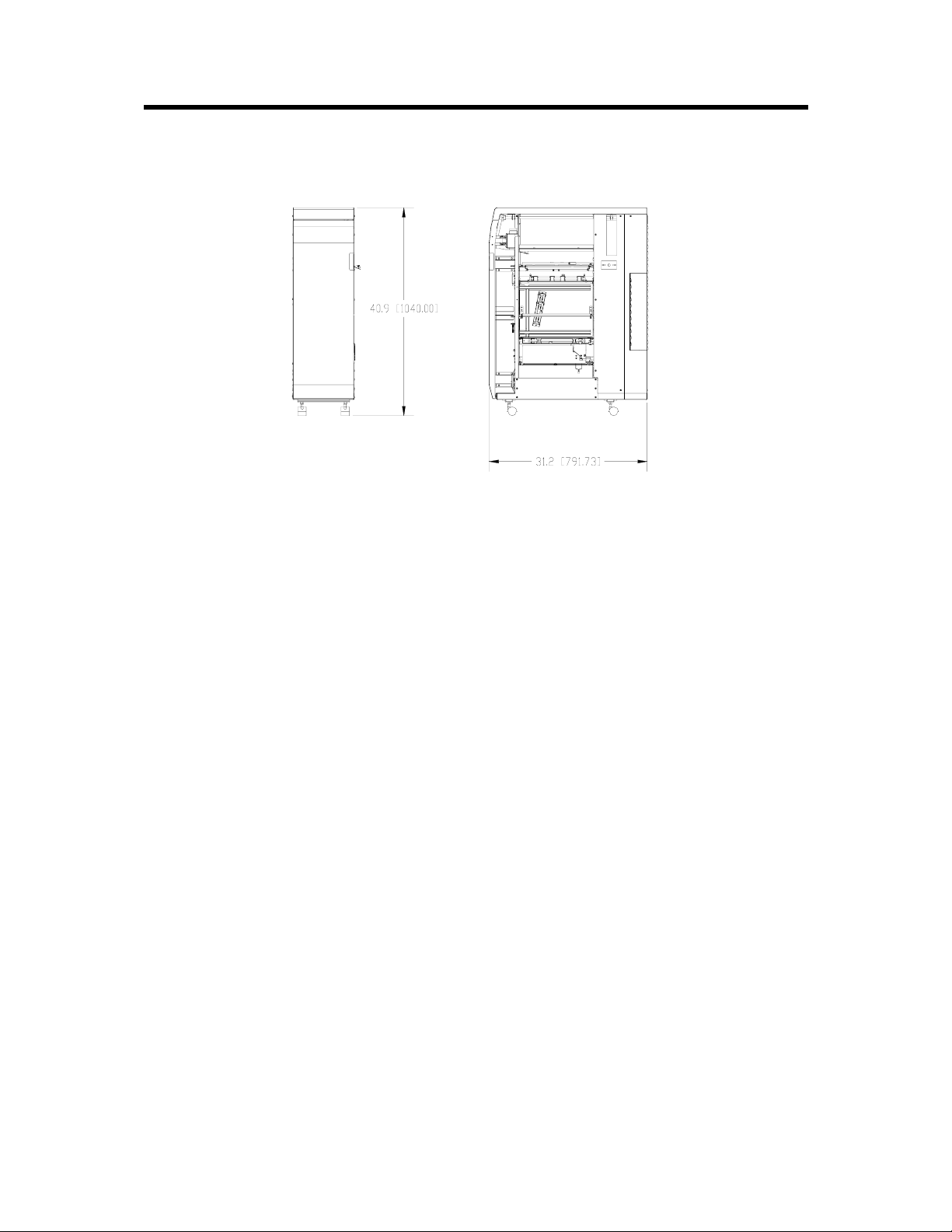

7. SPECIFICATIONS.......................................................................... 40

7.1 SPECIFICATIONS, 115V & 230V PROFESSIONAL PUNCHER-A1 ..........40

8. GLOSSARY OF TERMS ....................................................................

8.1 GLOSSARY OF TERMS ............................................ ........... ........ ............ .......

2

1. INTRODUCTION

1.1 INTRODUCTION

The Professional Puncher-A1 is an innovative solution for punching paper and

offers the following design features:

• Quick-change die sets that are self-latching without tools or levers.

• All Professional Puncher-A1 die sets include an Identifying Label providing user

with the hole pattern and name.

• Convenient storage area for three extra Die Sets located above the sheet bypass.

1.2 PROFESSIONAL PUNCHER-A1 FAQ’S

The CANON Professional Puncher-A1 will perform best when used for applications

that it was designed to perform. To ensure complete satisfaction, operate the

Professional Puncher-A1 within the following design parameters.

Professional 208V, 60Hz

(North America)

Sheet Sizes Supported:

Punching

Bypass Mode (not punching)

Paper Weights Supported:

Punching

Bypass Mode (not punching)

Physical Dimensions

Physical Weight

Shipping Weight

Power Consumption:

Power Supply

Electrical

Letter-21.59cm x 27.94cm

(29.74cm edge only)

5.5" x 8.5" upto 11" x 17"

supports all stocks and

weights that the printer

supports in bypass mode.

75gsm (20lb Bond) to 216

gsm (80lb Cover)

52 gsm (16lb Bond) to 216

gsm (80lb Cover)

12" width x 38.5" height x

28.5" depth

70kgs (154lbs)

115.5kgs (254lbs)

208V, 60Hz (Single Phase)

1.8A/1.7A, 240W, 1160

BTU/Hr

Professional 230/240V,

50Hz (Europe)

A4-21.59cm x 29.74cm

(29.74cm edge only)

5.5" x 8.5" upto 11" x 17"

supports all stocks and

weights that the printer

supports in bypass mode.

75gsm (20lb Bond) to 216

gsm (80lb Cover)

52 gsm (16lb Bond) to 216

gsm (80lb Cover)

12" width x 38.5" height x

28.5" depth

70kgs (154lbs)

115.5kgs (254lbs)

230/240V, 50Hz

(Single Phase)

1.8A/1.7A, 240W, 1160

BTU/Hr

3

8.5” x 11” (LEF) Only:

Professional Puncher-A1 is de signed to punch this size only (LEF) no exceptions

.

Attempting to punch a sheet size other than 8.5” x 11” (LEF) will cause a jam.

• Professional Puncher-A1 cannot

punch tabs. Tabs will have to be run, punched

and inserted offline.

• Use a colored sheet insert (instead of the tab) in the job workflow for easier tab

insertion after the job has been run.

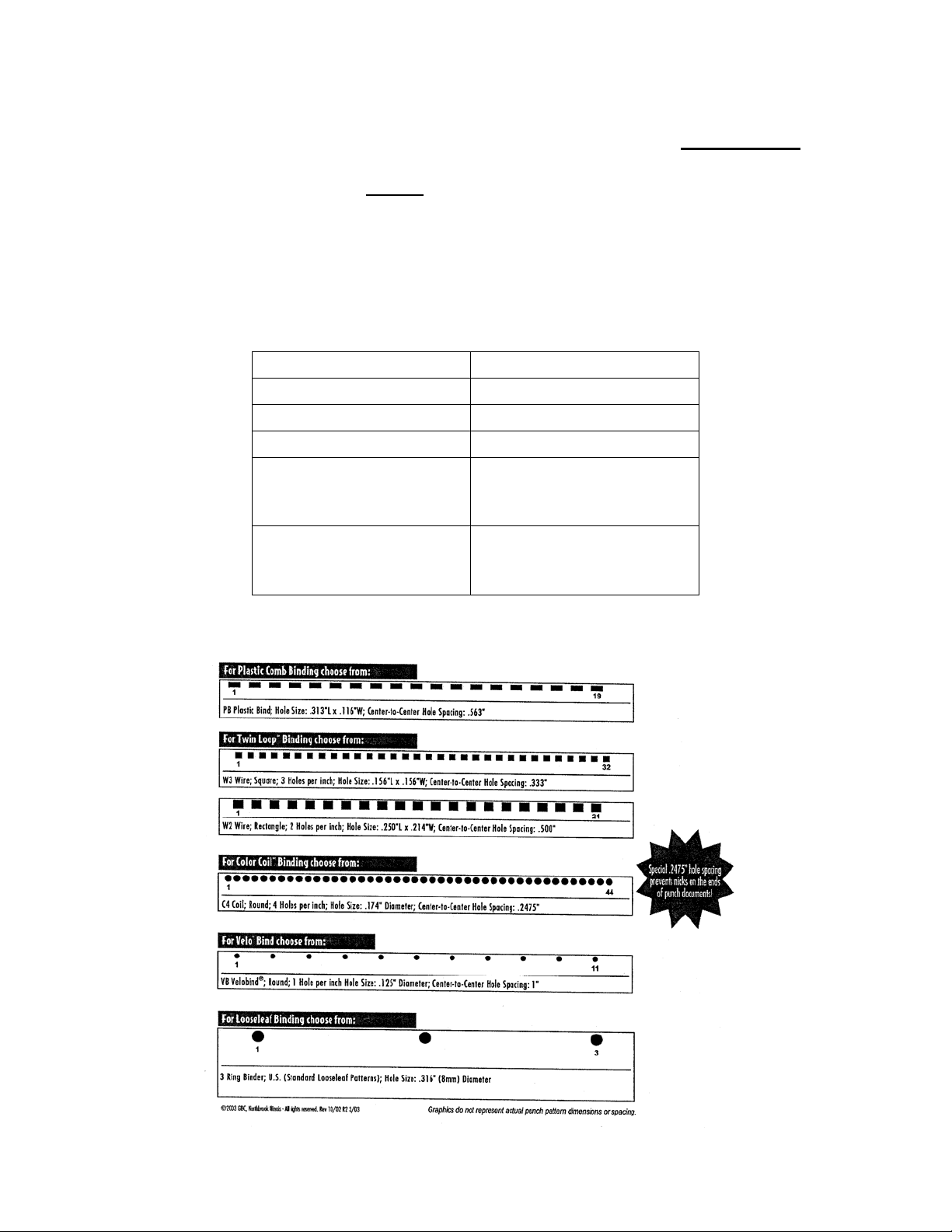

Die Sets:

The CANON Professional Puncher-A1 is capable of punching a variety of hole-punch

patterns by simply changing the Die Set. Die sets can be changed in seconds

without tools. The Die Sets currently available are listed below:

North America (Letter) Europe (A4)

3-hole 4-hole / 2hole

Velo Bind 11-hole Velo Bind 12-hole

CombBind 19-hole CombBind 20 or 21

Wire Bind (2 types) Square

- 21-hole Wire Bind

- 32-hole Wire Bind

Color coil 44-hole (2 types)

- 44-hole RND

- 44-hole Oval

Wire Bind (2 types) Round

- 23-hole Wire Bind

- 34-hole Wire Bind

Color Coil 47 hole (2 types)

- 47-hole – RND

- 47-hole – Oval

Punch Pattern Samples (North America – Letter Shown)

4

2. INSTALLATION

2.1 UNPACKING

UNPACKING

• Inspect the outside of the package for shipping damage. If there is evidence of

shipping damage, contact the shipping carrier immediately.

• Remove the punch from its shipping carton.

• Inspect for any concealed damage to unit. If there is evidence of concealed

shipping damage, contact the shipping carrier immediately.

• Remove all shipping tape from doors and levers.

2.2 UNIT SET-UP

Step One: Connect the communication cable.

Step Two: Connect the power cord.

2.3 UNIT OPERATION

• Check to ensure that the paper chip tray is securely in place.

• Check to ensure that a Die Set is installed properly and that any extra Die Sets are

securely stored in the Die Storage Area.

• Run a small test job in “Bypass” mode. Check to ensure that the job is not

punched and bypasses properly.

• Run a small job with Punch Enabled. Check the punched holes of the job.

5

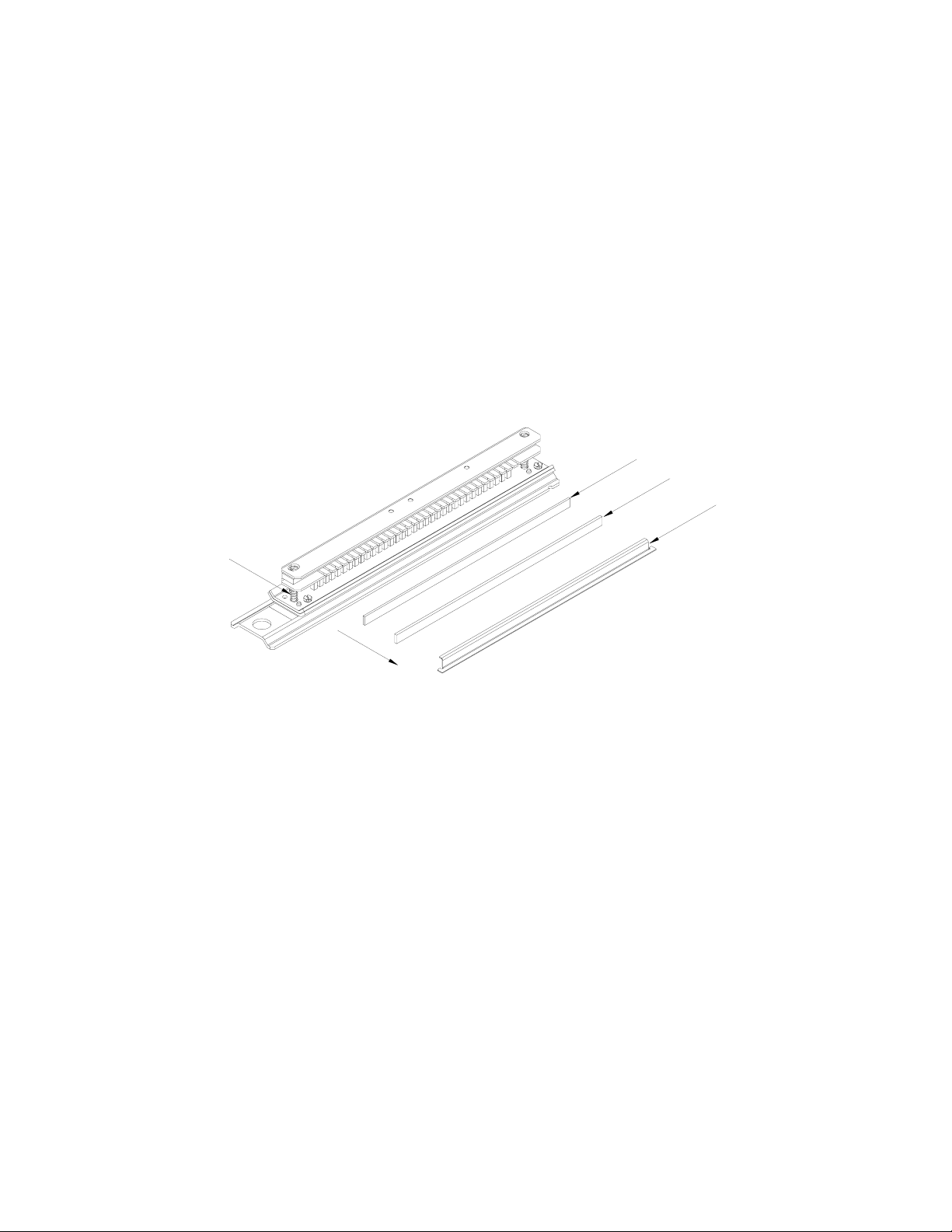

CANON PROFESSIONAL PUNCHER-A1 DIE SET - INFORMATION SHEET

IMPORTANT NOT ICE REGARDING TH E DIE SETS PLEASE REA D

Your CANON Professional Puncher-A1 die set (C4, W2 and W3 versions), is

supplied with a felt pad containing oil, a pad retaining magnet and shield*. Do not

throw these items away!

The felt pad will provide lubrication to the punch pins under normal usage and will

help to keep the punch pins clean. The magnet is intended to keep the felt pad in

place during typical handling. If the pad and magnet came off of this die set during

shipping or unpacking, please replace them as indicated in the accompanying

diagram.

Keep this sheet as a reference in the event that the pad and magnet are removed or

replaced.

FELT PAD

MAGNET

SHEILD

SHOULDER BOLT

WITH SPRING

Felt Pad and Retaining Magnet are not required or included with the 3-Hole, PB,

C4, ProClick

®

or VB die sets.

6

3. MAINTENANCE

3.1 INSPECTION, CLEANING AND LUBRICATION

The following maintenance should be performed once annually, u nder normal use.

Operational Inspection

1. If operating properly, the Professional Puncher-A1 will punch the same types of

copy paper and cover materials handled by the copier/printer. It will run at the

speed of the printer.

2. Hole quality will vary between different grades of paper.

External Cleaning

1. Make sure you disconnect the Professional Puncher-A1 from its power source

before cleaning. The cover may be cleaned with a soft cloth moistened with mild

detergent and warm water.

2. Do not use chemical cleaners or solvents as these may have a harmful effect.

Use detergent sparingly to avoid contact with electrical components.

Internal Cleaning

Before internal cleaning, be sure to disconnect power to the Professional PuncherA1 and ensure that you retain control of the power cord.

Occasionally, it will be necessary to remove the rear cover and remove paper dust

built up around the motor and other electrical components. Use a vacuum cleaner if

possible. A small paintbrush can also be used but extreme care should be used

around electrical components.

Internal Inspection

Whenever the cover has been removed for corrective maintenance, visually inspect

for defects such as loose screws or nuts, abraded wire insulation, loose terminals,

etc. Correct any defects before returning the machine to service.

Lubrication Points and Recommended Lubricant

• Lubricate the punch pins and/or the felt pad once every 50,000-punch cycles with

oil (High Quality Machine Oil is recommended).

• Method:

1. Sparingly depress the Pin Guide so that the Punch Pins protrude from

the bottom plate, oil the ends of the pins and wipe clean.

2. Apply oil directly to the felt pad (If so equipped).

3. Apply two drops of oil to each of the two shoulder bolts and springs.

• If Punch Drive Module Assembly is ever removed for service, check for sufficient

grease on the cranks.

7

GREASING CRANKS

Die Sets

Professional Puncher-A1 Die Sets have an average expected life of approximately

500,000 sheets of paper. This life may vary depending on variables such as

following the lubrication schedule described above, the type of paper being punched,

the cover stocks being punched and the typical length of the average job.

3.2 DIE SET MAINTENANCE

Die sets have a minimum life expectancy of 500,000 cycles depending on

application, environmental factors and maintenance. Periodic lubrication of the

punch pins can extend the life significantly. CANON recommends use of a high

quality machine oil (do not use spray oils) every 50,000-punch cycles.

SHOULDER BOLT

WITH SPRING

SPRING

S

N

I

P

E

H

T

E

T

A

C

I

R

B

U

L

The die set cannot be repaired or adjusted.

Other than lubrication, if a Die set is damaged or worn, the Die set should be

replaced.

8

3.3 PREVENTATIVE MAINTENANCE SCHEDULE

The following preventative maintenance should be performed during the regular

printer inspection intervals.

• Disconnect the main cord set and retain it in your control for your safety.

• Remove the rear cover.

• Perform a visual inspection; clean, adjust and replace components as required.

• Vacuum Paper Chad out of Back Gage Mechanism and Die Guide as well as

base.

• Optical Sensors; Remove dust and particles from the lens using a soft cloth.

• Inspect Timing Belts for wearing or fraying.

• Inspect any Latching Mechanisms, clear any jams paper debris.

• Inspect Left / Right Punch alignment by running paper with each die set, check for

even hole alignment by folding the paper in half. If adjustment is required, ensure

that the Die Latch is properly adjusted.

• Inspect the Door closing latch for proper alignment, if bent, instructs the operator

to avoid closing the door with paper path latches out of place.

• Lubrication of the Die Set Pins (see note above)

• Cams (when punch is pulled), lubricate with high quality grease

• Inspect the Idler Rollers, clean if necessary.

• Inspect the Drive Rollers, clean if necessary.

• Inspect the Paper Path Panels, clean if necessary.

• Inspect each Die Set for wear. Run at least 100 sheets of paper. Look for signs of

excess paper jamming. Inspect the hole quality. Hanging chad or ragged holes can

lead to paper jams. If the hole is cut sharp enough that there is no hanging chad

and the paper passes through the system without catching and jamming, the die

set still has life.

As with any electro-mechanical device, isolated component failures may occur.

3.4 SETTING THE RIGHT EXPECTATIONS

Product Positioning:

Professional Puncher-A1 provides a flexible, cost effective punching solution for light

to medium level production oriented customers.

• Designed for customers that have the need to punch their documents at a

maximum of 60-70% of their overall workflow.

• Recommended punching limit to 200k sheets per month. (600k sheets in

bypass mode)

• Die Sets will decrease in performance over time based on the types of stocks and

weights that are being punched.

• CANON guarantees a minimum of 500k punches per die set. However, if

paper stock punched is typically 20lb bond, then up to 2 million punches can

be achieved.

• Should be regarded as a long-term supply item.

9

4. ADJUSTMENT AND SPECIAL PROCEDURES

4.1 TOOL RECOMMENDATIONS

What you need to service the CANON Professional Puncher-A1:

1. Standard Measure Tools (English as opposed to metric)

a. Open End Ignition Wrench – ¼” (required only for Chad Kit installation)

b. Open the End Wrench 9/16”(for adjustable casters)

c. Nut Driver, 5/16”

d. Nut Driver, ¼” (see note below)

e. Allen Wrench, 3/32” (comes with Chad Control Kit )

f. Allen Wrench, 5/64”

g. Allen Wrench, 9/64”

2. Other recommended tools

a. Needle Nose Pliers (Side Cutters)

b. Wire Cutters

c. Screw Driver, Phillips Head

d. Screw Driver, Flat Head, Small

3. Supply of Wire Tie Wraps

NOTE: A nut driver head of ¼” is the most common size for the barrel of a

Magnetic or interchangeable tip screwdriver.

4.2 DIE SET POSITION CRADLE ADJUSTMENT, CENTERING

PUNCHED HOLES

The die set position cradle is set in the factory; however, because of the punchedhole spacing on the PB die sets, there is a minimal amount of paper on each edge of

the punched paper. The die set position cradle may have to be fine adjusted to

center the punched-hole pattern in the paper.

Listed below are the step-by-step instructions to adjust the die set to the proper

position:

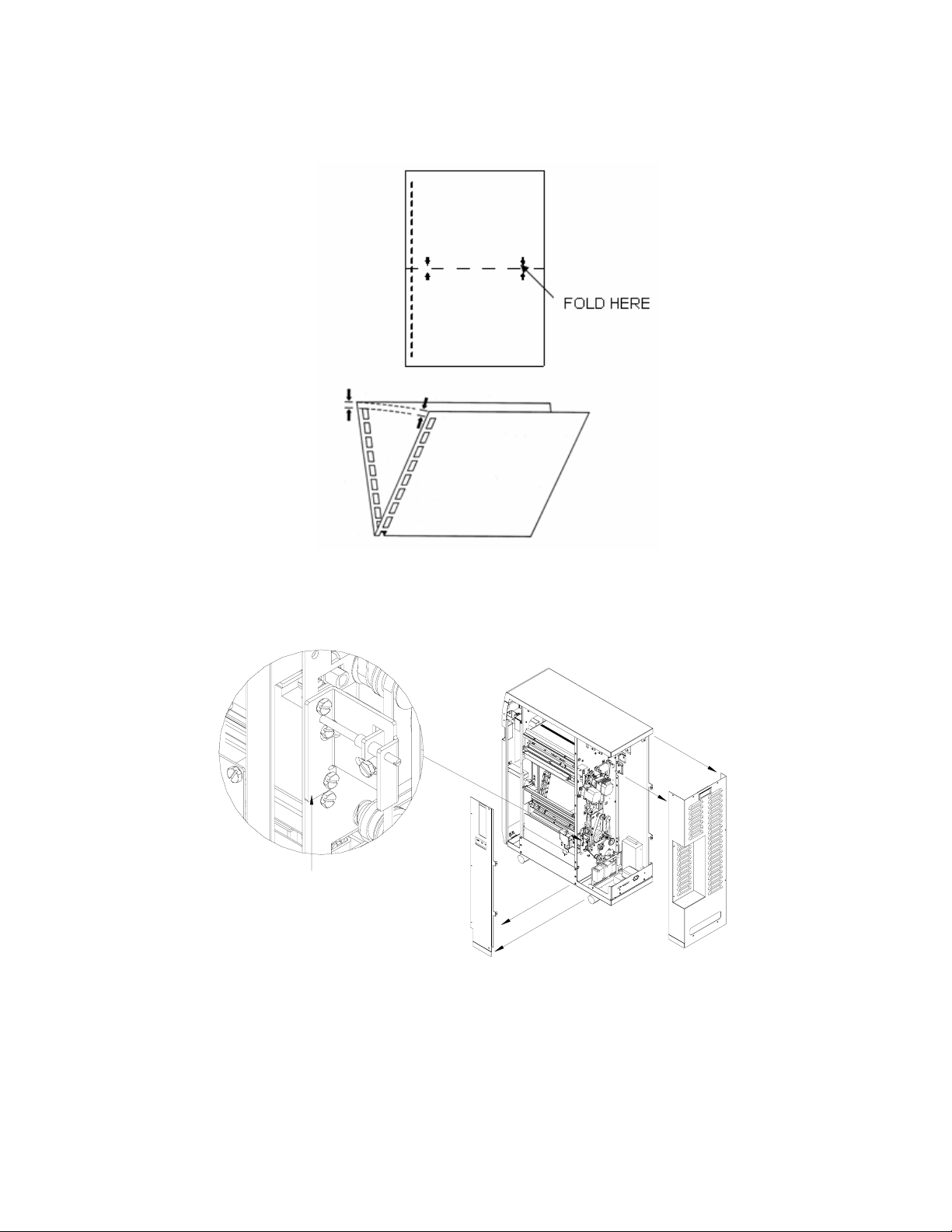

• The punched-hole alignment must be checked on a piece of punched paper. Fold

the punched sheet of paper in half and the punched-holes should be aligned. If the

punched-holes are not aligned, then the die set cradle must be adjusted to align

the punched holes.

NOTE: The paper path is always constant, if the holes are not centered; you

must adjust the die set crad l e .

10

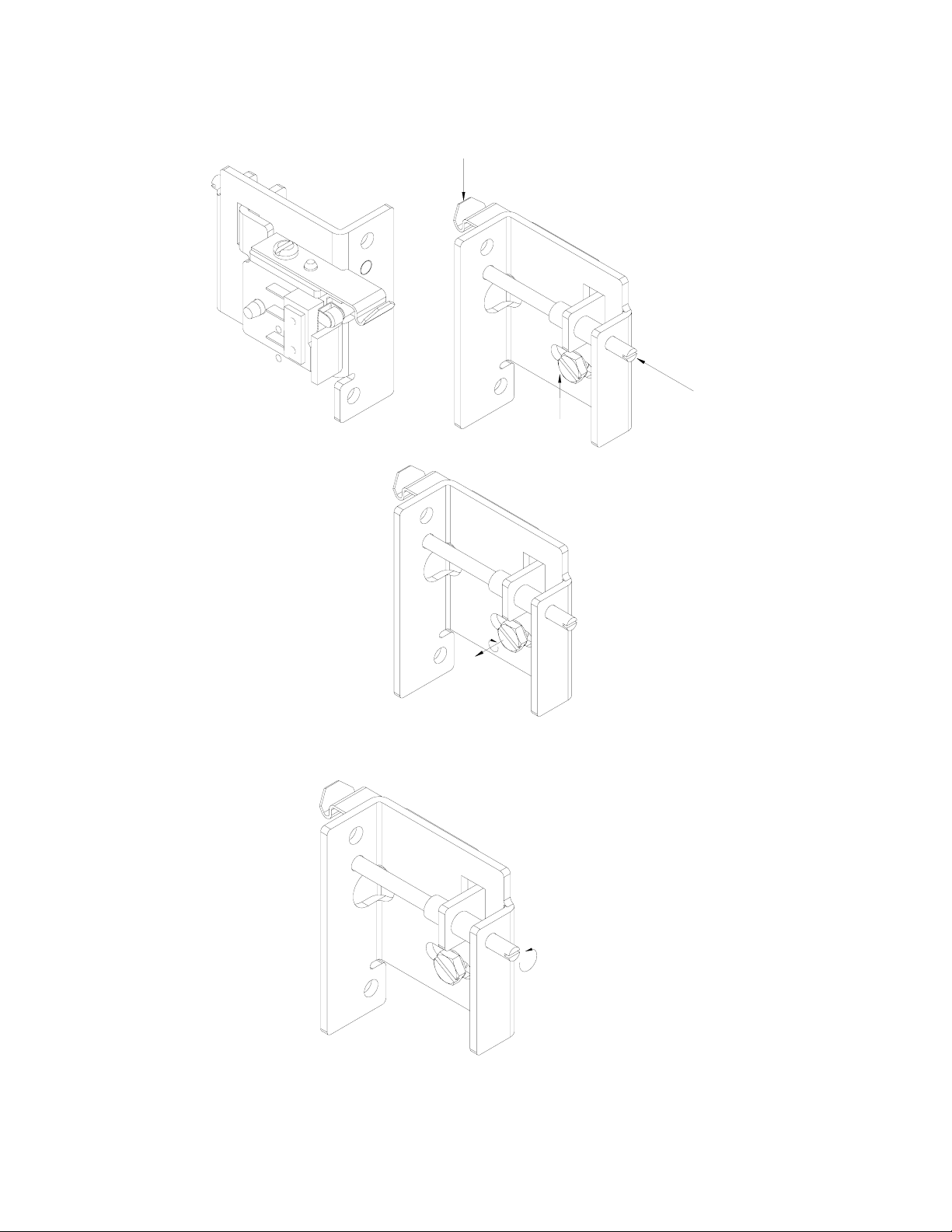

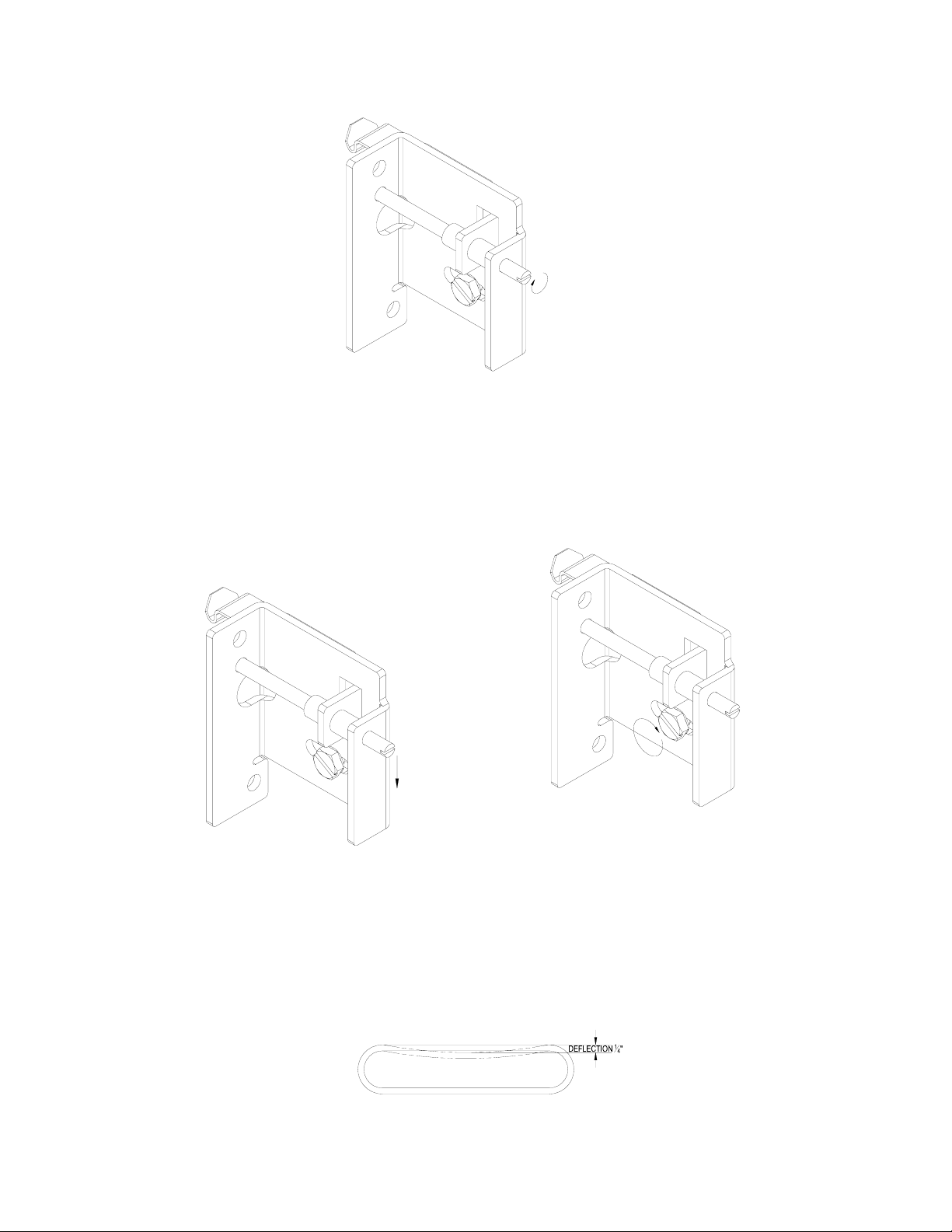

PUNCHED HOLE ALIGNMENT CHECKING

• The back cover on the Professional Puncher-A1 must be removed to a ccess the

die set position cradle.

CRADLE

• Before ad justing the die set position cradle, you must first no te what direction the

die set cradle must move.

• Before you adjust the die set position cradle, you must loosen the lock-down

screw.

11

PRESS HERE

TO TILT

ADJUSTMENT

SCREW

LOCK-DOWN

SCREW

LOOSEN

SCREW

• Observe the punched paper; if the punched-holes are too close to the rear of the

machine, then you must turn the adjustment screw counter-clockwise.

TURN COUNTERCLOCKWISE

• If the punched-holes are too close to the front of the machine, then you must turn

the adjustment screw clockwise.

12

TURN

CLOCKWISE

• Using a flat-head screwdriver, turn the adjustment screw clockwise or counter-

clockwise to move the die set position cradle.

NOTE: Seven full turns of the adjustment screw result in a ¼” change in the

punched hole position.

• Before tightening the lock-down screw, tilt or bias the assembly towards the

bottom of the machine an d tighten the lock-down screw. This will ensure positive

engagement between the locking lever and the die set.

TILT TO BOTTOM

OF M/C

TIGHTEN

SCREW

• Run a test sample of punched paper and recheck paper alignment. Re-adjust if

necessary.

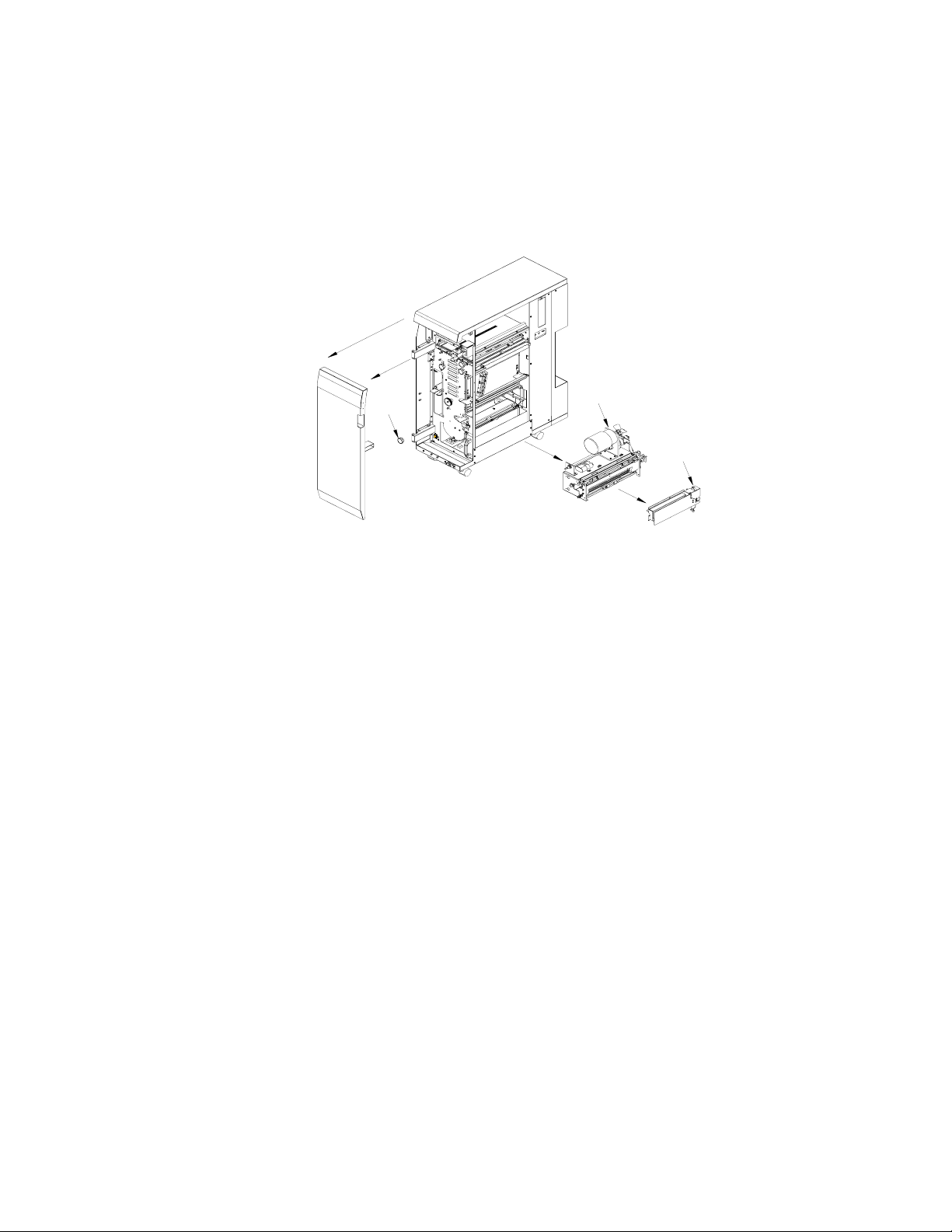

4.3 REMOVAL OF PUNCH MODULE

1. Examine the Drive Belts. Note the consistency in tightness of the belts. They

should all have approximately ¼” of deflection; remove the four drive belts items

1, 2, 3, 4.

Disconnect the Sensor Wire Connection

13

2. Remove 4 screws in front and 2 in back

3. Cut any wire ties that may prevent freedom of movement to slide the Punch

Module (A) outward

4. Remove the Back Gauge Assembly (B).

5. Remove the black Knob (C) at the front (customer side) of the Punch Module

Drive Shaft.

C

FRONT SIDE

A

B

6. Slide the Punch Module unit part way out to reach and unplug the Punch Sensor

Harness (Red, Black, White wires)

7. Slide the entire Punch Assembly (C) out and lay it beside the Professional

Puncher-A1. Take care not to damage wires or Rollers as you do so.

8. Lubricate the Drive Cams sparingly of the punch module using a multi-purpose,

extreme pressure lubricant, preferably formulated with Teflon.

Note: This lubrication is not required during the normal life but is reasonable to do

this of the mod ule every needs se r v ice.

9. To replace any component of the punch Module, disassemble components as

required

4.4 GREEN BELT REPLACEMENT, ALIGNER PANEL REMOVAL,

EXPLANATION

The following procedure explains how to remove the Entrance Side Aligner Panel

and the Exit Side Aligner Panel.

The basic intent of this procedure is to access and replace the Green Aligner Belts,

but once you know how to follow this procedure you are now able to access other

components as well.

SYMPTOM

Paper will stop moving through the Punch paper path.

CAUSE

One or both of the Green Aligner Belts have broken. If this break occurs, it would

usually occur at the Weld Splice.

14

Loading...

Loading...