Canon DU7-1100-010 User Manual

SERVICE

MANUAL

REVISION 1

JAN. 2000

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

DU7-1100-010

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY DIFFER SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO THE

COPIER SERVICE DEPARTMENT OF THE COMPANY.

COPYRIGHT 2000 CANON INC.

Printed in U.S.A.

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 3

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride, Ibaraki, 302-8501 Japan

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

INTRODUCTION

This Service Manual contains basic data and figures on the imageRUNNER 600

needed to service the machine in the field. The copier is a multifunction machine designed

to provide printer functions as an option.

This Service Manual consists of the following chapters; refer to the Copier Basic

Series as necessary for common technologies:

CHAPTER 1 General Description introduces the copier’s features and specifications,

shows how to operate the printer unit, and explains how copies are made.

CHAPTER 2 Basic Operation provides outlines of the steps used to generate copies.

CHAPTER 3 Exposure System discusses the principles of operation used for the

mechanical/electrical operations of the copier’s exposure system. It also explains the

timing at which the various units involved are operated, and shows how they may be

disassembled/assembled and adjusted.

CHAPTER 4 Image Processing System discusses the principles of operation used for

the mechanical/electrical operations of the copier’s image processing system. It also

explains the timing at which the various units involved are operated, and shows how they

may be disassembled/assembled and adjusted.

CHAPTER 5 Laser Exposure System discusses the principles of operation used for

the mechanical/electrical operations of the copier’s laser exposure system. It also

explains the timing at which the various units involved are operated, and shows how they

may be disassembled/assembled and adjusted.

CHAPTER 6 Image Formation System discusses the principles of how images are

formed. It also explains the timing at which the various units involved in image formation

are operated, and shows how they may be disassembled/assembled and adjusted.

CHAPTER 7 Pick-Up/Feeding System discusses the principles of how the printer unit

picks up and moves paper inside it. It also explains the timing at which the various units

involved are operated, and shows how they may be disassembled/assembled and

adjusted.

CHAPTER 8 Fixing System discusses the principles of how the printer unit fuses toner

images to paper. It also explains the timing at which the various units involved are

operated, and shows how they may be disassembled/assembled and adjusted.

CHAPTER 9 Externals/Auxiliary Mechanisms shows the copier’s external parts, and

explains the principles used for the copier’s various control mechanisms in view of the

functions of electrical and mechanical units and in relation to their timing of operation. It

also shows how these units may be disassembled/assembled and adjusted.

CHAPTER 10 Side Paper Deck discusses the principles of operation used for the

series of operations between pickup and delivery performed by the paper deck. It also

explains the timing at which the various units involved are operated, and shows how they

may be disassembled/assembled and adjusted.

CHAPTER 11 Installation introduces requirements for the site of installation, and

shows how the printer unit may be installed using step-by-step instructions.

COPYRIGHT © 1999 CANON INC. CANON GP605/605V REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CHAPTER 12 Maintenance and Servicing provides tables of periodically replaced

parts and consumables/durables and scheduled servicing charts.

CHAPTER 13 Troubleshooting provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

APPENDIX contains a general timing chart and general circuit diagrams.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

This Service Manual is prepared so that a full understanding may be attained when it

is used side by side with the separately available Copier Basic Series. Refer to the

appropriate section of the document when prompted as follows:

EX.

Part 2>Chapter 5>10.1

The Copier Basic Series is a combination of descriptions on the existing technologies

used in Canon copiers. It consists of the following seven volumes, and is intended to

supplement the contents of Service Manuals:

Part 1 Introduction

Fundamental Technology

Part 2 Applied Technology

Part 3 Applied Technology

Part 4 Applied Technology

Analog Copiers

Digital Copiers

Color Copiers

ii

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

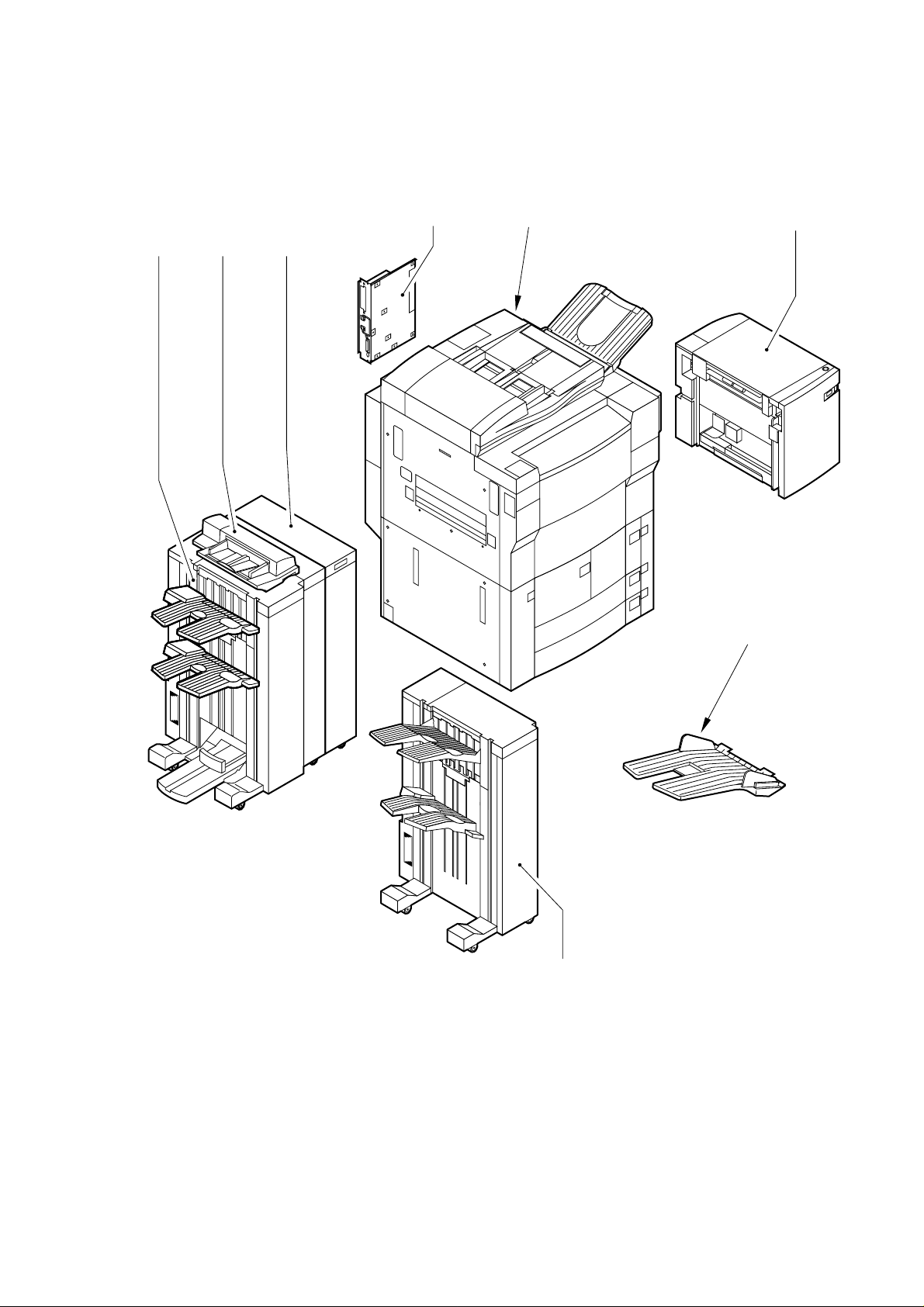

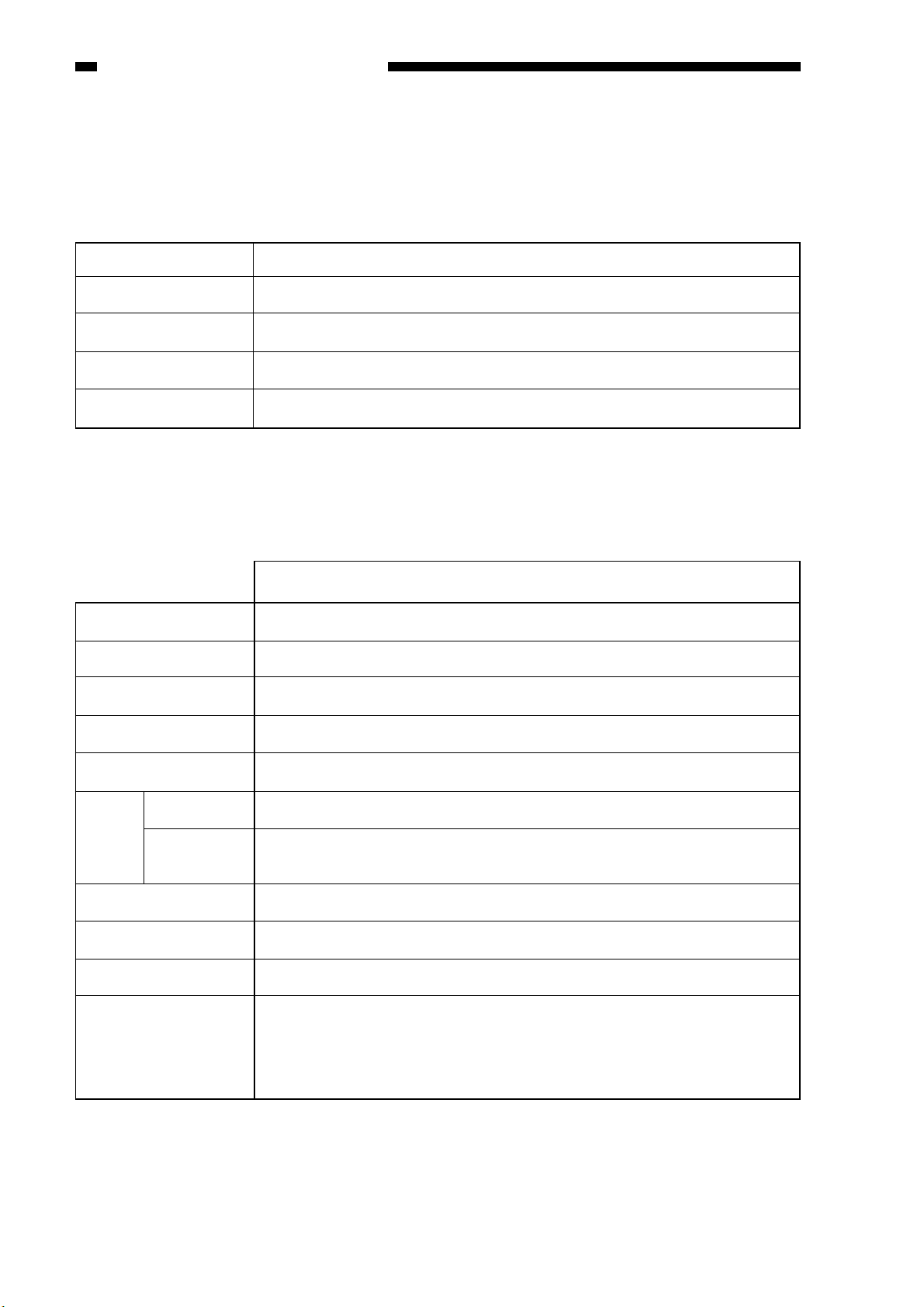

System Configuration

The imageRUNNER 600 may be configured as follows:

[1] [2]

[3]

[4]

[5]

[6]

[7]

[8]

[1] Saddle Finisher-D2

[2] Cover Insertion Unit-A1

[3] Paper Folding Unit-B1

[4] Printer Board

[5] imageRUNNER 600

[6] Side Paper Deck-C1

[7] Copy tray

[8] Finisher-D1

Figure 1

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

iii

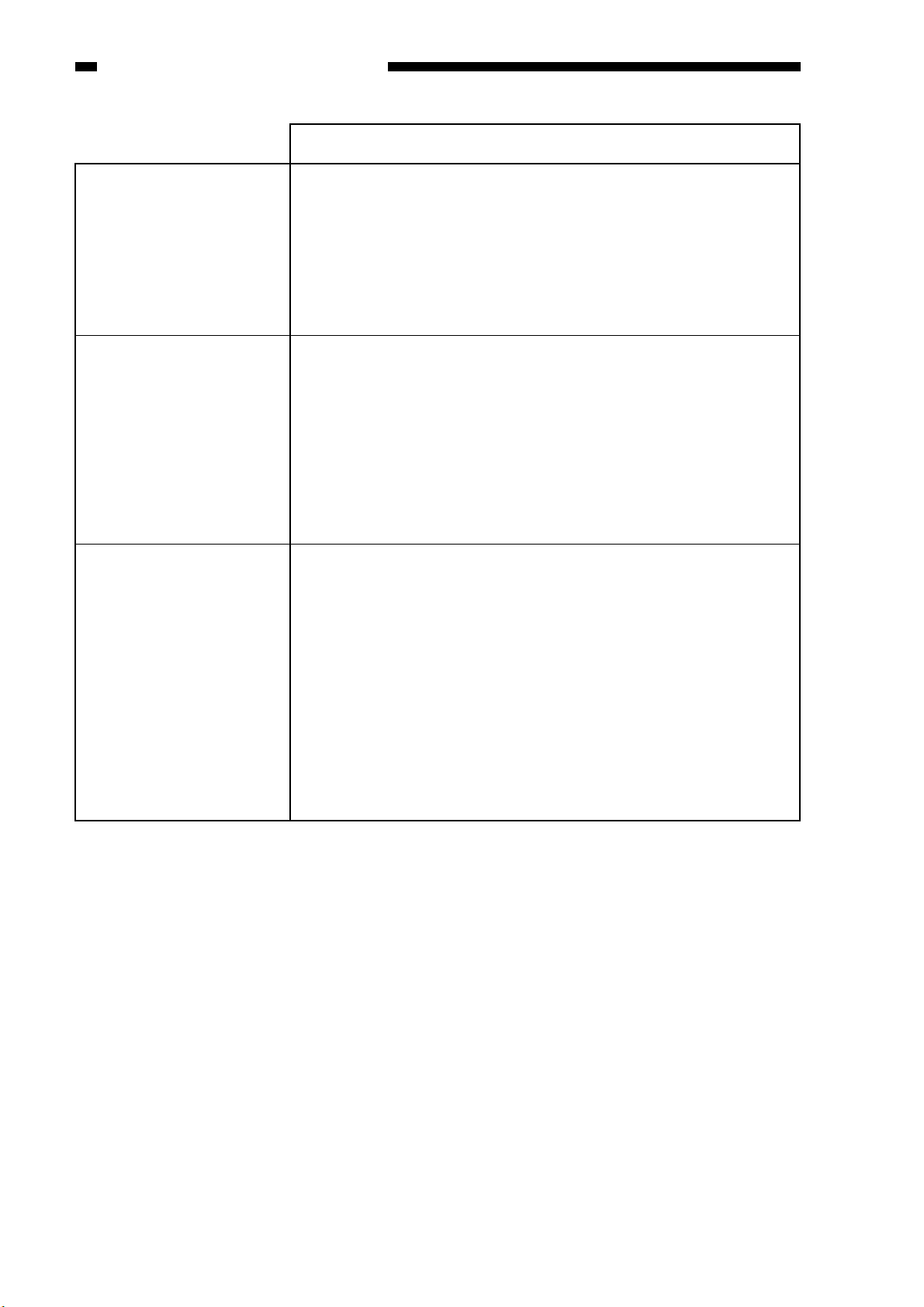

When Turning Off the Main Power Switch

Be sure to turn off the main power switch, and disconnect the power plug before starting

disassembly/assembly work with the following in mind:

1. When you turn off the main power switch for adding printer functions, any data

being processed at the time may be lost. Check to make sure that the data lamp on

the control panel is off before operating the main power switch.

After turning off the main power switch, disconnect the communication cable from

the printer board so that data will not be accepted during work.

2. Do not turn off the main power switch when downloading is taking place. Otherwise, the machine may stop operating.

3. Some units remain powered even when the control panel power switch is turned

off. Be sure to turn off the main power switch, and disconnect the power plug

before starting disassembly/assembly work.

(If the heater switch is on, the cassette heater and the drum heater remain powered even when the main power switch is turned off.)

4. Not all power will be removed even when the front door is opened if both the control

panel power switch and the main power switch are on.

[2][1]

Copying

Error

Copying

Error Data DataError Error

MAIL BOX

COPY A

COPY B

1 2 3

1 2 3

4 5 6

4 5 6

7 8 9

7 8 9

ID

ID

OPTIONS

0

0

C

C

ON/OFF

[3]

ONOFF

[4]

[1] Data lamp

[2] Power switch

[3] Main power switch

[4] Heater switch

iv

Figure 2 Arrangement of the Switches

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ................................1-1

II. SPECIFICATIONS......................1-2

A. Copier....................................1-2

1. Type .................................1-2

2. System .............................1-2

3. Performance.....................1-3

4. Others...............................1-7

B. Side Paper Deck-C1............1-10

III. NAMES OF PARTS..................1-11

A. External View ......................1-11

B. Cross Section ......................1-14

IV. OPERATING THE COPIER .....1-16

A. Turning on the Power Switch

............................................1-16

CHAPTER 2 BASIC OPERATIONS

I. BASIC OPERATIONS ................2-1

A. Functional Construction.........2-1

B. Electrical Circuitry..................2-2

1. Outline..............................2-2

2. MFC PCB .........................2-2

3. Image Processor PCB......2-2

4. DC Controller PCB ...........2-3

5. Control panel CPU PCB ...2-3

6. Original Orientation Detection

PCB..................................2-3

7. Image Server....................2-3

C. Basic Sequence of Operations

..............................................2-5

B. Control Panel.......................1-17

C. Extension Mode ...................1-18

D. User Mode...........................1-19

V. ROUTINE MAINTENANCE BY THE

USER .......................................1-21

VI. SAFETY ...................................1-22

A. Safety of Laser Light ...........1-22

B. CDRH Regulations ..............1-23

C. Handling the Laser Assembly

............................................1-24

D. Safety of Toner....................1-28

VII. IMAGE FORMATION ...............1-29

A. Outline .................................1-29

1. Basic Sequence of

Operations (power-on) .....2-5

D. Controlling the Main Motor (M1)

..............................................2-6

1. Outline..............................2-6

E. Inputs to and Outputs from the

Major PCBs ...........................2-7

1. Wiring Diagram of Major

PCBs ................................2-7

2. Inputs to the DC Controller

PCB..................................2-8

3. Outputs from the DC

Controller PCB ...............2-14

CHAPTER 3 ORIGINAL EXPOSURE SYSTEM

I. OPERATIONS............................3-1

A. Outline ...................................3-1

B. Basic Sequence of Operations

..............................................3-3

C. Changing the Reproduction Ratio

..............................................3-4

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

II. SCANNER DRIVE SYSTEM ......3-5

A. Outline ...................................3-5

B. Controlling the Scanner Motor

..............................................3-6

III. CONTROLLING THE SCANNING

LAMP..........................................3-8

v

A. Outline ...................................3-8

B. Controlling the Temperature by a

Fluorescent Lamp Heater....3-10

C. Controlling Pre-Heat Voltage

............................................3-10

D. Initial Activation ...................3-11

E. Detecting an Error ...............3-12

IV. DETECTING THE ORIGINAL SIZE

.................................................3-14

A. Outline .................................3-14

B. Detection by Original Sensors

............................................3-14

C. Detection by the Feeder......3-14

V. DISASSEMBLY/ASSEMBLY....3-15

A. No. 1 Mirror Mount ..............3-16

1. Removing the Scanning

Lamp/Scanning Lamp Heater

.......................................3-16

2. Points to Note When

Replacing the Scanning Lamp

.......................................3-19

3. After Replacing the Scanning

Lamp ..............................3-19

B. Scanner Drive Assembly .....3-20

1. Removing the Scanner Motor

.......................................3-20

2. Scanner Drive Cable ......3-21

C. PCBs ...................................3-28

1. Removing the Light Intensity

Control PCB ...................3-28

2. Removing the Inverter PCB

.......................................3-29

D. Others..................................3-31

1. Removing the Original Size

Sensor (1/2)....................3-31

2. Removing the Original Size

Sensor (3/4)....................3-32

3. Removing the Scanner Home

Position Sensor ..............3-33

4. Removing the Copyboard

Glass ..............................3-33

5. Removing the Image Leading

Edge Sensor ..................3-34

6. Removing the Standard White

Plate ...............................3-35

7. After Replacing the Standard

White Plate.....................3-36

CHAPTER 4 IMAGE PROCESSING SYSTEM

I. OUTLINE....................................4-1

II. ANALOG IMAGE PROCESSING4-4

A. Outline ...................................4-4

III. DIGITAL IMAGE PROCESSING 4-6

A. Outline ...................................4-6

B. Image Procesing Functional

Block......................................4-7

C. Shading Correction ................4-9

D. Line Conversion ..................4-10

E. Editing .................................4-11

F. Density Processing ..............4-12

1. Outline............................4-12

2. Density Adjustment during

Printing ...........................4-14

G. Binary Processing ...............4-15

1. Dither Screen Method ....4-15

2. Random Error Diffusion (R-

ED) Method ....................4-16

H. Image Memory ....................4-17

I. Detecting the Orientation of

Originals ..............................4-19

J. Black Pixel Count ................4-20

IV. DISASSEMBLY/ASSEMBLY....4-21

A. CCD PCB ............................4-22

1. Removing the CCD PCB

.......................................4-22

2. After Replacing the CCD Unit

.......................................4-23

B. Image Processor PCB.........4-24

1. Removing the Image

Processor PCB...............4-24

2. After Replacing the Image

Processor PCB...............4-25

C. Hard Disk (image server).....4-26

1. Removing the Hard Disk

(image server) ................4-26

2. After Replacing the Hard Disk

(image server) ................4-26

D. Others..................................4-27

1. Removing the System

Motherboard...................4-27

2. Removing the Memory Board

.......................................4-28

3. Removing the Various Printer

Boards............................4-28

4. Removing the Original

Detection PCB................4-29

vi

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

CHAPTER 5 LASER EXPOSURE SYSTEM

I. OPERATIONS............................5-1

A. Outline ...................................5-1

B. Basic Sequence of Operations

(laser exposure system) ........5-4

II. GENERATING THE BD SIGNAL5-5

A. Outline ...................................5-5

B. Flow of the BD Signal............5-5

III. LASER DRIVER PCB.................5-7

A. Outline ...................................5-7

B. Controlling the Laser Activation

..............................................5-8

C. Controlling the Laser Intensity

............................................5-10

CHAPTER 6 IMAGE FORMATION SYSTEM

I . PROCESSES .............................6-1

A. Outline ...................................6-1

B. Basic Sequence of Operations

(image formation) ..................6-3

II . POTENTIAL CONTROL.............6-5

A. Outline ...................................6-5

B. Determining the Optimum Grid

Bias .......................................6-8

C. Grid Bias Corrective Control..6-8

D. Determining the Optimum Laser

Output....................................6-9

E. Laser Output Corrective control

..............................................6-9

F. Determining the Optimum

Developing Bias ..................6-10

G. Potential Control for

Transparency Mode ............6-11

H. Target Potential Correction in

Each Mode ..........................6-12

1. Adjusting the Density during

Printing (PDL input)........ 6-13

2. Potential Control during High

Humidity Mode ...............6-14

3. Density Adjustment during

Printing (scanner input) ..6-15

III . CONTROLLING THE CHARGING

MECHANISMS .........................6-16

A. Controlling the Primary Charging

Mechanism ..........................6-16

1. Outline............................6-16

IV. Controlling the Laser Scanner Motor

.................................................5-12

A. Outline .................................5-12

V. DISASSEMBLY/ASSEMBLY....5-13

A. Laser Unit ............................5-14

1. Removing the Laser Unit

.......................................5-14

2. After Replacing the Laser Unit

.......................................5-15

B. BD Unit ................................5-16

1. Removing the BD Unit....5-16

2. Changing the Primary

Charging Level Setting... 6-17

3. Primary Charging Assembly

Cleaning Mechanism......6-18

4. Others.............................6-19

B. Dust-Collecting Roller Bias..6-20

1. Outline............................6-20

C. Controlling the Pre-Transfer

Charging Mechanism .......... 6-21

1. Outline............................6-21

2. Controlling the Output to Suit

the Environment (fuzzy

control) ...........................6-22

3. Pre-Transfer Charging

Assembly Cleaning

Mechanism .....................6-23

4. Others.............................6-24

D. Controlling the Transfer Guide

Bias .....................................6-25

1. Outline............................6-25

2. Controlling the Output to Suit

the Environment .............6-26

E. Controlling the Transfer Charging

Mechanism ..........................6-27

1. Outline............................6-27

2. Controlling the Output to Suit

the Environment (fuzzy

control) ...........................6-28

3. Correcting the Output at the

Trailing Edge of Paper....6-29

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

vii

4. Transfer charging Assembly

Cleaning Mechanism......6-30

5. Others.............................6-31

F. Controlling Separation Charging

............................................6-32

1. Outline............................6-32

2. Correcting the Output to Suit

the Environment and the

Toner Deposit.................6-33

3. Correcting the Output upon

Detection of Leakage .....6-34

4. Others.............................6-35

IV . DEVELOPING ASSEMBLY......6-36

A. Outline .................................6-36

B. Controlling the Developing

Assembly.............................6-37

C. Controlling the Toner Cartridge

Drive Mechanism.................6-38

D. Controlling the Developing Bias

............................................6-39

E. Detecting the Toner Level and

Controlling the Toner Supply

Mechanism ..........................6-41

V . DRUM CLEANER UNIT ...........6-45

A. Outline .................................6-45

B. Detecting the Waste Toner (case

full condition) .......................6-46

VI. CONTROLLING THE DRUM

HEATER...................................6-48

A. Outline .................................6-48

VII .DISASSEMBLY/ASSEMBLY....6-49

A. Photosensitive Drum Unit....6-50

1. Points to Note When Handling

the Photosensitive Drum 6-50

2. Removing the Photosensitive

Drum...............................6-51

3. Replacing the Photosensitive

Drum Heater...................6-53

4. Mounting the Photosensitive

Drum Unit .......................6-54

B. Parts Associated with the

Process Unit ........................6-55

1. Removing the Pre-Exposure

Lamp Unit.......................6-55

2. Removing the Potential

Sensor Unit.....................6-56

3. Removing the Primary

Charging Assembly ........6-57

4. Removing the Pre-Transfer

Charging Assembly ........6-57

5. Removing the Dust-Collecting

Roller..............................6-58

6. Removing the Transfer/

Separation Charging

Assembly........................6-58

C. Charging Wire .....................6-60

1. Outline............................6-60

2. Removing the Wire Cleaner of

the Primary Charging

Assembly........................6-60

3. Removing the Wire Cleaner of

the Transfer Separation

Charging Assembly ........6-61

4. Routing the Charging Wire

.......................................6-62

5. Routing the Grid Wire for the

Primary Charging Assembly

.......................................6-64

6. Adjusting the Height of the

Charging Wire ................6-65

D. Process Unit........................6-66

1. Removing the Process Unit

.......................................6-66

2. Mounting the Process Unit

.......................................6-68

E. Developing Assembly..........6-69

1. Removing the Developing

Assembly........................6-69

2. Removing the Hopper ....6-70

3. Removing the Blade Unit

.......................................6-71

4. Mounting the Blade ........6-72

5. Removing the Developing

Cylinder ..........................6-72

F. Drum Cleaner Unit...............6-75

1. Removing the Cleaning Blade

.......................................6-75

2. Mounting the Cleaning Blade

.......................................6-77

G. Separation Claw/Separation Claw

Drive Assembly ...................6-79

CHAPTER 7 PICK-UP/FEEDING SYSTEM

I. OUTLINE....................................7-1

A. Specifications and Construction

..............................................7-1

viii

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

B. Arrangement of Rollers and

Sensors .................................7-2

II. PICKUP ASSEMBLY..................7-3

A. Control System......................7-3

B. Sequence of Operations (pickup)

..............................................7-4

1. Right Deck........................7-4

2. Pickup from the Cassette 4

.........................................7-5

C. Controlling the Pickup Motor (M2)

..............................................7-6

1. Outline..............................7-6

D. Movement of the Lifter...........7-7

1. Outline..............................7-7

2. Lifter Limiter (deck right/left)

.........................................7-9

3. Detecting the Presence/

Absence of Paper...........7-10

4. Detecting the Level of Paper

.......................................7-10

E. Detecting the Cassette Paper

Size .....................................7-13

1. Cassette Deck Right/Left

.......................................7-13

2. Cassette 3/4 ...................7-13

3. Markings on the Width Guide

Rail .................................7-14

4. Paper Size......................7-15

F. Manual Feed Tray Pickup

Assembly.............................7-18

1. Pickup Operation............7-18

2. Detecting the Paper Size

.......................................7-19

III. CONTROLLING THE

REGISTRATION CLUTCH

.................................................7-20

A. Outline .................................7-20

B. Control System....................7-20

C. Sequence of Operations

(registration brake) ..............7-21

IV. MAKING DOUBLE-SIDED COPIES

.................................................7-22

A. Control System....................7-22

1. Copying on the First Side

.......................................7-22

2. Copying on the Second Side

.......................................7-23

B. Sequence of Operations......7-24

C. Controlling the Reversal Motor

(M11) ...................................7-25

1. Outline............................7-25

D. Controlling the Duplexing Feeder

Motor (M12).........................7-26

1. Outline............................7-26

E. No-Stacking Operation ........7-27

1. Outline............................7-27

2. Outline of Operations .....7-28

F. Detecting the Horizontal

Registration Position ...........7-32

1. Outline............................7-32

2. Operations......................7-33

3. Controlling the Horizontal

Registration Motor (M15)

.......................................7-34

V. CONTROLLING THE DELIVERY

ASSEMBLY ..............................7-35

A. Reversal Delivery ................7-35

VI. CONTROLLING THE CASSETTE

HEATER...................................7-36

VII. DETECTING JAMS ..................7-38

A. Outline .................................7-38

1. Arrangement of Jam Sensors

.......................................7-38

2. Types of Jams................ 7-39

B. Sequence of Operations (jam

detection).............................7-40

1. Delay Jams.....................7-40

2. Stationary Jams..............7-43

VIII.DISASSEMBLY/ASSEMBLY....7-44

A. Manual Tray Assembly........7-45

1. Removing the Manual Tray

Unit.................................7-45

2. Removing the Pickup Roller

.......................................7-46

3. Mounting the Pickup Roller

.......................................7-46

4. Removing the Feeding Roller

.......................................7-47

5. Orientation of the Feeding

Roller..............................7-47

6. Removing the Separation

Roller..............................7-48

7. Adjusting the Tension of the

Separation Roller............7-48

8. Removing the Manual Feed

Tray Paper Sensor .........7-49

9. Routing the Manual Feed Tray

Assembly Side Guide Timing

Belt .................................7-51

10. Position of the Pickup Roller

Releasing Solenoid of the

Manual Feed Tray ..........7-52

11. Removing the Manual Feed

Roller..............................7-52

12. Mounting the Manual Feed

Roller..............................7-54

B. Deck/Cassette Pickup Assembly

............................................7-55

1. Removing the Front Deck

(right) ..............................7-55

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

ix

2. Removing the Pickup

Assembly of the Front Deck

(left) ................................7-56

3. Removing the Cassette 3

Pickup Assembly ............7-57

4. Removing the Cassette 4

Pickup Assembly ............7-57

5. Removing the Pickup Roller

.......................................7-57

6. Removing the Feeding Roller

.......................................7-59

7. Orientation of the Feeding

Roller of the Cassette Pickup

Assembly........................7-59

8. Removing the Separation

Roller..............................7-59

9. Adjusting the Pressure of the

Separation Roller............7-61

10. Orientation of the Separation

Roller..............................7-61

11. Position of the Pickup Roller

Releasing Solenoid of the

Cassette (3/4).................7-62

12. Adjusting the Registration of

the Front Deck (right/left)

.......................................7-63

13. Adjusting the Registration of

the Cassette 3/4 .............7-63

14. Removing the Lifter Motor

(M16/M17) of the Cassette (3/

4) ....................................7-64

15. Adjusting the Position of the

Lifter Motor M16 (M17) for the

Cassette 3 (4).................7-65

C. Vertical Path Roller Assembly

............................................7-67

1. Removing the Vertical Path

Roller 1/3/4.....................7-67

2. Removing the Vertical Path

Roller 2...........................7-68

D. Registration Feeding Assembly

............................................7-70

1. Removing the Registration

Clutch/Registration Brake

Clutch .............................7-70

2. Removing the Registration

Brake Clutch...................7-70

3. Removing the Registration

Roller..............................7-71

4. Removing the Pre-

Registration Roller..........7-72

E. Feeding Assembly...............7-74

1. Removing the Feeding Belt

.......................................7-74

2. Removing the Fixing Feeding

Unit Releasing lever Sensor

.......................................7-76

F. Duplexing Unit.....................7-77

1. Removing the Duplexing Unit

.......................................7-77

2. Removing the Front Cover of

the Duplexing Unit..........7-77

3. Removing the Reversing

Flapper Solenoid ............7-78

4. Removing the Reversal Motor

.......................................7-78

5. Removing the Lower Feeder

Motor ..............................7-79

6. Removing the Horizontal

Registration Motor ..........7-79

7. Removing the Deck (left)

Draw-Out Clutch/Lower

Feeder Middle Clutch .....7-81

8. Removing the Lower Feeding

Right Clutch....................7-81

9. Removing the Duplexing

Reversal Sensor.............7-82

10. Removing the U-Turn Sensor

.......................................7-85

11. Removing the Pre-Confluence

Sensor............................7-85

12. Removing the Post-

Confluence Sensor.........7-86

13. Removing the Front Deck

(lifter) Draw-Out Sensor .7-87

14. Removing the Horizontal

Registration sensor ........7-87

CHAPTER 8 FIXING SYSTEM

I. OPERATIONS............................8-1

A. Outline ...................................8-1

x

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

B. Basic Sequence of Operations

(fixing system) .......................8-4

II. FIXING DRIVE SYSTEM............8-5

A. Outline ...................................8-5

B. Controlling the Fixing Roller Drive

Mechanism ............................8-6

C. Controlling the Cleaning Belt

Drive Mechanism...................8-8

D. Controlling the Fixing Inlet Guide

Drive Mechanism...................8-9

E. Controlling the Thermistor

Reciprocating Mechanism ...8-10

F. Controlling the Upper Separation

Claw Reciprocating Mechanism

............................................8-11

III. CONTROLLING THE FIXING

TEMPERATURE ......................8-12

A. Outline .................................8-12

B. Down Sequence Control .....8-13

C. Controlling Temperature by Mode

............................................8-14

1. Transparency Mode .......8-15

2. Thick Paper Mode .......... 8-16

3. Power Save Mode .......... 8-17

D. Error Detection ....................8-18

IV. CONTROLLING THE FIXING

ROLLER BIAS..........................8-24

A. Outline .................................8-24

V. DISASSEMBLY/ASSEMBLY....8-25

A. Fixing Assembly ..................8-26

1. Removing the Fixing

Assembly........................8-26

B. Fixing Roller Cleaning Assembly

............................................8-29

1. Removing the Fixing Cleaning

Belt .................................8-29

2. Mounting the Fixing Cleaning

Belt .................................8-31

C. Fixing Heater and Control Parts

............................................8-32

1. Removing the Main/Sub

Heater.............................8-32

2. Mounting the Main/Sub

Heater.............................8-33

3. Removing the Thermal Switch

.......................................8-34

4. Removing the Main

Thermistor ......................8-35

5. Removing the Sub Thermistor

.......................................8-36

D. Fixing Roller Assembly........8-37

1. Removing the Upper Fixing

Roller..............................8-37

2. Mounting the Upper Fixing

Roller..............................8-39

3. Removing the Lower Fixing

Roller..............................8-40

4. Adjusting the Nip ............8-40

E. Separation Claw Assembly . 8-42

1. Removing the Upper

Separation Claw............. 8-42

2. Removing the Lower

Separation Claw............. 8-42

F. Delivery Assembly............... 8-43

1. Removing the External

Delivery Roller ................8-43

2. Removing the Internal

Delivery Roller ................8-44

3. Removing the Delivery Speed

Switch Clutch..................8-45

G. Paper Sensors.....................8-46

1. Removing the Claw Jam

Sensor............................8-46

2. Removing the External

Delivery Roller ................8-46

3. Removing the Internal

Delivery Sensor ..............8-46

4. Removing the Reversal

Sensor............................8-47

5. Removing the Fixing/Feeding

Unit Outlet Sensor.......... 8-47

CHAPTER 9 EXTERNALS/AUXILIARY MECHANISMS

I. CONTROL PANEL .....................9-1

A. Outline ...................................9-1

II. DOWNLOADING........................9-2

A. Outline ...................................9-2

III. COUNTERS ...............................9-4

IV. FANS ..........................................9-6

A. Arrangement, Functions, and

Error Codes ...........................9-6

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

B. Sequence of Operations........9-8

1. 2-Speed Control ...............9-8

2. Sequence of Operations...9-9

V. POWER SUPPLY.....................9-10

A. Outline of the Power Supply

............................................9-10

B. Turning on the Power ..........9-12

1. Outline............................9-12

xi

2. Power Supply at Main Power

Switch-On....................... 9-14

3. Power Supply at Main Power

Switch-On and Control Panel

Switch-On....................... 9-15

C. Rated Outputs of the DC Power

Supply PCB .........................9-16

D. Protective Functions............9-17

E. Backup Battery ....................9-18

1. MFC PCB .......................9-18

2. Image Processor PCB....9-19

VI. OTHERS ..................................9-21

A. Sleep Mode .........................9-21

1. Outline............................9-21

2. Operation........................9-22

B. Low Power mode.................9-23

C. Silence Mode .......................9-24

D. Power Save Mode...............9-24

VII. DISASSEMBLY/ASSEMBLY....9-25

A. External Covers...................9-26

1. Removing the Front Door

.......................................9-27

2. Removing the Inside Upper

Cover..............................9-28

3. Removing the Fixing/Feeding

Unit Cover ......................9-28

4. Removing the Rear Cover

.......................................9-29

B. Control Panel.......................9-30

1. Removing the Control Panel

.......................................9-30

2. Removing the Control Panel

Controller (CPU) PCB and the

Control Panel Inverter PCB

.......................................9-31

3. Removing the Control Panel

PCB and the LCD Panel

.......................................9-32

C. Fans ....................................9-34

1. Removing the Primary

Charging Assembly Fan

.......................................9-34

2. Removing the Fixing Heat

Discharge Fan................9-35

3. Removing the Scanner

Cooling Fan....................9-35

4. Removing the Stream

Reading Fan...................9-36

5. Removing the Laser Cooling

Fan .................................9-37

6. Removing the De-Curling Fan

.......................................9-38

7. Removing the Feeding Fan

.......................................9-39

8. Removing the Drum Fan

.......................................9-40

9. Removing the Inverter Cooling

Fan .................................9-41

10. Removing the Pre-Transfer

Charging Assembly Fan

.......................................9-42

11. Removing the Power Supply

Cooling Fan 1.................9-43

12. Removing the Power Supply

Cooling Fan 2.................9-44

13. Removing the Separation Fan

.......................................9-45

14. Removing the Laser Scanner

Fan .................................9-46

D. Drive Assembly ...................9-48

1. Removing the Left Pickup

Drive Assembly ..............9-48

2. Removing the Pickup Drive

Assembly........................9-49

3. Removing the Developing

Drive Assembly ..............9-50

4. Removing the Vertical Path

Drive Assembly ..............9-51

5. Removing the Waste Toner

Drive Assembly ..............9-52

6. Removing the Multifeeder

Pickup Drive Assembly...9-53

7. Removing the Lifter Drive

Assembly (right deck).....9-54

8. Removing the Lifter Drive

Assembly (for the left deck)

.......................................9-55

9. Removing the Main Drive

Assembly........................9-56

10. Removing the Drum Drive

Assembly........................9-57

11. Removing the Cassette

Pickup Drive Assembly...9-60

12. Removing the Toner Cartridge

Drive Assembly ..............9-61

E. Switches ..............................9-62

1. Removing the Cover Switch

(door switch) Assembly

.......................................9-62

2. Removing the Manual Feed

Tray Switch Assembly ....9-63

3. Removing the Drum Heater

Switch Assembly ............9-64

F. DC Controller PCB ..............9-65

G. Power Supply Unit...............9-66

H. High-Voltage Transformer (AC)

............................................9-67

I. High-Voltage Transformer (DC)

............................................9-67

xii

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

J. Relay PCB...........................9-68

K. MFC PCB ............................9-68

CHAPTER 10 SIDE PAPER DECK

L. Routing the Belt...................9-71

I. SIDE PAPER DECK.................10-1

A. Inputs to and Outputs from the

Side Deck Driver .................10-1

1. Inputs to the Side Deck Driver

(1/2)................................10-1

2. Inputs to the Side Deck Driver

Input (2/2).......................10-2

3. Outputs from the Side Deck

Driver (1/1) .....................10-3

B. Pickup..................................10-4

1. Outline............................10-4

2. Pickup Operation............10-4

3. Sequence of Operations

(pickup from the deck)....10-6

C. Deck Paper Detection .........10-7

1. Detecting the Presence/

Absence of Paper...........10-7

2. Switching the Deck Paper

Size ................................10-7

3. Deck Paper Level Detection

.......................................10-8

D. Deck Lifter ...........................10-9

1. Detecting the Presence/

Absence of Paper...........10-9

2. Paper Level Indicator on the

Deck Front Cover .........10-11

E. Opening/Closing the Deck

(compartment) ...................10-12

1. Opening/Closing the Deck

.....................................10-12

2. Sequence of Operations

(opening/closing the deck)

.....................................10-13

F. Controlling the Deck Motor

..........................................10-14

1. Controlling the Deck Main

Motor (M101)................10-14

2. Controlling the Deck Lifter

Motor (M102)................10-16

II. DETECTING JAMS ................10-18

A. Outline ...............................10-18

III. DISASSEMBLY/ASSEMBLY..10-20

A. External Covers.................10-21

1. Removing the Front Cover

.....................................10-21

2. Removing the Rear Cover

.....................................10-24

3. Removing the Right Cover

.....................................10-24

4. Removing the Upper Cover

.....................................10-25

B. Deck Body.........................10-26

1. Detaching the Deck from the

Copier...........................10-26

2. Removing the Compartment

.....................................10-28

3. Changing the Deck Paper

Size ..............................10-30

4. Adjusting the Deck

Registration ..................10-31

5. Adjusting the Position of the

Roll ...............................10-31

C. Drive Mechanisms.............10-32

1. Removing the Deck Pickup

Clutch (CL102) .............10-32

2. Removing the Deck Feeding

Clutch (CL101) .............10-32

3. Removing the Deck Main

Motor (M101)................10-33

4. Removing the Deck Lifter

Motor (M102)................10-33

5. Removing the Lifter Cable

(front of the deck) .........10-34

6. Removing the Lifter Cable

(rear of the deck) ..........10-36

7. Routing the Lifter Cable

.....................................10-38

D. Feeding System ................10-39

1. Removing the Deck Pickup

Unit...............................10-39

2. Removing the Deck Pickup

Roller............................10-39

3. Orientation of the Deck Pickup

Roller............................10-40

4. Removing the Deck Pickup/

Feeding Roller..............10-40

5. Orientation of the Deck

Pickup/Feeding Roller ..10-41

6. Removing the Deck

Separation Roller..........10-41

7. Adjusting the Pressure of the

Deck Separation Roller

.....................................10-42

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

xiii

8. Positioning the Deck Pickup

Roller Releasing Solenoid

(SL101).........................10-43

E. Electrical System...............10-44

CHAPTER 11 INSTALLATION

1. Removing the Side Deck

Driver PCB ...................10-44

2. Removing the Open Switch

PCB..............................10-44

I . SELECTING THE SITE............11-1

II . UNPACKING AND INSTALLATION

.................................................11-4

A. Unpacking ...........................11-5

B. Mounting the Scanner .........11-8

C. Mounting the Fixing Assembly

............................................11-9

D. Mounting the Corona Assemblies

..........................................11-10

E. Checking the Developing

Assembly...........................11-13

F. Mounting the Pick-Up Assembly

..........................................11-14

G. Supplying Toner ................11-15

H. Mounting the ADF .............11-16

I. Checking Images/Operations

(user mode) .......................11-17

J. Changing the Size of the Front

Deck (right and left) ...........11-20

III . RELOCATING THE COPIER

...............................................11-21

IV . INSTALLING THE CONTROL

CARD V..................................11-22

1. Removing the Control Panel

.....................................11-22

2. Before Installing the Control

Card..............................11-24

3. Installing the Control Card

.....................................11-25

V . INSTALLING THE REMOTE

DIAGNOSTIC DEVICE II........11-27

VI . INSTALLING THE COPY DATA

CONTROLLER-A1 .................11-36

A. Setting the Board...............11-36

B. Installing to the Copier.......11-39

C. Checking the Operation .....11-42

VII .INSTALLING THE CASSETTE

HEATER (FOR 120V MODEL:

CASSETTE HEATER UNIT 15)

...............................................11-53

A. Installing to the Copier.......11-53

CHAPTER 12 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS .....................................12-1

II. DURABLES TABLE..................12-2

A. Copier..................................12-2

B. Side Paper Deck .................12-5

III. SCHEDULED SERVICING CHART

.................................................12-6

CHAPTER 13 TROBLESHOOTING

I . GUIDE TO TROUBLESHOOTING

TABLES....................................13-1

A . Image Adjustment Basic

Procedure............................13-3

IV. SCHEDULED SERVICING ITEMS

.................................................12-8

A. Copier..................................12-8

B. Work Steps........................12-11

1. Work 1..........................12-11

2. Work 2..........................12-12

B . Points to Note for Scheduled

Servicing..............................13-6

II . STANDARDS AND ADJUSTMENTS

.................................................13-7

xiv

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

A. Adjusting Images.................13-7

1. Adjusting the Image Position

.......................................13-7

2. Adjusting the Left/Right Image

Margin ............................13-8

3. Adjusting the Image Leading

Edge Margin.................13-12

4. Adjusting the Left/Right Non-

Image Width .................13-12

5. Adjusting the Image Leading

.....................................13-13

B. Scanner System ................13-14

1. Replacing the Scanner Drive

Cable............................13-14

2. Adjusting the Scanner Mirror

Mount ...........................13-14

3. After Replacing the Scanning

Lamp ............................13-14

C. Image Formation System ..13-15

1. Routing the Primary Charging

Assembly Grid Wire......13-15

2. Routing the Charging

Assembly Charging Wires

.....................................13-15

3. Mounting the Drum Cleaning

Blade ............................13-15

4. Mounting the Developing

Blade ............................13-15

5. Replacing the Potential

Sensor/Potential Control PCB

.....................................13-15

D. Pickup/Feeding System .....13-18

1. Orienting the Deck/Cassette

Pickup Roller ................13-18

2. Orienting the Deck/Cassette

Separation Roller..........13-19

3. Orienting the Deck/Cassette

Pickup Assembly Feeding

Roller............................13-19

4. Orienting the Manual Feed

Tray/Side Paper Deck Pickup

Roller............................13-20

5. Orienting the Manual Feed

Pickup Roller ................13-21

6. Orienting the Side Paper Deck

Feeding Roller..............13-21

7. Adjusting the Pressure of the

Deck/Cassette Separation

Roller............................13-22

8. Adjusting the Pressure of the

Manual Tray Pickup/Feeding

Roller............................13-23

9. Mounting the Solenoids

.....................................13-24

9-1.Position of the Fixing Inlet

Guide Solenoid (SL1) ...13-25

9-2.Position of the Fixing Cleaning

Belt Solenoid (SL2) ......13-26

9-3.Position of the Delivery

Flapper Solenoid (SL3)

.....................................13-27

9-4.Position of the Fixing/Feeding

Unit Locking Solenoid (SL4)

.....................................13-27

9-5.Position of the Multifeeder

Pickup Latching Solenoid

(SL6).............................13-28

9-6.Position of the Deck (right)

Pickup Solenoid (SL7)..13-29

9-7.Position of the Deck (left)

Pickup Solenoid (SL8)..13-30

9-8.Position of the Cassette 3/4

Pickup Solenoid (SL9/10)

.....................................13-31

9-9.Position of the Side Paper

Deck Pickup Roller Releasing

Solenoid .......................13-32

10. Routing the Manual Feed Tray

Assembly Side Guide Timing

Belt ...............................13-32

11. Routing the Drive Belt ..13-33

E. Fixing System....................13-34

1. Point to Note When Mounting

the Fixing Heater ..........13-34

2. Position of the Fixing

Assembly Inlet Guide ...13-34

3. Adjusting the Lower Roller

Pressure (nip)...............13-36

F. Laser Exposure System ....13-37

1 After Replacing the Laser Unit

.....................................13-37

2 Checking the Laser Power

.....................................13-38

G. Electrical Parts .................. 13-41

1 After Replacing the CCD Unit

.....................................13-41

2 After Replacing the Image

Processor PCB.............13-42

3 After Replacing the MFC PCB

.....................................13-43

4. After Replacing the Hard Disk

.....................................13-44

5. After Replacing the DC

Controller PCB .............13-45

6. Checking the Surface

Potential Control System

.....................................13-45

7. Checking the Potential

System .........................13-51

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

xv

8. Potential Control System

Conversion Table .........13-53

9. Checking the Environment

Sensor..........................13-57

10. Checking the

Photointerrupters..........13-58

III . TROUBLESHOOTING IMAGE

FAULTS..................................13-63

A. Making Initial Checks ........13-63

1. Checking the Site .........13-63

2. Checking the Originals

.....................................13-63

3. Copyboard Cover, Copyboard

Glass, and Standard White

Plate .............................13-64

4. Checking the Charging

Assemblies...................13-64

5. Checking the Developing

Assembly......................13-64

6. Checking Papers ..........13-64

7. Checking the Periodically

Replace Parts...............13-64

8. Others...........................13-64

B. Samples of Image Faults...13-66

C. Troubleshooting Image Faults

..........................................13-67

1. The copy is too light (halftone

area).............................13-67

2. The copy is too light (solid

black area)....................13-68

3. The copy is too light (entire

area, considerably).......13-68

4. The copy has uneven density

(darker at front).............13-69

5. The copy has uneven density

(lighter at front). ............13-69

6. The copy is foggy (entire

area).............................13-70

7. The copy is foggy (vertical).

.....................................13-71

8. The copy has black lines

(feeding direction, fuzzy,

thick).............................13-71

9. The copy has black lines

(feeding direction, fine).

.....................................13-72

10. The copy has white spots

(vertical)........................13-73

11. The copy has white lines

(vertical)........................13-73

12. The copy has white spots

(horizontal). ..................13-74

13. The back of the copy is soiled

.....................................13-75

14. The copy has poor fixing.

.....................................13-76

15. The copy has a displaced

leading edge (appreciably

excess margin). ............13-77

16. The copy has a displaced

leading edge (excess margin).

.....................................13-77

17. The copy has a displaced

leading edge (no margin).

.....................................13-77

18. The copy has a blurred image.

.....................................13-78

19. The copy is foggy (horizontal).

.....................................13-79

20. The copy has poor sharpness.

.....................................13-79

21. The copy is blank. ........13-80

22. The copy is solid black.

.....................................13-81

IV . TROUBLESHOOTING

MALFUNCTIONS ...................13-82

A. Troubleshooting Malfunctions

..........................................13-82

1. E000.............................13-82

2. E001.............................13-83

3. E002.............................13-83

4. E003.............................13-83

5. E004.............................13-84

6. E005.............................13-84

7. E010.............................13-84

8. E012.............................13-85

9. E013.............................13-85

10. E014 .............................13-86

11. E015 .............................13-86

12. E019 .............................13-86

13. E020 .............................13-87

14. E025 .............................13-87

15. E030 .............................13-88

16. E031 .............................13-88

17. E032 .............................13-88

18. E043 .............................13-89

19. E051 .............................13-89

20. E060 .............................13-90

21. E063 .............................13-90

22. E065 .............................13-91

23. E066 ..........................13-91-2

24. E067 ..........................13-91-3

25. E068 .............................13-92

26. E069 ..........................13-92-2

27. E100 ..........................13-92-3

28. E102 .............................13-93

29. E110 .............................13-93

30. E111 .............................13-93

xvi

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

31. E121 .............................13-94

32. E202 .............................13-94

33. E204 .............................13-94

34. E211 .............................13-95

35. E215 .............................13-95

36. E218 .............................13-95

37. E219 .............................13-95

38. E220 .............................13-95

39. E222 .............................13-95

40. E226 .............................13-96

41. E240 .............................13-96

42. E241 .............................13-96

43. E243 .............................13-96

44. E251 .............................13-97

45. E302 .............................13-97

46. E320 .............................13-97

47. E601 .............................13-97

48. E602 .............................13-98

49. E677 .............................13-98

50. E710 .............................13-98

51. E711 .............................13-98

52. E712 .............................13-98

53. E713 .............................13-99

54. E717 .............................13-99

55. E800 .............................13-99

56. E804 ...........................13-100

57. E805 ...........................13-100

58. E820 ...........................13-100

59. E823 ...........................13-101

60. E824 ...........................13-101

61. E830 ...........................13-101

62. AC power is absent. ...13-102

63. The DC power supply fails to

operate 1. ...................13-103

64. The DC power supply fails to

operate 2. ...................13-104

65. Pickup operation fails.

...................................13-105

66. The lifter fails to move up.

...................................13-106

67. The lifter fails to move up.

(cassette pickup) ........13-107

68. Pickup operation fails.

(multifeeder pickup)....13-108

69. The vertical path roller fails to

rotate. .........................13-109

70. The registration roller fails to

rotate. .........................13-109

71. The No. 1 mirror fails to

operate. ......................13-110

72. The pre-exposure lamp fails to

turn on. .......................13-111

73. The scanning lamp fails to

turn on. .......................13-111

74. The cartridge inside toner

feeder motor (M6) fails to

operate. ......................13-112

75. The hopper inside toner

feeder motor (M18) fails to

operate. ......................13-112

76. The drum heater fails to

operate. ......................13-112

77. The Add Toner indicator fails

to turn on. ...................13-113

78. The Add Toner fails to turn on

...................................13-113

79. The Control Card Set

message fails to turn on

...................................13-113

80. The Control Card Set

message fails to turn off.

...................................13-114

81. The Add Paper message fails

to turn off. (deck right/left)

...................................13-114

82. The Add Paper message fails

to turn off. (cassette 3/4)

...................................13-114

83. The fixing heater fails to

operate. ......................13-115

84. Pickup operation fails. (side

paper deck) ................13-116

85. The deck lifter fails to move

up. (side paper deck)

...................................13-117

V . TROUBLESHOOTING FEEDING

PROBLEMS .........................13-118

A. Copy Paper Jams............13-118

1. Pickup Assembly ........13-119

2. Separation/Feeding Assembly

...................................13-120

3. Fixing/Delivery Assembly

...................................13-121

4. Fixing/Delivery Assembly

(reversal delivery assembly)

...................................13-121

5. Cleaner Unit ...............13-122

6. Lower Feeding Assembly

...................................13-122

B. Faulty Feeding.................13-123

1. Double feeding ...........13-123

2. Wrinkles......................13-123

VI . ARRANGEMENT AND FUNCTIONS

OF PARTS ...........................13-124

A. Clutches ..........................13-124

B. Solenoids.........................13-126

C. Motors .............................13-128

D. Fans ................................13-130

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

xvii

E. Sensors 1 ........................13-132

F. Sensors 2 ........................13-134

G. Switches ..........................13-136

H. Counters, Heaters, Fuses, and

Others..............................13-138

I. PCBs ...............................13-140

J. Side Paper Deck .............13-142

1. Sensors and Switches

...................................13-142

2. Motors, Clatches, Solenoids,

and PCBs ...................13-144

K. Variable Registers (VR), Light-

Emitting Diodes, and Check Pins

by PCB ............................13-146

1. MFC PCB ...................13-147

2. Image Processor PCB

...................................13-148

3. DC Controller PCB .....13-149

4. DC Power Supply PCB

...................................13-150

5. Relay PCB..................13-150

6. Control Panel CPU PCB

...................................13-151

7. HV-DC PCB................13-152

8. Side Deck Driver (side paper

deck)...........................13-153

VII .UPGRADING THE COPIER.13-154

A. Replacing the DIMM........13-154

1. Removing the DIMM of the

Image Processor PCB

...................................13-155

2. Removing the DIMM of the

MFC PCB ...................13-156

B. Downloading....................13-157

1. Before the Work .........13-157

2. Downloading...............13-157

VIII . SERVICE MODE ...............13-160

A. Outline .............................13-160

1. Starting Service Mode and

Selecting an Item........13-161

2. Ending Service Mode

...................................13-162

3. Backing Up the RAM

...................................13-162

4. Basic Operation..........13-163

B. DISPALY Control Display Mode

........................................13-165

C. I/O Input/Output Display Mode

........................................13-176

1. DC-CON .....................13-177

2. IP................................13-179

3. FEEDER.....................13-189

4. SORTER ....................13-193

5. FM-CON ..................13-203-8

D. ADJUST Adjustment Mode

........................................13-204

E. FUNCTION Operation/Inspection

Mode ...............................13-218

F. OPTION Settings Mode...13-230

G. PG Test Print...................13-242

1. Grid (PG-TYPE 1) ......13-243

2. Vertical Lines (PG-TYPE 2)...

...................................13-243

3. Horizontal Lines (PG-TYPE 3)

...................................13-243

4. Halftone (PG-TYPE 4) 13-244

5. 17-Gradation (PG-TYPE 5)

...................................13-244

6. Blank (PG-TYPE 6) ....13-244

7. Halftone (PG-TYPE 7) 13-245

8. Solid Black (PG-TYPE 8)

...................................13-245

H. COUNTER Mode.............13-246

IX. SELF DIAGNOSIS ...............13-250

A. Copier Self Diagnosis......13-250

B. ADF Self Diagnosis .........13-258

C. Finisher -D1 Self Diagnosis

........................................13-259

D. Saddle Finisher -D2 Self

Diagnosis.........................13-261

1. Finisher.......................13-261

2. Saddle Stitcher...........13-264

3. Folder .........................13-265

4. Inserter .......................13-266

APPENDIX

A. GENERAL TIMING CHART ...... A-1

B. LIST OF SIGNALS/

ABBREVIATIONS ..................... A-3

C. GENERAL CIRCUIT DIAGRAM

.................................................. A-9

xviii

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

D. SPECIAL TOOLS TABLE........ A-17

E. SOLVENTS/OILS .................... A-19

CHAPTER 1

GENERAL DESCRIPTION

This chapter provides specifications of the copier, instructions on how to operate the

copier, and an outline of copying processes.

I. FEATURES ................................1-1

II. SPECIFICATIONS......................1-2

A. Copier ....................................1-2

B. Side Paper Deck-C1............ 1-10

III. NAMES OF PARTS.................. 1-11

A. External View ......................1-11

B. Cross Section ...................... 1-14

IV. OPERATING THE COPIER .....1-16

A. Turning on the Power Switch

............................................1-16

B. Control Panel.......................1-17

C. Extension Mode...................1-18

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

D. User Mode ........................... 1-19

V. ROUTINE MAINTENANCE BY THE

USER .......................................1-21

VI. SAFETY ...................................1-22

A. Safety of Laser Light ...........1-22

B. CDRH Regulations.............. 1-23

C. Handling the Laser Assembly

............................................1-24

D. Safety of Toner.................... 1-28

VII. IMAGE FORMATION ............... 1-29

A. Outline.................................1-29

CHAPTER 1 GENERAL DESCRIPTION

I . FEATURES

1. High-Speed Operation, High Quality Image

Copying speed : 60 copies/min (1-to-n),

55 copies/min (stream reading, 1-to-1)

Reading resolution : 600 × 600 dpi

Output resolution : 1,200-equivalent × 600 dpi

Printer output resolution (w/accessory) : 2,400-equivalent × 600 dpi

1,200-equivalent × 600 dpi (for 120-V UL model)

2. Image Server as Standard

The copier comes standard with a 2-GB hard disk, enabling electronic sorting.

When making multiple copies of a single original, the original may be read no more than once

to turn out as many copies as needed.

3. No-Stacking Duplexing Mechanism

The copier need not stack sheets in its duplexing unit, capable of processing double-sided

copies without disrupting smooth flow.

4. Large-Capacity Paper Source

The addition of accessories enables the copier to hold as many as 7,650 sheets of copy paper:

• Paper deck (right; 1,500 sheets)

• Paper deck (left; 1,500 sheets)

• Cassette 3 (550 sheets)

• Cassette 4 (550 sheets)

• Multifeeder (50 sheets)

• Side Paper Deck-C1 (accessory; 3,500 sheets)

5. Various Delivery Processing (w/ accessory)

• Finisher* (1- or 2-point stapling)

• Saddle finisher* (middle bound booklet)

*Accessory.

6. Printer Functions

The copier may be equipped with a printer board (accessory), servicing as a printer on a net-

work.

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

1-1

CHAPTER 1 GENERAL DESCRIPTION

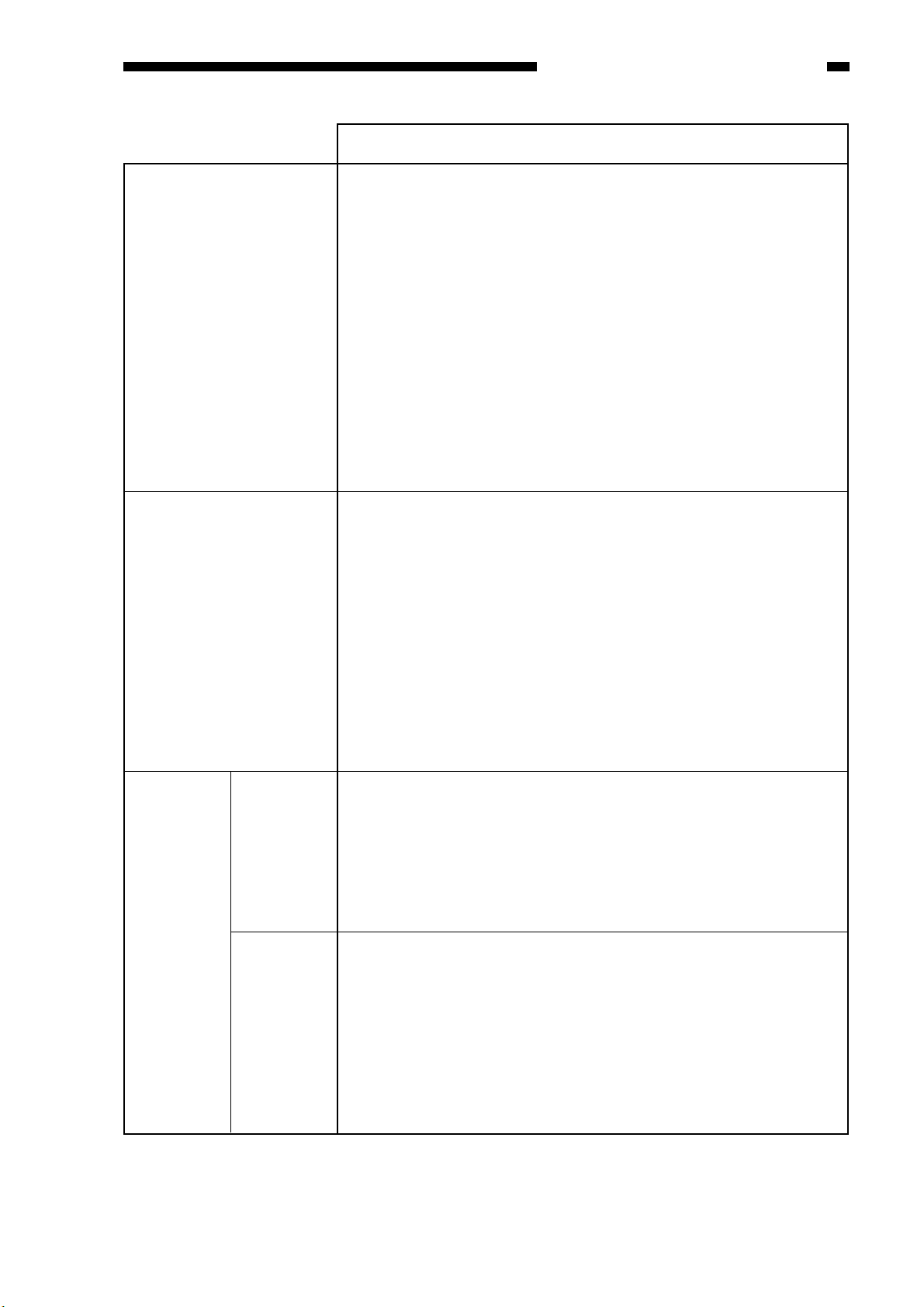

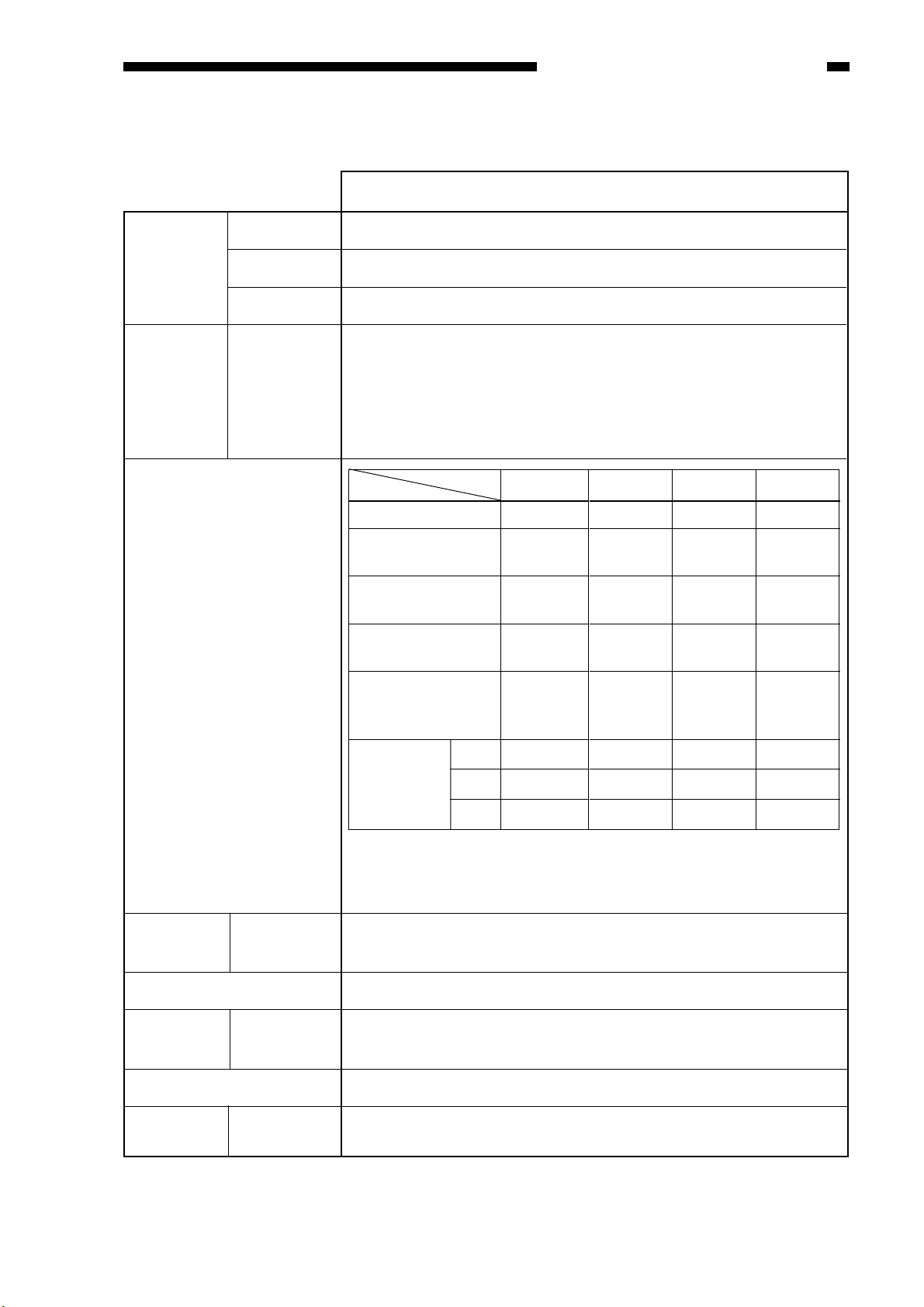

II . SPECIFICATIONS

A. Copier

1. Type

Body

Copyboard

Light source

Lens

Photosensitive medium

2. System

Copying

Charging

Exposure

Console

Fixed

Fluorescent lamp

Lens array (F3.7)

Amorphous silicon (108 mm dia.)

Table 1-201

imageRUNNER 600

Indirect photostatic

Corona

Twin laser

Copy density adjustment

Development

Pickup Auto

Manual

Transfer

Separation

Cleaning

Fixing

Auto or manual

Dry (toner projection)

Front deck (2 holders), front cassette (2 holders)

Manual feed tray

(about 5.5 mm deep; about 50 sheets of 80 g/m

Corona

Corona (static separation)

Blade

Heating rollers

GP605 (100-V model): 760 W (main) + 400 W (sub)

GP605V (100-V model): 850 W (main) + 360 W (sub)

imageRUNNER 600 (120/230-V model):910 W (main) + 390 W (sub)

2

paper)

Table 1-202

1-2

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

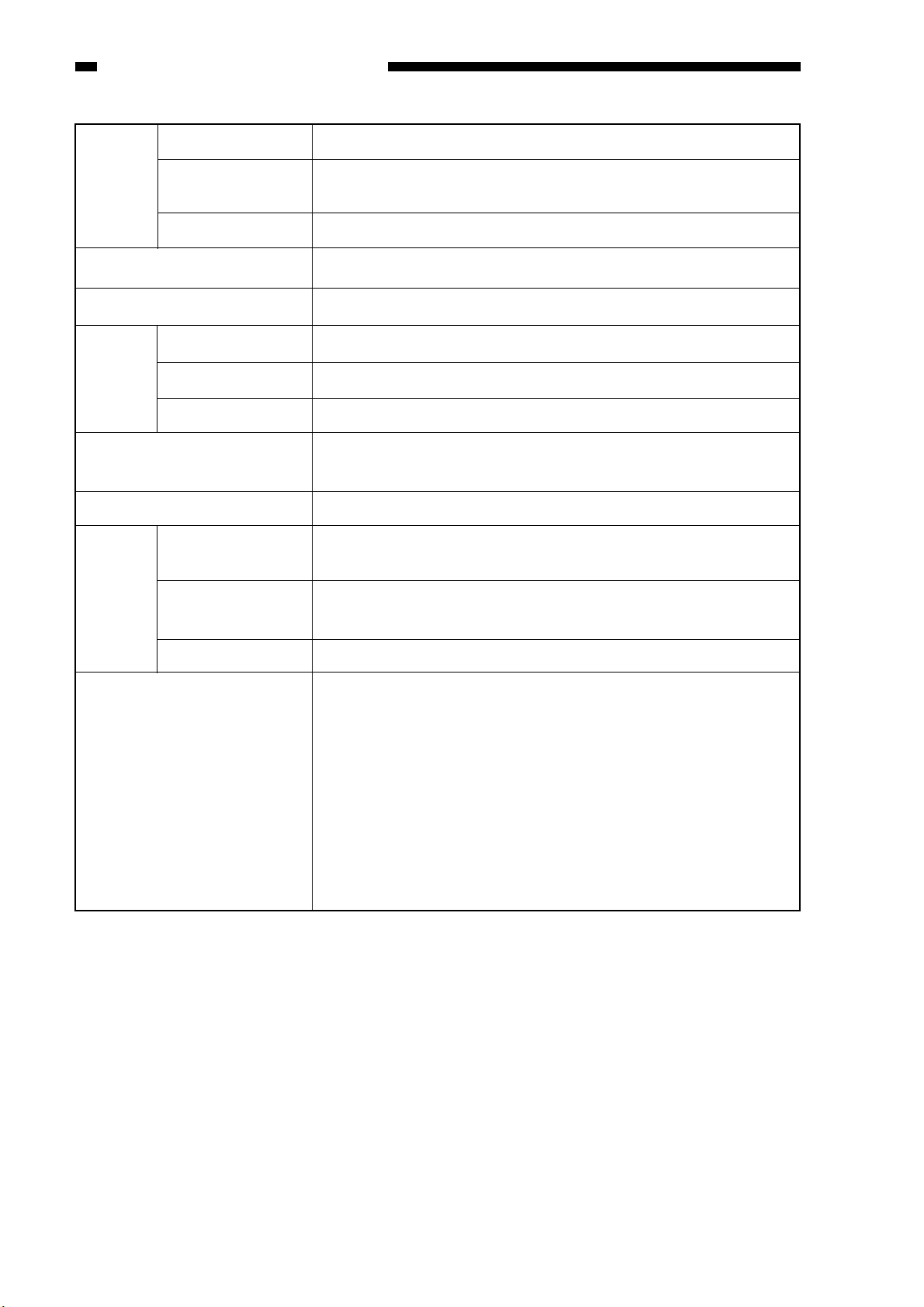

3. Performance

CHAPTER 1 GENERAL DESCRIPTION

imageRUNNER 600

Original type

Maximum original size

DIRECT

REDUCE I

REDUCE II

REDUCE III

REDUCE IV

REDUCE V

REDUCE VI

ENLARGE I

Reproduction ratio

ENLARGE II

ENLARGE III

ENALRGE IV

Sheet, book, 3-D object (2 kg max.)

A3

1 : 1

1 : 0.250

1 : 0.500

1 : 0.611

1 : 0.707

1 : 0.816

1 : 0.865

1 : 1.154

1 : 1.224

1 : 1.414

1 : 2.000

ENALRGE V

ZOOM

Wait time

First copy

Continuous copying

Copy size

1 : 4.000

1 : 0.250 to 4.00 (in 1% increments)

5 min or less (at 20°C room temperature)

6.5 sec (stream reading, right deck, Direct, A4/LTR, non-AE,

face-down delivery)

5.2 sec (book mode, cassette 1, Direct, A4/LTR, non-AE, straight delivery, not

including pre-heating of fluorescent lamp)

999 copies max.

Single-

AB

A3 max.; postcard min. (vertical feeding)

sided

Inch

279.4 × 431.8 mm (11"×17") max., STMT min. (vertical

feeding)

AB

A3 max., A5 min. (vertical feeding)

Doublesided

Inch

279.4 × 431.8 mm (11"×17") max., STMT min. (vertical

feeding)

Table 1-203-1

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

1-3

CHAPTER 1 GENERAL DESCRIPTION

• Plain Paper (64 to 80 g/m2)

A4, B5, LTR

Right deck

Left deck

• Tracing Paper (SM-1)

A4, B5

• Colored Paper (recommended by Canon)

A4

• Thick Paper (90 to 200 g/m

A4, B5, LTR

• Plain Paper (64 to 80 g/m

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

Cassette 3

• Tracing Paper (SM-1)

A3, B4, A4, B5, A4R, B5R

• Colored Paper (recommended by Canon)

B4, A4, A4R

• Thick Paper (90 to 200 g/m

A3, B4, A4, B5, AR, B5R, LTR, LTRR

Copy paper type

2

)

2

)

2

)

Manual feed tray

2

• Plain Paper (64 to 80 g/m

)

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

• Tracing Paper (SM-1, GNT-80, GSN-75)

A3, B4, A4, B5, A4R, B5R

• Colored Paper (recommended by Canon)

B4, A4, A4R

• Postcard (vertical feeding only)

Japanese government postcards

• Label Sheet (recommended by Canon)

B4, A4, A4R, LTR, LTRR

2

• Thick Paper (90 to 200 g/m

)

A3, B4, A4, B5, A4R, B5R, LTR, LTRR

Table 1-203-2

1-4

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

Single-sided mode

Face-down delivery mode

CHAPTER 1 GENERAL DESCRIPTION

Copy paper type

• Plain Paper (64 to 80 g/m2)

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

• Tracing Paper (SM-1, GNT-80, GSN-75)

A3, B4, A4, B5, A4R, B5R

• Transparency (recommended by Canon)

A4, A4R, LTR, LTRR

• Colored Paper (recommended by Canon)

B4, A4, A4R

• Postcard (vertical feeding only)

Japanese government postcards

• Label Sheet (recommended by Canon)

B4, A4, A4R, LTR, LTRR

2

• Thick Paper (90 to 200 g/m

)

A3, B4, A4, B5, A4R, B5R, LTR, LTRR

2

• Plain Paper (64 to 80 g/m

)

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

• Tracing Paper (SM-1, GNT-80, GSN-75)

A3, B4, A4, B5, A4R, B5R

• Colored Paper (recommended by Canon)

B4, A4, A4R

• Postcard (vertical feeding only)

Japanese government postcards

• Label Sheet (recommended by Canon)

B4, A4, A4R, LTR, LTRR

2

• Thick Paper (90 to 200 g/m

)

A3, B4, A4, B5, A4R, B5R, LTR, LTRR

Doublesided mode

Auto

Manual

feed tray

2

• Plain Paper (64 to 80 g/m

)

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

• Colored Paper (recommended by Canon)

B4, A4, A4R

2

• Thick Paper (90 to 200 g/m

)

A3, B4, A4, B5, A4R, B5R, LTR, LTRR

2

• Plain Paper (64 to 80 g/m

)

A3, B4, A4, B5, A5R, A4R, B5R, 279.4 × 431.8 mm (11"×17"),

LGL, LTR, LTRR, STMT (vertical feeding)

• Colored Paper (recommended by Canon)

B4, A4, A4R

• Postcard (vertical feeding only)

Japanese government postcards

2

• Thick Paper (90 to 200 g/m

)

A3, B4, A4, B5, A4R, B5R, LTR, LTRR

Table 1-203-3

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

1-5

CHAPTER 1 GENERAL DESCRIPTION

Claw

Tray

Paper deck (right,

left)

Cassette 3/4

Delivery tray

Image server (hard disk size)

Leading edge

Nonimage

Trailing edge

width

Left/right (1st side)

Auto clear

Auto power-off

Low power mode

Power

save

Auto sleep

mode

No

2

162 mm deep (approx.; about 1,500 sheets of 80 g/m

60 mm deep (approx.; about 550 sheets of 80 g/m

2

250 sheets (approx.; equivalent of 80 g/m

paper)

)

2

)

2GB

Direct, Enlarge/Reduce: 4.0 +1.5, -1.0 mm (4.0 + 1.8, -1.4 mm)*

Direct, Enlarge/Reduce: 2.5 ±1.5 mm (2.5 ±1.8 mm)*

Direct, Enlarge/Reduce: 2.5 ±1.5 mm (2.5 ±1.8 mm)*

Yes (2 min standard; may be changed between 0 and 9 min in 1min increments)

No

Yes (15 min standard; may be changed in user mode to 10, 15,

20, 30, 40, 50, 90 min or 2, 3, or 4 hr.)

Yes (60 min standard; may be changed in user mode to 10, 15,

20, 30, 40, 50, 90 min or 2, 3, or 4 hr)

Power save mode

Accessory

*When the ADF is used.

Yes

• Finisher-D1

• Saddle Finisher-D2

• Cover Insertion Unit-A1

• Paper Folding Unit-B1

• Side Paper Deck-C1

• Cassette Heater Kit-16 (for Side Paper Deck-C1)

• Remote Diagnostic Device II

• Copy Data Controller-A1

• Control Card V

• Copy Tray Unit-D1

• Original Base D1

Table 1-203-4

1-6

COPYRIGHT © 2000 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

4. Others

CHAPTER 1 GENERAL DESCRIPTION

imageRUNNER 600

Temperature

Operating

conditions

Humidity

Atmospheric

Pressure

Power

supply

Serial No.

Power consumption

15° to 30°C

5% to 80%

810.6 to 1013.3 hpa (0.8 to 1.0 atm)

100V : LLPxxxxx

100V (GP605V) : LEExxxxx

120V (UL) : NLExxxxx

120V : NLZxxxxx

230V (AMS) : ULExxxxx

230V (FRN) : SLExxxxx

100V/20A

Maximum (kW)

Continuous* (Wh)

: (Reference)

Standby (Wh)

: (Reference)

SLEEP (Wh)

: (Reference)

2.0

498

357

12

230V (UK) : QLExxxxx

230V (DL) : TLExxxxx

230V (ITA) : PLExxxxx

230V (CA) : RLExxxxx

230V : PLPxxxxx

100V/15A

1.5

497

355

12

120V

2.0

474

335

12

230V

2.0

467

330

16

Noise

(Sound power level

:impulse mode)

Copying

Stanby

Ozone (8 hr average)

Width

Dimensions

Depth

Height

Weight

Consumables

Copy paper

Toner

LOW-POWER

MODE (Wh)

158

155

141

135

: (Reference)

ENERGY

-10%

346

315

313

298

SAVER

MODE (Wh)

: (Reference)

-25%

-50%

311

269

269

224

270

216

255

200

*The operationg conditions are as follows:

As many as 10 originals are placed, the copy count is set to '20', and

this sequence is repeated three times with the intervals of jobs being

20 min.

78 dB or less

55 dB or less

0.05 ppm or less

764 mm

795 mm

1137 mm

251Kg

Keep copy paper wrapped to protect against humidity. Avoid direct

sunshine, and keep at 40°C/85% or less.

Table 1-204-1

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 600 REV.1 JAN. 2000 PRINTED IN U.S.A.

1-7