Page 1

X

X

I

I

6

6

//6

6

C

C

C

S

err

S

e

CCooppyyrriigghhtt ((CC)) CCaannoonn IInncc.. MMeeddiiccaall TTeecchhnniiccaall SSeerrvviiccee DDeepptt.. AAllll rriigghhttss RReesseerrvveedd..

D

D

vii

v

-

-

c

e

c

e

CCaannoonn IInncc.. JJaappaann

0

M

M

0

G

G

a

a

n

PPrriinntteedd bbyy CCaannoonn IInncc..

JJuull.. 22000099 RReevv..0011

Confidential

C

0

0

u

u

all

a

n

Page 2

Manual Control No. : BY8-2300-0E0

Name of Product : CXDI-60G/60C

Distribution Control No.

Issued on

Service Manual Introduction

This service manual belongs to a series of after-service guides Canon Inc. publishes as part of

its comprehensive product quality guarantee program.

This service manual consists of nine chapters; “General”, “Installation Manual”, “Functions”,

“Repair Guide”, “Parts Catalog”, “Troubleshooting”, “Service Manual Report”, “Tools” and

“Appendix”. It describes an overview of the product, its functions, product configuration,

installation procedures, dimensions, specifications, and notes.

If the product undergoes a large modification, a revised edition of the service manual will be

sent to you. In other cases, a service manual report will be sent to you to update the manual.

Note 1:

This service manual is published by Canon Inc. in accordance with Article 6 (Furnishing

the Referring Materials) of the Service Assignment Contract it has concluded with your

company.

Note 2:

This service manual is the property of Canon Inc. and the company may seek to have it

returned, depending on the circumstances. You are expected to keep it until then.

Note 3:

You inquiries, suggestions, etc. about the contents of this service manual should be

addressed to:

Medical Equipment Technical Service Dept.

Canon Inc. Headquarters

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146-8501, Japan

Page 3

Caution Regarding Service

This product was precisely assembled under strict manufacturing process control. There

are several hazardous locations inside of this product. Careless work while the cover is

removed can result in the pinching of fingers or electrical shock. Please perform the work

with the following important points in mind:

1. Setup, Repair, and Maintenance

In order to ensure safety, the best performance, setup, repair, and maintenance work can only

be performed by technicians who have received service training specified by Canon Inc. If

there are order required certificates or restrictions specified by the law or ordinances, those

regulations of the country must be observed.

2. Removing the external cover

When removing the cover during maintenance, repair, etc., perform the work after switching

the power off. Never touch the device with wet hands, as there is a risk of electric shock.

3. Fuse

When replacing the fuse, first resolve the reason for its failure and then replace the fuse with

the specified type. Never use a fuse other than the specified type.

4. Connecting the grounding wire

The provided ground wire must be connected to the ground terminal indoors. Make sure that

the device is properly grounded.

5. Alternation prohibition

Never modify the medical device in any way.

6. Waste control

The service provider is responsible for the disposal of used service parts, packing material,

etc. resulting from the setup, repair, or maintenance of the medical device. However, the

customer is responsible for the disposal of the medical device. Disposal activities must

follow the regulations (especially controlled industrial waste) of the country where the

device is used.

Page 4

VORSICHT

Befolgen Sie die unten angegebenen Sicherheitsanweisungen.

Mißachtung kann zu erletzungenoder Unfällen führen.

1.Zerlegung, Zusammenbau, Einstellung und Wartung

Zerlegung, Zusammenbau, Einstellung und Wartung dürfen nur von einem Wartungstechniker

durchgeführt werden, der an einem von Canon vorgeschriebenen Wartungslehrgang teilgenommen hat.

2.Entfernen von Abdeckungen

Schalten Sie unbedingt die Stromversorgung des Instruments aus, bevor Sie die Abdeckungen zwecks

Wartung und Reparatur entfernen.

Vermeiden Sie auch eine Berührung des Instruments mit nassen Händen.

Anderenfalls können Sie einen elektrischen Schlag erleiden, der zum Tod oder schwerer Verletzung

führen kann.

3.Sicherung

Wenn die Sicherung ausgewechselt werden muß, schalten Sie unbedingt die Stromversorgung des

Instruments aus, und beheben Sie die Ursache für das Durchbrennen der Sicherung.

Ersetzen Sie die Sicherung nur durch den vorgeschriebenen Typ.

Anderenfalls kann es zu einem Brand oder elektrischen Schlag kommen.

4.Erdleiter

Erden Sie das Instrument unbedingt an einer Schukosteckdose.

Anderenfalls kann es zu einem Brand oder elektrischen Schlag durch Leckstrom kommen.

5.Umbau

Jeder Umbau des Produktes ist strengstens untersagt, da dies zu einem Brand oder elektrischen Schlag

führen kann.

Page 5

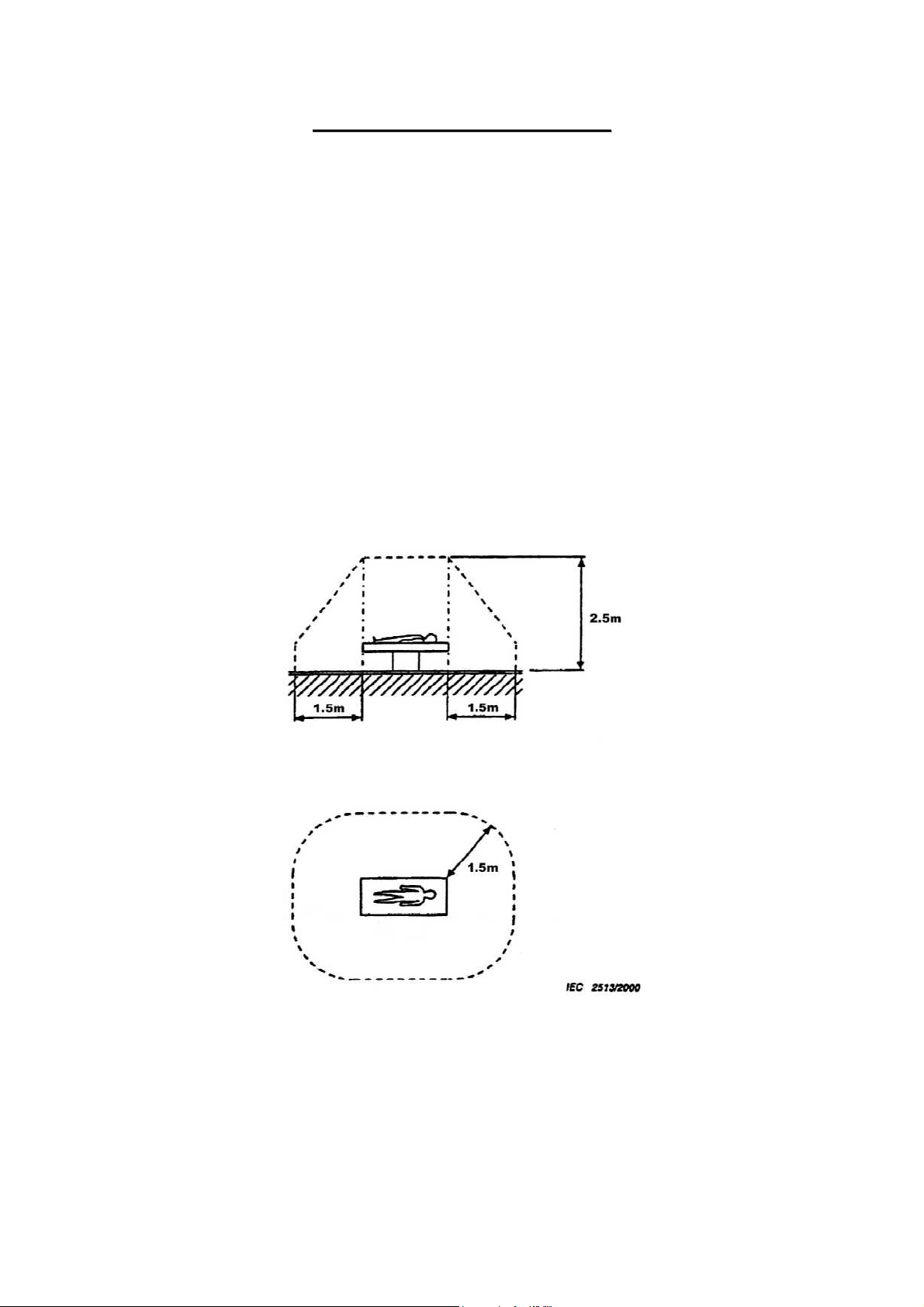

CCaauuttiioonn RReeggaarrddiinngg tthhee SSeettuupp

According to “IEC60601-1-1:2000”, devices installed in the patient environment are restricted

to “electric medical devices conforming to IEC60601-1”.

The Control PC and operation unit are classified under the data processing device standard

(IEC60950), therefore these items should not be installed in the patient environment.

The patient environment described below is an example cited from “IEC60601-1-1:2000” – the

measurements are only guidelines. However, the “IEC60601-1-1:2000” example must be treated

as the standard.

Therefore, the Control PC and operation unit must be installed in a location further than the

measurements below (outside of the patient environment).

*Areas where the patient moves (not only during imaging but when entering and leaving

the room, etc.) are also considered as part of the patient environment, therefore the

installation location should be determined upon consultation with the user regarding

areas outside of the patient environment.

Example of patient environment

Note: These measurements are only guidelines.

Page 6

r

r

C

C

CCooppyyrriigghhtt ((CC)) CCaannoonn IInncc.. MMeeddiiccaall TTeecchhnniiccaall SSeerrvviiccee DDeepptt.. AAllll rriigghhttss RReesseerrvveedd.

X

X

DII--

D

1..

1

G

G

6

0

6

0

e

n

e

n

CCaannoonn IInncc.. JJaappaann

G//

G

e

e

Printed by Canon Inc.

Jul. 2009 Rev.01

6

0

6

0

all

a

C

C

.

Page 7

Contents

1 General .................................................................................................................................. 1

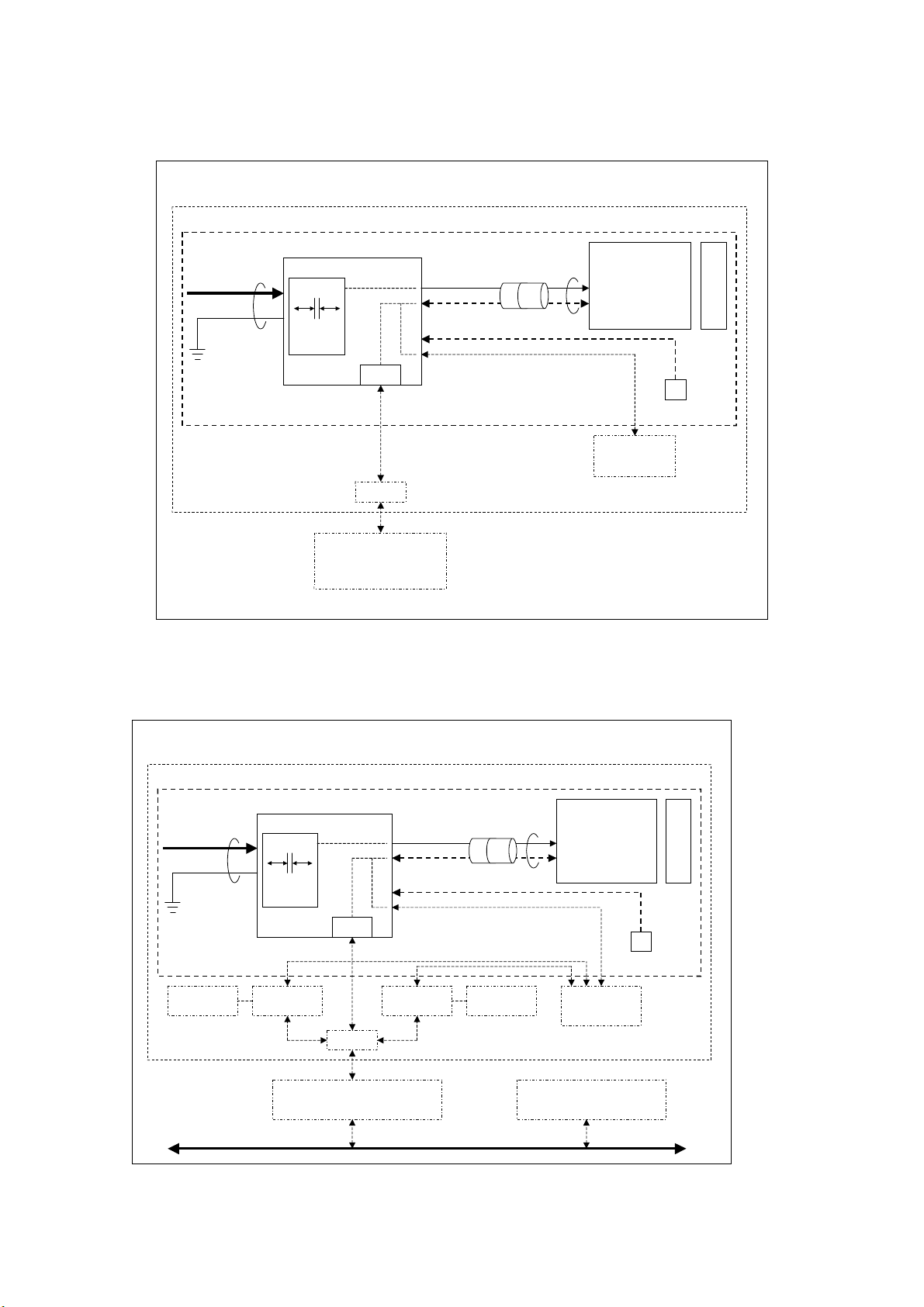

2 CXDI System Block Diagram ............................................................................................... 2

3 System Diagram .................................................................................................................... 3

4 CXDI Image Processing ........................................................................................................ 4

5 Specifications......................................................................................................................... 5

Page 8

1. General

1 General

CXDI-60G/60C represents a compact cassette model that enhances user convenience in cassettebased digital radiography. It is used in combination with Control computer (CXDI-C3, CXDI-C3S,

FC-24VE, FC-E21A or the general computers with equal performance).

The sensor cable is organized into two parts. The one is a sensor cable S150-60 (imaging unit side)

and the other is a sensor cable P630 (power box side). Two cables are connected with the connectors.

It adopts the detachable connector, which is compatible with the CXDI-55G/55C, allowing the use

of two sizes portable flat panel detector.

The vertical scanning drive (Drv-IC) and the data read out (Amp-IC) are located in one side of

LANMIT. Image data is read out from one direction.

The appearance of the CXDI-60G is almost the same as that of the CXDI-60C, but their fluorescence

substances that convert X-ray into visible light are different.

CXDI-60G

CXDI Software Ver.7.0 and later

Serial number of CXDI-60G imaging unit 100001 and later

Serial number of CXDI-60G imaging unit (nonlogo model)

CXDI-60C

CXDI Software Ver.7.2 and later

Serial number of CXDI-60C imaging unit 100001 and later

Notes on usage

From the view of risk management, guarantee is not made for the waterproofing for blood and

chemicals, hygienic safety in operating room, usage with a defibrillation device in ICU, outdoor

usage or application to animals. If the imaging unit needs to be used under such condition, the

system integrator should be responsible for the operation and understanding of the tolerance of the

product specification.

300001 and later

1

Page 9

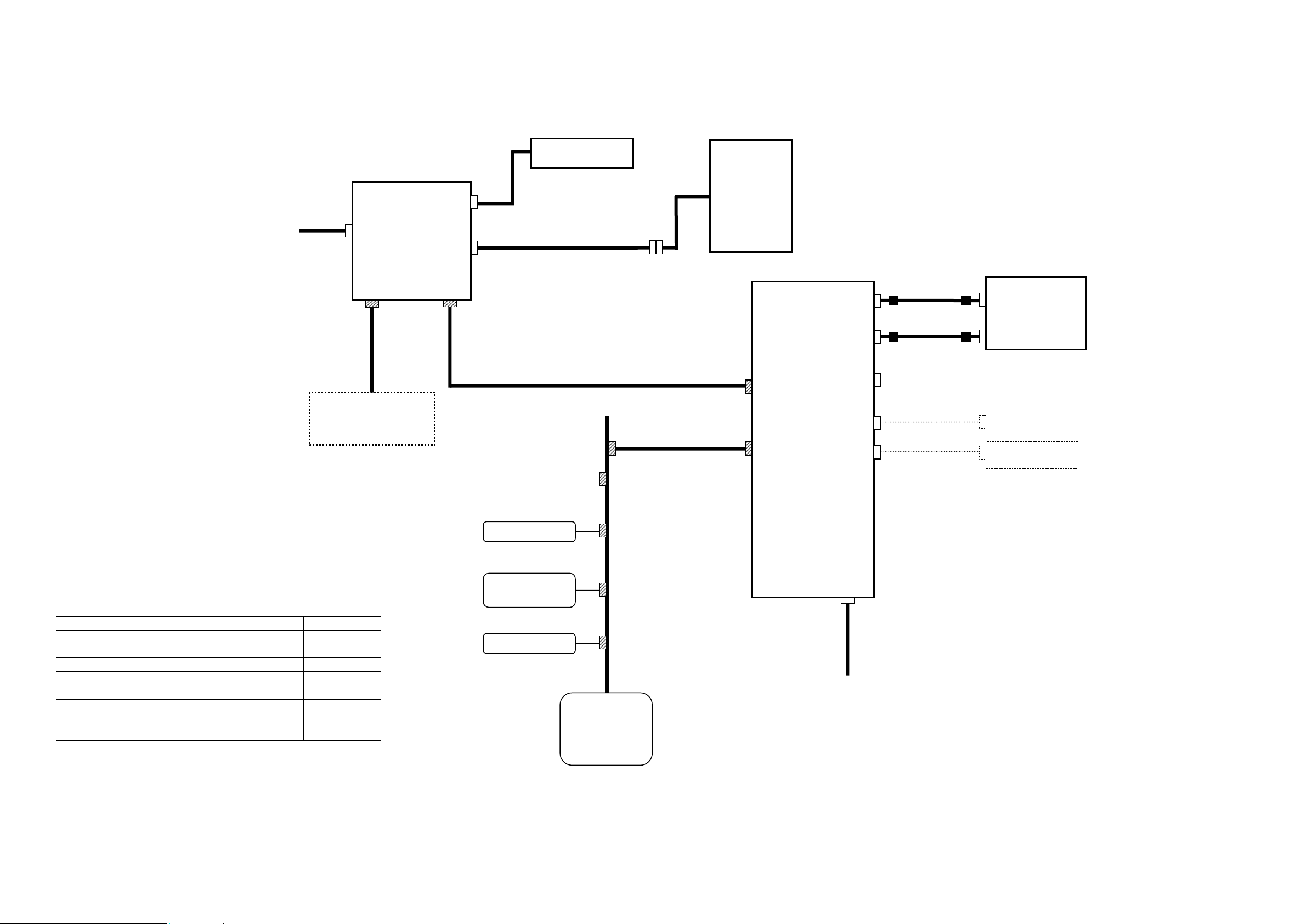

2 CXDI System Block Diagram

AC100/120V/230V

CA1

X-Ray Generator

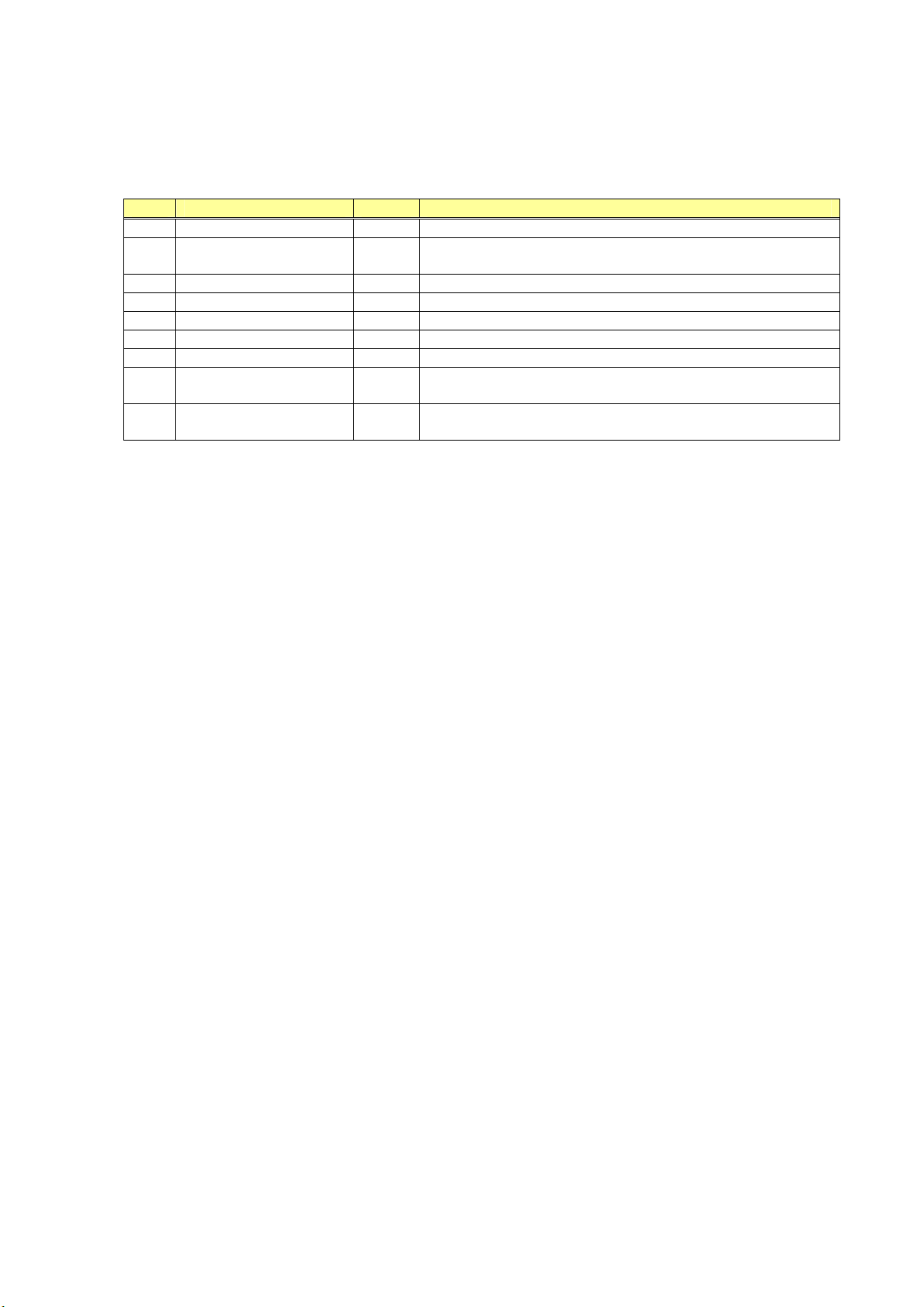

Symbol Description Remarks

CA1 AC Cable 3m

CA2 Sensor Cable 6.3m

CA3 X-Ray I/F Cable 20m

CA4 LAN Cable (Category 5)

CA5 LAN Cable (Category 5)

CA6 Serial Cable (Touch Panel)

CA7 VGA Cable

CA8 AC Cable 3m

Power Box

AC Power IN

X-Ray

I/F

CA3

OUT PUT 1

Control/Signal/

Power

OUT PUT 2

Control/Signal

Remote Switch

CA2

CA4

Printer

Image diagnosis

W/S

Image file device

1. General

Network

Ethernet

(100/10base-T)

CA5

Imaging Unit

(CXDI-60G/60C)

Control/Signal

/Power

LAN2

LAN1

AC100V~240V±10% 50/60Hz 2.2A

Control

computer

SERIA1(COM1)

VGA

SERIAL(COM2)

MOUSE

KEY BOARD

AC Power IN

CA8

CA6

CA7

RS232C

VGA

Mouse

Key Board

Operation

Unit

2

Page 10

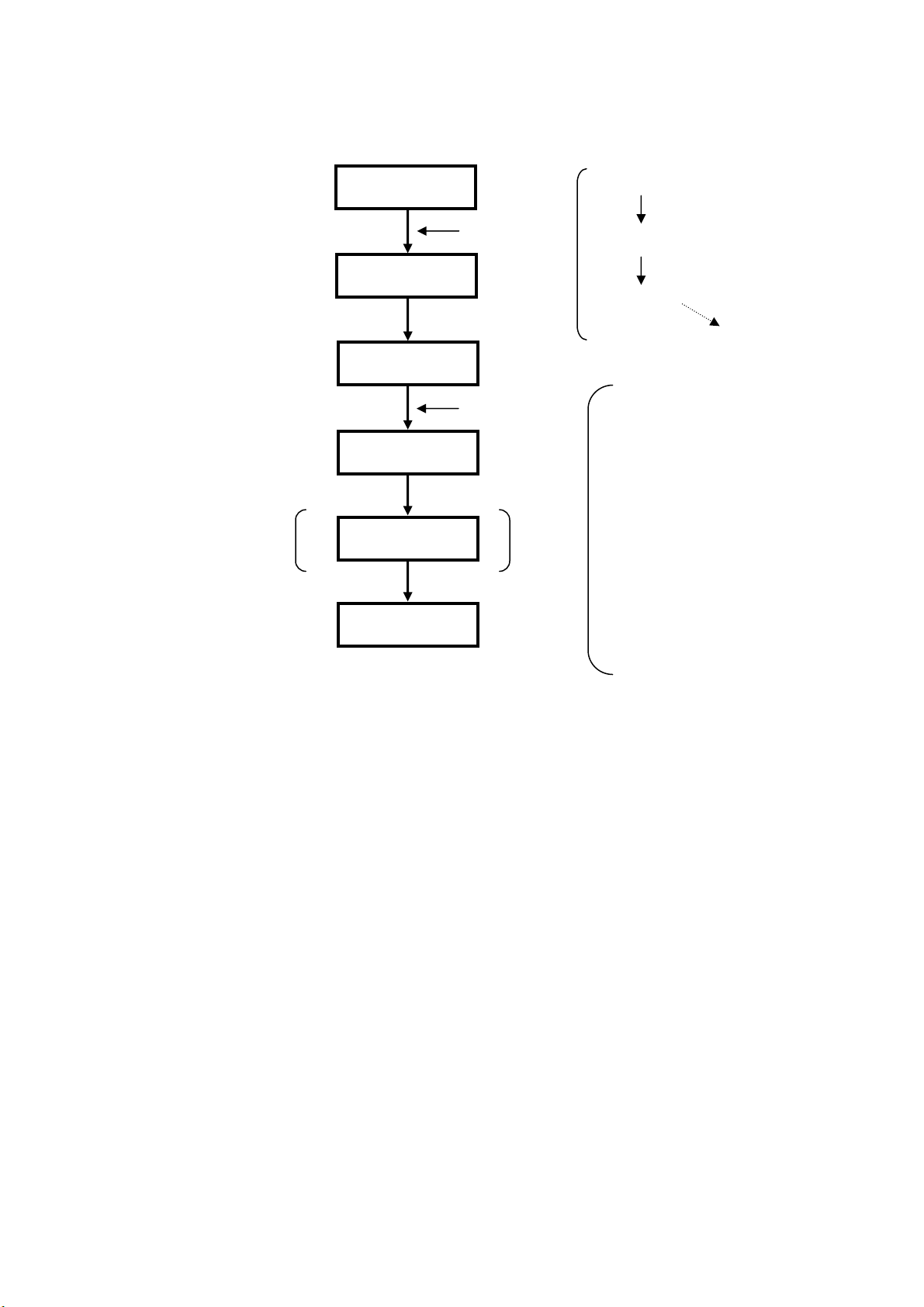

3 System Diagram

3.1 Standalone System

Standalone System Block Diagram

Patient Circumstances or Medical Room

CXDI-60G/60C

AC or DC IN

Protective

Grounding

Power Box

Power Supply

1st / 2nd

AC250V

Insulation with

reinforcement

Basic Insulation

General HUB

AC250V

1. General

Control/Signal

Ethernet

(1)

*

SELV

Control/Signal

Control

Control/Signal

Connector

Imaging Unit

(2)

Remote Switch

X-ray Generator

(601Compatible)

* SELV = Safety Extra-Low Voltage

Grid Unit

FC-24VE/FC-E21A

Recommended general computer

or

3.2 Total System

It can be connect to (1) and (2) of the system where the existing products have already been

connected. Extend the ethernet port by general switching HUB or ethernet card. The maximum

number of connections is limited to four by the control software specification.

Total System Block Diagram (Example)

Patient Circumstances or Medical Room

CXDI-60G/60C

AC or DC IN

Protective

Grounding

CXDI-40E

Imaging Unit

Power Box

Power Supply

1st/2nd

AC250V

Insulation

with rei nforcemen t

Power Box

AC250V

Basic Insulation

Control/Signal

Ethernet

SELV

Control/Signal

Control

Control/Signal

Power Box

*

Imaging Unit

Connector

Remote Switch

CXDI-50

Imaging Unit

X-ray generator

(601 Compatible)

Grid Unit

Control/Signal

Ethernet

General HUB

FC-24VE/FC-E21A

Recommended general computer

or

Ethernet

Control/Signal

Ethernet

*SELV = Safety Extra-Low Voltagej

Image Examination WS

Image File Equipment

Printer etc.

3

Page 11

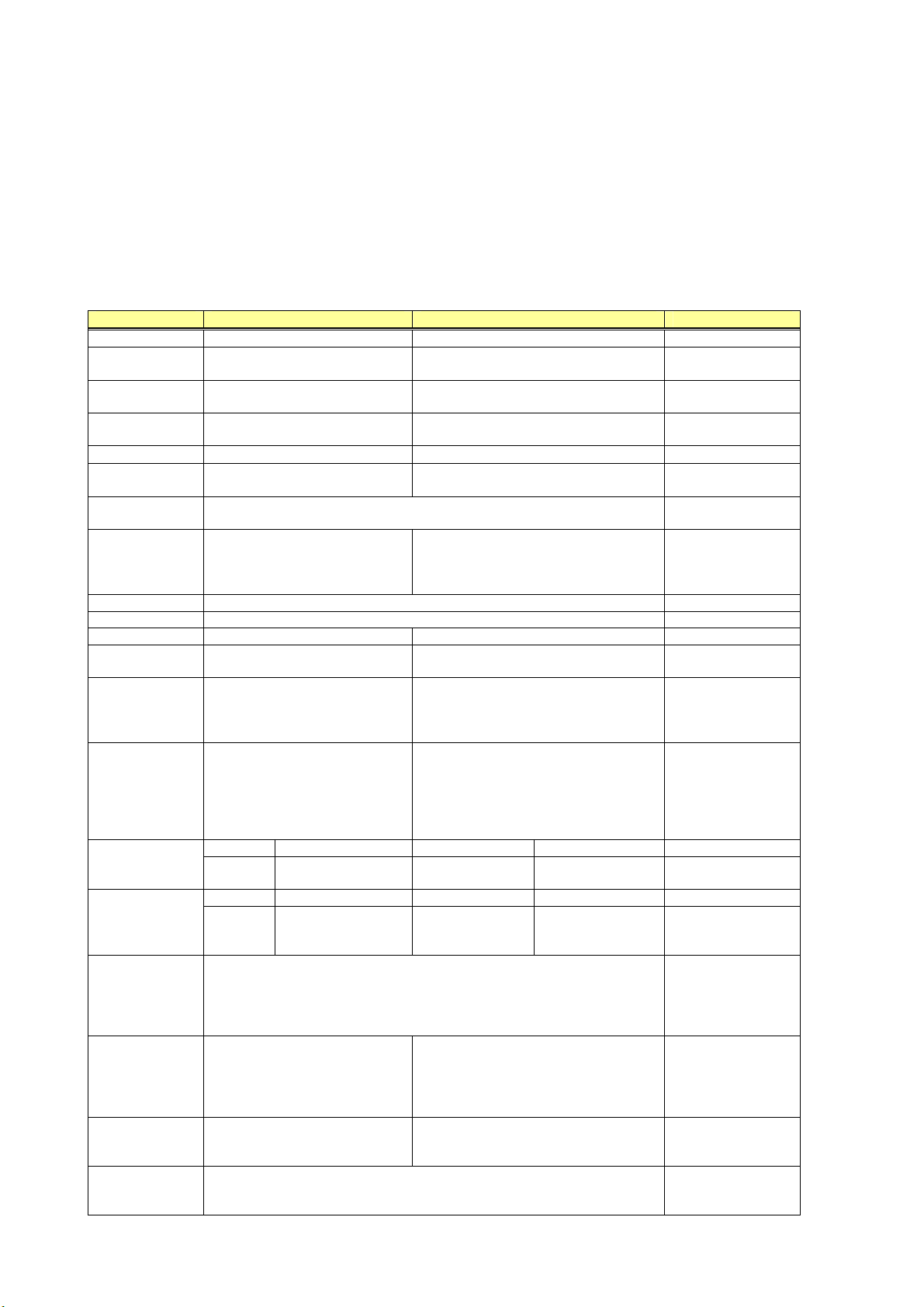

4 CXDI Image Processing

1. General

4.1 Proccess Flow

Born image

Raw image

Original image

QA image

DICOM output

Diagnosis image

Processed image

Correction

processing

QA processing

Offset correction

Gain correction

Defect correction

dtstore

Characteristic extraction

• Sensitivity correction

• Sharpening

• DEP

• Gradation processing

MTF enhancement

•

(Frequency enhancement)

• Grid stripe reduction

• High density clipping

request

4.2 Image Types

(1) BORN IMAGE

The image obtained with LANMIT before any correction is made.

Outside distribution of these images is prohibited, including dtstore images.

(2) RAW IMAGE

Born image after offset processing, gain correction.

This is the image with LANMIT specific characteristics corrected.

(3) ORIGINAL IMAGE

Raw image after preprocessing.

(4) QA IMAGE

Original image after gradation processing, sharpening, and other processing.

The CXDI performs image processing up to this point.

(5) DIAGNOSIS IMAGE

QA image after further image processing necessary for diagnosis.

Image processed by the user for diagnostic purposes.

(6) PROCESSED IMAGE

Diagnosis image after post-processing.

Image modified by the user or the default processed image.

4

Page 12

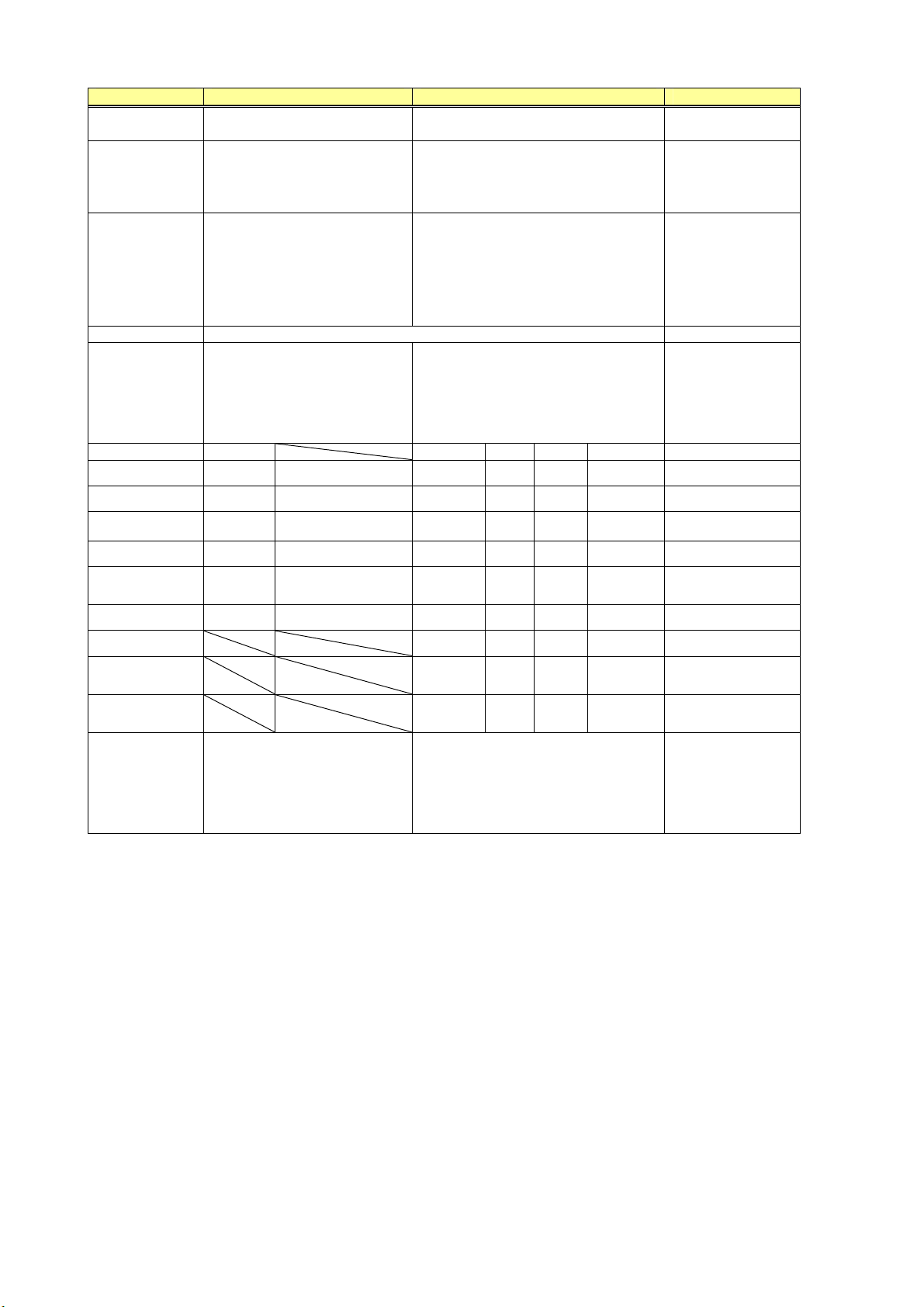

1. General

5 Specifications

The CXDI-60G/60C (Imaging Unit/Power Box) is the Digital Cassette that has the mobility and

can be used on the optional angles.

(1) Imaging Unit

This unit consists of the internal sensor, PWB-60Di, PCB-AD/REF, PWB-60LED and its

outer cover. The sensor unit converts the X-ray image to the electrical signal (O/E

Conversion) and after performing the A/D conversion, transfers its signal through the Power

Box with Ethernet cable to the Control computer.

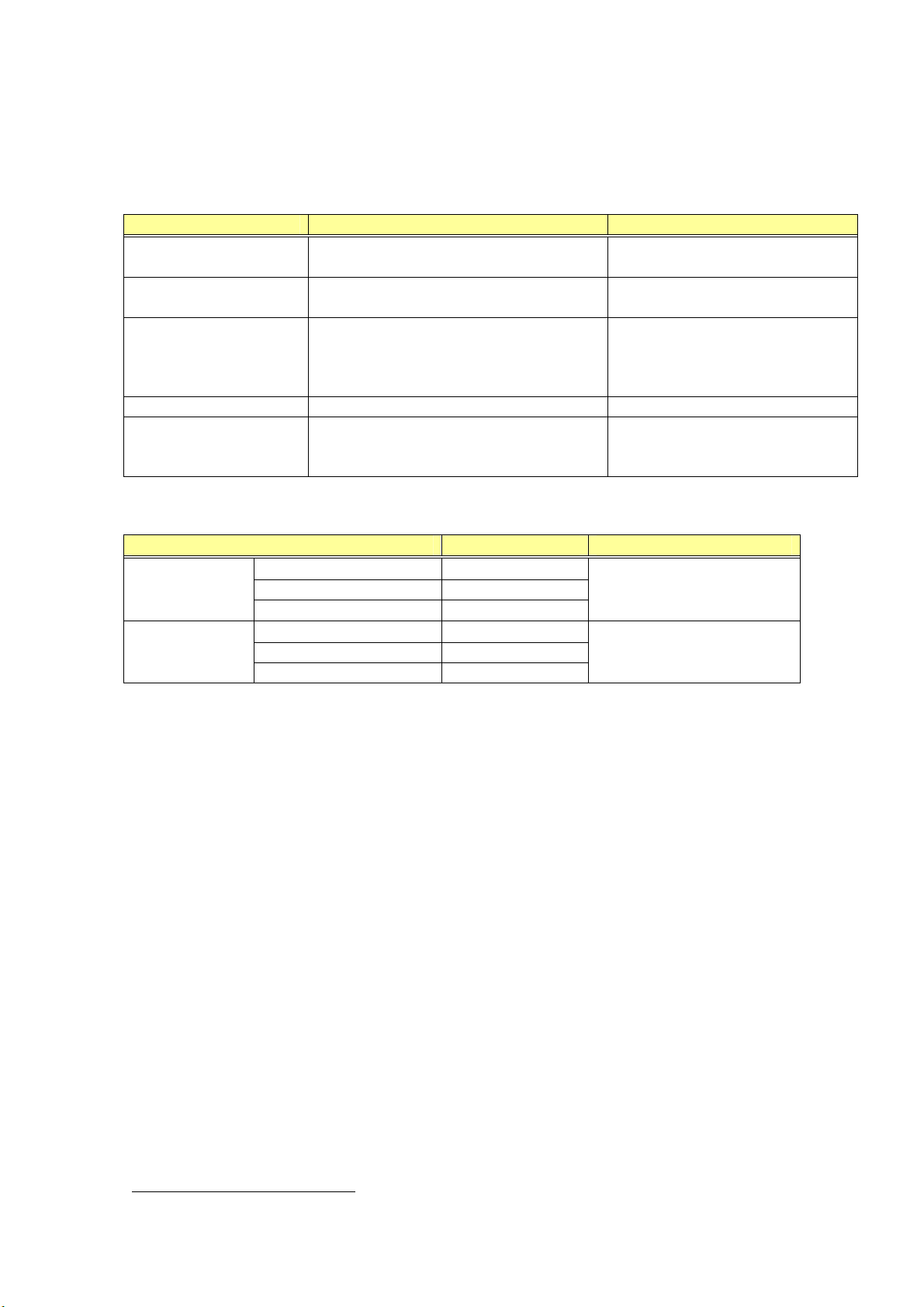

Item CXDI-31 CXDI-60G/60C Remarks

Object Cassette (built-in) Cassette (built-in)/Mobile

Effective filming

range

Number of Pixels

Effective

Number of Pixels

Pixel pitch

Fluorescent

substance

Output

gradations

Transfer method

Imaging time ~ 1 sec.

Imaging cycle 15 sec.

Dimension

Imaging Unit

coloring

Imaging Unit

mass

(w/o grid)

Space between

surface where

patient gets in

contact (CFRP)

and sensor

surface (glass)

Heat emission

Power

Consumption

Mechanical

*

strength

Control

computer

Power Control

(ON/OFF)

Grid

attach/remove

detector

226.00 x 288.00 mm 234.24 x 284.16 mm

2260 x 2280

(About 6,500,000 pixel)

2256 x 2878 1464 x 1776

100µm x 100µm 160µm x 160µm

GOS 60G:GOS/60C:CsI

12bit (4,096 gradations)

A/D 14bit

Metal: Imaging Unit to E/O BOX

Optical fiber: E/O BOX to

Control computer (Through the

Multi Box)

324(W) x 327(D) x 20.8(H) mm

Art gray Cool white

2.8Kg

(Except the cable)

3.3Kg

(Including the cable)

5.75mm Within 5.1±0.5mm.

Average (43.2kJ/h)

Max 162kJ/h Max load mode

Average (12W)

Max 45W Max load mode

Load uniformly: 1.47kN(150kgf), 1min

Load locally: 0.98kN(100kgf),

The imaging unit is put on the plain surface with the Sensor side (Detector) is

up.

-CXDI-C2

-CXDI-C3

Interface with a Control computer

Ethernet: Imaging Unit to Control

computer (Through the Power Box)

344.4 (W) x 380* (D) x 22.5 (H) mm

Remote SW OFF

Remote SW OFF

φ

40mm, 1min

-FC-24VE/FC-E21A for CXDI Control

Station

-General computer with a performance

equal to FC-24VE/FC-E21A

-CXDI-C3/C3S

None

(Power Box: Operation with Remote

switch manually)

Yes

1476 x 1790

(About 2,600,000 pixel)

2.5Kg

(Except the cable)

2.8Kg

(including the cable)

36kJ/h or less

126kJ/h or less

1 image per 15 Sec.

10W or less

35W or less

(1 image per 15

Sec.)

Self-imposed rule

For CXDI-31, local

strength applies to

the center of the

sensor.

Ethernet card is

necessary to connect

CXDI-60G/60C with

CXDI-C3

5

Page 13

1. General

Item CXDI-31 CXDI-60G/60C Remarks

Sensor cable

From imaging unit to E/O Box:

4.5m

Up to four imaging units are

Count of

connected sensor

connectable to a single control

computer via multi box. For the same

type of imaging unit, the maximum of

connection number will be three.

Scattered

radiation

backward block

sheet

Lead cover Mo sheet (0.3 mm thick)

Environmentconscious

unleaded type

Photo timer Cannot be built in

When the internal temperature of

Imaging

restriction

(Imaging

Prohibition)

User interface

Imaging Unit is above 45 degree

Celsius, its state is changed to sleep

mode. And the Imaging prohibition

will be continued when the internal

temperature is below 44 degree

Celsius.

Indication

Color Two colors

Imaging

unit is off

Imaging

unit is on

Preparing

imaging

Imaging

preparation

complete

Error status

Green light will flash*1

Green light will turn on

Green light will flash

Off

Orange light will turn

on

*1: Turns on and off for 0.5 seconds

each

*2: Turns on and off twice for 0.5

seconds, then turns off for 0.5

seconds

Sensor cable (imaging unit side): 1.5m

Sensor cable (power box side): 6.3m

Up to four Imaging Units are connectable to a

single control computer via Network switch.

For the same type of imaging unit, the

maximum of connection number will be three.

Each imaging unit requires a power box.

When the internal temperature of Imaging Unit

is above 49 degree Celsius, its state is changed

to sleep mode. And the Imaging prohibition

will be continued when the internal

temperature is below 48 degree Celsius.

Indication Busy Sensor Power

Orange

*2

Color

Imaging

unit is off

Imaging

unit is on

Preparing

imaging

Imaging

preparation

complete

Error status

Communicating

Initialization

(when

startup)

Network not

set (when

startup)

*1: Green for China

*2: Turns on and off for 0.5 seconds each

*3: Turns on and off twice for 0.5 seconds,

then turns off for 0.5 seconds

*4: Fades in for 1 second and fades out for 1

second

*5: Fades in for 2 seconds, and then turns off

Green Blue

*1

Off Off Off

-- Off On

Blinking

--

-- On On

--

On -- On

--

--

*2

Blinking

*3

Blinking

*4

Blinking

*5

Network switch

should be procured

at each sales

company.

On

On

On

On

6

Page 14

1. General

(2) Power Box

This unit consists of PWB-60X-RAY, 60 Sensor Power Supply and its outer cover.

The function; the signal transition between Imaging unit and Control computer, the interface

to the X-ray generator equipment and power supply to the Imaging unit has been

implemented.

Item Content Remarks

Communication method

with Control computer

Communication method

with PWB-60XRAY

IEEEE

Asynchronous serial communication

method

*

802.3u (100BASE-TX) * Connector type: RJ45

Data length: 10bit

Data rate: 15.625 kHz

Reference

Power supply AC 100-240V 50/60Hz 1.2-0.7A

60 Sensor Power supply

Rated Voltage:

AC 100-240V (AC 85-264V)

Mass 3.7 Kg Except the external cables

Except bottom rubber parts

Dimension 358(W) x 200(D) x 65(H)* mm

(With bottom rubber parts:

75mm)

(3) Environment rated parameters

Operating

environment

Storing or

transporting

environment

Item Content Remarks

Ambient temperature

Relative humidity 30 to 75% RH

+5 to +35°C

Must be without dewing

Atmospheric pressure 700 to 1060 hPa

Ambient temperature

Relative humidity 10 to 60% RH

-30 to 50°C

Must be without dewing

Atmospheric pressure 700 to 1060hPa

*

IEEE: Institute of Electrical and Electronic Engineers

7

Page 15

M

M

C

C

Copyright(C) Canon Inc. Medical Technical Service Dept. All rights reserved.

X

2.. II

2

DII--

X

D

nsstt

n

a

a

Canon Inc. Japan

6

0

6

0

allll

a

n

u

n

u

G//

G

attii

a

all

a

6

6

Printed by Canon

Jul. 2009 Rev. 01

0

0

o

n

o

n

C

C

Page 16

Contents

1 Caution During the Installation ............................................................................................ 1

2 Restrictions on Installation ................................................................................................... 1

3 Caution on Installation ......................................................................................................... 2

4 Product Configuration .......................................................................................................... 3

4.1 Product Configuration List........................................................................................... 3

4.2 Configuration ............................................................................................................... 4

4.3 Sensor Cable (Optional) ............................................................................................... 5

5 Packing Diagram .................................................................................................................. 6

5.1 X-ray Digital Radiography System (CXDI-60G/60C)................................................. 6

5.2 Grid (Optional)............................................................................................................. 8

6 Installation Procedures ......................................................................................................... 9

6.1 Lists of Tools Needed for Installation .......................................................................... 9

6.2 System Installation Procedures .................................................................................. 10

7 Installation .......................................................................................................................... 12

7.1 Connection to Each Unit ............................................................................................ 12

7.1.1 Connection Diagram ......................................................................................... 12

7.1.2 Connecting to the Power Box........................................................................... 13

7.1.3 Using the Imaging Unit in the Multiple Rooms................................................ 19

7.1.4 Interchanging a Imaging Unit........................................................................... 20

7.1.5 Sensor Cable (Optional).................................................................................... 22

7.1.6 Connection Diagram for Control Computer Rear Panel................................... 23

7.1.7 Adjusting the Length of the X-ray I/F Cable.................................................... 24

7.2 Starting up and Shutting down the System................................................................. 25

7.2.1 Sequence for Starting up the System ................................................................ 25

7.2.2 Sequence for Turning the Power off ................................................................. 25

7.3 X-ray Controller Interface .......................................................................................... 26

7.3.1 Interface Signal Description ............................................................................. 26

7.3.2 Signal Names and Functions in the Connection with the X-ray Generator...... 28

7.3.3 Rating and Characteristics for Relay and Photo Coupler (on PWB-XRAY).... 30

7.4 Network Settings ........................................................................................................ 32

7.5 Setting the Fixed ROI Areas ...................................................................................... 35

7.6 Settings....................................................................................................................... 38

7.7 Image Quality............................................................................................................. 94

7.8 Post-installation Checks ............................................................................................. 96

8 Dimension .......................................................................................................................... 98

Page 17

2. Installation

1 Caution During the Installation

Please pay attention to the followings when installing the system.

(1) If the equipment is hoisted, lowered or transported, it must be supported at both sides by a

minimum of two people so there is no danger of it falling.

(2) When installing the equipment, be sure the site meets the following criteria:

1) There must be no dripping water in the area.

2) The environment must be free of harmful elements such as humid or acidic air, air with

a saline or sulfur content, where there is poor ventilation or where air pressure or

temperature is unusual.

3) The equipment must not be placed at an angle or subjected to vibration or shock (this

includes during transportation).

4) The equipment must not be kept where chemical products are stored or where gasses are

generated.

5) The site’s power supply must be of the correct voltage and frequency for the equipment.

6) The site must be connected to a fully earthed cable with sufficient ground resistance to

meet standard values.

(3) After installation, be sure to dispose of waste product packaging with care and with full respect

for the environment.

2 Restrictions on Installation

(1) A clearance of at least 150mm must be left between a imaging unit and power box.

(2) It is forbidden to use the cables (Sensor cable, X-ray interface cable, etc.) from the power box

for moving parts. The only exception to this restriction is the sensor cable that is to be

connected to the imaging unit.

1

Page 18

2. Installation

3 Caution on Installation

(1) Do not install the imaging unit near electronic devices as noises and artifacts tend to appear on

images in the electromagnetic field.

e.g. CRT monitor, X-ray generator, and any other medical electronic devices.

(2) Follow the following steps to detach the sensor cable while the system is running.

1) To detach the sensor cable

- Check the LED of the imaging unit and the display of the control computer to make

sure the status of communication between the imaging unit and control computer is

idle. (*1)

- Turn off the main power switch of the power box or the remote switch. (*2)

- Make sure the LED on the imaging unit, switch on the power box and remote switch

are turned off. Power supply to the Imaging unit must be disconnected.

- Detach the connector of the sensor cable.

*1: Do not detach the sensor cable during the data transmission between the imaging

unit and control computer, it may cause data loss, system error or equipment

breakdown.

*2: Do not detach the sensor cable when the power is being supplied from the power box,

it may cause equipment breakdown. If you disconnect the imaging unit by improper

steps, the “Error” LED on the power box and remote switch will be turned on to alert

you the sensor cable is detached improperly. To restore from the error, turn off the main

switch of the power box or the remote switch. Then connect the sensor cable again by

following the steps described in the next column.

2) To attach the sensor cable

- Make sure the LED on the imaging unit, switch on the power box and remote switch

are turned off. Power supply to the Imaging unit must be disconnected.

- Connect the connector of the sensor cable.

- Turn on both the main switch of the power box and remote switch.

(3) Before proceeding with installation, ensure that the static accumulated in the bodies of the

installation personnel is discharged. Similarly, before touching the PCBs (when removing

them) or cable connectors, ensure that all static is discharged.

(4) With the launch of CXDI-60C, the specification of the CXDI-60G sensor cable is changed to

conform to CXDI-60C. For details, refer to “7.1.4 Interchanging a Imaging Unit”.

2

Page 19

2. Installation

4 Product Configuration

4.1 Product Configuration List

1) CXDI-60G/60C

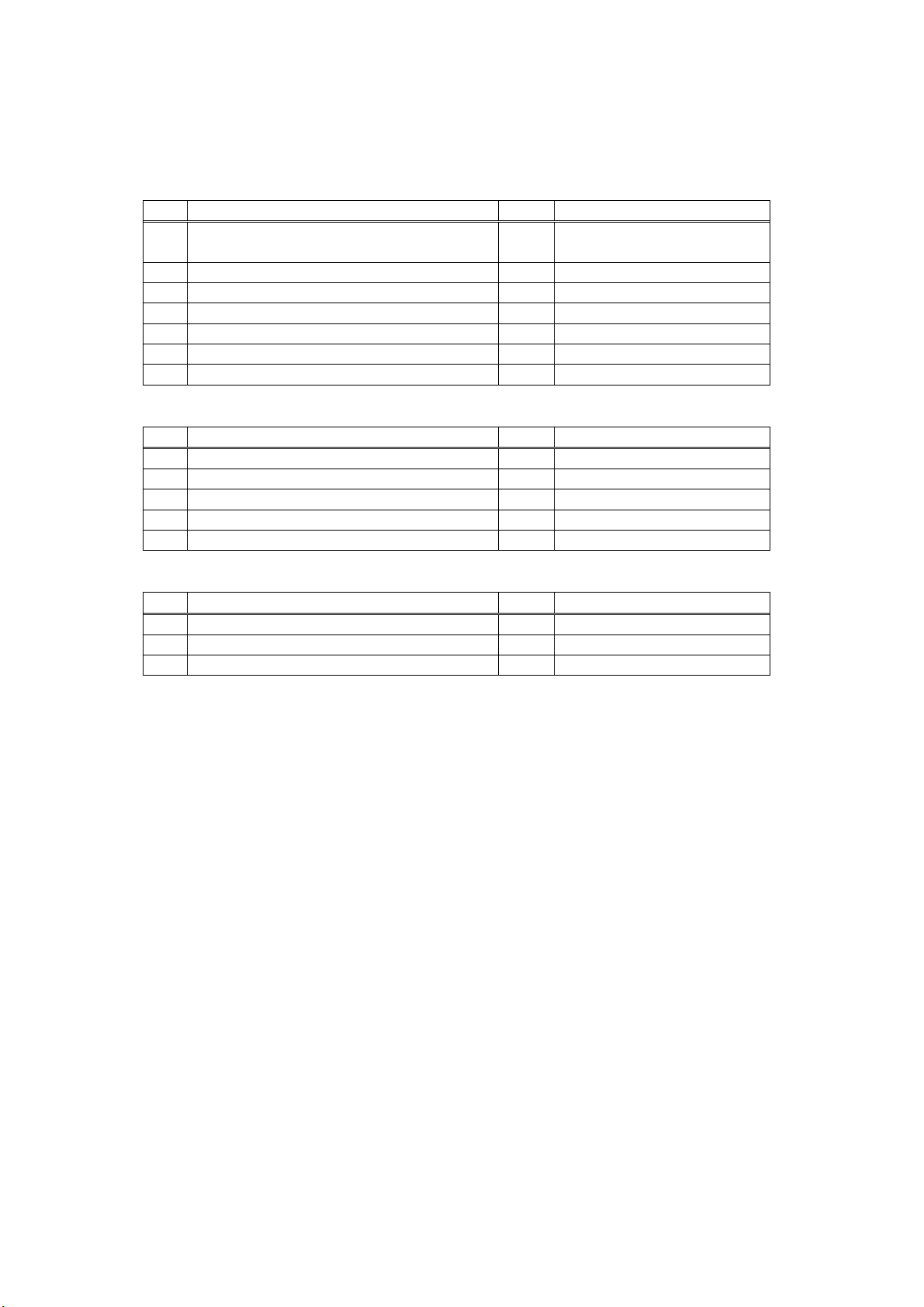

No. Item Name Qty Remarks

1 CXDI-60G/60C Imaging Unit 1

2 Sensor cable P630 (power box side) 1 6.3m

3 Operation manual (for imaging unit)

4 Attached documents for medical (JPN)

5 Warranty registration (JPN)

6 Warranty card (US)

7 German Security leaflet/WEEE leaflet (EU)

2) CXDI SYSTEM II

No. Item Name Qty Remarks

1 Power Box 1

2 X-ray I/F cable 1 20m

3 Remote switch 1 20m

4 Power supply cable (with AC plug) 1 3m (100/120/230V)

5 Operation manual (for power box)

3) Sensor Cable (Optional)

No. Item Name Qty Remarks

1 Sensor Cable P630-PM (Panel mount type) 1 6.3m

2 Sensor Cable P70-60 (imaging unit side) 1 0.7m

3 Sensor Cable SP780-60 (Straight type) 1 7.8 m

LAN cable for connecting Control Computer / Power Box and Network switch (Switching HUB)

for connecting the multiple Imaging Units shall be procured at each sales company.

with 1.5 m sensor cable

S150-60 ( imaging unit side)

- LAN cable (Over category 5)

Recommended length of the cable is 30m or less.

When Control Computer and Power Box are connected directly, Cross type is used, but when

they are connected via Network switch, Straight type is used. However, this is not applied

when Network switch has AUTO-MDI/MDI-X function*.

- Network switch (Switching HUB)

Sales companies adopt Network switch (Switching HUB) after conducting the test and the

operation check for Switching HUB that meets the general standard.

3

Page 20

2. Installation

4.2 Configuration

No. 1 No. 2

Name

Qty 1 Qty 1

Remarks

No. 3 No. 4

Name Power Box Name X-ray I/F cable

Qty 1 Qty 1

Remarks I/F and Power supply Remarks

CXDI-60G/60C Imaging Unit

Sensor cable S150-60

(imaging unit side)

Name

Remarks 6.3m

Sensor cable P630

(Power box side)

Connection with X-ray

generator

No. 5 No. 6

Name Remote switch Name Power supply cable

Qty 1 Qty 1

Remarks

Switch to turn on and off

Power Box

Remarks

For Power Box

(100/120/230V each type)

4

Page 21

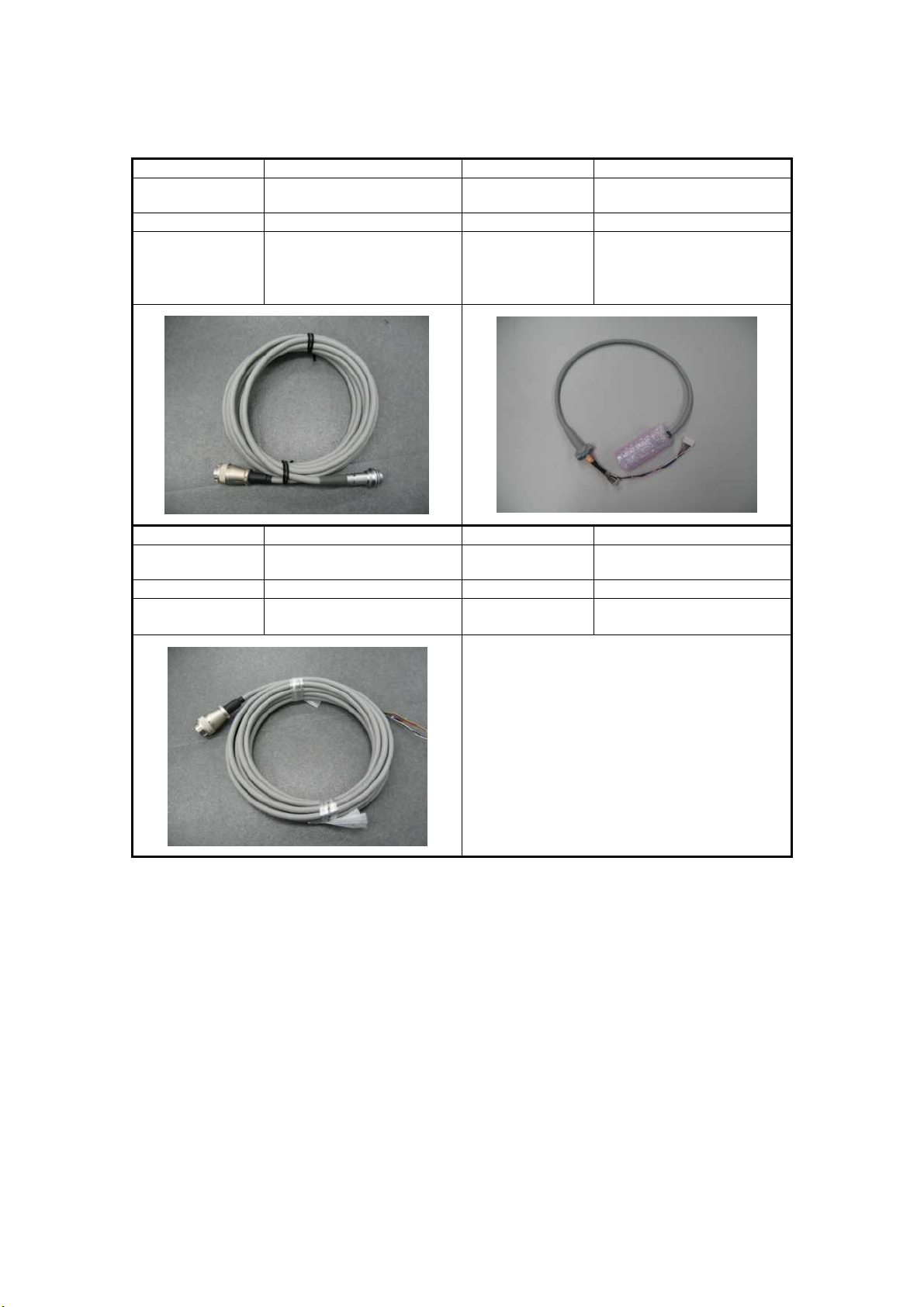

4.3 Sensor Cable (Optional)

No. 1 No. 2

Name

Qty 1 Qty 1

Remarks

Sensor Cable P630-PM

(Panel mount type)

6.3m

Detachable cable connector

2. Installation

Remarks

Name

Sensor cable S70-60

(Imaging unit side)

0.7m

Detachable cable connector

Connector form: New type

(External diameter φ18)

No. 3

Name

Qty 1

Remarks

Sensor Cable SP780-60

(Straight type)

7.8 m

Non-detachable cable

Sensor cable P630-PM (panel mount type)

This sensor cable can be used in place of a standard sensor cable P630 (power box side). Only the

difference between them is the form of the connector. There is no difference in the function of the

cables.

Sensor cable S70-60 (imaging unit side)

This sensor cable can be used in place of a standard sensor cable S150-60 (imaging unit side). Only the

difference between them is the length of the cable. The sensor cable S70-60 is 0.7m in length. There is

no difference in the function of the cables.

Sensor cable SP780-60 (straight type)

This is a single straight type sensor cable with no detachable connectors. This single cable can be used

in place of a standard sensor cable S150-60 (imaging unit side) and a standard sensor cable P630

(power box side). There is no difference in the function of the cables.

5

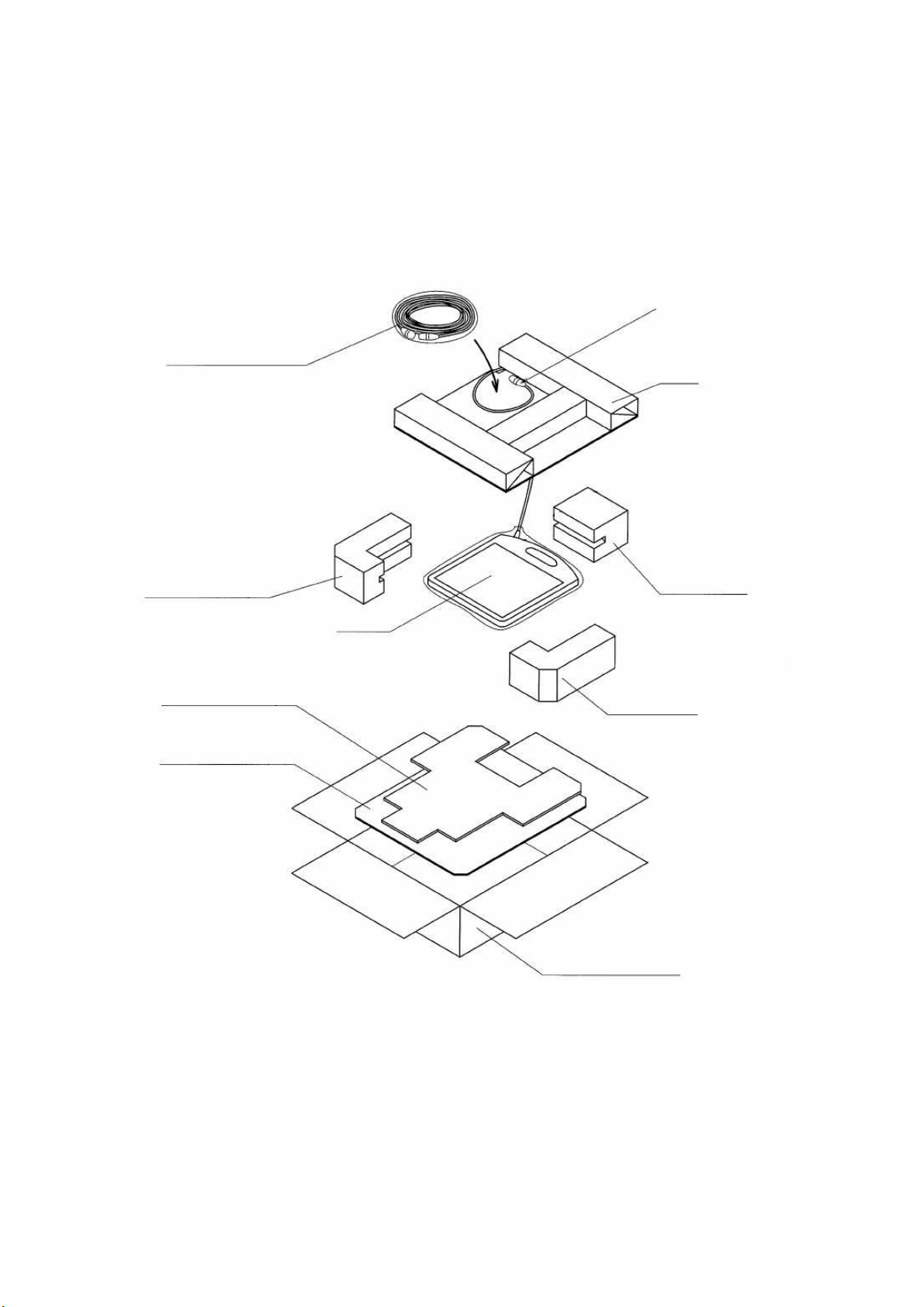

Page 22

2. Installation

5 Packing Diagram

5.1 X-ray Digital Radiography System (CXDI-60G/60C)

(1) CXDI-60G/60C Imaging Unit Package

Sensor cable P630

(6.3m)

Place the sensor cable

S150-60 on the packet

corner of the paper tube

Paper tube

Corner pad

Positioning sheet

Cardboard sheet

Center pad

Imaging unit

Corner pad

Cardboard box for imaging unit

6

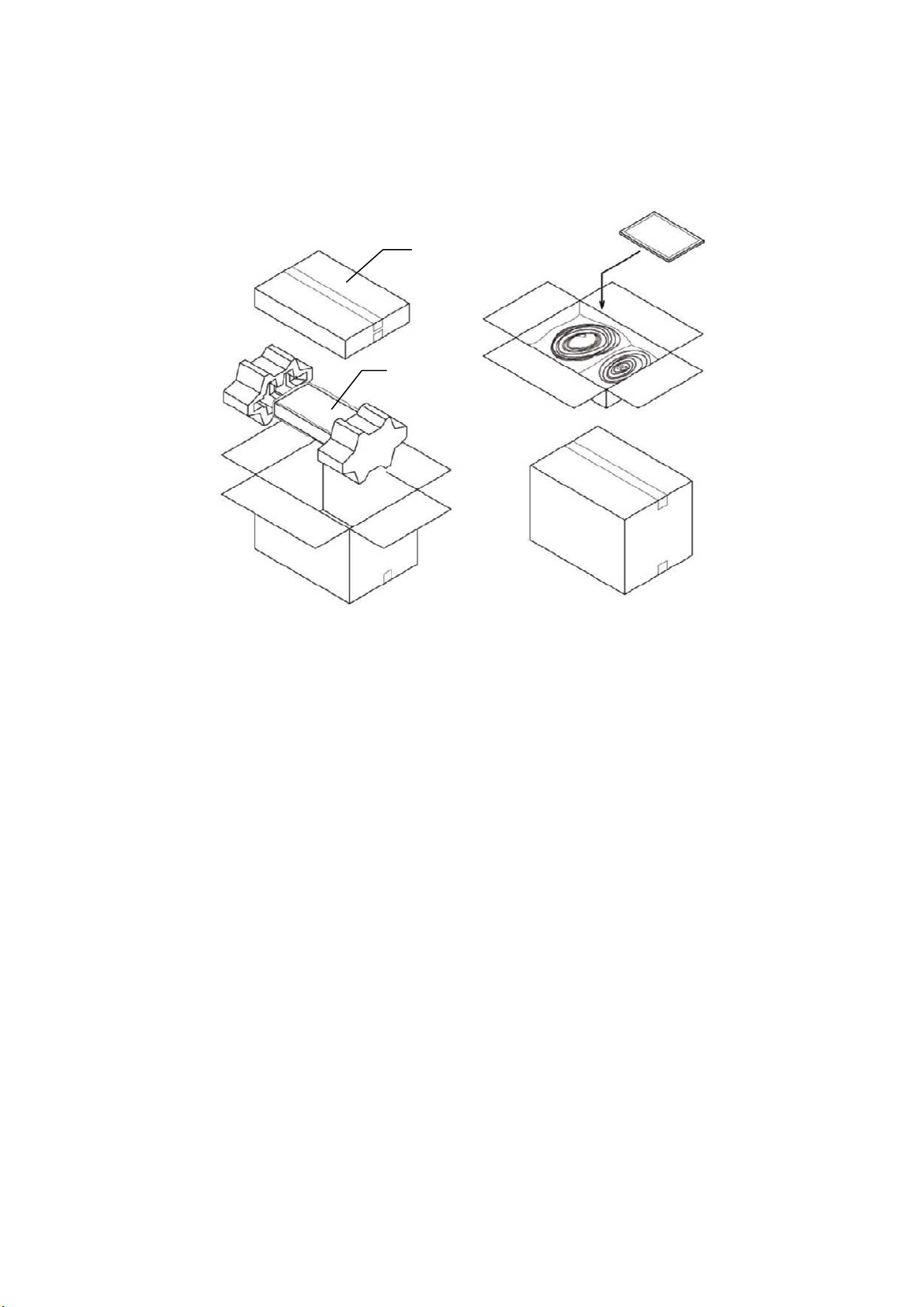

Page 23

2. Installation

(2) CXDI System II assembly package

Power box

Accessories

box

7

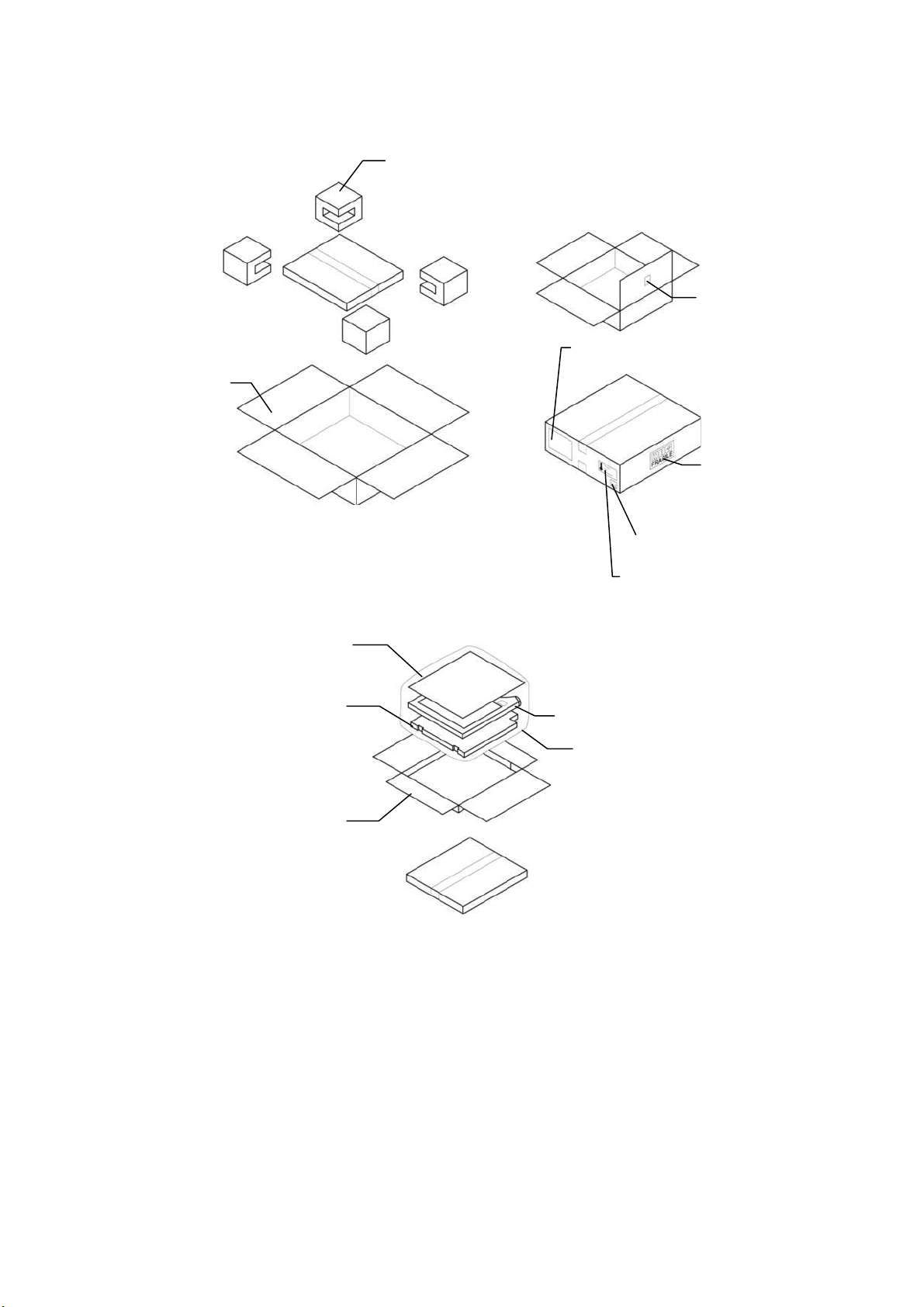

Page 24

Orig

abe

5.2 Grid (Optional)

2. Installation

(1) Outer packaging

Outer package

(2) Inner packaging

Protection sheet

Corner Packing

Material label

Product division label

Handle with

in l

Shipping

environment

label

care label

l

Protection board

Inner package

Grid unit

Plastic bag

8

Page 25

2. Installation

6 Installation Procedures

6.1 Lists of Tools Needed for Installation

No. Tool Name Unit Remarks

1. General Tools 1 set JIS Screwdriver Set

2. Laptop computer 1

3. LAN Card 1 For Laptop computer (as required)

4. Mouse 1 PS/2 type

5. Keyboard 1 PS/2 type

6. HUB 1 Connection between Control Computer and Laptop Computer

7. 10/100BASE-TX cable 2 Straight type (Control PC to Laptop computer)

CXDI Software version

8.

compatibility table

Mirror, oil-based marker

9.

and paper etc.

PC/AT compatible

(OS: Microsoft Windows XP Professional recommend)

-

1 For adjusting the alignment with the X-ray tube.

9

Page 26

2. Installation

6.2 System Installation Procedures

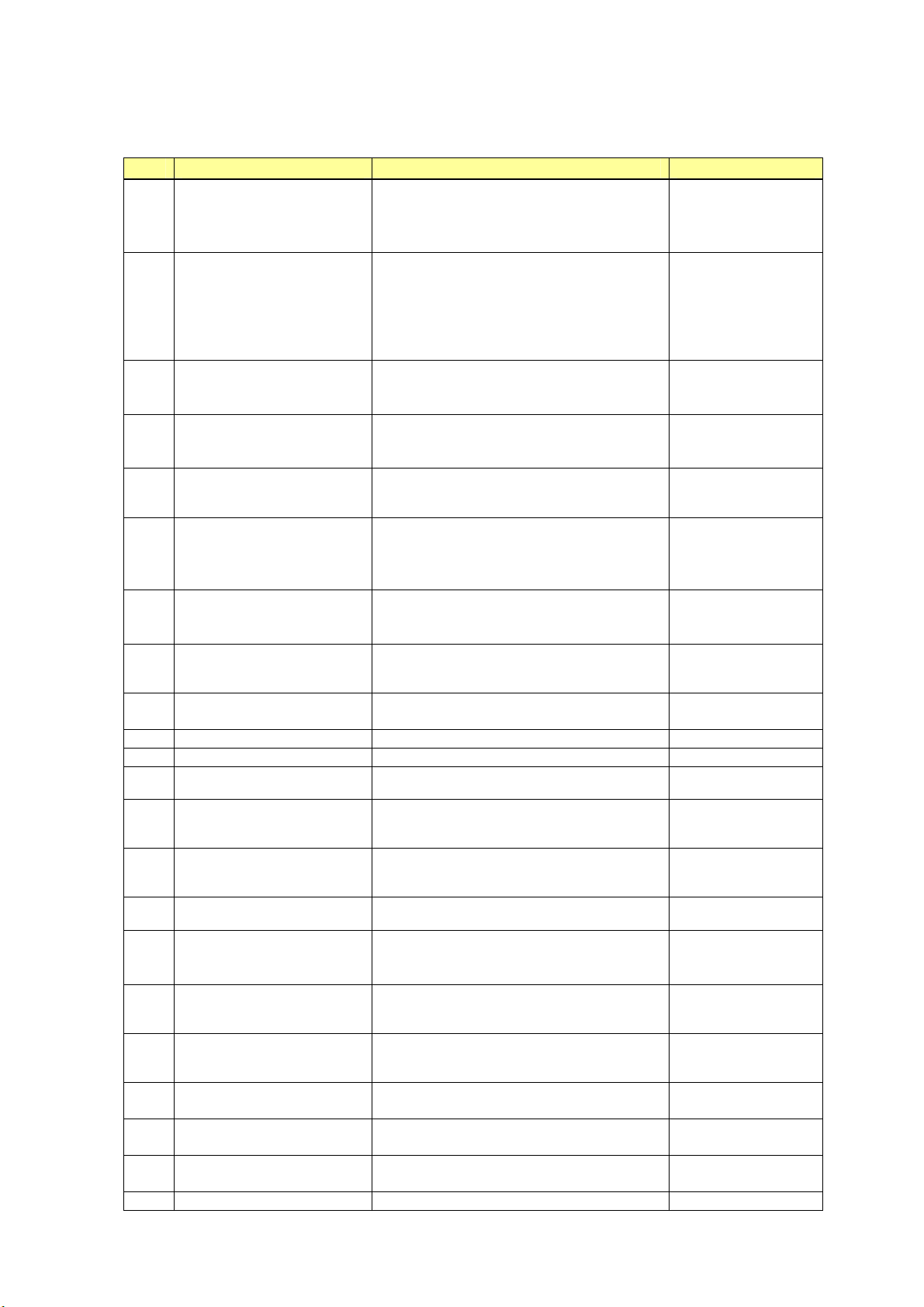

No. Step Conditions and Checkpoints Reference Section

1 Unpacking and checking the

product’s constituent parts

2 Connect the Imaging Unit

and the Power Box

3 Connect the Power Box and

the Control PC

4 Connect the Power Box and

the X-ray generators

5 Check date and time - Date and time must be changed according to

6 Check the software

program’s version

7 Identifying the Imaging Unit

(input the sensor serial

numbers)

8 Enter control computer serial

number.

(9) Adjusting the timing with

X-ray generator

10 Calibration -No error must be displayed.

11 Setting the Fixed ROI Areas If necessary, set the ROI area.

12 Set exposure parameter table -Set it in consultation with the technician.

13 Set annotation -Set it in consultation with the technician.

14 Connect the network and set

the output destination

15 Startup settings

16 Exposure testing -The data must be sent to the printer and

17 Check the linearity of the

transferred image density.

18 Operation unit Gamma

correction

19 Body parts settings -The engineer in charge must be consulted

20 Check and set the system

settings.

21 Total adjustments and delete

the unnecessary data.

22 Cleaning

-There must be no missing parts, damage,

dents, etc.

-There must no color changes in the shock

sensor.

-Handle the instrument carefully, as it may be

damaged if something is hit against it,

dropped or receives the strong jolt.

-The cable must be routed in such a way that

no unreasonable loads are brought to bear

upon them.

-The cable must be routed in such a way that

no unreasonable loads are brought to bear

upon them.

-The manufacturer of the X-ray generators

must be asked to handle the connections with

the generators.

the area where the instrument is installed.

-The compatibility of the imaging unit and

the Control PC must be checked on the

compatibility list, and the software program

must be installed or upgrade as required.

-No required usually.

storage and the image quality must be

checked.

prior to perform these settings.

-The engineer in charge must be consulted

prior to perform these settings.

-Conform according to the check sheet.

-Delete the unnecessary data.

“(1) Checking and

Setting the Date and

Time” in section 7.6.

“(2) Checking the

Firmware Version” in

section 7.6.

“(6) Identifying the

Imaging Units” in

section 7.6.

“(7) Entering Control

Computer Serial

Number” in section 7.6.

Operation Manual

“(8) Table Setup

Setting” in section 7.6.

“(9) Performing the

Annotation Setting” in

section 7.6.

“(10) Network

Connections” in section

7.6.

“(5) Set Up Startup

Menu” in section 7.6.

Section 5.7 Image

Quality.

“(11) Linearity Check

Image Density” in

section 7.6.

“(12) Operation Unit

Gamma Correction” in

section 7.6.

Operation Manual

Each section in section

7.6. Settings.

Section 7.9

Post-installation check.

10

Page 27

2. Installation

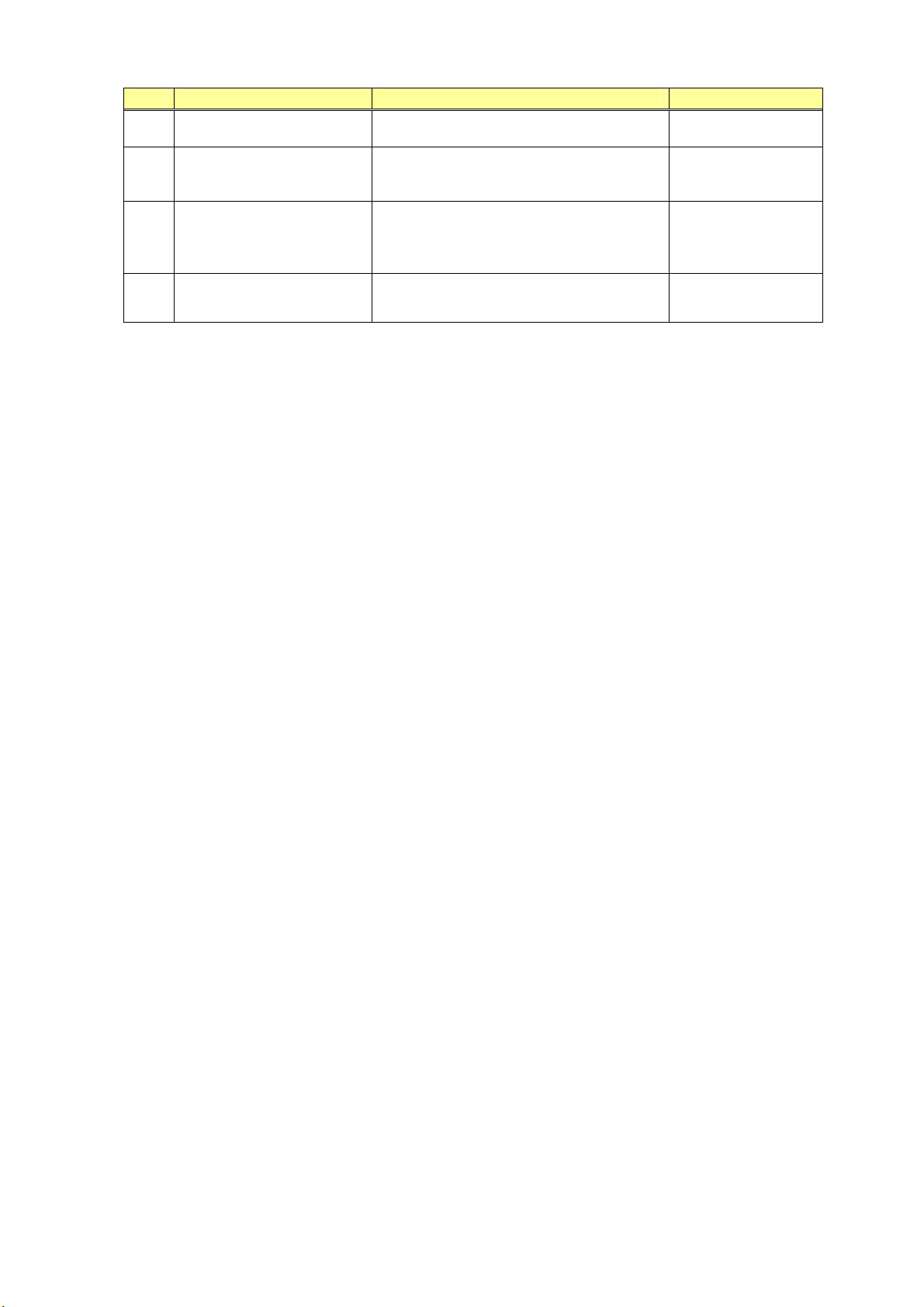

No. Step Conditions and Checkpoints Reference Section

23 Explain the operation to the

user

24 Final parameter adjustment -The engineer in charge must be consulted

prior narrowing down the adjustments to the

final values.

25 Inserting the backup floppy

disk.

-It must be confirmed at re-start that backup

files have been made.

-No necessary for the system installed in

vehicles.

26 Back up valuable data -Copy the CCR folder to the removal drive.

Operation Manual

Operation Manual

“(15) Backing up

Setting Data to FD” in

section 7.6.

“(14) Backing Up when

Installing” in section

7.6.

11

Page 28

2. Installation Manual

7 Installation

7.1 Connection to Each Unit

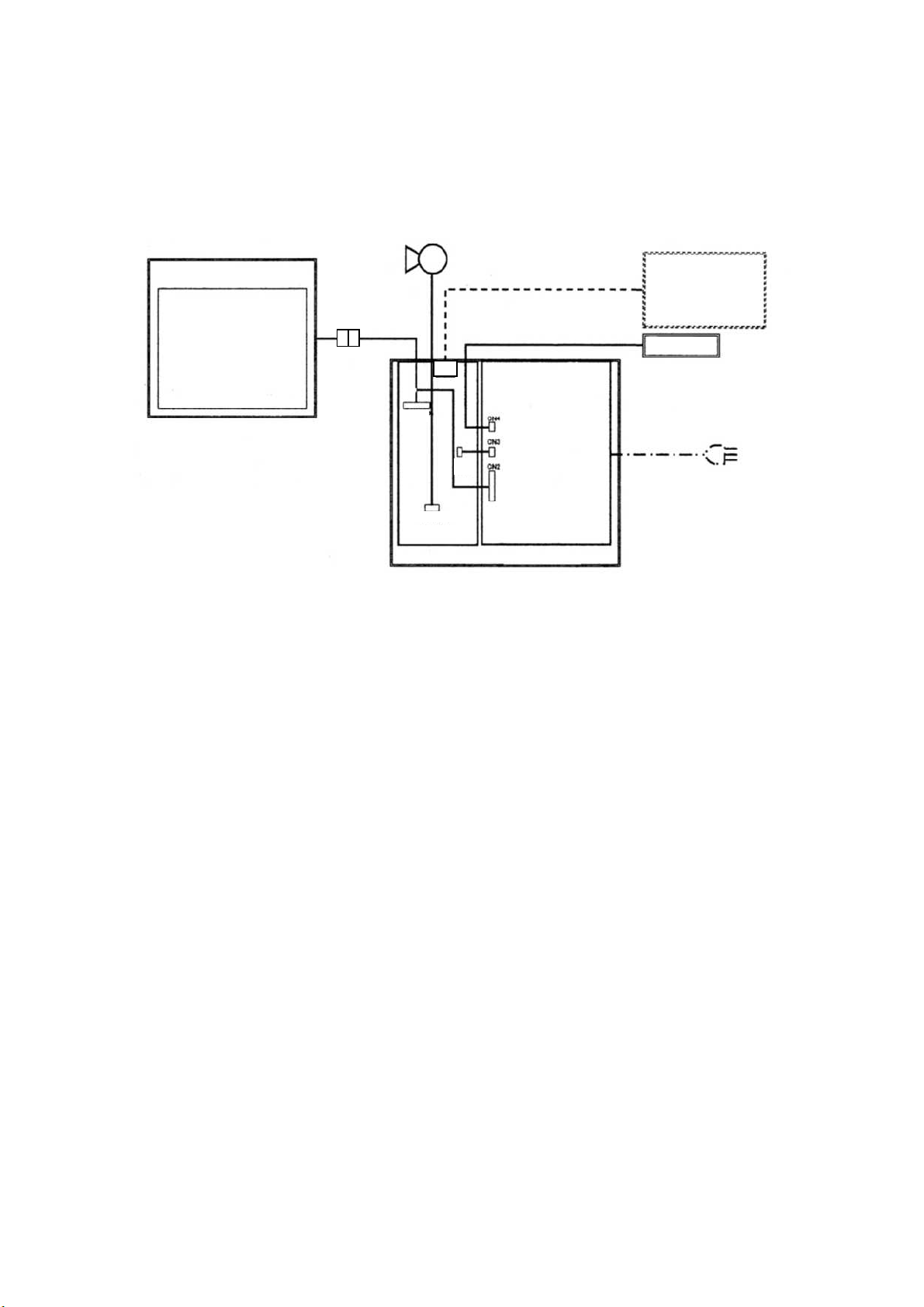

7.1.1 Connection Diagram

CXDI-60G/60C

Control

computer

J1

J2

J4

PWB-XRAY

POWER SUPPLY

J3

Remote Switch

POWER BOX

12

Page 29

2. Installation

7.1.2 Connecting to the Power Box

(1) Removing the cover

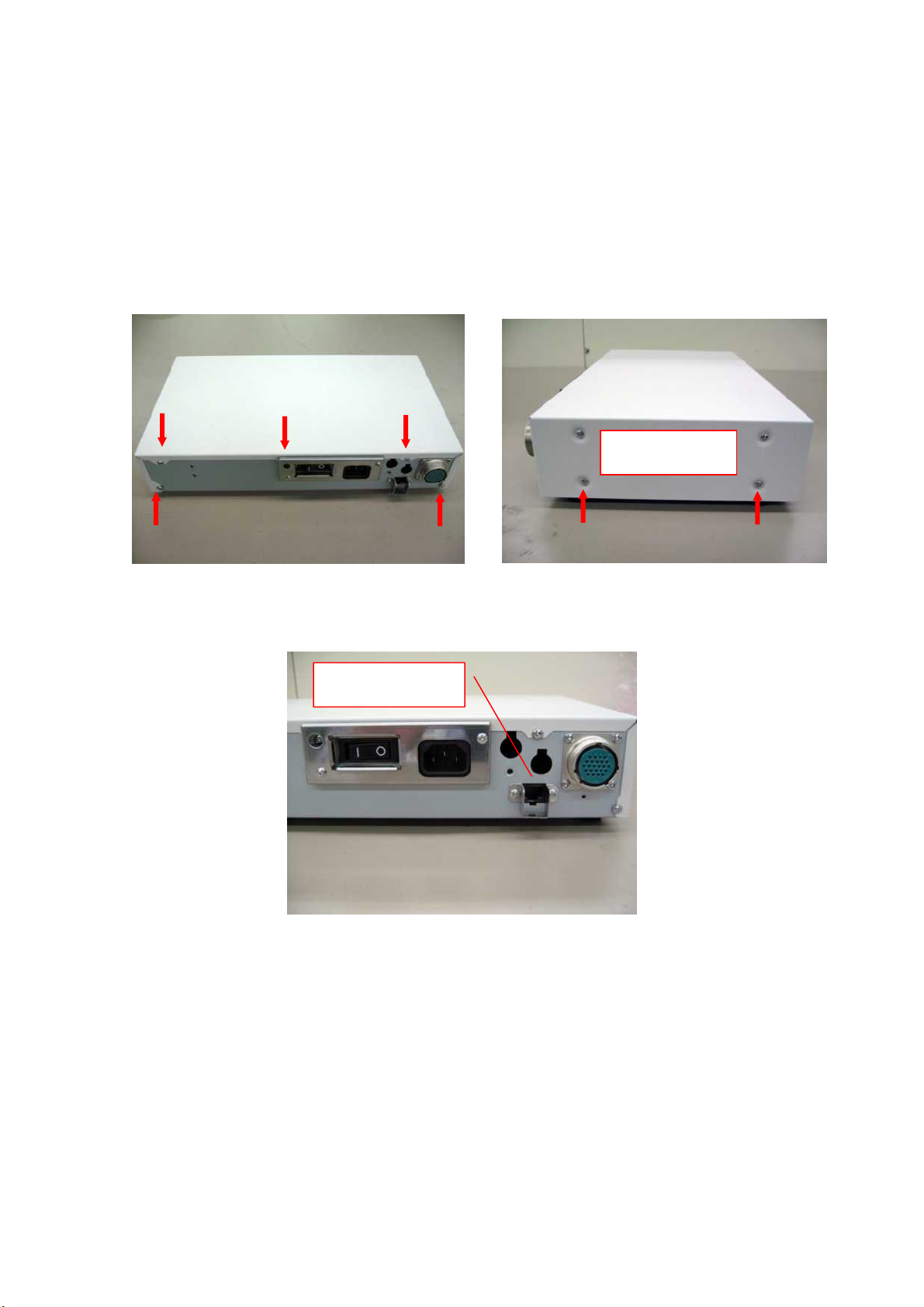

1) Remove the 5 screws from the back of the power box and the 2 screws on each side at the

bottom of the power box to remove the top cover.

Different types of screw are used for backside and lateral side. Make sure to use the proper type

of screw respectively on installation.

Also remove screws on

the far side

2) Before connecting the X-ray I/F cable and remote cable, remove the LAN cable connector

guard to avoid injury.

LAN cable connector guard

13

Page 30

(2) Cable connections

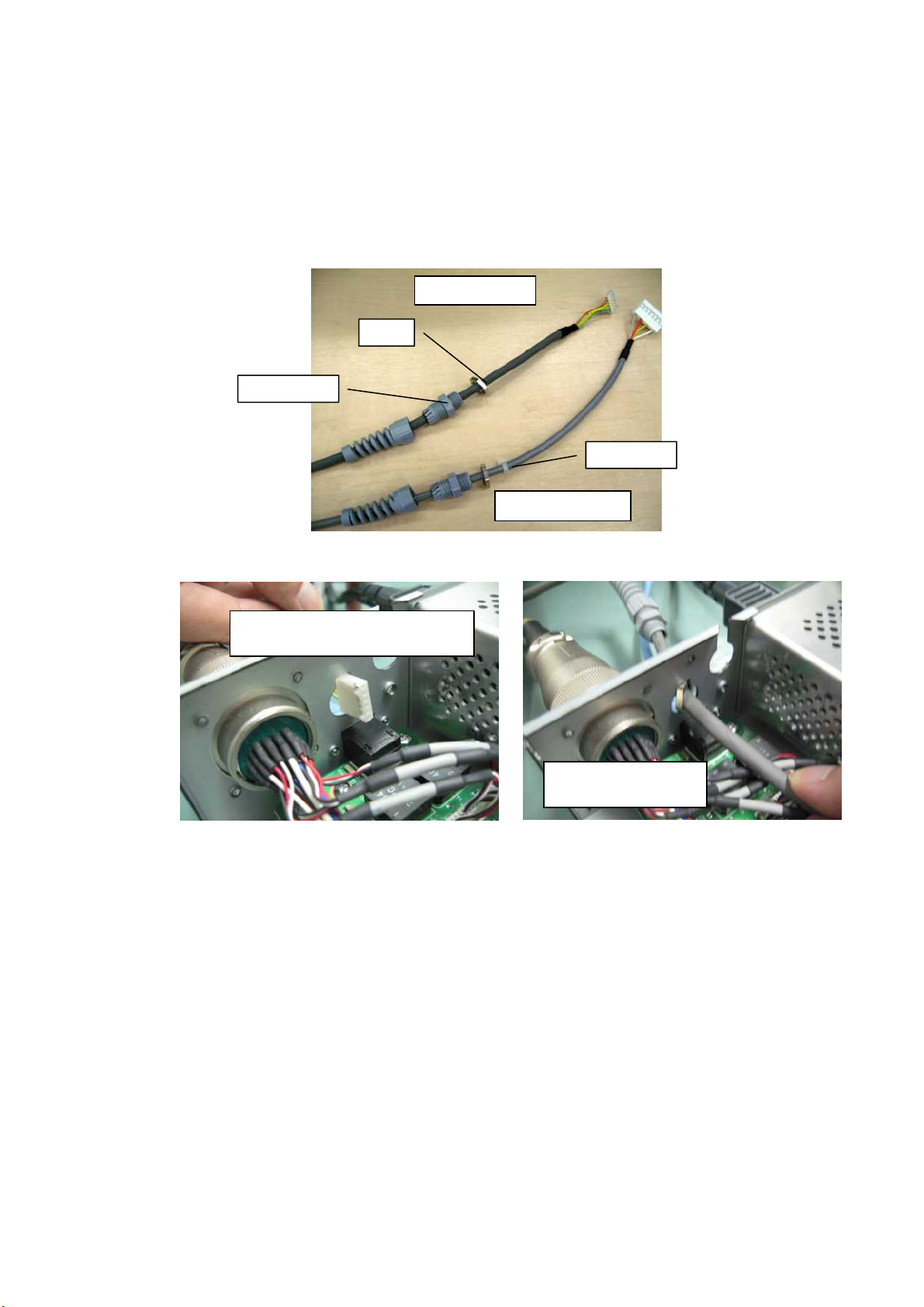

1) Loosen the skin top spiral and lock nut of the remote cable and X-ray I/F cable. Do not

remove the insulation lock from the X-ray I/F cable as it is put on the cable to prevent the

cable from falling off.

*The X-ray I/F cable is 20m in length. If the cable is too long, you may need to make it shorter.

Refer to “7.1.7. Adjusting the length of X-ray I/F cable” for details.

Skin top spiral

2) Get the connector and lock nut of the remote cable through the hole in a power box.

2. Installation

Remote Cable

Lock nut

Insulation lock

X-ray I/F Cable

Adjust the direction of the connector

to the notch of a hole.

Get the lock nut through

the hole.

14

Page 31

2. Installation

gap

3) Connect the connector of the remote cable to the power supply and joint the skin top spiral

and lock nut temporarily. Adjust the length of the cable with some margin in length for

wiring. After adjusting the length properly, fasten the skin top spiral tightly.

Skin top spiral

Lock nut

Connector

Note: To avoid the risk of damage when the cables are removed with very large force,

check skin top spiral of the bush (refer the following figure).

Gap 1.0 to 1.5mm

No

<Remote cable> <X-RAY I/F cable>

4) Fasten the skin top spiral and lock nut tightly using 15mm screw wrench.

15

Page 32

2. Installation

5) Connect the connector of X-RAY I/F cable to the power supply and joint the skin top spiral

and lock nut temporarily. Adjust the length of the cable so that the clearance of the skin top

spiral and insulation lock is 5mm. After adjusting the length, fasten the skin top spiral tightly.

Refer to the note in step 3.

Skin top spiral

Lock nut

Insulation lock

Connector

About 5mm clearances

6) Tighten the skin top spiral and lock nut using 15mm screw wrench.

7) After connecting the cables, attach the cover of power box and LAN cable connector guard.

*Different types of screw are used for backside and lateral side. Make sure to use proper

type of screw respectively on installation.

8) Connect the sensor cable, LAN cable, AC cable to the backside of the power box.

*1 Push the connector of the sensor cable into the connector terminal and fasten it tightly

until the lock ring stops.

*2 Only the AC cable attached to the product is allowed to use.

Sensor cable

AC Power cable

LAN cable

Lock ring

Fasten the sensor

cable while applying

the pressure

Gap

No gap

[Improper connection]

16

[Proper connection]

Page 33

2. Installation

[

9) Align the red marks on the connector of the sensor cable on both sides and joint the

connectors together until it locks. It snaps when it locks.

*1 Turn off the power of the power box before connecting or disconnecting the sensor

cable.

*2 Be careful not to drop the connector of the cable, it may cause injury or get the things

damaged as it is heavy.

Connector on the

imaging unit side

Connector on the

power box side

Gap

No gap

[Improper connection]

Proper connection]

17

Page 34

2. Installation

10) To disconnect the sensor cable, push the connector of the imaging unit side cable outward to

release the lock and pull out the connector of the imaging unit side straightforward. Do not grab

the cable itself.

*1 Turn off the power of the power box before connecting or disconnecting the sensor

cable.

*2 Be careful not to drop the connector of the cable, it may cause injury or get the things

damaged as it is heavy.

Release the lock

18

Page 35

2. Installation Manual

7.1.3 Using the Imaging Unit in the Multiple Rooms

Users can use one imaging unit in the multiple rooms with the CXDI SYSTEM II installed by

the service engineer. The steps to connect and disconnect the detachable connector of the

sensor cable are described in the operation manual.

Imaging

Unit

X-Ray R oom 1

Sensor Cable

Power Box

Control

Computer

Generator

X-Ray R oom 2

Sensor Cable

Power Box

Control

Com puter

Generator

19

Page 36

2. Installation

7.1.4 Interchanging a Imaging Unit

The detachable connector enables you to replace the imaging unit with the CXDI-55G/55C

imaging unit. As for the CXDI-60G having the old type sensor cable, plug and socket of the

connector does not match. Therefore, you need to replace it with the new type sensor cable.

With the launch of CXDI-60C, the new type sensor cable, which is conform to CXDI-60C, has

been adopted to CXDI-60G.

Operation unit

Control

Computer

Ethernet

CXDI-55G/55C

imaging unit

X-ray tube

X-ray

generator

Power box

Ethernet

CXDI-60G/60C

imaging unit

20

Page 37

2. Installation

Detachable connector of the CXDI-55G/55C sensor cable

CXDI-55G/55C

Imaging Unit

Power Box

Detachable connector of the CXDI-60G sensor cable (New type) and the CXDI-60C sensor

cable

CXDI-60G/60C

Imaging Unit

Power Box

Detachable connector of the old type sensor cable on the CXDI-60G imaging unit side

For the CXDI-60G imaging unit having the old type sensor cable, plug and socket of the

connector does not match. Refer to the Service Manual report CXDI-60G 09-002 for details.

CXDI-60G

Imaging Unit

(Old type sensor cable)

Power Box

21

Page 38

2. Installation

7.1.5 Sensor Cable (Optional)

(1) Sensor cable S70-60 (imaging unit side)

You can replace the sensor cable on the imaging unit side with the shorter type of 0.7meters

long sensor cable.

(2) Sensor cable SP780-60 (Straight type)

The sensor cable can be replaced with the straight type sensor cable with no detachable

connectors.

Operation unit

Control

Computer

Ethernet

Power box

Ethernet

(3) Sensor cable P630-PM (Panel mount type)

This sensor cable can be used in place of a standard sensor cable P630 (power box side). The

connector of the sensor cable P630-PM(panel mount type) can be tightened to a stand or a table.

Note that an insertion hole of 24.1mm in diameter is necessary for a stand or a table to fasten the

connector.

X-ray tube

X-ray

generator

CXDI-60G/60C

Imaging unit

22

Page 39

2. Installation

7.1.6 Connection Diagram for Control Computer Rear Panel

FC-E21A

VGA Port

(For Operation Unit)

COM2*

RS-232C Cable

(For Operation Unit)

Mouse

Power Supply

*Connect the RS-232C cable to the COM port, COM 1 or COM2, specified as the port in

the driver for Operation Unit.

LAN 2

For connecting to a power box

Keyboard

LAN 1

For connecting to a network

COM1*

RS-232C Port

(For Operation Unit)

23

Page 40

2. Installation

7.1.7 Adjusting the Length of X-ray I/F Cable

X-ray I/F cable is 20m in length. It may be too long for some installation sites and you

may need to make it short. Using the following parts is necessary and the output and input

condition should be satisfied.

Output

Relay: Voltage AC250V max/DC30V max, Current 10mA to 2A

Retardation

Retardation time: 20msec or less

Input

Electrical specification

Photo coupler: Current loop with the resistance 100 Ω or less

Retardation

Retardation time: 1msec or less

Parts

Key No. Part number Description Remark

1 Y67-2868-000 Splice terminal

Y67-2869-000 Wire Marker (Mark A)

2

Y67-2870-000 Wire Marker (Mark B)

Y67-2871-000 Wire Marker (Mark 1)

Y67-2872-000 Wire Marker (Mark 2)

3 KE2-2101-000 Insulation Tube, L=1 METER F2 (Z) 6X0.25 (SUMITOMO)

Use the specified tool (YNT-2622/JST) to press the splice terminal. For details, refer to

the instruction manual for splice terminal tool.

V0.5-4 Clear/ JST

Tool number: YNT-2622 / JST

VS-2 / HAGITEC

24

Page 41

2. Installation

7.2 Starting up and Shutting Down the System

Perform the following sequences when starting up and shutting down the system.

7.2.1 Sequence for Starting up the System

Perform the following sequence when turning the system power on.

If you do not perform the correct sequence, the imaging unit cannot be recognized, resulting in

an error. (This is because the system communicates with the imaging unit when turning the

system on.)

The power box cannot be turned on in conjunction with turning on the control computer.

Since the power box is equipped with a remote switch that turns on/off the secondary output,

you can install the switch on your side to turn it on/off.

1) Turn on the main power of the power box.

2) Turn on the remote switch of the power box.

3) Turn on the control computer.

Note:

Ccrstart.bat should be registered in Windows Startup.

7.2.2 Sequence for Turning the Power off (Shutdown)

1) From OPU, select SYSTEM → [SHUTDOWN] or [SHUTDOWN after transfer]

The control computer automatically turns off.

2) Turn off the remote switch of the power box.

3) Turn off the main power of the power box.

Note:

Turn off the main power of the power box and OPU power when not using the system for

a long period.

25

Page 42

2. Installation

g

(

(

7.3 X-ray Controller Interface

7.3.1 Interface Signal Description

X-ray Generator

X-ray emission signal

1st SW level ON)

X-ray emission signal

2nd SW level ON)

Start X-ray emission

Generator

Setup timer

End X-ray emission

X-ray emission signal OFF

RX_REQ

RX_COM

CXDI

Detect X-ray emission

nal ON

si

Imaging possible?

Enable X-ray emission

ON

Image Data read

Enable X-ray emission

OFF

26

Page 43

•

During normal imaging

2. Installation

• During timeout due to RX_REQ not negating

Timeout: 1100msec

27

Page 44

2. Installation

7.3.2 Signal Names and Functions in the Connection with the X-ray Generator

<X-ray Sync Signal>

Signal name Functions

X-ray exposure signal

Indicates that an X-ray exposure is ordered at the X-ray generator side.

RX_REQ

RX_COM

This signal needs to be retained at least for T

X-ray release signal (RX_COM) is not output if the T

period. It takes about 1 second in the worst case scenario before the operation can be

resumed when RX_REQ is negated in this period.

Time required to assert RX_COM after receiving the RX_REQ from the X-ray

generator

T

....................................................................... min.0 max.300ms

PREP

Since a captured image is read from the sensor when RX_REQ is negated (or RX_COM

is time out) as a trigger, reading action is delayed if RX_COM does not negate and time

out is used as the trigger, resulting in delay of image display timing.

We recommend using a configuration in which RX_REQ is negated.

Time required from X-ray exposure completion to negating RX_REQ

T

RX_REQ_NEG

............................................................min.0 max.100ms

* Image display timing is delayed if this is not fulfilled.

X-ray release signal

Checks whether or not imaging is ready at the CXDI side after receiving X-ray exposure

signal (RX_REQ) from the X-ray generator. This signal is output to the X-ray generator

side when imaging is ready.

Time required from asserting RX_COM to exposing X-ray

T

PRE_DELAY

..............................................................min.0 max.100ms

* Available imaging time is reduced if this is not fulfilled.

Time required to stop X-ray exposure after RX_COM halts

T

POST_DELAY

............................................................min.0 max.100ms

* Problems such as shading could occur on images if this is not fulfilled.

PREP

period.

PREP

is less than the necessary

28

Page 45

2. Installation

POWER BOX

X-ray Generator

+5V(isolated)

Photo coupler

RX_REQ

PC1

TLP281(GR/F)

Relay

Connector

J4

#2

#1

#4

YEL

WHT

GRY

A2

A1

X-ray request signal

*1:Impedance between A1-A2 < 100ƒ ¶

B2

X-ray permission signal

RX_COM

*2:Permitted Vold AC250Vmax/DC30Vmax

Permitted Current 10mA-2A

ORG

B1

RL1

NC2D-P-DC5V

#3

X-ray I/F Cable

The connection with CXDI-60G/60C and X-ray generator equipment

Connection conditions

1. The X-ray exposure signal line (including the switching function) must be insulated, and its total

impedance must be 100 ohms or less.

2. The maximum contact voltage of the X-ray exposure authorization signal line is AC 250V and

DC 30V, and its current ranges from 10mA to 2A.

Only the insulated secondary power supply can be connected.

3. Protective grounding for X-ray generator should be equipotent with the system.

29

Page 46

2. Installation

7.3.3 Rating and Characteristics for Relay and Photo Coupler (on PWB60XRAY)

(1) RL1 (Power Relay/Plug-in terminal type)

1) Rating (Operational coil)

Rated

Rated

voltage

(V)

DC5V 72 69.4 69.5 86.0

curre

nt

(mA) (Ω)

Coil

resistance

Coil Inductance

(mH)

Armature

OFF

Armature

ON

Pick-up

voltage

(V) (V) (V) (mW)

below

80%

Dropout

voltage

below

10%

Maximu

m voltage

135%

(at 50)

Power

consumption

Approx 360

2) Rating (Switch/Contact)

types Single stable

arrangement 2 Form C

Contact material Au-clad AgNi type

Relating capacity

AC250 5A

DC30V 5A

Max. switching power 1250VA 150W

Max. switching voltage 250V AC

Max. switching current 5A

Min. switching capacity

100µA 1V DC

3) Characteristics

Item Content

Operate time Max. 20ms

Reset time Max. 10ms

Mechanical 18,000 times/hour Maximum open/close

frequency

Withstand voltage

Life

Ambient temperature

Maximum operating frequency 50 times/Sec.

Rated load 1,800 times/hour

Between coil

contacts

Between same poles 1,000 Vrms

Mechanical 5x10

Electrical

2,000 Vrms

7

times

5

10

at 5A 250V AC

5

5x10

at 5A 30V DC

-40°C to +70°C (no freezing nor condensation)

30

Page 47

(2) PC1 (Photo-coupler)

1) Maximum Ratings (Ta = 25°C)

CHARACTERISTIC SYMBOL RATING

Forward Current IF(RMS) 50 mA

Forward Current

LED

Pulse forward current1 I

Reverse Voltage VR 5 V

Collector-Emitter Voltage V

Emitter-Collector Voltage V

Collector Current IC 50 mA

2. Installation

/°C -0.7(Ta≥53°C)

∆IF

1 A

FP

80 V

CEO

7 V

ECO

Collector Power Dissipation

DETECTOR

(1 Circuit)

Total Package Power Dissipation

(1 Circuit)

Isolation Voltage2 BVs 2500 Vms

Operation temperature

Storage temperature

2) Electrical Characteristics (Ta = 25°C)

CHARACTERISTIC SYMBOL

Forward Voltage VF I

LED

DETECTOR

SWITCH

Reverse Current IR V

Capacitance Ct V=0, f=1 MHz - 30 - pF

Collector-Emitter

Breakdown Voltage

Emitter-Collector

Breakdown Voltage

V

V

Collector Dark Current I

I

(BR)CEO

I

(BR)ECO

CEO

Rise Time tr - 2 -

Fall Time tf - 3 -

Turn-On Time tON - 3 -

Turn-Off Time t

Off

Turn-On Time tON - 2 -

CHARACTRISTIC

Storage Time tS - 25 -

Turn-Off Time t

OFF

150 mW

P

C

200 mW

P

T

T

-55 to 100

opr

T

-55 to 125

stg

TEST

CONDITION

=10 mA 1.0 1.15 1.3 V

F

=5 V - - 10 µA

R

=0.5 mA 80 - - V

C

=0.1 mA 7 - - V

E

VCE=48 V

Ambient Light

Below (100lx)

=48 V, Ta=85

V

CE

Ambient Light

Below (100lx)

V

=10 V

CC

I

=2 mA

C

R

=100Ω

L

MIN. TYP MAX. UNIT

-

-

0.01

(2)

2

(4)

0.1

(10)

50

(50)

- 3 -

V

=5 V

CC

I

=16 mA

F

R

=1.9 kΩ

L

- 40 -

µA

µs

µs

Note: Because of the construction, leak current might be increased by ambient light. Please use

photo-coupler with less ambient light

1

pulse amplitude 100µs, frequency 100Hz

2

AC, 1min R.H.≤60 LED side pins shorted together and DETECTOR side pins shorted together

31

Page 48

2. Installation

7.4 Network Settings

1. Objective

The imaging part communicates with the control computer by using Ethernet [IEEE802.3u

(100Base-TX)] to transfer X-ray images.

The control computer performs DICOM transfer in order to use Ethernet to transfer the obtained

images to the printer and storage device.

This section describes how to set up the TCP/IP that is necessary for the network connection.

Set up the following three items:

1) TCP/IP setting for the control computer network card

2) Network setting for Screwcap.ini

3) Network setting stored in the imaging unit.

2. Preparation

• Keyboard

• Mouse

Connect the keyboard and mouse to the back of the control computer.

Check if the system is connected, and then turn the system on.

3. Setup method

3.1 TCP/IP setting for the control computer network card

Perform the set up by referring to “FC-24VE (or FC-E21A) for CXDI Control Station Service

Manual” -> the chapter “System Manual” -> “Network Setup”.

Default values

IP Address:192.168.100.10

SubnetMask:255.255.255.0

32

Page 49

2. Installation

3.2 Network setting for Screwcap.ini

The CXDI software communicates with the imaging part through Screwcap.dll by using the

communication protocol for sending and receiving commands and responses.

In conjunction with the communication, Screwcap.ini retains the information of the connected

imaging unit such as network addresses.

It is necessary to edit Screwcap.ini to communicate with the imaging part.

Since the Screwcap.ini factory setting is the following default setting (see the figure below), it is

not necessary to edit the setting unless you changed the network protocol TCP/IP setting for the

LAN card that communicates with the imaging unit in the previous item, “3.1 TCP/IP setting for

the control computer network card”.

Screwcap.ini is located in the following directory:

D:\ccr\screwcap.ini

[HostInfo]

ResponseTimeout=30000

DataTimeout=60000

IntervalTimeout=30000

[SensorInfo]

SensorNum=1

[Sensor1]

IpAddress=192.168.100.11

CommandPort=12121

DataPort=12122

[Sensor2]

IpAddress=192.168.100.12

CommandPort=12121

DataPort=12122

[Sensor3]

IpAddress=192.168.100.13

CommandPort=12121

DataPort=12122

[Sensor4]

IpAddress=192.168.100.14

CommandPort=12121

DataPort=12122

[Log]

LogLevel=2

[SensorInfo]

SensorNum=1 Confirm this

Sensor IP address.*1

This must be the same as the

IP address stored in the

imaging part.

1

*

Imaging Unit IP address: This address must be the same as the IP address stored in

the next item, “3.3 Network setting stored in the sensor”.

33

Page 50

2. Installation

3.3 Network setting stored in the sensor

The factory default setting is shown in the table below.

This setting is not necessary

Item to be set Factory default value

Imaging unit IP address 192.168.100.11

Subnet mask 255.255.255.0

Host IP address 192.168.100.10

Port number for command 12121

Port number for data 12122

If you change the setting, refer to “Tool Software Operation Manual for Ethernet” → “Imaging

Part IP Address Setting”.

unless you have changed the setting.

34

Page 51

2. Installation

7.5 Setting the Fixed ROI Areas

1) Purpose

Set the fixed ROI area on the sensor to expose by the fixed ROI area because user can

not get the proper image by the Auto ROI area.

2) Setting method

2-1) Investigate the actual size and position of the ROI that is required.

2-2) Designate the SIZE, POSITION, and NUMBER (max 5)* on the sensor.

* However, in the case of using the new function “Display of AEC (Automated Exposure Control)

Field in Preview Screen” added from CXDI System Software Ver.6.2, NUMBER that can be

specified is max 3

.

(0,0)

Y

X

W

H

Hs=284mm

Sensor

Ws=234mm

2-3) Convert the size and position of the ROIs in 2) to pixel values. The pixel size of the

sensor is 160µm. For multiple values, use X’, Y’, W’, H’, X”, Y”, W”, and H” for

calculations.

X/160 µm Let this value equal A

Y/160 µm Let this value equal B

W/160 µm Let this value equal C

H/160 µm Let this value equal D

2-4) Open the “DENSITY ADJUSTMENT CONTROL” screen when the normal

imaging screen is active.

SYSTEMÆSETUP MENUÆSYSTEM SETTINGSÆ DENSITY

ADJUSTMENT CONTROL

35

Page 52

2. Installation

2-5) The “DENSITY ADJUSTMENT CONTROL” screen appears. Confirm that the

sensor is set with a sensor switch button. Press the [Fixed ROI Area] key.

2-6) Press the [Area setting] key.

Area setting button

2-7) The fixed ROI 1 setting screen appears. Input values A to D from step 3) into the

edit box, and press [ENABLE]. To set multiple fixed ROIs, input A’ to D’ and A”

to D” into fixed ROI 2 settings and fixed ROI 3 settings respectively.

-

B-B”

C-C”

D-D”

”

36

Page 53

2. Installation

2-8) The display returns to the “DENSITY ADJUSTMENT CONTROL” screen.

Confirm that POSITION and SIZE fields not set in step 5) to step 7) are disabled

(dimmed). If they are not dimmed, press the [Area setting] key, and press

[DISABLE] in fixed ROI * settings.

2-9) After Confirming all settings, and press [EXIT].

2-10) The display returns to the system settings screen. Press [OK].

2-11) “Change settings?” appears. Press [OK]. Be careful, because if [CANCEL] is

pressed, all changes made to the settings are deleted.

2-12) Return to the normal imaging screen, and turn off the power to

the CXDI.

37

Page 54

2. Installation

7.6 Settings

(1) Checking and Setting the Date and Time

Description about CXDI software in ‘Setting’ may change to some degree depending on

the versions of software. For CXDI software, see “New Function Descriptions” issued

for every version if necessary.

1) Purpose

The date and time is set to Japan standard time at factory shipment.

Reset the date and time to your local value as necessary.

2) Procedure

2-1) When CXDI application start, open the ADMINISTRATOR SETUP MENU.

SYSTEM → SETUP MENU → ADMINISTRATOR SETUP

2-2) When the “ADMINISTRATOR SETUP MENU” appears, and presses the [DATE]

button.

2-3) The dialog (Date / Time Properties) appears, and set the value properly each of the

fields which the tab sheet (Date&Time and Time Zone sheet) has. And then press

[OK].

38

Page 55

2. Installation

(2) Checking the Firmware Version

1) Purpose

1-1) Failing to use the proper versions of the firmware and PLD code with the CXDI

software can result in an error, and system operation cannot be guaranteed. Therefore,

the versions of the firmware must be checked to ensure that they are correct.

2) Notes

2-1) This check should always be performed at installation, and if necessary, the firmware

versions should be upgraded.

2-2) This check cannot be performed with only the control computer. Connect the imaging

units and other equipment, and start up in the normal imaging status.

3) Procedure

3-1) Checking the firmware alone

a. Start up the CXDI software.

b. Display the version information from the user mode.

SYSTEM > SETUP MENU > VERSION INFORMATION

c. Confirm the firmware version.

[System Module: Version Information]

B C

A

A. Hardware version

Product type: Product type is identified from Sensor serial No. that is set to the Imaging

unit. 0b.** indicates 60G and 0f.** indicates 60C.

B. Firmware initialization code version

This is the version of the initialization code written on the PWB-60Di. Initialization code

will be downloaded and settings will be reset to the default (factory) settings by turning

ON the power while pressing the initialization switch on the power box.

The display “3.0.08” on the screen indicates the version 3.00.08.

C. Firmware normal code version

This is the version of the normal code installed on the PWB-60Di. Usually the system

operates with this code. It must be updated as required.

The display “3.0.08” on the screen indicates the version 3.00.08.

39

Page 56

3-2) Checking the firmware and PLD code

(1) Connect the keyboard and mouse.

(2) Start up the CXDI system.

(3) Close the CXDI software if it starts up.

(4) Connect Telnet by referring to “Telnet Connection” in the Tool Software Operation

Manual for Ethernet.

(5) Check the versions of the firmware and PLD code on the screen displayed after the

login.

login: canon

Password: ********

CXDI-60 firmware Ver.3.00.08

build as May 19 2008 10:39:06

normal boot

HUB60 Ver.6004 prod code:0bc0

pwb-60di>

(6) After you finish checking, close HyperTerminal.

2. Installation

Firmware version

Hardware version

PLD code version

40

Page 57

2. Installation

(3) Installing Firmware and PLD Code

1) Purpose

Write exposure code and PLD code into the Flash ROM of the PWB-60Di in the imaging

unit.

2) Notes

Be sure to check that the CXDI is connected to the system.

3) Procedure

3-1) Installing the firmware

Write the firmware by referring to “Firm Write Tool Software (Firmwrite.exe)” in the Tool

Software Operation Manual for Ethernet.

Where to write: PWB-60Di

3-2) Installing PLD code

Write PLD code by referring to “PLD Write Tool Software (pldwrite.exe)” in the Tool

Software Operation Manual for Ethernet.

Where to write: PWB-60Di.

41

Page 58

2. Installation Manual

(4) Checking the Sensor Serial No.

1) Purpose

If the sensor serial number of the imaging unit differs from the sensor serial number stored

in the HD of the Control computer due to replacing the imaging unit, the connected imaging

unit cannot be detected after the CXDI software is launched and an error message appears.

In that case you need to register the sensor serial number.

2) Notes

2-1) Check the sensor serial number whenever the imaging unit is replaced.

2-2) This checking procedure must be performed with the Control computer, Imaging Unit

and all the other equipments connected and started up.

3) Sensor serial number registration

Register the sensor serial No. from CCR Console Menu. Refer to “Identifying the Sensor

Units” for details.

42

Page 59

2. Installation

(5) Set Up Startup Menu

1) Purposes

1-1) Register the CXDI software to the “Startup Group”.

The CXDI software is started automatically when the CXDI system is turned on.

1-2) Change the window view size

Hide the other application screen view except the CXDI software.

1-3) Delete the CXDI software from the “Startup Group”.

The CXDX software is not started when the CXDI system is turned on.

2) Notes

2-1) The CXDI software is not registered in the “Startup Group” at the factory setting.

Therefore register the CXDI software to the “Startup Group” after the system

installation.

2-2) The window view size of the program registered in “Startup Group” has one own size

with the each short-cut icon. Be sure to set the window view size of CXDI software at

the same time with the register to the “Startup Group”.

3) Register the CXDI software to the “Startup Group” procedure.

3-1) Connect keyboard and mouse to the control computer.

3-2) Turn the all CXDI system power on after the all installation finished. And after that

Windows XP starts.

3-3) Open the “Taskbar and Start Menu” from the Start Menu.

Start⇒Settings⇒Taskbar and Start Menu

3-4) “Taskbar and Start Menu Properties” appears. Click “Start Menu” tab, and then click

Taskbar and Start Menu Properties⇒Start Menu⇒Classic Start⇒Menu Customize

3-5) Click Add, and Create Shortcut appears. Click Browse.

3-6) Browse appears. Find a file named “ccrstart.bat” in drive [D:\ccr] and click OK.

3-7) D:\ccr\ccrstart.bat appears in the Command line. Click Next.

3-8) Select Program Folder appears. Select Startup folder and click [Next].

3-9) Select a name for the shortcut appears. Type ccrstart.bat. Click [Finish].

3-10) Close the Taskbar [Start], and login again to Windows XP.

Start⇒Shut Down⇒Log off cxdi.

3-11) After login the computer, make sure that the CXDI software starts up.

43

Page 60

2. Installation

4) Change the window view size

4-1) After the CXDI software starts, press [Alt] + [Tab] key to show the “CCR Console

Menu” prompt screen.

4-2) After the command prompt screen appears, click the icon (called System icon) where

is in right-top of its window.

4-3) System icon menu appears. Select Properties from the menu. [Fig 1]

Select the Properties item.

[Fig 1]

4-4) Click the “Font” tab from the “ccrstart.bat” properties and change its size to “6 x 13”.

4-5) Click the “Layout” tab and change the “Height” of the “Screen Buffer Size” to 5000.

Click [OK].

4-6) The “Apply Properties to Shortcut” appears and check the item of the “Modify

shortcut which started this window”. Click [OK].

5) Delete CXDI software from the “Startup Menu Group”.

5-1) Connect the keyboard and the mouse to the control computer.

5-2) Turns the all CXDI system power on, Windows XP start.

5-3) After the CXDI software start, press [Alt] + [Tab] key to show the “CCR Console

Menu” prompt screen.

5-4) Select “8 – Exit” to close the CXDI software on the “Welcome to CCR”.

5-5) After the CXDI application software closed and Window XP Desktop appear, open

the “Taskbar & Start Menu…” with “Start Menu” tab clicking.

Start>Settings>Taskbar and Start Menu

44

Page 61

2. Installation

5-6) “Taskbar and Start Menu Properties” appears. Click “Start Menu” tab, and then click

Taskbar and Start Menu Properties⇒Start Menu⇒Classic Start⇒Menu Customize

5-7) The “Remove Shortcuts/Folders” dialog box appears after click the “Remove” button.

And double-click the “Startup folder”

5-8) Remove the “ccrstart.bat” item from it.

5-9) After “Remove” button clicked, the confirmation of deleting file appears. If you are

going to remove it, click “Yes” button.

5-10) After confirm that the “ccrstart.bat” item is removed from “Startup Group”, close all

the application on the desktop and re-login to Windows XP.

5-11) Make sure that the CXDI software will not start automatically after login to Windows

XP. And then shutdown Windows XP, turn the CXDI system power off.

* When the CXDI software is deleted from the Start menu due to repair or other

reasons, be sure to always perform the procedures outlined in “Adding CXDI

software onto the Start menu” and “Changing the window size” when the repair is

complete.

45

Page 62

2. Installation

(6) Identifying the Imaging Units

1) Purpose

In order for the control computer to identify the imaging units connected, the sensor serial

number of each imaging unit is input to the Control computer.

2) Notes

2-1) These operations must always be implemented at the installation stage and when any

of the Imaging Units (sensor) or Control computer (hard disk) has been replaced or

when the combination of equipment has been changed.

2-2) The sensor serial numbers must always be input. If the serial numbers of the imaging

unit and Control computer do not match, “Sensor Unit: Detect Error (-5100)” will be

displayed on starting up the CXDI software. These numbers are the same as what is

input to the PWB-60Di. (Refer to “ Checking the sensor serial numbers”.)

3) Preparations (What to have ready)

Tool keyboard, tool mouse

4) Procedure

4-1) Start the CXDI software.

4-2) Once the normal sensor screen has appeared on the operation unit, use the keyboard to

enter the debugging mode (Use [ALT] + [TAB].).

4-3) “Welcome to CCR” appears. Select “1 Set-Up...”

4-4) “Setting Mode (0:Normal, 1:Expert)[0=0x0]:” appears. Select “0:Normal.”

4-5) “CCR SETUP MENU” appears. Select “7 Scan Sensor Setup.”

4-6) The “Capture Device Configuration Table” appears. Input “1” in “Max Capture

Devices” shown below.

4-7) Enter the serial number to “A/D Board Serial Number for SensorID#1”.

@@@@@@@ Capture Device Configuration Table @@@@@@@

Max Capture Devices [1=0x1]:1

Enter the serial

number here.

@@@@@@@ Capture Device Configuration No.0 (SensorID#1 OPU)@@@@@@@

-------A/D Board Serial Number 0-0 –> 60G: 0x13000000

A/D Board Serial Number for SensorID#1 [0x13000000=318767104]: 13000000

Custom Type [0:NO CUSTOM 1:STAND 2:TABLE 3:UNIV 4:CASSETTE 100um

5:CASSETTE 14X17_160um 6:CASSETTE 9X11_160um] [0=0x0]:0

Field of View Rotation (0:No 1:Yes) [0=0x0]:0

Constant for Exposure Index [-1.000000]: -1.000000

---- Need to re-start program to validate this change.

4-8) When “CCR SETUP MENU” appears, press the [Esc] key to return to “Welcome to

CCR.”

4-9) Select the command “8 - Exit” from “Welcome to CCR” menu to exit the CXDI

software.

4-10) After “Windows XP desktop” screen appears, start the CXDI software again.

* Restart the CXDI software. The screen displays the following message: Alert System Info

Error (-6) A/D board info is updated. Click “OK”.

*CXDI-60G sensor serial number: 1300****

*CXDI-60C sensor serial number: 1710****

46

Page 63

2. Installation

(7) Entering Control Computer Serial Number

1) Purpose

Set the product serial number (Control computer) to the “Device Serial Number” of the

“DICOM header”.

2) Procedure

2-1) Start up the CXDI system.

2-2) After the exposure screen appears on the operation unit, use the keyboard to enter

Debug mode. (Use [Alt] + [Tab].)

2-3) “Welcome to CCR” screen appears. Select the command “1. Set-Up…”

2-4) The “Setting Mode (0: Normal, 1: Expert) [0=0×0]:” is prompted. Select “0: Normal”

2-5) “CCR SETUP MENU” appears. Select the command ”1. System Setup”.