OPERATING INSTRUCTIONS

CAMPBELL

IMPACT WRENCH

HAUSFELD

MODELS TL1002, TL1017 AND TL1049

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE. RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Description

Do-It-Yourself (DIY) impact wrenches are air tools

designed for removing and installing nuts and bolts

such as lug nuts, exhaust system clamps, etc.

Unpacking

When unpacking this product, carefully inspect for any

damage that may have occurred during transit. Make

sure any loose fittings, bolts, etc., are tightened before

putting this product into service.

General Safety Information

This product is a part of a high pressure system and the

following safety precautions must be followed at all

times along with any other existing safety rules.

1. Read all manuals included with this product carefully. Be thoroughly familiar with the controls and

the proper use of the equipment.

2. Only persons well acquainted with these rules of

safe operation should be allowed to use the

air tool.

General Safety (Continued)

9. Always use attachments designed for use with air

powered tools. Do not use damaged or worn attachments.

!

WARNING

DO NOT USE HAND-TOOL SOCKETS. USE IMPACT-QUALITY SOCKETS ONLY. HAND-TOOL

SOCKETS ARE "GLASS-HARD" AND WILL SHATTER AND CAN CAUSE SERIOUS PERSONAL INJURY IF USED WITH AIR TOOLS.

10. Never trigger the tool when not applied to a work

object. Attachments must be securely attached.

Loose attachments can cause serious injury.

11. Protect air lines from damage or puncture.

12. Never point an air tool at oneself or any other

person. Serious injury could occur.

13. Check air hoses for weak or worn condition before

each use. Make sure all connections are secure.

!

!

DANGER

DO NOT EXCEED MAXIMUM OPERATING PRESSURE OF THE AIR TOOL (90 PSI). THE AIR TOOL

COULD EXPLODE AND RESULT IN DEATH OR

SERIOUS PERSONAL INJURY.

3. Do not exceed any pressure rating of any component in the system.

4. Disconnect the air tool from air supply before

changing tools or attachments, servicing and during nonoperation.

5. Always wear safety glasses during operation.

6. Do not wear loose fitting clothing, scarves, or neck

ties. Loose clothing may become caught in moving

parts and result in serious personal injury.

7. Do not wear jewelry when operating any tool.

Jewelry may become caught in moving parts

and result in serious personal injury.

8. Do not depress trigger when connecting the air

supply hose.

!

!

WARNING

RELEASE ALL PRESSURE FROM THE SYSTEM

BEFORE ATTEMPTING TO INSTALL, SERVICE,

RELOCATE OR PERFORM ANY MAINTENANCE.

14. Keep all nuts, bolts and screws tight and ensure

equipment is in safe working condition.

15. Do not put hands near or under moving parts.

!

Operation

LUBRICATION

Proper lubrication is the owner's responsibility. Failure

to lubricate the air tool properly will dramatically shorten

the life of the tool and will void the warranty.

!

CAUTION

This impact wrench REQUIRES lubrication BEFORE the initial use and BEFORE and AFTER each

additional use.

Impact wrenches require lubrication throughout the life

of the tool and must be lubricated in two separate areas:

– 1 –

IN230000AV 9/93

IN230000AV MODELS TL1002, TL1017 AND TL1049

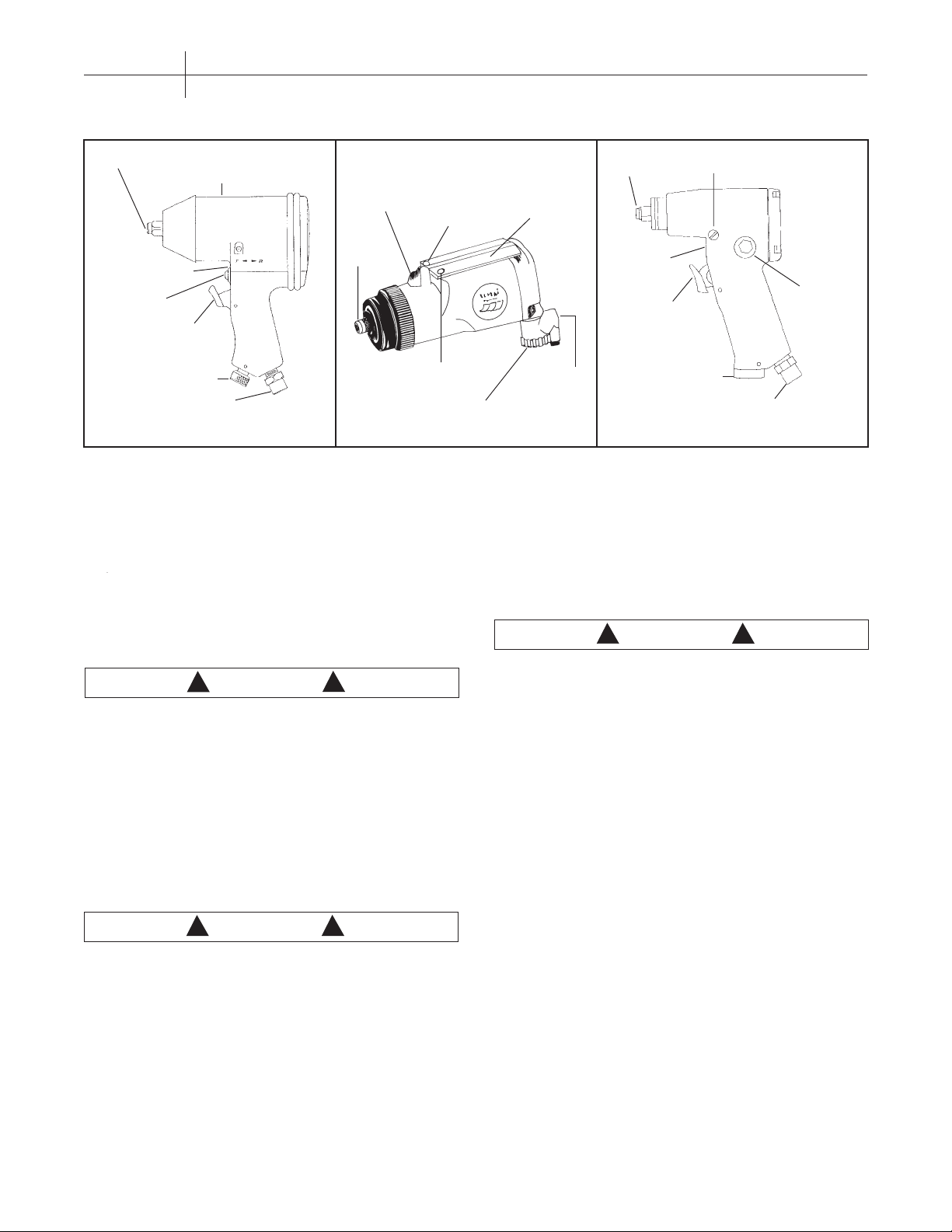

Operation (Continued)

ANVIL

EXHAUST PORT

FORWARD/

REVERSE

BUTTON

REGULATOR

1/4" NPT FEMALE

OIL PORT

HOLE ON

BACK SIDE

TRIGGER

AIR INLET

MODEL

TL1002

REMOVE

SCREW FOR

OIL PORT

HOLE

ANVIL

FORWARD

LEVER

REVERSE

LEVER

REGULATOR

Figure 1 Impact Wrench Features

the air motor and the impact mechanism. Follow the

outlined procedures and refer to Figure 1 for details.

Campbell Hausfeld air tool oil (ST127000AV) is recommended because this oil cleans, lubricates and inhibits

rust all in one step.

Air Motor Lubrication.

OIL PORT

EXHAUST

PORT

UNDER-

NEATH

1/4" NPT

FEMALE

AIR INLET

MODEL

TL1017

ANVIL

EXHAUST

PORT

TRIGGER

REGULATOR

HOLE

FORWARD/

REVERSE

SWITCH

1/4" NPT FEMALE

AIR INLET

MODEL

TL1049

reverse directions for 20 to 30 seconds. Oil will

discharge from the exhaust port when air pressure

is applied.

Impact Mechanism Lubrication.

The impact mechanism should be lubricated monthly.

The motor must be lubricated daily. An air motor cannot

be oiled too often.

!

WARNING

!

DISCONNECT THE IMPACT WRENCH FROM THE

AIR SUPPLY BEFORE LUBRICATING.

1. Disconnect the impact wrench from the air supply.

2. Turn the impact wrench upside down.

3. Simultaneously (at the same time), pull the trigger

and pour a teaspoon of Campbell Hausfeld oil in the

air inlet. Then, push the forward and reverse button

in both directions.

!

WARNING

!

AFTER AN AIR TOOL HAS BEEN LUBRICATED,

OIL WILL DISCHARGE THROUGH THE EXHAUST

PORT DURING THE FIRST FEW SECONDS OF

OPERATION. THUS, THE EXHAUST PORT MUST

BE COVERED WITH A TOWEL BEFORE APPLYING AIR PRESSURE. FAILURE TO COVER THE

EXHAUST PORT CAN RESULT IN SERIOUS INJURY.

4. Connect the impact wrench to the air supply and

cover the exhaust port with a towel (See Figure 1).

Run the impact wrench in both the forward and

!

WARNING

!

DISCONNECT THE IMPACT WRENCH FROM THE

AIR SUPPLY BEFORE LUBRICATING.

1. Disconnect the impact wrench from the air supply.

2. Remove the allen head screw from the oil port hole

on the right side of the tool that has "OIL" stamped

below the hole for model TL1002. For model TL1049,

the screw is located on the left hand side of the tool

near the exhaust port. For model TL1017, the screw

is located in front of the forward/reverse lever.

3. Put three teaspoons of Campbell Hausfeld air tool

oil in the oil port hole. Replace the screw.

4. Reconnect the air supply to the impact wrench and

run for 20 to 30 seconds. Lubricate the entire impact

mechanism by rotating the tool upside down and

sideways while running the tool.

5. Remove the screw and hold the oil port hole over a

suitable container to allow excess oil to drain.

6. If the oil is dirty, repeat the procedure above until

the oil comes out clear. Install the screw and

tighten. The residual oil remaining in the impact

mechanism chamber is all that is needed for proper

lubrication.

– 2 –

IN230000AV

MODELS TL1002, TL1017 AND TL1049

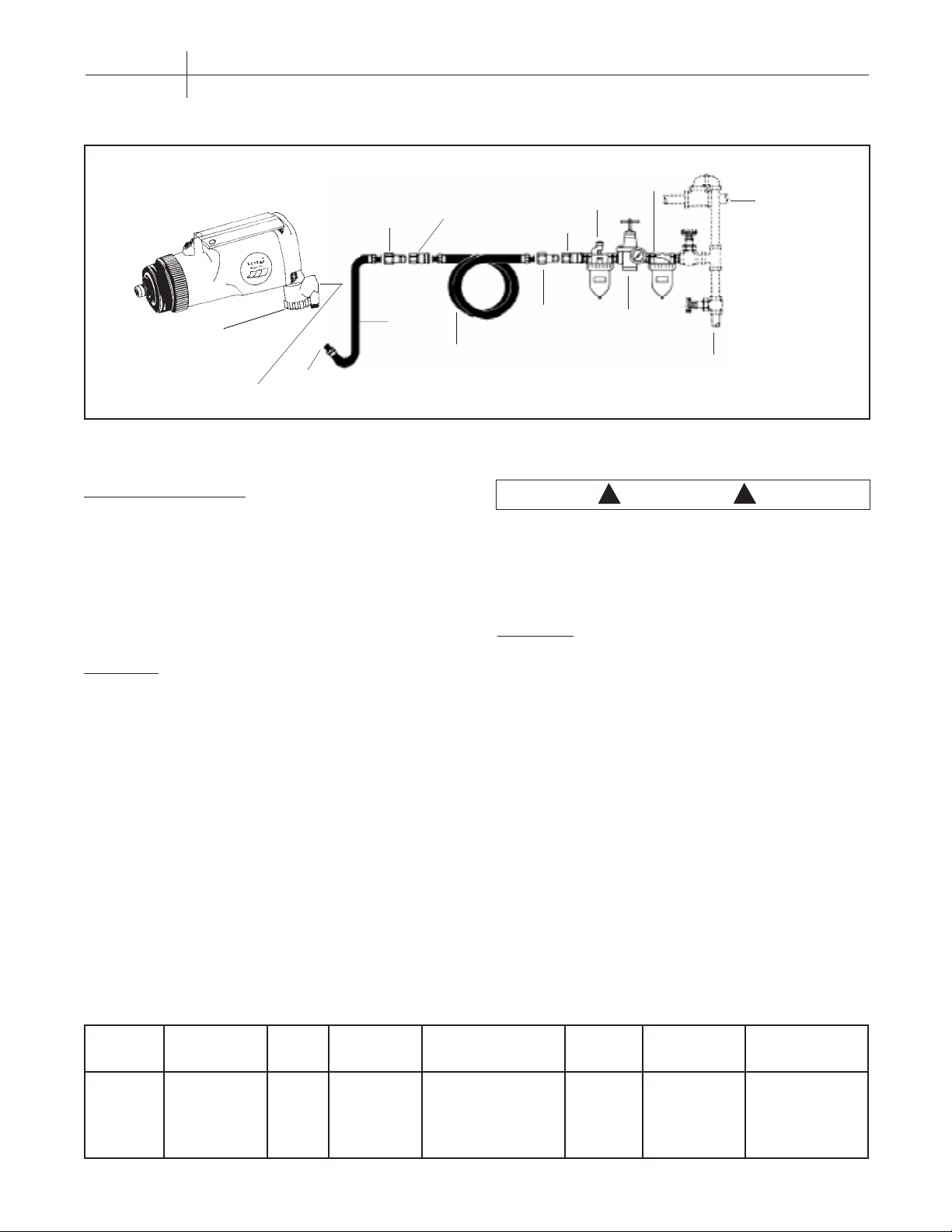

Operation (Continued)

QUICK

COUPLER

(WHIP)

HOSE

HOSE

REGULATOR

AIR INLET (OIL HERE

DAILY IF NOT USING

AN AIR TOOL OILER)

QUICK

CONNECTOR

LEADER

DO NOT INSTALL A

QUICK COUPLER HERE

Figure 2 - Air Hose Hook-up

SPEED ADJUSTMENT

The impact wrench should never be used to set torque.

Use a torque wrench to set the torque. Models TL1002,

TL1017 and TL1049 are equipped with regulators for

speed adjustment (See Figure 2).

To remove nuts, set the regulator to the maximum

setting. To install nuts, set the regulator to the minimum

to medium setting. Do not overtighten the nuts.

AIR HOSE

Figure 2 illustrates a recommended air hose hook-up.

NOTE: It is not recommended to install a quick coupler

between the impact wrench and the leader (whip) hose

(See Figure 2).

Using fittings or air hoses which are too small can create

a pressure drop and reduce the power of the tool. For

models TL1002, TL1017 and TL1049, using 3/8" (I.D.)

fittings with 1/4" NPT threads are recommended. Most

compressors are shipped with a short, 1/4" I.D. hose.

For proper performance and more convenience, use a

3/8" I.D. hose. Hoses longer than 50 feet should have a

1/2" I.D.

QUICK

COUPLER

(OPTIONAL)

QUICK

CONNECTOR

AIR

(OPTIONAL)

AIR TOOL MANUFACTURERS RECOMMEND THAT AN AIR FILTER AND OILER BE USED TO INCREASE THE LIFE OF THE TOOL.

OILER

FILTER

REGULATOR

!

WARNING

AIR SUPPLY

DRAIN (WATER TRAP)

!

NEVER CARRY A TOOL BY THE HOSE OR PULL

THE HOSE TO MOVE THE TOOL OR A COMPRESSOR. KEEP HOSES AWAY FROM HEAT, OIL AND

SHARP EDGES. REPLACE ANY HOSE THAT IS

DAMAGED, WEAK OR WORN.

STORAGE

The impact wrench must be lubricated before storing.

Follow the air motor lubrication instructions with an

exception to step 4. Only run the impact wrench for 2

to 3 seconds instead of 20 to 30 seconds because more

oil needs to remain in the impact wrench when storing.

Technical Service

For information regarding the operation or repair of this

product, please call 1-800-543-6400. If you are calling

from Ohio or outside the continental United States,

please call collect, 1-513-367-1182.

Specifications & Performance

MODEL AVERAGE MAX MAX AIR EXTENDED

# SCFM & PSI RPM TORQUE INLET DRIVE WEIGHT ANVIL

TL1002 5.1 @ 90 7000 230 ft/lb 1/4" NPT (Female) 1/2" Sq 5 lb NA

TL1017 2.4 @ 90 10,000 75 ft/lb 1/4" NPT (Female) 3/8" Sq 2 lb N/A

TL1049 2.5 @ 90 10,000 75 ft/lb 1/4" NPT (Female) 3/8" Sq 3 lb NA

– 3 –

IN230000AV MODELS TL1002, TL1017 AND TL1049

General Troubleshooting Guide

SYMPTOM POSSIBLE CAUSE (S) CORRECTIVE ACTION

Tool runs slowly or will

not operate.

Moisture blowing out

of tool

1. Grit or gum in tool.

2. No oil in tool.

3. Low air pressure.

4. Air hose leaks.

5. Pressure drops.

6. Worn rotor blade in motor.

7. Worn ball bearing in motor.

1. Water in tank.

2. Water in the air lines/hoses.

1. Flush the tool with Campbell Hausfeld air tool oil, gum

solvent, or an equal mixture of SAE 10 motor oil and

kerosene. If Campbell Hausfeld oil is not used, lubricate the

tool after cleaning.

2. Lubricate the tool according to the lubrication instructions in

this manual.

3.a. Adjust the regulator on the tool to the maximum setting.

3.b. Adjust the compressor regulator to tool maximum while the

tool is running free.

4. Tighten and seal hose fittings if leaks are found.

5.a. Be sure the hose is the proper size. Long hoses or tools using

large volumes of air may require a hose with an I.D. of 1/2"

or larger depending on the total length of the hose.

5.b. Do not use a multiple number of hoses connected together

with quick connect fittings. This causes additional pressure

drops and reduces the tool power. Directly connect the

hoses together.

6. Replace rotor blade.

7. Remove and inspect bearing for rust, dirt and grit or worn

race. Replace or clean and regrease bearing with bearing

grease.

1. Drain tank. (See air compressor manual). Oil tool and run

until no water is evident. Oil tool again and run

1-2 seconds.

2.a. Install a water separator/filter. NOTE: Separators only work

properly when the air passing through the separator is cool.

Locate the separator/filter as far as possible from the

compressor.

2. b. Install an air dryer.

2. c. If the original separator will not separate all the water from the

air, install a Campbell Hausfeld belt air filter (MP2121).

Impact Mechanism Troubleshooting Guide

Impacts slowly or

will not impact.

1. DURATION: One year from the date of purchase by the original purchaser.

2. WHO GIVES THIS WARRANTY (WARRANTOR):

Campbell Hausfeld

The Scott Fetzer Company

100 Production Drive

Harrison, Ohio, 45030

Telephone: (513) 367-4811.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld portable air compressor, air tool or supplementary air accessory supplied or manufactured

by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects on material and workmanship which occur within the duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL

PURCHASE. Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE

CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s manual(s) supplied

with product.

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment.

E. Normal adjustments which are explained in the owner’s manual(s) provided with the product, i.e. belts, pressure switch.

F. Items or service that are normally required to maintain the product, i.e. lubricants, filters and gaskets.

G. Electric motor and gasoline engine components are expressly excluded from coverage under this limited warranty. Such components should be returned by the purchaser to

the original manufacturer or to its authorized repair stations for service.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which have failed within duration of the

warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A. Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact the Campbell Hausfeld Product Service Department (see

paragraph 2).

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

1. Lack of lubrication.

2. Tool regulator set in wrong position.

3. In-line regulator or compressor regulator

set too low.

Limited Warranty

1. Lubricate the air motor and the impact mechanism. (See

Lubrication section of this manual).

2. Adjust the regulator setting of the tool.

3. Adjust regulators in the air system (See Figure 2).

– 4 –

Loading...

Loading...