Table of Contents

General Safety . . . . . . . . . . . .1-3

Specifications . . . . . . . . . . . . . . .2

Operating The Tool . . . . . . . .3-5

Troubleshooting . . . . . . . . . . .5-6

Warranty . . . . . . . . . . . . . . . . . .6

Description

This stapler is designed for cabinetry,

casebacks, decorative trim and crafts.

Features include: convenient bottom

loading magazine which holds up to

100 staples, sequential trip safety

mechanism and a narrow nose for

accurate fastener placement in tight

applications.

General Safety

Information

CALIFORNIA PROPOSITION 65

You

can

create dust when you cut,

sand, drill or grind materials such as wood, paint, metal, concrete, cement, or other masonry. This

dust often contains chemicals known

to cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

Excessive exposure

to vibration, working in awkward positions and repetitive work motions can cause injury to

hands and arms. Stop using any tool if

discomfort, numbness, tingling or pain

occur and consult a physician.

This manual contains safety, operational and maintenance information.

Contact your Campbell Hausfeld representative if you have any questions.

OPERATOR’S RESPONSIBILITY:

The tool operator is responsible for:

• Reading and understanding tool

labels and manual.

• Selecting an appropriate tool actuation system, taking into consideration the work application for which

the tool is used.

• The safe use of the tool.

• Ensuring that the tool

is used only when the

operator and all

other personnel in

the work area are

wearing ANSI Z87 eye protection

equipment, and when required,

other appropriate protection equipment such as head, hearing and foot

protection equipment. Serious eye or

permanent hearing loss could result.

• Assuring that the tool is kept in safe

working order as described in this

manual.

EMPLOYER’S RESPONSIBILITY:

• Selecting an appropriate tool actuation system, taking into consideration the work application for which

the tool is used.

• Ensuring that this manual is available

to operators and personnel performing maintenance.

• The safe use of the tool.

• Enforcing that the

tool is used only

when the operator

and all other personnel in the work area

are wearing ANSI Z87 eye protection

equipment, and when required,

other appropriate protection equipment such as head, hearing and foot

protection equipment. Serious eye or

permanent hearing loss could result.

• Assuring that the tool is kept in safe

working order as described in this

manual.

Finishing

Stapler

Operating Instructions Model SN258K

IN231204AV 7/03

• Assuring the proper maintenance

of all tools in employer’s possession.

• Ensuring that tools which require

repair are not further used before

repair. Tags and physical segregation are recommended means of

control.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious injury.

● Read and understand

tool labels and manual.

Failure to follow warnings, dangers, and cautions could result in

DEATH or SERIOUS

INJURY.

● Do not use any type

of reactive gases,

including, but not

limited to, oxygen

and combustible

gases, as a power

source. Use filtered, lubricated, regulated compressed air only. Use of a

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury, death and/or

property damage! Retain instructions for future reference.

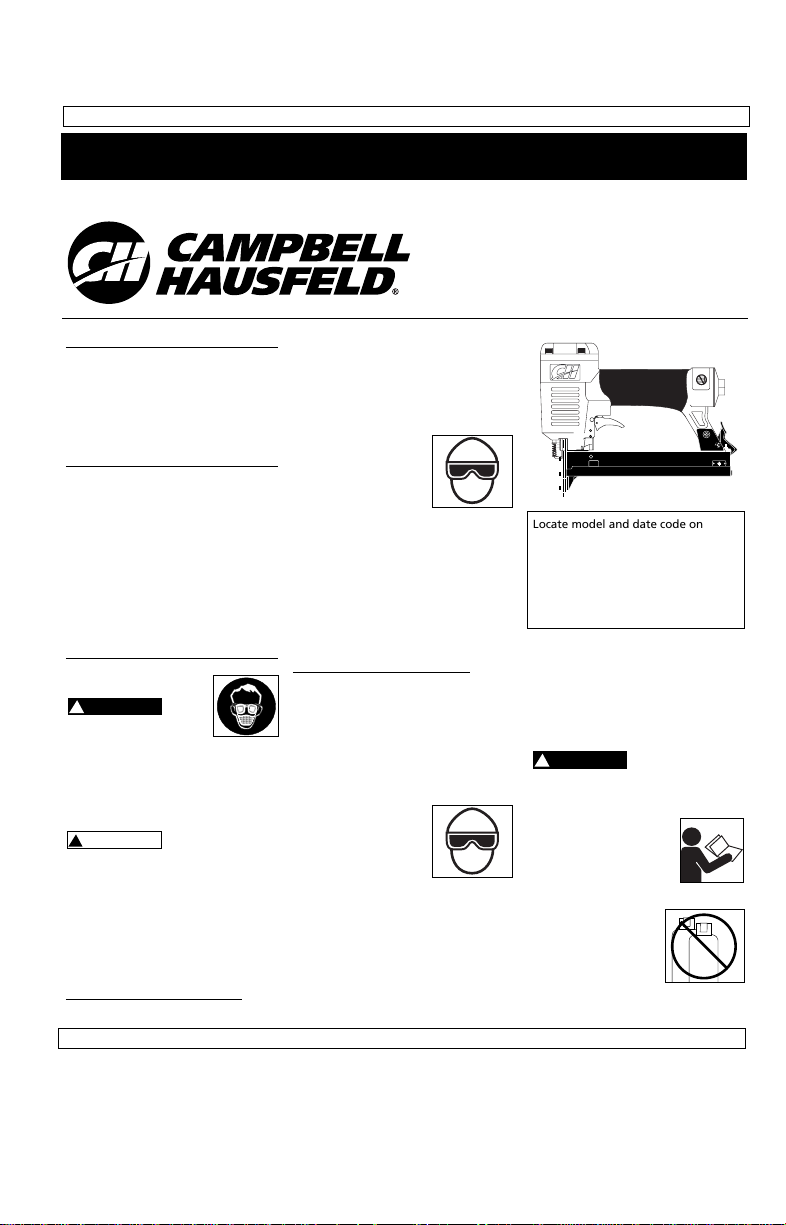

Model SN258K

Locate model and date code on tool

magazine and cap and record below:

Model No. ________________________

Date Code ________________

Retain these numbers for

future reference.

Campbell Hausfeld Nailers meet or exceed

Industries’ Standards as set forth by the

American National Standard

Institute/International Staple, Nail and Tool

Association in ANSI/ISANTA SNT-101-2002.

© 2003 Campbell Hausfeld/Scott Fetzer

For parts, product & service information

visit www.chpower.com

See Warranty on page 6 for important information about commercial use of this product.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

BUILT TO LAST

!

DANGER

!

WARNING

!

DANGER

O

CO

2

2

General Safety

Information (Continued)

reactive gas instead of compressed

air may cause the tool to explode

which will cause death or serious

personal injury.

● Use only a pressure-

regulated compressed

air source to limit the

air pressure supplied

to the tool. The regulated pressure must

not exceed 100 psi. If the regulator

fails, the pressure delivered to the

tool must not exceed 200 psi. The

tool could explode which will cause

death or serious personal injury.

● Never use gasoline

or other flammable

liquids to clean the

tool. Never use the

tool in the presence

of flammable liquids or gases.

Vapors could ignite by a spark and

cause an explosion which will result

in death or serious personal injury.

● Always remain in

a firmly balanced

position when

using or handling

the tool.

● Do not remove,

tamper with, or

otherwise cause

the Work Contact

Element (WCE) or

trigger to become

inoperable. Do not operate any tool

which has been modified in a like

fashion. Death or serious personal

injury could result.

● Do not touch the

trigger unless driving fasteners.

Never attach air

line to tool or

carry tool while

touching the trigger. The tool could

eject a fastener which will result in

death or serious personal injury.

Warning indicates

a potentially

hazardous situation which, if not avoided, COULD result in death or

serious injury.

● Always discon-

nect the tool

from the power

source when

unattended,

performing any

maintenance or repair, clearing a

jam, or moving the tool to a new

location. Always reconnect the air

line BEFORE loading any fasteners.

Do not load the tool with fasteners

when either the trigger is depressed

or the Work Contact Element (WCE)

is engaged. The tool could eject a

fastener causing death or serious

personal injury.

● Always fit tool

with a fitting or

hose coupling

on or near the

tool in such a

manner that all

compressed air in the tool is discharged at the time the fitting or

hose coupling is disconnected. Do

not use a check valve or any other fitting which allows air to remain in the

tool. Death or serious personal injury

could occur.

● Never place hands or

any other body parts in

the fastener discharge

area of the tool. The

tool might eject a fastener and could result

in death or serious personal injury.

● Never carry the

tool by the air

hose or pull the

hose to move the

tool or a compressor. Keep hoses

away from heat,

oil and sharp edges. Replace any

hose that is damaged, weak or

worn. Personal injury or tool damage could occur.

● Always assume the tool contains fas-

teners. Respect the tool as a working implement; no horseplay.

Always keep others at a safe distance from the work area in case of

accidental discharge of fasteners. Do

not point the tool toward yourself

or anyone whether it contains fasteners or not. Accidental triggering

of the tool could result in death or

serious personal injury.

● Do not drive a

fastener on top of

other fasteners.

The fastener

could glance and

cause death or a

serious puncture

wound.

● Do not operate

or allow anyone

else to operate

the tool if any

warnings or

warning labels

are not legible. Warnings or warning

Model SN258K

Operating Instructions

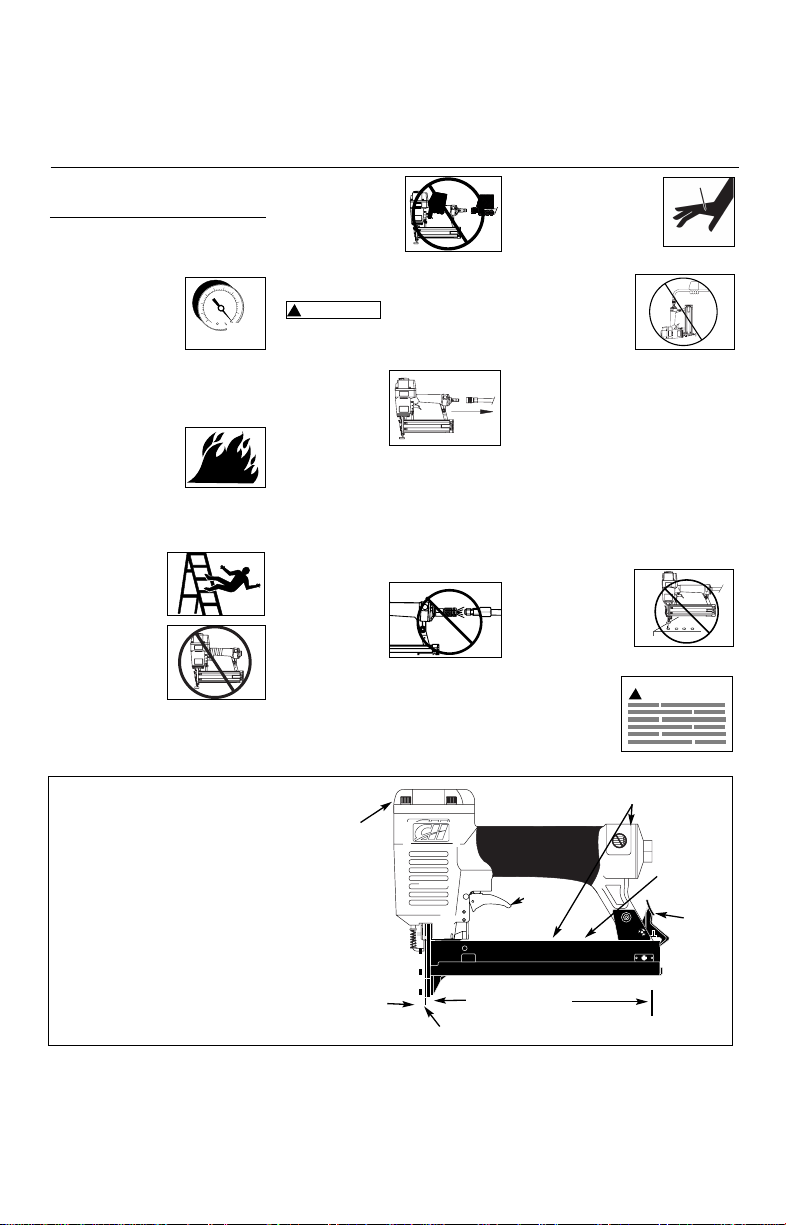

Staple Discharge Area

Trigger

Staple Loading Area

Magazine

• REQUIRES: .80 SCFM with 10 staples

per minute @ 90 psi

• AIR INLET: 1/4” NPT

• STAPLE SIZE RANGE: 3/8” to 1”

• MAGAZINE CAPACITY:

100 Staples per load, 18 gauge

• WEIGHT: 2 lbs., 9 oz.

• LENGTH: 9”

• HEIGHT: 7”

• MAXIMUM PRESSURE: 100 psi

• PRESSURE RANGE: 50 - 100 psi

Stapler Components And Specifications

Work Contact

Element (WCE)

Warning Labels

Cap Exhaust

Latch

CAMPBELL

CAMPBELL

PROFESSIONAL

HAUSFELD

www.chpower.com

100 psi

MAX.

HAUSFELD

PROFESSIONAL

!

WARNING

!

WARNING

O I L

30 W non-detergent oil into air

inlet. Do not use

detergent oils, oil

additives, or air tool

oils. Air tool oils

contain solvents

which will damage

the stapler's internal components.

3. After adding oil,

run stapler briefly.

Wipe off any

excess oil from the

cap exhaust.

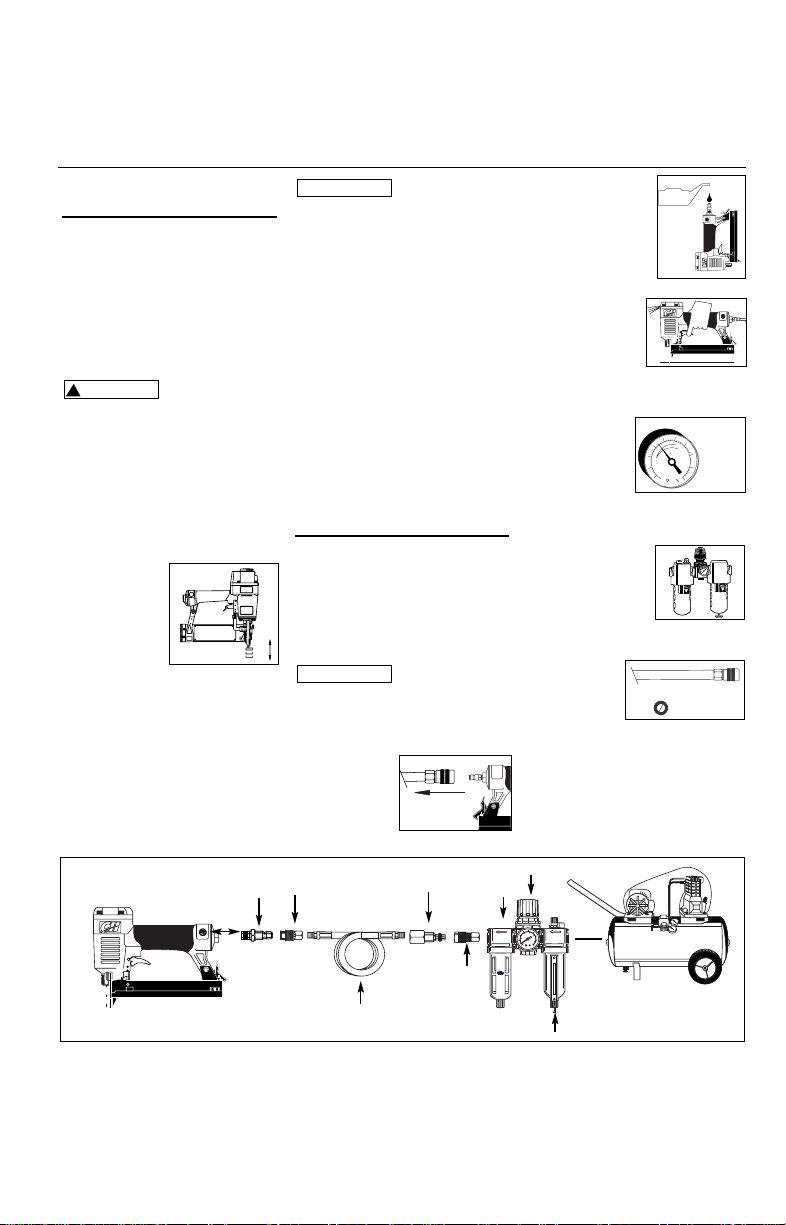

RECOMMENDED HOOKUP

The illustration below shows the

recommended hookup for the stapler.

1. The air compressor must be

able to maintain a minimum of 50 psi

when the stapler is being

used. An inadequate air supply can

cause a loss of power and inconsistent driving.

2. An oiler can be used

to provide oil circulation through the

stapler. A filter can

be used to remove

liquid and solid

impurities which

can rust or “gum up” internal parts of

the stapler.

3. Use 3/8” air

hoses with a

minimum

working pressure of 150

psi. Use 1/2”

air hoses for 50’ run or longer. For

better performance, install a 3/8”

quick plug (1/4” NPT threads) with

an inside diameter of .315" (8mm)

on the stapler and a 3/8” quick coupler on the air hose.

4. Use a pressure regulator on the

compressor, with an operating pressure of 0 - 125 psi. A pressure regu-

3

General Safety

Information (Continued)

labels are located on the tool magazine and body.

● Do not drop or throw the tool.

Dropping or throwing the tool can

result in damage that will make the

tool unusable or unsafe. If the tool

has been dropped or thrown, examine the tool closely for bent, cracked

or broken parts and air leaks. STOP

and repair before using or serious

injury could occur.

Caution indicates

a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate

injury.

● Do not make any modifications to the

tool without first obtaining written

approval from Campbell Hausfeld. Do

not use the tool if any shields or

guards are removed or altered. Do

not use the tool as a hammer.

Personal injury or tool

damage may occur.

● Always check

that the Work

Contact Element

(WCE) is operating properly. A

fastener could

accidentally be

driven if the

WCE is not

working properly. Personal injury

may occur (See "Checking the Work

Contact Element" Section).

● Disconnect air supply and release

tension from the pusher before

attempting to clear jams because

tools can be ejected from the front

of the tool. Personal injury may

occur.

Notice indicates

important infor-

mation, that if not followed, MAY

cause damage to equipment.

● Avoid using the tool when the mag-

azine is empty. Accelerated wear on

the tool may occur.

● Clean and check all air supply hoses

and fittings before connecting the

tool to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

● Air compressors providing air to the

tool should follow the requirements

established by the American

National Standards Institute

Standard B19.3-1991; Safety

Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for

information.

Operating The

Stapler

Read this manual and understand

all safety warnings and instructions before operating the stapler.

LUBRICATION

This stapler requires lubrication before

using the stapler for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily basis.

The work surface

can become damaged by excessive lubrication. Proper

lubrication is the owner’s responsibility.

Failure to lubricate the stapler properly

will dramatically shorten the life of the

stapler and void your warranty.

1. Disconnect the

air supply from

the stapler to

add lubricant.

2. Turn the sta-

pler so the air

inlet is facing up. Place 4-5 drops of

NOTICE

Model SN258K

Operating Instructions

50 psi

Min.

OIL

100 psi

Max.

150 psi WP

3/8” I.D.

Recommended Hookup

Quick

Coupler

Air

Hose

Quick Plug

(Optional)

Quick

Coupler

(Optional)

Oiler

Regulator

Filter

Quick

Plug

www.chpower.com

OIL

!

CAUTION

NOTICE

Operating The

Stapler (Continued)

lator is required to control the operating pressure of the stapler

between 50 and 100 psi.

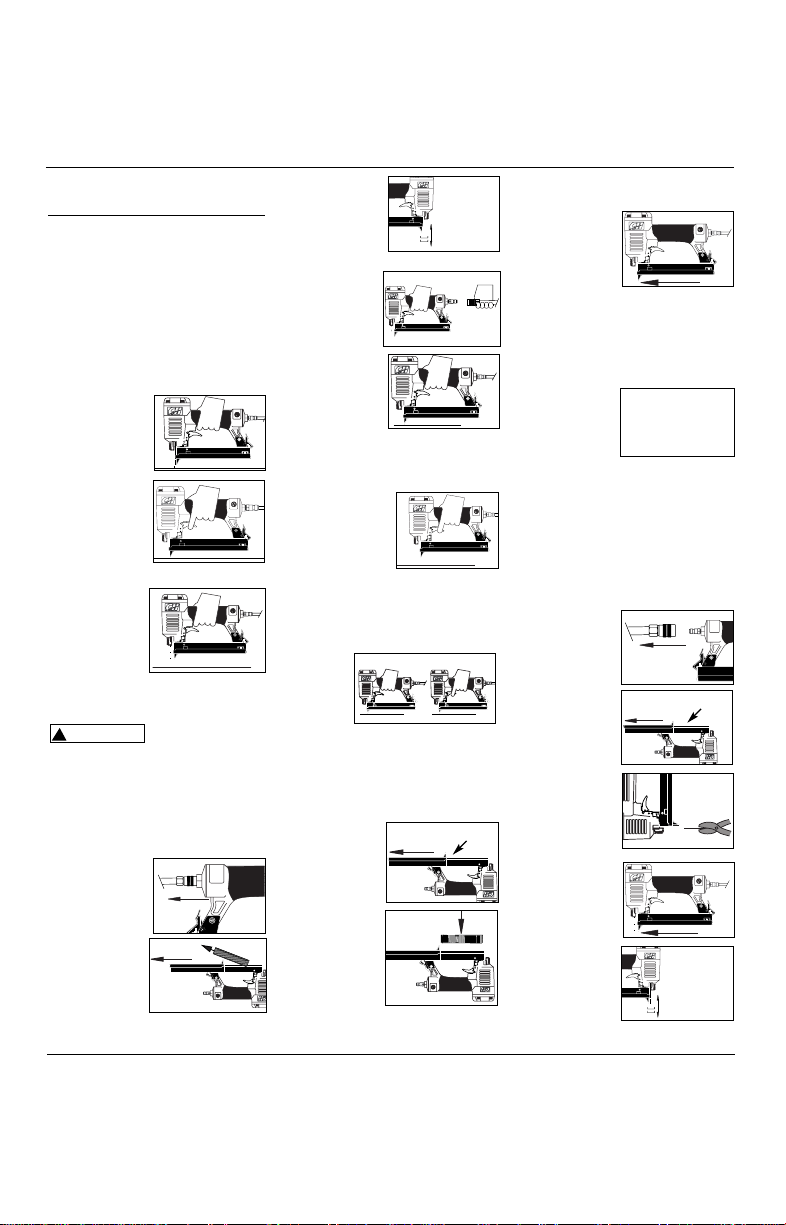

Sequential Trip Safety

Mechanism

The SN258K is equipped with a sequential trip safety mechanism. When the

operator depresses the Work Contact

Element (WCE) against the work surface

and then pulls the trigger, a fastener

will be driven.

OPERATING A SEQUENTIAL TRIP

STAPLER

1. Release trigger

and place nose

of tool against

work surface.

2. Depress the

Work contact

element (WCE)

against the

work surface

and pull the

trigger to drive

a fastener.

3. Release the

trigger and lift

the tool from

the work surface after each

fastener is driven.

CHECKING THE WORK CONTACT

ELEMENT (WCE)

Check the opera-

tion of the Work

Contact Element (WCE) trip mechanism

before each use. The WCE must move

freely without binding through its

entire travel distance. The WCE spring

must return the WCE to its fully extended position after being depressed. Do

not operate the stapler if the WCE trip

mechanism is not operating properly.

Personal injury may occur.

1. Disconnect the

air supply from

the stapler.

2. Remove all

staples from

the magazine

(See LoadingUnloading).

sure the staples are not dirty or

damaged.

4. Push the magazine cover forward until the

latch catches.

5. Always unload

all fasteners

before removing tool from service. Unloading is

the reverse of loading, except

always disconnect the air hose

before unloading.

ADJUSTING THE STAPLE

PENETRATION

1. Regulate the

air pressure to

50 psi at the

stapler.

2. Connect the

air supply and

test for penetration by driving staples into a sample piece of wood. If

the staples do not achieve the

desired penetration, adjust the air

pressure to a higher setting until

the desired penetration is achieved.

Do not exceed 100 psi at the stapler

or durability of the stapler will be

reduced.

CLEARING A JAM FROM THE

STAPLER

1. Disconnect the

air supply from

the stapler.

2. Depress the

latch and pull

back on the

magazine

cover.

3. Remove

jammed fastener from staple discharge

area.

4. Push magazine

cover forward

until latch

catches.

5. Make sure the

trigger and

Work Contact

Element (WCE)

move freely up

and down

without sticking or binding.

3. Make sure the

trigger and

Work Contact

Element (WCE)

move freely up

and down

without sticking or binding.

4. Reconnect air

supply to the

stapler.

5. Depress the

work contact

element (WCE)

against the

work surface

without pulling

the trigger. The stapler MUST NOT

OPERATE. Do not use the stapler if

it operates without pulling the trigger. Personal injury may result.

6. Remove the stapler from the

work surface.

The Work

Contact Element

(WCE) must

return to its

original down position. Pull the trigger. The stapler MUST NOT OPER-

ATE. Do not use the stapler if it

operates while lifted from the work

surface. Personal injury may result.

7. Depress

the

Work

Contact

Element

(WCE)

against the work surface. Pull the

trigger. The stapler MUST operate.

LOADING/UNLOADING THE STAPLER

1. Always connect the tool to the air

supply before loading fasteners.

2. Turn stapler

upside down

and depress

the latch. Pull

back on the

magazine

cover.

3. Insert a stick of

Campbell

Hausfeld

staples or

equivalent

(see Fastener

Section) into

the magazine

with the crown side down. Make

Model SN258K

Operating Instructions

4

Latch

Latch

movement

movement

www.chpower.com

OIL

!

CAUTION

O-rings in trigger valve housing are damaged

Loose screws in housing

Damaged o-rings

Damage to bumper

Loose screws

Damaged gasket

Worn bumper

Dirt in nose piece

Dirt or damage prevent staples or pusher from

moving freely in magazine

Damaged pusher spring

Inadequate air flow to stapler

Worn o-ring on piston or lack of lubrication

Damaged o-ring on trigger valve

Air leaks

Cap gasket leaking

Model SN258K

Operating Instructions

Fasteners

The following Campbell Hausfeld staples are available at local retail stores. If you need help locating any item, call customer

service at 1-800-543-6400. Campbell Hausfeld staples meet or exceed ASTM Standard F1667.

Wire Crown Staples Staples

Model # Length

Diameter Size

Point Finish Collation

Per Stick Per Box

FN158K00 1/2” 18 Gauge 1/4" Chisel Galvanized/Vinyl Coated Adhesive 100 5000

FN168K00 5/8” 18 Gauge 1/4" Chisel Galvanized/Vinyl Coated Adhesive 100 5000

FN208K00 3/4” 18 Gauge 1/4" Chisel Galvanized/Vinyl Coated Adhesive 100 5000

FN258K00 1” 18 Gauge 1/4" Chisel Galvanized/Vinyl Coated Adhesive 100 5000

Interchange Information

Staples used in the Campbell Hausfeld SN258K Finishing Stapler will also work in: Senco LN4450, SJS-LR, SKS L11-15,

Hitachi N3804A, Duofast BN-1832S, KN-1848, Stan-Tech SDS 18-14, Atro Minor 90/30, 90/32, 90/40, and Porter Cable NS100.

Air leaking at trigger valve

area.

Air leaking between housing

and nose.

Air leaking between housing

and cap.

Stapler skips driving staple.

Replace o-rings and check operation of

Work Contact Element (WCE)

Tighten screws

Replace o-rings

Replace bumper

Tighten screws

Replace gasket

Replace bumper

Clean drive channel

Clean magazine

Replace spring

Check fitting, hose, or compressor

Replace and lubricate o-rings

Replace o-rings

Tighten screws and fittings

Replace gasket

Troubleshooting Guide

Stop using stapler immediately if any of the following problems occur. Serious personal injury

could occur. Any repairs or replacements must be done by a Qualified Service Person or Authorized

Service Center.

Problem Cause Solution

5

Technical Support

Please call our Tool Hotline at 1-800543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual.

Fastener And Replacement

Parts

Use only

genuine Campbell

Hausfeld 18 gauge fasteners (or equivalent - see Fastener Interchange

Information). Tool performance, safety

and durability could be reduced if

improper fasteners are used. When

ordering replacement parts or fasteners, specify by part number.

Tool Repair

Only qualified personnel should repair

the tool, and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently.

Assembly Procedure For

Seals

When repairing a stapler, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W

non-detergent oil or equivalent, must

be added through the air line before

testing.

www.chpower.com

!

WARNING

!

WARNING

CAMPBELL

PROFESSIONAL

HAUSFELD

6

Model SN258K

Operating Instructions

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Products - One Year, Serious

Duty Products - Two Years, Extreme Duty Products - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun, inflator or air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED

FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial,

industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States

do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance

with instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or

failure to operate products in accordance with instructions shall also include the removal or alteration of any safety

devices. If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shields,

driver blades

, fuses, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants, mate-

rial hoses, filter elements

, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters, collets,

chucks, rivet jaws, screw driver bits

, sanding pads, back-up pads, impact mechanism, or any other expendable part

not specifically listed. These items will only be covered for ninety (90) days from date of original purchase.

Underlined items are warranted for defects in material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability

of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may

also have other rights which vary from state to state or country to country.

Troubleshooting Guide (Continued)

Stapler not lubricated sufficiently

Broken spring in cylinder cap

Exhaust port in cap is blocked

Guide on driver is worn

Staples are not correct size

Staples are bent

Magazine or nose screws are loose

Driver is damaged

Staples loaded incorrectly

O-rings or seals are damaged

Stapler runs slow or has loss

of power.

Staples are jammed in stapler.

Air leaking at trigger valve

stem.

Lubricate stapler

Replace spring

Replace damaged internal parts

Replace guide

Use only recommended staples

Replace with undamaged staples

Tighten screws

Replace driver

Review Loading/Unloading section in

this manual

Replace o-rings or seals

Problem Cause Solution

www.chpower.com

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

représentant Campbell Hausfeld si vous

avez des questions.

RESPONSABILITÉ DE L’UTILISATEUR

L'opérateur de l'outil est responsable de :

• Lire et comprendre les étiquettes et

le manuel sur les outils.

• Choisir un système d'activation de

l'outil approprié en tenant compte

de l'application de travail prévue

pour l'outil.

• L'utilisation sécuritaire de l'outil.

• S'assurer que l'outil

est utilisé seulement

lorsque l'opérateur

et tout autre personnel dans l'aire de travail portent un équipement de protection oculaire ANSI Z87 et, s'il y a

lieu, d'autre équipement de protection appropriée tel que de

l'équipement de protection pour la

tête, les oreilles et les pieds. Il pourrait y avoir de graves lésions oculaires ou perte auditive.

• S'assurer que l'outil soit conservé en

bon état tel que décrit dans ce

manuel.

RESPONSABILITÉ DE L’EMPLOYEUR

• Choisir un système d'activation de

l'outil approprié en tenant compte

de l'application de travail prévue

pour l'outil.

• S'assurer que ce manuel soit

disponible pour les opérateurs et le

personnel responsable de l'entretien.

• L'utilisation sécuritaire de l'outil.

• S'assurer que l'outil

est utilisé seulement

lorsque l'opérateur

et tout autre personnel dans l'aire de travail portent un équipement de protection oculaire ANSI Z87 et, s'il y a

lieu, d'autre équipement de protection appropriée tel que de

Table des Matières

Directives de Sécurité . . . . . . . .1-3

Spécifications . . . . . . . . . . . . . . . .2

Utilisation de l’outil . . . . . . . . . .3-5

Guide de Dépannage . . . . . . . . . .6

Garantie . . . . . . . . . . . . . . . . . . . . .7

Description

Cette agrafeuse est conçue pour l’assemblage d’armoires, de panneaux de fond

et de boiseries décoratives ainsi que pour

les travaux d’artisanat. Caractéristiques:

chargement du magasin par le dessous,

capacité de 100 agrafes, mécanisme de

sécurité à déclenchement séquentiel,

buse étroite pour plus de précision dans

les endroits exigus.

Généralités sur la

Sécurité

PROPOSITION 65 CALIFORNIE

Vous pouvez créer de la poussière en

coupant, ponçant, perçant ou meulant

les matériaux tels que le bois, la peinture, le métal, le béton, le ciment ou

autre maçonnerie. Cette poussière contient souvent des produits chimiques

reconnus pour causer le cancer, les

déformations congénitales ou autres

problèmes de la reproduction. Portez de

l’équipement de protection.

Toute

exposition excessive aux vibrations, tout travail dans des positions incommodes et

tous déplacements à répétition peuvent

causer des blessures aux mains et aux

bras. Cesser d’utiliser tout outil s’il y a

malaise, engourdissement, fourmillement ou douleur et consulter un

médecin.

Ce manuel contient des informations

concernant la sécurité, le fonctionnement et l’entretien. Contacter votre

Instructions D’Utilisation Modèle SN258K

l'équipement de protection pour la

tête, les oreilles et les pieds. Il pourrait y avoir de graves lésions oculaires ou perte auditive.

• S'assurer que l'outil soit conservé

en bon état tel que décrit dans ce

manuel.

• S'assurer du bon entretien de tous

les outils de l'employeur.

• S'assurer que les outils qui doivent

être réparés ne soient plus utilisés

avant leur réparation. Les moyens

de contrôle sont les étiquettes et la

ségrégation physique.

Danger

indique

une situation hasardeuse imminente

qui RÉSULTERA en perte de vie ou

blessures graves.

● Lire et comprendre les

étiquettes et le manuel

sur les outils. Ne pas

suivre les

avertissements, les

dangers et les mises en garde

pourrait causer la MORT ou de

GRAVES BLESSURES.

Agrafeuse

Pour Finition

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

IN231204AV 7/03

Modèle SN258K

BUILT TO LAST

Trouver le code de modèle et de date

sur le magasin de l'outil et bouchon et

enregistrer plus bas :

Nº du Modèle____________________

Code Date _______________________

Conserver ces numéros

comme référence.

Les Cloueuses Campbell Hausfeld conforment aux/ou dépassent les standards de l’American

National Standard/International Staple, Nail and Tool Association in ANSI/ISANTA SNT-101-2002.

© 2003 Campbell Hausfeld/Scott Fetzer

Voir la Garantie à la page 13 pour de l’information importante sur l’utilisation commercial de ce produit.

!

DANGER

!

AVERTISSEMENT

!

DANGER

Généralités sur la

Sécurité (Suite)

● Ne pas utiliser comme

source d'alimentation

tout type de gaz

réactif, y compris,

mais sans s'y limiter,

de l'oxygène et des

gaz combustibles. Utiliser seulement

de l’air comprimé filtré, lubrifié et

réglé. Utiliser un gaz réactif au lieu

d'air comprimé pourrait faire

exploser l’outil ce qui pourrait

provoquer des blessures graves

voire la mort.

● Utiliser seulement

une source d'air

comprimé à pression

pour limiter la

pression d'air fournie

à l'outil. La pression

contrôlée ne doit pas dépasser 689,5

kPa. S'il y a une défaillance du

régulateur, la pression livrée à l'outil

ne doit pas dépasser 1 379 kPa.

L'outil pourrait exploser ce qui

pourrait mener à la mort ou à des

blessures graves.

● Ne jamais utiliser de

l’essence ni les fluides

inflammables pour le

nettoyage de l’outil.

Ne jamais utiliser

l’outil près d’un liquide ou gaz

inflammable. Une étincelle peut

allumer les vapeurs et causer une

explosion qui peut résulter en perte

de vie ou blessures graves personnelles.

2-Fr

● Toujours bien

s’équilibrer pendant la manipulation ou l’utilisation de l’outil.

● Ne pas retirer,

modifier ou faire

quoique ce soit

qui pourrait rendre la gâchette ou

le mécanisme de

déclenchement par contact (WCE)

inutilisable. Ne pas faire fonctionner

d'outil qui a été modifié de cette

façon. Cela pourrait mener à la mort

ou à de graves blessures

● Ne toucher à la

gâchette qu’au

moment de poser

des attaches. Ne

jamais actionner

la gâchette

durant le transport de l’outil ou durant le raccordement de celle-ci au tuyau d’air comprimé. L’éjection accidentelle d’une

attache peut causer des blessures

graves ou mortelles.

Avertissement indique une situation

hasardeuse potentielle qui PEUT résulter en perte de vie ou blessures graves.

● Toujours

débrancher l'outil

de la source de

courant en votre

absence, en

effectuant des

réparations ou son entretien, en

débloquant l'appareil ou en le

déplaçant ailleurs. Le raccordement

du tuyau d’air comprimé doit

toujours s’effectuer AVANT le

chargement du magasin. Ne pas

charger l'outil d'attaches lorsque la

gâchette est enfoncée ou lorsque le

mécanisme de déclenchement par

contact (WCE) est engagé. L’éjection

accidentelle d’une attache peut

causer des blessures graves ou

mortelles.

● Toujours

installer un

raccord ou un

tuyau de

raccord sur ou

près de l'outil

afin que tout air comprimé de l'outil

soit déchargé au moment où l'on

débranche le raccord ou le boyau. Ne

pas utiliser un clapet ni autre raccord

qui permet que l’air reste dans l’outil.

Cela peut entraîner des blessures

graves ou mortelles.

● Ne jamais poser l’em-

bout de clouage sur la

main ou sur toute autre

partie du corps.

L’éjection accidentelle

d’un clou peut causer

des blessures graves ou mortelles.

● Ne jamais transporter

l’outil par le tuyau à

air. Ne jamais tirer sur

le tuyau pour déplacer l’outil ou le compresseur. Garder le

tuyau à air à l’écart de la chaleur,

l’huile et les objets pointus.

Remplacer les tuyaux endommagés,

faibles ou usés. Sinon, il y a risque de

blessures personnelles ou de dommage à l’outil.

Modèle SN258K

Instructions D’Utilisation

Endroit d’expulsion des agrafes

Chargeur

Loquet

• EXIGE: 0,02 m3/min avec 10 agrafes par minute à

621 kPa

• PRISE D’AIR: 1/4 po NPT

• TAILLES D’AGRAFES: 9,5 mm à 25,4 mm

• CAPACITÉ DU CHARGEUR:

100 Agrafes par charge, calibre 18

• POIDS: 1,16 kg

• LONGUEUR: 22,9 cm

• HAUTEUR: 17,8 cm

• PRESSION MAXIMALE: 690 kPa

• GAMME DE PRESSION: 345 - 690 kPa

Pièces Détachées et

Spécifications de

l’Agrafeuse

Étiquettes d’avertissement

Mécanisme de

déclenchement

par contact (WCE)

Endroit de chargement

de agrafes

Gâchette

689,5 kPa

CAMPBELL

PROFESSIONAL

HAUSFELD

O

CO

2

!

AVERTISSEMENT

CAMPBELL

HAUSFELD

PROFESSIONAL

Généralités sur la

Sécurité (Suite)

● Toujours prendre pour acquis que

l’outil contient des attaches.

Respecter l'outil comme accessoire

de travail non pas un jouet. Donc

aucun jeu brutal. Toujours garder les

autres personnes à une distance de

sécurité de l'aire de travail en cas de

décharge accidentelle des attaches.

Ne pas pointer l'outil vers vous ou

vers quelqu'un d'autre qu'il y ait ou

non des attaches dans l’outil. Le

déclenchement accidentel de l’outil

pourrait causer la mort ou de graves

blessures.

● Ne jamais enfoncer

les attaches un pardessus l’autre.

L’attache pourrait

ricocher et causer la

mort ou une

blessure grave de perforation.

● Ne pas utiliser

l’outil ni permettre qu’une autre

personne l’utilise

si les avertissements ou les étiquettes d’avertissement situés sur le

chargeur et corps de l’outil ne sont pas

lisibles.

● Ne pas échapper ni jeter l’outil car ceci

peut causer du dommage le rendant

dangereux à utiliser. Si l’outil s’est fait

échappé ou jeté, l’examiner soigneusement afin de déterminer s’il est courbé,

fendu ou s’il y a des fuites ou pièces

détachées endommagées. ARRÊTER et

réparer avant d’utiliser , sinon, il y a

risque de blessures graves.

Attention

indique

une situation hasardeuse potentielle

qui PEUT résulter en blessures.

● Ne pas apporter de modifications à

l'outil sans d'abord obtenir une

Modèle SN258K

Utilisation de

l’Agrafeuse

Lire attentivement ce manuel afin

de comprendre tous les avertissements de sécurité et instructions

avant d’utiliser l’agrafeuse.

GRAISSAGE

Cette agrafeuse exige le graissage avant

son usage initial et avant chaque usage. Si

vous utilisez un graisseur en canalisation,

le graissage manuel à travers la prise d’air

n’est pas exigé quotidiennement.

La sur-

face de

travail peut être endommagée par le

graissage excessif. Le graissage correct

est la responsabilité de l’utilisateur.

Manque de graisser l’agrafeuse correctement peut raccourcir la durée de l’agrafeuse et peut annuler votre garantie.

1. Débrancher la

source d’air de

l’agrafeuse

avant de

graisser.

2.

Tourner la

agrafeuse de

manière à ce

que la prise

d’air comprimé

soit dirigée vers le haut. Introduire 4

ou 5 gouttes d’huile non-détergente

dans la prise d’air comprimé. Ne pas

utiliser d’huile détergente, d’additif à

huile ni d’huile pour outils à air comprimé. Ces dernières contiennent des

solvants qui peuvent endommager les

pièces intérieures de la agrafeuse.

Instructions D’Utilisation

approbation écrite de Campbell

Hausfeld. N’utilisez pas l’outil si les

écrans ou protecteurs ont été enlevés

ou altérés. Cela peut entraîner des

blessures ou endommager l’appareil.

● Toujours vérifier

le bon fonctionnement du

mécanisme de

déclenchement

par contact

(WCE). L’éjection

accidentelle

d’attaches peut se produire si ce

mécanisme ne fonctionne pas correctement et cela pourrait entraîner

des blessures. (Voir “Vérification du

mécanisme de déclenchement par

contact”).

● Pour éviter l’expulsion d’une

attache, débrancher la source d’air

et relâcher la tension du poussoir

avant de procéder au déblocage.

Sinon, il y a risque de blessures

graves.

Avis

indique

de l’information importante pour

éviter le dommage de l’équipement.

● Éviter d’utiliser l’outil lorsque le

chargeur est vide. Sinon, il y a

risque d’usure accéléré de l’outil.

● Nettoyer et vérifier tous les tuyaux

et raccords avant de brancher l’outil

au compresseur d’air. Remplacer les

tuyaux ou les raccords endommagés

ou usés, sinon, le rendement et la

durabilité de l’outil seront affectés.

● Le compresseur d’air utilisé avec cet

outil doit conformer aux exigences

établies par l’American National

Standards Institute Standard B19.31981; Safety Standard for

Compressors for Process Industries.

Contacter le fabricant du compresseur pour plus d’informations.

3-Fr

OIL

D'huile

Branchement Recommandé

Bouchon

Rapide

Raccord

Rapide

Bouchon

Rapide

(Optionnel)

Tuyau À Air

Raccord

Rapide

(Optionnel

Graisseur

Filtre

Régulateur

!

ATTENTION

!

AVERTISSEMENT

O I L

AVIS

AVIS

OIL

Utilisation de

l’Agrafeuse (Suite)

3. Après l’addition

d’huile, faire fonctionner brièvement la

agrafeuse. Enlever

tout excès d’huile

sortant par le déflecteur d’échappement.

BRANCHEMENT RECOMMANDÉ

Le branchement recommandé est illustré ci-dessous.

1.

Le compresseur

d’air doit conserver un minimum de 345

kPa pendant l’u

tilisation de l’agrafeuse.

L’alimentation d’air insuffisante peut

réduire la puissance de l’agrafeuse et

peut affecter l’efficacité de l’enfoncement.

2.

Un graisseur peut être

utilisé pour fournir la

circulation d’huile à travers l’agrafeuse. Un filtre peut être utilisé pour

enlever les matières liquides et solides

qui peuvent encrasser ou rouiller les

pièces internes de l’agrafeuse.

3. Utiliser des

tuyaux d’air

de 9.5mm

avec une

pression de

service minimum de 1034 kPa.

Utiliser les tuyaux d’air de 1/2 po

pour 15 m ou plus. Pour un meilleur

rendement, installer un bouchon

rapide de 3/8 po avec (filets d’1/4 po

NPT) un diamètre intérieur de .315

po (8 mm) sur l’agrafeuse et un raccord rapide de 9,5 mm sur le tuyau

à air.

4. Utiliser un régulateur de pression

sur le compresseur avec une pression de service de 0 - 862 kPa. Le

régulateur de pression est indispensable pour maintenir la pression

de fonctionnement de l’agrafeuse

entre 345 et 690 kPa.

3. S’assurer que

la gâchette et

que le mécanisme de

déclenchement

(WCE) bougent du haut en bas sans

grippage.

4. Brancher à

nouveau la

source d’air à

l’agrafeuse.

5. Appuyer le

mécanisme de

déclenchement

par contact

(WCE) sur la

surface de travail sans actionner la

gâchette. La agrafeuse NE DOIT

PAS FONCTIONNER. Si l’éjection

d’un agrafe se produit sans que l’on

actionne la gâchette, ne pas utiliser

cet appareil. Il y a risque de

blessures.

6.

Oter la

agrafeuse de la

surface de travail. Le mécanisme de déclenchement par contact

(WCE) doit redescendre à sa position

initiale. La agrafeuse NE DOIT PAS

FONCTIONNER. Si l’éjection d’un

agrafe se produit lorsqu’on relève la

agrafeuse, ne pas utiliser celle-ci. Il y

a risque de blessures.

7. Actionner

la

gâchette.

Appuyer

le mécanisme de déclenchement

par contact (WCE) sur la surface de

travail. La agrafeuse DOIT FONC-

TIONNER.

CHARGEMENT/DÉCHARGEMENT DE

L’AGRAFEUSE

1. Toujours brancher l’outil à la

source d’air avant le chargement

des attaches.

2. Tourner l’agrafeuse à

l’envers et

presser le

loquet du chargeur. Tirer sur le couvercle du chargeur.

Mécanisme De Sécurité À

Déclenchement Séquentiel

Le modèle SN258K est équipé d’un mécan-

isme de sécurité à déclenchement séquen-

tiel.

Dès que l’utilisateur applique le

mécanisme de déclenchement par contact (WCE) sur la surface de travail et

qu’il appuie sur la gâchette, une agrafe

est enfoncée.

FONCTIONNEMENT D’UNE

AGRAFEUSE À DÉCLENCHEMENT

SÉQUENTIEL

1. Relâcher la

gâchette et

poser la buse

de l’appareil

sur la surface

de travail.

2. Appuyer le

mécanisme de

déclenchement

par contact

(WCE) contre

la surface de travail et actionner la

gâchette pour éjecter un agrafe.

3. Relâcher la

gâchette et

soulever l’appareil de la

surface de travail après l’éjection de chaque

agrafe.

VÉRIFIER LE MÉCANISME DE

DÉCLENCHEMENT PAR CONTACT

(WCE)

Vérifier le

fonctionnement du mécanisme de déclenchement

par contact (WCE) avant chaque usage. Le

WCE doit fonctionner librement sans se

gripper à travers la distance totale. Le

ressort WCE doit retourner le WCE à sa

position étendue après qu’il soit appuyer.

Ne pas utiliser l’agrafeuse si le mécanisme de déclenchement WCE ne fonctionne pas correctement. Ceci peut causer

des blessures personnelles.

1. Débrancher la

source d’air de

l’agrafeuse.

2. Enlever tous les

agrafes du

chargeur (Voir

ChargementDéchargement)

Modèle SN258K

Instructions D’Utilisation

4-Fr

Loquet

Mouvement

1034 kPa WP

3/8” I.D.

345 kPa

Min.

690 kPa

Max.

!

ATTENTION

Instructions D’Utilisation

Modèle SN258K

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Produits À Service Standard (Standard Duty) - Un

An, Produits À Service Sérieux (Serious Duty) - Deux Ans, Produits À Service Extrême (Extreme Duty) - Trois Ans.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio,

45030, Téléphone: (800) 543-6400

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit Campbell

Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tous les outils de fixation (cloueuses et agrafeuses), outils pneumatiques,

pistolets vaporisateurs, gonfleurs ou accessoires pneumatiques Campbell Hausfeld qui sont fournis par ou fabriqués par

le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables qui se révèlent pendant la

période de validité de la garantie.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE

SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est utilisé pour une fonction commerciale, industrielle ou pour la location, la durée de la garantie sera quatrevingt-dix (90) jours à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de durée

pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou exclusion précédente peut donc ne pas

s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant

pas les instructions données dans le(s) manuel(s) accompagnant le produit. Un accident, l’utilisation abusive par l’a-

cheteur, la négligence ou le manque de faire fonctionner les produits selon les instructions comprend aussi l’enlevage ou la modification de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la

garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

E. Articles ou services qui sont exigés pour l'entretien du produit; Joints torique, ressorts, amortisseurs, écrans de

débris, lames d'entraînement, fusibles, batteries

, joints d'étanchéité, garnitures ou joints, buses de fluide, aiguilles,

buses de sablage, graisses

, tuyaux de matériaux, cartouches filtrantes, pales de moteur, abrasifs, lames, meules de

coupage, burins, fixe-burins, coupeuses, douilles de serrage, mandrins. mâchoires de rivet, lames de tournevis, tampons de sablage, tampons de sauvegarde, mécanisme de percussion ou toute pièce qui n’est pas indispensable et qui

n’est pas indiquée. Ces articles seront couverts pour quatre-vingt-dix (90) jours à partir de la date d'achat original.

Les articles soulignés sont garanties pour défauts de matière et de fabrication seulement

.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du Garant, des

produits ou pièces qui se sont révélés défectueux pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Campbell Hausfeld au Centre De Service Autorisé Campbell

Hausfeld. Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE: La réparation

ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la

disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis.

L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

protección de cabeza, oídos y pies.

Pueden ocasionarse lesiones graves

o permanentes de ojos y oídos.

• Asegurarse de que la herramienta

se mantenga en un orden de

trabajo seguro según se describe

en este manual.

• Asegurar el mantenimiento

adecuado de todas las

herramientas en posesión del

empleador.

• Asegurarse de que las

herramientas que requieran

reparación no se usen antes de ser

reparadas. Se recomiendan el uso

de etiquetas y el retiro físico de la

herramienta como medidas de

control.

Ésto le indica que hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

● Lea y comprenda las etiquetas y el

manual de la herramienta. Si no

respeta las advertencias, los riesgos

Índice

Información General de Seguridad 1-3

Especificaciones . . . . . . . . . . . . . . . . .2

Cómo usar la Herramienta . . . . . . .3-5

Diagnóstico de averías . . . . . . . . . . . .6

Garantía . . . . . . . . . . . . . . . . . . . . . . .7

Descripción

La grapadora ha sido diseñada para

hacer armarios, cubiertas traseras para

armarios, adornos decorativos y artesanías. Entre las características se

incluyen: conveniente depósito que se

carga por la parte inferior con capacidad para 100 grapas, mecanismo de

seguridad de disparo secuencial, y

boca angosta para colocar los sujetadores con precisión en aplicaciones

estrechas.

Informaciones

Generales de

Seguridad

PROPOSICIÓN DE CALIFORNIA 65

Cuando corta lija, taladra o pule materiales como por ejemplo madera, pintura, metal, hormigón, cemento, u otro

tipo de mampostería se puede producir

polvo. Con frecuencia este polvo contiene productos químicos que se conocen como causantes de cáncer, defectos

congénitos u otros daños reproductivos. Use equipo de protección.

La

exposición excesiva a la vibración, trabajar en

posiciones incómodas y los movimientos de trabajo repetitivos pueden

causar lesiones a las manos y brazos.

Deje de usar cualquier herramienta si

aparece incomodidad, cosquilleo o

dolor y consulte a un médico.

Este manual contiene información

sobre seguridad, funcionamiento y

mantenimiento. Póngase en contacto

con su representante Campbell

Hausfeld si tiene alguna pregunta.

RESPONSABILIDAD DEL OPERADOR:

El operador de la herramienta es

responsable de:

• Leer y comprender las etiquetas y el

manual de la herramienta.

• Seleccionar un sistema de activación

de la herramienta adecuado,

tomando en cuenta la aplicación de

trabajo para la cual se usa la

herramienta.

• El uso seguro de la herramienta.

• Asegurarse de que la

herramienta se use

únicamente cuando

el operador y todo el

resto del personal en

el área de trabajo

estén usando equipo de protección

ocular ANSI Z87 y demás equipo de

protección de cabeza, oídos y pies.

Pueden ocasionarse lesiones graves

o permanentes de ojos y oídos.

• Asegurarse de que la herramienta

se mantenga en un orden de

trabajo seguro según se describe en

este manual.

RESPONSABILIDAD DEL

EMPLEADOR:

• Seleccionar un sistema de activación

de la herramienta adecuado,

tomando en cuenta la aplicación de

trabajo para la cual se usa la

herramienta.

• Asegurarse de que este manual esté

disponible para los operadores y el

personal que esté realizando el

mantenimiento.

• El uso seguro de la herramienta.

• Exigir que la

herramienta se use

únicamente cuando

el operador y todo el

resto del personal en

el área de trabajo

estén usando equipo de protección

ocular ANSI Z87 y demás equipo de

Manual de Instrucciones Modelo SN258K

Grapadora

para Acabado

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

IN231204AV 7/03

Modelo SN258K

BUILT TO LAST

Localice el modelo y el código de

fecha en el cargador y la tapa de la

herramienta y regístrelo debajo:

Modelo Nº ____________________

Código de fecha _______________

Conserve estos números

para referencia .

Las clavadoras de Campbell Hausfeld cumplen o exceden los estándares de la Industria establecidos

en los códigos SNT-101-2002 de las organizaciones norteamericanas ANSI/ISANTA .

© 2003 Campbell Hausfeld/Scott Fetzer

Ver la Garantía en página 20 para información importante sobre el uso comercial de este producto.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

BUILT TO LAST

!

PELIGRO

!

ADVERTENCIA

!

PELIGRO

Informaciones

Generales de Seguridad

(Continuación)

y las recomendaciones,

eso podría resultar en la

MUERTE o en LESIONES

GRAVES.

● No use ningún tipo de

gas reactivo,

incluyendo, pero no

limitado a, oxígeno y

gases combustibles,

como fuente de

energía. Use sólo aire

comprimido filtrado, lubricado y regulado. El uso de un gas reactivo en

vez de aire comprimido puede provocar que la herramienta explote, lo

cual puede ocasionar la muerte o

graves lesiones personales.

● Use solamente una

fuente de aire comprimido de presión

regulada para limitar

la presión de aire

suministrada a la herramienta. La presión regulada no

debe exceder los 6,90 bar. Si el regulador falla, la presión transmitida a

la herramienta no debe exceder los

13,79 bar. La herramienta puede

explotar, lo cual puede ocasionar la

muerte o graves lesiones personales.

● Nunca limpie la

herramienta con

gasolina o ningún

otro líquido inflamable. Nunca use la

herramienta en la cercanías de líquidos o gases inflamables. Una chispa

podría encender los vapores y oca-

2-Sp

sionar una explosión que podría ocasionarle la muerte o heridas graves.

● Siempre colóquese

en una posición

firme y balanceada

para usar o manipular la herramienta.

● No quite, modifique

ni haga de otro

modo que el WCE

(elemento de contacto de trabajo) o

el gatillo dejen de

funcionar. No haga

funcionar ninguna herramienta que

haya sido modificada de manera similar. Eso puede resultar en muerte o

graves lesiones personales.

● No toque el gatillo

a menos que se

estén clavando

sujetadores. Nunca

conecte la línea de

aire a la herramienta ni mueva la herramienta

cuando esté tocando el gatillo. La

herramienta podría expulsar un sujetador y producir la muerte o lesiones

personales graves.

Ésto le

indica

que hay una situación que PODRÍA ocasionarle la muerte o heridas graves.

● Desconecte

siempre la herramienta de la

fuente de

energía cuando

no la esté atendiendo, cuando le esté realizando

mantenimiento o reparaciones, des-

obstruyéndola o moviéndola a un

nuevo sitio. Siempre vuelva a conectar la tubería de aire ANTES de cargar

los sujetadores. No cargue la herramienta con sujetadores cuando el

gatillo esté oprimido o el WCE (elemento de contacto de trabajo) esté

conectado. La herramienta puede

expulsar un sujetador y producir la

muerte o lesiones personales graves.

● Siempre ajuste

la herramienta

con un conector

o acoplador de

mangueras

colocado en o

cerca de la herramienta de un modo

tal que se descargue todo el aire

comprimido en la herramienta en el

momento en que se desconecte el

conector o acoplador. No use una

válvula de chequeo o ninguna conexión que permita que el aire pemanezca en la herramienta. Se puede producir la muerte o lesiones personales

graves.

● Nunca ponga las manos

ni ninguna otra parte

del cuerpo en el área

de descarga de la

herramienta. Ésta

puede expulsar un sujetador y producir la muerte o lesiones

personales graves.

● Nunca cargue la

herramienta por la

manguera de aire ni

jale la manguera para

mover la herra-mienta o el compresor de

aire. Mantenga las mangueras alejadas del calor, aceite y objetos pun

Modelo SN258K

Manual de Instrucciones

Área de descarga

Gatillo

Área de carga de

las grapas

Cargador

Etiquetas de advertencia

Elemento de

Contacto

Componentes y Especificaciones

de la Grapadora

• REQUIERE: 0,02 m3/min para clavar 10 grapas por minuto

a 6,21 bar

• ENTRADA DE AIRE: 6,4 mm (1/4”) NPT

• RANGO DE LAS GRAPAS: 9,5 mm (3/8”) a 25,4 mm (1”)

• CAPACIDAD DEL CARGADOR:

100 Grapas por carga, calibre 18

• PESO: 1,16 kg

• LONG.: 22,86 cm

• ALT.: 17,78 cm

• PRESION MAX.: 6,90 bar

• RANGO DE PRESION: 3,45 bar - 6,90 bar

Pestillo

6,90 bar

CAMPBELL

PROFESSIONAL

HAUSFELD

O

CO

2

!

ADVERTENCIA

CAMPBELL

HAUSFELD

PROFESSIONAL

Informaciones

Generales de Seguridad

(Continuación)

tiagudos. Reemplace cualquier

manguera que esté dañada, débil o

desgastada. Ésto podría ocasionar

heridas o daños a la herramienta

● Siempre asuma que la herramienta

tiene sujetadores. Respete la

herramienta como un implemento

de trabajo; no jugue con ella.

Siempre mantenga a los demás a

una distancia segura del área de

trabajo, en caso de una descarga

accidental de sujetadores. No

apunte con la herramienta hacia

usted o hacia otra persona, ya sea

que contenga o no sujetadores. El

disparo accidental de la herramienta

podría resultar en la muerte o en

graves lesiones personales.

● No clave un suje-

tador encima de

otro. El sujetador

podría saltar y

ocasionarle la

muerte o heridas

graves.

● No opere la

herramienta ni

permita que

otros la operen

si las etiquetas

de advertencia

están ilegibles. Éstas se encuentran

en el cargador o en el cuerpo de la

herramienta.

● No deje que la herramienta se caiga

ni la tire. Ésto podría dañarla o convertirla en algo peligroso de usar. En

caso de que la herramienta se haya

caído o la hayan tirado, revísela con

cuidado a ver si está doblada o rota,

si tiene alguna pieza dañada o tiene

fugas de aire. DEJE de trabajar y

repárela antes de usarla o podría

ocasionarle heridas graves.

tadas. El rendimiento de la herramienta o su durabilidad podrían

reducirse.

● Los compresores de aire usados para

suministrarle aire a la herramienta

deben cumplir los requerimientos

establecidos por la organización

norteamericana ANSI en el código

B19.3-1981; sobre seguridad y

estándares para compresores de aire

industriales. Contacte al fabricante

de su compresor de aire para mayor

información.

Cómo usar la grapadora

Lea este manual y comprenda todas

las medidas de seguridad e instrucciones antes de utilizar la grapadora.

LUBRICACION

Esta grapadora requiere lubricación

antes de usarse por primera vez y antes

de cada uso. Si utiliza un lubricador

incorporado a la línea, no tendrá que

lubricarla manualmente a diario.

La

super ficie

de trabajo se podría dañar debido a la

lubricación excesiva. La lubricación adecuada es la responsabilidad del propietario. Si no lubrica la grapadora adecuadamente, ésta se dañará rápidamente y la garantía se cancelaría

1. Desconecte la

grapadora de

la fuente de

su-ministro de

aire para lubricarla.

2. Gire la grapadora de modo que la

entrada de aire quede mirando

hacia arriba. Agregue de 4 a 5 gotas

de aceite no detergente 30W en la

entrada de aire. No use aceites

detergentes, aditivos de aceite, ni

Ésto le

indica

que hay una situación que PODRÍA ocasionarle heridas no muy graves.

● No haga ninguna modificación a la

herramienta sin obtener primero la

aprobación por escrito de Campbell

Hausfeld. No use la herramienta si le

faltan alguna de las tapas

protectoras o si éstas han sido

modificadas. No use la herramienta

como un martillo. Se pueden

producir lesiones personales o daños

a la herramienta.

● Siempre revise

que el Elemento

de Contacto de

Trabajo esté funcionando correctamente. Puede que

se clave un sujetador por accidente

si el Elemento de Contacto de

Trabajo no está funcionando correctamente. Se pueden producir

lesiones personales (vea la sección

“Cómo Revisar el Elemento de

Contacto de Trabajo”).

● Desconecte la fuente de suministro

de aire y elimine la tensión del disparador antes de tratar de sacar

cualquier sujetador atascado, ya

que la herramienta podría disparar

un sujetador por el frente. Ésto

podría ocasionarle heridas.

Ésto

le indica

una información importante, que de no

seguirla, le PODRÍA ocasionar daños al

equipo.

● Evite usar la herramienta cuando el

depósito está vacío. Ésto podría acelerar su desgaste.

● Limpie y chequee todas las

mangueras de suministro de aire y

conexiones antes de conectar la

herramienta al compresor.

Reemplace las mangueras y conexiones que estén dañadas o desgas-

!

3-Sp

Modelo SN258K

Manual de Instrucciones

Conexión Recomendada

Conector

rápido

Acoplador

rápido

Manguera de

aire

Conector

rápido

(Opcional)

Acoplador

rápido

(Opcional)

Lubricador

Regulador

Filtro

PRECAUCION

!

ADVERTENCIA

O I L

AVISO

AVISO

8,62 bar) en el compresor. Se necesita

un regulador de presión para controlar la presión de operación de la grapadora entre 3,45 bar y 6,90 bar.

Mecanismo de Seguridad del

Disparo Secuencial

La grapadora SN258K tiene un mecanismo de seguridad para clavar en secuencia. Cuando el operador presiona el

Elemento de Contacto de Trabajo contra la superficie y luego aprieta el gatillo, se clavará un sujetador.

CÓMO OPERAR LA GRAPADORA DE DISPARO SECUENCIAL

1. Suelte el gatillo y

ponga la boca de

la herramienta

contra la superficie de trabajo.

2. Presione el

Elemento de

Contacto de

Trabajo contra la

superficie de trabajo y apriete el

gatillo para clavar un sujetador.

3. Suelte el gatillo y

levante la herramienta de la

superficie de trabajo después de

clavar cada sujetador.

COMO CHEQUEAR EL ELEMENTO DE

CONTACTO

Chequée

el funcionamiento del mecanismo del elemento de contacto antes de cada uso.

El elemento de contacto se debe

desplazar libremente, sin pegarse, a lo

largo del área de desplazamiento. El

resorte del elemento de contacto debe

regresar el elemento de contacto a su

posición original totalmente extendido.

No use la grapadora si el mecanismo del

elemento de contacto no está funcionando adecudamente. Podría ocasionarle heridas.

1. Desconecte la

grapadora de

la fuente de

suministro de

aire.

2. Saque todas

las grapas del

cargador (Vea

la Sección

Cómo usar la grapadora (Continuación)

aceites para herramientas

neumáticas. Los

aceites para herramientas

neumáticas contienen solventes que pueden averiar

los componentes internos de la grapadora.

3. Después de agregar aceite, haga

funcionar la grapadora brevemente. Limpie

todo exceso de aceite que salga del

escape de la tapa.

CONEXION RECOMENDADA

La ilustración de abajo le muestra la conexión recomendada para la grapadora.

1. El compresor

de aire debe

tener la capacidad de suministrar un mínimo de 3,45 bar

cuando la grapadora esté en uso. Si

el suministro de aire es inadecuado

podría haber pérdida de potencia y

falta de consistencia en el funcionamiento.

2. Puede utilizar un

lubricador para

lubricar la grapadora. Igualmente,

puede utilizar un filtro para remover las

impurezas líquidas y sólidas que

podrían oxidar u obstruir las partes

internas de la grapadora.

3.

Use

mangueras de

aire de 9,5

mm (3/8”) diseñadas para

presiones mínimas de trabajo de 10,34

bar. Use mangueras de aire de 12,7

mm (1/2”) si la longitud de las mismas

es de 15m ó más. Para un mejor

rendimiento, instalele a la grapadora

un conector rápido de 9,5 mm (3/8”)

(con roscas de 6,4 mm( 1/4”) NPT)

cuyo diámetro interno sea de 0,315

(8 mm) y un acoplador rápido de

9,5 mm (3/8”) a la manguera de aire.

4. Use un regulador de presión (de 0-

3,45 bar

Mín.

6,90 bar

Máx

10,34 bar WP

9,5 mm

(3/8”) I.D.

Carga-Descarga)

3. Cerciórese de

que el gatillo y

el elemento de

contacto se

muevan libremente en

ambos sentidos sin atascarse o

pegarse.

4.

Reconecte la

grapadora a la

fuente de suministro de aire.

5. Presione el

Elemento de

Contacto de

Trabajo contra

la superficie de

trabajo sin

apretar el gatillo. La grapadora NO

DEBE OPERAR. No use la herramienta si opera sin apretar el

gatillo. Se pueden producir lesiones

personales.

6. Remueva la

grapadora de

la superficie de

trabajo. El

Elemento de

Contacto de

Trabajo tiene que volver a su posición original. La grapadora NO

DEBE OPERAR. No use la herramienta si opera mientras está levantada de la superficie de trabajo.

7. Apriete el

gatillo y

presione el

Elemento

de

Contacto

de Trabajo contra la superficie de

trabajo. La grapadora DEBE OPER-

AR.

PARA CARGAR Y DESCARGAR LA

GRAPADORA

1. Siempre conecte la herramienta a

la fuente de suminsitro de aire

antes de colocarle las grapas.

2. Presione el

pestillo de alivio hacia abajo.

Tire la tapa del

cargador hacia

atrás.

Modelo SN258K

Manual de Instrucciones

4-Sp

Movemiento

OIL

Aceite

Pestillo

OIL

!

PRECAUCION

5-Sp

Modelo SN258K

Manual de Instrucciones

Cómo usar la grapadora (Continuación)

3. Coloque una

serie de grapas

Campbell

Hausfeld o

equivalentes

(Vea la sección

de grapas) en el cargador con la

corona hacia abajo. Cerciórese de

que las grapas no estén sucias ni

dañadas.

4. Tire la tapa del

cargador hacia

adelante hasta

que calce el

pestillo.

5.

Siempre descargue el sujetador antes

de remover la herramienta de servicio. La descarga se hace siguien-

do el proceso inverso de la carga; sin

embargo, siempre se tiene que

desconectar la manguera de aire

antes de descargarla.

PARA AJUSTAR LA PENETRACION DE

LAS GRAPAS

1. Regule la presión de aire en

la grapadora a

3,45 bar.

2. Conecte las mangueras de aire y

pruebe la penetración clavando

unas grapas en un pedazo de

madera. Si éstos no penetran hasta

el nivel deseado, aumente la presión de aire y pruebe una vez más,

conmtinue haciendolo hasta lograr

los resultados deseados. La presión

de la grapadora no debe exceder

690 bar ya que ésto reduciría la

durabilidad de la grapadora.

QUE HACER CUANDO LA GRAPADORA TENGA UNA GRAPA ATASCADA

1. Desconecte la

grapadora de

la fuente de

suministro de

aire.

2. Presione el

pestillo de alivio hacia abajo.

Tire la tapa del

cargador hacia

atrás.

3. Remueva el

sujetador atascado del área

de descarga de

la grapadora.

4. Tire la tapa del

cargador hacia

adelante hasta

que calce el

pestillo.

5. Asegúrese que

el gatillo y el

Elemento de

Contacto de

Trabajo se

mueven libremente, hacia arriba y hacia abajo

sin pegarse o atascarse.

Servicio Técnico

Si desea hacer alguna pregunta referente a la reparación u operación de las

herramientas, o para solicitar copias

adicionales de este manual, sírvase llamar a nuestro número especial, 1-800543-6400.

Sujetadores y Piezas de

Repuesto

Use solamente sujetadores Campbell

Hausfeld originales calibre 16 (o su

equivalente) - (vea la información sobre

intercambio de sujetadores). El

desempeño de las herramientas, la

seguridad y la duración pueden

disminuir si no se utilizan los

sujetadores adecuados. Cuando ordene

piezas de repuesto o sujetadores,

especifique el número de la pieza.

Para reparar la herramienta

La herramienta debe ser reparada únicamente por personal calificado, y

deben usar piezas de repuesto y accesorios originales Campbell Hausfeld, o

piezas y accesorios que funcionen de

manera equivalente.

Para colocarle los sellos

Cada vez que repare una grapadora

deberá limpiarle y lubricarle las partes

internas. Le recomendamos que use

Parker O-lube o un lubricante equivalente en todos los anillos en O. A cada

anillo en O se le debe dar un baño de

lubricante para anillos antes de instalarlos. Igualmente, deberá ponerle un

poco de aceite a todas las piezas que se

mueven y muñones. Finalmente,

después de haberla ensamblado y antes

de probar la herramienta deberá ponerle unas cuantas gotas de aceite sin

detergente 30W u otro aceite similar,

en las líneas de aire.

Pestillo

Movemiento

OIL

!

ADVERTENCIA

Loading...

Loading...