Page 1

Air-operated Grease Gun

Operating Instructions

Models: TL053700AV and TL053700DI

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

EN

IN744900AV 4/17

Page 2

Please read and save these instructions. Read carefully before

attempting to assemble, install, operate or maintain the product

described.

Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

Model #: ________________________________

Serial #: ________________________________

Purchase Date: __________________________

visit www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

REGISTER YOUR PRODUCT ONLINE NOW! www.campbellhausfeld.com

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS • DO NOT DISCARD

Page 3

BEFORE YOU BEGIN

Description

Air-operated grease guns are designed for lubricating automobiles,

recreational vehicles, machinery and lawn/farm equipment in shots—this tool

does NOT apply grease in a continuous flow. The container tube is capable

of dispensing bulk-filled or 14 ounce grease cartridges. A 9 inch flexible hose

allows access to hard to reach fittings.

UNPACKING

After unpacking the unit, inspect carefully for any damage that may have

occurred during transit. Check for loose, missing or damaged parts. Check

to be sure all supplied accessories are enclosed with the unit. In case of

questions, damaged or missing parts, please visit www.campbellhausfeld.com

for customer assistance.

Do not operate unit if damaged during shipping,

cause injury or property damage.

handling or use. Damage may result in bursting and

Other Parts (Not Provided)

You will need the following items and/or accessories to properly set-up and

use this air-operated grease gun:

• 1/4 in. Plug NPT (M)

- For less stress on your air hose and you, try a flex plug.

• 1/4 in. (ID) Air Hose

• 1/4 in. Coupler NPT (F)

- Eliminate coupler confusion with a universal coupler style.

- Quick-connect couplers quickly, easily join hoses to tools.

- If you don’t use a flex plug, consider a swivel coupler to prevent hose

kinks and reduce stress on your air hose.

• 1 Gallon air compressor or larger

• 14 Ounce grease cartridge or bulk grease

• Adjustable wrench and PTFE tape to ensure tight connections

See www.campbellhausfeld.com for additional information on accessories to

support your air tools and pneumatic system.

1

Page 4

SPECIFICATIONS

TL0537

Average Air Consumption 0.1 CFM @ 90 PSI

Operating Pressure 90 PSI

Air Inlet Size 1/4 inch NPT

Fill Method Cartridge or Bulk-Filled

Cartridge Size 14 ounces

Tool Weight 3 lbs. 3 oz.

DIMENSIONS

Dimensions (assembled air tool, without grease hose attached)

Length 6-1/2 in.

Width 2-3/8 in.

Height 15-1/4 in.

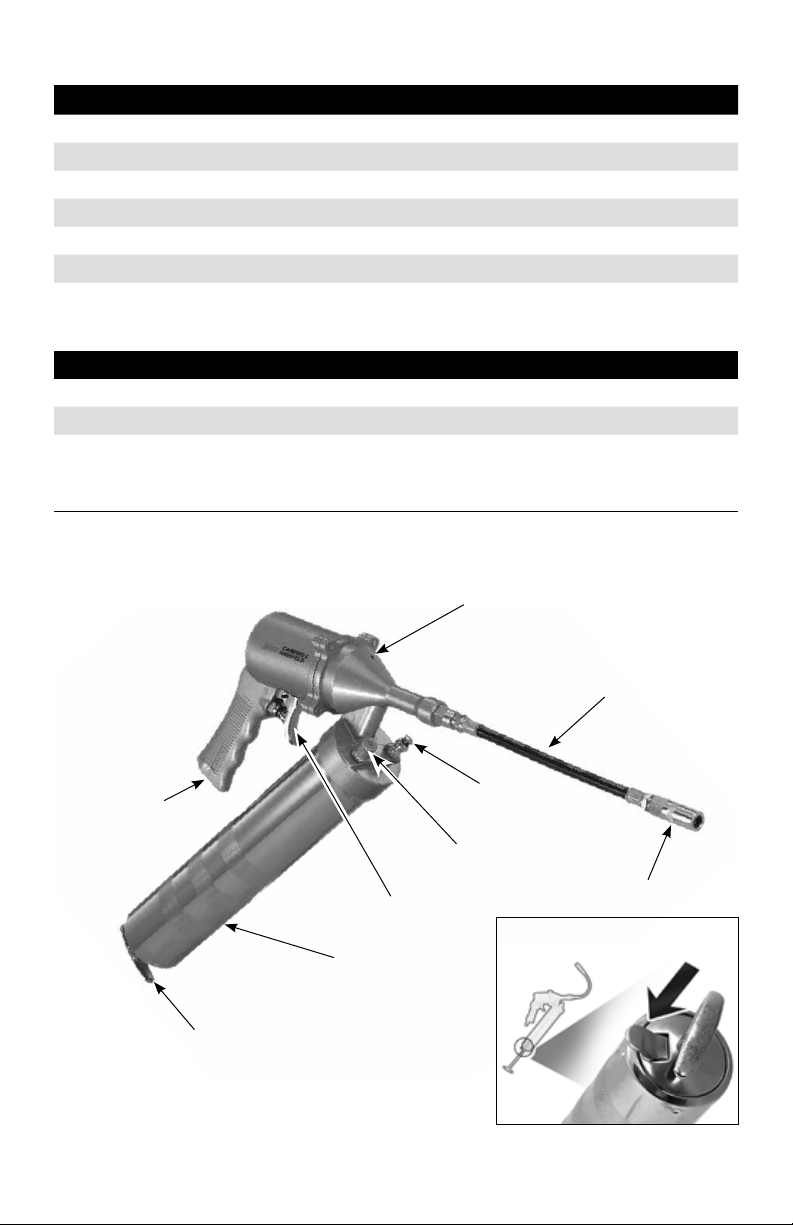

GETTING TO KNOW YOUR UNIT

Exhaust port hole

1/4 in. NPT (F)

air inlet

Figure 1

Plunger handle

Trigger

Container tube

2

Grease hose

Air vent

valve

Bulk-fill port

Grease fitting adapter

Handle

Release

Page 5

ASSEMBLY INSTRUCTIONS

Your grease gun comes from the manufacturer in 3 pieces. Unwrap each

piece from their protective poly bag. Thread the grease hose into the inlet

port of the grease gun and tighten. To prevent grease from seeping between

grease hose and grease gun, use PTFE tape and an adjustable wrench to

ensure a leak-proof connection.

Determine the method you will be using to fill the grease container tube

from the OPERATING INSTRUCTIONS below.

OPERATING INSTRUCTIONS

Fill container tube with grease using one of the 3 methods described below.

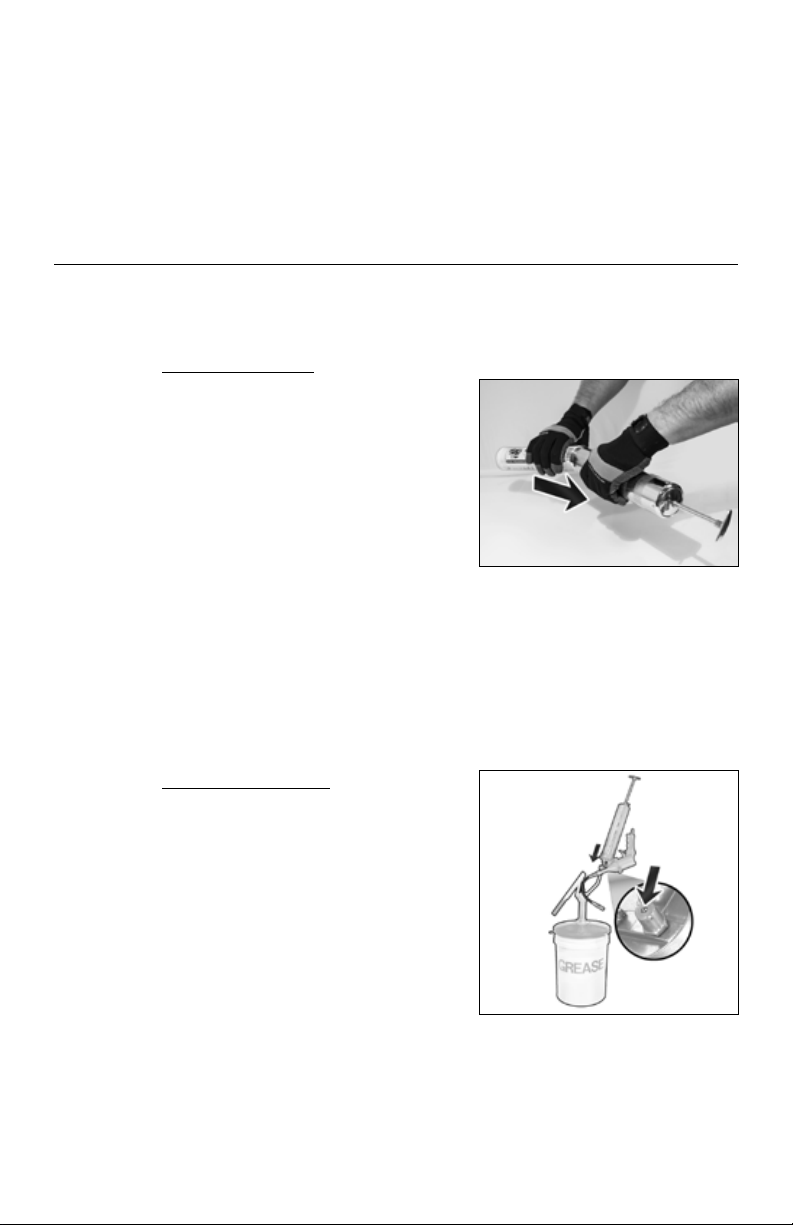

Grease Cartridges:

1. Unscrew the grease gun from the

container tube.

2. Pull the plunger handle back and out

of the container tube as far as it will

go.

3. Insert the open end of a 14 ounce

grease cartridge into the container

tube and push the cartridge

completely in to the container tube.

4. Remove the seal from the grease

cartridge.

5. Thread the grease gun and container tube back together and turn until

tight.

6. Press the handle release down to activate the plunger handle rod and

push the plunger handle back into the container tube.

7. Press the air vent valve several times to relieve any air pockets near the

top of the container tube.

Figure 2

Filler-Pump Method:

1. Thread the container tube on to the

grease gun and turn until tight.

2. Pull the plunger handle back and out

of the container tube as far as it will

go.

3. Connect the filler-pump hose to the

bulk-fill port.

4. Pump grease in to the container tube

until filled; disconnect the grease gun

from the filler-pump hose.

5. Press the handle release tab down to

activate the plunger handle rod and

push the plunger handle back into the container tube.

6. Press the air vent valve several times to relieve any air pockets near the

top of the container tube.

3

Figure 3

Page 6

OPERATING INSTRUCTIONS (CONTINUED)

Bulk-Filled Grease:

1. Unscrew the grease gun from the

container tube.

2. Insert open end of container tube in

to grease bucket (fully submerging

the opening).

3. Pull the plunger handle back to suck

grease in to the container tube. Pull

slowly and with consistent force to

ensure that the container tube is full

of grease by the time the plunger

handle is fully extended.

4. Thread the grease gun and container tube back together and turn until

tight.

5. Press the handle release tab down to activate the plunger handle rod

and push the plunger handle back into the container tube.

6. Press the air vent valve several times to relieve any air pockets near the

top of the container tube.

TIP: For best results, consider priming

grease gun before first use. To do this,

pack some grease in to the grease inlet

port of the gun, then operate as usual.

(See arrow in Figure 5.)

Connect grease gun to air compressor

system following Air Tool Set Up

Instructions (IN170102AV).

Figure 4

Figure 5 - Grease inlet port

CARE & MAINTENANCE

Failure to lubricate and maintain your air tools properly will dramatically

shorten their life. Use “air tool” oil every time you use your grease gun to

lubricate, clean and inhibit rust in one step. Campbell Hausfeld sells air tool

oil under part number ST1270.

In addition to regular lubrication of your air tool, the grease gun piston must

be lubricated periodically. Under heavy usage, the piston should be greased

with bearing grease every four months. For light usage only once a year.

To grease the piston:

1. Disconnect the tool from the air supply.

2. Remove the 4 screws on the gun head.

3. Separate the gun head from the pistol grip and remove the spring and

the piston.

4. Apply a film of bearing grease around the exterior of the rubber skirt on

the piston and a thin film of grease on the inside of the cylinder.

5. Install the spring and piston and reassemble the gun head and the pistol

grip. Insert and tighten 4 screws.

4

Page 7

TECHNICAL SERVICE

For information regarding the operation or repair of this product, please visit

www.campbellhausfeld.com.

GENERAL SAFETY INSTRUCTIONS

This manual contains information that is very important to know and

understand. This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information, observe the

symbols found on page 7. The Safety Symbols throughout this manual are to

alert you to important safety hazards and precautions.

The DANGER, WARNING, CAUTION, and NOTICE notifications

and instructions in this manual cannot cover all possible condi-

tions and situations that may occur. It must be understood by

the operator that caution is a factor which cannot be built into

this product, but must be supplied by the operator.

With any piece of equipment, new or used, the most important part of its

operation is SAFETY!

Campbell Hausfeld encourages you to familiarize yourself with your new

equipment and stresses safe operation.

The next few pages of this manual are a summary of the main safety aspects

associated with this unit. Be sure to read and understand completely before

operating the machine.

The symbols used throughout the operation and maintenance sections of

this manual call attention to safety procedures.

MANUAL

Important Safety Information

Please read and save these instructions. Read carefully before attempting to

assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain

instructions for future reference.

This manual contains important safety, operational and maintenance

information. If you have any questions, please visit www.campbellhausfeld.

com for customer assistance.

California Proposition 65

• This product or its power cord may contain chemicals known to the State

of California to cause cancer and birth defects or other reproductive

harm. Wash hands after handling.

5

Page 8

GENERAL SAFETY INSTRUCTIONS (CONTINUED)

General Safety

This product is part of a high pressure system and the following safety

precautions must be followed at all times along with any other existing safety

rules.

1. Read all manuals included with this product carefully. Be thoroughly

MANUAL

familiar with the controls and the proper use of the equipment.

2. Only persons well acquainted with these rules of safe operation should

be allowed to use the air tool.

Do not exceed the maximum operating pressure of

the air tool (90 psi). This can reduce the life of the

tool.

3. Do not exceed any pressure rating of any component in the system.

4. Disconnect air tool from air supply before changing tools or attachments, servicing and during non-operation.

Safety glasses must be worn during operation.

5. Do not wear loose fitting clothing, scarves, neck ties or jewelry when

operating any tool. Loose clothing or jewelry may become caught in

moving parts and result in serious personal injury.

6. Do not depress trigger when connecting the air supply hose.

7. Always use attachments designed for use with air powered tools. Do not

use damaged or worn attachments.

8. Never trigger tool when not applied to a work object. Attachments must

be securely attached. Loose attachments can cause serious injury.

9. Protect air lines from damage or puncture.

10. Never point an air tool at oneself or any other person. Serious injury

could occur.

11. Check air hoses for weak or worn condition before each use. Make sure

all connections are secure.

Release all pressure from the system before

attempting to install, service, relocate or perform

any maintenance.

12. Keep all nuts, bolts and screws tight and ensure equipment is in safe

working condition.

13. Do not put hands near or under moving parts.

14. Always secure work.

Excessive exposure to vibration, working in

awkward positions and repetitive work motions can

cause injury to hands and arms. Stop using any tool if discomfort, numbness,

tingling or pain occur and consult a physician.

Never carry a tool by the hose or pull the hose to

move the tool or a compressor. Keep hoses away

from heat, oil and sharp edges. Replace any hose that is damaged, weak or

worn.

6

Page 9

Safety Glossary

This manual contains information that is very important to know and

understand. This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information, observe the

following symbols.

Danger indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious

injury.

Warning indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

Caution indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or

moderate injury.

Notice indicates important information, that if not

followed, may cause damage to equipment.

IMPORTANT or NOTE: Information that requires special attention.

Safety Symbols

The following Safety Symbols appear throughout this manual to alert you to

important safety hazards and precautions.

MANUAL

Read Manual

First

Wear eye

and hearing

protection

Risk of

Pressure

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

7

Page 10

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Tool will not operate 1. No grease in tool 1. Lubricate the tool according to

2. Low air pressure 2. Adjust the compressor regulator as

3. Air hose leaks 3. Tighten and seal hose fittings if leaks

Tool operates, but

grease will not eject

from spout

Grease stops flowing

after initially working

1. Cold, thick grease 1. Bring tool inside and warm to room

2. Spring is still compressed 2. Pull the plunger handle back and

3. Out of grease 3. Refill container tube.

4. Air pockets in container tube 4. Remove air pockets (See below).

Air in the grease hose or

container tube

the lubrication instructions in this

manual.

needed.

are found.

temperature of 70°F - 85°F. Stand the

gun in an upright position to prevent

air pockets forming in the middle of

the cartridge.

release quickly. Make sure the catch

plate is released.

1. Remove air pockets from grease gun:

a. Partially unscrew the grease

gun from the container tube

(approximately 1 to 1-1/2 turns).

b. Pull the plunger handle back

and release it quickly by pressing

down on the handle release tab.

Repeat several times.

v. Release the handle release down

and tighten the grease gun and

container tube again.

d. Press the air vent valve several

times to relieve any air pockets

near the top of the container

tube.

e. When the grease gun container

tube has been properly bleed of

air, grease will start to seep out

of the air vent valve.

2. Prime grease gun by packing grease

in to the grease inlet port of the

gun (this is the section of the gun in

which the container tube threads).

8

Page 11

NOTES:

9

Page 12

Reminder: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it

for safekeeping.

LIMITED WARRANTY

1. DURATION: From the date of purchase by the original purchaser as follows: One (1) Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld a Marmon/Berkshire Hathaway

Company, 100 Production Drive, Harrison, Ohio, 45030. Visit www.campbellhausfeld.com

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of

resale) of the Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool,

spray gun, inflator or air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which

occur within the duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION.

If this product is used for commercial, industrial or rental purposes, the warranty will apply for

ninety (90) days from the date of purchase. Some States do not allow limitation on how long an

implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD

PRODUCT. Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate

products in accordance with instructions provided in the owner’s manual(s) supplied with

product. Accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions shall also include the removal or alteration of any safety devices. If such safety

devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs,

bumpers, debris shields, driver blades, fuses, batteries, gaskets, packings or seals, fluid nozzles,

needles, sandblast nozzles, lubricants, material hoses, filter elements, motor vanes, abrasives,

blades, cut-off wheels, chisels, chisel retainers, cutters, collets, chucks, rivet jaws, screw driver

bits, sanding pads, back-up pads, impact mechanism, or any other expendable part not

specifically listed. These items will only be covered for ninety (90) days from date of original

purchase. Underlined items are warranted for defects in material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s

option, products or components which are defective, have malfunctioned and/or failed to conform

within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld

Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the

owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair

or replacement will be scheduled and serviced according to the normal work flow at the servicing

location, and depending on the availability of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal

rights. You may also have other rights which vary from state to state or country to country.

10

Page 13

Graisseur pneumatique

Instructions d’Utilisation

Modèles: TL053700AV et TL053700DI

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

FR

IN744900AV 4/17

Page 14

Lire et conserver ces instructions. Il faut les lire attentivement avant

de commencer à assembler, installer, faire fonctionner ou entretenir

l’appareil décrit.

Pour se protéger et protéger autrui, observer toutes les informations sur

la sécurité. Négliger d’appliquer ces instructions peut causer

des blessures et/ou des dommages matériels! Conserver ces instructions

pour consultation ultérieure.

RAPPEL: Conservez votre preuve d’achat datée aux fins de garantie!

Attachez-le à ce manuel ou classez-le pour le garder en sécurité.

Pour de l’information sur les pièces,

produits et services veuillez visiter

N° de modèle : _____________________________

www.campbellhausfeld.com

N° de série : _______________________________

Date d’achat : _____________________________

ENREGISTREZ VOTRE PRODUIT EN LIGNE MAINTENANT !

www.campbellhausfeld.com

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS

CONSERVER CES INSTRUCTIONS • NE PAS JETER

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

Page 15

AVANT DE COMMENCER

Description

Les graisseurs pneumatiques sont conçus pour lubrifier les automobiles,

véhicules récréatifs, machinerie et équipement paysager/agricole – cet

outil n’applique PAS la graisse en un flot continu. Le tube contenant peut

distribuer par un remplissage en vrac ou d’une cartouche de graisse de

414 mL (14 oz). Un tuyau flexible de 22,86 cm (9 po) permet d’accéder aux

raccords graisseurs difficiles à atteindre.

DÉBALLAGE

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe

de dommages en transit. Vérifier s’il y a des pièces desserrées, manquantes

ou endommagées. Vérifier pour s’assurer que tous les accessoires fournis

sont inclus avec l’appareil. Pour toutes questions, pièces endommagées ou

manquantes, veuillez visiter www.campbellhausfeld.com pour l’assistance à la

clientèle.

Ne pas utiliser un modèle qui a été endommagé

Le dommage peut résulter en explosion et peut causer des blessures ou

dégâts matériels.

pendant le transport, la manipulation ou l’utilisation.

Autres pièces (non fournies)

Il vous faudra les éléments et/ou accessoires suivants pour correctement

mettre en marche et utiliser votre graisseur pneumatique :

• Bouchon 6,4 mm (1/4 po) NTP (M)

- Pour une réduction du stress pour vous et votre tuyau, essayez un

connecteur flexible.

• Tuyau d’air de 6,4 mm (1/4 po) (DIA. INT.)

• Coupleur 6,4 mm (1/4 po) NPT (F)

- Élimine la confusion du coupleur avec un coupleur de style universel.

- Les coupleurs à attache rapide raccordent rapidement et facilement

les tuyaux aux outils.

- Si vous n’utilisez pas un connecteur flexible, un raccord pivotant

pourrait être utilisé afin d’éviter l’entortillement et réduire le

stress imposé à votre tuyau d’air.

• Compresseur d’air 3,79 L (1 gal) ou plus.

• Cartouche de graisse 414 mL (14 oz) ou graisse en vrac

• Clé ajustable et ruban PTFE pour assurer des connexions étanches

Voir au www.campbellhausfeld.com pour d’autres informations sur les

accessoires pour accompagner vos outils et votre système pneumatique.

Fr1

Page 16

CARACTÉRISTIQUES TECHNIQUES

TL0537

Consommation d’air moyenne 2,8 l/min @ 621 kPa

Pression d’opération 621 kPa

Taille de l’arrivée d’air

Méthode de remplissage Cartouche ou

Taille de la cartouche 0,41 L

Poids de l’outil 1,45 kg

6,4 mm (1/4 po) NPT

remplissage en vrac

DIMENSIONS

Dimensions (assembled air tool, without grease hose attached)

Leng. 16,51 cm

Larg. 8,57 cm

Haut. 38,74 cm

APPRENEZ À CONNAÎTRE VOTRE UNITÉ

Orifice de la sortie de

l’échappement

Arrivée d’air

1/4 po NPT (F)

Figure 1

Poignée du poussoir

Détente

Tube contenant

Fr2

Purgeur

d’air

Port de remplissage

en vrac

Adaptateur de raccord

Tuyau de

graissage

de graissage

Poignée de

dégagement

Page 17

INSTRUCTIONS D’ASSEMBLAGE

Votre graisseur vous est livré du fabricant en 3 morceaux. Déballez chaque

morceau de son sac de plastique protecteur. Vissez le tuyau de graissage dans

l’orifice d’arrivée du graisseur puis serrez. Pour éviter que la graisse s’échappe

du tuyau de graissage et du graisseur, utilisez du ruban PTFE et une clé

ajustable pour assurer un raccordement étanche.

Déterminez la méthode que vous utiliserez pour remplir le tube contenant de

graisse à partir des INSTRUCTIONS DE FONCTIONNEMENT ci-dessous.

MODE D’EMPLOI

Remplir le tube contenant en utilisant l’une des 3 méthodes suivantes.

Cartouches de graisse :

1. Dévissez le graisseur du tube contenant.

2. Tirez sur la poignée du poussoir et

sortez-la du tube contenant, aussi

loin que possible.

3. Insérez l’extrémité ouverte d’une

cartouche de graisse de 414 mL

(14 oz) dans le tube contenant tout

en poussant la cartouche

entièrement dans le tube contenant.

4. Retirez le sceau de la cartouche de

graisse.

5. Revissez le graisseur et le tube contenant ensemble et tournez jusqu’à ce

qu’il soit serré.

6. Appuyez sur la poignée de dégagement pour activer la tige de la poignée

du poussoir et poussez sur la poignée du poussoir, dans le tube contenant.

7. Appuyez sur le purgeur d’air à plusieurs reprises afin de retirer l’air

accumulé près du haut du tube contenant.

Figure 2

Méthode de remplissage :

1. Vissez le tube contenant sur le graisseur

et tournez jusqu’à ce qu’il soit serré.

2. Tirez sur la poignée du poussoir et

sortez-la du tube contenant, aussi

loin que possible.

3. Connectez le tuyau de la pompe de

remplissage à l’orifice de remplissage

en vrac.

4. Pompez la graisse dans le tube

contenant, jusqu’à ce qu’il soit plein;

débranchez le graisseur du tuyau de

la pompe de remplissage.

5. Appuyez sur la languette de la poignée de dégagement pour activer la

tige de la poignée du poussoir et poussez sur la poignée du poussoir,

dans le tube contenant.

Fr3

Figure 3

Page 18

MODE D’EMPLOI (SUITE)

Remplissage en vrac :

1. Dévissez le graisseur du tube contenant.

2. Insérez l’extrémité ouverte du tube

contenant dans le seau de graisse (en y

submergeant entièrement l’ouverture).

3. Tirez sur la poignée du poussoir

pour y aspirer la graisse dans le tube

contenant. Tirez lentement avec une

force constante afin d’assurer que le

tube contenant est plein de graisse au

moment où la poignée du poussoir

est complètement sortie.

4. Revissez le graisseur et le tube contenant ensemble et tournez jusqu’à ce

qu’il soit serré.

5. Appuyez sur la languette de la poignée de dégagement pour activer la

tige de la poignée du poussoir et poussez sur la poignée du poussoir,

dans le tube contenant.

6. Appuyez sur le purgeur d’air à plusieurs

reprises afin de retirer l’air accumulé

près du haut du tube contenant.

CONSEIL : Pour de meilleurs résultats, songez

à amorcer le graisseur avant la première

utilisation. À cette fin, remplissez l’orifice

d’arrivée du graisseur avec un peu de graisse,

puis utilisez comme d’habitude. (Voir la

flèche de la figure 5)

Connectez le graisseur au système de compresseur d’air selon les Instructions

de mise en marche de l’outil (IN170102AV).

Figure 4

Figure 5 - Orifice d’arrivée de la graisse

SOINS ET ENTRETIEN

À défaut de lubrifier et de correctement entretenir vos outils pneumatiques

diminuera drastiquement leur durée de vie. Utilisez une huile à « outils

pneumatiques » chaque fois que vous utilisez votre graisseur pour le lubrifier,

le nettoyer et éviter la rouille en une seule étape. Campbell Hausfeld offre

une huile à outils pneumatiques sous le numéro de pièce ST1270.

En plus d’une lubrification régulière de votre outil pneumatique, le graisseur

doit être périodiquement lubrifié. Sous un usage intensif, le piston devrait

être graissé tous les quatre mois avec une graisse à roulements. Sous un usage

léger, une fois par année suffit.

Pour graisser le piston :

1. Débranchez l’outil de l’alimentation d’air.

2. Retirez les 4 vis de la tête du graisseur.

3. Séparez la tête du graisseur de la poignée révolver en retirant le ressort

et le piston.

4. Appliquez une couche de graisse à roulements autour de l’extérieur de la jupe

en caoutchouc sur le piston et une couche de graisse sur l’intérieur du cylindre.

5. Installez le ressort et le piston, puis réassemblez la tête du graisseur et la

poignée révolver. Insérez et serrez les 4 vis.

Fr4

Page 19

SERVICE TECHNIQUE

Pour de l’information sur le fonctionnement ou la réparation de ce produit,

veuillez visiter le www.campbellhausfeld.com.

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Ce guide contient de l’information très importante que vous devez connaître

et comprendre. Cette information est fournie à des fins de SÉCURITÉ et

dans le but d’ÉVITER DES PROBLÈMES AVEC L’ÉQUIPEMENT. Pour faciliter la

reconnaissance de cette information, observez les symboles se trouvant à la

pageFr7. Les symboles sur la sécurité de ce manuel, visent à vous alerter des

importants dangers à la sécurité et les précautions.

Les symboles DANGER, AVERTISSEMENT, ATTENTION et AVIS

ainsi que les instructions de ce manuel ne peuvent pas couvrir

toutes les conditions et situations qui pourraient se produire.

L’opérateur doit comprendre que le bon sens et des précautions

sont des facteurs qui ne peuvent pas être inclus dans ces

produits, mais doivent être fournis par l’opérateur.

Avec toute pièce d’équipement, neuve ou usée, la plus importante partie de

l’opération est la SÉCURITÉ!

Campbell Hausfeld vous encourage à vous familiariser avec votre nouvel

équipement et insiste sur un fonctionnement sécuritaire.

Les prochaines pages de ce manuel résument les aspects principaux sur la

sécurité liée avec cette unité. Assurez-vous de les lire et les comprendre

entièrement avant d’utiliser cet appareil.

Les symboles utilisés dans les sections de fonctionnement et d’entretien du

présent manuel attirent l’attention sur les procédures de sécurité.

MANUAL

Importantes instructions de sécurité

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant

de monter, installer, utiliser ou de procéder à l’entretien du produit décrit.

Se protéger ainsi que les autres en observant toutes les instructions de

sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces

instructions comme référence.

Ce manuel contient des informations concernant la sécurité, le

fonctionnement et l’entretien. Si vous avez des questions, veuillez visiter

www.campbellhausfeld.com pour l’assistance à la clientèle.

Proposition 65 de Californie

• Ce produit ou son cordon peuvent contenir des produits chimiques

qui, de l’avis de l’État de Californie, causent le cancer et des anomalies

congénitales ou autres problèmes de reproduction. Lavez-vous les mains

après la manipulation.

Fr5

Page 20

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ (SUITE)

Généralités sur la sécurité

Ce produit fait partie d’un système de haute pression et les précautions de

sécurité suivantes doivent être prises en permanence, en même temps que

toute autre règle de sécurité en vigueur.

1. Lire attentivement tous les manuels, y compris celui de ce produit.

MANUAL

Bien se familiariser avec les commandes et l’utilisation correcte de

l’équipement.

2. Seules les personnes bien familiarisées avec ces règles d’utilisation en

toute sécurité doivent être autorisées à se servir de l’outil pneumatique.

Ne pas dépasser la pression maximum de service de

l’outil pneumatique (621 kPa). Ceci peut diminuer la

durée de l’outil.

3. Ne pas dépasser la pression nominale de n’importe quelle pièce du

système.

4. Débrancher l’outil pneumatique de l’alimentation en air avant de

remplacer des outils ou des accessoires, de procéder à l’entretien ou

mettre l’outil à repos.

Il est nécessaire de porter des lunettes de protection

pendant l’utilisation.

5. Ne pas porter de vêtements flottants, d’écharpe, de cravate, ni de bijoux

pendant l’opération d’un outil. Les vêtements flottants et les bijoux

risquent de se prendre dans les pièces mobiles, ce qui peut provoquer

des blessures graves.

6. Ne pas appuyer sur la gâchette lorsque l’on branche le tuyau

d’alimentation en air.

7. Toujours utiliser des accessoires conçus pour les outils pneumatiques. Ne

pas utiliser des accessoires endommagés ou usés.

8. Ne jamais appuyer sur la gâchette de l’outil tant qu’il n’y ait pas contact

avec l’objet de travail. Les accessoires desserrés peuvent causer des

blessures graves.

9. Protéger les canalisations d’air contre les dommages ou les perforations.

10. Ne jamais diriger un outil pneumatique vers soi-même ni vers une autre

personne afin d’éviter tout risque de blessures graves.

11. Vérifier les tuyaux d’air pour rechercher tout signe de faiblesse ou

d’usure avant chaque utilisation. S’assurer que tous les branchements

soient bien serrés.

Dissiper toute la pression du système avant

d’essayer d’installer, de déplacer le produit ou de

procéder au service ou à l’entretien.

12. Vérifier le serrage des écrous, boulons et vis et s’assurer que

l’équipement soit en bon état de marche.

13. Ne pas se mettre les mains près ou en-dessous des pièces mobiles.

14. Travaillez toujours de manière sécuritaire.

Fr6

Page 21

Toute exposition excessive aux vibrations, tout

travail dans des positions incommodes et tous

déplacements à répétition peuvent causer des blessures aux mains et

aux bras. Cessez d’utiliser tout outil s’il y a malaise, engourdissement,

fourmillement ou douleur et consultez un médecin.

Ne jamais transporter un outil par le tuyau et ne

jamais l’utiliser pour déplacer l’outil ou le

compresseur. Garder les tuyaux à l’écart de la chaleur, l’huile et les objets

pointus. Remplacer un tuyau usé, faible ou endommagé.

Glossaire sur la sécurité

Ce manuel contient de l’information très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES PROBLÈMES D’ÉQUIPEMENT. Rechercher les

symboles suivants pour cette information.

Danger indique une situation dangereuse imminente

qui MÈNERA à la mort ou à des blessures graves si

elle n’est pas évitée.

Avertissement indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, POURRAIT

mener à la mort ou à de graves blessures.

Attention indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, PEUT mener

à des blessures mineures ou modérées.

Avis indique de l’information importante qui

pourrait endommager l’équipement si elle n’est pas

respectée.

IMPORTANT ou REMARQUE: Information qui exige une attention spéciale.

Symboles de sécurité

Les symboles de sécurité suivants apparaissent dans l’ensemble de ce manuel

pour vous aviser des dangers et précautions importants de sécurité.

MANUAL

Lire d’abord

le manuel

Portez une

protection

oculaire et

auditive

Risque de

pression

CONSERVER CES INSTRUCTIONS

NE PAS JETER

Fr7

Page 22

GUIDE DE DÉPANNAGE

SYMPTÔME CAUSE(S) POSSIBLE(S) ACTION CORRECTIVE

L’outil ne fonctionne

pas

L’outil fonctionne,

mais la graisse ne

s’éjecte pas du bec

Le flot de graisse

s’arrête après le travail

initial

1. Pas de graisse dans l’outil 1. Graisser l’outil selon les instructions

2. Pression d’air basse 2. Régler le régulateur du compresseur

3. Fuites dans le tuyau d’air 3. Serrer les raccords de tuyaux en cas

1. Graisse froide et épaisse 1. Mettre l’outil à l’intérieure là où la

2. Le ressort est serré 2. Tirer le manche du plongeur vers

3. Vide de graisse 3. Remplir de nouveau le tube de la

4. Poches d’air dans le tube de

la boîte

Ajoutez l’air dans le tuyau de

graissage ou le tube contenant

de graissage dans ce manuel.

au besoin.

de fuites.

température est de 22-29°C. Mettre

le pistolet d’aplomb afin d’empêcher

la formation de poches d’air au

milieu de la cartouche.

l’arrière et lâcher rapidement.

S’assurer que la plaque du loquet soit

lâchée.

boîte.

4. Enlever les poches d’air

(Voir ci-dessous).

1. Retirez l’air accumulé dans le graisseur :

a. Dévissez partiellement le

graisseur du tube contenant

(environ 1 à 1,5 tour).

b. Tirez la poignée du poussoir vers

l’arrière et relâchez-la rapidement

en appuyant vers le bas sur la

poignée de dégagement. Répétez

à plusieurs reprises.

c. Débloquez à poignée de

dégagement vers le bas et serrez

à nouveau le graisseur et le tube

contenant.

d. Appuyez sur le purgeur d’air à

plusieurs reprises afin de retirer

l’air accumulé près du haut du

tube contenant.

e. Lorsque le tube contenant de

graisse a été correctement saigné

de son air, la graisse commencera

à s’écouler peu à peu, hors du

purgeur d’air.

2. Amorcez le graisseur en remplissant

de graisse l’orifice d’arrivée de la

graisse du graisseur (il s’agit de

la section du graisseur où le tube

contenant est vissé).

Fr8

Page 23

NOTES:

Fr9

Page 24

Mémento: Gardez votre preuve datée d’achat à fin de la garantie! Joignez-la à ce manuel ou classez-la

dans un dossier pour plus de sécurité.

GARANTIE LIMITÉE

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Un (1) An.

2. GARANTIE ACCORDÉE PAR (GARANT):Campbell Hausfeld a Marmon/Berkshire Hathaway Company,

100 Production Drive, Harrison, Ohio, 45030. Visitez www.campbellhausfeld.com

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du

produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tous les outils de fixation (cloueuses et agrafeuses),

outils pneumatiques, pistolets vaporisateurs, gonfleurs ou accessoires pneumatiques Campbell

Hausfeld qui sont fournis par ou fabriqués par le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables qui se

révèlent pendant la période de validité de la garantie.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE

FONCTION PARTICULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE

QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est utilisé pour une fonction

commerciale, industrielle ou pour la location, la durée de la garantie sera quatre-vingt-dix (90)

jours à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de

durée pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT

DÉFAUT, PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD.

Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou

indirects. La limitation ou exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une

utilisation ne respectant pas les instructions données dans le(s) manuel(s) accompagnant le

produit. Un accident, l’utilisation abusive par l’acheteur, la négligence ou le manque de faire

fonctionner les produits selon les instructions comprend aussi l’enlevage ou la modification

de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la

garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le

produit.

E. Articles ou services qui sont exigés pour l’entretien du produit; Joints torique, ressorts,

amortisseurs, écrans de débris, lames d’entraînement, fusibles, batteries, joints d’étanchéité,

garnitures ou joints, buses de fluide, aiguilles, buses de sablage, graisses, tuyaux de matériaux,

cartouches filtrantes, pales de moteur, abrasifs, lames, meules de coupage, burins, fixe-burins,

coupeuses, douilles de serrage, mandrins. mâchoires de rivet, lames de tournevis, tampons

de sablage, tampons de sauvegarde, mécanisme de percussion ou toute pièce qui n’est pas

indispensable et qui n’est pas indiquée. Ces articles seront couverts pour quatre-vingt-dix (90)

jours à partir de la date d’achat original. Les articles soulignés sont garanties pour défauts de

matière et de fabrication seulement.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au

choix du Garant, des produits ou pièces qui se sont révélés défectueux pendant la durée de validité

de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Campbell Hausfeld au Centre De Service

Autorisé Campbell Hausfeld. Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s)

manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE

GARANTIE: La réparation ou le remplacement sera prévu et exécuté en fonction de la charge de

travail dans le centre de service et dépendra de la disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des

droits juridiques précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un

État ou d’un Pays à l’autre.

Fr10

Page 25

Pistola lubricante neumática

Manual de Instrucciones

Modelos: TL053700AV y TL053700DI

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

SP

IN744900AV 4/17

Page 26

Por favor, lea y guarde estas instrucciones. Lealas cuidadosamente antes

de tratar de montar, instalar, operar o dar mantenimiento al producto

aqui descrito.

Protejase usted mismo y a los demas observando toda la informacion de

seguridad. ¡El no cumplir con las instrucciones puede ocasionar daños,

tanto personales como a la propiedad! Guarde estas instrucciones para

referencia en el futuro.

RECORDATORIO: ¡guarde su comprobante de compra con fecha para

fines de la garantía! Adjúntela a este manual o archívela en lugar seguro.

Para ordenar repuestos, información de

productos y servicios visítenos en

Modelo #: ___________________________________

No. de Serie #: ______________________________

Fecha de Compra: ___________________________

www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

¡REGISTRE SU PRODUCTO EN LÍNEA AHORA MISMO!

GUARDE ESTAS INSTRUCCIONES • NO LAS DESECHE

www.campbellhausfeld.com

LEA Y SIGA TODAS LAS INSTRUCCIONES

Page 27

ANTES DE COMENZAR

Descripción

Las pistolas lubricantes neumáticas están diseñadas para lubricar automóviles,

vehículos recreativos, maquinaria y equipos de jardinería y agrícolas en

medidas; esta herramienta NO aplica grasa en un flujo continuo. El tubo

contenedor es capaz de aplicar cartuchos de grasa de 414 mL (14 onzas) o

llenados a granel. Una manguera flexible de 22,86 cm (9 pulgadas) facilita el

acceso a conectores difíciles de alcanzar.

DESEMPAQUE

Después de desempacar la unidad, inspecciónela cuidadosamente para

detectar cualquier daño que pueda haber ocurrido durante el envío.

Verifique que no haya piezas sueltas, faltantes ni dañadas. Asegúrese de que

todos los accesorios proporcionados vengan con la unidad. En caso de que

tenga preguntas, o de que haya piezas dañadas o faltantes, por favor visite

www.campbellhausfeld.com para asistencia al cliente.

No debe utilizar la unidad si se ha dañado durante

una explosión y ocasionarle heridas o daños a su propiedad.

el envío, manejo o uso. Los daños podrían ocasionar

Otras partes (no incluidas)

Necesitará los siguientes artículos o accesorios para preparar y utilizar

correctamente esta pistola lubricante neumática.

• Tapón NPT de 6,4 mm (1/4 pulg.) (M)

- Para reducir la tensión en su manguera de aire, pruebe con un tapón flexible.

• Manguera de aire de 6,4 mm (1/4 pulg.) (D.I.)

• Acoplador NPT de 6,4 mm (1/4 pulg.) (H)

- Elimine la confusión con los acopladores usando uno de estilo universal.

- Los acopladores de conexión rápida conectan las manguera y las

herramientas con facilidad y rapidez.

- Si no utiliza un tapón flexible, considere un acoplador con pivote para

evitar las torceduras y reducir la tensión en su manguera de aire.

• Compresor de aire de 3,79 L (1 galón) o más

• Cartucho de grasa de 414 mL (14 onzas) o grasa a granel

• Llave ajustable y cinta PTFE para garantizar una conexión hermética

Consulte www.campbellhausfeld.com para ver más información sobre

accesorios para complementar sus herramientas y sistema neumático.

Sp1

Page 28

ESPECIFICACIONES

TL0537

Consumo promedio de aire 2,8 l/min @ 6,2 bar

Presión de operación 6,2 bar

Tamaño de entrada de aire

Método de recarga Cartucho o a granel

Tamaño del cartucho 0,41 L

Peso de la herramienta 1,45 kg

6,4 mm (1/4 pulg.) NPT

DIMENSIONS

Dimensions (assembled air tool, without grease hose attached)

Long. 16,51 cm

Anch. 8,57 cm

Alt. 38,74 cm

CONOZCA SU UNIDAD

Puerto de escape

Entrada de aire de

1/4 pulg. NPT (H)

Figura 1

Manija del émbolo

Gatillo

Tubo contenedor

Sp2

Válvula de

venteo de aire

Puerto de llenado

a granel

Liberación de manija

Manguera

de grasa

Adaptador para

conector de grasa

Page 29

INSTRUCCIONES PARA EL ENSAMBLAJE

Su pistola lubricante viene empaquetada en 3 piezas. Saque cada pieza de su

bolsa protectora de polietileno. Atornille la manguera de grasa en el puerto

de entrada de la pistola lubricante y apriete. Para evitar que se filtre grasa

entre la manguera de grasa y la pistola lubricante, utilice cinta PTFE y una

llave ajustable para garantizar una conexión hermética.

Determine el método que utilizará para llenar el tubo contenedor de grasa,

consultando las siguientes INSTRUCCIONES DE OPERACIÓN.

INSTRUCCIONES DE OPERACIÓN

Llene el tubo contenedor de grasa usando uno de los 3 métodos que se

describen a continuación.

Cartuchos de grasa:

1. Desatornille la pistola lubricante del

tubo contenedor.

2. Jale la manija del émbolo hacia afuera

del contenedor hasta donde sea posible.

3. Inserte el extremo abierto de un

cartucho de grasa de 414 mL (14

onzas) en el tubo contenedor y

empuje el cartucho hasta meterlo

completamente en el tubo contenedor.

4. Quite el sello del cartucho de grasa.

5. Vuelva a enroscar la pistola lubricante con el tubo contenedor y

apriételos bien.

6. Empuje hacia abajo la lengüeta de liberación de la manija para activar

la varilla del émbolo y empuje la manija del émbolo al interior del tubo

contenedor.

7. Empuje la válvula de venteo de aire varias veces para eliminar las

burbujas que estén cerca de la parte superior del tubo contenedor.

Figura 2

Método de recarga con bombeo:

1. Enrosque el tubo contenedor en la

pistola lubricante y apriételo bien.

2. Jale la manija del émbolo hacia afuera

del contenedor hasta donde sea posible.

3. Conecte la manguera de la bomba de

llenado en el puerto de llenado a granel.

4. Bombee grasa hacia el tubo

contenedor hasta que se llene;

desconecte la pistola lubricante de la

manguera de la bomba de llenado.

5. Empuje hacia abajo la lengüeta de

liberación de la manija para activar la varilla del émbolo y empuje la

manija del émbolo al interior del tubo contenedor.

6. Empuje la válvula de venteo de aire varias veces para eliminar las

burbujas que estén cerca de la parte superior del tubo contenedor.

Sp3

Figura 3

Page 30

INSTRUCCIONES DE OPERACIÓN (CONTINUACIÓN)

Recarga de grasa a granel:

1. Desatornille la pistola lubricante del

tubo contenedor.

2. Inserte el extremo abierto del tubo

contenedor en la cubeta de grasa

(sumergiendo por completo la abertura).

3. Jale la manija del émbolo para

succionar grasa hacia el tubo

contenedor. Jale lentamente y con una

fuerza constante para asegurarse de

que el tubo contenedor esté lleno de

grasa cuando la manija del émbolo esté

completamente extendida.

4. Vuelva a enroscar la pistola lubricante con el tubo contenedor y

apriételos bien.

5. Empuje hacia abajo la lengüeta de liberación de la manija para activar la varilla

del émbolo y empuje la manija del émbolo al interior del tubo contenedor.

6. Empuje la válvula de venteo de aire varias veces para eliminar las

burbujas que estén cerca de la parte superior del tubo contenedor.

RECOMENDACIÓN: Para obtener mejores

resultados, es buena idea cebar la pistola

lubricante antes del primer uso. Para hacerlo,

inserte algo de grasa en el puerto de entrada

de grasa de la pistola, y luego utilícela con

normalidad. (Vea la flecha en la figura 5).

Conecte la pistola lubricante al sistema

del compresor de aire siguiendo

las instrucciones de instalación de

herramientas neumáticas (IN170102AV).

Figura 4

Figura 5 - Puerto de entrada de grasa

CUIDADO Y MANTENIMIENTO

De no lubricar y dar mantenimiento de manera apropiada a sus herramientas

neumáticas, reducirá dramáticamente su vida útil. Utilice aceite para

herramientas neumáticas cada vez que utilice su pistola lubricante para

lubricar, limpiar e inhibir la oxidación en un solo paso. Campbell Hausfeld

vende aceite para herramientas neumáticas con el número de parte ST1270.

Además de lubricar con regularidad su herramienta neumática, el pistón

de la pistola lubricante debe lubricarse periódicamente. En condiciones de

uso pesado, debe lubricar el pistón con grasa para rodamientos cada cuatro

meses. Para uso ligero, hágalo solo una vez al año.

Para engrasar el pistón:

1. Desconecte la herramienta del suministro de aire.

2. Quite los 4 tornillos en el cuerpo de la pistola.

3. Separe el cuerpo de la pistola del mango y quite el resorte y el pistón.

4. Aplique una capa de grasa para rodamiento alrededor de la parte

exterior de la falda de caucho del pistón y una capa delgada de grasa

en el interior del cilindro.

5. Instale el resorte y el pistón y vuelva a armar el cuerpo y el mango de la

pistola. Inserte y apriete los 4 tornillos.

Sp4

Page 31

SERVICIO TÉCNICO

Para obtener información sobre el funcionamiento o reparación de este

producto, visite www.campbellhausfeld.com.

INSTRUCCIONES GENERALES DE SEGURIDAD

Este manual contiene información que es muy importante que conozca y

comprenda. Esta información se proporciona para su SEGURIDAD y para

EVITAR PROBLEMAS CON EL EQUIPO. Para ayudarle a reconocer esta

información, observe los símbolos que se encuentran en la página Sp7. Los

símbolos de seguridad presentes en este manual sirven para alertarle sobre

riesgos de seguridad y precauciones importantes.

Los símbolos de PELIGRO, ADVERTENCIA, PRECAUCIÓN y AVISO

y las instrucciones en este manual no pueden posiblemente

cubrir todas las condiciones y situaciones posibles que puedan

presentarse. El usuario debe entender que las precauciones y el

sentido común son factores que no pueden incorporarse en este

producto: es el usuario mismo quíen debe contribuirlos.

Con cualquier pieza de equipo, nueva o usada, ¡la parte más importante de la

operación es la SEGURIDAD!

Campbell Hausfeld lo anima a que se familiarice con su nuevo equipo y

enfatiza además una operación segura.

Las siguientes páginas de este manual son un resumen de los principales

aspectos de seguridad relacionados con esta unidad. Asegúrese de leerlos y

comprenderlos por completo antes de usar el equipo.

Los símbolos utilizados en las secciones de operación y mantenimiento de

este manual dirigen su atención a los procedimientos de seguridad.

MANUAL

Importantes instrucciones de seguridad

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de

armar, instalar, manejar o darle servicio al producto descrito en este manual.

Protéjase usted. y a los demás observando todas las reglas de seguridad.

El no seguir las instrucciones podría resultar en heridas y/o daños a su

propiedad. Guarde este manual como referencia.

Este manual contiene información sobre seguridad, funcionamiento y

mantenimiento. Si tiene preguntas, por favor visite www.campbellhausfeld.

com para asistencia al cliente.

Proposición 65 de California

• Este producto, o su cordón eléctrico, puede contener productos químicos

conocidos por el estado de California como causantes de cáncer y

defectos de nacimiento u otros daños reproductivos. Lave sus manos

después de usar.

Sp5

Page 32

INSTRUCCIONES GENERALES DE SEGURIDAD (CONTINUACIÓN)

Generales seguridad

Este producto forma parte de un sistema de alta presión y siempre deben

acatarse las siguientes medidas de seguridad al igual que otras normas de

seguridad existentes.

1. Lea cuidadosamente todos los manuales incluidos con el producto.

MANUAL

Familiarícese completamente con los controles y el uso debido del

equipo.

2. Sólo aquellas personas completamente familiarizadas con estas normas

de funcionamiento seguro deben utilizar la herramienta neumática.

No exceda la presión máxima de funcionamiento

de la herramienta neumática (6,21 bar). Ésto

reduciría la duración de la herramienta.

3. No exceda las presiones especificadas para ninguno de los componentes

del sistema.

4. Desconecte la herramienta neumática del suministro de aire antes de

cambiar la herramienta o los accesorios, darle servicio y al no utilizarla.

Se deben utilizar lentes durante el funcionamiento.

5. No utilice ropas holgadas, bufandas, corbatas o joyas para operar

herramientas neumáticas. La ropas holgadas o joyas podrían atascarse en

las piezas en movimiento y ocasionarle lesiones graves.

6. No oprima el gatillo al conectar la manguera de suministro de aire.

7. Siempre utilice accesorios diseñados para herramientas neumáticas. No

utilice accesorios dañados o desgastados.

8. Nunca oprima el gatillo cuando la herramienta no esté aplicada a la

pieza de trabajo. Los accesorios deben estar firmente conectados. Los

accesorios flojos pueden ocasionarle lesiones graves.

9. Proteja las líneas de aire contra daños o perforaciones.

10. Nunca apunte la herramienta neumática hacia usted mismo u otras

personas. Ésto podría ocasionar lesiones graves.

11. Antes de cada uso, cerciórese de que la manguera de aire no esté

dañada o desgastada. Igualmente, cerciórese de que todas las

conexiones estén bien apretadas.

Libere toda la presión del sistema antes de tratar de

instalar, darle servicio, reubicar o realizar cualquier

mantenimiento.

12. Mantenga las tuercas, pernos y tornillos bien apretados y cerciórese de

que el equipo esté en buenas condiciones de funcionamiento.

13. No coloque las manos cerca o debajo de piezas en movimiento.

14. Siempre apriete bien el trabajo.

La exposición excesiva a la vibración, trabajar en

posiciones incómodas y los movimientos de trabajo

repetitivos pueden causar lesiones a las manos y brazos. Deje de usar

cualquier herramienta si aparece incomodidad, cosquilleo o dolor y consulte

a un médico.

Sp6

Page 33

Nunca cargue una herramienta neumática por la

manguera, ni hale la manguera para mover la

herramienta o el compresor. Mantenga las mangueras alejadas de fuentes de

calor, aceite u objetos afilados. Reemplace las mangueras dañadas, débiles o

desgastadas.

Glosario de seguridad

Este manual contiene información que es muy importante que se conozca

y comprenda. Esta información se proporciona con fines de SEGURIDAD y

para EVITAR PROBLEMAS CON EL EQUIPO. Para ayudar a reconocer esta

información, observe los siguientes símbolos.

Peligro indica una situación inminentemente

peligrosa, que si no se evita, dará como resultado la

muerte o lesiones graves.

Advertencia indica una situación potencialmente

peligrosa, que si no se evita, PODRÍA ocasionar la

muerte o lesiones graves.

Precaución indica una situación potencialmente

peligrosa, que si no se evita, PUEDE dar como

resultado lesiones leves o moderadas.

Aviso indica una información importante, que de no

seguirla, le podría ocasionar daños al equipo.

IMPORTANTE o NOTA: información que requiere atención especial.

Símbolos de seguridad

Los siguientes símbolos de seguridad aparecen a lo largo de este manual para

advertirle de importantes peligros y precauciones de seguridad.

MANUAL

Primero

lea el manual

Use protectores

para la vista y

los oídos

Riesgo de

presión

GUARDE ESTAS INSTRUCCIONES –

NO LAS DESECHE

Sp7

Page 34

GUIA DE IDENTIFICACION DE PROBLEMAS

SÍNTOMA CAUSA(S) POSIBLE(S) MEDIDA CORRECTIVA

La herramienta no

funciona

La herramienta

funciona pero no

emite lubricante

La grasa deja de fluir

después de funcionar

al principio

1. La herramienta no tiene

grasa

2. Baja presión de aire 2. Ajuste el regulador del compresor

3. Fugas en la manguera de

aire

1. La grasa está fria y espesa 1. Si está trabajando a la intemperie,

2. El resorte está comprimido 2. Hale el mango del cilindro hacia atrás

3. Se terminó el lubricante en

el tubo de lubricante

4. Hay vacíos de aire en el tubo

de lubricante

Aire en la manguera de grasa o

en el tubo contenedor

1. Lubrique la herramienta según las

instrucciones de lubricación en este

manual.

según sea necesario.

3. Apriete y selle las conexiones de la

manguera, si consigue fugas.

lleve la pistola adentro de su casa

o taller y permita que la pistola

se caliente hasta alcanzar una

temperatura de 22 °C a 29 °C.

Coloque la pistola boca arriba para

evitar que se formen vacíos de aire

en el medio del cartucho.

y suéltelo rápidamente. Cerciórese de

que el seguro no esté puesto.

3. Llene el tube de lubricante.

4. Elimine los vacíos de aire

(Ver más adelante).

1. Elimine las burbujas de aire de la

pistola lubricante:

a. Desatornille parcialmente la

pistola lubricante del tubo

contenedor (aproximadamente

1 a 1-1/2 vueltas).

b. Jale la manija del émbolo y

libérela rápidamente oprimiendo

la lengüeta de liberación de la

manija. Repita varias veces.

v. Suelte la lengüeta de liberación

de la manija y vuelva a apretar

la pistola lubricante y el tubo

contenedor.

d. Empuje la válvula de venteo de

aire varias veces para eliminar

las burbujas que estén cerca

de la parte superior del tubo

contenedor.

e. Cuando se haya eliminado

apropiadamente el aire del

tubo contenedor de la pistola

lubricante, empezará a fluir grasa

de la válvula de venteo de aire.

2. Cebe la pistola lubricante colocando

grasa en el puerto de entrada de

grasa de la pistola (esta es la sección

de la pistola en la que se enrosca el

tubo contenedor).

Sp8

Page 35

NOTAS:

Sp9Sp9

Page 36

Recordatorio: ¡Guarde su comprobante de compra con fecha para fines de la garantía! Adjúntela a este

manual o archívela en lugar seguro.

GARANTÍA LIMITADA

1 DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a

continuación: Un (1) año.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld a Marmon/Berkshire Hathaway

Company, 100 Production Drive, Harrison, Ohio 45030. Visite www.campbellhausfeld.com

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor)

del producto Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Cualquier clavadora, grapadora, herramienta

neumática, pistola pulverizadora, inflador o accesorio neumático suministrado o fabricado por el

Garante.

5. COBERTURA DE LA GARANTIA: Los defectos substanciales de material y fabricación que ocurran

dentro del período de validez de la garantía.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES

PARTICULARES, ESTAN LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. Si este

producto es empleado para uso comercial, industrial o para renta, la garantía será aplicable

por noventa (90) días a partir de la fecha de compra. En algunos estados no se permiten

limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos esta limitación

no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR

DE UN DEFECTO, FALLA O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En

algunos estados no se permite la exclusión o limitación de daños incidentales o consecuentes,

por lo tanto, en tales casos esta limitación o exclusión no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las

instrucciones de funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al

producto. Dichos accidentes, abusos por parte del comprador, o falta de operar el producto

siguiendo las instrucciones del manual de instrucciones suministrado también debe incluir

la desconexión o modificación de los instrumentos de seguridad. Si dichos instrumentos de

seguridad son desconectados, la garantía quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

E. Artículos o servicios normalmente requeridos para el mantenimiento del producto, tales

como: anillos en O, resortes, amortiguadores, defensas, hojas de impulsor, fusibles, baterías,

empaques, almohadillas o sellos, boquillas de fluído, agujas, boquillas para rociar arena,

lubricantes, mangueras de material, elementos filtrantes, álabes de motores, abrasivos,

hojillas, discos para cortar, cinceles, retenes para cinceles, cortadores, collarines, mandriles,

mordazas para remachadoras, brocas para desarmadores, almohadillas para lijar, soportes de

almohadillas, mecanismo de impacto o cualquier otro artículo desgastable que no se haya

enumerado específicamente. Estos artículos sólo estarán cubiertos bajo esta garantía por

noventa (90) días a partir de la fecha de compra original. Los artículos subrayados sólo están

garantizados por defectos de material o fabricación.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Reparar o reemplazar, como lo decida el

Garante, los productos o componentes que estén defectuosos, se hayan dañado o hayan dejado de

funcionar adecuadamente, durante el período de validez de la garantía

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Entregar o enviar el producto o componente Campbell Hausfeld al Centro de Servicio

autorizado Campbell Hausfeld más cercano. Los gastos de flete, de haberlos, deben ser pagados

por el comprador.

C. Seguir las instrucciones sobre operación y mantenimiento del producto, tal como se indica(n) en

el (los) manual(es) del propietario

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO BAJO ESTA

GARANTIA: La reparación o reemplazo dependerá del flujo normal de trabajo del centro de servicio y

de la disponibilidad de repuestos.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales

específicos. Usted también puede tener otros derechos que varían de un Estado a otro. o de un país a

otro.

Sp10

Loading...

Loading...