Page 1

See Warranty on page 8 for important information about commercial use of this product.

Operating Instructions TL0501

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

3/8 inch Ratchet

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . 1

Safety Guidelines . . . . . . . . . . . . . . . . 1

Important Safety Information . . . . . . 1

Tool Components and

Specifications. . . . . . . . . . . . . . . . . . . . 2

Operating Instructions . . . . . . . . . . . . 4

Lubrication . . . . . . . . . . . . . . . . . . . . 4

Recommended Hookup. . . . . . . . . . 4

Operational Mode . . . . . . . . . . . . . . 5

User-Maintenance Instructions . . . . . 5

Troubleshooting Chart . . . . . . . . . . . . 6

Warranty . . . . . . . . . . . . . . . . . . . . . . . 8

Description

Ratchets are air tools designed for

removing and installing spark plugs

and different engine parts such as

water pumps, radiators, etc. Use in

confined areas where hand tools are

cumbersome.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or

serious injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates

a potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed,

may cause damage to equipment.

NOTE: Information that requires special

attention.

Important Safety Instructions

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS

This manual contains safety, operational

and maintenance information. Contact

your Campbell Hausfeld representative

if you have any questions.

When using tools,

basic precautions

should always be followed,

including the following:

Model TL0501

Locate model and date code on

tool and record below:

Model No.: _____________________

Date Code: _____________________

Retain these numbers for

future reference.

CALIFORNIA PROPOSITION 65

This product or

its power cord

may contain chemicals known to

the State of California to cause

cancer and birth defects or other

reproductive harm. Wash hands

after handling.

You can create dust

when you cut, sand, drill

or grind materials such

as wood, paint, metal, concrete,

cement, or other masonry. This dust

often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

© 2011 Campbell Hausfeld / Scott Fetzer IN732700AV 6/11

For parts, product & service information

visit www.chpower.com

Page 2

Operating Instructions

Important Safety Instructions

(Continued)

GENERAL

a. To reduce the risks of

electric shock, fire, and

injury to persons, read all

the instructions before

using the tool.

b. Be thoroughly familiar with the

controls and the proper use of the

equipment. Follow all instructions.

Contact your Campbell Hausfeld

representative if you have any

questions.

c. Only persons well acquainted with

these rules of safe operation should

be allowed to use the unit.

Read and

understand tool

labels and manual. Failure to follow

warnings, dangers, and cautions

could result in DEATH or SERIOUS

INJURY.

WORK AREA

a. Keep the work area clean and well

lighted. Cluttered benches and dark

areas increase the risks of electric

shock, fire, and injury to persons.

b. Do not operate the tool

in explosive atmospheres,

such as in the presence of

flammable liquids, gases,

or dust. The tool is able to create

sparks resulting in the ignition of

the dust or fumes.

c. Keep bystanders, children, and

visitors away while operating the

tool. Distractions are able to result in

the loss of control of the tool.

PERSONAL SAFETY

a. Stay alert. Watch what you are

doing and use common sense

when operating the tool. Do not

use the tool while tired or under

the influence of drugs, alcohol,

or medication. A moment of

inattention while operating the

tool increases the risk of injury to

persons.

b. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long

hair increases the risk of injury to

persons as a result of being caught

in moving parts.

c. Avoid unintentional starting.

Be sure the switch is off before

connecting to the air supply. Do not

carry the tool with your finger on

the switch or connect the tool to the

air supply with the switch on.

d. Remove adjusting keys or wrenches

before turning on the tool. A key or

wrench attached to a rotating part

of the tool may result in personal

injury.

e. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in

unexpected situations.

f. Use safety equipment. A dust mask,

non-skid safety shoes and a hard

hat must be used for the applicable

conditions.

g. Always wear eye

protection.

h. Always wear hearing

protection when using

the tool. Prolonged

exposure to high intensity

noise is able to cause

hearing loss.

i. Do not attach the hose or tool to

your body. Attach the hose to the

structure to reduce the risk of loss of

balance if the hose shifts.

Always remain in

a firmly balanced

position when using or handling

the tool.

Avoid long

extended periods

of work with the tool. Stop using

the tool if you feel pain in hands or

arms.

j. Hold tool by insulated gripping

surface when performing an

operation where the tool may

contact hidden wiring. Contacting a

“live” wire will make exposed metal

parts of the tool “live” and shock

the operator.

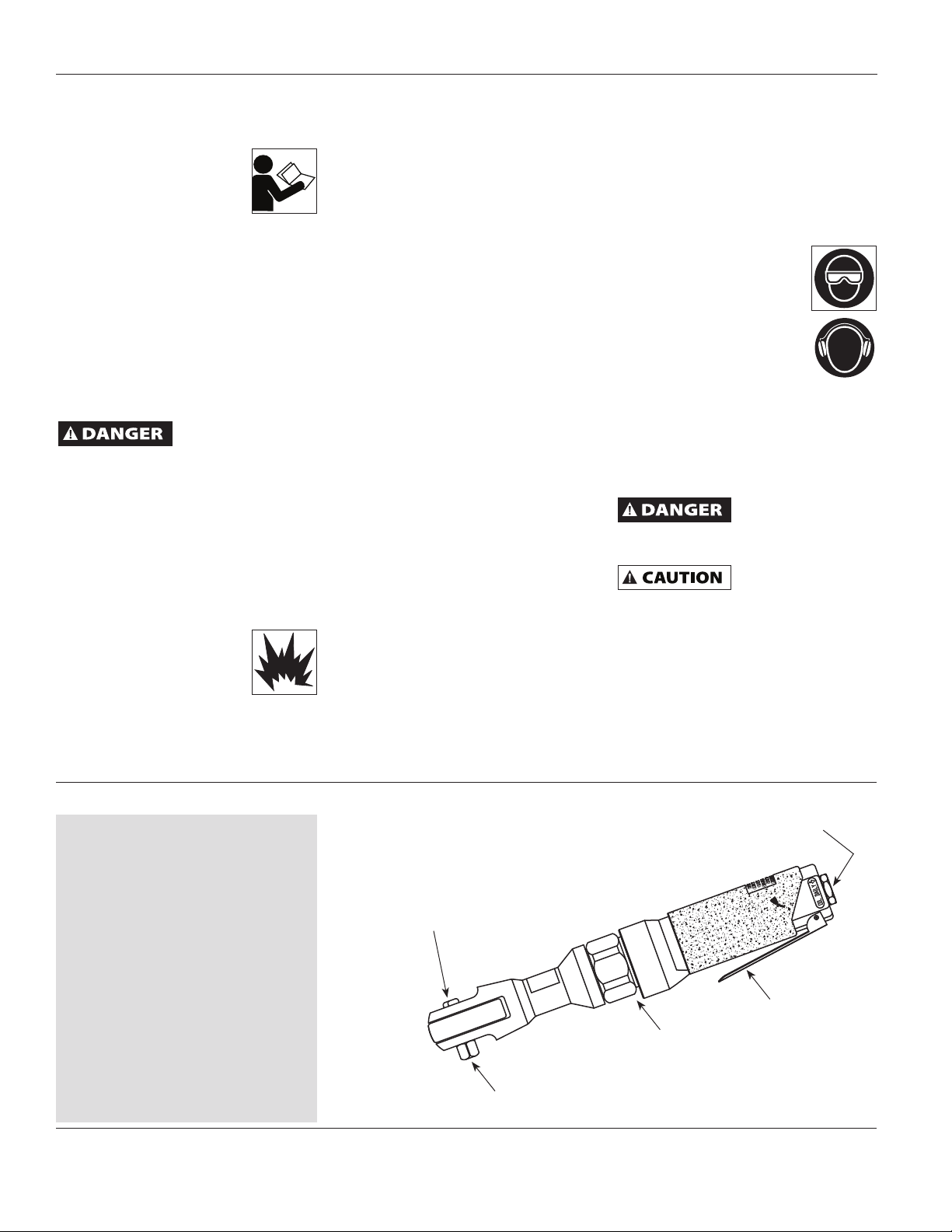

Tool Components and Specifications

Avg SCFM & psi . . . . . . . . 4.8 @ 90 PSIG

(25% usage)

Continuous SCFM . . . . . . 19.2 @ 90 PSIG

(100% usage)

Minimum Rated RPM . . . . . . . . . . . . 140

Max Torque . . . . . . . . . . . . . . . . .50 ft.lb.

Working Torque . . . . . . . . . 10-45 ft.lb.

Gear Type . . . . . . . . . . 3 Idler Planetary

Bolt Capacity. . . . . . . . . . . . . . . .3/8 inch

Air Inlet . . . . . . . . 1/4 inch NPT (Female)

Min. Hose Size . . . . . . . . . . . . . .3/8 inch

Drive . . . . . . . . . . . . . . . . . . . 3/8 inch sq.

Weight . . . . . . . . . . . . . . . . . . . . 2.5 lbs.

www.chpower.com

Forward/Reverse Dial

Air Inlet

Throttle

Exhaust

3/8 inch Anvil

2

Page 3

TL0501

Important Safety Instructions

(Continued)

k. Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges, and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

l. Explore the workpiece to avoid

contact with hidden wiring.

Thoroughly investigate the

workpiece for possible hidden

wiring before performing work.

Contact with live wiring will shock

the operator.

m. Never point an air tool at oneself

or any other person. Serious injury

could occur.

n. Do not put hands near or under

moving parts.

TOOL USE AND CARE

a. Use clamps or another practical way

to secure and support the workpiece

to a stable platform. Holding the

work by hand or against the body is

unstable and is able to lead to loss

of control.

b. Do not force the tool. Use the

correct tool for the application. The

correct tool will do the job better

and safer at the rate for which the

tool is designed.

c. Do not use the tool if the switch

does not turn the tool on or off. Any

tool that cannot be controlled with

the switch is dangerous and must be

repaired.

d. Disconnect the

tool from the

air source before making

adjustments, doing tool

maintenance, clearing jams,

leaving work area,loading,

or unloading the tool. Such

precautionary measures reduce the

risk of injury to persons.

e. Store the tool when it is idle out

of reach of children and other

untrained persons. A tool is

dangerous in the hands of untrained

users.

f. Maintain the tool with care. Keep

a cutting tool sharp and clean. A

properly maintained tool, with sharp

cutting edges reduces the risk of

binding and is easier to control.

g. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that affects

the tool’s operation. If damaged,

have the tool serviced before using.

Many accidents are caused by poorly

maintained tools. There is a risk of

bursting if the tool is damaged.

h. Use only accessories that are

identified by the manufacturer for

the specific tool model. Use of an

accessory not intended for use with

the specific tool model increases the

risk of injury to persons.

i. Selecting an appropriate tool

actuation system, taking into

consideration the work application

for which the tool is used.

Never

use

gasoline or other

flammable liquids to clean

the tool. Never use the

tool in the presence of flammable

liquids or gases. Vapors could

ignite by a spark and cause an

explosion which will result in death

or serious personal injury.

Release all

pressure from

the system before attempting to

install, service, relocate or perform

any maintenance.

Always disconnect

tool from the

power source when unattended,

performing any maintenance or

repair, clearing a jam, or moving

the tool to a new location.

Always fit tool

with a fitting or

hose coupling on or near the tool in

such a manner that all compressed

air in the tool is discharged at the

time the fitting or hose coupling is

disconnected. Do not use a check

valve or any other fitting which

allows air to remain in the tool.

Death or serious personal injury

could occur.

Never carry the

tool by the air

hose or pull the hose to move the

tool or a compressor. Keep hoses

away from heat, oil and sharp

edges. Replace any hose that is

damaged, weak or worn. Personal

injury or tool damage could occur.

Do not operate or

allow anyone else to

operate the tool if

any warnings or warning labels are

not legible. Warnings or warning

labels are located on the tool

magazine and body.

Do not drop or

throw the tool.

Dropping or throwing the tool can

result in damage that will make

the tool unusable or unsafe. If the

tool has been dropped or thrown,

examine the tool closely for bent,

cracked or broken parts and air

leaks. STOP and repair before using

or serious injury could occur.

Do not exceed

the maximum

operating pressure of the air tool

(90 psi). This can reduce the life of

the tool.

j. Do not exceed any pressure rating

of any component in the system.

Maximum operating pressure

of 90 psi is measured at the tool

inlet while the tool is running.

The pressure drop between the

compressor and tool needs to be

compensated for at the compressor.

k. Do not depress trigger when

connecting the air supply hose.

l. Never trigger the tool when

not applied to a work object.

Attachments must be securely

attached. Loose attachments can

cause serious injury.

Clean and check

all air supply

hoses and fittings before

connecting the tool to an air

supply. Replace any damaged

or worn hoses or fittings. Tool

performance or durability may be

reduced.

SERVICE

a. Tool service must be performed only

by qualified repair personnel.

b. When servicing a tool, use only

identical replacement parts. Use

only authorized parts.

c. Use only the lubricants supplied

with the tool or specified by the

manufacturer.

!

WARNING

www.chpower.com

3

Page 4

Operating Instructions

Important Safety Instructions

(Continued)

Do not make any

modifications to

the tool without first obtaining written

approval from Campbell Hausfeld. Do

not use the tool if any shields or guards

are removed or altered. Do not use the

tool as a hammer. Personal injury or

tool damage may occur.

AIR SOURCE

a. Never connect to an air source that

is capable of exceeding 200 psi.

Over pressurizing the tool is able

to result in bursting, abnormal

operation, breakage of the tool or

serious injury to persons. Use only

clean, dry, regulated compressed air

at the rated pressure or within the

rated pressure range as marked on

the tool. Always verify prior to using

the tool that the air source has been

adjusted to the rated air pressure or

within the rated air-pressure range.

b. Never use oxygen, carbon dioxide,

combustible gases or any bottled

gas as an air source for the tool.

Such gases are capable of explosion

and serious injury to persons.

Do not

type of reactive gases,

use any

including, but not

limited to, oxygen and

combustible gases, as a power

source. Use filtered, lubricated,

regulated compressed air only.

Use of a reactive gas instead of

compressed air may cause the tool

to explode which will cause death

or serious personal injury.

Use only

a pressure-regulated

compressed air source

to limit the air pressure

O

CO

90 psi

2

supplied to the tool. The regulated

pressure must not exceed 90 psi.

If the regulator fails, the pressure

delivered to the tool must not

exceed 200 psi. The tool could

explode which will cause death or

serious personal injury.

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

OPERATING INSTRUCTIONS

LUBRICATION

Proper lubrication is the owner’s

responsibility. Failure to lubricate the air

tool properly will dramatically shorten

the life of the tool and will void the

warranty.

This air tool

requires

lubrication before the initial

use and before and after each

additional use.

Air tools require lubrication throughout

the life of the tool. Air tool oil is

recommended because this oil cleans,

lubricates and inhibits rust all in one

step.

After an air tool

has been

lubricated, oil will discharge

through the exhaust port during

the first few seconds of operation.

Thus, the ex-haust port must

be covered with a towel before

applying air pressure. Failure to

cover the exhaust port can result in

serious injury.

1. Disconnect tool from air supply.

2. Turn tool upside down.

3. While pressing trigger, apply 5 - 10

drops of oil in the air inlet.

4. Connect the air tool to the air supply

and cover the exhaust port with a

towel. Run the air tool for 7 to 10

seconds. Oil will discharge from the

exhaust port when air pressure is

applied.

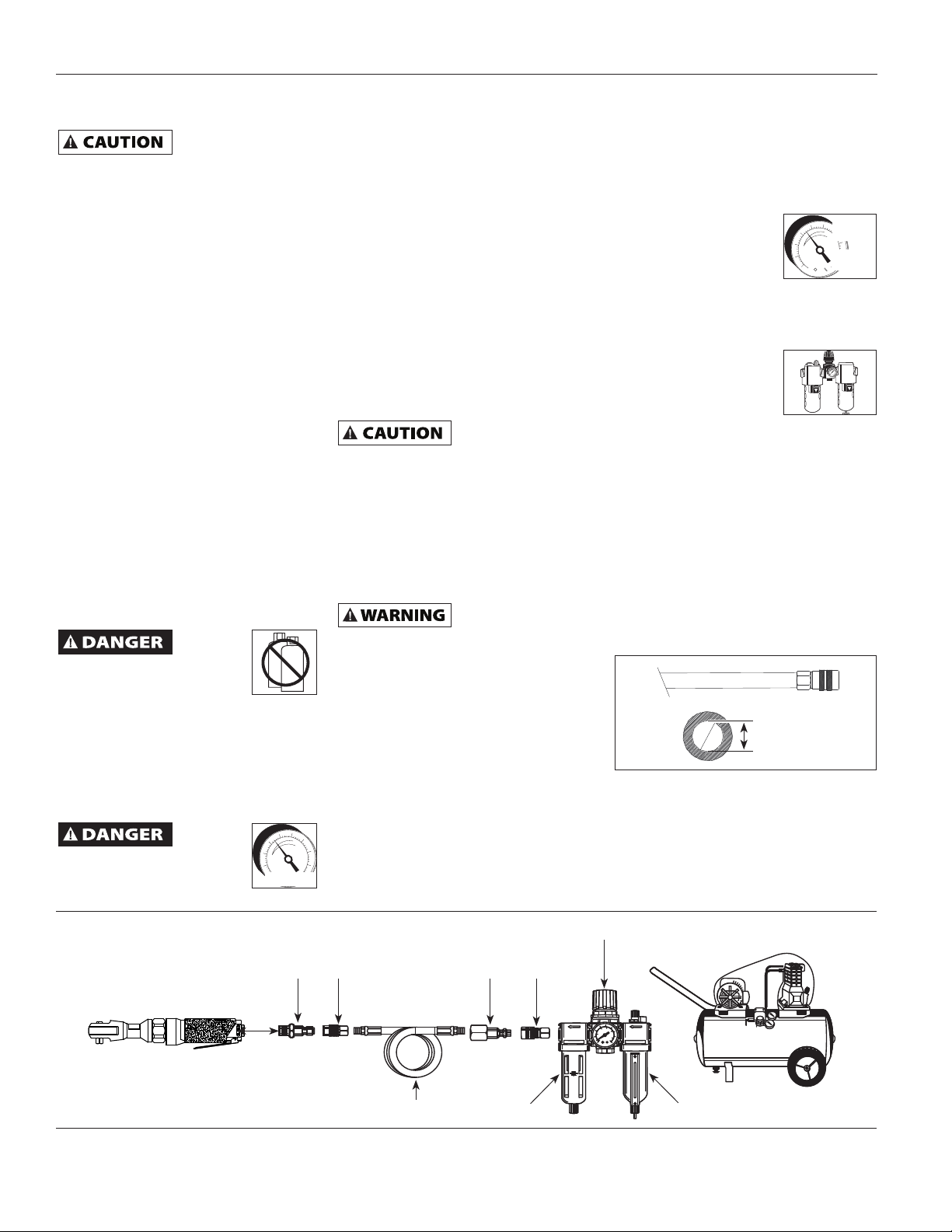

RECOMMENDED HOOKUP

The illustration below shows the

recommended hookup for the tool.

1. The air compressor

must be able to

maintain a minimum

of 60 psi when the

60 psi

Min.

90 psi

Max.

tool is being used. An inadequate air

supply can cause a loss of power and

inconsistent driving.

2. An oiler can be

used to provide oil

circulation through

the tool. A filter can

be used to remove

liquid and solid impurities which can

rust or “gum up” internal parts of

the tool.

3. Always use air supply hoses with

a minimum working pressure

rating equal to or greater than the

pressure from the power source if a

regulator fails, or 200 psi, whichever

is greater. Use 1/4 inch air hose for

runs up to 50 feet. Use 3/8 inch air

hoses for 50 foot run or longer.

200 psi or greater

3/8 inch I.D.

4. Use a pressure regulator on the

compressor, with an operating

pressure of 0 psi - 125 psi. A pressure

regulator is required to control

the operating pressure of the tool

between 60 psi and 90 psi.

Recommended Hookup

Quick Plug

www.chpower.com

Quick

Coupler

Air Hose

Quick Plug

(Optional)

Lubricator

4

Quick

Coupler

(Optional)

Regulator

Filter

Page 5

TL0501

OPERATING INSTRUCTIONS

(Continued)

OPERATIONAL MODE

To remove nuts, turn the forward/

reverse dial to the right. To install nuts,

turn the forward/reverse dial to the left.

Reverse the procedure if the threads

are left-handed. Do not overtighten the

nuts.

When tightening,

do not torque

down the nuts or bolts with the

ratchet as typically done with a

hand wrench. This can damage

the tool by breaking parts in the

ratchet mechanism.

Use of a whip

hose prevents

accidental triggering of the tool

when pressurized air is connected

to the system.

In addition, the tool’s vibration wears

out quick couplers prematurely.

Using fittings or air hoses which are too

small can create a pressure drop and

reduce the power of the tool. A 3/8 inch

(I.D.) fitting with 1/4 inch NPT threads

is recommended. Most compressors

are shipped with a short, 1/4 inch I.D.

hose. For proper performance and more

convenience, use a 3/8 inch I.D. hose.

Hoses longer than 50 feet should have a

1/2 inch I.D.

NOTE: It is not recommended to install

a quick coupler between the air tool

and the leader (whip) hose.

Never carry a tool

by the hose or

pull the hose to move the tool or a

compressor. Keep hoses away from

heat, oil and sharp edges. Replace

any hose that is damaged, weak or

worn.

USER-MAINTENANCE

INSTRUCTIONS

TECHNICAL SERVICE

Please call our Tool Hotline at 1-800543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual.

REPLACEMENT PARTS INFORMATION

For information regarding where to

order replacement parts, call toll free

1-800-543-6400. Please provide the

following information:

•Modelnumber

•Stampedcode

•Partnumberanddescription

TOOL REPAIR

Only qualified personnel should repair

the tool and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently.

ASSEMBLY PROCEDURE FOR SEALS

When repairing a tool, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W

non-detergent oil or equivalent, must

be added through the air line before

testing.

STORAGE

The air tool must be lubricated before

storing. Follow the air tool lubrication

instructions with an exception to step 4.

Only run the air tool for 2 to 3 seconds

instead of 7 to 10 seconds because more

oil needs to remain in the air tool when

storing.

www.chpower.com

5

Page 6

Operating Instructions

Troubleshooting Chart

Stop using tool immediately if any of the following problems occur. Serious personal injury

Authorized Service Center.

Symptom Possible Cause(s) Corrective Action

Tool runs slowly or will not

operate.

Moisture blowing out of

tool.

Ratchet mechanism slips or

will not loosen nut.

could occur. Any repairs or replacements must be done by a Qualified Service Person or

1. Grit or gum in tool. 1. Flush the tool with air tool oil, gum

solvent, or an equal mixture of SAE 10

motor oil and kerosene. If air tool oil is not

used, lubricate the tool after cleaning.

2. No oil in tool. 2. Lubricate the tool according to the

lubrication instructions in this manual.

3. Low air pressure. 3a. Adjust the regulator on the tool to the

maximum setting (If applicable).

3b. Adjust the compressor regulator to tool

maximum while the tool is running free.

4. Air hose leaks. 4. Tighten and seal hose fittings if leaks are

found.

5. Pressure drops. 5a. Be sure the hose is the proper size. Long

hoses or tools using large volumes of air

may require a hose with an I.D. of 1/2 inch

or larger depending on the total length of

the hose.

5b. Do not use a multiple number of hoses

connected together with quick connect

fittings. This causes additional pressure

drops and reduces the tool power. Directly

connect the hoses together.

6. Worn rotor blade in motor. 6. Replace rotor blade.

7. Worn ball bearing in motor. 7. Remove and inspect bearing for rust, dirt

and grit or worn race. Replace or clean and

regrease bearing with bearing grease.

1. Water in tank. 1. Drain tank. Oil tool and run until no water

is evident. Oil tool again and run 1–2

seconds.

2. Water in the air lines/hoses. 2a. Install a water separator/filter (PA2121).

NOTE: Separators only work properly when

the air passing through the separator is

cool. Locate the separator/filter as far as

possible from the compressor.

2b. Install an air dryer.

2c. Anytime water enters the tool, the tool

should be oiled immediately.

1. Ratchet mechanism is dirty. 1a. Clean mechanism with air tool oil.

1b. Replace worn mechanism.

www.chpower.com

6

Page 7

Notes

TL0501

www.chpower.com

7

Page 8

Operating Instructions

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One (1) Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld air tool.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period with the exceptions below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial, industrial

or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow

limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or failure

to operate products in accordance with instructions shall also include the removal or alteration of any safety devices.

If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, e.g. o-rings, springs, gaskets, packings or seals,

lubricants, motor vanes, impact mechanism, or any other expendable part not specifically listed. These items will only

be covered for ninety (90) days from date of original purchase. Underlined items are warranted for defects in material

and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within the duration of the specific warranty

period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (800) 543-6400 to obtain your warranty service options. Freight costs must be borne by the

purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may also

have other rights which vary from state to state or country to country.

www.chpower.com

8

Page 9

Voir la Garantie à la page 8-Fr pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions d’Utilisation TL0501

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire

fonctionner ou entretenir l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la

sécurité. Négliger d'appliquer ces instructions peut résulter en des blessures corporelles et/ou en des dommages

matériels ! Conserver ces instructions pour références ultérieures.

Rochet de 9,5 mm

(3/8 po)

Table des matières

Descripion . . . . . . . . . . . . . . . . . . . . 1-Fr

Déballage . . . . . . . . . . . . . . . . . . . . 1-Fr

Directives de sécurité . . . . . . . . . . . 1-Fr

Importantes instructions

de sécurité. . . . . . . . . . . . . . . . . . . . 1-Fr

Pièces détachées et fisch technique

mécanisme de la l'outil. . . . . . . . . . 2-Fr

Mode d’emploi . . . . . . . . . . . . . . . . 4-Fr

Graissage . . . . . . . . . . . . . . . . . . . 4-Fr

Branchement recommandé. . . . . 4-Fr

Mode d’opération . . . . . . . . . . . . 5-Fr

Instructions de maintenance

de l'utilisateur . . . . . . . . . . . . . . . . . 5-Fr

Guide de dépannage . . . . . . . . . . . 6-Fr

Garantie limitée . . . . . . . . . . . . . . . 8-Fr

Description

Les rochets sont des outils

pneumatiques conçus pour enlever

et installer les bougies d’allumage et

différentes pièces de moteurs telles que

les pompes à eau, radiateurs, etc. Les

utiliser dans les endroits restreints là où

les outils à main sont encombrants.

Déballage

Dès que l’appareil est déballé,

l’inspecter attentivement pour tout

signe de dommages en transit. S’assurer

de resserrer tous les raccords, boulons,

etc. avant de le mettre en service.

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique

une situation

hasardeuse imminente qui

RÉSULTERA en perte de vie ou

blessures graves.

Avertissement

indique une

situation hasardeuse potentielle

qui PEUT résulter en perte de vie ou

blessures graves.

Attention

indique une

situation hasardeuse potentielle

qui PEUT résulter en blessures.

Avis indique de

l’information

importante pour éviter le dommage

de l’équipement.

REMARQUE : L’information qui exige

une attention spéciale.

Importantes instructions

de sécurité

INSTRUCTIONS PORTANT SUR UN

RISQUE D’INCENDIE, UN CHOC

ÉLECTRIQUE OU DES BLESSURES

AUX PERSONNES

Ce manuel contient des informations

concernant la sécurité, le

fonctionnement et l’entretien.

Contacter votre représentant Campbell

Hausfeld si vous avez des questions.

En utilisant les

outils, il faut

suivre les précautions de base, y

compris ce qui suit :

Modèle TL0501

Trouver le numéro de modèle et

le code date sur le chargeur de

l’outil et inscrire plus bas :

o

N

du Modèle : __________________

Code de date : __________________

Conserver ces numéros

comme référence.

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

contenir des produits chimiques

qui, de l’avis de l’État de Californie,

causent le cancer et des anomalies

congénitales ou autres problèmes

de reproduction. Lavez-vous les

mains après la manipulation.

Vous pouvez créer de la

poussière en coupant,

ponçant, perçant ou

meulant les matériaux tels que

le bois, la peinture, le métal,

le béton, le ciment ou autre

maçonnerie. Cette poussière

contient souvent des produits

chimiques reconnus pour causer

le cancer, les déformations

congénitales ou autres problèmes

de la reproduction. Porter de

l’équipement de protection.

cordon peuvent

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2011 Campbell Hausfeld / Scott Fetzer IN732700AV 6/11

1-Fr

Page 10

Instructions d’utilisation

Importantes instructions

de sécurité (Suite)

GÉNÉRALITÉ :

a. Pour réduire les risques

de chocs électriques,

d’incendie ou de blessures

aux personnes, lire toutes

les instructions avant

d’utiliser l’outil.

b. Se familiariser avec ce produit, ses

commandes et son utilisation. Suivez

toutes les instructions. Contacter

votre représentant Campbell

Hausfeld si vous avez des questions.

c. Seules les personnes familières avec

ces règles d’utilisation sans danger

devraient utiliser cette unité.

Lire et

comprendre

les étiquettes et le manuel sur

les outils. Ne pas suivre les

avertissements, les dangers et les

mises en garde pourrait causer la

MORT ou de GRAVES BLESSURES.

AIRE DE TRAVAIL

a. Garder l’aire de travail propre et

bien éclairée. Les établis encombrés

et les coins sombres augmentent

les risques de chocs électriques,

d’incendie et de blessures aux

personnes.

b. Ne pas faire fonctionner

l’outil dans une

atmosphère explosive

comme en présence de

liquides, gaz ou poussières

inflammables. L’outil peut produire

des étincelles menant à une

inflammation de poussières ou de

fumées.

c. Garder les spectateurs, les enfants et

les visiteurs loin en utilisant l’outil.

Les distractions peuvent faire perdre

le contrôle de l’outil.

SÉCURITÉ PERSONNELLE

a. Rester vigilant. Il faut regarder ce

que vous faites et utiliser son sens

commun en faisant fonctionner

un outil. Ne pas faire fonctionner

l’appareil si vous êtes fatigué ou

sous l’influence de drogues, d’alcool

ou de médicaments. Un moment

d’inattention en faisant fonctionner

l’outil augmente le risque de

blessures.

b. Il faut s’habiller correctement.

Ne pas porter de bijoux ou de

vêtements amples. Attacher les

cheveux longs. Garder les cheveux,

les vêtements et les gants loin

des pièces mobiles. Les vêtements

amples, les bijoux ou les cheveux

longs augmentent le risque de

blessures si quelque chose se prend

dans les pièces mobiles.

c. Éviter tout démarrage accidentel.

S’assurer que l’interrupteur est

en position d’arrêt (off) avant de

brancher à l’alimentation d’air.

Ne pas transporter l’outil avec le

doigt sur l’interrupteur ni brancher

l’outil à l’alimentation d’air avec

l’interrupteur en marche.

e. Ne pas trop se pencher. Garder bon

pied et bon équilibre en tout temps.

Ceci permet d’avoir un meilleur

contrôle de l’outil dans les situations

imprévues.

d. Retirer les clés à ouverture fixe

ou les clés d’ajustement avant de

mettre l’outil en marche. Une clé ou

une clé à ouverture fixe installée sur

une pièce mobile de l’outil pourrait

mener à une blessure.

f. Utiliser l’équipement de sécurité.

Il faut utiliser un masque

antipoussières, des souliers de

sécurité antidérapants et un casque

de protection appropriés pour les

conditions en cours.

g. Toujours porter une

protection pour les yeux.

h. Toujours porter une

protection auditive en

utilisant l’outil. Toute

exposition prolongée

à des bruits de forte

intensité pourrait

provoquer une perte

auditive.

i. Ne pas attacher le boyau d’air ou

l’outil à votre corps. Fixer le boyau

à la structure pour réduire le risque

de perte d’équilibre si le boyau se

déplace.

Toujours bien

s’équilibrer

pendant la manipulation ou

l’utilisation de l'outil.

Éviter d’utiliser

l'outil pour une

période de temps prolongée. Cesser

d’utiliser l'outil si l’on ressent des

douleurs dans les mains ou dans les

bras.

Tool Components and Specifications

m3/min moyen . . . . . . . . .0,14 @ 621 kPa

et kPa (usage 25%)

m3/min continu . . . . . . . .0,54 @ 621 kPa

(usage 100%)

tr/min (nominale) minimale. . . . . . . 140

Couple Max. . . . . . . . . . . . . . . 6,92 kg m

Couple de Service . . . . . 1,38 - 6,22 kg m

Type d'engrenage . . . . . . . . .Planétaire

3 galets tendeurs

Capacité de boulon . . . . . . . . . . . 3/8 po

Arrivée d'air . . . . . 1/4 po NPT (Femelle)

Taille de tuyau min . . . . . . . . . . . . 3/8 po

Entraînement . . . . . . . . . . . 3/8 po carré

Poids . . . . . . . . . . . . . . . . . . . . . . 1,13 kg

Cadran de marche avant/arrière

Arrivée d'air

Étrangleur

Échappement

Enclume de 9,5 mm (3/8 po)

2-Fr

Page 11

TL0501

Importantes instructions

de sécurité (Suite)

j. Tenir l’outil par une surface de

prise isolée en effectuant le travail

lorsque l’outil pourrait entrer en

contact avec un câblage caché. Un

contact avec un fil « sous tension »

rendra les pièces de métal exposées

de l’outil « sous tension » et

produira un choc pour l’opérateur.

k. Éviter tout contact avec les surfaces

mises à la terre telles que les tuyaux,

les radiateurs, les cuisinières et les

réfrigérateurs. Il y a un risque accru

de choc électrique si votre corps est

mis à la terre.

l. Vérifiez la pièce de travail pour

éviter le contact avec un câblage

caché. Vérifiez minutieusement la

pièce de travail pour tout câblage

caché possible avant la travailler.

Le contact avec un câblage sous

tension donnera un choc électrique

à l'opérateur.

m. Ne jamais diriger un outil

pneumatique vers soi ni vers une

autre personne afin d’éviter tout

risque de blessure grave.

n. Ne pas mettre les mains près de ni

sous les pièces mobiles.

UTILISATION ET ENTRETIEN

DE L’OUTIL

a. Utiliser des pinces ou tout autre

moyen pratique pour fixer et

supporter le travail à une plateforme stable. Tenir le travail de la

main ou contre le corps est instable

et pourrait mener à une perte de

contrôle.

b. Ne pas forcer l’outil. Utiliser le bon

outil pour l’application. Le bon

outil effectuera le meilleur travail

sécuritaire au rythme pour lequel il a

été conçu.

c. Ne pas utiliser l’outil si l’interrupteur

ne met pas l’outil en marche ou ne

l’arrête pas. Tout outil qui ne peut

pas être contrôlé par l’interrupteur

est dangereux et doit être réparé.

d. Débrancher

la source d'air avant tout

ajustement, entretien de l'outil,

déblocages, avant de quitter

l'aire de travail, de charger ou

de décharger l'outil.

l'outil de

De telles

mesures de précautions réduisent le

risque de blessures.

e. Ranger l’outil lorsqu’il n’est pas

utilisé hors de portée des enfants

et autres personnes non formées.

Un outil est dangereux dans les

mains d’utilisateurs non formés.

f. Il faut entretenir l’outil avec soin.

Gardez un outil de coupe tranchant

et propre. Un outil bien entretenu

aux bords de coupe tranchants est

moins susceptible de bloquer et est

plus facile à contrôler.

g. Vérifier pour tout signe de mauvais

alignement ou grippage de pièces

mobiles, bris de pièces et toute

autre condition qui pourrait affecter

le fonctionnement de l’outil.

Si l’outil est endommagé, le réparer

avant de l’utiliser. De nombreux

accidents sont causés par des

outils mal entretenus. Il y a un

risque d’éclatement si l’outil est

endommagé.

h. Utiliser seulement des accessoires

identifiés par le fabricant pour le

modèle précis d'outil. Utiliser un

accessoire non prévu pour une

utilisation avec le modèle précis

d'outil augmente le risque de

blessures pour les personnes.

i. Choisir un système d'activation de

l'outil approprié en tenant compte

de l'application de travail prévue

pour l'outil.

Ne

jamais

utiliser de l’essence ni les

fluides inflammables pour

le nettoyage de l'outil.

Ne jamais utiliser l'outil près

d’un liquide ou gaz inflammable.

Une étincelle peut allumer les

vapeurs et causer une explosion

qui peut résulter en perte de vie ou

blessures graves personnelles.

Dissiper toute la

pression du

système avant d’essayer d’installer,

réviser, déplacer le produit ou de

procéder à son entretien.

Toujours

débrancher

l'outil de la source de courant en

votre absence, en effectuant des

réparations ou son entretien, en

débloquant l'appareil ou en le

déplaçant ailleurs.

Toujours installer

un raccord ou

un tuyau de raccord sur ou près de

l'outil afin que tout air comprimé

de l'outil soit déchargé au moment

où l'on débranche le raccord ou

le boyau. Ne pas utiliser un clapet

ni autre raccord qui permet que

l’air reste dans l'outil. Cela peut

entraîner des blessures graves ou

mortelles.

Ne jamais

transporter

l'outil par le tuyau à air. Ne jamais

tirer sur le tuyau pour déplacer

l'outil ou le compresseur. Garder le

tuyau à air à l’écart de la chaleur,

l’huile et les objets pointus.

Remplacer les tuyaux endommagés,

faibles ou usés. Sinon, il y a risque

de blessures personnelles ou de

dommage à l’outil.

!

AVERTISSEMENT

Ne pas utiliser l'outil

ni permettre qu’une

autre personne

l’utilise si les avertissements ou les

étiquettes d’avertissement situés

sur le chargeur et corps de l'outil

ne sont pas lisibles.

Ne pas échapper

ni jeter l’outil

car ceci peut causer du dommage

le rendant dangereux à utiliser. Si

l’outil s’est fait échappé ou jeté,

l’examiner soigneusement afin de

déterminer s’il est courbé, fendu

ou s’il y a des fuites ou pièces

détachées endommagées. ARRËTER

et réparer avant d’utiliser , sinon, il

y a risque de blessures graves.

Ne pas dépasser

la pression

maximum de service de l’outil

pneumatique (621 kPa). Cela

risquerait de réduire la durée de

service.

j. Ne pas dépasser la pression

nominale de tout élément du

système. Une pression de service

maximale de 621 kPa est jaugée à

la prise d’air de l’outil pendant son

fonctionnement. Il est nécessaire de

compenser pour la perte de pression

entre le compresseur et l’outil au

compresseur.

k. Ne pas appuyer sur la gâchette

lors du branchement du tuyau

d’alimentation en air.

l. Ne jamais appuyer sur la gâchette

de l’outil tant qu’il n’y a pas contact

avec l’objet de travail. Les accessoires

doivent être bien fixés pour éviter

tout risque de blessure grave.

Nettoyer et

vérifier tous

les tuyaux et raccords avant de

brancher l'outil au compresseur

d’air. Remplacer les tuyaux ou les

raccords endommagés ou usés,

sinon, le rendement et la durabilité

de l’outil seront affectés.

3-Fr

Page 12

Instructions d’utilisation

Importantes instructions

de sécurité (Suite)

SERVICE

a. Tout le travail d’entretien et de

réparation doit être effectué

seulement par un personnel de

réparation qualifié.

b. En réparant ou faisant l’entretien

d’un outil, utiliser seulement des

pièces de rechange identiques.

Utiliser seulement des pièces

autorisées.

c. Utiliser seulement les lubrifiants

fournis avec l’outil ou spécifiés par

le fabricant.

Ne pas apporter

de modifications

à l'outil sans d'abord obtenir une

approbation écrite de Campbell

Hausfeld. N’utilisez pas d'outil si

les écrans ou protecteurs ont été

enlevés ou altérés. Ne pas utiliser

l'outil comme marteau. Cela

peut entraîner des blessures ou

endommager l’appareil.

SOURCE D’AIR

a. Ne jamais brancher à une source

d’air pouvant dépasser 1379 kPa

(200 lb/po²). Une surpression de

l’outil peut mener à un éclatement,

une opération anormale, un bris

de l’outil ou de graves blessures.

Utiliser seulement de l’air comprimé

propre, sec, contrôlé à une pression

nominale ou dans la plage de

pression nominale tel qu’indiqué

sur l’outil. Toujours vérifier avant

d’utiliser l’outil que la source

d’air est ajustée à la pression d’air

nominale ou dans la plage de

pression d’air nominale.

b. Ne jamais utiliser d’oxygène,

de dioxyde de carbone, de gaz

combustible ou tout gaz en bouteille

comme source d’air de l’outil. De tels

gaz peuvent exploser et provoquer

de graves blessures.

utiliser comme source

Ne pas

O

CO

2

d'alimentation tout type

de gaz réactif, y compris,

mais sans s'y limiter, de l'oxygène

et des gaz combustibles. Utiliser

seulement de l’air comprimé filtré,

lubrifié et réglé. Utiliser un gaz

réactif au lieu d'air comprimé

pourrait faire exploser l'outil ce qui

pourrait provoquer des blessures

graves voire la mort.

Utiliser seulement une

source d'air comprimé à

pression pour limiter la

621 kPa

pression d'air fournie à

l'outil. La pression contrôlée ne

doit pas dépasser 621 kPa. S'il y a

une défaillance du régulateur, la

pression livrée à l'outil ne doit pas

dépasser 1 379 kPa. L'outil pourrait

exploser ce qui pourrait mener à la

mort ou à des blessures graves.

CONSERVER CES INSTRUCTIONS

NE LES JETEZ PAS

MODE D’EMPLOI

GRAISSAGE

L’utilisateur est responsable du

graissage correct. Un graissage incorrect

de l’outil pneumatique raccourcira de

façon spectaculaire sa durée de service

et annulera la garantie.

Cet outil

requiert un graissage avant le premier

usage et avant et après chaque usage

subséquent.

Les outils pneumatiques requièrent le

graissage pendant toute leur durée

de service. L’huile pour outils pneumatiques est recommandée parce qu’elle

nettoie, graisse et empêche la rouille en

une étape.

pneumatique

Après le

graissage d’un

outil pneumatique, de l’huile

s’écoulera de l’orifice de soitie lors

des quelques premières secondes

de fonctionnement. Pour éviter

tout risque de blessure grave,

recouvrir cet orifice d’un torchon

avant d’alimenter en air comprimé.

1. Déconnecter l’outil de la source d’air.

2. Inversez l'outil.

3. En appuyant sur le gâchette,

appliquez 5 -10 baisses d’huile dans

l’arrivée d’air.

4. Brancher l’outil pneumatique à

l’alimentation en air et couvrir

l’orifice de sortie avec un

torchon. Faire fonctionner l’outil

pneumatique pendant 7 à 10

secondes. De l’huile s’écoulera de

l’orifice de sortie lorsque l’outil est

alimenté en air.

BRANCHEMENT RECOMMANDÉ

Le branchement recommandé est

illustré ci-dessous.

1. Le compresseur

d’air doit conserver

un minimum de

414 kPa pendant

414 kPa

Min.

621 kPa

Max.

l’utilisation de l'outil.

L’alimentation d’air insuffisante

peut réduire la puissance de l'outil

et peut affecter l’efficacité de

l’enfoncement.

2. Un graisseur peut être

utilisé pour fournir

la circulation d’huile

à travers l'outil. Un

filtre peut être utilisé pour enlever

les matières liquides et solides qui

peuvent encrasser les pièces internes

de l'outil.

Branchement Recommandé

Bouchon

Rapide

Raccord

Rapide

Bouchon

Rapide

(Optionnel)

Tuyau À

Air

Graisseur

4-Fr

Raccord

Régulateur

Rapide

(Optionnel)

Filtre

Page 13

TL0501

MODE D’EMPLOI (Suite)

3. Toujours utiliser des tuyaux

d'admission d'air d'une pression

nominale minimum égale ou plus

grande que la pression de la source

d'alimentation si un régulateur cesse

de fonctionner correctement ou de

1 379 kPa, selon la pression la plus

élevée. Utiliser un tuyau d'air de

6,4 mm (1/4 po) pour les longueurs

jusqu'à 15 m (50 pieds). Utiliser les

tuyaux d’air de 9,5 mm (3/8 po) pour

15 m ou plus.

1 379 kPa ou plus

9,5 mm (3/8 po) I.D.

4. Utiliser un régulateur de pression

sur le compresseur avec une

pression de service de 0 kPa - 862

kPa. Un régulateur de pression est

indispensable pour maintenir la

pression de service de l'outil entre

414 kPa et 621 kPa.

MODE D’OPÉRATION

Pour enlever les écrous, tourner

l’inverseur de sens de rotation vers la

droite. Pour les installer, le tourner vers

la gauche. Faire l’inverse si le filetage

est à gauche. Ne pas trop serrer les

écrous.

Lors du serrage,

ne pas serrer les

écrous et boulons comme on le fait

généralement avec une clé à main.

Cela risque d’endommager l’outil

en cassant les pièces du mécanisme

de rochet.

L’utilisation d’un

tuyau fléchie

sert à éviter le déclenchement

accidentel de la gâchette de l’outil

quand l’air pressurisé est branché

au système.

Aussi, la vibration de l’outil peut causer

l’usure prémature des connecteurs

rapides.

L’utilisation de raccords ou tuyaux

d’air trop petits, peut créer une chute

de pression et réduire la puissance

de l’outil. Un raccord de 3/8 po de

diamètre intérieur avec filetage 1/4 po

NPT est recommandé. La plupart des

compresseurs sont livrés avec un tuyau

court de 1/4 po de diamètre intérieur.

Pour obtenir un bon rendement et une

meilleure fonctionnalité, utiliser un

tuyau de 3/8 po de diamètre intérieur.

Les tuyaux de plus de 15,24 m de long

doivent avoir un diamètre intérieur de

1/2 po.

REMARQUE: Il n’est pas recommandé

de monter un coupleur rapide entre

l’outil pneumatique et l’amorce (fléchie)

du tuyau.

Ne jamais

transporter un

outil en le tenant par le tuyau

ni tirer sur celui-ci pour déplacer

l’outil ou un compresseur. Garder

les tuyaux à l’écart de la chaleur,

de l’huile et des bords tranchants.

Remplacer tout tuyau endommagé,

peu robuste ou usé.

INSTRUCTIONS DE

MAINTENANCE DE

L’UTILISATEUR

SUPPORT TECHNIQUE

Pour tout renseignement sur le

fonctionnement ou la réparation de

cet outil, veuillez utiliser notre numéro

d’assistance 1-800-543-6400 ou pour

obtenir d’autres copies de ce manuel.

INFORMATION CONCERNANT LES

PIÈCES DE RECHANGE

Pour de l`information concernant la

commande de pièces de rechange,

composer le 1-800-543-6400. S’il vous

plaît fournir l’information suivante :

•Numérodemodèle

•Codeestampé

•No.etdescriptiondepièce

RÉPARATION D'OUTILS

Seul un personnel qualifié doit réparer

l’outil en utilisant seulement des

accessoires et des pièces de rechange

Campbell Hausfeld, ou des pièces

et accessoires qui fonctionnent de

manière équivalente.

MÉTHODE D’ASSEMBLAGE POUR LES

JOINTS D’ÉTANCHÉITÉ

Les pièces internes doivent être

nettoyées et graissées pendant la

réparation d'un outil. Utiliser le Parker

O-lube ou l’équivalent sur tous les

joints toriques. Chaque joint torique

doit être enrobé avec du O-lube avant

l’assemblage. Utiliser un peu d’huile sur

toutes les surfaces mouvantes et pivots.

Après le remontage, ajouter quelque

gouttes d’huile sans détergent 30W ou

l’équivalent à travers la canalisation

d’air avant de faire l’essai.

RANGEMENT

L’outil pneumatique doit être graissé

avant l’entreposage. Suivre les

instructions de graissage du moteur

pneumatique, à l’exception de l’étape

4. Ne faire tourner l’outil pneumatique

que pendant 2 à 3 secondes, au lieu de

7 à 10 secondes parce qu’il requiert plus

d’huile pour l’entreposage.

5-Fr

Page 14

Instructions d’utilisation

Guide de Dépannage

Cesser d’utiliser immédiatement l’outil si l’un des problèmes suivants apparaît. Toutes

Autorisé.

Problème Cause Solution

L’outil tourne trop lentement

ou ne fonctionne pas

Humidité expulsée de l’outil 1. Présence d’eau dans le réservoir 1. Purger le réservoir. Huiler l’outil et le faire

Le mécanisme de cliquet

dérape ou ne desserre pas

réparations doivent être effectuées par un Technicien Qualifié ou par un Centre De Service

1. Présence de grenaille ou de gomme

dans l’outil.

2. Absence d’huile dans l’outil. 2. Graisser l’outil conformément aux

3. Pression d’air trop basse. 3a. Régler le régulateur de l’outil à la position

4. Fuites dans le tuyau d’air. 4. Serrer et assurer l’étanchéité des raccords

5. Chute de la pression. 5a. Veiller à ce que le tuyau soit de la bonne

6. Usure d’une pale de rotor du moteur. 6. Remplacer la pale du rotor.

7. Usure d’un roulement dans le réservoir. 7. Enlever et inspecter le roulement pour voir

2. Présence d’eau dans la canalisation/le

tuyau d’air.

1.Le mécanisme de cliquet est sale. 1a. Nettoyer le mécanisme avec de la graisse à

1. Rincer l’outil avec de l’huile pour outil

pneumatique , du dissolvant de gomme ou

un mélange en proportions égales d’huile

moteur SAE10 et de kérosène. En cas

d’utilisation d’un produit autre que l’huile

pour outils pneumatiques, graisser l’outil

après l’avoir nettoyé.

instructions de graissage données dans ce

manuel.

maximum.

3b. Régler le régulateur du compresseur à la

position maximum lorsque l’outil tourne

dans le vide.

du tuyau en cas de fuites.

taille. Les longs tuyaux ou les outils

exigeant de grands volumes d’air peuvent

nécessiter un diamètre intérieur de tuyau

d’au moins 1/2 po, suivant la longeur totale

du tuyau.

5b. Ne pas utiliser plusieurs tuyaux reliés

ensemble au moyen de raccords rapides.

Cela provoque des chutes de pression

supplémentaires et réduit la puissance de

l’outil. Brancher les tuyaux directement les

uns aux autres.

s’il est rouillé, sale, contient de la grenaille

ou a une bague usée. Remplacer ou

nettoyer et regraisser le roulement avec la

graisse à roulements.

tourner jusqu’à ce qu’il semble ne plus

contenir d’eau. Huiler de nouveau l’outil et

le faire tourner pendant 1 ou 2 secondes.

2a. Monter un séparateur/filtre d’eau.

REMARQUE : les séparateurs ne

fonctionnent correctement que lorsque

l’air qui les traverse est frais. Positionner le

séparateur/filtre aussi loin que possible du

compresseur.

2b. Installer un sécheur d’air.

2c. Graisser l’outil immédiatement quand l’eau

entre dans l’outil.

outils pneumatiques.

1b. Remplacer le mécanisme s’il est usé.

6-Fr

Page 15

Notes

TL0501

7-Fr

Page 16

Instructions d’utilisation

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Un An.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio,

45030, Téléphone: (800) 543-6400

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Cet outil pneumatique Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts importants de matériaux et de main d'oeuvre qui se produisent durant

la période de garantie à l'exception de ce qui est noté plus bas.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE SONT

LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est

utilisé pour une fonction commerciale, industrielle ou pour la location, la durée de la garantie sera quatre-vingt-dix

(90) jours à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de durée pour les

garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas

l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou exclusion précédente peut donc ne pas

s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas

les instructions données dans le(s) manuel(s) accompagnant le produit. Un accident, l’utilisation abusive par l’acheteur,

la négligence ou le manque de faire fonctionner les produits selon les instructions comprend aussi l’enlevage ou la

modification de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la garantie sera

annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

E. Articles ou services qui sont exigés pour l’entretien normal du produit par ex. joints toriques, ressorts,

joints d'étanchéité, garnitures ou sceaux, lubrifiants, aubes du moteur, mécanisme à chocs, ou toute autre pièce

consommable non spécifiquement indiquée. Ces articles ne seront couverts que pendant quatre-vingt-dix (90)

jours de la date d'achat original. Les articles soulignés sont garantis contre les défauts de matériaux et de

fabrication seulement.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparer ou remplacer, au choix du Garant, les produits

ou composants défectueux, qui ont connu une défaillance et/ou qui ne sont pas conformes pendant la durée précise de

validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Appelez Campbell Hausfeld (800) 543-6400 pour obtenir vos options de service sous garantie. Les frais de transport

sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE: La réparation

ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la

disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis.

L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

8-Fr

Page 17

Ver la Garantía en página 8-Sp para información importante sobre el uso comercial de este producto.

Manual de Instrucciones de Operación TL0501

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar

o dar mantenimiento al producto aquí descrito. Protéjase usted mismo y a los demás observando toda la

información de seguridad. ¡El no cumplir con las instrucciones puede ocasionar daños, tanto personales como a

la propiedad! Guarde estas instrucciones para referencia en el futuro.

Trinquetes de

9,5 mm (3/8")

Índice

Descripción . . . . . . . . . . . . . . . . . . . 1-Sp

Desempaque . . . . . . . . . . . . . . . . . . 1-Sp

Medidas de Seguridad . . . . . . . . . . 1-Sp

Instrucciones de Seguridad

Importantes. . . . . . . . . . . . . . . . . . . 1-Sp

Componentes y Especificaciones de la

Herramienta . . . . . . . . . . . . . . . . . . 2-Sp

Instrucciones de Funcionamiento . 4-Sp

Lubricacion. . . . . . . . . . . . . . . . . . 4-Sp

Conexión Recomendada . . . . . . . 5-Sp

Modeo de Operación. . . . . . . . . . 5-Sp

Instrucciones de uso y

Mantenimiento. . . . . . . . . . . . . . . . 5-Sp

Guía de Diagnóstico de Averías. . . 6-Sp

Garantía Limitada . . . . . . . . . . . . . . 8-Sp

Descripción

Los trinquetes son herramientas

neumáticas diseñadas para sacar e

instalar bujías y otras piezas de motores

tales como bombas de agua, radiadores,

etc. Úselo en áreas poco accesibles

donde el uso de herramientas de mano

sea dificultoso.

Desempaque

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Cericiórese de

apretar todas las conexiones, pernos,

etc. antes de comenzar a utilizar la

unidad.

Medidas de Seguridad

Este manual contiene información

que es muy importante que sepa

y comprenda. Esta información se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

la muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica

una información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

NOTA: Información que requiere

atención especial.

Instrucciones de Seguridad

Importantes

INSTRUCCIONES EN REFERENCIA AL

PELIGRO DE INCENDIOS, CHOQUE

ELÉCTRICO O LESIONES PERSONALES

Este manual contiene información

sobre seguridad, funcionamiento y

mantenimiento. Póngase en contacto

con su representante Campbell Hausfeld

si tiene alguna pregunta.

Cuando se usen

herramientas,

siempre se deberán seguir

precauciones básicas, incluyendo

las siguientes:

Modelo TL0501

Localice el modelo y el código

de fecha en la herramienta y

regístrelo debajo:

Modelo: _____________________

Código de fecha ______________

Guarde estos números para

referencia futura.

PROPOSICIÓN 65 DE CALIFORNIA

Este producto,

o su cordón

eléctrico, puede contener productos

químicos conocidos por el estado

de California como causantes de

cáncer y defectos de nacimiento u

otros daños reproductivos. Lave sus

manos después de usar.

Cuando

corta

lija, taladra o pule

materiales como por

ejemplo madera, pintura,

metal, hormigón, cemento, u otro

tipo de mampostería se puede

producir polvo. Con frecuencia este

polvo contiene productos químicos

que se conocen como causantes de

cáncer, defectos congénitos u otros

daños reproductivos. Use equipo de

protección.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2011 Campbell Hausfeld / Scott Fetzer IN732700AV 6/11

1-Sp

Page 18

Manual de Instrucciones de Operación

Instrucciones de Seguridad

Importantes (Continúa)

GENERAL

a. Para reducir el riesgo de

choque eléctrico, incendio

y lesiones personales, lea

todas las instrucciones

antes de usar la

herramienta.

b. Familiarísece con los controles

y el uso adecuado del equipo.

Siga todas las instrucciones. Póngase

en contacto con su representante

Campbell Hausfeld si tiene alguna

pregunta.

c. Sólo se les debe permitir usar esta

unidad a aquellas personas bien

familiarizadas con estas reglas de

manejo seguro.

Lea y comprenda

las etiquetas y

el manual de la herramienta. Si

no respeta las advertencias, los

riesgos y las recomendaciones, eso

podría resultar en la MUERTE o en

LESIONES GRAVES.

ÁREA DE TRABAJO

a. Mantenga el área de trabajo limpia

y bien iluminada. Los bancos

desordenados y las áreas oscuras

aumentan el riesgo de choque

eléctrico, incendio y lesiones

personales.

b. No haga funcionar la

herramienta en entornos

explosivos, como por

ejemplo cuando haya

polvo, líquidos o gases inflamables.

La herramienta puede crear chispas

y provocar la ignición de polvo o

vapores.

c. Mantenga alejados a los

observadores, niños y visitantes

mientras hace funcionar la

herramienta. Las distracciones

pueden dar como resultado

la pérdida del control de la

herramienta.

SEGURIDAD PERSONAL

a. Manténgase alerta. Mire lo que

está haciendo y use el sentido

común cuando haga funcionar la

herramienta. No use la herramienta

si está cansado o bajo la influencia

de drogas, alcohol o medicamentos.

Un momento de desatención

mientras hace funcionar la

herramienta aumenta el riesgo

de lesiones personales.

b. Vístase adecuadamente. No use

alhajas ni vestimenta suelta.

Sujétese el cabello largo. Mantenga

el cabello, vestimenta y guantes

alejados de las piezas móviles.

La vestimenta suelta, las alhajas o el

cabello largo aumentan el riesgo de

lesiones personales como resultado

de quedar atrapados en las piezas

móviles.

c. Evite que se encienda

accidentalmente. Asegúrese de

que el interruptor esté en la

posición de apagado antes de

conectar el suministro de aire.

No lleve la herramienta con su dedo

sobre el interruptor ni conecte la

herramienta al suministro de aire

con el interruptor en la posición de

encendido.

d. Quite las llaves de ajuste o antes

de encender la herramienta. Una

conectada a una pieza giratoria

de la herramienta puede provocar

lesiones personales.

e. No intente alcanzar lugares alejados.

Mantenga un buen soporte y

equilibrio en todo momento.

Un soporte y equilibrio adecuados

permiten un mejor control de

la herramienta en situaciones

inesperadas.

f. Use equipo de seguridad. Se debe

usar una mascara para polvo,

calzado de seguridad antideslizante

y casco para las condiciones que se

apliquen.

g. Siempre use protección

para los ojos.

h. Use siempre una

protección para el

oído cuando use

la herramienta.

La exposición prolongada

a ruido de alta intensidad

puede causar pérdida de audición.

i. No ate la manguera ni la

herramienta a su cuerpo. Adjunte la

manguera a la estructura para

reducir el riesgo de pérdida de

equilibrio si la manguera se cambia

de posición.

Componentes y Especificaciones de la Herramienta

m3/min promedio . . . . . . 0,14 @6,21 bar

y bar (25% de uso)

m3/min continu. . . . . . . . 0,54 @ 6,21 bar

(100% de uso)

RPM (nominal) mínima . . . . . . . . . . .140

Torsíon Max. . . . . . . . . . . . . . 6,92 kg m

Torsíon de trabajo. . . . 1,38 - 6,22 kg m

Tipo de engranaje. . . .Triple planetario

intermedio

Capacidad del perno. . . . . . . . . 9,5 mm

(3/8 pulg.)

Admisión de aire 6,4 mm (1/4") NPT

(Hembra)

Tamano Min. de la

manguera . . . . . . . . 9,5 mm (3/8 pulg.)

Portaherramientas . . . . . . . . 9,5 mm Sq

(3/8 pulg. Sq)

Peso . . . . . . . . . . . . . . . . . . . . . . 1,13 kg

Disco de avance/retroceso

2-Sp

Entrada de aire

Válvula reguladora

Escape

Yunque de 9,5 mm (3/8 pulg.)

Page 19

TL0501

Instrucciones de Seguridad

Importantes (Continúa)

Siempre

colóquese en una

posición firme y balanceada para

usar o manipular la herramienta.

Evite trabajar con

esta herramienta

por largos periodos. Deje de usar la

herramienta si siente dolor en las

manos o en los brazos.

j. Sostenga la herramienta por la

superficie de sujeción aislada

cuando realice una operación en la

que la herramienta pueda entrar en

contacto con un cableado oculto.

Al entrar en contacto con un cable

de corriente las piezas metálicas

de la herramienta conducirán la

electricidad y el usuario recibirá un

choque eléctrico.

k. Evite el contacto corporal con las

superficies conectadas a tierra, tales

como tuberías, radiadores, cocinas

eléctricas o refrigeradores. Existe un

mayor riesgo de choque eléctrico si

su cuerpo está conectado a tierra.

l. Examine la pieza de trabajo para

evitar entrar en contacto con un

cableado oculto. Revise bien la pieza

de trabajo para verificar posibles

cableados ocultos antes de realizar

el trabajo. El contacto con un cable

bajo tensión eléctrica causará que el

usuario reciba un choque eléctrico.

m. Nunca apunte una herramienta

neumática hacia usted ni hacia

otra persona. Pueden ocurrir

lesiones graves.

n. No acerque las manos a las piezas

móviles ni las coloque debajo de ellas.

USO Y CUIDADO DE LA

HERRAMIENTA

a. Use sujetadores u otra manera

práctica de asegurar y apoyar la

pieza de trabajo a una plataforma

estable. Sostener el trabajo con

la mano o contra el cuerpo es

algo inestable y puede producir la

pérdida de control.

b. No fuerce la herramienta. Use la

herramienta correcta para la

aplicación. La herramienta correcta

hará el trabajo mejor y en forma

más segura a la velocidad para la

cual fue diseñada.

c. No use la herramienta si el

interruptor no la enciende o no

la apaga. Cualquier herramienta

que no pueda ser controlada con

el interruptor es peligrosa y debe

repararse.

d. Desconecte la

herramienta

del suministro de aire antes

de hacer cualquier ajuste,

realizar el mantenimiento

de la herramienta, eliminar

obstrucciones, dejar el área de

trabajo, cargar o descargar la

herramienta. Estas medidas de

precaución reducen el riesgo de

lesiones personales.

e. Cuando no esté en uso, guarde

la herramienta fuera del alcance

de los niños y otras personas no

capacitadas. Una herramienta es

peligrosa cuando está en manos de

usuarios inexpertos.

f. Cuide su herramienta. Mantenga

una herramienta para cortar

afilada y limpia. Una herramienta

mantenida adecuadamente con

bordes de corte afilados reduce el

riesgo de atascarse y es más fácil de

controlar.

g. Verifique que las piezas móviles no

estén desaliñadas ni adheridas, que

no haya piezas rotas y que no exista

ningún otro problema que afecten el

funcionamiento de la herramienta.

Si está dañada, haga que le realicen

un servicio a la herramienta antes

de usarla. Muchos accidentes son

causados por herramientas que no

tienen un mantenimiento adecuado.

Si la herramienta sufre un daño, hay

riesgo de explosión.

h. Use únicamente los accesorios que

están identificados por el fabricante

para el modelo de herramienta

específico. El uso de un accesorio no

diseñado para usarse con el modelo

de herramienta específico aumenta el

riesgo de lesiones personales.

i. Seleccionar un sistema de activación

de la herramienta adecuado,

tomando en cuenta la aplicación

de trabajo para la cual se usa la

herramienta.

Nunca

limpie

la herramienta con

gasolina o ningún otro

líquido inflamable. Nunca

use la herramienta en

la cercanías de líquidos o gases

inflamables. Una chispa podría

encender los vapores y ocasionar

una explosión que podría

ocasionarle la muerte o heridas

graves.

la presión del

sistema antes de intentar instalar,

realizar un servicio, reubicar

o realizar cualquier tipo de

mantenimiento.

Desconecte

herramienta de la fuente de

energía cuando no la esté

atendiendo, cuando le esté

realizando mantenimiento o

reparaciones, desobstruyéndola o

moviéndola a un nuevo sitio.

Siempre ajuste

con un conector o acoplador de

mangueras colocado en o cerca

de la herramienta de un modo

tal que se descargue todo el aire

comprimido en la herramienta en

el momento en que se desconecte

el conector o acoplador. No use

una válvula de chequeo o ninguna

conexión que permita que el aire

permanezca en la herramienta. Se

puede producir la muerte o lesiones

personales graves.

Nunca cargue la

herramienta por la

manguera de aire

ni hale la manguera para mover

la herramienta o el compresor de

aire. Mantenga las mangueras

alejadas del calor, aceite y objetos

puntiagudos. Reemplace cualquier

manguera que esté dañada, débil o

desgastada. Ésto podría ocasionar

heridas o daños a la herramienta.

herramienta ni permita que otros

la operen si las etiquetas de

advertencia están ilegibles. Éstas

se encuentran en el cargador o el

cuerpo de la herramienta.

No deje que la

caiga ni la tire. Ésto podría dañarla o

convertirla en algo peligroso de usar.

En caso de que la herramienta se

haya caído o la hayan tirado, revísela

con cuidado a ver si está doblada o

rota, si tiene alguna pieza dañada o

tiene fugas de aire. DEJE de trabajar

y repárela antes de usarla o podría

ocasionarle heridas graves.

presión de

funcionamiento máxima de la

herramienta neumática (90 psi).

Esto puede reducir la vida útil de

la herramienta.

j. No exceda ninguna clasificación

de presión en ningún componente

del sistema. La presión máxima de

funcionamiento de 90 psi se mide en

la entrada de la herramienta mientas

Libere toda

siempre la

la herramienta

!

ADVERTENCIA

No opere la

herramienta se

No exceda la

3-Sp

Page 20

Manual de Instrucciones de Operación

Instrucciones de seguridad

importantes (Continúa)

la misma está en funcionamiento.

La caída de presión entre el

compresor y la herramienta debe ser

compensada en el compresor.

k. No oprima el gatillo cuando conecte

la manguera de suministro de aire.

l. Nunca accione la herramienta si no

está aplicada a un objeto de trabajo.

Los accesorios deben colocarse en

forma segura. Los accesorios sueltos

pueden causar lesiones graves.

Limpie y

chequee todas

las mangueras de suministro de

aire y conexiones antes de conectar

la herramienta al compresor.

Reemplace las mangueras y

conexiones que estén dañadas o

desgastadas. El rendimiento de

la herramienta o su durabilidad

podrían reducirse.

SERVICIO

a. El servicio de la herramienta debe

ser realizado sólo por personal de

reparaciones calificado.

b. Al realizarle un servicio a la

herramienta, utilice únicamente

piezas de repuesto idénticas.

Use sólo piezas autorizadas.

c. Use sólo los lubricantes que el

fabricante proporciona con la

herramienta.

No haga ninguna

modificación a la

herramienta sin obtener primero la