Page 1

Low Oil Guard

for 5 to 25 HP

Compressors

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

© 2000 Campbell Hausfeld

Unpacking

Inspect for any damage that may have

occurred during transit. Check the parts

list to verify all the parts are accounted

for.

General Safety Information

Always disconnect,

lockout and tag

power before attempting to install,

service, relocate or perform any maintenance.

1. Read this instruction

manual before

installing this device

to the compressor

pump.

2. Read operator's instructions for

each component of compressor

package before putting into service.

3. Follow all local electrical and safety

codes, the United States National

Electric Code (NEC) and Occupational

Safety and Health Act (OSHA).

4. Electrical devices must always be

securely and adequately grounded.

Release all system pressure before attempting

to install, service, relocate or perform any maintenance.

5. Do not open the top housing cover

while the device is operating.

6. Do not bind the cord or allow the

cord to come in contact with oil,

grease, chemicals, or sharp object.

Operating Instructions and Parts Manual TF0628

7. After installation, inspect to make

sure all components seal properly.

8. Inspect to make certain that all fittings, bolts, etc. are tight and secure.

All wiring must be done

by a qualified (certified

or licensed) electrician.

Specifications

This device can be used with the following 5 through 25 HP, 230V single-phase

and 208/230V three-phase, two-stage,

Campbell Hausfeld compressors: TF

models, TK models, HD models, CI models and PROV models.

Installation

Release all system pressure before attempting

to install, service, relocate or perform

any maintenance.

IMPORTANT: The compressor must be

level for the low oil guard to operate

properly. If necessary, shim the mounting feet to bring the base on top of the

tank to a level position.

MECHANICAL INSTALLATION

1. Drain oil from crankcase.

2. Remove the oil level sight glass

from the compressor.

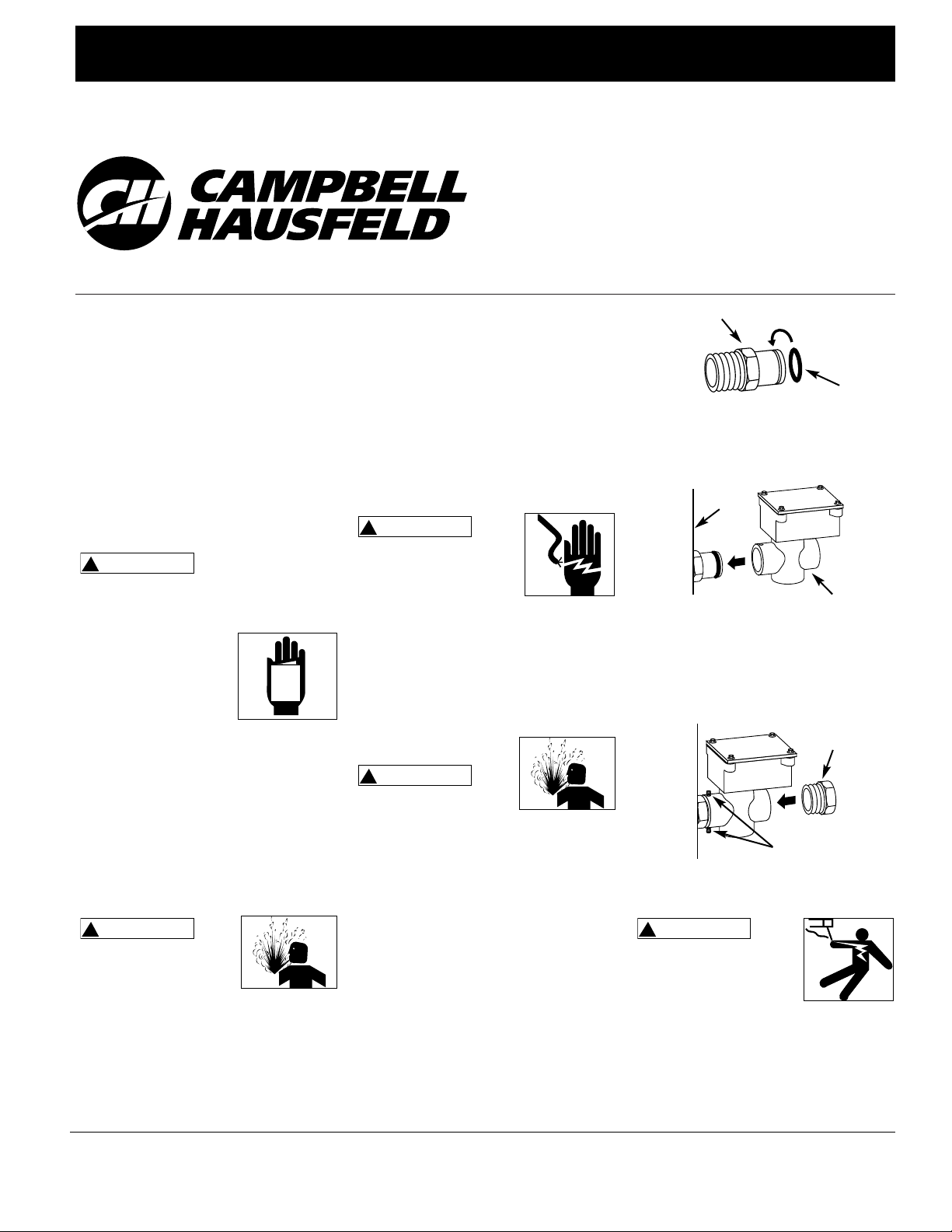

3. Install the o-ring in groove on the

adapter (See Figure 1).

4. Install the adapter in the oil sight

glass opening.

IN186602AV 9/00

Description

Campbell Hausfeld oil-level monitor is an accessory for two-stage air compressor

pumps. This monitor measures the level of oil in the compressor and shuts the

pump down if the level drops below a minimum. Can be used with 208-230 volt

single-phase and 208-230 volt three-phase, two-stage, cast iron Campbell Hausfeld

air compressor pumps equipped with a magnetic starter.

5. Push the oil level guard housing on

to the adapter (See Figure 2).

6. Tighten set screws in housing until

snug and then re-install oil level sight

glass on the front of the housing

(See Figure 3).

ELECTRICAL INSTALLATION

Always disconnect, lockout and tag power

before attempting to

install, service, relocate

or perform any maintenance.

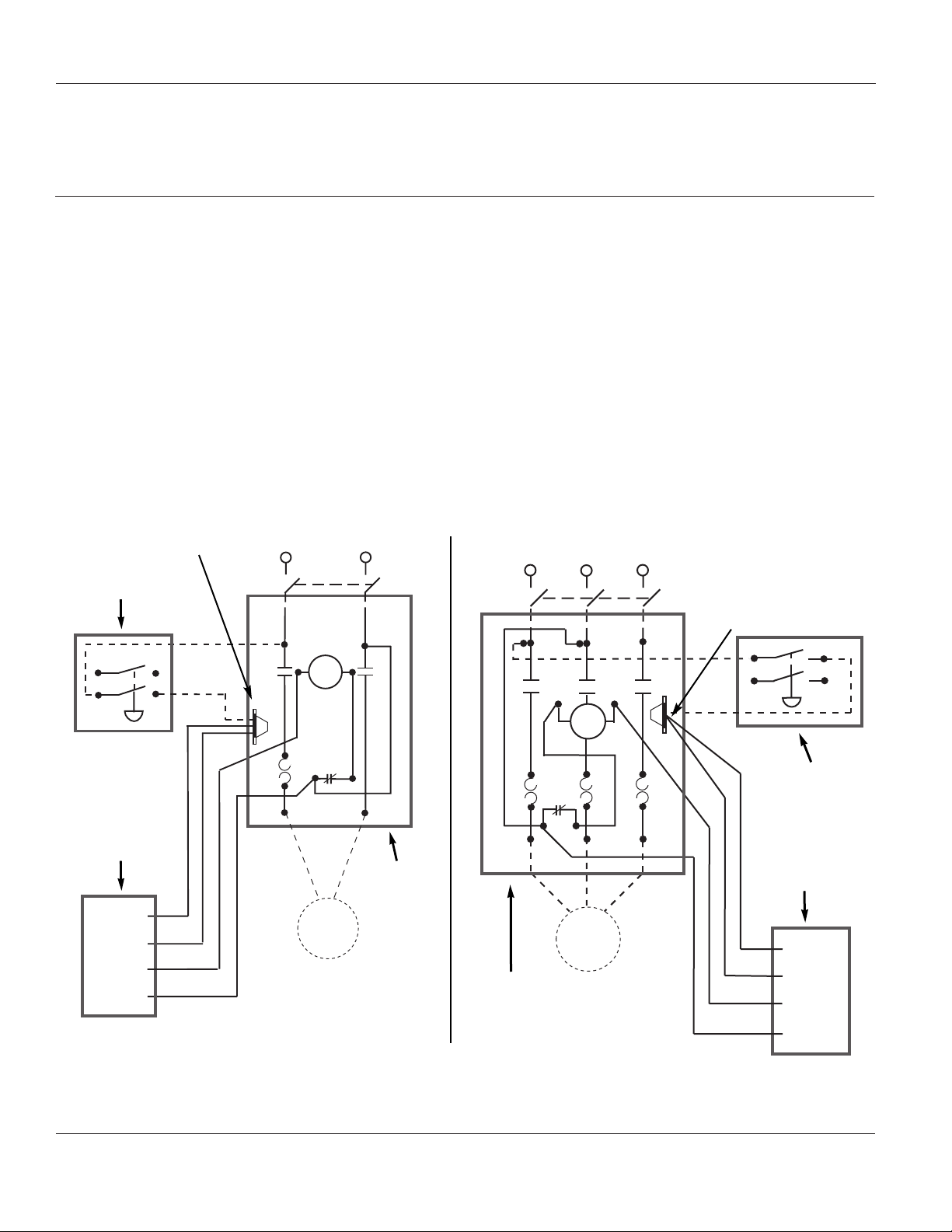

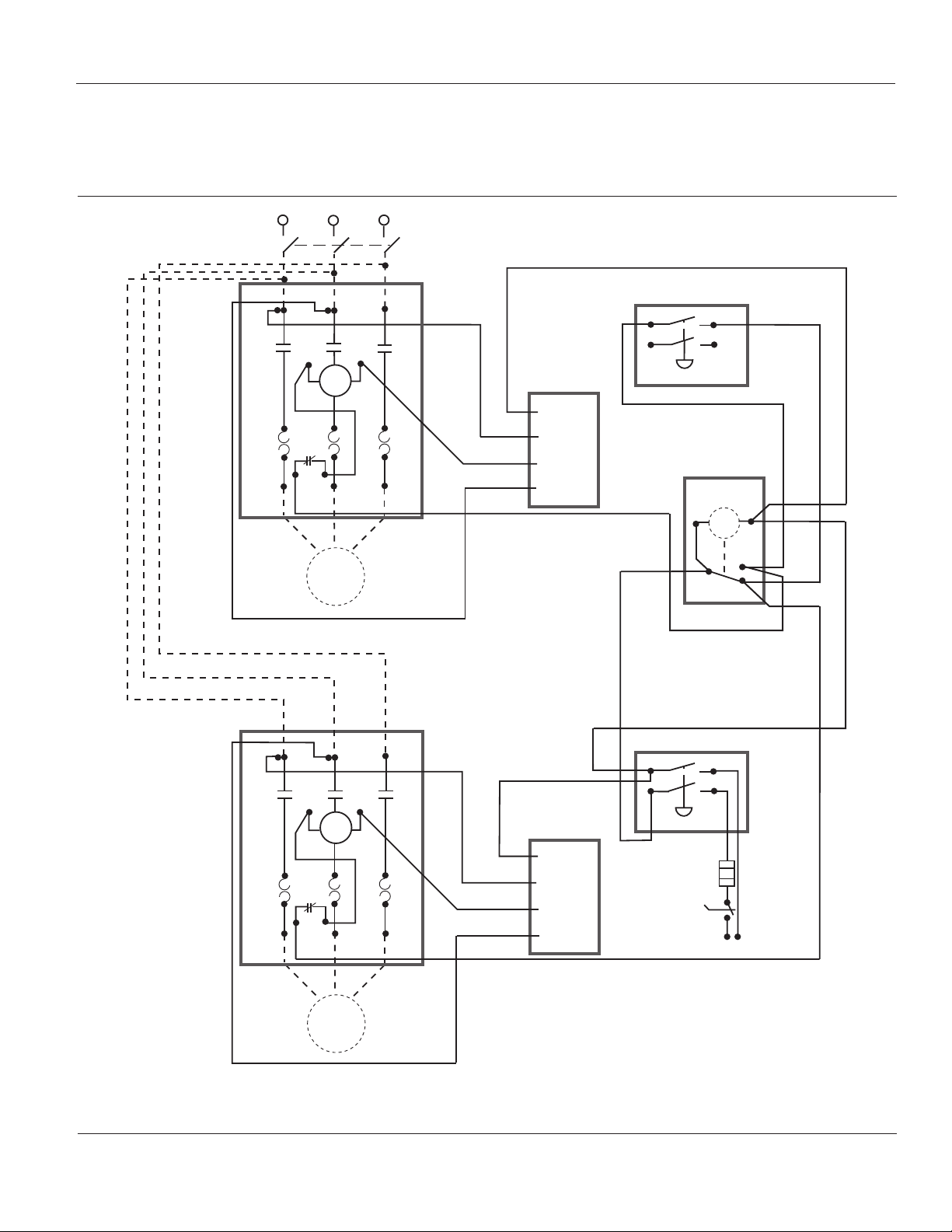

Use the diagram in Figure 4, 5 or 6 to

wire the unit to the compressor.

INITIAL TEST

After the mechanical and electrical in-

stallation is completed, the oil level

O-ring

Adapter

Figure 1 - Install O-ring

Housing

Pump

Figure 2

Sight Glass

Tighten

Set Screws

Figure 3

For parts, product & service information

visit www.chpower.com

TM

BUILT TO LAST

!

WARNING

!

WARNING

MANUAL

!

WARNING

!

WARNING

!

WARNING

Page 2

2

Operating Instructions and Parts Manual

Low Oil Guard

for 5 to 25 HP Compressors

Installation (Continued)

guard must be tested to verify proper

installation. Before refilling crankcase

with oil, briefly turn on power to the

compressor motor (2-3 seconds max.).

NOTE: Some oil film remains on the lubricated parts of the compressor.

Running the compressor dry for 2-3 seconds will not cause any damage.

If motor does not run, installation is

correct. If motor begins to run, turn

power off immediately. The installation

is wrong and the following items

should be checked:

1. Check for loose wire connections.

2. Check for wrong wiring (Refer to

Figure 4, 5 or 6).

3. Check to see if the float mechanism is

moving freely.

4. Check the compressor for a level

position.

After the monitor installation has been

tested and found correct, refill the compressor pump with compressor oil. For

complete information on compressor

pump oil, see your compressor pump

manual.

TF0628

Operation

In normal operation, the low oil-level

monitor should not have any effect on

the performance of the compressor. If

the oil level in the pump is too low, the

monitor will shut off power to the

motor, stopping the compressor pump.

Maintenance

The operation of the low oil-level monitor should be checked at every oil

change. After the oil has been drained

from the crankcase, repeat the initial

test as previously described.

Figure 4 - 208-230 Volt Single-Phase Wiring Diagram

Figure 5 - 208-230 Volt Three-Phase Wiring Diagram

Wire nut not

included

Wire nut not

included

www.chpower.com

PRESSURE

SWITCH

L1

FUSED DISCONNECT

OR BREAKER

L2

FUSED DISCONNECT

OR BREAKER

L1

L3L2

COIL

O.L.

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

SINGLE

PHASE

MOTOR

T2T1

MAGNETIC

STARTER

COIL

O.L.

T2T1 T3

THREE

PHASE

MOTOR

MAGNETIC

STARTER

PRESSURE

SWITCH

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

Page 3

Model TF0628

3

Operating Instructions and Parts Manual

Figure 6 - 208-230 Volt Single and Three-Phase Duplex Wiring Diagram

www.chpower.com

L

FUSED DISCONNECT

OR BREAKER

L3L

PRESSURE

SWITCH

MAGNETIC

STARTER

MAGNETIC

STARTER

COIL

O.L.

T2TT

MOTOR

L

L

COIL

L3

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

ALTERNATOR

ALT

PRESSURE

SWITCH

O.L.

TTT

MOTOR

* L3 LINE ONLY EXISTS ON 3-PHASE UNITS

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

110V

Page 4

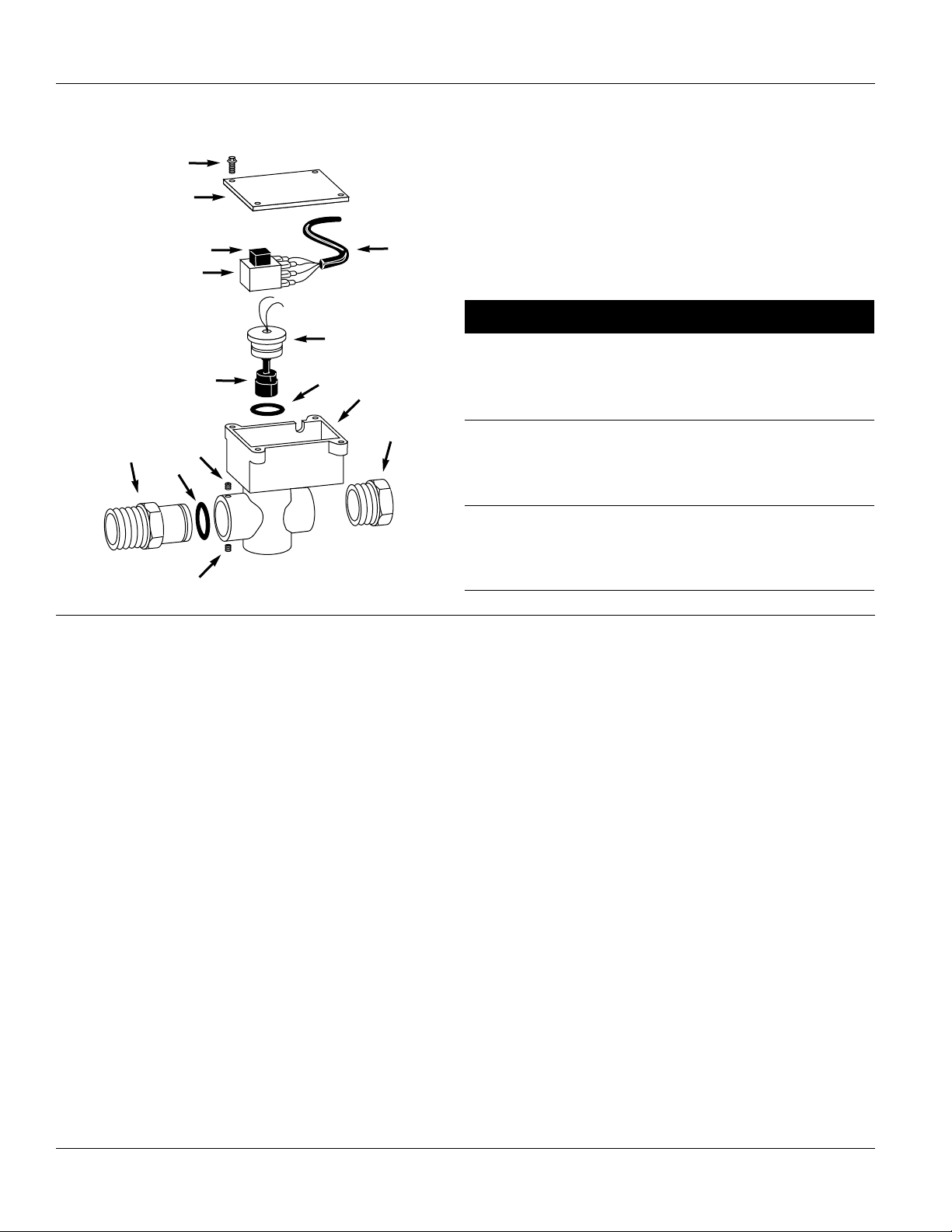

1 8-32 x 3/8” Screw ST074407AV 4

2 Housing cover TF064100AV 1

3 Electrical cord EC122200AV 4

4 Self-adhesive sponge TF063600AV 1

5 Relay CW217600AV 1

6 Level switch piston TF063800AV 1

7 Oil-level switch TF063700AV 1

8 1.049” ID O-ring ST070143AV 2

9 Housing TF062300AG 1

10 † Sight glass from compressor — 1

11 1/4-20 x 3/8” Set screw ST070558AV 2

12 Adapter TF063900AV 1

† Use compressor Model No. when ordering.

Ref.

No. Description Part Number Qty.

Operating Instructions and Parts Manual

TF0628

Figure 7 — Replacement Parts Illustration

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

The Campbell Group / Parts Department

100 Production Drive

Harrison, OH 45030

For Replacement Parts, Call 1-800-543-6400

Replacement Parts List

www.chpower.com

4

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty - One Year, Serious Duty - Two Years, Extreme Duty - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR):

Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell Hausfeld compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld air compressor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects due to material and workmanship with the exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN

THE DURATION. If this compressor is used for commercial, industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Four cylinder single-stage and two-stage compressors are not limited to a ninety (90) day warranty when used in commercial or industrial applications. Some States do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL

HAUSFELD PRODUCT. Some States do not allow the exclusion or limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s manual(s) sup-

plied with compressor.

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment.

E. Items or service that are normally required to maintain the product, i.e. lubricants, filters and gaskets, etc.

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser must comply with the warranty given by the engine

manufacturer which is supplied with the product.

G. Additional items not covered under this warranty:

1. All Compressors

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in accordance with installation and operation

guidelines or damaged by contact with tools or surroundings.

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Rusted tanks, including but not limited to rust due to improper drainage or corrosive environments.

e. Electric motors, check valves and pressure switches after the first year of ownership.

f. Drain cocks.

g. Damage due to incorrect voltage or improper wiring.

h. Other items not listed but considered general wear parts.

i. Pressure switches, air governors and safety valves modified from factory settings.

2. Lubricated Compressors

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or valve damage caused by any oil contamination or by failure to follow proper oil maintenance guidelines.

3. Belt Drive / Direct Drive / Gas Driven Compressors

a. Belts.

b. Ring wear or valve damage from inadequate filter maintenance.

c. Manually adjusted load/unload and throttle control devices.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or component which is defective, has malfunctioned and/or

failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Portable compressors or components must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service Center. Freight costs, if any, must be borne by the

purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A. Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact Campbell Hausfeld (see paragraph 2).

Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other rights which vary from State to State or country to country.

1

2

4

3

5

6

87

9

10

12

11

8

11

Page 5

Protecteur De Niveau

Bas D’Huile Pour

Compresseurs

De 5 À 25 HP

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

Déballage

Inspecter pour tout dommage susceptible

de s’être produit en cours de transport.

Vérifier la liste de pièces pour s’assurer

que toutes les pièces soient présentes.

Généralités Sur La Sécurité

Toujours

débrancher, verrouiller et étiquetter la source de

puissance avant d’installer, réparer,

déplacer ou de procéder à l’entretien

du modèle.

1. Lire le manuel d’instruc-

tions avant d’installer cet

appareil à la pompe du

compresseur.

2. Lire les instructions d’opération pour

chaque pièce détachée de l’ensemble

du compresseur avant de le mettre

en marche.

3. Respecter tous les codes locaux d’élec-

tricité et de sécurité, le National

Electric Code (NEC) et le Occupational

Safety and Health Act (OSHA).

4. Tout appareil électrique doit être mis

à la terre correctement et avec sûreté.

Dissiper toute la pression du

système avant d’essayer d’installer, réparer, déplacer ou

de procéder à l’entretien.

5. Ne pas ouvrir le couvercle de carter

supérieur pendant que l’appareil soit

en marche.

6. Ne pas tortiller le cordon d’alimenta-

tion ou le permettre de contacter

l’huile, la graisse, les produits chimiques ou les objets pointus.

Instructions d’Utilisation et Manuel de Pièces TF0628

7. Suite à l’installation, inspecter pour

s’assurer que toutes les pièces

détachées se scellent correctement.

8. L’inspecter pour s’assurer que tous raccords, boulons, etc soient serrés et sûrs.

Toute installation de fils doit

être effectuée par un électricien qualifié (certifié ou

authorisé).

Spécifications

Utiliser cet appareil avec les compresseurs Campbell Hausfeld suivants de

5 à 25 HP, 230 V monophasé et

208/230V triphasé à deux étages: modèles TF, modèles TK, modèles HD,

moèles CI et modèles PROV.

Installation

Dissiper toute pression du

système avant d’essayer d’installer, réparer, déplacer ou

procéder à l’entretien.

IMPORTANT: Le compresseur doit être

nivelé pour que le protecteur de niveau

bas d’huile fonctionne correctement. Si

nécessaire, caler les pieds de montage

pour mettre la base par dessus le réservoir à une position équilibrée.

INSTALLATION MÉCHANIQUE

1. Purger l’huile du carter.

2. Enlever le regard de niveau d’huile

du compresseur.

3. Installer le joint torique dans la rainure de l’adaptateur (Voir Figure 1).

4. Installer l’adaptateur dans l’ouverture du regard d’huile.

IN186602AV 9/00

Description

Le contrôleur de niveau d’huile Campbell Hausfeld est un accessoire pour pompes

de compresseur d’air à deux étages. Ce contrôleur mesure le niveau d’huile du

compresseur et coupe la puissance de la pompe si le niveau tombe sous un minimum. Peut être utilisé avec des pompes pour compresseurs en fonte Campbell

Hausfeld à deux étages, 208-230 volt monophasés et 208-230 volt triphasés

équipés de démarreurs magnétiques.

5. Pousser le carter du protecteur de

niveau d’huile sur l’adaptateur (Voir

Figure 2).

6. Serrer fermement les vis de pression et

remettre le regard de niveau d’huile

devant le carter (Voir Figure 3).

INSTALLATION ÉLECTRIQUE

Toujours débrancher, verrouiller et étiquetter la

source de puissance avant

d’essayer d’installer, réparer, déplacer

ou procéder à l’entretien.

Servez-vous du schéma à la Figure 4, 5

ou 6 pour l’installation de fils du modèle au compresseur

ESSAI INITIAL

Après avoir complété l’installation élec-

trique et mécanique, faire l’essai du

Joint Torique

Adaptateur

Figure 1 - Monter le joint torique

Carter

Pompe

Figure 2

Regard

Serrer la vis de

pression

Figure 3

© 2000 Campbell Hausfeld

TM

BUILT TO LAST

!

AVERTISSEMENT

!

AVERTISSEMENT

MANUAL

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 6

6Fr

Instructions D’Utilisation Et Manuel De Pièces

Protecteur De Niveau Bas D’Huile Pour

Compresseurs De 5 À 25 HP

Installation (Suite)

protecteur de niveau bas d’huile pour

vérifier que l’installation soit correcte.

Avant de remplir le carter d’huile, mettre le moteur en marche brièvement (23 secondes max.).

REMARQUE: Une mince couche d’huile

demeure sur les pièces graissées du

compresseur. Le fonctionnement du

compresseur sec pour 2-3 secondes ne

causera pas de dommage.

Si le moteur ne fonctionne pas, l’installation est incorrecte. Si le moteur commence à fonctionner, couper la puissance immédiatement. L’installation est

incorrecte. Vérifier les articles suivants:

1. Vérifier pour des connexions de fils

desserrées.

2. Vérifier pour l’installation de fils

incorrecte (Se référer à la Figure 4, 5

ou 6).

3. Vérifier que le méchanisme flottant

se déplace librement.

4. Vérifier que le compresseur soit

nivelé.

Après que vous avez vérifié l’installation

du contrôleur et que vous la jugez correcte, remplir la pompe du compresseur

à nouveau d’huile pour compresseur.

Pour plus de renseignements concernant l’huile de pompe, voir le manuel

de votre pompe pour compresseur.

TF0628

FUSED D SCONNECT

Fonctionnement

Pendant le fonctionnement normal, le

contrôleur de niveau bas d’huile ne

devrait pas avoir un effet sur le fonctionnement du compresseur. Si le niveau

d’huile de la pompe est trop bas, le contrôleur coupera la puissance du moteur,

arrêtant la pompe du compresseur.

Entretien

Vérifier le fonctionnement du contrôleur de niveau bas d’huile chaque

fois que vous changez l’huile. Après

que l’huile soit purgé du carter, répéter

l’essai initial décrit au paravant.

Figure 4 - Schéma d’installation de fils pour 208-230V

monophasé

Figure 5 - Schéma d’installation de fils

pour 208-230V triphasé

Manostat

Démarreur

Magnétique

Sectionneur à Fusible

ou Disjoncteur

Protecteur De

Niveau D’Huile

Rouge

Orange

Blanc

Noir

Moteur

Mono-

phasé

Bobine

Écrou De Fil

(Pas Compris)

Manostat

Démarreur

Magnétique

Sectionneur à Fusible

ou Disjoncteur

Protecteur De

Niveau D’Huile

Rouge

Orange

Blanc

Noir

Écrou De Fil

(Pas Compris)

Bobine

Moteur

Tri-

phasé

PRESSURE

SWITCH

L1

OR BREAKER

COIL

L2

FUSED DISCONNECT

OR BREAKER

L1

L3L2

O.L.

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

SINGLE

PHASE

MOTOR

T2T1

MAGNETIC

STARTER

COIL

O.L.

MAGNETIC

STARTER

T2T1 T3

THREE

PHASE

MOTOR

PRESSURE

SWITCH

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

Page 7

Modèle TF0628

7Fr

Instructions D’Utilisation Et Manuel De Pièces

Figure 6 - Schéma d’installation de fils pour 208-230V monophasé et triphasé, duplex

LA LIGNE L3 EXISTE SEULEMENT SUR LES

MODÈLES TRIPHASÉS

Manostat

Démarreur Magnétique

Sectionneur à Fusible

ou Disjoncteur

Protecteur

De Niveau

D’Huile

Rouge

Orange

Blanc

Noir

Alternateur

Manostat

Démarreur

Magnétique

Protecteur

De Niveau

D’Huile

Rouge

Orange

Blanc

Noir

Bobine

Moteur

Bobine

Moteur

L

MAGNETIC

STARTER

COIL

O.L.

T2TT

FUSED DISCONNECT

OR BREAKER

L3L

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

ALTERNATOR

PRESSURE

SWITCH

MAGNETIC

STARTER

MOTOR

L

O.L.

L

COIL

TTT

L3

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

ALT

110V

PRESSURE

SWITCH

MOTOR

* L3 LINE ONLY EXISTS ON 3-PHASE UNITS

Page 8

1 Vis 8-32 x 3/8 po ST074407AV 4

2 Couvercle de carter TF064100AV 1

3 Cordon d’alimentation EC122200AV 4

4 Éponge auto-collant TF063600AV 1

5 Relais CW217600AV 1

6 Piston d’interrupteur

de niveau TF063800AV 1

7 Interrupteur de niveau d’huile TF063700AV 1

8 Joint torique 1.049 po DI ST070143AV 2

9 Carter TF062300AG 1

10 † Regard du compresseur — 1

11 Vis de pression 1/4-20 x 3/8po ST070558AV 2

12 Adaptateur TF063900AV 1

† Utiliser le numéro de modèle du compresseur lorsque

vous commandez

No. de

Réf. Description Numéro de pièce Qté.

8

Instructions D’Utilisation Et Manuel De Pièces

TF0628

Figure 7 — Schéma de pièces de rechange

S’il vous plaît fournir l’information suivante:

-Numéro de modèle

-Numéro de série (si applicable)

-Numéro et description de la pièce

Correspondance:

The Campbell Group / Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

Pour Pièces de Rechange, appeler 1-800-543-6400

Liste de pièces de rechange

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit: Produits À Service Standard (Standard Duty) - Un An, Produits À Service Sérieux (Serious Duty) - Deux

Ans, Produits À Service Extrême (Extreme Duty) - Trois Ans.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Téléphone: (800) 543-6400

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: N’importe quel compresseur d’air Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables avec les exceptions indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE

TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce compresseur d’air est utilisé pour une fonction commerciale ou pour la location, la durée de la garantie sera quatrevingt-dix (90) jours à compté de la date d’achat. Les produits à quatre cylindres d’un ou de deux étages ne sont pas limités à une garantie de quatre-vingt-dix (90) jours

si utilisés dans les applications commerciaux ou industrielles. Quelques Provinces (États) n’autorisent pas de limitations de durée pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL

HAUSFELD. Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou l’exclusion précédente peut ne

donc pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas les instructions données dans le(s) manuel(s)

accompagnant le produit.

D. Service avant livraison; le montage, l’huile ou la graisse et les réglages par exemples.

E. Articles ou services qui sont exigés pour l’entretien normal du produit; graisses, filtres et joints d’étanchéités par exemples.

F. Les moteurs à essence et les pièces détachées sont expressément exclus de cette garantie limitée. L’acheteur doit observer la garantie du fabricant de moteur qui est

fournie avec le produit.

G. Articles supplémentaires qui ne sont pas couverts sous cette garantie:

1. Tous les Compresseurs

a. Toutes pièces détachées endommagées pendant l’expédition, n’importe quelle panne causée par un montage ou fonctionnement du modèle sous des conditions

qui ne conforment pas aux directives de montage et de fonctionnement ou dommage causée par le contact avec les outils ou les alentours.

b. La panne de la pompe ou de la soupape causée par la pluie, l’humidité excessive, un environnement corrosif ou autres polluants.

c. Les défauts de forme qui n’ont pas d’effet sur le fonctionnement du compresseur.

d. Les réservoirs rouillés, y compris mais pas limités à la rouille causé par le vidange incorrect ou par un environnement corrosif.

e. Les moteurs électriques, les clapets, et les manostats suivant la première année de possession.

f. Robinets de vidange.

g. Dommage dû à la tension ou installation de fils incorrecte.

h. Autres articles pas indiqués mais considérés pièces à fatigue générales.

i. Manostats, régulateurs d’air et soupapes de sûreté qui ont étés modifiés d’après les réglages de l’usine.

2. Compresseurs Graissés

a. Usure de la pompe ou dommage aux soupapes causé par l’utilisation d’huile non-spécifiée.

b. Usure de la pompe ou dommage aux soupapes causé par toute contamination d’huile ou par le manque de suivre les directives d’entretien d’huile.

3. Commande par Courroie / Commande Directe / Compresseurs à Essence

a. Courroies

b. Usure de bagues causée par l’entretien de filtre insuffisant

c. Appareils manuels de chargement/déchargement et appareils de commande d’obturateur.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du Garant, d’un compresseur ou d’une pièce détachée qui se sont

révélés défectueux ou qui ne se sont pas conformés pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. La livraison ou expédition des compresseurs portatifs ou des pièces détachées au Centre De Service Autorisé Campbell Hausfeld. Taux de frais, si applicables, sont la

responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE:

A. La réparation ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la disponibilité des pièces de

rechange.

B. Si l’acheteur n’est pas satisfait des services du Centre De Service Autorisé, l’acheteur devrait contacter Campbell Hausfeld (se référer au paragraph 2).

Cette Garantie Limitée s’applique aux É.-U. et au Canada et vous confère des droits judiciaires précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province,

d’un État ou d’un Pays à l’autre.

1

2

4

3

5

6

87

9

10

12

11

8

11

Page 9

Protector de Nivel de

Aceite para

Compresores

de 5 a 25 HP

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

Para desempacar

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Chequée la

lista de piezas para verificar que tiene

todo lo necesario.

Informaciones Generales de

Seguridad

Desco-

necte el

cordón eléctrico y amárrelo antes de

tratar de hacer instalaciones eléctricas,

darle servicio o cualquier tipo de mantenimiento.

1. Lea este manual antes de

instalar el instrumento en

el cabezal.

2. Lea los manuales de instrucciones

de cada componente del compresor

antes de comenzar a utilizarlo.

3. Siga todos los códigos de seguridad

laboral establecidos en su país, por

ejemplo, los de la OSHA en EE.UU.

4. Los artefactos eléctricos siempre se

deben conectar a tierra adecuadamente.

Libere la presión del sistema

antes de tratar de instalar,

darle servicio, moverlo de lugar o darle

cualquier tipo de mantenimiento.

5. No habra la tapa superior de la

cubierta mientras el monitor esté

funcionando.

6. No enrolle el cordón ni permita que

tenga contacto con aceite, grasa,

químicos u objetos afilados.

Manual de Instrucciones y Lista de Repuestos TF0628

7. Después de instalarlo, inspeccione

todos los componentes para cerciorarse de que estén bien sellados.

8. Inspeccione todas las conexiones,

pernos, para cerciorarse de que estén

bien apretados.

Todos los trabajos de alambrado los debe hacer un electricista calificado (con licencia o certificado).

Especificaciones

Este aparato puede usarse con los

siguientes compresores Campbell

Hausfeld desde 5 hasta 25 HP, 230V

monofásicos y 208/230V trifásicos, de

dos etapas: modelos TF, TK , HD , CI y

PROV.

Instalación

Libere la presión del sistema

antes de tratar de instalar,

darle servicio, moverlo de lugar o darle

cualquier tipo de mante-nimiento.

IMPORTANTE: El compresor debe estar

nivelado para permitir que el protector

del nivel de aceite opere adecuadamente. Si es necesario, acuñe las patas

del compresor para nivelar la base de la

parte superior del tanque.

INSTALACIONES MECANICAS

1. Drene el aceite de la caja del

cigüeñal.

2. Quítele el medidor visual de vidrio

al compresor.

IN186602AV 9/00

Descripción

El monitor de bajo nivel de aceite de Campbell Hausfeld es un accesorio para cabezales de compresores de aire de 2 etapas. Este monitor mide el nivel de aceite del compresor y apaga el cabezal si éste es inferior a un mínimo establecido. Úselo con

cabezales Campbell Hausfeld monofásicos de 208-230 voltios y trifásicos de 208-230

voltios, de dos etapas y hierro colado que tengan un motor de arranque magnético.

3. Instale el anillo en o en la ranura del

adaptador (Vea la Figura 1).

4. Conecte el adaptador al medidor

visual de vidrio.

5. Conecte la cubierta del monitor de

nivel de aceite al adaptador (Vea la

Figura 2).

6. Apriete bien los tornillos de la

cubierta y después reinstale el medidor visual de vidrio al frente de la

cubierta (Vea la Figura 3).

INTALACIONES ELECTRICAS

Desconecte el cordón eléctrico y amárrelo antes de tratar

de hacer instalaciones eléctricas, darle servicio o cualquier tipo de

mantenimiento.

Use los diagramas de las Figuras 4, 5 ó 6

para conectar la unidad al compresor.

Anillo

en O

Adaptador

Figura 1 - Instalación del anillo en O

Cubierta

Cabezal

Figura 2

Medidor visual

Apriete los

tornillos

Figura 3

© 2000 Campbell Hausfeld

TM

BUILT TO LAST

!

ADVERTENCIA

!

ADVERTENCIA

MANUAL

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

Page 10

10 Sp

Manual de Instrucciones y Lista de Repuestos

Protector de Nivel de Aceite para

Compresores de 5 a 25 HP

Instalación (Continuación)

PRUEBA INICIAL

Después de hacer las instalaciones mecáni-

cas y eléctricas, debe probar el monitor de

nivel de aceite para cerciorarse de que

esté instalado adecuadamente. Antes de

llenar de aceite la caja del cigüeñal,

encienda brevemente el motor del compresor (2-3 segundos máx.).

NOTA: Una capa de residuo de aceite

quedará en las piezas lubricadas del

compresor. Si lo deja funcionar sin

aceite por 2-3 segundos no le ocasionará daños.

Si el motor no funciona, lo instaló correctamente. Si el motor comienza a

funcionar, apáguelo inmediatamente.

No lo instaló correctamente y debe

chequear lo siguiente:

1. Chequée si alguna de las conexiones

eléctricas están flojas.

2. Chequée si el alambrado es el adecuado (Vea las Figuras 4, 5 ó 6).

3. Chequée si el mecanismo del flotante

se mueve libremente.

4. Chequée si el compresor está nivelado.

Después de instalar el monitor y probarlo para verificar que esté bien instalado,

llene el cabezal con aceite para compresores de aire. Para mayor información al

respecto, vea el manual del cabezal.

TF0628

Funcionamiento

Bajo funcionamiento normal, el monitor

de nivel de aceite no debe tener ningún

efecto en el rendimiento del compresor.

Si el nivel de aceite del cabezal es muy

bajo, el monitor apagará el motor para

que el cabezal no funcione.

Mantenimiento

Debe chequear el funcionamiento del

monitor de bajo nivel de aceite cada vez

que cambie el aceite. Después de drenar

el aceite xde la caja del cigüeñal, repita

la prueba inicial descrita anteriormente.

Figura 4 - Diagrama del Alambrado para modelos

monofásicos de 208-230 Voltios

Figura 5 - Diagrama del Alambrado para

modelos trifásicos de 208-230 Voltios

Presostato

Caja de Fusibles o

Cortacircuitos

Motor de

Arranque

Magnético

Protector

del Nivel de

Aceite

Rojo

Anararjado

Blanco

Negro

Motor

Mono-

fásico

Bo-

bina

Presostato

Caja de Fusibles o

Cortacircuitos

Motor de

Arranque

Magnético

Protector

del Nivel de

Aceite

Rojo

Anararjado

Blanco

Negro

Bo-

bina

Motor

Tri-

fásico

La Tuerca Para Los

Alambres (No Está

Incluida)

La Tuerca Para Los

Alambres (No Está

Incluida)

PRESSURE

SWITCH

FUSED DISCONNECT

OR BREAKER

FUSED DISCONNECT

OR BREAKER

L1

COIL

O.L.

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

SINGLE

PHASE

MOTOR

L2

T2T1

MAGNETIC

STARTER

L1

COIL

O.L.

T2T1 T3

THREE

PHASE

MOTOR

MAGNETIC

STARTER

L3L2

PRESSURE

SWITCH

OIL

LEVEL

GUARD

RED

ORANGE

WHITE

BLACK

Page 11

Modelo TF0628

11 Sp

Manual de Instrucciones y Lista de Repuestos

Figura 6 - Diagrama del Alambrado para modelos Duplex, monofásicos y trifásicos de 208-230 Voltios

Presostato

La Línea L# Solo Existe en las Unidades

Trifásicas

Motor de

Arranque

Magnético

Protector

del Nivel

de Aceite

Preso-

stato

Caja de Fusibles o

Cortacircuitos

Motor de

Arranque

Magnético

Protector

del Nivel

de Aceite

Rojo

Anararjado

Blanco

Negro

Bo-

bina

Bo-

bina

Alternador

Rojo

Anararjado

Blanco

Negro

L

MAGNETIC

STARTER

COIL

O.L.

T2TT

FUSED DISCONNECT

OR BREAKER

L3L

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

ALTERNATOR

PRESSURE

SWITCH

MAGNETIC

STARTER

MOTOR

L

O.L.

L

COIL

TTT

L3

RED

ORANGE

WHITE

BLACK

OIL

LEVEL

GUARD

ALT

110V

PRESSURE

SWITCH

MOTOR

* L3 LINE ONLY EXISTS ON 3-PHASE UNITS

Page 12

1 Tornillo de 8-32 x 3/8” ST074407AV 4

2 Tapa de la cubierta TF064100AV 1

3 Cordón eléctrico EC122200AV 4

4 Esponja auto-adhesiva TF063600AV 1

5 Relai CW217600AV 1

6 Pistón del interruptor TF063800AV 1

7 Interruptor del nivel de aceite TF063700AV 1

8 Anillo en O de 1.049” D.I. ST070143AV 2

9 Cubierta TF062300AG 1

10 † Medidor visual del compresor — 1

11 Tornillo de 1/4-20 x 3/8” ST070558AV 2

12 Adaptador TF063900AV 1

(†) Use el No. del Modelo del compresor para ordenarlo.

No. de

Ref. Descripción No. del repuesto Ctd.

12

Manual de Instrucciones y Lista de Repuestos

TF0628

Figura 7 - Ilustración de los repuestos

Sírvase suministrarnos la siguiente información:

-Número del modelo

-Número de Serie (de haberlo)

-Descripción y número del repuesto según la lista de repuestos

Puede escribirnos a:

The Campbell Group / Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

Lista de Repuestos

Para Ordenar Repuestos, Sírvase Llamer al Distribuidor Más Cercano

a Su Domicilio

Garantía Limitada

1. DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a continuación: Productos Estándard (Standard Duty) - Un año,

Productos Resistentes (Serious Duty) -Dos años, Productos Robustos (Extreme Duty) - Tres años.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100 Production Drive, Harrison, Ohio 45030 Teléfono: (800) 543-6400

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor) del producto Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Cualquier compresor de aire Campbell Hausfeld.

5. COBERTURA DE LA GARANTIA: Los defectos substanciales de material y fabricación que ocurran dentro del período de validez de la garantía.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES PARTICULARES, ESTAN LIMITADOS A LO ESPECIFICADO EN EL PAR-

RAFO DE DURACION. Si el compresor de aire es empleado para uso comercial, industrial o para renta, la garantía será aplicable por noventa (90) días a partir de

la fecha de compra. La garantía de los compresores de cuatro cilindros de una y dos etapas, no está limitada a noventa (90) días si éstos se utilizan para trabajos

comerciales o industriales. En algunos estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos esta limitación no

es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE UN DEFECTO, FALLA O MALFUNCIONAMIENTO DEL PRODUC-

TO CAMPBELL HAUSFELD. En algunos estados no se permite la exclusión o limitación de daños incidentales o consecuentes, por lo tanto, en tales casos esta limitación o exclusión no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones de funcionamiento y uso indicadas en el (los) manual(es)

que se adjunta(n) al compresor.

D. Los servicios requeridos antes de la entrega tales como: ensamblaje, aceite o lubricantes y ajustes.

E. Artículos o servicios normalmente requeridos para el mantenimiento del producto, tales como:lubricantes, filtros, empaques, etc.

F. Los motores de gasolina están específicamante excluidos de la cobertura de esta garantía limitada. El comprador debe seguir las clausulas de la garantía otorga-

da por el fabricante del motor de gasolina que se suministra con el producto.

G. Artículos adicionales no cubiertos bajo esta garantía:

1. Todos los Compresores

a. Cualquier componente dañado durante el envío o cualquier daño ocasionado por haber instalado u operado la unidad bajo condiciones contrarias a lo

indicado en las instrucciones para instalar u operar la unidad o daños ocasionados por el contacto con herramientas o los alrrededores.

b. Daños del cabezal o las válvulas ocasionados por la lluvia, humedad excesiva, agentes corrosivos u otros contaminantes.

c. Daños de apariencia que no afecten el funcionamiento del compresor.

d. Tanques oxidados, incluyendo pero no limitado al óxido debido al drenaje inadecuado u agentes corrosivos en el ambiente.

e. Motores eléctricos, válvulas de chequeo y presostatos después del primer año a partir de la fecha de compra.

f. Llaves de drenaje

g. Daños debidos al alambrado incorrecto o conexión a cicuitos con voltaje inadecuados para la unidad.

h. Otros artículos no enumerados pero considerados de desgaste general.

i. Presostatos, controles de flujo de aire y válvulas de seguridad cuyos parametros fijados de fábrica se modifiquen.

2. Compresores lubricados

a. Daños del cabezal o las válvulas debidos al uso de aceites no especificados.

b. Daños del cabezal o las válvulas debidos a cualquier contaminación del aceite o por no haber seguido las instrucciones de lubricación.

3. Compresores con bandas/ de accionamiento directo/ motores de gasolina

a. Bandas

b. Daños de los anillos debido al mantenimiento inadecuado del filtro.

c. Ajustes manuales de los instrumentos de carga/descarga y válvula de estrangulación.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Reparar o reemplazar, como lo decida el Garante, el compresor o componentes que estén defectuosos,

se hayan dañado o hayan dejado de funcionar adecuadamente, durante el período de validez de la garantía

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B.Entregar o enviar los compresores de aire portátiles o componentes lal Centro de Servicio autorizado Campbell Hausfeld más cercano. Los gastos de flete, de

haberlos, deben ser pagados por el comprador.

C.Tener cuidado al utilizar el producto, tal como se indica(n) en el (los) manual(es) del propietario.

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO BAJO ESTA GARANTIA:

A. La reparación o reemplazo dependerá del flujo normal de trabajo del centro de servicio y de la disponibilidad de repuestos.

B. Si el comprador no recibe resultados satisfactorios en el Centro de Servicio a Clientes de Campbell Hausfeld. (Vea el Párrafo 2).

Esta Garantía Limitada sólo es válida en los Estados Unidos de América y Canadá y le otorga derechos legales específicos. Usted también puede tener otros derechos que

varían de un Estado a otro. o de un país a otro.

1

2

4

5

12

11

8

11

3

6

87

9

10

Loading...

Loading...