Page 1

AUTOMAZIONE PER CHIUSURA INDUSTRIALE

CONTROL BOARD FOR AUTOMATIONS 24 V

SERIES Z

INSTALLATION MANUAL

ZL80 - ZL80C

Page 2

“IMPORTANT SAFETY INSTRUCTIONS WHEN INSTALLING”

WARNING: IMPROPER INSTALLATION MAY LEAD TO SERIOUS DAMAGE, FOLLOW ALL INSTRUCTIONS WHEN INSTALLING”

“THIS MANUAL IS EXCLUSIVELY INTENDED FOR PROFESSIONAL INSTALLERS OR OTHER COMPETENT PERSONS”

1 Legend of symbols

This symbols stands for parts that must be read very carefully.

This symbols stands for parts that have to do with safety.

English

This symbols stands for what needs to be notified to the client.

2 Intended use and limitations of use

2.1 Intended use

The ZL80_ZL80C control boards(The ZL80C: featuring incorporated buttons and safety stop) have been specifically designed for C-BXE24 automation, to drive sectional, sliding and folding doors.

2.2 limitations of use

- Respect cable distances and diameters as shown in the table in chapter 5.4

- Set up the control board in areas that are free of accidental impacts.

- For theZL80C version positions the control board at a height of 1.5 m from the ground.

3 Reference standards

This product complies with the following standards: EN 12978, UNI EN 954-1, CEI EN 60335-1, UNI EN 12453.

4 Description

4.1 230V a.c. control board

24V d.c. powered control board for gear motors; 50÷60 Hz frequency.

Designed and manufactured entirely by CAME Cancelli Automatici S.p.A. Container fi tted with air recycling intake.

Guaranteed 24 months unless tampered with.

4.2 Technical specifications

Control board

Power: 230V - 50÷60 Hz

Maximum output: 360 W

Draw at rest: 55 mA

Maximum output of 24V accessories: 36 W

Protection level: IP54

Insulation class: II

Material: ABS

Operatine temperature

2

#

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

#

Page 3

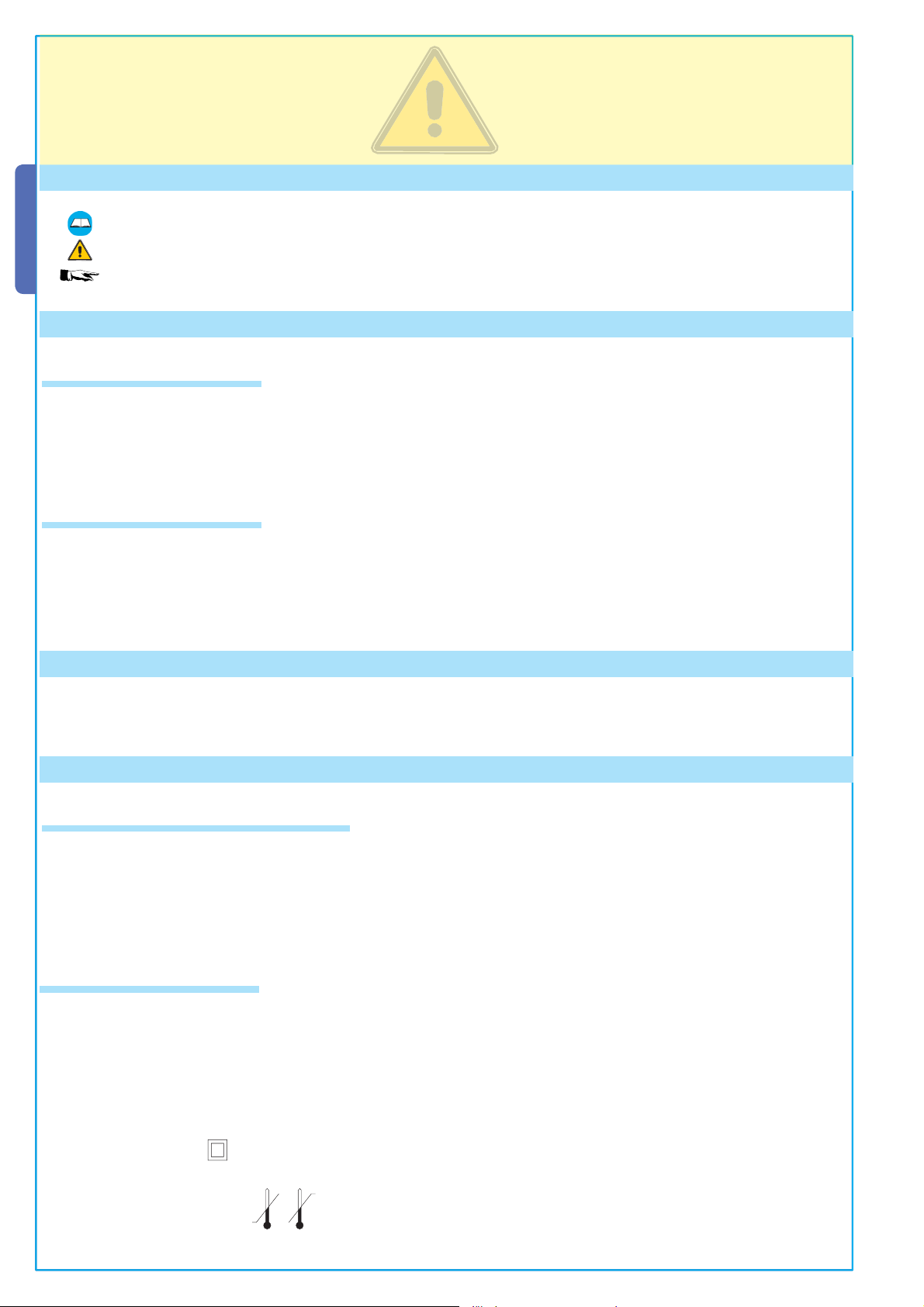

4.3 List of parts

ZL 80

CONTROL BOARD

ESC

ENTER

RSE

PROGRAMMING FUNCTION

R700

AF

LINE

FUSE

1,6 A

S1 GND

LN

+-

MN

L1T L2T 0 24

WARNING!

A

B

C

D

TERMICAL

PROTECTION

ACCESSORIES

FUSE 1,6 A

CONTROL BOARD

FUSE 1A

BATTERY

MOTOR

POT.ENC.

-

D

I

SPLA

Y

+

CON

TRAS

T.

MOTOR

FUSE 10A

#!-%

CONTROL BOARD

ZL 80

1

ZL80-ZL80C electronic board

PROGRAMMING FUNCTION

Emglish

12

CONTROL BOARD

FUSE 1A

MOTOR

FUSE 10A

ACCESSORIES

FUSE 1,6 A

432

TERMICAL

PROTECTION

9

13

ESC

><

ENTER

10

14

5

WARNING!

LINE

FUSE

1,6 A

%

P

#8 #9

19

6

8

RSE

%

'.$

!"

43

R700

AF

11

#!-%

1-Display

2- 1° Control unit fuses

3- 10 A motor fuses

1718

4- 1.6 A Accessories fuses

5- 1.6 A Line fuses

6-R700 board plug-in for decoding control devices (transponder slide-through cards)

7- AF board plug-in for radio frequency

8- RSE board plug-in for decoding PC interchange signal (for multiple control of to 16 units max.)

9-Led indicator: power

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

10-Led indicator: warns of open safety contacts error

11-Terminal board

12- Terminal board for connecting transformer

13-Programming buttons14-Trimmer to set display contrast

15- STOP button16- CLOSING button

17- OPENING button

18-safety stop

19- memory roll board connector ( backup device for system and user data)

ZTC5 pushbutton panel

15

16

3

Page 4

240

320

145

#!-%

240

320

165

#!-%

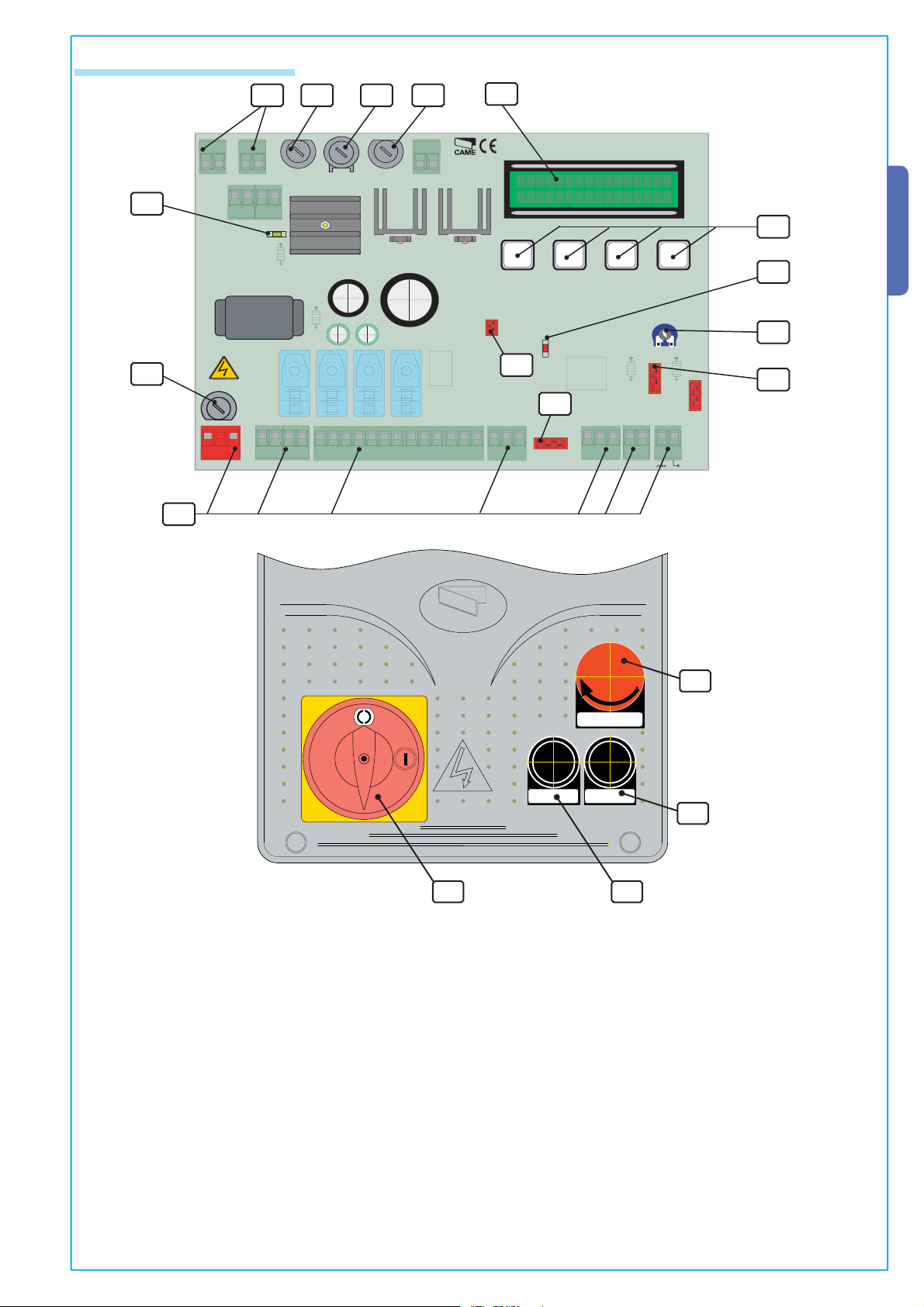

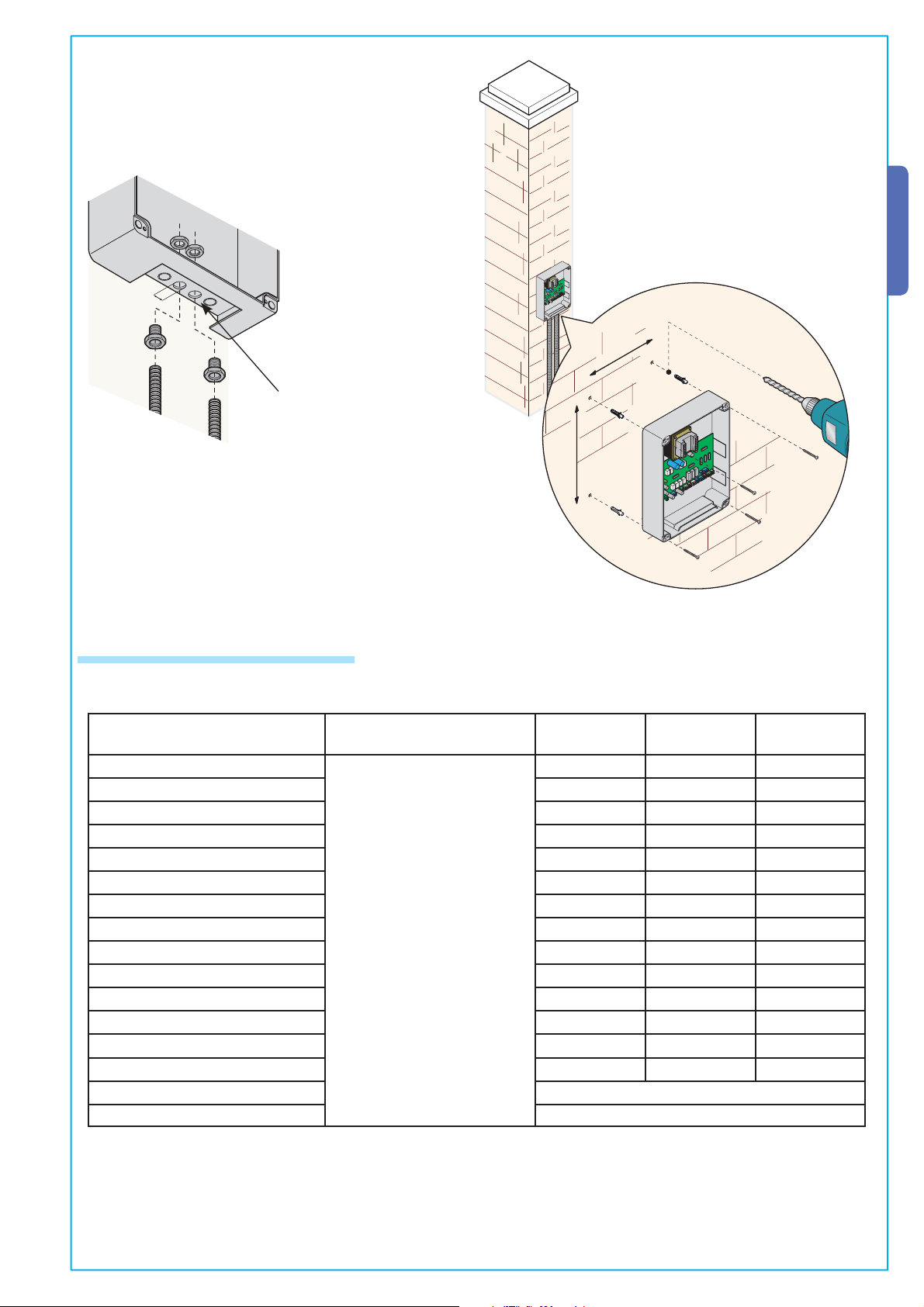

5 Installation

5 .1 Preliminary checks

Prior to installing the automation device do the following:

• Make sure that the control board is mounted in a sturdy manner and that it is protected from possible impacts. It must be

mounted using screws, anchor-plugs, etc. that are suitable for the type of surface;

• See to having a proper omnipolar disconnection device, with more than 3mm distances between contacts, and independent

English

(sectioned off) power;

• Make sure that any connections inside of the container (done for continuance of the protective circuit) be provided with

additional insulation as compared the other inside conducting parts;

• Install proper tubes and conduits to pull cables and wiring through making sure that these are protected from possible

mechanical damage.

5.2 Tools and materials

Make sure to have all the tools and materials required to for installation under maximum safety conditions and in compliance

with current standards. The figure shows some of the equipment needed by the installer.

5.3 Dimensions, centre spacing and securing holes.

It is best to use 6 mm max diameter rounded-top cross-head screws .

Dimensions of the ZL80 container

320

#!-%

240

145

Dimensions of the ZL80C container

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

320

#!-%

240

!02%

#()5$%

165

4

Page 5

The pre-punched holes have

a 20/21 mm diameter

Emglish

215

295

5.4 Spessori minimi e tipo cavi

Connections Cable type

Power supply line, 230/400V 3F

Power supply line, 230V 2F 3G 1,5mm² 3G 2,5mm² 3G 4mm²

Motors, 230/400V 2F/3F 4G 1mm² 4G 1,5mm² 4G 2,5mm²

Motor, 24V 2 x 1mm² 2 x 1,5mm² 2 x 2,5mm²

Flashing lamp 230V 2 x 0,5mm² 2 x 1mm² 2 x 1,5mm²

Flashing lamp 24V 2 x 0,5mm² 2 x 1mm² 2 x 1,5mm²

Cycle/courtesy lights 230V 3G 0,5mm² 3G 1mm² 3G 1,5mm²

Power supply accessories 24V 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

Warning light 24V 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

Output 24V “in motion” 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

Safety contacts 2 x 0,5mm² 2 x 0,5mm² 2 x 0,5mm²

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

N.O./N.C. control buttons 2 x 0,5mm² 2 x 0,5mm² 2 x 0,5mm²

End stop 3 x 0,5mm² 3 x 1mm² 3 x 1,5mm²

2nd motor control 1 x 0,5mm² 1 x 0,5mm² 1 x 1mm²

Antenna connection (max 50m) RG58

Encoder connection (max 30m) Insulated cable 2402C 22AWG

FROR CEI 20-22

CEI EN 50267-2-1

Cable length

1<10 M

4G 1,5mm² 4G 2,5mm² 4G 4mm²

Cable length

10<20 M

Cable length

20<30 M

PLEASE NOTE: If the cable length differs from that specifi ed in the table, then you must determine the cable diameter on the

basis of the actual power draw from the connected devices and depending on the standards specifi ed in CEI EN 60204-1.

For connections that require several, sequential loads on the same line, the sizes provided on the table must be reconsidered by

taking into account the actual distances and power draw. When connecting products that are not included in this manual then

follow the indications specifi ed in the documentation included with said products.

5

Page 6

LN

+-

MN

+

+ E

MN

MOTOR

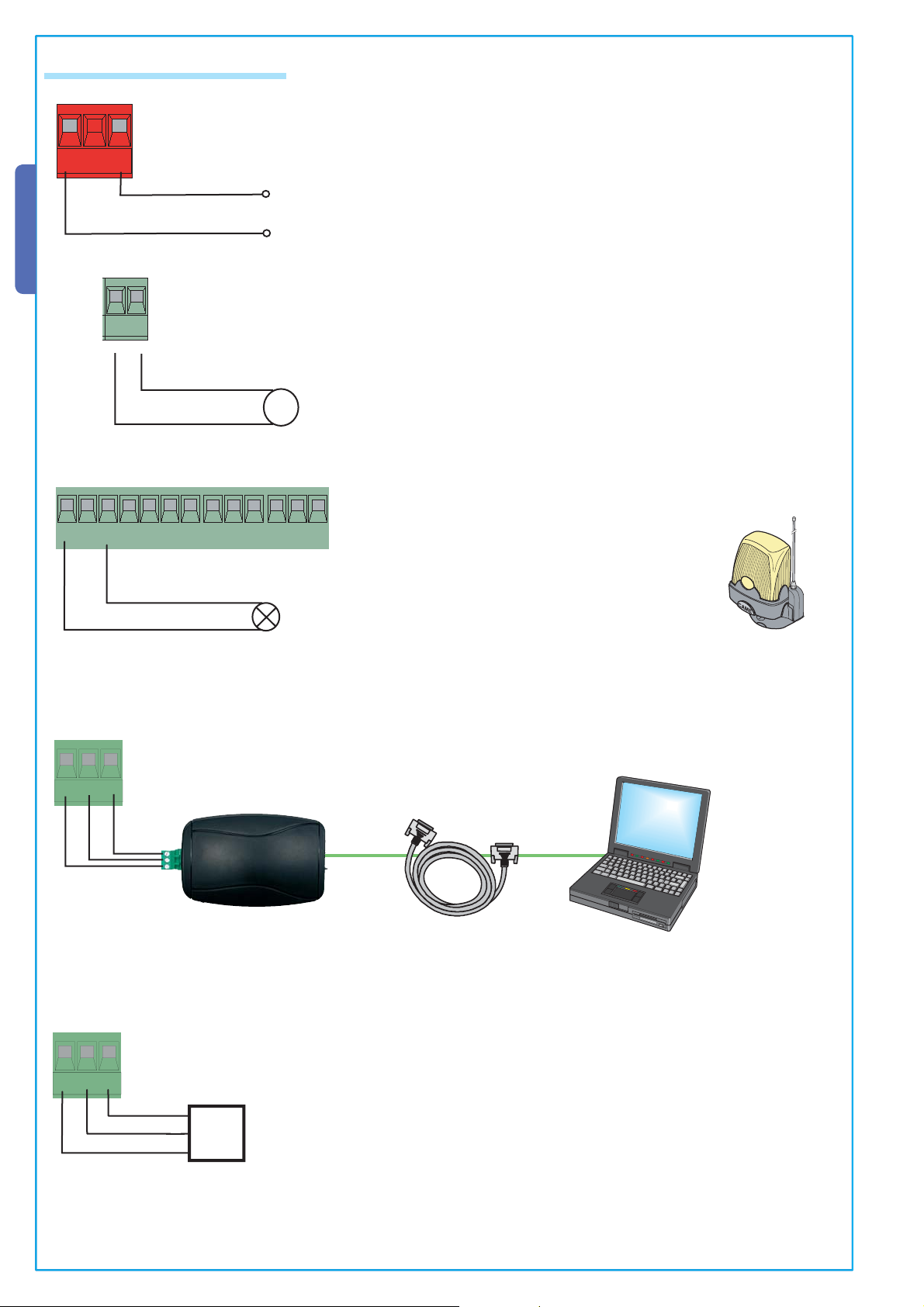

5.5 Electrical connections

English

230 V a.c. 50-60 Hz Power supply

24V D.C. Motor

M

AB

%

GND

P

#8 #9

43

24V a.c 25W Max. output terminal for flashing light (when moving)

Serial communication for PC connections: use mod. RS235 bipolar shielded cable with software (optional)

PC 40 o PC30

RS232 cable

Personal

Computer

-

+E

6

-

+E

E

E

-

-

+

Encode connection (to connect the automated device to the control board: use a type

2402C 22AWG shielded cable)

-

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

Page 7

5.5 Electrical connections

><

R700R700

AF

S1 GND

%

P

#8 #9

43

%

%

%

P

#8 #9

P

#8 #9

P

#8 #9

(1-2) N.C. STOP button

43

(2-3P) N.O. partial opening button

43

(2-3) N.O. complete opening button.

43

(2-4) N.O. closing button

Emglish

%

%

%

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

Antenna connection

TS

P

#8 #9

P

#8 #9

P

#8 #9

43

(2-7) N.O.open-close contact (in steps) or open-stop-close-stop (sequential)

43

(10-5) 24V 3W Max. opening indicator light

43

10-11 24V A.C accessories power supply output terminal, max 36 W

AF

7

Page 8

><

R700

AF

S1 GND

><

R700

AF

S1 GND

5.5 Electrical connections

English

Rx

10 2 TX C NC

10 11123p

Rx

10 2 TX C NC

DIR

3

457CX CY

DIR

Tx

(2-CX) DOC and DIR photocells connection

DOC

Rx

-

+

N.O.

C.

N.C.

Tx 2

TS

Tx

(2-CY) DOC and DIR photocells connection

10 11123p

3

457CX CY

Tx

+

-

TS

DOC

Tx

+

-

Tx 2

Rx

-

+

N.O.

C.

N.C.

10 11123p

Rx

10 2 TX C NC

10 11123p

3

457CX CY

DIR

3

457CX CY

TS

Tx

TEST DOC and DIR photocells working

10 11123p

3

457CX CY

TS

DOC

Rx

-

+

N.O.

C.

N.C.

Tx 2

TS

10 11123p

3

457CX CY

Tx

+

-

TS

(S1-GND) TSP00 (transponder) LT001 (slide-through card) sensor connection

Please note: for the board to recognise the sensors, the apposite (R700) decoder board needs to be connected.

TS

R700

LT001

R700

AF

CANCELLIAUTOMATICI

R700

CANCELLIAUTOMATICI

R700

ACCESSCONTROL

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

8

Red

Blak

TSP00

C

AME

TS

AF

Blak

Red

Page 9

ENTER

ENTER

ESC ENTER

><

PROGRAMMING FUNCTION

ENTER

ENTER

6 Programming

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

ESC

ENTER

>

<

PROGRAMMING FUNCTION

ENTER

ESC ENTER

><

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

PROGRAMMING FUNCTION

6.1 Description of display commands

PROGRAMMING FUNCTION

ENTER

the ENTER key is used to:

- access the menus

- confirm and memorise the set value

Emglish

WWW.CAME.IT

<>

ESC

LANGUAGE

CBXE 24

<

6.2 Browsing the menus

To enter a menu, keep the

ENTER key pressed for at least one

ENTER

second.

><

>

To select a menu

item, move with the

smaller than/greater

than keys…

ENTER

The ESC key is used to:

- exit the menus

ESC

<

...........

<>

<>

- cancel changes

the <> key are used to:

- move from one menu item to another

- increase or decrease any value

><

the <…..> symbols on the display indicate:

>

- the currently selected item

LANGUAGE

LANGUAGE

<>

TIMING

ENTER

><

EXAMPLE

Auto Clo.Time

<>

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

20 sec

Auto Clo. Time

<>

45 sec

Also for the “sub menus” move with the

smaller than/greater

than keys…

When the smaller than/

greater than <> symbols are on the TIME

function, its values may

be changed.

ENTER

…then press ENTER to

confirm…

…then press ENTER

Operation Time

<>

12 sec

Auto Clo.Time

<>

20 sec

To increase or reduce

the value use the smaller

than/greater than keys

><

…to exit the menu, wait 30

seconds, or press ESC, until

the initial screen reappears

ENTER

…then press ENTER

ESC

Please note: when the menu is active the system cannot be used.

9

Page 10

>

>

>

><

><

< >

< >

>

>

>

>

>

>

< >

< >

>

>

>

>

>

>

>

< >

< >

< >

< >

< >

>

>

>

< >

< >

>

>

><

><

>

>

>

< >

< >

< >

>

>

>

>

>

< >

< >

< >

< >

< >

< >

< >

< >

< >

< >

< >

< >

>

>

>

>

>

>

>

>

< >

< >

< >

>

< >

< >

>

>

>

6.3 Menu structure

ENTER

Press ENTER for 1 second

English

LANGUAGE

TIMES

FUNCTIONS

RADIO/

USERS

CALIBR.

INFO

ENTER

ENTER

ENTER

New user

Change user

Dele te user

Save memory

Load memory

Cancella tutti

ENTER

Run calibrat.

Obstr.sensitive

Partial ap. run

Network ID

ENTER

Version

No. manoeuv.

Startu p mess.

Operat. tim e

A.C.T.

ENTER

Flashing ti m e

A.P.C. tim e

Courtesy ti m e

ENTER

Radio funct.

Part. opening

ENTER

n.5 empty

ENTER

n.5 empty

ENTER

ENTER

ENTER

ENTER

ENTER

(Read only)

(Read only)

ENTER

< 10 sec >

ENTER

n.4 exists

< >

< >

n.4 exists

< >

ENTER

Writin g ...

ENTER

Reading ...

con firm?

<Y>

Procedu ra....

< >

< >

<N>

< 15% >

< >

< 40% >

< >

1 <-> 16

Procedu ra....

ENTER

< >

ENTER

< 10 sec >

ENTER

ENTER

< >

< >

< >

< 10 sec >

< >

< 10 sec >

< >

< >

< 10 sec >

< >

Aut. clos u re

2-7 co ntrol

User function

W. flashing

Dead Man

Dead Man clo s .

C1 Entryway

CX Entryway

Total stop

Service test

Ex outlet

Detect obstacle

Closin g push

Open indicator

Lang. selec.

ENTER

Italian

Englis h

French

Dutch

Spanisch

German

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Disact

ENTER

ENTER

Attivo su CX/CY

ENTER

ENTER

ENTER

ENTER

<ON >

Sequential

Step-by-step

2-7 control

<ON >

<ON >

C1

F.C 2

Enabled

OFF

<ON >

<ON >

Intermittente

Continua

< >

<OFF>

Opens only

< >

<OFF>

< >

<OFF>

<OFF>

<ON>

< >

Disabled

< >

Disabled

< >

Cycle

Movement

< >

<OFF>

< >

<OFF>

C2

F.C 3

F.C 4

< >

< >

< >

< >

< >

< >

< >

< >

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

10

Page 11

6.4 Description of menu items

>

>

>

>

< >

< >

>

< >

< >

< >

>

>

>

>

>

< >

< >

< >

>

< >

> >

Language

Select language: select the menu language among those available.

LANGUAGE

ENTER

Lang. select

ENTER

Italian

German

Englis h French

Spanisch

Dutch

Time intervals

Time of operation: operating time intervals of the gearmotor during the opening phase or closing phase (from 10” o 120”)

TIMES

T.C.A. : automatic closing time following an opening command (from 1” to 120”).

TIMES

Pre-flashing Time: operating interval of the pre-flashing (from 1” to 5”).

TIMES

ENTER

ENTER

ENTER

Oper. tim e

x 1

x 2

ENTER

< 10 sec >

T.C.A.

ENTER

Pre-flashing

ENTER

< >

< 10 sec >

< >

< 5 sec >

< >

Emglish

Pedestrian T.C.A.: automatic closing time following a pedestrian opening command (from 1” to 120”).

TEMPI

Courtesy interval: courtesy lamp interval (from 1” to 120”).

TIMES

ENTER

ENTER

Functions

x 3

T.C.A. Pedonale

x 3

Courtesy ti m e

ENTER

ENTER

< 10 sec >

< >

< 10 sec >

< >

Automatic Closing: activates or deactivates the automatic closing function

FUNCTIONS

ENTER

Automatic cl.

ENTER

<ON >

< >

<OFF>

2-7 command: sets the sequential or in-steps contact.

FUNCTIONS

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

ENTER

x 1

2-7 co m m and

ENTER

Sequential

Step-by-step

< >

User function: assigns to the user either the opening command or the 2-7 function.

FUNCTIONS

ENTER

x 2

User function

ENTER

2-7 comm and

Opens only

< >

Pre-flashing: activates or deactivates the pre-flashing function.

FUNCTIONS

ENTER

Pre-flashing

x 3

ENTER

<ON >

< >

<OFF>

11

Page 12

>

< >

>

< >

>

< >

>

>

>

>

>>

>

>

> >

>>

>

< >

>

> >

>

>

< >

>

< >

< >

>

6.4 Description of menu items

Person Present (Maintained Action): activates or deactivates the Maintained Action function.

FUNCTIONS

ENTER

x 4

Dead man

ENTER

<ON >

< >

<OFF>

Person Present Closing (Maintained Action Closing): activates or deactivates the Maintained Action Closing function.

FUNCTIONS

English

ENTER

x 5

Clos. dead man

ENTER

<ON >

< >

<OFF>

CY Input: input terminal for N.C. safety contacts.The following functions can be associated:

C1: Reopening during closing phase C2: Reclosing during opening phase C3: Partial stop

C4: Obstruction standby C6: Reopening during closing phase (for safety edge).

FUNCTIONS

ENTER

x6

CY inlet

ENTER

C1

Disabled

C2 C3

C6

C4

CX Input: input terminal for N.C. safety contacts.The following functions can be associated:

C1: Reopening during closing phase C2: Reclosing during opening phase C3: Partial stop

C4: Obstruction standby C6: Reopening during closing phase (for safety edge).

FUNCTIONS

ENTER

x7

CX inlet

ENTER

C1

Disabled

C2 C3

C6

C4

Complete Stop: activates or deactivates the complete stop.

FUNCTIONS

ENTER

x 8

Total stop

ENTER

<ON >

< >

<OFF>

Maintenance Test: checks the proper functioning of the safety and detection devices of the input terminal to which they are connected.

FUNCTIONS

ENTER

Service test

x 9

ENTER

<OFF >

Attivo su CX

Attivo su CYAttivo su CX/CY

Lamp output: Output terminal for connecting the 24V flashing light, may be set in two modes of operation: Cycle – the

flashing light operates until the automated device is completely closed. Motion – the flashing light operates only when the

automated device is in motion.

FUNCTIONS

ENTER

x 10

Lamp output

ENTER

Cycle

Movement

< >

Obstacle detector: when the gearmotor is still, it prevents any movement whatsoever if any obstacle is detected by the safety devices.

x 11

FUNCTIONS

ENTER

Obstacle detec.

ENTER

<ON >

< >

<OFF>

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

Closing Boost: additional boost to optimise closure (suitable when the ground is not level)

FUNCTIONS

ENTER

x 12

Closin g push

ENTER

<ON >

< >

<OFF>

Closing indicator light: to select the operating mode of the motion indicator light.

FUNCTIONS

ENTER

x 14

Open indicator

ENTER

Intermittente

Continua

< >

12

Page 13

6.4 Description of menu items

>

>

>

< >

>

>

>

>

< >

>

>

< >

>

< >

>

< >

Radio/Users

Before plugging in any decoding/coding board cut power off to the control board (see p. 15)

New User: Add new users

RADIO/USERS

ENTER

New user

Vedere descrizion e dettagliata

Edit User: to edit a user’s functions.

RADIO/USERS

ENTER

x 2

New user

Vedere descrizion e dettagliata

Delete user: to delete a user from the files. (e.g. user n. 4)

RADIO/USERS

ENTER

x 3

Remove user

ENTER

Save to memory: saves users to the memory roll

RADIO/USERS

ENTER

x 4

Save memory

ENTER

Load memory: loads the data saved in the memory roll.

RADIO/USERS

ENTER

x 5

Load memory

ENTER

Delete all: deletes all the users on file.

RADIO/USERS

ENTER

x 6

Dele te all

n.4 exists

n.5 empty

ENTER

Writin g ...

ENTER

Reading ...

< >

Emglish

ENTER

Confirm?

<Y>

< >

<N>

Calibrations

Travel Run calibration: adjusts the leaf’s travel run and the Opening/Closing direction. (see p. 14)

CALIBR.

ENTER

Sensitive Safety Strip obstacle detector (obstruction detection sensor): adjusts the gate’s sensitivity, when obstructions are detected during motion.

CALIBR.

ENTER

x 2

Partial opening travel run: adjusts the partial opening travel run.

CALIBR.

Web/Network Address: assigns a value of between 1 and 16 for purposes of software recognition.

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

ENTER

CALIBR.

ENTER

x3

x 4

New user

Vedere descrizion e dettagliata

Saf. rib sen.

ENTER

Partial ap. run

ENTER

Network ID

+oooo-

•

< >

< 40% >

< >

< >

ENTER

1 <-> 16

INFO

Version: Visualises the software version Number of cycles: visualises the number cycles made.

Welcome message: to set the welcome message on the display.

INFO

ENTER

Startu p message

Vedere descrizion e dettagliata

13

Page 14

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

>

<

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

>

<

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

>

<

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

>

<

6.5 Travel Run calibration

1

From the calibration menu, select

Calibrate Travel Run. Press ENTER to

confirm.

Run Calibrat.

<>

2

Perform a complete opening run

using (<>), until the complete opening

occurs.

English

ESC

4

Carry out a complete closing run

<

using (<>), until the leaf is completely

closed.

Do a full

closing Run

>

ENTER

ESC

5

Press ENTER to confirm.

Do a full

Opening Run.

><

ENTER

3

Press ENTER to confirm.

6

6 – Set the gate leaf in motion for

at least 3”

Set opening dir

<>:move ENT:OK

ESC

7

Press ENTER to confirm.

><

Direction store

Waiting...

ESC

10

Use the (<>) to fully open the

><

gate

Set opening pnt.

<>:move ENT:OK

ESC

><

ENTER

ENTER

ENTER

8

Use the (<>) to take the gate leaf

to its closing point

Set close Pnt

<>:move ENT:OK

ESC

11

Then press ENTER to confirm.

><

Set Up OK

Waiting...

ESC

<

>

ENTER

ENTER

ESC

9

Then press ENTER to confirm.

><

ENTER

Closure stored

Waiting...

ESC

12

If the calibration (a) has not been

<

>

ENTER

done properly or, (b) has not been

completed, one of the following warning messages will appear:

- (a) reprogram…thus start over from

point 1.:

- (b) reposition the encoder…proceed

with point 13.

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

13

– Move the wheel towards the

+ side or – side depending on what the

display requests.

Move 6 notches

in direction (+)

14

14

-Press ENTER to confirm and

start over form point 1

Adjustment ok

run calibration

Press Enter

to end

Page 15

6.6 Decoding board

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

ZL 80

CONTROL BOARD

ESC

ENTER

RSE

PROGRAMMING FUNCTION

R700

AF

LINE

FUSE

1,6 A

S1 GND

LN

+

-

MN

L1T L2T 0 24

WARN

I

NG

!

A

B

C

D

TERMICAL

PROTECTION

ACCESSORIES

FUSE 1,6 A

CONTROL BOARD

FUSE 1A

BATTERY

MOTOR

POT.ENC.

-

D

I

SP

L

A

Y

+

C

O

NT

R

A

ST

.

MOTOR

FUSE 10A

To control the board using remote controls or cards, connect the AF radio board chosen for the corresponding remote control,

and the R 700 board for the TSP00/LT001 proximity sensors.

Please note: users cannot be added without the proper decoding board (max. number of users is 250).

The AF and R700 boards must be inserted with the power source disconnected

WARN

TERMICAL

PROTECTION

MOTOR

CONTROL BOARD

FUSE 1A

ING!

LINE

FUSE

1,6 A

ACCESSORIES

FUSE 10A

%

FUSE 1,6 A

P

#8 #9

PROGRAMMING FUNCTION

CONTROL BOARD

ZL 80

ESC

'.$

!"

43

RSE

6.7 Adding users

1

From the Radio/Users menu, select New

User. Press ENTER to confirm

New User

<>

%

Emglish

R700

CANCELLIAUTOMATICI

><

ENTER

R700

AF

Frequency/MHz Board Trasmitter

FM 26.995 AF130 TFM

FM 30.900 AF150 TFM

AM 26.995 AF26 TOP

AM 30.900 AF30 TOP

AM 433.92 AF43S / AF43SM TAM / TOP

AM 433.92 AF43SR ATOMO

AM 40.685 AF40 TOUCH

2

Choose the function associated with the user

(User Function or Partial Opening). Press ENTER to

confirm…

Ass. function

User function

<>

3

remote control, a slide-through card or a transponder, depending on the type of sensors installed in the system at hand

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

4

code or not.

ESC

..a code will be required which may inserted with a

><

ENTER

Once the remote control or card code has been added,

the word Memorised will appear on the screen (if the

n. 1 Await. cod

.....

<>

In any case a window will appear asking whether we wish to add a new

Another code?

<>

NO

Another code?

<>

YES

ESC

><

ENTER

code has yet to be added), or the

word On file (if the code has already

been added).

ACCESSCONTRO L

n. 1 Await. cod

Saved!

n. 2 Await. cod

n. 1 exist

By selecting NO the user adding procedure will be terminated. By selecting YES

the procedure reopens at point 3.

ESC

><

ENTER

15

Page 16

ESC

ENTER

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ESC

ENTER

PROGRAMMING FUNCTION

>

<

ENTER

><

ENTER

ESC ENTER

><

PROGRAMMING FUNCTION

6.8 User changes (user fucntion)

1

From the Radio/Users menu, select

User Changes, press ENTER to confirme.

2

Select the user which requires a change in function (a) by using the <>

or (b), by pressing the relative transmitter button, and (c) pulling the card

through the sensor. Press ENTER to confirm.

Change users

<>

Change user

<>

n.1 exist

English

ESC

3

select the function requried for the user. Press ENTER to confirm.

P.N. pressing ENTER to confirm takes you back to the User Changes window.

Ass. function

User function

<>

><

ENTER

ESC

Ass. function

<>

Part. opening

ACCESSCONTRO L

><

ENTER

ESC

><

ENTER

>

ENTER

6.9 Changing the initial message

1

From the INFO menu, select Initial

Message. Press ENTER to confirm

ENTER

Startup mess.

<>

WWW.CAME.IT

ESC

2

Write the desired message: the maximum number of characters is 32 (16 per line). Once the message is written keep

><

ENTER

ESC

the ENTER key pressed for at least 3”

The Enter key servers to:

- Move the cursor to the right

- To confirm when it is kept pressed for more than 3”

The ESC key serves to:

- Move the cursor to the left

- To exit is it is kept pressed for more than 3”

The <> greater than/smaller than keys serve to:

- select the desired letter or the empty space.

><

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

16

WWW.CAME.IT

CBXE 24

Page 17

6.10 Error message

“STOP Contact Open”: Check proper connection or effi ciency of the device

“Service Check!!!” Malfunctions are present in the safety devices.

“Encoder Out of Order: check the proper connection or effi ciency of the device.

“CX-CY Contact Open”: check the proper connection or effi ciency of the device.

7 Mounting the container cover

Emglish

1

Assemble the pressare hinges

!!

2

Insert the hinges into the container (on the

15 mm~

right or the left as desired) and fix them using

the supplied nuts and screws.

they flow for rotating

Lock the cover

into hinges,

close it and fix

it using the supplied screws.

3

8 Product Disposal

I CAME products are made using several materials. For the most part they are (aluminium, plastic, iron, electrical cables)

and can be disposed of with solid urban waste. They may be recycled through differentiated waste collection and disposal

methods at authorised centres.

Other components (electrical boards, the batteries to the remote controls etc.,) may, however, contain polluting substances.

They must therefore be removed and turned over to specialised fi rms that are licensed to dispose of the same.

9 Statement of Confomity

MANUFACTURER’S DECLARATION

As per Enclosure II B of Machinery Directive 98/37/CE

Enclosed with the technical documentation (the original copy of the Declaration is available on request)

The representatives of

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

Tutti i dati e le informazioni quì contenute sono da ritenersi suscettibili di modifica in qualsiasi momento e a nostro giudizio

31030Dosson di Casier - Treviso - ITALYtel

(+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Hereby declare, under their own respons ibility, that the product/s called ...

ZL80 - ZL80C

… comply with the Italian National Legal Provisions that transpose the

following Community Directives (where specifi cally applicable):

ACHINERY DIRECTIVE 98/37/CE

M

OW VOLTAGE DIRECTIVE 73/23/EEC - 93/68/EEC

L

ECTROMAGNETIC COMPATIBILITY DIRECTIVE 89/336/EEC - 92/31/EEC

L

IRECTIVE 1999/5/CE

R&TTE D

Also, they furthermore represent and warrant that the product/s that are the subject of the present

Declaration are manufactured in the respect of the following main harmonized provisions:

EN 292 PART 1 AND 2 MACHINERY SAFETY.

EN 12453 I

EN 12445 I

EN 12978 SAFETY DEVICES FOR POWER OPERATED DOORS AND GATES ....

EN 60335 - 1 SAFETY IN APPARATUSES FOR HOME USE.

EN 60204 - 1 MACHINERY SAFETY.

EN 61000 - 6 - 2 E

EN 61000 - 4 - 4 E

EN 61000 - 4 - 5 ELECTROMAGNETIC COMPATIBILITY.

IMPORTANT CAUTION!

It is forbidden to market/use product/s that are the subject of this declaration before completing and/or

incorporating them in total compliance with the provisions of Machinery Directive 98/37/CE

NDUSTRIAL, COMMERCIAL AND OTHER CLOSING MECHANISMS.

NDUSTRIAL, COMMERCIAL AND OTHER CLOSING MECHANISMS.

LECTROMAGNETIC COMPATIBILITY.

LECTROMAGNETIC COMPATIBILITY.

Signatures of the Representatives

TECHNICAL MANAGER

Mr. Gianni Michielan

Date of the present declaration 07/12/2001

MANAGING DIRECTOR

Mr. Paolo Menuzzo

17

Page 18

CAME UNITED KINGDOM LTD

UNIT 3, ORCHARD BUSINESS PARK

TOWN STREET, SANDIACRE

NOTTINGHAM - NG10 5BP - U.K.

Tel 0044 115 9210430

Fax 0044 115 9210431

Cod.ZL80_ZL80C319T98 V0.1-02/06© CAME CANCELLI AUTOMATICI

Loading...

Loading...