Page 1

Type 8201

Electrolyte monitoring

Elektrolytüberwachung

Détecteur de niveau d‘électrolyte

Operating Instructions

Bedienungsanleitung

Manuel utilisateur

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2010-2012 Bürkert SAS

Operating Instructions 1202/1_EU-ML_562121_Original_EN

Page 3

Type 8201

Electrolyte monitoring for Type 8201

Contents:

1. ABOUT THIS MANUAL .................................................................................5

1.1. Symbols used .......................................................................................5

1.2. Definition of the term "device" .....................................................5

2. INTENDED USE ................................................................................................6

2.1. Restraints ................................................................................................6

3. BASIC SAFETY INFORMATION ...............................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Manufacturer's address and international contacts .........7

4.2. Warranty conditions ...........................................................................7

4.3. Information on the Internet ............................................................7

5. DESCRIPTION ...................................................................................................8

5.1. Area of application .............................................................................8

5.2. General description ...........................................................................8

5.2.1. Design ...................................................................................... 8

5.2.2. Measuring principle ..............................................................8

5.3. Version available .................................................................................9

6. TECHNICAL DATA ...........................................................................................9

6.1. Conditions of use ................................................................................9

6.2. Conformity to standards and directives..................................9

6.3. General technical data .....................................................................9

6.3.1. Mechanical data ....................................................................9

6.3.2. General data .........................................................................10

6.3.3. Electrical data.......................................................................10

6.3.4. Electrical connections ........................................................10

7. INSTALLATION AND WIRING .................................................................11

7.1. Safety instructions...........................................................................11

7.2. Installation on the electrolyte hose ........................................ 11

7.3. Electrical wiring .................................................................................12

8. COMMISSIONING ........................................................................................ 13

8.1. Safety instructions...........................................................................13

8.2. Commissioning ................................................................................. 13

8.3. Running ................................................................................................. 13

9. TROUBLESHOOTING .................................................................................14

9.1. Safety instructions...........................................................................14

English

3

Page 4

9.2. Disassembly of the electrolyte monitoring ........................ 14

9.3. In the event of problems .............................................................. 14

10. PACKAGING, TRANSPORT ...................................................................15

11. STORAGE ....................................................................................................... 15

12. DISPOSAL OF THE PRODUCT ........................................................... 15

Type 8201

4

English

Page 5

Type 8201

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

DANGER

Warns you against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

WARNING

Warns you against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or

even death.

CAUTION

Warns you against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

NOTE

Warns you against material damage.

• Failure to observe this warning may result in damage to the

device or system.

indicates additional information, advice or important recommendations for your safety and for the correct operation of

the device.

refers to information contained in this manual or in other

documents.

→ indicates a procedure to be carried out.

1.2. Definition of the term "device"

The term "device" used within the manual refers to the electrolyte

monitoring type 8201.

English

5

Page 6

Type 8201

Intended use

2. INTENDED USE

Use of the electrolyte monitoring that does not comply with

the instructions could present risks to people, nearby installations and the environment.

• The electrolyte monitoring is intended solely for the control of

the level of electrolyte in the electrolyte bottle of pH sensor type

8201.

• Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of the

climatic conditions.

• Use this device in compliance with the characteristics and

commissioning and use conditions specified in the contractual

documents and in the user manual.

• Requirements for safe and proper operation are proper transport, storage and installation as well as careful operation and

maintenance.

• Only use the device as intended.

2.1. Restraints

Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during assembly,

use and maintenance of the devices.

• the local safety regulations that the operator must ensure the staff

in charge of installation and maintenance observe.

Danger due to electrical voltage.

Danger due to the nature of the fluid.

Various dangerous situations

To avoid injury take care to:

• prevent any power supply switch-on.

• carry out installation and maintenance by qualified and skilled

staff with the appropriate tools.

• guarantee a set or controlled restarting of the process, after a

power supply interruption.

• use the device only if in perfect working order and in compliance with the instructions provided in the user manual.

• observe the general technical rules during the planning and use

of the device.

6

English

Page 7

Type 8201

General information

4. GENERAL INFORMATION

Various dangerous situations

To avoid injury take care to:

• Not use the device in a potentially explosive atmosphere.

• Not use the device in an environment that is incompatible with

the materials of which the electrolyte monitoring is made.

• Not make any external modifications to the device. Do not paint

or varnish any part of the device.

NOTE

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by

an electrostatically charged person or object. In the worst case

scenario, these components are instantly destroyed or go out of

order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the live electrical

components.

4.1. Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

The addresses of our international branches can be found on the

last pages of this manual.

They can also be found on the Internet under: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the device in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding the

type 8201 at: www.burkert.com

English

7

Page 8

5. DESCRIPTION

Type 8201

Description

5.1. Area of application

The electrolyte monitoring is intended to control the level of electrolyte

in the electrolyte bottle of the pH sensor type 8201.

5.2. General description

5.2.1. Design

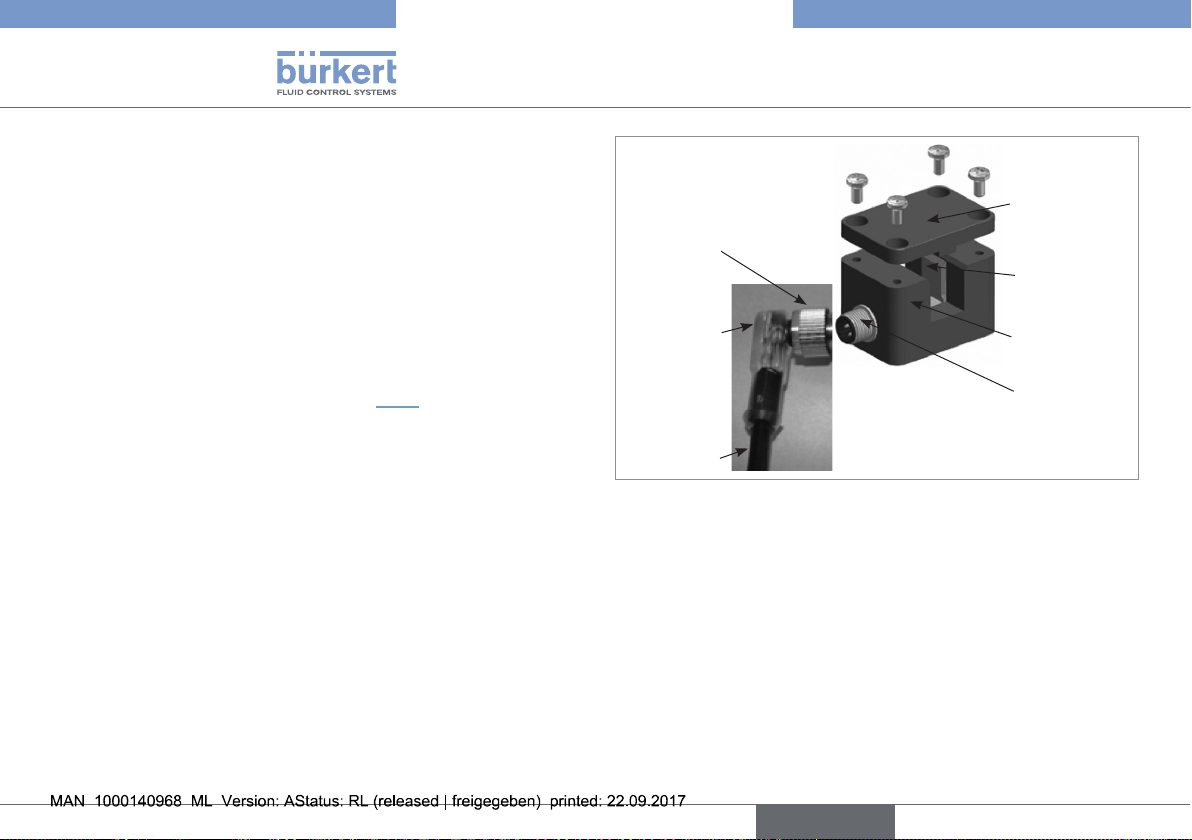

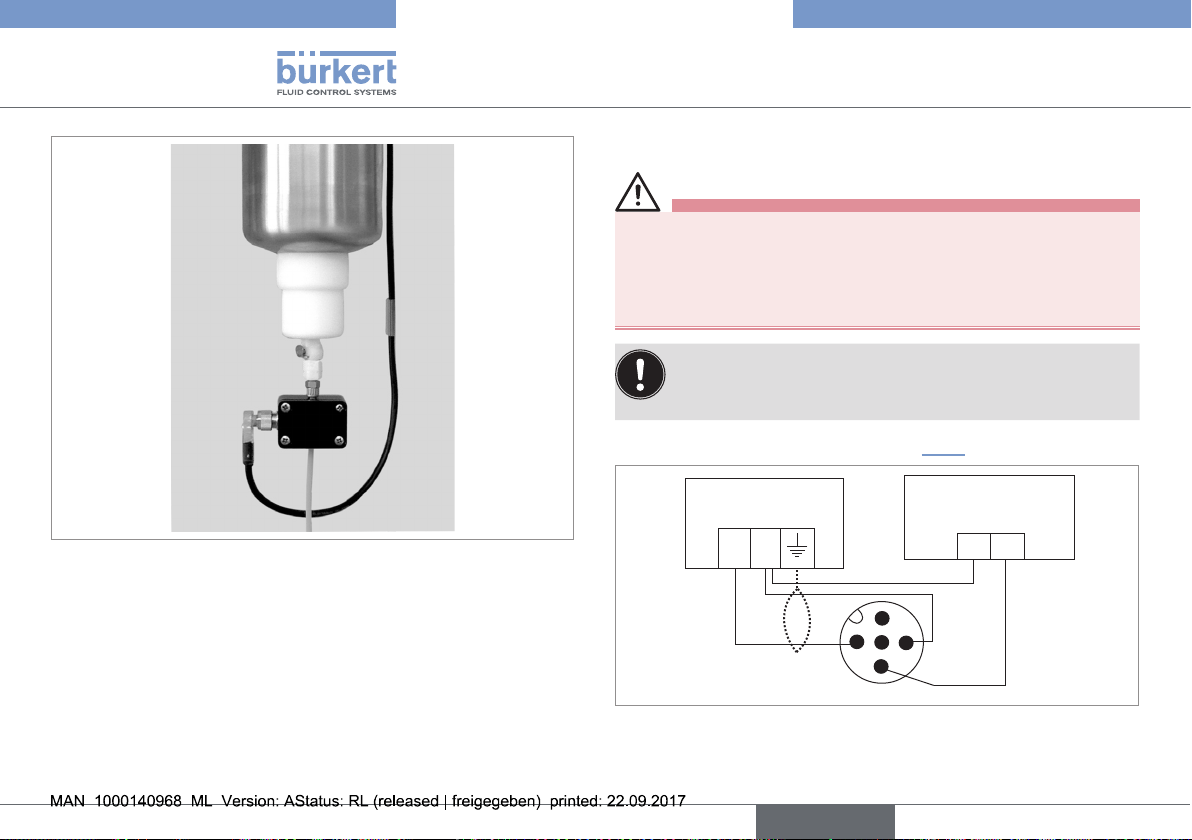

The electrolyte monitoring comprises (see Fig. 1):

• A sensor that contains two ultrasonic cells: an emitter and a

receiver;

• A screw-on cover that maintains the flexible hose in the sensor;

• A 5-m cable fitted with a right-angle M12 plug, that contains one

yellow and one green LEDs.

The electrolyte monitoring requires a power supply of 12-30 VDC and

has a PNP output which can be connected to an alarm. The electrolyte

monitoring is equipped with an M12 5-pin male fixed connector.

screw-on cover

right-angle

plug

LEDs

cable

Fig. 1: Exploded view of the electrolyte monitoring

ultrasonic cells

sensor

5-pin male

connector

5.2.2. Measuring principle

The sensor contains two ultrasonic cells: an emitter and a receiver.

The ultrasonic emitter transmits short high-frequency pulses. The

ultrasonic receiver analyzes the signal received:

• If the hose is filled with liquid, a part of the ultrasound is transferred by the emitter through the hose to the receiver. The yellow

LED is ON and the output is active.

• If the hose is empty or if there is a bubble, the part of the ultrasound received by the receiver is much lower. In that case, the

yellow LED of the connector goes out to indicate an error and the

8

English

Page 9

Type 8201

Technical data

output is set to zero.

5.3. Version available

The following version of the electrolyte monitoring is available. This

reference includes the ultrasonic module and a 5-meter long cable

including a 5-pin M12 plug.

Supply voltage Output Electrical

connection

12-30 VDC PNP

M12, 5-pin male

fixed connector

Ordering code

561533

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature: +5 to +60°C (operating)

Protection rating: IP67

6.2. Conformity to standards and

directives

The conformity of the device to the EC directives is fulfilled by the

following standards:

• EMC: EN 61000-4-3, EN 61000-4-4, EN 61000-4-6, EN 55011

6.3. General technical data

6.3.1. Mechanical data

Component Material

Sensor/Cover POM

Ultrasonic Cell PPMA

Mold of the plug PUR

O-ring FKM

English

9

Page 10

Type 8201

50

42

Technical data

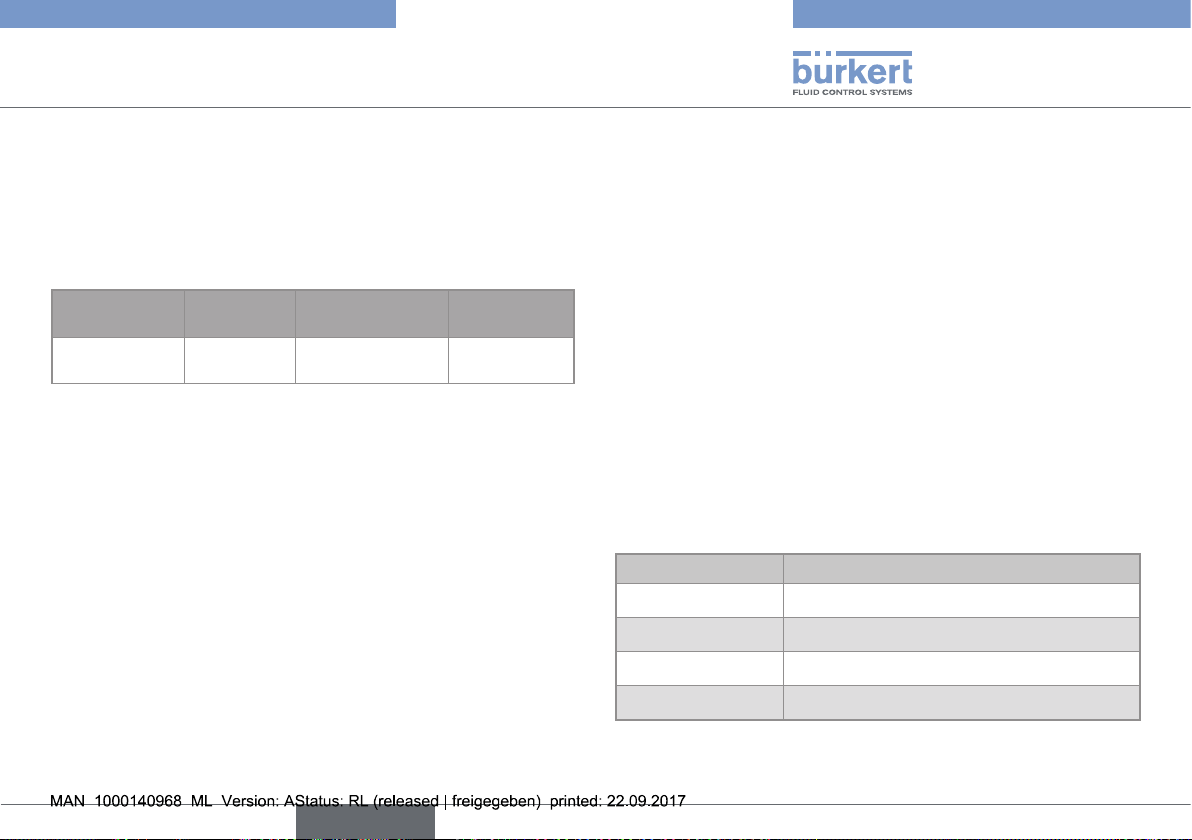

6.3.2. General data

M12x1

27

35

Fastening holes M4, depth 8

Fig. 2: Dimensions of the electrolyte monitoring, top view [mm]

24

30

12

Fig. 3: Dimensions of the electrolyte monitoring, side view [mm]

Hose

• Material

• Length

• Outer diameter

• Optimal wall thickness

• PTFE

• 5 m max.

• 3.0 to 8.5 mm

• 10 to 20% of outer diameter

6.3.3. Electrical data

Power supply 12-30 VDC, filtered and regulated,

modulated max. 10%

Power max. 50 mA (without switching

current)

Current output

• Accuracy

• Response time

• ± 1% (0,16 mA)

• ≤ 0.5 ms

6.3.4. Electrical connections

Version Connection type

M12 5-pin male fixed

connector

A 5-meter long cable equipped with a

right-angle plug

10

English

Page 11

Type 8201

Installation and wiring

7. INSTALLATION AND WIRING

7.1. Safety instructions

DANGER

Risk of injury due to electrical voltage

• Before starting work, make sure that you switch off the supply

voltage and secure it to prevent restarting.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

WARNING

Risk of injury due to non-conforming installation.

• The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Respect the assembly instructions.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Guarantee a set or controlled restarting of the process subsequent to the assembly of the device.

7.2. Installation on the electrolyte hose

DANGER

Risk of injury due to the nature of the fluid.

• Respect the regulations on accident prevention and safety relating to the use of aggressive fluids.

NOTE

The electrolyte monitoring may be irremediably damaged if

liquid is spraid between the ultrasonic cells.

• Always install a dry hose in the electrolyte monitoring.

The electrolyte monitoring is installed on the electrolyte hose which

joins the electrolyte vessel to the pH sensor type 8201.

→ Clamp the sensor on the electrolyte hose as close as possible to

the output of the electrolyte vessel (see Fig. 4).

English

11

Page 12

Type 8201

Installation and wiring

7.3. Electrical wiring

DANGER

Risk of injury due to electrical voltage

• Before starting work, make sure that you switch off the supply

voltage and secure it to prevent restarting.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

• Use a high quality electrical power supply (filtered

and regulated).

• Make sure the installation is equipotential.

→ Connect the wires of the cable (see Fig. 5).

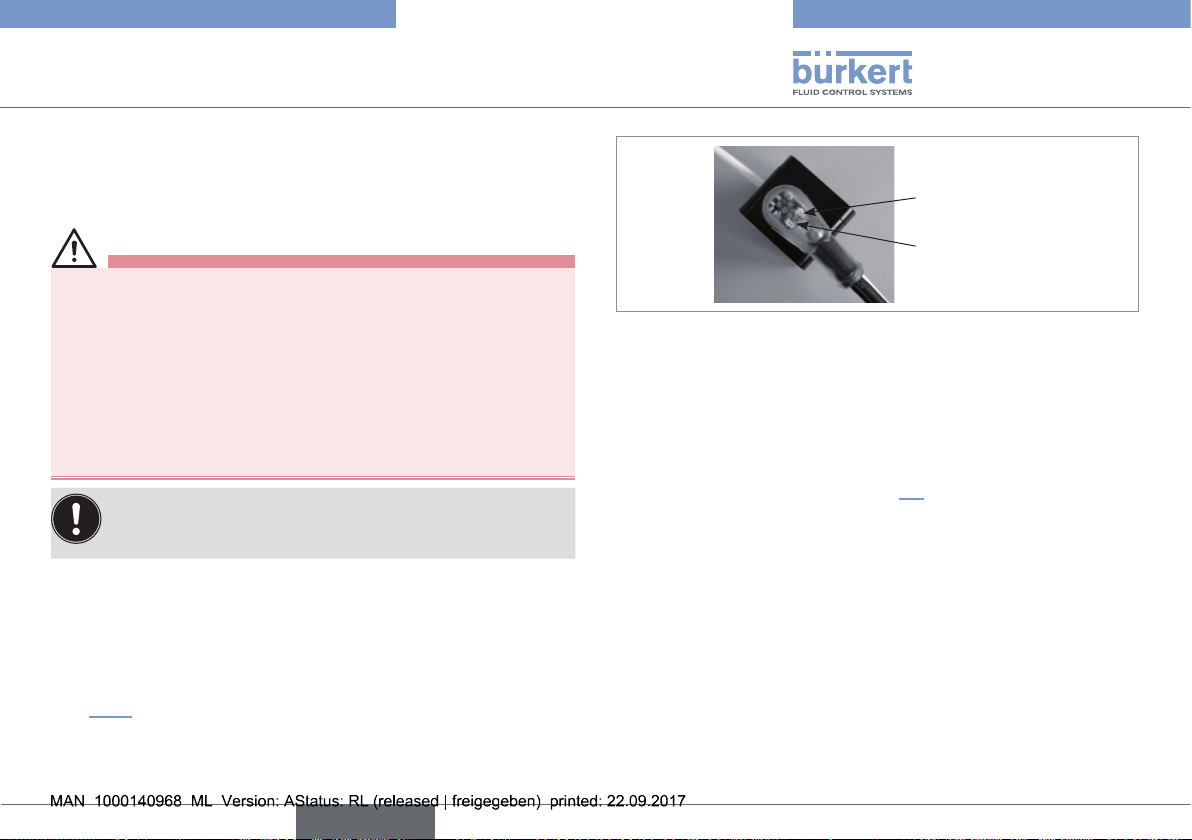

Fig. 4: Installation on the electrolyte hose

→ Screw the four screws of the cover onto the sensor in an

alternating pattern.

12

3

Alarm input

max. 200 mA

+ -

blue

black

Power supply

12-30 VDC

+-

brown

Fig. 5: Connection of the PNP output

2

1

5

4

→ If the cable is shielded, it should be grounded on the side of the

controlling unit.

English

Page 13

Type 8201

Electrolyte monitoring

green

yellow

Commissioning

8. COMMISSIONING

8.1. Safety instructions

WARNING

Danger due to non conforming commissioning.

Non conforming commissioning could lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

• In particular, observe the safety recommendations and intended

use.

• The device/installation must only be commissioned by suitably

trained staff.

Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of

the climatic conditions.

8.2. Commissioning

→ Plug the right-angle plug on the connector.

→ Tighten the plug nut.

The green LED of the connector lights up if the device is powered

(see Fig. 6).

green LED

yellow LED

Fig. 6: Position of the LEDs in the connector

8.3. Running

In normal running:

• the green LED is lit to ensure that the device is powered

• the yellow LED is on as long as electrolyte is in the bottle.

If the yellow LED goes off, see chap. 9.3.

English

13

Page 14

Type 8201

Troubleshooting

9. TROUBLESHOOTING

9.1. Safety instructions

DANGER

Risk of injury due to electrical discharge.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

WARNING

Risk of injury due to non conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

NOTE

The pH measurement drifts if the reference electrode is

lacking electrolyte.

• Replace the electrolyte bottle (see pH sensor type 8201

manual) as soon as possible.

9.2. Disassembly of the electrolyte monitoring

CAUTION

Risk of injury due to whipping of the electrolyte hose.

• Hold the electrolyte hose while disassembling the electrolyte

monitoring.

→ Unscrew the four screws of the sensor cover.

→ Unclamp the sensor from the electrolyte hose.

9.3. In the event of problems

LEDs status Meaning Resolution

green LED is ON

and yellow LED

is OFF

Electrolyte

bottle

empty

→ Verify level of the electrolyte

bottle (see pH sensor type

8201 manual).

→ Replace it if necessary

(see pH sensor type 8201

manual).

Sensor

defective

→ If, despite presence of

electrolyte in the electrolyte

bottle, the fault persists,

contact your Bürkert retailer.

14

English

Page 15

Type 8201

Damage due to transport

Poor storage can damage the device.

Damage to the environment caused by products contami-

Packaging, Transport

10. PACKAGING, TRANSPORT

NOTE

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

• Protect the electrical interfaces using protective plugs.

11. STORAGE

NOTE

• Store the device in a dry place away from dust.

• Storage temperature -20 to +70°C.

12. DISPOSAL OF THE PRODUCT

→

Dispose of the device and its packaging in an environmentallyfriendly way.

NOTE

nated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

Note:

Comply with the national and/or local regulations which

concern the area of waste disposal.

English

15

Page 16

Type 8201

16

English

Page 17

Typ 8201

Elektrolytüberwachung für Typ 8201

Inhaltsverzeichnis:

1. DIE BEDIENUNGSANLEITUNG ...............................................................5

1.1. Darstellungsmittel ..............................................................................5

1.2. Begriffsdefinition "Gerät" ................................................................5

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................6

2.1. Beschränkungen .................................................................................6

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................6

4. ALLGEMEINE HINWEISE .............................................................................7

4.1. Herstelleradresse und internationale Kontaktadressen 7

4.2. Gewährleistung ....................................................................................7

4.3. Informationen im Internet ...............................................................7

5. BESCHREIBUNG .............................................................................................8

5.1. Vorgesehener Einsatzbereich ......................................................8

5.2. Allgemeine Beschreibung ..............................................................8

5.2.1. Aufbau ...................................................................................... 8

5.2.2. Messprinzip ............................................................................. 8

5.3. Verfügbare Version ............................................................................9

6. TECHNISCHE DATEN ...................................................................................9

6.1. Betriebsbedingungen .......................................................................9

6.2. Einhaltung von Normen und Richtlinien .................................9

6.3. Allgemeine Technische Daten .....................................................9

6.3.1. Mechanische Daten .............................................................. 9

6.3.2. Allgemeine Daten ................................................................10

6.3.3. Elektrische Daten ................................................................10

6.3.4. Elektrische Anschlüsse ......................................................10

7. INSTALLATION UND VERKABELUNG ...............................................11

7.1. Sicherheitshinweise ....................................................................... 11

7.2. Installation am Elektrolytschlauch ..........................................11

7.3. Elektrischer Anschluss ................................................................. 12

8. INBETRIEBNAHME ...................................................................................... 13

8.1. Sicherheitshinweise ....................................................................... 13

8.2. Inbetriebnahme ................................................................................. 13

8.3. Betrieb ...................................................................................................13

9. PROBLEMLÖSUNG .....................................................................................14

9.1. Sicherheitshinweise ....................................................................... 14

deutsch

3

Page 18

9.2. Demontage der Elektrolytüberwachung ..............................14

9.3. Störungsbehebung ......................................................................... 15

10. VERPACKUNG, TRANSPORT .............................................................. 15

11. ENTSORGUNG ............................................................................................16

Typ 8201

4

deutsch

Page 19

Typ 8201

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder auch

der Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen, die für Ihre Sicherheit und die einwandfreie Funktion

des Gerätes wichtig sind.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät“ steht immer für

die Elektrolytüberwachung Typ 8201.

deutsch

5

Page 20

Typ 8201

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz der Elektrolytüberwachung können Gefahren für Personen, Anlagen in der

Umgebung und die Umwelt entstehen.

• Die Elektrolytüberwachung dient ausschliesslich der Kontrolle

des Elektrolytinhalts in der Elektrolytflasche des pH-Sensors

Typ 8201.

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

• Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebsund Einsatzbedingungen zu beachten.

• Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Gerätes gegebenenfalls bestehende

Beschränkungen.

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• Ortsbezogene Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Installations- und Wartungspersonal, der Betreiber

verantwortlich ist.

Gefahr durch elektrische Spannung!

Gefahr aufgrund der Art der Flüssigkeit!

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug durchgeführt werden.

• Nach einer Unterbrechung der elektrischen Versorgung ist ein

definierter oder kontrollierter Wiederanlauf des Prozesses zu

gewährleisten.

• Betreiben Sie das Gerät nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

• Bei der Einsatzplanung und dem Betrieb des Gerätes die allgemeinen Regeln der Technik einhalten.

6

deutsch

Page 21

Typ 8201

Allgemeine hinweise

4. ALLGEMEINE HINWEISE

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dieses Gerät nicht in explosionsgefährdeten Bereichen einsetzen.

• Dieses Gerät nicht in einer Umgebung verwenden, die mit den

Werkstoffen, aus denen es besteht, inkompatibel ist.

• Nehmen Sie keine äußerlichen Veränderungen an den Gerätegehäusen vor. Lackieren Sie keinen Teil des Geräts.

HINWEIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

• Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340-5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

4.1. Herstelleradresse und internationale Kontaktadressen

Sie können mit dem Hersteller des Gerätes unter folgender Adresse

Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

67220 TRIEMBACH-AU-VAL

Die Kontaktadressen finden Sie auf den letzten Seiten dieser

Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Gerätes unter Beachtung der im vorliegenden Handbuch

spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8201 finden Sie im

Internet unter: www.buerkert.de

deutsch

7

Page 22

Typ 8201

Beschreibung

5. BESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Die Elektrolytüberwachung ist für die Kontrolle des Elektrolytinhalts in

der Elektrolytflasche des pH-Sensors Typ 8201 vorgesehen.

5.2. Allgemeine Beschreibung

5.2.1. Aufbau

Zur Elektrolytüberwachung gehören (siehe Bild 1):

• Ein Sensor, der zwei Ultraschallzellen enthält, einen Sender und

einen Empfänger;

• Ein Deckel mit 4 Schrauben, der den Schlauch im Sensor hält;

• Ein 5 m langes Kabel mit einer abgewinkelten M12-Buchse, die

eine gelbe und eine grüne Leuchtdiode besitzt.

Die Elektrolytüberwachung erfordert eine 12-30 VDC Stromversorgung

und hat einen PNP-Ausgang, der als Alarmausgang genutzt werden

kann. Die Elektrolytüberwachung ist mit einem 5-poligen M12Gerätestecker ausgestattet.

Deckel mit Schrauben

abgewinkelte

Buchse

Ultraschall-

Leuchtdioden

5-poliger

Stecker

Kabel

Bild 1: Explosionszeichnung der Elektrolytüberwachung

zellen

Sensor

5.2.2. Messprinzip

Der Sensor enthält zwei Ultraschallzellen, einen Sender und einen

Empfänger. Der Ultraschallsender sendet kurze, hochfrequente

Impulse. Der Ultraschallempfänger analysiert das empfangene

Signal:

• Wenn der Schlauch mit Flüssigkeit gefüllt ist, wird ein Teil des

Ultraschalls vom Sender durch den Schlauch zum Empfänger

8

deutsch

Page 23

Typ 8201

Technische Daten

übertragen. Die gelbe Leuchtdiode leuchtet und der Ausgang ist

aktiv.

• Wenn der Schlauch leer ist oder eine Gasblase enthält, ist der

Anteil des vom Empfänger empfangenen Ultraschalls viel geringer.

Die gelbe Leuchtdiode ist aus und der Ausgang ist gleich Null.

5.3. Verfügbare Version

Die folgende Version der Elektrolytüberwachung ist erhältlich. Diese

Referenz umfasst das Ultraschallmodul und ein 5 Meter langes

Kabel mit einer 5-poligen M12-Buchse.

Versorgungsspannung

12-30 VDC PNP

Ausgang Elektrischer

Anschluss

5-poliger M12-

Stecker, starr

Bestellnummer

561533

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Umgebungstemperatur: +5 bis +60 °C (Betrieb)

Schutzart: IP67

6.2. Einhaltung von Normen und Richtlinien

Durch folgende Normen wird die Konformität mit den EG-Richtlinien

erfüllt:

• EMC: EN 61000-4-3, EN 61000-4-4, EN 61000-4-6, EN 55011

6.3. Allgemeine Technische Daten

6.3.1. Mechanische Daten

Element Werkstoff

Sensor/Deckel POM

Ultraschallzelle PPMA

Steckergehäuse PUR

O-ring FKM

deutsch

9

Page 24

Typ 8201

50

42

Technische Daten

6.3.2. Allgemeine Daten

M12x1

27

35

Befestigungslöcher M4, Tiefe 8

Bild 2: Abmessungen der Elektrolytüberwachung, Draufsicht [mm]

24

30

12

Bild 3: Abmessungen der Elektrolytüberwachung, Seitenansicht

[mm]

Schlauch

• Werkstoff

• Länge

• Außendurchmesser

• Optimale Wanddicke

• PTFE

• max. 5 m

• 3,0 bis 8,5 mm

• 10 bis 20 % des Außendurchmessers

6.3.3. Elektrische Daten

Stromversorgung 12-30 VDC, gefiltert und geregelt,

Modulation max. 10 %

Stromaufnahme max. 50 mA (ohne Schaltstrom)

Stromausgang

• Genauigkeit

• Reaktionszeit

• ± 1% (0,16 mA)

• ≤ 0.5 ms

6.3.4. Elektrische Anschlüsse

Version Anschlusstyp

5-poliger M12-Stecker Ein 5 Meter langes Kabel mit rechtwink-

liger Buchse

10

deutsch

Page 25

Typ 8201

Installation und Verkabelung

7. INSTALLATION UND

VERKABELUNG

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie die Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Fluidische und elektrische Installationen dürfen nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt werden!

• Beachten Sie die Montageanweisungen des verwendeten

Fittings.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Installation einen kontrollierten Wiederanlauf

gewährleisten.

7.2. Installation am Elektrolytschlauch

GEFAHR!

Verletzungsgefahr aufgrund der Art der Flüssigkeit.

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

aggressiver Flüssigkeiten beziehen.

HINWEIS!

Die Elektrolytüberwachung kann irreversibel beschädigt

werden, wenn Flüssigkeit zwischen die Ultraschallzellen

gelangt.

• Immer einen trockenen Schlauch in der Elektrolytüberwachung

installieren.

Die Elektrolytüberwachung wird an dem Elektrolytschlauch installiert,

der den Elektrolytbehälter mit dem pH-Sensor Typ 8201 verbindet.

→ Den Sensor so an den Elektrolytschlauch klemmen, dass er sich

so dicht wie möglich am Auslass des Elektrolytbehälters befindet

(siehe Bild 4).

deutsch

11

Page 26

Typ 8201

Installation und Verkabelung

7.3. Elektrischer Anschluss

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

• Verwenden Sie eine hochwertige (gefilterte und gere-

gelte) Stromversorgung.

• Den Potentialausgleich der Installation gewährleisten.

→ Die Leiter des Kabels anschließen (siehe Bild 5).

Bild 4: Installation am Elektrolytschlauch

→ Die vier Schrauben des Deckels über Kreuz an den Sensor

schrauben.

12

deutsch

3

4

Alarmeingang

max. 200 mA

+ -

blau

schwarz

Stromversorgung

12-30 VDC

+-

braun

Bild 5: Anschluss des PNP-Ausgangs

2

1

5

→ Falls es sich um ein abgeschirmtes Kabel handelt, sollte es auf

der Seite der Steuereinheit geerdet werden.

Page 27

Electrolyte monitoring

green

yellow

Typ 8201

Inbetriebnahme

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Inbetriebnahme!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise und die

bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal in Betrieb genommen werden.

HINWEIS!

Gefahr der Beschädigung des Geräts durch die Umgebung!

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

8.2. Inbetriebnahme

→ Die rechtwinklige Steckbuchse an den Gerätestecker stecken.

→ Die Überwurfmutter festziehen.

Die grüne Leuchtdiode der Buchse leuchtet auf, wenn das Gerät mit

Strom versorgt wird (siehe Bild 6).

grüne Leuchtdiode

gelbe Leuchtdiode

Bild 6: Position der Leuchtdioden in der Buchse

8.3. Betrieb

Im Normalbetrieb:

• Die grüne Leuchtdiode leuchtet, um sicherzustellen, dass das

Gerät mit Strom versorgt ist.

• Die gelbe Leuchtdiode leuchtet, solange Elektrolyt in der Flasche

ist.

Wenn die gelbe Leuchtdiode aus ist: Siehe Kap. 9.3.

deutsch

13

Page 28

Typ 8201

Problemlösung

9. PROBLEMLÖSUNG

9.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Verletzungsgefahr aufgrund der Art der Flüssigkeit.

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

aggressiver Flüssigkeiten beziehen.

WARNUNG!

Gefahr durch unsachgemäße Wartungsarbeiten!

• Wartungsarbeiten dürfen nur durch autorisiertes Fachpersonal

und mit geeignetem Werkzeug durchgefürht werden!

• Nach jedem Eingriff an der Anlage einen kontrollierten Wiederanlauf gewährleisten.

HINWEIS!

Die pH-Messwerte verschieben sich, wenn die Referenzelektrode zu wenig Elektrolyt hat.

• Ersetzen Sie die Elektrolytflasche (siehe Bedienungsanleitung

des pH-Sensors Typ 8201) so bald wie möglich.

9.2. Demontage der Elektrolytüberwachung

VORSICHT!

Verletzungsgefahr durch peitschenden Elektrolytschlauch.

• Halten Sie den Elektrolytschlauch fest, während die Elektrolytüberwachung demontiert wird.

→ Lösen Sie die vier Schrauben des Sensordeckels.

→ Ziehen Sie den Sensor vom Elektrolytschlauch ab.

14

deutsch

Page 29

Typ 8201

Transportschäden!

Falsche Lagerung kann Schäden am Gerät verursachen!

Verpackung, Transport

9.3. Störungsbehebung

Status der

Leuchtdioden

grüne Leuchtdiode leuchtet

und gelbe Leuchtdiode ist aus

Bedeu

tung

Elektrolytflasche

leer

Sensor

defekt

Maßnahme

→ Füllstand der Elektrolyt-

flasche überprüfen (siehe

Bedienungsanleitung des

pH-Sensors Typ 8201).

→ Ersetzen, falls erforderlich

(siehe Bedienungsanleitung

des pH-Sensors Typ 8201).

→ Falls der Fehler trotz Vorhan-

densein von Elektrolyt in der

Elektrolytflasche bestehen

bleibt, kontaktieren Sie bitte

Ihren Bürkert Händler.

10. VERPACKUNG, TRANSPORT

VORSICHT!

Ein unzureichend geschütztes Gerät kann durch den Transport

beschädigt werden.

• Transportieren Sie das Gerät vor Nässe und Schmutz geschützt

in einer stoßfesten Verpackung.

• Das Gerät keinen Temperaturen außerhalb des zulässigen Temperaturbereichs für die Lagerung aussetzen.

• Verschließen Sie die elektrischen Schnittstellen mit Schutzkappen vor Beschädigungen.

11. LAGERUNG

VORSICHT!

• Lagern Sie das Gerät trocken und staubfrei!

• Lagerungstemperatur: -20 bis +70 °C.

deutsch

15

Page 30

12. ENTSORGUNG

Umweltschäden durch Teile, die durch Flüssigkeiten kontami-

→

Entsorgen Sie das Gerät und die Verpackung umweltgerecht.

VORSICHT!

niert wurden!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten!

Hinweis:

Beachten Sie die nationalen Abfallbeseitigungsvorschriften.

Typ 8201

Entsorgung

16

deutsch

Page 31

Typ 8201

deutsch

17

Page 32

Typ 8201

18

deutsch

Page 33

Type 8201

Détecteur de niveau d'électrolyte pour le Type 8201

Sommaire :

1. A PROPOS DE CE MANUEL ......................................................................5

1.1. Symboles utilisés ................................................................................5

1.2. Définition du terme „appareil“ ......................................................5

2. UTILISATION CONFORME..........................................................................6

2.1. Restrictions ............................................................................................6

3. CONSIGNES DE SÉCURITÉ DE BASE ................................................6

4. INFORMATIONS GÉNÉRALES ..................................................................7

4.1. Adresse du fabricant et contacts internationaux ...............7

4.2. Conditions de garantie .....................................................................7

4.3. Informations sur internet ................................................................7

5. DESCRIPTION ...................................................................................................8

5.1. Secteur d'application ........................................................................8

5.2. Description générale .........................................................................8

5.2.1. Construction ........................................................................... 8

5.2.2. Principe de mesure ............................................................... 8

5.3. Version disponible ..............................................................................9

6. CARACTÉRISTIQUES TECHNIQUES ...................................................9

6.1. Conditions d'utilisation .....................................................................9

6.2. Conformité aux normes ...................................................................9

6.3. Caractéristiques techniques générales ..................................9

6.3.1. Caractéristiques mécaniques ............................................. 9

6.3.2. Caractéristiques générales ...............................................10

6.3.3. Caractéristiques électriques .............................................10

6.3.4. Raccordements électriques ..............................................10

7. INSTALLATION ET CÂBLAGE ÉLECTRIQUE .................................. 11

7.1. Consignes de sécurité .................................................................. 11

7.2. Installation sur le tube flexible .................................................11

7.3. Câblage électrique .......................................................................... 12

8. MISE EN SERVICE ....................................................................................... 13

8.1. Consignes de sécurité .................................................................. 13

8.2. Mise en service ................................................................................. 13

8.3. Fonctionnement ................................................................................ 13

9. MAINTENANCE ET DÉPANNAGE ........................................................ 14

9.1. Consignes de sécurité .................................................................. 14

français

3

Page 34

9.2. Démonter le détecteur de niveau ...........................................14

9.3. En cas de problème .......................................................................15

10. EMBALLAGE ET TRANSPORT ............................................................15

11. ELIMINATION DE L'APPAREIL .............................................................16

Type 8201

4

français

Page 35

Type 8201

A propos de ce manuel

1. A PROPOS DE CE MANUEL

Ce manuel décrit le cycle de vie complet de l'appareil. Conservez-le

de sorte qu'il soit accessible à tout utilisateur et à disposition de tout

nouveau propriétaire.

Ce manuel contient des informations importantes relatives à

la sécurité.

Le non-respect de ces consignes peut entraîner des situations

dangereuses.

• Ce manuel doit être lu et compris.

1.1. Symboles utilisés

DANGER

Met en garde contre un danger imminent.

• Son non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT

Met en garde contre une situation éventuellement

dangereuse.

• Son non-respect peut entraîner de graves blessures, voire la

mort.

ATTENTION

Met en garde contre un risque éventuel.

• Son non-respect peut entraîner des blessures légères ou de

gravité moyenne.

REMARQUE

Met en garde contre des dommages matériels.

• Son non-respect peut entraîner des dommages sur l'appareil ou

l'installation.

désigne des informations supplémentaires, des conseils ou

des recommandations importants pour votre sécurité et le

fonctionnement parfait de l‘appareil.

renvoie à des informations contenues dans ce manuel ou

dans d'autres documents.

→ indique une opération à effectuer.

1.2. Définition du terme „appareil“

→ Dans ce manuel d‘utilisation, le terme „appareil“ désigne toujours

le détecteur du niveau d'électrolyte Type 8201.

français

5

Page 36

Type 8201

Utilisation conforme

2. UTILISATION CONFORME

L'utilisation non conforme du détecteur de niveau d'électrolyte peut présenter des dangers pour les personnes, les

installations proches et l'environnement.

• Le détecteur de niveau d'électrolyte est destiné au contrôle du

niveau du réservoir d'électrolyte du capteur de pH type 8201.

• Protéger cet appareil contre les perturbations

électromagnétiques, les rayons ultraviolets et, lorsqu'il est installé à l'extérieur, des effets des conditions climatiques.

• Utiliser cet appareil conformément aux caractéristiques et

conditions de mise en service et d'utilisation indiquées dans les

documents contractuels et dans le manuel utilisateur.

• L'utilisation en toute sécurité et sans problème de l'appareil

repose sur un transport, un stockage et une installation corrects

ainsi que sur une utilisation et une maintenance effectuées avec

soin.

• Veiller à toujours utiliser cet appareil de façon conforme.

2.1. Restrictions

Respecter les restrictions éventuelles lorsque l'appareil est exporté.

3. CONSIGNES DE SÉCURITÉ DE BASE

Ces consignes de sécurité ne tiennent pas compte :

• des imprévus pouvant survenir lors de l'assemblage, de l'utilisation

et de l'entretien des appareils.

• des prescriptions de sécurité locales que l'exploitant est tenu de faire

respecter par le personnel chargé de l'assemblage et de l'entretien.

Danger dû à la tension électrique.

Danger dû à la nature du fluide.

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• empêcher toute mise sous tension involontaire de l'installation.

• ce que les travaux d'installation et de maintenance soient

effectués par du personnel qualifié et habilité, disposant des

outils appropriés.

• garantir un redémarrage défini et contrôlé du process, après

une coupure de l'alimentation électrique.

• n'utiliser l'appareil qu'en parfait état et en tenant compte des

indications du manuel utilisateur.

• respecter les règles générales de la technique lors de la

planification et de l'utilisation de l'appareil.

6

français

Page 37

Type 8201

Informations générales

4. INFORMATIONS GÉNÉRALES

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• Ne pas utiliser cet appareil dans une atmosphère explosible.

• Ne pas utiliser cet appareil dans un environnement incompatible

avec les matériaux qui le composent.

• N'apporter aucune modification extérieure au corps. Ne peindre

ni laquer aucune partie de l'appareil.

REMARQUE

Eléments / Composants sensibles aux décharges électrostatiques

• Cet appareil contient des composants électroniques sensibles

aux décharges électrostatiques. Ils peuvent être endommagés

lorsqu'ils sont touchés par une personne ou un objet chargé

électrostatiquement. Dans le pire des cas, ils sont détruits

instantanément ou tombent en panne sitôt effectuée la mise en

route.

• Pour réduire au minimum voire éviter tout dommage dû à une

décharge électrostatique, prenez toutes les précautions décrites

dans les normes EN 61340-5-1 et 5-2.

• Veiller également à ne pas toucher les composants électriques

sous tension.

4.1. Adresse du fabricant et contacts internationaux

Le fabricant de l‘appareil peut être contacté à l‘adresse suivante :

Bürkert SAS

Rue du Giessen

BP 21

67220 TRIEMBACH-AU-VAL

Les adresses des filiales internationales sont disponibles sur internet

sous : www.burkert.com

4.2. Conditions de garantie

La condition pour bénéficier de la garantie légale est l’utilisation

conforme du détecteur de niveau d'électrolyte type 8201 dans

le respect des conditions d’utilisation spécifiées dans le présent

manuel utilisateur.

4.3. Informations sur internet

Retrouvez sur internet les manuels utilisateur et les fiches techniques relatifs au type 8201 sous : www.burkert.fr

français

7

Page 38

5. DESCRIPTION

Type 8201

Description

5.1. Secteur d'application

Le détecteur de niveau d'électrolyte est destiné au contrôle du niveau

du réservoir d'électrolyte du capteur de pH type 8201.

5.2. Description générale

5.2.1. Construction

Le détecteur de niveau d'électrolyte se compose :

• d'un capteur qui contient deux cellules à ultrasons : un émetteur et

un récepteur ;

• d'un couvercle à vis qui maintient le flexible dans le capteur ;

• d'un câble de 5 m équipé d'un connecteur coudé M12, qui contient

un voyant jaune et un voyant vert.

Le détecteur de niveau d'électrolyte nécessite une alimentation de

12-30 VDC et possède une sortie PNP qui peut être connectée à

un système d'alarme.

Le détecteur de niveau d'électrolyte est équipé d'une embase M12

mâle à 5 broches.

couvercle à vis

connecteur

voyants

câble

Fig. 1 : Vue éclatée du détecteur de niveau

cellules à

ultrasons

capteur

embase mâle à

5 broches

5.2.2. Principe de mesure

Le capteur contient deux cellules à ultrasons : un émetteur et un

récepteur. L'émetteur émet de brèves impulsions haute-fréquence.

Le récepteur analyse le signal reçu :

• Si le tube flexible est rempli de liquide, une portion d'ultrasons est

transmis de l'émetteur au récepteur à travers le flexible. Le voyant

jaune est allumé et la sortie est active.

8

français

Page 39

Type 8201

Caractéristiques techniques

• Si le tube flexible est vide ou s'il contient une bulle, la quantité

d'ultrasons reçue par le récepteur est plus faible. Le voyant est

éteint et la sortie est à zéro.

5.3. Version disponible

La version suivante du détecteur de niveau d'électrolyte est disponible.

Cette référence comprend le module à ultrasons et le câble de 5m

équipé d'un connecteur coudé femelle M12 à 5 broches.

Tension

d'alimentation

12-30 VDC PNP

Sortie Raccordement

électrique

embase M12 mâle à 5

broches

Référence de

commande

561533

6. CARACTÉRISTIQUES

TECHNIQUES

6.1. Conditions d'utilisation

Température ambiante : +5...+60 °C (en fonctionnement)

Indice de protection : IP67

6.2. Conformité aux normes

La conformité de l'appareil aux directives CE est respectée par les

normes suivantes :

• CEM : EN 61000-4-3, EN 61000-4-4, EN 61000-4-6, EN 55011

6.3. Caractéristiques techniques générales

6.3.1. Caractéristiques mécaniques

Elément Matériau

Capteur / couvercle POM

Cellules à ultrasons PPMA

Moulage du connecteur PUR

français

Joint du connecteur

femelle

FKM

9

Page 40

Type 8201

50

42

Caractéristiques techniques

6.3.2. Caractéristiques générales

M12x1

27

35

Fixation M4, profondeur 8

Fig. 2 : Dimensions du détecteur de niveau d'électrolyte, vue de

dessus [mm].

24

30

12

Fig. 3 : Dimensions du détecteur de niveau d'électrolyte, vue de

profil [mm]

Tube flexible

• Matériau

• Longueur

• Diamètre externe

• Epaisseur optimale de

• PTFE

• 5m. max.

• 3.0...8.5 mm

• 10 à 20 % du diamètre externe

paroi

6.3.3. Caractéristiques électriques

Alimentation 12-30 VDC, filtrée et régulée, modu-

lation max. 10%

Courant max. 50 mA (sans courant d'interruption)

Sortie courant

• Précision

• Temps de réponse

• ± 1% (0,16 mA)

• ≤ 0.5 ms

(10%-90%)

6.3.4. Raccordements électriques

Version Type de raccordement

Embase M12 mâle à 5

broches

Câble de 5 m équipé d'un connecteur

femelle M12

10

français

Page 41

Type 8201

Installation et câblage électrique

7. INSTALLATION ET CÂBLAGE

ÉLECTRIQUE

7.1. Consignes de sécurité

DANGER

Risque de blessure par décharge électrique.

• Couper et consigner l'alimentation électrique avant d'intervenir

sur l'installation.

• Respecter la règlementation en vigueur en matière de prévention des accidents et de sécurité relative aux appareils

électriques.

AVERTISSEMENT

Risque de blessure dû à une installation non conforme.

• L'installation électrique et fluidique ne peut être effectuée

que par du personnel habilité et qualifié, disposant des outils

appropriés.

• Respecter les consignes de montage du raccord utilisé.

Risque de blessure dû à une mise sous tension involontaire

de l'installation et à un redémarrage incontrôlé.

• Protéger l'installation contre toute mise sous tension

involontaire.

• Garantir un redémarrage contrôlé de l'installation, après assemblage de l'appareil.

7.2. Installation sur le tube flexible

DANGER

Risque de blessure dû à la nature du fluide.

• Respecter la règlementation en vigueur en matière de prévention des accidents et de sécurité relative à l'utilisation de fluides

agressifs.

REMARQUE

Le détecteur de niveau peut être endommagé irrémédiablement si du liquide est projeté sur ou entre les cellules à

ultrasons.

• Toujours installer un tube flexible sec dans le détecteur de

niveau d'électrolyte.

Le détecteur de niveau d'électrolyte est installé sur le tube flexible

qui relie le réservoir d'électrolyte au capteur de pH type 8201.

→ Fixer le capteur sur le tube flexible aussi près que possible de la

sortie du réservoir d'électrolyte (voir Fig. 4).

français

11

Page 42

Type 8201

Installation et câblage électrique

7.3. Câblage électrique

DANGER

Risque de blessure par décharge électrique

• Couper et consigner l'alimentation électrique avant d'intervenir

sur l'installation.

• Respecter la règlementation en vigueur en matière de prévention des accidents et de sécurité relative aux appareils

électriques.

• Utiliser une alimentation électrique de qualité (filtrée

et régulée).

• Garantir l'équipotentialité de l'installation.

→ Connecter les fils du câble (voir Fig. 5).

Fig. 4 : Installation du détecteur de niveau d'électrolyte sur le

tube flexible.

→ Visser en croix les quatre vis du couvercle sur le capteur.

12

3

4

Entrée alarme

max. 200 mA

+ -

bleu

noir

Alimentation

12-30 VDC

+-

2

marron

Fig. 5 : Raccordement de la sortie PNP

1

5

→ Si le câble est blindé, relier le blindage à la terre de l'alimentation

(voir Fig. 5).

français

Page 43

Type 8201

Electrolyte monitoring

green

yellow

Mise en service

8. MISE EN SERVICE

8.1. Consignes de sécurité

AVERTISSEMENT

Risque de blessure dû à une mise en service non conforme.

La mise en service non conforme peut entrainer des blessures et

endommager l'appareil et son environnement.

• S'assurer, avant la mise en service, que le personnel qui en est

chargé a lu et parfaitement compris le contenu de ce manuel.

• Respecter en particulier les consignes de sécurité et l'utilisation

conforme.

• L'appareil / l'installation ne doit être mis(e) en service que par

du personnel suffisamment formé.

Protéger l’appareil contre les perturbations électromagnétiques, les rayons ultraviolets et, lorsqu’il est installé à l’extérieur, des effets des conditions climatiques.

8.2. Mise en service

→ Brancher le connecteur du câble sur l'embase.

→ Visser l'écrou du connecteur du câble.

Le voyant vert s'allume si l'appareil est alimenté (voir Fig. 6).

voyant vert

voyant jaune

Fig. 6 : Emplacement des voyants du connecteur

8.3. Fonctionnement

En fonctionnement normal :

• le voyant vert est allumé pour garantir que l'appareil est alimenté ;

• le voyant jaune est allumé lorsque le réservoir contient de

l'électrolyte.

Si le voyant jaune est éteint, voir chap. 9.3.

français

13

Page 44

Type 8201

Maintenance et dépannage

9. MAINTENANCE ET

DÉPANNAGE

9.1. Consignes de sécurité

DANGER

Risque de blessure par décharge électrique.

• Couper et consigner l'alimentation électrique avant d'intervenir

sur l'installation.

• Respecter la règlementation en vigueur en matière de

prévention des accidents et de sécurité relative aux appareils

électriques.

Risque de blessure dû à la nature du fluide.

• Respecter la règlementation en vigueur en matière de prévention

des accidents et de sécurité relative à l'utilisation de fluides

agressifs.

AVERTISSEMENT

Danger dû à une maintenance non conforme.

• Ces travaux doivent être effectués uniquement par du personnel

qualifié et habilité, disposant des outils appropriés.

• Après toute coupure de l'alimentation électrique, garantir un

redémarrage défini ou contrôlé du process.

REMARQUE

La mesure du pH dérive si l'électrode de référence manque

d'électrolyte.

• Remplacer le réservoir d'électrolyte (voir manuel du capteur de

pH type 8201) aussi vite que possible.

9.2. Démonter le détecteur de niveau

ATTENTION

Risque de blessure dû à un coup de fouet du tube flexible.

• Maintenir le tube flexible pendant le démontage du détecteur de

niveau d'électrolyte.

→ Dévisser les quatre vis du couvercle du capteur.

→ Désolidariser le capteur du tube flexible.

14

français

Page 45

Type 8201

Emballage et transport

9.3. En cas de problème

Etat des voyants

lumineux

voyant vert allumé

et voyant jaune

éteint

Signification Résolution

Réservoir d'électrolyte vide

Capteur

défectueux

→ Vérifier le niveau du

réservoir d'électrolyte

(voir manuel du capteur

de pH type 8201).

→ Remplacer le réservoir

si nécessaire (voir

manuel capteur de pH

type 8201).

→ Si malgré la présence

d'électrolyte dans le

réservoir, le défaut persiste, contacter votre

revendeur Bürkert.

10. EMBALLAGE ET TRANSPORT

REMARQUE

Dommages dus au transport

Le transport peut endommager un appareil insuffisamment

protégé.

• Transporter l'appareil dans un emballage résistant aux chocs, à

l'abri de l'humidité et des impuretés.

• Eviter les effets de la chaleur et du froid pouvant entrainer le

dépassement de la plage de température de stockage.

• Protéger les interfaces électriques à l'aide de bouchons de

protection.

11. STOCKAGE

REMARQUE

Un mauvais stockage peut endommager l'appareil.

• Stocker l'appareil dans un endroit sec et à l'abri de la poussière.

• Température de stockage -20 à +70 °C.

français

15

Page 46

12. ELIMINATION DE L'APPAREIL

→

Eliminer l'appareil et l'emballage dans le respect de l'environnement.

REMARQUE

Dommages à l'environnement causés par des pièces contaminées par des fluides.

• Respecter les prescriptions en vigueur en matière d'élimination

des déchets et de protection de l'environnement.

Remarque

Respecter les prescriptions nationales en matière d'élimination des déchets .

Type 8201

Elimination de l'appareil

16

français

Page 47

Page 48

www.burkert.com

Loading...

Loading...