Page 1

Operating Instructions

LEVEL TRANSMITTER

8136

4 … 20 mA/HART - two-wire

Page 2

Contents

Contents

1 About this document

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 For your safety

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 NAMUR recommendations . . . . . . . . . . . . . . . . . . . .

2.7 Radio license for Europe. . . . . . . . . . . . . . . . . . . . . .

2.8 Radio license for USA/Canada . . . . . . . . . . . . . . . . .

3 Product description

3.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Packaging, transport and storage . . . . . . . . . . . . . . .

3.4 Accessories and replacement parts . . . . . . . . . . . . . .

4 Mounting

4.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Collar or adapter flange . . . . . . . . . . . . . . . . . . . . . .

4.3 Mounting preparations, mounting strap. . . . . . . . . . . .

4.4 Instructions for installation . . . . . . . . . . . . . . . . . . . . .

4

4

4

5

5

5

5

6

6

6

6

7

8

8

9

10

10

11

12

5 Connecting to power supply

5.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

5.2 Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Wiring plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Switch-on phase. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Set up with the indicating and adjustment module

6.1 Insert indicating and adjustment module. . . . . . . . . . .

6.2 Adjustment system . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Parameter adjustment. . . . . . . . . . . . . . . . . . . . . . . .

6.4 Saving the parameter adjustment data . . . . . . . . . . . .

7 Setup with PACTware

7.1 Connect the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Parameter adjustment with PACTware . . . . . . . . . . . .

7.3 Saving the parameter adjustment data . . . . . . . . . . . .

8 Set up with other systems

8.1 DD adjustment programs . . . . . . . . . . . . . . . . . . . . .

8.2 Communicator 375, 475 . . . . . . . . . . . . . . . . . . . . . .

2 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

25

26

27

28

29

30

31

44

46

46

46

47

47

41783-EN-120316

Page 3

9 Diagnosis, Asset Management and service

9.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Diagnosis memory . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Asset Management function . . . . . . . . . . . . . . . . . . .

9.4 Remove interferences. . . . . . . . . . . . . . . . . . . . . . . .

9.5 Exchanging the electronics module . . . . . . . . . . . . . .

9.6 How to proceed in case of repair. . . . . . . . . . . . . . . .

10 Dismounting

10.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Supplement

11.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

48

48

49

53

57

57

58

58

59

67

Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

Editing status: 2012-02-29

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 3

Page 4

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Act

1 Sequence

4 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

ion

This arrow indicates a single action.

Numbers set in front indicate successive steps in a procedure.

41783-EN-120316

Page 5

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

LEVEL TRANSMITTER 8136 is a sensor for continuous level

measurement.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used

according to the specifications in the operating instructions manual as

well as possible supplementary instructions.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and guidelines. The instrument must only be operated in a

technically flawless and reliable condition. The operator is responsible

for the trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

The safety instructions in this operating instructions manual, the

national installation standards as well as the valid safety regulations

and accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary

conversions or modifications are explicitly forbidden.

The safety approval markings and safety tips on the device must also

be observed.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 5

Page 6

2 For your safety

Depending on the instrument version, the emitting frequencies are in

the C or K band range. The low emitting frequencies are far below the

internationally approved limit values. When used correctly, there is no

danger to health.

2.5 CE conformity

The device fulfills the legal requirements of the applicable EC

guidelines. With the CE mark, we provide confirmation of successful

testing.

2.6 NAMUR recommendations

NAMUR is the automation technology user association in the process

industry in Germany. The published NAMUR recommendations are

accepted as the standard in field instrumentation.

The device fulfills the requirements of the following NAMUR

recommendations:

l NE 21 – Electromagnetic compatibility of equipment

l NE 43 – Signal level for malfunction information from measuring

transducers

l NE 53 – Compatibility of field devices and indicating/adjustment

components

l NE 107 - Self-monitoring and diagnosis of field devices

For further information see

www.namur.de.

2.7 Radio license for Europe

The instrument is approved according to EN 302372-1/2 (2006-04) for

use in closed vessels.

2.8 Radio license for USA/Canada

The instrument is in conformity with part 15 of the FCC regulations.

Take note of the following two regulations:

l The device must not generate interfering emissions, and

l The device must be non-sensitive to interfering immissions,

including those that may cause undesirable operating conditions.

Modifications not expressly approved by the manufacturer will lead to

expiry of the operating licence according to FCC/IC.

The instrument is in conformity with RSS-210 of the IC regulations.

The instrument may only be operated in closed vessels made of metal,

concrete, or fibre-reinforced plastic.

6 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 7

3 Product description

2

1

10

11

12

13

9

8

3

4

5

6

7

3.1 Structure

3 Product description

Type

label

The type label contains the most important data for identification and

use of the instrument:

Fig. 1: Structure of the type label (example)

1 Instrument type

2 Product code

3 Approvals

4 Process and ambient temperature, process pressure

5 Signal output electronics, voltage supply

6 Protection rating

7 Order number

8 Serial number of the instrument

9 Symbol of the device protection class

10 ID numbers, instrument documentation

11 Note to observe the instrument documentation

12 Notified authority for CE marking

13 Approval directive

Sco

pe of the operating

instructions manual

Sco

pe of delivery

This operating instructions manual applies to the following instrument

versions:

l Hardware from 2.1.1

l Software from 4.4.0

The scope of delivery encompasses:

l Radar sensor

l Documentation

- this operating instructions manual

- Operating instructions manual "Indicating and adjustment

module" (optional)

- Ex-specific "Safety instructions" (with Ex versions)

- if necessary, further certificates

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 7

Page 8

3 Product description

3.2 Principle of operation

cation area

Appli

Func

tional principle

Packag

ing

The LEVEL TRANSMITTER 8136 is a radar sensor for continuous

level measurement of liquids under simple process conditions.

Dependent on the application range, different versions are used:

l Level measurement of aggressive liquids in small vessels:

encapsulated antenna system

l Flow measurement in open flumes or gauge measurement of

bodies of water: Plastic horn antenna

l Products with an ε

l Products with an ε

value ≥1.8: Standard electronics

r

value ≥1.5, < 1.8; applications with very poor

r

reflective properties: Electronics with increased sensitivity

The actual values that can be reached depend on the measurement

conditions, the antenna system or the standpipe or bypass.

The antenna of the radar sensor emits short radar pulses with a

duration of approx. 1 ns. These pulses are reflected by the product

and received by the antenna as echoes. The transit time of the radar

pulses from emission to reception is proportional to the distance and

hence to the level. The determined level is converted into an

appropriate output signal and outputted as measured value.

3.3 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

Tr

ansport

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

Tr

ansport inspection

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Stora

ge

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

8 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 9

Stora

ge and transport

temperature

3 Product description

l Protected against solar radiation

l Avoiding mechanical shock and vibration

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

3.4 Accessories and replacement parts

Indic

ating and adjust-

ment module

Electro

nics module

The indicating and adjustment module is used for measured value

indication, adjustment and diagnosis. It can be inserted into the sensor

and removed at any time.

You can find further information in the operating instructions "Indicating

and adjustment module" (Document-ID 41787).

The electronics module is a replacement part of the LEVEL TRANSMITTER series. An own version is available for each type of signal

output.

You can find further information in the operating instructions

"Electronics module LEVEL TRANSMITTER 813X" (Document-ID

41786).

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 9

Page 10

4 Mounting

4 Mounting

4.1 General instructions

wing in

Scre

Moisture

Suita

bility for the proc-

ess conditions

With instruments with threaded process fitting, suitable tools must be

applied for tightening the hexagon.

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

You can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry. Rain and condensation water can thus drain off. This

applies mainly to outdoor mounting as well as installation in areas

where high humidity is expected (e.g. through cleaning processes) or

on cooled or heated vessels.

Make sure that all parts of the instrument exposed to the process, in

particular the active measuring component, process seal and process

fitting, are suitable for the existing process conditions. These include

above all the process pressure, process temperature as well as the

chemical properties of the medium.

You can find the specifications in chapter "Technical data" and on the

type label.

4.2 Collar or adapter flange

For mounting the instrument on a socket, a combi compression flange

for DN 80 (ASME 3" or JIS 80) is also available for retro fitting.

Optionally, the instrument can be also equipped with an adapter flange

from DN 100 (ASME 4" or JIS 100).

With the housing versions plastic, aluminium single chamber and

stainless steel, the collar flange can be placed directly over the

housing. With the aluminium double chamber housing, retroactive

mounting in this way is not possible - the mounting type must be

specified with the order.

You can find drawings of these mounting options in chapter

"Dimensions".

10 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 11

4 Mounting

Fig. 2: Flange mounting of the radar sensor

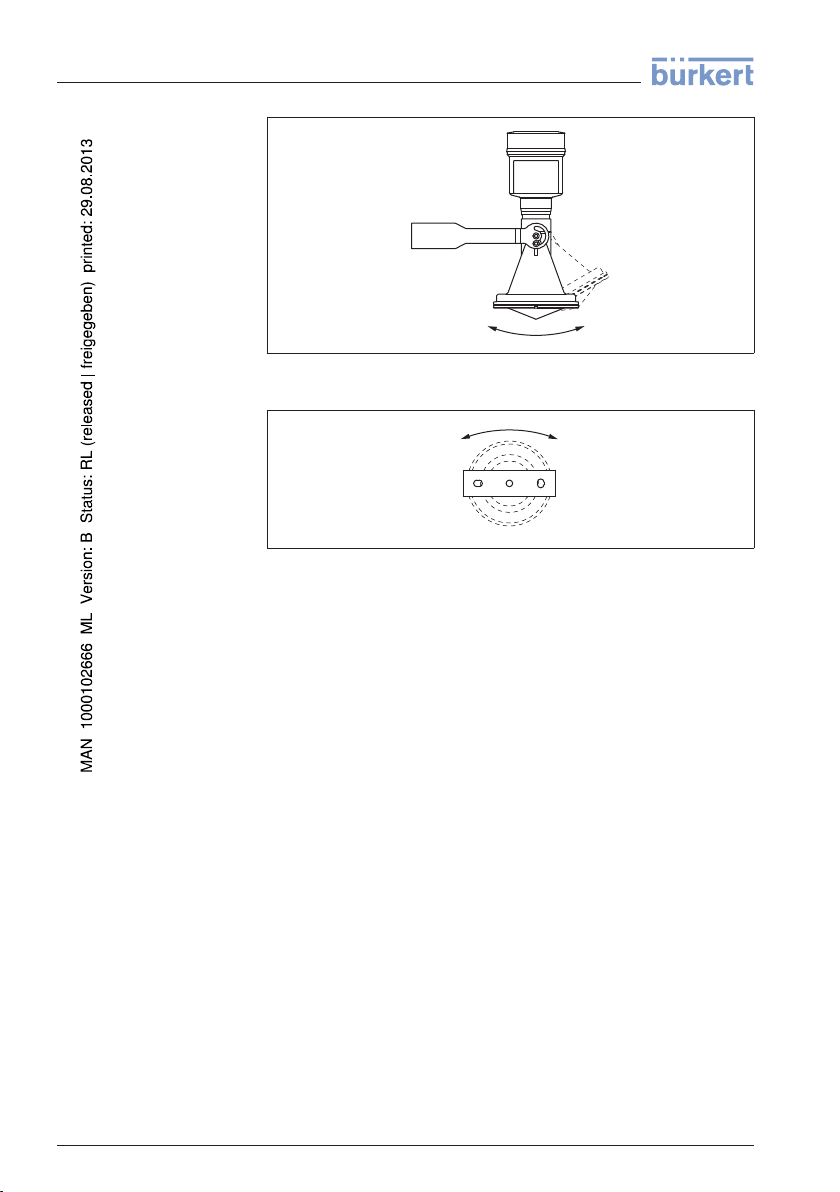

4.3 Mounting preparations, mounting strap

The mounting strap enables simple mounting on the vessel wall or silo

top. It is suitable for wall, ceiling or boom mounting. Especially in open

vessels this is a very easy and effective way to align the sensor to the

bulk solid surface.

The strap is supplied unassembled and must be screwed to the sensor

before setup with three hexagon screws M5 x 10 and spring washers.

Max. torque, see chapter "Technical data". Required tools: Allen

wrench size 4.

There are two ways to screw the strap onto the sensor. Depending on

the selected version, the sensors can be swivelled in the strap as

follows:

l Single chamber housing

- Angle of inclination 180°, infinitely variable

- Angle of inclination in three steps 0°, 90° and 180°

l Double chamber housing

- Angle of inclination 90°, infinitely variable

- Angle of inclination in two steps 0° and 90°

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 11

Page 12

4 Mounting

Fig. 3: Adjustment of the angle of inclination

Fig. 4: Turning by fastening in the centre

4.4 Instructions for installation

Ti

ght installation of the

plastic horn antenna

Polaris

ation plane

12 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

For tight installation of the version with plastic horn antenna with

compression or adapter flange, the following conditions must be

fulfilled:

1 Use suitable flat seal, e.g. of EPDM with Shore hardness 25 or 50

2 Make sure the number of flange screws corresponds to the

number of flange holes

3 Tighten all screws with the torque stated in the technical data

The emitted radar impulses of the radar sensor are electromagnetic

waves. The polarisation plane is the direction of the electrical wave

component. By turning the instrument in the connection flange or

mounting boss, the polarisation can be used to reduce the effects of

false echoes.

The position of the polarisation plane is marked on the process fitting

of the instrument.

41783-EN-120316

Page 13

1

1

4 Mounting

Fig. 5: P osition of the polarisation plane with LEVEL TRANSMITTER 8136 with

encapsulated antenna system

1 Marking hole

Fig. 6: P osition of the polarisation plane with LEVEL TRANSMITTER 8136 with

plastic horn antenna

1 Marking bars

Mountin

g position

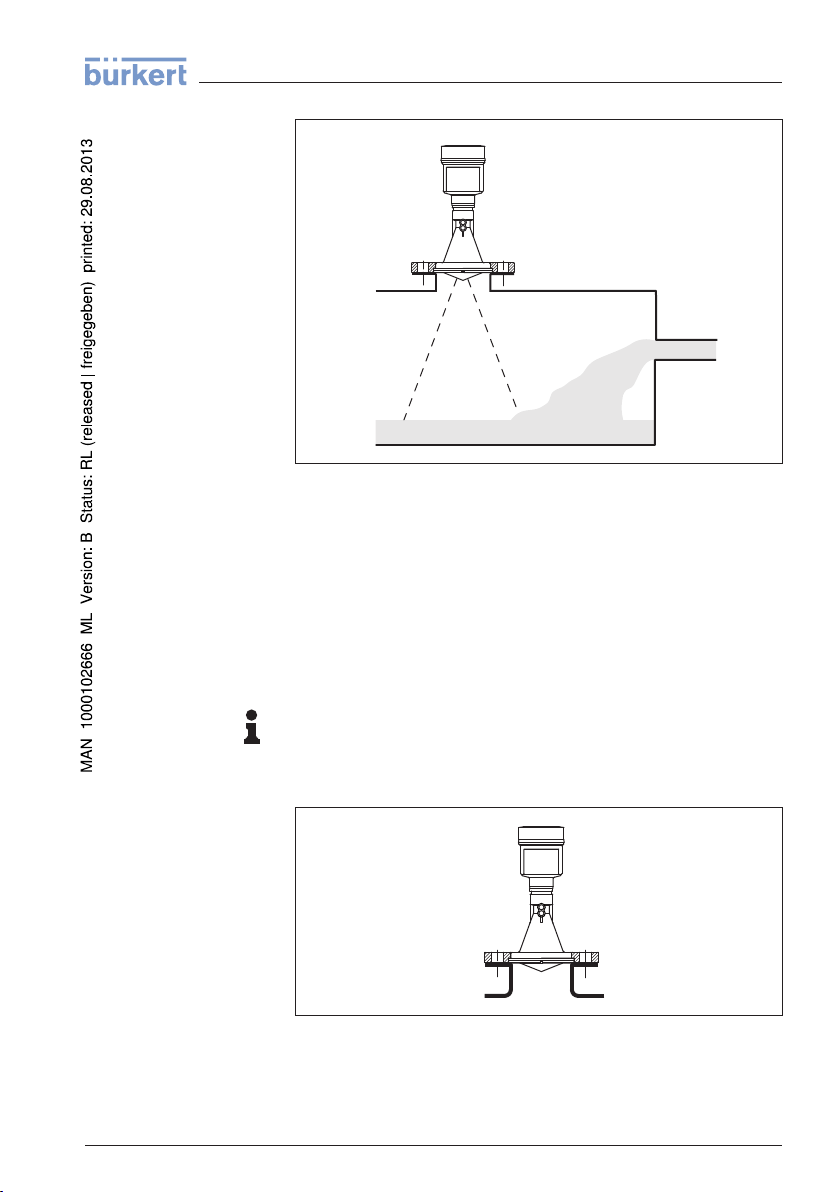

When mounting the sensor, keep a distance of at least 200 mm

(7.874 in) to the vessel wall. If the sensor is installed in the center of

dished or round vessel tops, multiple ec hoes can arise. These can,

however, be suppressed by an appropriate adjustment (see chapter

"Setup").

If you cannot keep this distance you should carry out a false echo

storage before setup. This applies mainly if buildup on the vessel wall

is expected. In this case, w e recommend repeating a false echo

storage later with existing buildup.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 13

Page 14

> 200 mm

(7.87

")

4 Mounting

Fig. 7: Mounting of the radar sensor on round vessel tops

In vessels with conical bottom it can be advantageous to mount the

sensor in the center of the vessel, as measurement is then possible

down to the lowest point of the vessel bottom.

Fig. 8: Mounting of the radar sensor on vessels with conical bottom

Inflow

ing medium

Do not mount the instruments in or above the filling stream. Make sure

that you detect the product surface, not the inflowing product.

14 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 15

Fig. 9: Mounting of the radar sensor with inflowing medium

4 Mounting

ket with plastic horn

Soc

antenna

A corresponding collar flange for DN 80 (ASME 3" or JIS 80) as well as

a suitable adapter flange are available for mounting LEVEL TRANS-

MITTER 8136.

With the housing versions plastic, aluminium single chamber and

stainless steel, the collar flange can be placed directly over the

housing. With the aluminium double chamber housing, retroactive

mounting in this way is not possible - the mounting type must be

specified with the order.

Information:

The socket should be as short as possible and the socket end should

be rounded. Interfering reflections from the vessel socket are thus

minimised.

Fig. 10: Recommended socket mounting

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 15

Page 16

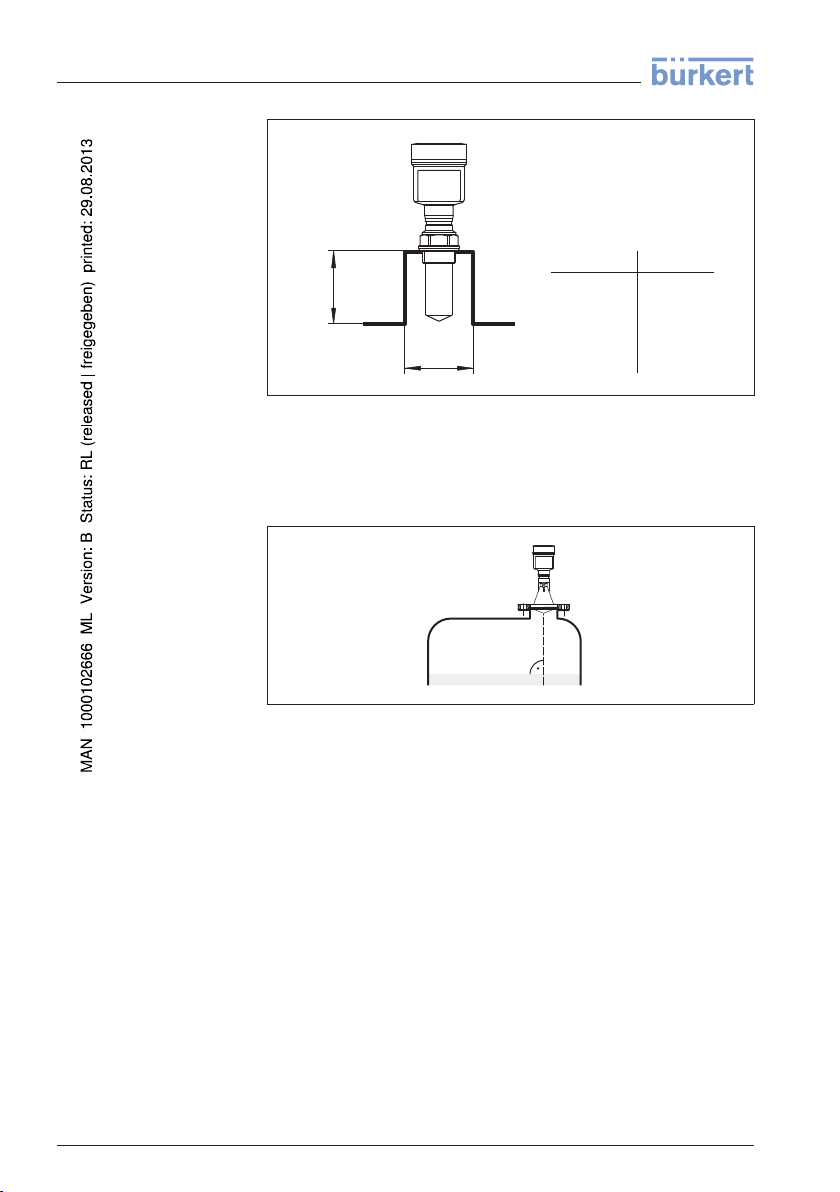

d

h

4 Mounting

If the medium has good reflective properties, LEVEL TRANSMITTER

8136 can also be mounted on a longer socket piece. Recommended

values for socket heights are specified in the following illustration. You

must carry out a false echo storage afterwards.

The below charts specify the max. socket piece length h depending on

the diameter d.

Socket diameter d Socket length h

80 mm 300 mm

100 mm 400 mm

150 mm 500 mm

Socket diameter d Socket length h

3" 11.8 in

4" 15.8 in

6" 19.7 in

Tip:

In new facilities it is useful to incline the vessel socket in the direction

of the outlet. False reflections from the vessel wall are thus reduced

and measurement all the way down to the bottom of the conical outlet

is possible.

16 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 17

Fig. 12: Alignment in silos

ca. 10 mm

4 Mounting

ket with encapsu-

Soc

lated antenna system

The socket piece should be dimensioned in such a way that the

antenna end protrudes at least 10 mm (0.4 in) out of the socket.

Fig. 13: Recommended socket mounting

If the reflective properties of the medium are good, you can mount

LEVEL TRANSMITTER 8136 on sockets which are higher than the

length of the antenna. You will find recommended values for socket

heights in the following illustration. The socket end should be smooth

and burr-free, if possible also rounded. After installation you must carry

out a false echo storage.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 17

Page 18

d

h

d

h

1½"

50 mm/2"

80 mm/3"

100 mm/4"

150 mm/6"

200 mm

250 mm

300 mm

500 mm

800 mm

4 Mounting

Fig. 14: Deviating socket dimensions

Sen

sor orientation

Vess

el installations

Align the sensor in liquids as vertical as possible to the product surface

to achieve optimum measurement results.

Fig. 15: Alignment in liquids

The mounting location of the radar sensor should be a place where no

other equipment or fixtures cross the path of the microwave signals.

Vessel installations, such as e.g. ladders, limit switches, heating

spirals, struts, etc., can cause false echoes and impair the useful echo.

Make sure when planning your measuring site that the radar sensor

has a "clear view" to the measured product.

In case of existing vessel installations, a false echo storage should be

carried out during setup.

If large vessel installations such as struts or supports cause false

echoes, these can be attenuated through supplementary measures.

Small, inclined sheet metal baffles above the installations scatter the

radar signals and prevent direct interfering reflections.

41783-EN-120316

18 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 19

Fig. 16: Cover smooth profiles with deflectors

4 Mounting

Agitato

Foam

rs

generation

If there are agitators in the vessel, a false signal memory should be

carried out with the agitators in motion. This ensures that the interfering

reflections from the agitators are saved with the blades in different

positions.

Fig. 17: Agitators

Through the action of filling, stirring and other processes in the vessel,

compact foams that considerably damp the emitted signals may form

on the product surface.

If foams are causing measurement errors, the biggest possible radar

antennas, the electronics with increased sensitivity or low frequency

radar sensors (C band) should be used.

As an alternative, sensors with guided microwave can be used. These

are unaffected by foam generation and are best suited for such

applications.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 19

Page 20

1

2

3

100%

4

5

8

6

7

0%

9

4 Mounting

rement in a surge

Measu

pipe

When using a surge pipe in a vessel, influences from vessel

installations and turbulences can be excluded. Under these prerequisites, the measurement of products with low dielectric values (ε

r

value ≥ 1.6) is possible. In very adhesive products, measurement in a

surge pipe is not recommended.

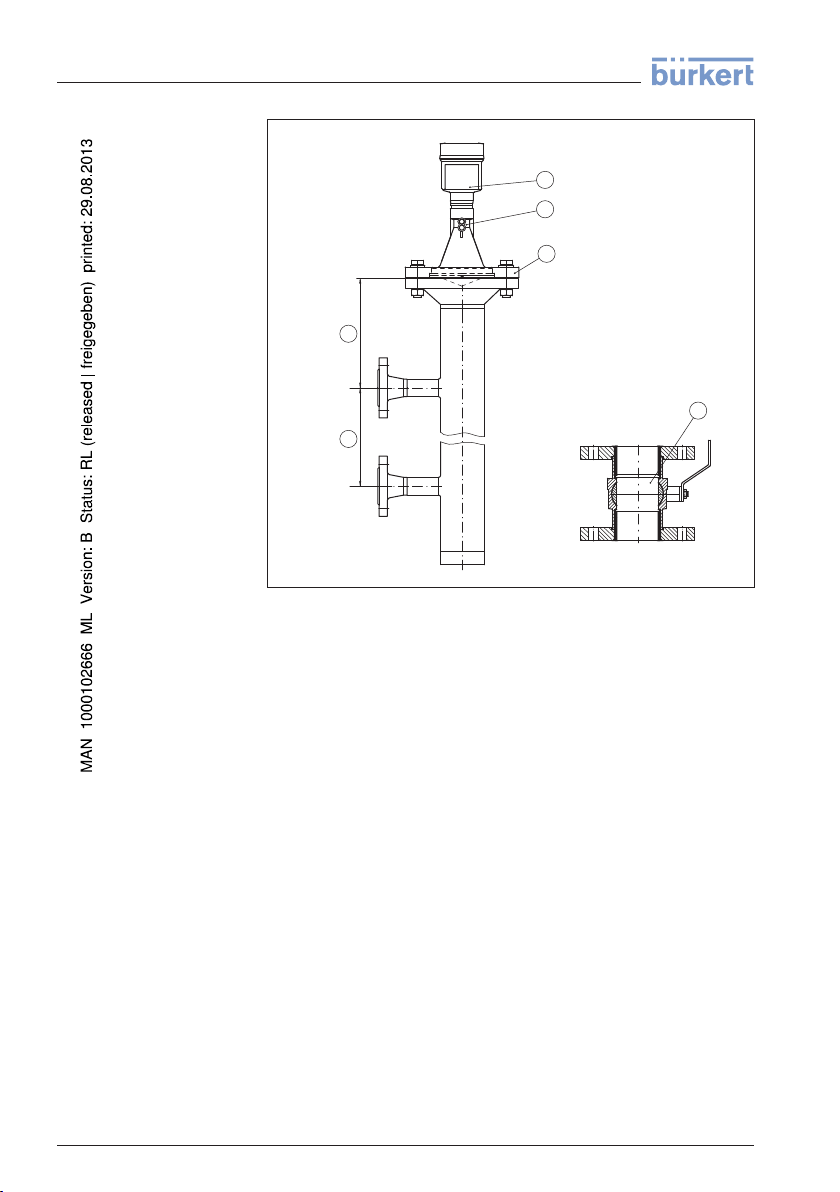

Fig. 18: Configuration surge pipe

1 Radar sensor

2 Marking of the polarisation direction

3 Thread or flange on the instrument

4 Vent hole

5 Holes

6 Weld joint

20 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

7 Welding neck flange

8 Ball valve with complete opening

9 Fastening of the surge pipe

Instructions for orientation:

l Note marking of the polarisation plane on the sensor

l With threaded fitting, the marking is on the hexagon, with flange

connection between the two flange holes

l All holes in the surge pipe must be in one plane with this marking

Instructions for the measurement:

41783-EN-120316

Page 21

4 Mounting

l The 100 % point must be below the upper vent hole and the

antenna edge

l The 0 % point is the end of the surge pipe

l The tube diameter must be at least DN 40 or 1½" with antenna

size 40 mm (1½")

l For the parameter adjustment, select "Application standpipe" and

enter the tube diameter to compensate errors due to running time

shift

l A false signal suppression with integrated sensor is recommended

but not mandatory

l The measurement through a ball valve with complete run is

possible

Constructional requirements on the surge pipe:

l Material metal, smoother inner tube

l Preferably pultruded or straight beaded stainless steel tube

l Welded joint should be straight and lie in one axis with the holes

l Flanges are welded to the tube according to the orientation of the

polarisation level

l In case of a extension with a welding neck flange or pipe collar as

well as when a ball valve is used, the inner surfaces should be

aligned and accurately joined together

l Gap size with junctions ≤ 0.1 mm

l Do not weld through the pipe wall. The surge pipe must remain

smooth inside. Roughness and beads on the inside caused by

unintentional penetration should be removed since they cause

strong false echoes and encourage buildup

l Surge pipes must extend all the way down to the requested min.

level, as measurement is only possible within the tube

l Diameter of holes ≤ 5 mm, any number OK, on one side or

completely through

l The antenna diameter of the sensor should correspond to the

inner diameter of the tube

l Diameter should be constant over the complete length

Measu

rement in the by-

pass

An alternative to measurement in a surge pipe is measurement in a

bypass tube outside of the vessel.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 21

Page 22

0 %

100 %

1

2

5

4

3

6

4 Mounting

Fig. 19: Configuration bypass

1 Radar sensor

2 Marking of the polarisation direction

3 Instrument flange

4 Distance sensor reference plane to upper tube connection

5 Distance of the tube connections

6 Ball valve with complete opening

Instructions for orientation:

l Note marking of the polarisation plane on the sensor

l With threaded fitting, the marking is on the hexagon, with flange

connection between the two flange holes

l The pipe connections to the vessel must be in one plane with this

marking

Instructions for the measurement:

l The 100 % point must not be above the upper tube connection to

the vessel

l The 0 % point must not be below the lower tube connection to the

vessel

l Min. distance sensor reference plane to the upper edge upper

tube connection > 300 mm

l The tube diameter must be at least DN 40 or 1½" with antenna

size 40 mm (1½")

l For the parameter adjustment, select "Application standpipe" and

enter the tube diameter to compensate errors due to running time

shift

41783-EN-120316

22 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 23

h

max

d

min

≥ 2 mm x h

max

90°

4

3 ... 4 h

max

≥ 50 mm

90

°

2

3

1

4 Mounting

l A false signal suppression with integrated sensor is recommended

but not mandatory

l The measurement through a ball valve with complete run is

possible

Constructional requirements on the bypass pipe:

l Material metal, smoother inner tube

l In case of an extremely rough tube inner surface, use an inserted

tube (tube in tube) or a radar sensor with tube antenna

l Flanges are welded to the tube according to the orientation of the

polarisation level

l Gap size with junctions ≤ 0.1 mm, for example, when using a ball

valve or intermediate flanges with single pipe sections

l The antenna diameter of the sensor should correspond to the

inner diameter of the tube

l Diameter should be constant over the complete length

ow measurement with

Fl

rectangular flume

The short examples give you introductory information on the flow

measurement. Detailed planning information is available from flume

manufacturers and in special literature.

Fig. 20: Flow measurement with rectangular flume: d

sensor (see chapter "Technical data"); h

flume

= max. filling of the rectangular

max.

1 Overflow orifice (side view)

2 Headwater

3 Tail water

4 Overfall orifice (view from bottom water)

= min. distance of the

min.

In general, the following points must be observed:

l Install the sensor on the headwater side

l Installation in the centre of the flume and vertical to the liquid

surface

l Distance to the overfall orifice

l Distance of orifice opening above ground

l Min. distance of the orifice opening to bottom water

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 23

l Min. distance of the sensor to max. storage level

Page 24

2

3 ... 4 x h

max

90°

h

max

d

1

B

4 Mounting

Fl

ow measurement with

Khafagi Venturi flume

Fig. 21: Flow measurement with Khafagi-Venturi flume: d = Min. distance to

sensor; h

= max. filling of the flume; B = tightest constriction in the flume

max.

1 Position sensor

2 Venturi flume

In general, the following points must be observed:

l Installation of the sensor at the inlet side

l Installation in the centre of the flume and vertical to the liquid

surface

l Distance to the Venturi flume

l Min. distance of the sensor to max. storage level

41783-EN-120316

24 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 25

5 Connecting to power supply

5 Connecting to power supply

5.1 Preparing the connection

Saf

ety instructions

Volta

ge supply

Conne

ction cable

Always keep in mind the following safety instructions:

l Connect only in the complete absence of line voltage

l If voltage surges are expected, install overvoltage arresters

Power supply and current signal are carried on the same two-wire

cable. The voltage supply range can differ depending on the

instrument version.

The data for power supply are specified in chapter "Technical data".

Provide a reliable separation between the supply circuit and the mains

circuits according to DIN VDE 0106 part 101.

Keep in mind the following additional factors that influence the

operating voltage:

l Output voltage of the power supply unit can be lower under

nominal load (with a sensor current of 20.5 mA or 22 mA in case of

fault message)

l Influence of additional instruments in the circuit (see load values in

chapter "Technical data")

The instrument is connected with standard two-wire cable without

screen. If electromagnetic interference is expected which is above the

test values of EN 61326-1 for industrial areas, screened cable should

be used.

For instruments with housing and cable gland, use cable with round

cross-section. A cable outer diameter of 5 … 9 mm (0.2 … 0.35 in)

ensures the seal effect of the cable gland. If you are using cable with a

different diameter, exchange the seal or use a suitable cable gland.

We generally recommend the use of screened cable for HART

multidrop mode.

Cable

gland ½ NPT

Cable

screening and

grounding

With plastic housing, the NPT cable gland or the Conduit steel tube

must be screwed without grease into the threaded insert.

Max. torque for all housings see chapter "Technical data"

If screened cable is necessary, connect the cable screen on both ends

to ground potential. In the sensor, the screen must be connected

directly to the internal ground terminal. The ground terminal on the

outside of the housing must be connected to the potential equalisation

(low impedance).

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 25

Page 26

5 Connecting to power supply

Cable

screening and

grounding

If potential equalisation currents are expected, the connection on the

processing side must be made via a ceramic capacitor (e. g. 1 nF,

1500 V). The low frequency potential equalisation currents are thus

suppressed, but the protective effect against high frequency interference signals remains.

If screened cable is necessary, connect the cable screen on both ends

to ground potential. In the sensor, the screen must be connected

directly to the internal ground terminal. The ground terminal on the

outside of the housing must be connected to the potential equalisation

(low impedance).

If potential equalisation currents are expected, the connection on the

processing side must be made via a ceramic capacitor (e. g. 1 nF,

1500 V). The low frequency potential equalisation currents are thus

suppressed, but the protective effect against high frequency interference signals remains.

5.2 Connect

Conne

ction technology

Conne

ction procedure

The voltage supply and signal output are connected via the springloaded terminals in the housing.

The connection to the indicating and adjustment module or to the

interface adapter is carried out via contact pins in the housing.

Proceed as follows:

1 Unscrew the housing cover

2 If an indicating and adjustment module is installed, remove it by

turning it slightly to the left.

3 Loosen compression nut of the cable entry

4 Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

41783-EN-120316

26 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 27

5 Connecting to power supply

5 Insert the cable into the sensor through the cable entry

Fig. 22: Connection steps 5 and 6

6 Insert the wire ends into the terminals according to the wiring plan

Information:

Solid cores as well as flexible cores with cable end sleeves are

inserted directly into the terminal openings. In case of flexible cores

without end sleeves, press the terminal head with a small screwdriver;

the terminal opening is freed. When the screwdriver is released, the

terminal closes again.

7 Check the hold of the wires in the terminals by lightly pulling on

them

8 Connect the screen to the internal ground terminal, connect the

outer ground terminal to potential equalisation

9 Tighten the compression nut of the cable entry. The seal ring must

completely encircle the cable

10 Screw the housing cover back on

The electrical connection is finished.

Information:

The terminal block is pluggable and can be removed from the

electronics. To do this, lift the terminal block with a small screwdriver

and pull it out. When inserting the terminal block again, you should

hear it snap in.

5.3 Wiring plan

The following illustration applies to the non-Ex as well as to the Ex-ia

version.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 27

Page 28

5

1

2

+

( )

(-)

6 7 8

4...20mA

2

3

4

1

5 Connecting to power supply

nics compart-

Electro

ment

Fig. 23: Electronics and connection compartment, single chamber housing

1 Voltage supply, signal output

2 For indicating and adjustment module or interface adapter

3 For external indicating and adjustment unit

4 Ground terminal for connection of the cable screen

5.4 Switch-on phase

After connecting the instrument to power supply or after a voltage

recurrence, the instrument carries out a self-check for approx. 30 s:

l Internal check of the electronics

l Indication of the instrument type, hardware and software version,

measurement loop name on the display or PC

l Indication of the status message "F 105 Determine measured

value" on the display or PC

l The output signal jumps to the set error current

As soon as a plausible measured value is found, the corresponding

current is outputted to the signal cable. The value corresponds to the

actual level as well as the settings already carried out, e.g. factory

setting.

28 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 29

6 Set up with the indicating and adjustment module

6 Set up with the indicating and adjustment

module

6.1 Insert indicating and adjustment module

The indicating and adjustment module can be inserted into the sensor

and removed any time. Four positions displaced by 90° can be

selected. It is not necessary to interrupt the power supply.

Proceed as follows:

1 Unscrew the housing cover

2 Place the indicating and adjustment module in the requested

position onto the electronics and turn to the right until it snaps in

3 Screw housing cover with inspection window tightly back on

Removal is carried out in reverse order.

The indicating and adjustment module is powered by the sensor, an

additional connection is not necessary.

Fig. 24: Insertion of the indicating and adjustment module with single chamber

housing

Note:

If you intend to retrofit the instrument with an indicating and adjustment

module for continuous measured value indication, a higher cover with

an inspection glass is required.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 29

Page 30

1

2

6 Set up with the indicating and adjustment module

6.2 Adjustment system

Fig. 25: Indicating and adjustment elements

1 LC display

2 Adjustment keys

Key

functions

l [OK] key:

- Move to the menu overview

- Confirm selected menu

- Edit parameter

- Save value

l [->] key:

- Presentation change measured value

- Select list entry

- Select editing position

l [+] key:

- Change value of the parameter

l [ESC] key:

- interrupt input

- Return to higher-ranking menu

Adjus

tment system

The sensor is adjusted via the four keys of the indicating and

adjustment module. The LC display indicates the individual menu

items. The functions of the individual keys are shown in the above

illustration. Approx. 10 minutes after the last pressing of a key, an

automatic reset to measured value indication is triggered. Any values

not confirmed with [OK] will not be sa ved.

30 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 31

Main

menu

6 Set up with the indicating and adjustment module

6.3 Parameter adjustment

Through the parameter adjustment the instrument is adapted to the

application conditions. The parameter adjustment is carried out via an

adjustment menu.

The main menu is divided into five sections with the following

functions:

Setup: Settings, e.g., for measurement loop name, medium, applica-

tion, vessel, adjustment, signal output

Display: Settings, e.g., for language, measured value display, lighting

Diagnosis: Information, e.g. on the instrument status, pointer,

reliability, simulation, echo curve

Further settings: Instrument unit, false signal suppression, linear-

isation curve, reset, date/time, reset, copy function

Info: Instrument name, hardware and software version, calibration

date, instrument features

Information:

In this operating instructions manual, the instrument-specific parameters in the menu sections "Setup", "Diagnosis" and "Additional

settings" are described. The general parameters in these menu

section are described in the operating instructions manual "Indicating

and adjustment module".

You can find in the operating instructions manual "Indicating and

adjustment module" also the description of the menu sections

"Display" and "Info".

In the main menu point "Setup", the individual submenu points should

be selected subsequently and provided with the correct parameters to

ensure the optimum adjustment of the measurement. The procedure is

described in the following.

Set

up/Medium

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 31

Each medium has different reflection properties. With liquids, further

interfering factors are fluctuation pr oduct surface and foam generation.

With bulk solids, these are dust generation, material cone and

additional echoes from the vessel wall.

To adapt the sensor to these different measuring conditions, the

selection "Liquid" or "Bulk solid" should be made in this menu item.

Page 32

6 Set up with the indicating and adjustment module

Through this selection, the sensor is adapted perfectly to the product

and measurement reliability, particularly in products with poor

reflective properties, is considerably increased.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

up/Application

Set

In addition to the medium, also the application, i.e. the measuring site,

can influence the measurement.

With this menu item, the sensor can be adapted to the applications.

The adjustment possibilities depend on the selection "Liquid" or "Bulk

solid" under "Medium".

The following options are available when "Liquid" is selected:

The selection "Standpipe" opens a new window in which the inner

diameter of the applied standpipe is entered.

41783-EN-120316

The following features form the basis of the applications:

Storage tank:

l Setup: large-volumed, upright cylindrical, spherical

32 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 33

6 Set up with the indicating and adjustment module

l Product speed: slow filling and emptying

l Process/measurement conditions:

- Condensation

- Smooth product surface

- Max. requirement to the measurement accuracy

Storage tanke with product circulation:

l Setup: large-volumed, upright cylindrical, spherical

l Product speed: slow filling and emptying

l Vessel: small laterally mounted or large top mounted stirrer

l Process/measurement conditions:

- Relatively smooth product surface

- Max. requirement to the measurement accuracy

- Condensation

- Slight foam generation

- Overfilling possible

Storage tank on ships (Cargo Tank):

l Product speed: slow filling and emptying

l Vessel:

- Installations in the bottom section (bracers, heating spirals)

- High sockets 200 … 500 mm, also with large diameters

l Process/measurement conditions:

- Condensation, buildup by movement

- Max. requirement on measurement accuracy from 95 %

Stirrer vessel (reactor):

l Setup: all vessel sizes possible

l Product speed:

- Fast to slow filling possible

- Vessel is very often filled and emptied

l Vessel:

- Socket available

- Large agitator blades of metal

- Vortex breakers, heating spirals

l Process/measurement conditions:

- Condensation, buildup by movement

- Strong spout generation

- Very agitated surface, foam generation

Dosing vessel:

l Setup: all vessel sizes possible

l Product speed:

- Fast filling and emptying

- Vessel is very often filled and emptied

l Vessel: narrow installation situation

l Process/measurement conditions:

- Condensation, buildup on the antenna

- Foam generation

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 33

Page 34

6 Set up with the indicating and adjustment module

Standpipe:

l Product speed: very fast filling and emptying

l Vessel:

- Vent hole

- Joins like flanges, weld joints

- Shifting of the running time in the tube

l Process/measurement conditions:

- Condensation

- Buildup

Bypass:

l Product speed:

- Fast up to slow filling with short up to long bypass tube

possible

- Often the level is hold via a control facility

l Vessel:

- Lateral outlets and inlets

- Joins like flanges, weld joints

- Shifting of the running time in the tube

l Process/measurement conditions:

- Condensation

- Buildup

- Separation of oil and water possible

- Overfilling into the antenna possible

Plastic tank:

l Vessel:

- Measurement fix mounted or integrated

- Measurement depending on the application through the vessel

top

- With empty vessel, the measurement can be carried out

through the bottom

l Process/measurement conditions:

- Condensation on the plastic ceiling

- In outside facilities water and snow on the vessel top possible

Transportable plastic tank:

l Vessel:

- Material and thickness different

- Measurement through the vessel top

l Process/measurement conditions:

- Measured value jump with vessel change

Open water (gauge measurement):

l Gauge rate of change: slow gauge change

l Process/measurement conditions:

- Distance sensor to water surface to big

- Extreme damping of output signal due to wave generation

41783-EN-120316

34 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 35

6 Set up with the indicating and adjustment module

- Ice and condensation on the antenna possible

- Spiders and insect nestle in the antennas

- Floating material and animals sporadically on the water

surface

Open flume (flow measurement):

l Gauge rate of change: slow gauge change

l Process/measurement conditions:

- Ice and condensation on the antenna possible

- Spiders and insect nestle in the antennas

- Smooth water surface

- Exact measurement result required

- Distance to the water surface normally relatively high

Rain water overfall (weir):

l Gauge rate of change: slow gauge change

l Process/measurement conditions:

- Ice and condensation on the antenna possible

- Spiders and insect nestle in the antennas

- Turbulent water surface

- Sensor flooding possible

Demonstration:

l Adjustment for all applications which are not typically level

measurement

l Sensor accepts all measured value changes within the measuring

range immediately

l Typical applications:

- Instrument demonstration

- Object recognition/monitoring (additional settings required)

Caution:

If a separation of liquids with different dielectric figure occurs in the

vessel, for example through condensation, the radar sensor can detect

under certain circumstances only the medium with the higher dielectric

figure. Keep in mind that layer interfaces can cause faulty measurements.

If you want to measure the total height of both liquids reliably, please

contact our service department or use an instrument specially

designed for interface measurement.

The following options are available when "Bulk solid" is selected:

The following features form the basis of the applications:

Silo (slim and high):

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 35

Page 36

6 Set up with the indicating and adjustment module

l Vessel of metal: weld joints

l Process/measurement conditions:

- Filling too close to the sensor

- System noise with completely empty silo increased

- Automatic false signal suppression with partly filled vessel

Bunker (large-volumed):

l Vessel of concrete or metal:

- Structured vessel walls

- Installations present

l Process/measurement conditions:

- Large distance to the medium

- Large angles of repose

Bunker with fast filling:

l Vessel of concrete or metal, also multiple chamber silo:

- Structured vessel walls

- Installations present

l Process/measurement conditions:

- Measured value jumps, e.g. by truck loading

- Large distance to the medium

- Large angles of repose

Heap:

l Sensor mounting on movable conveyor belts

l Detection of the heap profile

l Height detection during filling

l Process/measurement conditions:

- Measured value jumps, e.g. by the profile of the heap or

traverses

- Large angles of repose

- Measurement near the filling stream

Crusher:

l Vessel: installations, wear and protective facilities available

l Process/measurement conditions:

- Measured value jumps, e.g. by truck loading

- Fast reaction time

- Large distance to the medium

Demonstration:

l Adjustment for all applications which are not typically level

measurement

l Sensor accepts all measured value changes within the measuring

range immediately

l Typical applications:

- Instrument demonstration

- Object recognition/monitoring (additional settings required)

41783-EN-120316

36 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 37

6 Set up with the indicating and adjustment module

Through this selection, the sensor is adapted optimally to the

application or the location and measurement reliability under the

various basic conditions is increased considerably.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

up/Vessel height,

Set

measuring range

Set

up/Vessel form

With this selection, the operating range of the sensor is adapted to the

vessel height and the reliability with different frame conditions is

increased considerably.

Independent from this, the min. adjustment must be carried out.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Also the vessel form can influence the measurement apart from the

medium and the application. To adapt the sensor to these measurement conditions, this menu item offers you different options for vessel

bottom and ceiling in case of certain applications.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Set

up/Adjustment

Because a radar sensor is a distance measuring instrument, the

distance from the sensor to the product surface is measured. To have

the real product level displayed, an allocation of the measured

distance to the percentage height must be made. To carry out this

adjustment, the distance is entered with full and empty vessel. If these

values are not known, an adjustment with the distance values, e.g.

10 % and 90 % is also possible. Starting point for these distance

specifications is always the seal surface of the thread or flange. By

means of these settings, the real level is calculated.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 37

Page 38

6 Set up with the indicating and adjustment module

The real product level during this adjustment is not important, because

the min./max. adjustment is always carried out without changing the

product level. These settings can be made ahead of time without the

instrument having to be installed.

Setup/Min. adjustment

Set

up/Max. adjustment

Proceed as follows:

1 Select the menu item "Setup" with [->] and confirm with [OK]. Now

select with [->] the menu item "Min. adjustment" and confirm with

[OK].

2 Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3 Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the distance value.

4 Enter the suitable distance value in m for the empty vessel (e.g.

distance from the sensor to the vessel bottom) corresponding to

the percentage value.

5 Save settings with [OK] and move with [ESC] and [->] to the max.

adjustment.

Proceed as follows:

1 Select with [->] the menu item max. adjustment and confirm with

[OK].

2 Prepare the percentage value for editing with [OK] and set the

cursor to the requested position with [->].

38 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 39

6 Set up with the indicating and adjustment module

3 Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the distance value.

4 Enter the appropriate distance value in m (corresponding to the

percentage value) for the full vessel. Keep in mind that the max.

level must lie below the min. distance to the antenna edge.

5 Save settings with [OK]

sis/Peak value

Diagno

Diagno

sis/Measurement

reliability

Diagno

ses/Curve indica-

tion

Min. and max. measured values are saved in the sensor. The values

are displayed in the menu item "Peak values".

When non-contact level sensors are used, the measurement can be

influenced by the respective process conditions. In this menu item, the

measurement reliability of the level echo is displayed as dB value. The

measurement reliability equals signal strength minus noise. The higher

the value, the more reliable the measurement. With a functioning

measurement, the values are > 10 dB.

The "Echo curve" shows the signal strength of the echoes over the

measuring range in dB. The signal strength enables an evaluation of

the quality of the measurement.

The "False signal suppression" displays the saved false echoes (see

menu "Additional settings") of the empty vessel with signal strength in

"dB" over the measuring range.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 39

Page 40

6 Set up with the indicating and adjustment module

A comparison of echo curve and false signal suppression allows a

more accurate conclusion on measurement reliability. The selected

curve is continuously updated. With the [OK] key, a submenu with

zoom functions is opened:

l "X-Zoom": Zoom function for the meas. distance

l "Y-Zoom": 1, 2, 5 and 10x signal magnification in "dB"

l "Unzoom": Reset the presentation to the nominal measuring range

with single magnification

sis/Echo curve

Diagno

memory

Fur

ther settings/False

signal suppression

With the function "Echo curve memory" the echo curve can be saved

at the time of setup. This is generally recommended; for using the

Asset Management functions it is absolutely necessary. If possible, the

curve should be saved with a low level in the vessel.

With the adjustment software PACTware and the PC, the high

resolution echo curve can be displayed and used to recognize signal

changes over the operating time. In addition, the echo curve of the

setup can be also displayed in the echo curve window and compared

with the actual echo curve.

The following circumstances cause interfering reflections and can

influence the measurement:

l High sockets

l Vessel installations such as struts

l Agitators

l Buildup or welded joints on vessel walls

Note:

A false signal suppression detects, marks and saves these false

signals so that they are no longer taken into account for level

measurement.

This should be done with a low level so that possible interfering

reflections can be detected.

Proceed as follows:

41783-EN-120316

40 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 41

6 Set up with the indicating and adjustment module

1 Select the menu item "Additional settins" with [->] and confirm with

[OK]. With [->] you have to select the menu item "False signal

suppression" and confirm with [OK].

2 Confirm again with [OK].

3 Confirm again with [OK].

4 Confirm again with [OK] and enter the actual distance from the

sensor to the product surface.

5 All interfering signals in this section are detected by the sensor

and stored after confirming with [OK].

Note:

Check the distance to the product surface, because if an incorrect (too

large) value is entered, the existing level will be saved as false signal.

The filling level would then no longer be detectable in this area.

If a false signal suppression is already created in the sensor, then the

following menu window appears when selecting "False signal

suppression":

The menu item "Delete" is used to completely delete an already

created false signal suppression. This is useful if the saved false signal

suppression no longer matches the metrological conditions in the

vessel.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 41

Page 42

6 Set up with the indicating and adjustment module

The menu item "Extend" is used to extend an already created false

signal suppression. This is useful if a false signal suppression was

carried out with a too high level and not all false signals could be

detected. When selecting "Extend", the distance to the product surface

of the created false signal suppression is displayed. This value can

now be changed and the false signal suppression can be extended to

this range.

ther settings/Lineari-

Fur

zation curve

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level - e.g. in a horizontal cylindrical

or spherical tank - and the indication or output of the volume is

required. Corresponding linearization curves are preprogrammed for

these vessels. They represent the correlation between the level

percentage and vessel volume.

By activating the appropriate curve, the volume percentage of the

vessel is displayed correctly. If the volume should not be displayed in

percent but e.g. in l or kg, a scaling can be also set in the menu item

"Display".

Enter the requested parameters via the appropriate keys, save your

settings and jump to the next menu item with the [ESC] and [->] key.

Caution:

Note the following if the instrument with corresponding approval is

used as part of an overfill protection system according to WHG:

If a linearisation curve is selected, the measuring signal is no longer

compulsorily linear proportional to the level. This must be taken into

consideration by the user, particularly when adjusting the switching

point on the level switch.

Addition

set

42 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

al settings - Re-

With a reset, certain parameter adjustments carried out by the user are

reset.

The following reset functions are available:

41783-EN-120316

Page 43

6 Set up with the indicating and adjustment module

Delivery status: Restoring the parameter settings at the time of

shipment from the factory incl. the order-specific settings. A created

false signal suppression, user-programmable linearization curve as

well as the measured value memory will be deleted.

Basic settings: Resetting the parameter settings incl. special and

laboratory parameters to the default values of the respective instrument. A created false signal suppression, user programmable

linearization curve as well as the measured value memory will be

deleted.

Setup: Resetting of the parameter settings to the default values of the

respective instrument in the menu item Setup. Order-related settings

remain but are not taken over into the current parameters. Usergenerated false signal suppression, user-programmed linearization

curve, measured value memory as well as event memory remain

untouched. The linearization is set to linear.

False signal suppression: Deleting a previously created false signal

suppression. The false signal suppression created in the factory

remains active.

Peak values measured value: Resetting of the measured min. and

max. distances to the actual measured value.

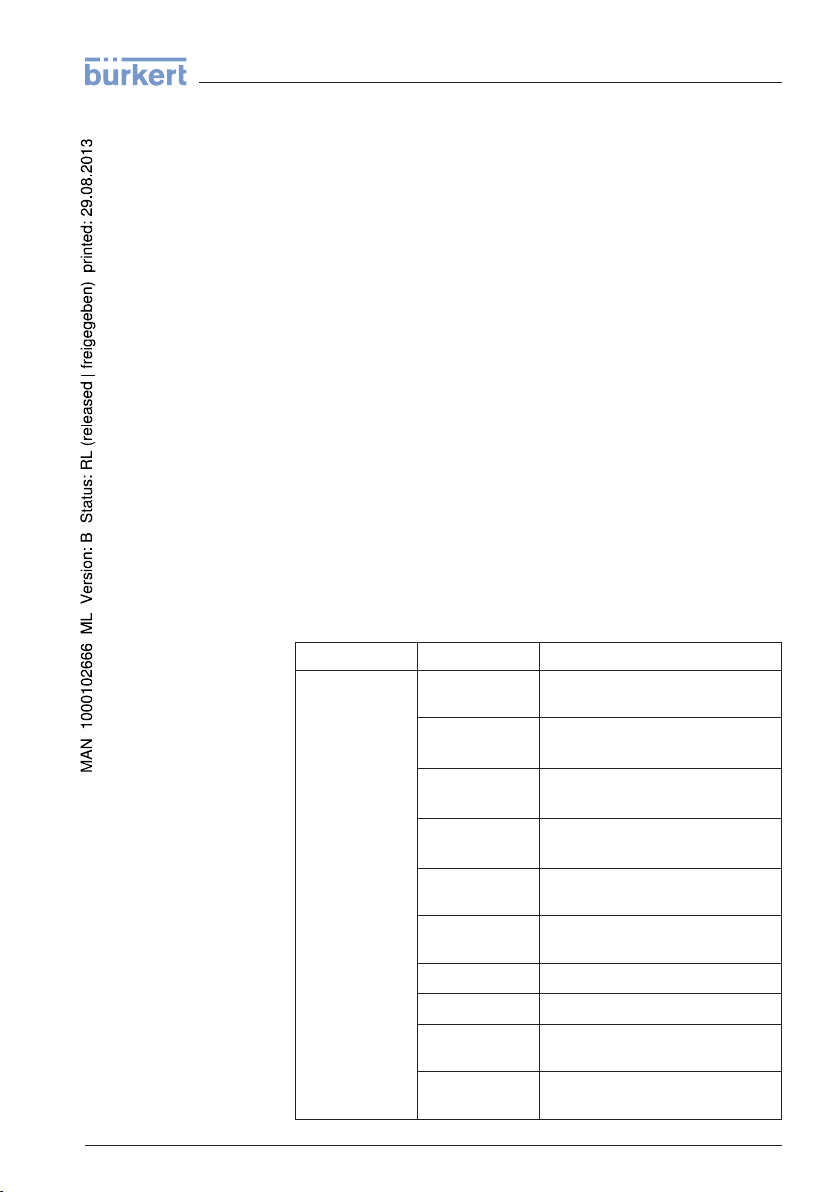

The following table shows the default values of the instrument.

Depending on the instrument version, not all menu items are available

or differently assigned:

Menu Menu

Setup Measurement

item Default value

loop name

Medium Liquid/Water

Application Storage tank

Vessel form Vessel bottom, dished boiler end

Vesell height/

Measuring range

Min. adjustment Recommended measuring range, see

Max. adjustment 0,000 m(d)

Damping 0.0 s

Current output

mode

Current output

Min./Max.

Sensor

Bulk solids/Crushed stones, gravel

Silo

Vessel top, dished boiler end

Recommended measuring range, see

"Technical data" in the supplement

"Technical data" in the supplement

4 … 20 mA, < 3.6 mA

Min. current 3.8 mA, max. current

20.5 mA

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 43

Page 44

6 Set up with the indicating and adjustment module

Menu Menu item Default value

Lock operation Released

Display Language Like order

Displayed value Distance

Display unit m

Scaling size Volume

Scaling 0.00 lin %, 0 l

Lighting Switched off

Further settings Distance unit m

Temperature unit °C

Probe length Length of the standpipe Ex factory

Linearisation

curve

HART mode Standard

l

100.00 lin %, 100 l

linear

Address 0

6.4 Saving

the parameter adjustment data

We recommended noting the adjusted data, e.g. in this operating

instructions manual, and archiving them afterwards. They are thus

available for multiple use or service purposes.

If the instrument is equipped with an indicating and adjustment

module, the data in the sensor can be saved in the indicating and

adjustment module. The procedure is described in the operating

instructions manual "Indicating and adjustment module" in the menu

item "Copy sensor data". The data remain there permanently even if

the sensor power supply fails.

The following data or settings for adjustment of the indicating and

adjustment module are saved:

l All data of the menu "Setup" and "Display"

l In the menu "Additional settings" the items "Sensor-specific units,

temperature unit and linearization"

l The values of the user programmable linearisation curve

The function can also be used to transfer settings from one instrument

to another instrument of the same type. If it is necessary to exchange a

sensor, the indicating and adjustment module is inserted into the

replacement instrument and the data are likewise written into the

sensor via the menu item "Copy sensor data".

44 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

41783-EN-120316

Page 45

6 Set up with the indicating and adjustment module

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 45

Page 46

1

3

2

5

4

7 Setup with PACTware

the interface adapter

Via

and HART

7 Setup with PACTware

7.1 Connect the PC

Fig. 26: Connecting the PC via HART to the signal cable

1 Sensor

2 HART resistance 250 Ω (optional depending on processing)

3 Connection cable with 2 mm pins and terminals

4 Processing system/PLC/Voltage supply

7.2 Parameter adjustment with PACTware

Prereq

uisites

46 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

For parameter adjustment of the sensor via a Windows PC, the

configuration software PACTware and a suitable instrument driver

(DTM) according to FDT standard are required. The up-to-date

PACTware version as well as all available DTMs are compiled in a

DTM Collection. The DTMs can also be integrated into other frame

applications according to FDT standard.

Note:

To ensure that all instrument functions are supported, you should

always use the latest DTM Collection. Furthermore, not all described

functions are included in older firmware versions. You can download

the latest instrument software from our homepage. A description of the

update procedure is also available in the Internet.

7.3 Saving the parameter adjustment data

We recommend documenting or saving the parameter adjustment data

via PACTware. That way the data are available for multiple use or

service purposes.

41783-EN-120316

Page 47

8 Set up with other systems

8 Set up with other systems

8.1 DD adjustment programs

Device descriptions as Enhanced Device Description (EDD) are

available for DD adjustment programs such as, for example, AMS™

and PDM.

8.2 Communicator 375, 475

Device descriptions for the instrument are available as DD or EDD for

parameter adjustment with the Field Communicator 375 or 475.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 47

Page 48

9 Diagnosis, Asset Management and service

9 Diagnosis, Asset Management and service

9.1 Maintenance

If the device is used correctly, no maintenance is required in normal

operation.

9.2 Diagnosis memory

The instrument has several memories which are available for

diagnosis purposes. The data remain even with voltage interruption.

Measu

red value memory

Event

memory

Echo

curve memory

Up to 70,000 measured values can be stored in the sensor in a ring

memory. Each entry contains date/time as well as the respective

measured value.

Stored values are for example:

l Original sensor value

l Filling height

l Measured value

l Meas. reliability

l Electronics temperature

The requested values and recording conditions are set via a PC with

PACTware/DTM or the control system with EDD. Data are thus read

out and also reset.

Up to 500 events are automatically stored with a time stamp in the

sensor (non-deletable). Each entry contains date/time, event type,

event description and value.

Event types are for example:

l Modification of a parameter

l Switching on and off times

l Status messages

l Error messages

The data are read out via a PC with PACTware/DTM or the control

system with EDD.

The echo curves are stored with date and time and the corresponding

echo data. The memory is divided into two sections:

Echo curve of the setup: This is used as reference echo curve for the

measurement conditions during setup. Changes in the measurement

conditions during operation or buildup on the antenna can thus be

recognized.

The echo curve of setup is stored via:

l PC with PACTware/DTM

l Control system with EDD

l Indicating and adjustment module

41783-EN-120316

48 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 49

4

1

2

3

9 Diagnosis, Asset Management and service

Further echo curves: Up to 10 echo curves can be stored in a ring

buffer in this memory section.

Additional echo curves are stored via:

l PC with PACTware/DTM

l Control system with EDD

9.3 Asset Management function

The instrument features self-monitoring and diagnosis according to NE

107 and VDI/VDE 2650. In addition to the status messages in the

following tables there are more detailed error messages available

under the menu item "Diagnosis" via the indicating and adjustment

module, PACTware/DTM and EDD.

Statu

s messages

The status messages are classified in the following categories:

l Failure

l Function check

l Out of specification

l Maintenance requirement

and explained by pictographs:

Fig. 27: Pictograms of the status messages

1 Failure - red

2 Function check - orange

3 Out of specification - yellow

4 Maintenance - blue

Failure: Due to a malfunction in the instrument, a failure message is

outputted.

This status message is always active. It cannot be deactivated by the

user.

Function check: The instrument is in operation, the measured value is

temporarily invalid (for example during simulation).

This status message is always active. It cannot be deactivated by the

user.

Out of specification: The measured value is unstable because the

instrument specification is exceeded (e.g. electronics temperature).

This status message is inactive by default. It can be activated by the

user via PACTware/DTM or EDD.

41783-EN-120316

LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire 49

Page 50

9 Diagnosis, Asset Management and service

Maintenance: Due to external influences, the instrument function is

limited. The measurement is affected, but the measured value is still

valid. Plan in maintenance for the instrument because a failure is

expected in the near future (e.g. due to buildup).

This status message is inactive by default. It can be activated by the

user via PACTware/DTM or EDD.

Fa

ilure

The following table shows the error codes in the status message

"Failure" and gives information on the reason and rectification. Keep in

mind that some information is only valid with four-wire instruments.

Code

mes-

Text

sage

F013

no measured

value available

F017

Adjustment

span too small

F025

Error in the

linearization

table

F036

No operable

software

F040

Error in the

electronics

F080 l General software error l Separate operating voltage

F105

Determine

measured value

F113

Communica-

tion error

Cause Rectification

l Sensor does not detect an

echo during operation

l Antenna system contami-

nated or defective

l Adjustment not within

specification

l Index markers are not

continuously rising, for examle unlogical value pairs

l Failed or interrupted soft-

ware update

l Hardware defect l Exchange of the elec-

l The instrument is still in the

start phase, the measured

value could not yet be

determined

l EMC interferences

l Transmission error with the

external communication

with 4-wire power supply

unit

l Check or correct installa-

tion and/or parameter adjustment

l Clean or exchange process

component or antenna

l Change adjustment ac-

cording to the limit values

(difference between min.

and max. ≥ 10 mm)

l Check linearization table

l Delete table/Create new

l Repeat software update

l Check electronics version

l Exchange of the elec-

tronics

l Send instrument for repair

tronics

l Send instrument for repair

briefly

l Wait for the warm-up phase

l Duration depending on the

version and parameter adjustment up to approximately 3 min.

l Remove EMC influences

l Exchange 4-wire power

supply unit or electronics

41783-EN-120316

50 LEVEL TRANSMITTER 8136 • 4 … 20 mA/HART - two-wire

Page 51

9 Diagnosis, Asset Management and service

Func

tion check

Code

Text mes-

sage

F125

Unpermissible

electronics

temperature

F260

Error in the

calibration

F261

Error in the

configuration

F264

Installation/S-

etup error

F265

Measurement

function disturbed

e following table shows the error codes and text messages in the

Th

Cause Rectification

l Temperature of the elec-

tronics in the non-specified

section

l Error in the calibration car-

ried out in the factory

l Error in the EEPROM

l Error during setup

l False signal suppression

faulty

l Error when carrying out a

reset

l Adjustment not within the

vessel height/measuring

range

l Max. measuring range of