Bunn JDF-4S User Manual 2

JDF-2S

JDF-4S

Silver Series®

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

44744.0002E 12/13 ©2012 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1)Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCP/MCA pod brewers thermal servers and Thermofresh servers (mechanical and digital)- 1 year parts and 1 year labor.

2)All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a)Electronic circuit and/or control boards - parts and labor for 3 years.

b)Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c)Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts and labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor water quality, damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal use including but not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, Velocity Brew, Air Brew, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red Line, Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2 |

44744.2 070913 |

|

CONTENTS |

|

Warranty......................................................................................................................... |

2 |

User Notices................................................................................................................... |

3 |

Initial Set-Up & Electrical Requirements......................................................................... |

4 |

Plumbing Requirements................................................................................................. |

4 |

CE Requirements............................................................................................................ |

4 |

Door Cover Installation................................................................................................... |

5 |

Plumbing Hookup........................................................................................................... |

6 |

Initial Fill......................................................................................................................... |

6 |

Loading........................................................................................................................ |

15 |

Priming......................................................................................................................... |

15 |

Operating Controls......................................................................................................... |

8 |

Dispenser Use.............................................................................................................. |

10 |

Portion Control Option................................................................................................. |

10 |

Cleaning....................................................................................................................... |

12 |

Adjustments & Optional Settings.................................................................................. |

14 |

Function Lists............................................................................................................... |

18 |

Troubleshooting........................................................................................................... |

20 |

Coolant Diagram........................................................................................................... |

26 |

Schematic Wiring Diagram........................................................................................... |

27 |

Quick Setup Guide........................................................................................................ |

29 |

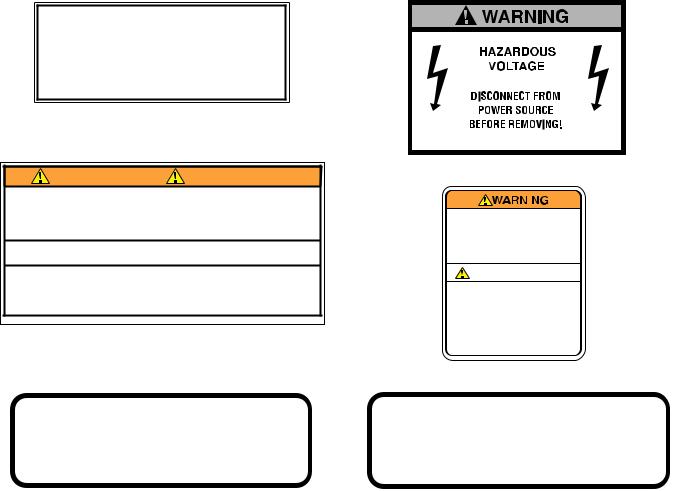

USER NOTICES

Carefully read and follow all notices on the equipment and in this manual. They were written for your protection. All notices are to be kept in good condition. Replace any unreadable or damaged labels.

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual of the Food and Drug Administration (FDA), this equipment must be installed with adequate backflow prevention to comply with federal, state and local codes. For models installed outside the U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

00656.0001

WARNING |

|

AVERTISSEMENT |

|

||

• DO NOT OVERLOAD CIRCUIT. |

|

• NE PAS SURCHARGER LE CIRCUIT. |

• ALWAYS ELECTRICALLY GROUND THE CHASSIS. |

|

• TOUJOURS METTRE LE BOITIER À LA MASSE. |

• DO NOT DEFORM PLUG OR CORD. |

|

• NE PAS DÉFORMER LA FICHE OU LE CORDON. |

• FOLLOW NATIONAL AND LOCAL |

|

• SE CONFORMER AUX CODES NATIONAL OU LOCAL |

ELECTRICAL CODES. |

|

D'ÉLECTRICITÉ. |

• KEEP COMBUSTIBLES AWAY. |

|

• GARDER LES PRODUITS COMBUSTIBLES À DISTANCE. |

FAILURE TO COMPLY RISKS EQUIPMENT |

|

TOUT MANQUEMENT À SE CONFORMER À CES DIRECTIVES PEUT |

|

ENTRAINER DES DOMMAGES À L'ÉQUIPMENT OU PRODUIRE DES |

|

DAMAGE, FIRE OR SHOCK HAZARD. |

|

|

|

DANGERS D'INCENDIE OU D'ÉLECTROCUTION. |

|

READ THE ENTIRE OPERATING MANUAL INCLUDING |

|

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT |

THE LIMIT OF WARRANTY AND LIABILITY BEFORE |

|

EN ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET |

|

RESPONSABILITÉS,AVANT D’ACHETER |

|

BUYING OR USING THIS PRODUCT. |

|

|

|

OU D'UTILISER LE PRÉSENT PRODUIT. |

|

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS |

|

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION |

ELECTRICALLY DISCONNECTED. |

|

LORSQU'IL N'EST PAS DÉBRANCHÉ. |

|

|

|

00986.7000A 10/07 ©2007 Bunn-O-Matic Corporation

00986.7000

12559.0003

Moving Parts. |

|

|

|

|

Risk Of Electrical Shock. |

||

|

|||

Do not operate |

|

Disconnect power before |

|

unit with this |

|

servicing unit. |

|

panel removed. |

|

|

|

|

|

|

|

AVERTISSEMENT |

|||

Pièces amovibles |

Risk de choc électrique. |

||

Ne pas utiliser |

Debrancher le cordon |

||

l'appareil lorsque |

d'alimentation de |

||

le panneau est |

l'appareil avant de faire |

||

enlevé. |

l'entretien. |

||

|

|

|

|

27442.7000

CHARGE

Type R134A, Amount 10 oz (283 gm) Design Pressures:

High 335 psi (23 bar) (2.31 MPa) Low 88 psi (6 bar) (0.61 MPa)

CHARGE

Type R134A, Amount 9 oz (255 gm) Design Pressures: High 255 psi (15.5 bar)

Low 36 psi (2.5 bar)

33461.0000 |

33461.0001 |

JDF-4S |

JDF-2S |

3 |

44744.2 082112 |

|

INITIAL SET-UP

CAUTION: The dispenser is very heavy! Use care when lifting or moving it. Use at least two people to lift or move the dispenser. Place dispenser on a sturdy counter or shelf able to support at least 150 lbs. (68 kg). This dispenser is designed for indoor use only.

Set the dispenser on the counter where it will be used. This dispenser requires a minimum of 4 inches (102 mm) of air clearance at the rear and 8 inches (203 mm) of air clearance above the dispenser. Minimal clearance is required between the dispenser sides and the wall or another appliance. For optimum performance, do not let warm air from surrounding machines blow on the dispenser. Leave some space so the dispenser can be moved for cleaning.

CE REQUIREMENTS

•This appliance must be installed in locations where it can be overseen by trained personnel.

•For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

•Appliance shall not be tilted more than 10° for safe operation.

•An electrician must provide electrical service as specified in conformance with all local and national codes.

•This appliance must not be cleaned by water jet.

•This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given instructions concerning use of this appliance by a person responsible for its safety.

•Children should be supervised to ensure they do not play with the appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with a special cord available from the manufacturer or its authorized service personnel in order to avoid a hazard.

• Machine must not be immersed for cleaning.

ELECTRICAL REQUIREMENTS

CAUTION: The dispenser must be disconnected from the power source until specified in Electrical Hook-Up.

The 120V rated dispensers have an attached cord set and require a 2-wire, grounded, individual branch circuit rated 120 volts ac, 15 amp, single phase, 60Hz. The mating connector must be a NEMA 5-15R.

The 220-230V rated dispenser has an attached cord set and requires an attachment plug cap rated at least 230 volts ac, 15 amp. The attachment plug cap must meet with applicable national/local electrical codes.

Refer to the data plate for exact electrical requirements.

ELECTRICAL HOOK-UP

CAUTION: Improper electrical installation will damage electronic components.

1.An electrician must provide electrical service as specified.

2.Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3.Confirm that the refrigeration switch near the main control board is in the OFF position.

4.Connect the dispenser to the power source.

5.If plumbing is to be hooked up later, be sure the dispenser is disconnected from the power source. If plumbing has been hooked up, the dispenser is ready for Initial Fill.

PLUMBING REQUIREMENTS

This dispenser must be connected to a COLD WATER system with operating pressure between 20 and 100 psi (138 and 690 kPa). This water source must be capable of producing a minimum flow rate of 3 fluid ounces (88.7 milliliters) per second. A shut off valve should be installed in the line before the dispenser. Install a regulator in the line when pressure is greater than 100 psi (690 kPa) to reduce it to 50 psi (345 kPa). The regulator is also necessary if the water source has pressure fluxuations. The main water inlet is a 3/8” (9.52 mm) MFL connection.

NOTE- At least 18 inches (457 mm) of an FDA approved flexible beverage tubing, such as reinforced braided polyethylene, before the dispenser will facilitate movement to clean the countertop. It can be purchased direct from BUNN-O-MATIC (part number 34325.10_ _ [see Illustrated Parts Catalog for complete part number.]) BUNN-O-MATIC does not recommend the use of saddle valves to install the dispenser. The size and shape of the hole(s) made in the supply line(s) by saddle valves may restrict water flow.

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual of the Food and Drug Administration (FDA), this equipment must be installed with adequate backflow prevention to comply with federal, state and local codes. For models installed outside the U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

4 |

44744.2 062912 |

|

DOOR COVER INSTALLATION

1. Install door cover by first plugging the door harness connector into the machine harness connector located at the bottom of the machine door.

JDF-2S |

P3577 |

JDF-4S |

|

|

|

2. On Portion Control models, connect membrane |

3. Install door cover |

|

switches to Door Circuit Board. |

|

|

JDF-4S Shown |

JDF-2S & JDF-4S |

P3578 |

|

4. Secure the door cover using 5 screws provided.

JDF-2S |

P3579 |

JDF-4S |

P3840 |

|

|

5 |

44744.2 110813 |

|

PLUMBING HOOKUP

The plumbing connection is located on the rear of the dispenser. A 3/8" (9.52 mm) male flare adapter fitting is supplied, installed on the rear of the dispenser.

NOTE - Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed and maintained in accordance with federal, state and local codes.

|

1 |

FIG 1 Plumbing Connections - JDF-2S |

FIG 2 Plumbing Connections - JDF-4S |

INITIAL FILL

CAUTION: The dispenser must be disconnected from the power source throughout the initial fill except when specified in the instructions.

1.Remove drip tray assembly and splash panel from the dispenser. Replace the drip tray.

2.Connect the water source to the back of the dispenser.

3.Pull the fill tube from the dispenser, remove the plug and connect it to the dispense nozzle (Fig. 5 & 6).

4.Set the Program Switch (Fig. 7) to the ON position. (On older models without program switch, set the Dispense Lockout Switch (Fig. 13) to the OFF position)

5.Connect dispenser to the power source. Press and hold the dispense button for the dispense station that the tube is connected to for 10 seconds, until you hear the water valve turn on. (For Portion Control machines, press and hold the PLUS/STOP switch)

6.Monitor the water bath fill level until water starts to trickle from the overflow tube. Then press the dispense

button again to stop the fill process.

NOTE: The fill timer may time out before filling is complete. Press and hold the dispense button for 10 seconds to start again if needed.

FIG 3 Initial Fill Hose - JDF-2S |

FIG 4 Initial Fill Hose - JDF-4S |

6 |

44744.2 110813 |

|

INITIAL FILL (Continued)

7.Turn ON the refrigeration switch near the main control board (Fig. 7). This will start the water bath pump circulation.

8.Check water level in the overflow tube and top off the tank if necessary (Step 5).

9.Disconnect the fill tube and allow excess water to drain into the drip tray. Replace the plug in the end of the fill tube and store back into the dispenser.

10.Set the Program Switch (near main control board) to the OFF position. (On older models without program switch, set the Dispense Lockout Switch to the ON position)

11.Replace the splash panel and drip tray.

12.It will take several hours to create the ice bank required for full dispenser performance. During this time, some further trickling from the water bath is expected due to expansion caused by ice bank formation. While the refrigeration system is creating the ice bank, the dispenser may be readied for use as described in Loading, Priming and Adjustment.

FIG 5 Initial Fill Connection - JDF-2S |

FIG 6 Initial Fill Connection - JDF-4S |

7 |

44744.2 110813 |

|

OPERATING CONTROLS

Refrigeration Switch

The refrigeration switch is located on the Electrical Panel of the dispenser near the Circuit Board. This switch controls power to the water bath pump and relay contacts for the compressor and condenser fan motor.

FIG 7 Refrigeration Switch

Product Dispense Switch (Mechanical Switch Machines)

Pressing and holding switch will initiate product flow from the respective nozzle; releasing the switch will stop the flow.

FIG 9 Product Dispense Switches - JDF-2S |

FIG 10 Product Dispense Switches - JDF-4S |

8 |

44744.2 110813 |

|

OPERATING CONTROLS (Continued)

Product Dispense Switch (Membrane Switch Machines)

A.Product Dispense Switch

Momentarily pressing and releasing one of the switches will initiate a timed dispense. Each station has three different timed dispenses which are preset at the factory. Refer to DISPENSER USE section for preset volumes and adjustment procedures.

B.Plus/Stop Switch

This switch can be used to “top-off” a beverage. Pressing and holding switch will initiate product flow from the respective nozzle; releasing the switch will stop the flow. Momentarily pressing this switch during a timed dispense will stop the flow.

C.Chilled Water Dispense Switch (Optional for JDF-4S only)

Pressing and holding switch will initiate chilled water flow from the nozzle; releasing the switch will stop flow.

FIG 11 Product Dispense Switches - JDF-2S |

FIG 12 Product Dispense Switches - JDF-4S |

Dispense Lockout Switch

This switch is located at the bottom front of the dispenser just behind the drip tray. It is used to turn ON and OFF the Dispensing function. It is also used for some programming and fill procedures.

FIG 13 Dispense Lockout Switch

Program Switch

This switch is located near the main control board next to the refrigeration switch.

FIG 14 Program Switch

9 |

44744.2 110813 |

|

OPERATING CONTROLS (Continued)

DISPENSER USE

Press and Hold Dispensing:

1.Place a cup on the drip tray beneath the desired dispensing nozzle.

2.Press and hold the “Product Dispense” switch until the beverage reaches the desired level, then release.

Portion Control Option (Mechanical Switch Machines)

The dispenser is also equipped with a portion control option. The following steps will guide you through the set up process for this option. Portion control can be set on one or all dispense heads as needed.

1.Unplug dispenser from power source.

2.Set the Program Switch (near main control board) to the ON position. (On older models without program switch, set the Dispense Lockout Switch to the OFF position)

3.Remove drip tray and splash panel from the front of the machine then replace the drip tray.

4.Press and hold the left most (Station 1) dispense switch while plugging the dispenser into the power source. Continue holding dispense switch(s) until all 4 temperature LED’s, Figs. 15 and 16 on the circuit board start flashing slowly (this takes about 5 seconds). Release dispense switch(s).

5.Press and release any dispense switch 6 times to enter the portion control set up mode. This will cause the 4 temperature LED’s to flash rapidly.

6.Place a container under the desired dispense nozzle to measure the portion size.

7.Press and hold the desired dispense switch to dispense product until the desired amount of product is achieved. (Maximum dispense time is 150 seconds). Repeat this on all dispense heads as desired.

8.Set the Program Switch (near main control board) to the OFF position. (On older models without program switch, set the Dispense Lockout Switch to the ON position)

9.Place a container under the dispense nozzle(s) and press the dispense button to confirm that the portion size is set correctly. Repeat steps 1-8 if any changes are needed.

10.Replace splash panel.

Note: The portion control dispense can be cancelled during a dispense by pressing the dispense button again. Note: If a portion size is not set for a dispense head while in the portion control set up mode, that dispense head will remain a push and hold dispense head.

Push and Hold Membrane Switch Machines

1. To set single portion sizes on a push and hold membrane type dispense switch, follow steps 1 - 10 above.

Portion Control Option (Membrane Switch Machines)

Portion sizes are preset but can be adjusted by following these steps below.

1.Set the Program Switch (near main control board) to the ON position. (On older models without program switch, set the Dispense Lockout Switch to the OFF position)

2.Press and hold the large and medium buttons on the left most (Station #1) dispense station until you hear the machine "beep" three times.

3.Place a measuring container under the station to be adjusted, then press and hold the apprpriate dispense switch until the desired amount is dispensed. The machine will record the amount of time that the button is pressed continously. If the button is released too soon, simply empty the container and start over.

4.Repeat step 3 for all stations as desired.

5.Turn the program switch to the OFF position.

10 |

44744.2 110813 |

|

Loading...

Loading...