BUNNEspress

ESPRESSO/CAPPUCCINO

COFFEE BREWER

TM

TM

ES•1A

ES•1A

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

P-176

10712.0000A 7/93 ©1993 Bunn-O-Matic Corporation

BUNN Espress™ Model ES•1A™

INDEX

Warranty..............................................................2

User notices ........................................................3

Features.......................................................... 4-9

Installation.........................................................10

Initial setup/use .................................................11

Programming ....................................................12

Cleaning............................................................13

Trouble-shooting ......................................... 14-15

Schematic-plumbing .........................................16

Schematic-electrical..........................................17

Replacement parts...................................... 18-25

Frequency of cartridge change ................... 26-28

1

BUNN Espress™ Model ES•1A™

WARRANTY

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from defects in material

and workmanship existing at the time of manufacture and appearing within one year from the date of installation. This warranty

does not apply to any equipment, component or part that was not manufactured by Bunn or that, in Bunn’s judgement, has

been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, damage or

casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are not authorized to make modifications to this

warranty or to make additional warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral

or written, do not constitute warranties and should not be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or

by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the Buyer shall ship the defective

equipment prepaid to an authorized Bunn service location. If Bunn determines, in its sole discretion, that the equipment does

not conform to the warranty, Bunn shall repair the equipment with no charge for parts during the one year warranty period and

no charge for labor by a Bunn Authorized Service Representative during the one year warranty period. If Bunn determines that

repair is not feasible, Bunn shall, at its sole option, replace the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS SPECIFIED HEREIN, TO

REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND. Bunn shall not be liable for any other damage or loss,

including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost

of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

2

BUNN Espress™ Model ES•1A™

The notices on this brewer should be kept in good condition. Replace unreadable or damaged labels.

USER NOTICES

This equipment is to be installed to

comply with the Basic Plumbing Code of

the Building Officials and Code

Administrators International, Inc. (BOCA)

and the Food Service Sanitation Manual

of the Food and Drug Administration (FDA).

00656.0000

WARNING

HAZARDOUS

VOLTAGE

CAUTION

HOT

Liquid-Steam-Surfaces

24246.0000

NOTICE

160 psig max operating pressure

UNPLUG BREWER

BEFORE REMOVING!

12652.0000

Fill water tank before turning -on

thermostat or connecting appliance

to power source.

Use only on a properly protected

circuit capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

!

WARNING

24247.0000

READ THE ENTIRE OPERATING MANUAL

BEFORE BUYING OR USING THIS PRODUCT

THIS APPLIANCE IS HEATED WHENEVER

CONNECTED TO A POWER SOURCE

00831.0000F 3/98 © 1988 BUNN-O-MATIC CORPORATION

00831.0000

3

BUNN Espress™ Model ES•1A™

FEATURES

Hot water rinse dispensing tube and steam dispensing tube

The ES•1A™ is equipped with a hot water rinse dispensing tube and a steam dispensing tube. They are

operated by moving the levers located at the bottom of the machine from to side-to-side; they can be placed

in a continuously open position if required. The outlet tubes can also be rotated.

STEAM

HOT WATER RINSE

P-157

Boiler

The boiler is made of copper plating, 1.5 mm thick; it operates under a pressure between 1.1 to 1.3 bar

(16-18.8 psi). This is measured by means of a pressure gauge with a scale from 0 to 2 bar (0-29 psi). The

safety valve assures that boiler pressure never exceeds the safety limits; it automatically discharges steam

when pressure inside the boiler exceeds 1.8 bar (26.1 psi). The water heating element is an electric resistance

unit controlled by a pressure switch. This switch automatically regulates the pressure of steam in the boiler.

The pressure switch will automatically shut off the heater when necessary.

Electrical pump

The electric pump incorporated in the machine is required to obtain optimum water pressure of 9 bar (130

psi) for espresso extraction. If water pressure from the tap exceeds 5 bar (73 psi), a pressure reducer should

be installed to avoid damaging the machine. If a pressure reducer is required, it should be installed in the water

inlet pipe just before the water conditioner or electric-pump.

4

BUNN Espress™ Model ES•1A™

FEA TURES

7

6

4

3

9

11

10

2

12

1

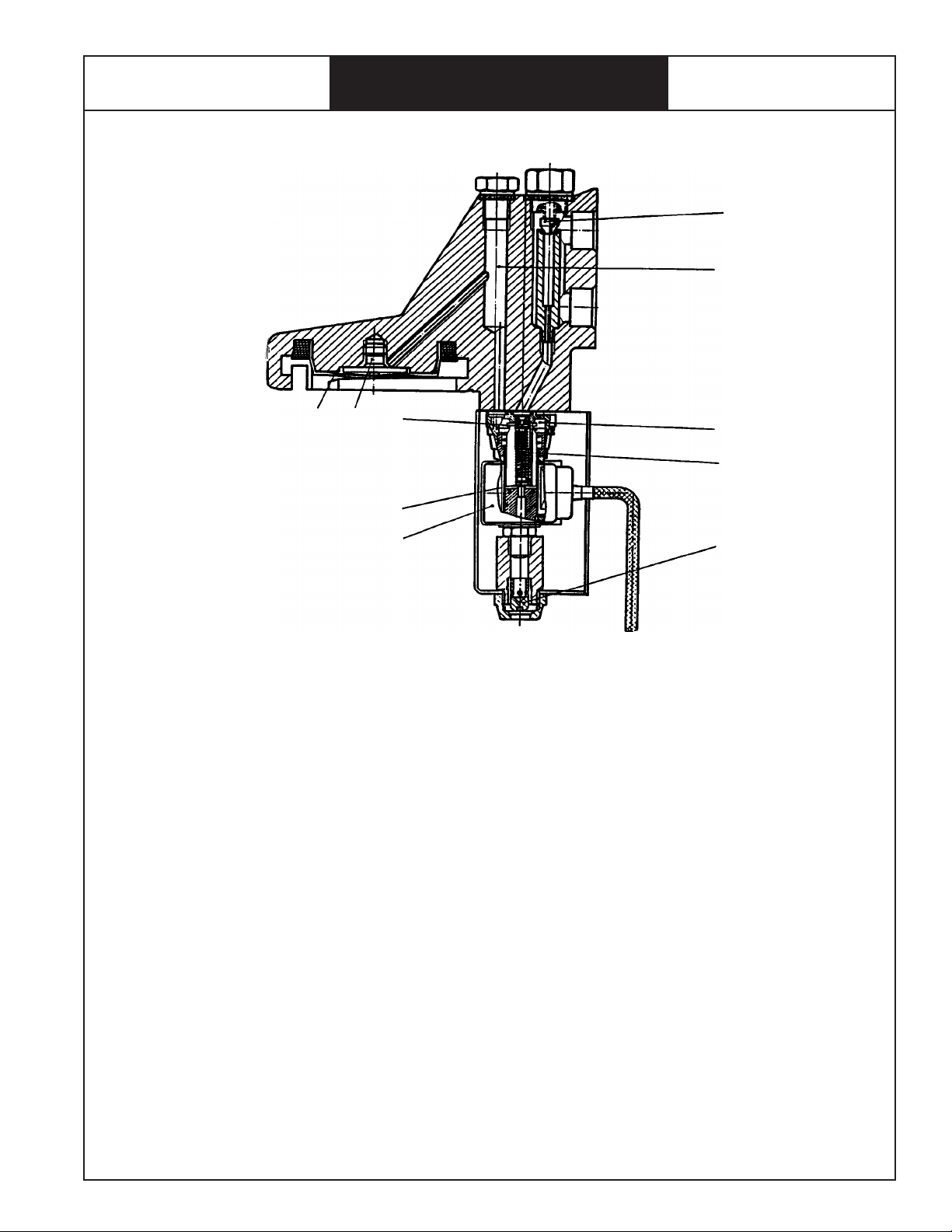

Group head (Espresso extraction chamber)

The group head-espresso extraction chamber is where the coffee infusion takes place. After extraction,

an electric pressure valve automatically discharges the accumulated pressure. When the coil (12) of the

electro-valve receives an electric current, causing the plunger (10) to move, thus closing the discharge valve

(2) and opening the water intake valve (9) allowing the water to pass towards the shower (4) through the

sprayer (3). This is when the brewing process (infusion) begins.

The bubbling effect is produced by an interchange between air, contained in a bubble formed in the

chamber, and water which progressively increases it’s pressure on that bubble. The mixture of air and water

produced then falls on coffee previously dampened by the infusion process. When the liquid extraction

process of the coffee is complete, excess pressure contained in the filter holder is then released through a

discharge valve (2). The atomizer (1) directs the water being discharged to the opening to avoid it’s splashing

outward.

Water softener

It is essential to install a water softener to prevent any calcium build up in the boiler and hydraulic circuit.

P-158

5

BUNN Espress™ Model ES•1A™

FEATURES

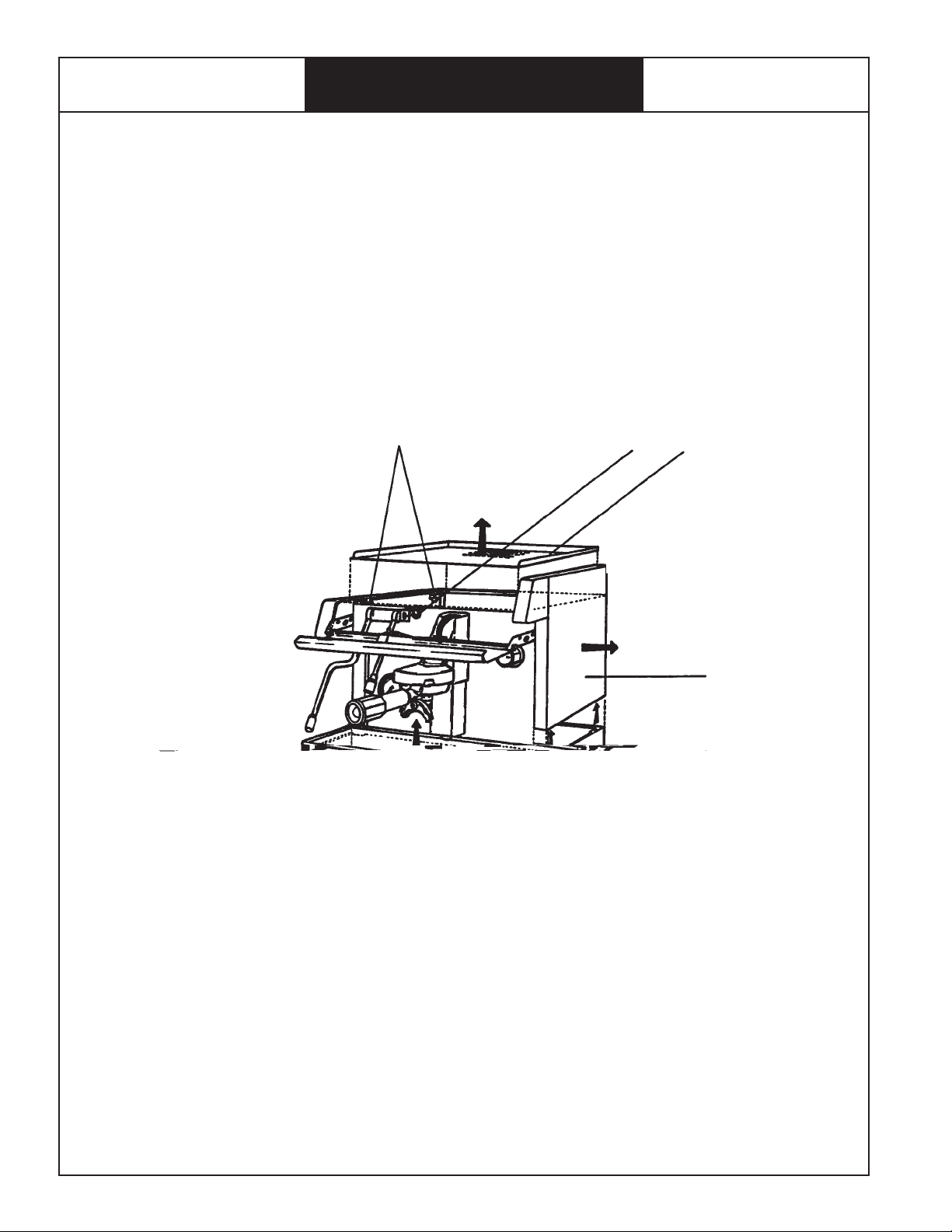

Chassis

The chassis of the ES•1A™ is made of painted steel and the work tray is stainless steel. To reach the

interior of the machine, proceed as follows:

• Remove the cup heater tray (1)

• Loosen the two screws (2) holding the side panel in place (2)

• Remove the side panel (3) by lifting it up carefully.

• By loosening the nut (4) that holds the control panel in position and by placing the front piece at a right

angle, access to the interior of the control panel is obtained.

• Finally, by removing the work tray (5) and the drainage tray (6), access is gained to all the elements

of the machine.

2

4

1

3

6

Technical features

Width......................... 400 mm(15.7 inches)

Height........................ 370 mm(14.5 inches)

Depth......................... 490 mm(19.3 inches)

Net weight ................. 30 kgs(66.12 lbs.)

Gross weight ............. 37 kgs(81.55 lbs.)

Hydraulic feed............3⁄8"-19 Straight pipe BSPP

5

P-159

Drainage .................... 25 mm (1.07 in)

Total brewer power.... 2000 W.

Electric feed...............120 V. Single phase

Consumption ............. 16.7 A.

Boiler capacity ........... 4.0 liters (1.05 gal)

6

BUNN Espress™ Model ES•1A™

FEATURES

8

7

6

5

4

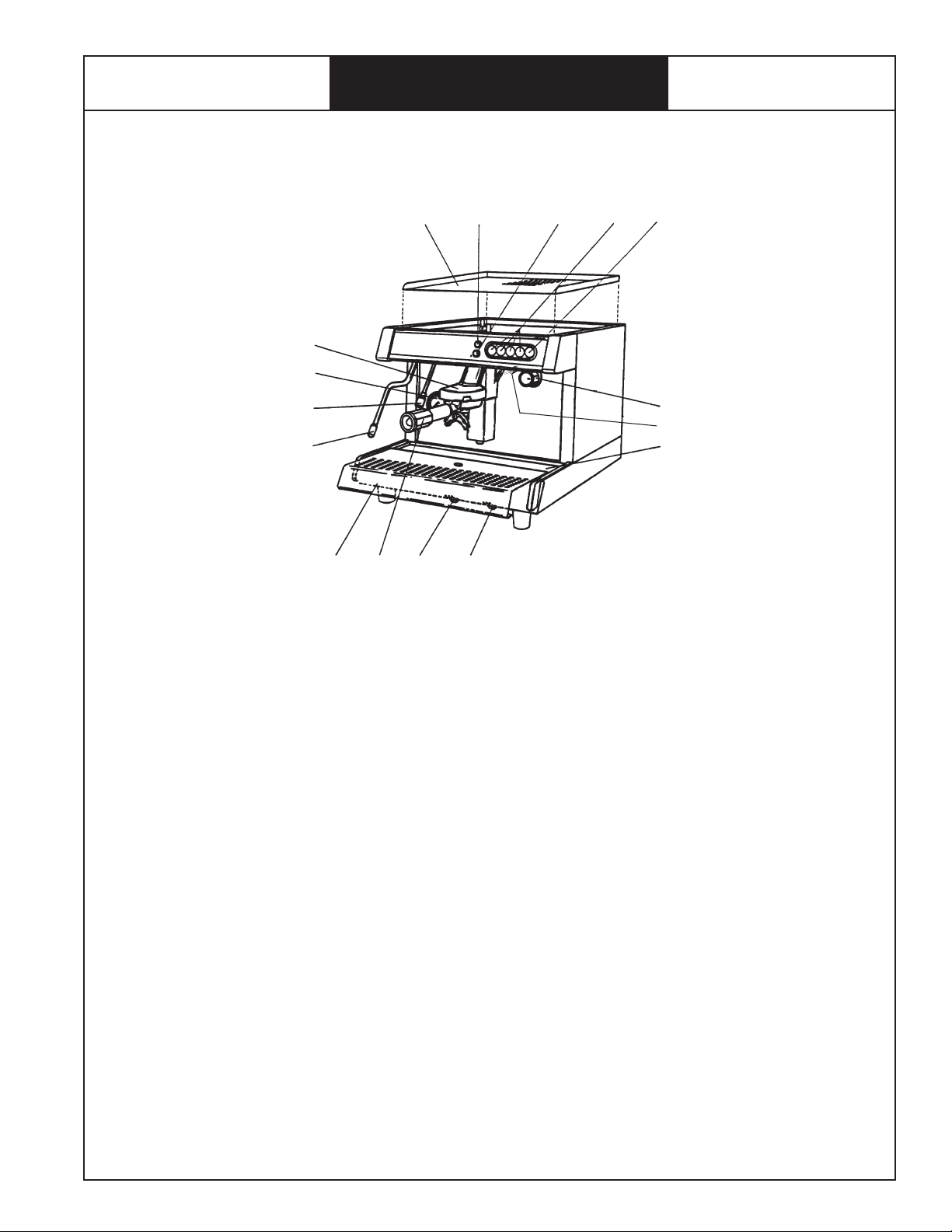

Component identification

9

10

11

12

13

15

14

16

P-161

2

13

1 ..................Hot water rinse outlet control lever

2 ..................Steam outlet control lever

3 ..................Hand grip-filter container for coffee

4 ..................Work tray

5 ..................Steam outlet tube

6 ..................Hot water rinse outlet tube

7 ..................Pressure gauge pump/steam

8 ..................Group head espresso extraction chamber

9 ..................Cup-heater tray

10 ................Power light

11 ................Refill light

12 ................Automatic dosification selector panel

13 ................Continuous flow control button

14 ................Program/Run toggle switch

15 ................General ON/OFF switch

16 ................Drainage tray

7

BUNN Espress™ Model ES•1A™

FEATURES

Warning alarm (visual only, not audible) on flow counter

This alarm goes off when impulses from the flow meter are not registered by the central control unit, or

when a period in excess of five seconds lapses between impulses from the flow meter . If the brewer is running

(i.e. pilot lamp on continually), brewer function will stop and the lamp will begin to flash. Begin trouble shooting

by checking the following:

• Excessively fine grind of the coffee or excessive tamping.

• Any possible obstruction in the coffee outlet (dirty shower unit, blocked set injector, etc.).

• Electrical connections on the volumetric counter.

• Electric valve (group solenoid.

• Electrical connection on the electric valve.

• Possible breakdown in the electric pump.

In order to eliminate the alarm signal simply press any of the buttons; however, if the problem persists,

the alarm will reappear every time a programmed dose button is pressed. This alarm does not effect the

machine’s functioning in the continuous liquid drawing mode or automatic refill.

Warning alarm (visual only, not audible) on automatic refill

This alarm goes off when the water entering the boiler does not reach its required level within a

predetermined period of time. The time limit control prevents any over-filling from taking place. Once the

alarm goes off, all automatic batch buttons a well as auto matic refill will not function. If the alarm goes off,

check the following:

• Level probe.

• Connections of the level probe.

• Water entrance (possible blockage at input).

• Electric valve controlling the entrance of the water into the boiler.

This alarm does not impede the machine’s functioning in the continuous liquid drawing mode and is not

effected if the machine is disconnected from the water supply and reconnected.

NOTE: After the problem has been solved the alarm can be reset in the following way: move the

programming switch (14) to the programming position; simultaneously press the “one short” and

“two short” buttons. When the alarm has been eliminated, the switch should be turned back into

the “run” position.

The alarm will most likely go off when filling an empty or nearly empty boiler (such as in the event

of repairs or setting up a new machine), it may happen more than once.

8

BUNN Espress™ Model ES•1A™

FEATURES

Central/Electronic unit

This component analyzes and controls all information received from the buttons and volumetric counter,

activating the different relays and thus causing the different electric valves and the electric pump to start

functioning.

The connections of the central unit, as shown on the diagrams, are divided into two parts. First of all, the

connections that are marked with a zero plus a number correspond to the power feed and to the output. The

connections that are marked with just a number correspond to the inputs and to the outputs of the information

coming to the central unit from the volumetric counter, the electronic level or the programming switch. There

is also a single connection with a flat wire for 10 conductors which corresponds to these connection with the

buttons.

013

07

010

06

05

F

1

F

2

F

2

1

2

5

7

3

14

Connection

to the

dose switch

05-06.....120v. feed

07 ..........Connection refill solenoid

010 ........Output for the group solenoid valve

013 ........Output for the electric pump

Fl ...........Feed fuse, electric pump

F2 ..........Feed fuse electric valves

F3 ..........Feed fuse for the central unit

1-2.........Output to the programming switch

3 ............Connection to ground

5 ............Feed output (-) volumetric counter (flowmeter)

7 ............Feed output (+) volumetric counter (flowmeter)

14 ..........Connection to the level probe

9

BUNN Espress™ Model ES•1A™

INSTALLATION

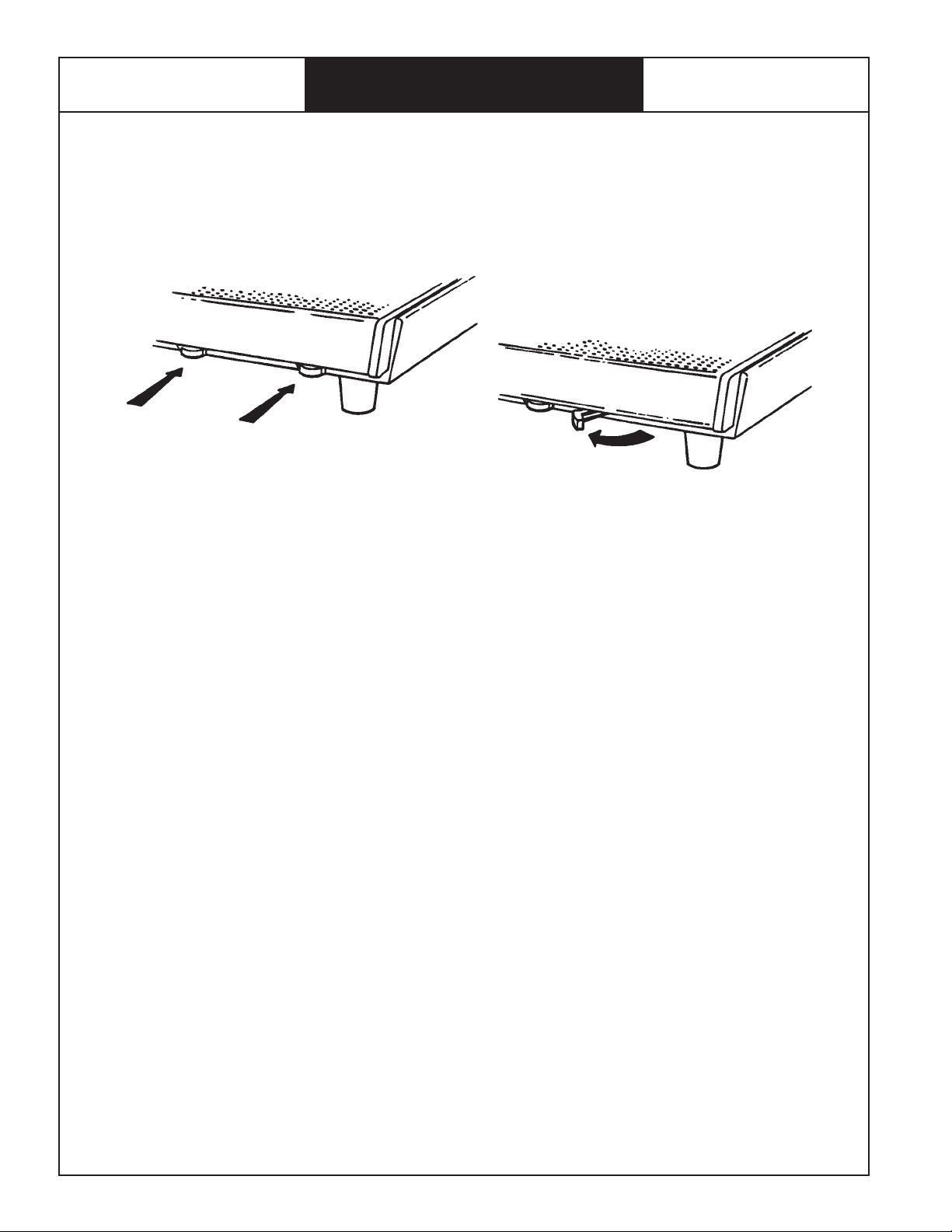

Placement and installation

Once the machine has been unpacked, it should be placed on a table or counter having sufficient space

for easy access to water, electricity and drainage per the following specifications.

• A water inlet pipe.

• An electric plug with ground wire.

• A drain pipe with minimum interior diameter of 35 mm.

2

4

1

3

1....Three-way or two-way plug with ground wire.

2....Pipe with a minimum internal diameter of 35mm (braided hose is provided).

3....Water conditioner 3⁄8" flare

4....Strainer assembly (part # 24744.0000)

Water installation

Pipes for water and drainage connections are located in the lower front part of the machine. To reach them,

raise the work and drainage trays. Connect the corresponding pipes, which are packed with the machine in

the following way:

From the electric pump to the water conditioner, and from the conditioner to the tap inlet. In the event a

water purifier is not installed, the connection from the electric pump should be made directly to the tap outlet.

One end of the flexible drain pipe must be connected to the drainage cup section and the other end to the

general drain.

NOTE: For cart applications, unit will function with pump suction line suspended into a container of water.

Be sure not to run the container dry, damage to the pump will occur.

Electrical installation

Be certain that the available voltage at the installation site is the same as that on the manufacturer’s data

plate. This plaque is located on the left side of the machine. The electrical connection should be made directly

to a wall socket equipped with a ground wire using the plug provided.

P-160

10

BUNN Espress™ Model ES•1A™

INITIAL SETUP/USE

Filling

1. Make sure power switch is OFF and water is connected and turned ON before plugging in.

NOTE - Plumbing must be connected to the brewer before proceeding.

2. Locate the ON/OFF switch knob. It is in the upper right corner of the front panel.

3. Rotate the knob to the "OFF" (farthest counterclockwise) position.

4. Plug-in the brewer.

5. Place the power switch in the “ON” position.

6. Rotate the ON/OFF Switch knob to the

fill with water without turning-on the heater.

7. The refill pilot light (lower indicator on the front panel) will glow and the tank will automatically fill with

water.

“OFF”

(farthest clockwise) position. This allows the tank to

NOTE:

8. Water will continue to flow into the tank until full. Simply repeat steps a-e above if the pump stops

again.

9. When the tank stops filling and the lower pilot light stops flashing, rotate the general ON/OFF switch

knob to the "ON" (center) position.

10. Allow the water in the tank to heat to the proper temperature before using the brewer.

11. Press any of the automatic brewing buttons. This causes hot water to circulate and the warming of the

extraction chamber to begin.

Proceed as follows if the pump stops and the pilot light flashes during the fill procedure:

a. Locate the small toggle switch on the upper right side of the front panel

b. Carefully place the switch in the right position.

c. Press the one-short and two-short cup brew switches simultaneously, flashing light

will stop.

d. Place the toggle switch in the left position.

e. The filling pilot light will glow and the tank will continue to fill with water if required.

Coffee extraction

1. Place ground coffee in the filter holder, shake it level, and compress the bed of coffee with the tamper on

the grinder.

2. Clean the edge of the filter holder with the palm of the hand before locking it on to the set. This will prevent

any coffee particles from imbedding themselves into the group head gasket.

3. Place the filter holder in the group head and twist it to the right until tight. Do not force the filter holder

excessively.

4. Press any one of the four dosification buttons (12) or the continuous draw button (13) according to the dose

required.

5. Extraction ends automatically. If the continuous liquid dispensing button (13) was pressed, dispensing

can be stopped by pressing on any one of the five buttons. The automatic liquid extraction caused by using

one of the four dosification buttons (12) can be stopped by pressing any of the dosification buttons.

NOTE: The automatic selections have regulated doses, these can be set between 0 and 500 cc

The machines leave the factory with regulators adjusted for the following approximate amounts:

One short coffee: 50 cc of water

One normal coffee: 100 cc of water

Two short coffees: 100 cc of water

Two normal coffees: 200 cc of water

It should be noted that these doses have been set without coffee in the filter holder. With coffee, the

11

BUNN Espress™ Model ES•1A™

volumes are slightly less. Should different volumes be required, refer to (Programming dosifications)

PROGRAMMING

Control panel

This panel is composed of five buttons (A, B, C, D, and E) and a pilot lamp (F). The buttons A, B, C and

D correspond to the selections of four possible dosifications. Button E is for continuous liquid dispensing; and

the (F) is the pilot light.

F

P-162

A

B

C

D

E

Programming dosifications

To change the factory set dosages, set the Program/Run toggle switch to the “Program” (right) position.

Depending on the dosage you wish to change (1 cup or 2 cups), fill the filter-holder with the proper amount

of ground coffee and place in the group head infusion unit of the machine. Press the corresponding dosage

push-button and hold for approximately 3 seconds. The brew light will be flashing. Once the desired amount

of coffee is achieved press any of the dosage push-buttons to save the new setting in memory. Return the

“Run/Program” switch lever to the “Run” (left) position.

NOTES:1. This operation must be repeated for each dosage you wish to reprogram.

2. The push-buttons which were not reprogrammed will continue using the previous dosage

sets.

3. The “Continuous dosage” is not programmable.

Pre-infusion programming

Pre-infusion causes a non-programmable amount of brew water to be injected into the bed of coffee at

the beginning of the brew cycle; thus wetting the coffee, this is followed by a short delay, followed by the

programmed amount of dispense.

In order to check whether or not the pre-infusion has been turned on, turn the programming switch (14)

to the “Program” (right) position. If the pilot lamp (F) comes on, pre-infusion is on. To eliminate the preinfusion, press the continuous dosage button (E) until the pilot lamp (F) turns off; then return the programming

switch to the “Run” position.

12

BUNN Espress™ Model ES•1A™

CLEANING

Cleaning

1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning

all surfaces on Bunn-O-Matic equipment.

2. Clean the gasket that seals the filter & the group head, located under the group head. Ground coffee

buildup on this gasket will result in a bad seal of the filter holder, and will leak brewed coffee onto the

outside of the filter holder when brewing. This is why it is important to wipe excess coffee off of the rim

of the filter prior to insertion in the group head.

4. The drip tray is to be cleaned daily. Remove the grill and drip pan, wash them out thoroughly, and place

them back into the brewer.

5. The steam wand must be cleaned after each use. Wipe with a damp cloth immediately after use. At the

end of the day, run the steam wand for about 15 seconds to clean it out.

6. The group head is to be cleaned daily.

a. Unit needs to be heated to normal operating temperature. This provides very hot water that will do

the best cleaning.

b. Install the “No hole” filter basket into a filter holder (porta filter).

c. Put a teaspoon of any espresso cleaner or automatic dishwasher detergent into the “No hole” filter

basket.

d. Install the filter holder as if brewing espresso.

e. Press the continuous brew switch (does not pertain to semi-automatic units) to activate the brew

cycle.

f. Allow the cycle to run for about 20 seconds.

g. Press the continuous brew switch to stop the brew cycle.

h. Repeat Step 5 except only allow the brew cycle to run for 10 seconds each time.

i. Repeat Step 6 until the water being discharged is clear. This may be viewed by noting the liquid that’s

being discharged onto the drip tray.

j. Remove filter holder (porta filter) containing the “No hole” filter basket.

k. Rinse thoroughly by turning brew cycle on and off several times.

l. Repeat process for all groups.

13

BUNN Espress™ Model ES•1A™

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department at 1-800-637-8606.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service

personnel.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will

help to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This brewer is heated at all times unless disconnected from the power source. Keep away from

combustibles.

• All electronic components have 120 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection

at a terminal or crimp.

WARNINGS

• Exercise extreme caution when servicing electrical equipment.

• Disconnect the brewer from the power source when servicing, except when specified.

• Follow recommended service procedures.

• Replace all protective shields and safety notices.

TROUBLESHOOTING

Problem

Equipment will not

operate

Brew cycle will not start

Pushing any of the

automatic batch buttons

results in only a short

flash of the brew light.

Will not brew. Continuous brew works as well

as automatic refill.

Probable cause

No power or incorrect

voltage

Toggle switch (Master

on/off)

No water

Water strainer or water

conditioner

Dose sizes were set

with a defective flowmeter. The result was no

flow pulses reached the

electronic controller.

during the dose size

programming.

Remedy

Connect the brewer to the power

source. Check for proper voltages.

Check circuit breaker/fuse.

Must be in the on position. Pilot

lamp will light.

Check plumbing and shut off

valves.

Direction of flow arrows must be

pointing toward the brewer.

Remove the strainer and/or filter

cartridge of the water conditioner

and check for obstructions. Clear

or replace.

Replace flowmeter. Repair loose

connector in wiring between

flowmeter and electronic controller.

14

BUNN Espress™ Model ES•1A™

TROUBLESHOOTING

Problem

Brew cycle will not

start (cont.)

Water is not hot or

long recovery time.

Probable cause

Solenoid valve

Pump

Solenoid valve

Limit thermostat(s)

Remedy

Check voltage at terminals. If voltage is

present when the dose switch is pressed,

disconnect power supply, remove wires

from coil terminals and check coil terminal continuity. If there is continuity replace solenoid.

When start switch is pressed, pump should

turn on immediately. If this dies not happen, check voltage at terminal block on the

pump. If correct voltage is present, use a

flat-blade screwdriver to turn the motor

shaft on the rear end of the motor to see if

the pump itself is locked up. If the shaft

does not turn, replace pump assembly.

Remove the solenoid valve and clear it of

any obstructions. Rebuild or replace the

valve if necessary.

Disconnect power supply , remove all wires

check across limit terminals for continuity.

If no continuity, replace limit thermostat(s).

Tank heater

Check tank heater terminals for correct

voltage. If voltage is present and machine

is not heating properly, replace tank heater.

15

BUNN Espress™ Model ES•1A™

SCHEMATIC-PLUMBING

10

5

6

7

8

9

11

12

4

3

2

1

1 ........ Electric pump

2 ........ Check valve

3 ........ Refill solenoid

4 ........ Flowmeter

5 ........ Steam valve

6 ........ Hot water rinse valve

7 ........ Liquid level probe

8 ........ Pressure relief valve

9 ........ Pressure switch

10 ...... Pressure gauge (Pump/Steam)

11 ...... Compensation valve (anti-siphon)

12 ...... Group head espresso extraction chamber

16

BUNN Espress™ Model ES•1A™

SCHEMATIC-ELECTRICAL

SCHEMATIC WIRING DIAGRAM

ES•1A

L1

BLK WHI

BLKBLU

ABCD

E

CONTROL

SWITCH

5

1234

GREEN

N

CONTROL SWITCH LOGIC TABLE

H

1

A

•

8

•

2

B

•

•

3

C

•

•

4

D

•

•

5

E

•

•

8

H

•

•

1

A

•

•

2

B

•

•

3

C

•

•

4

D

•

•

5

E

•

•

8

H

•

•

1

A

•

•

2

B

•

•

3

C

•

•

4

D

•

•

5

E

•

•

8

H

•

•

TANK HEATERS

BLU

1785 @ 120V

TOTAL WATTS

ELECTRONIC

CONTROLLER

BLU

BLK

TAN

TAN

TAN

PROGRAM

GRN

GRY

BRN

GRN/YEL

RED

GRN

(RIBBON CABLE)

SW

PRESSURE

BLU

BLU

BLU

PROBE

METER

CONTROL &

INDICATOR PANEL

SW

FLOW

BLKBLK

BLU

BLU

BLU

WHI

LIMIT

THERMOSTAT

GROUP

SOL

REFILL

SOL

PUMP

LIMIT

THERMOSTAT

BLK

120 VOLTS AC

2 WIRE

SINGLE PHASE

60 HZ

BLK

17

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

913147 8 10 11 12

6

5

4

3

2

1

24 23 22 21 20 19

Figure Description Part Number

1 ...... Drip tray guide (left) ........................23654.0000

2 ...... Pressure gauge ...............................24210.0000

3 ...... Pressure gauge mounting bracket ... 24212.0000

4 ...... Locating pin-lower side panel..........23648.0000

5 ...... Side panel (left) ...............................23669.0000

6 ...... Nut ..................................................23933.0000

7 ...... Outlet fitting.....................................23610.0000

8 ...... “U” clip ............................................23638.0000

9 ...... Center mtg. brkt., front panel ..........23652.0000

10 .... Screw .............................................. 24004.0800

11 .... Cable clamp ..................................... 23635.0000

12 .... Top cup warmer panel ..................... 23658.0000

15

16

17

P-165

18

Figure Description Part Number

13 .... Back panel .......................................23656.0000

14 .... Side panel (right).............................23668.0000

15 .... Programming switch-toggle ............22816.0000

16 .... Base frame ......................................23667.0000

17 .... Machine frame chassis .................... 23660.0000

18 .... Chrome front panel..........................23659.0000

19 .... Drain cup ......................................... 23634.0000

20 .... Drip tray guide (right)......................23653.0000

21 .... Rubber foot ..................................... 23633.0000

22 .... Nut ..................................................24045.0101

23 .... Drip tray ..........................................23655.0001

24 .... Drip tray grate .................................23657.0000

18

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

213

16

17

18

Figure Description Part Number

1 ...... Inlet water fitting .............................23609.0000

2 ...... Grommet liquid level probe ............. 23608.0000

3 ...... Terminal block ................................. 22814.0000

4 ...... Probe, liquid level ............................23607.0000

5 ...... Compression nut, level probe .......... 23629.0000

6 ...... Mounting nut, level probe................23606.0000

7 ...... Probe assy. hex fitting .....................23605.0000

8 ...... Seal washer .....................................23628.0000

9 ...... Pressure pop-off valve ....................22575.0000

10 .... Compensation valve ........................23603.0000

P-166

Figure Description Part Number

11 .... Flat washer ......................................24030.0001

12 .... Tank ................................................23647.0000

13 .... Drain plug, heat exchanger .............. 23602.0000

14 .... Drain plug, tank ...............................23601.0000

15 .... Tank heater/Gasket kit .....................24274.1001

16 .... Flat washer ......................................24029.0000

17 .... Screw .............................................. 23934.0000

18 .... Tank heater terminal shorting bar....23598.0000

19 .... Limit thermostat (not illustrated).....04680.0004

20 .... Band clamp (not illustrated) ............23468.0000

19

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

Figure Description Part Number

1 ...... Cover, group solenoid discharge .....23642.0000

2 ...... Screw-handle ..................................24005.0400

3 ..... Filter holder seal gasket...................23594.0000

4 ...... Sprayhead screen ............................23593.0000

5 ...... Sprayhead .......................................23592.0000

6 ...... Group head......................................23641.0000

7 ...... Flat washer ......................................24030.0000

8 ...... Access plug-group head .................. 23591.0000

9 ...... Access plug-groups.........................23590.0000

10 .... Flat washer ......................................22867.0000

11 .... Spring..............................................23589.0000

12 .... Filter screen ..................................... 23588.0000

13 .... Holder, filter screen .........................23587.0000

P-167

Figure Description Part Number

14 .... O-ring ..............................................23586.0000

15 .... Hex, seat group solenoid .................23585.0000

16 .... Gasket, group head to mtg. bkt. ...... 23584.0000

17 .... Flat washer ......................................24028.0000

18 .... Lock washer ....................................24028.0300

19 .... Screw .............................................. 24008.0001

20 .... Solenoid assembly 110 v.................23597.0000

21 .... O-ring ..............................................23596.0000

22 .... Coil 110v.-refill valve .......................23595.0000

23 .... Nut ..................................................24049.0101

24 .... Hex ftg, group solenoid discharge ... 23583.0000

25 .... Orifice, group solenoid discharge ....23582.0000

26 .... Nut ..................................................23581.0000

20

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

Figure Description Part Number

1 ...... Drain plug........................................23674.0000

2 ...... Flat washer ......................................24030.0002

3 ...... Pressure spring ...............................23573.0000

4 ...... Flat washer ......................................23936.0000

5 ...... Screw .............................................. 24005.0002

6 ...... Lock washer ....................................24025.0301

7 ...... End tube support .............................23673.0000

8 ...... Steam wand.....................................24662.0000

9 ...... Adapter ............................................ 24513.0000

10 .... Steam tube ......................................24465.0000

11 .... Nozzle (2 hole) ................................24464.0000

Nozzle (4 hole).................................24464.0001

12 .... Actuator shaft coupling ...................23662.0000

13 .... O-ring ..............................................23571.0000

14 .... Hot water rinse tube ........................23570.0000

P-168

Figure Description Part Number

15 .... Hot water rinse nozzle ..................... 22844.0000

16 .... Assy. steam & faucet wands ...........23574.0000

17 .... Hex ftg-hsg-steam faucet valve ....... 23650.0000

18 .... Flat washer ......................................22868.0000

19 .... Spring..............................................24234.0000

20 .... Ball .................................................. 23578.0000

21 .... Housing, ball-steam & faucet valve . 23643.0000

22 .... O-ring ..............................................23596.0000

23 .... Shoulder bolt-steam-faucet lever ....23577.0000

24 .... Lever ...............................................24743.0000

25 .... Actuator shaft coupling ...................23665.0000

26 .... Spring..............................................24442.0000

27 .... O-ring ..............................................23575.0000

28 .... Plunger shaft ...................................24567.0000

29 .... Assy.-steam & faucet valve .............23580.0000

21

BUNN Espress™ Model ES•1A™

6

REPLA CEMENT P AR TS

Figure Description Part Number

1 ...... Refill solenoid end fitting-outlet.......23569.0000

2 ...... Refill solenoid-complete 110v. ........23568.0000

3 ...... Refill solenoid end fitting-inlet ......... 23567.0000

4 ...... Knob, selector switch ......................23566.0000

5 ...... Screw .............................................. 23935.0000

6 ...... Pressure switch-heater control........22574.0000

7 ...... Main switch .....................................23564.0000

8 ...... Plumbing assy.-water inlet ..............23563.0000

9 ...... Relief valve adjuster ........................23562.0000

10 .... Pressure vent cap nut......................23561.0000

11 .... O-ring ..............................................23560.0000

12 .... Spring..............................................23579.0000

13 .... Seat holder-relief valve ....................23559.0000

14 .... Rubber seat-plunger........................23557.0000

15 .... Pressure vent housing.....................23558.0000

P-169

Figure Description Part Number

16 .... O-ring ..............................................23555.0000

17 .... Spring..............................................23556.0000

18 .... Ball, check valve ..............................23578.0000

19 .... Sleeve, check valve..........................23643.0000

20 .... O-ring ..............................................23596.0000

21 .... Pressure vent cap nut......................23554.0000

22 .... Pump assy. 110v.-complete ............23553.0000

23 .... Pump outlet fitting...........................23540.0000

24 .... Pump impeller unit ..........................22713.0000

25. ... Pump, mounting clamp ...................23639.0000

26 .... Capacitor-motor 110v .....................23552.0000

27 .... Motor assy. 110v.............................23664.0000

28 .... Screw-handle ..................................24005.0003

29 .... Flat washer ......................................24025.0000

30 .... Nut ..................................................24045.0101

22

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

Figure Description Part Number

1 ...... Filter support wire ...........................22819.0000

2 ...... Filter holder ..................................... 23632.0000

3 ...... Dispense nozzle-2 cups ...................23551.0000

4 ...... Cover, dual dispenser nozzle ...........23550.0000

5 ...... Screw .............................................. 23932.0000

6 ...... Handle .............................................23644.0000

7 ...... Complete filter holder assy-2 cup .... 23549.0000

8 ...... Dispense nozzle-1 cup.....................23547.0000

P-170

Figure Description Part Number

9 ...... Complete holder assy. -1 cup ..........23548.0000

10 .... Filter-2 cup ......................................23546.0000

11 .... Pressure test cup (no holes) ...........23544.0000

12 .... Filter-1 cup ......................................23545.0000

13 .... Drain hose .......................................22603.0000

14 .... Rubber seal washer-hose ................22638.0000

5

23

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

6

5

Figure Description Part Number

1 ...... Screw .............................................. 24004.0700

2 ...... Electronic module 110v. ..................24798.0000

3 ...... Mounting nut, electronics model .....24045.0101

4 ...... Cable protector, electronics model ..23631.0000

5 ...... Module bracket support ..................23627.0000

6 ...... Thumb nut, front panel ctr. mount ..23542.0000

7 ...... Front hood panel .............................23661.0000

8 ...... Screw .............................................. 24004.0702

9 ...... Circuit board assy............................23670.0000

14

13

1112

98

710

15

16

17

18

Figure Description Part Number

10 .... Module, dose switch automatic .......23626.0000

11 .... Switch select panel standoff ............23671.0000

12 .... Nut ..................................................24044.0100

13 .... Switch select panel .......................... 22695.0000

14 .... Bezel, indicator lights ......................23541.0000

15 .... Complete front hood panel ..............23625.0000

16 .... Fitting, flowmeter ............................23624.0000

17 .... Flat washer ......................................22868.0000

18 .... Flow meter complete .......................22775.0000

19 .... Ribbon cable ...................................24811.0000

P-171

24

BUNN Espress™ Model ES•1A™

REPLA CEMENT P AR TS

Figure Description Part Number

1 ...... Copper tube, pump inlet ..................23623.0000

2 ...... Copper tube, pump out to rlf. chk....23622.0000

3 ...... Lower copper tube, exch. to grp......23621.0000

4 ...... Copper tube, rlf./chk. to flowmeter ..23620.0000

5 ...... Copper tube, tank to steam valve ....23619.0000

6 ...... Copper tube, st. valve to swivel ftg. . 23618.0000

7 ...... Copper tube, faucet to swivel ftg. ....23617.0000

P-172

Figure Description Part Number

8 ...... Copper tube, tank to faucet valve ....23616.0000

9 ...... Copper tube, refill solenoid to tank .. 23615.0000

10 .... Copper tube, flowmeter to exch.......23614.0000

11 .... Copper tube-pressure switch ..........23613.0000

12 .... Upper copper tube, exch. to group ..23612.0000

13 .... Copper tube, press. gauge-pump ....23611.0000

25

Loading...

Loading...