Page 1

BROTHER PT-9700PC & PT-9800PCN

DESKTOP BARCODE AND LABEL PRINTERS

Giving your clients the best customer experience is one

of the highlights that builds your business. Whether it

is for tax preparation, giving your customers access to

immediate funds and settlements or helping to facilitate

business, on-site check printing can be the answer to

help your clients get their checks quickly with no delays.

Harsh Environment, Laminated Labels

Thermal Transfer Printers for

BROTHER MOBILE SOLUTIONS, INC.

Page 2

Desktop Barcode &

Label Printers

The Brother PT-9700PC and PT-9800PCN Desktop Barcode and Label Printers

produce high-quality laminated labels suitable for harsh environment applications.

With resolutions up to 360 x 720 dpi and a maximum print speed of 3.15 ips, the

PT-9700PC and PT-9800PCN can be configured to print on-demand, laminated

labels that will fit many vertical market applications.

The printers use thermal transfer technology and self-contained cassettes that

include the adhesive-backed label and the lamination all in one. This drop-in cassette

makes it easy to change consumables - there are no transfer ribbons to install and

align, no need to remove wrinkles from a transfer ribbon, and no need to perform

density calibrations at any time. The continuous label cassettes give you the

flexibility to print labels of any length with a half-cut feature that allows multiple

labels to be printed on a single strip and peeled off as needed.

The powerful Brother P-touch

printer to help you design and print customized, on-demand labels for just about

any application. You can create labels with text, graphics, and over 14 industrystandard linear and 2D bar codes. In addition, you can use P-touch Editor to

connect to and print labels from a variety of data files, includes text and CSV files,

®

Excel

spreadsheets, and Microsoft® Access® and SQL Server® databases.

A special feature with the PT-9700PC and PT-9800PCN printers is that large label

print jobs can be distributed among multiple printers simultaneously. The number

of labels to be printed will be automatically divided among the selected printers.

Using this distributed printing mode will reduce the total printing time and reduce

overall throughput. Distributed printing is available via the USB and Ethernet

(PT-9800PCN) interfaces.

Two Models

• PT-9700PC, with USB and Serial interfaces

• PT-9800PCN, with standard USB, Host USB, Serial, and

Ethernet interfaces

Both printers measure 4.6" (W) x 7.6" (D) x 5.5" (H), and are perfect for areas

where space is at a premium.

A Wide Range of Connectivity

Both printers include USB and serial interfaces, while the PT-9800PCN also includes

a built-in Ethernet interface and a Host USB interface. This gives end users and

system integrators the flexibility to print labels from several different platforms and

using different data formats:

• USB, serial, and Ethernet interfaces for optimized Windows

• USB and Ethernet interfaces for printing from Macintosh

• Ethernet, USB, and serial interfaces for printing from non-Windows

applications using ESC/P emulation or direct ASCII data.

• Serial interface, using ESC/P emulation or ASCII data streams, to

connect directly to medical instruments, test equipment, handheld

terminals, postage scales, and other stand-alone devices.

• Host USB interface for connecting a USB scanner and printing labels

from scanned barcode data to label templates downloaded to the printer.

®

Editor label design software is included with each

®

printing.

®

applications.

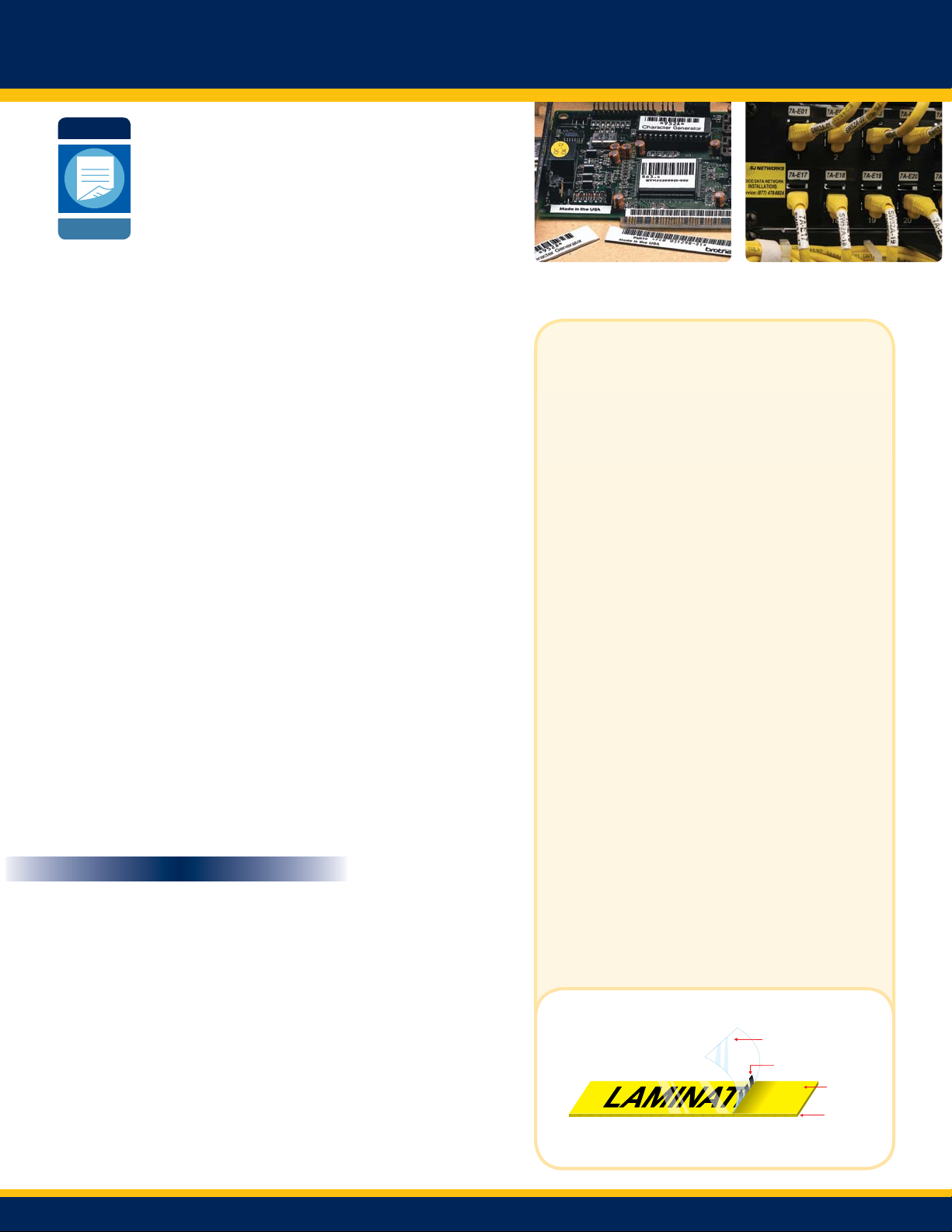

Manufacturing / Warehouse Telecom / Datacom

Harsh Environment Applications:

Manufacturing / Warehouse:

• Work-in-process labels

• Product and bin labels

• Asset management and calibration labels

Telecom / Datacom:

• Cable and wire markers

• Patch panels

• Asset management

Healthcare:

• Specimen labels

• Test tube and slide labels

• Autoclave / Sterilization tray labels

Retail:

• Freezer labels

• Shelf labels

• Small signage

P-touch laminated labels are designed and tested for use

in harsh environment applications to offer protection from

moisture, temperature extremes, industrial chemicals, UV,

and abrasion. Our Extra Strength Adhesive and Flexible ID

labels are UL recognized (UL-969) for indoor and outdoor

use. In addition, having the lamination applied as part of the

printing process saves time and eliminates the need for a

manual over-lamination process.

All printing is done on the underside of a clear polyester

lamination layer. The result is an extremely durable label that

stands up to the toughest conditions.

Laminated Tape Structure

Image is for illustrative purpose only

Clear Polyester Laminate

(Protects against abrasion and spills)

Thermal Transfer Ink

(Prints Under Laminate)

Colored

Polyester

Substrate

Adhesive

All images are for illustrative purposes only.

Page 3

Healthcare Retail

Key Product Features

• Harsh environment labeling - laminated labels offer protection

from moisture, temperature extremes, certain chemicals, and

abrasion.

• High speed, high resolution thermal transfer printing -

maximun print speed is 3.15 ips; maximum resolution is

360 x 720 dpi.

• Drop-in label cassettes eliminate the maintenance required

with other thermal transfer printers - no transfer ribbons to

install or align and no density calibrations required.

• Built-in auto cutter allows labels of various lengths to be

printed. Half-cut feature allows multiple labels to be printed

on a single strip and peeled off as needed.

• Built-in Ethernet port on the PT-9800PCN allows multiple

users to share one printer.

• Host USB port on the PT-9800PCN lets you connect a

USB scanner and print labels from scanned barcode data to

downloaded label templates.

• Print from non-Windows applications via the USB, serial and

Ethernet interfaces using ESC/P emulation or ASCII data.

• Distributed printing can spread large print jobs over multiple

printers.

• Five resident fonts and over 14 linear and two-dimensional

barcode symbologies.

• Bundled with P-touch Editor, a powerful software application for

designing and printing customized, on-demand labels. You

can also use it to connect to a variety of data files.

• BRAdmin Light network management software is included with

the PT-9800PCN to make it easier to set up and manage Brother

desktop barcode and label printers.

A Variety of Media Options

(Separate purchased required)

The Brother PT-9700PC and PT-9800PCN Desktop Barcode and

Label Printers use self-contained Genuine Brother P-touch media

cassettes to print the label and apply the lamination in a single

process. The thermal transfer technology provides a crisp, highquality output, while the simultaneous printing and lamination

process produces durable, protected labels that are suitable for

many applications. The media is available in a wide variety of colors

and sizes, with different adhesives and performance characteristics

to meet the needs for harsh-environment labeling:

• HG tape is a high-grade media that provides a high

resolution (up to 360 x 720 dpi) for printing fine text, graphics,

barcodes and logos, or a faster throughput (up to 3.15 ips)

for assembly line and other demanding applications.

• TZ tape is available with four different adhesives to match

your specific application:

• Standard adhesive for general purpose labeling on flat,

smooth surfaces.

• Extra Strength adhesive for labeling on textured,

rough, and uneven surfaces, and on a variety of

plastics and other hard-to-stick material.

• Flexible ID adhesive for labeling cables and wires,

pipes and fittings, beakers and test tubes, sharp

bends, hydraulic and electrical connectors, and other

rounded surfaces.

• Tamper-Evident adhesive that leaves behind a

checkerboard pattern if the label is removed. It’s

great for asset management, property tags, company

tools, calibration labels, and other security applications.

HG and TZ tapes can be used for both indoor and outdoor

applications. The Extra Strength and Flexible ID adhesive tapes

are UL recognized (UL-969) for indoor and outdoor labeling

applications. The following chart shows a comparison between

the HG and TZ tapes.

PT Desktop Barcode and Label Printers

PT-9700PC

((USB, Serial)

PT-9800PCN

(USB, Serial,

Host USB, Ethernet)

OUTPUT

High Speed

(HG only)

Standard

High Resolution

(HG only)

TAPE TYPE

TZ Tape HG Tape

–

0.78"/sec

(20 mm/sec)

–

3.15"/sec

(80 mm/sec)

2.05"/sec

(52 mm/sec)

0.78"/sec

(20 mm/sec)

RESOLUTION

360 x 180 dpi

360 x 360 dpi

360 x 720 dpi

Page 4

Technical Specifications

Features PT-9700PC PT-9800PCN

Model Type

Tape Families

Tape Sizes

Tape Length

Tape Technology

Tape Types

Max. Print Speed

Cutter

Interface

Desktop Barcode and Label Printer Desktop Barcode and Label Printer (Network)

HG, TZ

3.5mm, 6mm, 9mm, 12mm, 18mm, 24mm, 36mm

Most tapes are 8m (26.25')

Laminated Thermal Transfer

High Grade, Standard Adhesive, Extra-Strength Adhesive, Flexible ID, Tamper-Evident

HG Tape: Up to 3.15 ips (80 mm/sec)

TZ Tape: Up to 0.78 ips (20 mm/sec)

Automatic (Built-In) Cutter: full-cut mode and crack-and-peel mode

USB (1.1 or 2.0), Serial (RS-232C)

USB (1.1 or 2.0), Host USB, Serial (RS-232C),

Ethernet (10/100 Base-TX)

Software

P-touch® PT-Editor 5.0, PT-Editor for Mac® 5.0,

Transfer Manager 2.1, Transfer Express, Library 2.1

Database file compatibility

Resident Fonts

Resident Barcodes

Opperating System

Linear: Code39, ITF (I-2/5), UPC-A, UPC-E, EAN8, EAN13, Codabar (NW-7), Code128, UCC/EAN128, GS1 DataBar (RSS)

Windows® 2000 Professional/XP, Windows Vista®, Windows 7

Carton Contents

Power Supply

Warranty

Ask us about our other products

Mobile Printers and Scanners

Brother PocketJet® 3 Plus

Portable mobile printer with

optional Bluetooth

technology

®

wireless

BRAdmin Light 1.14, P-touch® PT-Editor 5.0,

Editor Lite Lan, PT-Editor for Mac® 5.0, Transfer Manager 2.1,

Transfer Express, Library 2.1

*.csv, *.txt, *.mdb, *.xls and Microsoft SQL Server

Helsinki, Brussels, Letter Gothic

2-Dimensional: PDF417, QR Code, Micro QR Code, Data Matrix, Maxicode

Windows® 2000 Professional/XP, Windows Vista®, Windows 7,

Mac OS® 10.3.9 - 10.6

Printer, AC Adapter, Power Cord, USB Cable, CD, HG-251 Tape (26.25'), User Guide

120VAC 60Hz

2 Years Limited Exchange Warranty

Windows Server® 2003/2008, Mac OS® 10.3.9 - 10.6

Desktop Barcode and Label Printers

TD-4000

Light, Industrial Thermal Printer

for Labels, Receipts, and Tags

Brother MPrint™ MW-260

Ultra-portable, small-format

mobile printer

Brother DSmobile® 600

Light-weight, mobile

color scanner

For more information, call 1-800-543-6144,

or visit www.brothermobilesolutions.com

Brother® is a registered trademark of Brother Industries, Ltd. in the United States. Microsoft®, Windows® and

Windows Vista

other counties. All other trademarks and registered trademarks are the properties of their respective companies.

© 2010 Brother International Corporation

®

are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

TD-4100N

Light, Industrial Thermal Printer

with built-in networking for printing

Labels, Receipts, and Tags

DX-0502-00

Loading...

Loading...