Page 1

SEWING MACHINE

MACHINE A COUDRE

PQ1300

OPERATION MANUAL

MANUEL D’UTILISATION

Page 2

“IMPORTANT SAFETY INSTRUCTIONS”

“Read all instructions before using.”

When using a sewing machine, basic safety precautions should always be taken,

including the following:

DANGER – To reduce the risk of electric shock.

● The sewing machine should never be left unattended while plugged in. Always unplug the sewing machine from the electrical outlet immediately after using and before

cleaning.

● Always unplug before changing the light bulb. Replace bulb with same type rated 120V 15 watts.

WARNING – To reduce the risk of burns, fire, electric shock, or injury.

● Do not allow this sewing machine to be used as a toy. Close attention is necessary when the sewing machine is used by or near children.

● Use this sewing machine only for its intended use as described in this manual. Use only accessories recommended by the manufacturer as contained in this manual.

● Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the

sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

● Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the accumulation of lint,

dust, and loose cloth.

● Never drop or insert any object into any opening.

● Do not use outdoors.

● Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

● To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from outlet.

● Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

● Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

● Always use the proper needle plate. The wrong plate can cause the needle to break.

● Do not use bent needles.

● Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

● Turn off power to the machine by flipping the ON/OFF switch to the symbol “O” before making any adjustments in the needle area, such as threading the needle,

changing the needle, threading the bobbin or changing the presser foot etc.

● Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the

instruction manual.

CAUTION – This appliance has a polarized plug (one blade wider than the other) to reduce the risk of electric shock, this plug is intended to fit in a polarized

outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit. Contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use.”

Page 3

CONGRATULATIONS ON CHOOSING

A BROTHER SEWING MACHINE

Your machine is the home use sewing machine available.

To fully enjoy all the features incorporated into it, we suggest that you study this booklet.

PLEASE READ BEFORE USING YOUR SEWING MACHINE

For safe operation

● Be sure to watch the needle while sewing. Do not touch moving parts such as the balance wheel, thread take-up or needle while the machine is operating.

● Remember to turn off the power switch and unplug the cord when:

●

Operation is completed

●

Replacing or removing the needle or any other parts

●

A power failure occurs during use

●

Maintaining the machine

●

Leaving the machine unattended

● Do not place anything on the foot controller.

● Plug the machine directly into the wall. Do not use extension cords.

For a longer service life

● When storing your sewing machine, avoid direct sunlight and high humidity locations. Do not store the sewing machine beside a space heater, iron, or other hot

objects.

● Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the case and machine, and should never be used.

● Do not drop or hit the machine.

● Always consult the operation manual when replacing or installing any accessories, the presser feet, needle, or other parts to assure correct installation.

For repair or adjustment

In the event that a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the operation manual to inspect and adjust the machine

yourself. If the problem persists, please consult your nearest authorized Brother service center.

Page 4

CONTENTS

Accessories ___________________________________ 1

Names of Parts ________________________________ 2

Before You Begin ______________________________ 3

Tension Dial ______________________________ 3

Power Cord and Foot Controller _______________ 3

Power Switch _____________________________ 3

Hand Wheel ______________________________ 3

Stitch Length Regulator _____________________ 3

Reverse stitch lever ________________________ 3

Presser Foot Lift Lever ______________________ 4

Knee Lift _________________________________ 4

Pressure Adjustment Dial ____________________ 4

Flat Bed Extension Table ____________________ 4

Thread Cutter Button _______________________ 5

Needle Stop Position Button __________________ 5

Light Switch_______________________________ 5

Feed Dog Adjustment Knob __________________ 5

Changing Needles and Light Bulb_________________ 6

Changing Upper Needle _____________________ 6

Changing Feed Pin _________________________ 6

Changing Light Bulbs _______________________ 6

Threading_____________________________________ 7

Bobbin Winding____________________________ 7

Bobbin Insertion ___________________________ 8

Upper Threading ___________________________ 9

Using the Automatic Needle Threader __________ 9

How to Pull Out the Bobbin Thread ___________ 10

Stitch Samples and Needle Chart ________________ 11

Stitch Samples ___________________________ 11

Thread Tension___________________________ 11

Changing Presser Feet _________________________ 12

Basic Sewing _________________________________ 13

Basic Sewing ____________________________ 13

Pin Feeding (for hard-to-handle fabrics) ________ 13

Pin Feeding Unit __________________________ 13

Rolled Hem Foot __________________________ 14

Zipper Foot ______________________________ 15

Invisible Zipper Foot _______________________ 16

Lining __________________________________ 16

Caring for Your Machine _______________________ 17

Trouble Shooting _____________________________ 18

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

4

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 5

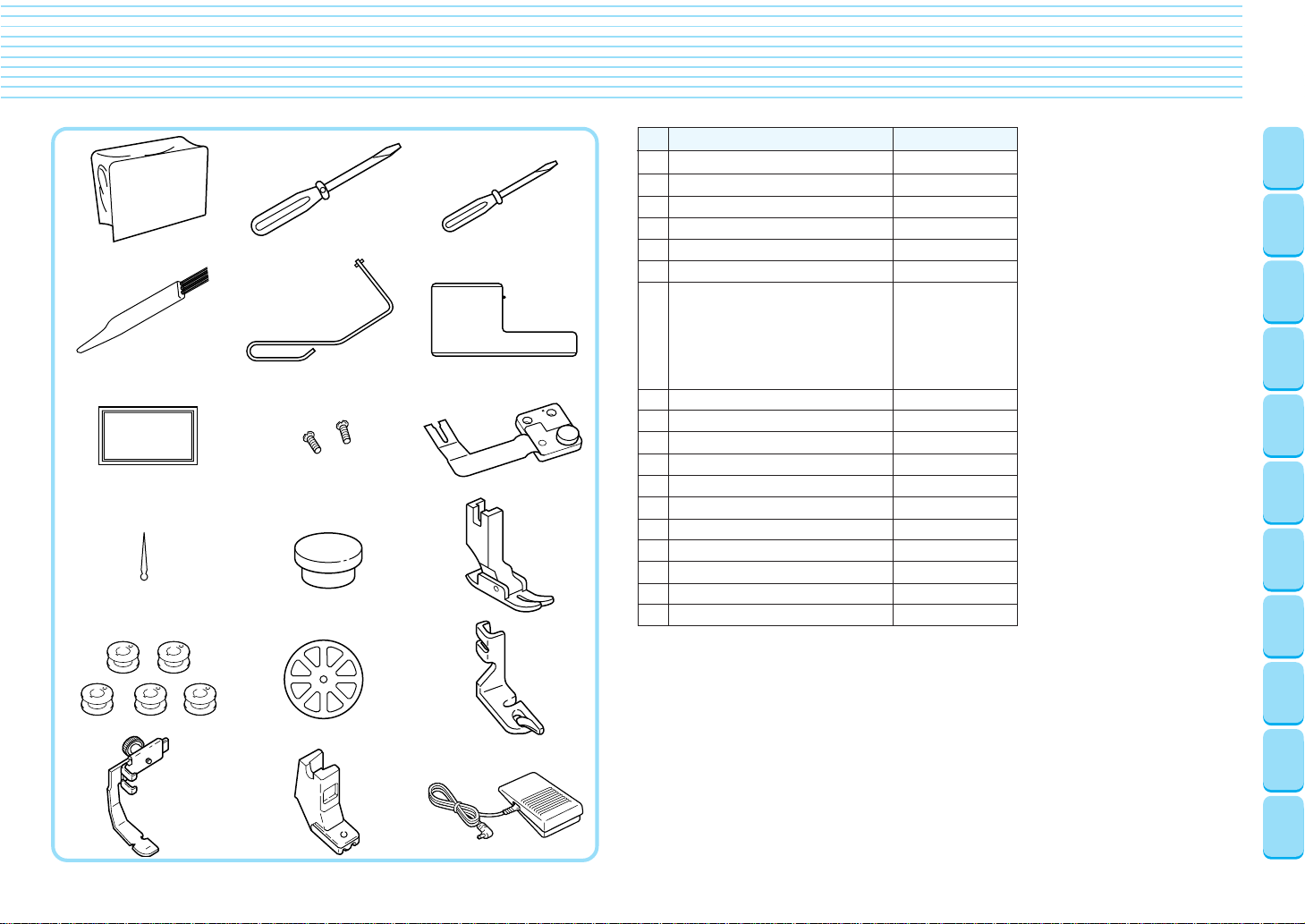

Accessories

123

456

789

10 11 12

13 14 15

16 17 18

No. Part Name Part Code

1 Cover XA0917-052

2 Medium Screwdriver 125877-001

3 Small Screwdriver 125878-001

4 Cleaning Brush XA4527-001

5 Knee Lift XA0830-001

6 Flat Bed Extension Table X81029-001

7 Needles and Case 1 Size 9

(ORGAN HLX5) 2 Size 11

1 Size 14 X80805-001

1 Size 16

1 Ballpoint Needle

8 Lining Plate Screw (2) 062670-812

9 Separater 184720-001

10 Feed Pin 138483-001

11 Feed Pin Remover 117934-009

12 General Purpose Foot XA1425-001

13 Bobbin (5) 100376-003

14 Spool Cap XA2111-000

15 Rolled Hem Foot X57138-001

16 Zipper Foot 112797-001

17 Invisible Zipper Foot 148475-001

18 Foot Controller XA3931-051

Note

Foot controller: Model N5V

This foot controller can be used f or sewing machine

model PQ1300.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

1

Page 6

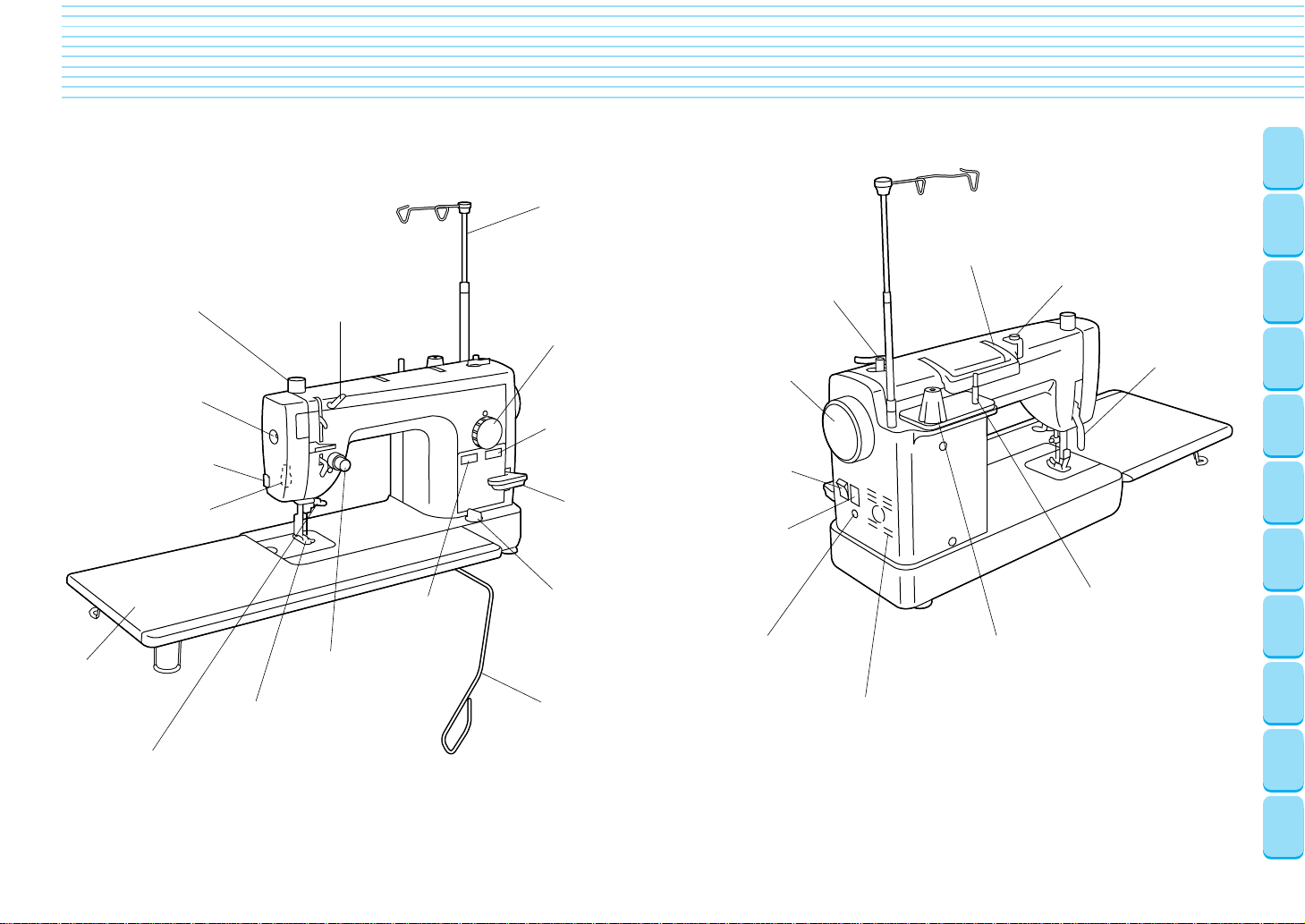

Names of Parts

CONTENTS

Pressure Adjustment Dial

(Page 4)

Light Switch

(Page 5)

Thread Trimmer

Sewing Area

Light (Page 6)

Extension

Table (Page 4)

Automatic Needle

Threader (Page 9 to 10)

Three Holed

Thread Guide (Page 9)

Tension Dial

(Page 3 and 11)

Feed Dogs

(Page 5 and 13)

Thread Cutter

Button (Page 5)

Thread Guide Bar

(Page 7)

Stitch Length

Regulator (Page 3)

Needle Stop Position

Button (Page 5)

Reverse Stitch

Lever (Page 3)

Feed Dog Adjustment

Knob (Page 5)

Knee Lift

(Page 4)

Bobbin Winder

(Page 7)

Hand Wheel

(Page 3)

Power Switch

(Page 3)

Power Socket

(Page 3)

Foot Controller Jack

(Page 3)

Air Vents

Handle

Spool Cushion

(Page 7)

Thread Guide for

Bobbin Winding (Page 7)

Presser Foot Lifter

(Page 4)

Spool Pin

(Page 7)

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

6

2

Page 7

Before You Begin (1)

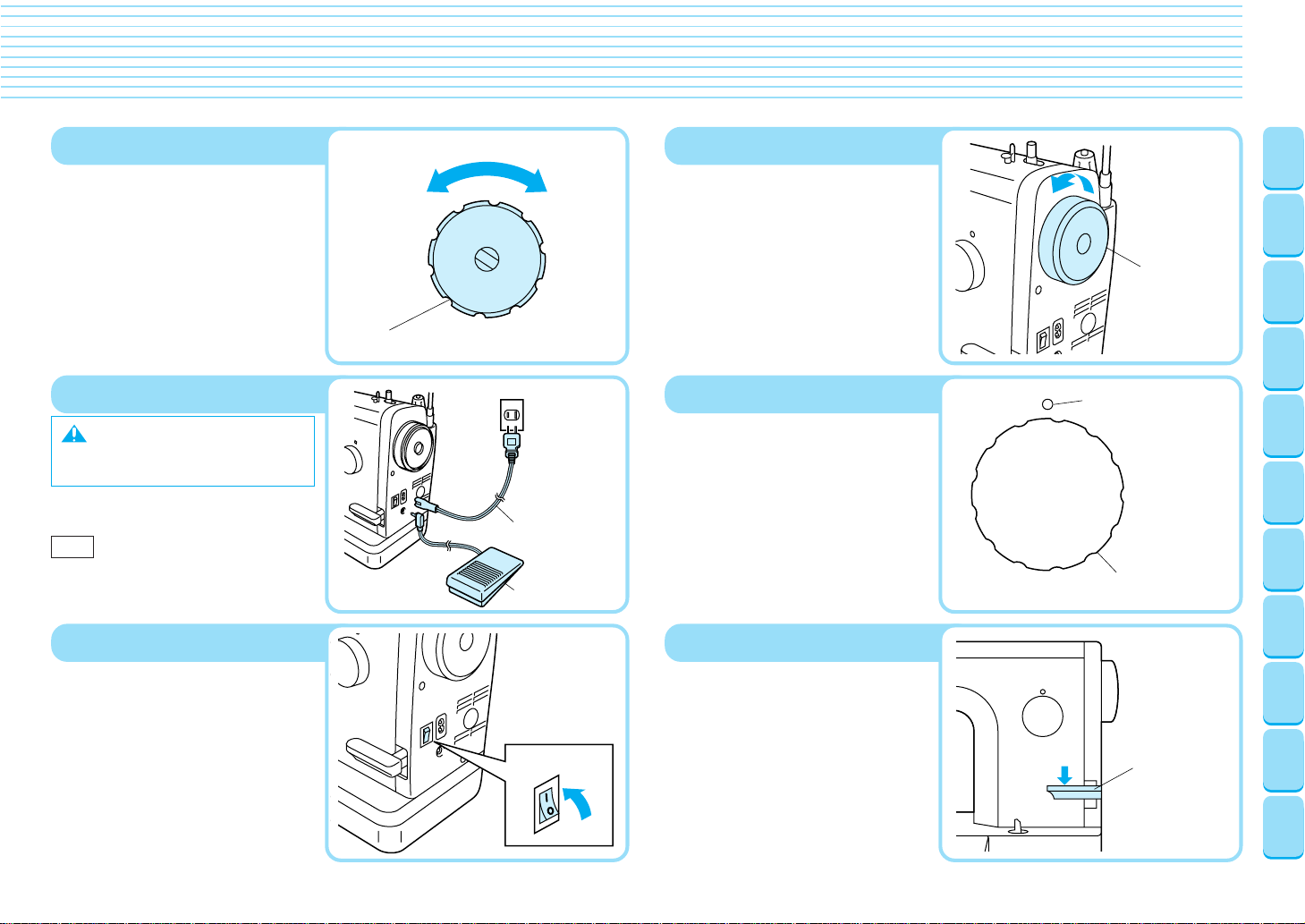

Tension Dial

Upper Thread Tension

CONTENTS

Hand Wheel

● When tighter tension is desired,

turn the tension dial to the right.

Upper and bobbin threads will

meat on right side of the fabric.

● When looser tension is desired,

turn tension dial to the left. Upper

and lower threads will then meet

on wrong side of fabric.

Tension Block

Power Cord and Foot Controller

Note

Please use common 120V

household current.

● Plug in cord.

● Plug foot controller into machine.

Note

Foot controller: Model N5V

This foot controller can be used for

sewing machine model PQ1300.

Power Switch

● Flip power switch to "I" position to

turn on.

● To switch power off, flip switch to

"O" position.

Loosen Tighten

AC120V

Power Cord

Foot Controller

Power Switch

● Position needle using hand

wheel.

✽ Always turn hand wheel towards

you.

Stitch Length Regulator

● Adjust desired stitch length using

stitch regulator dial.

Reverse Stitch Lever

● Sewing in reverse is possible

when the reverse stitch lever is in

the lowered position.

✽ Make sure to push the lever all

the way down when reverse

sewing is desired.

Reference Mark

1

7

6

2

3

4

5

Stitch Length Regulator

Hand Wheel

Reverse Stitch

Lever

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

3

Page 8

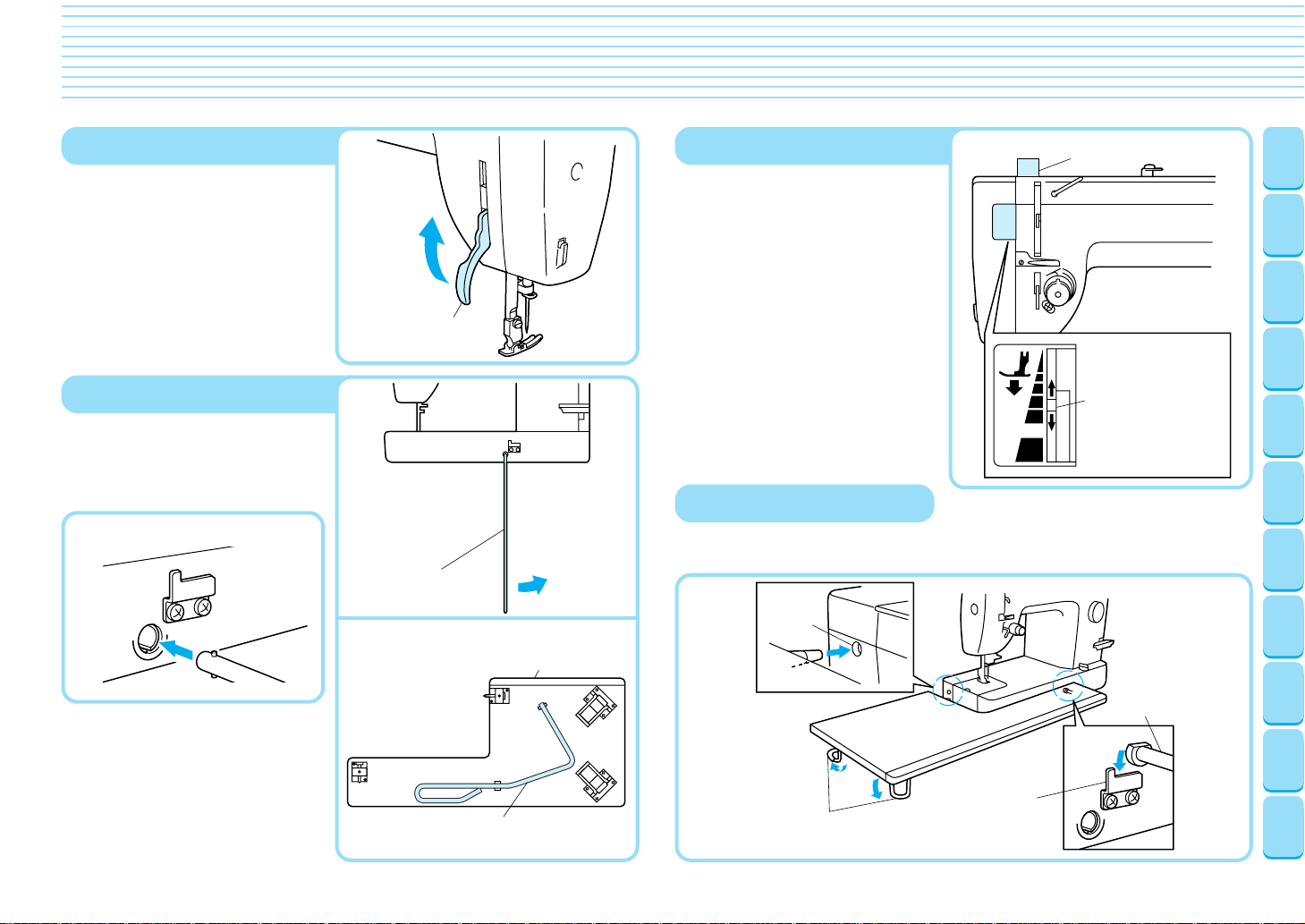

Presser Foot Lift Lever

Pressure Adjustment Dial

CONTENTS

Pressure Adjustment Dial

● Lowering the presser foot lift lever

lowers the sewing foot down onto

the fabric.

✽ When working with heavy fabrics

or other fabrics that don't slide

easily under the foot, raise the

presser foot lever to position the

fabric.

Knee Lift

● Using the convenient knee lift

enables you to lift the presser

foot easily leaving your hands

free to work with the fabric.

Setting up the knee control.

✽ Push the knee lift all the way in.

✽ When knee lift is not in use, it can

rest at the bottom of the

extension table.

Presser Foot

Lift Lever

Knee Lift

Knee Lift

Extension Table

● Turning the pressure adjustment

dial raises and lowers the pressure

indicator needle.

See also: "Feed Dog Adjustment

Knob" on page 5.

Pressure indicator

needle

N

Flat Bed Extension Table

● Lower table feet and attach extension table as shown in the below diagram.

2

Hole

Guide pin

Stopper

3

1

Hook

Table legs

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

8

4

Page 9

Before You Begin (2)

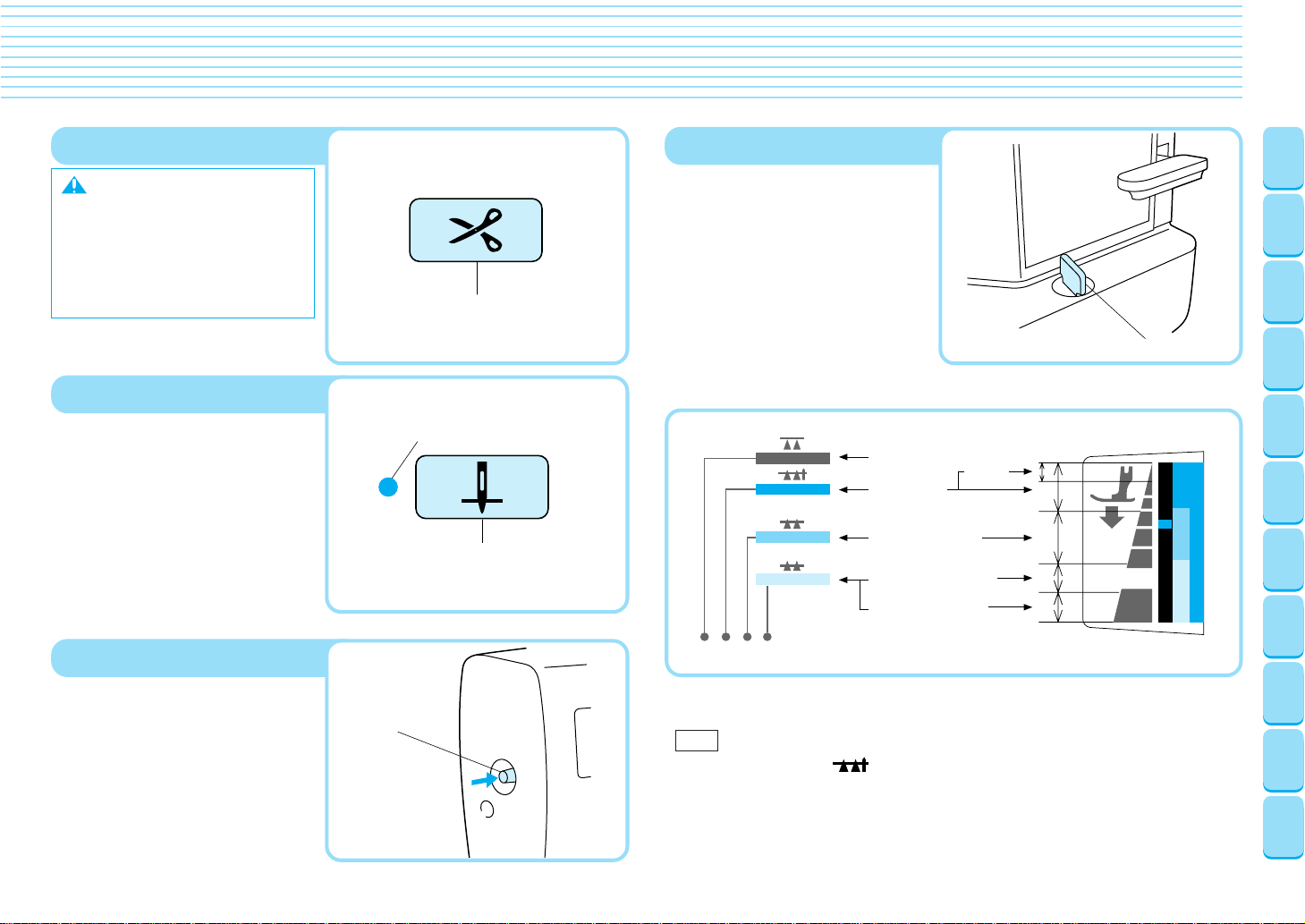

Thread Cutter Button

CONTENTS

Feed Dog Adjustment Knob

Note

When the machine stops due to jammed

threads and so forth, do not step on the

foot controller until turning the power off

and moving the needle with the hand

wheel to check the situation. Otherwise

broken needles could result.

●

The thread cutter trims upper and

bobbin threads at the end of seams.

Needle Stop Position Button

● When indicator lamp is lit up, the

machine will stop sewing with the

needle lowered through the

fabric.

● When indicator lamp is off,

position of the needle when

sewing stops will be random.

● If the safety mechanism is activated,

for example if the thread becomes

tangled, the red lamp flashes.

Light Switch

● Push light switch to turn the light

over the sewing area on and off.

Thread Cutter Button

Indicator Lamp

Needle Stop Position Button

Light Switch

● Height of feed dogs can be

adjusted to coincide with fabric

weights.

Feed Dog Adjustment Knob

Foot Pressure and Feed Dog Position

(Feed Dogs Down)

(Pin Feeding)

Lightweight Fabrics

Mediumweight Fabrics

Heavyweight Fabrics

Select one of four feed dog positions according to your needs.

Note

If a setting other than

is selected, the feed pin will not operate.

Velvet

N

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

5

Page 10

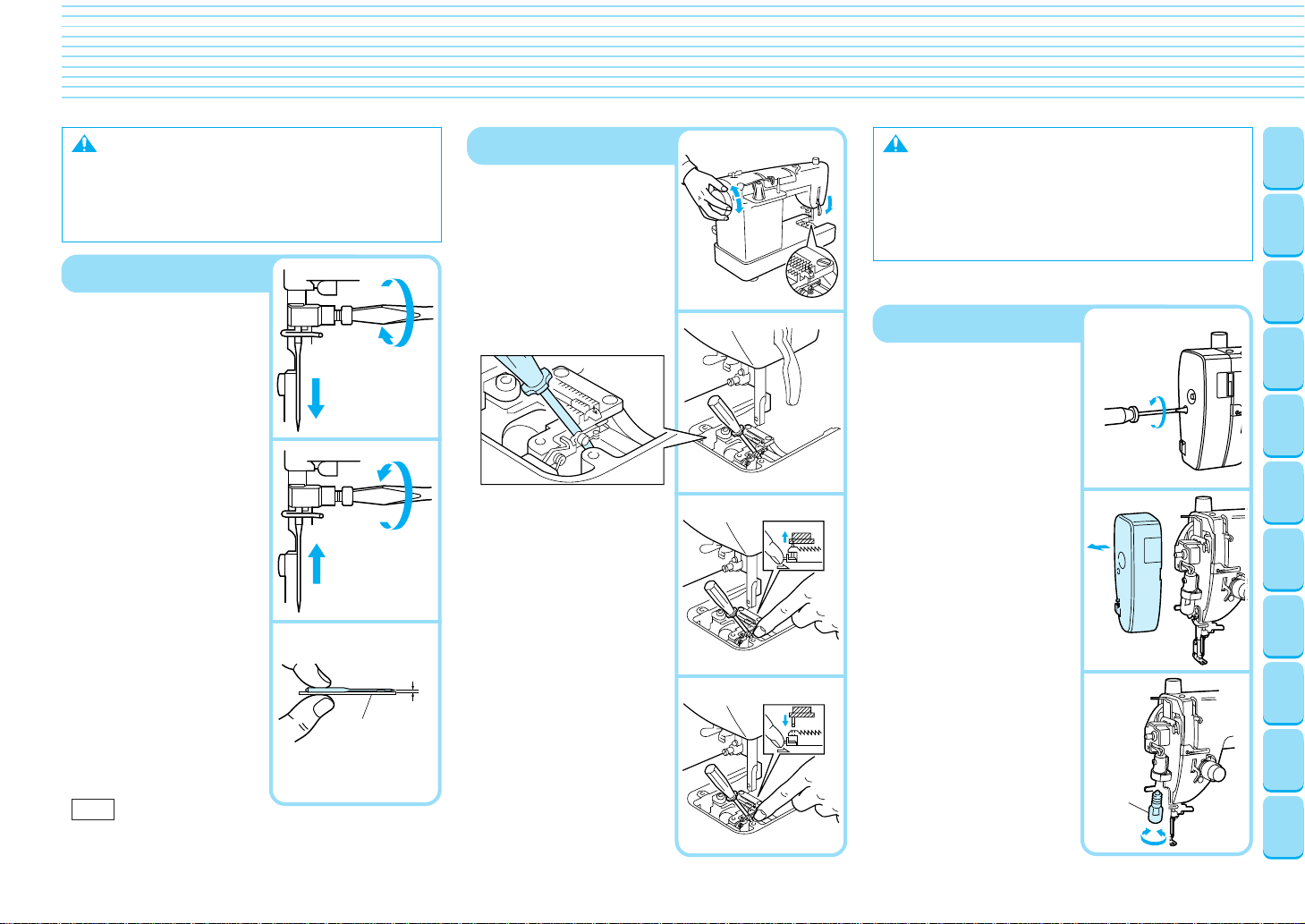

Changing Needles and Light Bulb

Note

Please make sure power is off before carrying out

the following operations. There is a chance of

injury if the machine accidentally starts running

during this operation.

Changing the Needle

1

Turn the sewing machine

off. Raise needle to

highest position using

hand wheel, and lower

presser foot.

2

Loosen screw with screwdriver, and remove needle.

3 Insert new needle, and

tighten screw. Make

sure needle is screwed

in tightly.

Screwdriver

Changing the Feed Pin

1

Set the feed dogs to "velvet"

position. (see Page 5)

2

Remove needle, presser

foot and needle plate.

3 Lower presser foot and

turn hand wheel until feed

pin is in its highest position.

4

Insert small screwdriver

(included) as shown in diagram.

5 While holding spring

with fingertip, lower the

feed pin changer onto

the needle to pick it up.

Note

Please make sure power is off before carrying out

the following operation. The glass plate over the

light bulb will be hot immediately after using the

machine, so you should wait until the machine has

had a chance to cool down before changing bulbs.

Changing Light Bulbs

1 Turn off power.

2 Remove screws from

head.

3 Remove head.

Screwdriver

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

✽ Check needles on a flat

surface to make sure

they're not bent.

The needle should lay

parallel to a surface.

Note

HLX5 needles should be uses; however, Schmetz

130/705H may also be used under normal

circumstances.

10

6

flat surface

Lay needle on a

flat surface

(such as the needle

plate or a plate

of glass).

6 Attach new feed pin to

feed pin changer, lower

and attach while holding

spring with fingertip.

7 Remove screwdriver.

8 Re-attach needle plate,

needle and presser foot.

4

Unscrew bulb and remove.

5 Screw in new bulb.

Rated 120V 15W

6 Re-attach head and

tighten screw.

Light

Bulb

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 11

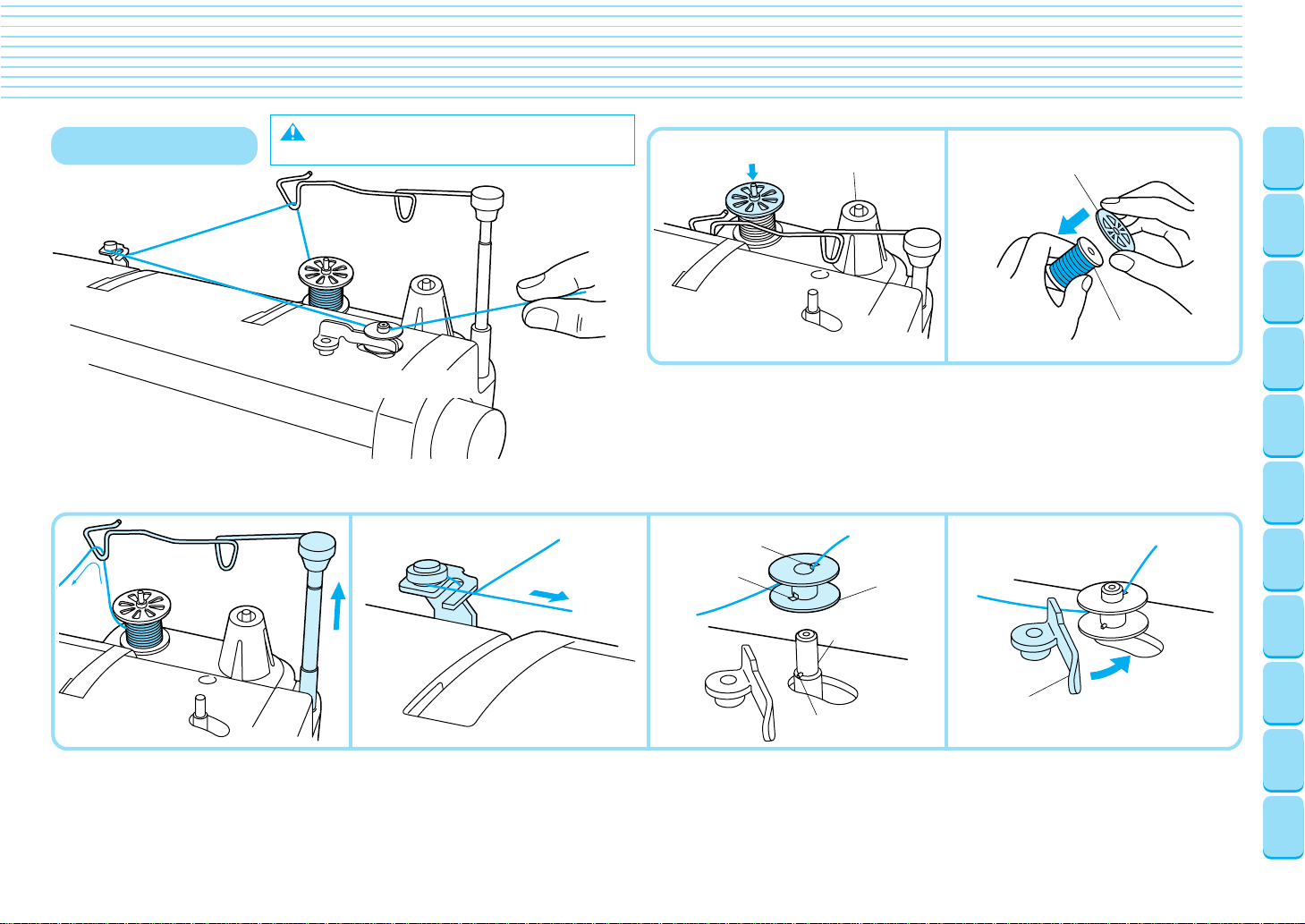

Threading (1)

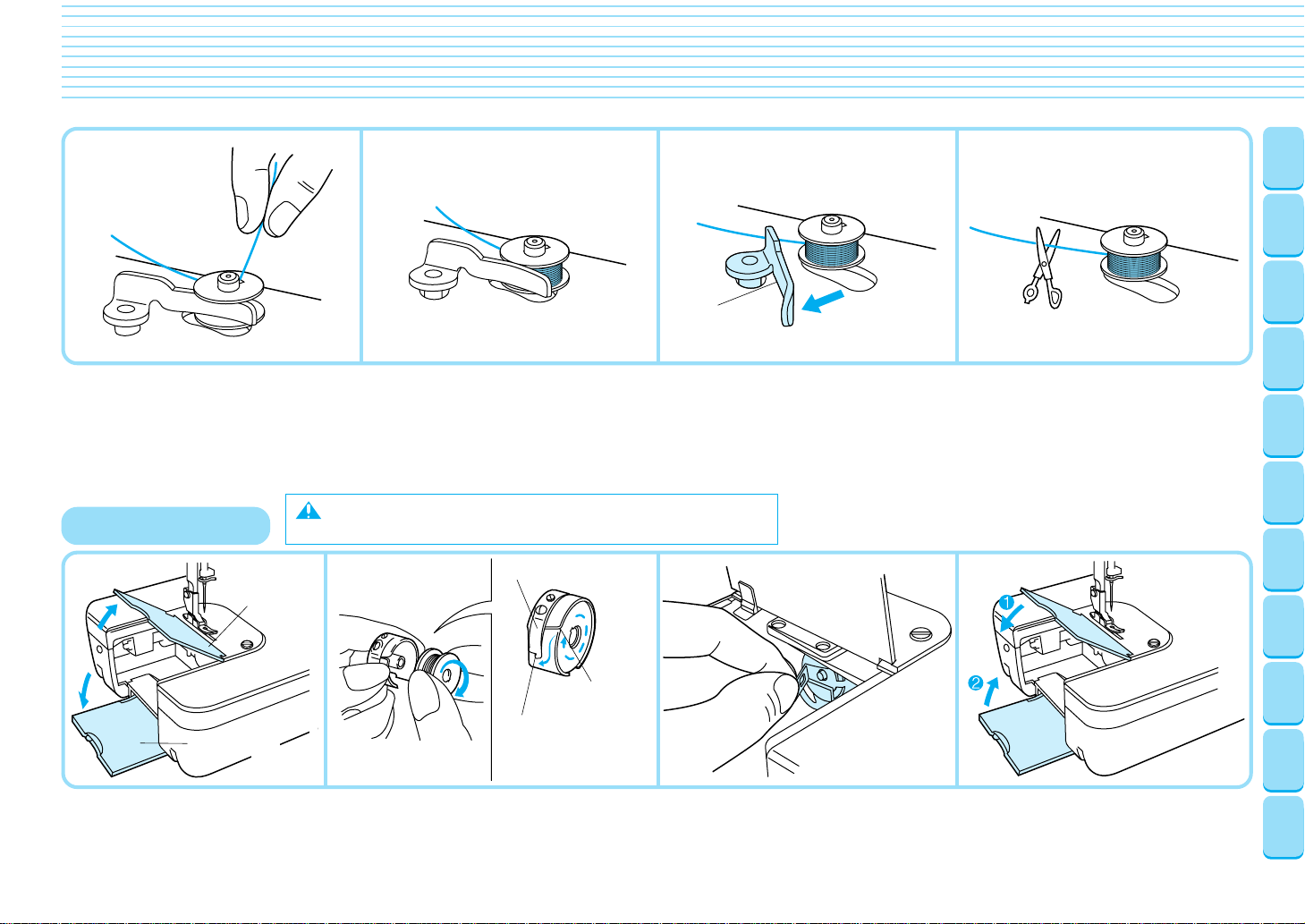

Bobbin Winding

3

2

Note

Do not move bobbin stop while machine is running.

2

1

4568 9

1

Spool Cushion

1 Put spool of thread on spool pin.

✽ Use spool cushion when using cross

wound thread.

Thread Notch 1

Thread Notch 2

Bobbins

Bobbin Winder

Shaft

Spool Cap

Spool of Thread

✽ Use spool cap when using parallel-

wound thread.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

2 Lift thread guide bar all the way up,

and run thread through triangular

thread guide as shown in drawing.

3 Run thread through bobbin winding

thread guide as shown in drawing.

Guide Pin

4 Run thread through top thread

notch, and align bottom thread notch

with guide pin on bobbin winder

shaft.

Bobbin Stop

5 Press bobbin stop up against empty

bobbin.

Machine

Your

Shooting

Trouble

7

Caring for

Page 12

CONTENTS

Accessories

Names of

Parts

6 While holding the end of the thread,

step on the foot controller for a few

seconds. Once enough thread has

wound itself around the bobbin to hold

itself in place, release the foot

controller and trim the excess thread.

Bobbin Insertion

Slide Plate

Bobbin Door

1 Lift slide plate (and open bobbin

door).

12

8

Bobbin Stop

7 Stop winding when bobbin is full.

Take foot of foot controller.

8 Manually move bobbin stop back to

original position.

CAUTION – Moving parts –

To reduce risk of injury, switch off before servicing. Replace cover.

Latch Spring

Thread Notch

✽ Bobbin should be

positioned so it

winds to the left

2 Put bobbin into the bobbin case.

✽ Run thread through thread notch and

under latch spring, so that a length of

about 10 centimeters is exposed.

3

Pull the latch lever of the bobbin case

out and push the bobbin case into the

shuttle race and release the latch lever.

✽ If the latch lever is not all the way on

the hook, it may fly off during sewing

and cause lower thread breakage.

9 Cut thread and remove bobbin.

4 Lower slide plate and close bobbin

door.

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 13

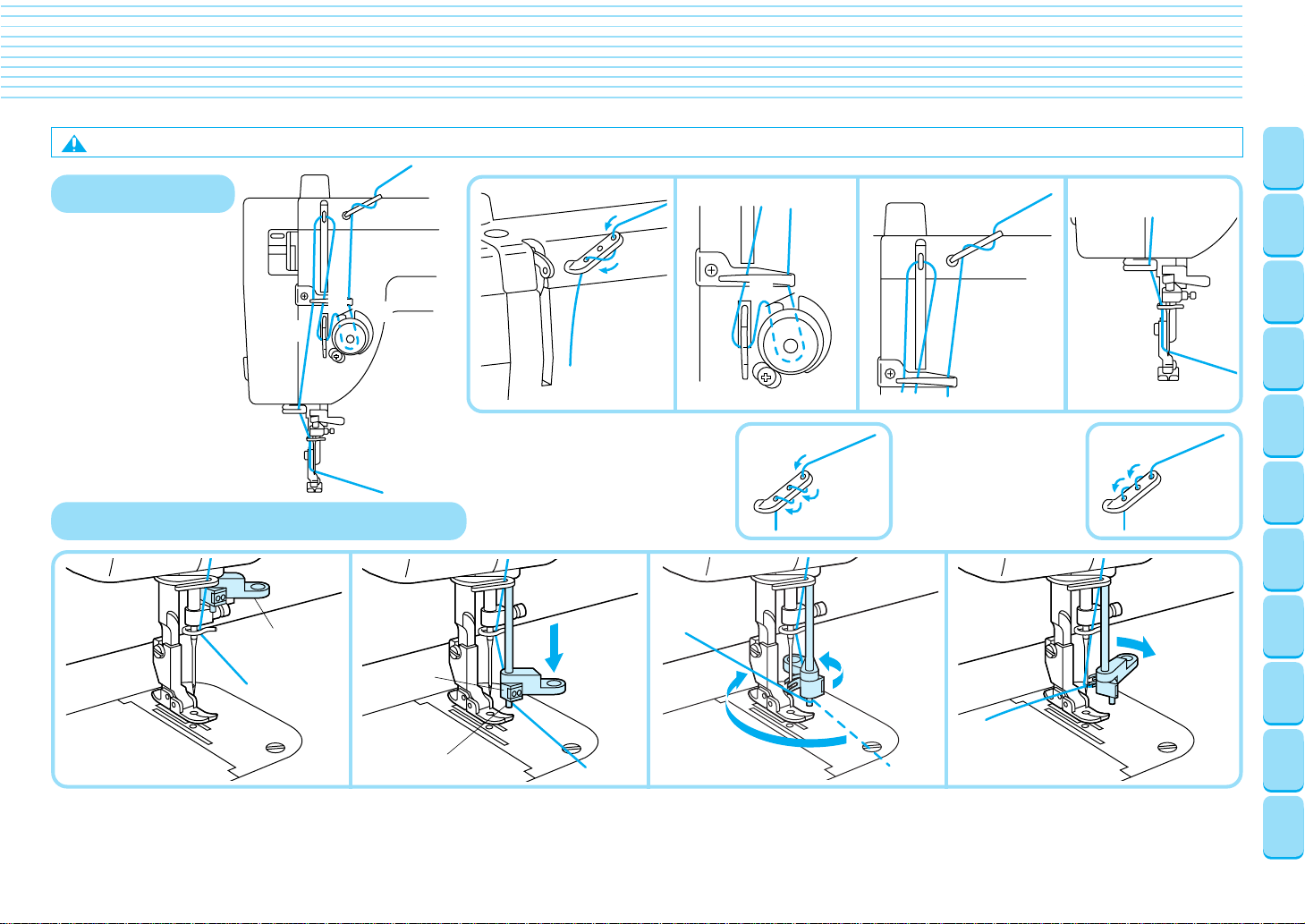

Threading (2)

7

8

Note

Please turn power is off before using automatic needle threader. Accidentally stepping on the foot controller during this operation could cause bodily injury or damage to the machine.

CONTENTS

1

Upper Threading

7

6

8

4

2

3

5

9

0

A

Using the Automatic Needle Threader

Automatic

Needle

Threader

Hook

1

● Make sure thread take-up lever

is in highest position and presser

foot is up.

✽ When using polyester, you

should run the thread through all

three holes of the thread guide.

5

4

6

2

3

✽ If the thread is still

twisted, run the

thread through the

holes backwards as

shown in diagram.

9

0

A

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

1 Pull hand wheel towards you until

needle is in the highest position, and

lower presser foot.

2 Take thread in your left hand, and

gently pull it forwards.

Pin

3 Lower automatic needle threader.

✽ Pull thread along the right side of the

pin.

4 Catch thread with hook.

✽ Pull thread to the right, and make

sure it has been caught with the

hook.

5 Raise needle threader lever while

gently holding the end of the thread.

Machine

Your

Shooting

Trouble

9

Caring for

Page 14

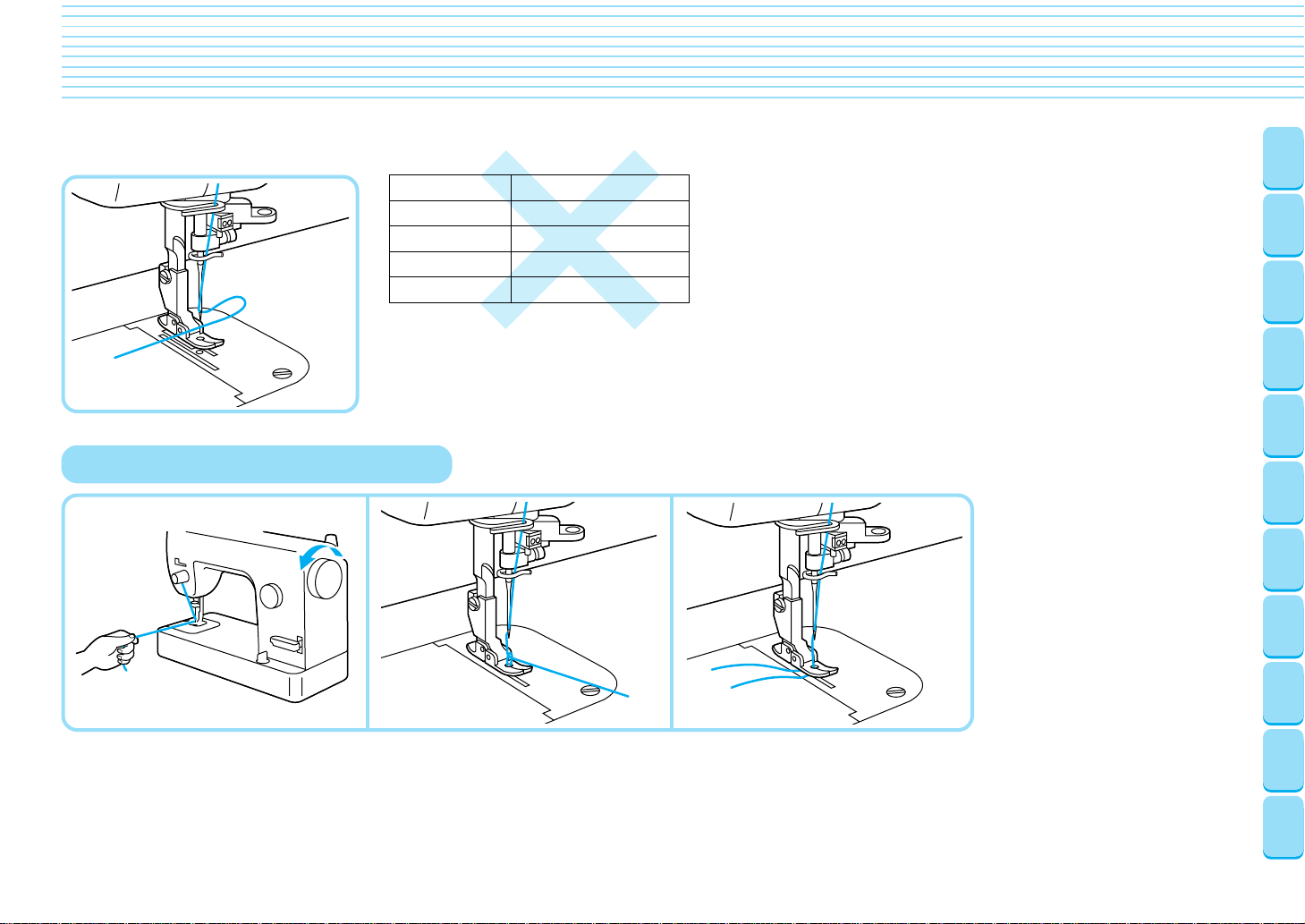

CONTENTS

Needle (HLX5) Thread

6 Pull loop to the right.

How to Pull Out the Bobbin Thread

#9

#11

#14

#16

#30

#30

#30

#20

#50 #60

● The automatic needle threader

cannot be used with the threadneedle combinations illustrated in

the chart to the left. Transparent

nylon thread can be used regardless

of the chart, providing the needle

used is a #14 or #16.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

✽ Insert threaded bobbin in sewing

machine and then begin.

1 While gently holding the end of the

thread, turn the hand wheel towards

you to raise the needle.

✽ Turn once to pull out the bobbin

14

10

thread.

2 Pull out the bobbin thread. 3 Pull approximately 15 centimeters of

upper and bobbin threads out.

✽ Lift foot and run both upper and

bobbin threads under and behind

presser foot.

Caring for

Machine

Your

Shooting

Trouble

Page 15

Stitch Samples and Needle Chart

Stitch Samples

1 Set stitch length regulator to

desired stitch length.

2 Make sure approximately 15cm

of upper and bobbin threads are

pulled out and laying behind

presser foot. While needle is in

raised position, insert a test strip

from the garment fabric under the

foot.

3 Lower presser foot.

4 Lower needle through fabric,

then step gently on presser foot

and begin.

5 Raise needle to highest point.

6 Lift needle, remove fabric and

then cut thread.

✽ When using thread cutter:

5 Push thread cutter button

6 Lift foot and remove fabric.

Thread Tension

Using the right needle

Fabric

Upper

Thread

Lower

Thread

Using the wrong needle can lead to

such undesirable results as messy

stitches, puckered seams and

thread breakage.

●

Selecting the proper needle for use with the fabric and thread you are working with.

✽ Bobbin thread should feed smoothly. Adjust bobbin thread

to match that of upper thread. (If bobbin thread is too tight it

may cause fabric to bunch up)

Adjust needle thread tension with dial

to increase

needle

thread

tension

Adjust needle thread tension with dial

to reduce

needle thread tension

to reduce

bobbin

tension

to increase

bobbin

tension

Right side of Fabric

Bobbin tension

Right side of fabirc

Bobbin tension

Wrong side of fabric

· · ·

Wrong side of fabric

· · ·

Proper

When it is week

Lower

Thread

Upper

Thread

Proper

When it is strong

Lower

Thread

Upper

Thread

✽ The following chart applies to many different sewing methods.

Special

fabric

Light

weight

fabrics

Medium

weight

fabrics

Heavy

weight

fabrics

Cloth

Velvet

Synthetic Suede

Lawn

Tricot

Silk Georgette

Wool Georgette

Gingham

Lightweight Jersey

Gabardine, Flannel

Denim

Jersey

Tweed

Fabric - Thread - Needles

Thread

Silk, Polyester #30 – #50

Polyester #20 – #50

Cotton #80

Polyester #60

Silk #50

Silk, Polyester #50

Cotton #60 – #80

Polyester #60

Silk #50

Cotton #20 – #50

Polyester #20 – #50

Silk #20 – #50

Needle (HLX5)

#11 – #14

#11 – #16

#9

#11

#11 – #14

#11

#14 – #18

#11 – #16

Schmetz

HLX5

130/705H

#9 #65

#11 #75

#14 #90

#16 #100

✽ HLX5 needles are recommended; however, Schmetz 130/705H needles may

also be used under normal sewing conditions.

✽ Adjust pressure of sewing foot and drop feet height according to chart.

✽ When sewing on knit fabrics such as jersey or tricot, use a ballpoint needle or

other needle designed for use with knit fabrics.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

11

Page 16

Changing Presser Feet

Note Make sure the power is off before changing presser feet.

CONTENTS

Changing Sewing Feet

(Zipper Foot)

1 Raise presser foot, and raise

needle to highest position.

2 Loosen and remove screw using

screwdriver.

3 Attach zipper foot and tighten

screw.

✽ The same method is used for

changing all sewing feet.

✽ Use the position knob on back of

the zipper foot to adjust position

of foot in relation to needle.

Presser Feet

● Pin Feed Foot

For perfect stitching on otherwise

difficult fabrics like velvet, leather

and suede.

● Regular Foot

This foot is used for most sewing.

(Included with sewing machine.)

Can also be used with pin feeding

✽

● Rolled Hem Foot

Use on the edges of fabric, such

as on hems of dress shirts, to fold

the edge of the fabric in three

while sewing.

● Zipper Foot

Use to attach fasteners other

than concealed fasteners.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

16

12

● Invisible Zipper Foot

Use to attach concealed fasteners.

Caring for

Machine

Your

Shooting

Trouble

Page 17

Basic Sewing (1)

Basic Sewing

CONTENTS

Before

sewing.

1 Lift foot, pull about 15cm of upper

and bobbin thread under and behind

foot, and position fabric under foot.

Begin

sewing.

2 Lower foot.

3 While needle is pierced all the way

through fabric, step gently on foot

controller.

Pin Feeding (for hard-to-handle fabrics)

Indicator Needle

Fabric:

Velvet

Synthetic Suede

Others

N

Finish

Sewing.

4 Raise needle to highest position.

5 Lift foot, remove fabric and cut

thread.

✽ When using thread trimmer:

4 Push thread trimmer button (this will

cause the upper and bobbin threads

to be cut automatically and the

needle to stop in a raised position.)

5 Lift presser foot and remove fabric.

✽

When changing sewing directions.

1 Make sure needle is pierced all the

way through fabric.

2 Lift presser foot, and turn fabric using

needle as an axis.

3 Lower foot and continue sewing.

Pin Feeding Unit

Feed Pin

Reinforcement stitches

1cm

1cm

✽ At the beginning of a seam, sew a

few stitches with the hand wheel, hit

the reverse stitch button and sew a

few stitches back to reinforce your

seam, then go back to normal sewing

and finish the seam. Do the same at

the end of a seam.

Fabric

Feed Pin

Feed Dog

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

✽ The above fabrics

can be sewed

neatly by sewing

by pin feeding.

1 Move feed adjustment knob

to pin feeding position.

2

Adjust pressure adjustment dial until indicator

needle is in the right position.

3 Gently pull thread until feed pin

catches fabric and sew.

The feed pin passes up through all layers of fabric moving with the feed dog's motion

to feed all layers of the fabric evenly.

✽ Feed pin is automatically lowered when presser foot is raised.

13

Shooting

Trouble

Page 18

Basic Sewing (2)

Note Make sure power is off before changing feet.

CONTENTS

Rolled Hem Foot

1 Attach rolled hem foot.

✽ Refer to page 12 for instructions

on changing sewing feet.

2 Insert needle approximately

0.5cm from the edges of the

fabric and sew 2-3 stitches.

3 Raise needle and foot, pull fabric

towards you while gently holding

thread in left hand.

4 Gently pull strands of thread

behind foot as shown.

0.5cm

0.5cm

5 While holding threads with left

hand, position fabric under foot

with right hand so the edge of the

fabric lies directly under the

needle.

6 Pull gently on threads in left hand

while sewing the first 3-4 stitches

to hold them in place.

7 Fold hem over about .5 cm and

continue feeding folded hem

under foot while sewing.

Rolled Hem

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

18

14

Caring for

Machine

Your

Shooting

Trouble

Page 19

Basic Sewing (3)

Note

Make sure power is off before changing feet.

Zipper Foot

1 Attach zipper foot.

2 Turn hand wheel to lower needle

and adjust position of foot to

needle.

3 Line up zipper to the section of

fabric it will be attached to, and

mark the base of the opening on

the fabric. It should be set

approximately .5 centimeters

below zip stop.

0.5cm

4 Fold hem about .2 cm from mark,

and make a mark along the edge.

Slide

0.2cm

Stop

A

Base of

Opening

5 Sew zipper onto fabric along

mark.

6 Line up folded seam to stitches.

7 Change position of zipper foot.

8 Turn hand wheel to lower needle

and make sure the needle and

position of the foot are lined up

properly.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

B

9 Baste zipper onto fabric and sew

along edge with fabric right side

up.

✽ Reinforce base of opening by

sewing over it twice.

✽ If the zipper slide gets in the way,

lower the needle all the way

through the fabric, lift the foot,and

move the slider out of the way.

15

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 20

Invisible Zipper Foot

1 Attach invisible zipper foot.

2

Alight zipper with fabric. Mark the

base of the opening approximately

2 cm above the end of the zipper.

3 Fold the area to be sewed.

4 Line up zipper with fabric on the

wrong side of the fabric, open

zipper, and baste zipper to the

fabric.

5 Sew the zipper to the fabric with

the wrong side of the zipper and

fabric up.

✽ When sewing with the teeth to

the right, the left side of the foot

should line up with the left teeth

of the zipper.

Slide

Teeth

Basting

Base of

Opening

2cm

Lining

1 Raise needle and foot.

2 Move separater so it sits under

presser foot.

3 Make sure it is lined up so that

the needle passes through the

slot of the separater without

hitting the plate itself.

4 Secure liner plate in place with

lining plate screws.

5 Set pressure of sewing feet and

feed position to pin feeding

position.

6 Pull thread until lower needle

catches fabric.

✽ Sew 2-3 reinforcement stitches.

7 When not using separater, it can

be swung off to the side as

illustrated in drawing.

Needle

Separater

Separater

Needle

Lining

Separater

Velvets

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

20

16

Shooting

Trouble

Page 21

Caring for Your Machine

Note

Make sure power is off before

cleaning sewing machine.

1 Turn machine off.

2 Remove foot.

3 Remove needle plate.

4 Clean out dust and thread scraps.

✽ Thread scraps can be swept out

through the bobbin door.

5 When the area under the needle

plate is cleaned out, oil hook of

bobbin case with sewing

machine oil.

6 Attach needle plate and foot.

■ Keep Your Sewing Machine Clean

Please use a soft, dry cloth to wipe off light dirt and

dust. If sewing machine is very dirty, wipe with a cloth

soaked in warm water, or in warm water containing a

neutral detergent. Then wipe off any detergent

residue, and wipe off water with a dry cloth.

■ Precautions

Please keep sewing machine away from heat sources

such as irons and space heaters. Do not use chemicals

like benzine or thinner to clean your machine. When

machine is not in use, please keep machine out of

direct sunlight.

Item

Sewing Speed

(maximum)

Stitch Length

(pitch)

Stroke of

Needle

Stroke of

Thread TakeUp Lever

Foot Height

Specification

1,300 stitches per minute

0 – 7mm

34.1mm

61.4mm

Foot Lift

Knee control Over 10mm

One 6mm

Two 9mm

Item

Height of feed dog

Height of

lower needle

Needles that

may be used

Bed dimensions

Total weight

Motor

Sewing Light

Sewing area

Hook

Specification

0.7mm 1.1mm

3mm – 3.5mm

HLX5#9 – #16

SCHMETZ 130/705H #65 – #100

439mmX178mm

10kg

120V 60Hz

120V 15W 60Hz

595mmX285mm

CONTENTS

Accessories

Parts

Begin

Needles and

Light Bulb

Threading

Samples and

Needle Chart

Presser Feet

Sewing

Machine

Your

Shooting

17

Names of

Before You

Changing

Stitch

Changing

Basic

Caring for

Trouble

Page 22

Trouble Shooting

✽ Before taking your sewing machine in for service, check the following chart.

Thread

Breakage

Bobbin Thread

Breakage

Skipped

Stitches

Fabric

Puckers

Fabric Won't

Feed Properly

Loop In

Seam

Needle

Breakage

Sewing Machine

Doesn't Run

Machine Is

Noisy

Automatic Needle

Threader Doesn't

Work

Thread Cutter

Doesn't Work

22

18

Upper threading is not

threaded correctly.

Re-thread machine

properly.

Bobbin thread is not passing

correctly from bobbin case.

Reinsert bobbin

properly.

Needle is not attached

correctly.

Reattach.

Threading is incorrect.

Rethread machine.

Stitch length is too short.

Adjust stitch length.

Upper threading is

incorrect.

Re-thread machine

properly.

Needle is not attached

correctly.

Reattach.

The power isn't on.

Turn the power on.

The area under the needle

plate needs to be cleaned.

Clean feed dog and

bobbin case.

Needle is not raised

all the way up.

Turn hand wheel to

raise needle.

Needle is not properly

attached.

Reattach.

8 – 10

17

Thread is getting tangled.

Rethread machine.

Clean bobbin case and

9

under needle plate.

Thread is getting tangled.

Rethread machine.

Clean bobbin case and

8

under needle plate.

Wrong needle.

See chart on p.11 to choose the

needle that best fits your

fabric-thread combination.

6

Wrong needle for the fabric

and thread you are using.

See chart on p.11 to choose the

needle that best fits your

fabric-thread combination.

Pressure of sewing foot

is too weak.

Adjust foot pressure.

3

Thread is not passing through

bobbin case correctly.

Reset bobbin case.

9

Wrong needle.

Change needles.

6

Machine's not plugged in.

Check to make sure the

machine's plugged in.

3

Wrong needle for the

thread you're using.

See chart on p.10.

3

Wrong needle.

See chart on p.11 to choose the

needle that best fits your

6

fabric-thread combination.

8 – 10

8 – 10

11

11

4

8

6

3

10

11

Upper thread tension is

too high.

Reduce tension.

Bobbin tension is too high.

Reduce tension.

Needle is bent, or tip is

dulled.

Change needles.

Upper thread tension is

too high.

Reduce tension.

Sewing heavyweight fabric with

feed dogs in lightweight fabric

position.

Adjust feed dogs.

Wrong needle.

See chart on p.11 for the right

needle to use with your fabric

and thread.

Wrong needle.

See chart on p.11 for the right

needle to use with your fabric

and thread.

The foot controller has

come unplugged.

Reattach foot controller.

Hook of needle threader doesn't

pass through eye of needle.

Check to make sure the

hook isn't bent.

Needle is bent, or tip is

dulled.

Change needles.

11

11

6

11

5

11

11

3

6

Wrong needle.

See chart on p.11 for the right

needle to use with your fabric

and thread.

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Area under needle plate

needs to be cleaned.

Clean feed dog and

bobbin case.

Bobbin tension is too high.

Reduce tension.

Thread is getting tangled.

Rethread machine. Clean needle

plate and bobbin case.

You're pulling the fabric

too hard.

Pull the fabric

more gently.

Area under needle plate

needs to be cleaned.

Clean feed dog and

bobbin case.

11

17

11

8 – 10

13 – 16

17 9

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Machine is not threaded

properly.

Rethread machine.

You're sewing a lightweight fabric with

feed dogs in heavyweight position.

Adjust feed dogs.

Upper threading is

incorrect.

Rethread.

8 – 10

5

CONTENTS

If you still cannot find the problem, please take your sewing machine into the

shop where you purchased it, or to your nearest Brother dealer for repair.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 23

Memo

CONTENIDO Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

coudre

Dépannage

19

Entretien de

Page 24

NOUS VOUS REMERCIONS D’AVOIR CHOISI LA

MACHINE A COUDRE ELECTRONIQUE BROTHER.

Il s’agit de la machine à coudre domestique la plus sophistiquée pour son automatisme.

Cependant, nous vous conseillons la lecture de ce fascicule afin de profiter pleinement de toutes les fonctions intégrées.

RECOMMENDATIONS AVANT D’UTILISER VOTRE MACHINE A COUDRE BROTHER

Précautions d’utilisation

● Surveiller l’aiguille pendant la couture. Ne pas toucher le volant, le releveur de fil, l’aiguille ou les autres parties en mouvement.

● Se rappeler qu’il faut éteindre la machine et débrancher le cordon secteur quand:

●

I’utilisation est terminée

●

vous remplacez ou échangez l’aiguille ou toutes autres pièces

●

une panne de courant se produit en cours d’utilisation

●

vous faites l’entretien et la lubrification de la machine

●

vous laissez la machine sans surveillance

● Ne rien poser sur la pédale de commande.

● Brancher directement la machine dans la prise murale. Ne pas utiliser de rallonge électrique.

Pour une vie prolongée de votre machine

● Ne pas ranger votre machine dans des endroits exposés au soleil et très humides. Ne pas ranger votre machine à coudre à proximité d’un appareil de chauffage, d’un

fer à repasser, ou de tout autre appareil dégageant de la chaleur.

● Utiliser seulement des savons ou des détergents neutres pour nettoyer le coffret de la machine. Ne jamais utiliser de benzine, de diluants, de décapants, car ces

produits risquent endommager le coffret et la machine.

● Ne pas laisser tomber ou heurter la machine.

● Toujours consulter le manuel d’instructions lors de l’installation des pieds presseurs, des aiguilles et des autres dispositifs afin d’effectuer une installation correcte.

Pour la réparation et le réglage

Dans le cas d’une anomalie ou lorsqu’un réglage est nécessaire, se rapporter au chapitre “Résolution des problèmes” afin d’inspecter et de régler vous-même la machine.

Si le problème persiste, consultez votre revendeur Brother.

CONTENIDO

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

24

20

la machine à

Entretien de

coudre

Dépannage

Page 25

CONTENIDO

Accessoires __________________________________ 22

Nom des pièces_______________________________ 23

Avant de commencer __________________________ 24

Sélecteur de tension _______________________ 24

Cordon d'alimentation et pédale ______________ 24

Interrupteur d'alimentation __________________ 24

Volaut __________________________________ 24

Sélecteur de lougueur de point _______________ 24

Levier de poiut arriére ______________________ 24

Levier du pied-de-biche ____________________ 25

Levier de levage au genou __________________ 25

Sélecteur de réglage de pression _____________ 25

Table d'exteusion plate _____________________ 25

Bouton de ciseaux ________________________ 26

Bouton de position d'arrêt d'aiguille ___________ 26

Interrupeur de lampe_______________________ 26

Boutou de réglage des griffes d'entraînement ___ 26

Remplacement de l'aiguille et de l'ampoule de lampe _ 27

Remplacement de l'aiguille __________________ 27

Remplacement de lérgot d'eutraînement _______ 27

Remplacement de l'ampoule ________________ 27

Enfilage _____________________________________ 28

Remplissage de la canette __________________ 28

Insertion de la canette______________________ 29

Mise en place du fil supérier _________________ 30

Utilisation de lénfileur automatique ____________ 30

Comment sortir le fil de la canette ____________ 31

Points d'essai et tableau d'aiguilles ______________ 32

Points d'essai ____________________________ 32

Tension des fils ___________________________ 32

Changement du pied-de- biche __________________ 33

Couture de base ______________________________ 34

Couture de base __________________________ 34

Entaînement par ergot

(pour les tissus difficiles à manipuler) __________ 34

Ergot d'eutraînemeut ______________________ 34

Pied pour ourlet rouleauté___________________ 35

Pied pour fermeture à glissière _______________ 36

Pied pour fermeture à glissière tnvisible ________ 37

Doublure ________________________________ 37

Entretien de la machine à coudre ________________ 38

Dépannage___________________________________ 39

CONTENIDO Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

coudre

21

Couture de

base

la machine à

Entretien de

Dépannage

Page 26

Accessoires

123

456

789

10 11 12

13 14 15

16 17 18

No. de pièce Désignation Code de pièce

1 Couvercle XA0917-052

2 Tournevis moyen 125877-001

3 Petit tournevis 125878-001

4 Brosse de nettoyage XA4527-001

5 Levier de levage au genou XA0830-001

6 Table d'extension plate X81029-001

7 Aiguilles et boîte 1 Taille 9

(ORGAN HLX5) 2 Taille 11

1 Taille 14 X80805-001

1 Taille 16

1 aiguille à pointe-bille

8 Vis de plaque de doublure (2) 062670-812

9 Séparateur 184720-001

10 Axe d'avance 138483-001

11 Extracteur d'axe d'avance 117934-009

12 Pied à usage général XA1425-001

13 Canette (5) 100376-003

14 Capuchon de bobine XA2111-000

15 Pied pour ourlet rouleauté X57138-001

16 Pied pour fermeture à glissière 112797-001

17

18 Pédale du rhéostat XA3931-051

Remarque

Pédale du rhéostat : Modèle N5V

Cette pédale du rhéostat peut être utilisée avec la

machine à coudre modèle PQ1300.

Pied pour fermeture à glissière invisible

148475-001

CONTENIDO

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

26

22

Dépannage

Page 27

Nom des pièces

CONTENIDO Accessoires

Barre de guidage

du fil (Page 28)

Sélecteur de réglage

de pression (Page 25)

Interrupteur de la

lampe (Page 26)

Lampe de section de

couture (Page 27)

Table d'extension

(Page 25)

Enfileur automatique

(Pages 30 et 31)

Coupe-fil

Griffes d'entraînement

(Pages 26 et 34)

Guide-fils à trois

trous (Page 30)

Bouton de

ciseaux (Page 26)

Sélecteur de tension

(pages 24 et 32)

Sélecteur de longueur

de point (Page 24)

Bouton de position

d'arrêt d'aiguille

(Page 26)

Levier de point

arrière (Page 24)

Bouton de réglage des

griffes d'entraînement

(Page 26)

Levier de levage

au genou (Page 25)

Dévidoir (Page 28)

Volant (Page 24)

Interrupteur

d'alimentation

(Page 24)

Prise de courant

(Page 24)

Prise de pédale du

rhéostat (Page 24)

Orifices de ventilation

Poignée

Coussinet de

bobine (Page 28)

Guide-fils du

dévidoir (Page 28)

Levier du

pied-de-biche

(Page 25)

Porte-bobine

(Page 28)

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

23

Page 28

Avant de commencer (1)

Sélecteur de tension

Tension de fil supérieur

CONTENIDO

Volant

● Pour accroître la tension, tourner

le sélecteur de tension vers la

droite. Le fil supérieur et le fil de

la canette se rejoignent sur le

bon côté du tissu.

● Pour réduire la tension, tourner le

sélecteur de tension vers la

gauche. Le fil supérieur et le fil de

la canette se rejoignent sur le

mauvais côté du tissu.

Desserrer Serrer

Bloc de tension

Cordon d'alimentation et pédale

Remarque

Utiliser un courant secteur 120 V

domestique ordinaire.

● Brancher le cordon.

● Brancher la pédale sur la machine.

Remarque

Pédale de rhéostat : Modèle N5V

Cette pédale du rhéostat peut être utilisée

avec la machine à coudre modèle PQ1300.

Interrupteur d'alimentation

● Basculer l'interrupteur sur la

position "I" pour allumer la

machine à coudre.

● Pour éteindre la machine,

basculer l'interrupteur sur la

position "O".

AC120V

Cordon

d'alimentation

Pédale de rhéostat

Interrupteur

d'alimentation

● Positionner l'aiguille à l'aide du

volant.

✽ Toujours tourner le volant vers

soi.

Sélecteur de longueur de point

● Régler la longueur de point à

l'aide du sélecteur de longueur

de point.

7

6

Levier de point arrière

● Pour coudre en marche arrière,

abaisser le levier de point arrière.

✽ Bien abaisser le levier de point

arrière à fond pour coudre en

marche arrière.

Volant

Repère de référence

1

2

3

4

5

Sélecteur de longueur de point

Levier de

point arrière

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

28

24

Page 29

Levier du pied-de-biche

Sélecteur de réglage de pression

Sélecteur de réglage de pression

CONTENIDO Accessoires

● Abaisser le levier du pied-debiche pour abaisser le pied-debiche sur le tissu.

✽ Pour travailler dans du tissu lourd

et des tissus qui ne glissent pas

facilement sous le pied, relever le

levier du pied-de-biche pour

placer le tissu.

Levier de levage au genou

● Le levier de levage au genou est

pratique pour relever le pied-debiche sans retirer les mains du

tissu.

Réglage du lerrir de levage au genou

✽ Appuyer à fond sur le levier de

levage au genou.

Levier du

pied-de-biche

Réglage de la

pédale du

rhéostat

Table d'extension

● Tourner le sélecteur de réglage de

pression pour faire monter et

descendre l'aiguille de l'indicateur

de pression.

Voir également : "Bouton de réglage

des griffes d'entraînement", page

26.

Aiguille de

l'indicateur de

N

pression

Table d'extension plate

● Abaisser les pieds de table et fixer la table d'extension comme indiqué sur le

schéma ci-dessous.

2

Trou

Tige de guidage

Butée

3

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

✽ Lorsqu'on ne se sert pas du

levier de levage au genou, on

pourra le laisser sur l'envers de

la table d'extension.

Levier de levage au genou

1

Pieds de table

Crochet

Dépannage

25

Page 30

Avant de commencer (2)

g

Bouton de ciseaux

CONTENIDO

Bouton de réglage des griffes d'entraînement

Remarque

Si la machine s'arrête, parce que les fils

sont emmêlés par exemple, ne pas

appuyer sur la pédale tant que la machine

n'est pas éteinte et l'aiguille déplacée à la

main pour vérifier la situation. Sinon

l'aiguille risque de se casser.

●

Les ciseaux coupent le fil supérieur et le

Bouton de ciseaux

fil de la canette à la fin des coutures.

Bouton de position d'arrêt d'aiguille

● Quand le voyant est allumé, la

machine arrêtera la couture

lorsque l'aiguille sera abaissée et

enfoncée dans le tissu.

● Si le voyant est éteint, la position

de l'aiguille au moment de l'arrêt

de la couture sera aléatoire.

● Si le mécanisme de sécurité s'est

déclenché, par exemple si le fil est

emmêlé, le voyant rouge clignote.

Voyant indicateur

Bouton de position d'arrêt d'ai

Interrupteur de lampe

● Appuyer sur l'interrupteur pour

allumer et éteindre la lampe sur

la section de couture.

Interrupteur

de lampe

uille

● Il est possible de régler la hauteur

des griffes d'entraînement en

fonction du poids du tissu.

Bouton de réglage des

griffes d'entraînement

Pression du pied-de-biche et position

des griffes d'entraînement

(Griffes d'entraînement rentrées)

(Entraînement par tige)

Tissus légers

Tissus moyens

Tissus lourds

Sélectionner l'une des quatre positions de griffes d'entraînement, en fonction des

besoins.

Velours

N

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

30

26

Remarque

Si l'on sélectionne un réglage autre que

, l'ergot d'entraînement ne

Dépannage

fonctionnera pas.

Page 31

Remplacement de l'aiguille et de l'ampoule de lampe

)

Remarque

Bien éteindre la machine à coudre avant d'effectuer

les opérations suivantes. Sinon, la machine risque

de se mettre en marche accidentellement et de

provoquer des blessures.

Remplacement de l'aiguille

1

Eteindre la machine.

Relever l'aiguille sur la

position de levage

maximal à l'aide du

volant, et abaisser le

pied-de-biche.

2

Desserrer la vis avec un

tournevis et retirer

l'aiguille.

3 Insérer la nouvelle

aiguille et visser à fond.

S'assurer que l'aiguille

est bien vissée à fond.

Tournevis

Remplacement de l'ergot d'entraînement

1

Régler les griffes d'entraînement sur

la position "velours". (Voir Page 26.)

2

Retirer l'aiguille, le pied-debiche et la plaque à aiguille.

Abaisser le pied-de-biche et tourner le volant

3

jusqu'à ce que l'ergot d'entraînement soit à la

position de levage maximale.

4

Insérer le petit tournevis (fourni)

comme indiqué sur le schéma.

5 Tout en tenant le ressort

du bout des doigts,

abaisser le changeur

d'ergot d'entraînement

sur l'aiguille pour relever

la tige.

Remarque

Bien éteindre la machine à coudre avant d'effectuer

les opérations suivantes. La plaque de verre qui

abrite l'ampoule de lampe est chaude quand on

vient d'utiliser la machine ; en conséquence,

attendre que la machine ait refroidi avant de

remplacer l'ampoule.

Remplacement de l'ampoule

1 Eteindre la machine.

2 Retirer les vis de la tête.

3 Retirer la tête.

Tournevis

CONTENIDO Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

✽ Vérifier les aiguilles sur

une surface plane pour

s'assurer qu'elles ne

L'aiguille doit être parallèle par

rapport à une surface plane.

Surface plane

sont pas tordues.

(Poser l'aiguille sur une

surface plane (par

exemple la plaque à

aiguille ou une plaque

de verre

.

Remarque

Utiliser des aiguilles HLX ; toutefois, on pourra

également utiliser des aiguilles Schmetz 130/705H

dans des conditions normales d'utilisation.

Fixer un nouvel ergot

6

d'entraînement au changeur

d'ergot d'entraînement,

abaisser et fixer tout en

tenant le ressort du bout des

doigts.

7 Retirer le tournevis.

8 Remonter la plaque à

aiguille et le pied-debiche.

4 Dévisser l'ampoule et

la retirer.

5 Visser une nouvelle

ampoule, de capacité

nominale de 120 V, 15 W.

6 Remonter la tête et

visser à fond.

Ampoule

de lampe

coudre

27

Couture de

base

la machine à

Entretien de

Dépannage

Page 32

Enfilage (1)

Remplissage de la canette

3

2

Ne pas déplacer la butée de canette pendant que la

machine fonctionne.

2

1

Remarque

1

4568 9

Coussinet de bobine

1 Mettre la bobine de fil sur le porte-

bobine.

✽ Avec un fil enroulé croisé, utiliser le

coussinet de bobine.

Encoche à fil 1

Encoche à fil 2

Canettes

Arbre du dévidoir

Capuchon de bobine

Bobine de fil

✽ Avec un fil enroulé parallèlement,

utiliser le capuchon de bobine.

CONTENIDO

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

2 Relever la barre de guidage du fil au

maximum et faire passer le fil dans

le guide-fils triangulaire comme

indiqué sur le schéma.

32

28

3 Faire passer le fil dans le guide-fils

du remplissage de canette comme

indiqué sur le schéma.

Tige de guidage

4 Faire passer le fil dans l'encoche à fil

supérieure et aligner l'encoche à fil

inférieure sur la tige de guidage de

l'arbre du dévidoir.

Butée de canette

5 Appuyer sur la butée de canette

contre la canette vide.

la machine à

Entretien de

coudre

Dépannage

Page 33

CONTENIDO Accessoires

Nom des

pièces

6

Tout en tenant l'extrémité du fil, appuyer

sur la pédale pendant quelques

secondes. Quand il s'est enroulé

suffisamment de fil sur la canette pour

que le fil reste en place, relâcher la pédale

et couper l'excédent de fil.

Insertion de la canette

Pour éviter tout risque de blessure, bien éteindre la machine avant toute opération d'entretien. Remettre le couvercle en place.

Plaque coulissante

Volet de canette

1 Soulever la plaque coulissante

(et le volet de la canette).

7 Cesser d'enrouler le fil lorsque la

8 De la main, ramener la butée de

canette est pleine. Retirer le pied de

la pédale.

Attention – Déplacement des pièces –

Ressort de verrouillage

Encoche à fil

✽

La canette doit être placée

de façon qu'elle se bobine

vers la gauche.

2 Mettre la canette dans le boîtier de la

canette.

✽ Faire passer le fil dans l'encoche à fil et

sous le ressort de verrouillage de façon

qu'il ressorte environ 10 centimètres de fil.

3

✽

Butée de canette

9 Couper le fil et enlever la canette.

canette sur sa position d'origine.

Tirer sur le levier de verrouillage du boîtier de la canette,

enfoncer le boîtier de la canette dans la coursière de

4 Abaisser la plaque coulissante et

refermer le volet de la canette.

navette et relâcher le levier de verrouillage.

Si le levier de verrouillage n'est pas complètement

sur le crochet, il risque de se dégager pendant la

couture, ce qui pourrait casser le fil inférieur.

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

29

Page 34

Enfilage (2)

7

8

Remarque

Bien éteindre la machine avant d'utiliser l'enfileur automatique. Une pression accidentelle sur la pédale pendant cette opération pourrait provoquer des blessures ou endommager la machine.

CONTENIDO

1

Mise en place du fil supérieur

7

6

8

4

2

3

5

9

0

A

Utilisation de l'enfileur automatique

Enfileur

automatique

Crochet

1

5

●

Vérifier que le levier de relevage du fil se

trouve sur la position de levage maximale

et que le pied-de-biche est relevé.

✽ Lorsqu'on utilise du polyester,

faire passer le fil dans les trois

orifices du guide-fils.

4

6

2

3

✽ Si le fil est encore

torsadé, faire passer

le fil dans les

orifices arrière,

comme indiqué sur

le schéma.

9

0

A

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

1

Tirer le volant vers soi jusqu'à ce que

l'aiguille soit à la position de levage

maximal, et abaisser le pied-de-biche.

2 Tenir le fil de la main gauche, et le

34

30

tirer légèrement vers l'avant.

Axe

3 Abaisser l'enfileur automatique.

✽ Tirer le fil sur la droite de l'axe.

4 Attraper le fil avec le crochet.

✽ Tirer le fil vers la droite et s'assurer

qu'il est bien pris dans le crochet.

5 Relever le levier d'enfileur tout en

tenant délicatement l'extrémité du fil.

la machine à

Entretien de

coudre

Dépannage

Page 35

CONTENIDO Accessoires

Aiguille (HLX5) Fil

6 Tirer la boucle vers la droite.

Comment sortir le fil de la canette

#9

#11

#14

#16

#30

#30

#30

#20

#50 #60

● Certaines combinaisons de fil et

d'aiguille ne permettent pas d'utiliser

l'enfileur automatique, comme

indiqué sur le tableau de gauche. Un

fil de nylon transparent pourra être

utilisé indépendamment des

indications du tableau, à condition

d'utiliser une aiguille #14 ou #16.

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

✽

Insérer la canette pleine dans la machine à

coudre avant de commencer.

1 Tout en tenant délicatement

l'extrémité du fil, tourner le volant

vers soi pour relever l'aiguille.

✽ Tourner une fois pour faire sortir le fil

de la canette.

2 Sortir le fil de la canette. 3 Sortir environ 15 centimètres de fil

supérieur et de fil de canette.

✽ Relever le pied, sortir le fil supérieur

et le fil de canette et les faire passer

derrière le pied-de-biche.

coudre

31

la machine à

Entretien de

Dépannage

Page 36

Points d'essai et tableau d'aiguilles

Points d'essai

1 Régler le sélecteur de longueur

de point sur la longueur de point

voulue.

2 Vérifier qu'il y a environ 15 cm

de fil supérieur et de fil de

canette de sortis, et qu'ils sont

placés derrière le pied-de-biche.

L'aiguille étant en position

relevée, mettre un morceau de

tissu sous le pied-de-biche pour

faire un essai.

3 Abaisser le pied-de-biche.

4 Abaisser l'aiguille sur le tissu, et

appuyer délicatement sur la

pédale pour commencer à

coudre.

5 Relever l'aiguille à la position

maximale.

6 Relever l'aiguille, enlever le tissu

et couper le fil.

✽ Si l'on utilise les ciseaux :

5 Appuyer sur le bouton des

ciseaux.

6 Relever le pied et enlever le

tissu.

36

32

Tension des fils

Utiliser la bonne l'aiguille

Tissu

Fil

supérieur

Fil

inférieur

Le fait d'utiliser une mauvaise aiguille peut

entraîner des résultats médiocres, par

exemple des points peu nets, un froncement

des coutures et une rupture du fil.

✽ Le fil de canette doit être alimenté régulièrement. Régler le

fil de canette en fonction de la tension du fil supérieur. (Si

le fil de canette est trop serré, le tissu risque de se plisser.)

Mauvais côté du tissu

Bon côté du tissu

Tension de canette

Tension de canette

· · ·

Bon côté du tissu

· · ·

Fil

inférieur

Fil

supérieur

Correcte

Trop forte

Mauvais côté du tissu

Fil

inférieur

Fil

supérieur

Correcte

Trop faible

Régler la tension du fil de canette avec le sélecteur

pour

augmenter

la tension

du fil

Régler la tension du fil de canette avec le sélecteur

pour réduire la

tension du fil d'aiguille

pour

réduire la

tension de

canette

pour réduire

la tension

de la canette

● Sélectionner l'aiguille qui convient pour le tissu et le fil.

✽ Le tableau ci-dessous s'applique à différentes méthodes de couture.

Tissu

spécial

Tissu

léger

Tissu

moyen

Tissu

lourd

Tissu

Velours

Daim synthétique

Batiste

Tricot

Soie Georgette

Laine Georgette

Vichy

Tricot léger, jersey

Gabardine, flanelle

Jeans

Jersey

Tweed

Combinaisons tissu-fil-aiguille

Fil

Soie, polyester #30, #50

Polyester #20, #50

Coton #80

Polyester #60

Soie #50

Soie, polyester #50

Coton #60

Polyester #80

Soie #50

Coton #20, #50

Polyester #20, #50

Soie #20, #50

Aiguille (HLX5)

#11 – #14

#11 – #16

#9

#11

#11 – #14

#11

#14 – #18

#11 – #16

Schmetz

HLX5

130/705H

#9 #65

#11 #75

#14 #90

#16 #100

✽ Il est recommandé d'utiliser des aiguilles HLX ; toutefois, on pourra également

utiliser des aiguilles Schmetz 130/705H dans des conditions normales

d'utilisation.

✽ Régler la pression du pied-de-biche et la hauteur de chute du pied chute en

fonction du tableau.

✽ Avec des tissus comme du tricot et du jersey, utiliser une aiguille à bille ou

toute autre aiguille pour tricot.

CONTENIDO

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

Page 37

Changement du pied-de-biche

Remarque Bien éteindre la machine avant de changer le pied-de-biche.

CONTENIDO Accessoires

Changement du pied-de-biche

(pied pour fermeture à glissière)

1

Relever le pied-de-biche et relever

l'aiguille à la position maximale.

2 Desserrer la vis à l'aide d'un

tournevis et la retirer.

3 Fixer le pied pour fermeture à

glissière et resserrer la vis.

✽ La méthode de changement est

la même pour tous les pieds-debiche.

✽ Utiliser le bouton de position au

dos du pied pour fermeture à

glissière pour régler la position

du pied par rapport à l'aiguille.

Les différents pieds-de-biche

● Pied à ergot d'entraînement

Pour obtenir des points parfaits

sur des tissus difficiles comme le

velours, le cuir et le daim.

● Pied ordinaire

Ce pied convient pour la plupart

des travaux de couture.

(Fourni avec la machine à coudre)

✽

Peut également être utilisé avec un

entraînement par ergot.

● Pied pour ourlet rouleauté

S'utilise sur les bords du tissu,

par exemple pour des ourlets de

chemises de soirée, de façon à

replier le bord du tissu en trois

pendant la couture.

● Pied pour fermeture à glissière

Permet de fixer des fermetures à

glissière autres que les fermetures

dissimulées.

●

Pied pour fermeture à glissière invisible

Permet de fixer des fermetures à

glissière dissimulées.

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

33

Page 38

Couture de base (1)

Points de renfort

1cm

1cm

Couture de base

CONTENIDO

Avant de

coudre

1 Relever le pied-de-biche, sortir

Entraînement par ergot (pour les tissus difficiles à manipuler)

✽

38

34

environ 15 cm de fil supérieur et de fil

de canette et les faire passer derrière

le pied-de-biche, puis placer le tissu

sous le pied-de-biche.

Tissu :

Velours, daim

synthétique,

autres

Les tissus ci-dessus

seront plus faciles à

coudre avec un

entraînement par

ergot.

1 Mettre le bouton de réglage

d'entraînement sur la

position d'entraînement par

ergot.

Commencer

à coudre.

2 Abaisser le pied-de-biche.

3 Quand l'aiguille a complètement

traversé le tissu, appuyer doucement

sur la pédale.

Aiguille de l'indicateur

N

2

Régler le sélecteur de

réglage de pression jusqu'à

ce que l'aiguille de l'indicateur

de pression se trouve sur la

position voulue.

Fin de la

couture.

4 Relever l'aiguille au maximum.

5 Relever le pied-de-biche, retirer le

tissu et couper le fil.

✽ Si l'on utilise le coupe-fil :

4 Appuyer sur le bouton du coupe-fil (le

fil supérieur et le fil de canette se

coupent automatiquement et

l'aiguille s'arrête en position relevée).

5 Relever le pied-de-biche et retirer le

tissu.

3 Tirer délicatement sur le fil jusqu'à

ce que l'ergot d'entraînement

attrape le tissu, et coudre.

✽

Pour modifier le sens de la couture

1 S'assurer que l'aiguille a complètement

traversé le tissu.

2 Relever le pied-de-biche et tourner le

tissu en utilisant l'aiguille comme

axe.

3 Abaisser le pied-de-biche et continuer à

coudre.

✽ Au début d'une couture, coudre

quelques points avec le volant,

appuyer sur le bouton de point

arrière et faire quelques points en

marche arrière pour renforcer la

couture, puis revenir à la couture

normale. Faire la même chose à la

fin de la couture.

Ergot d'entraînement

Tissu

Ergot

d'entraînement

Ergot d'entraînement

L'ergot d'entraînement remonte de façon à traverser toutes les épaisseurs de tissu et

il se déplace sous l'effet du mouvement des griffes d'entraînement de manière à

entraîner le tissu de façon uniforme.

✽ L'ergot d'entraînement s'abaisse automatiquement quand on relève le pied-de-

biche.

Griffes d'entraînement

Accessoires

Nom des

pièces

commencer

Avant de

l'ampoule de lampe

Remplacement de

l'aiguille et de

Enfilage

Points d'essai

d'aiguilles

et tableau

Changement du

pied-de- biche

Couture de

base

la machine à

Entretien de

coudre

Dépannage

Page 39

Couture de base (2)

Remarque Bien éteindre la machine avant de changer le pied-de-biche.

CONTENIDO Accessoires

Pied pour ourlet rouleauté

1 Fixer le pied pour ourlet rouleauté.

✽ Pour le changement des pieds-

de-biche, voir page 32.

2 Enfoncer l'aiguille à environ 0,5

cm des bords du tissu et coudre

2 ou 3 points.

3 Relever l'aiguille et le pied-de-

biche, tirer le tissu vers soi tout

en tenant délicatement le fil de la

main gauche.

4 Tirer délicatement sur les brins

du fil, comme indiqué.

0.5cm

0.5cm

5 Tout en tenant les fils de la main

gauche, placer le tissu sous le