Page 1

brothec

DC

SERVOMOTOR

MD-803

l\/ID-813

(Single-Phase Type)

(Three-Phase Type)

""I.

•g

^*«her

K93S1I

Page 2

INTRODUCTION

This service manual is compiled forthe technical staff responsible for maintaining

automatic

Read

thread

trimming machine.

the

service manual carefullysothat you

DESCRIPTION

SPECIFICATIONS

NAME

PRINCIPLE

OF

EACH

OF

The

manual

TABLE

OF

THE

PART

CONTROL

describes

understand

OF

MOTOR

SYSTEM

the

motor

and

the

right handling

CONTENTS

CONFIGURATION

COMPATIBILITY

(except

MOTOR

OPERATION

OPERATION

ADJUSTMENT

B738

OF

MD-802,

or

B7380) 7

812

AND

MD-803,

PANEL

INSTRUCTION

TROUBLESHOOTING

CHECKING

CHECKING

PARTS

SPEED

NOTES

DC

MOTOR

CONTROL

CONTROL

TIMING

BLOCK

DETAILS

TIMING

HIC

CIRCUIT

FRAME

INSTALLATION

USING

USING

THE

THE

CODE

NOS.

ADJUSTMENT

REGARDING

TROUBLESHOOTING

BOX

TROUBLESHOOTING

BOX

TROUBLESHOOTING

CHART

DIAGRAM

OF

CONNECTOR

CHART

ASSEMBLY

THE

THE

OF

DIAGRAM

OF

MATERIAL

PRODUCTION

MOTOR

MACHINE

FOR

FOR

DC

OF

CONTROL

OP.

#2

REPLACEMENT

OPTIONS

SOLENOIDS

SPACE

EACH

MOTOR

PANEL

PANEL

EDGE

QUANTITY

PARTS

MACHINE

INSTALLATION

GUIDE

GUIDE

GUIDE

CIRCUIT

E-40

SENSOR

COUNTER

and

inspecting the drive motor

the

control box

and

adjustment.

813

OUTLINE

DETAILS

and

also

covers

1

2

3

5

6

8

8

9

10

17

18

19

20

22

24

25

34

35

57

58

60

73

77

80

84

91

92

designed

adjustments.

for

the

Page 3

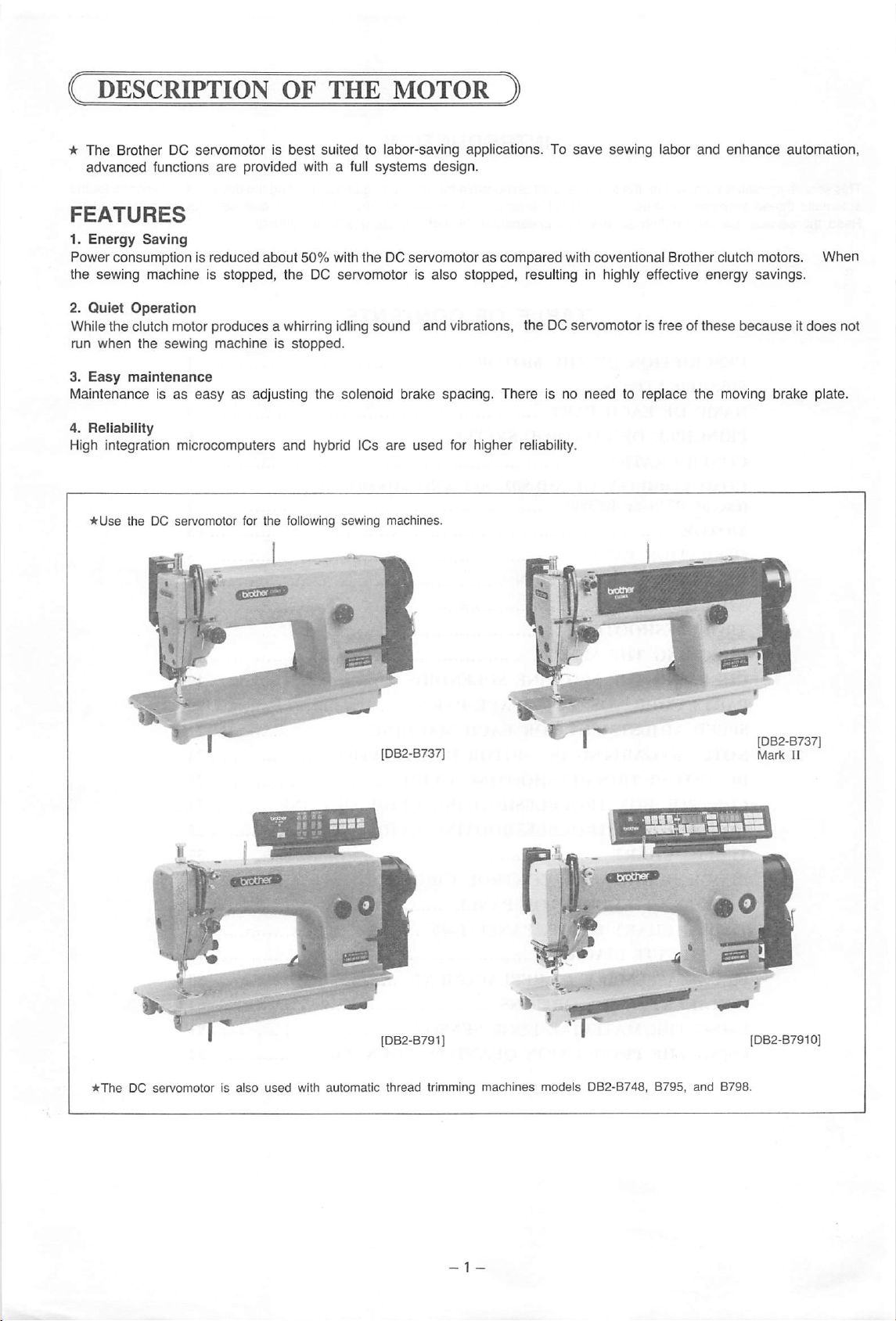

★

The

Brother DC servomotor is

advanced

functions

are

best

suited to labor-saving applications. To

provided with a full

systems

design.

FEATURES

1.

Energy

Power consumption is

the sewing machine is stopped, the DC servomotor is

2.

Quiet

Whilethe clutch motor produces a whirring idling sound

run

3.

Easy

Maintenance isaseasyasadjusting the solenoid brake spacing.

4.

Reliability

High integration microcomputers

when

maintenance

Saving

Operation

the

sewing

reduced

machineisstopped.

about

and

50%

hybrid ICs

with the DC servomotorascompared

also

stopped, resulting in highly effective

and

vibrations, the DC servomotor is free of

are

used

for higher reliability.

There

save

sewing labor

and

enhance

with coventional Brother clutch motors.

energy

these

becauseitdoes

is no

needtoreplace

the

moving brake plate.

automation,

When

savings.

not

★The

DC servomotor is also

wotref

•

used

with

automatic

[DB2-B791J

thread

trimming

machines

models

A;

DB2-B748,

•iflrL'^SlIiLSS

8795,

and

B798.

[DB2-B7910]

Page 4

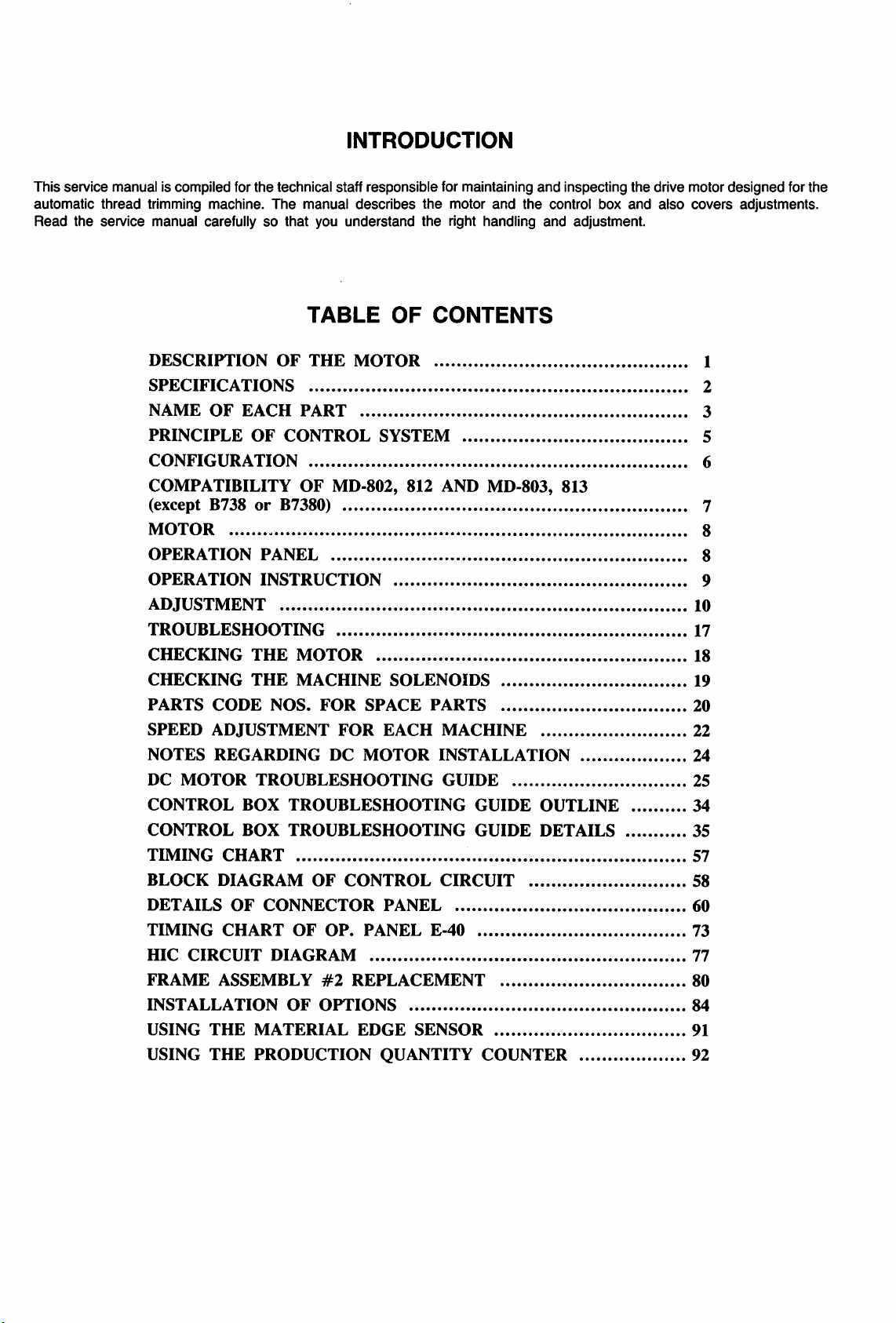

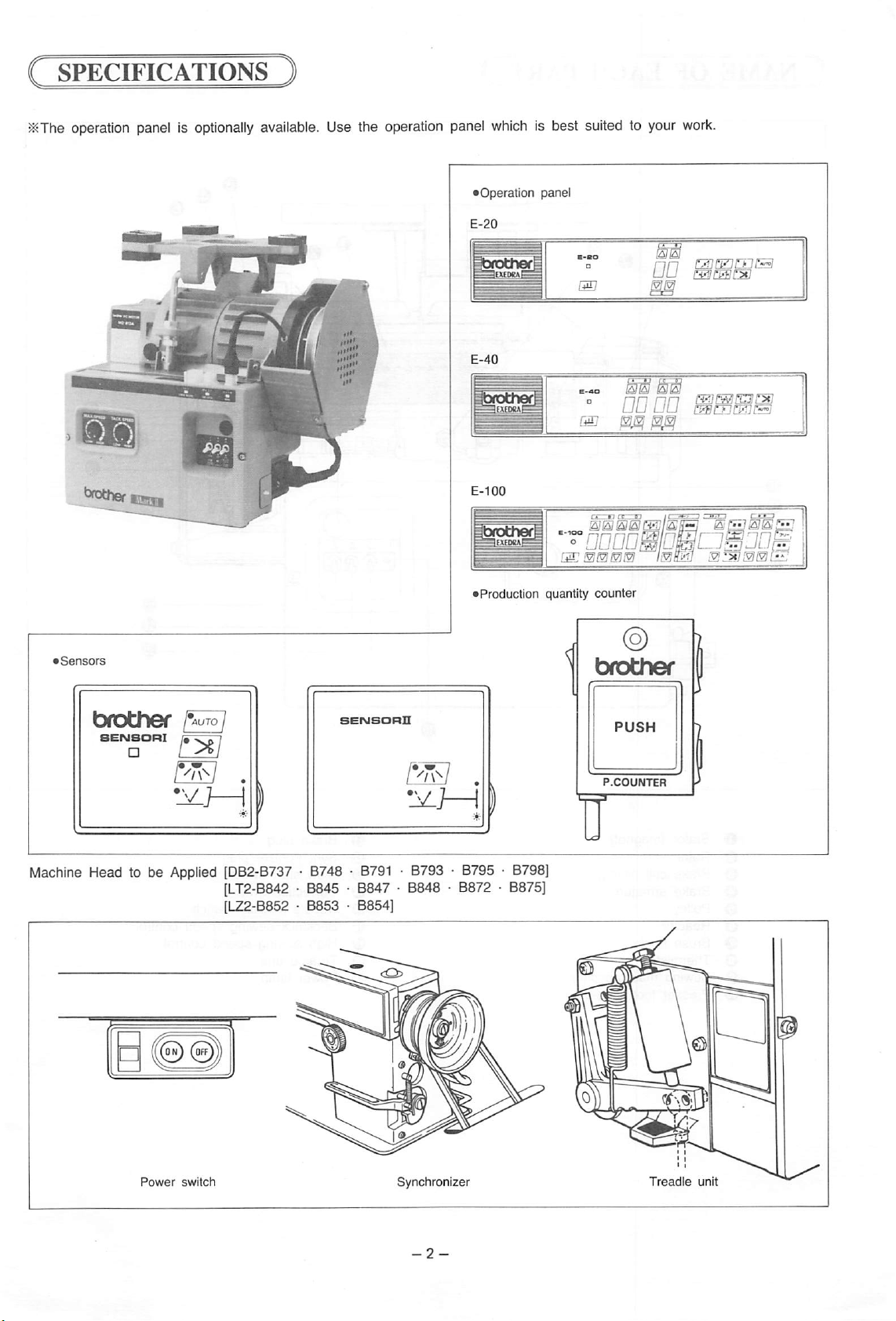

SPECIFICATIONS

J«The

operation panel is

optionally

available.

Use the operation panel

which

is best suited to your

Operation panel

work.

Machine

Head to be

Applied

.

[DB2-B737

[LT2-B842

[L22-B852 • B853 • B854]

• B748 •

• B845 • B847 • B848 • B872 • B875]

B791

Production quantity

• B793 • B795 •

counter

P.COUNTER

B798]

i

Power

switch

Synchronizer

Treadle

unit

Page 5

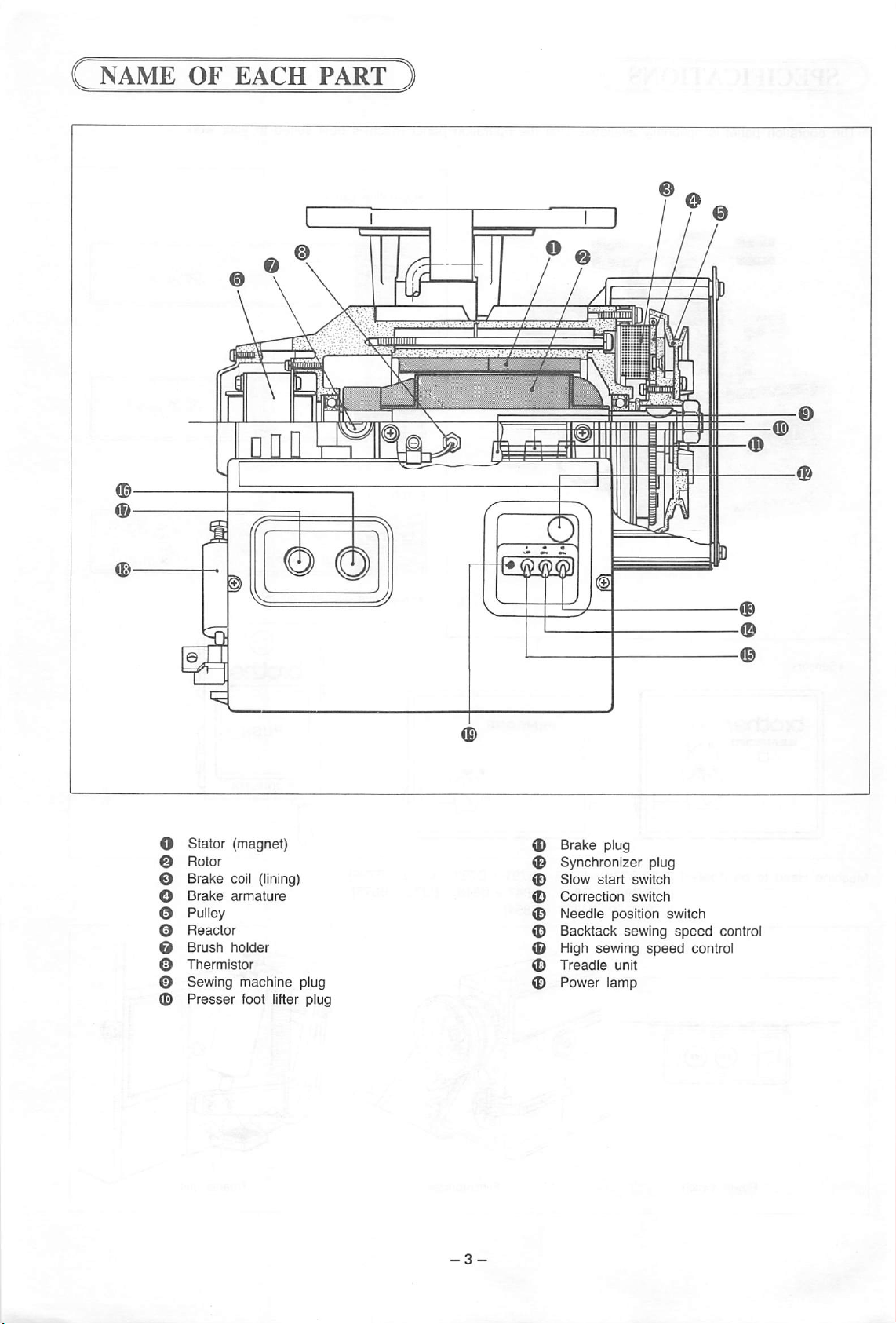

NAME

OF

EACH

PART

Stator (magnet)

Rotor

Brake

coil (lining)

Brake

armature

Pulley

Reactor

Brush

holder

Thermistor

Sewing machine plug

Presser

foot lifter plug

Brake

plug

Synchronizer plug

Slow

start

switch

Correction

Needle

Backtack

High

Treadle

position

sewing

sewing

unit

switch

speed

Power lamp

switch

speed

control

control

Page 6

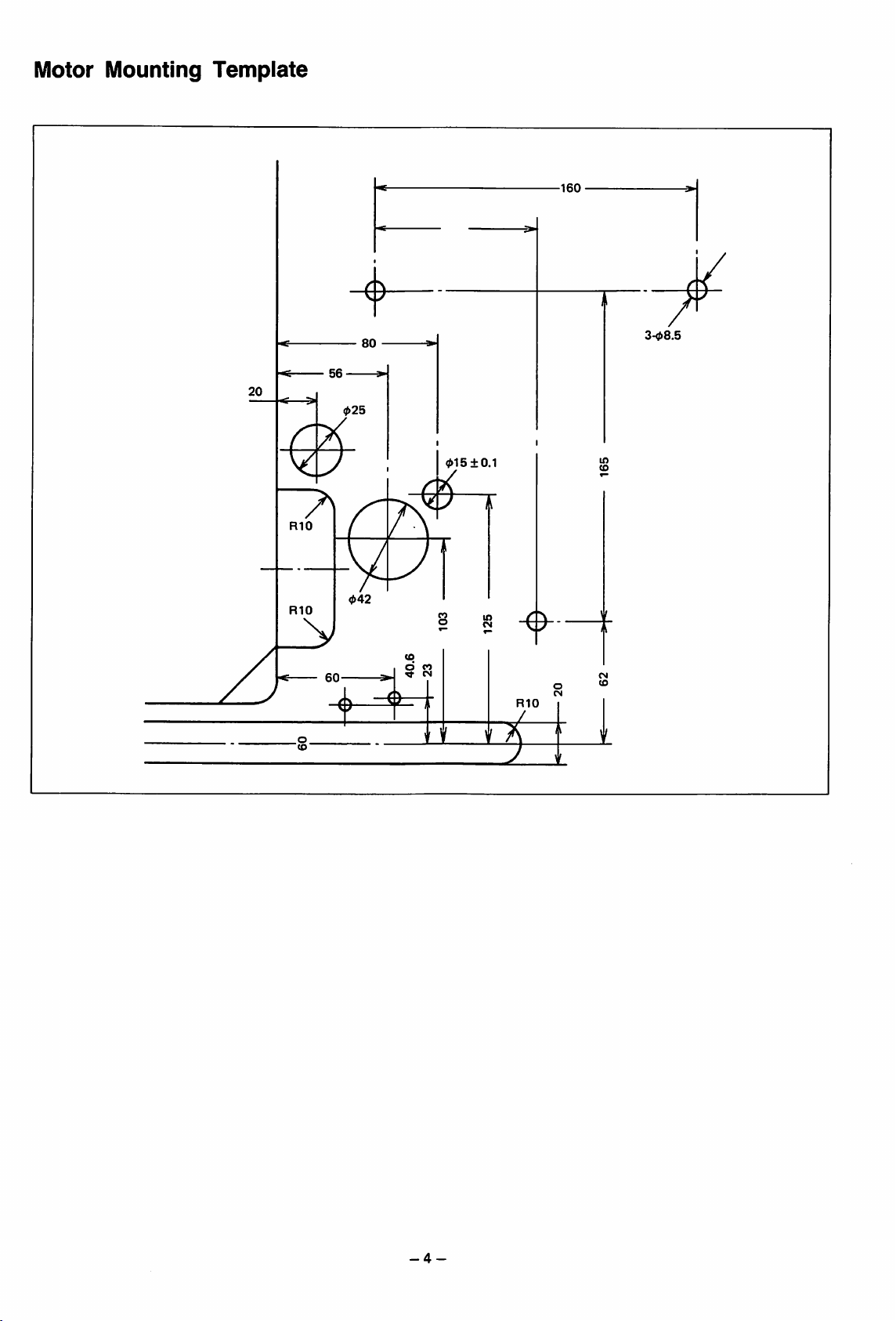

Motor

Mounting

Template

160

80

20

RIO

RIO

01510.1

CO

in

O CO

60

(O

^ CN

RIO

in

-4-

Page 7

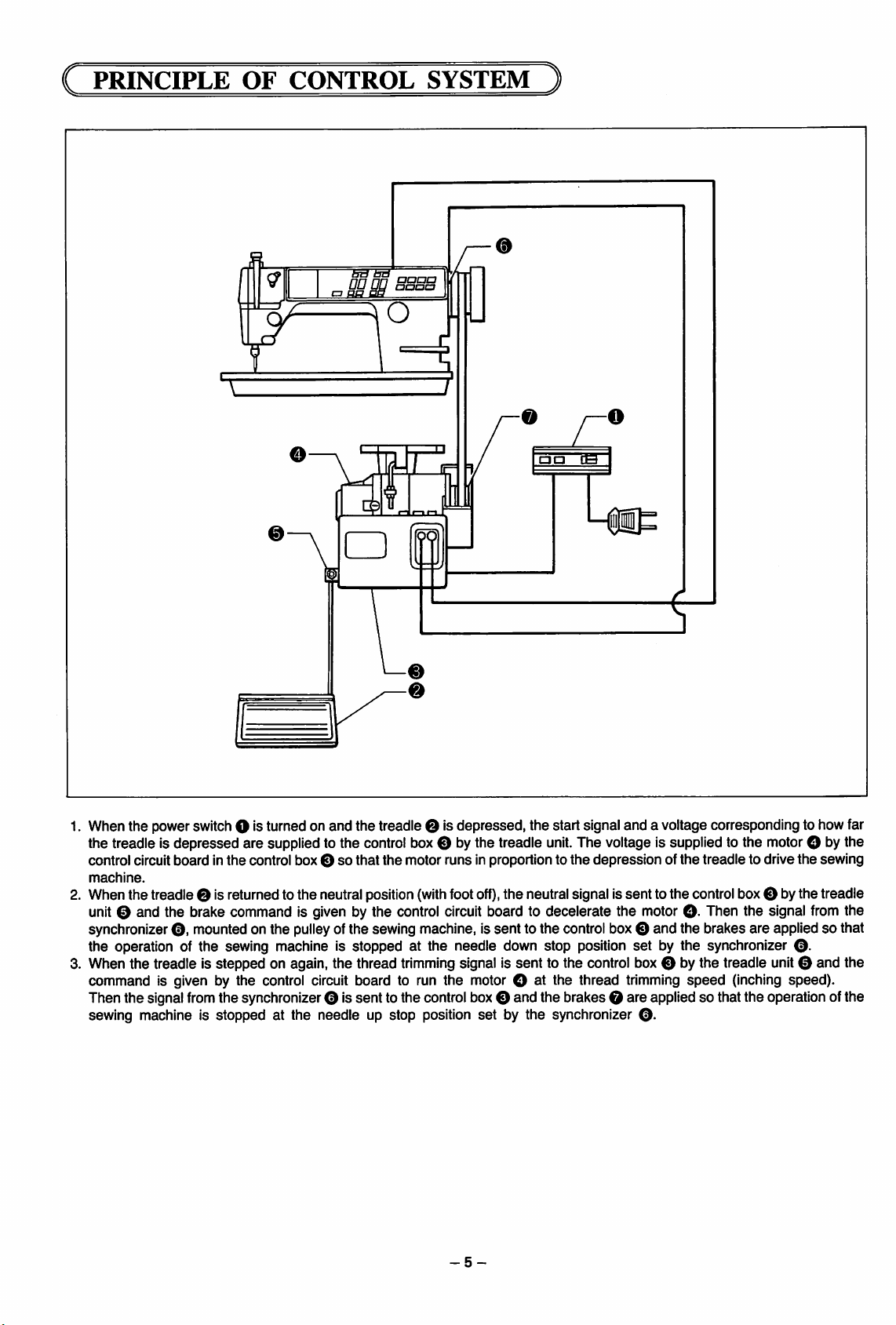

C PRINCIPLE OF CONTROL

m

aa

p

aa

SYSTEM

)

gg

CB

1. When the powerswitchO is turned on and the treadle O Isdepressed, the start signal and a voltage corresponding to how far

the treadle Is depressed are suppliedto the control box O by the treadle

control circuit board Inthe control box Osothat

machine.

2. When the treadle 0 Isreturnedto the neutralposition

the

motor runs Inproportion to

(with

foot

off),

unit.

The voltageIs supplied to the motorO by the

the

depression of

the

treadle to drive the sewing

the neutral signal Issent to the controlboxO bythetreadle

unit 0 and the brake command Is given by the control circuit board to decelerate the motor O- Then the signal from the

synchronizer

the operation of the sewing machine Is stopped at the needle down stop position set by the synchronizer

3. When the treadle Is stepped on again, the thread

command Is given by the control circuit board to run the motor O at the thread trimming

O,

mounted on the pulleyof the sewing machine. Issent to the controlbox O and the brakes are applied so that

O.

trimming

signal Is sent to the control boxO by the treadle unit0 and the

speed

(Inching speed).

Then the signalfromthe synchronizer 0 Issent to the controlbox0 and the brakes O are applied so that the operation of the

sewing machine Is stopped at the needle up stop position set by the synchronizer

-5-

0.

Page 8

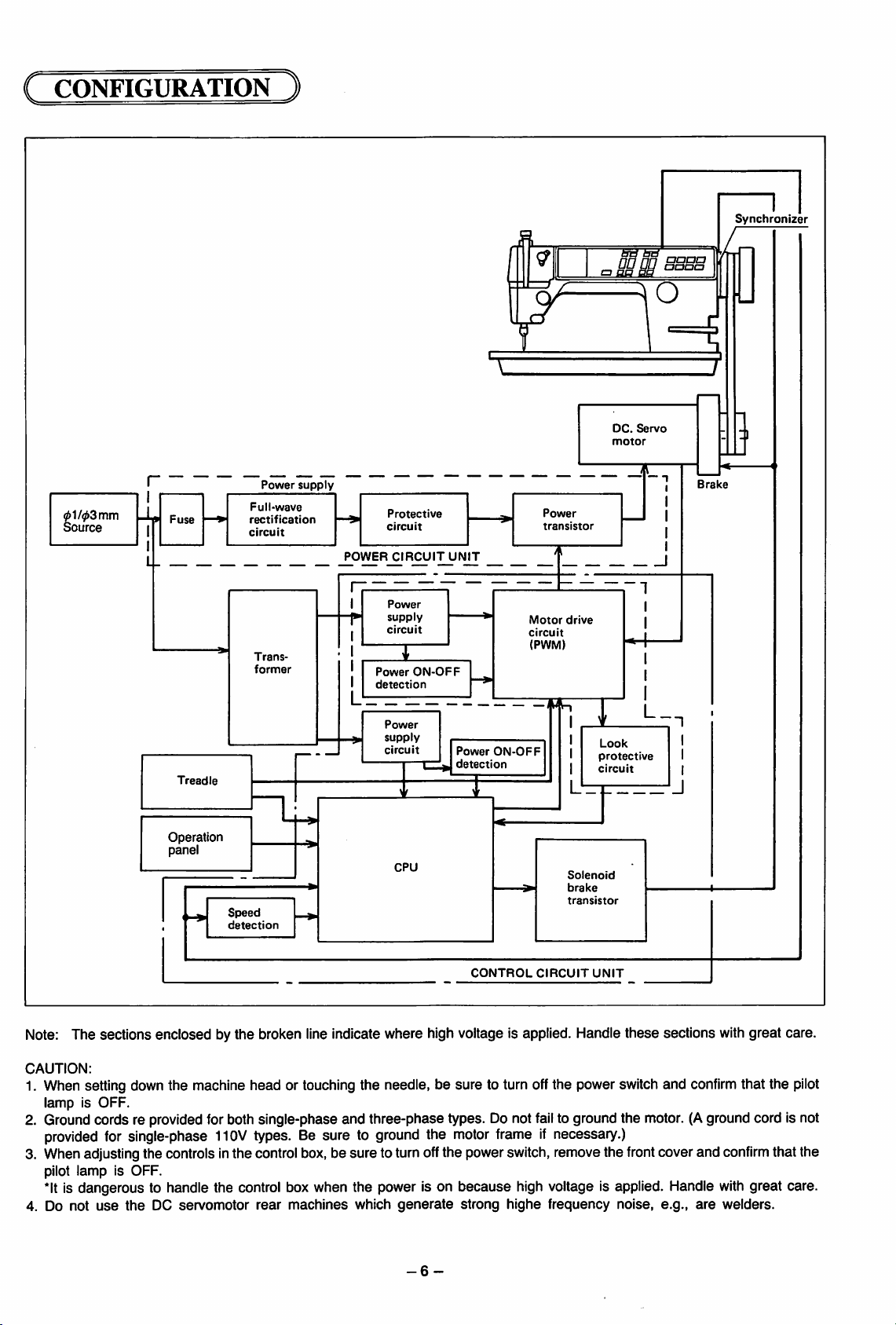

CONFIGURATION )

anon

gP

DC.

motor

bdbd

BS

Servo

O

aaaa

Synchronizer

auaa

61/03 mm

Source

r

I

Mt-

I

I

Fuse

Treadle

Operation

panel

Full-wave

rectification

circuit

Trans

former

Speed

detection

Power

supply

Protective

circuit

POWER

CIRCUIT

Power

supply

circuit

Power

detection

ON-OFF

UNIT

Motor

circuit

(PWM)

^ — ——/5

Power

supply

circuit

CPU

Power

detection

ON-OFF

Power

transistor

drive

5^

Solenoid

brake

transistor

Look

protective

circuit

Brake

I

L_.

CONTROL

CIRCUIT

UNIT

Note: The sections enclosed by the broken line indicate where high voltage is applied. Handle these sections with great care.

CAUTION:

1. When setting down the machine head or touching the needle, be sure to turn offthe power switch and

confirm

that the

lamp is OFF.

2. Groundcords re providedforboth single-phase and three-phase types. Do not

provided

for

single-phase

110V

types.

Be sure to

ground

the

motor

3. Whenadjustingthe controlsinthe controlbox, be sure to tum offthe powerswitch,removethe

fail

to ground the motor. (Aground cord is not

frameifnecessary.)

front

cover and

confirm

pilot lamp is OFF.

*lt

is dangerous to handle the control boxwhen the power is on because high voltage is applied. Handle

4. Do not

use

the

DC

servomotor

rear

machines

which

generate

-6-

strong

highe

frequency

noise,

e.g.,

are

with

great care.

welders.

pilot

that the

Page 9

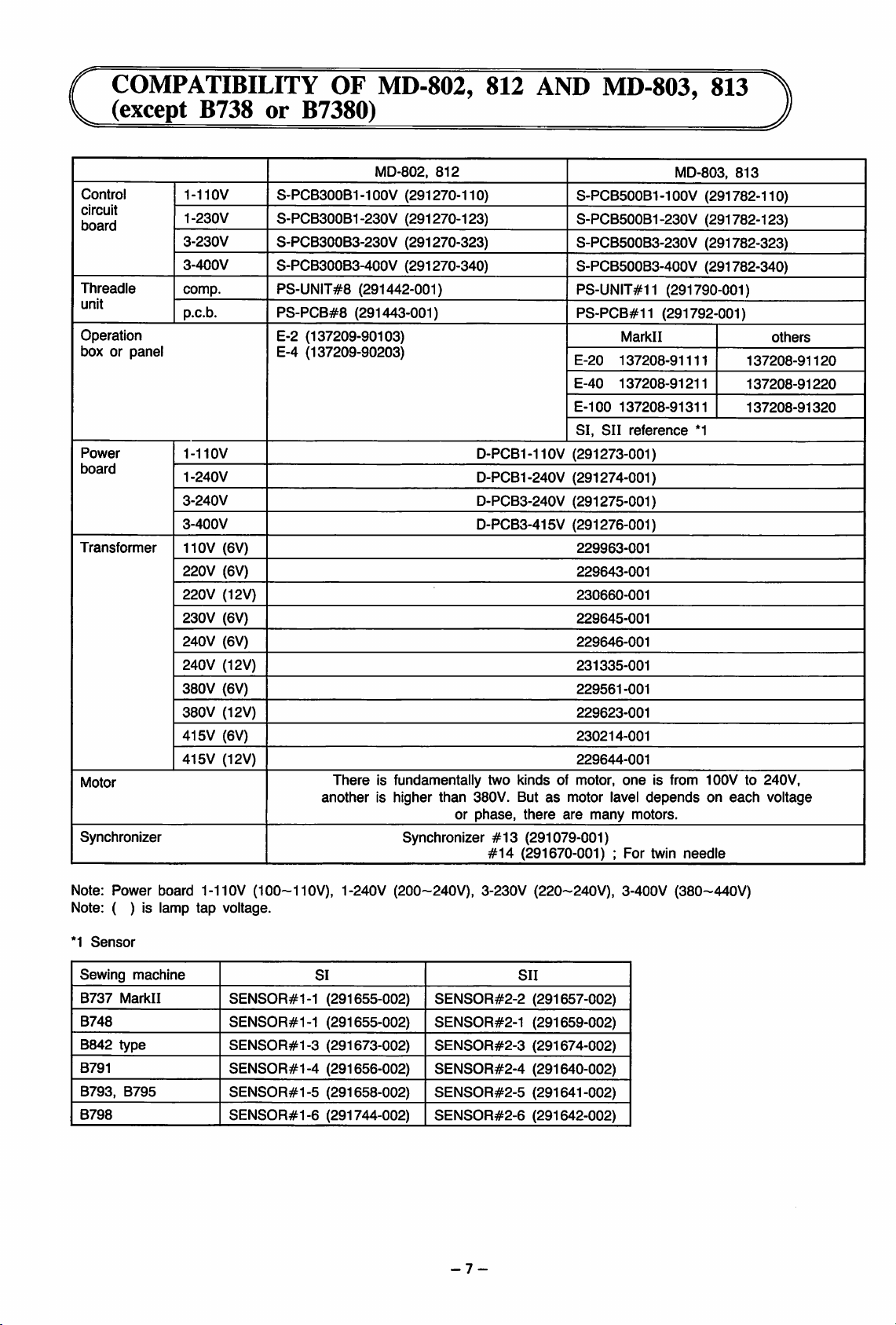

f COMPATIBILITY OF MD-802, 812

V

(except

B738

or

B7380)

AND

MD-803,

813

Control

circuit

board

Threadle

unit

Operation

box or panel

Power

board

Transformer

Motor

Synchronizer

1-110V

1-230V

3-230V

3-400V

comp.

p.c.b.

1-110V

1-240V

3-240V

3-400V

110V

(6V)

220V

(6V)

220V

(12V)

230V (6V)

240V

(6V)

240V (12V)

380V

(6V)

380V

(12V)

415V (6V)

415V

(12V)

S-PCB300B1

MD-802,

-1OOV

812

(291270-110)

S-PCB300B1-230V (291270-123)

S-PCB300B3-230V (291270-323)

S-PCB300B3-400V (291270-340)

PS-UNIT#8

PS-PCB#8

(291442-001)

(291443-001)

E-2 (137209-90103)

E-4 (137209-90203)

There

is fundamentally two kinds of motor,

anotherishigher

than

380V. Butasmotor lavel

or

phase,

Synchronizer

S-PCB500B1 -1

S-PCB500B1-230V (291782-123)

S-PCB500B3-230V (291782-323)

S-PCB500B3-400V (291782-340)

PS-UNIT#11 (291790-001)

PS-PCB#11

Markll

E-20

137208-91111

E-40

137208-91211

E-100

137208-91311

SI,

SII

reference

D-PCB1-110V (291273-001)

D-PCB1-240V (291274-001)

D-PCB3-240V (291275-001)

D-PCB3-415V (291276-001)

229963-001

229643-001

230660-001

229645-001

229646-001

231335-001

229561-001

229623-001

230214-001

229644-001

one

there

are

many

motors.

#13

(291079-001)

#14

(291670-001):For

MD-803,

OOV

813

(291782-110)

(291792-001)

others

137208-91120

137208-91220

137208-91320

*1

is from 100V to 240V,

depends

twin

on

needle

each

voltage

Note: Power board 1-110V

Note: ( ) is lamp

*1

Sensor

tap

Sewing machine

B737

Markll

B748

B842

type

B791

B793,

B795

B798

(100-110V),

voltage.

SENS0R#1-1

SENS0R#1-1

SENS0R#1-3

SENS0R#1-4

SENS0R#1-5

SENS0R#1-6

1-240V (200~240V), 3-230V (220~240V), 3-400V (380~440V)

SI

(291655-002)

(291655-002)

(291673-002)

(291656-002)

(291658-002)

(291744-002)

SENSOR#2-2

SENS0R#2-1

SENSOR#2-3

SENSOR#2-4

SENSOR#2-5

SENSOR#2-6

-7-

SII

(291657-002)

(291659-002)

(291674-002)

(291640-002)

(291641-002)

(291642-002)

Page 10

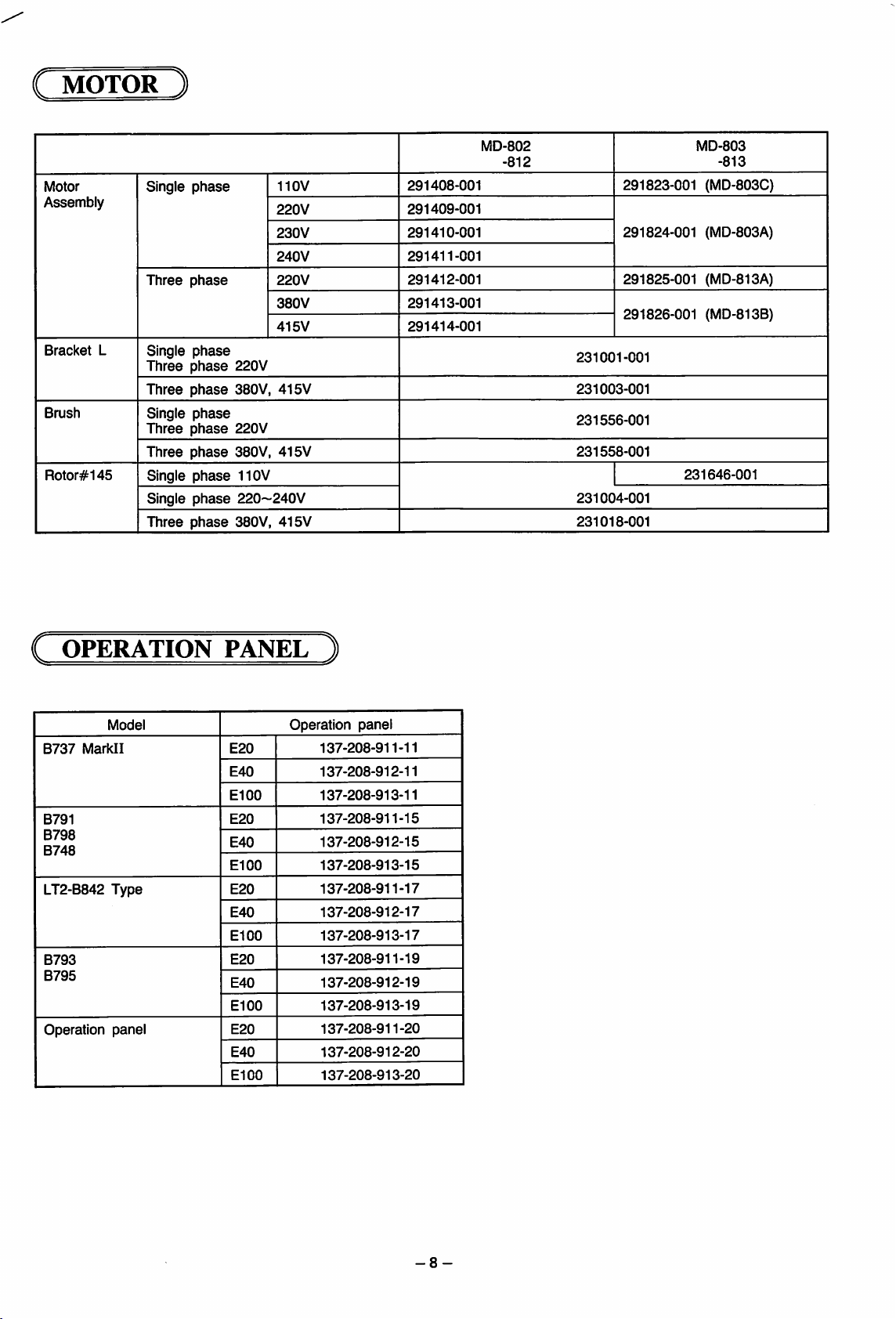

i MOTOR )

Motor

Assembly

Bracket

Brush

Rotor#145

MD-802

-812

phase

Single

Three

phase

L

Single

phase

Three

phase

Three

phase

Single

phase

Three

phase

Three

phase

Single

phase

Single

phase

Three

phase

110V

220V

230V

240V

220V

380V

415V

220V

380V,

415V

220V

380V, 415V

110V

220~240V

380V,

415V

291408-001

291409-001

291410-001

291411-001

291412-001

291413-001

291414-001

291823-001 (MD-803C)

291824-001 (MD-803A)

291825-001

291826-001

231001-001

231003-001

231556-001

231558-001

231004-001

231018-001

MD-803

-813

(MD-813A)

(MD-813B)

231646-001

( OPERATION PANEL )

00

00

00

00

00

Operation

137-208-911-11

137-208-912-11

137-208-913-11

137-208-911-15

137-208-912-15

137-208-913-15

137-208-911-17

137-208-912-17

137-208-913-17

137-208-911-19

137-208-912-19

137-208-913-19

137-208-911-20

137-208-912-20

137-208-913-20

B737

Markll

B791

B798

B748

LT2-B842

B793

B795

Operation

Model

Type

panel

E20

E40

El

E20

E40

El

E20

E40

El

E20

E40

El

E20

E40

El

panel

-8-

Page 11

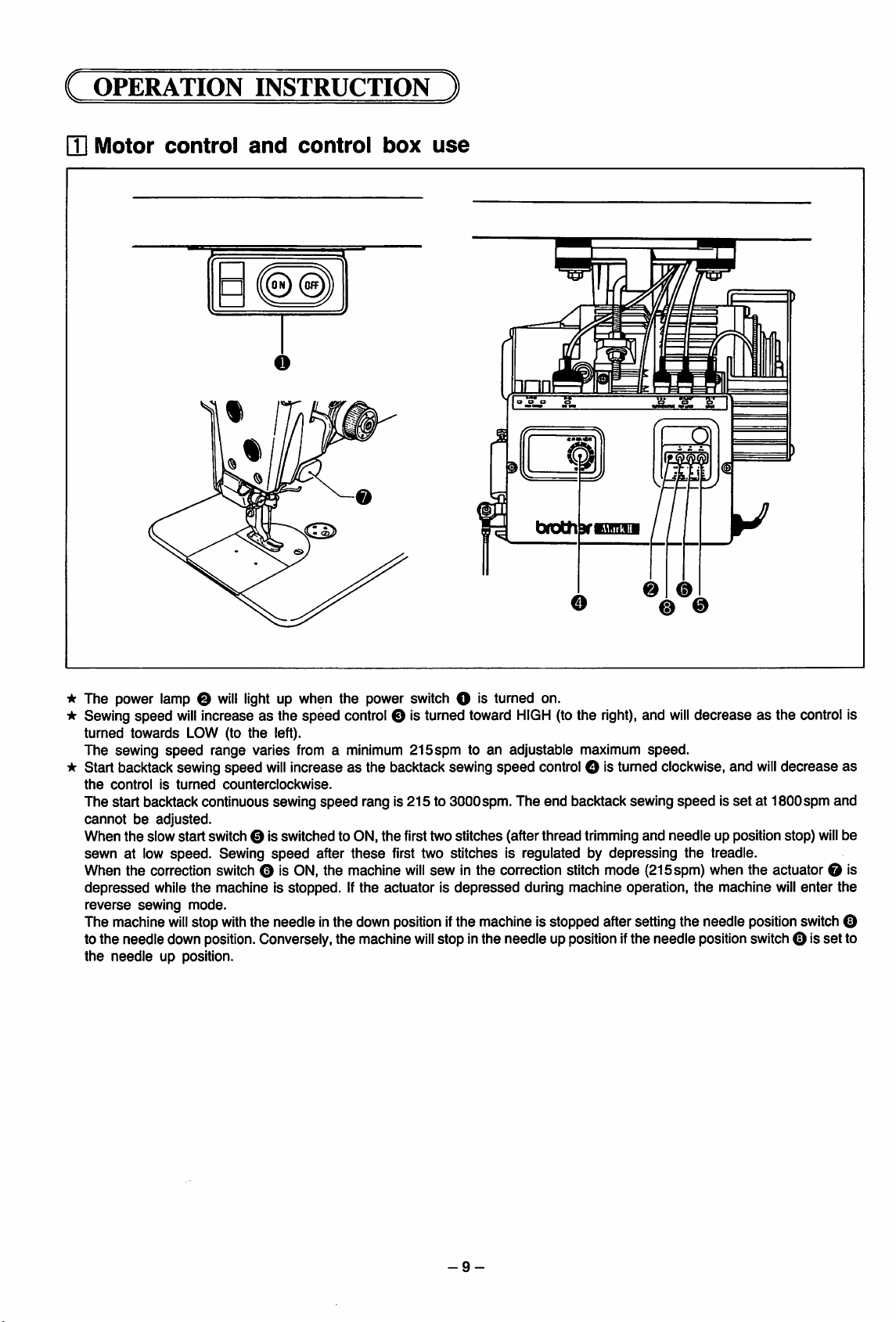

(

OPERATION

[U

Motor

control

INSTRUCTION

and

ONI

o

control

(OFF

box

)

use

tDDl

o o o o

oiocn

ycsssm

-At

The power lamp O

•k Sewing speed

turned

towards

The sewing

-k Start backtack sewing speed

the

controlisturned

The start backtack continuous sewing

cannotbeadjusted.

When

sewn

When the correction switch 0 is ON, the machine

depressed

reverse

The machine

to the needle down position. Conversely,the machine

the

needle

the

slow

at low

sewing

speed

speed.

while

will

up position.

will

light up when the power switch O is turned on.

will

increaseasthe speed control O is turned toward

LOW (to

start

the

mode.

stop

the

left).

range varies from a minimum 215spm to an adjustable maximum speed.

will

increaseasthe backtack sewing speed control O is turned clockwise, and

counterclockwise.

speed

rang is 215 to 3000spm. The end backtack sewing

switch 0 is switched to ON,

Sewing

machine is stopped. If

with

speed

after

these

the

the needle inthe down positionifthe machine is stopped after setting the needle positionswitch0

I

right),

0

and

and

o

HIGH

(to the

the

first two

first two stitches is regulated by depressing

will

actuator is

stitches

sew

depressed

will

stop inthe needle up positionifthe needle positionswitchO<sset to

(after

thread

trimming

in the correction stitch mode (215spm) when the actuator 0 is

during machine operation,

@ 0

will

decreaseasthe control is

will

speedisset

needle

the

the

at 1800spm and

up position stop)

treadle.

machine

decrease

will

enter

will

as

be

the

-9-

Page 12

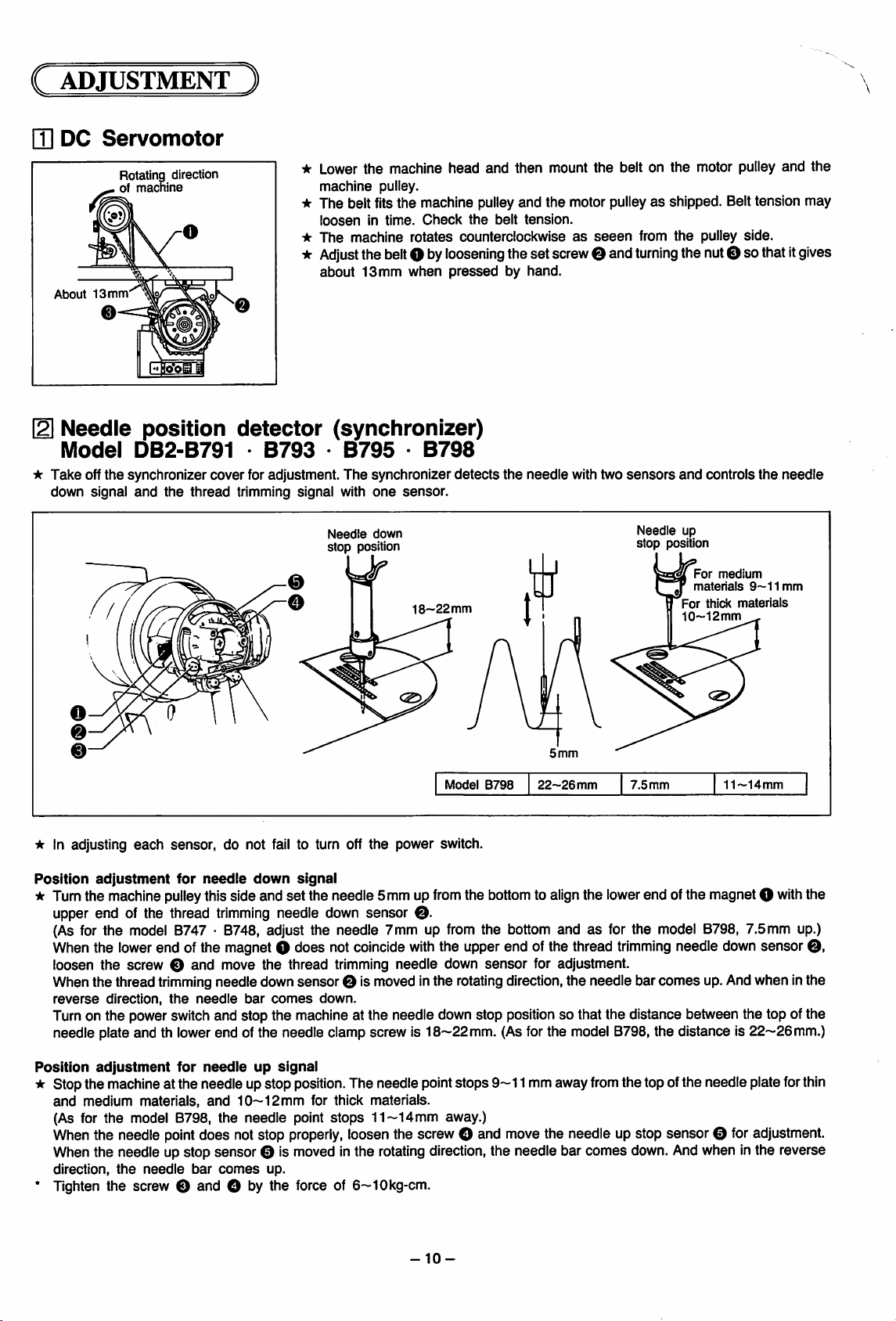

i

ADJUSTMENT

)

[U DC

About13mm

Needle

Model

★

Take

down signal

Servomotor

Rotatinq

of

machine

0

position

DB2-B791

off

the

synchronizer

and

the

direction

thread

detector

•

B793

cover

for adjustment.

trimming signal with

Lower

the

machine

machine

pulley.

head

and

then

mount

the

belt on

the

motor pulley

and

the

The belt fitsthe machine pulleyand the motor pulleyas shipped. Belttension may

loosenIntime.

The

machine rotates counterclockwiseasseeen

Adjust

the

about

13 mm

belt

Check

O by

when

the

loosening

pressed

belt

tension.

theset screw0 and

by hand.

from

the

pulley side.

turning

thenut0 sothatItgives

(synchronizer)

•

B795

The

Needle

stop

position

•

B798

synchronizer

one

sensor.

down

18-22

detects

mm

the

needle

I]"

with two

sensors

Needie up

stop

and

controls

position

For

medium

materials

'For thick materiais

10~12mm

9~11mm

the

needle

11—14mm

* In adjusting

Position

★

Tumthe machine

each

adjustment

upper end of the thread

Model

sensor, do not fall to turn off the power switch.

for

needle

pulley

thisside and set the needle5mm up

down

trimming

signal

needle down sensor

from

0.

B798

the

bottomtoalign

22-26

mm

the

7.5

mm

lower

end ofthe magnetO

(As for the model 8747 • 0748, adjust the needle 7 mm up from the bottom andasfor the model 8798, 7.5mm up.)

When

the

lower

loosen

the

end ofthe magnetO does not

screw 0

and

move

the

thread trimming needle down

coincide

with

the upperend of the thread

sensor

for adjustment.

trimming

needle

down

sensor

When the thread trimming needle down sensor0 Ismoved Inthe rotating direction, the needle bar comes up.And when Inthe

reverse

direction,

the

needle

bar

comes

down.

Turnon the power switchand stop the machine at the needle downstop position so that the distance between the top ofthe

needle plate and th lowerend of the needle clamp screw Is 18~22mm. (Asfor the model 8798, the distance Is22~26mm.)

Position

★

adjustment

for

needie

up

signal

Stopthe machineatthe needleupstop

and

medium materials,

and

10—12mm

position.

The needle pointstops

for thick materials.

9—11

mmaway

from

the topofthe needle plateforthin

(As for the model 8798, the needle point stops 11—14mm away.)

When

the needle

point

does notstop

properly,

loosenthe screwO and movethe needie up stop sensor 0 foradjustment.

When the needle up stop sensor 0 Is moved Inthe rotatingdirection, the needle bar comes down. Andwhen Inthe reverse

direction,

the

needle

bar

comes

up.

• Tighten the screw 0 and O by the force of 6—lOkg-cm.

with

the

0,

-10-

Page 13

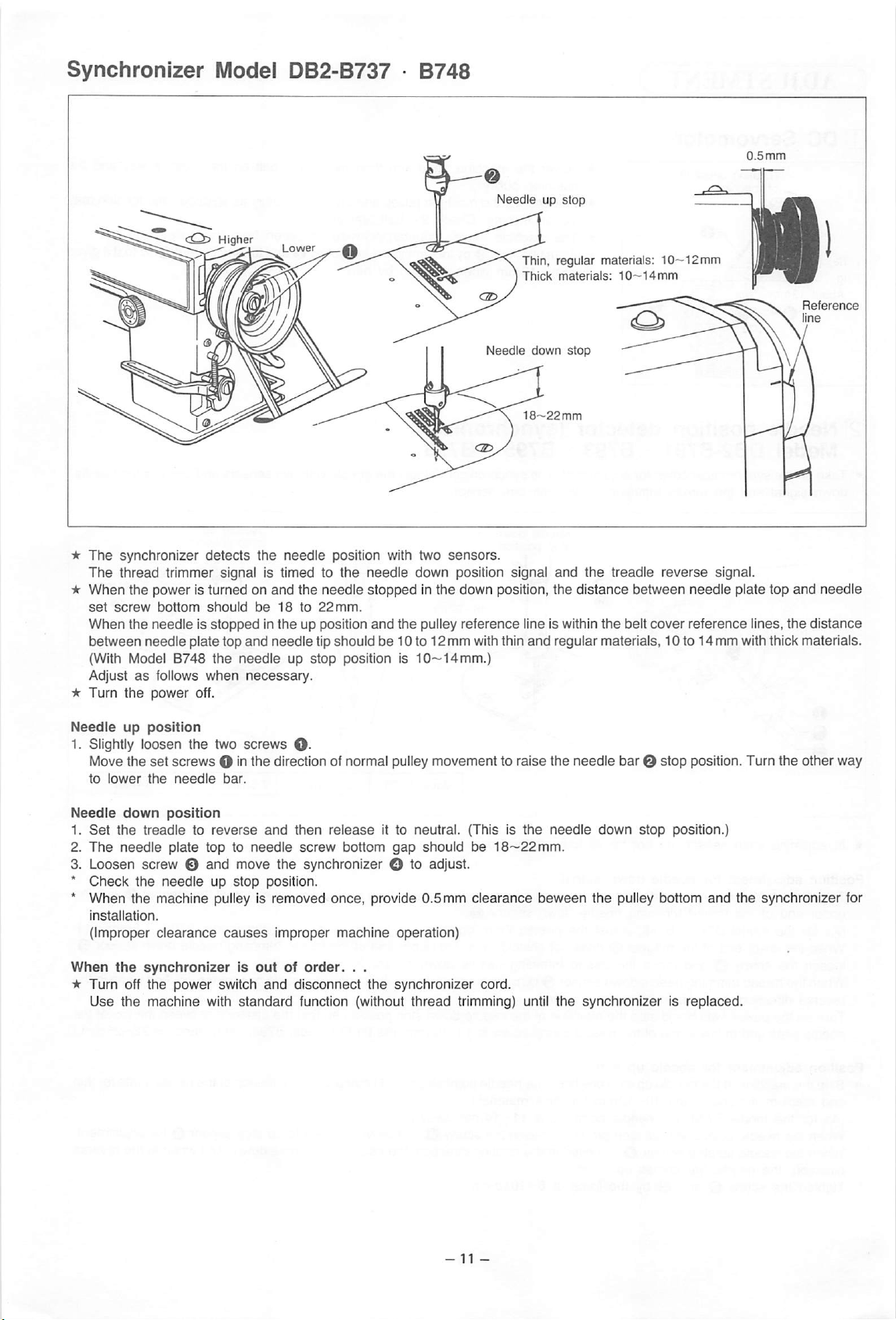

Synchronizer

Model DB2-B737 •

B748

18--22

mm

Reference

e

★

The

synchronizer

The

thread trimmer signal is timed to the

★

When the power is turned on and the needle stopped in the down position, the distance between needle plate top and needle

set

screw

When the needle Is

between

needle

(With Model B748

Adjustasfollows

★

Turn

the

power

Needle

up

position

1. Slightly loosen the two screws

Move the

to

Needle

1.

Set

The

2.

set

lower

the

down

the

treadletoreverse

needle

bottom

detects

should

plate top

when

the

be

stopped

in the up position

and

the

needleupstop

necessary.

needle

18to22mm.

needle

position with two

needle

down position signal

and

the pulley reference line is within

tip should be 10 to 12 mm withthin

position is

10~14mm.)

sensors.

and

the treadle

the

and

reguiar materials, 10 to 14 mm withthick materials.

belt

reverse

cover

signal.

reference

lines, the

distance

off.

O-

screws O inthe direction of normal pulley movement to raise the needle bar O stop position. Turn the other way

needle

position

plate top to

bar.

and

needle

then

screw

release

bottom

it to neutral. (This is

gap

should

be

18—22mm.

the

needle

down

stop

position.)

3. Loosen screw and move the synchronizer O to adjust.

★

Check

the

needleupstop

★

When the machine puliey is removed

installation.

(Improper

When

★

Turn

Use

clearance

the

synchronizerisoutoforder.

off

the

power

switch

the

machine

with

causes

standard

position.

improper

and

disconnect

function (without

once,

machine

. .

provide

operation)

the

synchronizer

0.5mm

thread

clearance

cord.

trimming) until

beween

the

pulley bottom

the

synchronizerisreplaced.

and

the

synchronizer for

-11-

Page 14

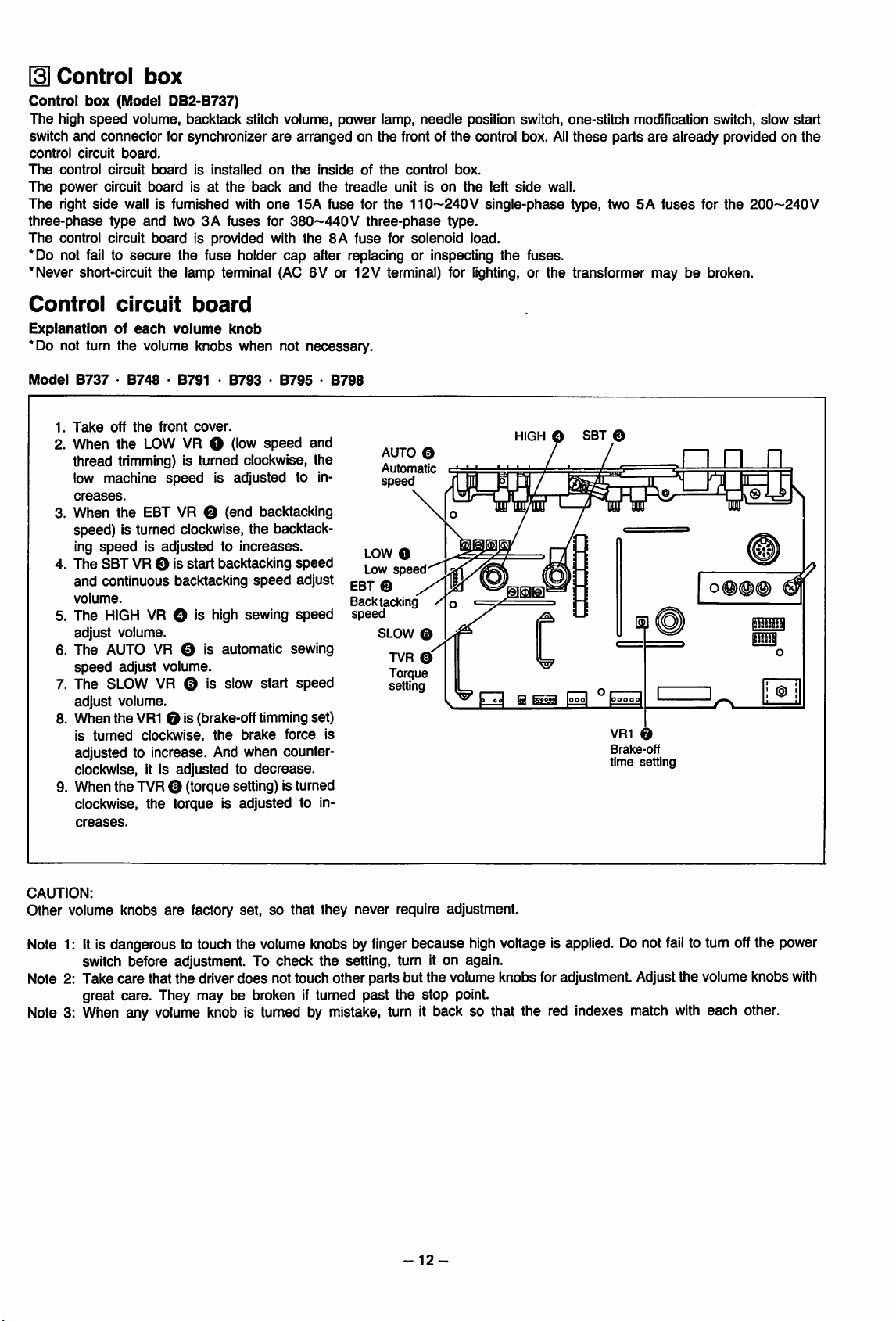

[^Control

Control

The high

box

speed

box

(Model DB2-B737)

volume, backtack stitch volume, power lamp, needle position switch, one-stitch modification switch, slow start

switch and connector for synchronizer

control

The

The

The

three-phase

The

*Do not fail to

•Never

circuit

board.

control

power

right

control circuit board is provided with

circuit

boardisinstalled

circuit

board

side

wall is furnished with

type

and

secure

short-circuit

the

two

the

is at

3A

fuse

lamp

the

fuses

holder

terminal

are

arranged on the front of

on

the

insideofthe

back

and

the

treadle

one

15A fuse for

for 380—440V

the

8A

cap

after replacing or inspecting

(AC6Vor

the

control box.

control

unit is on

the

three-phase

fuse

for solenoid load.

12V

terminal)Wlighting,orthe

box.

the

110~240V

type.

single-phase type, two 5A

left

the

side

fuses.

All

these

wall.

transformer

parts

are

fuses

maybebroken.

already provided on the

for

the

200~240V

Control

Explanationofeach

*Do not turn

Model

1.

2.

circuit

the

volume knobs when not necessary.

B737•B748•B791•B793•B795•B798

Take

off

the

When

the

LOW VR O (low

volume

front

board

knob

cover.

speed

thread trimming) is turned clockwise, the

low machine

creases.

3. When

the

speed

is adjusted to in

EBT VR O (end backtacking

speed) is turned clockwise, the backtack

ing

speedisadjustedtoincreases.

4.

The

SBT

VR O is

and

continuous backtacking

volume.

start

backtacking

speed

5. The HIGH VR O is high sewing

adjust volume.

6.

The

AUTO VR 0 is

speed

adjust volume.

automatic

7. The SLOW VR 0 is slow start

adjust

volume.

8. When the

is

turned

VR1

O is (brake-offtimming set)

clockwise,

the

brake

adjusted to increase. And when counter

clockwise, it is

adjustedtodecrease.

9. When the TVR0 (torque setting) is turned

clockwise, the torque is adjusted to in

creases.

and

speed

adjust

speed

sewing

speed

force is

AUTO 0

Automatic

speed

LOW O

Low

speed

EBT 0

Backtacking

speed

SLOW ©

TVR ©

Torque

setting

m

Brake-off

time setting

CAUTION:

Other volume knobs are factory set, so that they never require adjustment.

Note 1: Itis dangerous to touch the volumeknobs by finger because highvoltage is applied. Do not

fail

to turn offthe power

switch before adjustment. To check the setting, tum it on again.

Note 2: Take care that the driverdoes not touch other parts but the volume knobs for adjustment. Adjustthe volumeknobs

great care. They may be broken if turned past the stop point.

Note 3: When any volume knob is turned by mistake, turn it back so that the red indexes match

-12-

with

each other.

with

Page 15

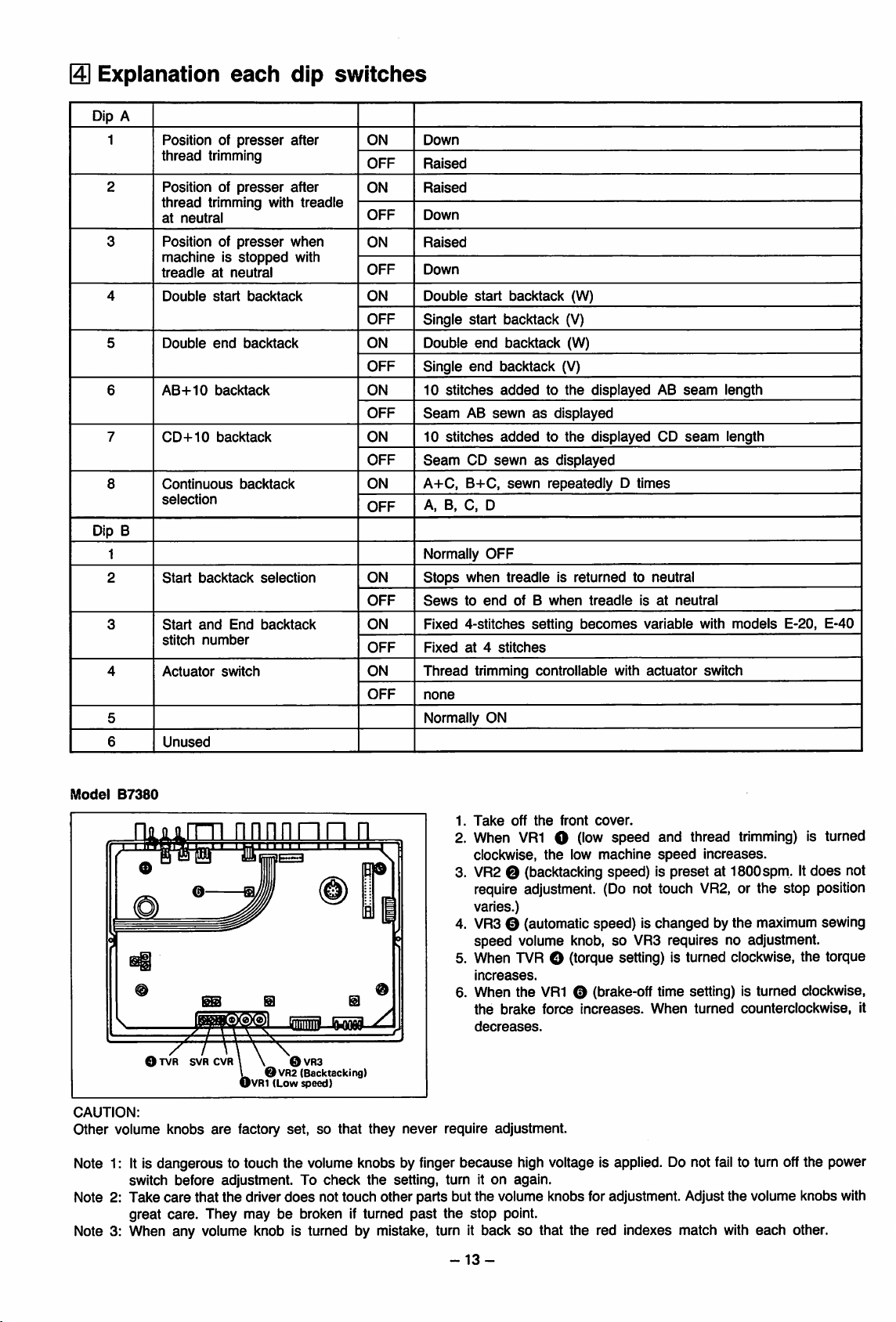

Explanation

each

dip

switches

Dip A

1

2 Position of

3 Position of

4

5

6

7

8

Position of

thread

presser

trimming

presser

thread

trimming with

at

neutral

presser

machineisstopped

treadle

Double

Double

AB-i-10

CD-I-10

Continuous

selection

at

neutral

start

end

backtack

backtack

backtack

backtack

backtack

after

after

treadle

when

with

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Down

Raised

Raised

Down

Raised

Down

Double

Single

Double

Single

10

stitches

Seam

10

stitches

Seam

A-l-C, B-i-C,

A, B, C, D

Dip B

1

2

3

4

5 Normally ON

6

Start

Start

stitch

Actuator

Unused

backtack

and

End

number

switch

selection

backtack

ON

OFF

ON

OFF

ON

OFF

Normally

Stops

Sews

to

Fixed 4-stitches setting

Fixed

at4stitches

Thread

none

start

backtack

start

backtack

end

backtack

end

backtack

addedtothe

AB

sewnasdisplayed

addedtothe

CD

sewnasdisplayed

sewn

(W)

(V)

(W)

(V)

displayed

displayed

repeatedlyDtimes

OFF

when

treadle

endofB

is returned to neutral

when

treadle

becomes

trimming controllable with

AB

seam

CD

seam

isatneutral

variable with

actuator

length

length

switch

models

E-20, E-40

Model

B7380

1.

Take

off

the

front

cover.

mnn

n

2. When

VR1

O (low speed and thread trimming) is turned

clockwise, the low machine

speed

increases.

3. VR2 O (backtacking speed) is preset at ISOOspm. It

require adjustment. (Do not touch

i

varies.)

4. VR30 (automatic speed) is changed bythe maximum sewing

speed

volume knob,soVR3 requires no adjustment.

VR2,

5. When TVR O (torque setting) is turned clockwise, the torque

increases.

6. When the

the

decreases.

CAUTION:

other

volume knobs

O

SVR

CVR

are

BD

\ \ ©

\ OVR2

OVRI (Low speed)

factory

VR3

(Backtacking)

set,

OS

so that they never require adjustment.

Note 1: It is dangerous to touch the volume knobs by finger because high voltage is applied. Do not

switch before adjustment. To

Note 2: Take care that the driver

great care. They may be broken if turned

check

the

setting, turn it on again.

does

not touch other parts but the volume knobs for adjustment. Adjustthe volume knobs with

past

the stop point.

brake

VR1

O (brake-off time setting) is turned clockwise,

force

increases.

When

turned

fail

Note 3: When any volume knob is turned by mistake, turn it back so that the red indexes match with

does

not

or the stop position

counterclockwise,

to turn offthe power

each

other.

it

-13-

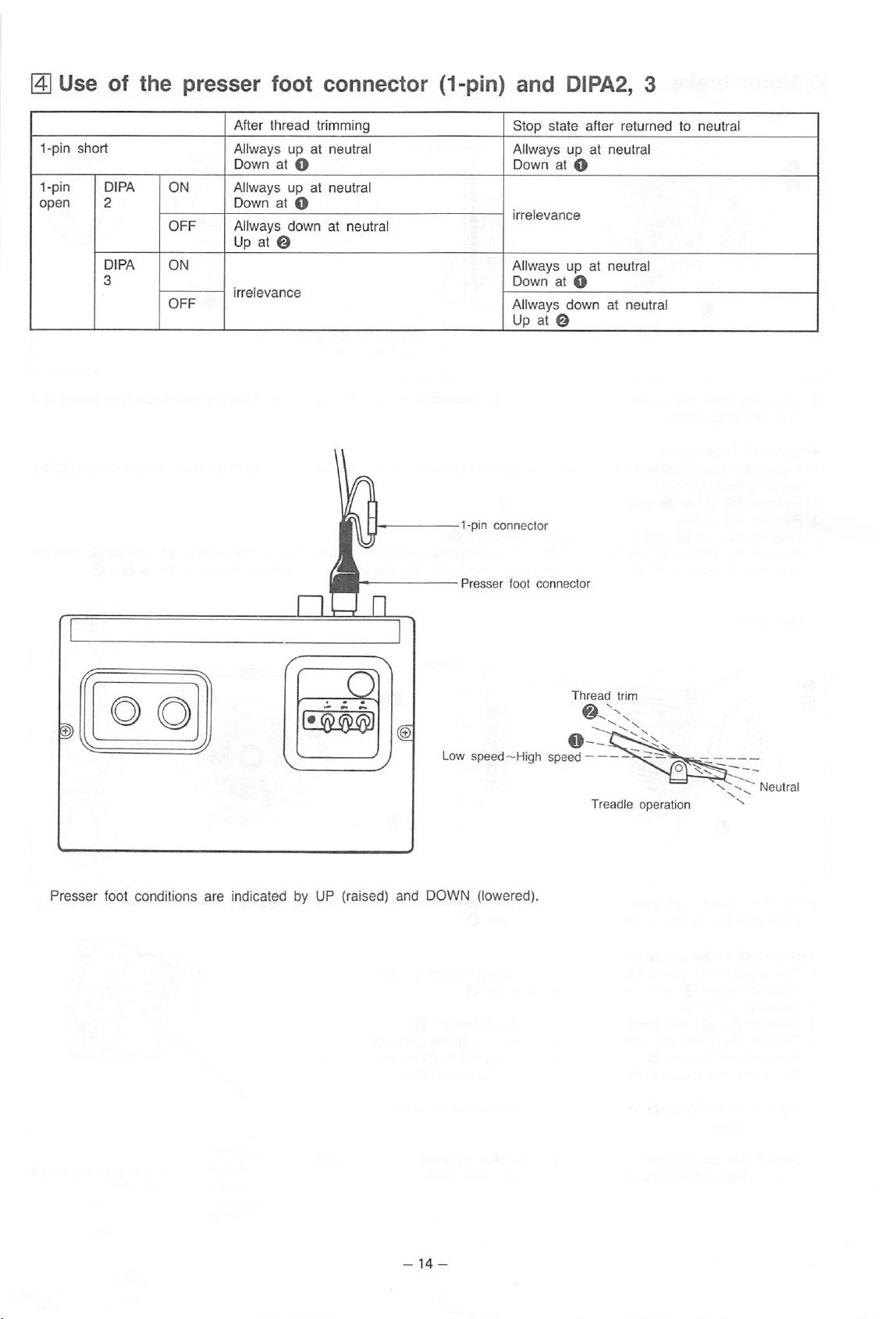

Page 16

Use

1-pin

1-pin DlPA ON

open

short

of

2

DlPA

3

the

OFF

ON

presser

After

Allways up at neutral

Down

Allways upatneutral

DownatO

Allways

Up at O

irrelevance

foot

thread

at O

down

connector

trimming

at neutral

(1-pin)

1-pin

and

Stop

Allways up

Down at O

irreevance

Allways up at neutral

Down at O

Allways

DIPA2, 3

state

after

at

downatneutral

Up at O

connector

returned

neutral

to neutral

Presser

foot conditions

Presser

Low

are

indicated by UP (raised) and DOWN (lowered).

foot

speed-High

connector

speed

Thread

trim

Treadle

operation

Page 17

Motor

brake

Asbestos

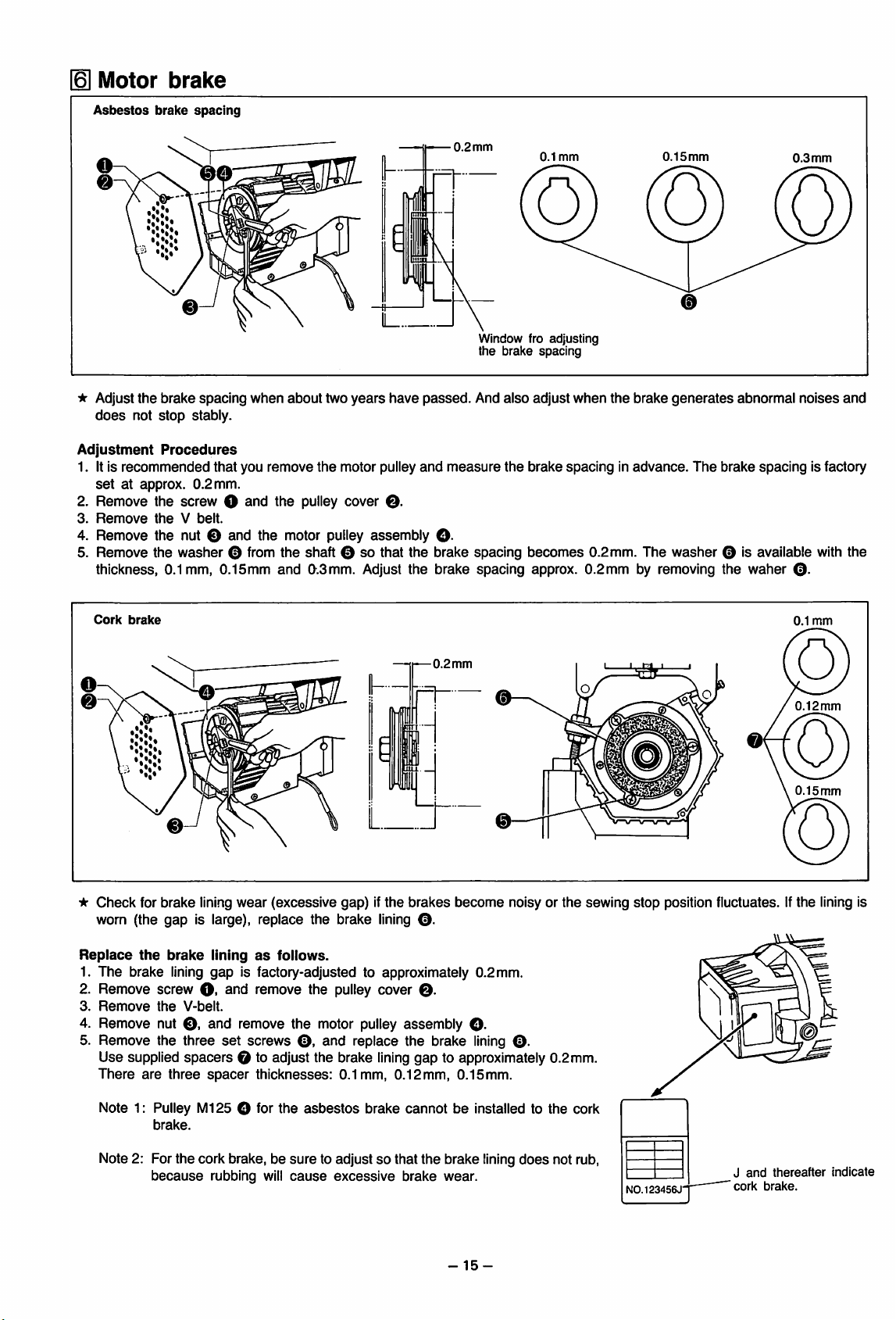

* Adjust

does

Adjustment

1. It is

setatapprox.

2. Remove the screw O

3.

Remove

brake

spacing

the

brake

not

stop

stably.

Procedures

recommended

0.2

theVbelt.

spacing

that

mm.

when

about

you

remove

and

the pulley cover

two

years

the

motor pulley

have

O.

passed.

and

4. Remove the nut O and the motor pulley assembly O-

5. Remove the

thickness, 0.1mm, 0.15mm and

washer

© from the shaft ©sothat

0^.3mm.

Adjust the brake spacing approx. 0.2mm by removing the waher

the

brake spacing

0.2

mm

Window fro adjusting

the brake spacing

And

also

measure

the

0.1

mm

O

adjust

when

brake

spacingInadvance.

becomes

0.2mm. The

the

brake

0.15mm

generates

The

washer

0.3

mm

abnormal

brake

spacing

noises

is factory

and

© is available with the

©.

Cork

brake

★

Check

for

brake

lining

wear

(excessive

worn (the gap is large), replace the brake

Replace

1. The brake

2. Remove screw

3.

4. Remove nut

5. Remove the three

Remove

the

brake

the

liningasfollows.

lining

gap is factory-adjusted to approximately 0.2mm.

O.

and remove the pulley cover

V-belt.

©.

and remove the motor pulley assembly

set

screws

©,

Use supplied spacers © to adjust the brake

There

are

three

spacer

thicknesses:

gap)ifthe

lining

and

replace the brake

lining

0.1mm,

-—0.2

mm

brakes

become

noisy or

©.

©.

©.

lining

©.

gap to approximately 0.2mm.

0.12mm,

0.15mm.

the

sewing

stop

position fluctuates. If

0.1

mm

O

0.12mm

0.15mm

0

the

lining is

Note 1: Pulley Ml25 O for

brake.

Note 2: For the cork brake, be

because

rubbing will

the

asbestos

sure

cause

brake cannot be installed to the cork

to adjust so that the brake

excessive

brake

wear.

-15-

lining

does

not rub,

N0.123456J"

J

cork

and

thereafter

brake.

indicate

Page 18

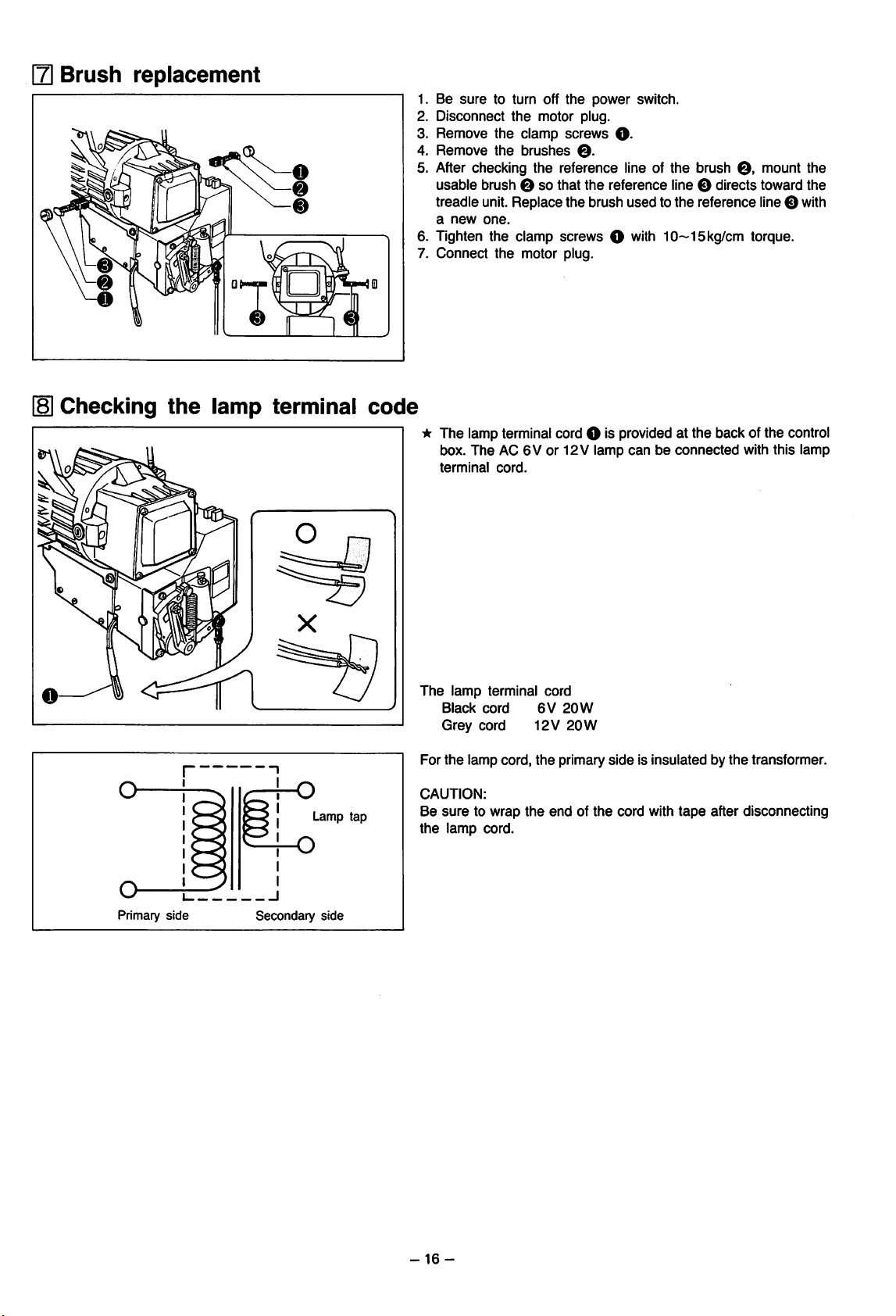

[7|

Brush

replacement

1. Be

sure

to turn off tfie

2. Disconnect tfie motor plug.

3. Remove tfie clamp

4.

Remove

tfie

bruslies

power

screws

©.

switcfi.

O-

5. After cfiecking tfie reference line of tfie brusfi

usable

brusfi Osotfiat tfie

treadle unit. Replace tfie brusfi

a

new

one.

6. Tigfiten tfie clamp screws ©

7. Connect tfie motor plug.

reference

used

witfi

line O directs toward tfie

to tfie reference line©

10~15kg/cm

0,

torque.

mount tfie

witfi

Checking

o

the

lamp

terminal

f-o

Lamp

o

tap

code

* Tfie lamp terminal cord © is provided at tfie back of tfie control

box. Tfie AC 6V or 12 V lamp

terminal

Tfie lamp terminal cord

Black

Grey

For tfie lamp cord, tfie primary

CAUTION:

Be

suretowrap

tfie

lamp

cord

cord

cord.

cord.

tfie

6V

12V

end

20W

20W

of tfie

canbeconnected

side

is insulated by tfie transformer.

cord

witfi

tape

witfi tfiis lamp

after

disconnecting

o

Primary

side

Secondary

side

-16-

Page 19

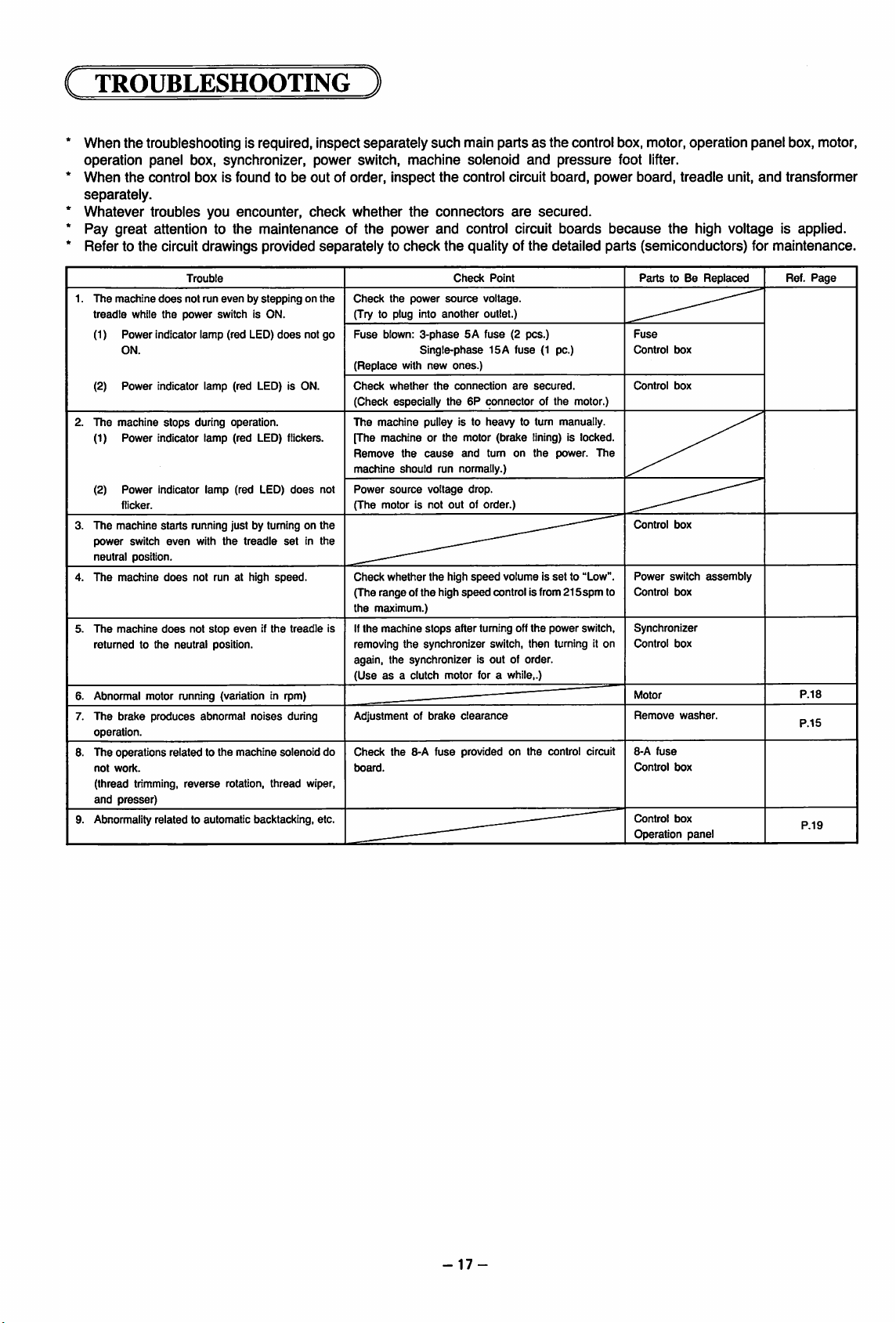

TROUBLESHOOTING

When

the

troubleshooting is required, inspect

operation panel box, synchronizer, power switch, machine solenoid

When

the

control box is found to be out of order, inspect

separately.

Whatever

troubles

you

encounter,

check

Pay great attention to the maintenance of

Refer to

1.

2. The machine

3. The machine

4.

5.

6. Abnormal motor running (variation in rpm)

7.

8. The operations related to the machine solenoid do

9. Abnormality related to automatic backtacking, etc.

the

circuit drawings provided

The

machine

does

treadle while

(1)

(2)

(1)

(2)

power

neutral position.

The

The

returnedtothe

The

operation.

not

work.

(thread trimming,

and

the

Power

indicator lamp (red LED)

ON.

Power

indicator lamp (red LED) is ON.

stops

Power

indicator

Power

indicator

flicker.

starts

switch

machine

does

machine

does

brake

produces

presser)

Trouble

not run

evenbysteppingonthe

power

switch is ON.

during operation.

lamp

(red LED) flickers.

lamp

(red LED)

running just by tuming on the

even

with

the

treadle

not run at high

not

stop

evenifthe

neutral position.

abnormal

reverse

rotation,

noises

thread

does

does

set

speed.

treadle

during

not go

in the

wiper,

separately

whether

the

separatelytocheck

Check

(Try to plug into

Fuse

blown:

(Replace

Check

(Check especially the 6P connector of the motor.)

The

machine

[The machine or the motor (brake lining) is locked.

Remove

machine

Power

not

(The motor is not out of order.)

Check whether the high

(The

rangeofthe

the

maximum.)

If

the

is

machine

such

main

the

control circuit board, power board, treadle unit,

the

connectors

power

and

control circuit boards

the

quality of

Check

the

power

source

voltage.

another

outlet.)

3-phase5Afuse

Single-phase 15 A fuse (1 pc.)

with

new

ones.)

whether

the

connection

the

should

source

pulley is to

cause

run normally.)

voltage

high

stops

heavy

and

tumonthe

drop.

speed

speed

after tuming off

removing the synchronizer switch, then turning it on

again, the synchronizer is out of order.

(Useasa clutch motor for a while,.)

Adjustment of

Check the 8-A fuse provided on the control circuit

traard.

brake

clearance

_________

partsasthe

and

are

secured.

the

Point

(2 pcs.)

are

secured.

to tum manually.

volume is

control is from

the

control box, motor, operation

pressure

detailed

power.

set

to "Low".

215spm

power switch,

foot lifter.

because

parts

The

to

the

(semiconductors) for maintenance.

Parts

to Be

Fuse

Control

t}ox

Control

box

Control

box

Power

switch

Control

box

Synchronizer

Control

box

Remove

washer.

8-A

fuse

Control

box

Control

box

Operation

panel

panel

box, motor,

and

transformer

high voltage is applied.

Replaced

assembly

Ref.

P.I

Page

5

P.19

-17-

Page 20

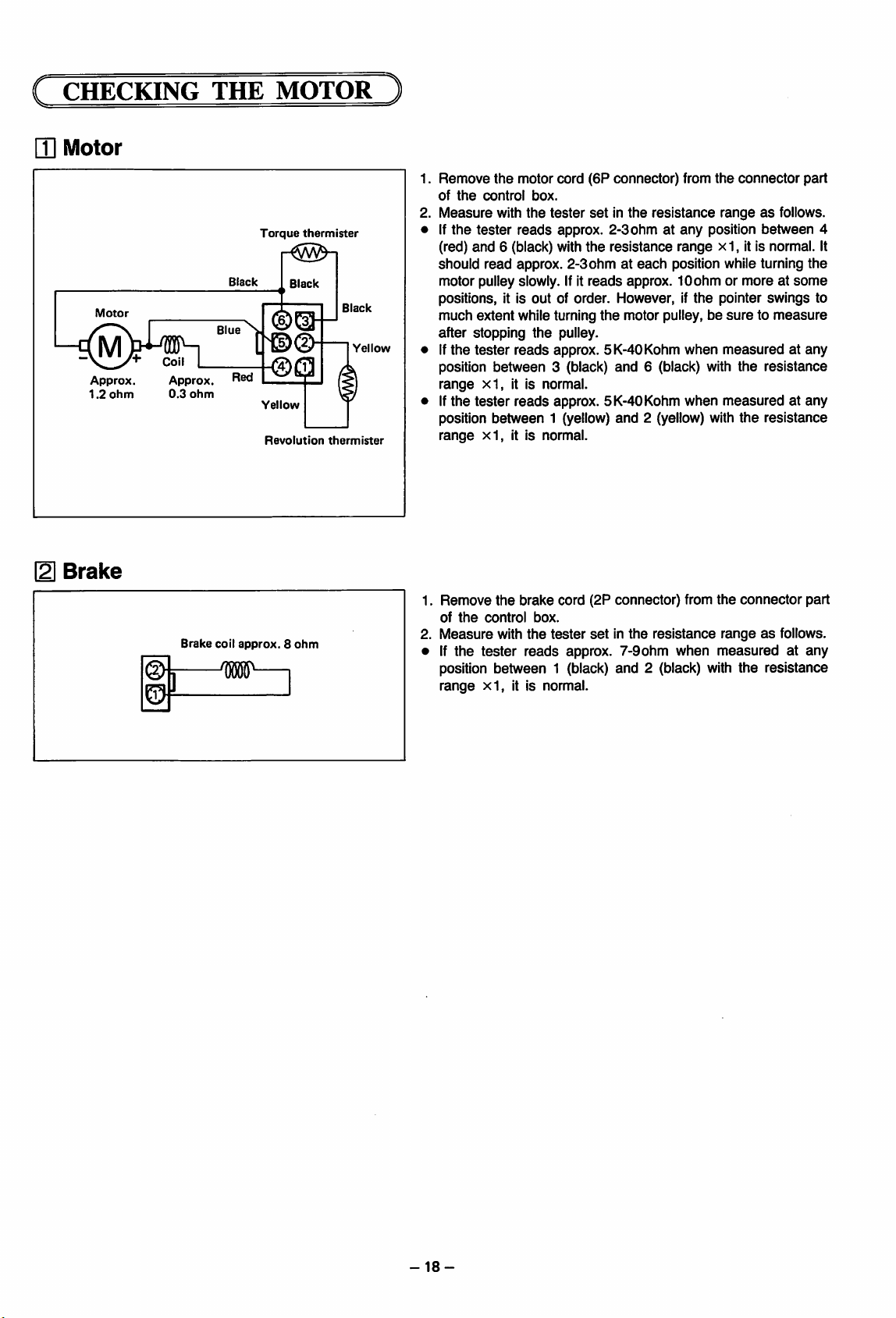

CHECKING

Q]

Motor

THE

MOTOR

Motor

Approx.

1.2

Brake

ohm

Approx.

0.3

ohm

Brake

Black

coil

approx.8ohm

W

Torque

Yellow

Revolution

thermister

Black

Black

Yellow

thermister

Remove

of

Measure

If

(red)

should

motor pulley slowly. If it

the

the

the

motor cord

control

tester

and

read

box.

with

the

reads

6 (black) with the resistance range x 1, it is normal. It

approx.

(6P

connector)

tester

setinthe

approx. 2-3 ohm at

2-3ohmateach

reads

approx. 10

resistance

any

position while turning

positions, it is out of order. However, if

much

extent

while turning

after stopping

If

the

tester

the

reads

position between 3 (black)

range

x1,

it is normal.

If

the

tester

reads

position between 1 (yellow)

range

x1,

it is normal.

Remove

1.

of

2.

Measure

• If

the

the

the

control

with

tester

brake

box.

the

reads

tester

the

motor pulley,besuretomeasure

pulley.

approx. 5K-40Kohm

and

6 (black) with

approx. 5K-40Kohm when

and

2 (yellow) with

cord

(2P

connector)

setinthe

resistance

approx. 7-9 ohm when

position between 1 (black) and 2 (black) with

range

xl,

it is normal.

from

the

connector

rangeasfollows.

position

between

ohmormoreatsome

the

pointer swings to

when

measuredatany

the

resistance

from

measured

the

the

connector

at any

resistance

rangeasfollows.

measuredatany

the

resistance

part

4

the

part

-18-

Page 21

CHECKING

Q]

Solenoid

load

THE

of

MACHINE

the

machine

SOLENOIDS

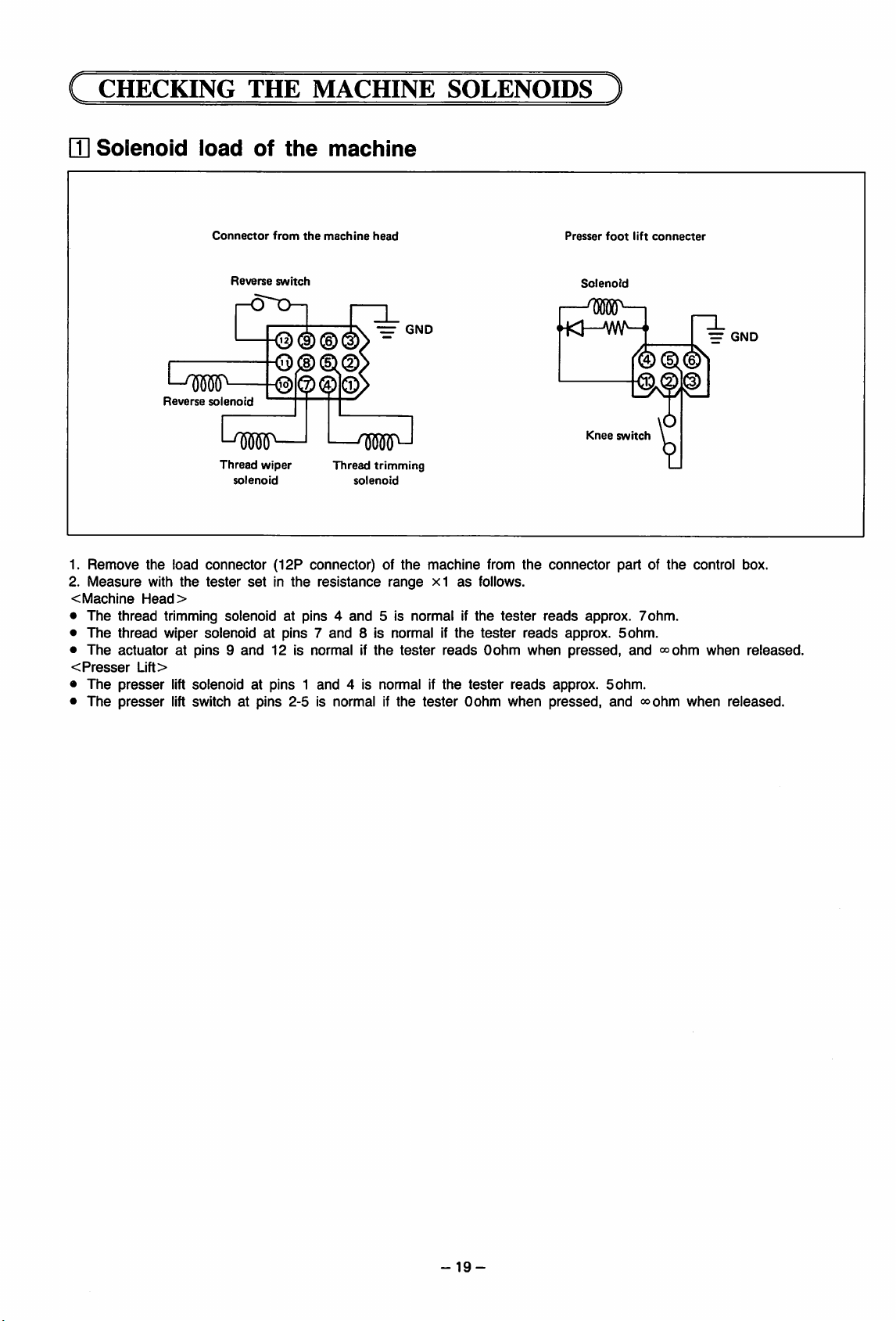

1.

Remove

2.

Measure

<

Machine

•

The

•

The

•

The

<

Presser

•

The

•

The

Connector

Reverse

Reverse

solenoid

l-W—I

Thread

solenoid

the

load

connector

with

the

tester

Head>

thread

trimming solenoid at pins 4

thread

wiper

solenoidatpins7and

actuator

presser

presser

at pins 9

Lift>

lift solenoid at pins 1

lift switch at pins 2-5 is normal if

from

switch

<5®©i

wiper

(12P

setinthe

and

12

the

machine

®®|®.

—w-l

Thread

solenoid

connector) of

resistance

and

is normal if

and

4 is normal if

head

-=•

GND

trimming

the

machine

range

xl

5 is normal if

8 is normal if

the

tester

the

tester

as

the

reads

the

follows.

the

tester

Oohm

tester

Oohm

from

tester

the

reads

reads

when

reads

when

Presser

foot

Solenoid

[—W—I

Knee

switch

connector

approx.

pressed,

approx. 5ohm.

pressed,

partofthe

approx.

5ohm.

and

lift

connecter

®©®

7ohm.

and

<»ohm

<»ohm

=

GND

control box.

when

when

released.

released.

-19-

Page 22

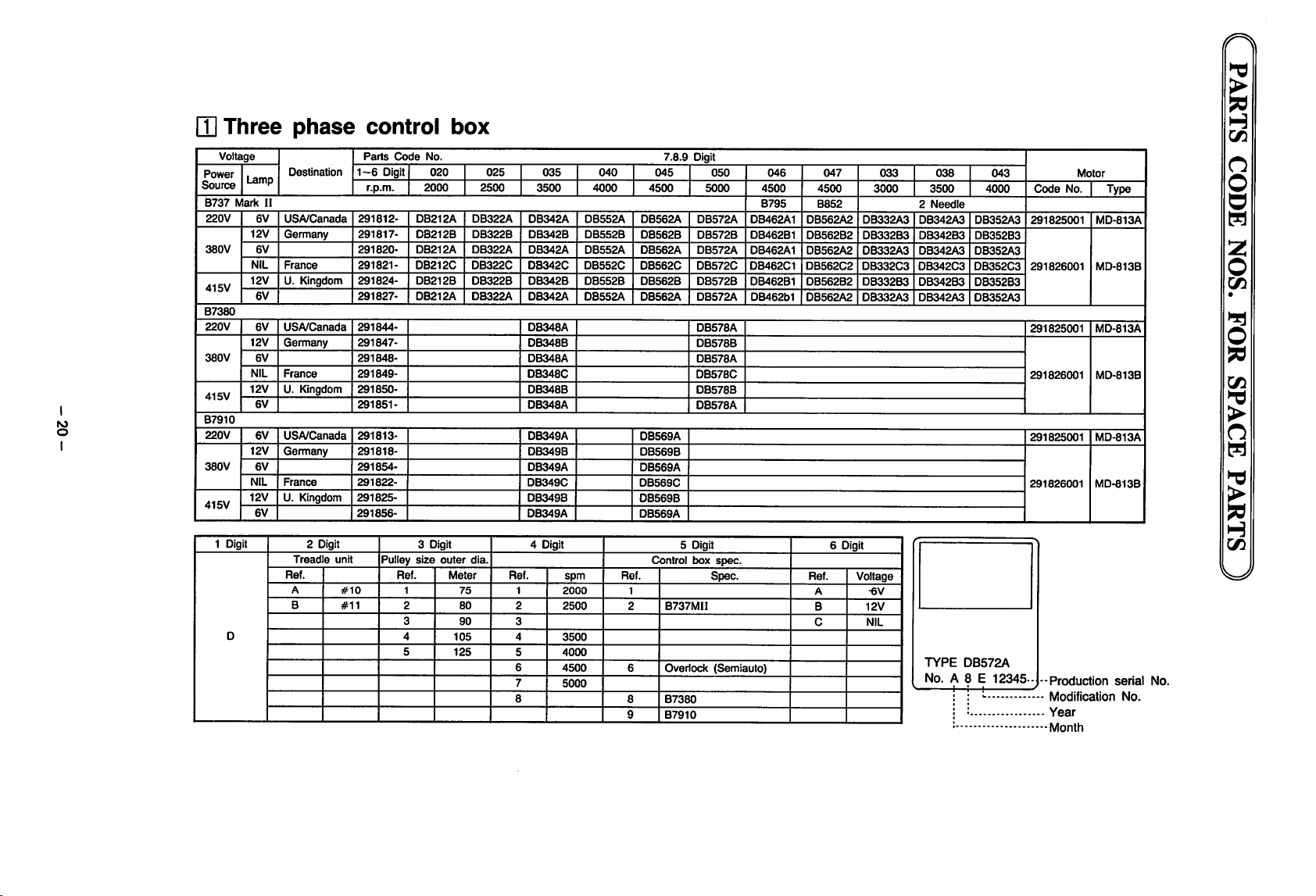

/r\

>

9S

lU

Three

Voltage

Power

Source

B737

Mark

220V

380V

415V

B7380

220V

380V

415V

to

o

B7910

220V

380V

415V

1 Digit

D

La

12V

NIL

12V

12V

NIL

12V

12V

NIL

12V

mp

II

6V

6V

6V

6V

6V

6V

6V

6V

6V

phase

Destination

USA/Canada

Germany

France

U. Kingdom

USA/Canada

Germany

France

U. Kingdom

USA/Canada

Germany

France

U. Kingdom

2 Digit

Treadle

Ref.

A

B

1-6

291812-

291817-

291820291821-

291824-

291827-

291844291847291848291849-

291850291851-

291813-

291818-

291854-

291822-

291825-

291856-

unit

#10

#11

control

Parts

Code

Digit

r.p.m.

DB212A

DB212B

DB212A

DB212C

DB212B

DB212A

3 Digit

Pulley

size

Ref.

1

2

3

4

5

box

No.

020 025 035

2000 2500

DB322A DB342A

outer

Meter

DB322B

DB322A

DB322C

DB322B

DB322A

dia.

75

80

90

105

125

DB342B

DB342A DB552A

DB342C

DB342B DB552B

DB342A

DB348A

DB348B

DB348A

DB348C

DB348B

DB348A

DB349A

DB349B

DB349A

DB349C

DB349B

DB349A

4 Digit

Ref.

1

2

3

4

5

6

7

8

3500

DB552A

DB552B

DB552C

DB552A

spm

2000

2500

3500

4000

4500

5000

040

4000 4500

045

DB562A

DB562B

DB562A

DB562C

DB562B

DB562A

DB569A

DB569B

DB569A

DB569C

DB569B

DB569A

Control box

Ref.

1

2

6 Overlock

8

9

7.8.9

5 Digit

B737MII

B7380

B7910

Digit

050

5000

DB572A

DB572B

DB572A

DB572C

DB572B

DB572A

DB578A

DB578B

DB578A

DB578C

DB578B

DB578A

Spec.

(Semiauto)

spec.

046

4500

B795

DB462A1

DB462B1

DB462A1

DB462C1

DB462B1

DB462b1

047

4500

B852

DB562A2

DB562B2

DB562A2

DB562C2

DB562B2

DB562A2

6 Digit

Ref.

A

B

C

033

3000

DB332A3

DB332B3

DB332A3

DB332C3

DB332B3

DB332A3

Voltage

•6V

12V

NIL

038

3500

2

Needle

DB342A3

DB342B3

DB342A3

DB342C3

DB342B3

DB342A3

TYPE

No.

DB572A

A 8 E

043

4000

DB352A3

DB352B3

DB352A3

DB352C3

DB352B3

DB352A3

12345-

Code

291825001

291826001

291825001

291826001

291825001

291826001

-Production

Modification

Year

Month

No.

Motor

Type

MD-813A

MD-813B

MD-813A

MD-813B

MD-813A

MD-813B

serial

No.

No.

H

Vi

O

o

o

(S)

2

o

(/I

o

fd

Cfl

Id

>

H

C/5

W

Page 23

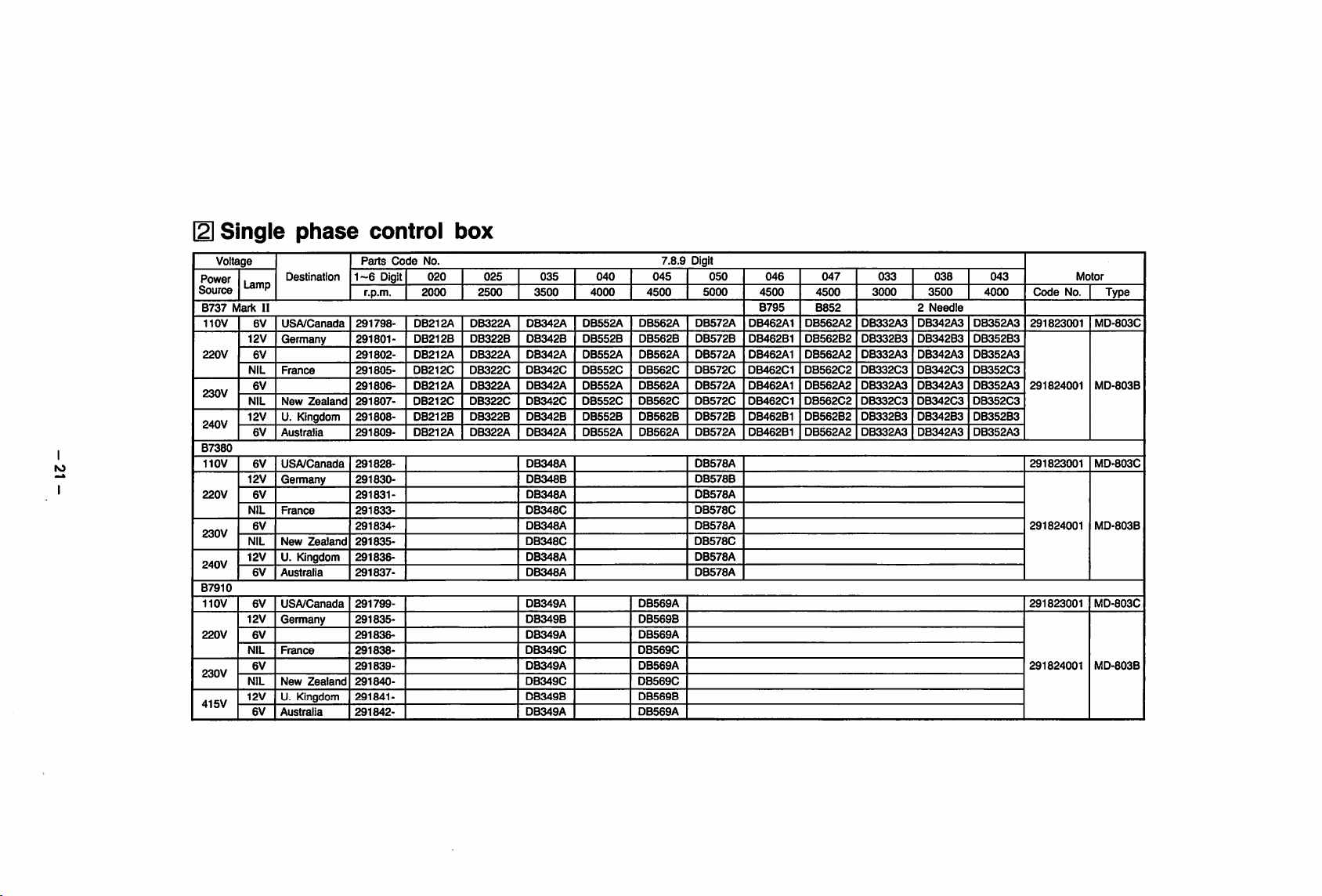

Single

Voltage

Power

Lamp

Source

B737

Mark

110V

12V

220V

NIL

230V

NIL

12V

240V

B7380

lO

I

110V

220V

230V

240V

B7910

110V

220V

230V

415V

12V

NIL

NIL

12V

12V

NIL

NIL

12V

II

6V

6V

6V

6V

6V

6V

6V

6V

6V

6V

6V

6V

phase

Destination

USA/Canada

Germany

France

New

Zealand

U. Kingdom

Australia

USA/Canada

Germany

France

New

Zealand

U. Kingdom

Australia

USA/Canada

Germany

France

New

Zealand

U. Kingdom

Austraiia

control

Parts

Code

1-6

Digit

r.p.m.

291798-

291801291802-

291805291806-

291807-

291808-

291809-

291828291830291831291833-

291834-

291835-

291838-

291837-

291799-

291835-

291836-

291838291839291840-

291841-

291842-

box

No.

020

2000 2500

DB212A

DB212B

DB212A

DB212C

DB212A

DB212C

DB212B

DB212A

025

DB322A

DB322B

DB322A

DB322C

DB322A

DB322C

DB322B DB342B

DB322A DB342A

035

3500

DB342A

DB342B

DB342A

0B342C

DB342A DB552A

DB342C

DB348A

DB348B

DB348A

DB348C

DB348A

DB348G

DB348A

DB348A

DB349A

DB349B

DB349A

DB349C

DB349A

DB349C

DB349B

DB349A

040

4000

DB552A DB562A

DB552B

DB552A

DB552C

DB552G DB562G

DB552B

DB552A DB562A

045 050 046 047

4500

DB562B

DB562A

DB562G

DB562A

DB562B

DB569A

DB569B

DB569A

DB569G

DB569A

DB569G

DB569B

DB569A

7.8.9 Digit

DB572A

DB572B

DB572A

DB572G

DB572A

DB572G

DB572B

DB572A

DB578A

DB578B

DB578A

DB578G

DB578A

DB578G

DB578A

DB578A

5000

4500

B795 B852

DB462A1

DB462B1

DB462A1

DB462G1

DB462A1

DB462G1

DB462B1

DB462B1

033

4500

DB562A2

DB562B2

DB562A2

DB562G2

DB562A2

DB562G2

DB562B2 DB332B3

DB562A2

3000

DB332A3

DB332B3

DB332A3 DB342A3 DB352A3

DB332G3 DB342G3

DB332A3

DB332G3 DB342G3 DB352G3

DB332A3

038

3500

2

Needle

DB342A3 DB352A3

DB342B3

DB342A3

DB342B3

DB342A3

043

4000

DB352B3

DB352G3

DB352A3

DB352B3

DB352A3

Code

291823001

291824001

291823001

291824001

291823001

291824001

No.

Motor

Type

MD-803G

MD-803B

MD-803G

MD-803B

MD-803G

MD-803B

Page 24

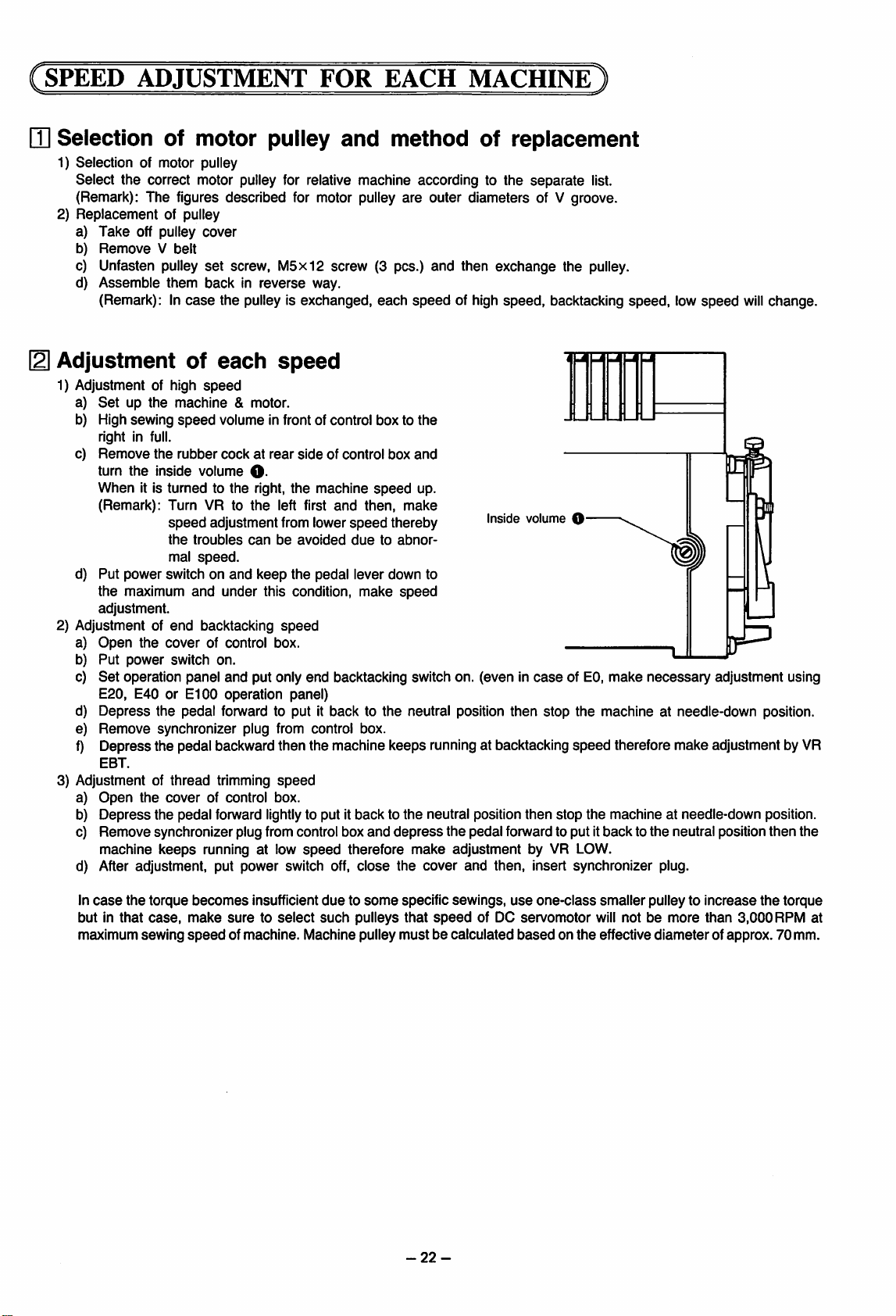

SPEED

HI

Selection of motor pulley

1) Selection of motor pulley

Select the correct motor pulley for relative machine according to the

ADJUSTMENT

(Remark): The figures described for motor pulley are outer diameters of V groove.

2)

Replacement

a)

Take

b)

Remove

c) Unfasten pulley

d) Assemble them back in reverse way.

(Remark): In

121

Adjustment of

1) Adjustment of high

a)

Setupthe

b) High sewing

right in full.

c)

Remove

turn

When

(Remark): Turn VR to

d) Put power switch on

the maximum

adjustment.

2) Adjustment of

a)

Open

b)

Put

Set

c)

E20, E40 or

Depress

d)

Remove

e)

Depress the pedal backward then the machine keeps running at backtacking

f)

EBT.

3) Adjustment of

a)

Open

Depress

b)

Remove synchronizer plug from control box

c)

machine

After adjustment, put power switch off,

d)

of pulley

off pulley

V belt

cover

set

screw,

case

the pulley is exchanged,

each

speed

machine

speed

the

rubber

the

inside volume

it is turned to

speed

the

mal

end

the

cover

power

switch

operation panel and put only end backtacking switch on. (even in

E100

the pedal forward to put it back to the neutral position then stop the machine at needle-down position.

synchronizer plug from control box.

thread

the

cover

the pedal forward lightlyto put it back to

keeps

& motor.

volume in front of control box to the

cockatrear

O-

the

right,

the

adjustmentfrom lower

troubles

speed.

and

backtacking

can

and

keep

under this condition, make

of control box.

on.

operation panel)

trimming

of control box.

running at low

M5xl2

FOR

screw (3 pcs.)

and

EACH

method of replacement

each

speed

sideofcontrol

the

machine

left first

be

speed

speed

and

avoided

the pedal lever down to

speed

box

speed

then,

speed

thereby

duetoabnor

and

depress

therefore

close

MACHINE

speed

and

up.

make

speed

separate

and

then

exchange

of high speed, backtacking speed, low

Inside volume O

list.

the pulley.

speed

0^

caseofEO,

the

neutral position then stop the machine at needle-down position.

the

pedal forward to put it back to

make

adjustment by VR LOW.

the

cover

and

then, insert synchronizer plug.

make

necessary

speed

therefore make adjustment by VR

the

adjustment using

neutral position then the

will

change.

In

case

the

torque

but in

that

case,

maximum sewing

becomes

make

speed

insufficient

suretoselect

of machine. Machine pulley

duetosome

such

pulleys

specific sewings,

that

speed

of DC servomotor will notbemore

mustbecalculated

-22-

use

one-class

basedonthe

smallerpulley to

effective

diameter

increase

than

of approx. 70 mm.

the

3,000

torque

RPM at

Page 25

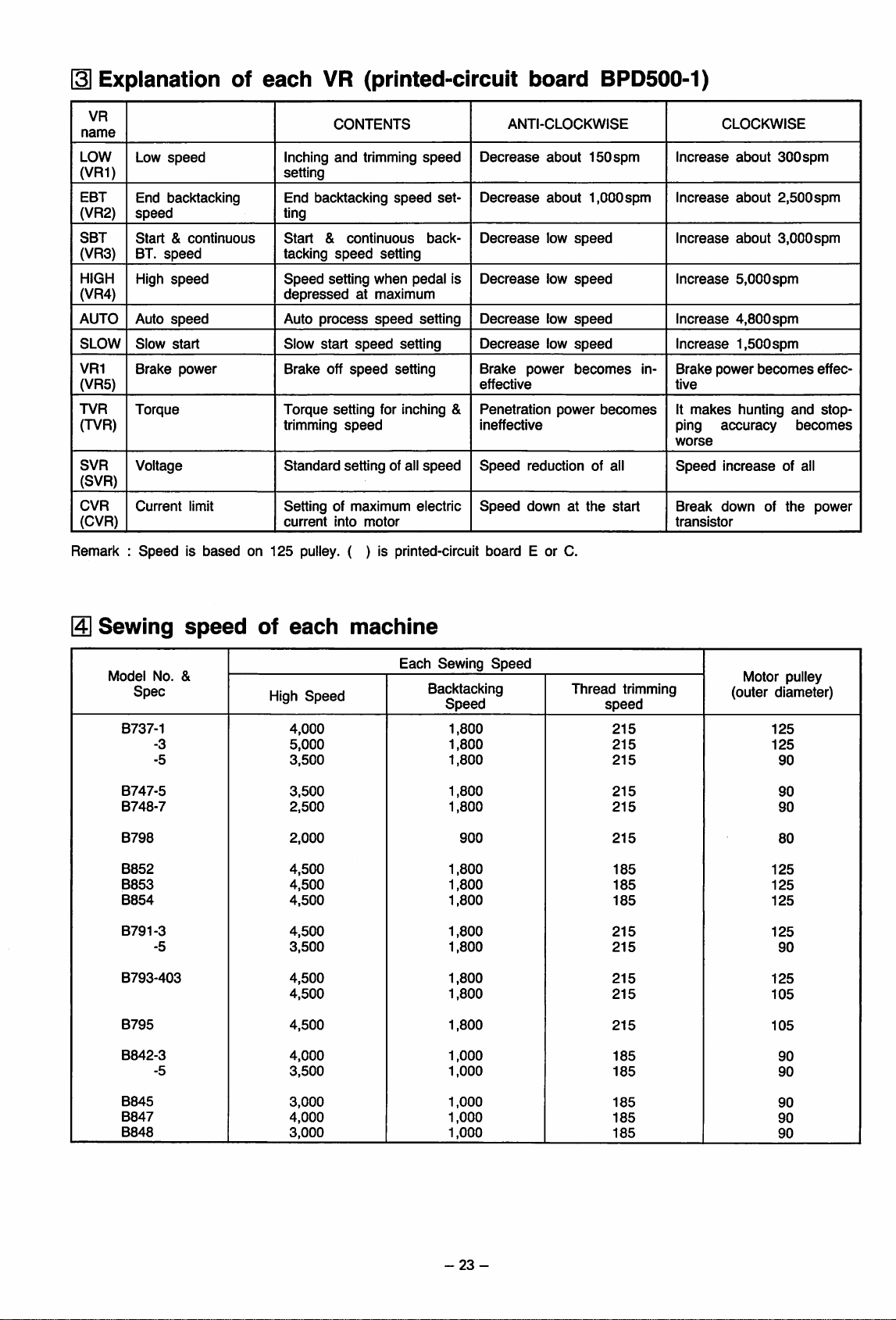

Explanation

of

each

VR

(printed-circuit

board

BPD500-1)

VR

name

LOW

(VR1)

EBT

(VR2)

SBT

(VR3)

HIGH

(VR4)

AUTO

SLOW

VR1

(VR5)

TVR

(TVR)

SVR

(SVR)

CVR

(CVR)

Remark :

Low

speed

End

backtacking

speed

Start&continuous

BT.

speed

High

speed

Auto

speed

Slow

start

Brake

power

Torque

Voltage

Current

limit

Speedisbased

CONTENTS

Inching

and

trimming

setting

End backtacking

ting

Start

&

tacking

Speed

depressed

Auto

Slow

Brake off

Torque

trimming

Standard

continuous

speed

setting when pedal Is

at maximum

process

start

speed

speed

speed

setting for Inching &

speed

setting of all

Setting of maximum electric

on

current

125

Into

motor

pulley. ( ) Is prlnted-clrcult board E or C.

speed

setting

setting

setting

speed

set

back

setting

speed

ANTI-CLOCKWISE

Decrease

about

Decrease

Decrease

Decrease

Decrease

Decrease

Brake

effective

power

Penetration

Ineffective

Speed

Speed

reduction of all

down at

about

low

low

low

low

power

150spm

I.OOOspm

speed

speed

speed

speed

becomes

becomes

the

start

In

CLOCKWISE

Increase

Increase

Increase

Increase

Increase

Increase

at>out

about

about

5,000spm

4,800spm

1,500spm

Brake power

tive

It

makes

ping

accuracy

worse

Speed

transistor

Break

Increase

downofthe

becomes

hunting

300spm

2,500spm

3,000spm

effec

and

stop

becomes

of all

power

Sewing

Model

No.

Spec

B737-1

-3

-5

B747-5

B748-7

B798

B852

B853

B854

B791-3

-5

B793-403

B795

B842-3

-5

speed

&

of

High

each

Speed

4,000

5,000

3,500

3,500

2,500

2,000

4,500

4,500

4,500

4,500

3,500

4,500

4,500

4,500

4,000

3,500

machine

Each

Sewing

Speed

Backtacking

Speed

1,800

1,800

1,800

1,800

1,800

900

1,800

1,800

1,800

1,800

1,800

1,800

1,800

1,800

1,000

1,000

Thread

trimming

speed

215

215

215

215

215

215

185 125

185

185

215

215

215

215

215

185

185

Motor pulley

(outer

diameter)

125

125

90

90

90

80

125

125

125

90

125

105

105

90

90

B845

B847

B848

3,000

4,000

3,000

1,000

1,000

1,000

-23-

185

185

185

90

90

90

Page 26

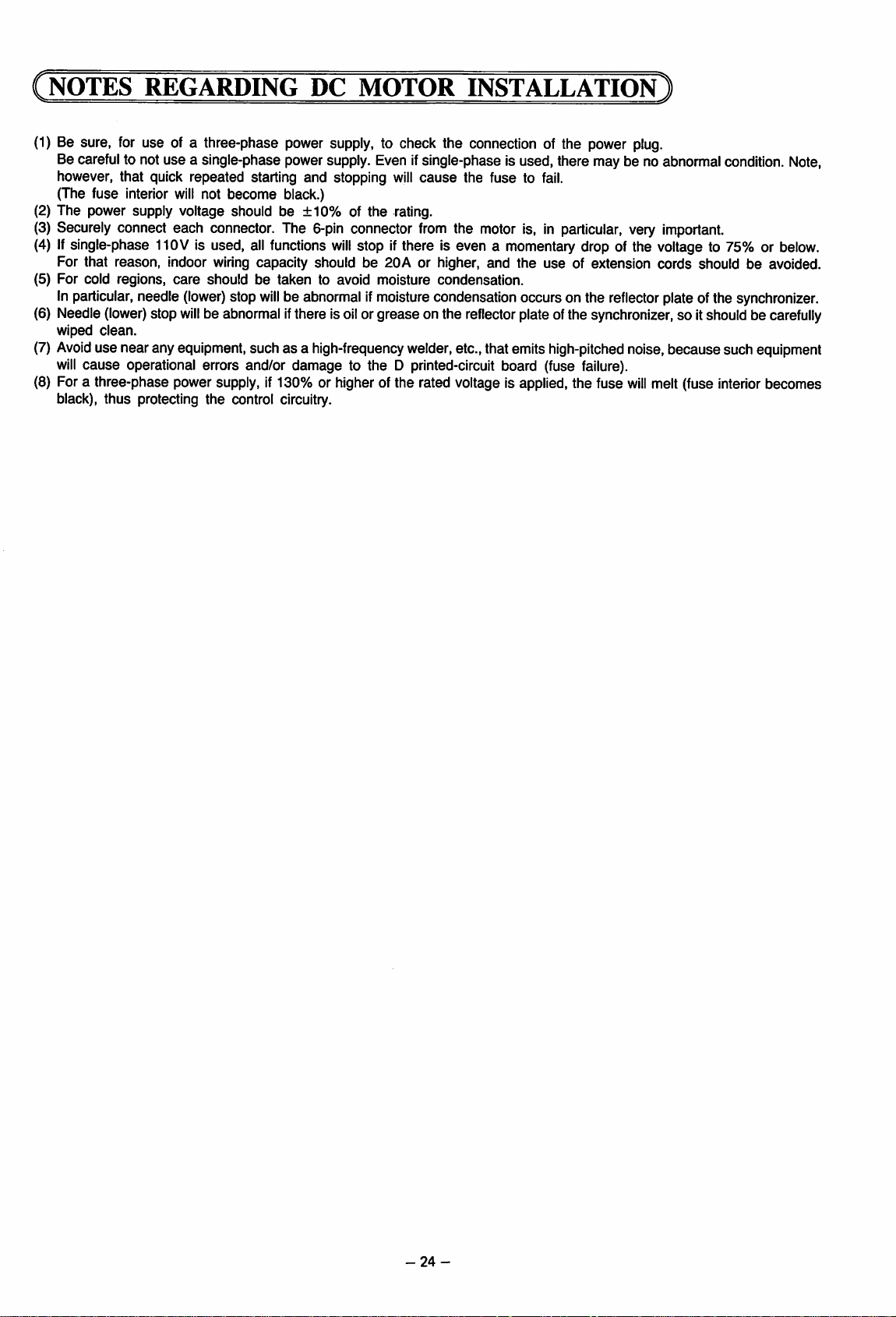

NOTES

(1)

Be sure,

Be careful to not use a single-phase powersupply. Even ifsingle-phase is used, there may be no abnormal condition.

however, that quick repeated starting and stopping

(The fuse interior

(2) The power supply voltage should be

(3)

Securely connect each connector. The

(4)Ifsingle-phase 110V is used,

For that reason, indoor

(5) For cold regions,

Inparticular, needle

(6)

Needle

wiped

(7)

Avoid

use near anyequipment, such as a

will

cause operational errors and/or damage to the D printed-circuit board (fuse

(8) For a three-phase powersupply, if130% or higher of the rated voltage is applied,the fuse

black), thus protecting the control circuitry.

REGARDING

for

use of a three-phase

will

care

(lower)

(lower)

stop

willbeabnormal

clean.

DC

power

not become black.)

±10%

all

functions

wiring

capacity should be 20A or higher, and the use of extension cords should be avoided.

shouldbetaken

stop

will

be abnormal ifmoisture condensationoccurs on the reflector plate of the synchronizer.

ifthere is

MOTOR

supply,

6-pin

will

to avoid moisture condensation.

high-frequency

to check the

will

cause

of the rating.

connector

stopifthere is even a

oil

orgrease onthe

from

welder,

INSTALLAtTo^

connection

the fuse to

the

motor

reflector

etc.,thatemits

of the

power

plug.

fail.

is, in

particular,

momentary

plateofthe synchronizer, so itshouldbe

drop of the voltage to 75% or

high-pitched

failure).

very

important.

noise,because such equipment

will

melt (fuse interior becomes

Note,

below.

carefully

-24-

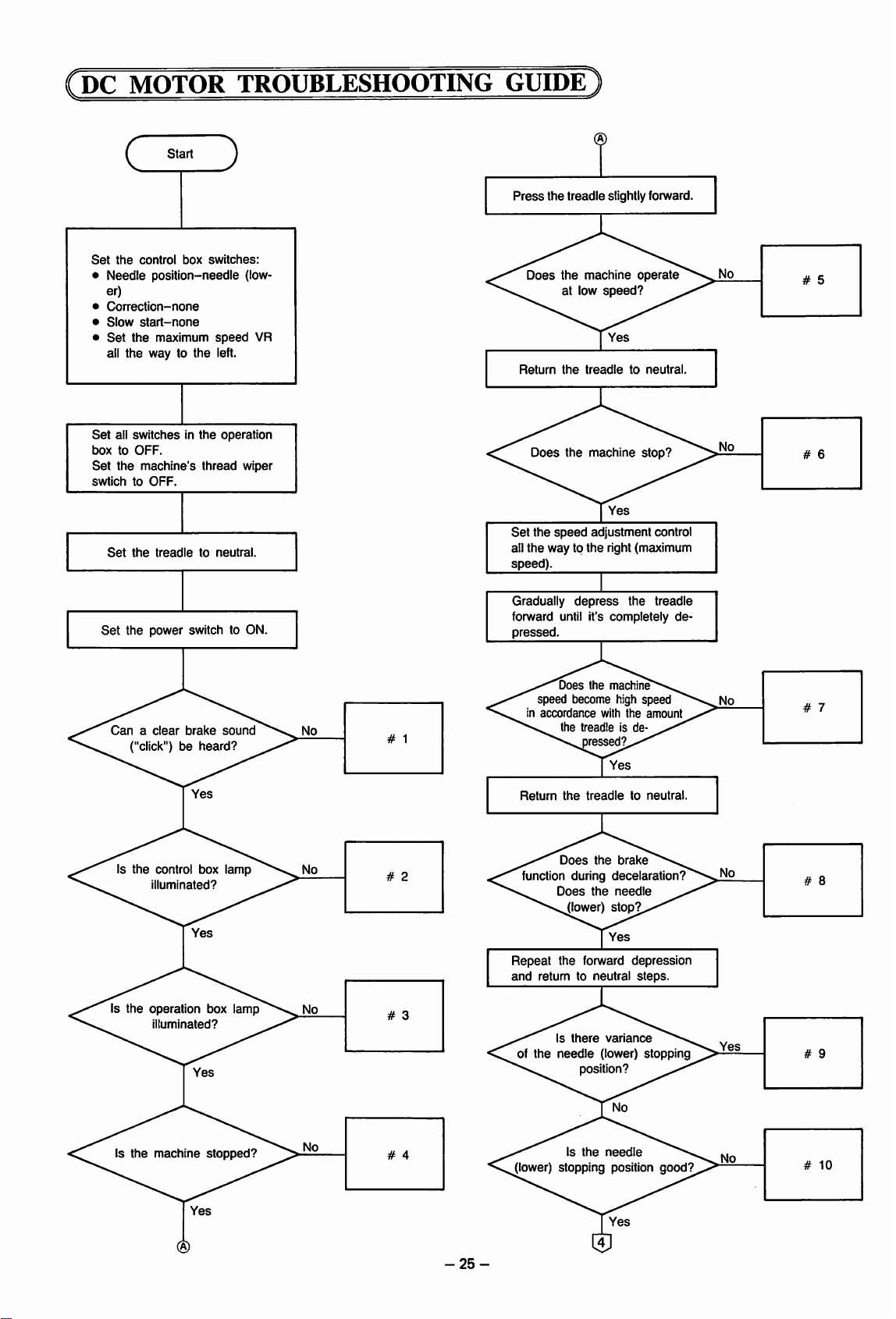

Page 27

(DC

MOTOR TROUBLESHOOTING GUIDE

CjEZD

Set

the

control

• Needle

er)

•

Correction-none

•

Slow

start-none

•

Set

the

all the way to the left.

Set

all

switchesinthe

boxtoOFF.

Set

the

swtichtoOFF.

Set

the

box

position-needle

maximum

machine's

thread

treadletoneutral.

switches:

speed

operation

(low

VR

wiper

Press

Does

Return

Does

Set

the

all

the

speed)

the

treadle

the

machine

at low

the

treadletoneutral

the

speed

way to

the

slightly forward

operate

speed?

machine

stop?

adjustment

right (maximum

control

Set

the

Canaclear

power

switchtoON.

brake

sound

("click")beheard?

Is

the

control box

illuminated?

lamp

Is the operation box lamp

illuminated?

Gradually

depress

the

treadle

forward until it's completely

pressed

Does

the

machine

speed become high speed

in

accordance

the

treadleisde

with

the

amount

pressed?

Return

the

treadletoneutral

Does

the

the

forward

there

brake

decelaration?

needle

stop?

depression

steps

vanance

(lower)

stopping

function during

Does

(lower)

Repeat

the

and

return to neutral

Is

of

the

needle

position?

de

Is

the

Is

the

machine

stopped?

needle

(lower) stopping position

-25-

good?

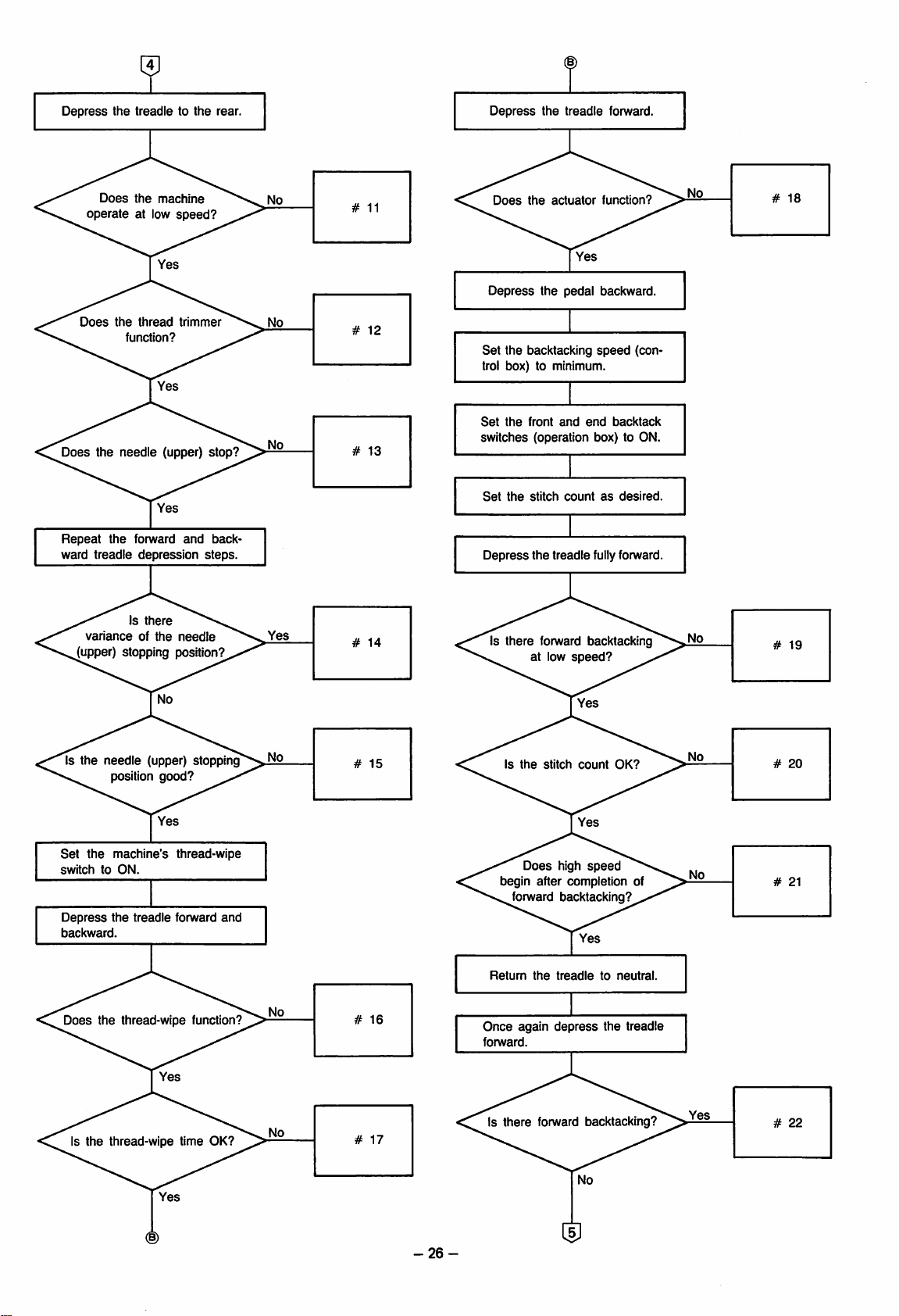

Page 28

Depress

operate

the

Does

treadletothe

the

machine

at low

speed?

rear

Depress

Does

the

the

actuator

treadle

fonivard

function?

Does

the

thread

tnmmer

(upper)

Yes

fonvard

depression

there

needle

Does

the

Repeat

ward

treadle

varianceofthe

function?

needle

the

Is

(upper) stopping position?

and

stop?

back

steps.

Depress

Set

the

pedal backward

the backtacking

speed

(con

trol box) to minimum.

Set

the

front

and

end

backtack

switches (operation box) to ON.

Set

the

stitch

countasdesired

Depress

the

treadle

fully forward.

Is

there

forward backtacking

at low

speed?

Is the

needle

position

Set

the

switchtoON

Depress

backward

Does

machine's

the

the

Is

the

thread-wipe time OK?

(upper)

good?

treadle

thread-wipe

stopping^No

thread-wipe

fonivard

and

function?

Is

the

stitch

count

Does

high

speed

begin after completion of

forward backtacking?

Return

the

treadle

Once

again

depress

forward.

Is

there

forward backtacking?

OK?

to

neutral

the treadle

-26-

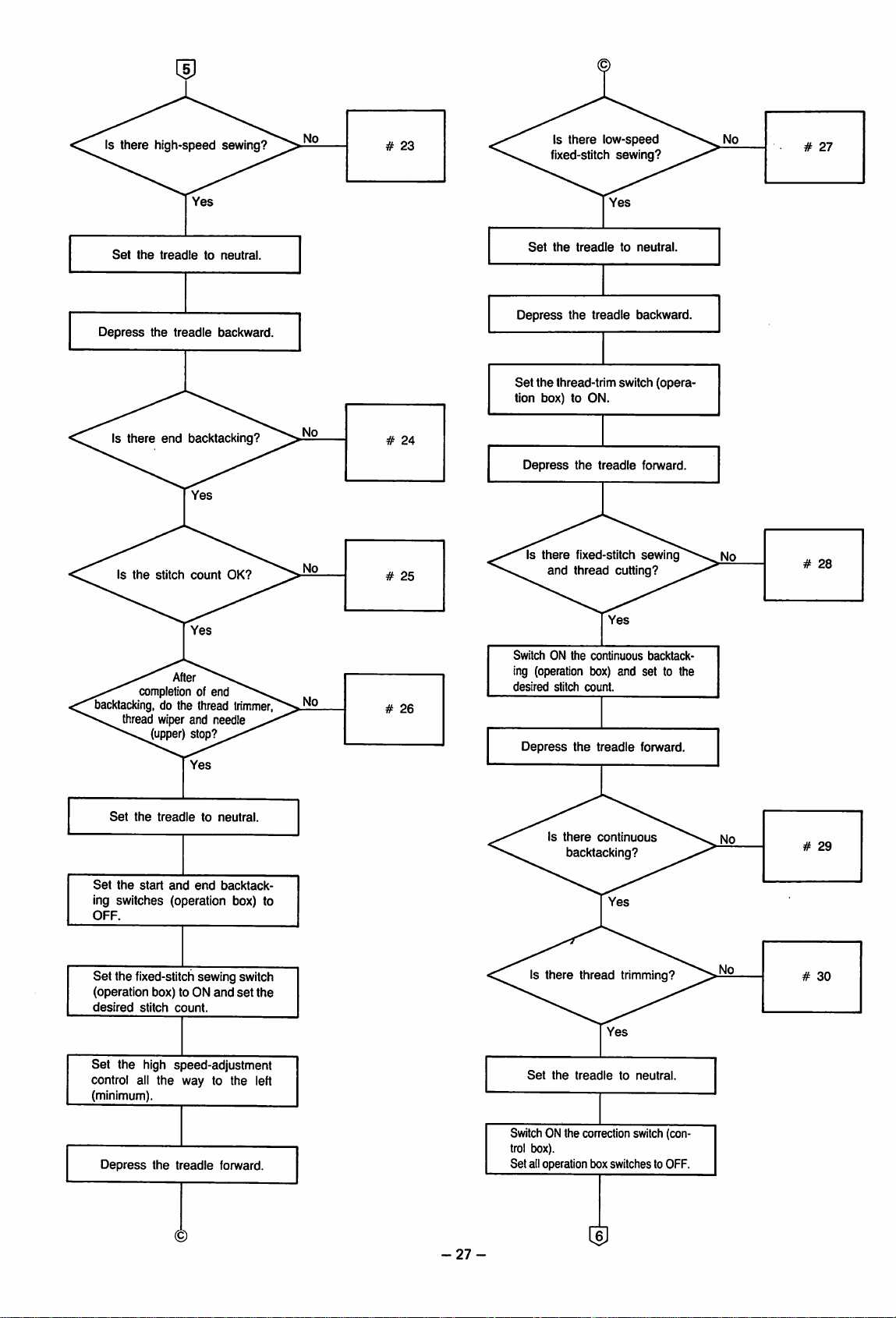

Page 29

Is there high-speed sewing?

Set

the

treac

Jletoneutral.

Set

Is

there

fixed-stitch

the

treadleto

low-speed

sewing?

neutral.

Depress

Is

Is

there

the

the

stitch

tr(

end

After

completion of end

backtacking,

do the thread

thread wiper and needle

(upper) stop?

^adle

backward.

backtacking?

count

OK?

trimmer

Depress

Set

the treadle backward.

the

thread-trim switch

tion box) to ON.

Depress

SwitchONthe

Is

there

and

the

fixed-stitch

thread

co

ing (operation bo

desired

stitch

cou

Depress

the

(opera

t

readle

forward.

sewing

cutting?

ntinuous

backtack-

x) and set to the

nt.

t

readle

forward.

No

Set

the

treac

tietoneutral.

Set

the

start

and

end

backtack

ing switches (operation box) to

OFF.

Set

the fixed-stitchsewing switch

(operation box) to ON

desired

stitch

Set

the high speed-adjustment

count.

and

set

the

control all the way to the left

(minimum).

Depress

the

tr

eadle

forward.

-27-

Is

there

backtacking?

there

Is

Set

SwitchONthe

thread trimming?

the

treac

con

trol box).

Set alloperationbe

continuous

lietoneutral.

ection switch (con-

)x

switchestoOFF.

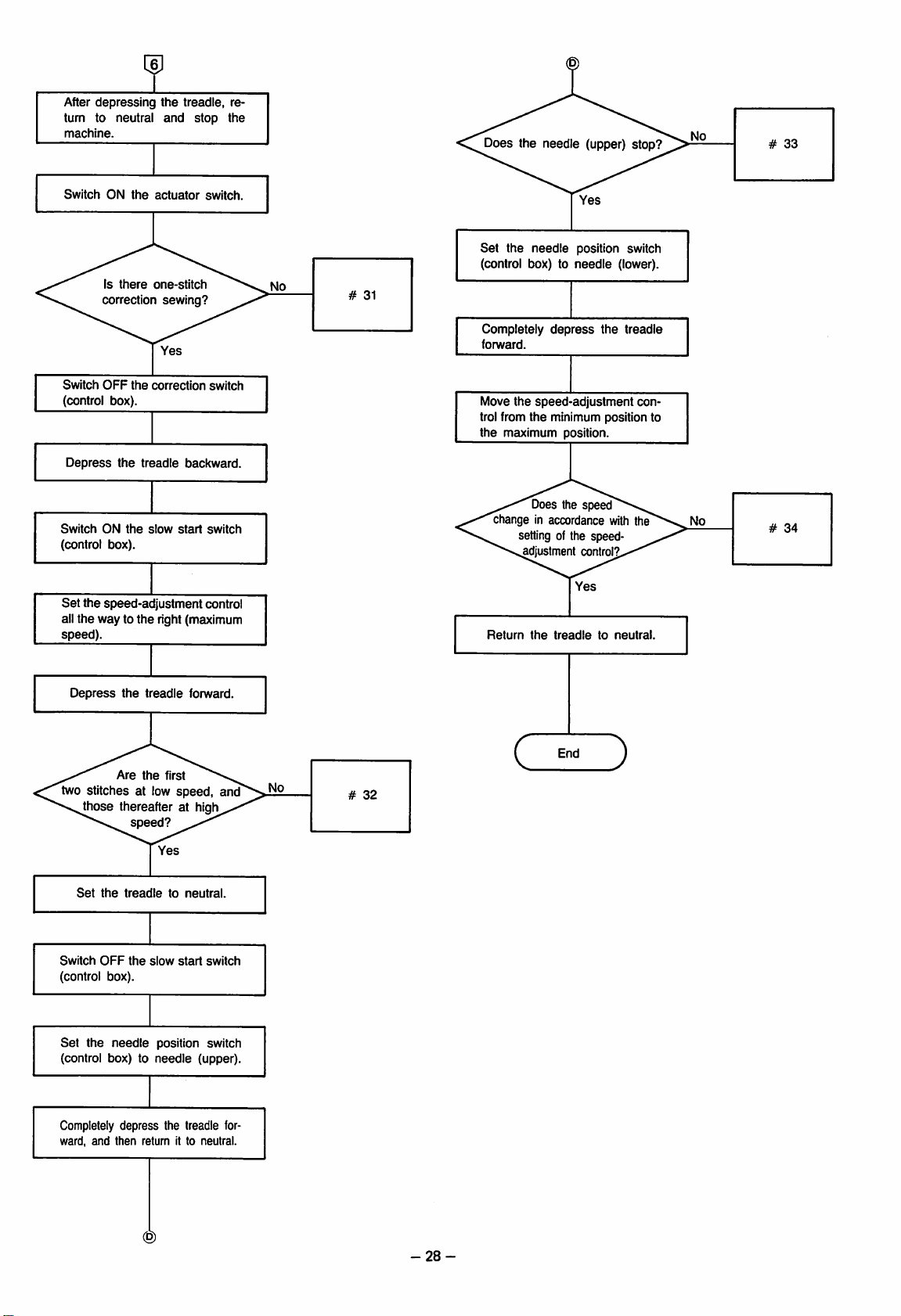

Page 30

After

depressing

turn to neutral

machine.

Switch

ON

the

Is

there

correction

the

treadle, re

and

actuator

one-stitch

sewing?

stop

switch

the

Does the needle (upper) stop?

Set

the

needle

(control box) to

#

31

position switch

needle

(lower).

Switch

OFF

the

correction

switch

(control box).

Depress

Switch

ON

the

the

treadle

slow

backward.

start

switch

(control box).

Set

the speed-adjustmentcontrol

all the way to

the

right (maximum

speed).

Depress

Are

the

the

ti

eadle

forward.

first

two stitches at lowspeed, and"

^hose thereafter at higl^

speed?

No

Completely

forward.

Move

trol

from

the

depress

the

speed-

the

min

maximum p

the treadle

adjustment

mum

position to

osition.

Does the speed

change in accordance with the

setting of the speed-

adjustment control?

Yes

Return

the

treadletoneutral.

End

C

)

con-

Set

the

treat

Switch

OFF

the

(control box).

Set

the

needle

(control box) to

Completely depre

ward,

and

then

Yes

lietoneutral.

slow

start

position switch

needle

(upper).

5S

the

treadle

tumitto

re

switch

for-

neutral.

-28-

Page 31

ITEM

#1

and

#2

#3

#4

#5

#6

#7

PROBLEM

No

"click"

from

power

ON.

Control box

doesn't

No

illumination

sound

brake

when

is switched

lamp

illuminate.

of

operation box lamp.

Machine

starts

when

power is switched

ON.

Machine

operate.

Machine

reverse.

Unsuitable

speed

Machine

high

speed.

Machine

when

treadleisset

neutral.

Operation

correspond

amount

doesn't

operates

low-

operation.

operates

doesn't

doesn't

to

of

treadle

stop

depression.

CHECKING

• Is

the

PROCEDURES

connection

4-pin or 3-pin power plug

OK?

•

The

fuse

(outer

control box)

•

Fuse

fails

again

placement.

•

The

fuse

(8A

the

control box)

•

Other

than

the

•

Does

the

operation

function correctly? (YES)

•

Other

than

the

•

Does

the

control box

flash?

•Isthereamotor

•

Other

than

the

in

at

to

•

Uneven

dle

• Initial

operation at

maximum.

operation

fast (no low-speed range).

has

failed.

fuse

has

above.

above.

above.

speed

of

side

(YES)

after

failed.

noise?

the

of

re

inside

box

(NO)

lamp

(YES)

(YES)

trea

PROBABLE

Power

connected.

Fuse

Malfunctionof8A

plug is incorrectly

has

CAUSE

failed.

control printed-circuit board.

Malfunction

of

the

printed-circuit board.

Bulb

failure-no

problem.

Malfunction of

box.

Malfunction

printed-circuit

Malfunction

the

of

board.

of

the

the

printed-circuit board.

Malfunction of

circuit

board.

(single

phase

the

110

er)

Large

torque

Malfunction

printed-circuit

Malfunction

Large

torque

Malfunction

Malfunction

Malfunction

Malfunction

Synchronizer

position is not

Synchronizer

(head).

of

control

board

of

treadle

(head).

of

treadle

of

treadle

of

treadle

of

treadle

installation

good.

malfunction.

Control printed-circuit board

malfunction.

is

Malfunction

Malfunction

Malfunction

of

of

of

treadle

control

treadle

fuse,

the

control

functional

operation

control

control

D printed-

V or high

unit.

unit.

unit.

unit.

unit.

unit.

box.

unit.

REMEDY

Connect

the

power

rectly.

Replace

Replace

trol

Replace

box.

Replace

Replace

Replace

Replace

Replace

motor.

Reduce

Replace

Replace

Reduce

Replace

Replace

Replace

box.

the

fuse.

the

motor

the

fuse

the

control box.

the

operation box.

the

control box.

the

control box.

the

the

torque.

the

control box.

the

control box.

the

torque.

the

control box.

the

control box.

the

control box.

Adjust VR LOW

Replace

Position

Replace

Replace

Replace

Replace

Replace

the

control box.

adjustment:

the

synchronizer.

the

control box.

the

control box.

the

control box.

the

control box.

plug

cor

and

con

and

control

control box

and

TVR.

0.5mm

-29-

Page 32

ITEM

#8

#9

#10

#11

#12

#13

PROBLEM

Needle

doesn't

(lower)

stop.

Needle (lower)

at

various

Poor

dle

After

places.

position of

stop.

treadle

machine won't

ate

at low

speed.

Thread

doesn't

Needle

doesn't

trimmer

function.

(upper)

stop.

stops

nee

return,

oper

CHECKING

• Is

the

PROCEDURES

synchronizer

OK?

(NO)

(YES)

• Is

the

V-belt

loose?

(YES)

• Is

there

oil,

grease,

scratches,

etc.onthe

chronizer's reflecting

face?

the

• Is

motor's

braking

loud?

dirt

syn

sur

(YES)

noise

(YES)

(NO)

Is adjustment at synchroniz

er

possible?

(YES)

(NO)

• Is

thread

OK?

trimming

speed

(YES)

(NO)

• Is

the

pins) in

connected?

•

Does

1-pin plug (of

the

the

thread

the

control box

(NO)

trimmer

solenoid switch ON?(YES)

(NO)

• Switch

OFF

measure

the

thread

noid.

Is

there7ohms

and

© of

the

the

the

power

resistance

trimmer

between

12-pin?

and

sole

(NO)

•

Does

the

8A

fuse

(at

topofthe

circuit board)

mal?

• Is

the

OK?

control printed-

appear

speed

at low

nor

(NO)

speed

(NO)

• Is the synchronizer OK?

(NO)

(YES)

PROBABLE

Synchronizer

installation

position is not good.

Synchronizer

malfunction.

Control printed-circuit board

malfunction.

Insufficient

V-belt

Malfunction of

nizer.

Reduced motor braking

force.

Malfunction of

nizer.

Malfunction

of

printed-circuit board.

Poor position of needle (low

er) stop.

Reduced motor braking

force.

Low

speedistoo

Malfunction

printed-circuit

12

Improper

connectionofthe

1-pin plug.

Malfunction

thread

Malfunction

related

trimming.

printed-circuit board.

of

Malfunction

trimmer

of

solenoid.

O

8A

fuse

the

Speed

fast.

failure.

at low

Improper installation of

synchronizer.

Malfunction

of

printed-circuit board.

CAUSE

the

the

the

of

board.

of

the

speed

the

tension.

synchro

synchro

control

fast.

control

to

head

control

thread

is too

control

Position

Replace

Replace

Adjust

Replace

Adjust

ance.

Replace

Replace

Adjust

18—22

Replace

Adjust VR LOW

Replace

Connect

rectly.

Adjust.

Replace

Replace

solenoid.

Replace

Adjust VR LOW

the

Replace

Replace

REMEDY

adjustment;

the

synchronizer.

the

control box.

the

V-belt tension.

the

synchronizer.

the

motor

the

synchronizer.

the

control box.

needle

(lower)

mm.

the

motor.

the

control box.

the

1-pin plug cor

the

control

the

thread

the

8A fuse.

the

synchronizer.

the

control box.

brake

and

and

0.5

mm

clear

stop

by

TVR.

box.

trimmer

TVR.

-30-

Page 33

ITEM

#14

#15

#16

#17

#18

#19

PROBLEM

Needle

(upper)

stops

at various places.

The

stop

needle

position of

(upper) is

the

not good.

Thread

function.

Thread

tion

function.

backtack.

timeistoo

Reverser

(when

pressed

is

switched

Does

wiper

doesn't

wiper

opera

short.

doesn't

treadieisde

and

actuator

ON)

not

forward

CHECKING

• Is

the

• Is

there

scratches,

chronizer's

face?

PROCEDURES

V-belt

oil,

etc.onthe

reflecting

loose?

grease,

(YES)

dirt

syn

sur

(YES)

(NO)

• Are

the

speed

and

torque

at low

speed

OK? (NO)

(YES)

•

Can

at

the

adjustment

synchronizer?

be

made

(YES)

(NO)

• Switch OFF the power

switch

and

then

measure

the

resistanceofthe

wiper

• Is

there5ohms

and

O of

solenoid.

the

thread

between

12-pin?

(NO)

(YES)

•

Other

than

above.

•

Can

the

reverser be

atedbythe

reverse

oper

lever?

(NO)

• Switch OFF the power

switch

and

then

measure

of

the

between

• Is

the

verse

resistance