Broan QP136SS, QP130SS, QP130SSC, QP130WWC, QP130BLC User Manual

...

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

EVOLUTIONTM 1

QP130, QP136 Series Range Hoods

READ AND SAVE THESE INSTRUCTIONS

FOR DOMESTIC COOKING ONLY

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring (including switch location) must be done by a qualified person(s) in accordance

with all applicable codes and standards, including fire-rated

construction.

4. Provide sufficient air for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the combustion equipment

standards such as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE),

and local codes.

5. This product may have sharp edges. Be careful to avoid cuts

and abrasions during installation and cleaning.

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. Use only metal

9. Do not use this fan with any solid-state speed control device.

10. As an alternative, this product may be installed with the ULapproved cord kit designated for the product, following instructions packed with the cord kit.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

3. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for

the size of the surface element.

Installer: Leave this manual with the homeowner.

Homeowner: Cleaning, Maintenance and Operating

ductwork.

instructions on page 2.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal t ray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — Yo u may be burned or

spread the fire.

3. DO NOT USE WATER, including wet dishcloths or towels violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. Yo u can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. F o r indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced impeller, keep drywall spray, construction dust, etc.,

off power unit.

4. Do not use over cooking equipment greater than 60,000

BTU/hr. as the blower motor will shut down intermittantly.

5. Your hood motor has a thermal overload which will automatically shut off the motor if it becomes overheated. The motor

will restart when it cools down. If the motor continues to shut

off and restart, have the hood serviced.

6. The top of the hood MUST NOT BE LESS than 24” and at a

maximum of 30” above cooktop for best capture of cooking

impurities.

7. This hood is not intended to be used as a shelf.

8. Please read specification label on product for further information and requirements.

NOTE If hood is to be installed non-ducted:

Purchase a set of (2) non-ducted filters from your

local distributor or retailer and attach them to the

aluminum mesh filters.

Register your product online at: www.broan.com/register

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

Page 2

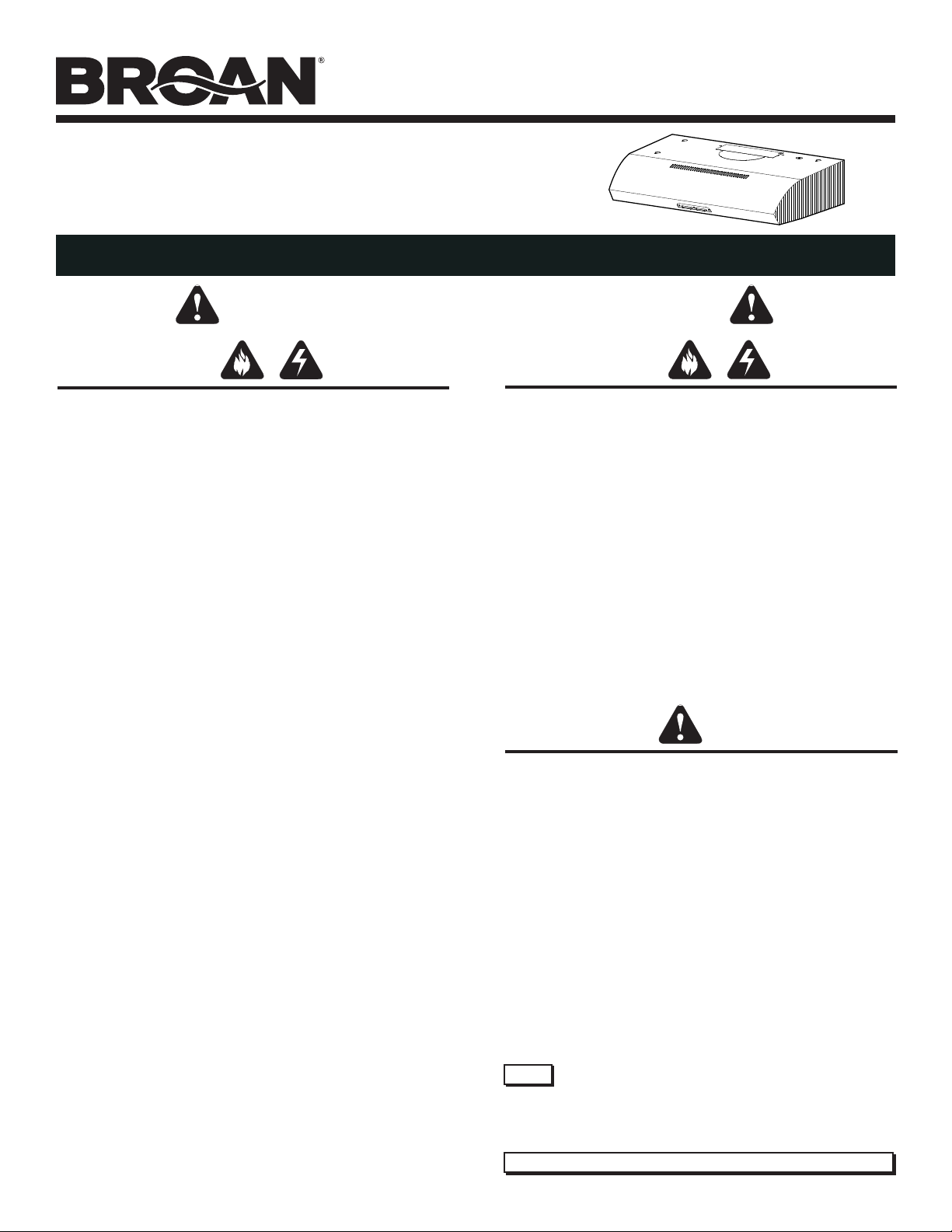

CONTENTS

INCLUDED WITH THE HOOD:

(1) 3¼” X 10”

DAMPER / DUCT

CONNECTOR

(2)

GREASE

FILTERS

(1) 7” ROUND

DUCT

CONNECTOR

(1) PARTS BAG CONTAINING:

(3)

WIRE

NUTS

(9)

#8 X 1/4”

DUCT

CONNECTOR

SCREWS

(1)

BULB

SUCTION

CUP TOOL

(5)

#10 X 5/8”

RD. HD.

MOUNTING

SCREWS

CLEANING & MAINTENANCE

For performance, appearance, and health reasons, clean filter,

fan and grease-laden surfaces. Use only a clean cloth and mild

detergent solution on stainless and painted surfaces.

Clean all-metal filters in the dishwasher using a non-phosphate

detergent. Discoloration of the filter may occur if using phosphate

detergents, or as a result of local water conditions - but this will

not affect filter performance. This discoloration is not covered by

the warranty.

Clean the non-duct recirculating filter surfaces frequently with

a damp cloth and a mild detergent. DO NOT immerse filters in

water or put in dishwasher. The special “Clean Sense” feature

indicates when the filter is to be replaced. The blue and yellow

strips will blend to green when it is time to change the filter. The

“Clean Sense” feature works best when facing toward the cooking surface. Change the non-duct recirculating filters every 6

months. For replacement non-duct recirculating filters - purchase

S99010353 or Model BPPF30 for 30” hoods, or S99010354 or

Model BPPF36 for 36” hoods.

The motor is permanently lubricated and never needs oiling. If

the motor bearings make excessive or unusual noise, replace

the motor with the exact service motor. The impeller should also

be replaced.

V, 35

Use 120

Purchase bulbs separately.

W, shielded halogen bulbs - MR16 with GU10 base.

OPERATION

Always turn the hood ON before cooking in order to establish an

air flow in the kitchen. After turning off the range, let the hood run

for a few minutes to clear the air.

Operate the hood as follows:

1 20

BLOWER SWITCH

This 3-position rocker switch turns blower ON and OFF and

controls blower speed.

Left rocker position (0) turns blower OFF.

Center rocker position (1) turns blower ON to low speed.

Right rocker position (2) turns blower ON to high speed.

LIGHT SWITCH

This 3-position rocker switch turns lights ON and OFF and controls

their intensity.

Left rocker position (0) turns lights OFF.

Center rocker position (1) turns lights ON to low intensity.

Right rocker position (2) turns lights ON to high intensity.

NOTE:

This hood utilizes an offset blower design to achieve greater

performance and lower sound levels. As a result, you may notice

that cooking impurities are more attracted to one side or appear

to be pulled-in faster than they appear on the opposite side. This

is completely normal. The hood has been designed and tested to

provide good capture of cooking impurities and odors under all

normal cooking conditions regardless of the cooking location on the

cooktop. Please note that cooking on the rear burners will always

result in the best capture results, regardless of the hood design.

1 20

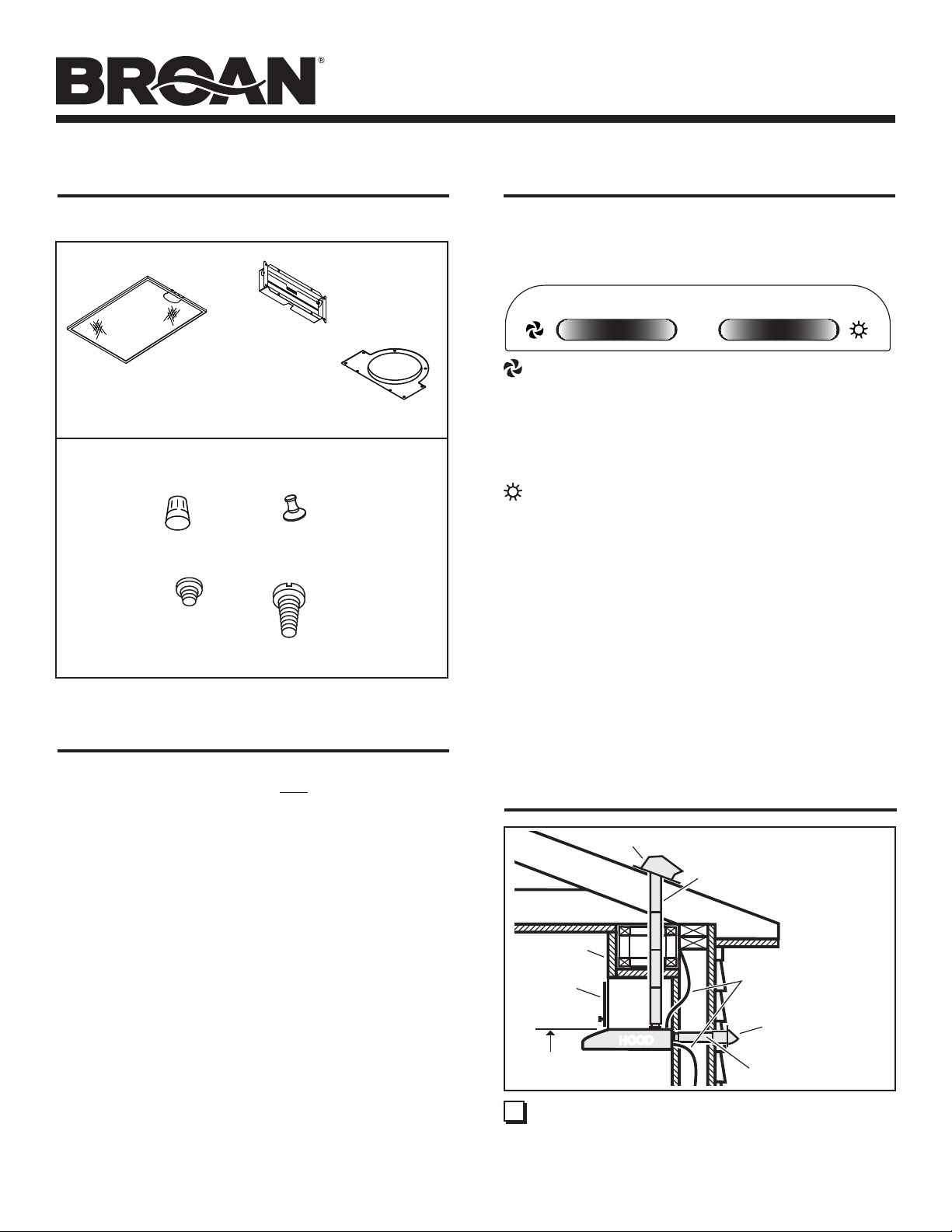

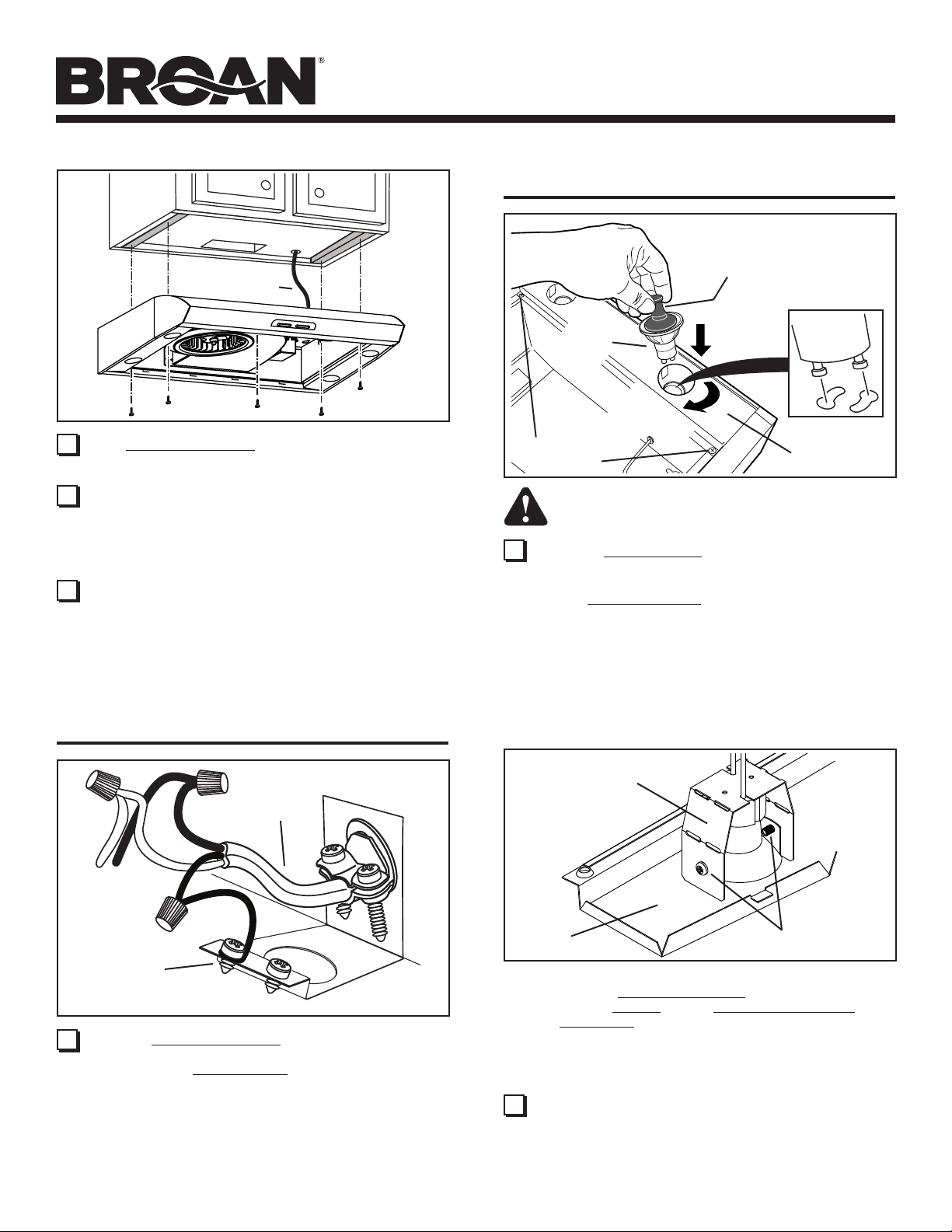

PREPARE HOOD LOCATION

ROOF CAP

SOFFIT

CABINET

HOODHOOD

24" - 30" ABOVE

COOKING SURFACE

1 Determine whether hood will discharge vertically (3¼”

x 10” or 7” Round), or horizontally (3¼” x 10” only). For

vertical or horizontal discharge, run ductwork between

the hood location and a roof cap or wall cap. For best

results, use a minimum number of transitons and elbows.

3¼" X 10" or

7" ROUND DUCT

(For vertical

discharge)

HOUSE WIRING

(Top or Back of hood)

WALL CAP

3¼" X 10" DUCT

(For horizontal discharge)

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

WOOD SHIMS

VERTICAL DUCT

ACCESS HOLE

¾"

10

7

/

8

"

5¼"

5¼"

CENTER

LINE

HOOD MOUNTING SCREWS (5)

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

WOOD SHIMS

(recessed-bottom

cabinets only)

CABINET FRONT

CABINET

BOTTOM

14

5

/

8

" (36" hood)

4½"

2

3

/

8

"

14

5

/

8

" (36" hood)

11

5

/

8

" (30" hood)

11

5

/

8

" (30" hood)

2

5

/

8

"

4

7

/

8

"

*

8

1

/

2

"

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

Page 3

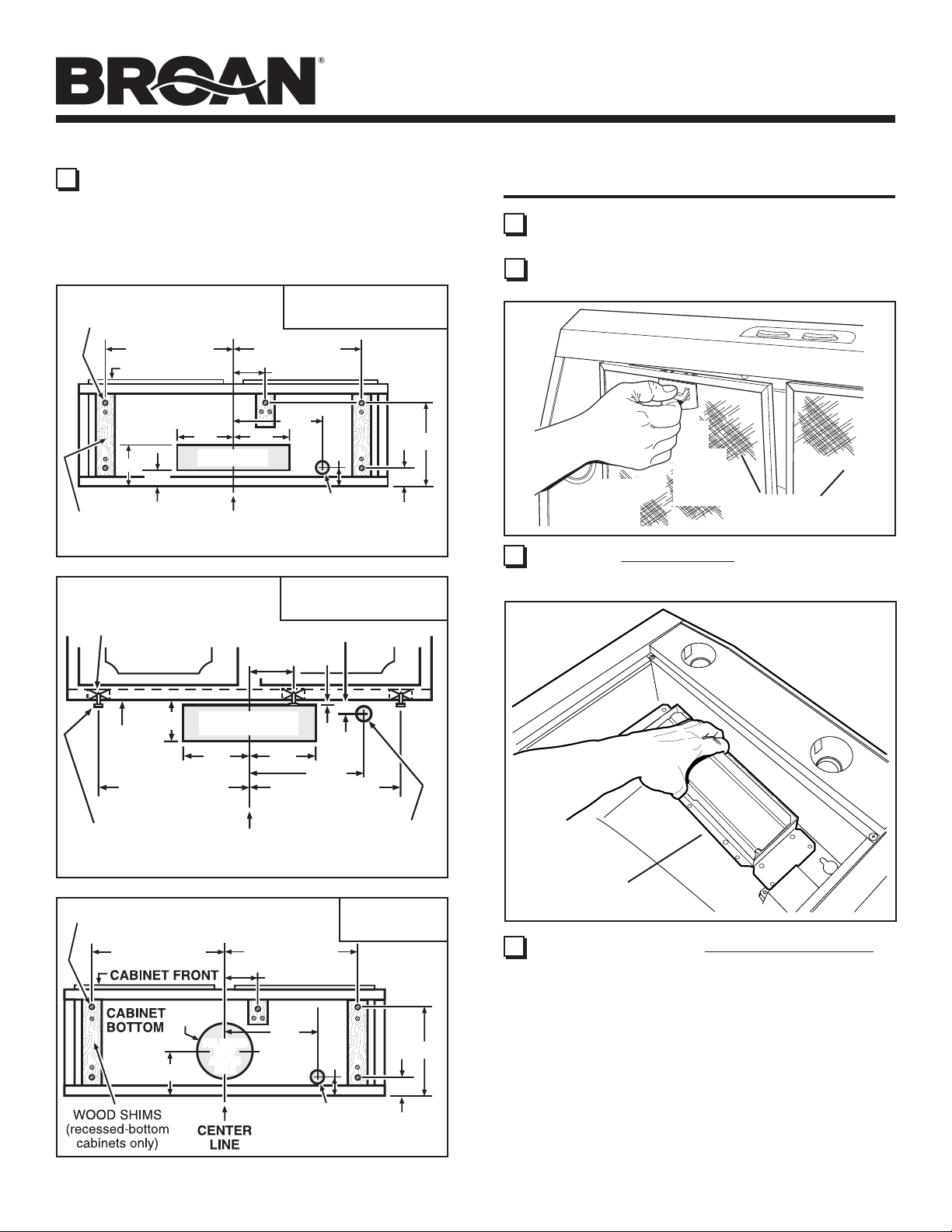

2 Use the proper diagram below, for placement of

ductwork and electrical cutout in cabinet or wall. For a

non-ducted installation, DO NOT cut a duct access hole.

Note the extra wood shim and mounting screw near

*

the cabinet front, 4-7/8” to the right of the cabinet

center line.

3¼” X 10”

VERTICAL DUCTING

3¼” X 10”

(recessed-bottom

cabinets only)

CABINET FRONT

HORIZONTAL DUCTING

1½"

7

4

3

/

8

/8"

"

*

PREPARE THE HOOD

3 Remove parts bag from inside the foam packaging end

cap.

4 Remove all protective polyfilm from the hood (stainless

steel hoods only).

è

(1)

è

(2)

LIFT

OUT

5 Remove the Aluminum Filters from the hood.

PULL

DOWN

ALUMINUM

FILTERS

CABINET

4"

BOTTOM

115/8" (30" hood)

145/8" (36" hood)

HOOD

MOUNTING

SCREWS (5)

HOOD MOUNTING SCREWS (5)

115/8" (30" hood)

14

5

/8" (36" hood)

8" DIA.

HOLE

45/8"

HORIZONTAL DUCT

ACCESS HOLE

5¼"

CENTER

LINE

115/8" (30" hood)

145/8" (36" hood)

7-IN. ROUND

7-IN. ROUND

DUCT

DUCT

ACCESS

ACCESS

HOLE

HOLE

5¼"

8½"

115/8" (30" hood)

145/8" (36" hood)

ELECTRICAL

ACCESS HOLE

(in wall)

7

/

4

"

8

*

8½"

23/8"

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

7-IN. ROUND

DUCTING

107/8"

5

2

/8"

DAMPER /

DUCT CONNECTOR

6 Remove 2 screws holding Damper / Duct Connector to

hood. Remove damper/duct connector from inside the

hood.

FOR DUCTED INSTALLATIONS - Skip to Step 9.

CENTER

RETAINING SCREW

PULL OUT

è

RECIRCULATION

SLIDE PLATE

OUTER

RETAINING SCREWS

7 NON-DUCTED INSTALLATION ONLY:

Remove Center Retaining Screw and loosen Outer

Retaining Screws holding Recirculation Slide Plate

in place. Pull out slide plate and replace and tighten

retaining screws to hold slide plate in new (non-ducted)

position.

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

Page 4

TOP/BACK

EDGE OF

HOOD

7” ROUND

DUCT

PLATE

3¼” X 10”

DAMPER /

DUCT

CONNECTOR

8 NON-DUCTED INSTALLATION ONLY:

Purchase a set of (2) non-ducted filters from your local

distributor or retailer. Attach the non-ducted filters to the

aluminum mesh filters following instructions packed with

the non-ducted filters.

FOR NON-DUCTED INSTALLATIONS - Skip to “INSTALL

THE HOOD”.

7” ROUND

KNOCKOUT

PLATE (also

remove 3¼” x 10”

vertical plate)

3¼” X 10”

VERTICAL

3¼” X 10”

HORIZONTAL

KNOCKOUT

PLATE

9 DUCTED INSTALLATION ONLY:

Remove 3¼” x 10 vertical, 3¼” x 10” horizontal, or 7-inch

round knockout plate(s) as appropriate for your ducting

method.

KNOCKOUT

PLATE

10 DUCTED INSTALLATION ONLY:

Attach 3¼” x 10” Damper/Duct Connector (if using 3¼”

x 10” duct) or 7” Round Duct Plate (if using 7-inch round

duct) over the knockout opening.

Note:

To accomodate off-center ductwork, the 3¼” x 10” damper/

duct connector can be installed up to ½” on either side

of the hood center and the 7” round duct plate can be

installed up to ½” on either side of the hood center.

Tri m the flange on the duct connector or duct plate if it

interferes with the electrical cable clamp.

Install the 3¼” x 10” Damper/Duct Connector with the

Damper Flap Pivot nearest the Top/Back Edge of Hood.

INSTALL THE HOOD

WARNING

To reduce the risk of electrical shock, switch power off

at service panel. Lock or tag service panel to prevent

power from being switched on accidentally.

ELECTRICAL

WIRING BOX

COVER

ELECTRICAL POWER

CABLE KNOCKOUT

11 Remove Electrical Wiring Box Cover from inside

of hood and appropriate Electrical Power Cable

Knockout from top or back of hood.

HOUSE

POWER CABLE

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

Page 5

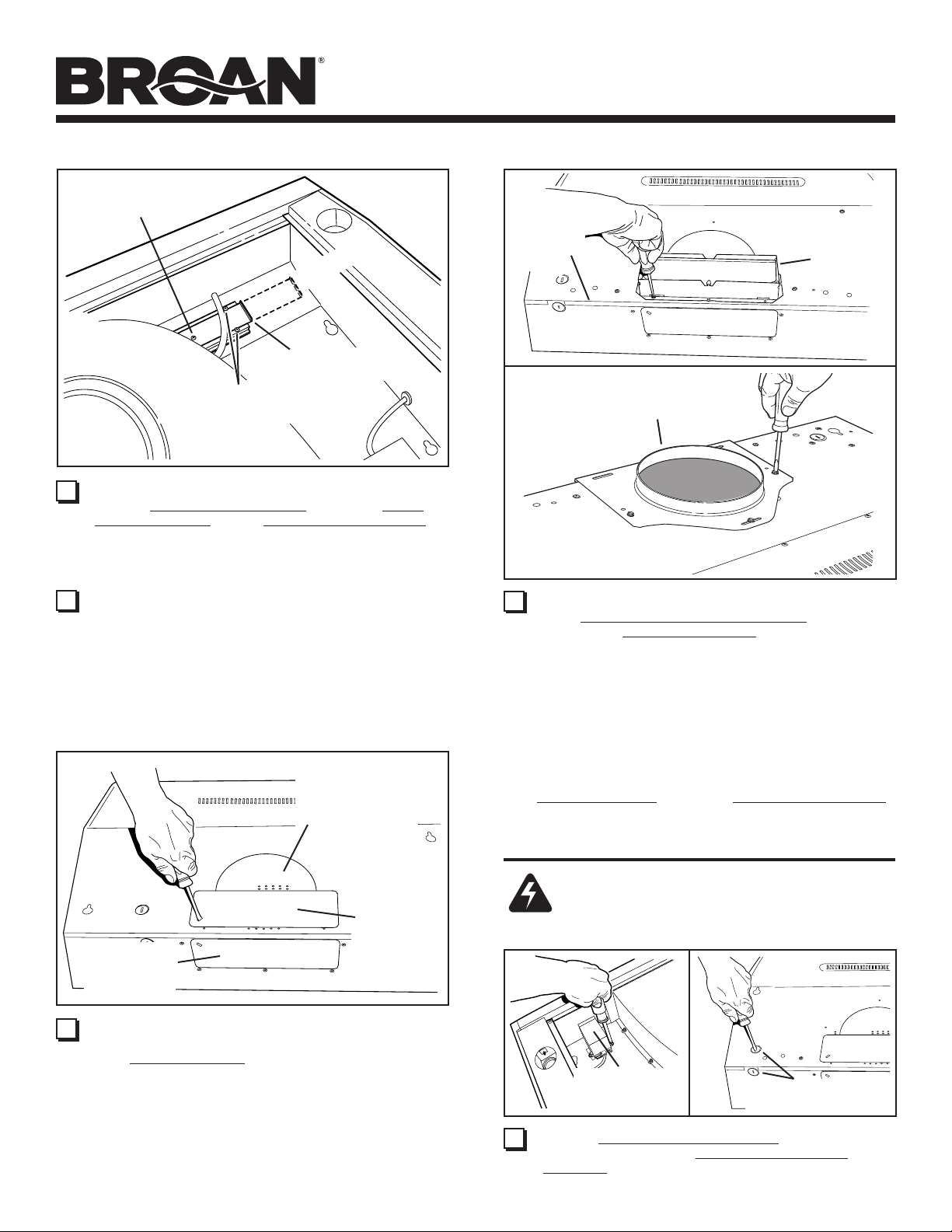

INSTALL LIGHT BULBS

SUCTION

CUP TOOL

12 Run House Power Cable between service panel

and hood location. Attach power cable to hood using

appropriate clamp.

13 Hang hood from (5) mounting screws driven part-way

into cabinet locations (shown in illustrations under

“PREPARE HOOD LOCATION”). Mounting screws are

included in parts bag. Slide hood back towards wall until

mounting screw heads are engaged in narrow end of

keyhole slots in top of hood. Tighten screws securely.

14 DUCTED INSTALLATION ONLY:

Connect ductwork to hood and use duct tape to make

joints secure and air-tight. Make sure the damper / duct

connector enters the ductwork and that the damper

opens and closes freely.

CONNECT THE WIRING

HOUSE

POWER

CABLE

HALOGEN

BULB

(2)

ROTATE

CLOCKWISE

LIGHT PANEL

SCREWS

CAUTION: Bulbs may be hot. Refer to bulb

packaging for further information.

16 Install (4) Halogen Bulbs. Use 120 V, 35 W, shielded

halogen bulbs - MR16 with GU10 base. Purchase bulbs

separately.

NOTE: Suction Cup Tool (included with hood) can be

used to install and remove light bulbs.

Align pins on bulb with large diameter opening on socket,

then push bulb in towards hood and rotate clockwise until

firmly seated.

The position of the bulb socket (depth) is adjustable and

may be necessary when:

a) certain brands of bulbs are difficult to install.

b) the bulb protrudes too far below the light panel.

LAMP SOCKET

BRACKET

(1)

PUSH IN

LIGHT PANEL

GROUND

SCREW

15 Connect House Power Cable to range hood wiring -

BLACK to BLACK, WHITE to WHITE, and GREEN or

BARE WIRE to Ground Screw. Replace electrical wiring

box cover.

LIGHT

PANEL

To change the depth of bulb sockets:

- Remove 2 Light Panel Screws. Set screws aside.

- Loosen 2 Screws holding Lamp Socket Bracket to

Light Panel.

- Adjust socket/bracket to desired depth.

- Re-tighten screws securely.

- Re-attach light panel.

17 DUCTED INSTALLATION ONLY:

Re-install aluminum filters removed in Step 5.

NON-DUCTED INSTALLATION ONLY:

Install aluminum filters and non-ducted filters - purchased

and assembled in Step 8.

SCREWS

MODELS QP130BL • QP130BLC • QP130SS • QP130SSC

QP130WW • QP130WWC • QP136BL • QP136SS • QP136WW

Page 6

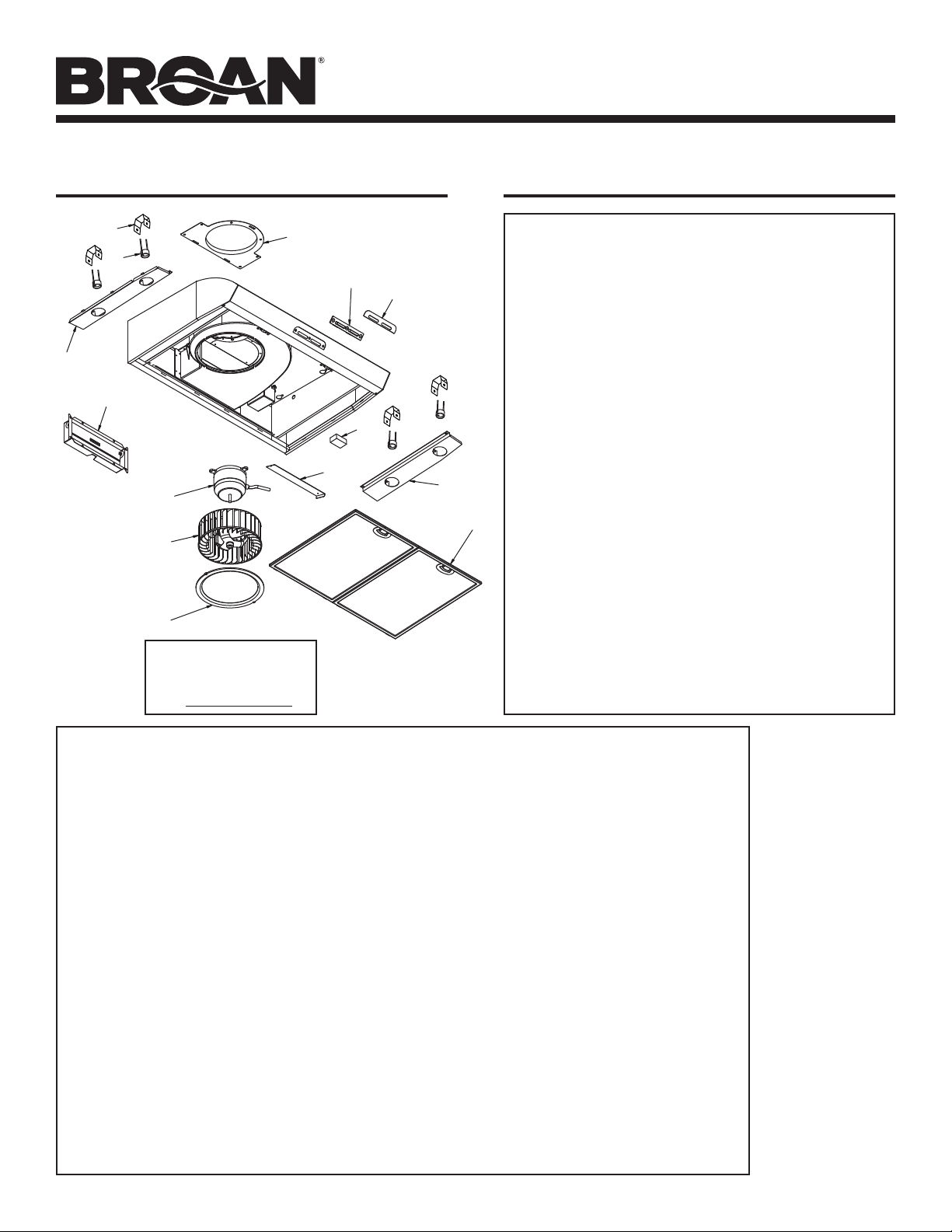

SERVICE PARTS

14

13

12

11

10

9

8

Replacement parts can

now be ordered on our

website. Please visit us

at www.broan.com

WARRANTY

1

2

3

4

5

6

Broan-NuTone warrants to the original consumer purchaser of its products

that such products will be free from defects in materials or workmanship for a

period of one (1) year from the date of original purchase. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

During this one year period, Broan-NuTone will, at its option, repair or replace,

without charge, any product or part which is found to be defective under normal

use and service. THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT

LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS, FUSES,

FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR

DUCTING. This warranty does not cover (a) normal maintenance and service

or (b) any products or parts which have been subject to misuse, negligence,

accident, improper maintenance or repair (other than by Broan-NuTone), faulty

installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one year period as specified

for the express warranty. Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROANNUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF

7

OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights, which vary from state to

state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address

or telephone number below, (b) give the model number and part identification

and (c) describe the nature of any defect in the product or part. At the time of

requesting warranty service, you must present evidence of the original purchase

date.

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario Canada

L5T 1H9 www.broan.ca 877-896-1119

One Year Limited Warranty

KEY NO. PART NO. DESCRIPTION

1 97017727 7” Round Duct Plate (includes mounting hardware)

2 97017729 Switch Assembly White (includes 2 switches, nameplate, mounting hardware)

97017730 Switch Assembly Black (includes 2 switches, nameplate, mounting hardware)

3 99526653 Nameplate, White

99526652 Nameplate, Black

4 97017736 Capacitor Kit (includes wire nuts, mounting screw)

5 97017753 Non-duct Slide, White (includes mounting hardware)

97017821 Non-duct Slide, Black (includes mounting hardware)

6 97017755 Light Panel RH White (includes mounting hardware)

97017756 Light Panel RH Black (includes mounting hardware)

97017757 Light Panel RH Stainless (includes mounting hardware)”

7 97017720 Filter Kit for 30”” Hood (2 per bag)

97017721 Filter Kit for 36”” Hood (2 per bag)

8 97017754 Venturi Ring (includes mounting hardware)

9 97017734 Blower Wheel (includes mounting nut)

10 97017732 Motor Kit (includes motor, isolators, mounting hardware)

11 97017728 Damper / Duct Connector (includes mounting hardware)

12 97017758 Light Panel LH White (includes mounting hardware)

97017759 Light Panel LH Black (includes mounting hardware)

97017760 Light Panel LH Stainless (includes mounting hardware)

13 97017731 Lamp Socket (includes lamp socket, wire nuts, mounting screws)

14 97018233 Lamp Socket Bracket (includes mounting hardware)

Not Shown 97017735 Parts Bag

Not Shown 99010353 Non-Duct Filter Kit for 30” Hood (2 charcoal filters and 8 filter clips)

Not Shown 99010354 Non-Duct Filter Kit for 36” Hood (2 charcoal filters and 8 filter clips)

Not Shown 99526707 Suction Cup Tool

Not Shown 97018234 Light Diode (includes wire nuts)

Not Shown 99526798 35W Halogen GU10 Bulb

Order replacement

parts by PA RT NO.

- not by KEY NO.

Loading...

Loading...