Broan HRVH100SE, ERVH100SE Installation Manual

VB0189

INSTALLATION GUIDE

BROAN MODELS HRVH100SE AND ERVH100SE

These products earned the ENERGY STAR® by meeting strict energy efficiency guidelines set by Natural Resources

Canada and the US EPA. They meet ENERGY STAR requirements only when used in Canada.

RESIDENTIAL INDOOR USE ONLY

! !

READ AND SAVE THESE INSTRUCTIONS

Broan-NuTone LLC; Hartford, Wisconsin www.broan.com 800-558-1711

REGISTER YOUR PRODUCT ONLINE AT: www.broan.com/register

For additional information - visit www.broan.com

99528512A

ABOUT THIS GUIDE

Please take note that this manual uses the following symbols to emphasize particular information:

!

WARNING

Identies an instruction which, if not followed, might cause serious personal injuries including possibility of death.

CAUTION

Identies an instruction which, if not followed, may severely damage the unit and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

ABOUT THESE UNITS

LIMITATION

For residential (domestic) installation only. Installation work and electrical wiring must be done by a qualied person(s) in accordance with

all applicable codes and standards, including re-rated construction codes and standards.

WARNING

!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. We recommend that your unit be inspected by a specialized technician once a year.

3. Before servicing or cleaning the unit, disconnect power cord from electrical outlet.

4. This unit is not designed to provide combustion and/or dilution air for fuel-burning appliances.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Do not use the units with any solid-state speed control device other than the corresponding ones listed below:

UNIT MAIN CONTROL AUXILIARY CONTROL

HRVH100SE AND W02BV01404SE001HVRE

7. This unit must be grounded. The power supply cord has a 3-prong grounding plug for your personal safety. It must be plugged in to a

mating 3-prong grounding receptacle, grounded in accordance with the national electrical code and local codes and ordinances.

Do not remove the ground prong. Do not use an extension cord.

8. Do not inst

9. Do not use to exhaust hazardous or explosive materials and vapors.

10. When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

11. Due to the weight of the unit, two installers are recommended to perform installation.

12. When applicable local regulations comprise more restrictiv e installation and/or certication r equirements, the aforementioned requirements

prevail on those of this document and the installer agrees to conform to these at his own expenses.

all in a cooking area or connect directly to any appliances.

CAUTION

1. To avoid prematurate clogged lters, turn OFF the unit during construction or renovation.

2. Please read specication label on product for further information and requirements.

3. Be sure to duct air outside – Do not intake/exhaust air into spaces within walls or ceiling or into attics, crawl spaces, or garage.

4. Intended for residential installation only in accordance with the requirements of NFPA 90B.

5. Do not run any air ducts directly above or closer than 2 ft (0.61 m) to any furnace or its supply plenum, boiler, or other heat producing

appliance. If a duct has to be connected to the furnace return plenum, it must be connected not closer than 9’ 10” (3 m) from this plenum

connection to the furnace.

6. The ductwork is intended to be installed in compliance with all applicable codes.

7. When leaving the house for a long period of time (more than two weeks), a responsible person should regularly check if the unit

operates adequately.

8. If the ductwork passes through

maintenance and/or repair. Also, the ambient temperature of the house should never drop below 65°F (18°C).

an unconditioned space (e.g.: attic), the unit must operate continuously except when performing

2

TABLE OF CONTENTS

1. DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

YPICAL INSTALLATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. T

2.1 FULLY DUCTED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 CENTRAL DRAW POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 SIMPLIFIED INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

3.1 INSPECT THE CONTENT OF THE BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 TOOLS AND MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 LOCATING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 PLANNING OF THE DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 INSTALLING NON-INSULATED DUCTS AND DIFFUSERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

3.5.1 FULLY DUCTED SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

3.5.2 CENTRAL DRAW POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.3 SIMPLIFIED INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.6 INSTALLING INSULATED FLEXIBLE DUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

3.6.1 CONNECTION TO THE UNIT PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6.2 CONNECTION TO TANDEM TRANSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6.3 LOCATING EXTERIOR PORTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.7 CONNECTING INSULATED DUCTS TO EXTERIOR PORTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 INSTALLING TANDEM® TRANSITION KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9 CONNECTING THE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

4.1 BOOTING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 DEFROST CYCLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 MAIN WALL CONTROL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14

4.4 WALL CONTROL(S) CONNECTION TO THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ERVICE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6. S

ROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

7. T

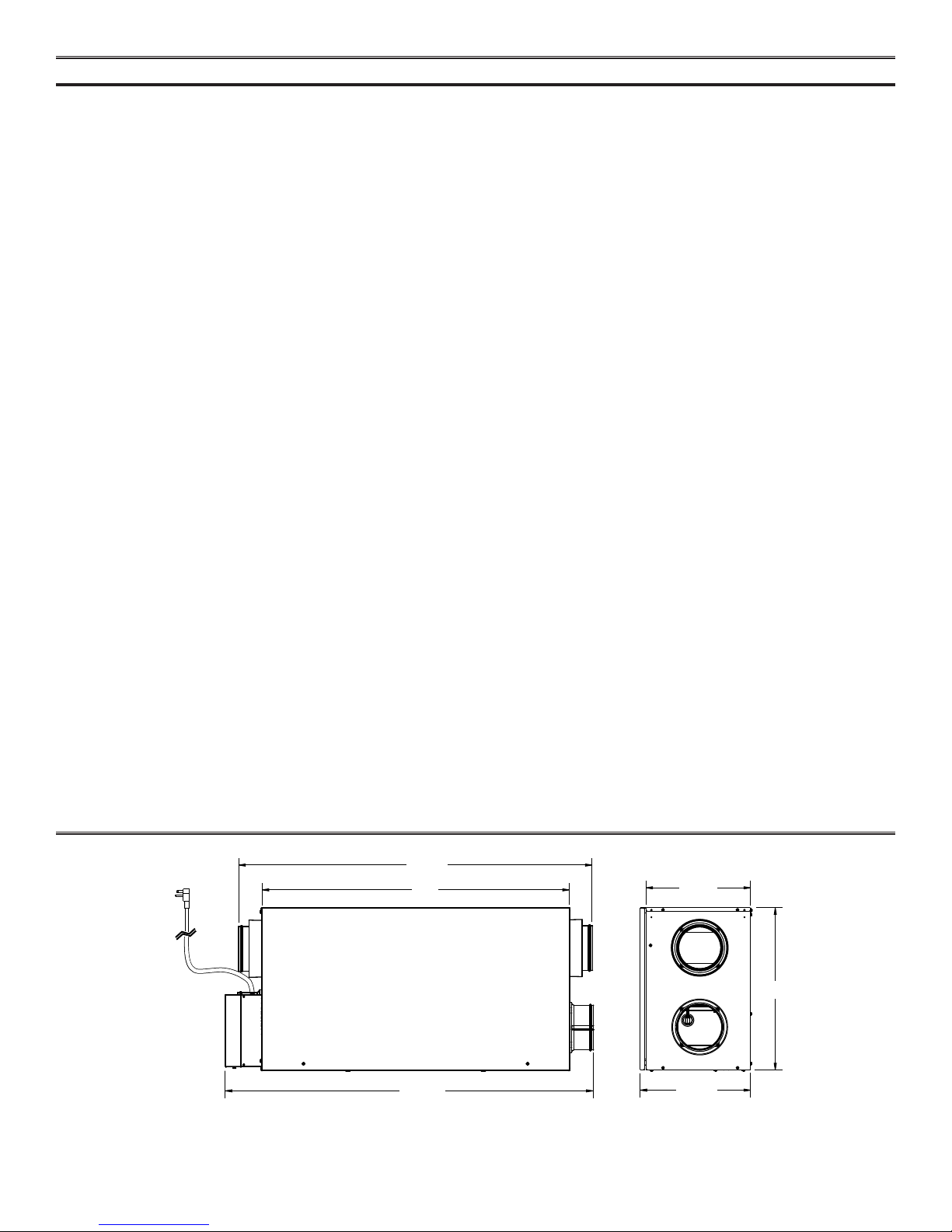

1. DIMENSIONS

VK0085A

7

37

33"

39 /8"

/8"

11 ¼"

7

/16"

17

7

/8"

11

3

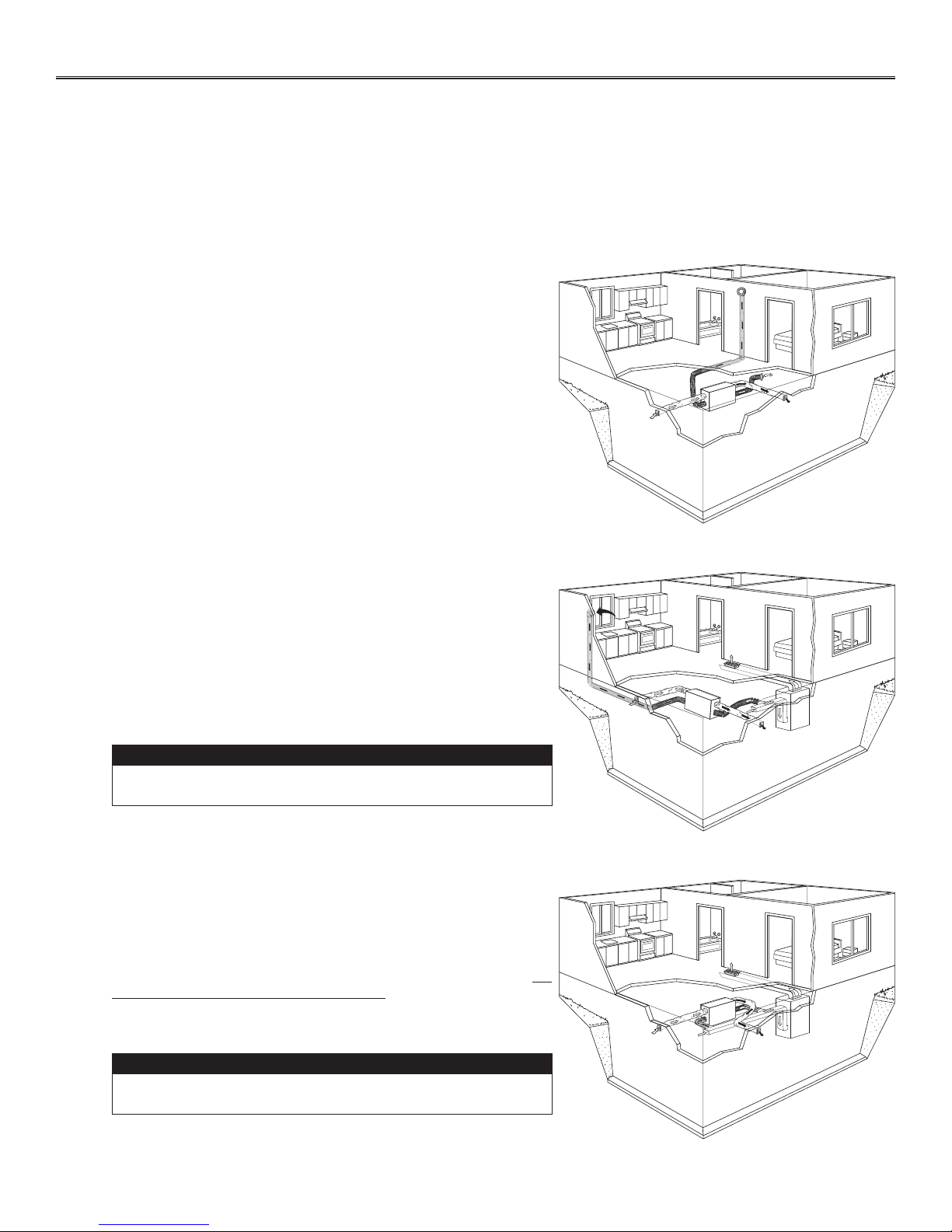

2. TYPICAL INSTALLATIONS

Use the following illustrations as guidelines to help you decide on how the unit will be installed.

All the units should be hung from the joists.

In every case, bathroom fans and a range hood could be used to exhaust stale air. Also, for homes with more than one level, we recommend

one exhaust register at the highest level.

There are 3 installation methods: Fully Ducted System, Central Draw Point and Simplified Installation.

NOTE: An electrical outlet has to be available within 3 feet of the unit.

2.1 FULLY DUCTED SYSTEM (PRIMARILY FOR HOMES WITH RADIANT HOT WATER OR ELECTRIC BASEBOARD HEATING)

Stale air coming from the register located at the highest level of the

house is exhausted to the outside. Fresh air from outside is filtered and

supplied by the register located in the lowest liveable level.

Homes with more than one level require at least one exhaust register at

the highest level.

See figure at right.

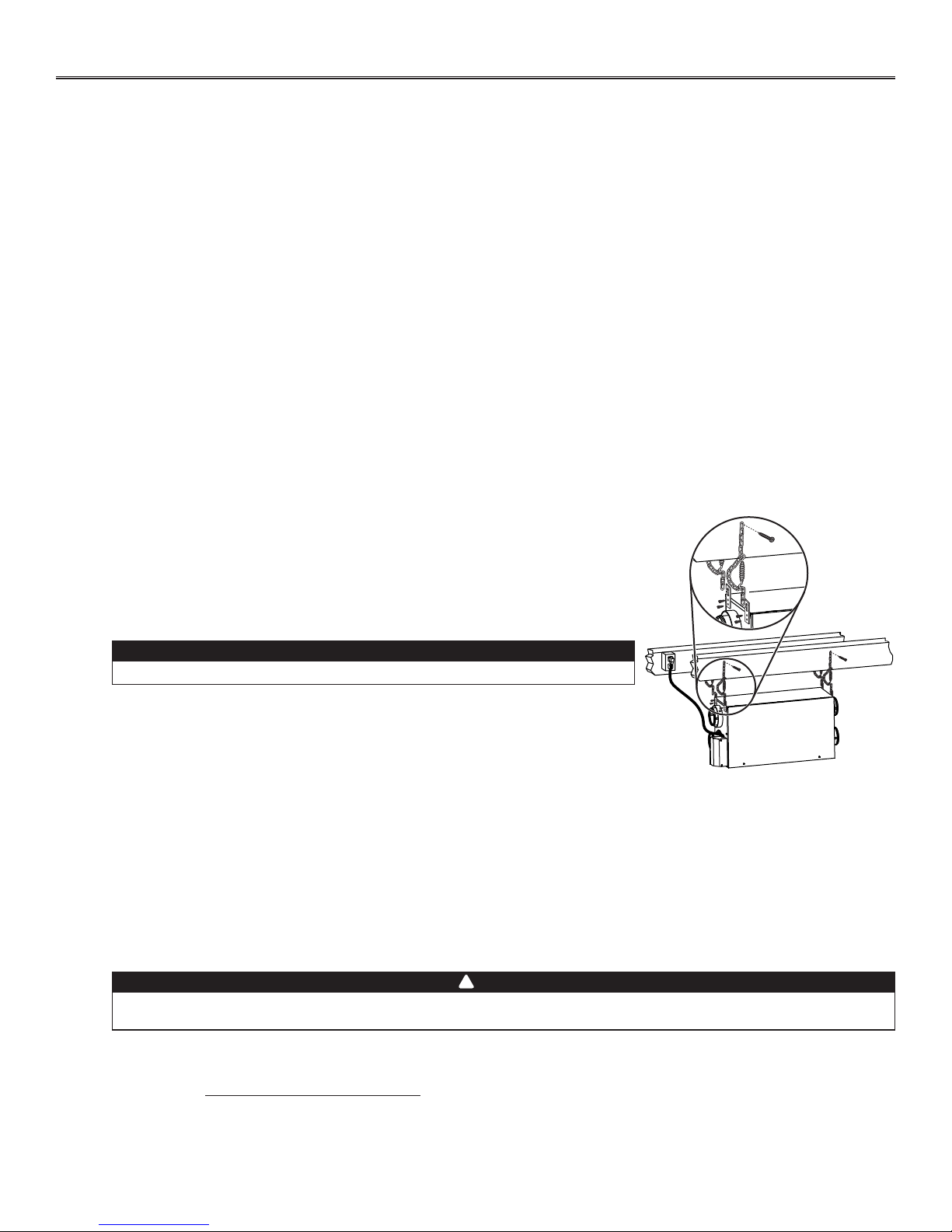

2.2 CENTRAL DRAW POINT (CONNECTION TO A FORCED AIR SYSTEM)

Stale air coming from the register located at the highest level of the

house is exhausted to the outside. Fresh air from outside is filtered and

supplied to the return (plenum) of the forced air unit. See figure at right.

For this type of installation, it is not essential that the forced air system

blower runs when the unit is in operation, but we recommend it.

NOTE: Home with multiple forced air systems should have one unit on

each system.

CAUTION

Do not connect the unit to any forced air system supply

duct.

2.3 SIMPLIFIED INSTALLATION (CONNECTION TO A FORCED AIR SYSTEM)

Stale air is exhausted to the outside. Fresh air from outside is filtered and

supplied to the return (plenum) of the forced air unit.

See figure at right.

To avoid cross-contamination and achieve the highest efficiencies, the

forced air system blower must always be ON.

NOTE: Home with multiple forced air systems should have one unit on

each system.

VH0091

VH0092

CAUTION

Do not connect the unit to any forced air system supply

duct.

VH0093

4

3. INSTALLATION

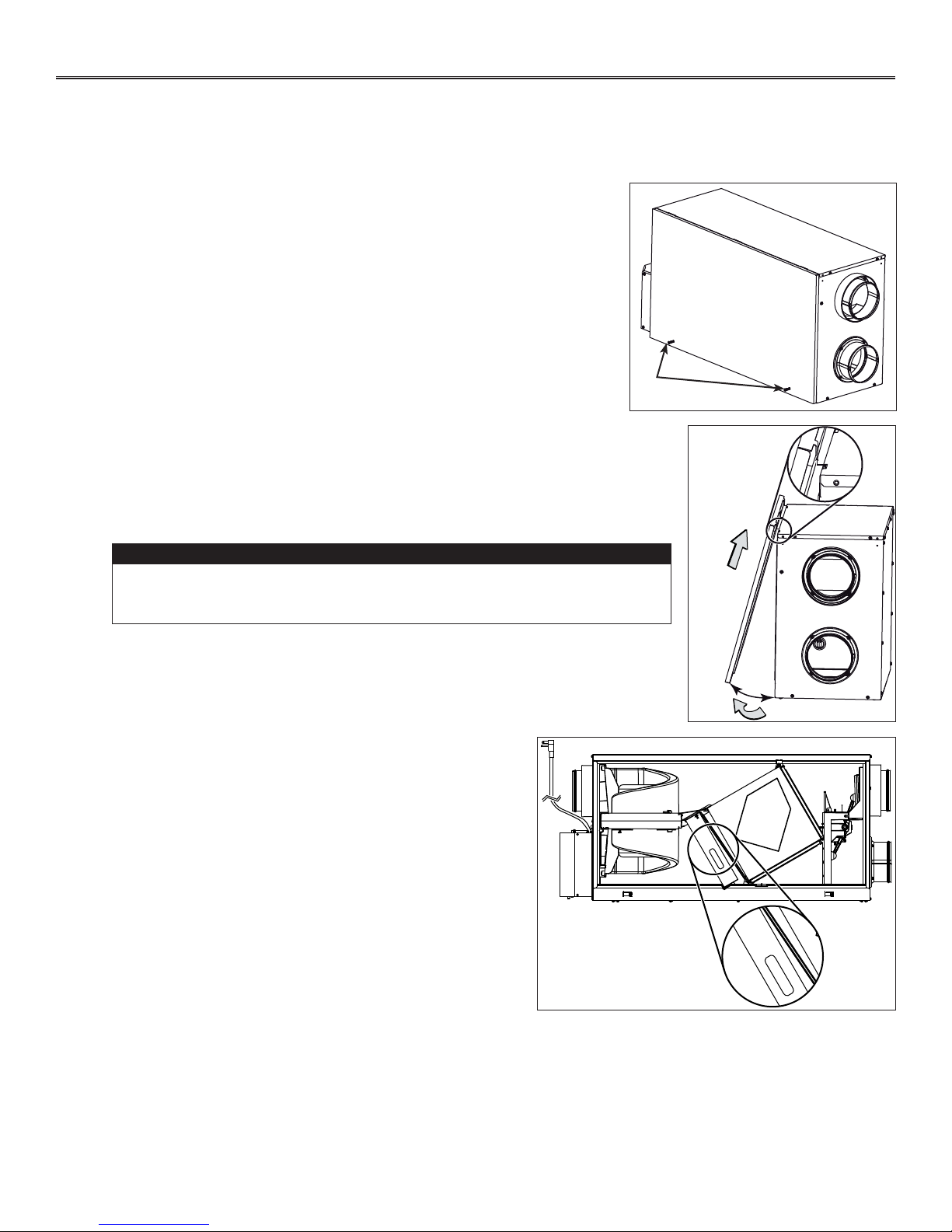

3.1 INSPECT THE CONTENT OF THE BOX

NOTE: Before proceeding to the installation, check the content of the box. If items are missing or damaged, contact the

manufacturer. Remove all packaging material from the unit.

• Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, ports, power cord, etc.

• Using a Phillips or a Robertson screwdriver, loosen both door screws (A).

NOTE: The screws will stay attached to the door.

A

VD0302

• Open (B) and lift out (C) the door.

CAUTION

In order to prevent damages to the door hooks, do not open completely the

unit door; tilt it about 3” from the unit base and lift it up. See illustration at

right.

• Remove the transport tape over the heat or energy recovery core

of the unit.

• Inspect the inside of the unit for damage. Ensure that blower

assembly, heat or energy recovery core, core filters, insulation,

dampers, prefilter and HEPA filter, etc. are all intact, then reinstall

the door.

NOTE: Write the installation date on the HEPA filter frame for future

reference (see illustration at right).

C

B

VD0303A

TOP

DESSUS

FRONT

AVANT

Instal. date:

Date d’instal. :

__ / __ / ____

±3”

21293

FRONT

AVANT

Instal. date:

Date d’instal. :

__ / __ / ____

VD0322

5

3. INSTALLATION (CONT’D)

3.2 TOOLS AND MATERIAL

Following are the tools and material needed:

• Phillips no. 2 or Robertson no. 2 screwdriver

• Small flat blade screwdriver (for wall control connection)

• Wire stripper (for wall control connection)

• Hammer and flat blade screwdriver (for plenum connection installation only, to make holes in existing metal duct)

• Scissors or utility knife (to cut duct tape)

• Measuring tape

• Duct tape

• Tin snips or metal shear (for plenum connection installation only, to cut ductwork)

• Aluminum duct tape (for plenum connection installation only)

• Jig saw

• Caulking gun and caulking.

3.3 LOCATING THE UNIT

Choose an appropriate location for the unit.

• Within an area of the house where the ambient temperature is kept between 50°F (10°C) and 104°F (40°C).

• Away from living areas (dining room, living room, bedroom), if possible.

• So as to provide easy access to the interior of the unit, for maintenance.

• Close to an exterior wall, so as to limit the length of the insulated flexible duct to and from the unit.

• Away from hot chimneys and other fire hazards.

• Allow for a power source (standard 3-prong grounding outlet).

• FOR HRV UNITS ONLY: Close to a drain. If no drain is close by, use a pail to collect

run-off.

Hang the unit with the four hooks, chains and springs provided. See illustration at right.

CAUTION

Make sure the unit is level.

3.4 PLANNING OF THE DUCTWORK

• Keep it simple. Plan for a minimum of bends and joints.

• Keep the length of insulated ducts to a minimum.

• Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or a range hood. This

would cause clogging of the filters and recovery module.

• If the house has two floors or more, be sure to plan for at least one exhaust register on the highest lived-in level.

3.5 INSTALLING NON-INSULATED DUCTS AND DIFFUSERS

3.5.1 FULLY DUCTED SYSTEM (AS ILLUSTRATED IN SECTION 2.1)

Never install a stale air exhaust diffuser in a closed room where a combustion device operates, such as a

gas furnace, a gas water heater or a fireplace.

Stale air exhaust ductwork

• Install the stale air exhaust diffuser in the main area where the contaminants are produced: kitchen, living room, etc. Position

the diffuser as far from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in the house.

If desired, you can install another diffuser (sold separately).

• If a diffuser is installed in the kitchen, it must be located at least 4 feet (1.2 m) from the range.

• Install the diffuser 6 to 12 inches (152 to 305 mm) from the ceiling on an interior wall OR install it in the ceiling.

!

WARNING

VD0305

6

3. INSTALLATION (CONT’D)

3.5 INSTALLING NON-INSULATED DUCTS AND DIFFUSERS (CONT’D)

3.5.1 F

ULLY DUCTED SYSTEM (AS ILLUSTRATED IN SECTION 2.1) (CONT’D)

Fresh air distribution ductwork

• Install the fresh air distribution diffuser in a large, open area in the lowest level to ensure the greatest possible air circulation.

• Keep in mind that the fresh air diffuser must be located as far as possible from the stale air diffuser. If desired, you can install

another diffuser.

• Install the diffuser either in the ceiling OR 6 to 12 inches (152 to 305 mm) from the ceiling on an interior wall. (The cooler air

will then cross the upper part of the room and mix with room air, before descending to occupant’s level.)

• If a register must be floor installed, direct the airflow up the wall.

HOW TO CONNECT THE FLEXIBLE DUCTS TO THE DIFFUSERS

Once the diffusers location is determined, cut out 5¼” diameter hole.

Run one end of the flexible duct through the hole and fix it to the diffuser base (1),

using a tie wrap and duct tape. Assemble the diffuser base to the wall (or ceiling)

using its 4 no. 8 x 3/4” screws. Then, slide in the diffuser (2).

See illustration at right.

Ø 5¼”

VJ0094A

1

2

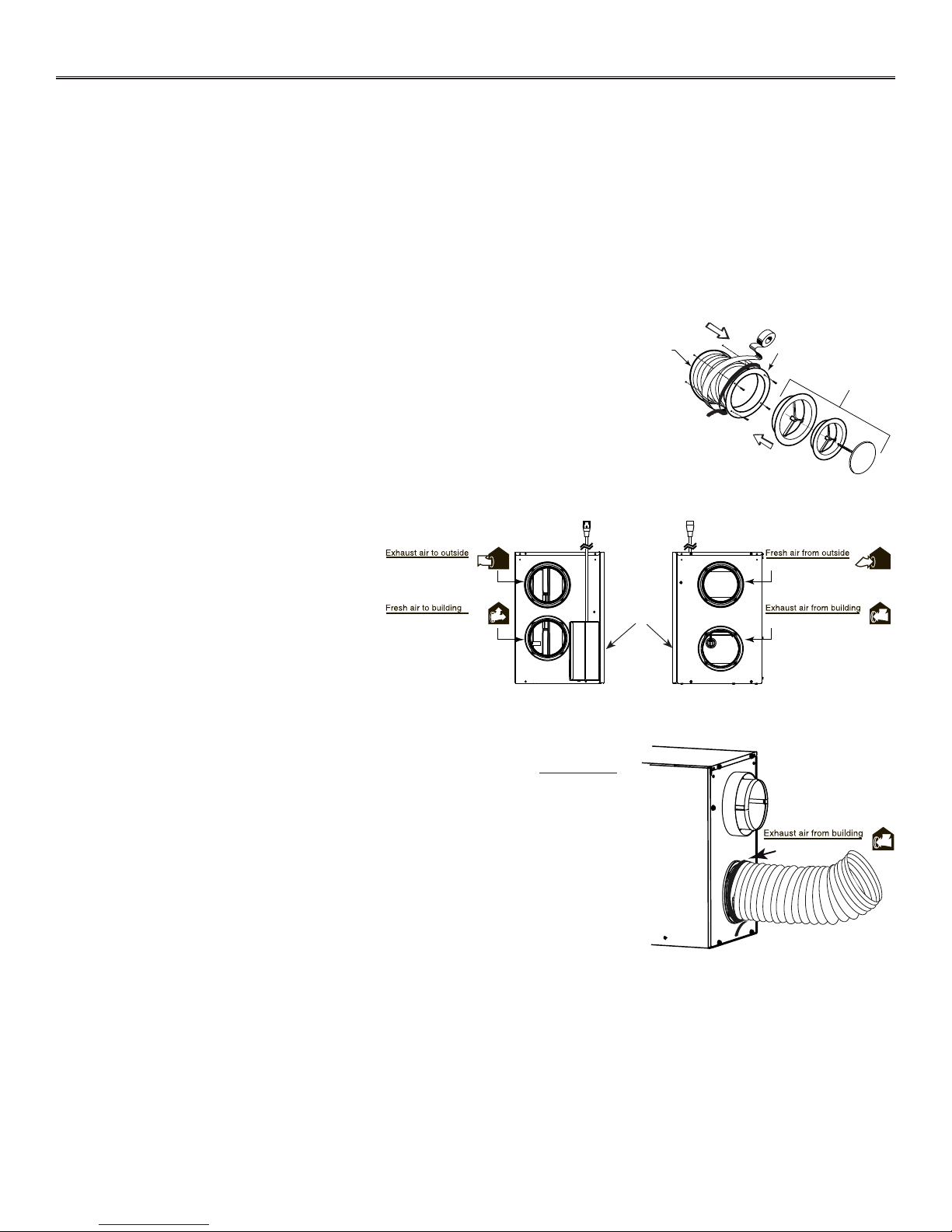

UNIT PORTS IDENTIFICATION

Aire de salida hacia el exterior

Each unit port has an identification label

beside it to avoid wrong duct connections to

the unit. Always refer to these labels before

Aire fresco hacia el interior

DOOR

performing any duct and port connection.

VJ0106

HOW TO CONNECT THE FLEXIBLE DUCTS TO THE UNIT PORTS

Both flexible ducts attached to the diffusers must be connected to the bottom ports of

the unit. When facing the unit door, the fresh air to building port is located on left side

and the exhaust air from building port is on the right side. Refer to the identification

labels affixed beside each unit ports. Using tie wrap, attach the fresh air to building

duct to its corresponding port, then do the same for the exhaust air to building duct

and port. See illustration at right.

NOTE: Use an insulated duct if the duct will have to go through a space where it is

possible to experience extreme temperature conditions (eg: in northern area,

unheated attic in winter or uncooled attic in southern area). Also, if you plan

to stop the unit for more than 12 hours, we recommend to cover the duct with

R12 insulation.

Aire fresco desde el exterior

UNIT

Aire de salida desde el interior

RIGHT SIDE OF THE UNIT

Aire de salida desde el interior

VJ0107

7

3. INSTALLATION (CONT’D)

3.5 INSTALLING NON-INSULATED DUCTS AND DIFFUSERS (CONT’D)

3.5.2 C

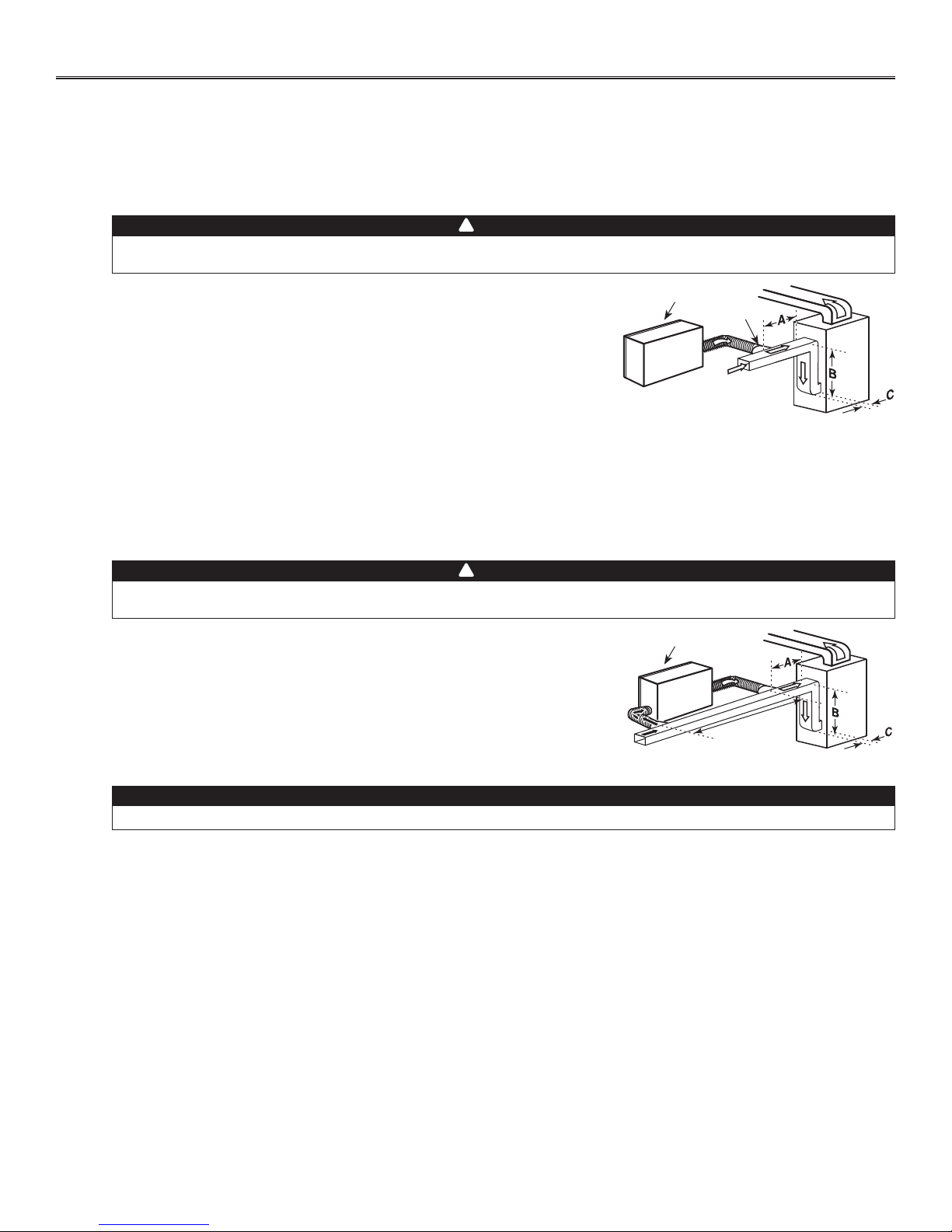

ENTRAL DRAW POINT (AS ILLUSTRATED IN SECTION 2.2)

Stale air exhaust ductwork

Same as for Fully Ducted System, described in step 3.5.1

Fresh air distribution ductwork

When performing duct connections, always use approved tools and materials. Respect all corresponding

laws and safety regulations. Please refer to your local building code.

• Locate the opening for fresh air ductwork on the forced air unit return duct

at a minimum linear distance of 9’ 10” (3 m) upstream (from forced air unit drop:

A+B+C). Cut out a 5” Ø hole in this location, using metal shear.

• Use a metal transition (not included, available in hardware store) to connect the

unit duct to the forced air unit return duct.

• Attach the other end of the flexible duct to the Fresh air to building port (see

icon on the left side of the unit). Use tie wrap and duct tape to seal the connection.

See illustration at right.

3.5.3 S

IMPLIFIED INSTALLATION (AS ILLUSTRATED IN SECTION 2.3)

Fresh air distribution ductwork (return side connection)

Same as for Central Draw Point, described in step 3.5.2

!

WARNING

U

VJ0099

NIT DOOR

TRANSITION

A + B + C = NOT LESS

THAN 9’ 10” (3 M)

METAL

Stale air exhaust ductwork (return side connection)

!

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding

laws and safety regulations. Please refer to your local building code.

• Locate the opening for stale air ductwork on the forced air unit at least 3’ (0.9 m)

from fresh air ductwork connection. Cut out a 5” Ø hole in this location, using

metal shear.

• Use a steel transition (not included, available in hardware store) to connect the

unit duct to the forced air unit return duct.

• Attach the other end of the flexible duct to the Exhaust air from building port

(see icon on the right side of the unit). Use tie wrap and duct tape to seal the

connection. See illustration at right.

VJ0109

UNIT DOOR

3’ (0.9 M)

MINIMUM

A + B + C = NOT LESS

THAN 9’ 10” (3 M)

CAUTION

The furnace blower must be running when the ventilation unit is in operation.

8

3. INSTALLATION (CONT’D)

3.6 INSTALLING INSULATED FLEXIBLE DUCTS

Make sure the vapor barrier on the insulated ducts does not tear during installation to avoid condensation

within the ducts.

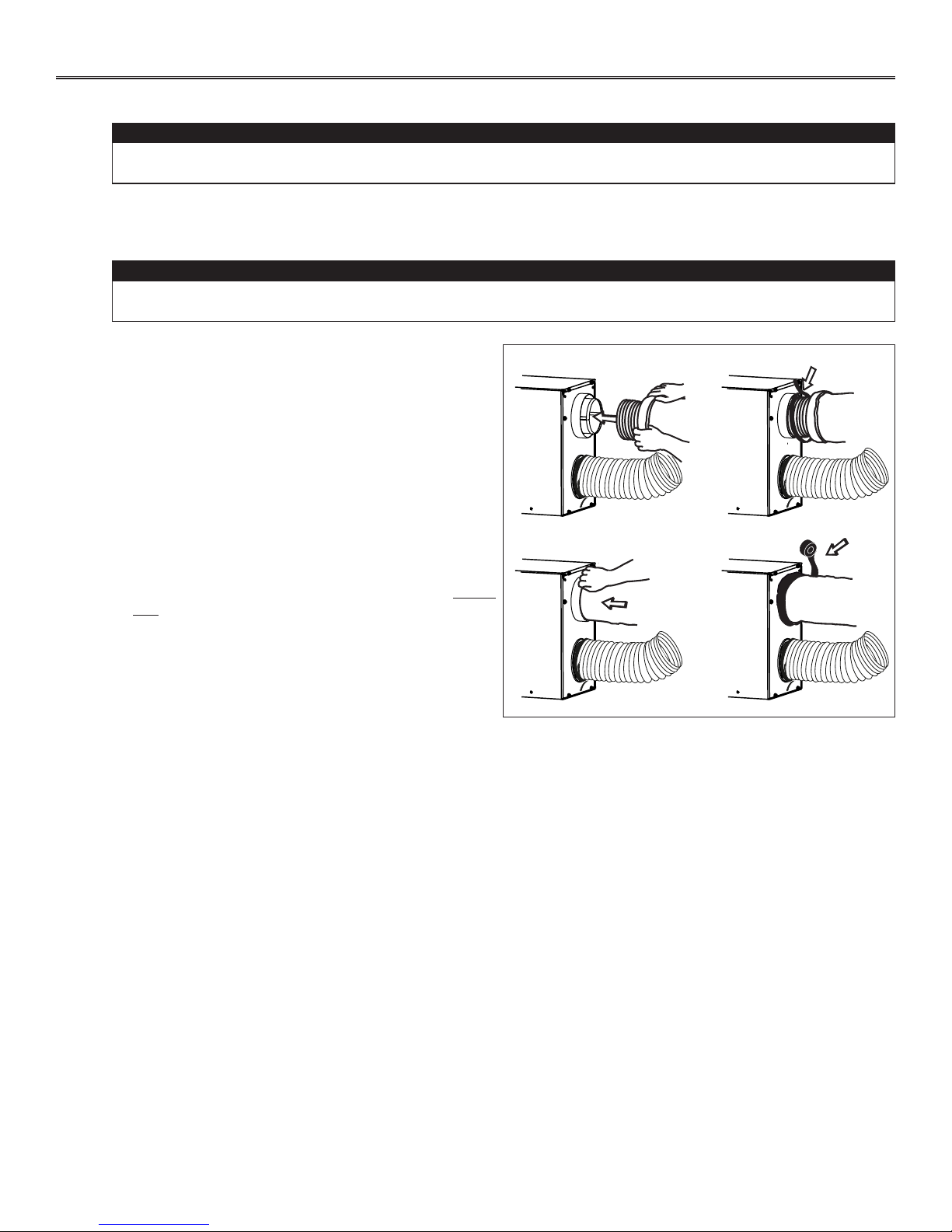

3.6.1 C

ONNECTION TO THE UNIT PORTS

Use the following procedure for connecting the insulated flexible ducts to the unit ports (exhaust air to outside and fresh air from

outside). Refer to identification labels beside ports before performing any duct and port connection.

Avoid compressing the insulation pulling the tape tightly around the joint. Compressed insulation loses its

insulation properties and causes water dripping due to condensation on the exterior surface of the duct.

For both remaining ducts, pull back the insulation to expose

the interior flexible duct.

Connect the interior flexible duct to the smaller part of the

inner ring of the port using a tie wrap.

Pull the insulation over the joint and tuck it between the

inner and outer rings of the port. Pull the vapor barrier over

the insulation and over the outer ring of the port.

Apply duct tape gently to the joint in order to make an airtight

seal. See figures at right.

CAUTION

CAUTION

VJ0102

9

3. INSTALLATION (CONT’D)

3.6 INSTALLING INSULATED FLEXIBLE DUCTS (CONT’D)

OCATING EXTERIOR PORTS

3.6.2 L

Choose an appropriate location for installing the exterior ports:

• There must be a minimum distance of 6’ (1.8 m) between the hoods to avoid cross-contamination

• There must be a minimum distance of 18” (457 mm) from the ground

Make sure the fresh air intake port is located at least 6 feet (1.8 m) away (or more, as per applicable building

codes or standards) from sources of contamination such as:

• Dryer exhaust, high efficiency furnace vent, central vacuum vent

• Gas meter exhaust, gas barbecue grill

• Garbage bin

• Any exhaust from a combustion source

!

WARNING

STALE AIR

EXHAUST PORT

FRESH AIR

INTAKE PORT

18’’

(457 MM)

6’

(1.8 M)

VD0203

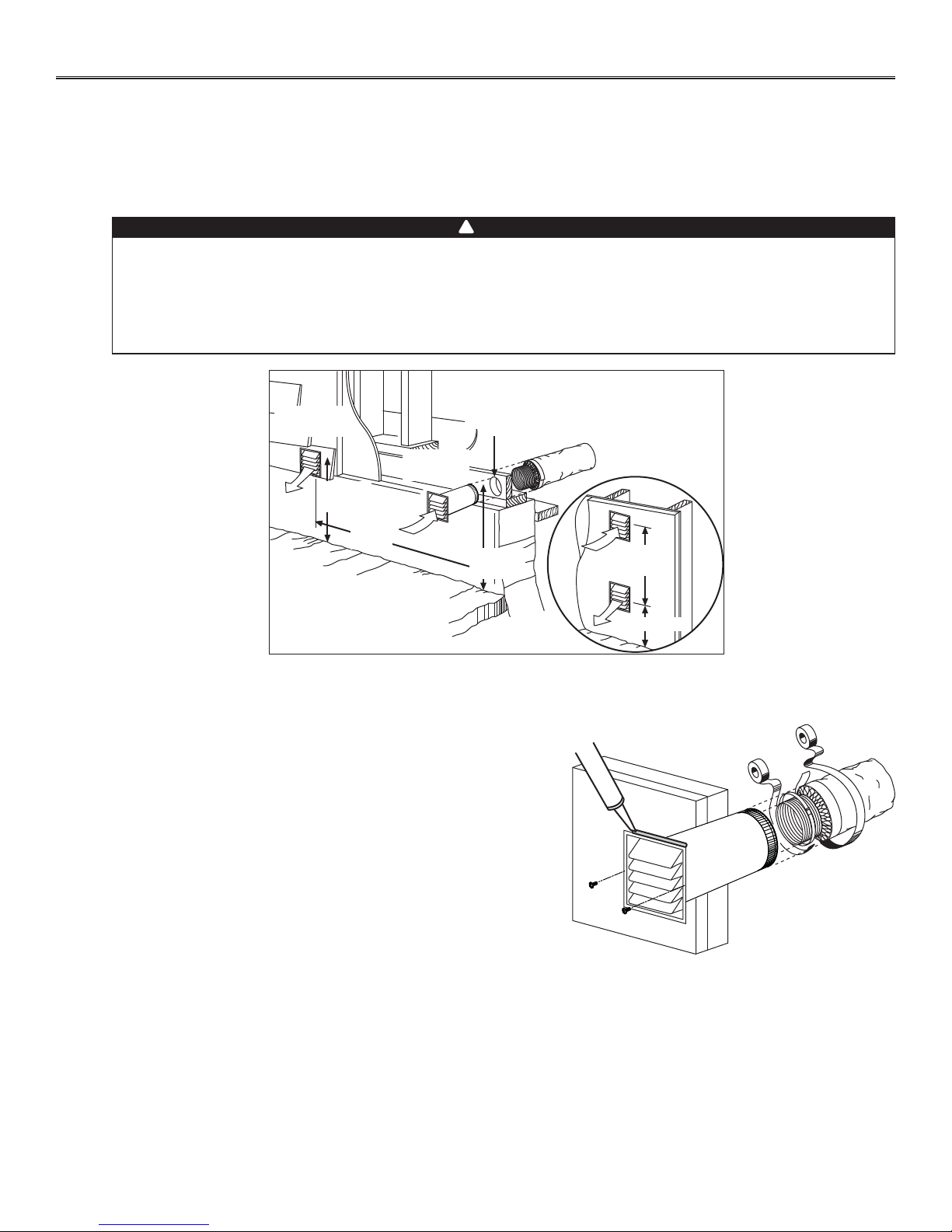

3.7 CONNECTING INSULATED DUCTS TO EXTERIOR PORTS

• For each exterior port, using a jig saw, cut a 5’’ diameter hole in the

exterior wall.

• From the outside, slide the exterior port in place and attach it to the

exterior wall, using 2 no. 8 x 1½” provided screws. Seal the outline with

silicone.

• From the inside, pull back the insulation to expose the flexible duct and,

using a tie wrap, attach it to the exterior port rigid duct. Carefully seal

with duct tape. Pull the insulation over the joint. Pull the vapor barrier

over the insulation and over the joint. Apply gently duct tape to the joint

making an airtight seal. See illustration at right.

5’’ Ø

(127 MM)

5’’ Ø

(127 MM)

OPTIONAL

LOCATION

6’

(1.8 M)

18’’ (457 MM)

VR0028

10

3. INSTALLATION (CONT’D)

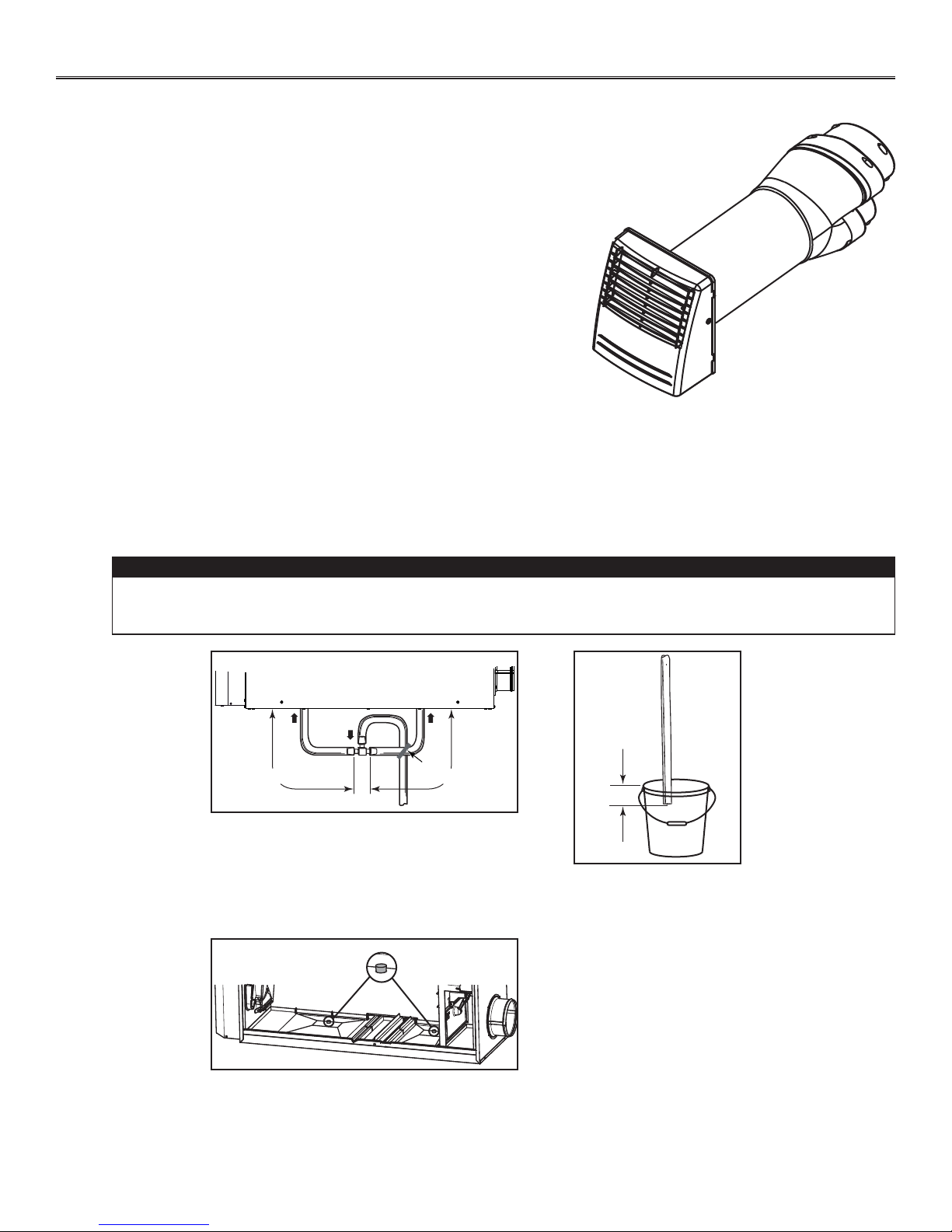

3.8 INSTALLING TANDEM® TRANSITION KIT

If desired, it is possible to perform insulated ducts connection with the outside

using the Tandem transition kit (purchase separately, part number TYIK1). The

joist opening needed to install the Tandem transition must be 9¾” minimum.

The maximum height of the Tandem transition is 8¾”. To connect the insulated

flexible ducts to the Tandem transition (Exhaust air to outside and Fresh air

from outside), follow the instructions included with the kit.

*Patented.

VR0003

Tandem transition kit

3.9 CONNECTING THE DRAIN

A drain tubing (included) must be installed for all HRV units. For ERV units, it is not required, however, it

is recommended for climates where the outside temperature typically remains below -13°F (-25°C), (over a

24-hour period) for several days in a row, combined with an indoor humidity of 40% or higher.

VD0311A

Cut two sections of plastic tubing, approximately

12” long, and connect each one to both inner drain

fittings located under the unit as shown.

Join these both sections to the “T” junction and

main tube as shown, to prevent the unit from

drawing unpleasant odors from the drain source.

VD0323

NOTES: 1. For ERV unit, remove both drain plugs

inside the unit prior to install tubing.

2. ERV core and blower assembly removed

from illustration to ease understanding.

± 12” ± 12”

TIE WRAP

CAUTION

± 1”

VD0308A

Run the tube to the floor

drain or to an alternative

drain pipe or pail.

IMPORTANT

If using a pail to collect

water, locate the tube end

approximately 1” from the

top of the pail in order to

prevent water from being

drawn back up into the unit.

11

Loading...

Loading...