Broan 15XESSEXF Installation Guide

Service Manual

Trash Compactor

Models 15XESSEXF

99044663A November 2010

Broan-NuTone LLC • 926 West State Street • Hartford, WI 53027 • 1-800-637-1453

2

Safe Servicing Practices

Safe Servicing Practices

To avoid personal injury and/or property damage, it is important that Safe Servicing Practices be

observed. The following are some limited examples of safe practices.

DO NOT attempt a product repair if you have any doubts as to your ability to complete it in a safe 1.

and satisfactory manner.

Before servicing or moving an appliance, remove the power cord from the electrical outlet, trip the 2.

circuit breaker to the OFF position, or remove the fuse.

Never interfere with the proper operation of any safety device.3.

USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE. SUBSTITUTIONS MAY 4.

DEFEAT COMPLIANCE WITH SAFETY STANDARDS SET FOR HOME APPLIANCES.

GROUNDING: The standard color coding for safety ground wires is GREEN, or GREEN WITH 5.

YELLOW STRIPES. Ground leads are not to be used as current-carrying conductors. It is

EXTREMELY important that the service technician re-establish all safety grounds prior to completion

of service. Failure to do so will create a hazard.

Prior to returning the product to service, ensure that:6.

All electrical connections are correct and secure•

All electrical leads are properly dressed and secured away from sharp edges, high-temperature •

components, and moving parts

All non-insulated electrical terminals, connectors, heaters, etc., are adequately spaced away from •

all metal parts and panels

All safety grounds (both internal and external) are correctly and securely connected•

All panels are properly and securely re-assembled•

NOTE

This service manual is intended for use by persons having electrical and mechanical training and a

level of knowledge of these subjects considered acceptable in the appliance repair trade. BroanNuTone cannot be responsible, or assume any liability, for injury or damage of any kind arising from

the use of this manual.

Grounding Instructions

IMPORTANT: TO REDUCE THE RISK OF ELECTRIC SHOCK - PLEASE READ CAREFULLY.

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PROPERLY GROUNDED.

IF THERE IS ANY DOUBT AS TO WHETHER THE WALL RECEPTACLE IS PROPERLY GROUNDED,

HAVE IT CHECKED AND PROPERLY GROUNDED BY A QUALIFIED ELECTRICIAN.

A 220-240 volt, 50-60 Hz., A.C., 10 amp fused and grounded electrical supply is required (time-delay

fuse or circuit breaker is recommended). It is recommended that a SEPARATE CIRCUIT serving only this

appliance be provided.

DO NOT USE AN EXTENSION CORD OR PLUG ADAPTER WITH THIS APPLIANCE.

Table of Contents

3

Table of contents

Safe Servicing Practices ............................................................ 2

Grounding Instructions .............................................................. 2

Features ....................................................................................... 4

Section A – Installation .............................................................. 5

Free-Standing ............................................................................... 5

Built-In Installation ........................................................................ 5

Mounting Straps....................................................................... 5

Under-Counter Opening .......................................................... 5

Cord Clamp ............................................................................. 6

Leveling the Compactor ................................................................ 6

Section B – Cabinet .................................................................... 7

Trash Bucket ................................................................................. 8

Remove ................................................................................... 8

Bucket Handle .............................................................................. 8

Remove and Replace .............................................................. 8

Slide Rails (Cabinet) ..................................................................... 9

Remove and Re-install ............................................................ 9

Slide Rails (Bucket) ...................................................................... 9

Remove and Re-install ............................................................ 9

Door Assembly ............................................................................. 10

Remove and Re-install ............................................................ 10

Reverse Door Hinge Position ................................................... 10

Safety Interlock Actuator .............................................................. 11

Remove and Re-install ............................................................ 11

Gasket Assembly .......................................................................... 12

Remove and Re-install ............................................................ 12

Top Trim Cover Assembly ............................................................. 13

Remove and Re-install ............................................................ 13

Section C – Power Unit Mechanism .......................................... 14

Drive Belt ...................................................................................... 15

Remove and Re-install ............................................................ 15

Main Motor .................................................................................... 16

Remove and Replace .............................................................. 16

Complete Power Unit Mechanism ................................................ 17

Remove and Re-install ............................................................ 17

Drive Wheels ................................................................................ 17

Remove and Replace .............................................................. 17

Ram Screw Assembly................................................................... 18

Remove and Replace .............................................................. 18

Section D – Electrical Components .......................................... 21

Start Switch .................................................................................. 22

Remove and Replace .............................................................. 22

Access to Components ................................................................. 22

Remove Cabinet Cover ............................................................ 22

Re-install Cabinet Cover .......................................................... 24

Control Panel Assembly ............................................................... 25

Remove and Re-install ............................................................ 25

Display Module Assembly............................................................. 26

Remove and Re-install ............................................................ 26

Power Supply Board ..................................................................... 26

Remove and Re-install ............................................................ 26

Control Board ............................................................................... 27

Remove and Re-install ............................................................ 27

Key Switch .................................................................................... 28

Remove and Replace .............................................................. 28

Interlock Switch Assembly ............................................................ 28

Remove and Re-install ............................................................ 28

Upper Limit Switch Assembly ....................................................... 29

Remove and Replace .............................................................. 29

Lower Limit Switch ........................................................................ 29

Remove and Replace .............................................................. 29

Motor Centrifugal Switch Assembly .............................................. 30

Remove and Replace .............................................................. 30

Motor Capacitor ............................................................................ 30

Test, Remove and Replace ...................................................... 30

Odor Disk Gear Motor .................................................................. 32

Remove and Replace .............................................................. 32

Section E – Troubleshooting

Troubleshooting Table ................................................................... 33

Section F – Specifications

Specifications Table ...................................................................... 36

Section G – Diagrams and Parts Lists

Wiring Schematic ......................................................................... 37

Drawing and Parts List – Cabinet ................................................ 38

Drawing and Parts List – Mechanism .......................................... 39

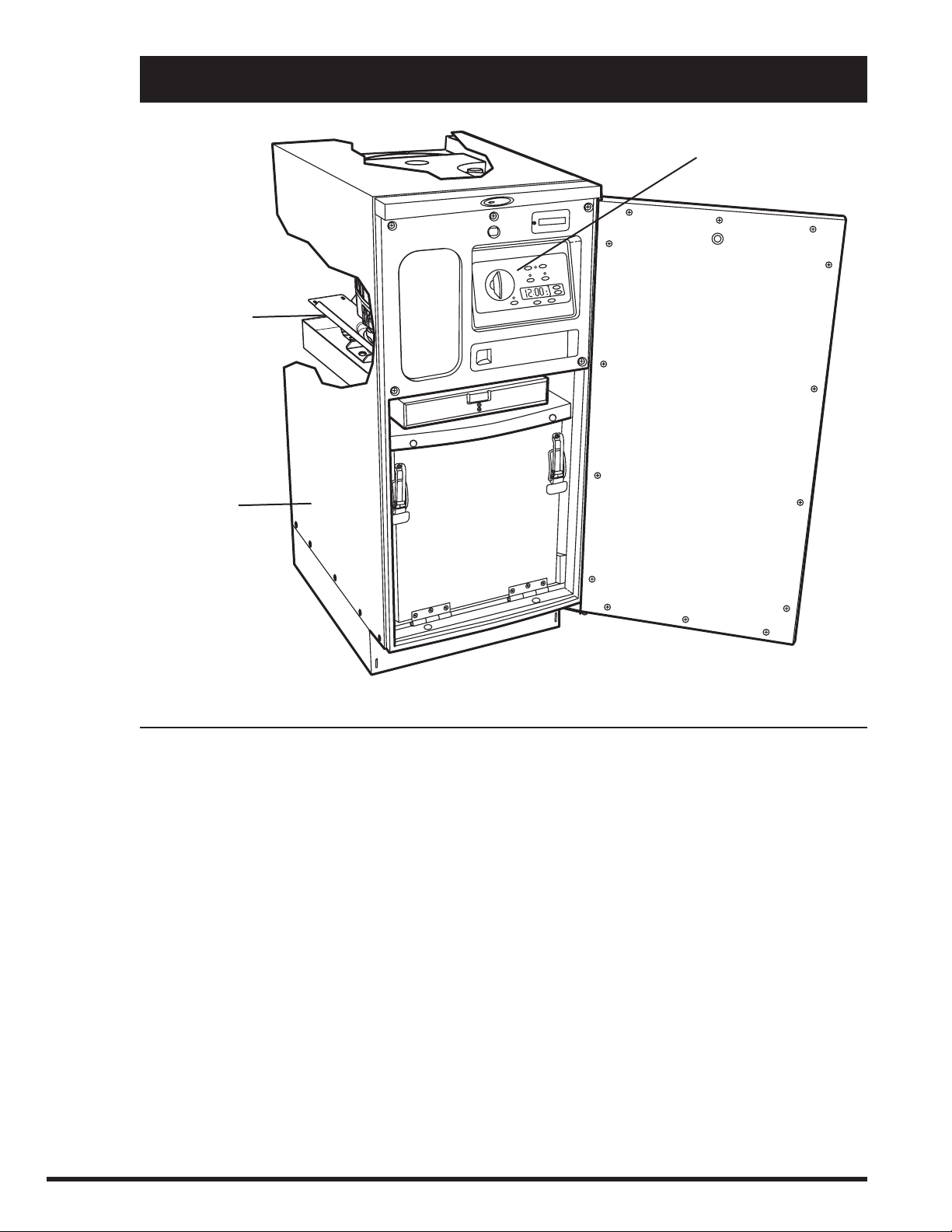

4

Features

ELECTRICAL

COMPONENTS

(SECTION D)

POWER UNIT

MECHANISM

(SECTION C)

CABINET

(SECTION B)

How the compactor works

The compactor compresses household trash up to 1/6 of its original volume. It will compact normal household trash

including milk cartons, glass and plastic bottles, containers and jars, tin cans, wrappings, boxes, food wastes, etc.

When you start the compactor, an electrically powered ram moves down into the trash bucket, compresses the trash

and then returns to the “UP” position and shuts off automatically.

NOTE: The ram travels about 2/3 of the way down into the trash bucket. Because of this, the trash bucket must be at

least 1/3 full before you will notice any compression.

Section A – Installation

CAUTION

Opening

15" Wide

34-1/2" High

22" Deep

5

Your compactor has been designed to require minimum

space without loss of capacity whether free-standing or

built-in.

Free-Standing

As shipped, the compactor is only congured for built-in

installations. This appliance can be converted from builtin to free-standing with the use of Toe Kick Accessory Kit

Model 15TCTK (sold separately).

If additional cord length is required for free-standing

installation, remove the cord clamp and wire tie on the

back of the unit.

Failure to use Toe Kick Assembly Kit Model 15TCTK in

a free-standing installation may cause the compactor

to be unstable during operation.

Built-in Installation

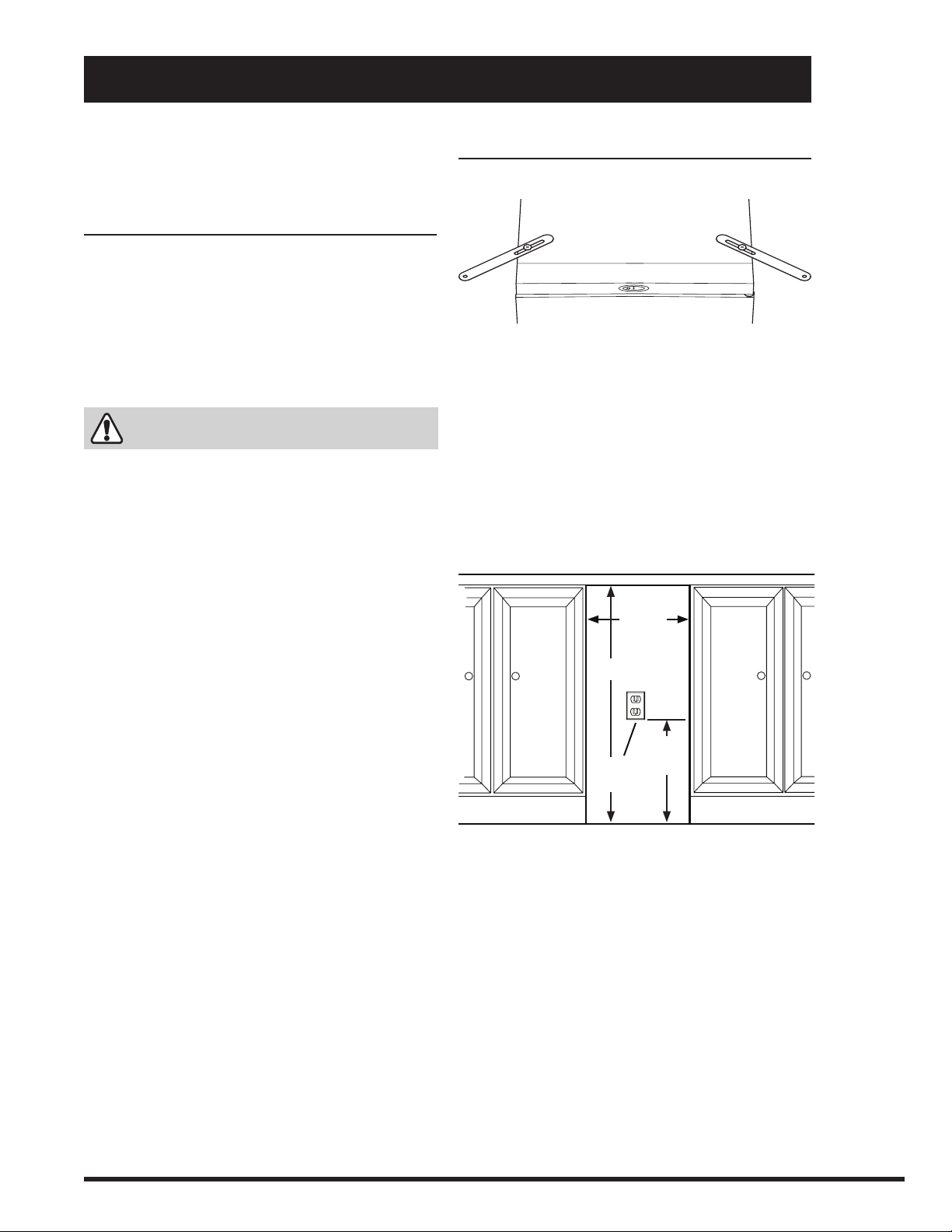

MOUNTING STRAPS

TOP OF

COMPACTOR

FRONT OF

COMPACTOR

Two under-counter mounting straps are provided. Use

these straps to secure the compactor to the underside

of a countertop.

Fasten the slotted end of the straps to the compactor

using the holes in the top of the compactor cabinet as

shown.

NOTE: When installation compactor under granite or

solid surface countertops, bend the mounting straps so

they can be secured to the adjacent cabinetry.

UNDER-COUNTER OPENING

15" W

22" D

341/2" H

12" MIN

ELECTRICAL

OUTLET

The compactor requires an under-counter opening 15-in.

wide, 34-1/2-in. high, and 22-in. deep.

Plan to provide an electrical outlet in the opening that

meets all applicable electrical codes and requirements.

See “Grounding Instructions” on Page 2 for specic

information.

6

Section A – Installation

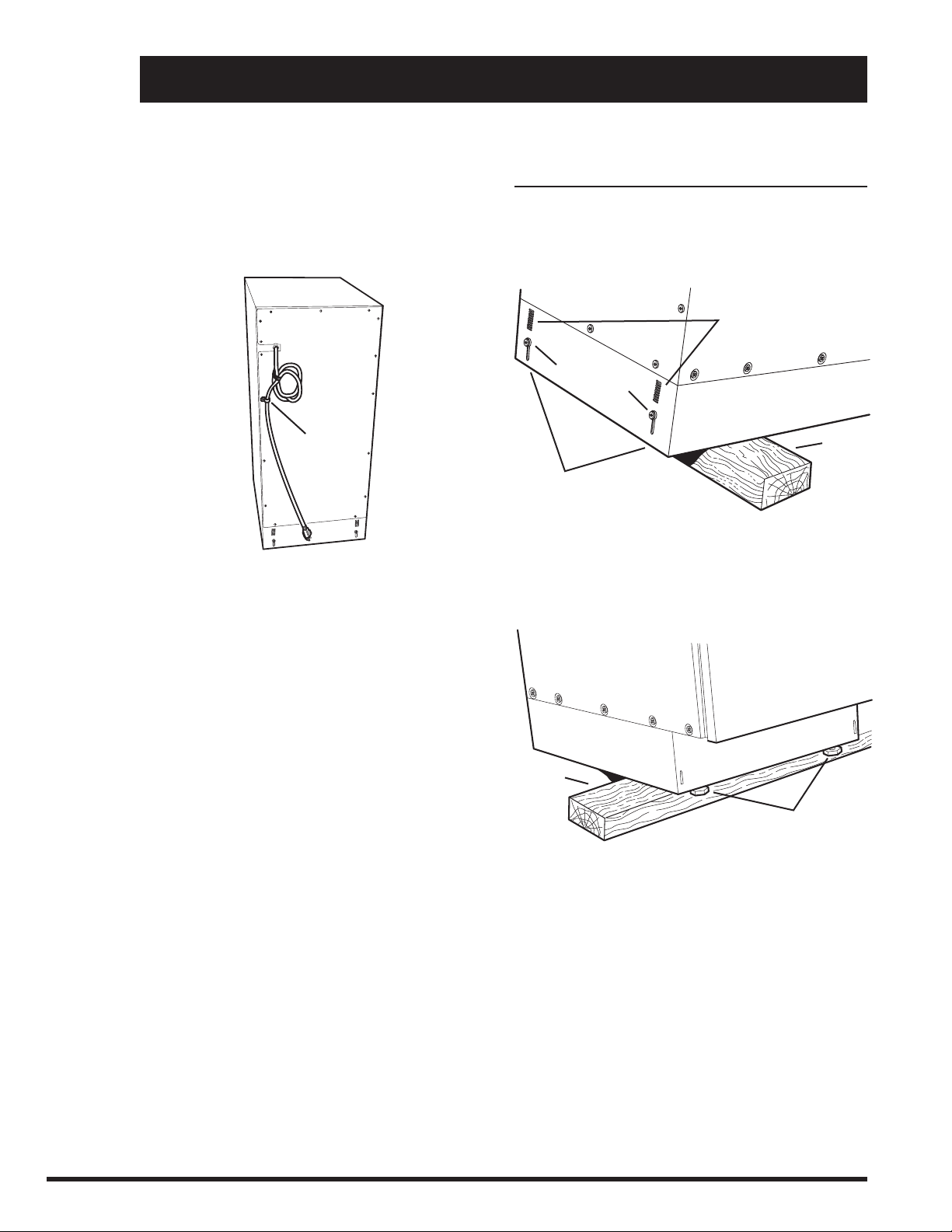

CORD CLAMP

The compactor is equipped with a 6-ft. long power cord.

Use the cord clamp to prevent excess power cord from

being pinched beneath the cabinet during installation or

service.

CORD

CLAMP

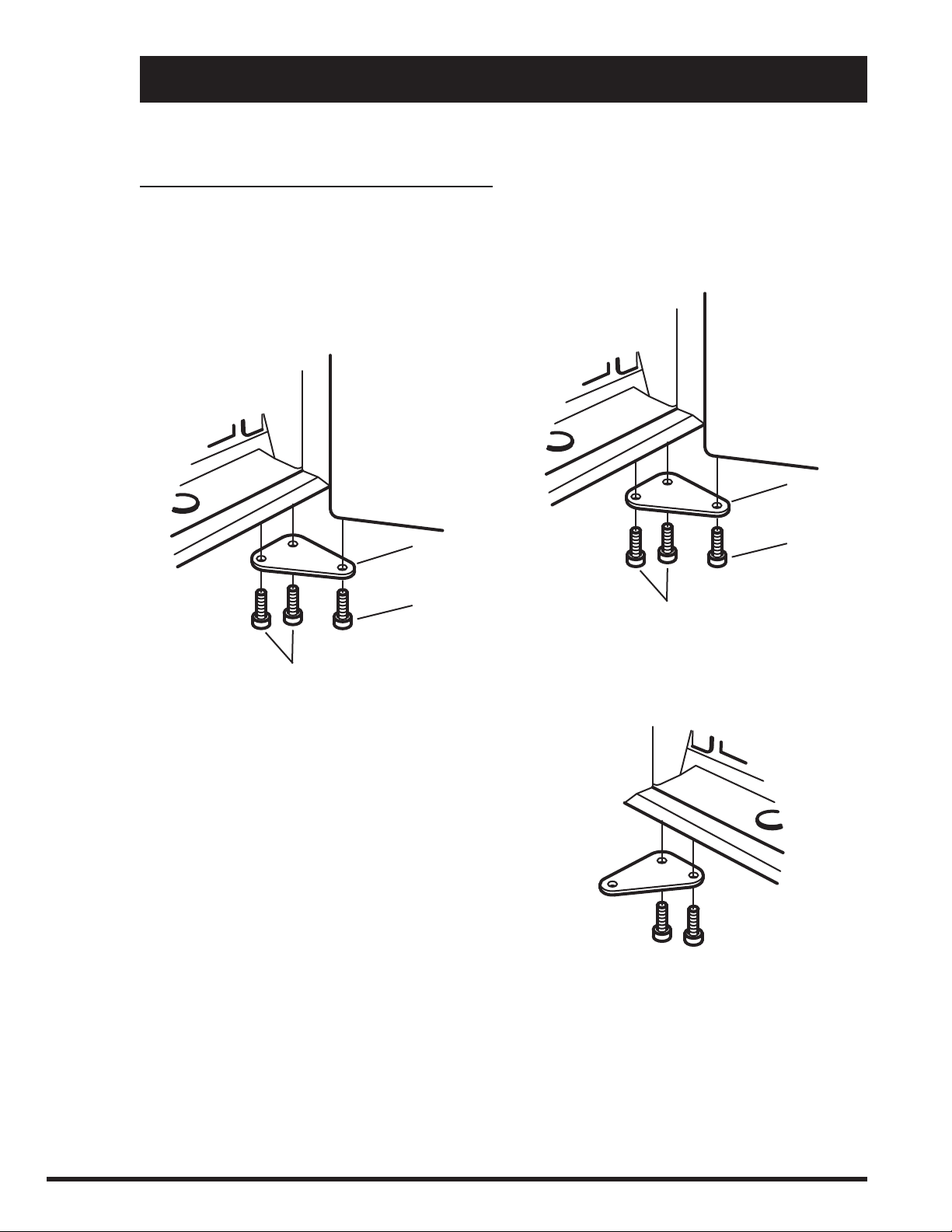

Leveling the Compactor

Your compactor has four adjustable levelers; (2) rollers in

the rear and (2) legs in the front. They allow you to adjust

for uneven oors and also trim the unit up to t an undercounter installation.

BACK OF

COMPACTOR

ADJUSTING

SCREWS

ROLLERS

To level the back of the compactor:

Tip the back of compactor up and onto a wood block.

Loosen the adjusting screws only far enough to move the

rollers to a higher or lower slot. Retighten the adjusting

screws and remove the wood block.

SLOTS

WOOD

BLOCK

FRONT OF

COMPACTOR

WOOD

BLOCK

LEVELING

LEGS

To level the front of the compactor:

Tip the front of compactor up and onto a wood block.

Turn the leveling legs in or out to the desired position.

Remove the wood block.

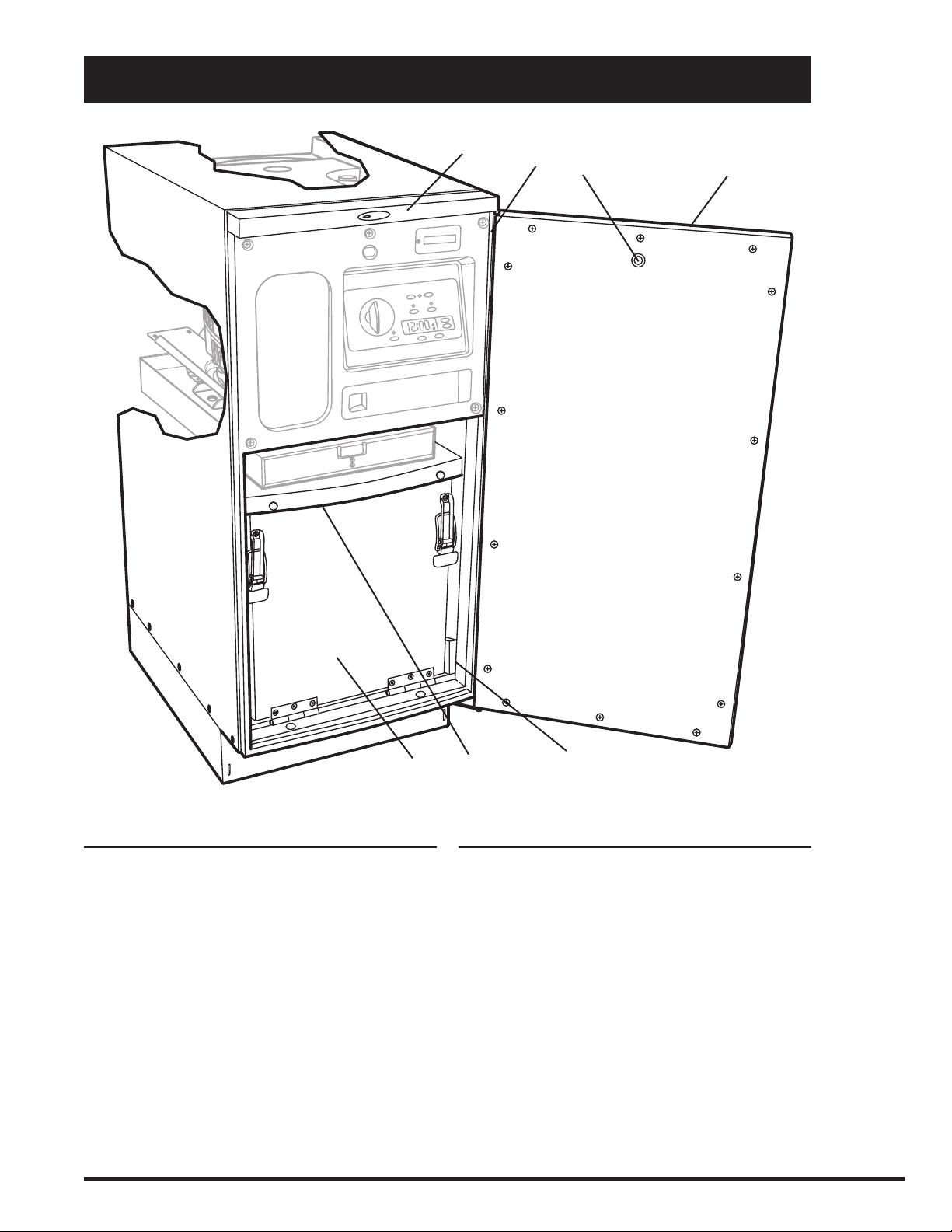

Section B – Cabinet

H

FG

E

7

A

Cabinet

The compactor’s main cabinet supports and encloses

a number of sub-assemblies. These include the trash

bucket, the door, the motor, the ram, and the electrical

controls and components.

B

C, D

Legend

A. Trash Bucket

B. Bucket Handle

C, D. Slide Rails

E. Door Assembly

F. Safety Interlock Actuator

G. Gasket Assembly

H. Top Trim Cover

8

Section B – Cabinet

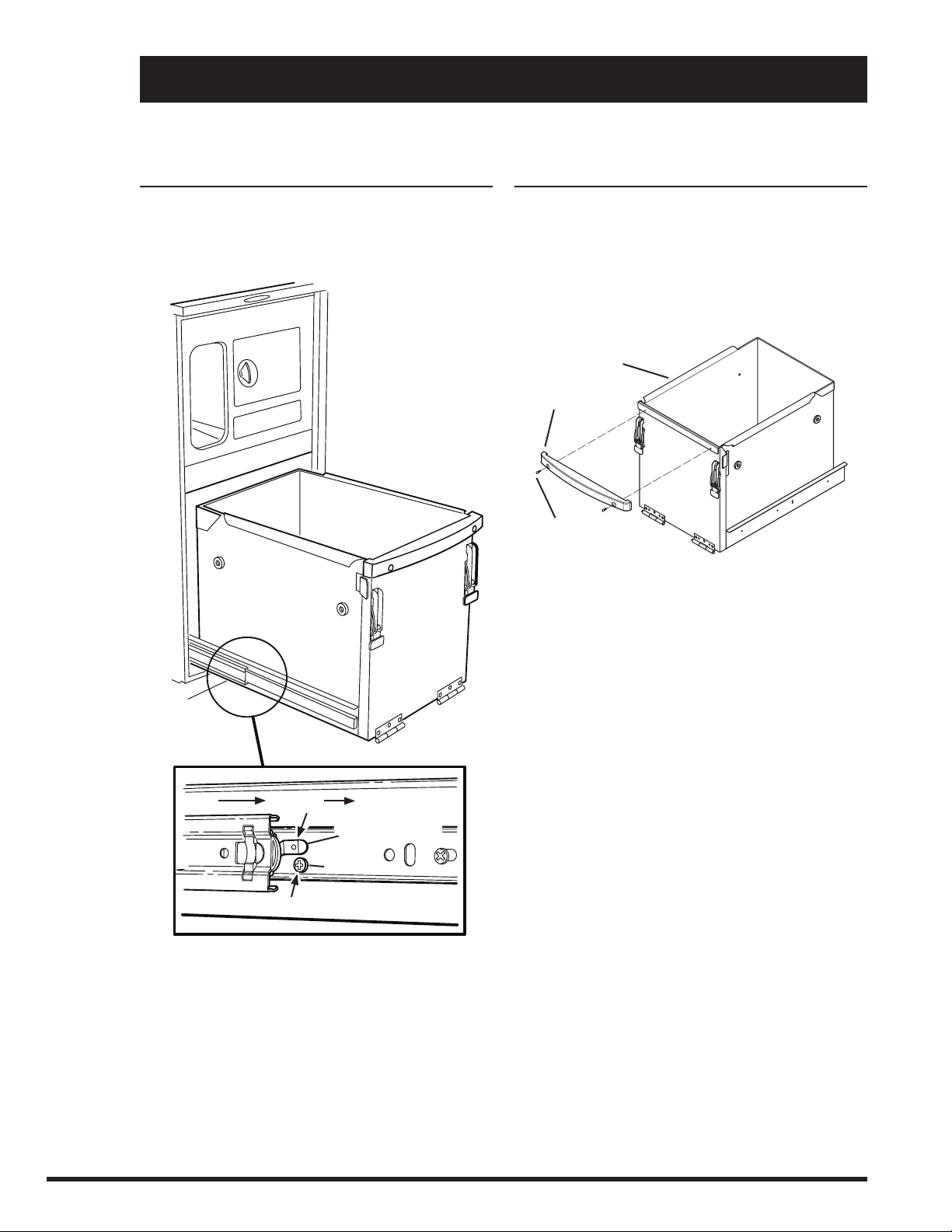

Trash Bucket

REMOVE

To remove the bucket completely from the cabinet for

repairs or cleaning, follow these instructions.

Bucket Handle

REMOVE AND REPLACE

The plastic bucket handle may receive a lot of “wear and

tear” simply because the operator uses it every time he

or she places trash into the compactor, or removes or

replaces the bag. If the handle is scratched, chipped or

broken, replace it.

BUCKET

HANDLE

SCREW

Remove two Phillips head screws and detach the 1.

handle from the bucket.

3.

BUCKET SLIDE

RELEASE TAB

SCREW

2.

Pull out trash bucket until it stops.1.

Remove one screw from each of the bucket slides. 2.

Press down on left and right bucket slide release tabs 3.

while pulling the bucket out of the cabinet.

Installation is the reverse of removal.2.

Section B – Cabinet

9

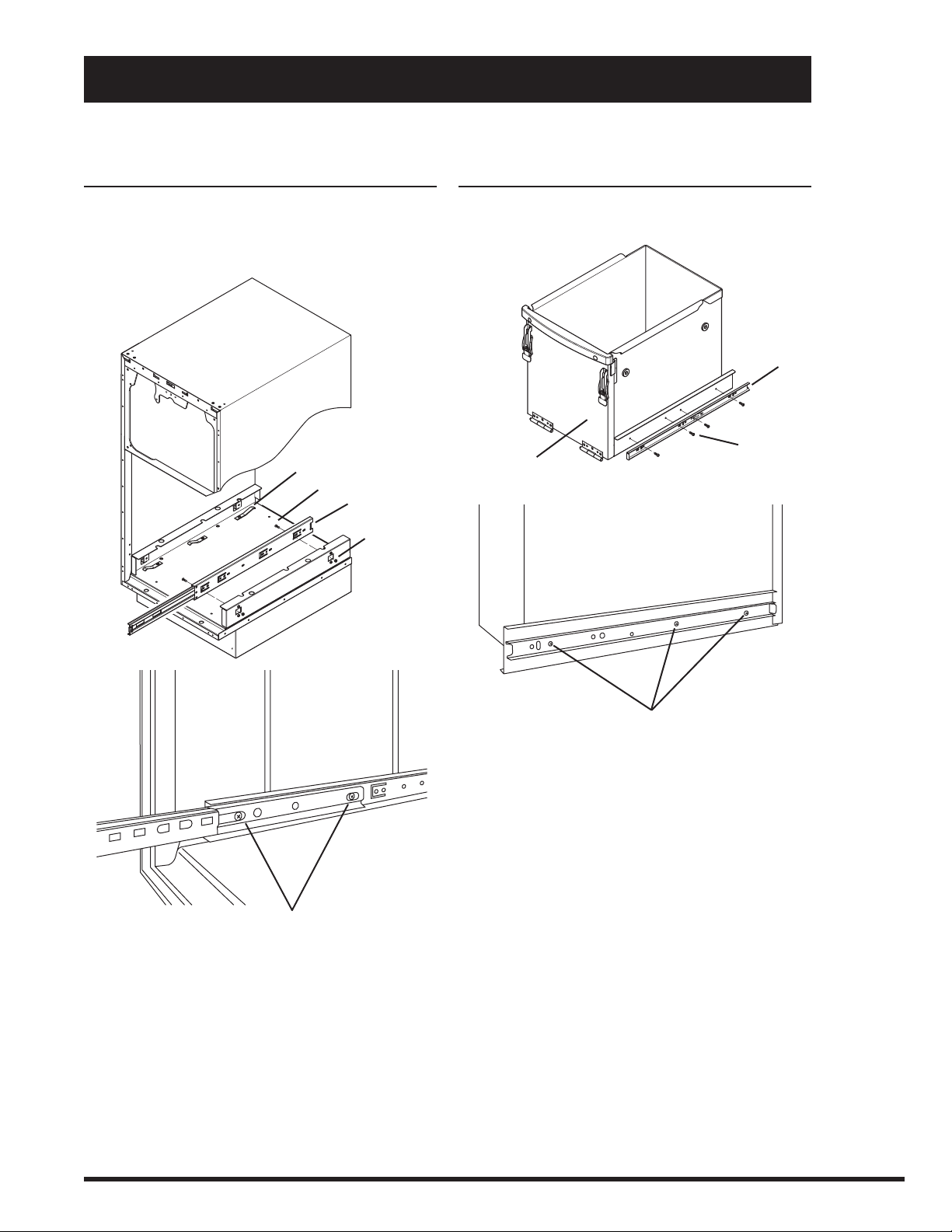

Slide Rails (Cabinet)

REMOVE AND RE-INSTALL

The compactor’s slide rails may become bent from misuse or the ball bearings may become worn.

SPRING CLIPS

SCREW

RAIL

NUT

Slide Rails (Bucket)

REMOVE AND RE-INSTALL

RAIL

SCREW

BUCKET

SCREWS

Remove trash bucket assembly. (See Trash Bucket, 1.

Remove.)

Remove two Phillips head screws from the front and 2.

rear of the left track slide rail. NOTE: It is necessary to

slide the inner rail to access both screws.

Remove the slide rail from the cabinet.3.

To re-install, place slide rail onto the three “spring 4.

clips” inside of the cabinet. Align holes in rail with

bracketed holes on inside of cabinet and secure with

two Phillips head screws. Repeat for other side.

SCREWS

Remove four Phillips head screws that secure the left 1.

slide rail to the bucket. Remove the rail.

Repeat Step 1 for the right slide rail. 2.

Installation is the reverse of removal.3.

10

Section B – Cabinet

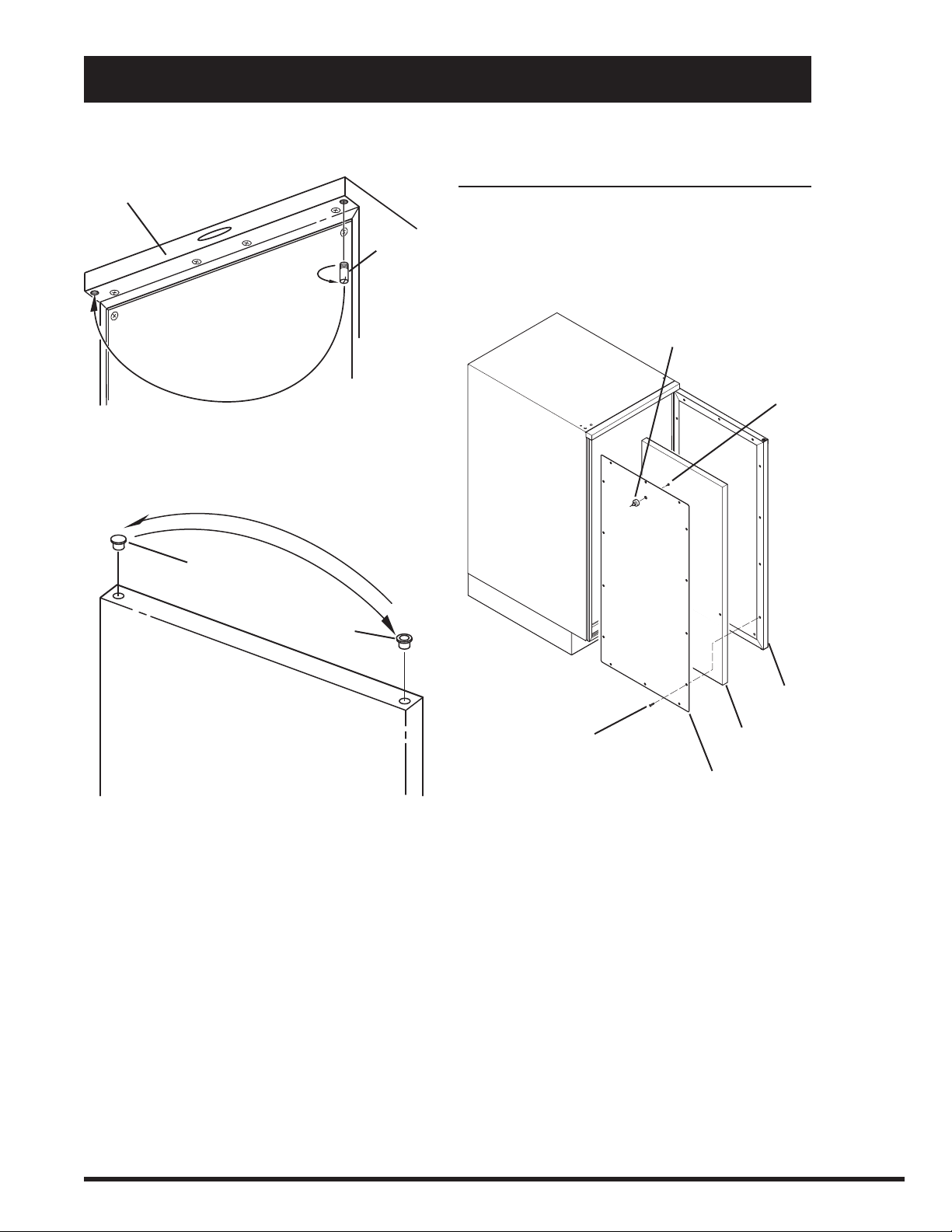

Door Assembly

REMOVE AND RE-INSTALL

The heavy-duty door could become dented, scratched

or bent and require replacement. Door removal is also

necessary for some service procedures.

IMPORTANT: Firmly support the door during removal

and re-installation.

DOOR

LOWER

HINGE

BRACKET

LOWER

HINGE

PIN

REVERSE DOOR HINGE POSITION

The compactor comes from the factory with the door

in the right-hand opening position. Use the following

instructions to reverse the door.

Remove the door (see Remove and Re-install).1.

DOOR

LOWER

HINGE

BRACKET

LOWER

HINGE

PIN

SCREWS

SCREWS

With the door closed, use a 3/16" allen wrench to 1.

remove the lower hinge pin.

Carefully remove door by opening and sliding the 2.

bottom of the door away from the cabinet.

To re-install, lift the door, insert the upper hinge pin 3.

into the upper door bushing and move the door into

place. Insert the lower hinge pin from Step 1 and

tighten securely.

Use a 3/16" allen wrench to remove the lower hinge 2.

pin from the cabinet (2 screws).

Turn the bracket over and install the bracket on the 3.

opposite side of the cabinet using the same screws.

TRIM PIECE

UPPER

HINGE

PIN

Use a screwdriver to remove the upper hinge pin from 4.

the trim piece and re-install the pin on the opposite

side.

Section B – Cabinet

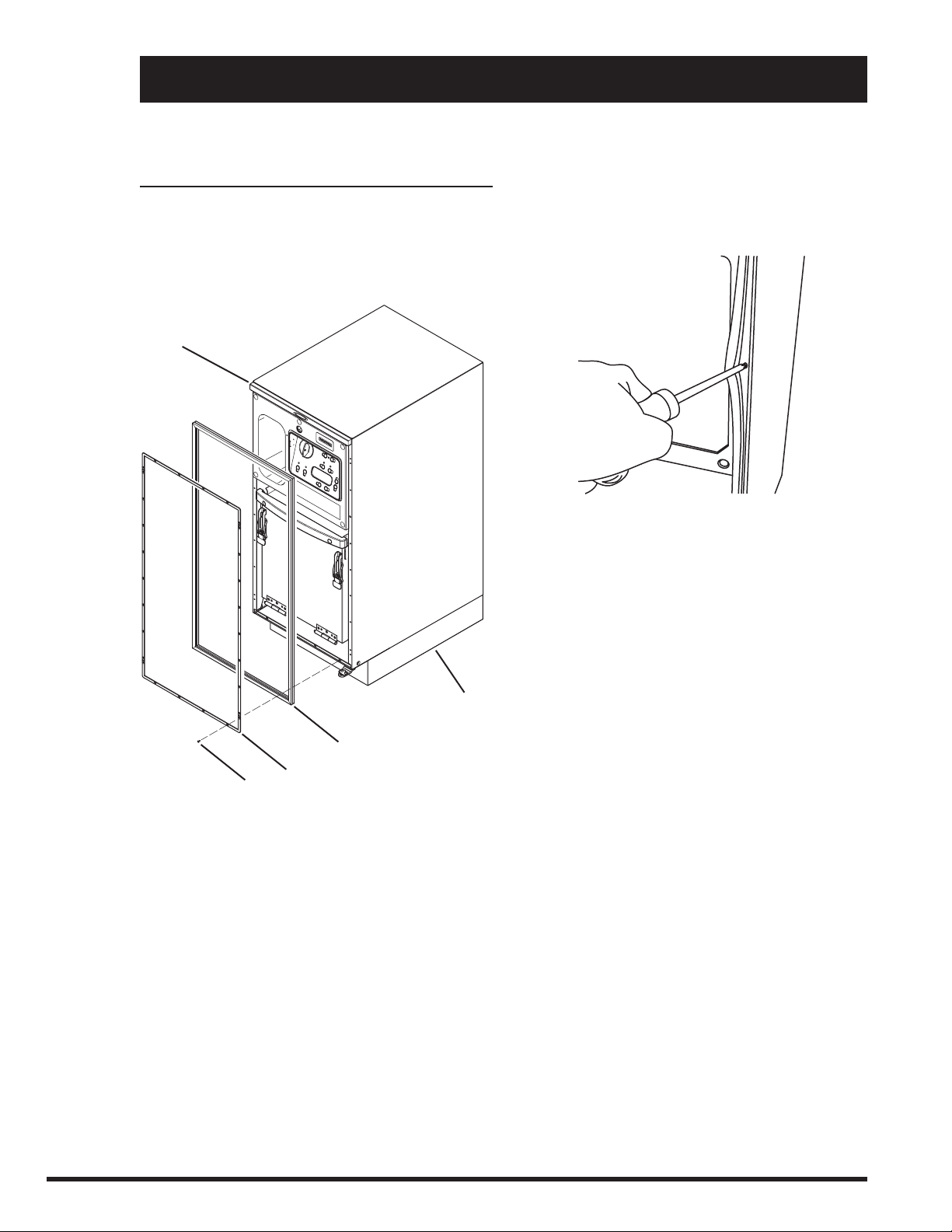

Safety Interlock Actuator

REMOVE AND RE-INSTALL

This safety device prevents the compactor from operating

except when the door is closed. NOTE: If the interlock

actuator should break off, the compactor will not function;

replace it promptly.

ACTUATOR

SCREW

11

CAP

BUSHING

DOOR

Being careful not to scratch the door, remove the 5.

plastic door bushing and cap from the top and bottom

of the door using a small at screwdriver. Install the

bushings on the side of the door panel that will be

hinged and install the caps on the opposite side.

Re-install the door (see Remove and Re-install).6.

DOOR

14

SCREWS

Remove the 14 Phillips head screws from the inner 1.

door panel. Remove panel and set aside.

Remove insulation pad from door.2.

Remove Phillips head screw from inside of door panel 3.

and remove actuator.

Installation is the reverse of removal. NOTE: Fully seat 4.

actuator in the door panel before re-installing screw.

INSULATION

PAD

INNER DOOR

PANEL

12

Section B – Cabinet

Gasket Assembly

REMOVE AND RE-INSTALL

The gasket is made of a exible vinyl material with

imbedded magnets. Over time it may become brittle or

cracked, and lose its exibility. If this happens the door

may not close properly, so replace the gasket.

TRIM

COVER

Remove door assembly (see Door Assembly, Remove 1.

and Re-install).

Remove control panel (see 2. Electrical Components,

Control Panel Assembly).

Lift the outer edge of the gasket to expose the 3.

retainer strips and the screws that are used to fasten

the strips to the cabinet. NOTE: There are six retainer

strips: two each on the top and bottom and one each

for the left and right sides.

SCREWS

GASKET

RETAINER

STRIPS

CABINET

Remove the Phillips head screws that secure the 4.

retainer strips to the cabinet; then remove the strips

from underneath the gasket. Pull the gasket off of the

cabinet.

To install a new gasket, place retainer(s) under the 5.

outer edge of the gasket, then use the screws to

fasten the retainers and gasket to the cabinet.

Re-install the control panel.6.

Loading...

Loading...