Page 1

Operating Instructions

Hydronic Gas Condensing Boiler

Condens 5000 W

6 720 613 085-00.1O

ZSB 30-2 A ...| ZWB 37-2 A ...

6 720 644 144 (2010/09) NZ/AU

Page 2

2

Contents

6 720 644 144 (2010/09)

Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . 4

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Explanation of model code . . . . . . . . . . . . . . . . . . . . 8

3 Preparing the appliance for use . . . . . . . . . . . . . . . . . . . . 9

3.1 Turn on the gas service cock . . . . . . . . . . . . . . . . . . 9

3.2 Turn on the isolators . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Opening the control panel cover . . . . . . . . . . . . . . 11

3.4 Check the central heating system pressure . . . . . . 12

3.5 Top up the heating system . . . . . . . . . . . . . . . . . . . 13

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Overview of controls . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Switching the appliance on/off . . . . . . . . . . . . . . . . 18

4.3 Starting the central heating . . . . . . . . . . . . . . . . . . 19

4.4 Setting the heating control unit . . . . . . . . . . . . . . . 21

4.5 Appliances with hot water cylinder:

setting the hot water temperature . . . . . . . . . . . . . . 22

4.6 ZWB appliances - setting hot water temperature . . 24

4.7 Summer mode (central heating off, DHW only) . . . 26

4.8 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.9 Holiday mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.10 Further displays . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 3

3

Contents

6 720 644 144 (2010/09)

5 Carry out thermal disinfection . . . . . . . . . . . . . . . . . . . . . 30

6 Tips on saving energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10 Operating instructions quick reference . . . . . . . . . . . . . . 38

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Page 4

4 | Key to symbols and safety instructions

6 720 644 144 (2010/09)

1 Key to symbols and safety

instructions

1.1 Explanation of symbols

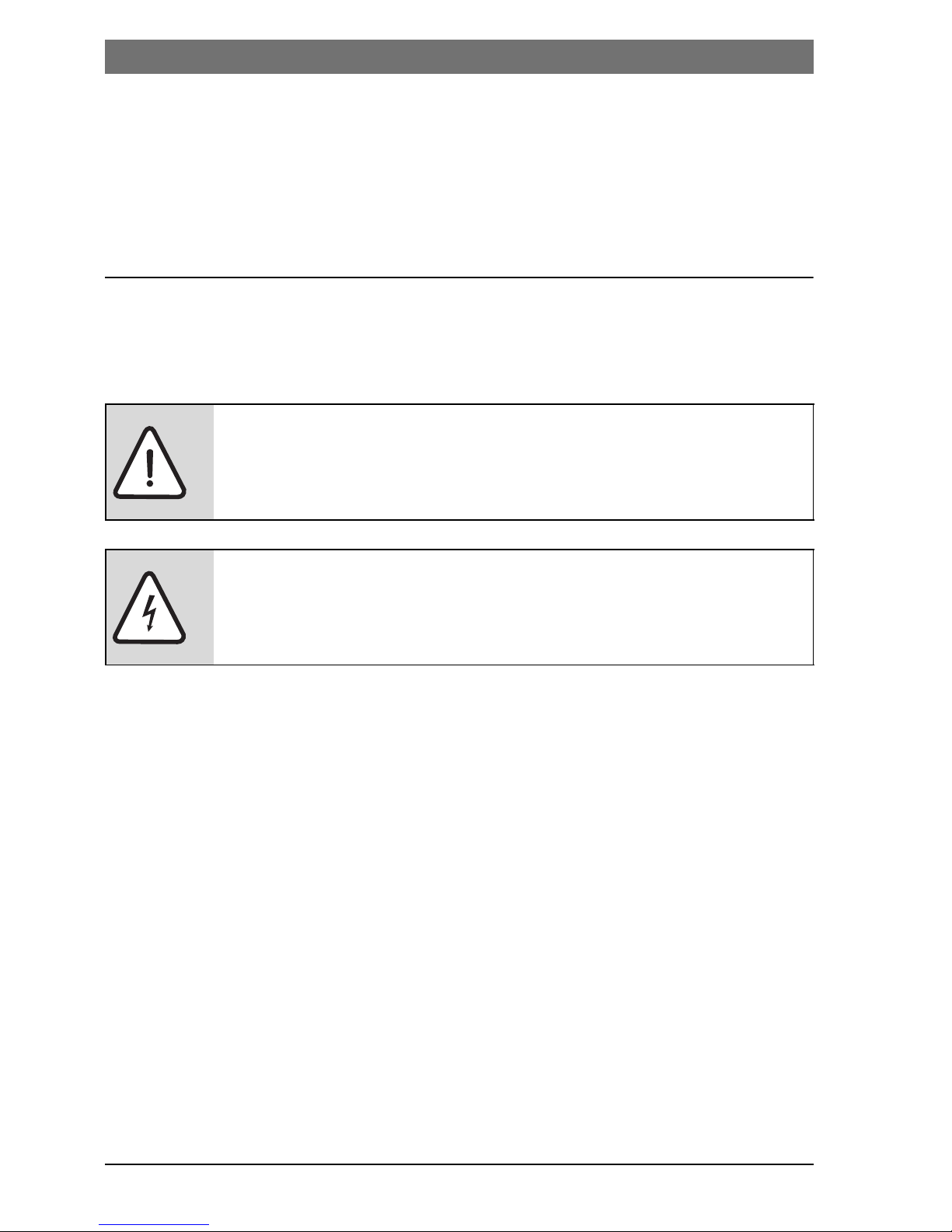

Warning symbols

Signal words indicate the seriousness of the hazard in terms of the

consequences of not following the safety instructions.

• NOTICE indicates possible damage to property or equipment,

but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Safety instructions in this document are framed

and identified by a warning triangle which is

printed on a grey background.

Electrical hazards are identified by a lightning

symbol surrounded by a warning triangle.

Page 5

Key to symbols and safety instructions | 5

6 720 644 144 (2010/09)

Important information

Additional symbols

Notes contain important information in cases where

there is no risk of personal injury or material losses

and are identified by the symbol shown on the left.

They are bordered by horizontal lines above and

below the text.

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the document or

to other related documents

• a list entry

– a list entry (second level)

Table 1

Page 6

6 | Key to symbols and safety instructions

6 720 644 144 (2010/09)

1.2 Safety instructions

If you smell gas

B Turn off gas tap (Æ page 16).

B Open windows and doors.

B Do not operate any electrical switches.

B Extinguish any naked flames.

B Leave the building and telephone your gas supply utility and

authorised contractor from an outside phone.

If you smell flue gas from the appliance

B Switch off the appliance (Æ page 16).

B Open windows and doors.

B Inform your heating contractor.

Installation and conversion

B This appliance may only be installed or converted by an

approved installer.

B Never modify any parts of the flue system.

B If the appliance has a type B.. flue system: Do not seal off or

reduce the size of air vents in doors, windows or walls. If

draught-sealed windows are installed, ensure there is an

adequate supply of air to the appliance for combustion.

Thermal disinfection

B Risk of scalding!

It is imperative to monitor operation at temperatures over

60 °C (Æ page 30).

Page 7

Key to symbols and safety instructions | 7

6 720 644 144 (2010/09)

Risk of damage due to operator error

Operator errors can result in injury and damage to property.

B Ensure that children never operate this appliance unsupervised

or play with it.

B Ensure that only personnel who can operate this appliance

correctly have access to it.

Inspection/Maintenance

B We recommend that you take out a contract to have the

system regularly serviced in order to ensure that it functions

reliably and safely.

B The user is responsible for the general and environmental

safety of the system.

B Only use genuine spare parts!

Combustible materials

B Do not store or use any combustible materials (paper,

thinners, paints etc.) in the vicinity of the appliance.

Combustion air/Ambient air

B Keep combustion air/ambient air free of corrosive substances

(e.g. halogenated hydrocarbons which contain chlorine or

fluorine compounds). In that way corrosion can be prevented.

Page 8

8 | Product details

6 720 644 144 (2010/09)

2 Product details

2.1 Intended use

The appliance may only be installed in sealed hot-water central

heating systems to EN 12828.

Using the appliance for any other purpose will be considered

incorrect use. Bosch accepts no liability for any damage resulting

from such use.

The commercial and industrial use of appliance to generate

process heat is not permitted.

2.2 Explanation of model code

Z Central heating appliance

S Cylinder connection

W DHW heating

B Condensing boiler technology

30 Output up to 30 kW

37 DHW output up to 37 kW

-2 Version

A Fan-assisted appliance without draught hood

Condens 5000 W ZSB 30-2 A

ZWB 37-2 A

Table 2

Page 9

Preparing the appliance for use | 9

6 720 644 144 (2010/09)

3 Preparing the appliance for use

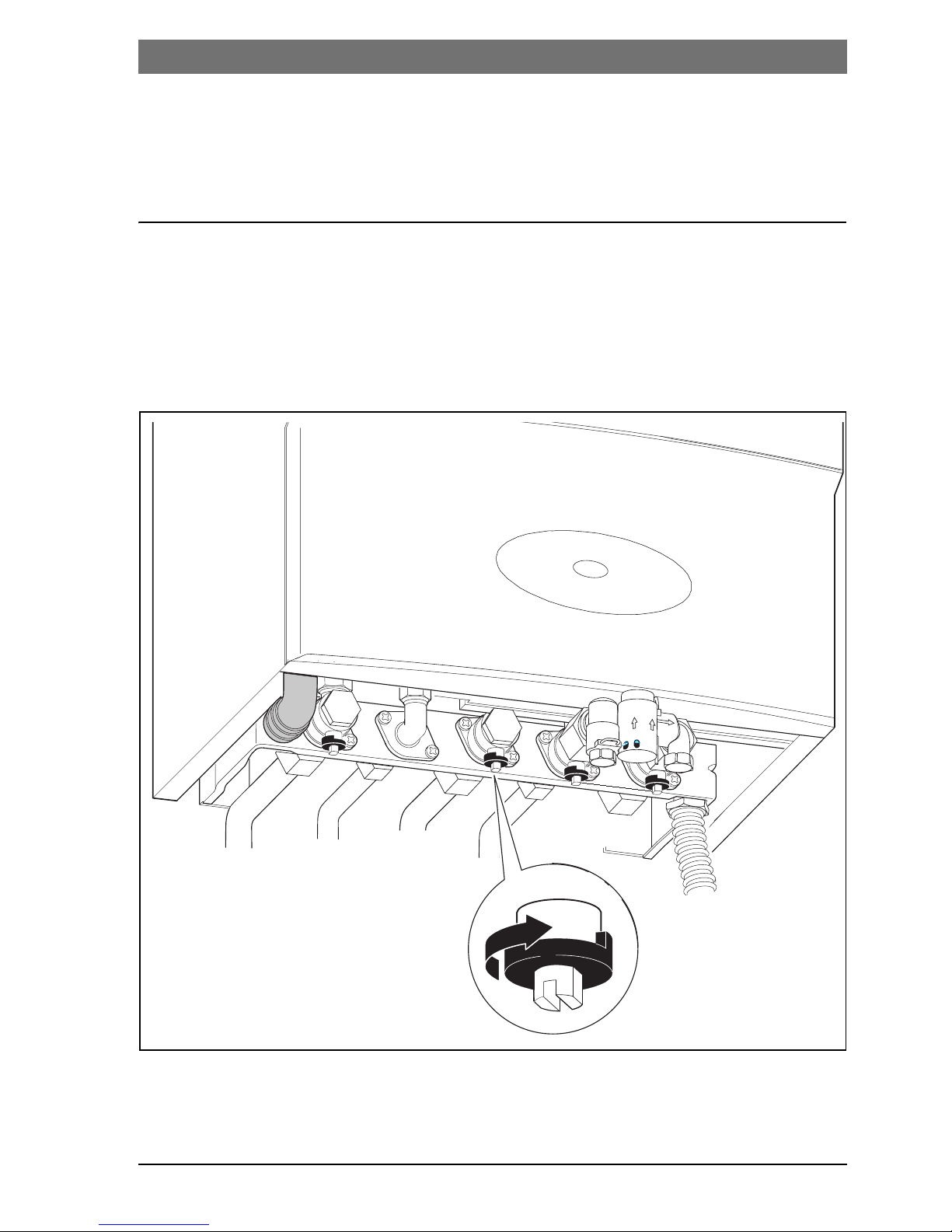

3.1 Turn on the gas service cock

B Using a screwdriver, turn the square tap handle so that the slot

is in line with the direction of flow.

Slot at right-angles to direction of flow = off.

Fig. 1

6 720 644 144-01 .1O

Page 10

10 | Preparing the appliance for use

6 720 644 144 (2010/09)

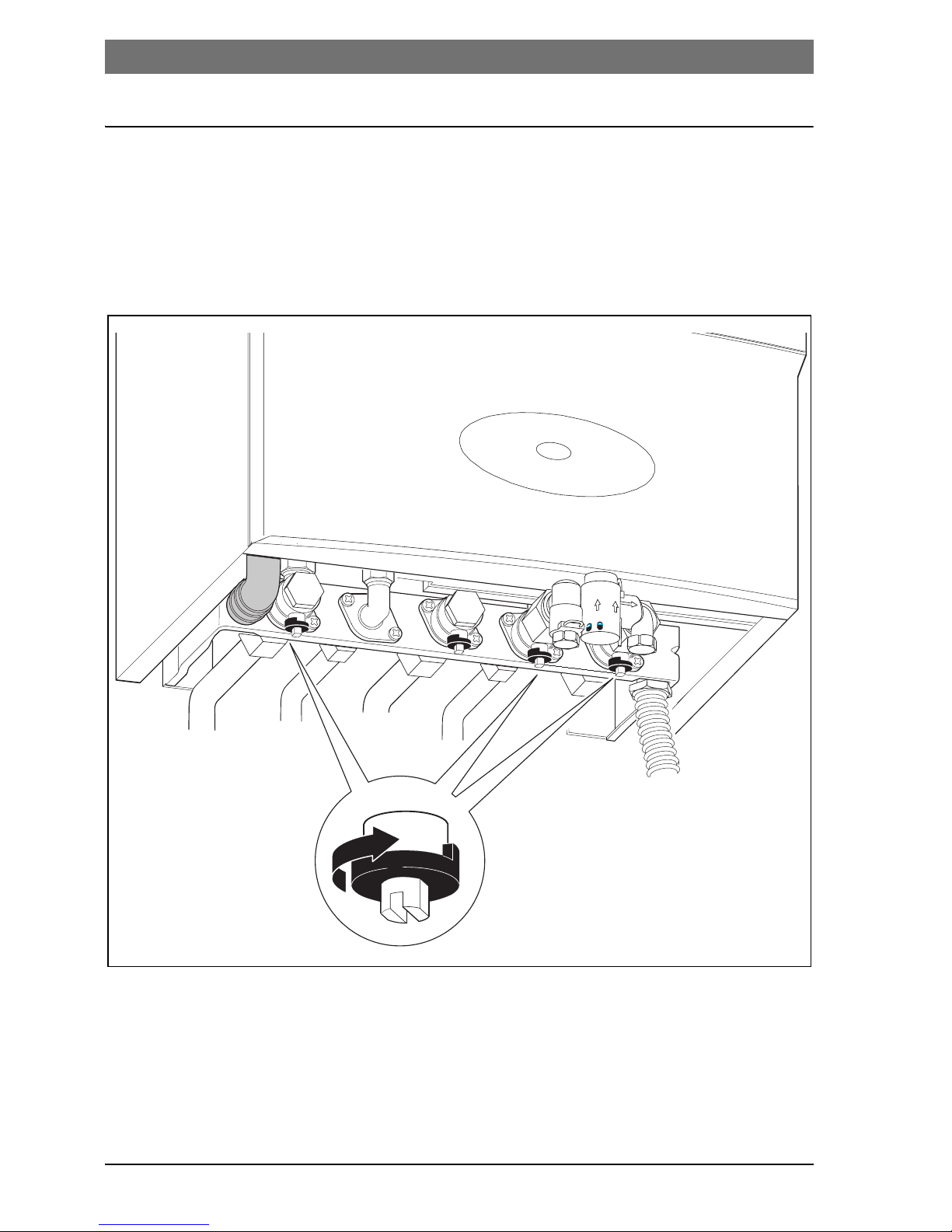

3.2 Turn on the isolators

B Using a screwdriver, turn the square tap handle so that the slot

is in line with the direction of flow.

Slot at right-angles to direction of flow = off.

Fig. 2

6 720 644 143-02.1O

Page 11

Preparing the appliance for use | 11

6 720 644 144 (2010/09)

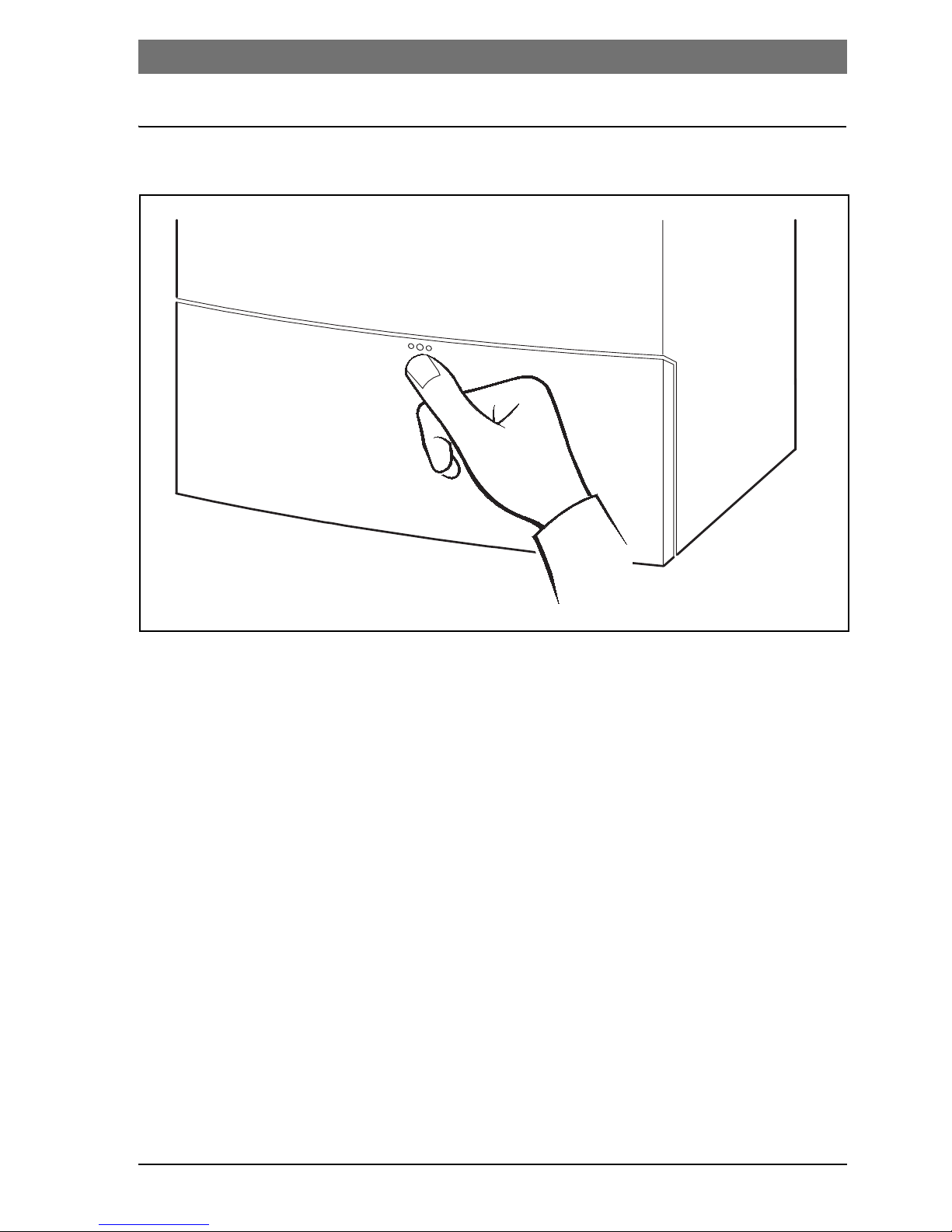

3.3 Opening the control panel cover

Fig. 3

6 720 612 660-01.2R

Page 12

12 | Preparing the appliance for use

6 720 644 144 (2010/09)

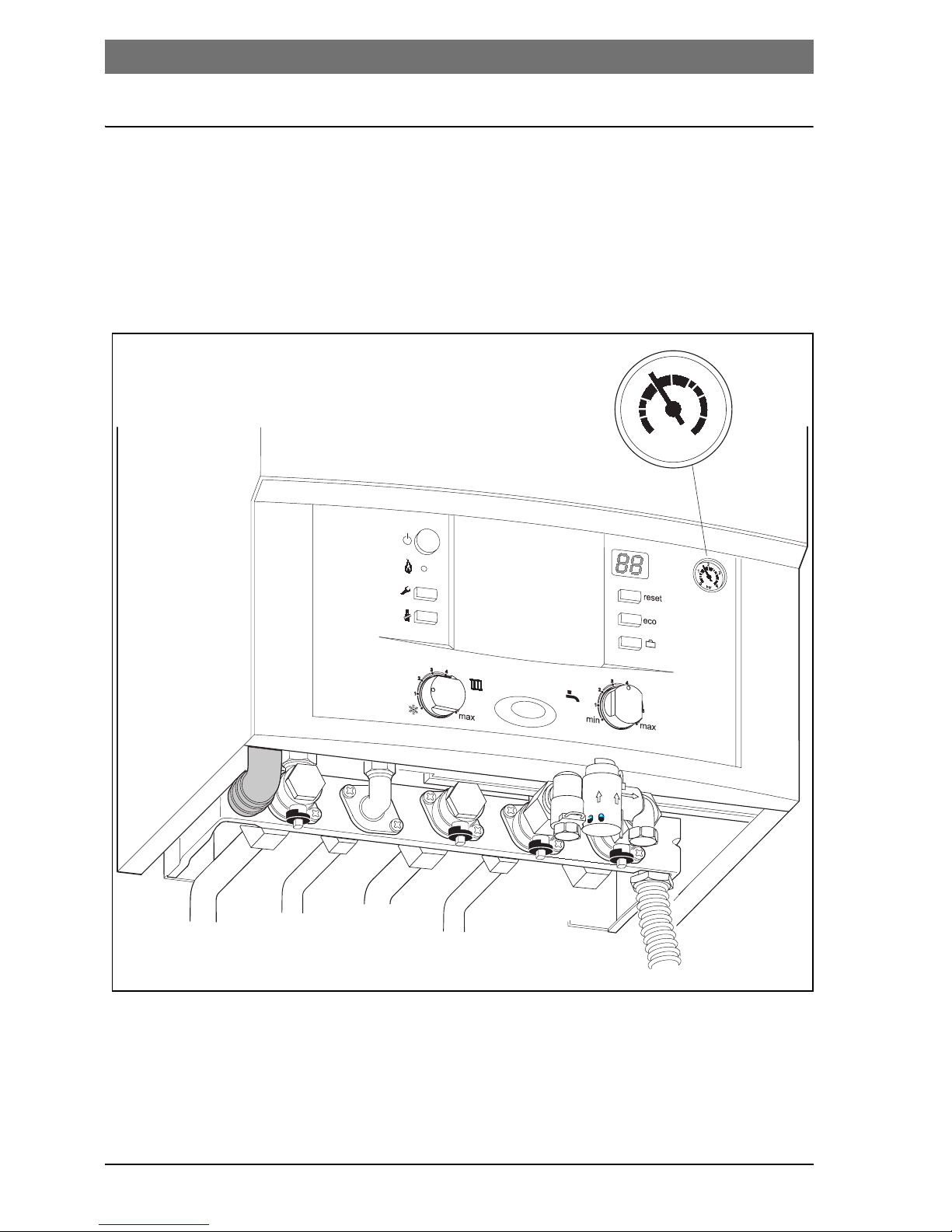

3.4 Check the central heating system pressure

The normal operating pressure is 1 - 2 bar.

If a higher setting is required, you will be informed by your

installer.

Fig. 4

6 720 644 144-03.1O

1

0

2

3

4

bar

Page 13

Preparing the appliance for use | 13

6 720 644 144 (2010/09)

3.5 Top up the heating system

The way in which the heating system is topped up is different on

every system. Therefore, you should ask your installer to show you

how it is done.

Maximum pressure of 3 bar at maximum heating water

temperature must not be exceeded (safety valve will open).

CAUTION: Risk of damaging the appliance.

B Only top up the heating system when the

appliance is cold.

Page 14

14 | Operation

6 720 644 144 (2010/09)

4 Operation

These Operating Instructions apply only to the boiler.

Depending on the heating controller used, some functions may be

controlled differently.

The following possibilities for controlling the heating system may

be employed:

• weather-dependent controller built into the boiler Æ page 16,

item 7.

• weather-dependent controller external to the appliance

• room thermostat

Therefore, please read the operating instructions

for the heating controller used.

Page 15

Operation | 15

6 720 644 144 (2010/09)

Fig. 5

Page 38 contains brief operation instructions. You

can fold this outwards and push the operating

instructions into the appliance facia for

safekeeping.

max

6 720 613 086-04.1O

Page 16

16 | Operation

6 720 644 144 (2010/09)

4.1 Overview of controls

Fig. 6

6 720 644 144-04.1O

1819

reset

10

11

12

eco

15161714

4

3

2

5

1

6

8

7

9

20

13

Page 17

Operation | 17

6 720 644 144 (2010/09)

1 Flow temperature control

2 DHW temperature control

3 Chimney sweep button

4 Service button

5 Burner ON indicator

6 Main switch

7 Here, a weather-compensated control unit or a time switch

(accessories) can be plugged in

8 Display

9 Pressure gauge

10 reset button

11 eco button

12 Holiday button

13 Drain from pressure relief valve (heating circuit)

14 Gas tap

15 CH return isolator

16 Filling loop (ZWB)

17 Cold water tap (ZWB),

cylinder return (ZSB)

18 DHW connection (ZWB),

cylinder flow (ZSB)

19 CH flow isolator

20 Condensate hose

Page 18

18 | Operation

6 720 644 144 (2010/09)

4.2 Switching the appliance on/off

Switching on

B Switch appliance on at the main switch.

The display shows the heating water flow temperature.

Fig. 7

Switching off the appliance

B Switch appliance off at the main switch.

The display goes out.

B If the appliance is to be switched off for a longer period of time:

observe correct frost protection procedures (Æ Section 4.8).

If the display shows alternately with the flow

temperature, the appliance will operate with the

lowest output for 15 minutes.

m

a

x

1

2

3

4

5

6

6 720 613 896-05.1O

Page 19

Operation | 19

6 720 644 144 (2010/09)

4.3 Starting the central heating

The maximum flow temperature can be matched to the heating

system by the flow temperature controller. The current flow

temperature is shown on the display.

Setting on flow

temperature

controller

Flow

temperature

Sample

application

1 Approx. 35 °C

2 Approx. 43 °C

3 Approx. 50 °C Underfloor

heating system

4 Approx. 60 °C

5 Approx. 67 °C

6

Approx. 75 °C

Radiator heating

system

max. Approx. 90 °C Convector

heating system

Table 3

With underfloor heating systems, take care to

observe the maximum permissible CH flow

temperatures.

Page 20

20 | Operation

6 720 644 144 (2010/09)

B Turn flow temperature controller to adjust the maximum

flow temperature.

Fig. 8

When the burner is firing, the green indicator lamp lights up.

eco

reset

6 720 644 143-27.1O

max

1

2

3

4

5

6

max

1

2

3

4

e

6

min

Page 21

Operation | 21

6 720 644 144 (2010/09)

4.4 Setting the heating control unit

Fig. 9

Follow the operating instructions for the heating

controller used. Those instructions will tell you

B how to set the operating mode and the heating

curve for weather-dependent controllers,

B how to adjust the room temperature,

B how to heat economically and save energy.

9

12

h

15

18

21

24

h

3

6

6 720 612 660-07.2O

Page 22

22 | Operation

6 720 644 144 (2010/09)

4.5 Appliances with hot water cylinder: setting

the hot water temperature

B Set the DHW temperature on the DHW temperature control

.

The set DHW temperature flashes on the display for

30 seconds.

Fig. 10

WARNING: Danger of scalding!

B In normal operation, do not set the temperature

higher than 60 °C.

To prevent bacterial contamination such as

legionella, we recommend setting the DHW

temperature controller to “6” (60 °C).

6 720 644 143-28.1O

max

1

2

34

5

6

reset

eco

max

1

2

3

4

e

6

Page 23

Operation | 23

6 720 644 144 (2010/09)

eco button

Pressing and holding the eco button until it lights up switches

between Comfort mode and Economy mode.

Comfort mode, Eco button is not lit (default setting)

In Comfort mode, the hot water cylinder has priority. The hot

water cylinder is heated to the set temperature first. Then the

appliance switches to central heating mode.

Economy mode, Eco button lit

In Economy mode, the appliance switches between central

heating mode and hot water mode every ten minutes.

DHW thermostat DHW temperature

min Approx. 5 °C (frost

protection)

e Approx. 55 °C

6 Approx. 60 °C

max. Approx. 70 °C

Table 4

Page 24

24 | Operation

6 720 644 144 (2010/09)

4.6 ZWB appliances - setting hot water

temperature

B Set the DHW temperature on the DHW temperature control

.

The set DHW temperature flashes on the display for

30 seconds.

Fig. 11

DHW thermostat DHW temperature

min Approx. 40 °C

eApprox. 50°C

max. Approx. 60 °C

Table 5

eco

reset

max

1

2

3

4

e

6

6 720 644 143-29.1O

max

1

2

34

5

6

Page 25

Operation | 25

6 720 644 144 (2010/09)

eco button

Pressing and holding the eco button until it lights up switches

between Comfort mode and Economy mode.

Comfort mode, (Eco button is not lit - default setting)

The appliance is held constantly at the set temperature. This

means that hot water is available almost instantaneously at the

tap.

Consequently the appliance will switch on at intervals, even if no

hot water is being drawn.

Economy mode, Eco button lit

• The water is not heated up until a hot water tap is turned on.

• With a demand signal (only with start delay switched off for

the supply of water preheated by solar energy). Briefly turning

a hot water tap on and then off signals demand so that the

water is then heated up to the set temperature.

If a start delay for the supply of water preheated by

solar energy has been set (service function b.F), the

appliance does not switch on until the start delay

has elapsed.

The demand signal enables gas and water savings.

Page 26

26 | Operation

6 720 644 144 (2010/09)

4.7 Summer mode (central heating off, DHW

only)

B Note position of CH flow temperature control .

B Turn CH flow temperature control anti-clockwise as far as

the stop .

The heating circuit pump and consequently central heating are

switched OFF. However, the DHW supply as well as the power

supply to the heating programmer and timer remain 'live'.

Fig. 12

Additional instructions are contained in the operating instructions

for the heating programmer.

NOTE: Heating system at risk from frost.

6 720 644 143-30.1O

eco

reset

max

1

2

3

5

6

max

1

2

3

4

e

6

min

Page 27

Operation | 27

6 720 644 144 (2010/09)

4.8 Frost protection

Frost protection for the heating system:

B Leave appliance switched on, set CH flow temperature control

to position 1 at least.

Fig. 13

B Add anti-freeze to the heating water (see installation

instructions) and drain the DHW circuit.

Additional instructions are contained in the operating instructions

for the heating programmer.

Frost protection for the cylinder:

B Turn DHW temperature controller clockwise as far as it will go

(5 °C).

Fig. 14

eco

reset

max

1

2

3

5

6

max

1

2

3

4

e

6

6 720 644 143-31.1O

min

max

1

2

3

e

6

max

1

2

34

5

6

eco

6 720 644 143-32.1O

min

Page 28

28 | Operation

6 720 644 144 (2010/09)

4.9 Holiday mode

To switch on holiday mode:

B Press and hold holiday button on the appliance until it

lights up, and switch on holiday mode on the heating

controller.

In holiday mode, heating and DHW heating are switched off;

frost protection remains active (Æ chap. 4.8).

To switch off holiday mode:

B Press and hold holiday button on the appliance until it

goes out, and cancel holiday mode on the heating controller.

The appliance returns to operation in standard mode according

to the settings at the heating control unit.

Page 29

Operation | 29

6 720 644 144 (2010/09)

4.10 Further displays

Display

code

Description

Fault code (Æ chapter 7)

Inspection due

Pump anti-seize function active

Trap filling function active

Bleeding function active

Excessively rapid increase in CH flow temperature

(temp. gradient monitoring).

Heating mode is disabled for two minutes.

Drying function. If the floor drying function is activated

on the weather-dependent controller, refer to

controller instructions.

Table 6

Page 30

30 | Carry out thermal disinfection

6 720 644 144 (2010/09)

5 Carry out thermal disinfection

To prevent the DHW becoming contaminated by bacteria such as

legionella, we recommend you pasteurise the system after longer

idle periods.

Pasteurisation covers the DHW system including the draw-off

points. For solar DHW cylinders, the solar portion of the cylinder

is not covered.

B Turn off all hot water points.

B Warn occupants of risk of scalding.

B If the heating programmer has a DHW program, set the time

and DHW temperature accordingly.

B If there is a circulation pump, set it to run continuously.

With some heating controllers, thermal disinfection

can be programmed for a fixed time; see heating

controller operating instructions.

DANGER: Risk of scalding!

Hot water can result in severe scalding.

B Carry out thermal disinfection only outside the

normal hours of use.

B The water in the tank will take a while to cool

down to the set hot water temperature as a

result of heat loss. Be aware that, after thermal

disinfection, the hot water may be hotter than

the set temperature.

Page 31

Carry out thermal disinfection | 31

6 720 644 144 (2010/09)

B Turn hot water temperature control clockwise as far as the

stop (approx. 70 °C).

Fig. 15

B Wait until the water reaches the maximum temperature.

B Draw off water in turn from the nearest to the furthest hot

water point until hot water has been running out at a

temperature of 70 °C for 3 minutes.

B Reset DHW temperature control, circulation pump and heating

programmer to their standard settings.

If you want to interrupt thermal disinfection:

B Switch the appliance off and then on again at the

main switch.

The appliance will start up again and the central

heating flow temperature will be displayed.

6 720 644 143-33.1O

max

1

2

34

5

6

reset

eco

max

1

2

3

4

e

6

Page 32

32 | Tips on saving energy

6 720 644 144 (2010/09)

6 Tips on saving energy

Heating economically

The boiler is designed to provide a high level of comfort while

keeping gas consumption and the resulting environmental impact

as low as possible. The gas supply to the burner is controlled

according to the level of demand for heat. The boiler continues to

operate with a low flame if the demand for heat reduces. The

technical term for this process is modulating control. Modulating

control keeps temperature fluctuations small and provides even

distribution of heat throughout the home. This means that the

boiler may stay on for relatively long periods but will use less gas

than an appliance that continually switches on and off.

Inspection/Maintenance

To ensure that gas consumption and environmental impact

(pollution, etc.) remain as low as possible over an extended

period of time, we recommend that you take out an inspection/

maintenance contract with an authorised installer covering the

annual inspection and servicing and maintenance at other times

as required.

Heating control system

Additional instructions are contained in the operating instructions

for the heating controller.

Page 33

Tips on saving energy | 33

6 720 644 144 (2010/09)

Thermostat

Fully open the thermostat to ensure that the required room

temperature is reached in all cases. Only after the required

temperature has been reached and maintained for an extended

period of time should you change the setting for the heating curve

or the room temperature on the controller.

Underfloor heating

Do not set the heating-up temperature higher than the maximum

level recommended by the manufacturer.

Ventilating

Do not keep windows slightly open for ventilation purposes. This

would continuously cool down the room without significantly

improving the air in the room. It is better to ventilate fully for a

short time (with completely open windows).

Turn off the thermostat when ventilating.

Hot water

Always set the hot water temperature to as low as possible.

A lower setting on the thermostat means a higher rate of energy

savings.

Furthermore, higher hot water temperatures result in increased

limescale deposits and thereby impair the function of the

appliance (e.g. longer heating-up times or lower output).

Circulation pump

If there is a circulation pump for hot water, use a timer programme

to control its operation according to the specific requirements

(e.g. morning, afternoon, evening).

Page 34

34 | Troubleshooting

6 720 644 144 (2010/09)

7Troubleshooting

All safety, modulation and control components are monitored by

the Heatronic system.

If a fault occurs during operation, a warning tone sounds.

The display indicates a fault (e. g. ) and the reset-button may

also flash.

If the reset button flashes:

B Press and hold the reset button until the display shows .

The appliance will start up again and the flow temperature will

be displayed.

If the reset button does not flash:

B Switch the appliance off and then on again at the main switch.

The appliance will start up again and the central heating flow

temperature will be displayed.

If the fault persists:

B Contact your authorised contractor or customer service for

assistance, providing details of the fault and the appliance.

If you press a button, the warning tone stops.

An overview of the display indications can be found

on page 29.

Page 35

Troubleshooting | 35

6 720 644 144 (2010/09)

Appliance details

If you need to call Customer Services, it is helpful if you have the

precise details of your appliance at hand.

Those details can be found on the identification plate or

identification sticker inside the control panel cover.

Condens 5000 W (e. g. ZWB 37-2A...)..............................

Serial number.................................................................

Date commissioned: ........................................................

System installed by: ........................................................

Page 36

36 | Maintenance

6 720 644 144 (2010/09)

8 Maintenance

Inspection and maintenance

The operator is responsible for the safety and environmental

compatibility of the heating system (see local regulations).

It is therefore recommended that you enter into a maintenance

and inspection contract with an approved contractor that

provides annual inspection and maintenance. This ensures high

efficiency and environmentally compatible combustion.

Cleaning the outer casing

Wipe down with a damp cloth. Do not use any abrasive or

corrosive cleaning agents.

Page 37

Environment / disposal | 37

6 720 644 144 (2010/09)

9 Environment / disposal

Environmental protection is a fundamental corporate strategy of

Bosch Group.

The quality of our products, their economy and environmental

safety are all of equal importance to us and all environmental

protection legislation and regulations are strictly observed.

We use the best possible technology and materials for protecting

the environment taking account of economic considerations.

Packaging

We participate in the recycling programmes of the countries in

which our products are sold to ensure optimum recycling.

All of our packaging materials are environmental-friendly and can

be recycled.

Used appliances

Used appliances contain valuable materials that should be

recycled.

The various assemblies can be easily dismantled and synthetic

materials are marked accordingly. Assemblies can therefore be

sorted by composition and passed on for recycling or disposal.

Page 38

38 | Operating instructions quick reference

6 720 644 144 (2010/09)

10 Operating instructions

quick reference

Switching on

Switching on the central

heating

Heating control

Set weather-dependent heating

controller to the relevant

heating curve and operating

mode or set room thermostat to

the desired temperature

.

Domestic hot water

temperature

Eco button lit – Economy mode.

Eco button not lit – Comfort

mode.

Frost protection

m

a

x

1

2

3

4

5

6

6 720 613 896-05.1O

eco

reset

6 720 644 143-27.1O

max

1

2

3

4

5

6

max

1

2

3

4

e

6

min

WARNING:

Risk of scalding

B Do not set the

temperature

control to more

than “e”.

6 720 644 143-28.1O

max

1

2

34

5

6

reset

eco

max

1

2

3

4

e

6

eco

reset

max

1

2

3

5

6

max

1

2

3

4

e

6

6 720 644 143-31.1O

min

Page 39

Index | 39

6 720 644 144 (2010/09)

Index

A

Appliance

- Switching off......................................................................... 18

C

Carry out thermal disinfection................................................... 30

Central heating

- Switching on ................................................................... 19, 38

Comfort mode...................................................................... 23, 25

E

Eco button ........................................................................... 23, 25

Economy mode .................................................................... 23, 25

Environment / disposal .............................................................. 37

Explanation of model code .......................................................... 8

F

Frost protection......................................................................... 27

H

Heating control .......................................................................... 38

I

Intended use ................................................................................ 8

O

Operation................................................................................... 14

Page 40

40 | Index

6 720 644 144 (2010/09)

P

Packaging................................................................................... 37

Preparing the appliance for use................................................... 9

Product details ............................................................................ 8

- Explanation of model code ..................................................... 8

R

Recycling.................................................................................... 37

S

Safety instructions....................................................................... 6

Setting the heating control unit................................................. 21

Setting the hot water temperature

- Appliances with hot water cylinder ...................................... 22

Summer mode ........................................................................... 26

Switching off the appliance ....................................................... 18

Switching on the central heating......................................... 19, 38

T

Thermal disinfection .................................................................. 30

Troubleshooting......................................................................... 34

U

Used appliances......................................................................... 37

Page 41

| 41

6 720 644 144 (2010/09)

Notes

Page 42

42 |

6 720 644 144 (2010/09)

Notes

Page 43

| 43

6 720 644 144 (2010/09)

Notes

Page 44

Australia

Robert Bosch (Australia) Pty Ltd

1555 Centre Rd

Clayton, VIC 3168

Phone 1300 30 70 37

Fax 1300 30 70 38

www.bosch.com.au/hotwater

New Zealand

Phone 0800 4 Bosch or 08 543 352

www.bosch.co.nz

Loading...

Loading...