Page 1

Installation and servicing instructions for contractors

Hydronic Gas Condensing Boiler

Condens 5000 W

6 720 613 085-00.1O

ZSB 30-2 A ...| ZWB 37-2 A ...

6 720 644 143 (2010/09) NZ/AU

Page 2

2 | Contents

6 720 644 143 (2010/09)

Contents

1 Key to symbols and safety instructions . . . . . . . 5

1.1 Explanation of symbols . . . . . . . . . . . . . . 5

1.2 Safety instructions . . . . . . . . . . . . . . . . . . 5

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Explanation of model code . . . . . . . . . . . 7

3.3 Gas type . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Type plate . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Description of appliance . . . . . . . . . . . . . 8

3.6 Accessories . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Dimensions and minimum clearances . . . 9

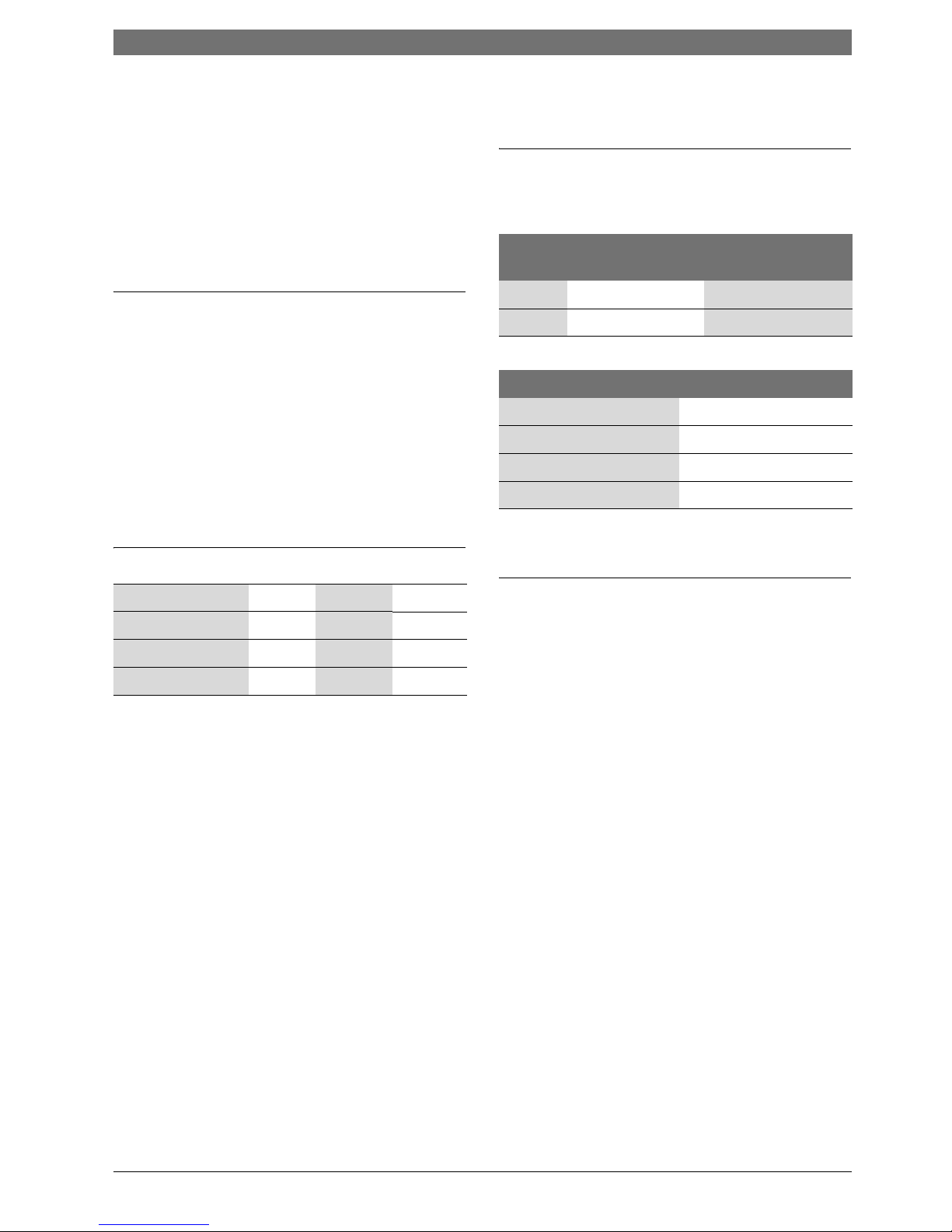

3.8 Appliance layout . . . . . . . . . . . . . . . . . . 10

3.9 Electrical wiring diagram . . . . . . . . . . . . 12

3.10 Specification ZSB 30-2 ... . . . . . . . . . . . 16

3.11 Specification ZWB 37-2 ... . . . . . . . . . . . 17

3.12 Condensate composition . . . . . . . . . . . . 18

4 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Water system and pipe work . . . . . . . . . 20

5.2 Condensate pipe work . . . . . . . . . . . . . 22

5.2.1 Internal connections . . . . . . . . . . . . . . . 22

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Important notes . . . . . . . . . . . . . . . . . . . 24

6.2 Checking the size of the expansion

vessel . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Siting the appliance . . . . . . . . . . . . . . . . 25

6.4 Pre-installing pipes . . . . . . . . . . . . . . . . 26

6.5 Fitting the appliance . . . . . . . . . . . . . . . 28

6.6 Checking the connections . . . . . . . . . . . 32

7 Electrical connections . . . . . . . . . . . . . . . . . . . . 33

7.1 General information . . . . . . . . . . . . . . . . 33

7.2 Connecting accessories . . . . . . . . . . . . . 33

7.2.1 Connecting the heating controller or

remote control units . . . . . . . . . . . . . . . 34

7.2.2 Connecting the DHW cylinder . . . . . . . . 34

7.2.3 Connecting temperature limiter TB 1

from the flow of an underfloor

heating system . . . . . . . . . . . . . . . . . . . 34

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1 Before commissioning . . . . . . . . . . . . . 36

8.2 Switching the appliance on/off . . . . . . 36

8.3 Starting the central heating . . . . . . . . . 37

8.4 Setting the heating control unit . . . . . . 37

8.5 After commissioning . . . . . . . . . . . . . . . 37

8.6 Appliances with hot water cylinder:

setting the hot water temperature . . . . 38

8.7 ZWB appliances - setting hot water

temperature . . . . . . . . . . . . . . . . . . . . . 39

8.8 Summer mode (central heating off,

DHW only) . . . . . . . . . . . . . . . . . . . . . . . 39

8.9 Frost protection . . . . . . . . . . . . . . . . . . 39

8.10 Holiday mode . . . . . . . . . . . . . . . . . . . . 40

8.11 Fault mode . . . . . . . . . . . . . . . . . . . . . . 40

9 Thermal disinfection on appliances

with hot water cylinder . . . . . . . . . . . . . . . . . 41

10 Pump anti-seizing function . . . . . . . . . . . . . . . . 42

11 Heatronic settings . . . . . . . . . . . . . . . . . . . . . . . 43

11.1 General information . . . . . . . . . . . . . . . 43

11.2 Overview of service functions . . . . . . . 44

11.2.1 Service level 1 . . . . . . . . . . . . . . . . . . . 44

11.2.2 Service level 2 . . . . . . . . . . . . . . . . . . . 44

11.3 Description of service functions . . . . . 45

11.3.1 Service level 1 . . . . . . . . . . . . . . . . . . . 45

11.3.2 Service level 2 . . . . . . . . . . . . . . . . . . . 49

12 Converting the appliance to different

gas types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

12.1 Gas-type conversion . . . . . . . . . . . . . . . 50

12.2 Setting the gas-air ratio (CO2 or O2) . . 50

12.3 Checking the gas supply pressure . . . . 52

13 Flue gas testing . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.1 Central heating boost button . . . . . . . . 53

13.2 Checking flue system for leaks . . . . . . . 53

13.3 Measuring CO content of flue gas . . . . 53

14 Environmental protection . . . . . . . . . . . . . . . . . 54

Page 3

Contents | 3

6 720 644 143 (2010/09)

15 Inspection/Servicing . . . . . . . . . . . . . . . . . . . . . 55

15.1 Checklist for inspection/servicing

(Inspection/Servicing report) . . . . . . . . 56

15.2 Description of various servicing

operations . . . . . . . . . . . . . . . . . . . . . . . 57

15.2.1 Retrieving last fault stored

(service function 6.A) . . . . . . . . . . . . . . 57

15.2.2 Checking electrodes . . . . . . . . . . . . . . . 57

15.2.3 Strainer in cold water pipe (ZWB) . . . . 57

15.2.4 Plate type heat exchanger (ZWB) . . . . . 58

15.2.5 Heat exchanger . . . . . . . . . . . . . . . . . . 59

15.2.6 Burner . . . . . . . . . . . . . . . . . . . . . . . . . 61

15.2.7 Diaphragm in mixer unit . . . . . . . . . . . . 62

15.2.8 Cleaning condensate trap . . . . . . . . . . 62

15.2.9 Checking the expansion vessel

(see also page 25) . . . . . . . . . . . . . . . . . 62

15.2.10 Setting the heating system pressure . . 63

15.2.11 Checking electrical wiring . . . . . . . . . . 63

16 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

17 Fault mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

17.1 Troubleshooting . . . . . . . . . . . . . . . . . . 66

17.2 Faults that are shown on the

display . . . . . . . . . . . . . . . . . . . . . . . . . . 67

17.3 Faults that are not shown

on the display . . . . . . . . . . . . . . . . . . . . 70

17.4 Sensor values . . . . . . . . . . . . . . . . . . . . 71

17.4.1 Outside temperature sensor

(for weather-compensated controllers,

accessory) . . . . . . . . . . . . . . . . . . . . . . . 71

17.4.2 Flow and DHW sensors . . . . . . . . . . . . 71

17.5 Code Plug . . . . . . . . . . . . . . . . . . . . . . . 71

17.6 Settings for heating output with

ZSB 30 ...23 . . . . . . . . . . . . . . . . . . . . . . 72

17.7 Settings for heating output with

ZSB 30 ...31 . . . . . . . . . . . . . . . . . . . . . . 72

17.8 Settings for heating output with

ZWB 37 ...23 . . . . . . . . . . . . . . . . . . . . . 73

17.9 Settings for heating output with

ZWB 37 ...31 . . . . . . . . . . . . . . . . . . . . . 73

18 Commissioning report for the appliance . . . . . 74

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Page 4

4 | Contents

6 720 644 143 (2010/09)

Page 5

Key to symbols and safety instructions | 5

6 720 644 143 (2010/09)

1 Key to symbols and safety instructions

1.1 Explanation of symbols

Warning symbols

Signal words indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates possible damage to property or

equipment, but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Important information

Additional symbols

1.2 Safety instructions

If you smell gas

B Turn off gas tap (Æ page 35).

B Open windows and doors.

B Do not operate any electrical switches.

B Extinguish any naked flames.

B Leave the building and telephone your gas supply

utility and authorised contractor from an outside

phone.

If you smell flue gas from the appliance

B Switch off the appliance (Æ page 36).

B Open windows and doors.

B Inform your heating contractor.

Explosive and easily flammable materials

Never use or store easily flammable materials (paper,

thinners, paints, etc.) near the appliance.

Combustion air/ambient air

To prevent corrosion, keep the supply of combustion/

ambient air free of corrosive substances (e.g.

halogenated hydrocarbons that contain chlorine or

fluorine compounds).

Thermal disinfection

B Risk of scalding!

It is imperative to monitor operation at water

temperatures over 60 °C (Æ page 41).

Safety instructions in this document are

framed and identified by a warning triangle

which is printed on a grey background.

Electrical hazards are identified by a

lightning symbol surrounded by a warning

triangle.

Notes contain important information in

cases where there is no risk of personal

injury or material losses and are identified

by the symbol shown on the left. They are

bordered by horizontal lines above and

below the text.

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the

document or to other related documents

• a list entry

– a list entry (second level)

Table 1

Page 6

6 | Standard delivery

6 720 644 143 (2010/09)

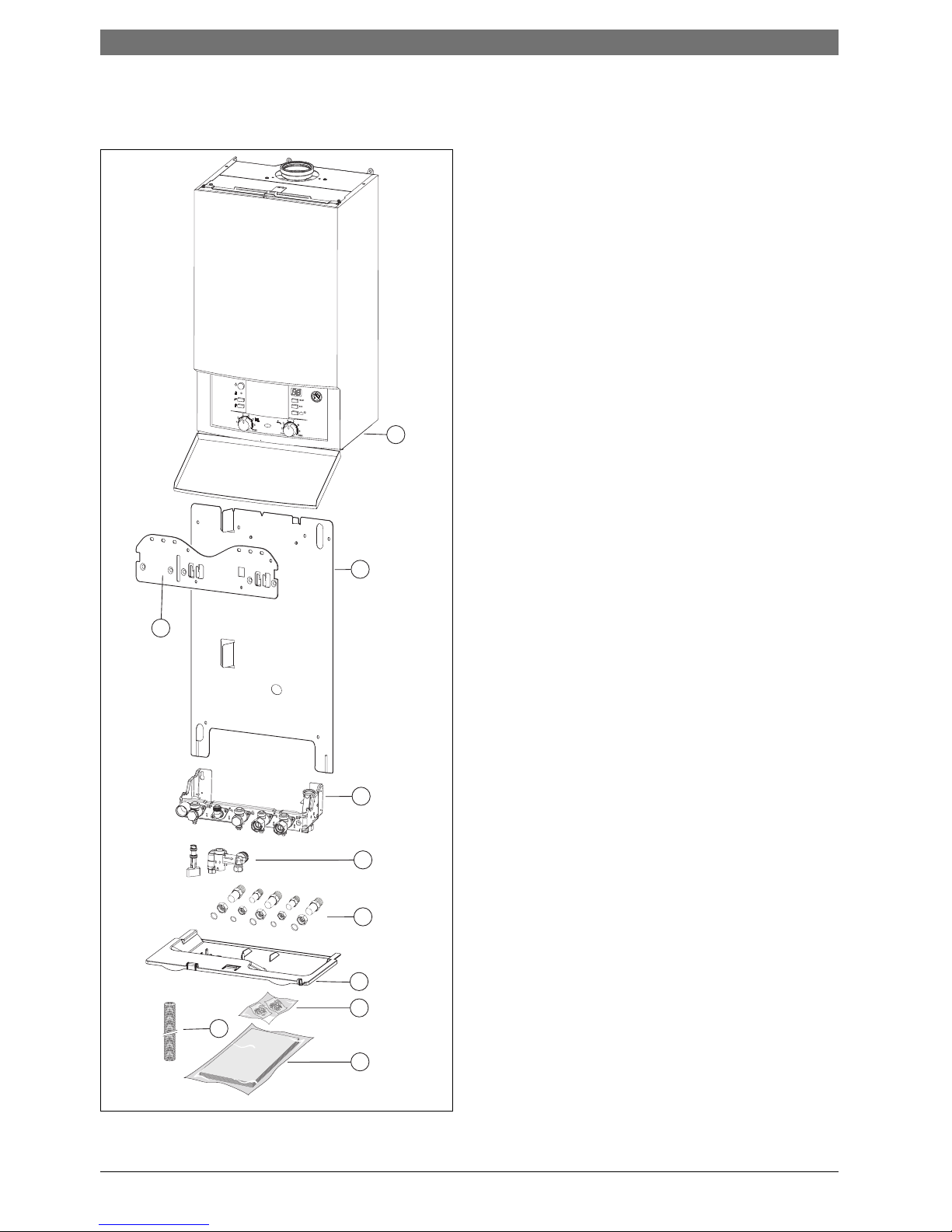

2 Standard delivery

Fig. 1

Key:

1 Gas condensing boiler

2 Pre-plumbing jig

3 Mounting rail

4 Pre-plumbing jig for ZWB appliances

(for ZSB appliances without cold and DHW water

connections)

5 Filling loop with key (ZWB)

6 Adaptors for ZWB appliances

(for appliances ZSB without adaptors for cold cold and

DHW water connections)

7 Lower cover

8 Pressure relief valve hose (heating circuit)

9 Fixing kit

10 Set of printed documents for the appliance

6 720 644 143-01.1O

1

2

8

9

10

3

4

6

7

5

Page 7

Product details | 7

6 720 644 143 (2010/09)

3 Product details

ZSB appliances are boilers for heating. They can be

fitted with the diverter valve accessory to connect to an

indirectly heated hot water cylinder.

ZWB appliances are combi boilers for central heating

(CH) and domestic hot water (DHW) heating according

to the instantaneous water heating principle.

3.1 Intended use

The appliance may only be installed in a sealed unvented

central heating system.

This appliance is intended for indoor use only. It is not

to be used as a pool heater.

Using the appliance for any other purpose will be

considered incorrect use. Bosch accepts no liability for

any damage resulting from such use.

The commercial and industrial use of the appliance to

generate process heat is not permitted.

3.2 Explanation of model code

Z Central heating appliance

S Cylinder connection

W DHW heating

B Condensing boiler technology

30 Output up to 30 kW

37 DHW output up to 37 kW

-2 Version

A Fan-assisted appliance without draught hood

23 Natural gas H

Note: Appliances can be converted to LPG.

31 LPG

S2414 Special number for Australia/New Zealand

3.3 Gas type

The code number indicates the gas family according to

AS 4552:

3.4 Type plate

The type plate [47] can be found on the inside of the

appliance at the bottom right (Æ Fig. 3, page 10).

It contains details of the output of the appliance, the

order number, the approval data and the date of

manufacture in encoded form.

ZSB 30-2 A 23 S2414

ZSB 30-2 A 31 S2414

ZWB 37-2 A 23 S2414

ZWB 37-2 A 31 S2414

Table 2

Code

number

Wobbe index

(W

S

) (15 °C) Gas type

23 12.2 - 55.0 MJ/m3NG

31 72.9 - 87.2 MJ/m3LPG

Table 3

LPG type1)

1) according to NZS 5435

Use

Commercial Propane recommended

Commercial Butane permitted

General Product permitted

Universal LPG (U-LPG) permitted

Table 4

Page 8

8 | Product details

6 720 644 143 (2010/09)

3.5 Description of appliance

• Wall mounted boiler; installation independent of

chimney location or room size.

• Intelligent heating circuit pump control when

connected to an weather-dependent heating

controller

• Heatronic 3 controls with 2-wire BUS

• ZWB appliances can be supplied with water

preheated by solar energy, Æ page 24

• Optimised electronic heating circuit pump with:

– 2 proportional pressure curves

– 3 constant pressure curves

– 6 stages can be selected

– Run-dry protection and anti-seizing function

• Connecting lead with mains plug

• Display

• Automatic ignition

• Modulating output control

• Fully featured safety system provided by Heatronic

module with flame failure detection and solenoid

valves to EN 298

• No minimum water circulation rate required

• Suitable for underfloor heating

• Connection option for concentric pipe for flue gas/

combustion air Ø 80/125 mm, Ø 60/100 mm

• Variable speed fan

• Premix burner

• Temperature sensor and temperature control for

central heating

• Temperature sensor in flow

• Safety temperature limiter in 24 V electrical circuit

• Pressure relief valve, pressure gauge, expansion

vessel

• Optional for DHW cylinder temperature sensor (NTC)

• Flue gas temperature limiter

• DHW priority

• Plate type heat exchanger (ZWB)

• Motorised three-way valve (ZWB)

• Filling loop (ZWB)

• Pre-plumbing jig

3.6 Accessories

• Flue kits

• Weather-compensated controller, e.g. FW 100

• Room temperature controller, e.g. FR 10, FR 110

• Digital time switch, e.g. DT 10 RF, DT 20 RF

• Cylinder temperature sensor SF 2 for third party

cylinders

• Optional Diverter Valve Kit for DHW cylinder

connection including cylinder temperature sensor

(ZSB only).

Below is a list of typical accessories for this

appliance. You can find comprehensive

details of all available accessories in our

catalogue.

Page 9

Product details | 9

6 720 644 143 (2010/09)

3.7 Dimensions and minimum clearances

Fig. 2

1 Pre-plumbing jig

2 Casing

3 Fascia

A Additional 30 mm above elbow

B Using 100 mm flue kit: 1112 mm /

120 mm flue kit: 1152 mm

C 20 mm to reversible door /

600 mm front clearance for service

440

min.

5

067

2

360

85

3

125

80

min.

5

087

6 720 644 143-02.2J

340

55

1

0200

A

B

C

Page 10

10 | Product details

6 720 644 143 (2010/09)

3.8 Appliance layout

Fig. 3

6 720 644 143-03.1O

30

31

32

33

34

35

39

40

38

37

36

41

42

43

44

45

46

47

48

49

12

10

9

8

7

1

2

3

4

5

6

11

29

28

27

26

25

24

23

22

21

20

17

18

19

16

15

14

13

Page 11

Product details | 11

6 720 644 143 (2010/09)

Key to figure 3:

1 Heatronic 3

2 Main switch

3 Burner ON indicator

4 Service button

5 Central heating boost button

6 Here, a weather-compensated control unit or a time switch

(accessories) can be plugged in

7 CH Flow temperature control

8 DHW temperature control

9 Holiday button

10 eco button

11 reset button

12 Display

13 DHW (ZWB)

14 CH flow

15 Adaptor for condensate hose

16 Condensate syphon

17 Gas supply pressure test port

18 Gas valve

19 DHW temperature sensor

20 Adjustable gas throttle

21 Test point for control pressure

22 Flue gas temperature limiter

23 Fan

24 Flow temperature sensor

25 Expansion vessel

26 Mixer unit

27 Bracket

28 Removable cover

29 Combustion air inlet

30 Flue pipe

31 Sight glass

32 Set of electrodes

33 Heat exchanger

34 Temperature limiter for heat exchanger

35 Access port for cleaning heat exchanger

36 Condensate tray

37 Automatic air vent valve

38 Plate-type heat exchanger (ZWB)

39 Turbine (ZWB)

40 Heating circuit pump

41 3-way diverter valve

42 Pressure relief valve (heating circuit)

43 Pressure gauge

44 Drain tap

45 Cold water inlet

46 Heating return

47 Type plate

48 Filling loop (ZWB)

49

Gas connection

Page 12

12 | Product details

6 720 644 143 (2010/09)

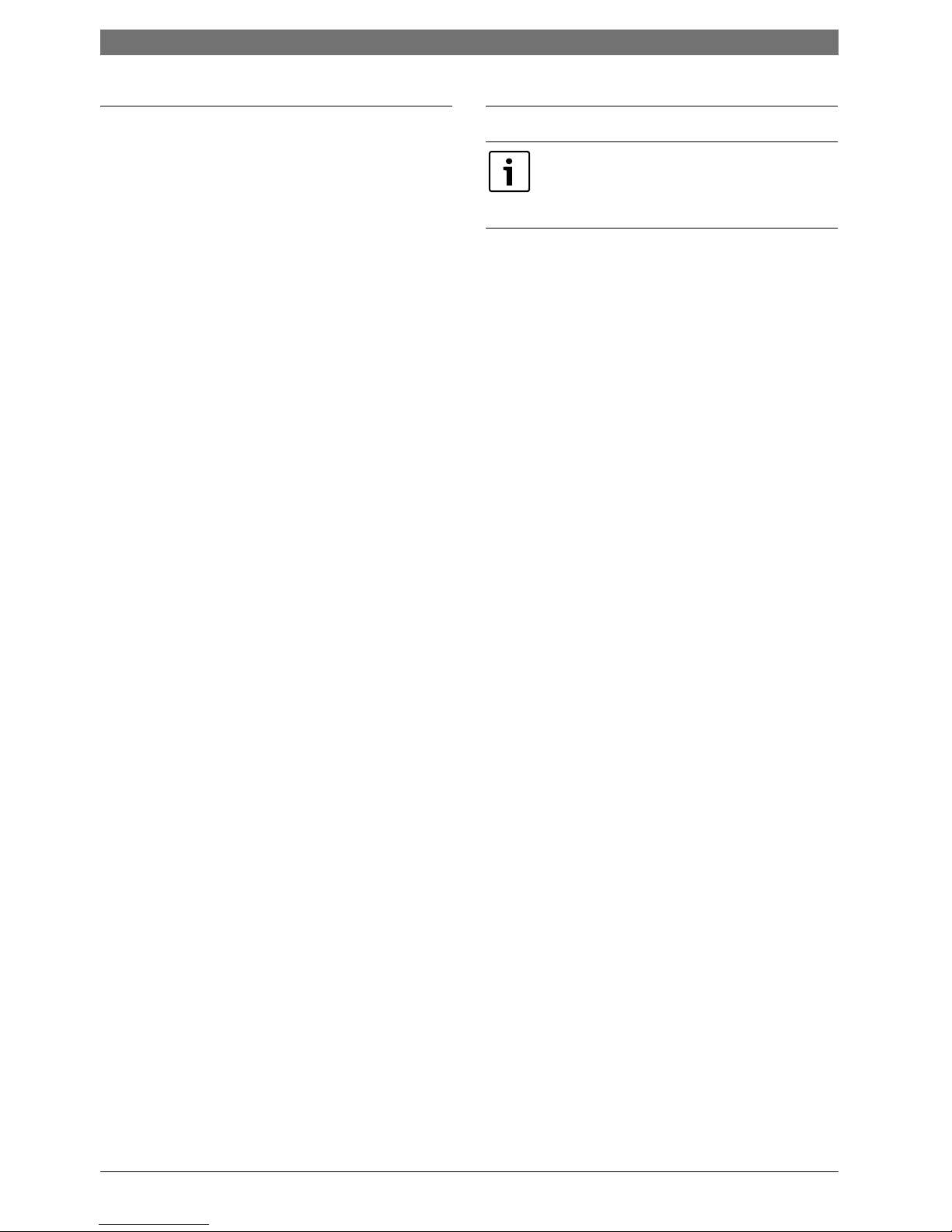

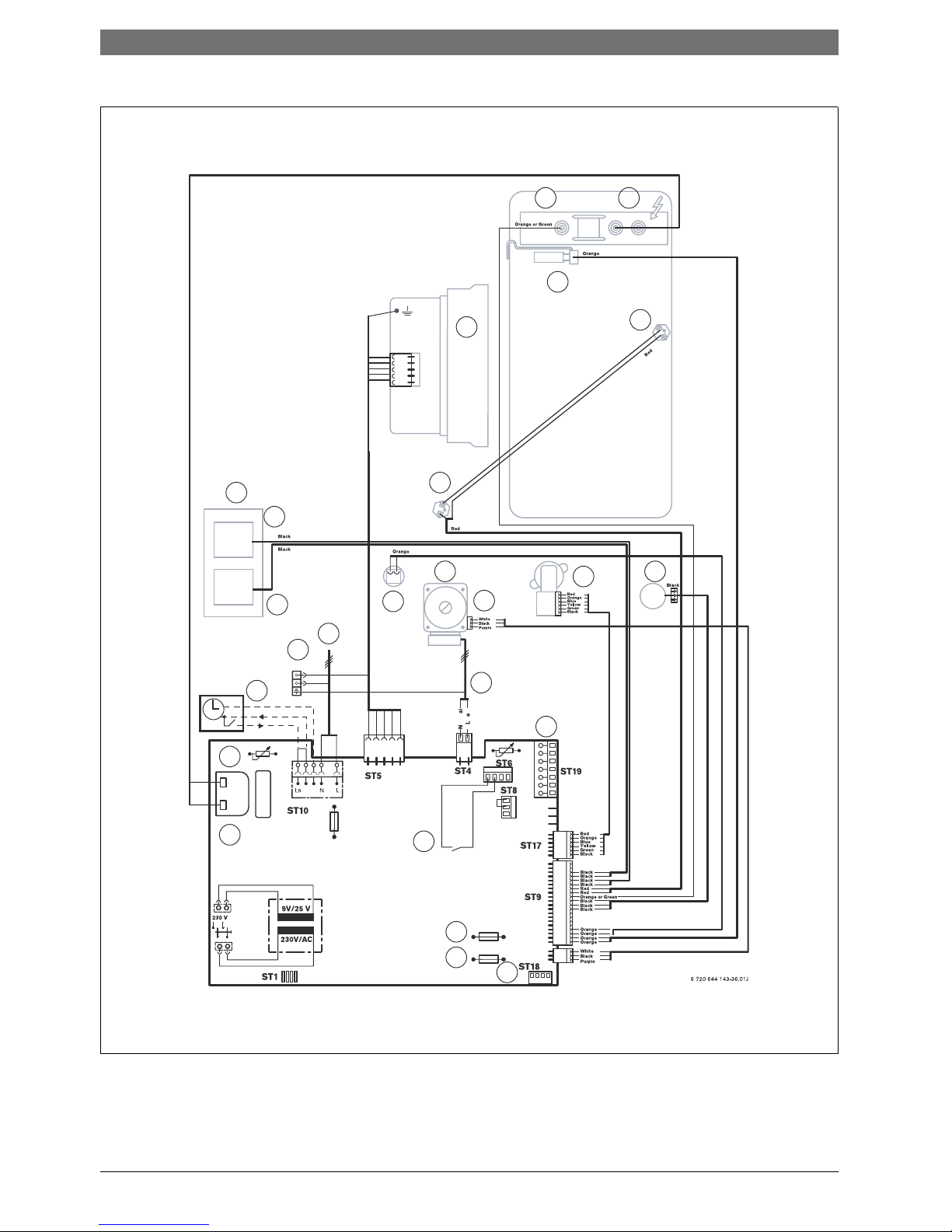

3.9 Electrical wiring diagram

Fig. 4 ZSB 30-2

ST1

k

k

B

B

2

4

F

1

A

14

15

16

17

12

13

11

18

22

21

10

1

2

3

4

5

6

7

8

9

19

20

Page 13

Product details | 13

6 720 644 143 (2010/09)

1 Spark transformer

2 CH temperature control

3 Wiring centre

4 Safety solenoid

5 Safety solenoid

6 Gas valve

7 Fan

8 Flame sense eletrode

9 Spark electrodes

10 Flow NTC

11 Heat exchanger overheat stat.

12 Flue overheat stat.

13 Earth

14 Mains supply

15 Pump

16 Pump control

17 Diverter valve (optional)

18 Pump supply

19 DHW temperature control

20 Fluse slow T 0.5 A

21 Fluse slow T 1.6 A

21 Code plug

Page 14

14 | Product details

6 720 644 143 (2010/09)

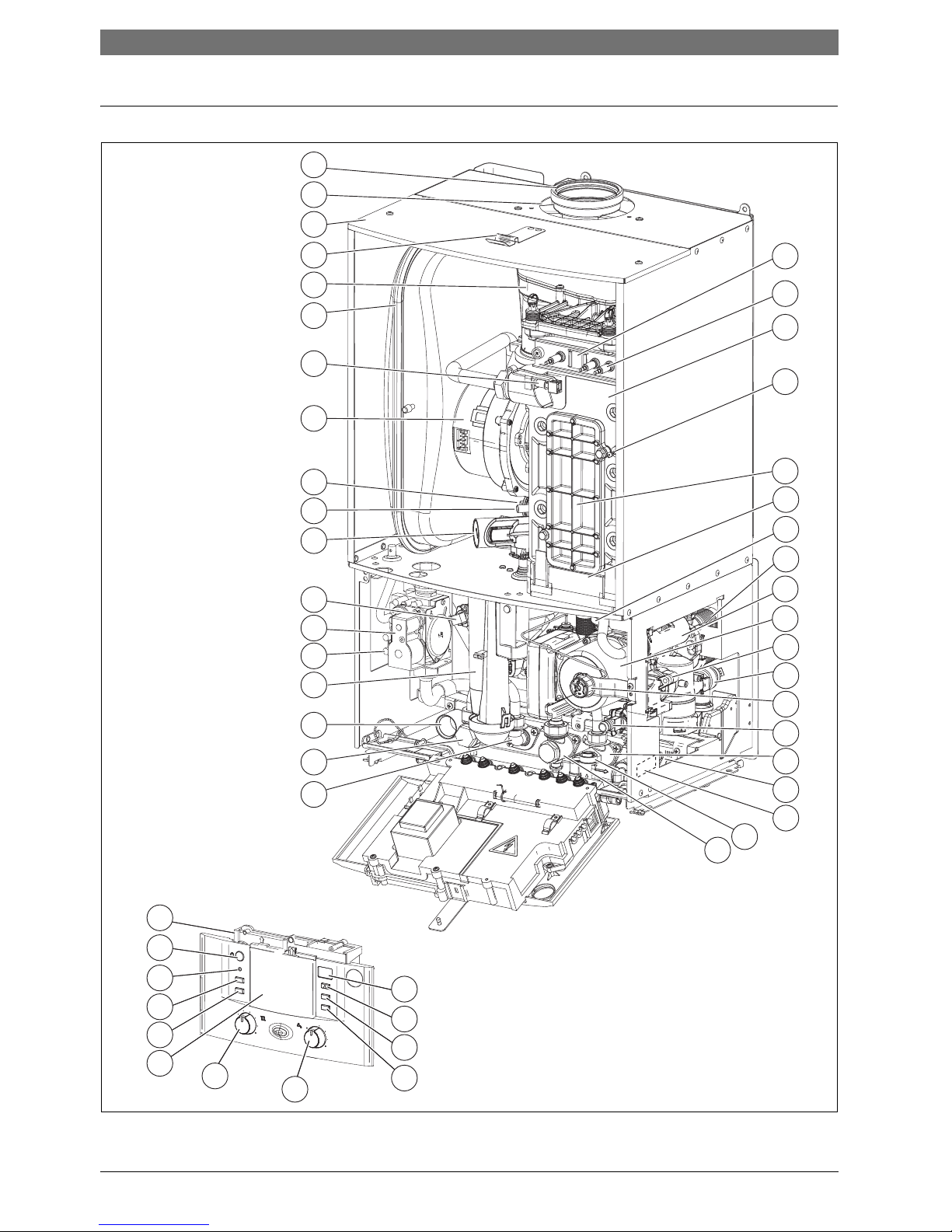

Fig. 5 ZWB 37-2

Ls Ns

rtue

vi

B

B

2

4

F

1

A

14

15

16

17

12

13

11

18

23

24

22

25

21

10

1

2

3

4

5

6

7

8

9

19

20

Page 15

Product details | 15

6 720 644 143 (2010/09)

1 Spark transformer

2 CH temperature control

3 230 V room stat/programmer

4 Safety solenoid

5 Safety solenoid

6 Gas valve

7 Fan

8 Flame sense eletrode

9 Spark electrodes

10 Flow NTC

11 Heat exchanger overheat stat.

12 Flue overheat stat.

13 Earth

14 Mains supply

15 DHW sensor

16 Pump

17 Pump control

18 Diverter valve

19 Flow turbine

20 Pump supply

21 DHW temperature control

22 External frost stat (optional)

23 Fluse slow T 0.5 A

24 Fluse slow T 1.6 A

25 Code plug

Page 16

16 | Product details

6 720 644 143 (2010/09)

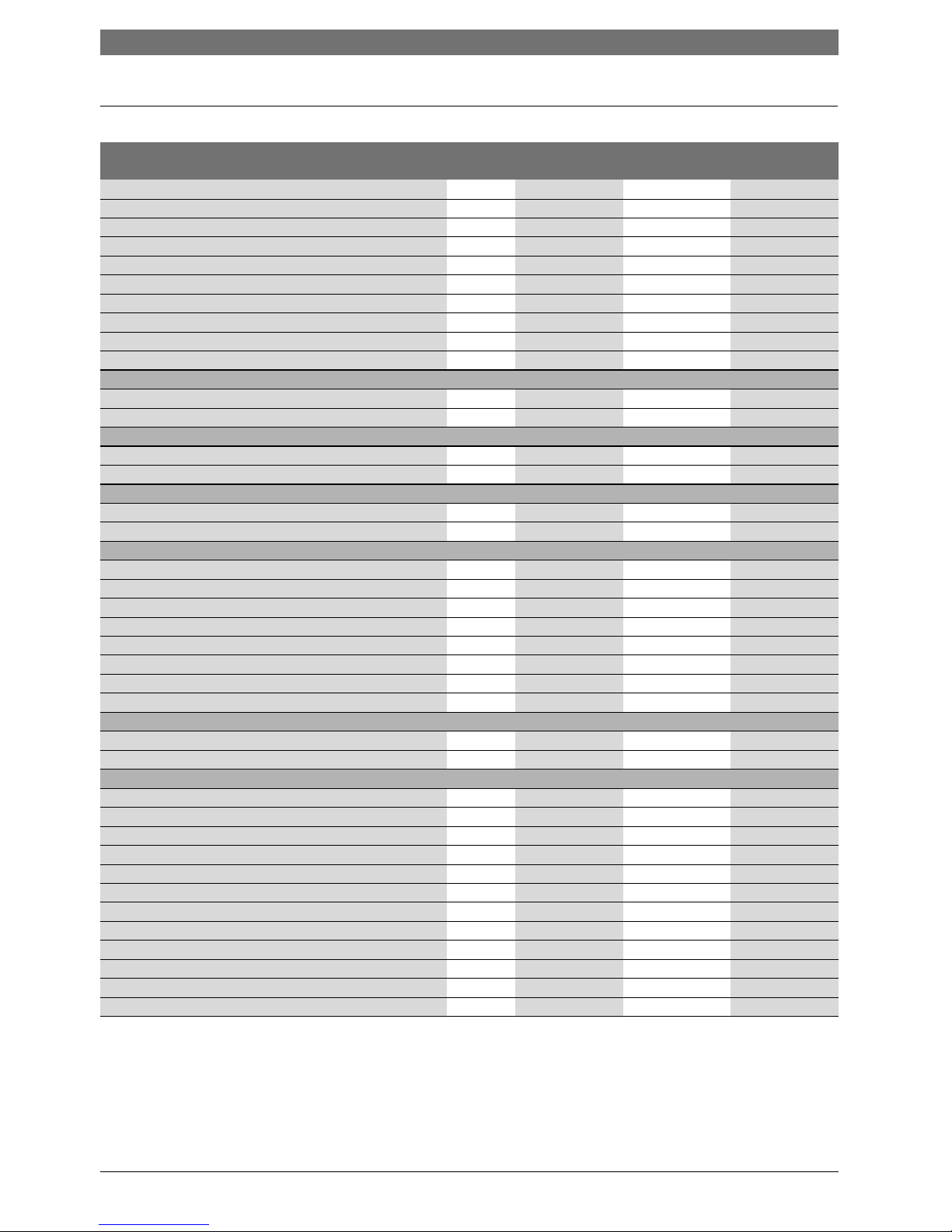

3.10 Specification ZSB 30-2 ...

ZSB 30-2 ...

Unit Natural gas Propane Butane

Max. heat output (P

max

) 40/30 °C kW 32.1 32.1 36.6

Max. heat output (P

max

) 50/30 °C kW 31.8 31.8 36.3

Max. heat output (P

max

) 80/60 °C kW 30.0 30.0 34.2

Max. gas consumption (Q

max

), central heating MJ/h 123.4 123.4 140.5

Min. heat output (P

min

) 40/30 °C kW 8.6 12.4 14.2

Min. heat output (P

min

) 50/30 °C kW 8.6 12.3 14.0

Min. heat output (P

min

) 80/60 °C kW 7.7 11.0 12.6

Min. gas consumption (Q

min

), central heating MJ/h 31.9 11.5 52.3

Max. heat output (PnW), DHW kW 30.9 45.9 35.2

Max. gas consumption (QnW), DHW MJ/h 123.4 123.4 140.5

Gas supply rate

Natural gas (gross heating value 37.8 MJ/m3)m

3

/h 3.2 - -

Butane/propane (gross heating value 50 MJ/kg) kg/h -2.42.8

Permissible gas supply pressure

NG kPa 1.1 - 3.0 - LPG kPa -2.752.75

Expansion vessel

Pre-charge pressure kPa 75 75 75

Total capacity l 10 10 10

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow rate, max./min. rated g/s 13.6/3.7 12.8/5.2 12.8/5.2

Flue gas temperature 80/60 °C max./min. rated °C 76/58 76/58 76/58

Flue gas temperature 40/30 °C max./min. rated °C 55/33 55/33 55/33

Residual pump head Pa 80 80 80

CO2 at max. rated output % 9.6 10.8 12.2

CO2 min. rated output % 9.0 10.2 11.5

Flue gas rating group to G 636/G 635 G61/G

62

G61/G

62

G61/G

62

NOx class 555

Condensate

Max. condensate quantity (tR = 30 °C) l/h 2.7 2.7 2.7

pH level, approx. 4.8 4.8 4.8

General data

Power supply voltage AC ... V 220 - 240 220 - 240 220 - 240

Frequency Hz 50 50 50

Max. power consumption (central heating mode) W 150 150 150

EMC limit class - BBB

Noise output level ≤ dB(A) 43 43 43

Appliance enclosure rating IP X4D X4D X4D

Max. flow temperature °C Approx. 90 Approx. 90 Approx. 90

Max. permissible operating pressure (PMS) heating kPa 300 300 300

Permissible ambient temperature °C 0 - 50 0 - 50 0 - 50

Nominal capacity of appliance heating l 3.5 3.5 3.5

Weight (excluding packaging) kg 46.5 46.5 46.5

Dimensions, W x H x D mm 440 x 760 x 360 440 x 760 x 360 440 x 760 x 360

Table 5

Page 17

Product details | 17

6 720 644 143 (2010/09)

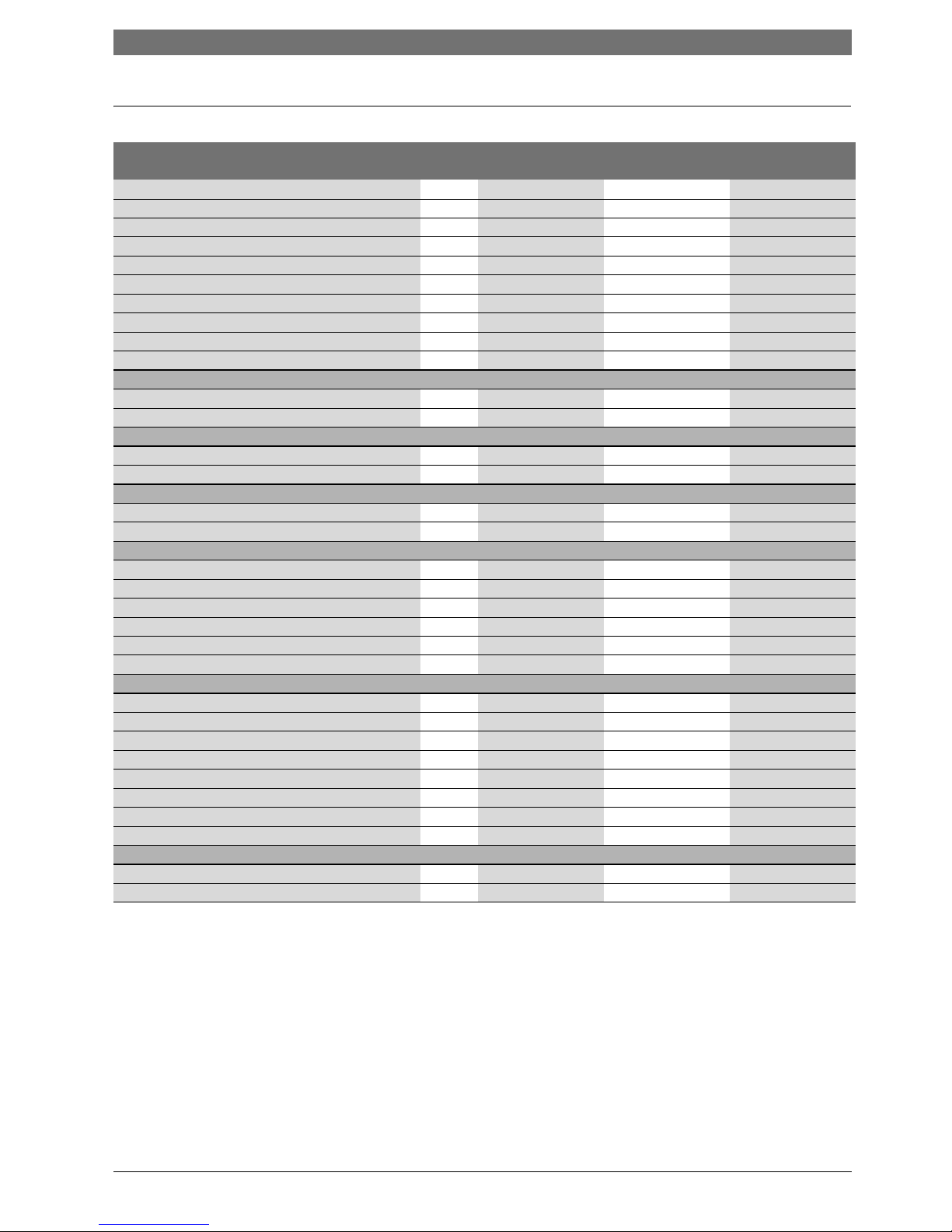

3.11 Specification ZWB 37-2 ...

ZWB 37-2 ...

Unit Natural gas Propane Butane

Max. heat output (P

max

) 40/30 °C kW 32.1 32.1 36.6

Max. heat output (P

max

) 50/30 °C kW 31.8 31.8 36.3

Max. heat output (P

max

) 80/60 °C kW 30.0 30.0 34.2

Max. gas consumption (Q

max

), central heating MJ/h 123.4 123.4 140.5

Min. heat output (P

min

) 40/30 °C kW 10.6 15.7 17.9

Min. heat output (P

min

) 50/30 °C kW 10.5 15.5 17.7

Min. heat output (P

min

) 80/60 °C kW 9.4 13.9 15.9

Min. gas consumption (Q

min

), central heating MJ/h 39.1 57.9 65.9

Max. heat output (PnW), DHW kW 37.0 37.0 42.2

Max. gas consumption (QnW), DHW MJ/h 147.7 147.7 168.5

Gas supply rate

Natural gas H (gross heating value 37.8 MJ/m3)m3/h 3.9 - Butane/propane (gross heating value 50 MJ/kg) kg/h -2.93.4

Permissible gas supply pressure

NG kPa 1.1 - 3.0 - LPG kPa -2.752.75

Expansion vessel

Pre-charge pressure kPa 75 75 75

Total capacity l 10 10 10

DHW

Max. DHW flow rate l/min 13.0 13.0 13.0

Outlet temperature range °C 40 - 60 40 - 60 40 - 60

Max. cold water inlet temperature °C 60 60 60

Max. permissible water supply pressure kPa 1000 1000 1000

Min. inlet pressure kPa 20 20 20

Specific flow rate acc. to EN 625 (D) l/min 16.9 16.9 16.9

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow rate, max./min. rated g/s 16.2/4.5 15.3/6.5 15.3/6.5

Flue gas temperature 80/60 °C max./min. rated °C 83/58 83/58 83/58

Flue gas temperature 40/30 °C max./min. rated °C 60/35 60/35 60/35

Residual pump head Pa 80 80 80

CO2 at max. rated output % 9.7 10.8 12.2

CO2 min. rated output % 9.1 10.2 11.5

Flue gas rating group to G 636/G 635 G61/G

62

G61/G

62

G61/G

62

NOx class 555

Condensate

Max. condensate quantity (tR = 30 °C) l/h 2.7 2.7 2.7

pH level, approx. 4.8 4.8 4.8

Table 6

Page 18

18 | Product details

6 720 644 143 (2010/09)

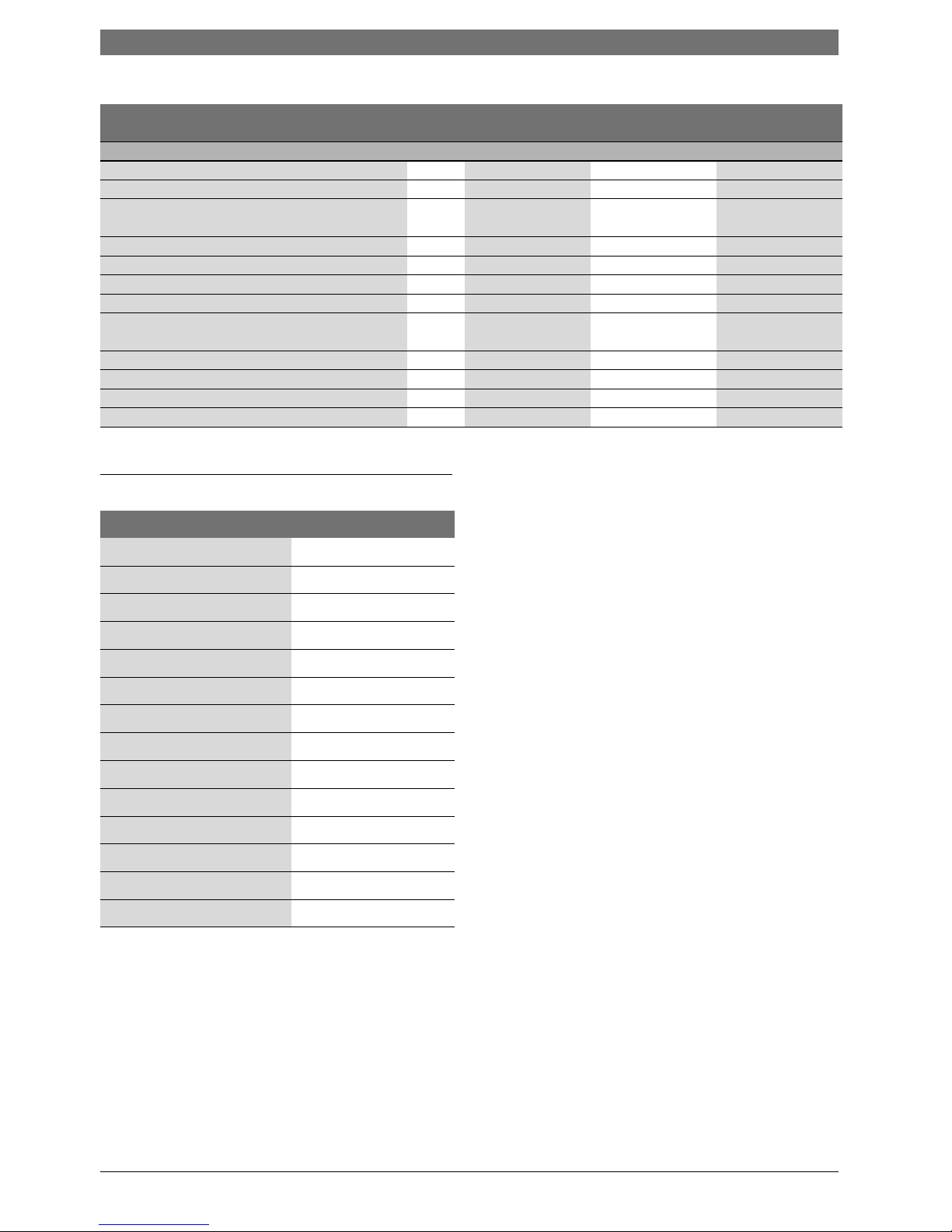

3.12 Condensate composition

General data

Power supply voltage AC ... V 220 - 240 220 - 240 220 - 240

Frequency Hz 50 50 50

Max. power consumption (central heating

mode) W

160 160 160

EMC limit class - BBB

Sound pressure level (in heating mode) ≤ dB(A) 45 45 45

Appliance enclosure rating IP X4D X4D X4D

Max. flow temperature °C Approx. 90 Approx. 90 Approx. 90

Max. permissible operating pressure (PMS)

heating kPa

300 300 300

Permissible ambient temperature °C 0 - 50 0 - 50 0 - 50

Nominal capacity of appliance heating l 3.75 3.75 3.75

Weight (excluding packaging) kg 48.5 48.5 48.5

Dimensions, W x H x D mm 440 x 760 x 360 440 x 760 x 360 440 x 760 x 360

ZWB 37-2 ...

Unit Natural gas Propane Butane

Table 6

Material Value [mg/l]

Ammonium 1.2

Lead ≤ 0.01

Cadmium ≤ 0.001

Chrome ≤ 0.005

Halogenated hydrocarbons ≤ 0.002

Hydrocarbons 0.015

Copper 0.028

Nickel 0.1

Mercury ≤ 0.0001

Sulphate 1

Zinc ≤ 0.015

Tin ≤ 0.01

Vanadium ≤ 0.001

pH value 4.8

Table 7

Page 19

Regulations | 19

6 720 644 143 (2010/09)

4Regulations

Where no specific instruction is given, reference should

be made to the following standards:

• AS 5601 Gas Installations,

• AS 1596 LPG storage and handling,

• AS 4552 Gas fired water heaters for hot water supply

and/or central heating,

• AS/NZS 3000 Electrical Installations,

• AS1697 Installation and maintenance of steel pipe

systems for gas,

• AS 4032 Water supply - valves for the control of hot

water supply temperatures,

• AS 3498 Authorization requirements for plumbing

products - water heaters and hot-water storage tanks.

• AS 1910 Water supply - float control valves for use in

hot and cold water, AS 3500 National plumbing and

drainage code.

Page 20

20 | Pre-Installation

6 720 644 143 (2010/09)

5 Pre-Installation

5.1 Water system and pipe work

Plastic pipe work:

• Any plastic pipe work must have a polymeric barrier

with 600 mm (minimum) length of copper pipe

connected to the boiler.

• Plastic pipe work used for underfloor heating must be

correctly controlled with a thermostatic blending

valve limiting the temperature of the circuits to

approximately 50 °C.

Primary systems connections/valves:

• All system connections, taps and mixing valves must

be capable of sustaining a pressure up to 3 bar

(300 kPa).

• Bosch recommends that thermostatic radiator valves

(TRV’s) be used on all radiators within the sleeping

accommodation but not the radiator where the room

thermostat is sited. This must be fitted with lockshield valves and left open.

• A drain point is required at the lowest part of the

system.

• An air vent is required at all the high points in the

system.

Sealed primary system:

• The CH sealed system must be filled using an

approved filling loop or comply with figure 6 for

system fill.

• Do not use galvanised pipes or radiators.

System fill

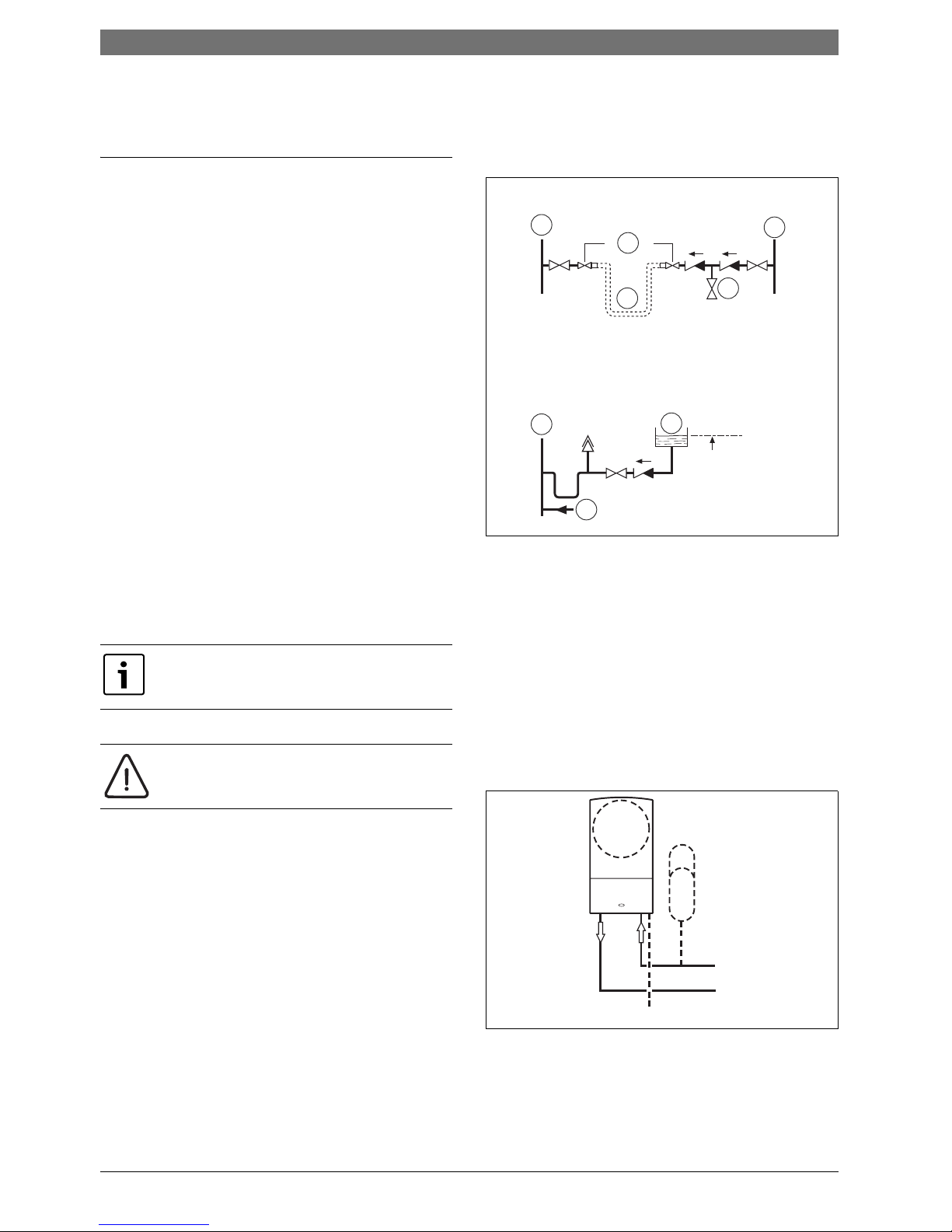

Fig. 6

A System fill

AA Auto air vent

B System make up

CV Check valve

D 1000 mm (39 in.) above the highest point of the system

SV Stop valve

1 Heating return

2 Hose union

3 Temporary hose

4 Test point

5 Mains supply

6 Make-up vessel

7 Fill point

Fig. 7 Additional expansion vessel

1 Boiler expanison vessel - CH

2 Extra expanison vessel - CH return

3 Pressure relief discharge-

The boiler is equipped with an automatic

internal by-pass.

NOTE: Artificially softened water must not

be used to fill the CH system.

SV SV

CV

CV

SV

CV

A

6720644143-41.1J

D

1

3

4

6

7

2

B

1

5

1

2

3

6720644743-09.1Wo

Page 21

Pre-Installation | 21

6 720 644 143 (2010/09)

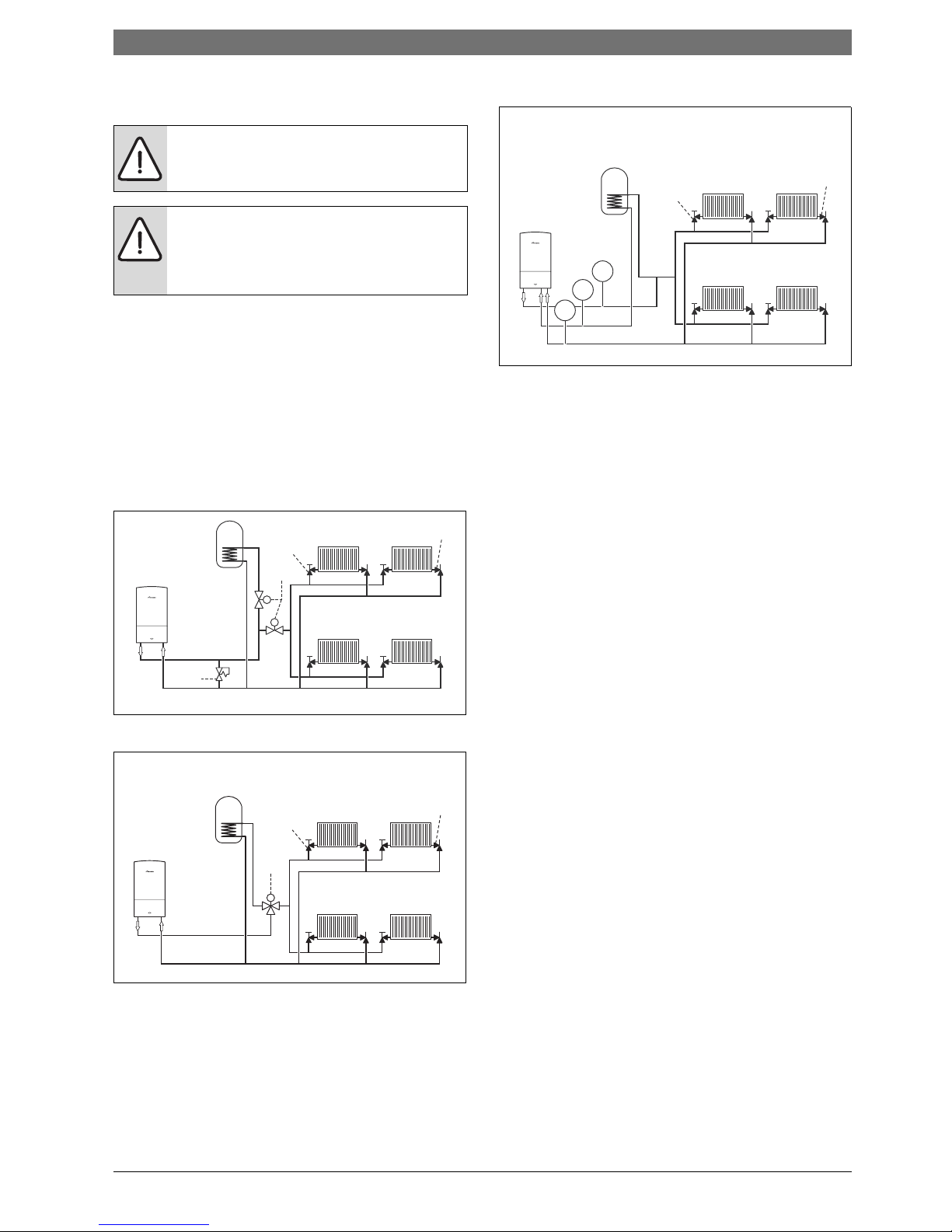

S and Y plan systems:

Optional diverter valve

This boiler is designed to operate on a sealed system

only and will require a second return pipe from the water

cylinder to the wall mounting frame.

Hot water supplied to sanitary fixtures

In accordance with AS 3498 a temperature control

device such as a tempering valve must be fitted when

hot water is supplied to sanitary fixtures used primarily

for the purposes of personal hygiene.

Fig. 8 S plan layout

Fig. 9 Y plan layout with external diverter valve

Fig. 10 System layout with optional internal diverter

valve (not supplied with boiler)

Legend to Fig. 8 to Fig. 10:

1 Diverter valve

2 Radiater valve (flow)

3 Lock shield valve (return)

4 Bypass

5 Boiler flow

6 Cylindr return

7 Heating return

NOTE: The boiler is fitted with its own

internal bypass.

NOTE:

B A drain point should be fitted at the

lowest part of the heating circuit and

beneath the boiler.

3

2

1

4

M

M

6720644143-39.1J

3

2

1

M

6720644143-38.1J

3

2

6720644143-40.1J

5

6

7

Page 22

22 | Pre-Installation

6 720 644 143 (2010/09)

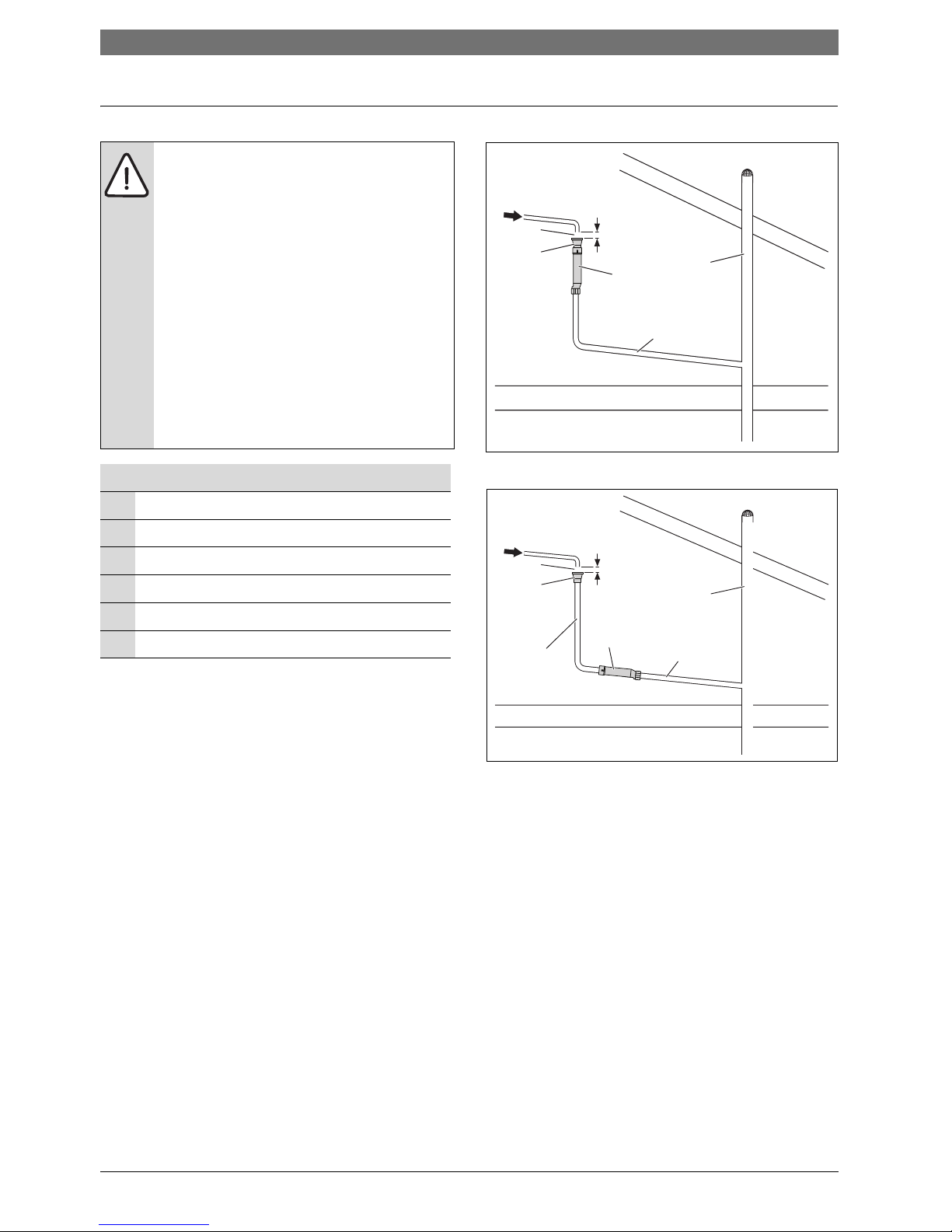

5.2 Condensate pipe work

5.2.1 Internal connections

Where there is the possibility of freezing conditions and

In order to minimise the freezing risk during prolonged

cold spells, the following methods of installing

condensate drainage pipe should be adopted, in order of

priority.

Wherever possible, the condensate drainage pipe should

be routed and terminated so that the condensate drains

away from the boiler under gravity to a suitable internal

soil and vent stack. A suitable permanent connection to

the foul waste pipe should be used.

A self sealing device should be incorporated in the

drainage path, if possible, in an upright position.

A tundish should be used as a suitable air gap just before

the self sealing device. The self sealing device can be

used on a gradient as long as it preceded by a vertically

mounted tundish.

Fig. 11 Disposal to soil vent stack - vertical position

Fig. 12 Disposal to soil vent stack - on gradient

NOTE:

B Where a new or replacement boiler is

being installed and freezing conditions

are possible, access to an internal drain

“gravity discharge” point should be one

of the factors considered in determining

boiler location.

B The condensate pipe must be a minimum

of 40 mm Ø plastic pipe.

B The condensate pipe work must fall at

least 50 mm per metre towards the outlet

and should take the shortest practicable

route.

B Ensure that there are no blockages in the

pipe run.

Key to condensate illustrations

1 Condensate discharge

2Air gap (20mm)

3Tundish

4 Self sealing device

5 Dishwasher connection

6Vent stack

Table 8

20mm

1

40mm Ø

2

3

6

4

6720646195-18.1Wo

6720646195-19.1Wo

20mm

1

40mm Ø

40mm Ø

2

3

6

4

Page 23

Pre-Installation | 23

6 720 644 143 (2010/09)

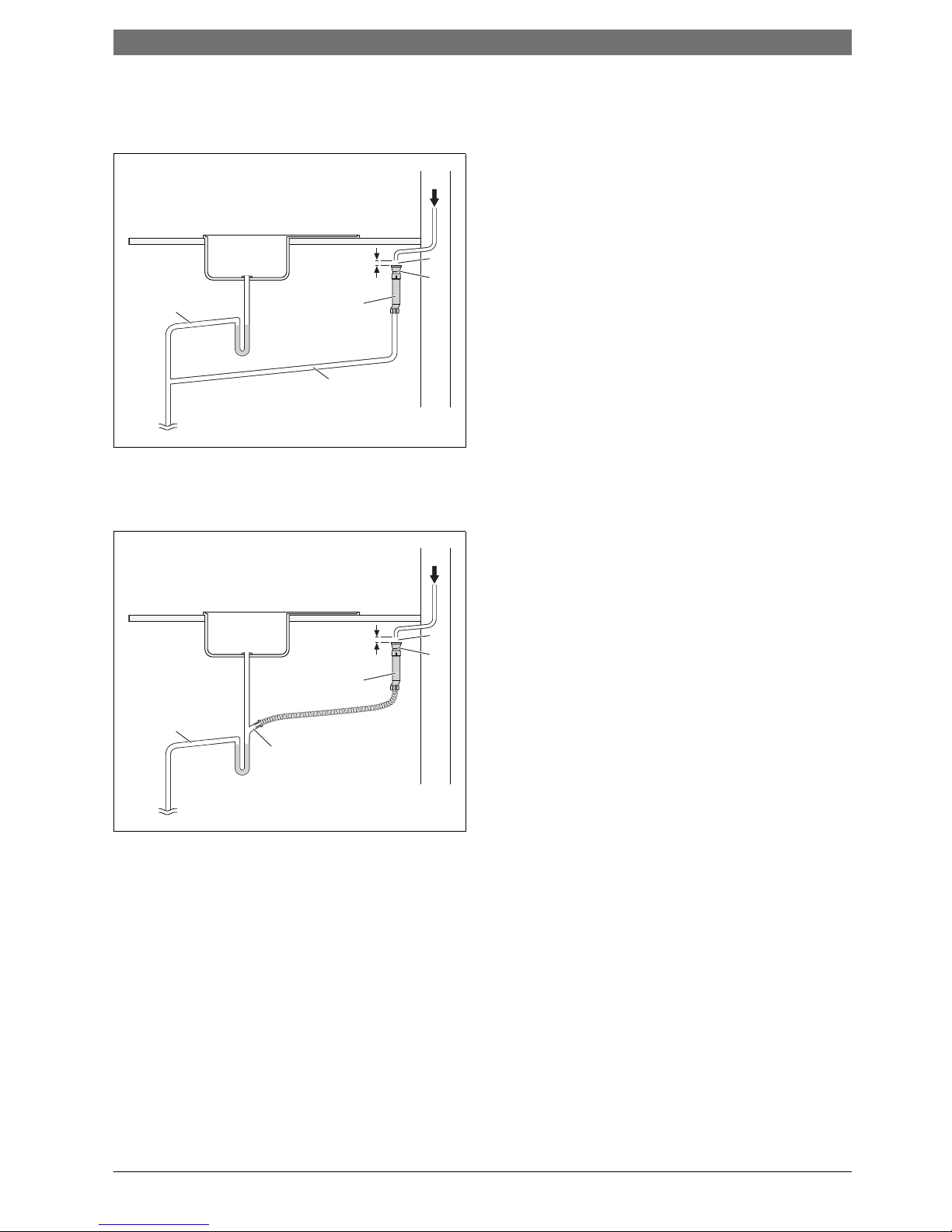

Alternatively if the first option is not possible an internal

kitchen or bathroom waste pipe can be used.

Fig. 13 Disposal to a waste pipe

A washing machine waste pipe or bifurcated pipe etc.

can also be used.

Fig. 14 Bifurcated pipe disposal

20mm

1

40mm Ø

40/50mm Ø

4

2

3

6720646195-16.1Wo

20mm

1

40/50mm Ø

4

2

5

3

6720646195-17.1Wo

Page 24

24 | Installation

6 720 644 143 (2010/09)

6 Installation

6.1 Important notes

B Prior to installation, obtain the approval of the gas

supply utility.

Supply of water preheated by solar energy (only ZWB)

Heating system water

Unsuitable fill and top-up water in the heating system

can result in the heat exchanger scaling up and failing

prematurely.

Anti-freeze

The following anti-freeze fluids are permitted:

Corrosion inhibitor

The following corrosion inhibitors are permissible:

Open vented heating systems

B Open vented heating systems must be converted to

sealed systems.

Gravity fed heating systems

B Connect the appliance to the existing pipework via a

low loss header with a dirt separator.

Underfloor heating systems

B The appliance is suitable for underfloor heating

systems; observe permissible flow temperatures.

If a room thermostat is used

B Do not fit a thermostatic radiator valve to the radiator

in the primary room.

To increase efficiency of the sysetm, thermostatic

radiator valves should be used on all other radiators.

Sealants

In our experience, adding sealants to the heating water

may result in problems (deposits in the heat exchanger).

We therefore advise against using them.

Water circulation noises

To prevent water circulation noises:

B Fit an overflow valve, or, with two-pipe heating

systems, a 3-way valve to the radiator furthest from

the boiler.

DANGER: Risk of explosion!

B Isolate the gas supply before working on

gas-carrying components.

B Check for leaks before working on gas-

carrying components.

Installation, power connection, connection

on the gas and flue gas side and

commissioning must only be carried out by

a contractor approved for such work by the

local gas or power supply utility.

WARNING: Risk of scalding!

Hot water can lead to severe scalding.

NOTE: Excessive temperatures through

water preheated by solar energy can

damage the equipment.

B Install a solar transfer valve upstream of

the appliance and set to 60 °C.

B To prevent excessive lime scale being

deposited, set the thermostatic mixer to

55 °C when encountering a total

hardness of 15 °dH or higher.

Hardness range Water treatment

soft (≤ 8.4 °dH) not required

medium (8.4 - 14 °dH) recommended

hard (≥ 14 °dH) required

Table 9

Product Concentration

Varidos FSK 22 - 55 %

Alphi - 11 see manufacturer’s

instructions

Glythermin NF 20 - 62 %

Table 10

Designation Concentration

Fernox see supplier information

Sentinel see supplier information

Table 11

Page 25

Installation | 25

6 720 644 143 (2010/09)

Mono-lever taps and thermostatic mixer taps

All types of mono-lever taps and thermostatic mixer taps

can be used.

LPG

To protect the appliance against excessive pressure:

B Fit a pressure regulator with a safety valve.

6.2 Checking the size of the expansion

vessel

The integrated expansion vessel is pre-charged to

0.75 bar (75 kPA).

Where the system volume is more than 100 litres or

exceeds 2.65 bar (265 kPa) at maximum heating

temperature, an additional expansion vessel must be

fitted as close as possible to the appliance in the central

heating return.

All expansions vessels must have the same pressure.

6.3 Siting the appliance

Regulations concerning the installation site

B Observe relevant national regulations.

B Consult the flue kit installation instructions for details

of minimum clearances required for flue gas routing.

B Do not install the appliance outside.

If the appliance is fitted into a cupboard or a

compartment is built around the compliance after

installation, then the compartment must be built from or

lined with a non-combustible material.

Combustion air

In order to prevent corrosion, the combustion air must

not contain any corrosive substances.

Substances classed as corrosion-promoting include

halogenated hydrocarbons which contain chlorine and

fluorine compounds. They may be found in solvents,

paints, adhesives, aerosol propellants and household

cleaners, for example..

Surface temperature

The maximum surface temperature of the appliance is

below 85 °C. Therefore no special safety measures are

required to protect flammable materials and fitted

furniture.

Ventilation

This is a room sealed appliance and does not require any

air for combustion from inside the property.

There is no need for ventilation openings to be provided

in the compartment because of the low heat loss from

the appliance casing, if the clearances shown are

maintained (Æ Section 3.7, Page 9)

Page 26

26 | Installation

6 720 644 143 (2010/09)

6.4 Pre-installing pipes

B Hook mounting rail into the mounting plate.

B Position mounting plate against the wall, observing

minimum side clearances of 100 mm (Æ page 9).

B Mark out four holes:

– One of holes A

– One of holes B

– Hole C

– Hole D

B Drill Ø 10 mm holes.

Fig. 15 Mounting plate

B Secure mounting plate with mounting rail to the wall

using the screws provided; do not tighten the two

lower screws.

B Hook in pre-plumbing jig and tighten screws.

Gas and water connections

Fig. 16 Pipe connections

Additional adaptors are provided in the fittings kit for

easy connection.

6 720 615 662-06.1O

A

B

C

D

It is very important to ensure that pipes

are not secured in such a way that the

fittings come under strain.

Ø 3/4" Ø 1/2" Ø 3/4" Ø 1/2"

Ø 3/4"

6 720 644 143-07.1O

65

65

65

65

340

28

55

75

85

364

370

158

120

R 3/4" R 1/2" R 3/4"R 1/2"R 3/4"

Page 27

Installation | 27

6 720 644 143 (2010/09)

Fig. 17 Pipe connections

1 Pre-plumbing jig

2 Adaptor BSP 3/4" tapered thread with union nut G3/4" and

olive to adapt to local piping connections

3 Adaptor BSP 1/2" tapered thread with union nut G1/2" and

olive (ZWB) to adapt to local piping connections

4 Pressure relief valve drain

5 Heating return

6 ZWB: Cold water connection

ZSB: Cylinder return

7 Filling loop (ZWB)

8 Gas connection

9 ZWB: DHW connection

ZSB: Cylinder flow

10 Heating flow

11 Condensate connector

B The pipe for gas supply must be larger than 18 mm in

diameter.

B For filling and draining the system, fit drain & fill

valves at the lowest point of the system.

Pipework behind the appliance

The pipes can be routed behind the appliance in the

guide on the mounting plate (Æ Fig. 18).

Fig. 18 Pipework

1 Heating flow

2 ZWB: DHW

ZSB: Cylinder flow

3 Gas

4 ZWB: Cold water

ZSB: Cylinder return

5 Heating return

6 Filling loop (ZWB)

6 720 644 143-05.1O

1

2

2

3

3

2

4

1011

5

9

6

8

7

6 720 644 143-10.1O

1

2

3

4

5

6

Page 28

28 | Installation

6 720 644 143 (2010/09)

6.5 Fitting the appliance

B Remove packing, taking care to observe the

instructions on the packing.

B Check the destination country on the type plate and

make sure that the gas type specified on the

identification plate matches that of the gas supplied

by the gas utility company (Æ page 10).

Removing the outer casing

B Untighten the screws.

B Lift bracket and remove casing towards the front.

Fig. 19

Preparing for fixing

B Place sealing washers on the pre-plumbing jig

connections.

B Pull lever on pressure relief valve connection forwards

and push down as far as it will go (Æ Fig. 12).

Fig. 20

Securing the appliance

B Hook appliance into the mounting rail at the top and

position it at the bottom on the prepared pipework

connections.

B Tighten the union nuts on the pipe connections.

NOTE: Dirt and corrosion in the pipework

can damage the appliance.

B Flush out the system to remove all dirt

residues.

The casing is secured with two screws to

prevent against unauthorised removal for

electrical safety.

B Always secure the outer casing with these

screws.

6 720 644 143-06.1O

1.

1.

3.

2.

6 720 644 143-12.1O

Page 29

Installation | 29

6 720 644 143 (2010/09)

Drain from pressure relief valve (heating circuit)

B Push lever on slider up until catch [1] rests on metal

bracket [2] (Æ Fig. 13).

Fig. 21

B Route the drain line where it will be easily visible in

the frost-protected area to a drainage point.

Creating the condensate drain

B Push the condensate hose into the adaptor on the

pre-plumbing jig.

B Create the drain.

B Do not use copper pipe.

Fig. 22

WARNING: Risk of scalding

Hot water or steam can lead to scalding

B Stay clear of the pressure relief outlet

during operation of the appliance.

1

2

6 720 644 143-08.1O

CAUTION:

B Do not modify or seal off drain pipes.

B Hoses must always slope downwards.

NOTE:

B Ensure there are no blockages in the pipe

run.

B Insulate external pipework when freezing

conditions can occur.

6 720 644 143-15.1O

Page 30

30 | Installation

6 720 644 143 (2010/09)

Fitting the filling loop (ZWB)

B Close the isolating valves on the mains water inlet [9]

and the CH return [1] connections.

B Remove the blanking plugs [2].

B Place the filter [7] into the inlet side of the filling loop

[4] ensuring that the filter mesh faces into the filling

loop.

B Fit the filling loop [4] to the mains water inlet [9] and

CH return [1] connections. Ensure that the filling loop

is completely pushed into the stop ta bs [6, 3] on b oth

sides of the filling loop.

B Fit two screws and washers [8] to each of the two

connections [9] and [1]. Do not try to turn the brass

hexagon connectors.

Fig. 23

Filling the heating circuit (ZWB)

B Ensure that all system and boiler drain points are

closed.

B Tigthen screw [1] on the filling loop as far as it will go

(Æ Fig. 24).

B Open the cold water supply tap [3] and heating return

tap [2].

B Insert key [4] in the filling direction so the arrow

points to symbol .

B Turn key [4] to position .

B Fully undo screw [1] on the filling loop and fill the

heating circuit to a pressure of 1 - 2 bar.

Fig. 24

B After filling, turn in screw [1] as far as it will go.

1

2

3

6

4

5

7

8

9

1.1

6 720 644 143-26.1O

6 720 644 143-13.1O

1

4

2

3

Page 31

Installation | 31

6 720 644 143 (2010/09)

B Turn key [4] to position , remove and insert into the

lower cover.

Fig. 25

Fitting the lower cover

B Push the lower cover into the two guide rails at the

bottom of the appliance.

Fig. 26

Connecting the flue pipe

B Push on the flue gas accessories and secure with the

screws supplied.

Fig. 27 Fitting the flue kit

1 Flue/adaptor

2 Screws

B Check the flue gas path for tightness

(Æ chapter 13.2).

6 720 644 143-14.1O

6 720 644 143-18.1O

For more precise details of connecting the

flue, refer to the installation instructions for

the flue routing manual.

6 720 615 886-22.1O

1

2

Page 32

32 | Installation

6 720 644 143 (2010/09)

6.6 Checking the connections

Water connections

B Open the heating flow and return valves and fill the

heating system.

B Check sealing points for leaks (testing pressure:

max. 2.5 bar (250 kPA) at the pressure gauge).

B Open the cold water valve on the appliance and a turn

on a hot water tap until water runs out. Max pressure:

10 bar (1000 kPA).

Gas supply pipe

B Close the gas valve to protect the gas valve from

pressure damage.

B Check sealing points for leaks.

B Release the pressure on the gas supply pipe.

Page 33

Electrical connections | 33

6 720 644 143 (2010/09)

7 Electrical connections

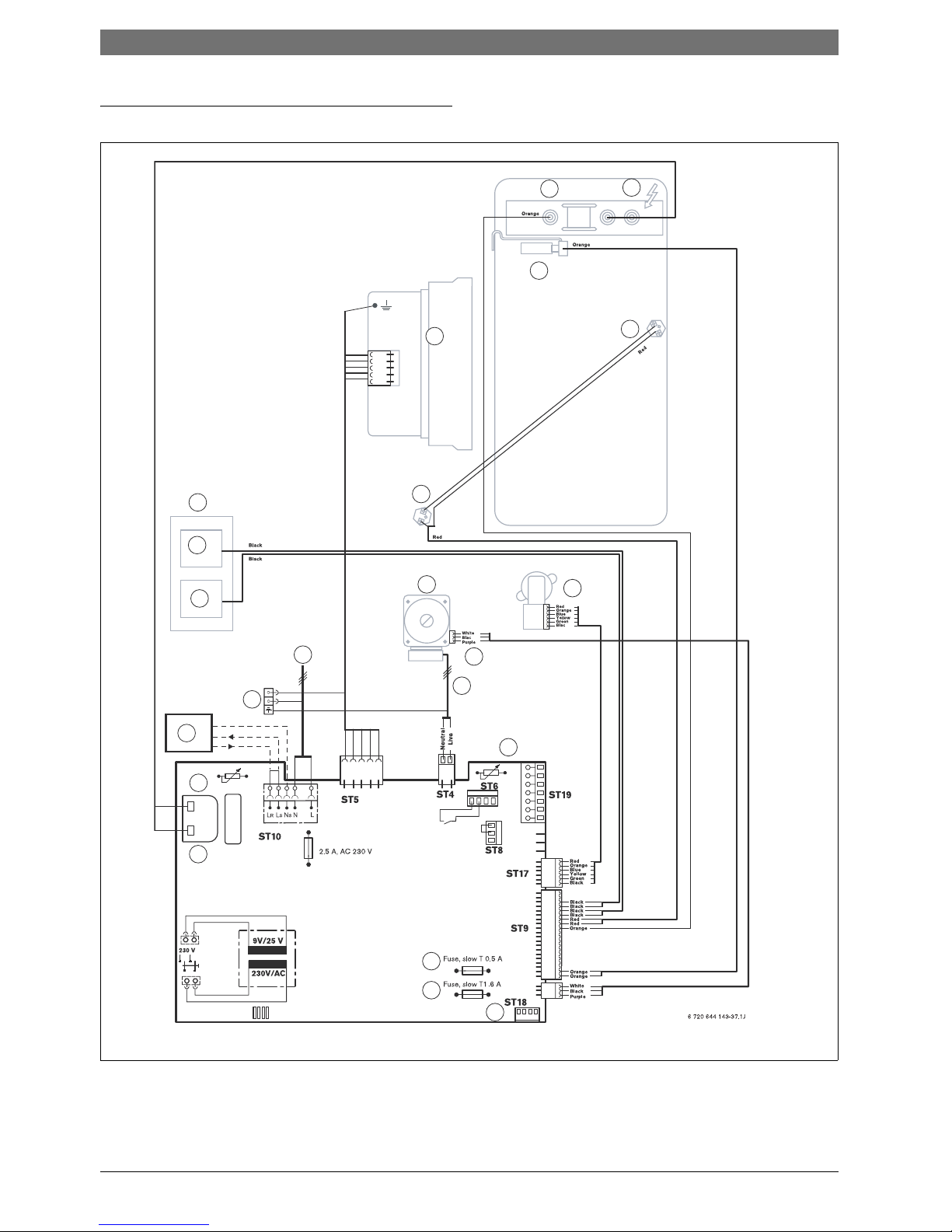

7.1 General information

• Supply: 220 - 240 V, 50 Hz.

• The appliance must be earthed.

• All pipes to the appliance must be earthed.

All appliance modulation, control and safety

components are tested and ready-wired for use.

Observe safety measures according to the relevant

regulations and AS/NZS 3000.

No other electrical consumer units may be connected to

the same power cable.

Fuses

The appliance is protected by three fuses. They are

located on the circuit board (Æ Fig. 4, page 12).

7.2 Connecting accessories

Opening the Heatronic unit

B Slide the clip down and pivot the Heatronic.

Fig. 28

B Remove screws, unhook cable and remove cover.

Fig. 29

DANGER: Risk of electric shock!

B Before carrying out work on electrical

components, disconnect the power

supply (230 V AC) (fuse, circuit breaker)

and secure against unintentional

reconnection.

Replacement fuses can be found on the

back of the cover (Æ Fig. 29).

CAUTION: Cable offcuts can damage the

Heatronic.

B Always strip cables away from the

Heatronic.

6 720 644 143-34.1O

1.

1.

1.

2.

6 720 612 659-15.1R

Page 34

34 | Electrical connections

6 720 644 143 (2010/09)

B To provide anti-splash protection (IP), always cut

cable grip to fit cable diameter.

Fig. 30

B Feed cable through cable grip and connect as

appropriate.

B Secure cable in cable grommet by means of cable

grip.

7.2.1 Connecting the heating controller or remote

control units

Only operate this appliance with a Bosch controller.

Heating controller FW 100 can also be mounted right at

the front in the Heatronic 3.

For installation and electrical connection, see the

relevant installation instructions.

7.2.2 Connecting the DHW cylinder

Cylinders with Bosch cylinder temperature sensors are

connected directly to the appliance PCB.

B Snap off the plastic tongue.

B Insert the cylinder temperature sensor lead.

B Plug the connector into the PCB.

Fig. 31

7.2.3 Connecting temperature limiter TB 1 from the

flow of an underfloor heating system

Only for underfloor heating systems connected directly

to the appliance.

Fig. 32

If the temperature limiter trips, central heating and DHW

modes are interrupted.

5-7

6 720 612 259-30.1R

13-14

10-12

8-9

Replace existing cylinder temperature

sensor with Bosch cylinder temperature

sensor.

6 720 612 659-18.3O

TB1

6 720 612 659-19.2O

B

B

4

2

1

F

A

PR

PO NPLP

LS NS

LZ

NZ

9

8

7

1

2

C

J

Page 35

Commissioning | 35

6 720 644 143 (2010/09)

8 Commissioning

Fig. 33

1 Flow temperature control

2 DHW temperature control

3 Chimney sweep button

4 Service button

5 Burner ON indicator

6 Main switch

7 Automatic air vent valve

8 Display

9 Pressure gauge

10 reset button

11 eco button

12 Holiday button

13 Drain from pressure relief valve (heating circuit)

14 Gas tap

15 CH return isolator

16 Filling loop (ZWB)

17 Cold water tap (ZWB),

cylinder return (ZSB)

18 DHW connection (ZWB),

cylinder flow (ZSB)

19 CH flow isolator

20 Condensate hose

6 720 644 143-17.1O

1819

reset

10

11

12

eco

15161714

4

3

2

5

1

6

8

7

9

20

13

Page 36

36 | Commissioning

6 720 644 143 (2010/09)

8.1 Before commissioning

B Adjust pre-charge pressure of expansion vessel to

static head of the heating system (Æ page 25).

B Open all system radiator valves.

B Open cold water tap (Æ Fig. 33, [17]) and one DHW

tap until water flows out.

B Open heating flow and return taps [19 and 15] and fill

heating system to 1 to 2 bar (100 - 200 kPa) (via filling

loop [16]) and close filling tap.

B Bleed radiators.

B Top up heating system to pressure of 1 - 2 bar (100 -

200 kPa).

B Check that the gas type specified on the type plate

matches that of the gas supply.

B Open gas tap [14].

B Do not operate the appliance if the flue terminal fitted

on the outside wall or roof is obstructed or damaged.

B Check that the pressure relief connector, located on

the right hand side at the bottom of the wall frame, is

in its up position.

B Check that the condensate pipe has been connected

to the adaptor.

B Briefly open the pressure relief valve to test its

operation.

8.2 Switching the appliance on/off

Switching on

B Switch appliance on at the main switch.

The display shows the heating water flow

temperature.

Fig. 34

B Open automatic air vent valve [7] and close again

after venting (Æ page 35).

Switching off the appliance

B Switch appliance off at the main switch.

The display goes out.

B If the appliance is to be switched off for a longer

period of time: observe correct frost protection

procedures (Æ chapter 8.9).

NOTE: Commissioning without water

destroys the appliance!

B Never run the appliance without water in

it.

When the appliance is switched on for the

first time, it performs a once-only venting

sequence. This involves the heating circuit

pump switching on and off at intervals (for

approx. 8 minutes).

The display shows in alternation with the

flow temperature.

If the display shows in alternation with

the flow temperature, the trap filling

function is active (Æ page 48).

m

a

x

1

2

3

4

5

6

6 720 613 896-05.1O

Page 37

Commissioning | 37

6 720 644 143 (2010/09)

8.3 Starting the central heating

The maximum flow temperature can be matched to the

heating system by the flow temperature controller. The

current flow temperature is shown on the display.

B Turn flow temperature controller to adjust the

maximum flow temperature.

Fig. 35

When the burner is firing, the green indicator lamp

lights up.

8.4 Setting the heating control unit

Fig. 36

8.5 After commissioning

B Check the gas supply pressure (Æ page 52).

B Check the condensate drain to ensure that

condensate runs out. If that is not the case, switch the

main switch off and on again. This activates the

siphon filling program (Æ page 48). Repeat this

procedure several times until condensate starts

running out.

B Record the settings in the commissioning report

(Æ page 74).

B Affix the “Heatronic settings” label to the casing in a

clearly visible position (Æ page 43).

Setting on flow

tem-perature

controller

Flow

temperature

Sample

application

1Approx. 35°C

2Approx. 43°C

3Approx. 50°CUnderfloor

heating system

4Approx. 60°C

5Approx. 67°C

6 Approx. 75 °C Radiator

heating system

max. Approx. 90 °C Convector

heating system

Table 12

With underfloor heating systems, take care

to observe the maximum permissible CH

flow temperatures.

eco

reset

6 720 644 143-27.1O

max

1

2

3

4

5

6

max

1

2

3

4

e

6

min

Follow the operating instructions for the

heating controller used. Those instructions

will tell you

B how to set the operating mode and the

heating curve for weather-dependent

controllers,

B how to adjust the room temperature,

B how to heat economically and save

energy.

9

12

h

15

18

21

24

h

3

6

6 720 612 660-07.2O

Page 38

38 | Commissioning

6 720 644 143 (2010/09)

8.6 Appliances with hot water cylinder:

setting the hot water temperature

B Set the DHW temperature on the DHW temperature

control .

The set DHW temperature flashes on the display for

30 seconds.

Fig. 37

eco button

Pressing and holding the eco button until it lights up

switches between Comfort mode and Economy mode.

Comfort mode, Eco button is not lit (default setting)

In Comfort mode, the hot water cylinder has priority. The

hot water cylinder is heated to the set temperature first.

Then the appliance switches to central heating mode.

Economy mode, Eco button lit

In Economy mode, the appliance switches between

central heating mode and hot water mode every ten

minutes.

WARNING: Danger of scalding!

B In normal operation, do not set the

temperature higher than 60 °C.

To prevent bacterial contamination such as

legionella, we recommend setting the DHW

temperature controller to at least “6”

(60 °C).

This setting ensures economical and

convenient DHW heating.

DHW thermostat DHW temperature

min Approx. 5 °C (frost

protection)

eApprox. 55°C

6 Approx. 60 °C

max. Approx. 70 °C

Table 13

6 720 644 143-28.1O

max

1

2

34

5

6

reset

eco

max

1

2

3

4

e

6

Page 39

Commissioning | 39

6 720 644 143 (2010/09)

8.7 ZWB appliances - setting hot water

temperature

B Set the DHW temperature on the DHW temperature

control .

The set DHW temperature flashes on the display for

30 seconds.

Fig. 38

eco button

Pressing and holding the eco button until it lights up

switches between Comfort mode and Economy mode.

Comfort mode, (Eco button is not lit - default setting)

The appliance is held constantly at the set temperature.

This means that hot water is available almost

instantaneously at the tap.

Consequently the appliance will switch on at intervals,

even if no hot water is being drawn.

Economy mode, Eco button lit

• The water is not heated up until a hot water tap is

turned on.

• With a demand signal

Briefly turning a hot water tap on and then off signals

demand so that the water is then heated up to the set

temperature.

Hot water supplied to sanitary fixtures

In accordance with AS 3498 a temperature control

device limited to +50 °C, such as a tempering valve must

be fitted when hot water is supplied to sanitary fixtures

used primarily for the purposes of personal hygiene.

8.8 Summer mode (central heating off,

DHW only)

B Note position of CH flow temperature control .

B Turn CH flow temperature control anti-clockwise

as far as the stop .

The heating circuit pump and consequently central

heating are switched OFF. However, the DHW supply

as well as the power supply to the heating

programmer and timer remain 'live'.

Fig. 39

Additional instructions are contained in the operating

instructions for the heating programmer.

8.9 Frost protection

Frost protection for the heating system:

B Leave appliance switched on, set CH flow

temperature control to position 1 at least.

Fig. 40

B Add anti-freeze to the heating water (Æ page 24) and

drain the DHW circuit.

Additional instructions are contained in the operating

instructions for the heating programmer.

Frost protection for the cylinder:

B Turn DHW temperature controller counter clockwise

as far as it will go (5 °C).

Fig. 41

DHW thermostat DHW temperature

min Approx. 40 °C

eApprox. 50°C

max. Approx. 60 °C

Table 14

The demand signal enables gas and water

savings.

eco

reset

max

1

2

3

4

e

6

6 720 644 143-29.1O

max

1

2

34

5

6

NOTE: Heating system at risk from frost.

6 720 644 143-30.1O

eco

reset

max

1

2

3

5

6

max

1

2

3

4

e

6

min

eco

reset

max

1

2

3

5

6

max

1

2

3

4

e

6

6 720 644 143-31.1O

min

max

1

2

3

e

6

max

1

2

34

5

6

eco

6 720 644 143-32.1O

min

Page 40

40 | Commissioning

6 720 644 143 (2010/09)

8.10 Holiday mode

To switch on holiday mode:

B Press and hold holiday button on the appliance

until it lights up, and switch on holiday mode on the

heating controller.

In holiday mode, heating and DHW heating are

switched off; frost protection remains active

(Æ chap. 8.9).

To switch off holiday mode:

B Press and hold holiday button on the appliance

until it goes out, and cancel holiday mode on the

heating controller.

The appliance returns to operation in standard mode

according to the settings at the heating control unit.

8.11 Fault mode

All safety, modulation and control components are

monitored by the Heatronic system.

If a fault occurs during operation, a warning tone

sounds.

The display indicates a fault and the reset button may

also flash.

If the reset button flashes:

B Press and hold the reset button until the display

shows .

The appliance will start up again and the flow

temperature will be displayed.

If the reset button does not flash:

B Switch the appliance off and then on again at the main

switch.

The appliance will start up again and the central

heating flow temperature will be displayed.

If the fault persists:

B Contact your authorised contractor or customer

service for assistance, providing details of the fault

and the appliance (Æ page 7).

If you press a button, the warning tone

stops.

For an overview of faults, see page 67.

For an overview of displays, see page 64.

Page 41

Thermal disinfection on appliances with hot water cylinder | 41

6 720 644 143 (2010/09)

9 Thermal disinfection on appliances with hot water cylinder

To prevent the DHW becoming contaminated by bacteria

such as legionella, we recommend you pasteurise the

system after longer idle periods.

Pasteurisation covers the DHW system including the

draw-off points. For solar DHW cylinders, the solar

portion of the cylinder is not covered.

B Turn off all hot water points.

B Warn occupants of risk of scalding.

B If the heating programmer has a DHW program, set

the time and DHW temperature accordingly.

B If there is a circulation pump, set it to run

continuously.

B Turn DHW temperature control clockwise as far as the

stop (approx. 70 °C).

Fig. 42

B Wait until the water reaches the maximum

temperature.

B Draw off water in turn from the nearest to the furthest

hot water point until hot water has been running out

at a temperature of 70 °C for 3 minutes.

B Reset DHW temperature control, circulation pump

and heating programmer to their standard settings.

With some heating controllers, thermal

disinfection can be programmed for a fixed

time; see heating controller operating

instructions.

WARNING: Risk of scalding!

Hot water can lead to severe scalding.

B Only carry out thermal disinfection at

times when the system is not normally in

use.

B The water in the cylinder will take a while

to cool down to the set DHW temperature

as a result of heat loss. Be aware that,

after thermal disinfection, the hot water

may be hotter than the set temperature.

6 720 644 143-33.1O

max

1

2

34

5

6

reset

eco

max

1

2

3

4

e

6

Page 42

42 | Pump anti-seizing function

6 720 644 143 (2010/09)

10 Pump anti-seizing function

Every time the pump is switched off, a timer starts to

briefly switch on the heating circuit pump and the 3-way

valve at regular intervals.

This function prevents the heating circuit

pump and the 3-way valve seizing up during

long periods of inactivity.

Page 43

Heatronic settings | 43

6 720 644 143 (2010/09)

11 Heatronic settings

11.1 General information

The Heatronic unit enables easy setting and testing of a

large number of appliance functions.

For an overview of the service functions see

chapter 11.2 on page 44.

Fig. 43 Appliance controls

1 Chimney sweep button

2 Service button

3 Display

4 eco button or “Up” for service functions

5 Holiday button or “Down” for service functions

Selecting service functions

The service functions are subdivided into two levels

(Æ tables 15 and 16 on page 44).

B Press and hold the service button until it lights

up.

The display shows a code such as 1.A (service level 1).

B Press eco button and holiday button simultaneously

until a code such as 8.A appears (service level 2).

B Repeatedly press the holiday button or eco button

until the required service function is displayed.

B Press and release the chimney sweep button .

The chimney sweep button will light up and the

display shows the setting for the selected service

function.

Making a setting

B Repeatedly press the holiday button or eco button

until the required service function value is displayed.

B Enter the value on the “Heatronic settings” label

supplied and affix in a clearly visible position.

Fig. 44

Saving a setting

B Press and hold chimney sweep button until the

display shows .

Exiting the service function without saving settings

B Briefly press the central heating boost button .

The light in the central heating boost button will go

out.

Restoring standard settings

To restore all values from service levels 1 and 2 to the

standard settings:

B In service level 2, select service function 8.E and save

value 00. The appliance starts with the standard

setting.

By using the "Heatronic settings" label, you

will make it easier for your contractor to set

modified service functions during servicing

at a later date.

max

1

2

3

4

e

6

max

1

2

3

4

5

6

1

2

3

4

5

6 720 644 143-11.1O

reset

eco

min

The unit automatically exits the service level

if no button is pressed for 15 minutes.

System installer:

6 720 644 145 (2010/09)

Settings on the Heatronic

Service function Value

Page 44

44 | Heatronic settings

6 720 644 143 (2010/09)

11.2 Overview of service functions

11.2.1 Service level 1

B Press service button until it illuminates.

11.2.2 Service level 2

Access from service level 1; service button lights up.

B Press eco button and holiday button simultaneously

until a code such as 8.A appears.

Service function

Display

code Page

1.A Max. output (heating) 45

1.b Max. output (hotwater - ZWB

only)

45

1.C Pump map (heating) 45

1.d Map pump step (heat.) 46

1.E Pump switch mode 46

2.b Max. flow temperature 46

2.C Air purge mode(burner keeps off

while air purge mode is on)

47

2.F Operating mode 47

3.b Anti-cycle time 47

3.C Anti-cycle flow temperature

differential

47

3.E Pre heat cycle time (hot

water)(ZWB only)

47

3.F Burner off after DHW demand

(hot water) (ZWB only)

47

4.F Syphon-fill programme 48

5.A Reset service reminder 48

5.b Fan run-on time 48

6.A Last fault 48

6.d Actual flow rate turbine

(ZWB only)

48

6.E Programmer input 48

7.A Fault indicator LED on/off 48

Table 15 Service functions, level 1

Service function

Display

code

Page

8.A Software version 49

8.b Code plug number 49

8.C GFA status (not applicable) 49

8.d GFA error (not applicable) 49

8.E Reset all parameters 49

8.F Permanent ignition 49

9.A Operation mode permanent 49

9.b Actual fan speed 49

9.C Actual heat output 49

9.d Start fan speed 49

9.E Turbine signal delay (ZWB only) 49

9.F Heating circuit pump run-on time 49

Table 16 Service functions, level 2

Page 45

Heatronic settings | 45

6 720 644 143 (2010/09)

11.3 Description of service functions

11.3.1 Service level 1

Service function 1.A: MAX. OUTPUT (HEATING)

Some gas supply utilities charge a basic rate based on

output.

The heating output can be set to any level between min.

rated heat output and max rated heat output to limit it

to the specific heat requirements.

The factory setting is maximum rated heat output:

B Select service function 1.A.

B Refer to the settings tables (Æ page 72) for the

output in kW and the corresponding setting code.

B Enter the setting code.

B Measure the gas flow rate and compare with the

figures for the setting shown. If they do not match,

change the setting.

B Save the setting.

B Enter the selected output on the “Heatronic settings”

label supplied (Æ page 43).

B Exit service functions.

The display will show the CH flow temperature again.

Service function 1.b: Max. output (hot water - only

ZWB)

The hot water output can be set to any level between

minimum rated hot water output and maximum rated

hot water output to limit it to the specific hot water

requirements.

The factory setting is maximum rated output – display

shows U0.

B Select service function 1.b.

B Take the DHW output in kW and the associated

parameter from the setting tables (Æ page 72 to 73).

B Enter the setting code.

B Measure the gas flow rate and compare with the

figures for the setting shown. If they do not match,

change the setting.

B Save the setting.

B Enter the selected DHW output on the “Heatronic

settings” label supplied (Æ page 43).

B Exit service functions.

The display will show the CH flow temperature again.

Service function 1.C: Pump map (heating)

The appliance is supplied with this function set to 4

(Proportional pressure high). See pump characteristics

below.

The pump map indicates how the pump is controlled in

heating mode. The pump switches between the various

pump speeds so as to reproduce the characteristic curve

selected.

Changing the pump characteristic can be helpful if a

lower pressure difference will guarantee the necessary

circulation on the basis of the system dimensions and

pump characteristic.

Even if the output is limited, the full rated

heat output remains available for hot water.

Appliance type Display indication

ZSB 30 ... U0 (100%)

ZWB 37 ... 84

Table 17

In order to save as much energy as

possible and to minimise the possibility of

water circulation noise, a low

characteristic should be chosen.

Page 46

46 | Heatronic settings

6 720 644 143 (2010/09)

The following can be selected as the pump characteristic

map:

• 00 Pump step adjustable, service function 1.d

(Æ page 46 )

• 01 Constant pressure high

• 02 Constant pressure medium

• 03 Constant pressure low

• 04 Proportional pressure high

• 05 Proportional pressure low

The factory setting is 04.

Fig. 45 Constant pressure

Fig. 46 Proportional pressure

Legend for Fig. 45 and 46:

1-5 Characteristics

H Pressure

Q Water circulation rate

Service function 1.d: Map pump step (heating)

This service function corresponds to the pump speed

switch used on conventional heating pumps.

However, the setting is only active if function 1.C (Pump

map (heating)), is set to 0.

The factory setting is 07.

Fig. 47 Characteristics

Key to Fig. 47:

1-7 Characteristics

H Pressure

Q Water circulation rate

Service function 1.E: Pump switch mode

• Pump control mode 0:

The BUS controller controls the central heating circuit

pump.

• Pump control mode 1:

The pump is controlled by the central heating flow

temperature control.

• Pump control mode 2 (factory setting):

For heating systems with room thermostat. The

central heating flow temperature control controls

only the gas, the pump is not affected. The room

thermostat controls both the gas and the pump. The

pump and fan have an over-run time of between 15 s

and 3 min.

• Pump control mode 3:

Not applicable.

Service function 2.b: Maximum flow temperature

The maximum CH flow temperature can be set to

between 35 °C and 88 °C. Even if the CH flow

temperature control is set higher, the setting entered for

2.b (Max. flow temperature) is not exceeded.

The factory setting is 88.

200 400 600 800

1200

14001000 1600

0

0,6

0,5

0,4

0,3

0,2

0,1

0

(bar)

H

Q

(l/h)

6 720 612 126-43.1O

1

2

3

200 400 600 800

1200

14001000 1600

0

0,6

0,5

0,4

0,3

0,2

0,1

0

(bar)

H

Q

(l/h)

6 720 612 126-44.1

O

4

5

200 400 600 800

1200

14001000 1600

0

0,6

0,5

0,4

0,3

0,2

0,1

0

(bar)

H

Q

(l/h)

3

2

4

5

6

7

6 720 612 126-45.1

O

Page 47

Heatronic settings | 47

6 720 644 143 (2010/09)

Service functions 2.C: Air purge mode

The first time the appliance is switched on, a onceonlyventing function is activated. The heating pump then

switches on and off at intervals. This sequence lasts

about 8 minutes.

The 2-digit display shows in alternation with the flow

temperature.

The automatic vent will open during venting and then

close once the venting sequence is complete.

If the venting function is set to “On” (with automatic

deactivation), the function is set to “Off” once the

sequence has been completed.

Service function 2.F: Operating mode

There are 3 operating modes to choose from.

• Normal mode: the appliance operates according to

the commands received from the programmer. The

• display shows 0.

• Minimum mode: the appliance runs constantly at

minimum output.

The display shows 1. The 2-digit display alternates

between the CH flow temperature and . After 15

min. the minimal mode changes to normal mode.

• Maximum mode: the appliance runs constantly at

maximum output.

The display shows 2. The 2-digit display alternates

between the CH flow temperature and . After 15

min. the maximal mode changes to normal mode.

The factory setting is 0.

Service function 3.b: Anti-cycle time

The anti-cycle time is factory set to 3 minutes.

The shortest possible anti-cycle time is 1 minute

(recommended for single-pipe and hot-air heating

systems).

If the setting 0 is entered, the anti-cycle time is disabled.

B Enter the anti-cycle time on the commissioning record

enclosed with the appliance.

Service function 3.C: Anti-cycle flow temperature

differential

The switching difference is the permissible differential

from the specified CH flow temperature. It can be set in

increments of 1 K. The adjustment range is 0 to 30 K. The

minimum CH flow temperature is 35 °C.

B Enter the switching difference setting on the

commissioning record supplied with the appliance.

The factory setting is 10 K.

Service function 3.E: Cycle time (Hot water) (ZWB

only)

The appliance is supplied with the pre-heat cycle time

set to 20 minutes.

After pre-heating or DHW demand, this function will

stipulate the period of time before the next permissible

pre-heat. This will prevent excessive pre-heat cycling.

Service function 3.F: Burner off after DHW demand

(Hot water - ZWB only)

The appliance is supplied with the hot water duration

set to 1 minute.

The “hot water duration” time specifies how long, after

hot water has been drawn, that the heating mode

remains disabled.

The venting function can be activated after

servicing.

Note: 1 K = 1 °C.

Page 48

48 | Heatronic settings

6 720 644 143 (2010/09)

Service function 4.F: Siphon-fill programme

The syphon filling function ensures that the syphon trap

is filled when the appliance is first installed or shut down

for a long period. Flue gas is prevented from escaping

into the room where the appliance is installed.

The trap filling function is activated when:

• the appliance is switched on at the main switch

• the burner has not been in use for at least 48 hours

• the appliance is switched from summer to winter

mode

The next time the heating or hot water system calls for

heat, the appliance is held at minimum output for

15 minutes.

The syphon filling programme remains active until the

appliance has completed 15 minutes of operation at

minimum output.

The 2-digit display alternates between and the CH

flow temperature.

Service function 5.A: Reset service reminder

The burner service interval of 2324 hours has run out.

After the service inspection store 0 for resetting the

service interval.

Service function 5.b: Fan over-run time

B Set the time of fan over-run after a boiler demand.

Service function 6.A: Last fault

The last fault can also be recalled for servicing purposes

when the appliance is functioning correctly.

Service function 6.d: Current turbine flow rate (ZWB

only)

The actual flow rate of the turbine is displayed.

Service function 6.E: Programmer input

Shows the status of channel 1 of the timer DT10/20. Left

digit is “Heat demand”, heating mode will be activated

according to the programmer commands. Shows the

status of channel 2 of the timer DT20. Right digit is

“DHW demand”, hot water mode will be activated

according to the programmer commands.

Service function 7.A: Fault indicator LED ON/OFF

The fault indicator LED flashes in case of error even

when its setting is off (0).

DANGER: If the syphon is not filled, flue gas

can escape.

B Only deactivate the syphon filling

programme in order to carry out servicing

work.

B Always re-activate trap filling programme

once servicing is complete.

Page 49

Heatronic settings | 49

6 720 644 143 (2010/09)