Bosch ECU MS 25 Sport User Manual

Engine Control Uni MS 25 Sport

Manual

Version 1.0 12/03/2019

Content

ii/40 Engine Control Unit MS 25 Sport Bosch Motorsport

Content

1 Technical data ................................................................................................................................................................. 3

1.1 System Layout........................................................................................................................................................................................................ 3

1.2 Application.............................................................................................................................................................................................................. 4

1.3 Pin Layout................................................................................................................................................................................................................ 5

1.4 Input Channels....................................................................................................................................................................................................... 9

1.5 Output Channels................................................................................................................................................................................................... 9

1.6 Power Supply ......................................................................................................................................................................................................... 9

1.7 Trigger Wheel ........................................................................................................................................................................................................ 10

2 Starting up the ECU ........................................................................................................................................................ 13

2.1 Installation of software tools............................................................................................................................................................................ 13

2.2 Communication PC to device .......................................................................................................................................................................... 13

2.3 MS 25 Sport programming............................................................................................................................................................................... 13

2.4 Initial Data Application....................................................................................................................................................................................... 22

3 Peripherals....................................................................................................................................................................... 33

4 Getting Started................................................................................................................................................................ 36

5 Engine Performance Calibration ................................................................................................................................... 37

6 Bosch Motorsport support ............................................................................................................................................ 38

7 Wiring Harness................................................................................................................................................................ 39

Technical data | 1

Bosch Motorsport Engine Control Unit MS 25 Sport 3/40

1 Technical data

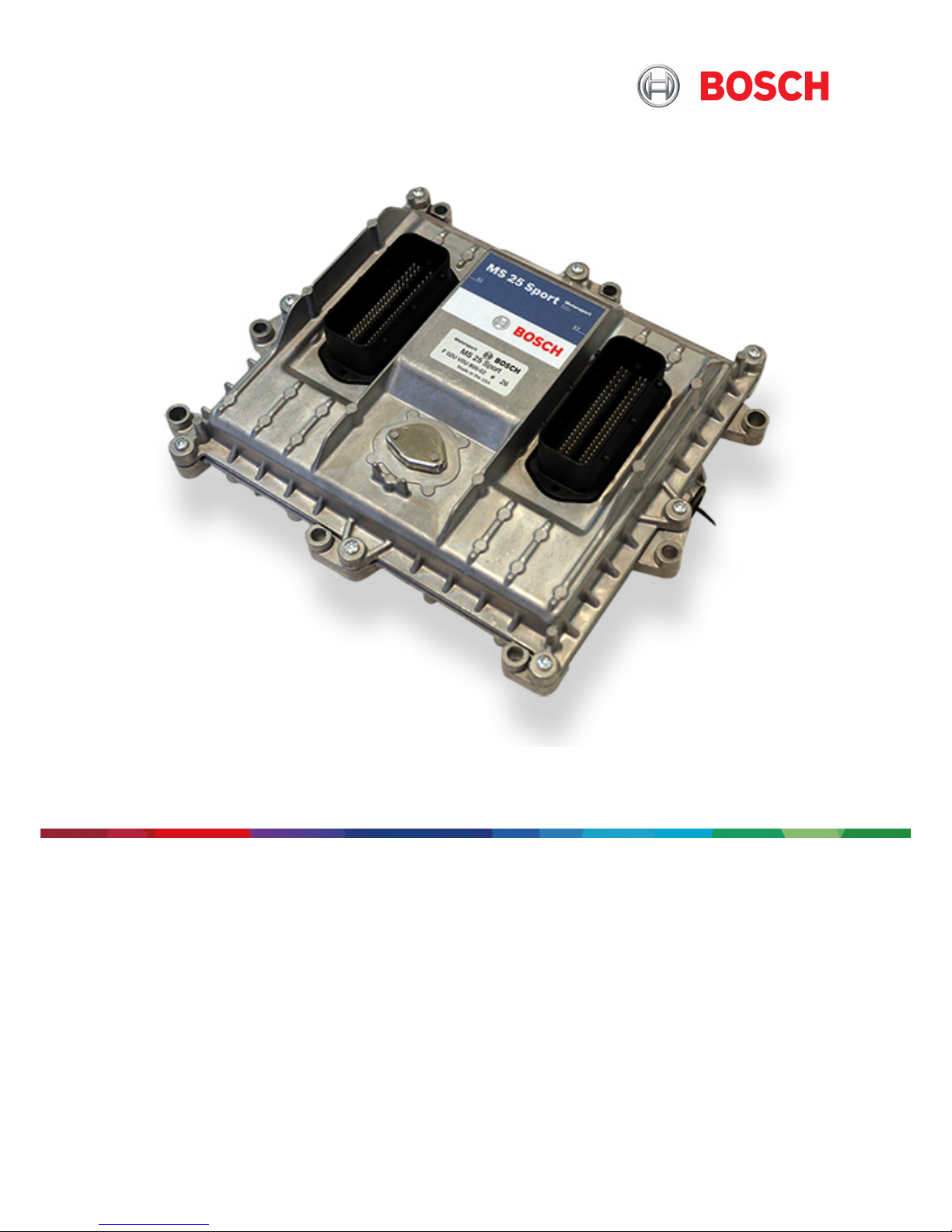

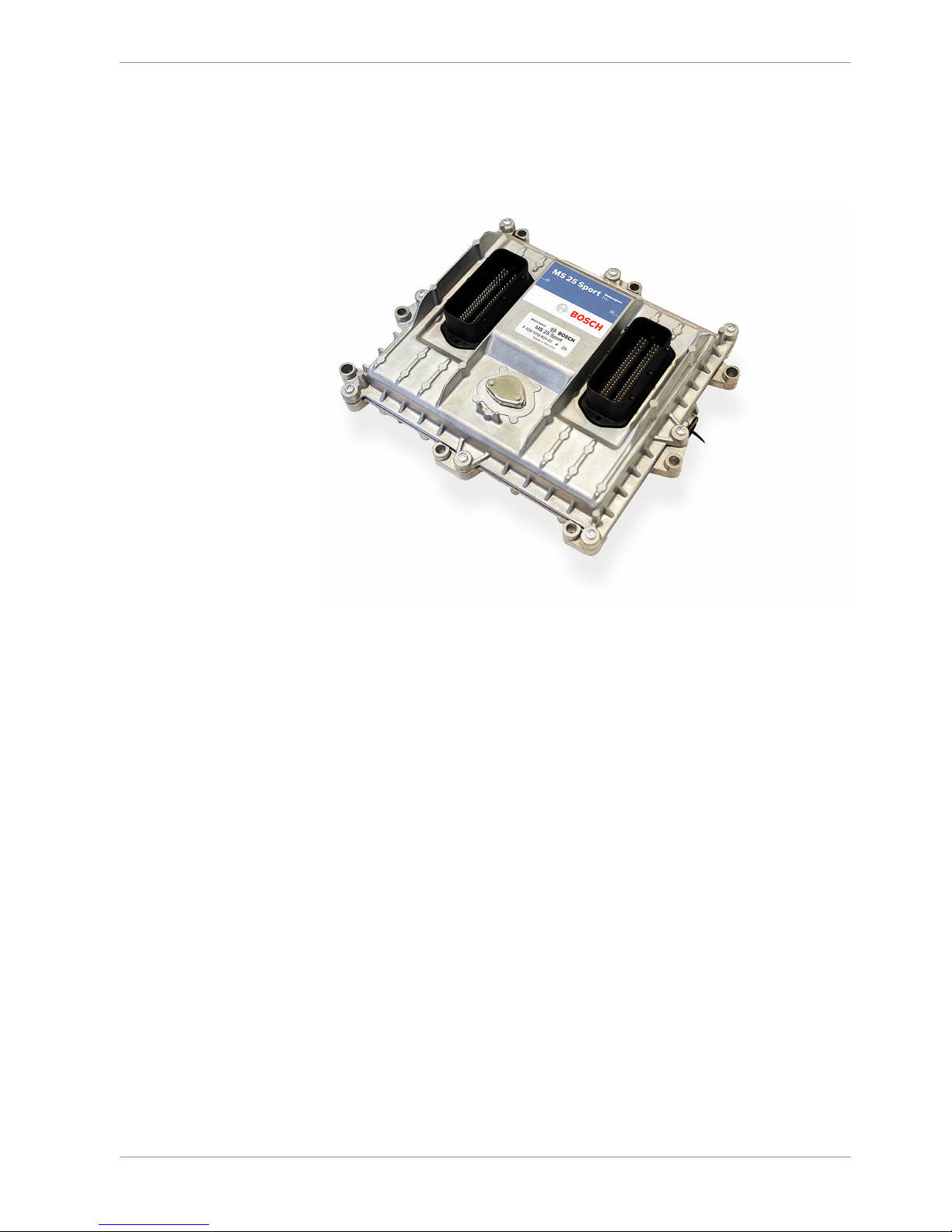

The ECU MS 25 Sport engine control unit manages common rail Diesel engines with

solenoid valve injectors up to 8 cylinders. The MS 25 Sport utilizes software development

process based on MATLAB® & Simulink®.

1.1 System Layout

– Controls max. 8 cylinders with 5 injections (Pilot2-, Pilot1-, Main-, Post2- and Post1 in-

jection)

– Two engine hydraulic bank measurement, control and monitoring strategy for rail

pressure with one (FMU) or two actuator (FMU+PCV) operation

– Two engine bank related separated lines for physical air mass, boost pressure and

turbo speed determination and control

– One lambda LSU 4.9 measurement supported directly by MS 25 Sport. 2-bank meas-

urement and control as option via external CAN measurement

– Integrated torque‐structure for power control functions as speed‐ and launch limita-

tions or regulations. Gear and map position dependent torque limitations

– Gear cut support with rail pressure control feedback

1 | Technical data

4/40 Engine Control Unit MS 25 Sport Bosch Motorsport

1.2 Application

Installation Notes

Communication

Ordering Information

Engine Control Unit MS 25 Sport F 02U V0U 800-02

Technical data | 1

Bosch Motorsport Engine Control Unit MS 25 Sport 5/40

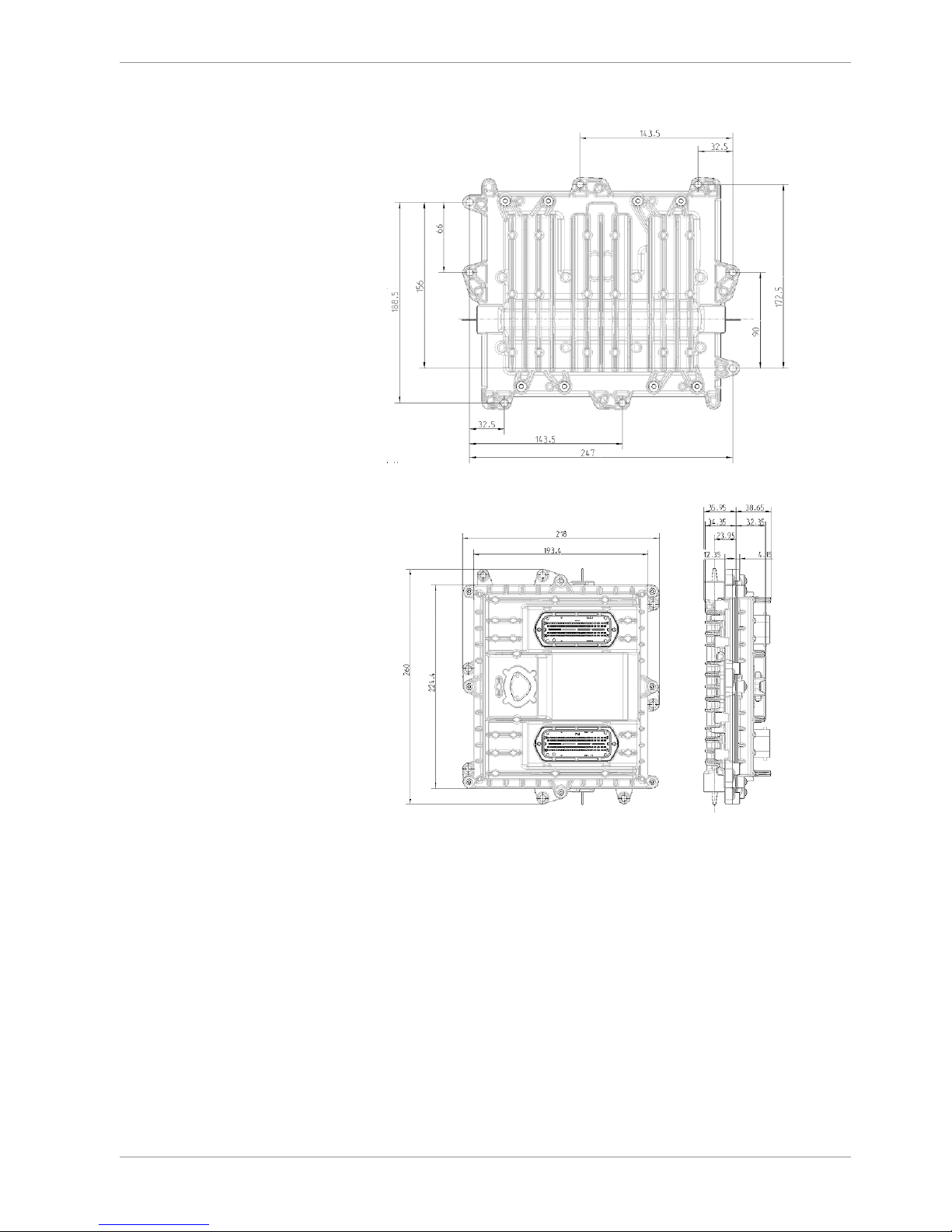

Mechanical Drawing

1.3 Pin Layout

The pin layout is also placed at Bosch Motorsport Homepage.

Some pins and functions are optional and not included in the base version of the MS 25

Sport software.

1 | Technical data

6/40 Engine Control Unit MS 25 Sport Bosch Motorsport

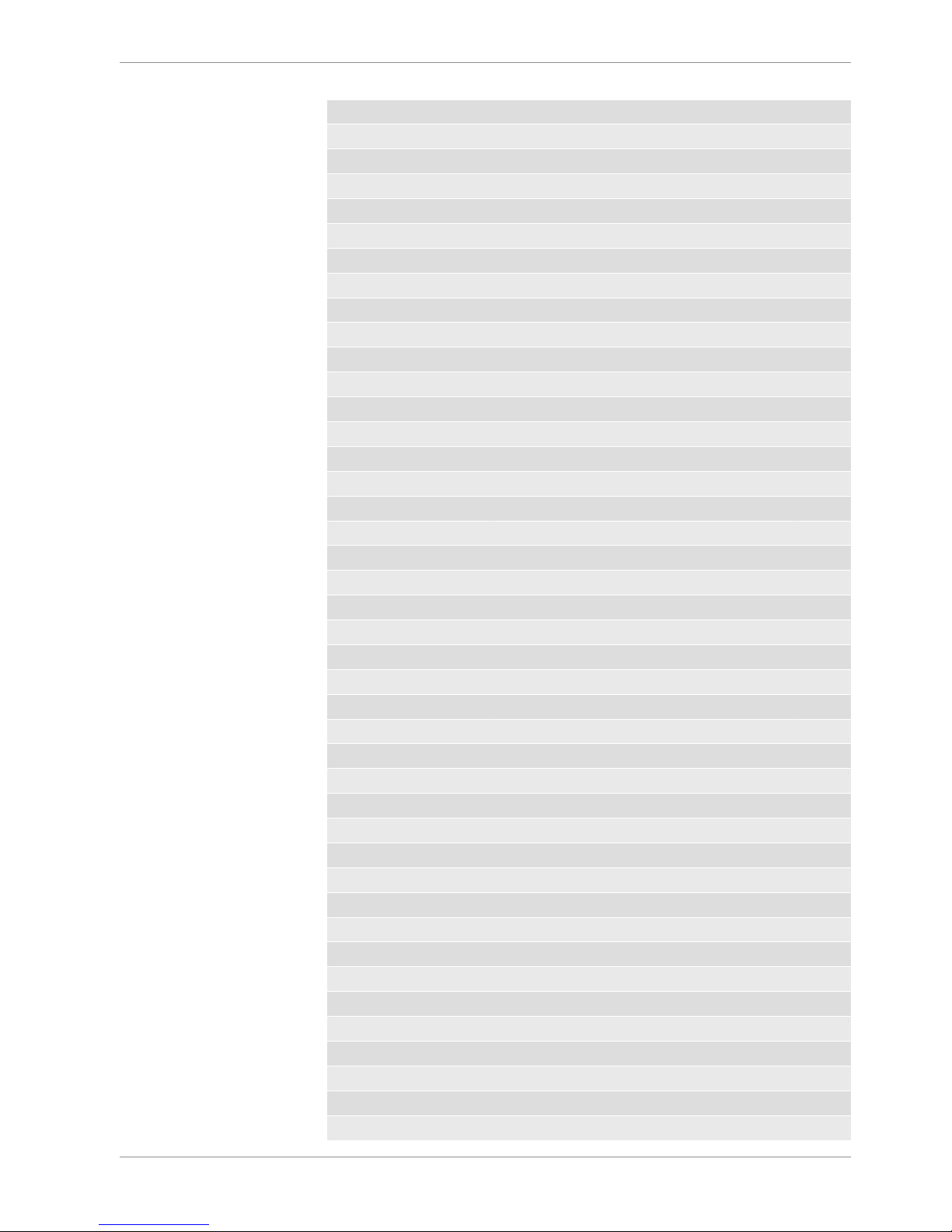

Engine connector (X2 - Engine) 1928405313

PIN Name Main function PIN Name Signal

1 InjectorPwrStg 2 - InjectorPwrStg 2 "bank2" O_P_SVL21

2 InjectorPwrStg 5 - InjectorPwrStg 5 "bank2" O_P_SVL22

3 InjectorPwrStg 8 - InjectorPwrStg 8 "bank2" O_P_SVL23

6 Oil press./temp. gnd Oil Pressure and Temperature Ground G_R_DF03

7 Boost press. supply +5V Boost pressure sensor supply V_V_5VSS1A

8 5V sens. Supply 5 5V Sensor supply 5 V_V_5VSS2C

9 CAM/CRK hall supply +5V CAM/CRK speed sensor supply (HALL) V_V_5VSS2F

10 5V sens. Supply 6 5V sensor supply 6 V_V_5VSS2E

11 rail press. supply +5V Rail pressure sensor supply V_V_5VSS3B

12 Fuel Temp Signal Fuel Temp Signal I_A_AN18 tfuel

13 oil temp. signal Oil temperature sensor signal I_A_AN15 toil

14 fuel feed press. Fuel Feed Pressure I_A_AN09 pfuel

16 exhaust/water1 press. signal Exhaust gas / water pressure 1 I_A_AN02 pwat

17 CAN3+ (Display) CAN Interface (Display/logger) B_D_CANH2

18 CAN3- (Display) CAN Interface (Display/logger) B_D_CANL2

19 Sens. Gnd 5 Sensor ground 5 G_R_AN02

21 waste gate 2 / VGT2 Waste Gate 2 / Variable Turbine Geometry 2 O_T_RL3

22 GPU5 LS General purpose output 5 (LS) O_T_RL07

23 GPU3 LS General purpose output 3 (LS) O_T_RL09

24 Battery plus output 32 Battery Plus Output 32 O_V_RH32

25 InjectorPwrStg 2 + InjectorPwrStg 2 "bank2" O_P_SVH21

26 InjectorPwrStg 5 + InjectorPwrStg 5 "bank2" O_P_SVH22

27 InjectorPwrStg 8 + InjectorPwrStg 8 "bank2" O_P_SVH23

30 Wheelspeed ground Wheel sensor ground rear G_R_AMS

31 oil press. supply +5V Oil pressure sensor supply V_V_5VSS1F

32 Sensor Supply 7 +5V Sensor supply 7 V_V_5VSS1E

33 Water press. Supply +5V Water press sensor supply V_V_5VSS2B

34 5V Sensor supply 8 Sensor supply 8 V_V_5VSS3C

35 oil press. signal Oil pressure sensor input signal I_A_AN01 poil

36 rail press. signal Rail pressure sensor signal I_A_RAILPS prail

37 boost temp. signal MAT (Boost temperature) I_A_AN16 tint

39 coolant temp. signal Coolant temperature sensor signal I_A_AN17 tmot

40 Sensor gnd 8 Sensor ground 8 G_R_AN08

41 SENT (optional) input for SENT interface I_D_SENT

42 Sensor gnd 7 Sensor ground 7 G_R_AN20

45 fuel pump relay Fuel Pump O_S_RL19

46 GPU2 LS General purpose output 2 (LS) O_T_RL06

47 GPU1 LS General purpose output 1 (LS) O_T_RL05

49 InjectorPwrStg 1 + InjectorPwrStg 1 "bank1" O_P_SVH11

50 InjectorPwrStg 4 + InjectorPwrStg 4 "bank1" O_P_SVH12

Technical data | 1

Bosch Motorsport Engine Control Unit MS 25 Sport 7/40

51 InjectorPwrStg 7 + InjectorPwrStg 7 "bank1" O_P_SVH13

52 InjectorPwrStg 3 + InjectorPwrStg 3 "bank3" O_P_SVH32

53 InjectorPwrStg 6 + InjectorPwrStg 6 "bank3" O_P_SVH33

54 fwheel_rl Wheelspeed frequency input, rear left (Hall) I_F_AMS vwheel_rl

55 LIN (OPTIONAL) LIN interface (Optional) B_D_LIN

56 fwheel_rr Wheelspeed frequency input, rear right (Hall) I_F_IATS vwheel_rr

57 waste gate 1 / VGT1 Waste Gate 1 / Variable Turbine Geometry 1 O_T_RL02

58 FMU1 supply Supply FMU O_V_MEU

59 Cooland/fuel temp gnd Coolant and fuel temperature sensor ground G_R_AN18

60 rail press. gnd Rail pressure sensor ground G_R_RAILPS

61 amb/water2 press. signal ambient pressure / water pressure 2 I_A_AN03 pwat2

62 Wastegate press. Signal wastegate pressure sensor 1 signal I_A_AN07 pwgc

63 LSU VM LSU4.9 - VM G_R_LSVG

64 LSU IP LSU4.9 - IP I_A_LSCP

65 crankshaft - Crankshaft speed sensor signal Negative (Inductive) I_F_CRSNEG

66 crankshaft + Crankshaft speed sensor signal Positive (Inductive) I_F_CRSPOS

67 camshaft - (OPTIONAL) Optional CamShaft Sensor Signal (Inductive) I_F_CASNEG

68 camshaft + (OPTIONAL) Optional CamShaft Sensor Signal (Inductive) I_F_CASPOS

69 Sensor gnd 6 Sensor ground 6 G_R_AN07

72 LSU heat- lambda sensor heater low side PWM output O_T_LSH

73 InjectorPwrStg 1 - InjectorPwrStg 1 "bank1" O_P_SVL11

74 InjectorPwrStg 4 - InjectorPwrStg 4 "bank1" O_P_SVL12

75 InjectorPwrStg 7 - InjectorPwrStg 7 "bank1" O_P_SVL13

76 InjectorPwrStg 3 - InjectorPwrStg 3 "bank3" O_P_SVL32

77 InjectorPwrStg 6 - InjectorPwrStg 6 "bank3" O_P_SVL33

78 CAM/CRK (hall) ground CAM/CRK speed sensor ground (Hall) G_R_DF02

79 cam hall signal camshaft position sensor (Hall) I_F_DF02

80 CrankShaft Hall (OPTIONAL) Optional crankshaft speed sensor signal (Hall) I_F_DF06

81 PCV1 (FMU2) LS Rail pressure control valve 1 LS (opt FMU2 LS) O_T_PCV

82 PCV1 Supply Supply PCV1 O_V_PCV

83 FMU1 LS Fuel Metering Unit 1 LS O_T_MEU

84 Sens. Supply 12V Sensor supply O_V_VDD12

86 boost press. signal MAP (boost pressure) I_A_AN05 pboost

87 LSU UN LSU4.9 - UN I_A_LSVN

88 LSU IA LSU4.9 - IA I_A_LSCA

89 Shield GND Shield ground G_R_RES

90 boost press./temp. gnd boost pressure and temperature sensor Ground G_R_AN05

91 turbospeed2+ Turbocharger speed 2 (Inductive) I_F_DF05 nturbo2

92 turbospeed2- Ground for turbocharger speed 2 (Inductive) G_R_DF05

93 turbospeed1+ Turbocharger speed 1 (Inductive) I_F_DF04POS nturbo1

94 turbospeed1- Ground for turbocharger speed 1 (Inductive) I_F_DF04NEG

96 LSU heat+ Battery plus output 22 O_V_RH22

1 | Technical data

8/40 Engine Control Unit MS 25 Sport Bosch Motorsport

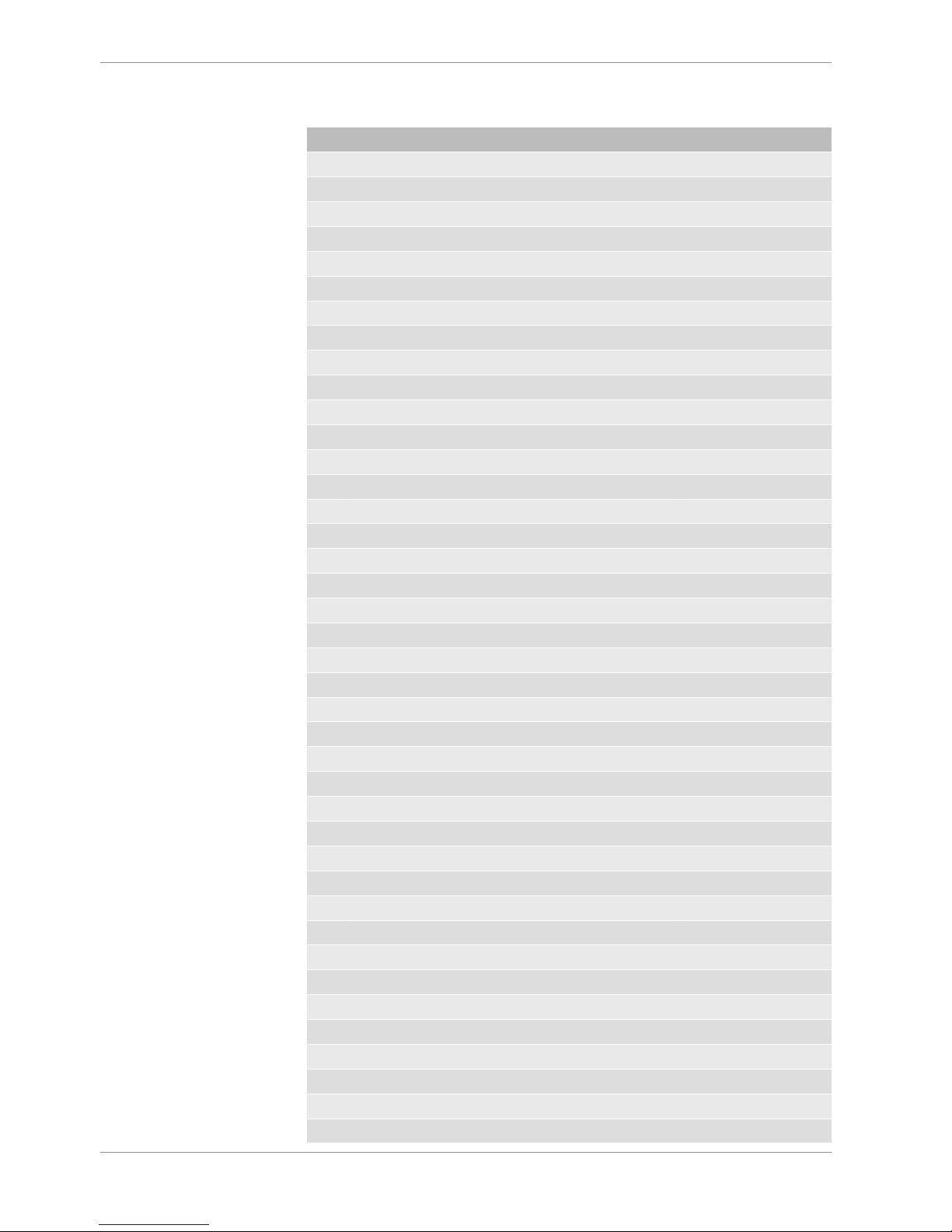

Vehicle connector (X1 - Vehicle) 1928405312

PIN Name Main function PIN Name Signal

1 Battery plus 4 Battery plus % V_V_BAT+4

3 Battery minus 1 Battery minus % G_G_BAT-1

5 Battery minus 4 Battery minus % G_G_BAT-4

7 airbox press. signal airbox pressure sensor signal I_A_AN23 pairbox

9 fuel return temp temperature sensor signal for return fuel I_A_AN22 tleak

10 Sensor gnd 1 Sensor Ground 1 G_R_AN10

11 pit speed sw pit speed limiter digital switch I_S_DIG03

14 Launch sw Launch control switch I_S_DIG07

16 egt1 signal Exhaust gas temperature sensor signal 1 I_A_AN13 texh

17 egt2 signal Exhaust gas temperature sensor signal 2 I_A_AN19 texh2

18 egt1/egt2 gnd EGT1 / EGT2 Ground G_R_AN13

21 glowplug relay HS Glowplug Relay HS O_T_RH06

25 Battery plus 3 Battery plus % V_V_BAT+3

26 Battery plus 5 Battery plus % V_V_BAT+5

27 12V Sw/FMU3 (HS) Supply Supply for switches and FMU3 (HS) O_V_RH31

28 Battery minus 2 Battery minus % G_G_BAT-2

32 Map Switch Map position switch I_A_AN24 mapsw

33 Sensor gnd 4 Sensor Ground 4 G_R_AN11

34 Engine Speed Output Engine Speed Output Signal (tach) O_F_DA01

36 Laptrg Laptrigger input I_S_DIG08

37 Pace sw Pace switch I_S_DIG04

39 Sensor gnd 2 Sensor Ground 2 G_R_AN12

40 gearbox temp. signal Gearbox Temperature Sensor Signal I_A_AN14 tgear

41 Ambient temp. signal Ambient Temperature Sensor Signal I_A_AN26 tamb

43 Sensor gnd 3 Sensor Ground 3 G_R_AN14

46 CAN1 + CAN Interface B_D_CANH0

47 CAN1 - CAN Interface B_D_CANL0

49 Battery plus 2 Battery plus % V_V_BAT+2

50 12V Supply Relay (HS) Relay Supply (HS) O_V_RH11

52 Battery minus 5 Battery minus % G_G_BAT-5

53 VSS Vehicle speed sensor signal (Hall) I_F_VSS speed

54 VSS GND Vehicle Speed Sensor Ground G_R_VSS

57 aps2 gnd Accelerator pedal position sensor 2 ground G_R_APP2

60 fuel reset sw Fuel Reset Switch I_S_DIG02

61 MILSpec MILSpec Warning Lamp (LS) O_S_RL20

64 fwheel_fr Wheelspeed frequency input, front right (Hall) I_F_DF01 vwheel_fr

65 Wheel sens. Gnd. Front Wheel Sensor Ground Front G_R_DF01

66 aps1 supply +5V Accelerator pedal supply 1 V_V_5VSS2D

67 5V sens. Supply 4 Sensor Supply 4 V_V_5VSS2A

68 5V sens. Supply 2 Sensor Supply 2 V_V_5VSS1D

Technical data | 1

Bosch Motorsport Engine Control Unit MS 25 Sport 9/40

PIN Name Main function PIN Name Signal

69 terminal 15 Terminal 15 (switched BAT+) I_S_T15

71 CAN 2 + (Diag) CAN Interface (Diag) - MSA-Box2 ecu interface B_D_CANH1

72 MIL MIL Warning Lamp (LS) O_S_RL12

73 Battery plus 1 Battery plus % V_V_BAT+1

75 Battery minus 3 Battery minus % G_G_BAT-3

78 aps2 signal Accelerator pedal position signal 2 I_A_APP2 aps_b

79 aps1 signal Accelerator pedal position signal 1 I_A_APP1 aps_a

80 aps1 gnd Accelerator pedal position sensor 1 ground G_R_APP1

81 Wet sw Wet switch I_S_DIG06

84 fwheel_fl Wheelspeed frequency input, front left (Hall) O_T_RL13 vwheel_fl

86 GPU4 LS General purpose output 4 (LS) O_T_RL08

87 FMU3 LS Fuel Metering Unit 3 LS O_T_RL01

89 Shield GND Shield ground G_G_RL13

90 5V sens. Supply 3 Sensor Supply 3 V_V_5VSS3A

91 5V sens. Supply 1 Sensor Supply 1 V_V_5VSS1C

92 aps2 supply +5V Accelerator pedal supply 2 V_V_5VSS1B

93 Auxiliary Relay LS Auxiliary Relay LS O_S_RL27

94 glowplug relay LS Glowplug Relay LS O_S_RL26

95 CAN 2 - (Diag) CAN Interface (Diag) - MSA-Box2 ecu interface B_D_CANL1

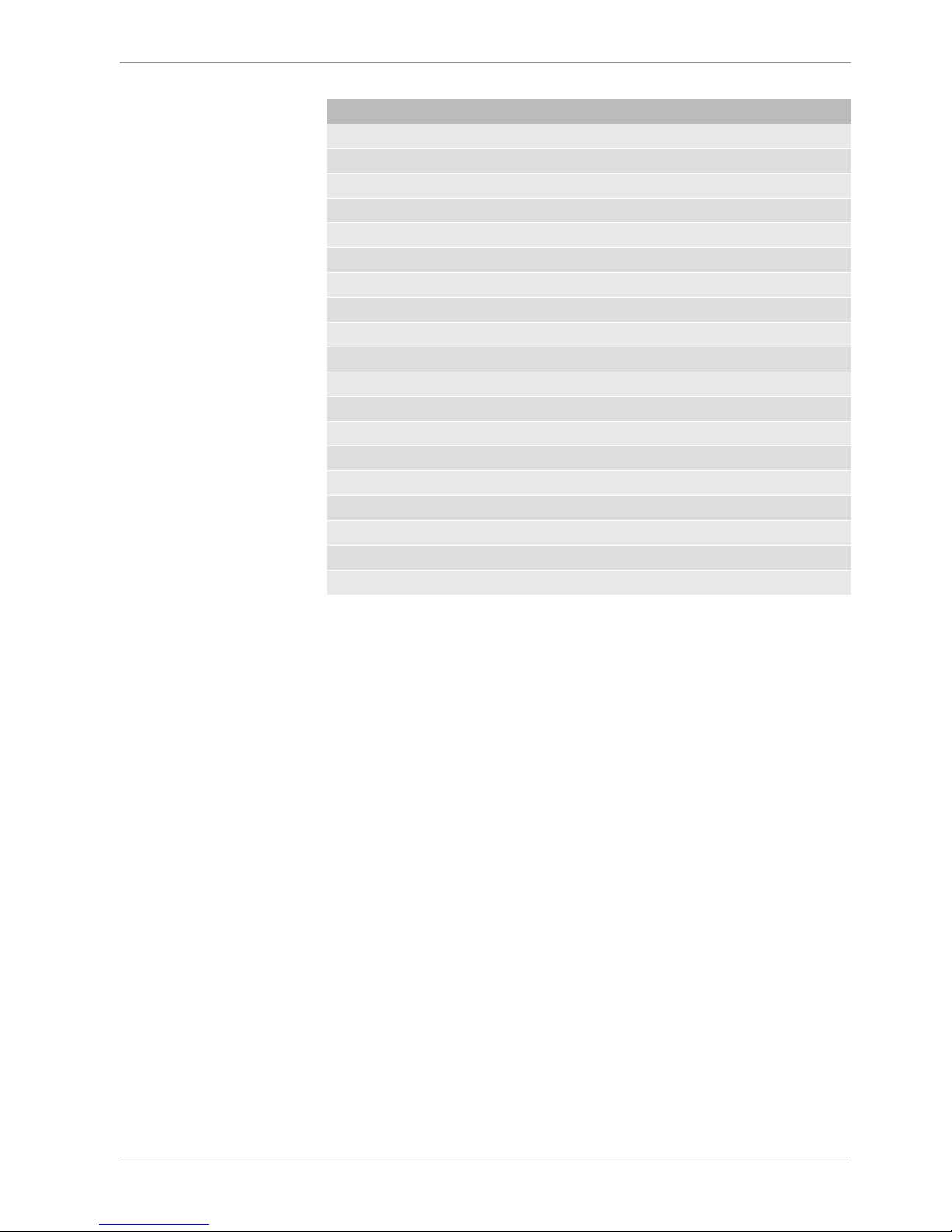

1.4 Input Channels

Only active (0 to 5 V) exhaust gas temperature sensors are supported.

See chapter Initial Data Application [}22] for further information and calibration examples for different sensors.

1.5 Output Channels

The MS 25 Sport has 8 injector power stages on three banks. Only solenoid valve type

common rail injectors are supported. Injector current profile must be calibrated for used

injector type (CRIN1, CRIN3, CRI2.X, ...).

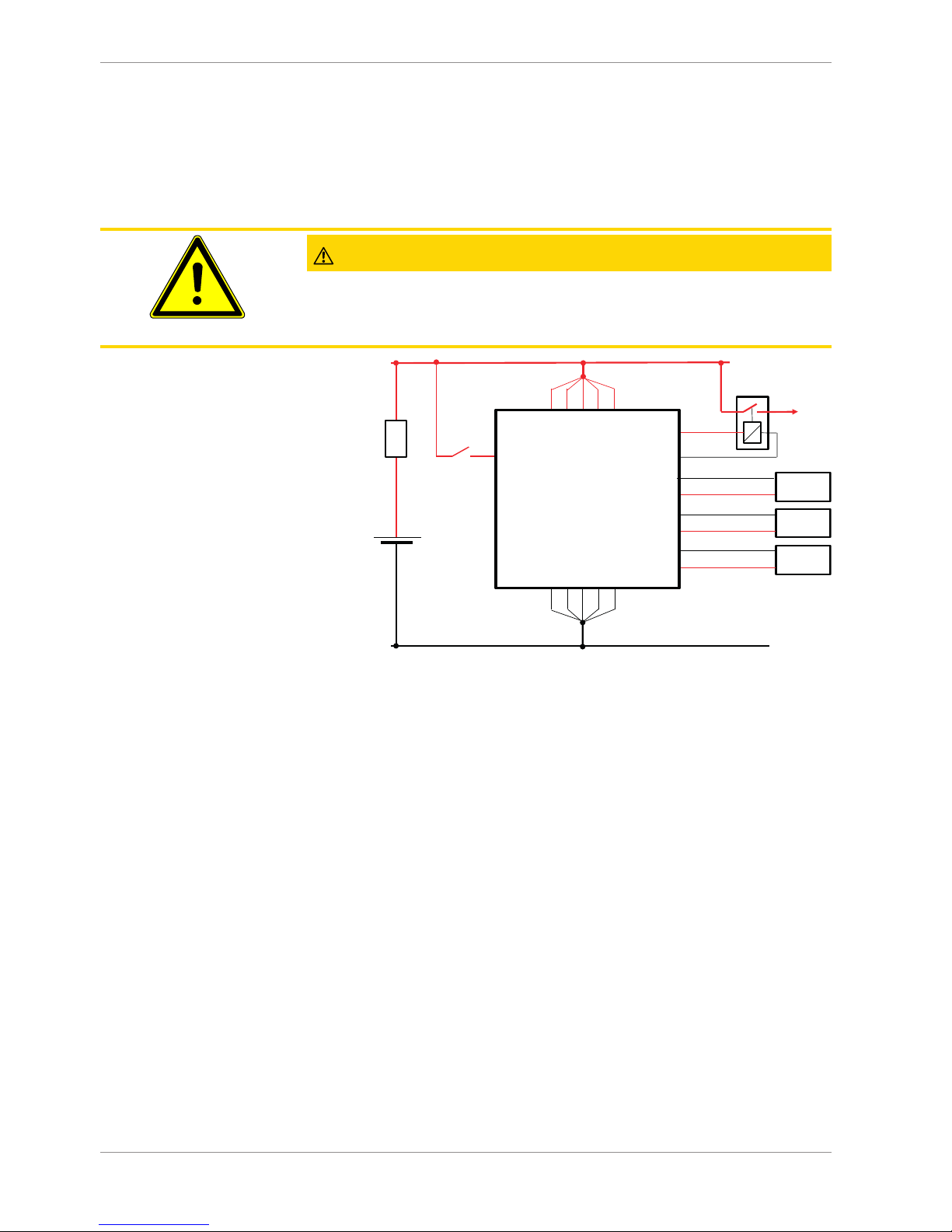

1.6 Power Supply

Please ensure that you have a good ground installation. That means:

– A ground that has a solid, low resistance connection to the battery minus terminal.

– Connection should be free from dirt, grease, paint, anodizing, etc.

– Use large diameter wire.

– More metal-to-metal contact is better

Connection of the power supply

The following notations for power signals are used:

– Term 15 is a switched battery rail controlled by the Engine On-switch.

1 | Technical data

10/40 Engine Control Unit MS 25 Sport Bosch Motorsport

– Term 30 is an unswitched battery positive rail (same as battery positive terminal).

– Term 31 is an unswitched ground rail (same as battery negative terminal).

– MS 25 Sport needs constant Term 30 and ECU should be powered on and off only

with Engine On-switch (Term 15). Constant voltage on Term 30 is required to preserve

critical information during ECU shutdown.

CAUTION

Wrong polarity / high currents

Wrong polarity of the terminals and high currents damage the MS 25 Sport. Be careful to

observe current limits of wires and connector pins!

T30 (UBat)

T31 (GND)

+

-

Battery

Fuse

(30A)

V01 V25 V26 V49 V73

V03 V05 V28 V52 V75

Engine On

Switch

V69

V93

Auxiliary

Relay

PCV

FMU

E83

E58

E81

E82

LSU

Heat

E72

E96

+

+

+

MS 25 Sport

V50

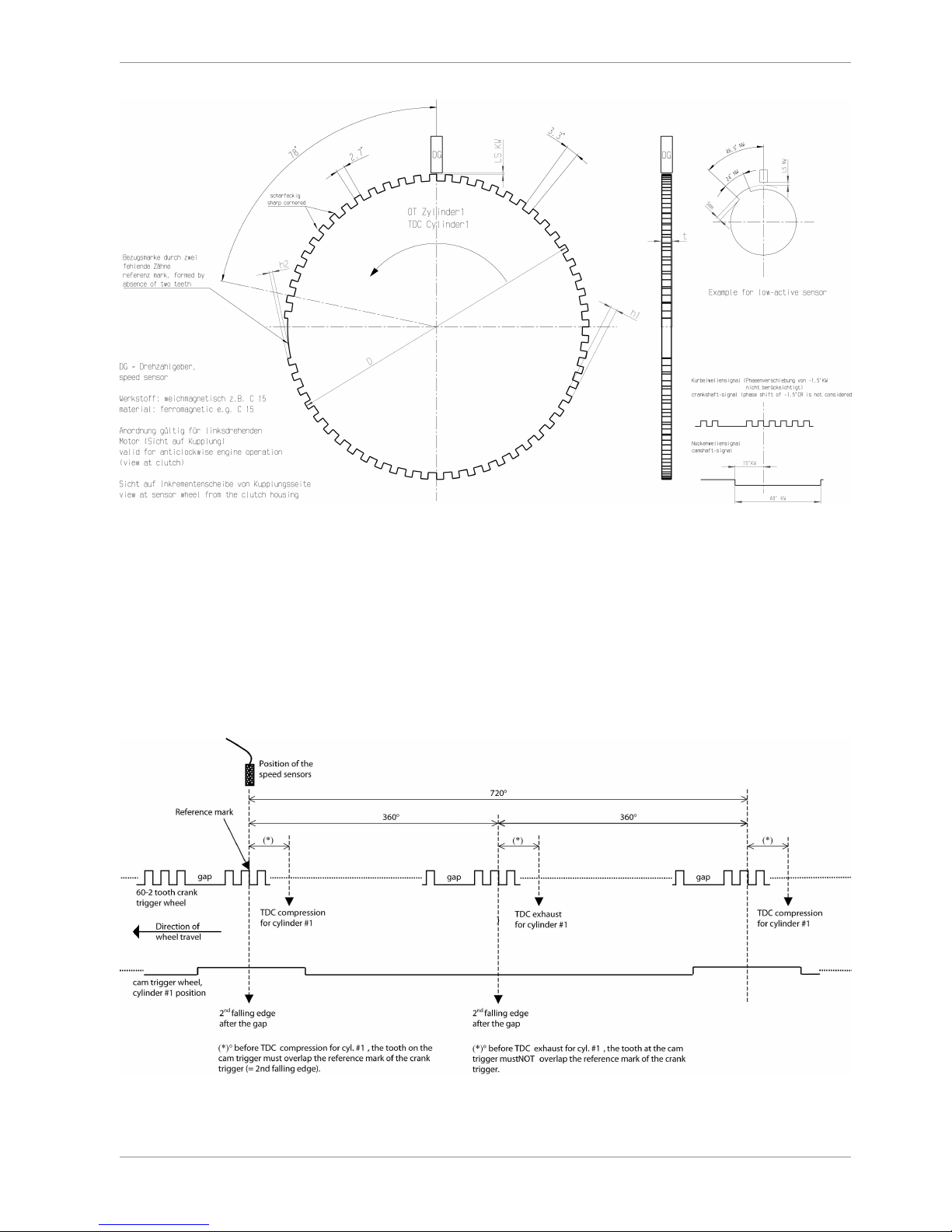

1.7 Trigger Wheel

The software assumes a toothed trigger wheel for proper operation. The number of the

teeth is hard coded by Bosch Motorsport and can’t be changed by the customer. Custom

gap teeth numbers are optional.

We recommend 60 (-2) teeth as shown in the following picture. The crank wheel trigger

sensor must be an inductive type for the default configuration, Hall-effect crank sensor is

optional and requires software change.

The camshaft trigger sensor is a Hall-effect type with a single tooth trigger wheel, but

other configurations can be configured with calibration. Inductive cam sensor is optional

and requires software change. The picture below shows the correct installation position.

Technical data | 1

Bosch Motorsport Engine Control Unit MS 25 Sport 11/40

Recommended values:

– D=min. 160 mm

– h1=3.5 mm

– h2=h1/2

– LSKW=0.8 mm ± 0.3 mm

– t=min. 5 mm

– LSNW=1 mm ± 0.5 mm

The procedure for correct adjustment of the trigger wheel is described in the drawing on

the next page.

Procedure to find the right position for the crank and cam trigger

1. Rotate the engine to the precise position of TDC compression for cylinder #1

1 | Technical data

12/40 Engine Control Unit MS 25 Sport Bosch Motorsport

2. Rotate the engine 78 crankshaft degrees backwards

3. Adjust the position of the crank trigger wheel in reference to its inductive speed

sensor: the longitudinal axis of the sensor must point exactly towards the reference

mark (2nd falling edge after the gap)

4. Rotate the engine further 15 crankshaft degrees backwards

5. Adjust the position of the cam trigger in reference to its Hall Effect speed sensor: the

sensor must be at the begin of the tooth

6. Turn the engine by 345 crankshaft degrees to reach the position of 78° before TDC

exhaust for cylinder #1

7. Verify that the crank trigger reference is in alignment with the longitudinal axis of the

sensor (same as step 3) and that the cam trigger tooth is at the opposite side of its

speed sensor

NOTICE

All angles are shown and indicated in crankshaft degrees

The width of the cam trigger tooth is not important, however it is recommended to use at

least 48 crankshaft degrees (24 cam degrees)

The Hall effect signal may be the inversion of its cam trigger: the tooth effects a “low” signal at the sensor and vice versa for other trigger wheel configurations the indicated values

may vary.

Loading...

Loading...