Bosch DS935Z Installation Instructions Manual

Installation Instructions

for the DS935Z

ASIC-Based PIR Intrusion Detector

1.0 Specifications

• Input Power: 9.0 VDC to 15.0 VDC

• Current Draw: 15 mA @ 12.0 VDC

• Standby Power: There is no internal standby battery.

Connect to DC power sources

capable of supplying standby power

if primary power fails. For each hour

of standby time needed, 15 mAh are

required. For UL Listed

Requirements, four hours (60 mAh)

minimum are required.

• Coverage:

Broad (standard): 35 ft. x 35 ft. (10.7 m x 10.7 m)

Barrier (optional): 35 ft. x 10 ft. (10.7 m x 3.1 m)

Long Range (optional): 70 ft. x 10 ft. (21.4 m x 3.1 m)

Pet (optional): 35 ft. x 35 ft. (10.7 m x 10.7 m)

with 70 ft. (21.4 m) long range

• Sensitivity: Selectable for Standard or

Intermediate.

• Alarm Relay: Form “C” reed relay with contacts rated

at 28 VDC, 125 mA maximum for DC

resistive loads.

• Tamper Switch: Normally Closed (with cover in place)

tamper switch. Contacts rated at

28 VDC, 125 mA maximum.

• Trouble Output: A solid state open collector shorts to

ground (-) when the detector is in a

trouble condition. The maximum

current load is 25 mA. Vsat @10 mA =

0.5 VDC.

• Temperature: The storage and operating range is

-40°F to +120°F (-40°C to +49°C). For

UL Certificated Installations, the

temperature range is +32°F to +120°F

(0°C to +49°C).

• Options: B335 Low Profile Swivel Mount

Bracket, B338 Ceiling Mount Bracket,

OMB93-3* Barrier Mirror, OMLR93-3*

Long Range Mirror, OMP93-3* Pet

Mirror.

*Shipped in packages of three.

NOTE: Misalignment of the detector when using an optional

mounting bracket may reduce range and increase dead

zones.

• Reading Bosch Security Systems, Inc. Product Date Codes

For Product Date Code information, refer to the Bosch Security

Systems, Inc. Web site at: http://www.boschsecurity.com/datecodes/

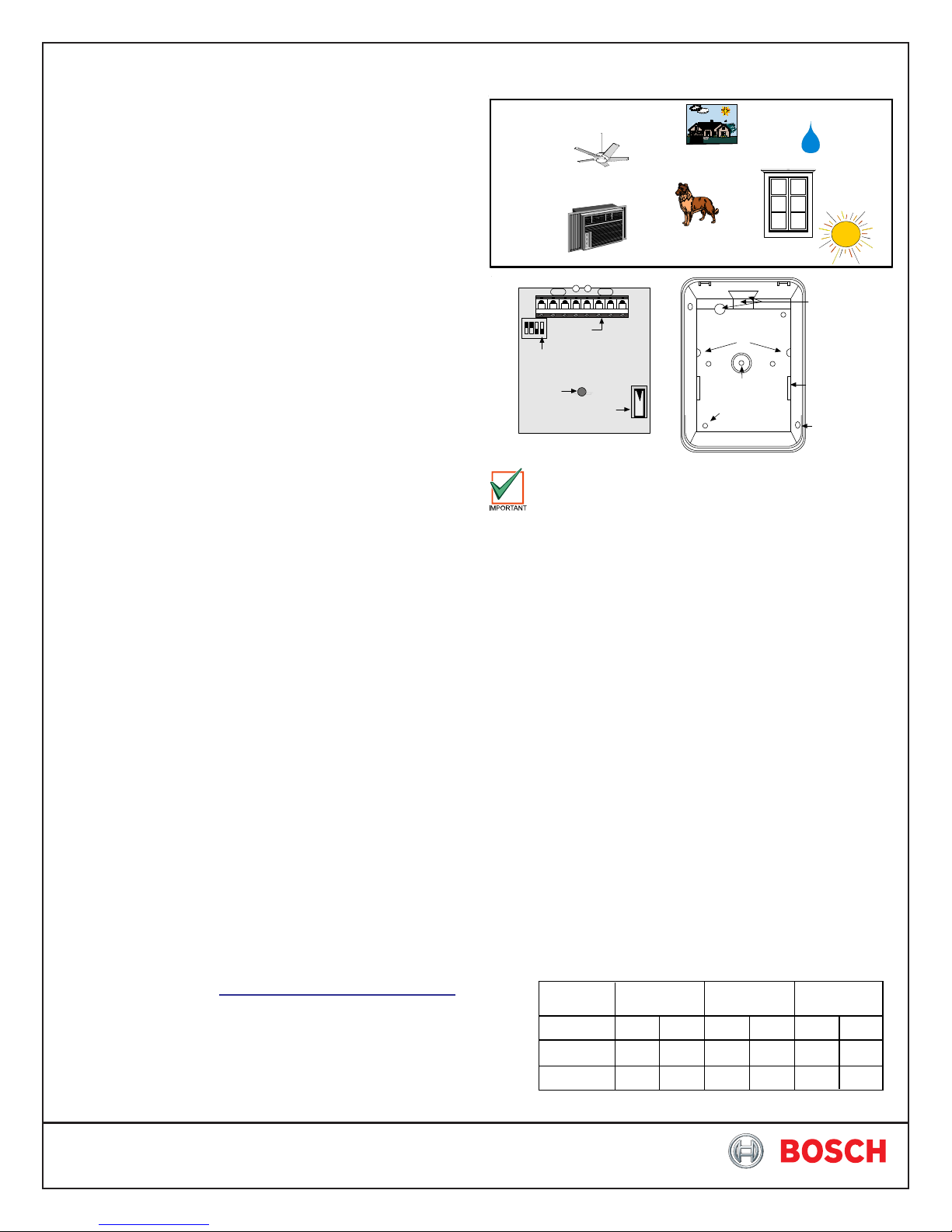

2.0 Mounting

Avoid

Moving objects

Mounting Outdoors

Hot or cold air

directed onto

sensor

Pets or animals

T-Strip

Configuration

Switches

LED

Tamper Switch

Location of major items - Circuit Board

Circuit Board

Retainer Tabs (2)

Bracket Mounting

Hole

Surface

Mounting

Holes (4)

Rear enclosure and mounting holes

The mounting surface should be solid and vibration free.

• Select a location that is most likely to intercept an intruder moving

across the coverage pattern. The recommended mounting

height range is 6.5 ft. to 8.5 ft. (2 m to 2.6 m).

• Remove the cover. Insert a thin flathead screwdriver into the

notch at the bottom of the cover and pry up.

• Remove the circuit board by depressing the circuit board retainer

tab and lifting the board out from the enclosure. Then remove

the mirror by sliding it towards the bottom and out of its tracks.

• Open the knock-out wire entrance and route the wiring through.

3.1 Surface or Corner Mounting

• Open two holes for surface or corner mounting.

• Mark the location for the mounting screws. Use the enclosure

as a template. Pre-start the mounting screws.

• Securely attach the detector.

• Replace the circuit board/mirror unit.

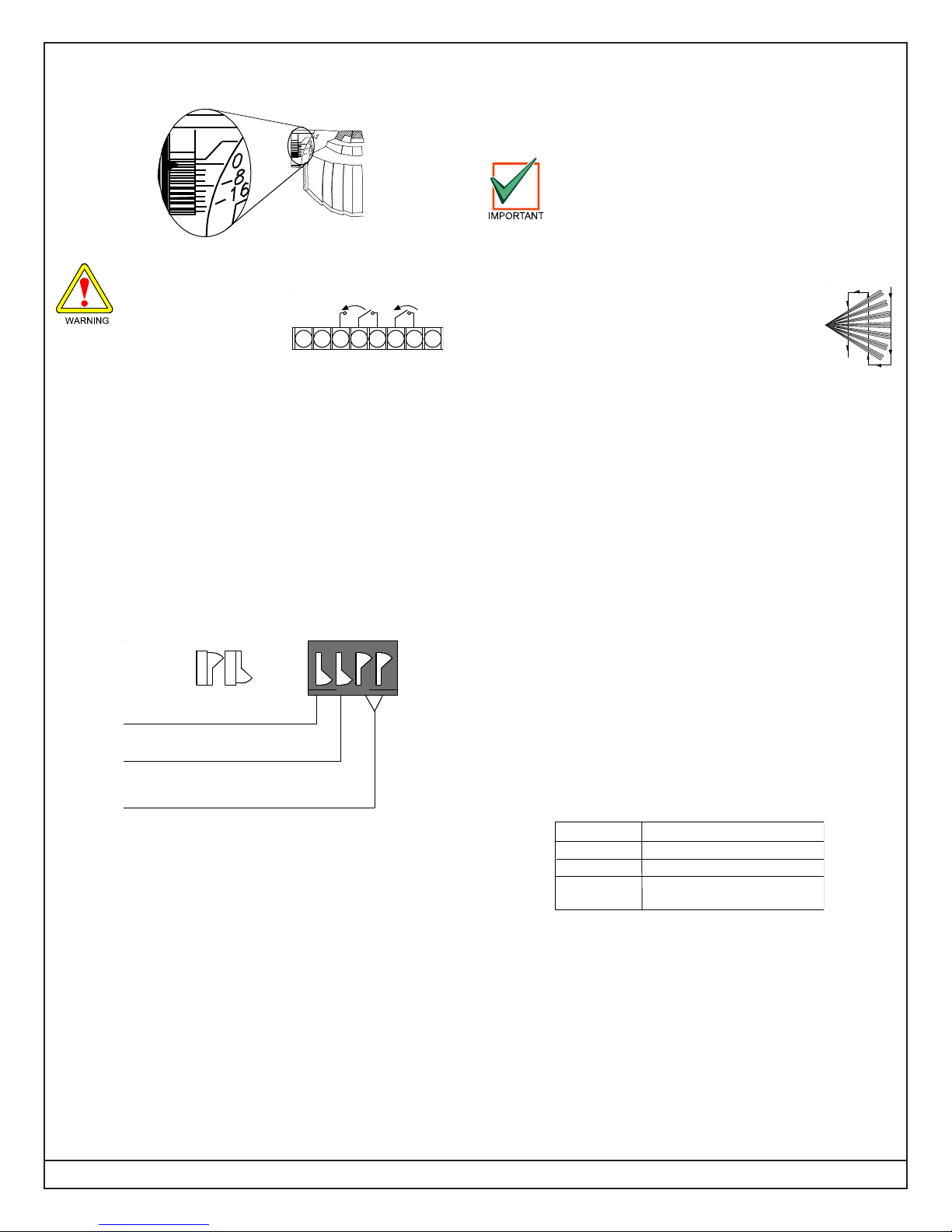

• Select the Vertical Angle.

Mirror Information: The mirror is adjustable from +1° to -18°

vertically by sliding the mirror forward or back and ±10° horizontally

by rocking the mirror side to side. To change the mirror, just pull it

out from its resting grooves.

NOTE: Excessive handling of the mirror surfaces may lead to

performance degradation.

- The following chart will help you set the correct Vertical

Angle based on the mounting height, mirror type, and

desired range.

Mounting

Height

6.5(2)

7.5(2.3)

8.5(2.6)

Broad Barrier Long Range

35(10) 20(6) 35(10) 40(12)

20(6)

-6°

-10°

-12°

-14°

-10°

-6° -4°

-8°

-8° -6° -4°

-12° -8° -6°

Moisture

Direct or

reflected

sunlight

Wiring

Knockouts

Mirror

Tracks (2)

Corner

Mounting

Holes (2)

-4°

70(20)

-2°

-2°

-4°

Height and desired Range li sted in feet (meters)

- The angle adjust markings are on the mirror. Slide the

A

mirror forward or back until the angle hash marks are inline with the markers on each side of the frame.

5.3 S3 and S4 - Motion Monitor:

Set for the desired Motion Monitor time (see Supervision

Features). The detector is shipped with the Motion Monitor

feature disabled.

6.0 Setup and Walk Testing

Before walk testing, the system should be fully wired,

powered, and programmed.

3.0 Wiring

Only apply power after all connections have been

made and inspected.

• Connect wiring as shown.

larmAlarm

1 2 3 4 5 6 7 8

+

NO C NC TT

-

TR

NOTE: Do not coil excess wiring inside unit.

• Seal the Wire Entrance using the foam plug provided.

Terminal Descriptions

• 1 (-) & 2 (+): Input Power. Use no smaller than #22 AWG

(0.8 mm) wire pair.

• 3, 4, 5: Form "C" reed relay contacts rated at 3 W, 125 mA,

28 VDC maximum for DC resistive loads and protected by a

4.7 ohm resistor in the common "C" leg of the relay. Do not use

with capacitive or inductive loads.

• 6 & 7: Tamper Contact, rated 28 VDC, 125 mA.

• 8: Trouble. Solid state open collector; maximum current load is

25 mA. Shorts to ground (-) when the detector is in a Trouble

condition.

5.0 Configuring Detector

OFF

ON

(ON) 1

(OFF) 0

1 ON = LED ON

1 OFF = LED OFF

2 ON = Standard

2 OFF = Inte r mediate

3 ON and 4 OFF = 4 Day Motion Monitor

3 OFF and 4 ON = 30 Day Motion Monitor

3 OFF and 4 OF F = Motion Monitor D isab le d

5.1 S1 - LED Operation

• ON: Allows the LED to operate when activated by alarm.

• OFF: The LED will not operate on alarm.

5.2 S2 - Sensitivity Mode

• Standard Sensitivity: Recommended setting for maximum

false alarm immunity. Tolerates environment extremes on this

setting. Not recommended for Long Range or Barrier type

patterns. The detector is shipped in Standard Sensitivity

mode.

• Intermediate Sensitivity: Recommended setting for any location

where an intruder is expected to cover only a small portion of the

protected area. Tolerates normal environments on this setting.

This setting will improve your intruder catch performance.

12 34

OPEN

• Turn LED Switch ON.

• Replace the front cover.

NOTE: All testing must be performed with the front

cover in place.

• Wait at least two minutes (with no motion in the

coverage area) for the detector to setup.

• Walk test across the coverage pattern.

• The edge of the coverage is determined by activation of the

LED.

• Walk test the unit from both directions to determine the

boundaries.

7.0 Supervision Features

A supervision trouble condition is indicated at the detector by the

LED. The LED indicates the cause of the trouble using coded

pulses. The trouble signal activates the Trouble output available

at Terminal 8, which should be connected to a 24-hour zone.

The supervision features function as follows:

• PIR: PIR operation is checked electronically approximately every

12 hours. If the circuit fails, the LED will pulse four times, the

Trouble output will activate and the unit must be replaced.

• Motion Monitor Supervision: This feature verifies that the

detector has a clear view of the detection area.

- When selected, a supervision timer is activated. A trouble

condition will be indicated if the detector has not alarmed at

least once during the selected time period (this feature can be

disabled by placing both switches [S3 and S4] in the OFF

position). The time period selected should be long enough to

allow adequate time for holiday weekends.

- If the time period selected has elapsed from the last alarm,

the LED will flash two times and the Trouble output will activate.

The following chart displays the LED response to the supervision

features:

LED

ON

Two Flashes

Four Flashes

Cause

Unit Alarm

Motion Monitor Timeout

PIR Self-Test Failure

(replace detector)

• Trouble Reset: An alarm activation will reset a motion monitor

trouble condition.

8.0 Maintenance

At least once a year, the range and coverage should be checked

in accordance with the Walk Testing section. To ensure continual

daily operation, the end user should be instructed to daily walk

through the outer edge of the coverage pattern and observe the

LED operation (if used). This assures an alarm output prior to

arming.

Page 2 © 2011 Bosch Security Systems, Inc. DS935Z Installation Instructions

Loading...

Loading...