Page 1

Control Panels

D9412GV4/D7412GV4 v2.00

en Installation and System Reference Guide

Page 2

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | Certifications and Approvals

.

equivalence number (REN). If requested, this

Certifications and Approvals

The D9412GV4/D7412GV4 v2.00 Literature Pack

includes an Approved Applications chapter in this

guide. Refer to this chapter for additional

guidelines on installing the control panels in

Underwriters Laboratories Inc. (UL) and firespecific applications.

Listings and Approvals

UL

The D9412GV4 and D7412GV4 are listed as UL

864 Commercial Fire control panels. The

D9412GV4 and D7412GV4 are also UL Listed for

Central Station, Local, Auxiliary, Proprietary, and

Household Fire Alarm, and Central Station, Local,

Police Station Connect, Holdup, Household

Burglar Alarm and Encrypted line Security when

communicating via a network.

cUL

The D9412GV4 and D7412GV4 are cUL listed for

Local Burglar Alarms, Signal Receiving Centre and

Premise Alarm, Residential Fire, Household

Burglar, Propriety Burglar, and Digital Apparatus.

Department of Defense (DOD)

The D9412GV4/D7412GV4 was granted approval

for Department of Defense (DoD) installations in

Sensitive Compartmented Information Facilities

(SCIF).

Federal Communications Commission

(FCC) Rules

Part 15

This equipment was tested and found to comply

with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can radiate

radio frequency energy; and if not installed and

used according to the instructions, can cause

harmful interference to radio communications.

Operation of this equipment in a residential area

is likely to cause harmful interference, in which

case the user is required to correct the

interference at his or her own expense.

Part 68

This equipment complies with Part 68 of FCC

rules. A label contains, among other information,

the FCC registration number and ringer

information must be provided to the telephone

company.

The D9412GV4 and D7412GV4 Control Panels are

registered for connection to the public telephone

network using an RJ38X or RJ31X jack.

The REN is used to determine the number of

devices that can be connected to the telephone

line. Excessive RENs on the telephone line may

result in the devices not ringing in response to an

incoming call. In most, but not all areas, the sum

of the RENs should not exceed five. To be certain

of the number of devices that may be connected

to the line, as determined by the RENs, contact

the telephone company to determine the

maximum REN for the calling area.

If you experience trouble with the control panel,

please contact Bosch Security Systems Customer

Service for repair and warranty information. If the

trouble is causing harm to the telephone

network, the telephone company might request

that the equipment be removed from the network

until the problem is resolved. User repairs must

not be made, and doing so will void the user’s

warranty.

If the D9412GV4, or D7412GV4 Control Panels

causes harm to the telephone network, the

telephone company attempts to notify you in

advance. If advance notice is not practical, the

telephone company notifies you as soon as

possible. Also, you will be advised of your right to

file a complaint with the FCC if you believe it is

necessary.

The telephone company might make changes in

its facilities, equipment, operations, or

procedures that could affect the operation of the

equipment. If this happens, the telephone

company provides advance notice in order for the

necessary modifications to be made, resulting in

uninterrupted service.

This equipment cannot be used on public coin

service provided by the telephone company.

Connection to Party Line service is subject to

state tariffs. (Contact your state public utilities

commission for information.)

FCC Registration Number:

US:ESVOT00BD9412GV3

Service Center in USA:

Bosch ST Service Center

8601 East Cornhusker Hwy

Dock B

Lincoln, NE 68507 - 9702 USA

Ringer Equivalence: 0.0B

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 2

Page 3

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | Contents

.

Contents

Federal Communications Commission (FCC)

Rules ........................... 2

1.0 Introduction ...................... 7

2.0 Lightning Strikes .................. 9

2.1 Effects .......................... 9

2.2 Precautions during Installation ....... 9

3.0 Overview ....................... 10

3.1 Configuration and Parts ............ 10

3.1.1 Parts List ............................................... 11

3.1.2 Parts Available by Separate Order ......... 11

3.2 Accessories ..................... 12

3.3 Features in the GV4 Series Control Panels

............................... 13

3.3.1 SDI Interconnect Wiring ........................ 13

3.3.2 Tip and Ring Posts ................................. 13

3.3.3 Telephone Line Sniff .............................. 13

3.3.4 Points .................................................... 14

3.3.5 Areas and Accounts ............................... 14

3.3.6 Digital Communicator ............................ 14

3.3.7 Keypads ................................................. 14

3.3.8 Keyswitch .............................................. 15

3.3.9 Access Control ....................................... 15

3.3.10 Event Memory ........................................ 15

3.3.11 Event Log ............................................... 15

3.3.12 Ground Fault Detection ......................... 15

3.3.13 Ground Fault Detection Added Feature 15

3.3.14 Conettix Functions ................................ 16

3.3.15 Programming ......................................... 16

3.3.16 Dual Authentication ............................... 16

3.3.17 Other Features ...................................... 16

4.0 Installation ...................... 17

4.1 Installation Preparation ............ 17

4.2 Enclosure Options ................ 17

4.3 Mounting Enclosure ............... 17

4.4 Installing the Control Panel ......... 18

4.5 Connecting Earth Ground .......... 18

4.5.1 Terminal 10 ............................................ 18

4.5.2 Ground Fault Detect Enable .................. 18

4.5.3 Enabling Ground Fault Detection .......... 18

4.5.4 Ground Fault Specifications .................. 18

4.5.5 Locking the Reset Pin ............................ 19

4.6 Completing the Installation ......... 19

4.6.1 Charging the Battery .............................. 19

4.6.2 Installing and Wiring Detection Devices 19

4.6.3 Installing Modules and Outputs ............. 20

4.6.4 Connecting the On-board Points and

Keypads ................................................. 20

4.6.5 Powering Up .......................................... 20

4.7 Updating Control Panel Firmware .... 20

4.8 Programming the Control Panel ..... 20

4.9 Installing the Point Chart Label ...... 20

4.10 Testing the System ............... 20

4.11 Service Walk Test ................ 21

5.0 Power Supply .................... 24

5.1 Primary Power Terminals 1 and 2 .... 24

5.1.1 Primary (AC) Power Circuit ................... 24

5.1.2 Installing the Transformer ..................... 24

5.2 Secondary Power Terminals ........ 24

5.2.1 Secondary (DC) Power .......................... 24

5.2.2 Installing the Battery ............................. 25

5.2.3 Replacing the Battery ............................ 26

5.2.4 Battery Supervision ............................... 27

5.2.5 Battery Charging Circuit Float Charge .. 27

5.2.6 Battery Discharge and Recharge Schedule

.............................................................. 28

6.0 Power Outputs ................... 30

6.1 Circuit Protection ................ 30

6.2 Total Available Power ............. 30

6.3 Continuous Power Output Terminals 3, 8,

24, and 32 ...................... 30

6.4 Programmable Power Output Terminals 6,

7, and 8 ........................ 30

6.4.1 Programming ......................................... 31

6.4.2 Terminals 6 and 7 .................................. 31

6.4.3 Fire System Power Formula .................. 31

6.4.4 Terminal 8.............................................. 31

7.0 Telephone Connections ............ 32

7.1 Registration ..................... 32

7.2 Notification ..................... 32

7.3 Location........................ 32

7.4 Telephone Cord Connection ........ 32

7.5 Phone LED (Red) ................. 33

7.6 Operation Monitor LED (Green) ..... 33

7.7 Dialing Format ................... 33

7.8 Telephone Line Monitor ........... 33

7.9 Called Party Disconnect ........... 34

7.10 Communication Failure ............ 34

7.11 D928 Dual Phone Line Switcher ..... 34

7.11.1 Description ............................................ 34

7.11.2 Operation .............................................. 34

7.11.3 Installing the D928 ................................ 35

7.11.4 D928 Status LEDs ................................. 35

8.0 On-Board Points ................. 37

8.1 Terminals 11 to 22 Description ...... 37

8.2 Point Sensor Loops ............... 37

8.3 Point Parameters ................. 37

8.4 Point Response Time .............. 38

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 3

Page 4

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | Contents

.

Wiring Information for Installations Using

8.5

the Rothenbuhler 5110/4001-42 High

Security Bell .................... 38

9.0 Off-Board Points ................. 41

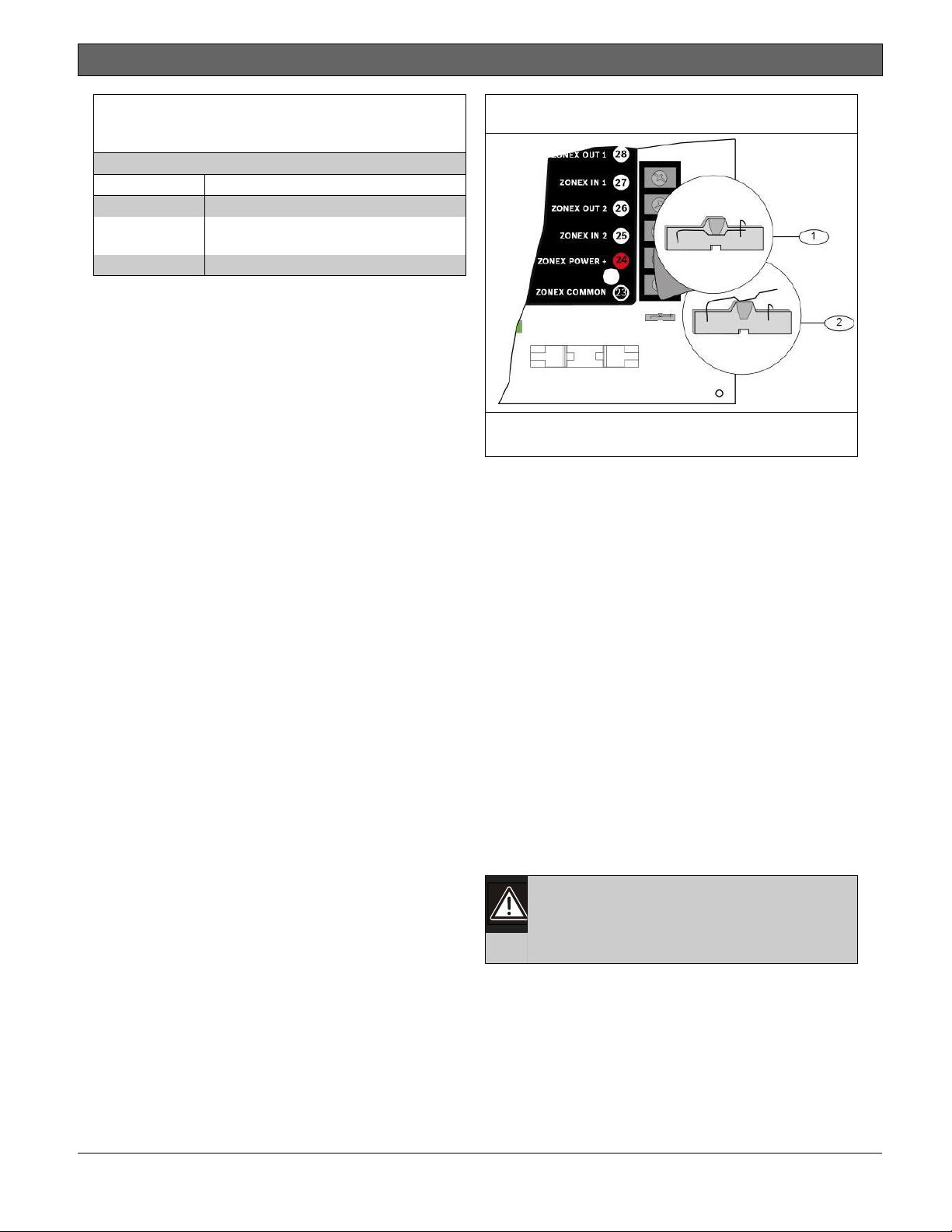

9.1 Zonex Buses .................... 41

9.1.1 POPIT Modules ...................................... 41

9.1.2 POPEX Modules ..................................... 41

9.1.3 Missing Conditions ................................ 41

9.1.4 Control Panel Responses to Missing Point

Conditions ............................................. 41

9.2 D8125 and D9127 POPIT Modules ... 41

9.3 Installing the D8125 POPEX Module .. 43

9.3.1 Mounting ................................................ 43

9.3.2 Wiring the D8125 to the Control Panel . 43

9.3.3 Wiring POPITs to the Data Expansion

Loop ...................................................... 44

9.3.4 Wiring Data Expansion Loops to POPEX

Modules ................................................. 44

9.3.5 POPIT Sensor Loops .............................. 44

9.3.6 POPIT Module Point Assignments ......... 45

9.3.7 Program Record Sheet .......................... 45

9.3.8 POPIT Labels ......................................... 45

9.4 D8128D OctoPOPIT Module ........ 46

9.4.1 Description ............................................ 46

9.4.2 Listings .................................................. 46

9.4.3 Installation ............................................. 46

9.4.4 Setting the OctoPOPIT Switches ........... 47

9.4.5 Mounting OctoPOPITs ........................... 47

9.4.6 Wiring OctoPOPITs ................................ 48

9.4.7 OctoPOPIT Sensor Loops ...................... 52

9.5 Testing Off-Board Points ........... 53

9.6 SDI2 Octo-input Point Modules ...... 53

9.7 Extra Point Events ................ 53

10.0 Off-Board Outputs .................. 55

10.1 D8129 OctoRelay ................. 55

10.1.1 Configuring the D8129 OctoRelay ......... 57

10.1.2 Relay Outputs ........................................ 57

10.1.3 Installation ............................................. 57

10.1.4 Wiring Connections ............................... 57

10.2 D811 Arm Status Relay Module ...... 58

10.2.1 Relay Output .......................................... 58

10.2.2 Installation ............................................. 58

10.2.3 Wiring Connections ............................... 58

10.3 SDI2 Octo-output Relay Modules .... 58

11.0 Arming Devices ..................... 60

11.1 Description ..................... 60

11.2 SDI/SDI2 Bus Terminals 29 to 36 .... 60

11.2.1 Shortcuts and Custom Functions .......... 60

11.2.2 Assigning an Address for the Keypad .... 61

11.2.3 Installation ............................................. 61

11.3 D279A Independent Zone Control .... 62

11.4 Keyswitch ...................... 62

11.4.1 Description ............................................ 62

11.4.2 Programming ......................................... 62

11.4.3 Installation ............................................. 62

11.4.4 Operation .............................................. 62

12.0 SDI Devices ....................... 64

12.1 Description ..................... 64

12.2 Installation ...................... 64

12.2.1 Open Wire Trouble on SDI .................... 64

12.3 D9210C Access Control Interface Module

.............................. 64

12.3.1 Access ................................................... 64

12.3.2 Switch Settings ..................................... 64

12.4 SDI Addresses 88 and 92 .......... 65

12.4.1 Local RPS Programming ........................ 65

12.5 SDI Network Interface Modules ..... 65

12.5.1 Address Settings ................................... 66

12.5.2 Supervision ............................................ 66

13.0 SDI2 Devices ...................... 67

13.1 Description ..................... 67

13.2 Installation ...................... 67

13.2.1 Open Wire Trouble on SDI2 .................. 67

13.3 B208 Octo-input Module ........... 67

13.3.1 Address Settings ................................... 67

13.3.2 Supervision ............................................ 68

13.4 B308 Octo-output Module .......... 68

13.4.1 Address Settings ................................... 68

13.4.2 Supervision ............................................ 69

13.5 B426 Ethernet Communication Module 69

13.5.1 Address and Emulation Settings ........... 69

13.5.2 Supervision ............................................ 69

13.5.3 Local RPS Programming ........................ 69

13.5.4 Ethernet Communications Module Faults

.............................................................. 69

13.6 B420 Ethernet Communication Module 70

13.6.1 Address and Emulation Settings ........... 70

13.6.2 Supervision ............................................ 70

13.6.2 Local RPS Programming ........................ 70

13.6.3 Ethernet Communications Module Faults

.............................................................. 70

13.7 B520 Auxiliary Power Supply Module . 71

13.7.1 Address Settings ................................... 71

13.7.2 Supervision ............................................ 71

13.7.3 Auxiliary Power Supply Faults ............... 71

13.8 B810 wireless receiver ............ 72

13.8.1 Supervision ............................................ 72

13.8.2 Wireless Receiver Faults ........................ 72

13.8.3 Wireless Repeater Faults ........................ 72

13.9 B820 SDI2 Inovonics Interface Module 72

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 4

Page 5

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | Contents

.

13.9.1

13.9.2 Wireless Receiver Faults ........................ 72

13.9.3 Wireless Repeater Faults ...................... 73

13.10 B920 Two-lined Alphanumeric Keypad 73

13.10.1 LCD Backlit Settings ............................. 73

13.10.2 LCD Power Up Status ........................... 73

13.10.3 LCD Communication Status ................. 73

13.11 B930 ATM Style Alphanumeric Keypad 73

13.11.1 LCD Backlit Settings ............................. 74

13.11.2 LCD Power Up Status ........................... 74

13.11.3 LCD Communication Status ................. 74

14.0 Installer Menu .... Error! Bookmark not

14.1 RPS Access Reports . Error! Bookmark

15.0 Accessory Connector ................ 75

16.0 Faceplates ........................ 76

16.1 D9412GV4/D7412GV4 v2.00 Faceplate 76

17.0 Specifications ...................... 77

17.1 Control Panel Power Supply ........ 77

17.2 B520 Power Supply ............... 78

17.3 Control panel Terminal Wiring ....... 79

18.0 Approved Applications ............... 81

18.1 Optional Compatible Equipment ..... 81

18.2 Burglary Applications .............. 81

18.3 Bank Safe and Vault Applications .... 81

18.3.1 Control Panel Enclosure Requirements . 81

18.3.2 Battery Connections .............................. 81

18.3.3 Bell Requirements ................................. 81

18.3.4 System Configuration Requirements ..... 81

18.3.5 Exit Delay ............................................... 82

18.3.6 Equipment Requirements ...................... 82

18.4 Fire Applications ................. 82

18.4.1 Four-Wire Smoke Detectors .................. 82

18.4.2 Two-Wire Smoke Detectors ................... 83

18.4.3 Two-Wire Smoke Detector Specifications

18.4.4 NFPA Style A (Class “B”) Circuit ............ 83

18.4.5 Other Devices ........................................ 83

18.4.6 UL Listed Two-Wire Smoke Detectors

18.4.7 UL Listed Synchronization (Sync)

18.5 Enclosures ...................... 91

18.5.1 D8103 Enclosure ................................... 91

18.5.2 D8108A Enclosure ................................. 91

18.5.3 D8109 Red Fire Enclosure ..................... 91

19.0 Keypad Installer Menu ............... 92

19.1 [1] Program Menu ................ 95

Supervision ............................................ 72

defined.

not defined.

............................................................... 83

Compatible with the D125B .................. 84

Modules and Strobes Compatible with the

D9412GV4/D7412GV4 ........................... 86

19.1.1 [1] Reporting > [1] Phone Menu

Parameters ............................................ 95

19.1.2 [1] Reporting > [2] Network Menu

Parameters ............................................ 96

19.1.3 [1] Reporting > [3] Routing Menu

Parameters ............................................ 99

19.1.4 [2] IP Module > [1] B42x (1) or [2] B42x

(2) Module Parameters ....................... 101

19.1.5 [2] IP Module > [1] B42x (1) or [2] B42x

(2) [2] Address Parameters ................ 102

19.1.6 [2] IP Module > [1] B42x (1) or [2] B42x

(2) [3] DNS Parameters ...................... 104

19.1.7 [3] RPS > [1] RPS Passcode Menu

Parameters .......................................... 105

19.1.8 [3] RPS > [2] RPS Phone Number Menu

Parameters .......................................... 106

19.1.9 [3] RPS > [3] RPS IP Address Menu

Parameters .......................................... 106

19.1.10 [3] RPS > [4] RPS Port Number Menu

Parameters .......................................... 107

19.1.11 [4] Area Options Menu Parameters ... 107

19.1.12 [5] Keypad > [1] Scope Menu Parameters

............................................................ 109

19.1.13 [6] Users Menu Parameters ............... 110

19.1.14 [7] Points Menu Parameters .............. 112

19.1.15 [8] Disable Programming Menu

Parameters .......................................... 119

19.2 [2] Wireless Menu ............... 120

19.2.1 [1] Points > [1] Enroll Point RFID Menu

Parameters .......................................... 120

19.2.2 [1] Points > [2] Replace Point RFID Menu

Parameters .......................................... 120

19.2.3 [1] Points > [3] Remove Point RFID Menu

Parameters .......................................... 121

19.2.4 [2] Repeaters > [1] Add Repeater Menu

Parameters .......................................... 121

19.2.5 [2] Repeaters > [2] Replace Repeater

19.2.6 [2] Repeaters > [2] Remove Repeater

19.2.7 [3] Diagnostics > [1] RF Points ............ 123

19.2.8 [3] Diagnostics > [2] RF Repeaters ...... 124

19.3 [3] Network Menu ............... 126

19.3.1 [1] B42x > [1] Settings Menu Parameters

19.4 [4] Srvc Byp Menu ............... 127

19.5 [5] Versions Menu ............... 127

20.0 UL/NFPA Compliant Installations ... 128

20.1 Required Components ............. 128

20.2 Installing Combination Fire and Intrusion

Menu Parameters ................................ 122

Menu Parameters ................................ 123

............................................................ 126

Alarm Systems .................. 128

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 5

Page 6

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | Contents

.

20.2.1

20.2.2 Zonex Bus Devices ............................... 128

20.2.3 SDI2 Bus Devices ................................. 129

21.0 Compatible UL Listed Components.. 130

22.0 Current Ratings Charts .............. 131

22.1 D8125MUX ....................... 131

22.2 Standby Battery Calculations ........ 131

23.0 NFPA 72 Fire Alarm Applications ...... 134

23.1 Household Burglary and Commercial

23.2 Bank Safe and Vault .............. 134

23.3 Standby Battery Calculation ....... 134

23.4 Central Station or Local Systems ... 135

23.5 Remote Station or Auxiliary Systems 135

23.6 Household Fire Warning Equipment . 136

23.7 UL 609 ........................ 136

23.8 UL 365 ........................ 136

23.9 UL 636 ........................ 137

23.10 ULC S304 Requirements .......... 137

Appendix A: System Wiring Diagrams ....... 138

A.1 Power Supply Side System Wiring .. 138

A.2 Input Points and Peripheral Devices

A.3 SDI and Zonex Devices System Wiring 140

A.4 SDI2 Bus Wiring Recommendations . 143

Appendix B: Point Address Charts ......... 145

B.1 Zonex 1 Points .................. 145

B.2 SDI2 Points .................... 146

SDI Bus Devices ................................... 128

Burglary ....................... 134

Wiring Diagrams ................ 139

Figures

Figure 1: System Configuration ............ 10

Figure 2: Enclosure Mounting ............ 17

Figure 3: Enabling Ground Fault Detection . 18

Figure 4: Reset Pin .................... 19

Figure 5: Service Walk Test Flow Chart Example

............................ 23

Figure 6: Battery Terminals ............. 25

Figure 7: Non-Power-Limited Wiring ....... 26

Figure 8: Charging and Battery LEDs ...... 27

Figure 9: RJ31X/RJ38X Wiring (RJ31X shown)

............................ 32

Figure 10: Phone Connector, Phone LED, and

Operation Monitor LED Locations . 33

Figure 11: D928 Dual Phone Line Switcher .... 35

Figure 12: On-board Point Sensor Loop Wiring 37

Figure 13: Rothenbuhler 5110/4001-42 High

Security Bell Wiring Configuration 39

Figure 14: Wiring the Rothenbuhler 5110/4001-

42 High Security Bell to the Control

Panel ....................... 40

Figure 15: Connecting the D8125 POPEX to the

D9412GV4 Control Panel ....... 42

Figure 16: Connecting the D8125 POPEX to the

D7412GV4 Control Panel ....... 43

Figure 17: D8128D OctoPOPIT Layout ...... 46

Figure 18: Connecting D8128D OctoPOPITs to

the D9412GV4 ................ 49

Figure 19: Connecting D8128D OctoPOPITs to

the D7412GV4 ................ 50

Figure 20: Wiring Multiple D8128Ds Using

Figure 21: D8128D OctoPOPIT Sensor Loops 52

Figure 22: D8129 Connections to the D9412GV4

Figure 23: D8129 Connections to the D7412GV4

Figure 24: D811 Arm Status Relay Module Wiring

Figure 25: D811 Arm Status Relay Module Wiring

Figure 26: External Power to SDI2 Devices .. 62

Figure 27: Keyswitch Wiring .............. 63

Figure 28: DX4020 DIP Switch Settings ..... 66

Figure 29: B208 Switches Set to Address 9 .. 67

Figure 30: B308 Switches Set to Address 9 .. 68

Figure 31: B426 Switch Set to Address 1 ... 69

Figure 32: B420 Switch Set to Address 1 ... 70

Figure 33: B520 Switch Set to Address 2 ... 71

Figure 34: B810 Switch Set to Address 1 ... 72

Figure 35: B820 Switch Set to Address 1 ... 72

Figure 36: Accessory Connection on D9412GV4

Figure 37: D9412GV4/D7412GV4 v2.00 Faceplate

Figure 38: Keypad Installer menu tree ...... 94

Figure 39: D9412GV4/D7412GV4 v2.00 Power

Figure 40: D9412GV4/D7412GV4 v2.00 Input

Figure 41: D9412GV4 SDI and Zonex Devices

Figure 42: D7412GV4 SDI and Zonex Devices

Figure 43: D9412GV4/D7412GV4 SDI2 Devices

Figure 44: SDI2 Bus Wiring ............. 143

Interconnect Wiring ............ 52

........................... 56

........................... 56

to the D9412GV4 .............. 59

to the D7412GV4 .............. 59

and D7412GV4 ............... 75

........................... 76

Supply Side System Wiring (Power

and Phone) ................. 138

Points and Peripheral Devices System

Wiring ..................... 139

System Wiring ............... 140

System Wiring ............... 141

System Wiring ............... 142

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 6

Page 7

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 1.0 Introduction

.

1.0 Introduction

This manual addresses the operation and installation of the D9412GV4/D7412GV4 v2.00 Control

Panels. Throughout this guide, the words “control panel” refer to all control panels (D9412GV4 and

D7412GV4). Table 2 on page 11 provides an overview of the differences in the control panels.

To obtain any of the documents in Table 1, contact Bosch Security Systems, Inc.

Customer Service at (800) 289-0096 and request the documentation by its corresponding

part number.

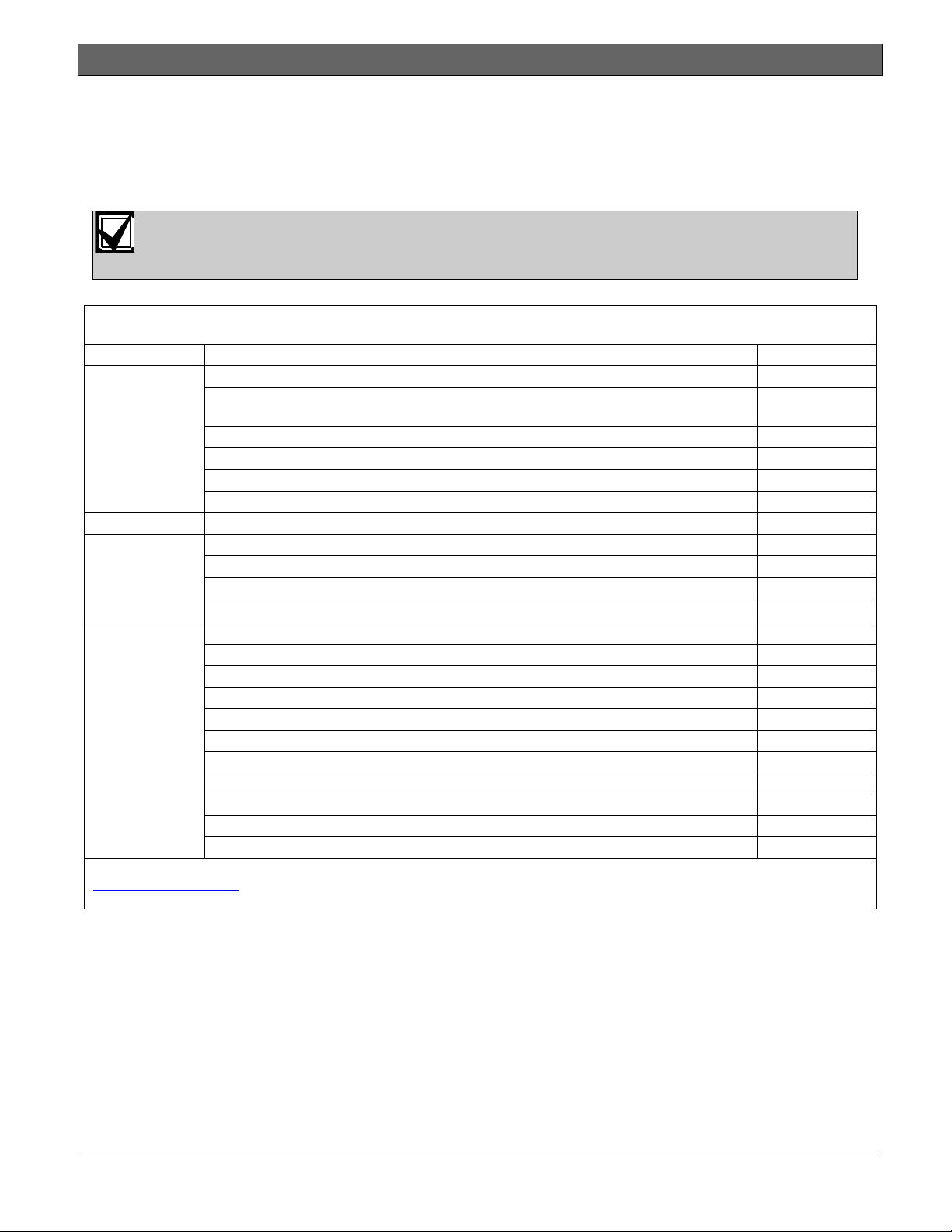

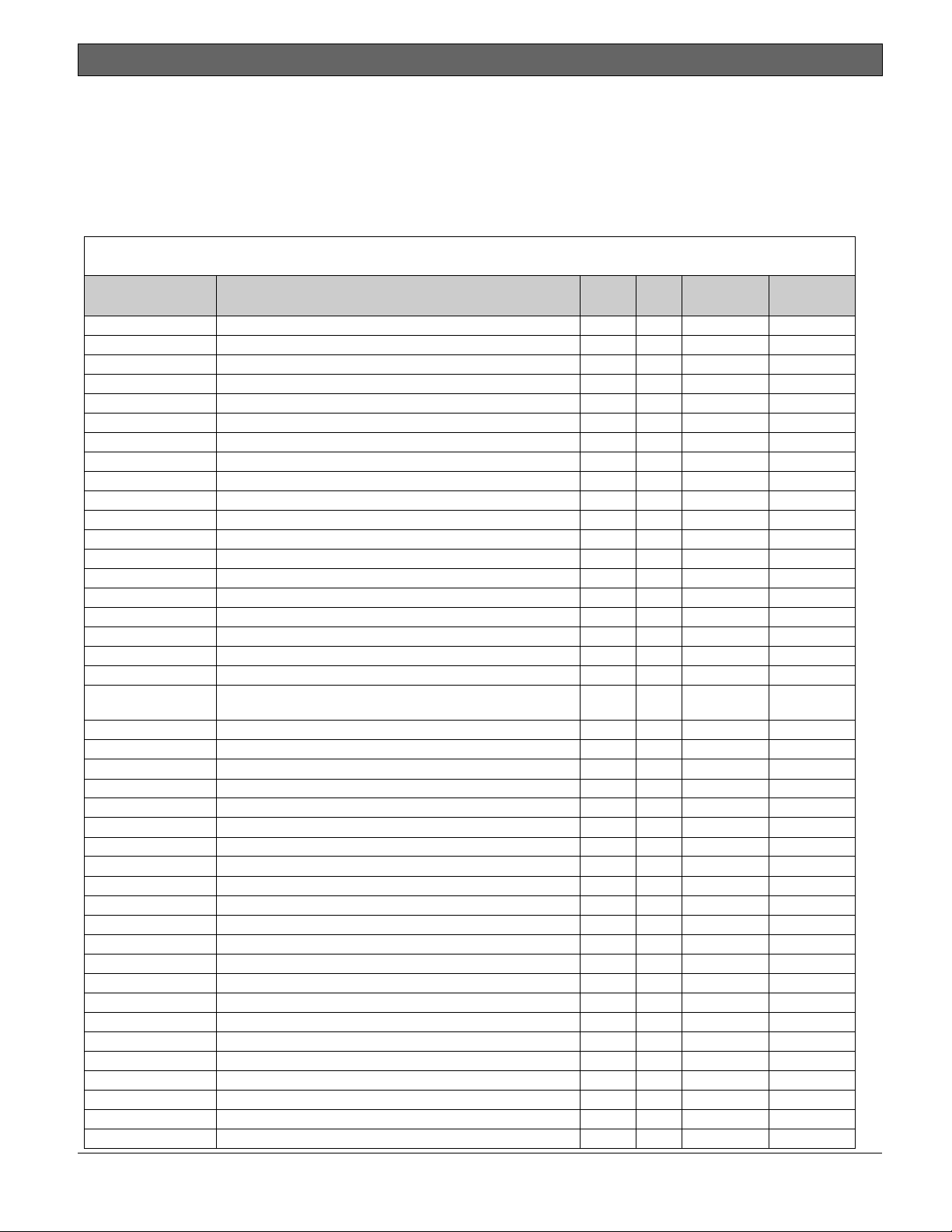

Table 1: Related Documentation

Product Type Name of Documentation Part Number

Control Panels Control Panels (D9412GV4/D7412GV4 v2.00) Release Notes

Control Panels (D9412GV4/D7412GV4 v2.00) Installation and System Reference

Guide (this document)

UL Certificated Bank Safe and Vault Applications Technogram 73-07302-0003

Control Panels (D9412GV4/D7412GV4 v2.00) Program Entry Guide F01U265459

Control Panels (D9412GV4/D7412GV4 v2.00) UL Installation Guide F01U2654621

Control Panels (D9412GV4/D7412GV4 v2.00) Quick Reference Guide F01U2654631

Control Panels (D9412GV4/D7412GV4 v2.00) SIA Quick Reference Guide F01U2654661

Keypads D279A Operation and Installation Instructions 464585

Two-line Alphanumeric Keypad (B920) Installation Guide F01U2654504

ATM Style Alphanumeric Keypad (B930)Installation Guide F01U2654514

Control Panels (D9412GV4/D7412GV4 v2.00) Control Panel Owner’s Manual F01U2654521

Expansion

Devices

Octo-input Module (B208) Installation and Operation Guide F01U2654565

Octo-output Module (B308) Installation and Operation Guide F01U2654585

RADION receiver SD (B810) Reference Guide F01U2618395

SDI2 Inovonics Interface Module (B820) Installation Guide F01U2654605

Conettix Ethernet Communication Module (B420) Installation and Operation Guide F01U2152366

Conettix Ethernet Communication Module (B426) Installation and Operation Guide F01U2662266

Auxiliary Power Supply Module (B520) Installation and Operation Guide F01U2654455

D8128D Installation Guide F01U0705375

D8125MUX Operation and Installation Guide F01U0349735

ISW-D8125CW-V2 Installation and Operation Guide F01U1616915

D9210C Installation and Operation Guide F01U2152325

1

Shipped with the control panel. 2Located on the documentation CD shipped with the control panel. 3Located on

www.boschsecurity.com

documentation CD shipped with the module.

. 4Shipped with the keypad. 5These documents ship with the modules. 6Find these documents on the

F01U265461

F01U265457

1

2

2

Copyright

This document is the intellectual property of Bosch Security Systems, Inc. and is protected by copyright. All

rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered trademarks and must

be treated accordingly.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 7

Page 8

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 1.0 Introduction

.

Determine Bosch Security Systems, Inc. Product Manufacturing Date

Use the serial number located on the product label and refer to the Bosch Security Systems, Inc. web site at

http://www.boschsecurity.com/datecodes.

Thefollowingimageshowsanexampleofaproductlabelandhighlightswheretofindthemanufacturingdatewithintheserial

number.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 8

Page 9

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 2.0 Lightning Strikes

.

2.0 Lightning Strikes

The control panels are designed to significantly

reduce electromagnetic interference and

malfunction generally caused by lightning.

2.1 Effects

Any electronic system can be struck directly by

lightning or be adversely affected by a lightning

strike near the system. When lightning strikes,

several things happen:

An electromagnetic wave spreads from

the point of the strike inducing high

voltages in nearby conductors.

The voltage changes substantially on

electrical grounds near the lightning

strike.

High voltages are induced in anything

directly struck by lightning.

The effects of a lightning strike can include

Missing Trouble, Missing Alarm, or Point Bus

Trouble events. Occasionally, Reboot and

Watchdog events might be sent because the

control panel tried to reset itself.

Electronic systems, including control panels,

cannot be completely immune to direct or

indirect lightning strikes; however, some proven

installation practices might greatly reduce the

risk of undesirable affects.

2.2 Precautions during Installation

To minimize the risk of undesirable effects from

lightning strikes on high risk installations that use

a point-bus technology:

Do not run wiring outside the building.

If you must install the unit in a metal

building, keep the wiring at least 0.61 m

(2 ft) away from external metal surfaces.

Earth ground the unit correctly. Do not

use an electrical ground or telephone

ground.

Avoid running wires near telephone, data,

or power lines inside a building. Historical

evidence shows that locating control

panel wiring at least 0.61 m (2 ft) away

from telephone, data, or power lines is

successful at minimizing lightning

damage. When your data lines must cross

the path of AC or other wiring, cross the

lines perpendicularly.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 9

Page 10

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

3.0 Overview

3.1 Configuration and Parts

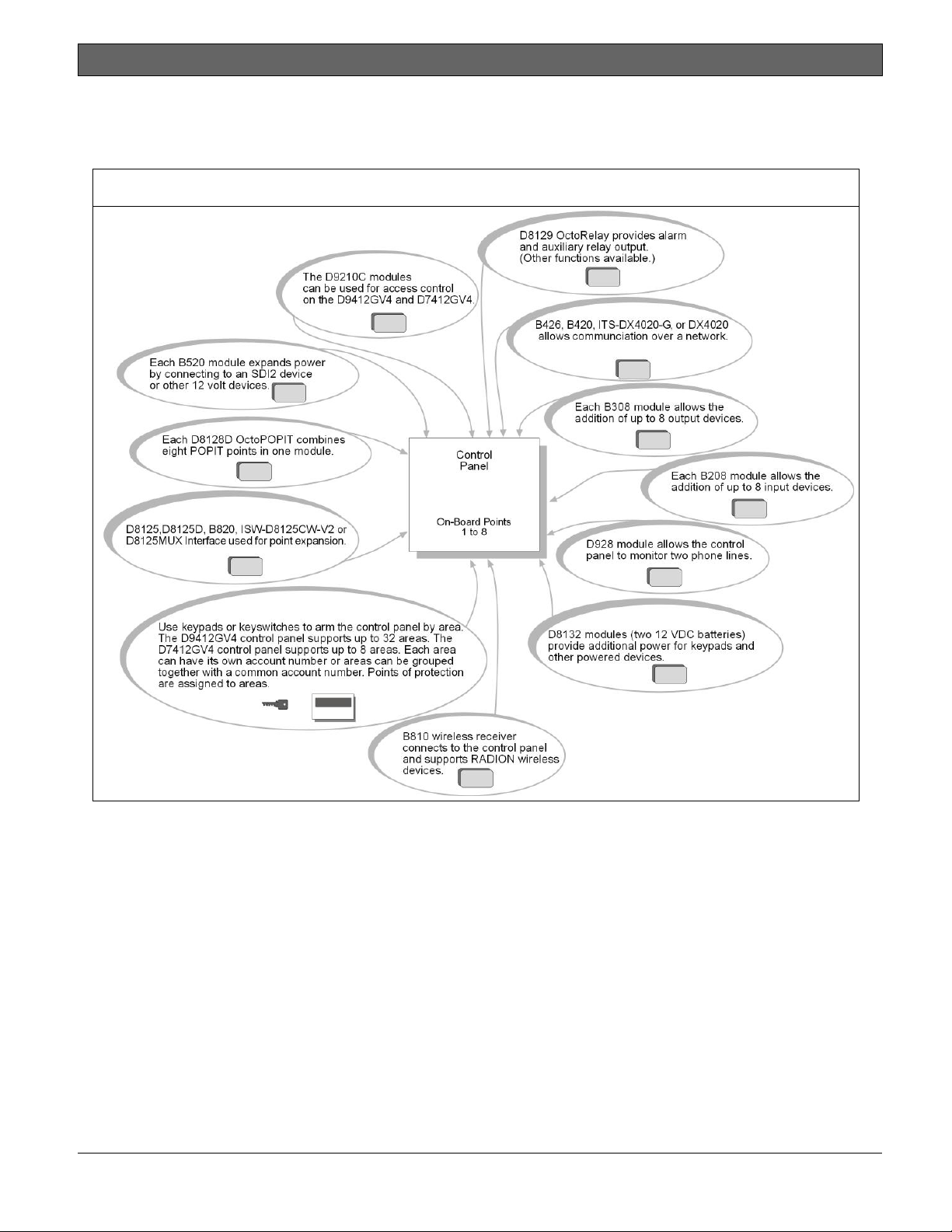

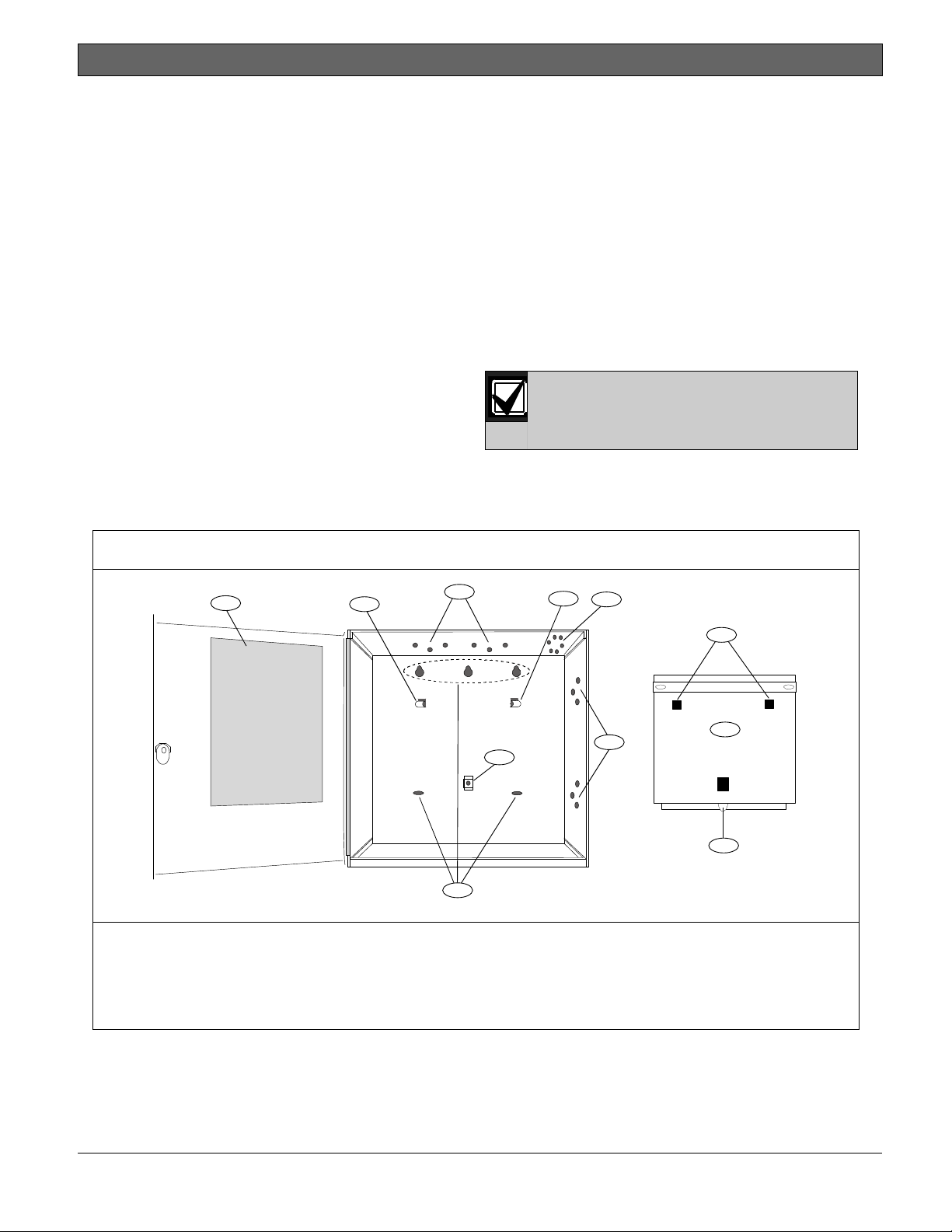

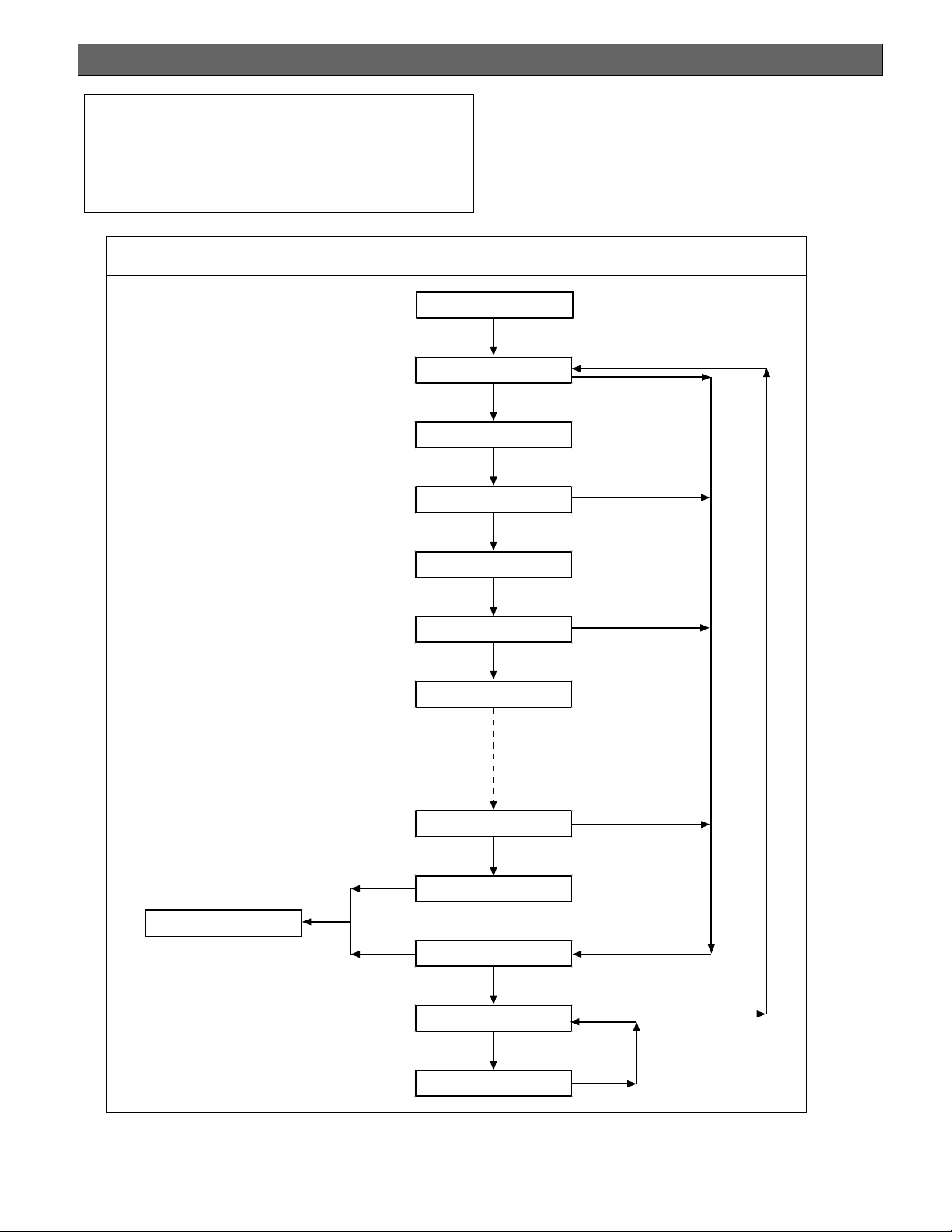

Figure 1: System Configuration

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 10

Page 11

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

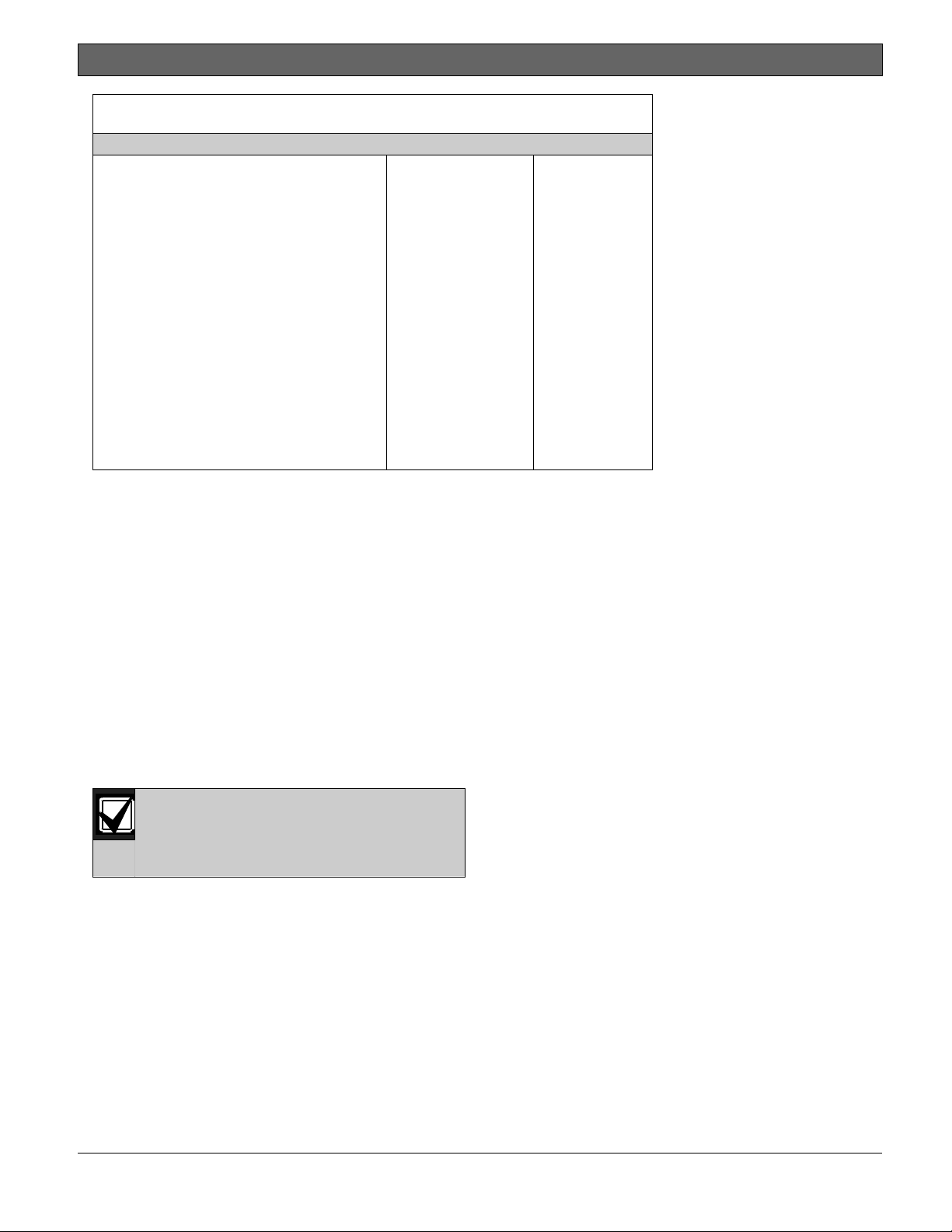

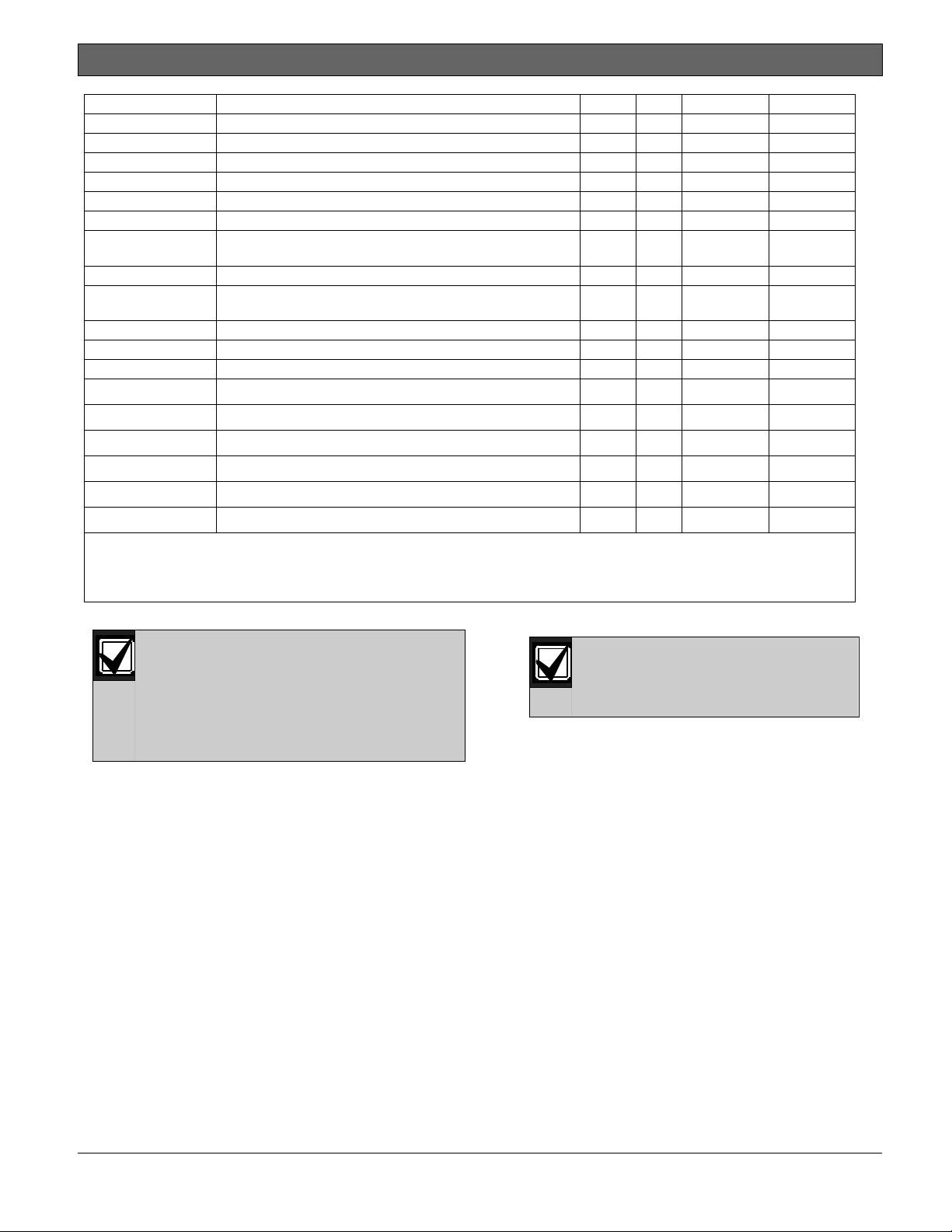

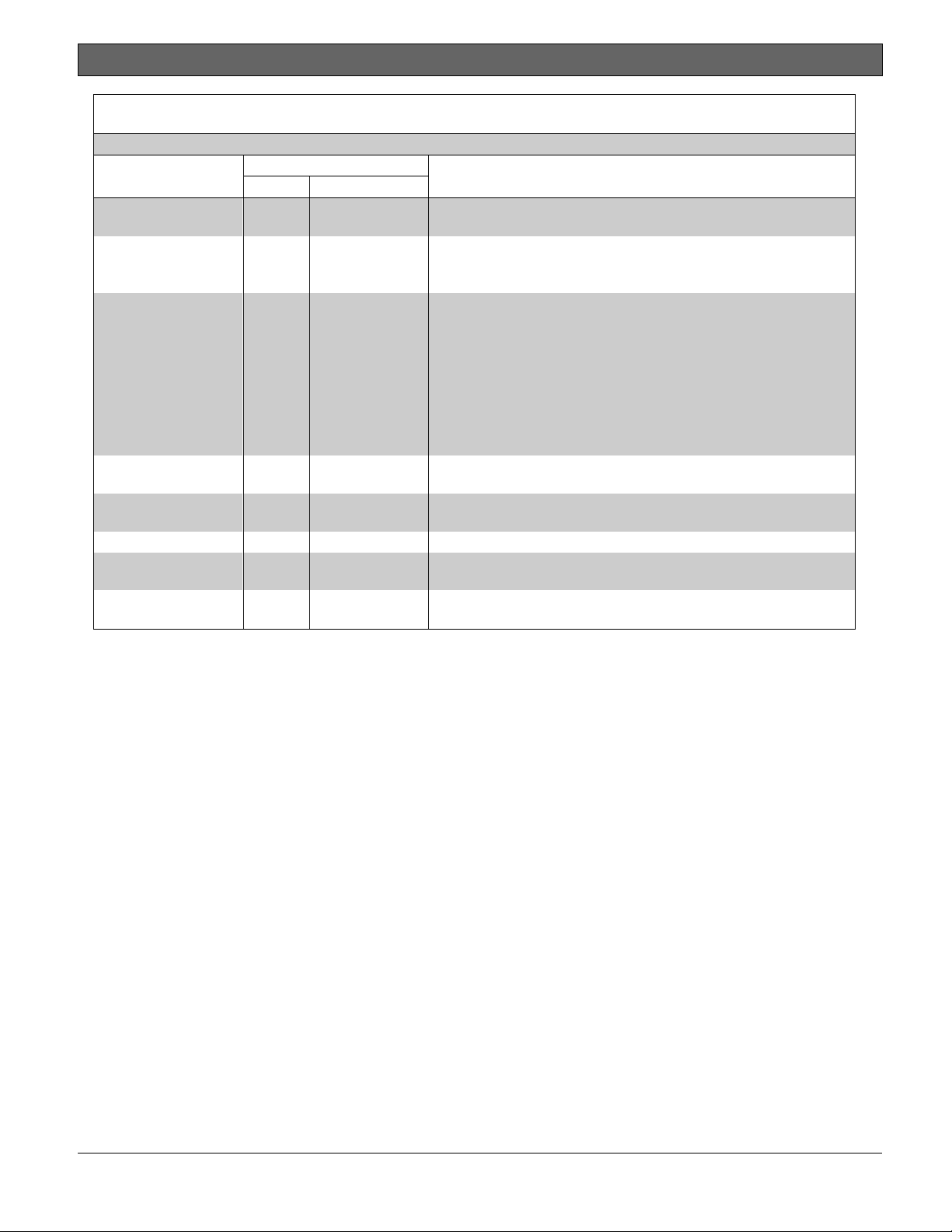

Table 2: Control Panel Comparrisons

Features D9412GV4 D7412GV4

Access Control

Arm/Disarm Users

Cards/Tokens

Passcode-Protected Custom Functions

Number of Points 246 75

Number of Off-board Relays 128 64

Number of Areas 32 8

Number of B920 Two-line Alphanumeric

Keypads

Number of B930 ATM Style

Alphanumeric Keypads

Number of D1255 Keypads 16 16

Number of D1260 Keypads 8 8

Number of Phone Lines Supported 2 2

Yes - 8 doors Yes - 2 doors

999 399

999 399

16 4

16 16

16 16

3.1.1 Parts List

The control panels are shipped assembled

from the factory with the following parts:

Literature Pack

7000/9000 Series Point Chart Label

(P/N: 79-06660-000)

Assembly

PC board

Faceplate shield

Mounting skirt

One #6 x 3/4-in screw

3.1.2 Parts Available by Separate Order

Order the following components separately to

complete a basic eight-point installation.

The D1260 and D1260B Keypads must

have firmware version 1.04 or higher

for use with the D9412GV4/D7412GV4

v2.00 Control Panels.

B520 Auxiliary Power Supply Module

B420, B426 Ethernet Communication

Modules

B920, B930 Keypad

D1255B, D1255, D1260, D1260B

Keypad, or D720 Keypad

D1255RB Fire Keypad, D1256RB Fire

Keypad, or D1257RB Fire Alarm

Annunciator

D1640 Transformer

D1640-CA Transformer (for Canada)

D126 or D1218 Battery

D162 Phone Cord (order two cords if

using the D928 Dual Phone Switcher)

D8103, D8108A, or D8109 Enclosure

Configured packages are also available. Please

consult the Bosch Security Systems, Inc.

Product Catalog.

Control Panels (D9412GV4/D7412GV4

v2.00) Installation and System Reference

Guide (P/N: F01U265457)

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 11

Page 12

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

3.2 Accessories

Refer to the Bosch Security Systems, Inc. product catalog for additional information.

The compatible accessories listed in the table below are specific to the D9412GV4/D7412GV4 with firmware

v2.00 or greater.

Table 3: Compatible Accessories

Model Title UL

B208 Octo-input Module X X X X

B308 Octo-output Module X X X X

B420 Ethernet Communication Module X X X X

B426 Ethernet Communication Module X X X X

B520 Auxiliary Power Supply Module X X X X

B810 RADION receiver SD X X

B820 SDI2 Inovonics Interface Module X X

B920 Two-line Alphanumeric Keypad X X X

B930 ATM Style Alphanumeric Keypad X X X

D113 Battery Lead Supervision Module X X X X

D122/D122L Dual Battery Harness X X X

D125B Powered Loop Interface Module X X X X

D126 Standby Battery (12V, 7Ah)

D129 Dual Class A Initiation Circuit Module X X X

D130 Relay Module X X X

D185 Reverse Polarity Module X X X

D161 Phone Cord

D162 Phone Cord

D192G Bell Circuit Supervision Module X X X

D279A Independent Zone Control (On-Board and OctoPOPIT

Points)

D720R LED Keypad (red) X X X

D720W LED Keypad (white) X X X

D928 Dual Phone Line Switcher X X X X

D1255RB Fire Keypad X X X X

D1256RB Fire Keypad X X X

D1257RB Fire Alarm Annunciator X X X X

D1218 12 V, 17.2 Ah Rechargeable Battery

D1255/D1255B Keypads (General Purpose) X X X

D1255W Text Keypad (white) X X X

D1260/D1260B2 Keypads X X X

D1640 16.5 VAC 40 VA Transformer X X X

D1640-CA 16.4 VAC 40 VA Transformer for Canada X

D8004 Transformer Enclosure X X X

D8125 POPEX Module X X X X

D8125MUX Multiplex Bus Interface X X X

D8128D OctoPOPIT Module X X X X

D8129 OctoRelay Module X X X X

D8130 Release Module X X X

D8132 Battery Charger Module X X X

D9127U/T POPIT Module X X X X

D9210C Access Control Interface Module X X X X

DX4010V2 USB/Serial Interface Module

1

Intrusion

UL

864

985

X

cUL

Intrusion

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 12

Page 13

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

DX4020 Network Interface Module X X X X

ITS-DX4020-G GPRS/GSM Communicator X X X

ICP-SDI-9114 SDI Splitter X X X

ITS-EZTS Tamper Switch X X X

ISW-D8125CW-V2 Commercial Wireless Interface Module

ZX776Z PIR Motion Sensor [15 m (50 ft)] with POPIT X

ZX794Z PIR Motion Sensor [24 m (80 ft)] with POPIT X

ZX865

ZX938Z PIR Motion Sensor [18 m (60 ft)] with POPIT X

ZX970

RFBT-A RADION speciality X

RFDL-11-A RADION tritech X

RFDW-SM-A RADION contact SM X

RFDW-RM-A RADION contact RM

RFSM-A RADION smoke X

RFRP-A RADION repeater X

RFPR-12-A RADION PIR

RFPR-C12-A RADION PIR C

RFUN-A RADION universal transmitter

1

Where the fire alarm transmitter is sharing on premise communications equipment, the shared equipment must be UL Listed

(ITE or fire protective signaling).

2

Refer to for compatible Inovonics devices.

3

Version 1.04 or above.

PIR/Microwave Motion Sensor [+1.7C (+35F)] with

POPIT

PIR/Microwave Motion Sensor [+1.7C (+35F)] with

POPIT

X

X

X

X

X

X

X

X

No wireless detectors have been

approved for use with alarm

verification points.

For specific installation and operation

instructions, please refer to

manufacturers’ manuals.

3.3 Features in the GV4 Series

Control Panels

3.3.1 SDI Interconnect Wiring

Use interconnect wiring to easily connect an

SDI bus device to the SDI bus or an SDI2

device to the SDI2 bus without needing to

disconnect wires connected to the bus

terminals. Possible applications include:

Connecting a DX4010v2 to program the

control panel with Remote

Programming Software (RPS) at the

premises.

Connecting a keypad to test the control

panel.

UL requires that the DX4010v2

be used as a temporary

programming interface only.

3.3.2 Tip and Ring Posts

The tip and ring posts allow connecting a

phone or buttset for the purpose of

troubleshooting communications between the

control panel and the central station. This

connection allows monitoring of the dial tone,

handshaking tones from the receiver, and

communications signals.

3.3.3 Telephone Line Sniff

The control panels monitor the phone line for

the programmed supervision interval before

indicating phone line trouble.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 13

Page 14

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

3.3.4 Points

The Bosch Security Systems, Inc. D9412GV4

Control Panel provides up to 246 points of

protection. The D7412GV4 Control Panel

provides up to 75 points of protection. Point

programming parameters determine the

control panel’s response to open and shorted

conditions on the sensor loop for the point.

Several options allow individual point

programming to custom-fit the protection to

the installation.

Points 1 to 8 are located on the circuit board

(on-board points). They are standard sensor

loops. The remaining off-board points can be

located on point expansion modules on a

ZONEX bus, an SDI bus, and/or an SDI2 bus.

The ZONEX bus supports any combination of

POPIT points using D8128D OctoPOPITs,

D8125 POPEX Modules and D9127 POPITs, a

ISW-D8125CW-V2 Zonex Inovonics Interface

Module, or D8125MUX Modules. The SDI2 bus

supports any combination of B208 Octo-input

modules, B810 wireless receiver, or a B820

Inovonics Interface Module.

Any points programmed as fire

supervisory points are latching.

3.3.5 Areas and Accounts

The D9412GV4 supports up to 32 areas. The

D7412GV4 supports up to 8 areas. You can

assign all points to a single area or distribute

them over all supported areas.

The control panel is armed and disarmed by

area, and several areas can be armed and

disarmed with one menu function. A passcode

can also be assigned an authority level that

allows a user to arm an area from a remote

keypad in another area. Assigning each area its

own account number creates up to 32 separate

accounts in the D9412GV4 and up to 8

separate accounts in the D7412GV4. Assigning

the same account number to different areas,

groups them together in a single account.

Area options include exit tone and delay,

separate fire and burglary outputs, and

multiple opening and closing windows. Area

type can be used to create area

interdependencies for arming purposes.

3.3.6 Digital Communicator

The control panel uses a built-in digital

communicator to send reports to the receiver.

The control panel sends reports in either the

Modem4 or ANSI-SIA Contact ID format.

The control panel connects to an RJ31X or

RJ38X jack for telephone line seizure.

Connecting to the RJ31X complies with FCC

regulations for using the public telephone

network. The control panel can be

programmed to direct reports to four separate

telephone numbers. Adding the D928 Dual

Phone Line Switcher Module to the D9412GV4

or the D7412GV4 allows connection and

supervision of a second telephone line.

The system can route groups of Event Reports

to four different destinations through the

phone or over a network. Each report group

can be programmed to send reports to one or

more destinations. Primary and backup

reporting paths can be programmed for each

destination and each report group. A custom

option allows specification of individual Event

Reports to be sent.

3.3.7 Keypads

Up to 32 unsupervised keypads can be

connected to the system. The available power,

number of supervised keypads, and number of

areas covered affect the total number of

keypads that can be connected.

The system can supervise up to sixteen D1255

keypads, and up to eight D1260 keypads. If the

control panel loses communication with the

keypad, it sends SDI FAILURE in the Modem4

format or Expansion Module Failure (333) in

Contact ID format. The system can support

more SDI keypads (up to 32 unsupervised).

In addition to the SDI keypads, the system can

support up to 16 B920 and B930 keypads on

the SDI2 bus. The control panel supervises all

keypads on the SDI2 bus. Any failure to receive

an expected response from an SDI2 keypad

results in a system fault display on all keypads

and an SDI Fault event is sent to the central

station if programmed to do so.

Table 4 on page 15 shows the keypads that are

compatible with D9412GV4/D7412GV4 v2.00

Control Panels. Refer to 18.0 Keypad Installer

Menu for complete details on programming

keypad options.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 14

Page 15

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

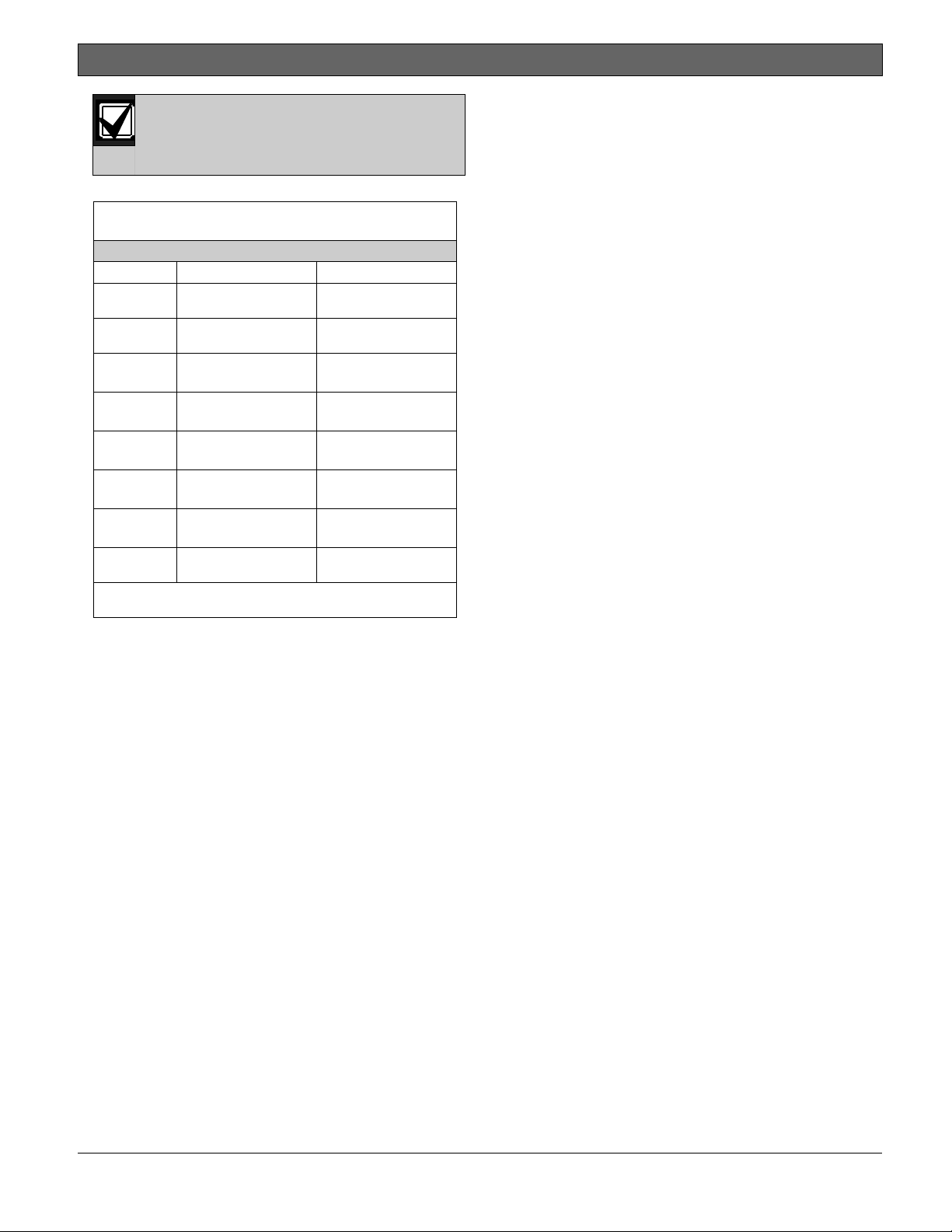

UL requires all Fire System keypads to

be supervised.

Table 4: Compatible Keypads

Model Display Application

B930 5-line LCD display Burglary/Access

B920 2-line LCD display Burglary/Access

D1255RB

D1256RB

D1257RB

D1255/

D1255B/

D1260/

D1260B

D1265* LCD Touch screen Burglary

*D1265 keypad has not been investigated by UL.

16-character

alphanumeric

16-character

alphanumeric

16-character

alphanumeric

16-character

alphanumeric

4-line by 20character

Fire

Fire

Fire

Burglary

Burglary

3.3.8 Keyswitch

Maintained or momentary closure devices such

as keyswitches allow any of the available areas

to be armed or disarmed. Point programming

determines the loop response and which area

a keyswitch controls.

3.3.9 Access Control

The D9412GV4 can control eight access doors

(each requiring the optional D9210C Access

Control Interface Module) with up to 999

uniquely identified cards or tokens. The

D7412GV4 can control two access doors with

up to 399 uniquely identified cards or tokens.

Any of the following can grant access:

Wiegand-style access control device

(card reader) connected to the D9210C

Access Control Interface Module

Request to enter (RTE) or request to

exit (REX) input

Unlock command on a B920/B930

The access control features of the D9412GV4

and D7412GV4 can deny access during armed

periods. The control panel can also grant

access only to certain authorized users

depending on whether the area is all on, part

on, or off. Programming for automatic

disarming when designated authorized users

are granted access is also possible.

The Dual Authentication feature can optionally

require passcode entry with presentation of

door credentials before access authorization is

granted.

3.3.10 Event Memory

The control panel retains point alarm and

trouble events in memory for each area. A

B930, B920, D1255 (any model), as well as a

D1260 (any model) can be used to view event

memory by using the Events menu. The control

panel clears the previous events for an area

from the event memory when the area is

turned off.

3.3.11 Event Log

The system stores 1023 events from all areas

in its event log. For example, the system adds

at least two items to the log each time an area

is turned on (arm) or off (disarm), the open (or

close) event also contains the previous arming

state.

All events can be stored even if the control

panel does not send a report for them. The log

can be viewed at a keypad, or uploaded using

Remote Programming Software (RPS).

3.3.12 Ground Fault Detection

The Earth Ground Terminal on the control

panels is electrically isolated from all other

terminals to allow the control panels to detect

ground fault conditions. A Ground Fault Detect

Enable switch (S4) is located just under

Terminal 10, Earth Ground, on the control

panel. Refer to Section 4.5.2 Ground Fault

Detect Enable on page 18 for information on

operating this function.

3.3.13 Ground Fault Detection Added Feature

When Ground Fault Detect is enabled (S4

closed), Points can be used for non-powered

fire-initiating devices such as heat detectors,

four-wire smoke detectors, and pull stations. A

D125B Powered Loop Interface or a D129 Dual

Class A Interface Module is not required when

connecting the non-powered fire-initiating

devices to Points.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 15

Page 16

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 3.0 Overview

.

3.3.14 Conettix Functions

The D6600/D6100i/D6100IPV6 Conettix

System supports data network

communications. Conettix allows the

D6600/D6100i/D6100IPV6 Receiver/Gateway

devices to connect to various network

technologies including Ethernet, UDP/IP, and

GPRS (General Packet Radio System).

Connecting to a data network is possible using

the COM4 or COM1 connection from the

D6600/D6100i Receiver to the D6680 Network

Adapter. Control panels can send reports

through telephone lines, Ethernet, UDP/IP, or

GPRS networks to the

D6600/D6100i/D6100IPV6 receiver to the

central station. Once events are received, they

can then be issued to automation software or a

network printer through a local area network

(LAN) or wide area network (WAN).

Sending events to the central station over a

LAN or WAN requires a network interface

module (NIM), such as the B426, B420, or

DX4020. Sending events over GPRS requires a

special NIM, the ITS-DX4020-G.

3.3.15 Programming

Use the RPS, or the Keypad Installer menu, to

program the control panels. Refer to the

Control Panels (D9412GV4/D7412GV4 v2.00)

Program Entry Guide (P/N: F01U265459)for

programming options.

3.3.16 Dual Authentication

The D9412GV4 and D7412GV4 control panels

can be configured to require two forms of

identification before processing certain system

commands. This feature requires a door

controller and a keypad to be installed within

proximity to each other for user convenience.

Dual Authentication requires a

D9210C door controller module even

though the configured operation may

not be access.

A standard system user has authority to use

Dual Authentication if they have a passcode, a

door credential (token or card), and

appropriate command authority permissions

assigned in the door and keypads assigned

area. When enabled at a keypad, only the

following Passcode Functions require access

credentials with passcode entry, Arm / Disarm,

Cycle Door (Grant Access), Cycle Relay, and

Auto Re-arm. Refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459)and D9210C

Installation and Operation Guide (P/N:

F01U215232) for details on installation,

configuration and operation of this feature.

3.3.17 Other Features

The D9412GV4/D7412GV4 v2.00 Control

Panels have many programmable features.

Some of the features are listed below.

Complete details on all features are in the

Control Panels (D9412GV4/D7412GV4 v2.00)

Program Entry Guide (P/N: F01U265459):

Supervision of AC (primary power),

battery (secondary power), Zonex, SDI

and SDI2 buses, central processing unit

(CPU), and two telephone lines

Automatic System Test Reports

Remote access for programming,

diagnostics, and log uploads using the

remote programming software (RPS)

Fire alarm verification

Programmable alarm outputs

Programmable relay outputs

Opening and closing windows

Skeds (scheduled events)

Limited local programming

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 16

Page 17

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

4.0 Installation

4.1 Installation Preparation

This section contains a general installation

procedure and refers to other sections of the

document for detailed instructions.

Review this document and the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459)before beginning the

installation to determine the hardware and wiring

requirements for the features used.

Have the following documentation available when

reading through this guide:

Control Panels (D9412GV4/D7412GV4

v2.00) Control Panel Owner’s Manual.

Before installation, become familiar with the

operation of RPS or the local Programmers menu.

4.2 Enclosure Options

Mount the control panel assembly in any of the

Bosch Security Systems, Inc. enclosures listed:

D8103 Universal Enclosure (tan)

D8109 Fire Enclosure (red)

D8108A Attack Resistant Enclosure (tan)

Refer to chapter 17.0 Approved Applications in

this guide to determine if the application requires

a specific enclosure.

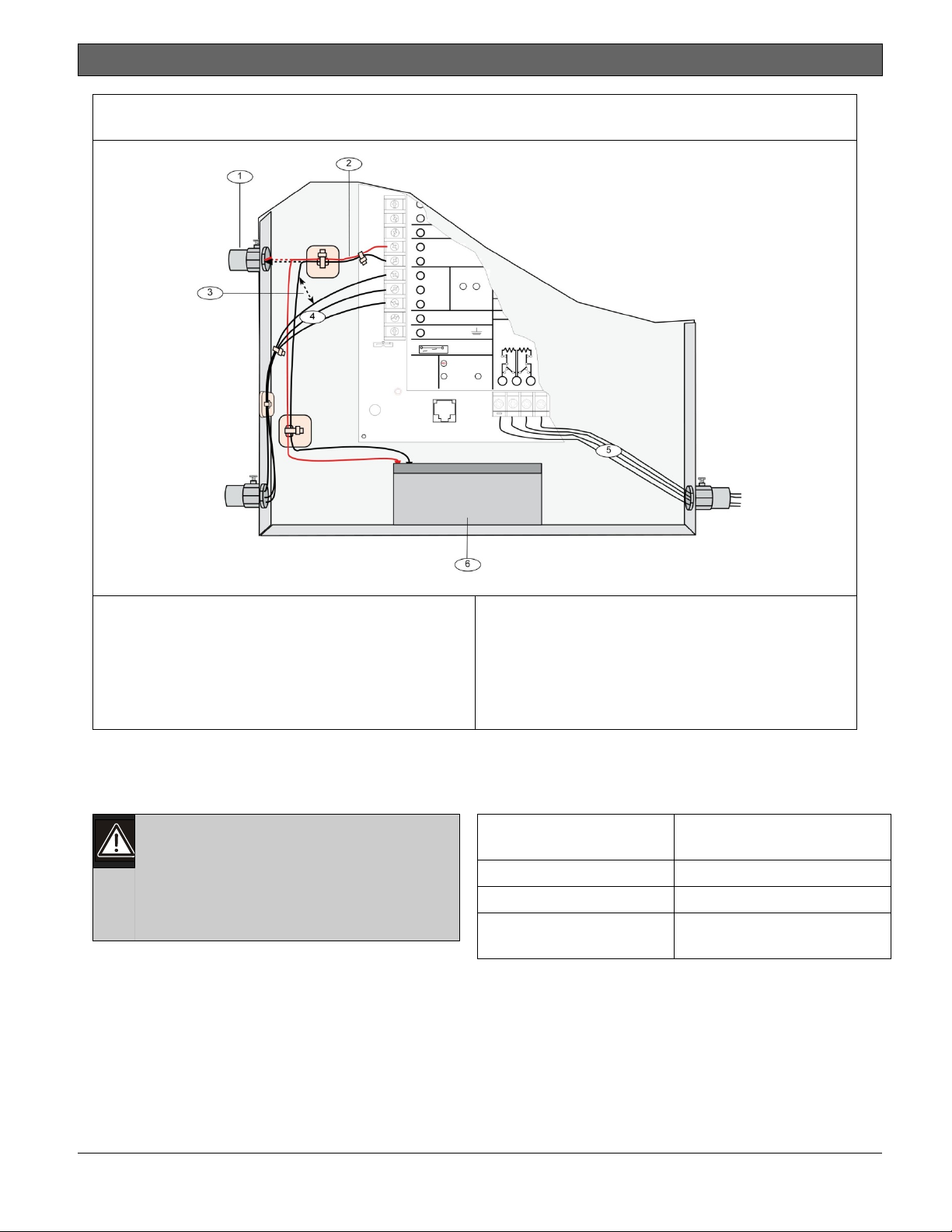

4.3 Mounting Enclosure

1. Run the necessary wiring throughout the

premises.

2. Mount the enclosure in the desired location.

Use all five enclosure mounting holes. Refer

to Figure 2.

3. Pull the wires into the enclosure.

Electromagnetic interference (EMI)

can cause problems on long wire runs.

Figure 2: Enclosure Mounting

1

2

1 - Point chart label

2 - Mounting skirt hooks (2)

3 - Module mounting holes (12)

4 - Tamper switch mounting holes (5)

5 - Skirt mounting hole (1)

3

5

6

2

4

7

3

8

9

6 - Enclosure mounting holes (5)

7 - Mounting skirt hook holes (2)

8 - Back of D9412GV4/D7412GV4 Control Panel

9 - Lock down tab

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 17

Page 18

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

4.4 Installing the Control Panel

1. Place the control panel over the inside back

of the enclosure, aligning the large

rectangular openings of the mounting skirt

with the mounting hooks of the enclosure.

Slide the control panel down so that it hangs

on the hooks. Refer to Figure 2, Item 2 on

page 17.

2. Remove the tape from the #6 x 1/4-in screw

in the mounting tab on the control panel. The

screw passes through the mounting tab and

into the skirt mounting hole in the enclosure.

Tighten the screw to secure the control panel

in the enclosure.

3. Connect earth ground to the control panel

before making any other connections. Refer

to Section 4.5 Connecting Earth Ground.

4.5 Connecting Earth Ground

4.5.1 Terminal 10

When the control panel recognizes that the

ground fault condition is corrected, and remains

corrected for between 5 to 45 consecutive sec, a

Restoral Report is sent.

The D9412GV4 and D7412GV4 control

panels log and print a Ground Fault

event as GROUND FAULT. If

communicating in Modem4 format. If

communicating in Contact ID format,

the control panels generate a Ground

Fault (310) event.

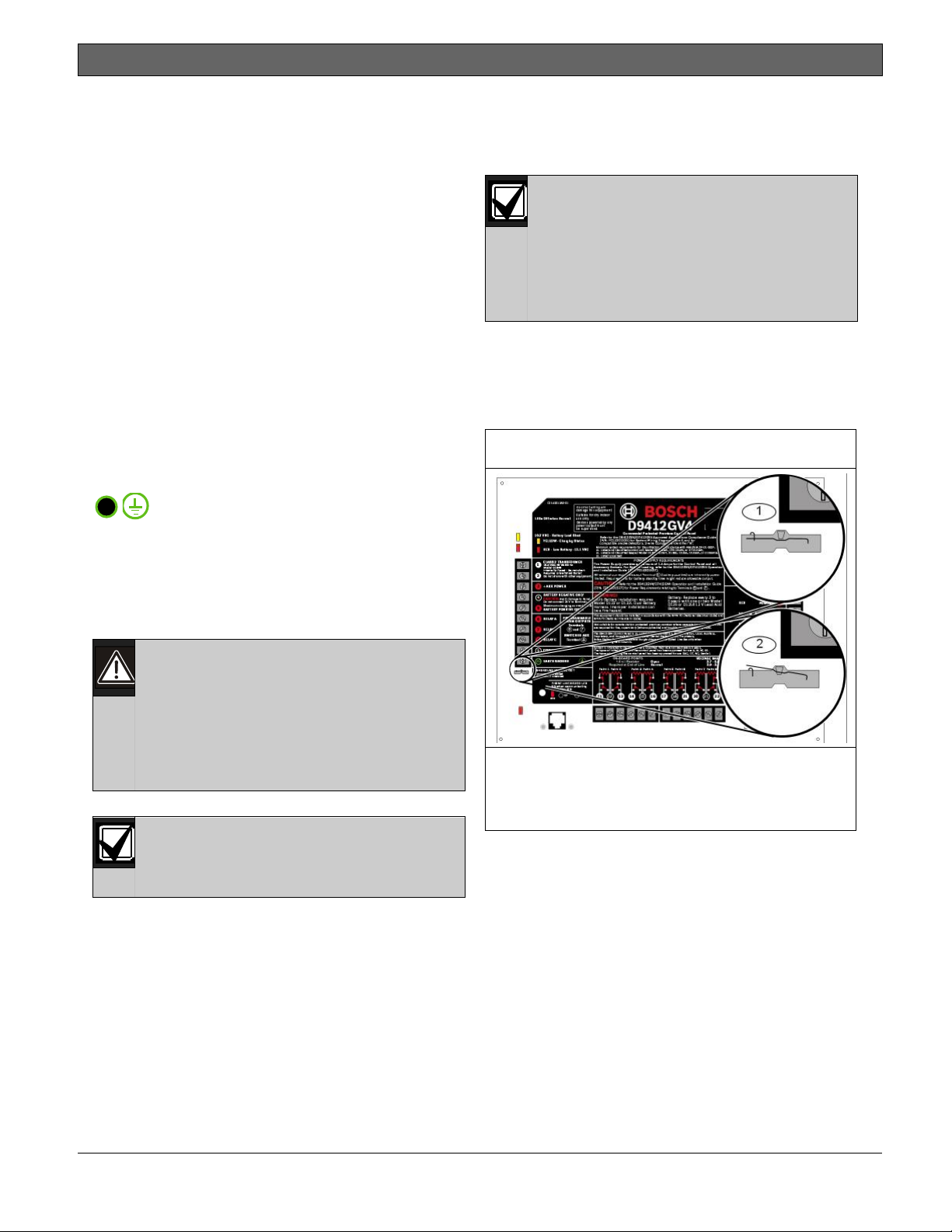

4.5.3 Enabling Ground Fault Detection

To enable Ground Fault Detect Enable, lock

(close) the S4 Ground Fault Detect Pin on the

control panel (Figure 3).

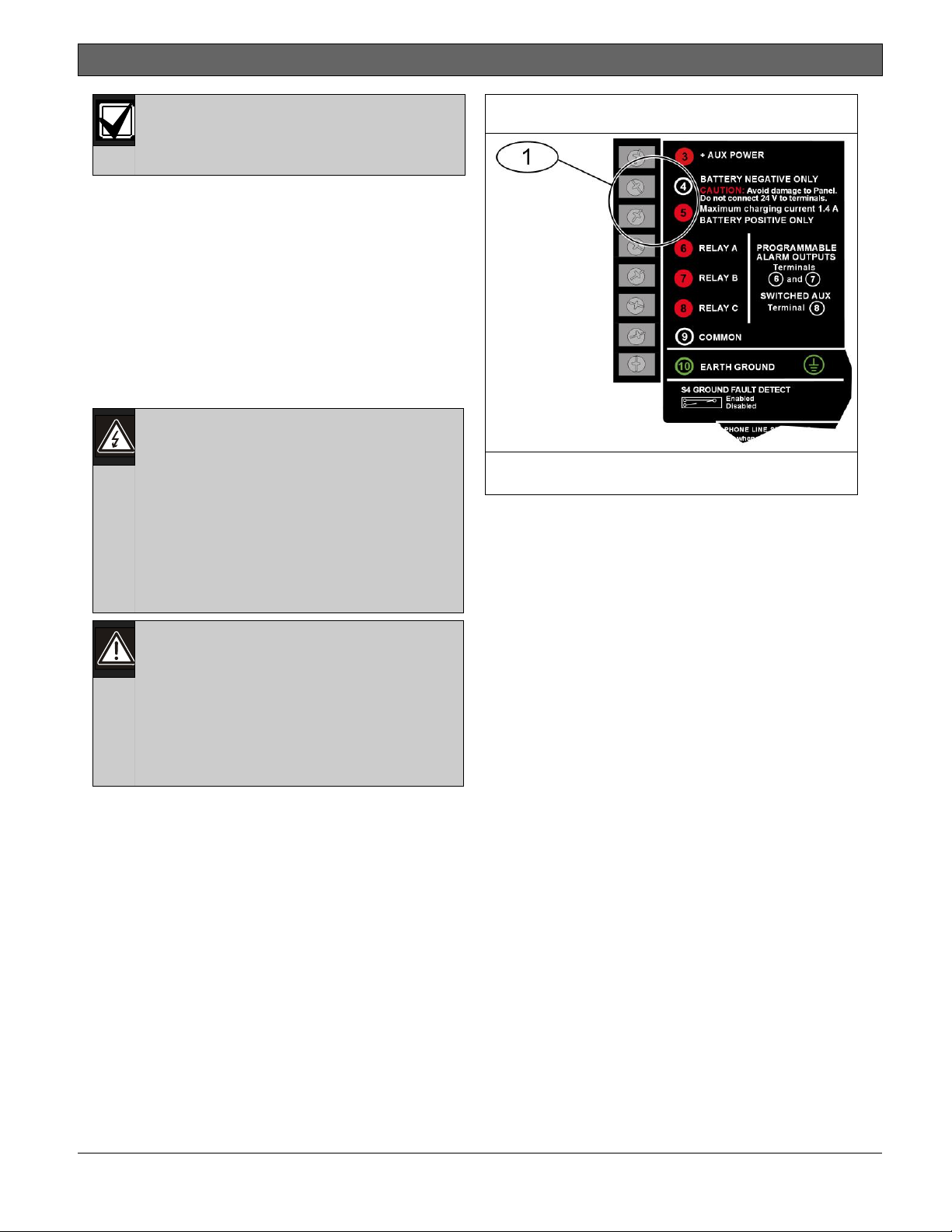

Figure 3: Enabling Ground Fault Detection

10

To help prevent damage from electrostatic

charges or other transient electrical surges,

connect the system to earth ground at Terminal

10 before making other connections.

Recommended earth ground references are a

grounding rod or a cold water pipe.

Caution: Do not use telephone or

electrical ground for the earth ground

connection. Use 14 AWG (1.8 mm) to

16 AWG (1.5 mm) wire when making

the connection.

Do not connect other control panel

terminals to earth ground.

4.5.2 Ground Fault Detect Enable

To meet UL 864 requirements, enable

Ground Fault Detect.

A ground fault is a circuit impedance to earth

ground. The control panel has a ground fault

detection circuit that, when enabled, detects

ground faults on Terminals 1 to 9 and 11 to 32.

The control panel also detects and annunciates

ground faults on any device connected to it.

If a ground fault condition occurs, the keypads

display SERVC GND FAULT and the control panel

transmits a GROUND FAULT TROUBLE, AREA 1.

1 - S4 Locked (Closed). Control panel detects

ground faults.

2 - S4 Unlocked (Open). Control panel does not

detect ground faults.

4.5.4 Ground Fault Specifications

Table 5 provides the impedance specifications for

detecting ground faults when any terminal or

field wiring is shorted to ground.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 18

Page 19

.

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

Table 5: Ground Fault Impedance

Specifications

Impedance Control Panel Detects Ground Fault

≤ 300 Ω Yes

300 Ω to

200 k Ω

≥ 200 k Ω No

Detection depends upon the

terminal

4.5.5 Locking the Reset Pin

Locking the reset pin disables the control panel

(Figure 4). When the control panel is disabled,

the system ignores most keypad commands and

points. Call for Service appears in some keypad

displays when the pin is locked down. SDI2

keypads display “Installation Passcode” when the

pin is locked down.

On-board outputs (Terminals 6 and 7) and offboard outputs deactivate when the control panel

is reset. Terminal 8 has power when the output is

deactivated. Activation interrupts power at that

terminal. The on-board output (Terminal 8)

remains deactivated when the reset pin is locked

in the disable position.

Releasing the reset pin from the closed position

resets the control panel. The control panel resets

all its timers, counters, indexes, and buffers. Any

points that restore after a reset do not generate

Restoral Reports.

If the reset pin is placed in the Lock position and

all areas are armed, the control panel will not

answer RPS over a phone line unless Answer

Armed program item has a value other than zero

in it. No entry is required for network or RPS

Enhanced direct connect communication. Refer

to RPS Parameters in RPS Help.

Figure 4: Reset Pin

1 - Reset pin locked (closed)

2 - Reset pin normal (open)

4.6 Completing the Installation

If not already complete, make the earth ground

connection to Terminal 10 and lock the reset pin

in the closed position.

4.6.1 Charging the Battery

Connect the battery, then the transformer to

allow the control panel to charge the battery

while you complete the installation. Refer to

Section 5.0 Power Supply on page 24 for

instructions.

On-board Buzzer Sounds at Power Up and Reset:

The system performs a series of self-diagnostic

tests of hardware, software, and programming at

power up and at reset. The buzzer on the control

panel sounds during the tests. The selfdiagnostics tests complete in approximately 1 to

3 sec.

If the control panel fails any test, the buzzer

continues sounding and a System Trouble

message appears at the keypads.

Avoid electrostatic discharge. Always

touch Terminal 10, the earth ground

connection, before beginning work on

the control panel.

If the control panel receives an electrostatic

discharge, it might generate Watchdog Reset and

Param Fail events.

4.6.2 Installing and Wiring Detection Devices

Install and wire detection devices and keypads at

their locations throughout the premises. Do not

connect the control panel yet.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 19

Page 20

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

Section 8.0 On-Board Points on page 37

contains instructions for wiring the on-board

points to detection devices. Section 11.0 Arming

Devices on page 60 contains instructions for

wiring the keypads.

Instructions for wiring the off-board point POPIT

sensor loops are found in the instructions

packaged with the POPIT modules.

4.6.3 Installing Modules and Outputs

1. Power down the unit by unplugging the

transformer and disconnecting the battery.

Always power down the unit when

installing modules or outputs, or when

2. Install and wire any modules required for the

3. If using the power outputs at Terminals 7 or

4.6.4 Connecting the On-board Points and

Connect the on-board points and keypad wiring

to the system. Refer to Section 8.0 On-Board

Points on page 37 and Section 11.0 Arming

Devices on page 60 for instructions.

4.6.5 Powering Up

Reconnect the battery, then plug in the

transformer. The buzzer sounds for two sec when

the control panel is powered up. Leave the reset

pin in the locked position.

making wiring connections to the

control panel.

installation as described in the module’s

installation instructions.

Instructions for the D8125 POPEX Module,

D8128D OctoPOPIT Module, D8129

OctoRelay Module, D811 Arm Status Relay

Module, and D928 Dual Phone Line Switcher

appear in this guide.

Refer to Section Off-Board Points on page 41

for D8125 and D8128D instructions. Refer to

Off-Board Outputs on page 55 for D8129 and

D811 instructions. Refer to Section 7.11

D928 Dual Phone Line Switcher on page 34

for D928 instructions.

8, refer to Section Programmable Power

Output Terminals 6, 7, and 8 on page 30 for

instructions.

Keypads

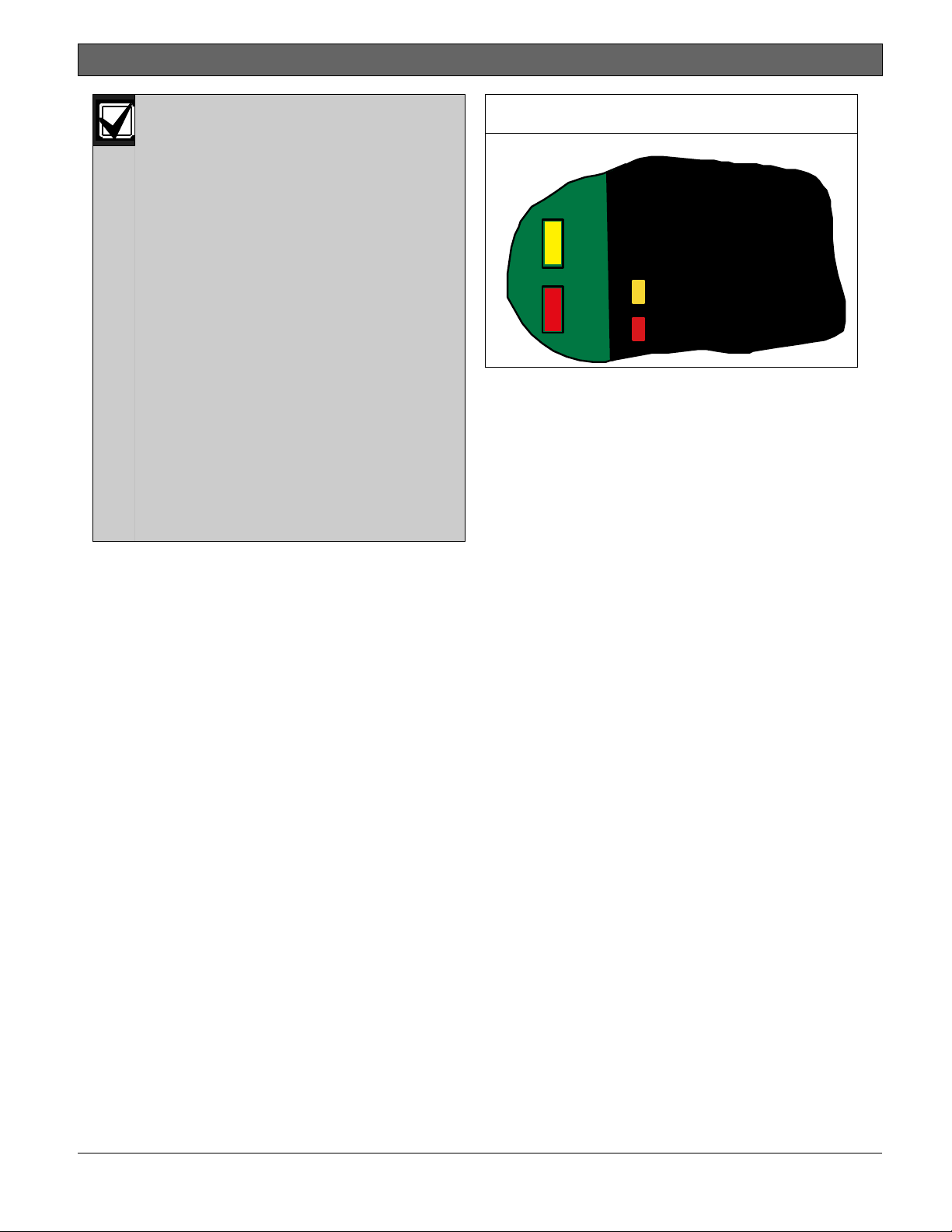

Yellow Charging Status LED Remains Lit: If the

yellow charging status LED remains lit after five

minutes of powering up the control panel, either

the battery is deeply discharged or too many

powered devices were connected to the control

panel. Combined continuous current draw for

Terminals 3, 8, 24, and 32, and the accessory

connector cannot exceed 1.4 A. Refer to Section

6.0 Power Outputs on page 30 for help.

4.7 Updating Control Panel Firmware

When a firmware update is available, installation

of the update is performed using either a ROM

Update Key or using RPS. Refer to the GV4 Series

Control Panel ROM Update Key Instructions on the

underside of the control panel faceplate, or refer

to RPS Online Help.

4.8 Programming the Control Panel

If the control panel is not already programmed,

review the Control Panels (D9412GV4/D7412GV4

v2.00) Program Entry Guide (P/N: F01U265459).

Ensure that all accessory modules for desired

features are available for installation.

Use RPS to load a custom program into the

control panel as needed.

4.9 Installing the Point Chart Label

The point chart label is required for

fire systems with verifications points.

A point chart label is included in the literature

pack. Install the point chart label for fire or

combined fire-and-burglary systems that use

verification points.

Use the Control Panels (D9412GV4/D7412GV4

v2.00) Program Record Sheet (P/N: F01U265460)

to gather the necessary information for

completing the point chart. Fill out the label and

install it on the inside of the enclosure door

(refer to Figure 2 on page 17).

Avoid smearing the entries on the

chart. Use the peel-off backing to

press the label in place.

4.10 Testing the System

After installing and programming the control

panel, test the system completely. Test the

control panel and all devices for proper

operation.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 20

Page 21

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

Test after initially programming the

control panel.

To meet UL 864 requirements,

perform a full system test after any

subsequent programming session.

Refer to Section 4.11 Service Walk Test on page

21 for complete Service Walk Test instructions.

Clear after Test: To clear the event memory and

report buffer, momentarily close the reset pin.

Events stored in the control panel’s event log are

not cleared.

4.11 Service Walk Test

The Service Walk Test differs from the standard

Walk Test. In the standard Walk Test, point

expansion modules whose switches are set for a

point number not programmed in the control

panel do not appear in the test. In the Service

Walk Test, POPITs whose switches are set for a

point number that is not programmed in the

control panel do appear in the test.

The Service Walk Test allows a user to walk test

all 246 points from a control-panel-wide keypad,

regardless of the point index type.

A Service Walk Test can also be initiated by

account-wide or area-wide keypads but test only

those points that are within the scope of the

keypad that initiated the function. The Service

Walk Test does not test points in armed areas.

Only Walk Test Start and Walk Test

End are reported to the central

station.

During a Service Walk Test, the

summary alarm and summary fire

remain off, because there are no Fire

or Burg alarm conditions to

summarize. The P# Output Response

Type feature operates as

programmed.

The D7412GV4 does not include the

Service Walk Test in the Service Menu.

To enable the Service Walk Test

function for any GV4 Series Control

Panel, add its function code to the

Function List of a keypad.

Service Walk Test Procedure (B920/B930)

Refer to Walk Test procedures for Service Walk

Test options in compatible keypad

documentation when using a B920 or B930

Keypad.

1. Choose a keypad to conduct the test. Ensure

that the display shows the idle disarmed text.

2. Press the [MENU] key and then go to the [3]

Actions > [3] Test > [1]Walk Test > [3]

Service menu option.

3. Enter your passcode and press [ENTER]. The

keypad shows the number of points that

remain to be tested.

4. To view the points, press [ENTER] on a B920

keypad or press the View untested points

softkey on a B930 keypad. To scroll through

the list of points, use the [PREV] or [NEXT]

key.

5. When you fault a point (move in front of a

motion sensor for example), the keypad emits

a brief tone and shows the point name and

information (for example, Area-1 Point-7

Onboard: Short).

Extra Points display default text: If the switches

on a POPIT are set incorrectly to a point number

that is not in the program for the control panel,

the default text for that point number (PT ###)

appears when the point is faulted.

Faulting the point a second time produces the

tone and shows the point text, but does not

decrease the count in the ## PTS TO TEST

message.

To see the points that remain untested during the

Service Walk Test:

a. Press [ESC] when point text appears. The

display shows ## PTS TO TEST.

b. Press the [ESC] key. VIEW UNTESTED ?

appears.

c. Press [ENT]. ## PTS UNTESTED appears.

d. Press [NEXT] to see a list of the points

that have not yet been tested. Move

through this list by pressing the [NEXT]

key.

e. To resume the Service Walk Test, press

[ESC]. ## PTS UNTESTED appears.

f. Press [ESC]. ## PTS TO TEST appears.

g. Resume testing points. To end the Service

Walk Test, press [ESC] twice.

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 21

Page 22

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

6. After the last point is tested, 0 PTS TO TEST

appears. Press [ESC]. The display shows ALL

PTS TESTED briefly before returning to idle

text.

The Service Walk Test, when

performed on a D7412GV4, cannot

show “0 PTS TO TEST” because the

D7412GV4 is physically unable to

connect to the second POPEX Module

(used for Points 129-247).

Automatic time-out returns the system

to idle text: If there is no point or

keypad activity for 20 min., the

Service Walk Test ends automatically.

The keypad returns to idle text.

4.11.1 Program the Control panel

Use RPS or the keypads to program the control

panel. Refer to:

Control Panels (D9412GV4/D7412GV4

v2.00)) Program Entry Guide (P/N:

F01U265459).

Keypad Installer menu

RPS Help

4.11.2 Service Bypass

To facilitate system maintenance for service

personnel, a special point bypass option is

provided through this menu to remove any point

from service. The status of points in Service

Bypass can be viewed through the Service Bypass

Menu. For details in navigation and operation of

this function refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459).

4.11.3 RF Points and Repeaters

With a B810 wireless receiver, the control panels

can support up to 238 wireless points, 1000 key

fobs, and 8 repeaters within the RADION wireless

portfolio. The RF Points menu provides the tools

necessary to enroll, remove or replace wireless

points. For details in navigation and operation of

these functions refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459).

With a B820 SDI2 Inovonics Interface Module, the

control panels can support up to 350 RF devices

and up to eight RF Repeater modules. The RF

Points menu provides the tools necessary to

enroll, remove or replace wireless points. For

details in navigation and operation of these

functions refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459).

The RF Points menu does not affect

the RFIDs learned by the D8125INV

Wireless Interface Module nor the

ISW-D8125CW-V2 Commercial

Wireless Interface Module if installed

on the Zonex bus.

4.11.4 RF Diagnostics

With a B810 wireless receiver, or B820 SDI2

Inovonics Interface Module installed, the control

panel can show detailed wireless communication

information for RF points, keyfobs and repeaters.

The RF Diagnostics menu can show real-time

signal strength information for enrolled RF

devices. By monitoring the signal strength of an

individual RF device, the optimal position for

installation can be found.

RF device diagnostic information also includes AC

status, battery status, supervision status, and

tamper status for all supporting devices. For

details in navigation and operation of these

functions refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459).

4.11.5 IP Diagnostics

With at least one B420 Ethernet Communication

Module, or B426 Ethernet Communication

Module installed on the SDI2 bus, the control

panels can use the diagnostic functions of this

menu to retrieve the auto-configured settings

from the module and perform a series of network

communication tests. This menu does not apply

to the DX4020 modules on the SDI bus.

The Settings option retrieves the following from

the selected B420 module: Unit Host Name, MAC

ID, and current IPV4 Address. For the B426

module, the Settings option retrieves: Unit Host

Name, MAC ID, and current IPv6 Address.

The Connection Test option performs the

following automated tests for the selected

B426/B420 module:

Link [OK] if Ethernet cable is detected

[Missing] if Ethernet cable is not

detected.

Gateway [OK] if an ICMP echo request (PING)

response is received from the Gateway

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 22

Page 23

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 4.0 Installation

.

Address. [Failure] if response is not

received.

Internet [OK] if an ICMP echo request (PING)

response is received from the IP Test

Address. [Failure] if response is not

received.

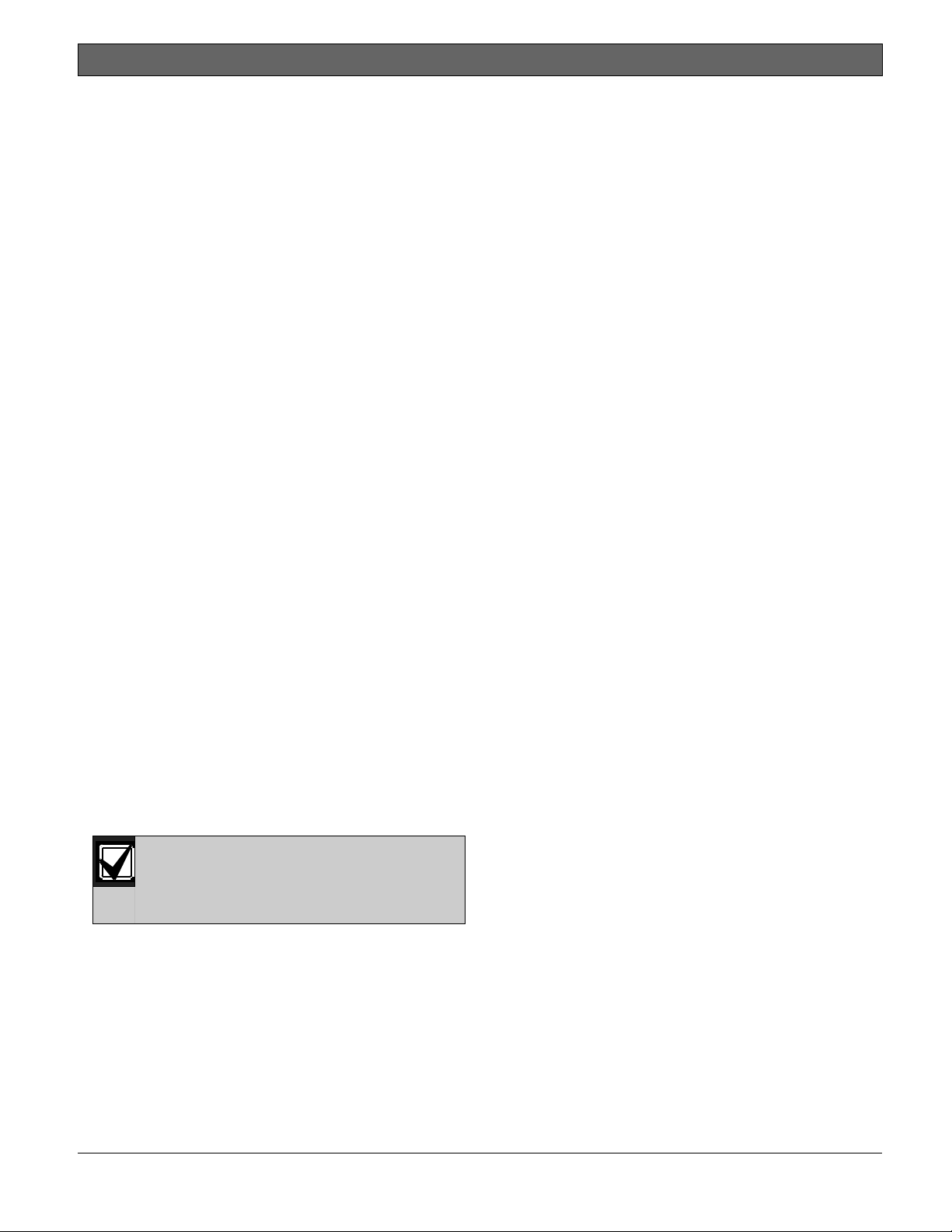

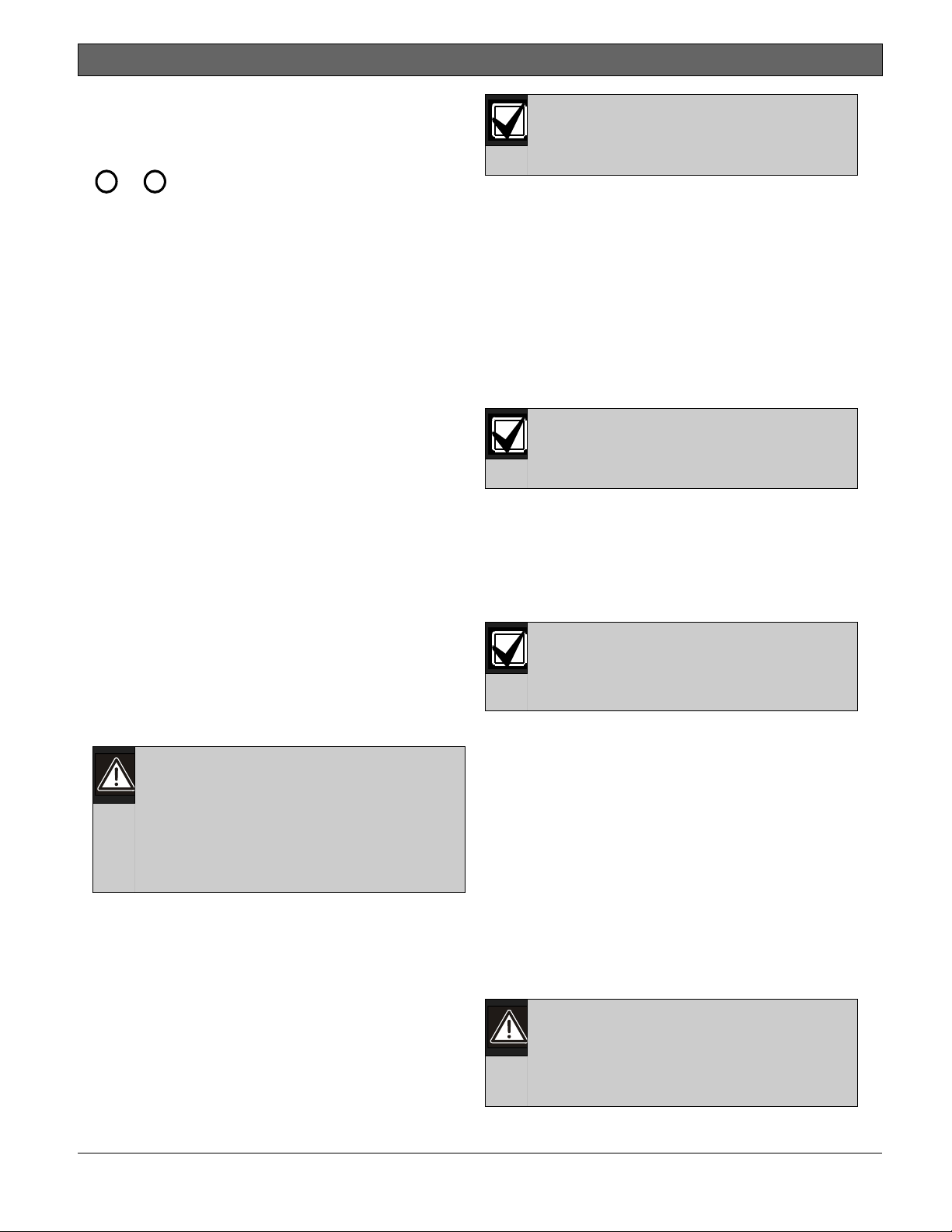

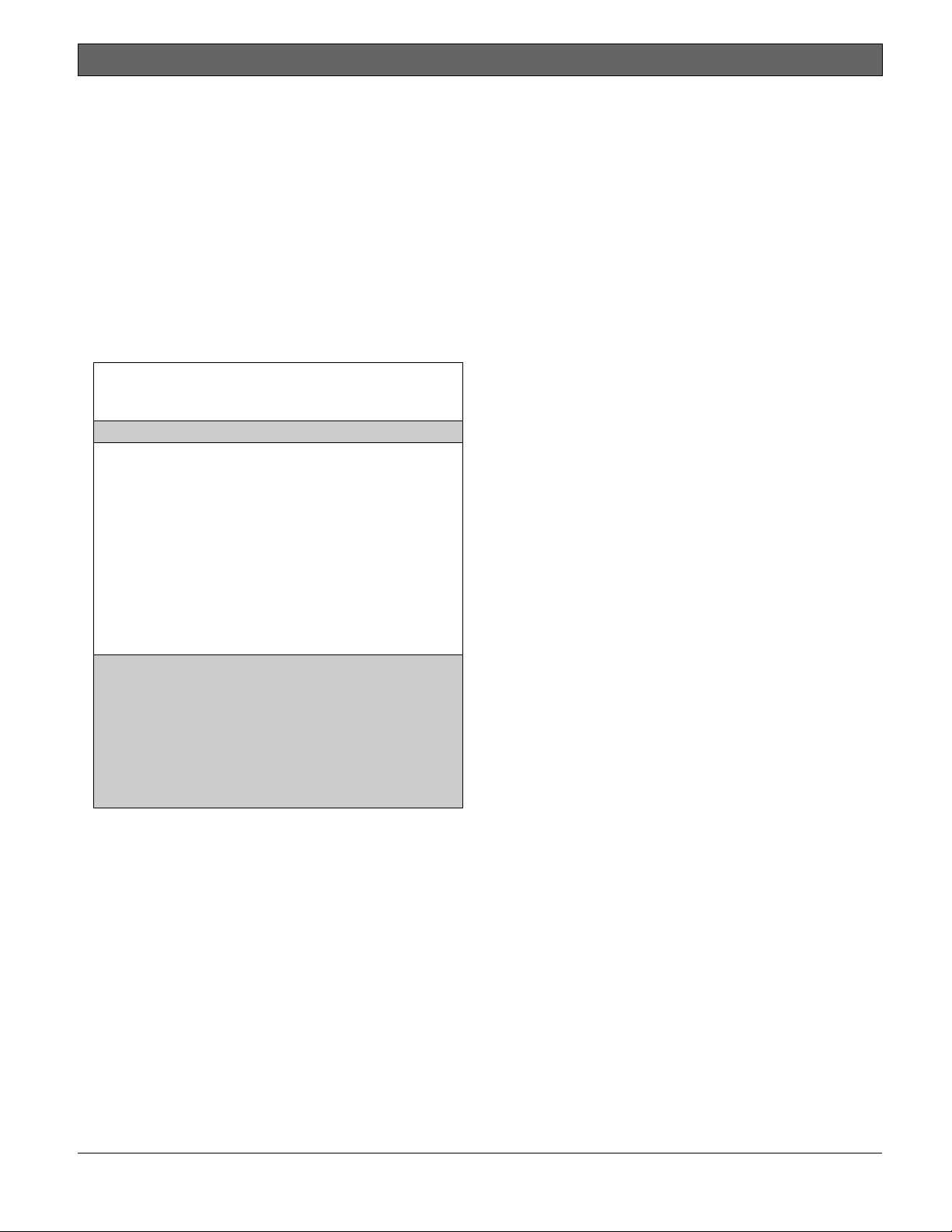

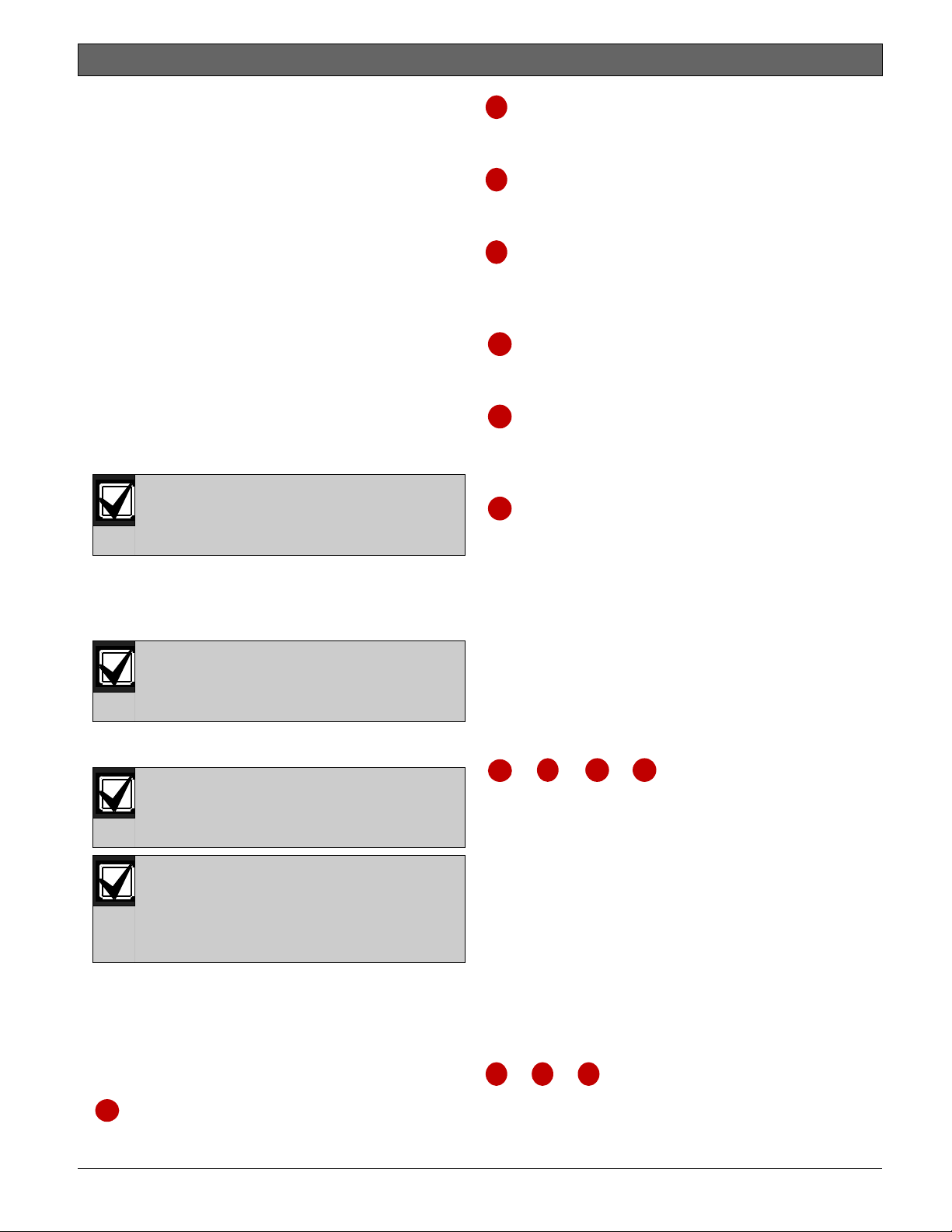

Figure 5: Service Walk Test Flow Chart Example

SERVICE WALK?

246 PTS TO TEST

Refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459) for details on the

B426/B420 Ethernet Communication Module

configuration.

[ENT]

Test a device

POINT TEXT

(Text displays for 60 seconds)

[ESC]

IDLE TEXT

[ESC]

245 PTS TO TEST

Test a device

POINT TEXT

(Text displays for 60 seconds)

244 PTS TO TEST

Test a device

POINT TEXT

1 PTS TO TEST

Test a device

0 PTS TO TEST

[ESC]

[ESC]

[ESC]

VIEW UNTESTED?

[ENT]

# PTS UNTESTED

[NEXT]

POINT TEXT

[ESC]

[ESC]

Bosch Security Systems, Inc. | 2/13 | F01U265457-03 23

Page 24

.

D9412GV4/D7412GV4 v2.00 | Installation and System Reference Guide | 5.0 Power Supply

5.0 Power Supply

5.1 Primary Power Terminals 1 and 2

1 2

,

5.1.1 Primary (AC) Power Circuit

The primary source is a 16.5 VAC, 40 VA,

internally-fused transformer (Bosch Security

Systems, Inc. Model D1640). The control panel

draws 200 mA when idle and 300 mA when in an

alarm state. The total available auxiliary current is

1.4 A.

Transient suppressors and spark gaps protect the

circuit from power surges. This protection relies

on the ground connection at Terminal 10. Ensure

that you connect Terminal 10 to a proper ground.

Refer to Section 4.5 Connecting Earth Ground on

page 18.

AC Power Fail

The system indicates an AC power failure when

Terminals 1 and 2 do not have power. The AC Fail

Time parameter sets the number of minutes or

secs without AC power before the control panel

acknowledges the failure and the number of

minutes or secs after the power returns before

the control panel acknowledges restored power.

Refer to the Control Panels

(D9412GV4/D7412GV4 v2.00) Program Entry

Guide (P/N: F01U265459)for additional

information about AC Fail Time and UL 864

requirements.

5.1.2 Installing the Transformer

Do not short-circuit the terminals of the

transformer: Shorting the terminals

opens the internal fuse, causing

1. Use 18 AWG (1.22 mm) wire (minimum) to

2. Route telephone and sensor loop wiring away

permanent failure. Connect the

transformer to Terminals 1 and 2 of

the control panel before plugging it

into the power source.

connect the transformer to the control panel.

The wire length should be as short as

possible. The maximum length is 50 ft (15 m).

Connect the battery and plug in the

transformer.

from any AC conductors, including the

transformer wire.

AC wiring can induce noise and low level

voltage into adjacent wiring. Route data

wiring away from AC and telephone wiring.

Always connect the battery first and

then plug in the transformer.

3. Connect the battery. Refer to Section 5.2.2

Installing the Battery on page 25.

4. Plug the transformer into an unswitched, 120

VAC, 60 Hz power outlet only.

5. Secure the transformer to the outlet with the

screw provided.

D8004 Transformer Enclosure Required for Fire

Systems

Use the D8004 Transformer Enclosure for the

D1640 Transformer in fire and combined fire and

burglary applications.

Check with the Authority Having

Jurisdiction (AHJ) about mounting

transformers on specific circuits.

5.2 Secondary Power Terminals

5.2.1 Secondary (DC) Power

A 12 V sealed lead-acid rechargeable battery

(D126) supplies secondary power for auxiliary

and alarm outputs, and powers the system during

interruptions in primary (AC) power.

Use Lead Acid Batteries Only: The

charging circuit is calibrated for lead-

Extra Batteries Increase Back-up Time

To increase battery back-up time, connect a

second 12 V battery in parallel to the first

battery. Use a D122 Dual Battery Harness to

ensure proper and safe connection. Refer to the

Standby Battery and Current Rating Chart in 17.0

Approved Applications in this guide for battery

standby time calculations.

D1218 Battery

The D1218 is a 12 V, 18 Ah battery for use in

applications requiring extended battery standby

time. Up to two D1218 batteries can be

connected when used with a D122 Dual Battery

Harness.

acid batteries. Do not use gel-cell or

nicad batteries.

Caution: When connecting two D1218

Batteries to the control panel, both

must have the same capacity (use two

17.2 Ah batteries or two 18 Ah