Page 1

R A D I O N I C S

D9112 Control/Communicator

Operation and Installation Manual

74-06144-000-C 2/96

© 1993-1996 Radionics

Page 2

Notice

FCC Notices

Part 15

The material and instructions covered in this manual have been carefully checked for

accuracy and are presumed to be reliable. However, Radionics, Inc. assumes no

responsibility for inaccuracies and reserves the right to modify and revise this manual

without notice.

It is our goal at Radionics to always supply accurate and reliable documentation. If a

discrepancy is found in this documentation, please mail a photocopy of the corrected

material to:

Radionics, Inc.

c/o Technical Writing

1800 Abbott Street

P.O. Box 80012

Salinas, CA 93912-0012

© 1993 Radionics, Inc., Salinas, CA, U.S.A. All rights reserved.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Part 68

This equipment complies with Part 68 of FCC rules. A label contains, among other

information, the FCC registration number and ringer equivalence number (REN). If

requested, this information must be provided to the telephone company.

The Radionics D9112 Control/Communicator is registered for connection to the public

telephone network using an RJ38X or RJ31X jack.

The ringer equivalence number (REN) is used to determine the number of devices that

may be connected to the telephone line. Excessive RENs on the telephone line may

result in the devices not ringing in response to an incoming call. In most, but not all areas,

the sum of the RENs should not exceed five (5). To be certain of the number of devices

that may be connected to the line, as determined by the RENs, contact the telephone

company to determine the maximum REN for the calling area.

If the D9112 Control/Communicator causes harm to the telephone network, the telephone

company will notify you in advance. If advance notice isn’t practical, the telephone

company will notify the customer as soon as possible. Also, you will be advised of your

right to file a complaint with the FCC if you believe it is necessary.

D9112 Operation & Installation Manual

Page 274-06144-000-C 2/96

© 1993-1996 Radionics

Page 3

Part 68 (Continued)

The telephone company may make changes in its facilities, equipment, operations, or

procedures that could affect the operation of the equipment. If this happens, the

telephone company will provide advance notice in order for you to make the necessary

modifications in order to maintain uninterrupted service.

If trouble is experienced with the D9112 Control/Communicator, please contact Radionics

Customer Service for repair and/or warranty information. If the trouble is causing harm to

the telephone network, the telephone company may request that you remove the

equipment from the network until the problem is resolved. User repairs must not be

made, and doing so will void the user’s warranty.

This equipment cannot be used on public coin service provided by the telephone

company. Connection to Party Line service is subject to state tariffs. (Contact your state

public utilities commission for information.)

FCC Registration Number: AJ9USA-18808-AL-E

Ringer Equivalence: 0.1A 0.2B

Service Center in U.S.A.: Radionics, Inc.

1800 Abbott Street

P.O. Box 80012

Salinas, CA 93912-0012

(800) 538-5807

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 3

© 1993 Radionics

Page 4

Table of Contents

Introduction ......................................................... 7

Areas and Accounts........................................ 8

Communicator ................................................ 8

D1255 Alpha III Command Center................... 8

Keyswitch ....................................................... 8

Event Memory ................................................ 9

Event Log ....................................................... 9

EMI/Lightning Transient Protection.................. 9

Programming .................................................. 9

Other Features.............................................. 10

D9112 Control/Communicator Assembly ....... 11

Ordered Separately .................................. 11

Listings and Approvals .................................. 12

Fire........................................................... 12

Burglary.................................................... 12

Installation......................................................... 13

Before You Begin.......................................... 13

Enclosure Options......................................... 13

Beginning the Installation .............................. 13

Mounting the Enclosure ............................ 13

Premises Wiring ....................................... 14

Installing the D9112 Assembly .................. 14

Connecting Earth Ground.............................. 14

Locking the Reset Pin ................................... 15

Finishing the Installation................................ 16

Charge the Battery as You Finish.............. 16

Install and Wire Detection Devices............ 16

Install Modules and Relays ....................... 16

Make the Telephone Connections............. 17

Connect the On-Board Points and Command

Centers..................................................... 17

Power Up ................................................. 17

Programming the Panel ................................ 17

Install the Point Chart Label .......................... 17

Testing the System ....................................... 18

Power Supply .................................................... 19

Primary Power .............................................. 19

Primary (AC) Power Circuit ....................... 19

Installing the Transformer ......................... 19

Secondary Power ......................................... 20

Secondary (DC) Power ............................. 20

Installing the Battery ................................. 20

Battery Supervision................................... 20

Battery Charging Circuit ............................ 21

Battery Discharge/Recharge Schedule

(No AC Power) ......................................... 21

Charging Status and Low Battery LEDs ........ 22

Charging Status LED (Yellow)................... 22

Low Battery LED (Red) ............................. 22

Power Outputs .................................................. 23

Circuit Protection .......................................... 23

Available Power ............................................ 23

Continuous Power Outputs ........................... 24

Continuous Current Draw ......................... 24

Programmable Power Outputs ...................... 25

Programming............................................ 25

Optional Relays Required ......................... 25

Terminals 6 and 7..................................... 26

Terminal 8 ................................................ 26

Fire System Power Formula...................... 26

Telephone Connections .................................... 27

Registration .................................................. 27

Notification.................................................... 27

Location........................................................ 27

Phone Cord Connection................................ 28

Phone LED (Red) ......................................... 28

Operation Monitor LED (Green) .................... 28

Dialing Format .............................................. 28

Phone Line Monitor....................................... 28

Phone Line Test Points ................................. 29

Communication Failure ................................. 29

Ground Start ................................................. 29

Relay Installation ...................................... 29

Ground Start Jumper ................................ 30

D128 Dual Phone Line Switcher.................... 30

Operation ................................................. 30

Primary Phone Lines,

Primary Phone Numbers........................... 31

Watchdog Feature .................................... 31

Installing the D128 .................................... 31

D128 Status LEDs .................................... 32

On-Board Points ............................................... 33

Description ................................................... 33

Point Sensor Loops....................................... 33

Point Parameters .......................................... 34

Point Response Time.................................... 34

Off-Board Points ............................................... 35

Point (ZONEX) Buss ..................................... 35

D8125 POPEX Module

D8127 POPIT Modules ................................. 35

Installing the D8125 POPEX Module............. 36

Wiring the D8125 to the D9112 ................. 36

Wiring POPITs to the

Data Expansion Loop ............................... 38

Wiring Data Expansion Loops to

POPEX Modules....................................... 39

POPIT Sensor Loops................................ 39

Point Assignments .................................... 40

D9112 Operation & Installation Manual

Page 474-06144-000-C 2/96

© 1993-1996 Radionics

Page 5

D8128A OctoPOPIT Module ......................... 42

Listing....................................................... 42

Installing the OctoPOPIT .......................... 42

Wiring OctoPOPITs to the D9112.............. 43

Line Termination ....................................... 44

OctoPOPIT Sensor Loops......................... 45

Testing Off-board Points ............................... 47

Installation Guide for UL and Fire Applications61

Listings and Approvals .................................. 61

Fire........................................................... 61

Burglary.................................................... 61

Optional Compatible Equipment .................... 62

Burglary Applications ................................ 62

Fire Applications ....................................... 62

Off-board Relays ............................................... 48

D8129 OctoRelay ......................................... 48

Configuring the D8129 OctoRelay............. 48

Relay Outputs........................................... 48

Installation ................................................ 50

Wiring Connections................................... 50

D811 Arm Status Relay Module .................... 51

Relay Output ............................................ 51

Installation ................................................ 51

Wiring Connections................................... 52

Arming Devices ................................................. 53

Description.................................................... 53

D1255 Command Centers............................. 53

Assigning the D1255 an Address .............. 53

Installation ................................................ 54

D268/D269 Independent Zone Control

D279 Independent Zone Control ................... 55

Keyswitch ..................................................... 56

Description ............................................... 56

Programming ............................................ 56

Installation ................................................ 56

Keyswitch Operation ................................. 56

Programmer and Accessory Connections ....... 57

Programmer Connector (J7).......................... 57

Expansion Port (J4) ...................................... 58

Programmer Access Reports .................... 58

Accessory Connector (J2) ............................. 58

System Chart..................................................... 64

System Wiring Diagram, Issue A ...................... 65

Current Rating Chart for

Standby Battery Calculations ........................... 66

Standby Battery Requirements ........................ 67

Standby Battery Calculation for

Fire Alarm Applications .................................... 68

Troubleshooting Guide ..................................... 70

Introduction................................................... 70

Self Diagnostics ............................................ 70

Phone Line Trouble....................................... 72

Communications Failure ............................... 73

Problems Programming the Panel................. 74

Problems with Points..................................... 75

Problems with the D8125 POPEX

Data Expansion Loops .................................. 78

Checking Shielded Cable .............................. 79

EMI on Long Wire Runs ................................ 79

Problems with Command Centers ................. 80

Battery and Power Reports ........................... 81

Watchdog Reset Reports .............................. 81

Runaway Reports to the Receiver ................. 81

Overloaded Power Supply............................. 82

Service Walk Test ......................................... 83

Command 57 Toggles Default Idle Text ........... 85

D9112 Faceplate ................................................ 59

Quick Reference Terminal Description ............ 60

D9112 Operation & Installation Manual

74-06144-000-C 2/96

Command 59 Toggles Default Idle Text ........... 85

Specifications.................................................... 85

Page 5

© 1993 Radionics

Page 6

Figures and Tables

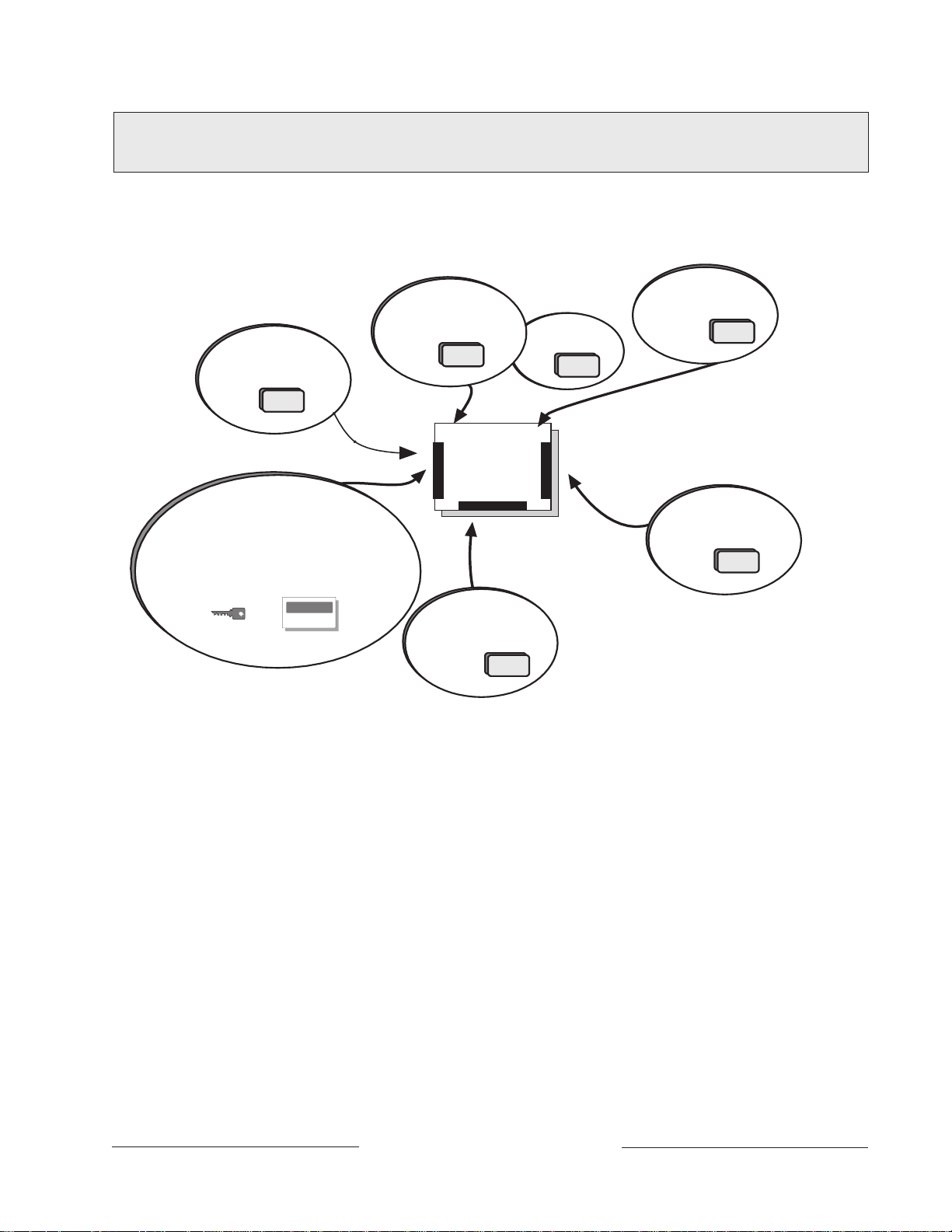

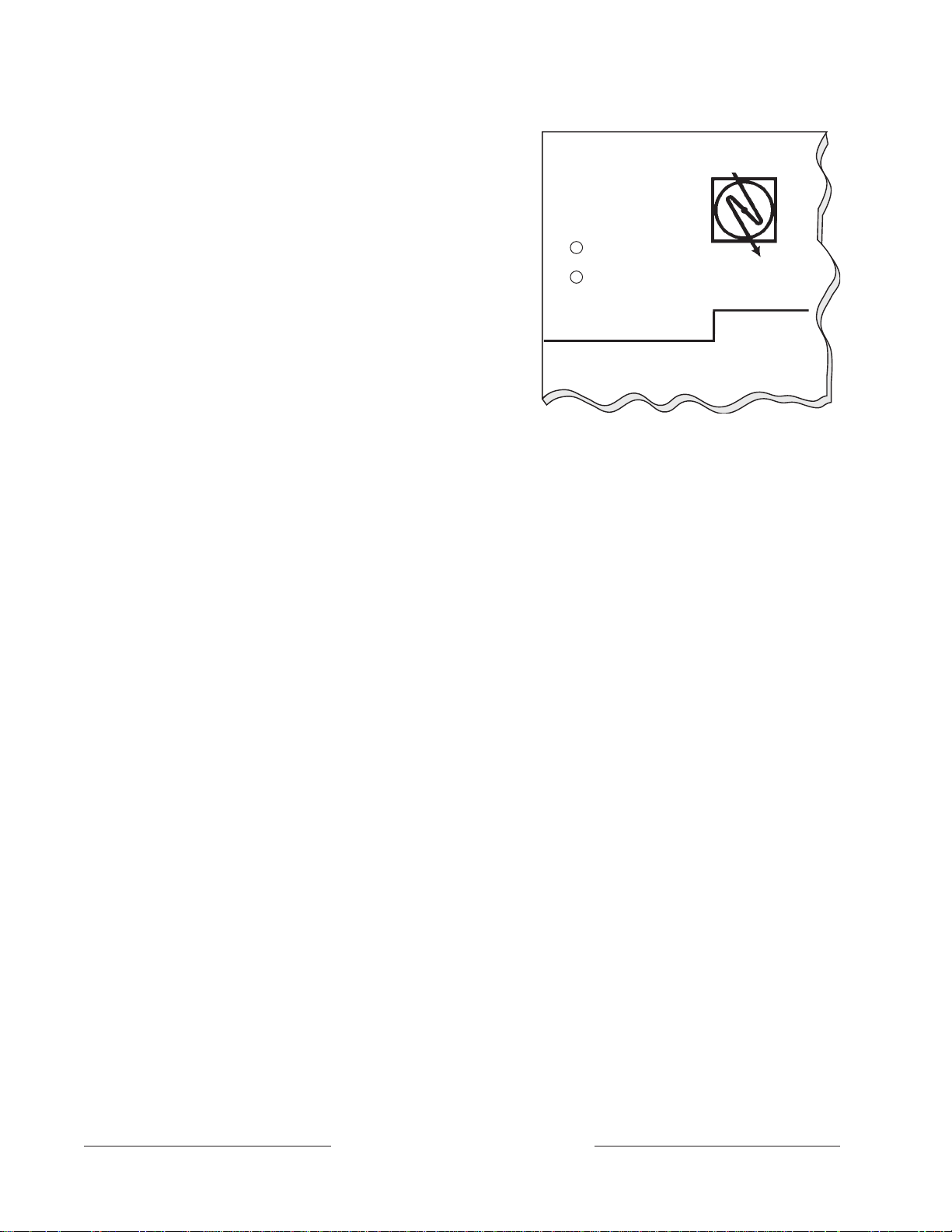

Figure 1: D9112 System Configuration ....................................................7

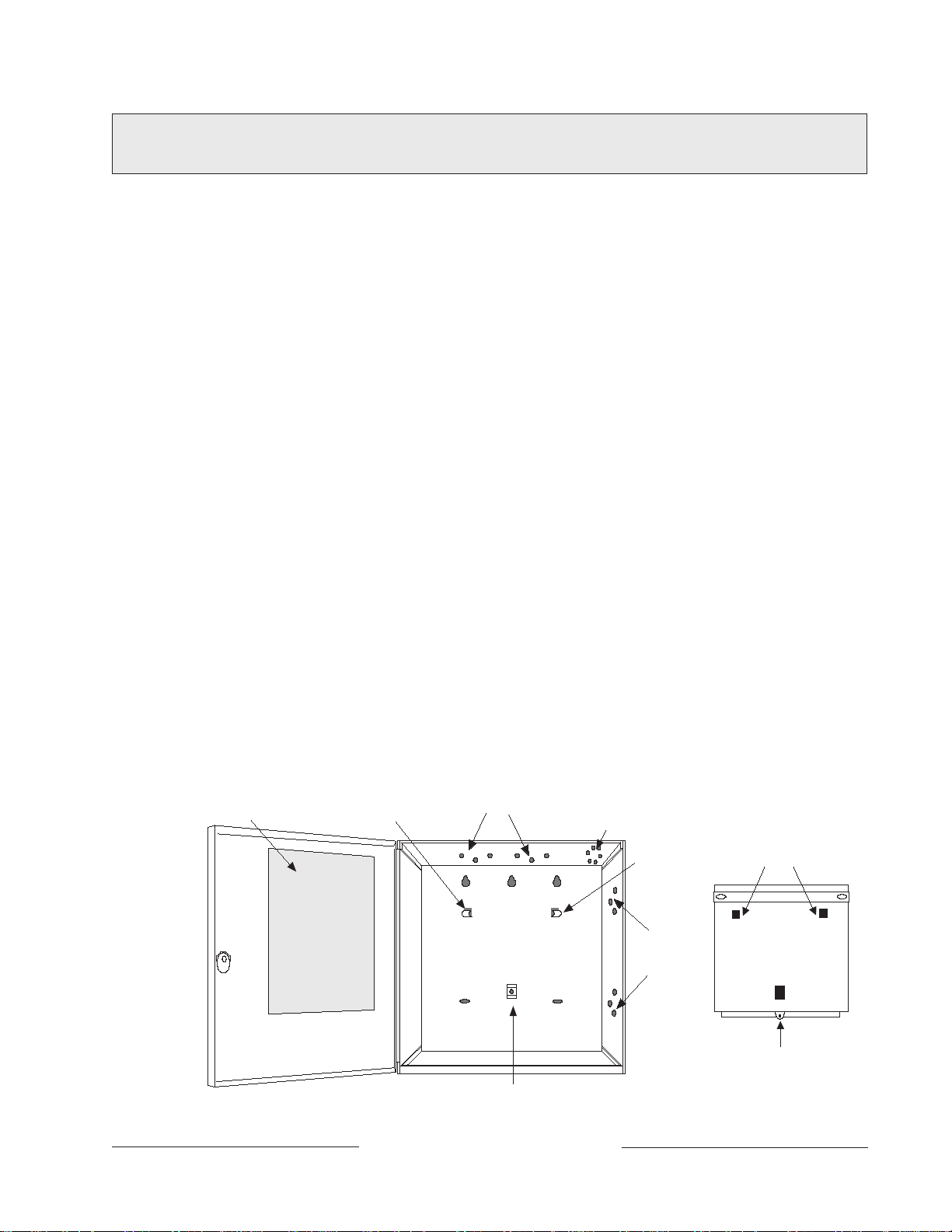

Figure 2: Enclosure Mounting ................................................................13

Figure 3: Reset Pin..................................................................................15

Figure 4: Charging and Battery LEDs .................................................... 22

Figure 5: Relays for Terminals 7 and 8 .................................................. 25

Figure 6: RJ31X Wiring ...........................................................................27

Figure 7: Telephone Connections ..........................................................29

Figure 8: Ground Start Relay ..................................................................29

Figure 9: Ground Start Jumper...............................................................30

Figure 10: D128 Dual Phone Line Switcher

Figure 11: On-board Point Sensor Loop Wiring .................................... 33

Figure 12: D8125 Connections ............................................................... 37

Figure 13: Typical Expansion Loop/POPIT Configuration.....................39

Figure 14: D9112 Program Record Sheet............................................... 40

Figure 15: POPIT Labels .........................................................................41

Figure 16: D8128A OctoPOPITs..............................................................43

Figure 17: D8129 OctoRelay Connections .............................................50

Figure 18: D811 Module Wiring .............................................................. 52

Figure 19: Power at Command Centers ................................................. 55

Figure 20: Keyswitch Wiring...................................................................56

Figure 21: Reset Pin................................................................................ 57

Figure 22: Programmer and Accessory Connections ........................... 58

Figure 23: Service Walk Test Flow Chart ...............................................84

Table 1: Data Expansion Loop Wire Specifications...............................38

Table 2: D8128A OctoPOPIT Switch Settings ........................................46

Table 3: D8129 Switch Settings .............................................................. 49

Table 4: D1255 Address Settings ........................................................... 53

Table 5: D1255 Connections ................................................................... 54

D9112 Operation & Installation Manual

Page 674-06144-000-C 2/96

© 1993-1996 Radionics

Page 7

Introduction

D9112

D8128 COctoPOPIT combines

8 POPIT Points in one module.

D8125 Interface for

D8127POPITS

Points 9-71

Use D1255 Command Centers and/or

keyswitches to arm the D9112 by area. Each

panel can have up to 8 areas.Each area can

have its own account number or areas can be

grouped together with a common account number.

Points of protection are assigned to areas.

D128 module allows the

D9112 to monitor two

phone lines.

D9131 module connects

to a parallel printer to

print event log locally.

On-board Points

1 to 8

2nd D8125 adds

Points 73-135

D8129 OctoRelay

provides alarm and

auxiliary relay output.

(Other functions available.)

Points

74-06144-000-C 2/96

Figure 1: D9112 System Configuration

The Radionics D9112 Control/Communicator panel provides up to 134 separate points of

protection. Point programming parameters determine the panel’s response to open and

shorted conditions on the point’s sensor loop. Points are programmed individually with

several options to custom-fit the protection to your installation.

Points 1 to 8 are located on the D9112 circuit board (on-board points). They are standard

sensor loops. The remaining 126 off-board points are POPIT (Point of Protection Input

Transponder) points. Each off-board point requires a POPIT module. D8127 POPIT

modules require the D8125 POPEX module. The D8128A OctoPOPIT module combines

eight POPITs in a single module and does not require the D8125 POPEX module.

D9112 Operation & Installation Manual

Page 7

© 1993 Radionics

Page 8

Areas and Accounts

The D9112 supports up to eight separate areas. You can assign all points to a single

area or spread them out over up to eight areas.

You arm and disarm the D9112 panel by area. You can arm and disarm several areas

with one menu function. You can also assign a passcode an authority level that allows a

user to arm an area from a remote command center in another area. Assigning each

area its own account number creates eight separate accounts in one D9112 panel.

Assigning the same account number to different areas, groups them together in a single

account.

Area options include: exit tone and delay, separate fire and burglary outputs, and multiple

opening and closing windows.

Communicator

The Radionics D9112 Control/Communicator panel uses a built-in digital communicator

to send reports to the receiver. The panel transmits reports in either the Modem II or

BFSK format. Your D6500 receiver's MPU and line cards must have software revision

6.00 (or greater) installed to accept Modem II reports from the D9112. Power your

receiver down and up to print the software revision numbers.

The D9112 connects to an RJ31X jack for phone line seizure. Connection to the RJ31X

complies with FCC regulations for using the public telephone network. You can program

the panel to direct reports to four separate phone numbers. Adding the D128 Dual Phone

Line Switcher module allows you to connect and supervise a second phone line.

D1255 Alpha III Command Center

The D1255 Alpha III Command Center offers complete system control and annunciation.

The D1255 features an illuminated keypad, a 16-character English language display, and

a built-in speaker that offers several distinct warning tones. Switches on the D1255

assign an address (1 to 8) to the command center. You assign addresses to areas in the

Command Center Assignments section of the program.

You can connect a maximum of 32 command centers to the D9112. The available power,

number of supervised command centers, and number of areas you intend to use, affect

the total number of command centers you can connect to the D9112.

The D9112 can supervise up to 8 command centers. The panel transmits a serial device

trouble report, SDI FAILURE in the Modem II format or TROUBLE ZN D in the BFSK

format, if it loses communication with a supervised command center. You can add more

command centers but only eight can be supervised. See Command Center in the D9112

Program Entry Guide (74-06145-000) for complete details on command center options.

Keyswitch

You can arm and disarm any of the eight available areas with maintained or momentary

closure devices such as keyswitches. Keyswitches connect to points. Point programming

determines which area a keyswitch controls. See Options in the Point Index Parameters

module of the D9112 Program Entry Guide (74-06145-000).

D9112 Operation & Installation Manual

Page 874-06144-000-C 2/96

© 1993-1996 Radionics

Page 9

Event Memory

The D9112 uses event memory to store events for each area. You can view the events

for an area at a D1255 Command Center assigned to the area. The D9112 panel clears

the events for an area from event memory and starts storing new events when you

master arm the area.

NCI

154

Event Log

The D9112 stores up to 500 events and event modifiers from all areas in it's event log.

Event modifiers add information about an event to the log. Some events are always

followed by a modifier. For example, the D9112 adds at least two items to the log each

time you arm or disarm an area, the open (or close) event and an event modifier showing

the previous arming state.

All events and their modifiers are stored even if the D9112 does not send a report for

them. You can view the log at a D1255 Command Center, print it locally using the

D9131 Parallel Printer Interface and a parallel printer, or upload it to a D5300 Remote

Account Manager II (RAM II).

See S- View Log in the Security System User's Guide (71-06141-000) for a complete

listing of log events and event modifiers.

EMI/Lightning Transient Protection

The D9112 maintains the Radionics high level of quality and field dependability. Its

design significantly reduces electromagnetic interference and malfunction generally

caused by lightning.

Programming

74-06144-000-C 2/96

Use either the Radionics D5200 Programmer, or the D5300 Remote Account Manager II

(RAM II) to program the D9112. Refer to the D9112 Program Entry Guide (74-06145-000)

for programming options.

D9112 Operation & Installation Manual

Page 9

© 1993 Radionics

Page 10

Other Features

The D9112 has many programmable features. A short list of some of the features follows.

Complete details on all the D9112’s features can be found in the D9112 Program Entry

Guide (74-06145-000).

• Supervision of AC (primary power), battery (secondary power), ZONEX and SDI

• Automatic system test reports

• Remote access for programming, diagnostics, and log uploads using the Radionics

• RAM Line Monitor answering machine work-around

• Fire Alarm Verification

• Programmable Alarm Output

• Programmable Relay Output using the D8129 OctoRelay Module

• Opening and Closing Windows

• Skeds (scheduled events)

buses, CPU (Central Processing Unit), up to 3 printers, and telephone lines

D5300 Remote Account Manager II (RAM II)

D9112 Operation & Installation Manual

Page 1074-06144-000-C 2/96

© 1993-1996 Radionics

Page 11

D9112 Control/Communicator Assembly

The Radionics D9112 Control/Communicator is shipped pre-assembled from the factory.

You should receive the following parts with your D9112 panel.

Literature Pack

• D9112 Installation Reference Guide (74-06144-000)

• D9112 Program Record Sheet (74-06100-000)

• UL Smoke Detector Compatibility Technogram (73-06143-000)

• Point Chart Label (79-06660-000)

• Eight 1k ý end-of-line resistors

• Two 14", 18 AWG, color-coded battery leads

D9112 Assembly:

• D9112 PC board

• Faceplate shield

• Mounting Skirt

• One #6x1¦4" screw

Ordered Separately

Order the following to complete a basic 8 point D9112 installation.

• D1255 Command Center (or keyswitch)

• D1640 Transformer

• D126 Battery

• D161 or D162 Phone Cord

(order two cords if you are using the D128 Dual Phone Switcher)

• D8103, D8109, or D8108A Enclosure

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 11

© 1993 Radionics

Page 12

Listings and Approvals

Fire

UL

Underwriters Laboratories lists the D9112 Control/Communicator as a Signal System Control

Unit for:

Central Station, Local, Auxiliary, Remote Station, and Household Fire Warning.

CSFM

Approved by the California State Fire Marshal.

NYC-MEA

Approved by New York City's Materials and Equipment Acceptance System.

Factory Mutual (FM)

Submitted for evaluation by Factory Mutual.

Burglary

UL

Underwriters Laboratories lists the D9112 Control/Communicator for:

Central Station, Local, Police Connect, Mercantile Safe and Vault, and Grade A Household

systems.

Department of Defense (DOD)

The D9112 has been granted approval for Department of Defense (DOD) installations in

Sensitive Compartmented Information Facilities (SCIF).

D9112 Operation & Installation Manual

Page 1274-06144-000-C 2/96

© 1993-1996 Radionics

Page 13

Before You Begin

This

Installation

sections of the manual for detailed instructions.

Radionics recommends you review this manual and the

(74-06145-000) before you begin the installation to determine the hardware and wiring

requirements for the features you want to use.

Have the following additional documents handy as you read through this manual:

•

D9112 Program Record Training Sheet

•

Security System Owner’s Manual

•

D1255 Command Center Installation Manual

Before you begin the installation of the D9112 you should be familiar with the operation of

the D5200 programmer or the RAM II remote programmer.

Enclosure Options

Mount the D9112 Control/Communicator assembly in any of the Radionics enclosures

listed below. Refer to the

determine if your application requires a specific enclosure.

Installation

section contains a general installation procedure. It refers you to other

D9112 Program Entry Guide

(74-06447-000)

(71-06633-000)

(74-06819-000)

Installation Guide for UL and Fire Applications

in this manual to

• D8103 Universal Enclosure (gray)

• D8109 Fire Enclosure (red)

• D8108A Attack Resistant Enclosure (gray)

Beginning the Installation

Mounting the Enclosure

Mount the enclosure in the desired location. Be certain to use all five mounting holes. See

Figure 2.

POINT CHART LABEL

MOUNTING

SKIRT HOOK

MODULE MOUNTING

LOCATIONS

TAMPER SWITCH

MOUNTING LOCATION

MOUNTING

SKIRT HOOK

MODULE

MOUNTING

LOCATIONS

HOOK OPENINGS

BACK OF D9112

LOCK-DOWN TAB

74-06144-000-C 2/96

SKIRT MOUNTING HOLE

Figure 2: Enclosure Mounting

D9112 Operation & Installation Manual

Page 13

© 1993 Radionics

Page 14

Premises Wiring

Run the necessary wiring throughout the premises and pull the wires into the enclosure.

EMI (Electro Magnetic Interference) may cause problems: EMI may occur if you

install the D9112 system or run system wires near the following:

• Computer network system

• Electrical lines, fluorescent fixtures or telephone cabling

• Ham radio transmitter site

• Heavy machinery and motors

• High voltage electrical equipment or transformers

• PBX telephone system

• Public service (police, fire departments, etc.) using radio communications

• Radio station transmitter site, or other broadcast station equipment

• Welding shop

If you think that EMI may be a problem, use shielded cable. The drain wire for the

shielded cable must have continuity from terminal 10 on the D9112 to the end of the wire

run. If continuity is not maintained, the shielded cable may aggravate potential noise

problems rather than eliminate them.

Connecting the drain wire to ground at other than terminal 10 may also produce

problems. If you cut the drain wire to install devices be certain to splice it together. Solder

and tape all splices.

Installing the D9112 Assembly

1. Place the D9112 assembly over the inside back of the enclosure, aligning the large

rectangular openings of the mounting skirt with the mounting hooks of the enclosure.

Slide the D9112 down so it hangs on the hooks. See Figure 2.

2. Remove the tape from the #6x1/4" screw in the mounting tab on the D9112

assembly. The screw passes through the mounting tab and into the skirt mounting

hole in the enclosure. Tighten the screw to secure the D9112 assembly in the

enclosure.

3. Connect earth ground to the panel before making any other connections. See Connecting Earth Ground below.

Connecting Earth Ground Terminal 10

To help prevent damage from electrostatic charges or other transient electrical surges,

connect the D9112 to earth ground at terminal 10 before making any other connections.

A grounding rod or cold water pipe are recommended earth ground references.

Do not use telephone or electrical ground for the earth ground connection. Use 16

AWG wire when making the connection. Do not connect any other panel terminals to

earth ground.

D9112 Operation & Installation Manual

Page 1474-06144-000-C 2/96

© 1993-1996 Radionics

Page 15

Locking the Reset Pin

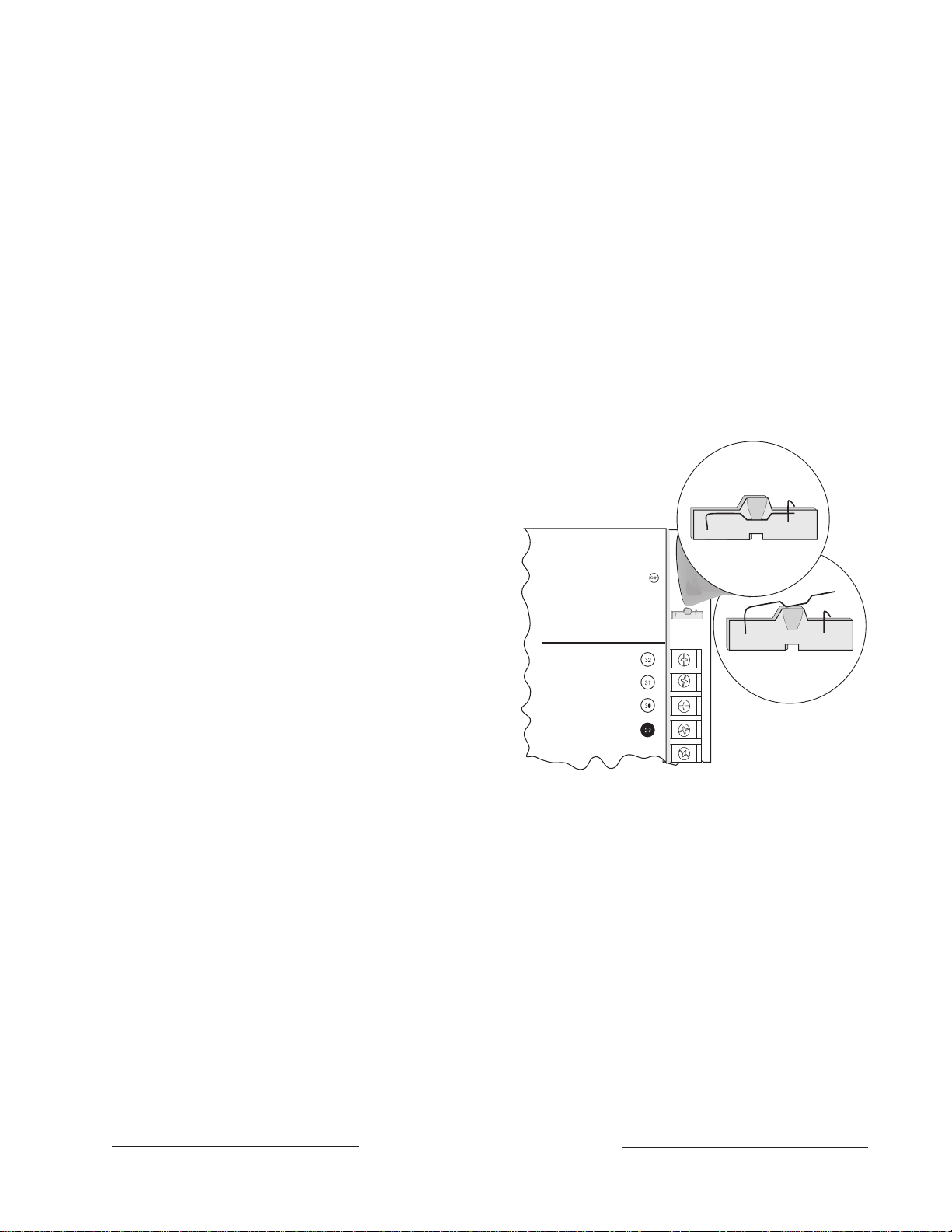

RESET PIN

LOCKED (CLOSED)

RESET PIN

NORMAL (OPEN)

Operation Monitor

Pulses When Normal

Flickers When Ringing

Reset Pin

Disable All Except Battery

Charging and Local Programming

RED POWER +

YELLOW DATA BUS A

GREEN DATA BUS B

BLACK COMMON

Locking the Reset Pin disables the panel. See Figure 3. The D9112 ignores the command

centers and points while disabled. CALL FOR SERVICE appears in command center

displays while the pin is locked down.

Existing reports transmitted with Reset Pin locked down:

Any reports that are in the

panel’s report buffer when you lock down the Reset Pin, will be transmitted. However, no

new reports can be created with the pin locked down.

To prevent buffered reports from being transmitted, momentarily close the Reset Pin, wait

for the buzzer to stop sounding, and then lock the pin down to prevent new reports from

being generated.

Locking Reset Speeds Programming:

If you have supervised command centers or

other supervised devices connected to the Data Bus (terminals 30 and 31), locking the

Reset Pin will speed communication between the panel and the D5200.

On-board relays (terminals 6, 7, and 8) and off-board relays,

deactivate when the panel is reset. There is power at

terminal 8 when the relay is deactivated. Activation

interrupts power at that terminal. The relays remain

deactivated while the Reset Pin is

locked in the disable position.

You can program the panel while it

is locked in the disable position with

either the D5200 or D5300 (RAM II)

programmers. If you place the reset

pin in the disable position with one

or more areas disarmed, there must

be an entry in the

Answer Disarmed

program item to use RAM II.

NCI

142,

347, 353

74-06144-000-C 2/96

If you place the reset pin in the

disable position when all areas are

armed, there must be an entry in the

Answer Armed

program item. See

RAM Parameters

in the

Figure 3: Reset Pin

D9112 Program Entry Guide

(74-06145-000).

Releasing the reset pin from the closed position resets the panel. The panel resets all its

timers, counters, indexes, and buffers.

Changes to some program parameters require a reset before they become

effective:

Radionics recommends that you reset the panel after changing program

parameters with the D5200 programmer. The D5300 (RAM II) programmer prompts you

for a "RESET BYE" when a program change requires that the panel be reset.

Lock the Reset Pin Now

Locking the pin in the disable position allows you to power up the panel and charge the

battery as you install the detection devices and command centers. Lock the pin down

now.

D9112 Operation & Installation Manual

Page 15

© 1993 Radionics

Page 16

Finishing the Installation

Earth ground and reset pin first: Make the earth ground connection to terminal 10 and

lock the reset pin in the closed position if you haven’t already done so.

Charge the Battery as You Finish

Connect the battery and then the transformer so that the panel can charge the battery as

you finish the installation. See the Power Supply section for instructions.

On-board Buzzer Sounds at Power Up and Reset: The D9112 performs a series of

self diagnostic tests of its hardware, software, and program at power up and at reset. The

buzzer on the D9112 sounds during the tests. They take about 10 seconds to complete.

If the panel fails any of the tests, the buzzer continues sounding and a system trouble

message appears at the command centers. See Self Diagnostics in the Trouble Shooting

section for a description of each system trouble message.

Touch Terminal 10 first: If the on-board buzzer sounds briefly when you touch the

panel, you're discharging any static charge you may be carrying to the panel. The panel

may generate WATCHDOG RESET and/or PARAM FAIL events. See the Trouble

Shooting section for a description of these events. Always touch terminal 10, the panel's

earth ground connection, before beginning work on the panel.

Install and Wire Detection Devices

Install and wire detection devices and command centers at their locations throughout the

premises. DO NOT make the connections at the panel end of the wiring yet.

The On-Board Points section of this manual contains instructions for wiring the on-board

points to detection devices. The Arming Devices section contains instructions for wiring

the command centers.

Instructions for wiring the off-board point POPIT sensor loops are found in the

instructions packaged with the POPIT modules.

Install Modules and Relays

1. Power Down First: Power down the D9112 by unplugging the transformer and

disconnecting the battery. Radionics recommends that you power down the D9112

when installing modules or relays, or when making wiring connections to the panel.

2. Install and wire any modules required for your installation as described in the

module’s installation instructions.

Instructions for the D8125 POPEX Module, the D8128A OctoPOPIT Module, the

D8129 OctoRelay Module, the D811 Arm Status Relay Module, and the D128 Dual

Phone Line Switcher appear in this manual.

See Off-board Points for D8125 and D8128A instructions. See Relays for D8129 and

D811 instructions. See Dual Line Transmitting in the Telephone Connections section

for instructions for the D128.

3. If you are using the power outputs at terminals 7 or 8, install a D136 relay in the

appropriate sockets. See Programmable Power Outputs in the Power Outputs

section for instructions.

4. If you are using a ground start phone system, insert a D136 relay in socket K6/J5 and

set the ground start pin in the ground start position. See Ground Start in the

Telephone Connections section.

D9112 Operation & Installation Manual

Page 1674-06144-000-C 2/96

© 1993-1996 Radionics

Page 17

Make the Telephone Connections

See Telephone Connections. If you are connecting the D9112 to a ground start phone

system, you need to install D136 relay, see Install Modules and Relays on the previous

page.

Connect the On-Board Points and Command Centers

Connect the on-board point and command center wiring to the D9112. See the On-Board

Points and Arming Devices sections for instructions.

Power Up

Reconnect the battery and then plug in the transformer. Remember the buzzer sounds

for 10 seconds when you first power up the panel.

Leave the reset pin locked down for now.

Yellow Charging Status LED doesn’t go out: If the yellow charging status LED doesn’t

go out within 5 minutes of powering up the panel, the battery may be deeply discharged,

or you may have connected too many powered devices to the panel. Combined

continuous current draw for terminals 3, 8, 24, and 32, the Accessory Connector (J2),

and the Expansion Port (J4) cannot exceed 1.4A. See the Power Outputs section for

help.

Programming the Panel

If you haven’t created a program for the panel, review the D9112 Program Entry Guide

(74-06145-000). Check to be certain you have all the required accessory modules

installed for the features you want to use.

Use the D5200 Programmer or the RAM II remote programmer to load your custom

program into the panel.

Move the reset pin to the normal position. See Figure 3. The panel transmits reboot and

battery reports to the receiver.

Install the Point Chart Label

Radionics recommends you fill out the Point Chart Label (79-06660-000) provided in the

literature pack and install it inside the enclosure doors for all systems.

Point chart label required for fire systems with verification points: You must install

the point chart label for fire or combined fire/burglary systems using verification points.

Use the program record sheet to gather the information you need to fill out the point

chart. Install the label on the enclosure door as shown in figure 2. To avoid smearing your

entries on the chart, use the label's peel off backing to press the label in place.

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 17

© 1993 Radionics

Page 18

Testing the System

After finishing the installation and programming of the panel, make a complete functional

test of the D9112 system. Test the panel and all devices for proper operation. Test after

you first program the panel and after any subsequent programming session.

Service Walk Test shows extra points: Use the service walk test at a panel wide

command center to perform a complete test of the panel. The service walk test function is

similar to the ordinary walk test function, with the additional ability to display points that

are not properly programmed.

If you test a POPIT with it’s switches set for a point with a blank point index and/or no

area assignment, it appears as an extra point during a Service Walk Test.

If you test a device, and the panel doesn’t respond, there may be a problem with the

device, the wiring, the POPIT ID setting, or the programming for the point. If you

incorrectly set the switches on a POPIT, you may create both a missing and extra point.

When you find a missing point, performing a service walk test for extra points may help

diagnose the problem.

See the Trouble Shooting Section of this manual for complete service walk test

instructions.

Clear after test: To clear the event memory and report buffer, momentarily close the

reset pin. Events stored in the panel's event log are not cleared.

D9112 Operation & Installation Manual

Page 1874-06144-000-C 2/96

© 1993-1996 Radionics

Page 19

Power Supply

Primary Power Terminals 1 2

Primary (AC) Power Circuit

A 16.5 VAC, 40 VA internally fused transformer (Radionics model D1640) is the primary

power source for the D9112. The AC power circuit provides 1.9 Amps of rectified AC

power. The panel reserves 500 mA of this power for internal operations leaving 1.4 Amps

for powered devices.

Transient suppressors and spark gaps protect the circuit from power surges. This

protection relies on the ground connection at terminal 10. Make sure you connect

terminal 10 to a proper ground. See Connecting Earth Ground in the Installation section.

AC Power Failure

The D9112 indicates an AC power failure when the power at terminals 1 and 2 is missing.

The AC Fail Time program item sets the number of seconds that AC must be missing

before the panel acknowledges the failure and the number of seconds after the power

returns before the panel acknowledges the restoral of power.

You can program AC Fail Time from 1 to 90 seconds. The Radionics default sets AC

Fail Time at 10 seconds.

Installing the Transformer

Do not short the terminals of the transformer: Shorting the terminals opens the

internal fuse causing permanent failure. Connect the transformer to terminals 1 and 2 of

the panel before plugging it into the power source.

Use 18 AWG (minimum) wire to connect the transformer to the panel. Wire length should

be kept as short as possible. Maximum length is 50 feet.

Connect the battery and then plug in the transformer: Radionics recommends that

you always connect the battery first and then plug in the transformer. Instructions for

Installing the Battery appear on the next page.

Only plug the transformer into an unswitched, 120 VAC, 60 Hz power outlet. Secure the

transformer to the outlet with the screw provided.

Never share the transformer with other equipment: Foreign grounds on the AC input

damage the D9112 power circuit.

AC wiring can induce both noise and low level voltage into adjacent wiring. Route phone

and sensor loop wiring away from any AC conductors, including the transformer wire.

Route data wiring away from AC and phone wiring.

D8004 Transformer Enclosure required for fire systems: Use the D8004 Transformer

Enclosure for the D1640 transformer in fire and combined fire/burglary applications.

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 19

© 1993 Radionics

Page 20

Secondary Power Terminals 4 5

Secondary (DC) Power

A 12V, 7 Ah sealed lead-acid rechargeable battery (Radionics D126) supplies secondary

power for auxiliary and alarm outputs, and powers the system during interruptions in

primary (AC) power.

Lead Acid Batteries ONLY: The D9112 charging circuit is only calibrated for lead-acid

batteries. Do not use gel-cell or nicad batteries.

Extra Batteries Increase Back-up Time: To increase battery back-up time, connect a

second 12V, 7 Ah battery in parallel to the first battery to form a 12V, 14 Ah battery. Use

a D122 Dual Battery Harness to ensure proper and safe connection. You can use the

D8132 Battery Charger Module to connect two additional batteries for a total of four. See

the D9112 Standby Battery and Current Rating Chart in this manual for battery standby

time calculations.

Installing the Battery

Place the battery upright in the base of the enclosure. Locate the red and black leads

supplied in the literature pack. Connect the black battery lead to terminal 4, and then to

the negative (-) side of the battery. Connect the red battery lead to terminal 5, and then to

the positive (+) side of the battery.

Warning, High Current Arcs Possible: The positive (red) battery lead and Terminal 5

can create high current arcs if shorted to other terminals or the enclosure. Use caution

when working with the positive lead and terminal 5. Always disconnect the positive (red)

lead from the battery before removing it from terminal 5.

Replacement

Radionics recommends battery replacement every 3 to 5 years under normal use.

Exceeding the maximum output ratings, or installing the transformer in an outlet that is

routinely switched off, causes heavy discharges. Routine heavy discharges can lead to

premature battery failure.

D8132 boosts battery backup: Adding a D8132 Battery Charger Module supports

additional batteries of up to 36 Ah capacity if required.

Warning: The transformers for the D9112 and any D8132 modules connected to it must

be powered from the same 120 VAC circuit. The D9112 supervises AC power by

monitoring the power from the transformer connected to terminals 1 and 2. It cannot

supervise the AC power for D8132 modules if their transformers are not plugged into the

same AC circuit as the transformer for the panel.

Battery Supervision

When the battery voltage drops to 13.8 VDC, the yellow Charging Status LED lights.

When the battery drops to 12.1 VDC the red Low Battery LED lights and the panel, if

programmed for power supervision, transmits a BATTERY LOW report in the Modem II

transmission format. It transmits a TROUBLE ZN 9 report in the BFSK format.

If the battery is missing or shorted, the red Low Battery LED flashes at the same rate as

the green Operation Monitor LED. If the panel is programmed for power supervision, it

transmits a BATTERY MISSING report in the Modem II transmission format, or TROUBLE

ZN 9 report in the BFSK format.

D9112 Operation & Installation Manual

Page 2074-06144-000-C 2/96

© 1993-1996 Radionics

Page 21

Battery Supervision (Continued)

When battery voltage returns to 13.7 VDC the Low Battery LED goes out. If the panel is

programmed for power supervision, it transmits a BATTERY RESTORAL report in the

Modem II transmission format or RESTORAL ZN 9 report in the BFSK format. At 13.9

VDC the Charging Status LED goes out.

Investigate low battery reports right away

discharge continues, the panel becomes inoperative when the battery voltage drops

below 10.2 VDC.

: If primary (AC) power is off and the

Battery Charging Circuit

Float Charge

The float voltage for the battery charging circuit is 13.9 VDC at a maximum current of 1.4

Amps. Deduct any continuous load for devices connected to the panel from 1.4 Amps to

find the actual current available for charging.

Load Shed Relay protects battery:

power to the security system. If the battery voltage falls below 10.2 volts during an AC

power loss, a “load shed” relay isolates the battery from the panel and disables the panel.

Load shed protects the battery from being damaged by deep discharge. When AC power

restores, the load shed relay resets and battery voltage is again available.

Reset or power down required for shorted battery:

battery is shorted, it uses the load shed relay to disconnect the battery. You must reset or

power down the panel after correcting the problem to reset the load shed relay and

reconnect the battery.

Reset the panel by momentarily placing the reset pin in the disable position. See Figure

3. The red Low Battery LED continues to flash until you reset the panel.

During an AC power loss the battery supplies all

If the D9112 determines the

Battery Discharge/Recharge Schedule (No AC Power)

74-06144-000-C 2/96

A shorted battery condition is created either by a shorted cell inside the battery or by a

short on terminals 4 and 5. A shorted battery may generate WATCHDOG RESET

reports.

Discharge Cycle

AC OFF AC fail report when AC fails if panel is programmed to report AC failure at

occurrence.

13.9 VDC Charging float level

13.8 VDC Charging Status LED on

12.1 VDC Low Battery & AC fail reports if programmed; Low Battery LED on

10.2 VDC Battery load shed (processing functions continue if AC is present)

Recharge Cycle

AC ON Load shed relay resets, battery charging begins, battery trouble and

AC restoral reports sent.

13.7 VDC Battery restoral reports sent, Low Battery LED off

13.9 VDC Charging Status LED off, battery float charged

D9112 Operation & Installation Manual

Page 21

© 1993 Radionics

Page 22

Charging Status and Low Battery LEDs

Low Battery

LEDs Off When Normal

YEL

RED

Charging Status

Charging Status LED (Yellow)

The yellow LED shows the charging status

of the battery. Figure 4 shows its location.

• Yellow LED off

The yellow LED is off when the battery is

fully charged.

LED off when battery is missing,

shorted, or reversed:

is off when the battery is missing,

shorted, or reversed, but the red Low

Battery LED is flashing.

• Yellow LED on

A steadily lit yellow LED indicates the

battery float voltage is below 13.8. If AC

is present the battery is charging.

The yellow LED also comes on when the combined current draw from all outputs

exceeds 1.4 Amps. This is normal under alarm conditions for non-fire systems when

sirens or bells draw more than 1.4 Amps. If the LED comes on regularly for extended

periods or doesn’t go out, check the current draw for devices connected to the power

outputs. See the

• Yellow LED flashing once per minute

The yellow LED normally flashes once per minute as the D9112 checks the battery.

• Yellow and red LEDs flashing once per minute

The yellow and red LEDs flash on once every minute when current draw for devices

connected to the power outputs exceeds 1.4 Amps and the battery is missing.

The charging LED

Power Outputs

section in this manual for instructions.

Figure 4: Charging and Battery LEDs

74-06144-000-C 2/96

Low Battery LED (Red)

The red LED shows the condition of the battery. Figure 4 shows the location of the LED.

• Red LED off

The red LED is off when the battery is fully charged. When battery voltage drops below

12.1 VDC, the red LED comes on. It goes out when battery voltage reaches 13.7 VDC.

• Red LED on

A steadily lit red LED indicates battery voltage has fallen below 12.1 VDC. The LED

goes out when battery voltage reaches 13.7 VDC.

• Red LED flashing (same rate as green LED)

The red LED flashes with the green Operation Monitor LED when the battery is

missing or shorted.

Reset required for shorted battery:

battery remains disconnected and the red Low Battery LED continues to flash until you

reset the panel.

No missing battery with D192A

from recognizing a missing battery condition.

• Red and yellow LEDs flashing once per minute

The yellow and red LEDs flash once every minute when current draw for devices

connected to the power outputs exceeds 1.4 Amps and the battery is missing.

D9112 Operation & Installation Manual

Page 22

If the D9112 detects a shorted battery, the

Using a D192A with a D9112, prevents the D9112

© 1993-1996 Radionics

Page 23

Circuit Protection

Three self-resetting thermal circuit breakers protect the panel from short circuits on both

the continuous and programmable power outputs. The circuit breakers are thermal rated

and open at 3 to 5 Amps. If the panel is programmed for power supervision and short is

sustained on one of the power outputs, the panel transmits a BATTERY LOW or

BATTERY MISSING for Modem II, or TROUBLE ZN 9 for BFSK.

One thermal circuit breaker protects Terminal 3 - Auxiliary Power and Terminal 24 ZONEX Power and the Expansion Port (J4). A short on one disrupts the power to the

others.

One breaker protects Terminal 6 - Alarm Power Output, Terminal 7 - Alternate Alarm

Power Output, and Terminal 8 - Switched Auxiliary Power. A short on one of these

terminals disrupts the power to the other two.

One circuit breaker protects terminal 32 - Power +.

Power Outputs

Warning, Minimum Requirement for Wire Length:

terminals 3, 6, 7, 8, 24, and 32 with at least 5 feet of 22 AWG wire or 14 feet of 18 AWG

wire. A D9112, with devices connected with shorter lengths of wire, may not operate

properly if AC power is interrupted.

Available Power

The D9112 produces up to 1.4A of power at 10.2 VDC to 13.9 VDC for powered devices.

The outputs listed below share the available power.

Terminal 3 - Auxiliary Power

Use this terminal to power devices requiring continuous power.

Terminal 6 (Relay A) - Alarm Power Output

Terminal 7 (Relay B) - Alternate Alarm Power Output

Use terminals 6 and 7 to power devices requiring power on alarm. See

Power Outputs.

Terminal 8 (Relay C) - Switched Auxiliary Power

Use this terminal to power devices requiring a programmable power interruption.

Command 47 or Alarm Verification interrupts the power . See

Outputs

Terminal 24 - ZONEX Power

Use this terminal to power ZONEX modules such as the D8125, D8128A, and D8129

modules.

Terminal 32 - Power +

Use this terminal to power SDI (Serial Device Interface) devices such as the D1255

Command Center and the D9131 Parallel Printer Interface.

Connect powered devices to

Programmable

Programmable Power

in this manual.

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 23

© 1993 Radionics

Page 24

Available Power (Continued)

Accessory Connector (J2)

The D128 Dual Phone Line Switcher connects to J2.

Expansion Port (J4)

The Expansion Port is reserved for future use.

Continuous Power Outputs Terminals 3 24 32

J2 J4

Continuous Current Draw

The continuous current draw for powered devices connected to terminals 3, 8, 24, and

32, the Expansion Port (J4), and the Accessory Connector (J2) must not exceed 1.4A .

Devices powered from these outputs must operate over a range of 10.2 VDC to 13.9

VDC.

Power restricted for fire and combined fire/burglary systems:

Power Formula

systems. See

to calculate the current available for fire and combined fire/burglary

Programmable Power Outputs

.

Use the

Fire System

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 24

© 1993-1996 Radionics

Page 25

Programmable Power Outputs Terminals 6 7 8

J1

J9

Programming

The power outputs at terminals 6, 7, and 8 are programmed as relays A, B, and C. All

relays are programmed in the

relay type, Fire Bell for example, when they are assigned to an area. Relays can be

assigned to one or more areas.

The Radionics defaults set relay A (terminal 6) as an Alarm Bell output, relay B (terminal

7) as a Fire Bell output, and relay C (terminal 8) as a Verification/Reset output. The

D9112 Program Entry Guide

programming relays. Descriptions of the functional characteristics of each terminal

appear on the next page.

Relays

module of the program. Relays are assigned a

(74-06145-000) contains complete instructions for

See the

Bell Parameters

section of the program to set the Fire Bell, Alarm Bell output

responses for relays. Four annunciation patterns: Steady, Pulsed, California Standard,

and Temporal Code 3 are available.

Unexpected Output at Terminals 6, 7 and 8:

If terminals 6, 7, and 8 don’t provide the

output you expect:

• Check the programming for relays A, B, and C in the

• Check the

Bell Parameters

section of the program to verify the Alarm and Fire Bell

Relays

module of the program.

responses are programmed for the duration and pattern you expect.

• Check the

Point Assignments

to verify each point is programmed for the local

response you expect.

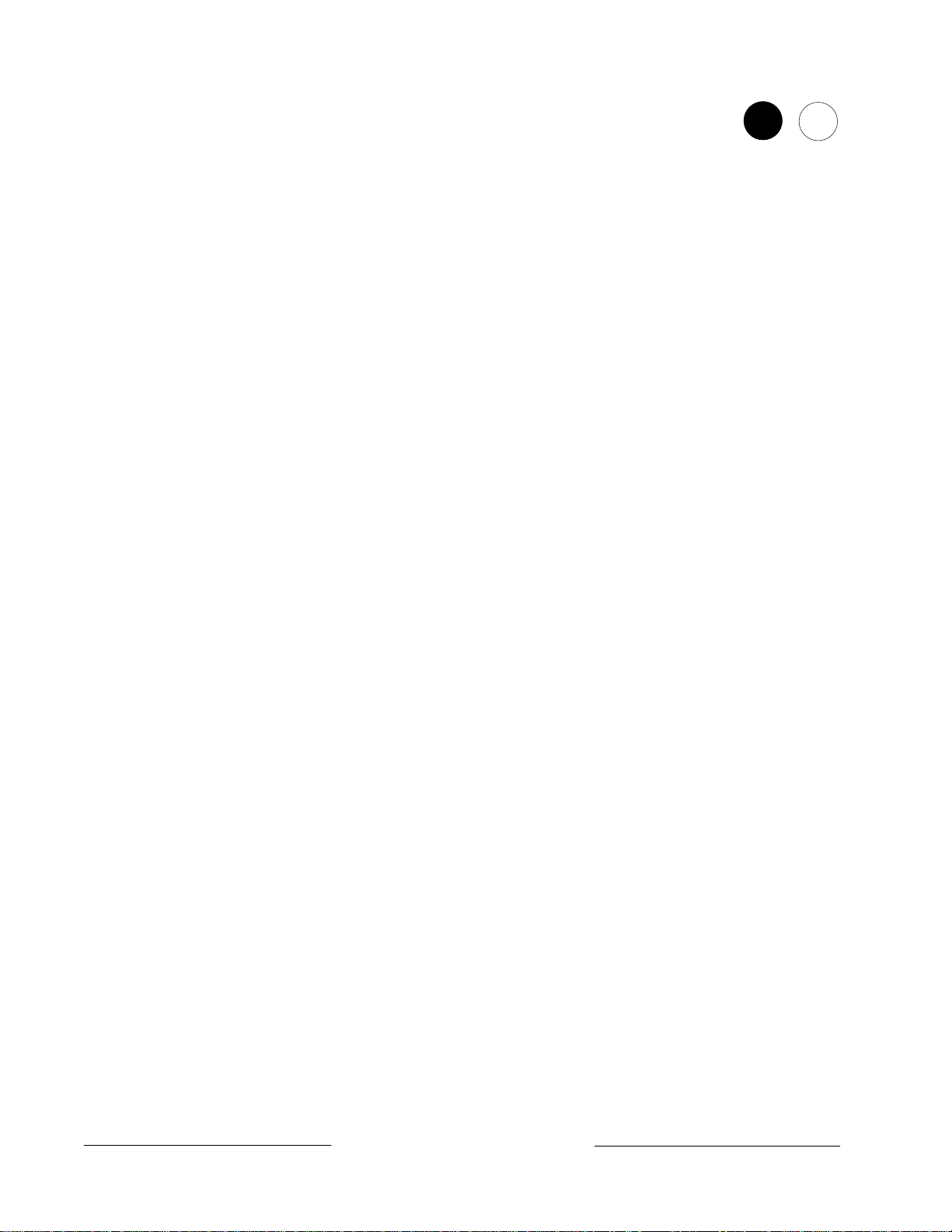

Optional Relays Required

Install an optional D136 plug-in relay into socket J1 to enable the output at terminal 7.

Install a D136 in socket J9 to enable the output at terminal 8. The relay sockets are under

the faceplate as shown in Figure 5.

Relay Installation

Power down the D9112 before

inserting the D136 relays. The plug-

M

in relays are shorter than the

sockets they plug into. See Figure

5. You can install them in either the

left or right end of the socket.

Aromat

DS2E-M-DC12V

M

Aromat

DS2E-M-DC12V

K6

74-06144-000-C 2/96

Don’t rely on relay labelling:

You shouldn’t rely on the labelling

to install D136 relays. Check for the

side with three pins. The three pins

go on the top side.

Incorrect insertion does not

damage the relay or the D9112,

however the related circuits do not

function properly.

D9112 Operation & Installation Manual

Page 25

J1

J9

M

Aromat

DS2E-M-DC12V

GND START

Figure 5: Relays for Terminals 7 and 8

© 1993 Radionics

Page 26

Terminals 6 and 7

Terminals 6 (relay A) and 7 (relay B), provide positive (+) 10.2 VDC to 13.9 VDC power

output when activated. Use the power at terminals 6 and 7 to power bells, siren drivers,

piezo fire sounders, electronic horns, or other devices. Programming determines the

format of the output and the conditions that activate it. One self-resetting circuit breaker

protects terminals 6, 7, and 8 against shorts.

Available Power

The D9112 combines the 1.4A of primary power produced by the power supply with the

secondary power source (the battery) to produce a total of 2.0A of alarm power at 10.2 to

13.9 VDC. Terminals 6 and 7 share the available alarm power.

Power restricted for fire and combined fire/burglary systems:

Power Formula

systems.

below to calculate the current available for fire and combined fire/burglary

Use the

Fire System

Fire System Power Formula

To calculate the current available at terminals 6 and 7 for fire and combined fire/burglary

systems:

1. Add together the current draws for all devices connected to terminals 3, 8, 24, and

32, the Expansion Port (J4), and the Accessory Connect (J2). This total is the total

current required for the Normal Standby Condition (NSC).

2. The current available for Normal Standby Condition (NSC) for the D9112 is 1.4A.

Subtract the NSC current required calculated in step 1 from the NSC current

available, 1.4A. The difference is the Alarm Current available for terminals 6 and 7.

In formula format:

NSC current available – NSC current required = Alarm Current available

Terminal 8

Terminal 8 provides continuous positive (+) 10.2 VDC to 13.9 VDC power. Relay C

interrupts the power at terminal 8 when activated. Use terminal 8 to power smoke

detectors or other devices that are reset by interrupting power. One self-resetting circuit

breaker protects terminals 6, 7, and 8 against shorts.

74-06144-000-C 2/96

Verification/Reset Relay

The D9112 default program sets relay C (terminal 8) as a verification/reset relay. See the

Relay Parameters

(74-06145-000) for instructions on programming verification/reset relays and points.

Performing a CMD 47 at a command center produces a 5 second relay activation of

verification/reset relays. The panel ignores verification/reset points during the 5 seconds

of relay activation.

and

Point Assignments

D9112 Operation & Installation Manual

Page 26

modules in the D9112 Program Entry Guide

© 1993-1996 Radionics

Page 27

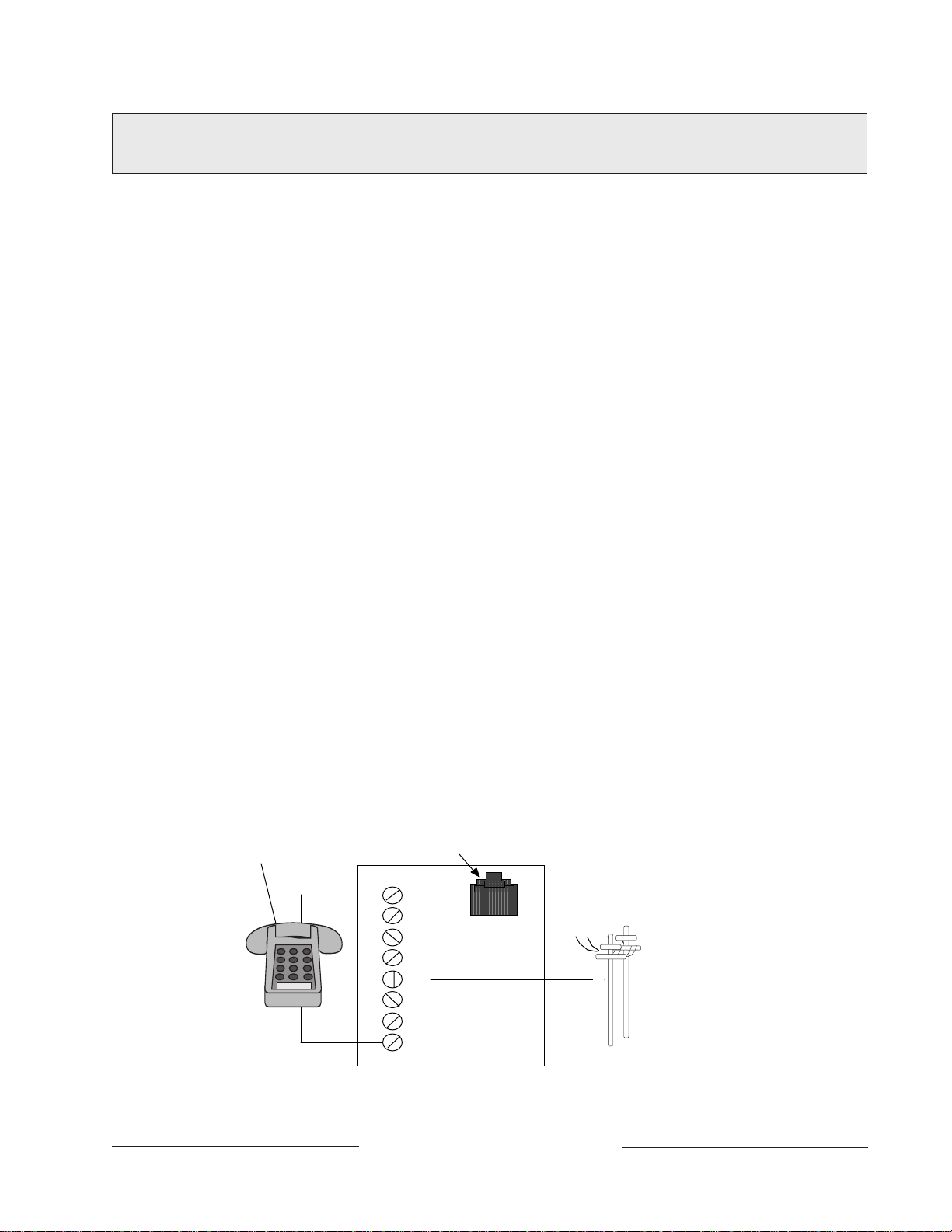

Registration

PREMISES

E

Notification

Telephone Connections

The Radionics D9112 Control/Communicator panel is registered with the Federal

Communication Commission under part 68, for connection to the public telephone system

using an RJ31X jack installed by your local phone company.

FCC Registration Number: AJ9USA-18808-AL-E

Ringer Equivalence: 0.1A 0.2B

Do not connect registered equipment to party lines or coin-operated telephones. You

must notify the local telephone company and supply them with the following information

before connecting the panel to the telephone network.

• The particular line you are going to connect the panel to

• Make (Radionics), model (D9112), and serial number of the panel

Location

• FCC registration number and ringer equivalence for the panel (see

above)

To prevent jamming of signals, wire the RJ31X jack before the in-house phone system to

support line seizure. See Figure 6. Install the jack on the street side of the phone switch,

wired ahead of any PBX equipment. Line seizure provides for a temporary interruption of

normal phone usage while the communicator transmits data. After installation, confirm

that the panel seizes the line, acquires dial tone, reports correctly to the receiver, and

releases the phone line to the in-house phone system.

PHONE

FULL MODULAR PHONE JACK

R1

1

Registration

2

3

R

T

INCOMING

TELCO LIN

%

4

5

6

T1

7

8

74-06144-000-C 2/96

RJ31X MODULE

Figure 6: RJ31X Wiring

D9112 Operation & Installation Manual

Page 27

© 1993 Radionics

Page 28

Phone Cord Connection

Connect one end of a D161 (8') or D162 (2') Telephone Cord to the D9112 TELCO Cord

connector, J3, located on the bottom left corner of the D9112. See Figure 7. Connect the

other end to the RJ31X jack.

Phone LED (Red)

The red Phone LED lights when the panel seizes the phone line and remains lit until the

panel returns the phone line. See Figure 7 for the location of the red LED.

Operation Monitor LED (Green)

The green LED indicates the operation of the CPU (Central Processing Unit). When the

CPU is operating normally, the LED flashes 0.5 second on, 0.5 second off.

The green LED also serves as a ring indicator. See Figure 7 for the location of the LED.

When there is ring voltage on the phone line (the phone is ringing), the green LED

flickers at a faster rate for the duration of each ring. Ring voltage must reach a minimum

of 45 VAC before the D9112 detects it.

Dialing Format

You can program the D9112 to use DTMF or pulse dialing. See

D9112 Program Entry Guide

Phone Line Monitor

The D9112 panel has a built-in phone line monitor that tests the phone line for voltage

and current. If you use the D128 Dual Phone Line Switcher to connect 2 phone lines to

the D9112, the panel monitors both lines. The normal voltage on a telephone line is

approximately 48 VDC (24 VDC for some phone systems). The phone line monitor

senses trouble when the voltage on the line falls below 4.5 to 7.5 VDC, without a

corresponding current increase to 8 to 13 mA.

If the monitor senses trouble, it starts a programmable phone line trouble timer. The timer

continues to run as long as the monitor senses trouble. It resets to zero when the panel

senses a normal line. If the timer reaches the delay time in the

program item, it begins a phone line trouble response. Programming determines what the

response is. See

NCI

#221

The panel stops monitoring the phone line during its phone line trouble response. If the

response includes sending a report, the panel does not resume monitoring until the report

is acknowledged or it goes into communication failure.

Bad line may test OK:

test the status of the phone line. In some instances a given telephone line may be out of

service without affecting the voltage on the line. The phone line monitor can not

recognize this trouble condition.

Phone Parameters

(74-06145-000).

Phone Supervision

Phone Parameters

The telephone line monitor uses voltage and current levels to

in the

D9112 Program Entry Guide

(74-06145-000)

in the

.

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 28

© 1993-1996 Radionics

Page 29

Phone Line Test Points

EARTH GROUND

COMMON

LINE SNIFFER SELECT

Loop Start

Ground Start

TELCO CORD

MODEL No. D161

PHONE

LED

ON WHEN

COMMUNICATING

OFF WHEN IDLE

Requires

Optional Relay

Model No. D136

Operation Monitor

Pulses When Normal

Flickers When Ringing

Solid When Held In Reset

32

31

30

+

25

27

28

RED

GROUND

START

YEL

RED

RADIONICS D9112

23

29

26

Reset Pin

Disable All Except Battery

Charging And Local Programming

GRN

+

+

+

24

Also Suitable for Supplementary and Supervisory Electrically Actuated Transmitter Use

ALL TERMINALS EXCEPT #5 (BATTERY POSITIVE) POWER LIMITED

See 73-06143-000 for Compatible Smoke Detectors

12 15 18 211311 14 16 17 19 20 22

3

5

6

7

8

9

10

1

4

2

OPERATION

MONITOR LED

(GREEN)

M

Aromat

DS2E-M-DC12V

You can attach a telephone test set to

the D9112 at the TELTEST points

located above the TELCO jack on the

lower left corner of the panel. See

Figure 7.

Communication Failure

After 10 attempts to reach the

receiver, the panel goes into

communication failure. The

panel clears any reports in its

phone buffer. SERVC COMM

FAIL appears in the display at

command centers.

If you use the D128 Dual Phone Line

Switcher, the D9112 makes 10 attempts on each line before going into communication

failure.

Pressing Command 4 silences the tone. When communication restores (a report is

acknowledged by the receiver), the display clears automatically. See

in the

D9112 Program Entry Guide

PHONE LINE

MONITOR SELECT

JUMPER

PHONE LINE

TELCO CORD

CONNECTOR (J3)

TEST POINTS

M

M

GROUND START

RELAY (J5)

PHONE LED

(RED)

Figure 7: Telephone Connections

Phone Parameters

(74-06145-000) for reporting options

.

Ground Start

74-06144-000-C 2/96

Some telephone systems require a momentary ground input to initiate dial tone. To

interface with a ground start system, insert a plug-in relay (D136) into socket K6/J5 and

set the ground start jumper in the GND START position. Terminal 10 must be connected

to an earth ground reference.

Relay Installation

Power down the D9112 before inserting the D136 relay into socket K6/J5. The relay

socket is in the lower left corner as shown in Figure 8. The plug-in relay is shorter than

the socket it plugs into. You can install it in either the left or right end of the socket.

Don’t rely on relay labeling:

relays. Check for the side with three pins. The three pins go on the top

side.

Incorrect insertion does not damage the

relay or the D9112, however the

related circuits do not function

properly. A ground start relay must

not be inserted when dialing loop

start.

D9112 Operation & Installation Manual

You shouldn’t rely on the labelling to install D136

GROUND START RELAY

Figure 8: Ground Start Relay

Page 29

© 1993 Radionics

Page 30

LINE SNIFFER SELECT

8

9

10

RED

GROUND

START

EARTH GROUND

COMMON

Ground Start

Loop Start

TELCO CORD

MODEL No. D161

Requires

Optional Relay

Model No. D136

M

LOOP START

POSITION

Ground Start Jumper

The ground start jumper is above the TELCO

connector and TELTEST point at the lower left

corner of the panel. Set it in the ground start

position. See Figure 9.

GROUND START

POSITION

Figure 9: Ground Start Jumper

Ground start not for use in NFPA applications:

telephone systems for NFPA 71 Central Station Protective Signaling or NFPA 72 (Chap.

8) Remote Station applications.

D128 Dual Phone Line Switcher

Description

The optional D128 Dual Phone Line Switcher allows the D9112 to transmit reports over a

primary or secondary phone line. The D9112 monitors both phone lines. You can hear a

relay click as the D128 switches between the two phone lines.

Do NOT use the instructions packaged with the D128:

D128 Dual Phone Line Switcher does not include complete instructions for connecting

the module to the D9112 panel. Use the instructions that follow.

Set the ring count above 2 on answering machines:

feature may not operate correctly if you connect an answering machine with a ring count

of less than 2 rings, to a phone line used by the D128 module.

Operation

The D9112 always uses the primary phone line to initiate phone calls, unless it has been

detected as faulty. See

D9112’s phone line monitor operation.

Phone Line Monitor

You can not use ground start

The manual packaged with the

The D9112's RAM Monitor

in this manual for a description of the

74-06144-000-C 2/96

See the

Entry Guide

the

Phone

(74-06145-000) for phone supervision and reporting options. You must set

Two Phone Lines

section of the

Panel Wide Parameters

prompt to YES to use the D128.

D9112 Operation & Installation Manual

Page 30

module of the

D9112 Program

© 1993-1996 Radionics

Page 31

Primary Phone Lines, Primary Phone Numbers

Don’t confuse primary phone lines with primary phone numbers:

Dual Phone Line Switcher installed, the D9112 uses two phone lines, primary and

secondary, to dial up to four phone numbers.

With the D128

These four phone numbers are designated as primary, backup, or duplicate. See

Routing

06145-000) for a description of these designations.

The D128 uses the primary or secondary phone line to dial a primary, secondary, or

backup phone number. After two failed attempts to reach the receiver on the primary

phone line, the D9112 switches to the secondary line.

It alternates between the two phone lines, making two attempts on each line, until it

makes ten attempts on each line. After ten failed attempts on each phone line, the

D9112 goes into communication failure. See

in the

Panel Wide Parameters

module of the

D9112 Program Entry Guide

Communication Failure

in this section.

Watchdog Feature

The D128 Watchdog circuit monitors the D9112’s CPU (Central Processing Unit) for

proper operation. If the CPU fails, the buzzer on the D128 sounds in addition to the

sounder on the D9112. The D128 only stops sounding when the D9112’s CPU begins

operating normally.

Installing the D128

1. Mount the D128 on the lower right side of the enclosure using the screws provided

with the switcher. See Figure 2.

2. Connect the green lead from the D128 to terminal 1 on the D9112.

3. Connect the black lead from the D128 to terminal 9 on the D9112.

4. Plug one end of the ribbon cable provided with the D128 into J4 on the D128. Plug

the other end into J2 (ACCESSORY) on the D9112.

5. Plug one end of the D162 (2') phone cord provided with the D128 into J3 on the

D128. Plug the other end into J3 (TELCO) on the D9112.

6. Plug one end of a D161 (8') or D162 (2') phone cord into J1 on the D128. Plug the

other end into the RJ31X for the primary phone line.

7. Plug one end of a D161 or D162 phone cord into J2 on the D128. Plug the other end

into the RJ31X for the secondary phone line.

Phone

(74-

74-06144-000-C 2/96

D9112 Operation & Installation Manual

Page 31

© 1993 Radionics

Page 32

D128 Status LEDs

Four LEDs mounted on the front edge of the D128 module show the status of AC power

for the D9112, the status of the two phone lines, and communication failure. See Figure

10.

AC Power LED

The green AC power status LED lights when there is AC power at terminals 1 and 2 on

the D9112 panel.

Primary Fail LED

The yellow Primary Fail LED lights when the D9112’s phone line monitor determines the

primary phone line is faulted. See

phone line monitor operation.

Secondary Fail LED

The yellow Secondary Fail LED lights when the D9112’s phone line monitor determines

the secondary phone line is faulted. See

description of phone line monitor operation.

Communication Failure LED

The yellow Communication Failure LED lights when the D9112 is in communication

failure. See

Communication Failure

Phone Line Monitor

Phone Line Monitor

in this section.

in this section for a description of

in this section for a

CONNECT TO D91 12 ACCESSORY

CONNECTOR (J2) WITH RIBBON CABLE

PHONE JACK TO PRIMARY

PHONE LINE - RJ31X

PHONE JACK TO SECONDARY

PHONE LINE - RJ31X

PHONE JACK TO D9112 TELCO

CONNECTOR (J3)

GREEN ÊÑ TO D9112

TERMINAL 1

BLK ÊÑ TO D9112

TERMINAL 9

AC POWER

LED

(GREEN)

PRIMARY

FAIL LED

(YELLOW)

SECONDARY

FAIL LED

(YELLOW)

COMMUNICATIONS

FAILURE LED

(YELLOW)

74-06144-000-C 2/96

Figure 10: D128 Dual Phone Line Switcher

D9112 Operation & Installation Manual

Page 32

© 1993-1996 Radionics

Page 33

On-Board Points

Description Terminals 11 to 22

The D9112 panel provides eight on-board points. Each point functions independently and

does not interfere with the operation of the others. The panel monitors the sensor loops

for normal, shorted, or open conditions between an input terminal (11, 13, 14, 16, 17, 19,

20, or 22) and any of the point common terminals (12, 15, 18, and 21). Programming for

the point determines how the panel responds to those conditions. See the

Program Entry Guide (74-06145-000)

Point Sensor Loops

When wiring the on-board points, install a 1k ý resistor at the far end of the sensor loop

to provide a reference for supervision. You can connect dry contact sensing devices in

series (normally-closed) and/or in parallel (normally-open) to any of these loops.

The number normally-open and/or normally-closed detection devices each sensor loop

can supervise is limited only by the resistance on the loop. Resistance on each sensor

loop must be less than 100ý with the detection devices connected.

for point programming options.

D9112

Ground shunts cause missed alarms:

The possibility of “ground shunts” increases

significantly if you don’t install the resistor at the end of the line. If you install the resistor

for points 1 to 8 before a detection device on the sensor loop and the loop becomes

grounded after the resistor, any devices beyond the ground are “ground shunted”. Alarm

or trouble conditions beyond the ground are not seen by the panel.

POINT INPUT

TERMINAL

1K Ω

COMMON

POINT INPUT

TERMINAL

COMMON

POINT INPUT