Bontrager 231793 User Manual

HUB INSTRUCTIONS

PART NUMBER 231793 SERVICE MANUAL 2003

HUB INSTRUCTIONS

STANDARD

Front Hubs

Loose ball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Loose ball, semi-cartridge; Formula FCM . . . . . . .4-5

Cartridge bearing, alloy axle . . . . . . . . . . . . . . . . .6-7

Cartridge bearing, threaded alloy axle . . . . . . . . . .8-9

Rear hubs

Freehub body information (non-DT Swiss) . . . . . . . 11

Loose ball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Loose ball, double sealed (Formula FCM) . . . . . .14-15

Cartridge bearing . . . . . . . . . . . . . . . . . . . . . . . . .16-17

DT-SWISS

Comp series hubs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Comp front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-21

Comp rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-24

Pro series hubs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pro front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-27

Pro rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-31

Please note: Many sections of this manual must be

read in their entirety before performing procedures.

In some cases, revised or updated information may

be available on the Bontrager wheelworks website at

www.bontrager.com.

If you cannot find the information you need to service

Bontrager wheels, please contact a technical service

representative.

Copyright Trek Bicycle Corporation 2002

All rights reserved

2003 Bontrager Service Manual

1

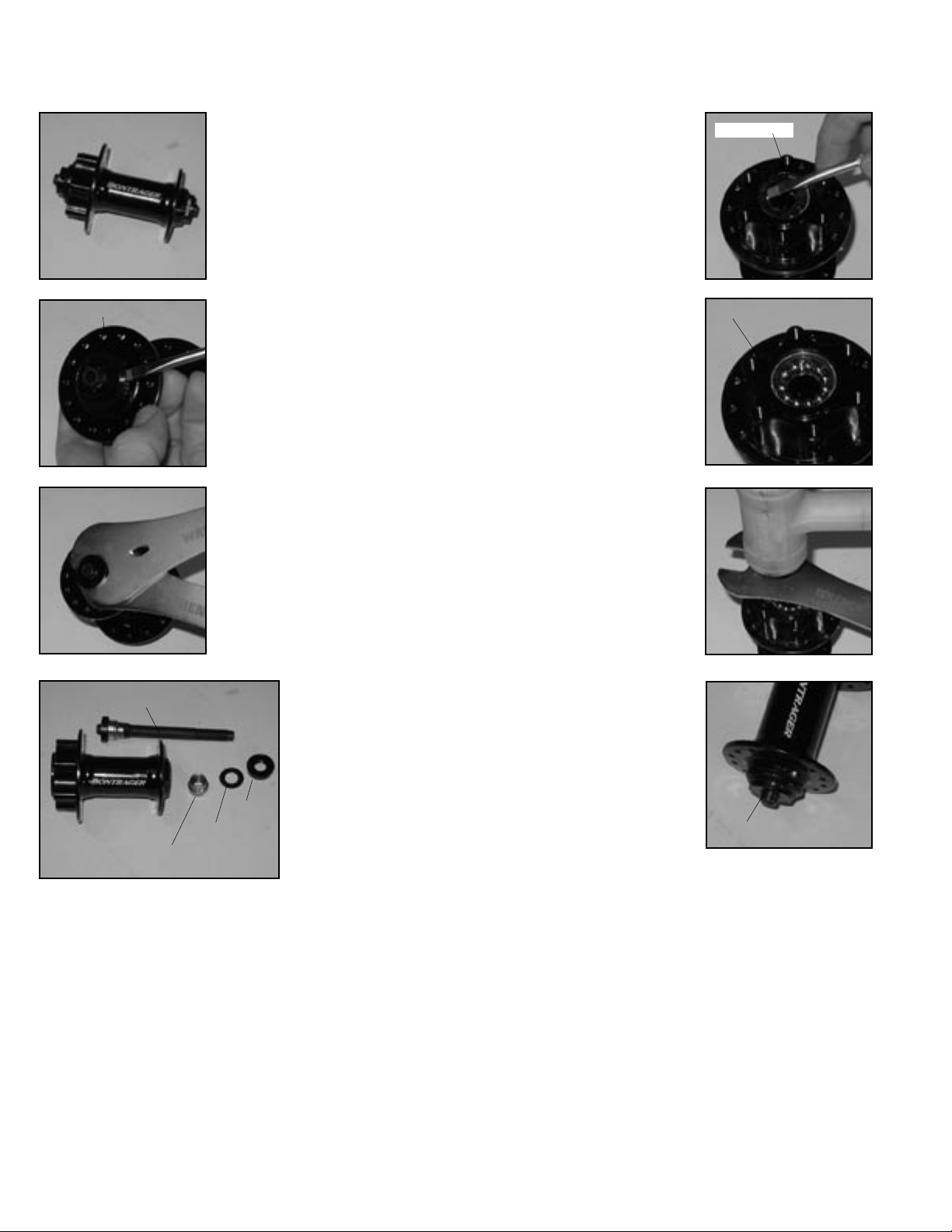

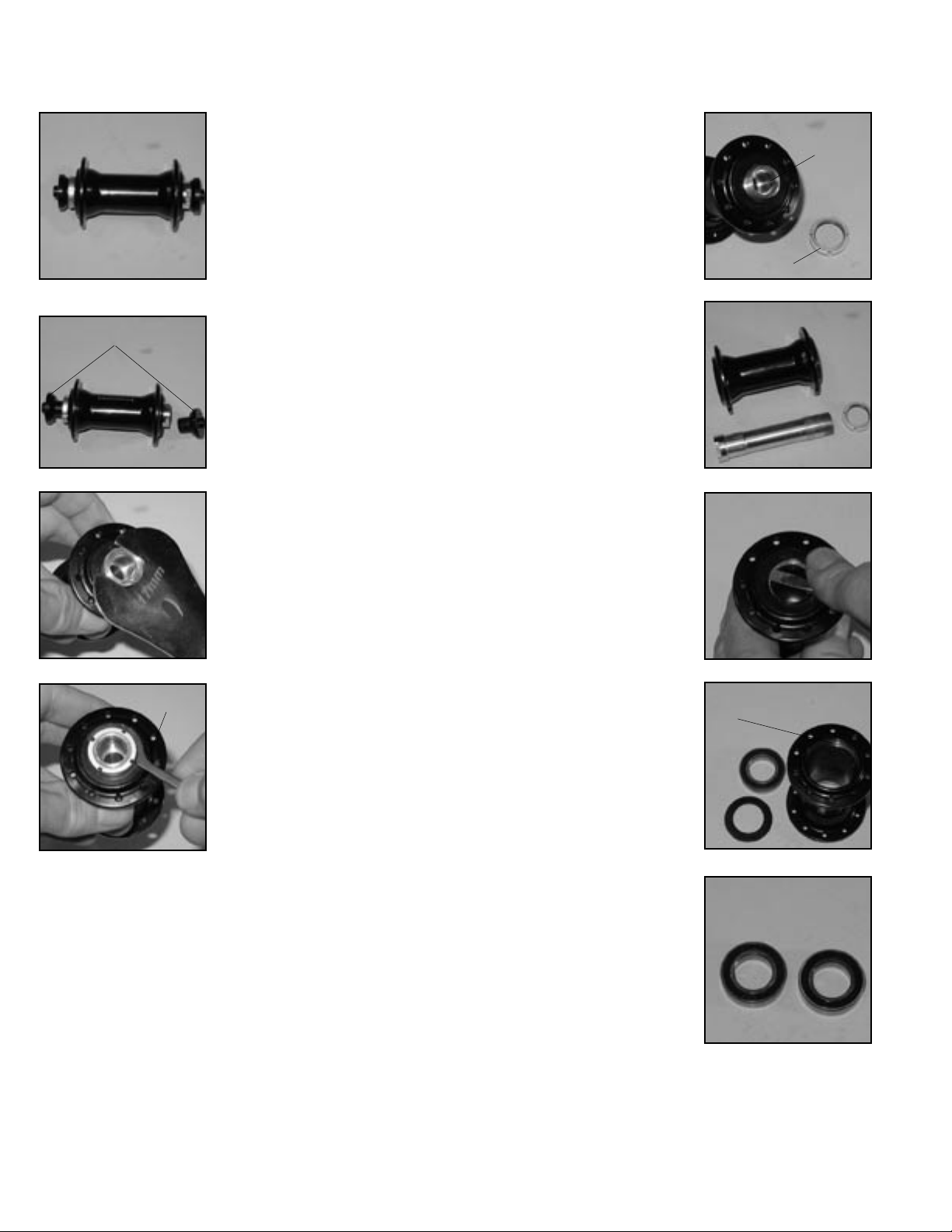

Front hubs- Loose ball

Bontrager Superstock, Superstock Disc, Select ATB, Select ATB Disc, Select Road, and Select Hybrid front wheels;

plus Bontrager Comp II front hub

Recommended tools

13mm cone wrench

17mm cone wrench

Small slot screwdriver

Hammer (soft faced)

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

Fig. 1A

External seal

Fig. 2A

Fig. 3A

Axle

Ball cone

Fig. 4A

Clean and inspect the parts

1. Use solvent to completely remove all old grease and

debris from the hub, axle, and axle parts.

2. Inspect the bearing running surfaces of both the

ball cones and the ball cups (inside the hub). Replace any

cones. If the cups are worn, replace the hub shell.

1. Remove external seals

(Fig. 2A) with a screwdriver. Be

careful not to tear or mar the

rubber.

2. On one side (either) of the

hub place a 13mm cone wrench

on the ball cone. Place a 17mm

cone wrench on the end nut (Fig.

3A). Loosen the end nut.

3. Remove the end nut,

washer, and ball cone from the

axle (Fig. 4A).

4. Slide the axle, with the

other end nut, washer, and ball

cone still attached, out of the

hub (Fig. 4A).

5. Gently insert a thin

screwdriver blade under the

shell shield (Fig. 5A) and lift to

remove the shield from the hub.

Pry off the shell shields from

both sides of the hub.

6. If inspection

shows it necessary,

remove the other end

nut and ball cone.

End nut

Washer

ASSEMBLY

Shell shield

1. Place eleven 3/16” balls in

the ball cup on one side of the hub.

2. Place the shell shield, with

its sharp edges facing out (Fig.

6A), into the hub. The shell shield

is a press fit, so must be tapped

lightly to fully seat. Lay a cone

wrench over the shell shield and

tap the wrench with a hammer

(Fig. 7A) to protect the shield

and ensure that it is flush with

Bearings in bearing cup

the shell.

3. Repeat Assembly steps 1-2

for the other side of the hub.

4. Tighten the end nut

against the ball cone on the axle.

Hold the ball cone with a 13mm

cone wrench on the axle flats

while turning the end nut with a

17mm cone wrench.

5. Insert the axle through the

hub from either side.

6. Thread the ball cone, washer, and end nut onto the axle in

that order. The serrated surface

of the end nut faces out.

7. Hold the ball cone with a

13mm cone wrench and tighten

the end nut with a 17mm cone

wrench.

8. Check the bearing adjustment by turning the axle with

your fingers. The axle should

spin smoothly without binding or

feeling gritty. There should be no

lateral play of the axle in the hub.

Readjust the hub as necessary,

and re-lock the end nut.

9. Install the external seals,

and apply grease where the seals

Seal not seated

contact the hub shell and axle

parts. Make sure the seals properly seal against both the end nut and the hub shell. There

should be a smooth transition from seal to sealing surface.

An improperly installed seal (Fig. 8A) will allow rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Fig. 5A

Fig. 6A

Fig. 7A

Fig. 8A

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Place a bead of grease all the way around each ball

cup, sufficient to hold the balls.

2

2003 Bontrager Service Manual

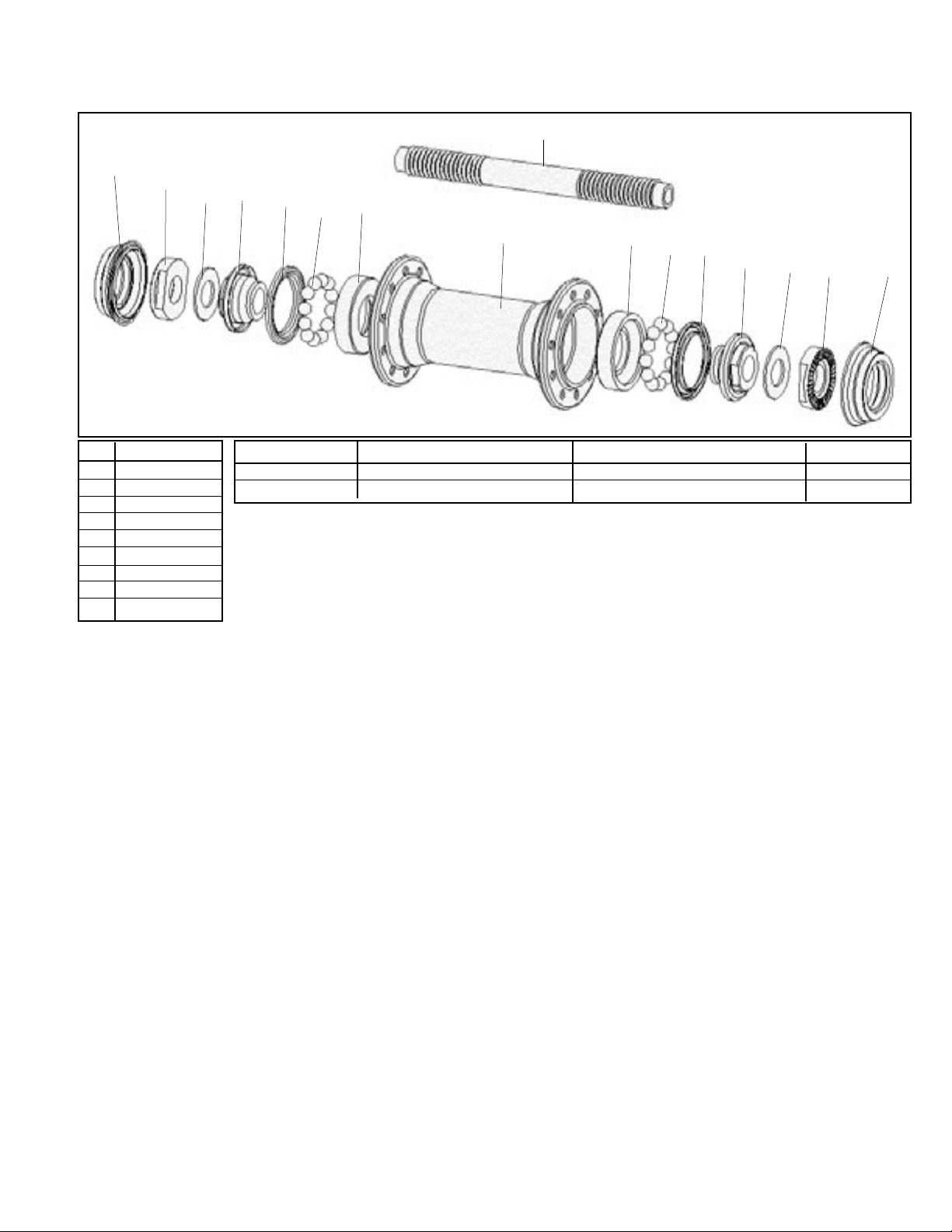

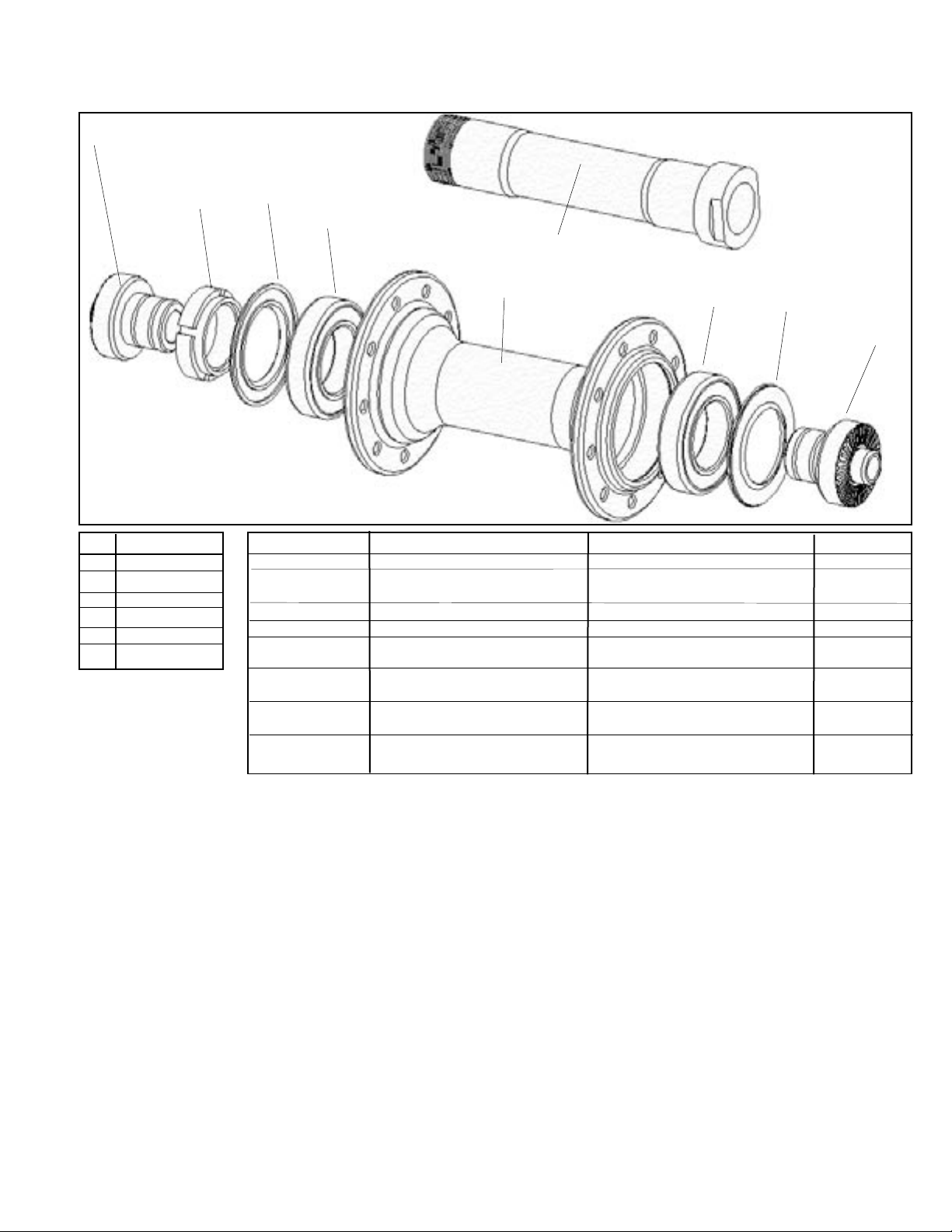

Exploded view and Parts list

9

1

2

4

3

5

7

6

8

7

6

5

4

3

2

1

Pos Description

1 External seal

2 End nut

Description Model year Model for Parts included (qty) TCG Part #

Axle set 99/00/01/02 all 1(2), 4(2), 3(2), 9 68257

Locknut set 99/00/01/02 all 2(2) 68543

3 Washer

4 Ball cone

5 Shell shield

6 Ball bearings

7 Ball cup

8 Hub shell

9 Axle

1999 Bontrager Comp II

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

2000/2001/2002/2003 Superstock

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Superstock Disc, Select ATB Disc

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2002/2003 Select ATB

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Select Road, Hybrid

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2003 Bontrager Service Manual

3

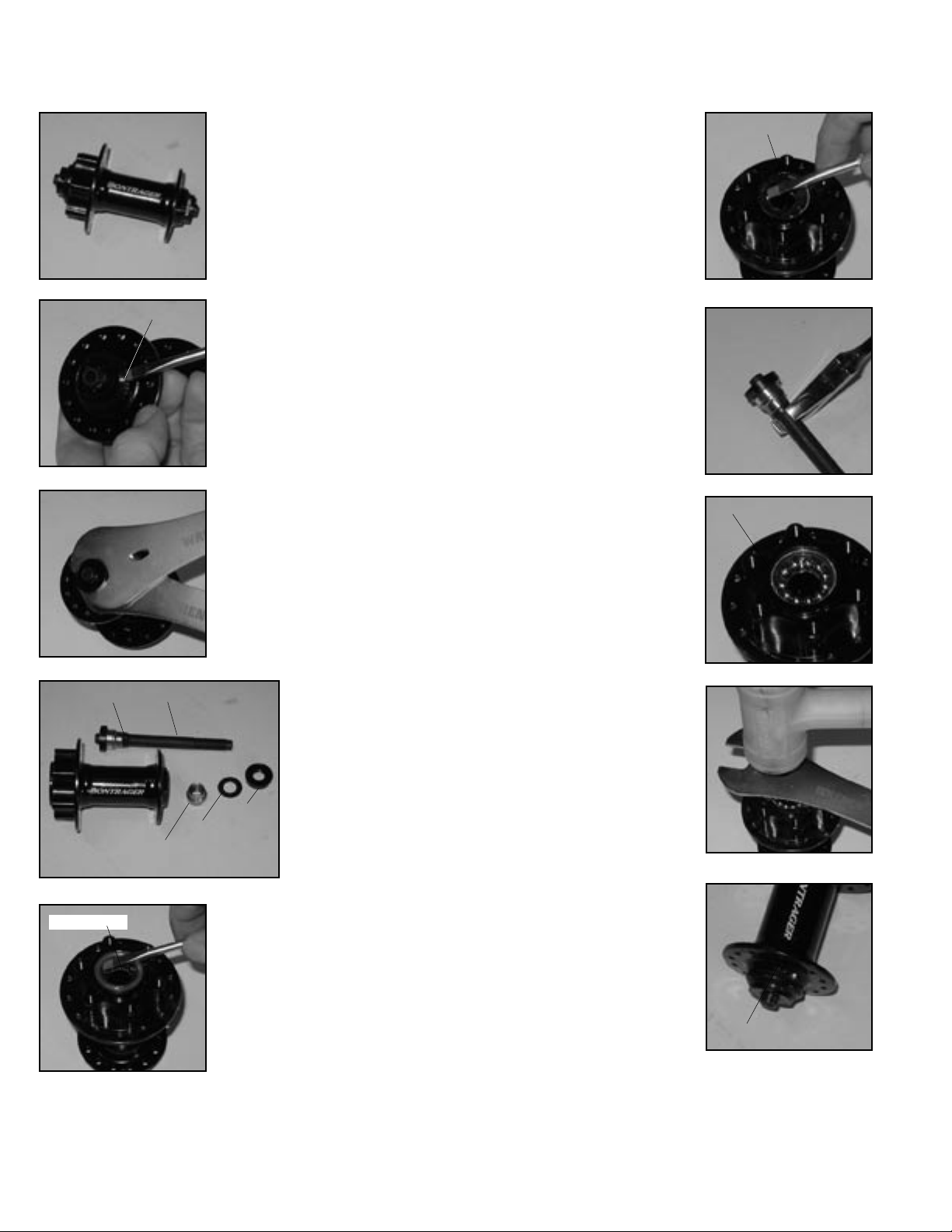

Front hubs- Loose ball, semi-cartridge; Formula FCM

'99, 2000, 2001 Bontrager Race, Race Disk front wheels

Recommended tools

13mm cone wrench

17mm cone wrench

Adjustable wrench

Hammer (soft faced)

Small slot screwdriver

DISASSEMBLY

Hub parts and names are referenced on next page.

Fig. 1B

External seal

Fig. 2B

Fig. 3B

Collar

Fig. 4B

Shell shield

Fig. 5B

Axle

Ball cone

ning surfaces of both the ball cones and the ball cups

(inside the hub). Replace any worn parts.

Note: If the ‘fixed’ ball cone is worn, the axle assembly (axle and ball cone) must be replaced.

Remove the axle

1. Remove external seals

(Fig. 2B) with a screwdriver. Be

careful not to tear or mar the

rubber.

2. On one side of the hub

(usually left), the cone is locked

against a collar on the axle (Fig.

4B). On the other side, place a

13mm cone wrench on the ball

cone. Place a 17mm cone wrench

on the end nut (Fig. 3B). Loosen

the end nut.

3. Remove the end nut, washer, and ball cone from the axle

(Fig. 4B).

4. Slide the axle, with the

other end nut, washer, and ball

cone still attached, out of the hub.

6. Gently insert a thin

screwdriver blade between the

shell shield (Fig. 5B) and bearing seal (Fig. 6B). Pry off the

shell shields from

both sides of the hub.

Do not attempt to pry

off both shield and

seal at the same time

as you may damage

the bearing seal.

End nut

Washer

7. Gently pry off

the bearing seals (Fig.

6B) from both sides of

the hub.

8. If inspection

shows it necessary,

remove the other end nut. Hold

the axle by the wrench flats

(Fig. 7B) while turning the end

nut with a 17mm cone wrench.

Clean and inspect the parts

1. Use solvent to completely

remove all old grease and debris

from the hub, axle, and axle

parts.

2. Inspect the bearing run-

Lubricate bearings and threads

Bearing seal

1. Lubricate the threads on

the axle with Wrench Force™ synthetic grease, or a similar product.

2. Place a bead of grease all

the way around each ball cup,

sufficient to hold the balls.

ASSEMBLY

1. Place eleven 3/16” balls in

the ball cup on one side of the

hub (Fig. 8B).

2. Place the bearing seal,

with the lettered side facing out,

into the ball cup.

3. Place the shell shield, with

its sharp edges facing out, into

the hub. The shell shield is a press

fit, so must be tapped lightly to

fully seat. Lay a cone wrench

over the shell shield and tap the

wrench with a hammer (Fig. 9B)

Bearings in ball cup

to protect the shield and ensure

that it is flush with the shell.

4. Repeat Assembly steps 1-3

for the other side of the hub.

5. Tighten the end nut

against the fixed ball cone

(attached to axle). Hold the axle

with an adjustable wrench on the

axle flats while turning the end

nut with a 17mm cone wrench.

6. Insert the axle through the

hub from either side.

7. Thread the ball cone, washer, and end nut onto the axle in

that order. The serrated surface

of the end nut faces out.

8. Hold the ball cone with a

13mm cone wrench and tighten

the end nut with a 17mm cone

wrench.

9. Check the bearing adjustment by turning the axle with

your fingers. The axle should

spin smoothly without binding or

feeling gritty. There should be no

lateral play of the axle in the hub.

Readjust the hub as necessary,

and re-lock the end nut.

10. Install the external seals.

Make sure the seals properly seal

Seal not seated

against both the end nut and

the hub shell. There should be a

smooth transition from seal to sealing surface. An improperly installed seal (Fig. 10B) will allow rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Fig. 6B

Fig. 7B

Fig. 8B

Fig. 9B

Fig. 10B

4

2003 Bontrager Service Manual

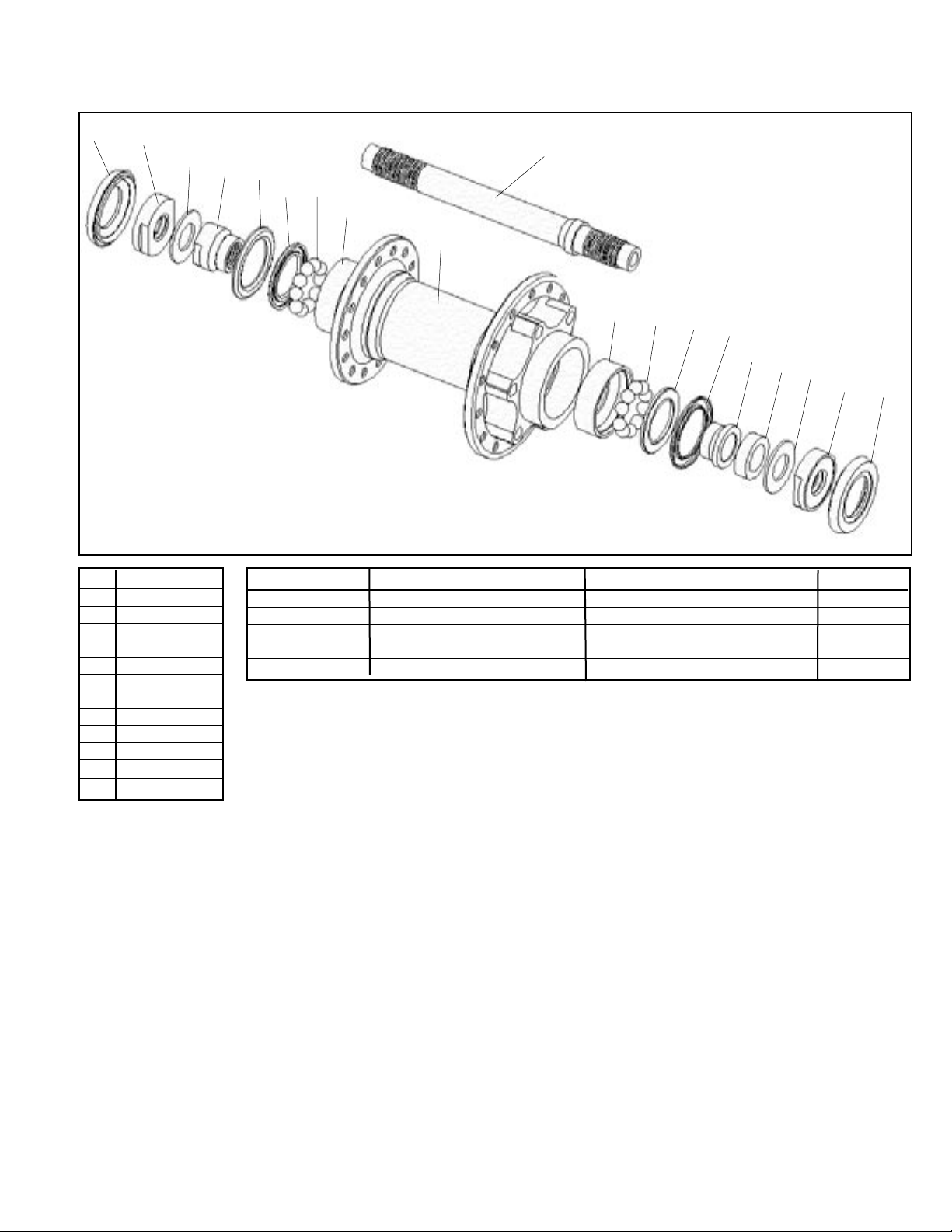

Exploded view and Parts list

1

Note:

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

2

3

4

5

6

10

7

8

9

8

7

6

5

12

11

3

2

1

Pos Description

1 External seal

2 End nut

3 Washer

4 Adjust cone

5 Shell shield

Description Model year Model for Parts included (qty) TCG Part #

Axle set 99/00/01 all 10, 4, 2, 5(2), 11, 6(2), 3(2) 68524

Locknut set 99/00/01 all 2(2) 68527

Rotor adapter 99/00 Hayes, RST Not shown 991083

w/screws

Disc bolt set 99/00 all Not shown 991153

6 Bearing seal

7 Ball bearings

8 Ball cup

9 Hub shell

10 Axle

11 Spacer

12 Ball cone

1999 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

1999/2000 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.0 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2001 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2000/2001 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2003 Bontrager Service Manual

5

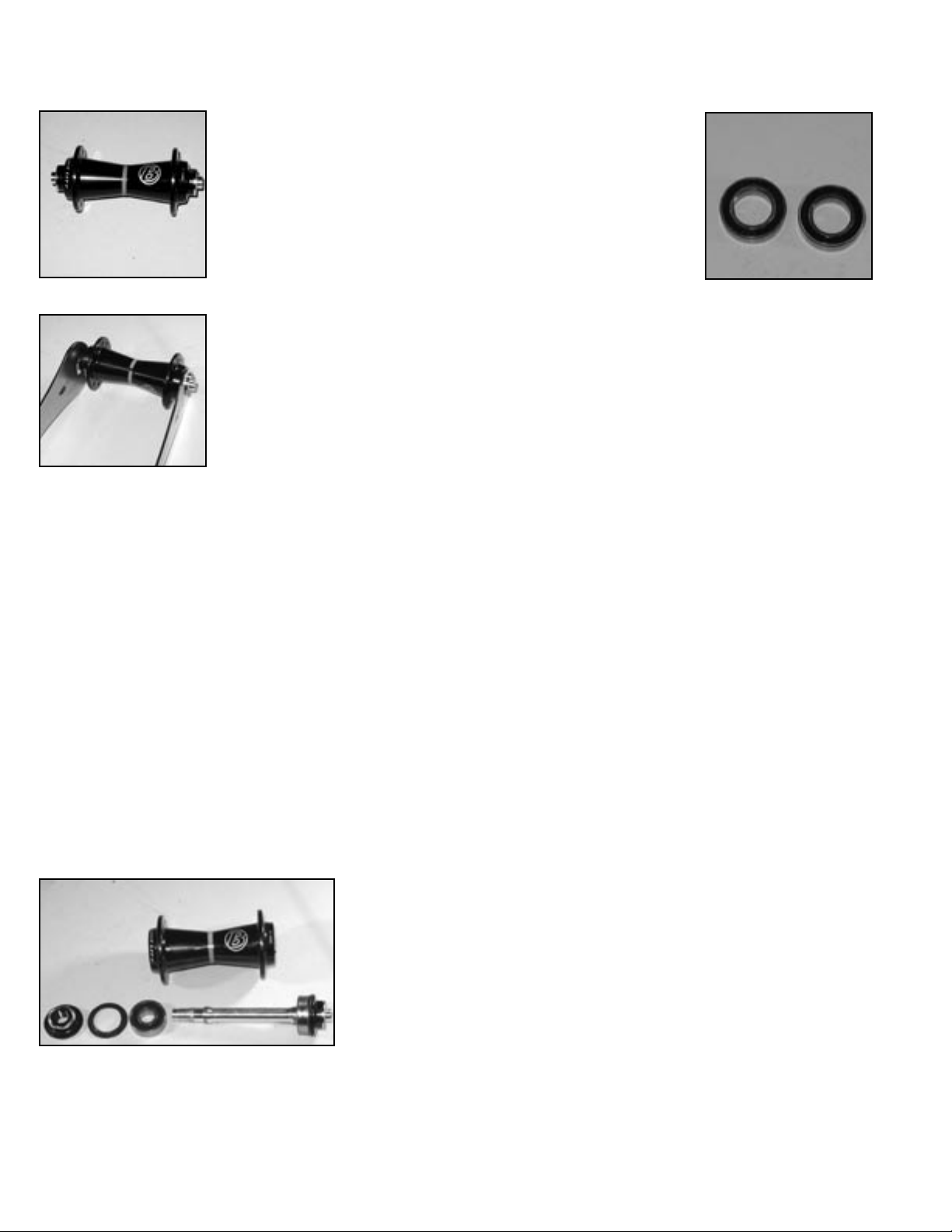

Front hubs- Cartridge bearing, alloy axle

2002/2003 Bontrager Race, Race Disc front wheels

Fig. 1C

Fig. 2C

Fig. 3C

Fig. 4C

End caps

Axle nut

Recommended tools

17mm cone wrench

Special hook spanner

Hammer and broad punch

Bearing removal tool

Bearing press

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

1. Remove axle end caps

(Fig. 2C) by sliding them out of

the axle with your fingers.

2. Hold the axle with a

17mm cone wrench (Fig. 3C)

while loosening the axle nut

with the special hook spanner

(Fig. 4C).

3. Partially unthread the

axle nut (Fig. 5C) until it

slightly protrudes past the end

of the axle.

4. Tap the axle nut with a

soft-faced hammer until the axle

slides through the opposite bearing. Once loose, the axle should

come out with your fingers.

5. Remove the axle nut, and

extract the axle (Fig. 6C).

6. Gently insert a thin screwdriver blade between the bearing

seal (Fig. 7C) and bearing. Pry

off the bearing seals from both

sides of the hub.

7. Insert a bearing removal

tool into the bearing. Place a

blunt punch through the hub

and against the bearing removal

tool. Tap the punch with the

hammer to drive the bearing out

of the hub (Fig. 8C). Repeat for

the other bearing.

ASSEMBLY

1. Press a bearing into the

hub with a bearing press.

Note: the black seal faces out (Fig. 9C).

2. Press the second bearing

with the bearing press.

3. Place the bearing seals

into the hub with the lettered

surface facing out.

6. Insert the axle through the

hub from either side.

7. Thread the axle nut onto

the axle.

8. Hold the axle with a 17mm

cone wrench and tighten the axle

nut with the special hook spanner until finger tight.

Do not over-tighten the axle nut. The axle should turn freely

with no lateral play in the hub shell.

9. Press the axle end caps

into both ends of the axle.

After completing assembly of the hub, check its function by

spinning the axle with your fingers. It should rotate freely

without irregular friction. A small amount of lateral play

is acceptable if the play is eliminated when the wheel is

installed with the quick release properly closed.

Axle

Axle nut

Fig. 5C

Fig. 6C

Fig. 7C

Bearing

seat

Fig. 8C

Clean and inspect the parts

1. Wipe old grease or debris from the hub bearing

seats.

2. Normally, bearings are not re-used. If you are reinstalling an old bearing, wipe off any grease or debris

from both the inner and outer surfaces.

Do not use solvent on the bearing, as the solvent will

contaminate the grease. This may cause bearing failure.

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Lightly grease the inner and outer surfaces of

each bearing.

6

2003 Bontrager Service Manual

Fig. 9C

Exploded view and Parts list

1

2

Note:

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

Pos Description

1 End cap

2 Adjustable nut

3 Seal

4 Bearing

5 Hub shell

6 Axle

3

Description Model year Model for Parts included (qty) TCG Part #

Seal 99/00/01 all 3(2) 68261

Bearing 99/00/01 all 4(2) 68262

#6903

Axle set 99/00/01 all 6, 4(2) 68263

Adjustable nut 99/00/01 all 2 68264

End cap, 99/00/01/02 all 1(2) 211645

20.5mm O..D.

Rotor adapter 99/00 Hayes, RST Not shown 991083

w/screws

Disc bolt set 99/00 all Not shown 991153

4

6

5

4

3

1

Special 99/00/01/02 all Not shown, see Fig. 4C 68259

hook spanner

2002 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2003 Bontrager Service Manual

7

2003 Bontrager Service Manual

Needs photos and text

Front hubs- Cartridge bearing, threaded alloy axle

2002/2003 Bontrager Race Lite Road front wheels

Recommended tools

17mm cone wrench (2)

Hammer and broad punch

Bearing press

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

1. Remove one of the thread-

Fig. 1H

Fig. 2H

second bearing from the axle. To do this, clamp the

middle of the axle, loosen the end cap, and remove it.

Support the bearing and tap the axle out with a softfaced hammer.

ed axle end caps (Fig. 2H) by

loosening with the pair of 17mm

cone wrenches.

2. With one end cap

removed, drive the axle from

the hub shell with a soft-faced

hammer.

3. Place a broad punch

through the hub, and tap the

punch with a hammer to drive

the second bearing (Fig. 3H),

with its seal, from the hub.

4. If needed, remove the

ASSEMBLY

1. Press a new bearing onto

the axle with a bearing press.

Note: the black seal faces out (Fig. 4H).

2. Place the hub seal onto the

axle, and thread on the axle end

cap. Clamp the middle of the axle

and tighten the axle end cap with

the 17mm cone wrench.

3. Press the bearing, with the

axle attached, into the hub.

4. Press the second bearing into the hub.

Note: the black seal faces out (Fig. 4H).

5. Place the hub seal over the bearing, and press into

the hub shell.

6. Thread on the second axle end cap, and tighten with

the 17mm cone wrench.

Do not over-tighten the axle nut. The axle should turn freely with no lateral play in the hub shell.

Fig. 4H

Clean and inspect the parts

1. Wipe old grease or debris from the hub bearing

seats.

2. Normally, bearings are not re-used. If you are reinstalling an old bearing, wipe off any grease or debris

from both the inner and outer surfaces.

Do not use solvent on the bearing, as the solvent will

contaminate the grease. This may cause bearing failure.

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Lightly grease the inner and outer surfaces of

each bearing.

8

Fig. 3H

2003 Bontrager Service Manual

Loading...

Loading...