Page 1

PM-B Automatic group

PM-B

PM-B Automatic group for rolled

bread and slack dough

The PM group is a multi-purpose work station planned to combine the functions of three different machines in

one compact and versatile unit: ""ciabatta"" divider, rolled bread group, long moulder.

The new conception divider head, the two highly tested moulders and the long moulding device offer the possibility to process the typical slack dough of "zoccoletti", "ciabatte", "francesine", etc. besides the traditional

shapes of rolled bread and rolled loaves.

The feeding belt lowered to a height of 1405 mm. to ease dough loading and the powered conveyor belt for dough portion

collection at the exit of the secondo moulder improve the comfortable and ergonomic use of the group.

•

Features

•

•

Steel structure mounted on wheels.

•

Outer casing painted with dual cycle anti-corrosion treatment using epoxy powders (food contact).

•

24V low voltage electric control panel.

•

The automatic feeding belt h. mm. 1405 features a

system controlled by an electromagnetic detector apt at

self-adjusting the dough input to the divider so as to prevent clogging.

•

The dividing and rolling head is planned and manufactured to divide both slack and dry dough: the rolling

system is formed by a central grooved roller and five

rolling cylinders made of stainless steel. It is adjustable

on three positions and allows to obtain a dough sheet

having variable thickness, according to the consistence

and softness of the dough. The possibility to change the

portion thickness, besides their length, increases the range of shapes to produce.

•

Teflon-coated stainless steel blades easy to change, to

work at one, two or three ways (this last one only for

cutting) and to guarantee a perfect cut and dough division.

•

Stainless steel flour sifters equipped with two independent small tanks at adjustable dosage till exclusion. One

is placed in the rolling area while the other is placed in

the cutting area, in order to ease slack dough processing

during the most delicate phases.

•

Two counter-moving conveyor belts inside the head.

Thanks to a practical selector, it is possible to take off

portions after dividing or going on with the following

moulding and long moulding. The collecting and exit belt

is placed on the head back. It can be lifted and overturned when it is not used, to maintain the characteristics

of extreme compactness which inspired the design of the

PM group.

•

•

These photos and this document are not contractually binding.

Page 2

PM-B Automatic group

•

The PM-B group features a four cylinder moulder with stainless steel collecting tray as well as a turnable three cylinder

moulder with indipendently powered collecting belt. Useful

•

•

•

•

•

work width 460 mm, thus allowing to have two way

production without any risk of contact between portions.

•

A double anti-rejection device on both moulders, adjustable

by means of a micrometric handwheel, has been designed to

obtain a better rolling up of large pieces and dry dough.

•

A device disactivating the upper belt functioning of both

moulders stops the rolling up process and allows to obtain

the simple calendering of portions.

•

Long moulding belt with adjustable pressing device enabling

to lengthen portions after the first moulding and to obtain

•

rolled loaves long up to 480 mm.

•

Stainless steel collecting tray.

•

Electrical power supply: V.400/3/50 Hz (different voltages on

request).

•

This machine complies regulations.

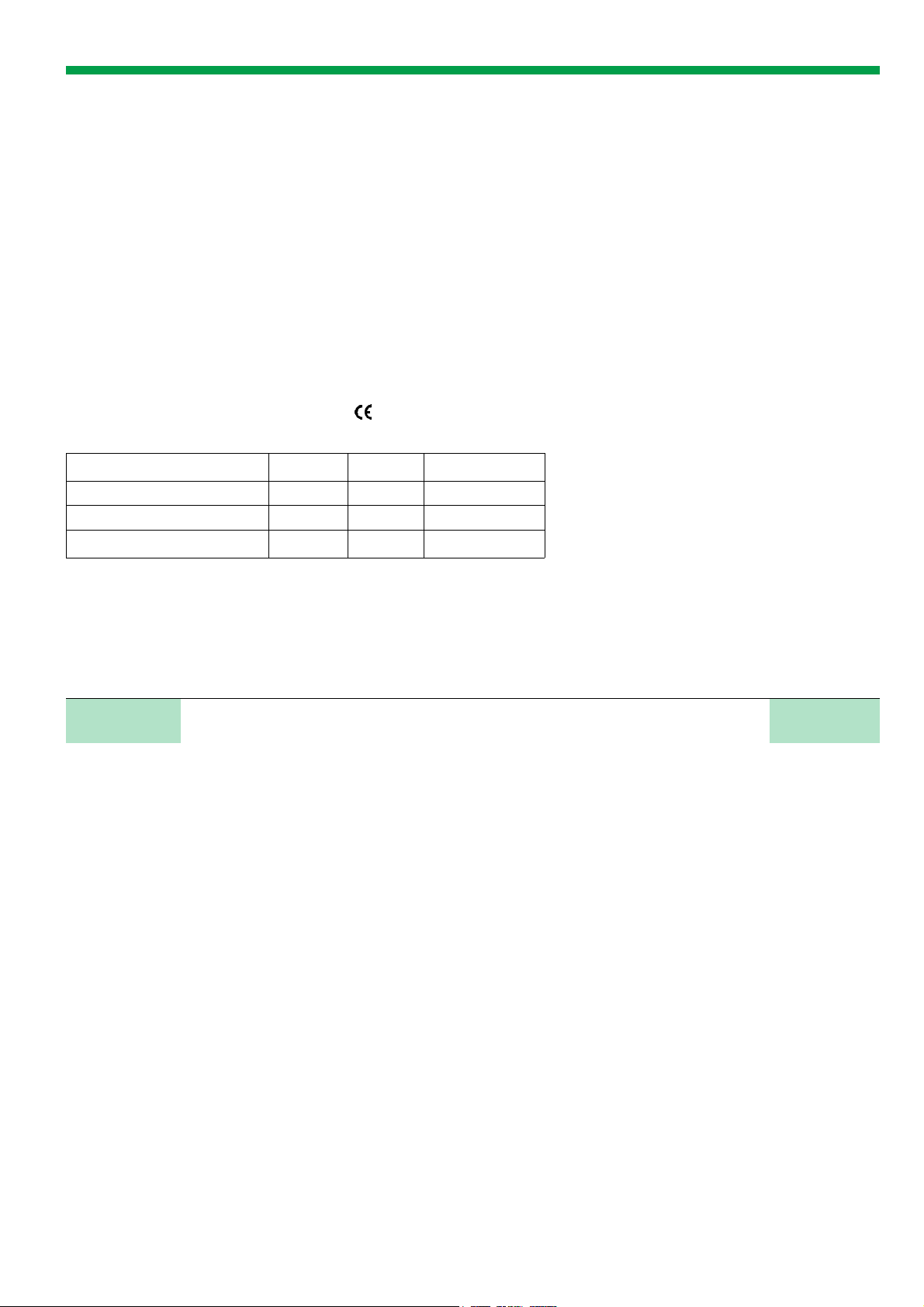

PERFORMANCES

SINGLE PORTIONS gr 50 gr 800 pz/h 4000

DOUBLE PORTIONS gr 25 gr 400 pz/h 8000

TRIPLE PORTIONS - ONLY CUT gr 17 gr 270 pz/h 8000

* Minimum and maximum weight are approximate and can change

according to the processing method and the dough specific weight.

min.

weight*

max.

weight*

(*) referred to minimum weights.

max.

output (*)

Controls

The PM-B group is equipped with a microprocessor controlled electronic control panel. Once single, double or triple

output and dough thickness have been selected, the user

can choose the desired weight and hourly output by means

of a digital keyboard. Work speed and dough portion length

are automatically determined by the microprocessor. The

electronic control panel allows to finely adjust the product

weight so as to compensate for weight fluctuations due to

changes in the dough specific weight. The +/- weight correction value is visible on the display.

Divider start/stop double controls placed at the exit of the

second moulder.

MODEL

Ref. Description

PM-B 03956802 Automatic group for rolled bread and soft dough

Page 3

PM-B Automatic group

Loading...

Loading...