Page 1

A

INSTALLATION,OPERATION & M

INTENANCE

SERIES C

Commercial Evaporative

Air Conditioning

Bonaire 700C – 1500C

• IMPORTANT NOTICE •

Please leave this manual with the owner of this air conditioner.

Please keep this important manual in a safe place. It is the owner’s responsibility to ensure that regular servicing as

per the Bonaire Evaporative Air Conditioner service recording planner is carried out. Failure to complete and record

the periodic service work as outlined will void all guarantees beyond statutory and legal requirements.

Page 2

INSTALLATION, OPERATION & MAINTENANCE

Contents

TABLE OF CONTENTS

TABLE OF CONTENTS __________________________________________________ 2

INTRODUCTION _______________________________________________________ 3

Dealer Responsibility _____________________________________________________ 3

Before Commencing______________________________________________________ 3

UNIT INSTALLATION ___________________________________________________ 4

Unit Location Check List___________________________________________________ 4

Precautions_____________________________________________________________ 4

Location and Orientation___________________________________________________ 4

Duct Connection Details___________________________________________________ 5

Lifting the Unit___________________________________________________________ 6

Mounting the Air Conditioner _______________________________________________ 6

Ductwork System ________________________________________________________ 7

WATER CONNECTIONS _________________________________________________ 8

Unit Base Layout ________________________________________________________ 8

Water Installation ________________________________________________________ 9

Connecting the Water Supply____________________________________________________ 9

Dump Valve ________________________________________________________________ 10

Drain______________________________________________________________________ 10

ELECTRICAL CONNECTIONS ____________________________________________ 11

Wiring Connections______________________________________________________ 11

Wiring – Important Notes _________________________________________________ 11

Wiring Diagram_________________________________________________________ 12

COMMISSIONING_____________________________________________________ 13

Water Levels___________________________________________________________ 13

Bleed-off Rate__________________________________________________________ 13

Distribution Flow________________________________________________________ 13

Fan Operation__________________________________________________________ 14

Controls ______________________________________________________________ 14

Customer hand Over ____________________________________________________ 14

Unit_______________________________________________________________________ 15

Ductwork and general ________________________________________________________ 15

Site_______________________________________________________________________ 15

Customer Hand Over_________________________________________________________ 15

OPERATING INSTRUCTIONS _____________________________________________ 16

WARRANTY – AUSTRALIA ONLY _________________________________________ 17

SERVICE & MAINTENANCE _____________________________________________ 21

Bonaire Commercial / Industrial EAC

Page 2

Page 3

INSTALLATION, OPERATION & MAINTENANCE

Introduction

INTRODUCTION

Please take the time to fully read this Installation manual. Failure to follow these instructions may

result in injury to you and damage to the air conditioner or your customer’s property.

Installation of this Bonaire Evaporative Air Conditioner must conform to local building rules and

regulations, electrical and plumbing codes, Environmental Protection Authority (EPA) regulations,

and all applicable Australian Standards.

Should you not follow these instructions the unit warranty may be void. The cost of warranty would

then be the cost of the customer or the installer / dealer.

Refer to the tick box Commissioning Checklist to ensure you have covered all points when the

installation is complete.

DEALER RESPONSIBILITY

Training

It is the responsibility of all dealers to adequately train their staff to ensure the product

•

is correctly sized and specified.

• It is the responsibility of all dealers to ensure their installation teams / sub-contractors

are trained in the correct installation techniques of both the product and the ducting.

• Climate Technologies will provide technical assistance and training to the dealer as

required. “Train the trainer” will be an on going requirement by Climate Technologies.

Variations to Standard

• Where a variation to standard configuration has been requested or applied during

installation, it is the dealer’s responsibility to ensure such variations will not exceed the

design operating capabilities of the unit e.g. variation to construction materials, drive

requirements, system static etc.

Please Note:- Motor operating current must be verified on ALL UNITS as

detailed in the commissioning section under Fan Operation.

Legal & Statutory obligations

• It is the dealer / installer responsibility to comply with all codes, statutory and legal

requirements, state and council / shire by laws.

Safety and O.H.&S. Requirements

• It is the responsibility of the dealer / installer to insure the environment is safe for the

installer to carry out the installation.

• It is the responsibility of the dealer / installer to ensure safe access to the unit can be

achieved for service.

• It is the responsibility of the dealer / installer to ensure the roof is provided with access

footings and platform where the pitch of the roof is greater than acceptable standards.

• It is the responsibility of the dealer / installer to ensure harness anchorage points are

provided where the pitch of the roof is greater than acceptable standards. See

Australian Standard 1891.4:2000 Part 4 Selection use and maintenance, Table 2.1.

BEFORE COMMENCING

• Packaging – check there is no damage before removing packaging.

• Have you got all the system components?

• Have you got the right unit?

Bonaire Commercial / Industrial EAC

Page 3

Page 4

INSTALLATION, OPERATION & MAINTENANCE

Unit Installation

UNIT INSTALLATION

UNIT LOCATION CHECK LIST

• Place the unit well away from sources of smoke, dust and objectionable fumes so

that only clean, fresh outside air will be drawn into the unit. (Refer AS1668)

• Check the proposed location to ensure that building members are structurally

capable of supporting the operating weight of the air conditioner.

• Provide easy access to the unit(s) for service. It is the responsibility of the dealer

/ installer to ensure safe access to the unit can be obtained for servicing.

• Access to the unit and platform / safe roof area must be provided for safe

service.

• NOTE: The manufacturer and its agents reserve the right to refuse service

unless safety and accessibility to the unit can be guaranteed.

• The cost of any extra equipment required to provide access to the unit for

servicing is the responsibility of the owner.

EPA

Any issues with noise abidance, on an installation that contravenes local council or

EPA requirements and is not installed to the manufacturer’s specification will be the

responsibility of the dealer / installer.

P

RECAUTIONS

Please read this manual thoroughly as failure to do so could result in injury to you or

damage to the air conditioner and property.

Installation of the air conditioner must conform to local electrical, water supply and

environmental codes, rules and regulations and to applicable National Standards.

LOCATION AND ORIENTATION

Check the proposed unit location first to ensure that it is structurally capable of supporting

the weight of the unit. A level stand is required which must be capable of supporting the

operating weight of the unit, including wind loading. Check the technical data for

operating weight.

The preferred location for an evaporative air conditioner on a sloping or pitched roof is on

the side from which the prevailing winds come in the summer season.

Always locate the unit where it will receive a plentiful supply of fresh air and not in a

recess where it may be starved or where the air is polluted.

Keep the unit well away from exhaust fans and ducts. Never undersize the duct system.

Allow adequate access around the unit for maintenance. Provision must be made for

access to electricity, water supply and drains. High roofs need to be provided with

permanent access to carry out maintenance or warranty work.

NOTE: It is the owner’s responsibility to provide safe access to the unit. Climate

Technologies may refuse to do maintenance or warranty work if access is

unsafe. If any additional equipment is needed to provide access to the unit,

this will be provided (and paid for) by the owner.

Bonaire Commercial / Industrial EAC

Page 4

Page 5

INSTALLATION, OPERATION & MAINTENANCE

Unit Installation

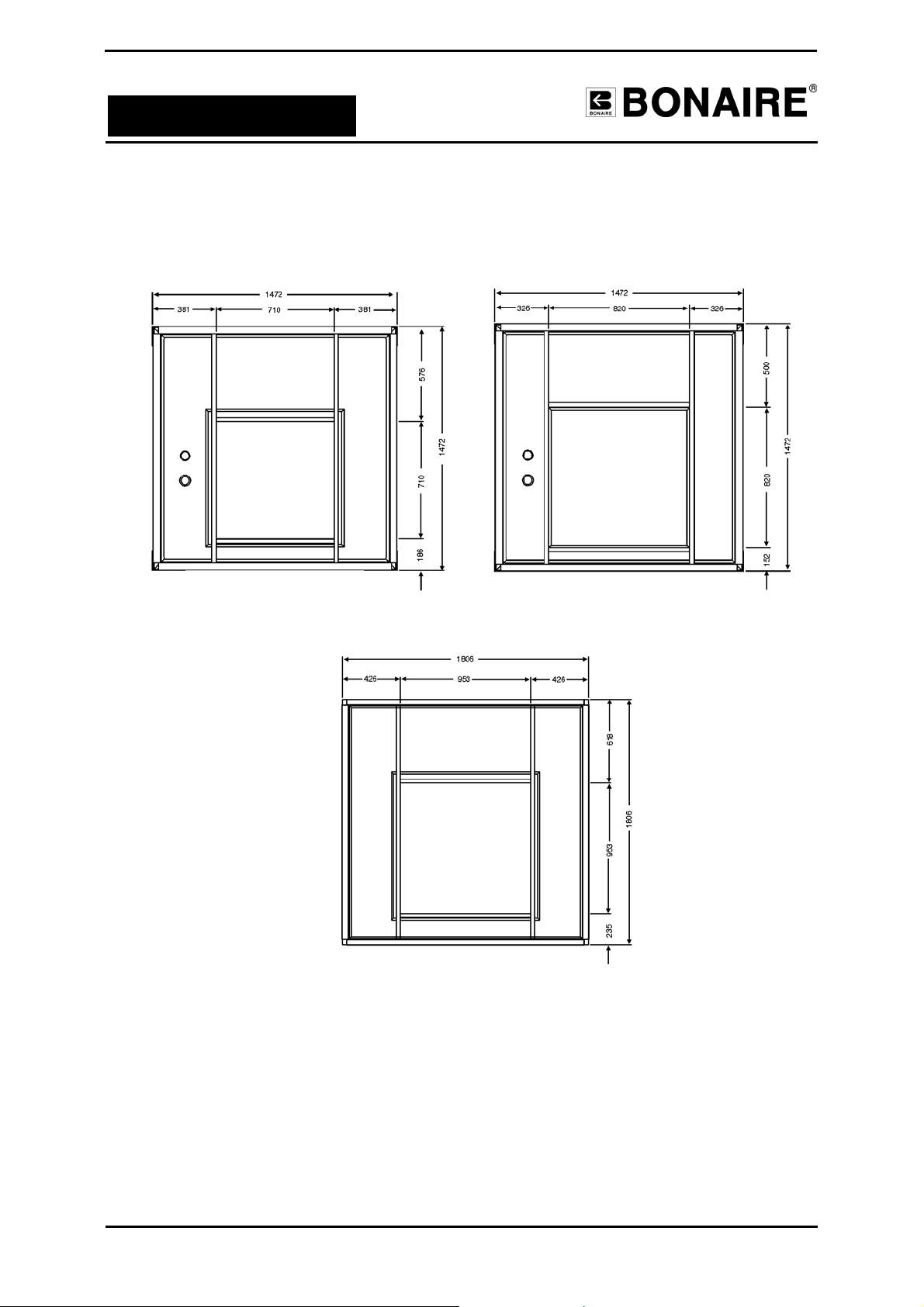

DUCT CONNECTION DETAILS

700 Series C 900 Series C

1200, 1400, 1500 Series C

Bonaire Commercial / Industrial EAC

Page 5

Page 6

INSTALLATION, OPERATION & MAINTENANCE

Unit Installation

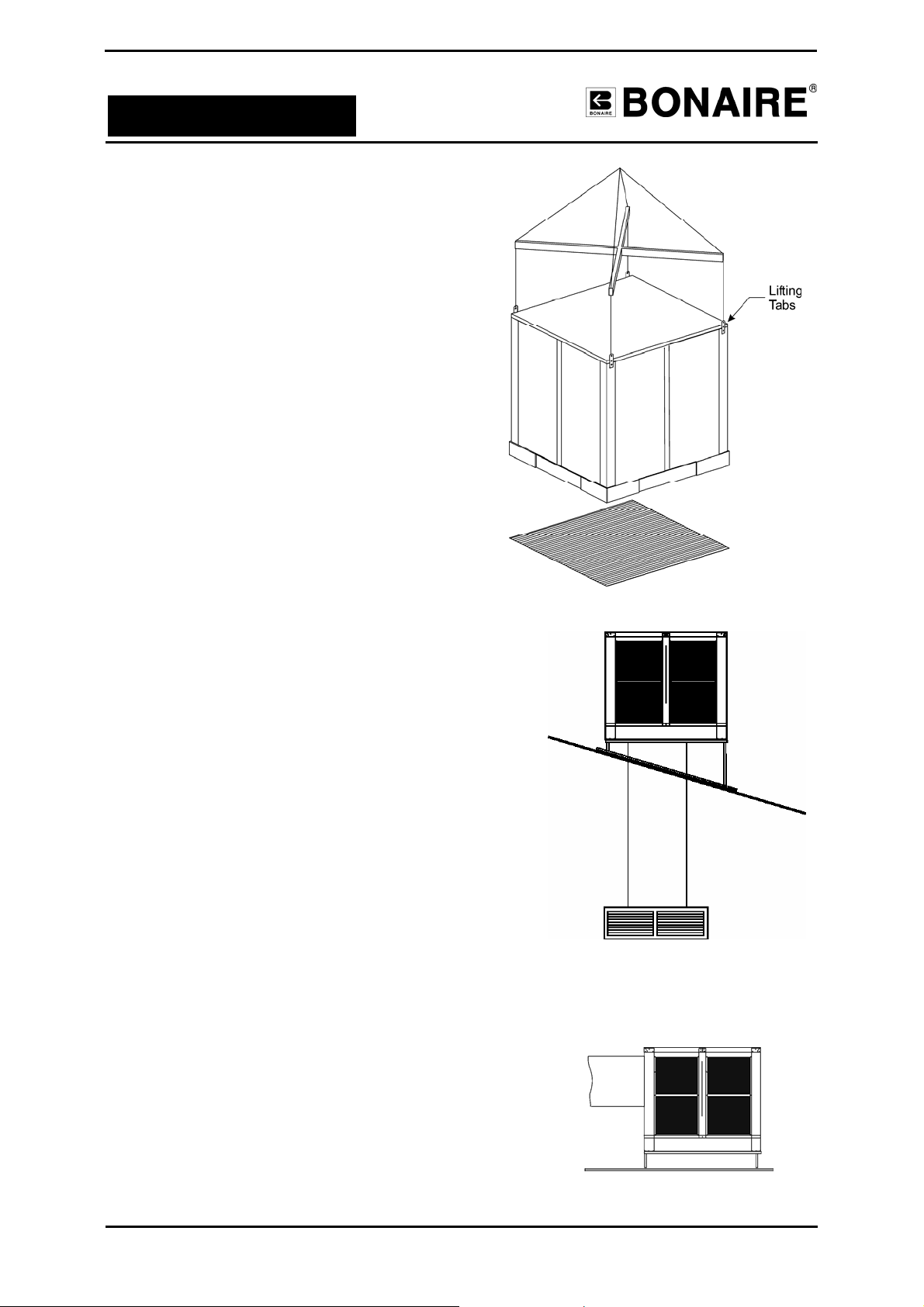

LIFTING THE UNIT

When lifting the units with a crane, fit the

lifting tabs supplied to the 4 corner posts

of the unit in the holes provided. Ensure

a spreader bar is used to lift vertically

from each lifting lug.

Where lifting with a forklift, ensure the

lifting tines are long enough to reach right

through the bottom of the unit pallet.

Extension fork tines may be required.

Should you fail to do so, the water

reservoir may get damaged.

OUNTING THE AIR CONDITIONER

M

1. A mounting stand must be provided with each

unit installed.

2. The stand must be designed to carry the

operating weight of the product. Where the units

are fitted on a roof, ensure the stand is installed

on a structurally sound section.

All installations must comply with the

relevant building codes, regulations and

engineering specifications for the building.

3. An insulator should be installed between the unit

base and stand to eliminate any possible

reaction between the metal stand and the

aluminium chassis.

4. Always ensure the unit is level.

5. Allow adequate access around the unit for

maintenance. Provision must be made for

access to electricity, water supply and drains.

High roofs need to be provided with permanent

access to carry out maintenance or warranty

work. It is the owner’s responsibility to provide

safe access to the unit. Climate Technologies

may refuse to do maintenance or warranty work

if access is unsafe. If any additional equipment

is needed to provide access to the unit, this must

be provided (and paid for) by the owner.

Bonaire Commercial / Industrial EAC

Page 6

Page 7

INSTALLATION, OPERATION & MAINTENANCE

Unit Installation

6. Down Discharge, Side Discharge and Top

Discharge units should have a minimum of

300mm from base of unit to bottom / ground level

for connecting plumbing.

7. Unit installation should have a minimum of

750mm clearance on all the service sides.

D

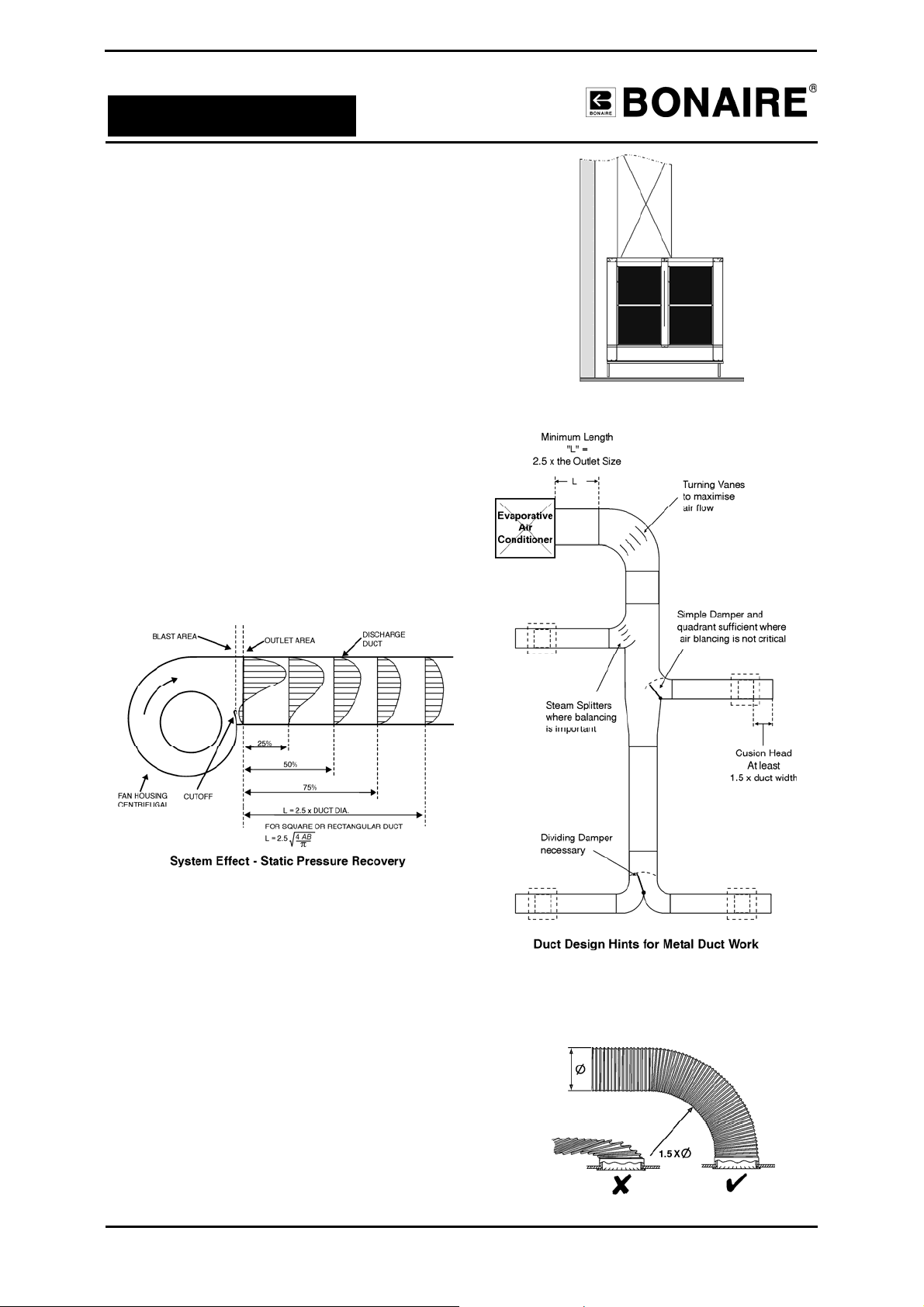

UCTWORK SYSTEM

It is essential that water cannot enter the building as

a result of inadequate sealing (caulking or flashing) of

the fixings, the ductwork system, system pipes and

wiring.

All duct designs and airflows must be

calculated by a qualified air conditioning

consultant or contractor in accordance with

normal good ducting practices.

Discharge duct design critical to the air

performance of the product. See diagram

below.

Where flexible ductwork is used, all bends

must have a minimum radius of 1.5 times

the diameter. All joins must be taped

airtight.

The last bend to each ceiling register

must be a smooth radius so that airflow is

even into the room.

Bonaire Commercial / Industrial EAC

Page 7

Page 8

INSTALLATION, OPERATION & MAINTENANCE

Water Connections

WATER CONNECTIONS

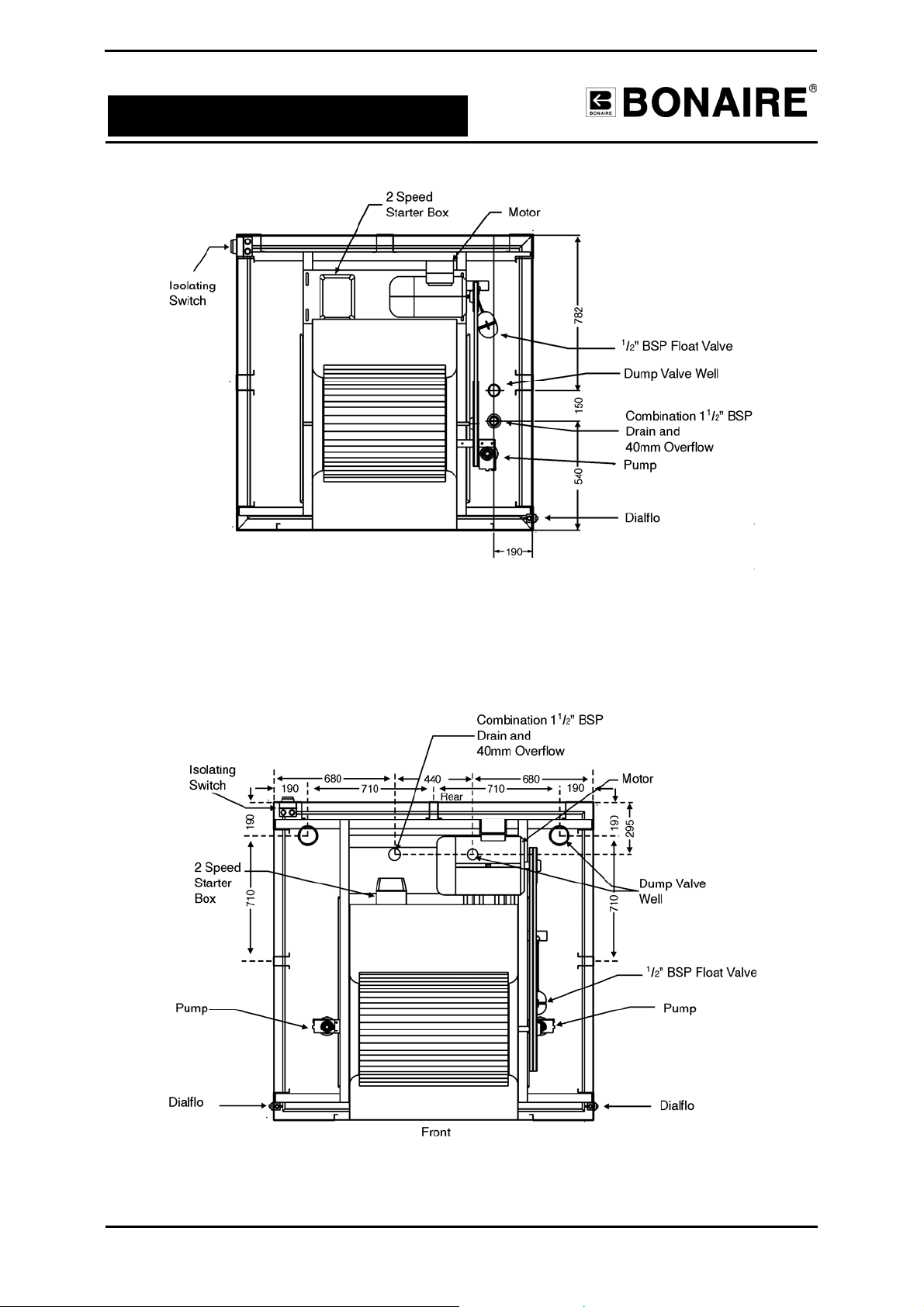

UNIT BASE LAYOUT

Series C 700 – 900

Series C 1200 – 1500

Bonaire Commercial / Industrial EAC

Page 8

Page 9

INSTALLATION, OPERATION & MAINTENANCE

Water Connections

WATER INSTALLATION

A permanent water supply is required to be connected to the float valve, for float valve

installation. Units have been type test certified to MP52, Spec101. Certificate No.8663.

700C – 1500C

Connecting the Water Supply

• The water supply pipe work and connection

to the air conditioner must be installed by a

licensed plumber and conform to all local

regulations. The ball valve connection is

inside the unit.

• Ensure copper inlet pipe is secured to

prevent movement of the float valve.

• The supply pipe should be copper pipe or

similar approved. A manual water-isolating

tap must be installed on the supply pipe near

the unit for ease of maintenance. Do not use

duo or non-return valves of any kind.

NOTE: Non return type valves can have

and effect on the operation of the

water solenoid valves. Lock up

and damage can be caused.

• Fit water supply tap close to the unit to assist in routine servicing.

• Before connecting the supply pipe flush it of any swarf or debris that may cause the

float valve to leak.

NOTE: In areas where water pipes freeze, provisions will be needed to drain

the water piping to prevent damage to the air conditioner.

Bonaire Commercial / Industrial EAC

Page 9

Page 10

INSTALLATION, OPERATION & MAINTENANCE

Water Connections

Dump Valve (Optional)

• Where a Dump Valve is to be fitted, the

solenoid MUST be installed in series on the

unit side of the water-isolating tap.

• Fit the black pressure tube between the

dump valve and the solenoid valve.

• The 24V solenoid will be supplied with an

in-line transformer for 240V connection.

• Connect the 240V solenoid transformer

leads in parallel with the pump

terminations.

Or

Connect to a timed / delay independent

circuit supplied by the installer.

• The tank in the unit will only fill once power

has been applied to the solenoid valve

transformer and pressure through the black

tube has closed the dump valve.

Drain

The combination drain/overflow pipe outlet must be connected to a drainpipe, which has

sufficient capacity to take the discharge of water from the reservoir. The pipe must

connect to a suitable waste point.

Note: Refer to local regulations to ensure discharge of drain / overflow water is in

accordance with statutory requirements.

40mm Version

Bonaire Commercial / Industrial EAC

50mm Version

Page 10

Page 11

INSTALLATION, OPERATION & MAINTENANCE

Electrical Connections

ELECTRICAL CONNECTIONS

WIRING CONNECTIONS

• Have a licensed Electrician install a dedicated circuit from the distribution board with a

separate circuit breaker for each unit installed.

• Unit connection isolating switch provided on the corner post of each unit.

WARNING: Multiple unit connections to a single wall control. Live wires

for the control circuit may not be isolated. Isolate the master unit.

• Circuit breaker selection and cable size must be made relevant to the current rating of

the motor and the circuit breaker motor kW specifications.

• Where the units are turned on and off in the high speed setting, a soft start timer must

be provided by the installer to start the unit on low speed.

• The control panel connection point must be easily accessible for service and

maintenance.

• Check to see if the voltage of the air conditioner is compatible with your electrical

system voltage. Check that there will not be excessive voltage drop, which will cause

the unit to run inefficiently or even cause motor burn out. ±5% of the motor

nameplate voltage is usually acceptable by motor manufacturers.

• Prior to completing the installation an electrician must check that the air conditioner is

operating correctly, and that the fan is rotating in the correct direction, on both

speeds.

• Replace all lids and covers.

• The manufacturer advises that they will not be held responsible for replacement of

parts or labour costs on electrical components which fail as a result of incorrect

wiring.

W

IRING – IMPORTANT NOTES

• A LICENSED ELECTRICIAN must carry out all electrical connection wiring to

the unit. It is the responsibility of the LICENSED ELECTRICIAN that the unit is

connected as per AS3000 (Wiring rules) and any local regulations and statutory

or legal requirements.

• Where units are clustered using a single wall control for multiple units, the unit

control box must be labelled indicating live wires inside. There will be voltage

in the control circuit if all units in the cluster are not isolated in the multiple

connections.

Bonaire Commercial / Industrial EAC

Page 11

Page 12

INSTALLATION, OPERATION & MAINTENANCE

Electrical Connections

WIRING DIAGRAM

700C – 1500C

Bonaire Commercial / Industrial EAC

Page 12

Page 13

INSTALLATION, OPERATION & MAINTENANCE

g

Commissionin

COMMISSIONING

WATER LEVELS

• Turn water on to unit and allow the reservoir to fill. The water should be 65mm to

70mm from the bottom of the tank.

• If a dump valve is fitted, turn the pump (or dump circuit) on to activate the solenoid.

Water pressure will be applied to the dump valve plunger via the black pressure pipe,

causing it to close allowing the reservoir to fill.

Note: the dump valve has minimum and maximum operational pressures of 100 kPa

to 1000kPa. Where pressures are below 100 kPa, the dump valve may not

close and the reservoir will not fill.

• Adjust float valve arm as required to set the water level (65 – 70mm).

• Fit Louvre panels and check for even wetting of the filter medium

B

LEED-OFF RATE

• All evaporative air conditioners need some

water bleed-off to prevent build-up of mineral

deposits in the system. The correct setting of

the bleed rate will ultimately govern the life of

the unit.

• Recommended bleed rates should be set at

approximately 5 litres per hour per 1000 litres

of air. Increased water hardness may require

a higher bleed rate and increased

maintenance.

• It is recommended to plumb the bleed off hose

through the overflow fitting and the bleed-off

away to a downpipe in situations where the

discharge may cause unsightly stains.

• To control the bleed-off rate rotate the bleed

dial clockwise for more water and anticlockwise for less water.

NOTE: It is the responsibility of the installer to set a correct bleed rate to suit

local conditions.

• If a dump valve is fitted and is set up for regular timed dumping periods during

operation; the bleed may not need to be set.

• If a dump valve is fitted and is only to be used for the purpose of a dry sump when not

in use, the bleed rate will have to be set for normal operation.

D

ISTRIBUTION FLOW

Generally the flow rate to the water distributors will be set to full. However there will be

some circumstances where water carry-over may occur. To stop water carry over where

there appears to be an excess of water on the filters, adjust the outer knob of the Dialflo

to clockwise to reduce the amount of water to the filters.

Note: Hold the bleed knob while adjusting the distribution flow, as this may go

out of adjustment when turning the distribution flow knob.

Bonaire Commercial / Industrial EAC

Page 13

Page 14

INSTALLATION, OPERATION & MAINTENANCE

g

Commissionin

FAN OPERATION

• Check that pulleys are correctly

aligned.

• Check the belt tension is correct.

Nominally 15 – 20mm

depression.

• Check bearings are tight on shaft

• Check bearings are packed with

grease.

• Set the fan running and check.

• Check that the air is being evenly

distributed through the ductwork.

• Make adjustments, as required, to any manual

air dampers that may be fitted.

• Fan Motor Current. Check the motor

operating current is not greater the rating plate

value.

o For systems with high statics and

non standard drive check motor

current. Where required, review

pulley requirements relative to the

system static. Where variable pitch

pulleys are fitted adjust accordingly.

o For systems with minimal static e.g.

straight dropper and plenums,

check motor current. A smaller

motor pulley to standard may be

required.

C

ONTROLS

Check all control functions are working

USTOMER HAND OVER

C

Instruct the customer in the use of the product.

• Controls

• Bleed off

• Venting the air via the side of the premises the wind is not blowing from.

• Maintenance Requirements

Hand over of the customer’s operational manual.

Bonaire Commercial / Industrial EAC

Page 14

Page 15

INSTALLATION, OPERATION & MAINTENANCE

g

Commissionin

You must complete, date and sign the ‘tick box’ checklist in the owner’s

warranty card. Use this copy to check the installation prior to completing the

owner’s documentation.

Unit

All equipment ordered by the

customer is installed.

The unit is level and secure.

The water supply line has been

flushed to clear swarf and debris and

is free of leaks.

The tank is free of foreign matter and

debris and the water isolating tap is

turned ON.

Water drainpipe work is completed

and sealed.

The water basin fills with water and

the float valve closes correctly when

the water level is 65 -75mm from the

bottom of the tank.

The water pump(s) operates correctly

when turned ON at the controller.

The Dialflow water bleed rate is

adjusted to suit local water

conditions.

The Dump Valve (option). The tank

drains correctly when unit turns off.

All Controller functions for the

appliance operate.

Fan motor current draw.

Ductwork and general

All ductwork is completed to plan,

correctly supported and airtight.

Air distribution checked, dampers are

adjusted and all outlets correctly

adjusted and wiped clean.

All roof penetrations are fully sealed

and watertight.

Man-hole cover replaced.

Site

All rubbish has been removed from

inside and on the roof.

Customer Hand Over

You have explained the following to the

customer.

The fan deck is correctly located and

the fan blade spins freely.

The mains and control wiring are

complete and the circuit breaker is

turned ON.

The fan operates correctly on all

speeds.

Water distribution is even with the

filter pads fitted and the air

conditioner operating pump and fan.

Bonaire Commercial / Industrial EAC

The operation of the Controller.

Adequate exhaust is required for the

effective cooling. Air exit areas

should be at least 0.5 square meters

per 1000 litres of air.

The operation of the bleed or

dumping system and it’s importance

to operate all the time

Maintenance requirements

Page 15

Page 16

INSTALLATION, OPERATION & MAINTENANCE

Operating Instructions

OPERATING INSTRUCTIONS

USING YOUR AIR CONDITIONER

Evaporative Air Conditioners must always function on 100% fresh outside air.

Therefore they require you to open or provide exhaust outlets in the space being cooled.

Such outlets may be provided by the opening of doors and/or windows in various rooms or

sections. They may also be provided by the installation of special exhaust grilles through

doors, walls or into the ceiling (attic) space of the building.

Where the building does not allow such easy exhaust provisions, there must be some kind of

mechanical ventilation installed, such as an exhaust fan which can extract approximately

80% of the air that the air conditioner is discharging.

Never allow conditioned air to exhaust into a closed space, it must always be allowed to

exhaust to the outside.

Generally, the higher the relative humidity, the higher the air quantity required from the air

conditioner. You should therefore control the speed of your air conditioner accordingly. On

very dry days the air conditioner will give maximum cooling and this will decrease as the

humidity increases.

The air distribution system in your building has been fitted with air outlet grilles and they

probably have adjustable louvre blades. You can adjust the blades yourself to create your

own pattern of air distribution in the space.

If you close the louvres too much you may get undesirable air noise.

PERATING INSTRUCTIONS

O

Turn on the water supply at the source and

make sure that the water isolation valve at

the unit is also turned on.

Turn on the electrical power at the source

and make sure that the isolating switch

outside the unit is turned on.

Turn COOL switch on.

It is recommended that you wait 10 minutes

for the pump to saturate the filter pads. A

longer period may be required where a dump

valve is fitted.

Select LOW fan speed, using the switch on

the control panel inside the building, then

switch unit ON. (It is recommended to start

the unit on LOW speed, and then switch to

HIGH if required).

At times, when the outside humidity is very

high, you may feel more comfortable using

ventilation system only. For ventilation

system only, turn the COOL switch off and

run the fan only. The fan speed can be

selected as described above.

Follow the above instructions about providing exhaust opening in the building. This is very

important. When unit is turned OFF the COOL switch should also be turned OFF as the

pump is independently switched.

Bonaire Commercial / Industrial EAC

Page 16

Page 17

INSTALLATION, OPERATION & MAINTENANCE

y

Warranty – Australia Onl

WARRANTY – AUSTRALIA ONLY

IMPORTANT:

Please read this warranty information and complete the Dealer/Product information on the following

page. KEEP this with your original purchase documents for any claim under warranty.

WARRANTY PROCEDURES:

Firstly refer to your owners manual to ensure you have followed the correct operating procedures of your

product, and refer to the trouble shooting guide to assist solving any problems you may have.

1. Read this warranty statement carefully befor e you request warranty service as items relation to

installation are not covered by this appliance warranty.

2. A proof of product purchase must be provided for warranty service, to validate the appliance is within the

manufacturer’s warranty periods.

3. This warranty is only for products and associated original controls for Climate Technologies

manufactured product.

4. Only an authorised Climate Technologies service provi der must carry out warranty servic e .

5. Statutory warranty is 12 months from date of purchase and all additional periods are classified as

manufacturer’s voluntary warranty.

Climate Technologies provides the following Manufacturers warranty on new product additional to

all implied warranties and other statutory rights which you may have under the Trade Practices Act

and similar State & Territory Laws, subject to the following terms and conditions.

TERMS AND CONDITIONS:

Conditions to Warranty

• Subject to the exclusions noted, Climate Technologies warrant the product for the period as prescribed

in the table following this statement to be free from Inherent defects in materials and workmanship for

functional and structural components.

• This product is only valid if the product is operated in accordance with the manufacturers instructions

• The appliance must not be modified or changed in any way.

• Your proof of purchase MUST be produced b efore free service will be provided.

• Travelling time and mileage are included within 30km of either your authorised Climate Technologies

dealer or service provider’s premises. Customers in areas other than the above are responsible for any

travelling time and mileage required to carry out warranty repairs.

• The product must be installed by a qualified person in the manner prescribed by local & statutory

regulations and to the manufacturer’s specifications.

• Service within the terms of this warranty wil l be recognised where we are satisfied that the ap pliance or

part was supplied within the relevant time limi ts. Documents of purchase and Dealer/Installer

information will assist in this process.

• Product fitness for purpose and overall system design / sizing is solely the responsibility of the dealer /

installer. This includes but is not limited to heat load calculations, air flow, system balancing, humidity,

water quality etc.

• The product must be installed in an easily and safe accessible area for service, appliances installed in

areas not easily and safely assessable, costs will be borne by the owner for access equi pment should

maintenance be required.

Bonaire Commercial / Industrial EAC

Page 17

Page 18

INSTALLATION, OPERATION & MAINTENANCE

y

Warranty – Australia Onl

DIY installation Warranty

• If the product has been installed as a DIY, a supply part only warranty will apply. Parts only will be

supplied free of charge on the return of the faulty part and the owner will be responsible for all labour

charges incurred for the part to be fitted by a qualified person. Labour warranty as prescribe d in the

following table is void in this situation.

Remote Location Warranty

• If the product has been installed outside the Climate Technologies service network, a supply part only

warranty will apply. Parts only will be supplied free of charge on the return of the faulty part and the

owner will be responsible for all labour charges incurred for the part to be fitted by a quali fied person.

Labour warranty as prescribed in the following table is void in this situation.

Exclusions to Warranty.

• Consumable items subject to wear and t ear such as filter pads, drive belts and bearings are not covered

by this warranty.

• Components used as part of the installation such as grilles, filters, ducting, fittings, zone motors and

consumer services pipe work are warranted from your place of purchase and not covered by this

warranty.

• Damage caused by elements such as w ind, rain, lighting, floods etc along with power spiking and

brownouts are not considered defective material or workmanship and as such are not co nsidered

warranty.

• No responsibility will be accepted for outside elements such as pests, animals, pets and vermin that may

cause damage to the unit.

• Harsh environmental situations such as salt air that may cause cabinet damage / rusting can not be

considered warranty.

• The manufacturer does not accept liability or any claims for dam age to building contents, carpet, walls,

ceilings, foundations or any other consequential loss either direct or indirect. Damage resulting from,

power spikes, incorrect operation, incorrect installation, incorrect maintenance is also not covered.

• All warranties are NOT transferable.

Conditions Where Warranty May Be Void.

• If there is no certificate of compliance for plumbing, e lectrical or refrigeration as required by State &

Territory Laws. Climate Technologies reserves the right to r efuse service on non-compliant installations.

• The defective operation of the appliance that is due to failure of electricity, gas, water or refrigerant gas

supplied.

• Defects are caused by neglect, incorrect application, abuse or by accidental damage of th e appliance.

• An unauthorised person has attempted to repair the appliance.

• A situation arises referenced in the trouble-shooting guide.

• A charge will be made for work done or a service call where there is nothing wron g with the appliance.

Bonaire Commercial / Industrial EAC

Page 18

Page 19

INSTALLATION, OPERATION & MAINTENANCE

y

Warranty – Australia Onl

PROOF OF PURCHASE

It is important that the name of the Dealer or Retailer from whom y ou purchased your prod uct and the name of

the installer are recorded on this page. The installer is responsible for the correct installation, start up and

demonstrating the operation of this product. The Dealer or retail er is also responsible for issuing the relevant

certificates of compliance for the electrical co nnections. (These may differ from state to state)

Please attach your proof of purchase here. Your receipt is your warranty and will be required to validate any

warranty.

DEALER PRODUCT INFORMATION:

Dealer/Retailer:

Dealer Address:

Dealer Phone Number:

Unit Model Number:

Serial No:

Date Installed:

Installed by:

Date Commissioned:

Commissioned by:

Signature:

PERIODS OF WARRANTY – YEARS BY PRODUCT AND APPLICATION:

Unit Components

Corrosion on Cabinet 2 2

Structural Guarantee 2 2

** All other components 2 2

Parts Labour

** Consumables e.g. filter pads, “V” belts and bearings are not covered by this warranty

Bonaire Commercial / Industrial EAC

Page 19

Page 20

INSTALLATION, OPERATION & MAINTENANCE

y

Warranty – Australia Onl

AGED NEW PRODUCT WARRANTIES

For a new product warranty to apply, a product needs to be purchased and installed within 3 years of the

manufacturing date by the original purchaser.

Product that is aged as the result of extended storage or being used for demonstration purposes, the following

warranty conditions will apply.

• For a product that is greater than 3 years and less than 5 years old from date of manufacture the statutory warranty

will apply and any voluntary warranty originally supplied will be reduced by 1 year

•

For a product that is greater than 5 years of age from date of manufacture, the statutory warranty will apply to

electrically functioning components only. All other components being cabinets, louvres, filters etc. will not be

covered by warranty.

WARRANTY ON REPLACEMENT PARTS:

Parts replaced under warranty are warranted for the balance of the original warranty period.

ERVICE CENTRES:

S

Only qualified service personnel should conduct any service work carried out on your ducted air conditioning

system. It is important that periodical service is carried out on your product to ensure your will receive the

efficiency benefits the product provides.

For Metro Service only ring the numbers below.

South Australia/ (08) 8307 5230

Northern Territory

New South Wales / (03) 8795 2457

Australian Capital Territory

Western Australia (08) 9454 1000

Victoria/Tasmania (03) 8795 2456

Queensland (03) 8795 2457

Bonaire Commercial / Industrial EAC

Page 20

Page 21

INSTALLATION, OPERATION & MAINTENANCE

Service & Maintenance

SERVICE & MAINTENANCE

PROBLEM SOLVING

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

•

Undersized air conditioner. • Replace with larger air conditioner.

•

Clogged or dirty filter pads. • Clea n or replace pads.

Inadequate

Cooling

•

Insufficient air discharge openings

or inadequate exhaust from area

being cooled, causing high

• Check water distribution system for

possible obstruction in tubing. Check

pump.

humidity and discomfort.

•

Excessive Ambient Humidity (see

also item above re-inadequate

exhaust).

• On days during summer when the

ambient humidity is very high, the air

conditioner will not reduce

temperature as mush as on drier

days. There is no remedy except to

shut off the pump.

•

Fan turning backwards. • Re-connect motor for correct rotation.

•

Fan running too slowly. • Check motor amps. If below

nameplate amperage, re-adjust motor

pulley (sheave) to increase fan

speed.

•

Belt slipping. • Tighten belt by re-adjusting position

of motor. Replace belt if worn.

•

Circuit breaker tripped or fuse

blown.

•

Loose electrical connections. • Check all electrical connections.

• Reset circuit breaker or broken fuse.

Check circuit breaker size correct

Fan fails to

start

Belt slipping or

wearing

excessively

•

Defective control switch. • Replace.

•

Motor burnt out. • Replace.

•

Belt or pulley loose. • Tighten belt and pulleys.

•

Belt broken or missing. • Install new belt

•

Belts too tight. • Adjust belt tension.

•

Belt loose. • Tighten belt.

•

Pulleys out of line. • Align pulleys.

•

Moisture getting on belt. • Stop any water leaks. Adjust Dialflo to

stop water carry over.

•

Worn belts. • Replace belt

•

Worn pulleys. • Replace pulleys.

Bonaire Commercial / Industrial EAC

Page 21

Page 22

INSTALLATION, OPERATION & MAINTENANCE

Service & Maintenance

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

•

Pump motor failure. • Replace complete pump.

Pump fails to

operate

•

Loose electrical connections. • Tighten electrical connectio ns.

•

Pump control switch faulty. • Replace pump control switch.

•

Insufficient water in pan. • Adjust float level.

Pump runs but

•

does not

circulate water;

Pump strainer blocked. • Clean strainer.

•

Blocked water in tubing. • Clean the tubing.

Pump runs but

pads lack water

Foreign matter lodge in the water

• Clean out foreign matter.

•

distribution piping.

•

Fan rubbing on housing. • Re-position fan.

•

Fan out of balance due to dirt, etc. • Clean fan.

Noisy air

conditioner

Continuous

overflow of

water

Water into the

duct work

Unpleasant

odour

•

Air conditioner delivering more air

than needed.

•

Belt ‘squealing’. • Tighten belt by adjusting motor. Apply

• Adjust ducting baffles to reduce airflow

or balance flow to outlets.

belt dressing to belt. In some cases it

may be necessary to replace belt.

Check the pulley alignment

•

Inadequately sized ducts or grilles. • Increase size or add additional ducts or

grilles.

•

Float valve adjustment incorrect. • Adjust float valve.

•

Loose water tubing connections. • Tighten all connections.

•

Break in water tubing.

•

Too much water from the pump

• • Replace any cracked or broken tubing.

Adjust the dialflo outer knob to reduce

the flow of water to the filter pads.

•

Air conditioner located near source

of unpleasant odour.

• Remove source of odour or place a

barrier between air conditioner and

source of odour.

•

Algae in pan water. • Drain pan and clean thoroughly. Fill

with fresh water. Install new pads.

•

Pads remain wet after shut down. • Allow fan to run for about 10 minutes

Rapid formation

of white

•

High mineral content of supply

water.

deposits

Bonaire Commercial / Industrial EAC

after pump is shut off to dry out pads.

• Increase the bleed rate. Fit a dump

valve and timer for cyclic dumping.

Page 22

Page 23

INSTALLATION, OPERATION & MAINTENANCE

Service & Maintenance

REGULAR MAINTENANCE

A qualified service technician should conduct any service work carried out on your

commercial cooling product. It is important that periodical service is carried out on your

product to ensure your will receive the efficiency benefits the product provides.

Note: Local regulations and codes may require the owner to carry out and record

specific maintenance in a log book e.g. cleaning and draining the

evaporative cooler sump.

Maintenance

1. Turn on the electric power supply.

2. Turn on water isolation valve

3. Remove the winter cover if fitted.

4. Remove the filter frames and clean filters with water

5. Replace filter pads where required

The frequency depends on the daily use of the air conditioner, the state of the

environment and the quality of the water. Each of these factors affects the life of the

pad.

Please note that the filter pads supplied, being CELdek or aspen, have been selected

to give the highest possible cooling performance. Use only Climate Technologies

genuine replacement filters. The manufacturer is not responsible for the performance

of the air conditioner when alternative materials are used.

Note: Filter pads are a consumable and are therefore not covered by warranty

6. Flush and clean the reservoir

7. Check the water level and reset the float arm setting if required.

8. Check the pump operation and clean the filter basket

9. Check the fan bearings.

- Check there is no bearing wear on the shaft and that the bearings are tight on the

shaft.

- Grease the fan bearings. Fan bearings will require regular checking and greasing

subject to the duty cycle e.g. 24/7 operation - review monthly.

Note: Bearings are a consumable and are therefore not covered by warranty

10. Check the fan belt tension and adjust if necessary. To adjust the belts:

- Remove the belts from the drive.

- Mark the motor tray location on the chassis.

- Loosen the motor tray bolts on each side, and slide the tray back in 5mm

increments.

- Tighten the motor tray bolts on each side and refit the vee belts.

- Check the belt tension and pulley alignment. The belt should only depress

approximately 15-20mm in the centre of its span.

Note: Vee belts are a consumable item and are not covered by warranty

Bonaire Commercial / Industrial EAC

Page 23

Page 24

www.climatetechnologies.com.au

Manufactured by

Climate Technologies

ABN 13 001 418 042

P/N 1-M00-05-907/E

Loading...

Loading...