BONAIRE Integra VSS50, Integra VSS55, Integra VSM60, Integra VSM65, Integra VSL70 Installation Instructions Manual

...

Installation Instructions

EAC

Domestic Ducted Evaporative Air Conditioners

Integra

VSS50/55, VSM60/65, VSL70/75

Installation Instructions

Page 2

Table of Contents

BONAIRE EAC

1. I

NTRODUCTION

____________________________________________________ 4

1.1. Important Notes ____________________________________________________ 4

1.2. Dealer / Installer Responsibility ________________________________________ 4

1.2.1. Training _____________________________________________________________ 4

1.2.2. Legal & Statutory obligations_____________________________________________ 4

1.2.3. Safety and O.H. & S. Requirements _______________________________________ 5

1.3. Before Commencing ________________________________________________ 5

2. UNIT L

OCATION

___________________________________________________ 6

3. UNIT I

NSTALLATION

________________________________________________ 7

1.1. Installing the Dropper Duct ___________________________________________ 7

3.2. Installing the Enviroseal Duct Shutter ___________________________________ 8

3.3. Installing the Air Conditioner __________________________________________ 9

3.4 Installing the Duct Work_____________________________________________ 11

4. CONNECTIONS _________________________________________________ 13

4.1 Water Management __________________________________________________ 13

4.2 Inlet Water Connections_______________________________________________ 13

4.2.1 Fitting the Float Valve_____________________________________________________ 13

4.2.2 Connecting the Water Supply_______________________________________________ 13

4.3 Drain Connections – Bonaire Aquamiser __________________________________ 14

4.3.1 Fitting the Bonaire Aquamiser ______________________________________________ 14

4.3.2 Drainage Provisions ______________________________________________________ 16

4.4 Aquamiser Wiring Diagram_____________________________________________ 19

5. COMMISSIONING _______________________________________________ 20

5.1 Water Levels _____________________________________________________ 20

5.2 Dialflow Settings_____________________________________________________ 20

5.3 Bonaire Aquamiser Settings____________________________________________ 21

5.3.1 Setting the Draining Cycle Times (Dump Interval)_______________________________ 22

5.3.2 Setting the Drain Off delay time (Dump Delay) _________________________________ 23

5.4 Installation of Transceiver______________________________________________ 24

5.5 Pairing the Navigator Controller (Remote Only)_____________________________ 24

5.6 Operation of Multiple Navigator Controllers ________________________________ 25

5.6.1 Multiple Wireless Remote Controllers ________________________________________ 25

5.6.2 Joining Navigator Controller (JOin) __________________________________________ 25

5.6.3 Accessing Installer Navigator Controller Setups ________________________________ 26

5.6.4 Navigator Controller Parameters Table _______________________________________ 27

5.7 Navigator Controller Installation – Evaporative Cooler________________________ 28

5.7.1 Accessing Evaporative Cooler Installer Setup __________________________________ 28

5.7.2 EAC Installer Parameters Table_____________________________________________ 29

Installation Instructions

Page 3

Table of Contents

BONAIRE EAC

5.7.3 Multiple Controllers – Shared Zones _________________________________________ 30

5.7.4 Single EAC In Shared Zone (2 Wired Navigators)_______________________________ 30

5.7.5 Single EAC In Shared Zone (2 Remote Navigators) _____________________________ 30

5.7.6 Single EAC In Shared Zone (3 or 4 Navigators) ________________________________ 30

5.8 Fan Operation_______________________________________________________ 31

5.9 Controls ___________________________________________________________ 31

5.10 Customer hand Over ________________________________________________ 31

5.11 Commissioning Check List____________________________________________ 31

6. SERVICE ______________________________________________________ 33

Installation Instructions

Page 4

1.0 Introduction

BONAIRE EAC

1. INTRODUCTION

Please take the time to fully read this Installation manual. Failure to follow these

instructions may result in injury to you and damage to the air conditioner or your

customer’s property.

Installation of this Bonaire Evaporative Air Conditioner must conform to local building

rules and regulations, electrical and plumbing codes, Environmental Protection Authority

(EPA) regulations, and all applicable Australian Standards.

Should you not follow these instructions the unit warranty may be void. The cost of

warranty would then be the cost of the customer or the installer / dealer.

Refer to the tick box Commissioning Checklist to ensure you have covered all points

when the installation is complete. Please complete the Commissioning Checklist tick box

in the owner’s manual, as a completed, signed and dated checklist will be required to

verify certain warranty claims.

1.1. Important Notes

• TEXT AND ILLUSTRATION COPYRIGHT CLIMATE TECHNOLOGIES 2011

• All rights reserved. No part of this document may be reproduced or transmitted

in any form or by any means, electronic or mechanical, including photocopying,

recording or by any information storage and retrieval system, without prior

permission in writing from Climate Technologies.

• Climate Technologies is constantly researching and developing improved

product features and therefore reserves the right to change the

specifications without notice. E. & O.E.

1.2. Dealer / Installer Responsibility

1.2.1. Training

• It is the responsibility of all dealers to ensure their staff are adequately

trained to ensure the product is correctly specified.

• It is the responsibility of all dealers to ensure their installation teams / subcontractors are trained in the correct installation of product, duct & fittings

as well as relevant installation codes and OH&S requirements.

• Climate Technologies will provide technical assistance and training to the

dealer as required. On going technical support will only be provided to

those dealers and installers who attend regular training provided by

Climate Technologies.

1.2.2. Legal & Statutory obligations

• It is the dealer / installer’s responsibility to comply with all codes &

standards, statutory and legal requirements, state and council / shire by

laws.

• Relevant certificates of compliance for the installation must be issued.

Service may be refused or warranty may be void if the installation is not

compliant.

Installation Instructions

Page 5

1.0 Introduction

BONAIRE EAC

1.2.3. Safety and O.H. & S. Requirements

• It is the responsibility of the dealer / installer to ensure the environment is

safe for the installer to carry out the installation. A risk assessment should

be carried out in conformance to state codes of practice. An industry guide

to “safe Work at Heights” is available from Climate Technologies.

• It is the responsibility of the dealer / installer to ensure safe access to the

unit can be achieved for service and that the access conforms to the

relevant standards and codes.

• It is the responsibility of the dealer / installer to ensure the roof is provided

with access footings and platform where the pitch of the roof is unsafe for

service access.

• It is the responsibility of the dealer / installer to ensure harness anchorage

points are provided where units are located on a roof greater than single

story or if the pitch and roof construction do not allow safe access. See

Australian Standard 1891.4:2000 Part 4 Selection use and maintenance,

Table 2.1.

1.3. Before Commencing

• Packaging – check there is no damage before removing packaging. Damaged

units should not be installed. Climate Technologies should be contacted prior to

installation. Careless transportation by installer will not be covered by warranty.

• Do not install damaged products. Contact your nearest Climate Technologies

office for further advice.

NOTE: These 3 appliances VSS55, VSM65 & VSL75 have fan speed turn

down ability to adjust their air output to match unit sizes of VSS50, VSM60

& VSL70 as calculated in the Bonres system design. Installers should

adjust fan speed accordingly to the design requirements.

Installed damaged products will not be covered by warranty.

• Have you got all the system components?

• Have you got the right unit?

• Does the system design conform to the minimum specification of Bonaire’s

specification and as such fall in line with sound engineering design practices.

Installation Instructions

Page 6

2.0 Unit Location

BONAIRE EAC

2. UNIT LOCATION

2.1 Unit Location Check List

• EPA - A correctly installed unit will perform to specification on sound pressure

radiated noise. As an installer, you have a professional obligation to ensure that

every practical and reasonable effort is made to install this product to best

practice guidelines and ensure that any operational noise does not affect

neighbours. Complying with EPA / council by laws for noise abates is the

responsibility of the dealer / installer / owner.

NOTE: Do not mount the unit on a section of roof that slopes towards a

neighbour’s property.

• Place the unit well away from sources of smoke, dust and objectionable fumes so

that only clean, fresh outside air will be drawn into the unit. Reference should be

made to relevant gas codes and state plumbing regulations.

• Check the proposed location to ensure that building members are structurally

capable of supporting the operating weight of the air conditioner. You may need

to consult the roof truss manufacturer.

• The unit must be installed in a position that gives safe access for service. It is

the responsibility of the dealer / installer to ensure safe access to the unit can be

obtained for servicing the product.

• Where roof height, pitch or construction will cause OH&S concerns as previously

mentioned, service footing supports / platform and or harness anchorage must

be provided for safe service.

NOTE: The manufacturer and its service providers reserve the right to

refuse service unless safety and accessibility to the unit can be

guaranteed.

• The cost of any extra equipment required to give access to the unit for servicing

or warranty repairs is the responsibility of the owner.

The unit should face into the customer’s back yard, as low as possible on the roof, with easy,

unobstructed access. Keep the unit away from chimneys, flues and vents that will pollute the

filter pads and the fresh air being drawn into the house.

Installation Instructions

Page 7

3.0 Unit Installation

BONAIRE EAC

3. UNIT INSTALLATION

1.1. Installing the Dropper Duct

All Bonaire Fresh Air Conditioners are designed to be fully supported by a metal

dropper duct. Metal dropper ducts must be designed, located and fixed to comply with

the relevant building codes. Plastic dropper ducts are not recommended for use.

• Use the recommended dropper duct as advised above.

• The dropper must be installed square and level.

• It should not touch ceiling joists or other structural members that allow noise and

vibration to be transmitted into the building.

• Ensure the dropper duct is installed so the unit does not touch the roof.

• Fix the duct dropper to the roof structure so that it’s secure and vibration free.

• All droppers must be fitted with a splitter pyramid in the base to ensure correct

airflow.

• All ductwork, electrical cables, water pipes and drains must be fully flashed and

sealed to prevent the entry of water into the building.

• Plastic dropper ducts should not be used as these may void warranty.

Recommended Dropper S

izes

Model Dropper Duct Size

VSS50/55

VSM60/65

550mm x 550mm

VSL70/75 550mm x 800mm

Dropper Duct Height - Roof

Roof Pitch Clearance Height

17° 165 mm

22.5° 185mm

25° 195 mm

36° 240mm

Installation Instructions

Page 8

3.0 Unit Installation

BONAIRE EAC

3.2. Installing the Enviroseal Duct Shutter

STEP 1 The Enviroseal duct shutter must be

installed a minimum of 150mm below the

top of the dropper duct. If the dropper duct

is fitted with insulation, remove insulation to

give the shutter free operation.

STEP 2 Ensure the Enviroseal is secured

horizontally on both angles.

STEP 3 Ensure electrical cables are not draped

across the top of the Enviroseal

mechanism

STEP 4 Ensure the Enviroseal is installed the correct way up. The Enviroseal flaps

must open downwards.

For more details refer to instructions in the Enviroseal kit.

Installation Instructions

Page 9

3.0 Unit Installation

BONAIRE EAC

3.3. Installing the Air Conditioner

• Remove 4 Louvre panels from unit and place in a safe place to ensure no

damage. To remove Louvre:

STEP 1. Lift the Louvre assembly up approximately 15mm over the corner

post location.

STEP 2. Tilt the Louvre back from the top of unit and remove.

• The venturi / fan assembly can be removed to assist in carrying the unit on the

roof. To remove the fan / venturi assembly:-

STEP 1. Disconnect the motor loom from the control box in unit.

Caution: Ensure motor wires are reconnected correctly

otherwise the product warranty may be void.

It is also possible to remove the electrical control box and

pump assembly to avoid disconnecting the electrics.

STEP 2. Remove fan / venturi assembly by releasing the venturi from the

location notches lifting vertically. (There are 4 location notches

holding the venturi in place.)

STEP 3. Carefully remove fan from the cabinet, not bumping the fan

assembly.

Installation Instructions

Page 10

3.0 Unit Installation

BONAIRE EAC

NOTE: Handle the fan/venturi assembly with care, as the fan blade is not

protected by the venturi once removed.

• Store the fan / venturi assembly in a safe

area until final installation to ensure no

damage. Store the fan upside down (on

the motor) ensuring no damage to the fan

assembly. (Do not store in the gutter.)

NOTE: Warranty claims for damaged motors, impellers or venturis will not

be recognised if the motor / venturi have been damaged during

installation.

• Lift unit chassis onto the roof. When locating the unit onto the dropper duct,

ensure the water reservoir is on the low roof side of the dropper duct.

• Fit the unit level on the dropper duct to ensure even water distribution.

• Check the unit is located correctly on the dropper duct. Locate the unit on the

correct chassis duct location points for the appropriate dropper duct size. The unit

should be central on the dropper duct.

• Fix the unit into position with self-tapping type screws by screwing through the

unit duct adaptor flange and into the dropper duct. A minimum of 4 screws should

be used on each accessible side of the unit.

Installation Instructions

Page 11

3.0 Unit Installation

BONAIRE EAC

• Lift the fan deck onto the roof and reinstall into the unit. Ensure the venturi is

correctly rotated for the motor wiring loom and has snapped into the location

notches. Spin fan blade by hand to ensure that the blade does not touch the inlet

ring.

• Reconnect the fan loom to the control box.

• Connect communication cables to the control box

• Feed the communication cable and the 240-volt plug and cable set through the

50mm electrical entry drilled into the dropper duct. Ensure the 50mm rubber

grommet supplied is used to ensure an electrical hazard is not created.

3.4 Installing the Duct Work

• Use only insulated ductwork to a thermal resistance of insulation

minimum of R1.0, designed and installed to ‘BONRES’ System

Design guidelines. All bends must have a minimum radius of 1.5

times the diameter. All joins must be taped airtight.

• Flexible ductwork connected to the dropper duct must be designed and installed

to the ‘BONRES’ System Design Guide in conjunction with industry based best

guidelines.

• Cut flexible duct to the correct length to ensure no excess duct is left in the

system. This will ensure minimum system resistance and maximum air flow.

• All duct work should be streamlined. Avoid sharp angles that will reduce airflow.

• The minimum bend radius is 1.5 times the duct diameter

• The last bend to each ceiling register must be a smooth radius so that airflow is

even into the room.

• Do not squash duct work to fit through small openings, as airflow will be

restricted. Find a better location.

• If more than 6 metres of flexible duct work are required in one length, the next

size up flexible duct must be used.

• All duct work in ceiling spaces or hot areas must be well insulated.

• All external exposed duct work must be weatherproofed.

• All duct work must be taped airtight.

Installation Instructions

Page 12

3.0 Unit Installation

BONAIRE EAC

The last bend to each ceiling register must be a smooth radius

so that airflow is even into the room

Installation Instructions

Page 13

4.0 Connections

BONAIRE EAC

4. CONNECTIONS

4.1 Water Management

• Water bleed rates or the drain cycle times must be set to a rate appropriate to the local

supply water conditions. No scaling should be evident where the drain cycle / bleed rates

are set correctly. This will ensure maximum cooling and filter pad life, reduced opportunity

for scaling and therefore less regular maintenance.

NOTE: Where water quality is of high mineral content e.g. bore water, bleed off will be

required in conjunction with a regular timed draining cycle.

4.2 Inlet Water Connections

4.2.1 Fitting the Float Valve

STEP 1 Remove nut from float valve assembly.

STEP 2 Ensure rubber washer is fitted inside the tank on the float valve. Fit float valve

assembly in tank.

STEP 3 Fit nut to the valve on the underside of the tank. Do not over tighten.

NOTE: In areas of low water pressure it may be necessary to remove the water flow

restrictor from the inside of the valve. Minimum water pressure required to

operating the float valve is 100 kPa.

STEP 4 After the nut has been tightened, ensure the ball

is not contacting the filter pad, the side of the

base of the unit or the Bonaire Aquamiser. It

should be positioned central.

STEP 5 Fit elbow supplied to the float valve.

STEP 6 Fit the 24-Volt AC water solenoid valve to the

elbow (Direction- Horizontal Not vertical).

STEP 7 Fit Flexible Connector to solenoid valve

4.2.2 Connecting the Water Supply

• The water supply pipe work and connection to the evaporative air conditioner must be

installed by a licensed plumber and conform to AS 3500, state & local plumbing

regulations.

• Ensure water pressure to the appliance does not exceed the maximum static pressure of

500kPa (50 m head) as per AS 3500 (section 3.3)

• Unit water connection is a ½” BSP fitting. Use the flexible connector supplied for the

connection between the isolating cock and the solenoid / float valve.

NOTE: In areas where water pipes freeze, a low level drain tap or pressure expansion

control valve provision will be needed to drain the water piping to prevent damage to

the air conditioner. The customer should also be advised on its operation by the

dealer / installer.

Installation Instructions

Page 14

4.0 Connections

BONAIRE EAC

2” BSP

Connector

x1

Seal

x1

40mm Fitting

x1

20mm Fitting

x1

25-19mm

Fitting

x1

• Ensure the water supply pipe is of the correct length and is secured to prevent tension on

the solenoid / float valve fittings.

• The supply pipe should be 12mm copper pipe or similar approved. A ¼ turn ball isolating

valve must be installed on the supply pipe near the unit for ease of maintenance. Do not

use duo or non-return valves of any kind including stop taps with jumper washer.

NOTE: Non return type valves can have an effect on the operation of the water

solenoid valves. Lock up and damage can be caused. Non return valves are not

required as the product conforms to MP52 Spec 101:2001 Plumbing safety licences.

• Ensure connection in to cold water supply.

• Before connecting the supply pipe flush it of any swarf or debris that may cause the float

valve or solenoid to leak.

NOTE: Failure of the Solenoid valve or Ball Float due

to debris or swarf will not be covered by warranty and

is therefore the responsibility of the installer / owner.

4.3 Drain Connections – Bonaire Aquamiser

4.3.1 Fitting the Bonaire Aquamiser

The Bonaire Aquamiser connection size is 2” BSP.

STEP 1 Remove the rubber washer from Bonaire Aquamiser Assembly.

STEP 2 Place the rubber washer under basin and fit the Bonaire Aquamiser assembly.

NOTE: The Aquamiser sticker must face the corner post and solenoid lead

must not be touching ball float.

STEP 3 Fit the drain fitting to the Bonaire Aquamiser thread on the underside of the tank and

tighten ensuring no leaks.

Select appropriate drain connection for your local plumbing regulations (40mm

Recommended)

The Bonaire Aquamiser Kit should include

1 of each of the following items:

Installation Instructions

Page 15

4.0 Connections

BONAIRE EAC

When the drain

fitting components

are assembled

together, it should

look like the above

40mm option 20mm option 25-19mm option

To use the 25mm option on this

fitting, simply cut off the 19mm

tail as shown

Screw the drain fitting onto the Bonaire

Aquamiser from the underside of the tank

as shown

Installation Instructions

Page 16

4.0 Connections

BONAIRE EAC

4.3.2 Drainage Provisions

The discharge pipe must have an internal diameter of no less than the internal diameter of the

unit connection provision supplied by the manufacturer. Provided are a 40mm, 20mm and a 2519mm fitting for the Bonaire Aquamiser. The following diagrams are typical and provide

guideline for drainage connections to the evaporative cooler in accordance with the plumbing

regulations and standards.

Note: Discharge water must be managed in accordance with State and Local Government

statutory requirements and local by laws.

ECO FRIENDLY

SUGGESTION

For water conservation

purposes, the waste

water from the

evaporative unit could

be stored and used at a

later date for watering

pot plants.

OPTION 1 A discharge point to a roof gutter

pop outlet, providing the downpipe is not

used for the collection of water for potable

use

OPTION 2 Direct to downpipe via a

tundish, providing the downpipe is

not used for the collection of water for

potable use

OPTION 3 A surface stormwater drainage system

provided the surface is graded away from the building and

ponding does not occur and the discharge does not

present a safety risk to pedestrians (eg. across a

footpath)

Installation Instructions

Page 17

4.0 Connections

BONAIRE EAC

OPTION 6 To a suitable water spreader

• Tiled rooves only

• Spreader design should be such that water

will not spill over the gutter

• Providing the roof is not used for the

collection of water for potable use

OPTION 5 An absorption pit. Provided the

following conditions can be met:

• Only permitted where no sanitary or

surface water drainage is available.

• The pit can only be constructed in

permeable ground

• Of a size appropriate for the volume of

discharge

• Located so the discharge water will not

cause damage to buildings by changing

moisture conditions

i) To a floor waste gully ii) Direct to sanitary drain

OPTION 4 A sanitary drainage system via

a tundish in one of the following forms in

accordance with AS/NZS 3500.2.2 - 1996

clause 4.6.7.8 & 11.22.

Installation Instructions

Page 18

4.0 Connections

BONAIRE EAC

STEP 4 Fit the 240V cable between the solenoid and the control box routing it through the

electrical post inside the tank. Connections are not colour specific.

Ensure cables are not submerged in water!

STEP 5 Connect electrical wiring from the Bonaire Aquamiser to the Control Box as shown

below

Solenoid Loom

(2 Wires)

Electrical post

(Solenoid Loom to be

routed through here)

Aquamiser Loom

(4 Wires

Sheathed)

Bonaire

Aquamiser

Control Box

Solenoid Valve

240V

Power

Supply

Aquamiser

Connection

Installation Instructions

Page 19

4.0 Connections

BONAIRE EAC

4.4 Aquamiser Wiring Diagram

Control Box

Installation Instructions

Page 20

5.0 Commissioning

BONAIRE EAC

5. COMMISSIONING

5.1 Water Levels

STEP 1 Turn the water on to unit and allow unit to fill. The water level should be 65mm to

70mm from the overflow window on the Bonaire Aquamiser

STEP 2 Turn the unit on and set the pre-cool function. This will activate the solenoid valve

and allow time to check the float valve setting.

STEP 3 Adjusting the float valve ball: While the float valve ball is factory set some

adjustment may be required. Adjust with care. To adjust the water level, simply

screw the ball up or down the thread on the arm. (Do Not Bend the ARM)

STEP 4 Fit Louvre panels and check for even wetting of the filter medium.

5.2 Dialflow Settings

Filter Rate – Outer Knob

• Ensure the filter knob is opened to get water

flow to the distributor. Turn Filter anti

clockwise to increase water flow.

• If water lift off is noticed, the flow rate can be

adjusted. Turn anti-clockwise to reduce the

flow to the distributor.

Bleed off Rate (if required) – Inner Knob

• All evaporative air conditioners need some water

bleed-off to prevent build-up of mineral deposits

in the system. The correct setting of the bleed

rate will ultimately govern the life of the unit.

• With normal mains water supply, bleed rate should be adjusted so that the discharge is not

less than 10 litres per hour. Increased water hardness may require a higher bleed rate and

increased maintenance

Aquamiser

overflow

Water Level 65 – 70mm below

overflow window on the

Aquamiser

Installation Instructions

Page 21

5.0 Commissioning

BONAIRE EAC

• A bleed off may not be required if the Bonaire Aquamiser is fitted and the water quality is

below 300ppm. In which case the bleed rate should be set to completely off and the hose

secured in bottom of basin.

• Always set the bleed rate after the flow rate has been determined.

• To set the bleed rate, hold the filter flow knob (Outer) at its current setting while adjusting the

bleed rate (Inner Knob).

NOTE: It is the responsibility of the installer / owner to set a correct bleed rate (If

required) to suit local water conditions and ensure that rate is maintained.

5.3 Bonaire Aquamiser Settings

Correct water management in an evaporative air conditioner is vitally important to the operation

and longevity of the product. If the water management is not set correctly by the installer to the

local water condition, warranty will be void. Maintaining correct water management is the

responsibility of the owner of this appliance and warranty will also be void if correct settings are

not maintained.

Fit Bleed Pipe into

the li

d as show

n

Bleed Pipe is now

fitted correctly

Installation Instructions

Page 22

5.0 Commissioning

BONAIRE EAC

• Where a Bonaire Aquamiser is fitted and is set up for regular timed draining periods during

operation, the bleed may not need to be switched off. Check the water quality and if it is

below 300ppm Total Dissolved Solids (TDS), timed draining periods will be all that is

necessary to maintain TDS concentration levels. Over 300ppm TDS you may need a

combination of both bleed and drain. Please contact our technical support for more

information if needed. (www.bonaire.com.au)

• Where a Bonaire Aquamiser is only used for the purpose of a dry sump when not in use, the

bleed rate will have to be set for the conditions of operation.

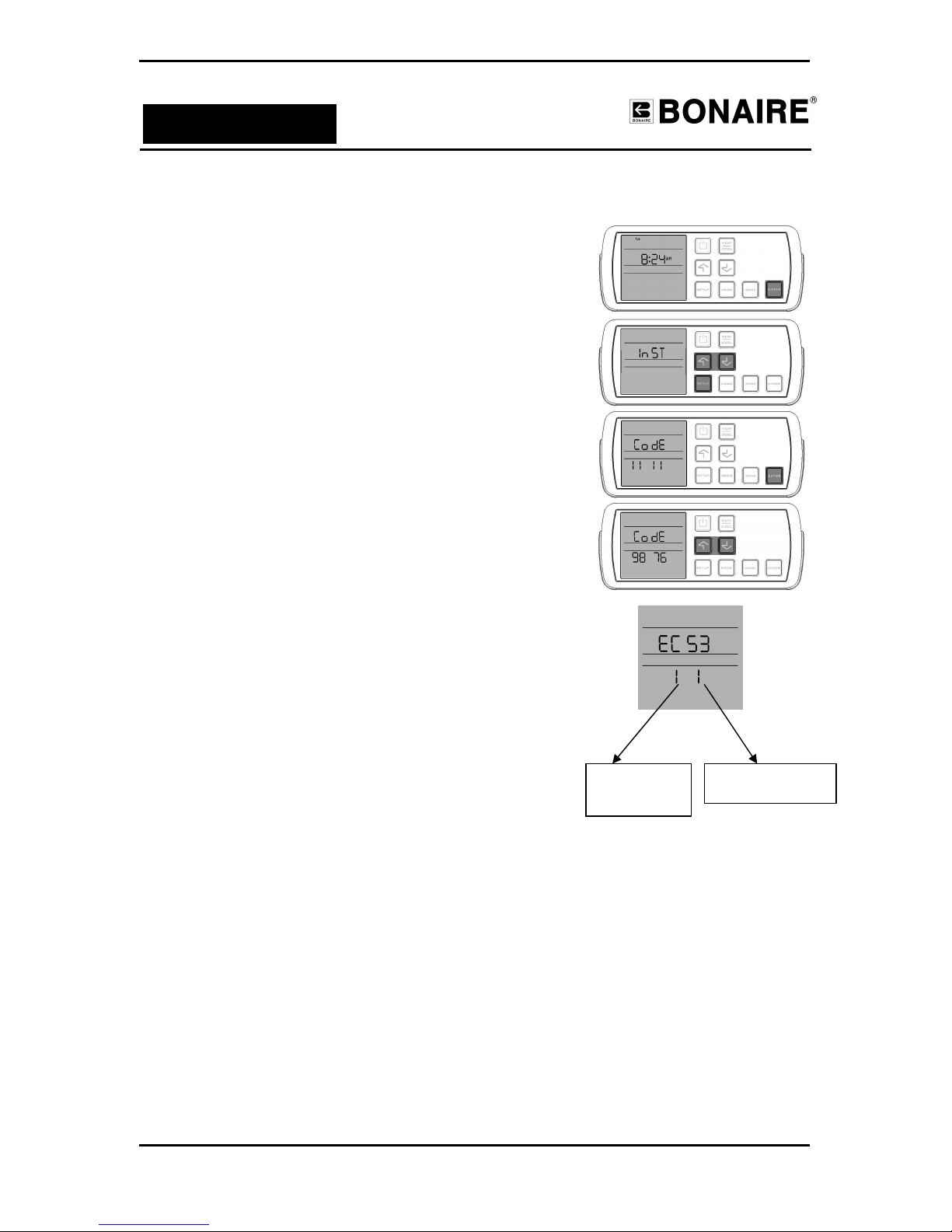

5.3.1 Setting the Draining Cycle Times (Dump Interval)

In the setting of Draining Cycle Times, Navigator Control

must be in the OFF mode. To set the Draining Cycle Time,

1. Press and hold the ENTER button for 3 seconds.

2. Press and release the “UP”, “DOWN”, and “SETUP”

buttons in sequence.

3. The word “InST”, “nSTA”, “STAL”, “TALL”, “ALLE”,

“LLER” (Installer) will scroll across the upper part of

the display. Press the ENTER button now to access.

4. When the CodE “11 11” appears input the code “98

76” using the UP/DOWN buttons and ENTER button

to move on to the next digit.

5. The display will flash the type of unit and address of

the unit. For example “EC 53” (EC- Evaporative

cooler, 53- Different number for every Unit) and “1

1 1

1 1

11

1”

parameter on the screen. Press the ENTER button to

go to the”1 1” parameter.

6. The display will flash the first number “1”. Move to

parameter “3” by pressing the UP/DOWN button then

press the ENTER button.

7. The display will flash the second number “1”. User

can set “0, 1, 2, 4, 8 or 12” hours by pressing

UP/DOWN button. The default dumping time is 4

hours.

8. Press ON/OFF button to finish.

The draining cycle times have now been set.

Installation Instructions

Page 23

5.0 Commissioning

BONAIRE EAC

5.3.2 Setting the Drain Off delay time (Dump Delay)

DRAIN OFF Delay Time gives the option for immediate

draining of the water from the tank or a one hour delay after

the unit has been turned OFF. Setting the 1 hour delay is

preferable if the unit is going to be used in thermostat (AUTO)

mode. To set the 1 hour delay:

1. Press the ENTER button for 3 seconds.

2. Press the “UP”, “DOWN”, and “SETUP” buttons in

sequence.

3. The word “InST”, “nSTA”, “STAL”, “TALL”, “ALLE”,

“LLER” (Installer) will scroll across the upper part of

the display. Press the ENTER button now to access.

4. When the CodE “11 11” appears input the code “98

76” using the UP/DOWN buttons and ENTER button

to move on to the next digit.

5. The display will flash the type of unit and address of

the unit. For example “EC 53” (EC- Evaporative

cooler, 53- Different number for every Unit) and “1 1”

parameter on the screen. Press the ENTER button to

go to the “1 1” parameter.

6. The display will flash the first number “1”. Enter “1” by

pressing the UP/DOWN button and press the ENTER

button.

7. The display will flash the second number “1”. User

can set “0, 1” value by pressing the UP/DOWN

button. Set “0” for immediate draining of water from

the tank or “1” for 1 hour dump delay. (If an

Aquamiser is connected the user can set “0, 1, 2, 3,

4, 5” hours dependant on Hour setting parameter).

The default HOUR is 1 and default day is 1.

8. Press ON/OFF button to finish.

NOTE: It is the responsibility of the installer to set the

correct draining period to suit local water conditions.

Installation Instructions

Page 24

5.0 Commissioning

BONAIRE EAC

5.4 Installation of Transceiver

The transceiver cable connects to the control box as shown.

Fully extend the transceiver cable (4 meters) and attach the

transceiver housing to a solid surface such as a rafter or

vertical column using the two screws provided. Avoid direct

contact with metal surfaces. Connect the transceiver plug to

one of the two thermostat connections on the control box.

When the installation is complete and the power to the cooler

is turned on, a green LED in the transceiver case should be

visible confirming it is connected correctly and is ready for

pairing with a Navigator controller.

To ensure trouble free operation, the transceiver

housing & connecting cable should not be installed

within 200mm of any power cables or other radio

transmitting devices. The transceiver housing should be

placed 1m away from any metal object.

Do not screw the transceiver to the back of the

control box; it must be run into roof space.

5.5 Pairing the Navigator Controller (Remote Only)

The BONAIRE Navigator Controller and transceiver does not

have any pairing information when they are delivered from

the factory.

On the first power up, the transceiver will request to PAir with

Navigator Controller for period of a 30 min window and its

green light will be illuminated. If it does not PAir within that

time, it will PAir on the next power up. Put the Navigator

Control in pairing mode -

1. Press & hold the ENTER button for 3 seconds.

2. Press the Heat/Cool, Mode & Setup buttons in

sequence. The display will flash the “PAir”.

3. After a few seconds the Navigator Controller displays the

“ro XX” (“XX” is the unique serial number. For example

“ro 22”). It will also display the strength of signal.

4. Press the ENTER button to pair the transceiver and the

Navigator Controller.

NOTE: Wait until the backlight turns off and press

any key after 2 minutes.

5. Press the ON/OFF button to go to the main display.

RF Transceiver & cable

assembly

Navigator Controller & Transceiver

Connections

1

2

3

Installation Instructions

Page 25

5.0 Commissioning

BONAIRE EAC

5.6 Operation of Multiple Navigator Controllers

The Navigator control system is capable of supporting up to

4 controllers. By default, the system will allow one controller

to control the appliance or multiple appliances. Certain

parameter set ups must be made to configure multiple

controllers.

The options available are

• 2 wired Navigators only

• 1 wired Navigator and up to 3 Remote Navigators.

5.6.1 Multiple Wireless Remote Controllers

In a multiple Navigator controller system, the other controller

may be joined to a master by putting the slave controller into

a PAir mode. It will then send out a PAir request to the

master controller. The master controller is then put in a JOin

state and can then join the request to set up a Navigator

system.

5.6.2 Joining Navigator Controller (JOin)

Controllers requesting to JOIn another controller in the

Navigator system, can be put in the join mode as follows.

1. To enter the JOIn state, press and hold the ENTER button

for 3 seconds & release.

2. Press and release the, MODE, HEAT/COOL and SETUP

buttons in sequence.

3. The master wireless Remote controller should display

JOin state to receive a command from the other handset

to JOIn the Navigator system.

4. The slave controller should be placed into a Pair state to

join with the master controller. The slave controller

should display Pair. (Refer “Paring the Navigator

Controller”).

1

2

3

Installation Instructions

Page 26

5.0 Commissioning

BONAIRE EAC

5.6.3 Accessing Installer Navigator Controller Setups

NOTE: The Navigator Controller must be in the OFF

status to enter into the setup mode.

1. Press and hold the ENTER button for 3 seconds.

2. Press & release the then then SETUP buttons to

enter the installer set up mode.

3. The word “InST”, ”nSTA”, ”STAL”, ”TALL”, ”ALLE”, ”LLEr”

(Installer) scrolls across the upper part of the display.

Press the ENTER button.

4. When the CodE “11 11” appears, then set the code to

“98 76” using the and buttons to select each digit,

and press the ENTER button to move to the next digit

NOTE: The Navigator Controller will display the

abbreviated name of the appliance such as

“EC XX” for Evaporative Cooler, “HE XX” for

Central Heater or “th XX” for the Navigator

controller settings (“XX” is the unique serial

number). For example “th 06”.

5. Use the and buttons to scroll to the “th XX” and

then press the ENTER button to access Navigator

Installer setup.

The display will now show digits “1 1”. The lower left digit

is the parameter number and the lower right digit is the

parameter option value. Parameter numbers and option

values can be found in the Navigator Controller Installer

Parameters Table.

6. To select the parameter number use the and

buttons to find the desired parameter and press

ENTER.

7. Adjust the option value (See Navigator Parameter

Table) to the required value and press ENTER. This

will set the option value and return you to the

parameter number selection menu.

8. When finished press the ON/OFF button to exit.

Parameter

Number

Options value

Installation Instructions

Page 27

5.0 Commissioning

BONAIRE EAC

5.6.4 Navigator Controller Parameters Table

th parameter Table (“th XX”)

Parameter Description Default Definition Options Values

1 Un switched

Zone Option

1 Tells system if

there is a common

zone present

1= common zone

present.

0= no common zone

(Note that a cooler is

usually installed into the

common zone)

2 Switched

Zones

15 To display all

available switched

zones

15= Zone 1, 2,3 & 4

6 = Zone 2&3

127 = 8

Using ZONE and

buttons whilst in this

parameter will set the

number

3 Temperature

Display zone

0 Selects which zone

the Navigator will

display the

temperature of

0 –Common zone

1-8 Zones 1-8

4 Temperature

Measurement

-Un switched

Zone option

1 Determines if the

navigator is

measuring the

temperature in the

common zone

1Measuring common

zone.

0= Not measuring

common zone

5 Temperature

Measurement

- Switched

Zones

15 Determines which

of the switched

zones the

Navigator is

measuring,

15= Zone 1, 2,3 & 4

6 = Zone 2&3

127 = 8

Using ZONE and

buttons whilst in this

parameter will set the

number

6 Not Used 0

7 Not Used

8 RF Network

(RF handset

only)

0 The current RF

network number

0 = not assigned

Any other = actual

network

0 Not Used 0

Installation Instructions

Page 28

5.0 Commissioning

BONAIRE EAC

5.7 Navigator Controller Installation – Evaporative Cooler

5.7.1 Accessing Evaporative Cooler Installer Setup

NOTE: The Navigator Controller must be in OFF status

to change the parameters.

1. Press and hold the ENTER button for 3 seconds.

2. Press & release the then then SETUP buttons

to enter the installer set up mode.

3. The word “InST”, ”nSTA”, ”STAL”, ”TALL”, ”ALLE”,

”LLEr”(Installer) will scroll across the upper part of the

display. Press the ENTER button now to access.

4. When the CodE “11 11” appears input the code “98

76” using the or buttons to change each digit,

and press the ENTER button to move on to the next

digit.

NOTE: The Navigator Controller will display the

appliance controller ID “EC XX” for an

Evaporative Cooler (“XX” is the unique ID

number).For example “EC 53”.

5. Press the ENTER button when “EC XX” appears.

The display will now show digits “1 1”. The lower left digit

is the parameter number and the lower right digit is the

parameter option value. Parameter numbers and option

values can be found in the EAC Installer Parameters

Table.

6. To select the parameter number use the or

buttons to find desired number and press ENTER.

7. Adjust the option value (see EAC parameter table) to

the required value and press ENTER. This will set

option value and return you to the parameter

selection menu.

8. When finished press the ON/OFF button to exit.

Parameter

Number

Options Value

Installation Instructions

Page 29

5.0 Commissioning

BONAIRE EAC

5.7.2 EAC Installer Parameters Table

EC Parameters Table (“EC XX”)

To access the installer setups refer the section 5.7.1.

*Day Hour Flag. Only used where salinity sensor and water level sensor used.

Incorrect setting of this flag may result in damage to the EAC, its components and also

damage can occur to property. This will not be covered by manufacturer’s warranty.

The Days option is not to be used for the Sump dump valve system.

The Days option can be used if the EAC is operating on rainwater (low TDS)

Parameter Action Definition Options/Values Default

1 Drain delay

after shut down

Delay between pump

off and water drain.

0 or 1 Hr

1 Hour

2 Pre Cool time 90 second pre cool

after pre fill – No fan

0 = Off

1 = On

On

3 Drain Interval Run time between

forced drain periods.

1-12Hrs / 1-12

Days*

4 Hours

4 Pre fill time 60 second pre fill-

Solenoid - No pump

0 = OFF

1 = On

On

5

6

7

8

9

10

11

DO NOT ADJUST ANY OF

THESE PARAMETERS

Installation Instructions

Page 30

5.0 Commissioning

BONAIRE EAC

5.7.3 Multiple Controllers – Shared Zones

This feature enables all the Navigator Controllers connected to the system to be assigned to

all the zones on the system (either switched or unswitched).

Any key press that changes the operating state or operating condition on any one of the

controllers will be reflected on the other controllers on the Navigator control system.

5.7.4 Single EAC In Shared Zone (2 Wired Navigators)

With two Navigators, you need to ensure that only one Navigator controller is measuring the

temperature for the common/ shared zone.

No modifications are required to Navigator 1 parameters but Navigator 2 will require

parameter changes. The installer will need to set parameters as below,

Navigator Controller 2 Installer Parameters

Parameter Id Value Meaning

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 0 No measurement from switched zones

All temperature measurement from Navigator 2 is now disabled

5.7.5 Single EAC In Shared Zone (2 Remote Navigators)

1. Pair the Navigator Controller 1 to the Transceiver as for a normal single thermostat

installation.

2. Put Navigator 2 into the “Pairing state” (Refer “Pairing the Navigator Controller).

3. Put Navigator 1 into “Joining Mode” (Refer “Joining Navigator Controller”)

4. Navigator 1 should display “Join” and Navigator 2 should display “Pair” and then the

network will be joined.

NOTE: No modifications are required to Navigator 1. With two Navigators, you need to

ensure that only one is measuring the temperature for the common/ shared zone.

Remote Navigator 2 will require parameter changes. The installer will need to set

parameters as per the table above.

5.7.6 Single EAC In Shared Zone (3 or 4 Navigators)

Set up primary and subsequent controllers (wired wall mounted or wireless remote) as

above, ensuring all subsequent controllers are set to not measure temperature.

Installation Instructions

Page 31

5.0 Commissioning

BONAIRE EAC

5.8 Fan Operation

• Check the fan is clear of the venturi.

• Set the fan running.

• Check that the air is being evenly distributed through the ductwork.

• Make adjustments, as required, to any manual air dampers that may be fitted.

5.9 Controls

• Refer to your control installation and commissioning instructions.

5.10 Customer hand Over

Instruct the customer in the use of the product.

• Controls

• Bleed off

• Venting/Exhausting the air via the side of the home the wind is not blowing from.

• Maintenance Requirements

Hand over of the customer’s operational manual with the commissioning check list

completed.

5.11 Commissioning Check List

You must complete, date and sign the ‘tick box’ checklist in the owner’s manual. Use

this copy to check the installation prior to completing the owner’s documentation.

Unit

All equipment ordered by the customer is installed.

The unit is level and secure.

The water supply line has been flushed to clear swarf and debris and is free of

leaks.

The tank is free of foreign matter and debris. The water isolating tap is turned ON.

Water drainpipe work is completed and sealed.

The fan assembly is correctly located and the fan blade spins freely in the venturi.

The mains and control wiring are complete and the circuit breaker and GPO are

turned ON.

The minimum & maximum fan speeds are correctly set.

The water basin fills with water and the float valve closes correctly when the water

level is 65-70mm below the overflow level.

Installation Instructions

Page 32

5.0 Commissioning

BONAIRE EAC

The water pump operates correctly when turned ON at the controller.

The Aquamiser cycle times and / or dialflow water bleed rate are set to suit local

water conditions.

Aquamiser drain valve is operating correctly and the tank drains correctly when unit

turns off.

The fan operates through the entire speed range.

Water distribution is even with the filter pads fitted and the air conditioner operating

pump and fan.

All Controller functions for the appliance operate

Ductwork and general

The Enviroseal functions correctly with the shutters opening downwards at 90°

All roof penetrations are fully sealed and watertight.

All ductwork is completed to plan, correctly supported and airtight, with no bend

tighter than 1.5 x the ductwork diameter.

Air distribution checked, dampers are adjusted and all outlets correctly adjusted and

wiped clean.

Man hole cover replaced.

Site

All rubbish has been removed from inside and on the roof.

Customer Hand Over

You have explained the following to the customer:

The operation of the Controller.

The need to open windows and doors for the correct operation of Evaporative Air

Conditioning

The operation of the bleed or dumping system and it’s importance to operate all the

time

Stick the Serial Number Label of the unit in the owners manual

Maintenance requirements

Installation Instructions

Page 33

6.0 Service

BONAIRE EAC

6. SERVICE

A qualified service technician should conduct any service work carried out on this ducted

cooling product. It is important that periodical service is carried out on the product to ensure

the customer receives the efficiency benefits the product provides.

Only an authorised Climate Technologies service provider can carry out warranty service.

For Metro Service only ring the numbers below

South Australia 1300 665 087 Email: saservice@climtech.com.au

New South Wales/ 1300 665 087 Email: nswservice@climtech.com.au

Queensland

Australian Capital Territory 1300 665 087

Western Australia 1300 665 087 Email: waservice@climtech.com.au

Victoria/Tasmania (03) 8795 2456 Email: vicservice@climtech.com.au

Mobile Callers all states 03 8795 2460

Outside Metro areas please contact your nearest Climate Technologies Service Provider

6062217D

Manufactured by

Climate Technologies

ABN 13 001 418 042

26 Nylex Avenue

Salisbury, SA 5108

Australia

www.bonaire.com.au

Loading...

Loading...