Page 1

BLODGETT OVEN COMPANY

www.blodgett.com

1400 Toastmaster Drive, Elgin, IL USA 60120 • Phone: (847) 741-3300 • Fax: (847) 741-0015

EXTERIOR CONSTRUCTION

Stainless steel front, top and sides

Aluminized steel back and bottom

Vitreous fiber insulation at bottom, back, top and sides

Ceramic fiber insulation at blower and heater installations

INTERIOR CONSTRUCTION

Aluminized steel air flow plate at top and bottom

18" (457mm) stainless steel wire mesh conveyor belt

Two single inlet blowers behind the heat source for air circulation, independ-

ently supplying top and bottom air flow

Chimney kit for cooling fan vents

OPERATION

Heat transferred through forced convection (impingement)

Open vented baking compartment

Tubular resistance heating element

Integral controls with solid state 550°F (288°C) maximum thermostat and belt

speed control with digital display, 1 - 12 minute cook time

Two blower motors with thermal overload protectors

Four blower area cooling fans

STANDARD FEATURES

Front mounted solid state manual controls

Belt direction: (must specify)

left to right right to left

Product stop

NEMA #650 Cord

Removable single unit belt assembly

One year parts & labor warranty*

* For all international markets, contact your local distributor.

Project

Item No.

Quantity

Blodgett conveyor oven with 18" (457mm) wide belt and 20" (508mm) baking

zone length. Single or double stack models are available.

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

12" (305mm) Shelf extension

4" (102mm) legs

24" (610mm) stand with casters

One year additional extended warranty*

MODEL MT1820E

Electric Conveyor Oven

MT1820E

Page 2

ELECTRICAL CONNECTION

BLODGETT OVEN COMPANY

www.blodgett.com

1400 Toastmaster Drive, Elgin, IL USA 60120 • Phone: (847) 741-3300 • Fax: (847) 741-0015

MODEL MT1820E

SHORT FORM SPECIFICATIONS

Provide Blodgett model MT1820E conveyor oven. Unit shall be electrically heated and shall cook by means of forced, heated air. Unit shall be (single/double) deck supported by (specify stand type from options list). Each deck shall be fully independent, of stainless steel construction, and fully insulated on all sides. Provide with electrically heated baking compartment with two blowers to evenly distribute heat across baking zone. Conveyor belt shall be 18" (457mm) wide and constructed of stainless steel wire mesh; baking zone length shall be

20" (510mm). Side mounted control panel shall be solid state with 550°F (288°C) maximum thermostat and digital display of adjustable belt speed. Provide options and accessories as

indicated.

DIMENSIONS:

Floor space 32" (815mm) W x 42" (1075mm) L

Product clearance 3" (76mm)

Combustible wall clearance 0" (0mm)

Belt width 18" (455mm)

Baking zone length 20" (510mm)

POWER SUPPLY:

V.A.C. Hz Phase K.W. Amperes

L1 L2 L3 N

DOMESTIC

208 60 1 8 38 38 - 240 60 1 8 33 33 - INTERNATIONAL

220 50 1 8 36 36 - CE MODEL

230 50 1 8 34 - - 34

230/400 50 3N 8 12 12 12 1

MAXIMUM INPUT:

Single 8 KW

Double 16 KW

MINIMUM ENTRY CLEARANCE:

Uncrated 16" (407mm)

Crated 24" (610mm)

SHIPPING INFORMATION:

Approx. Weight:

Single: 262 lbs. (119 kg)

Double: 638 lbs. (289 kg)

Crate sizes:

21" (533mm) W x 45" (1143mm) L x 32" (812mm) H

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to make

substitutions of components without prior notice

APPROVAL/STAMP

P/N M9987 Rev E (1/04)

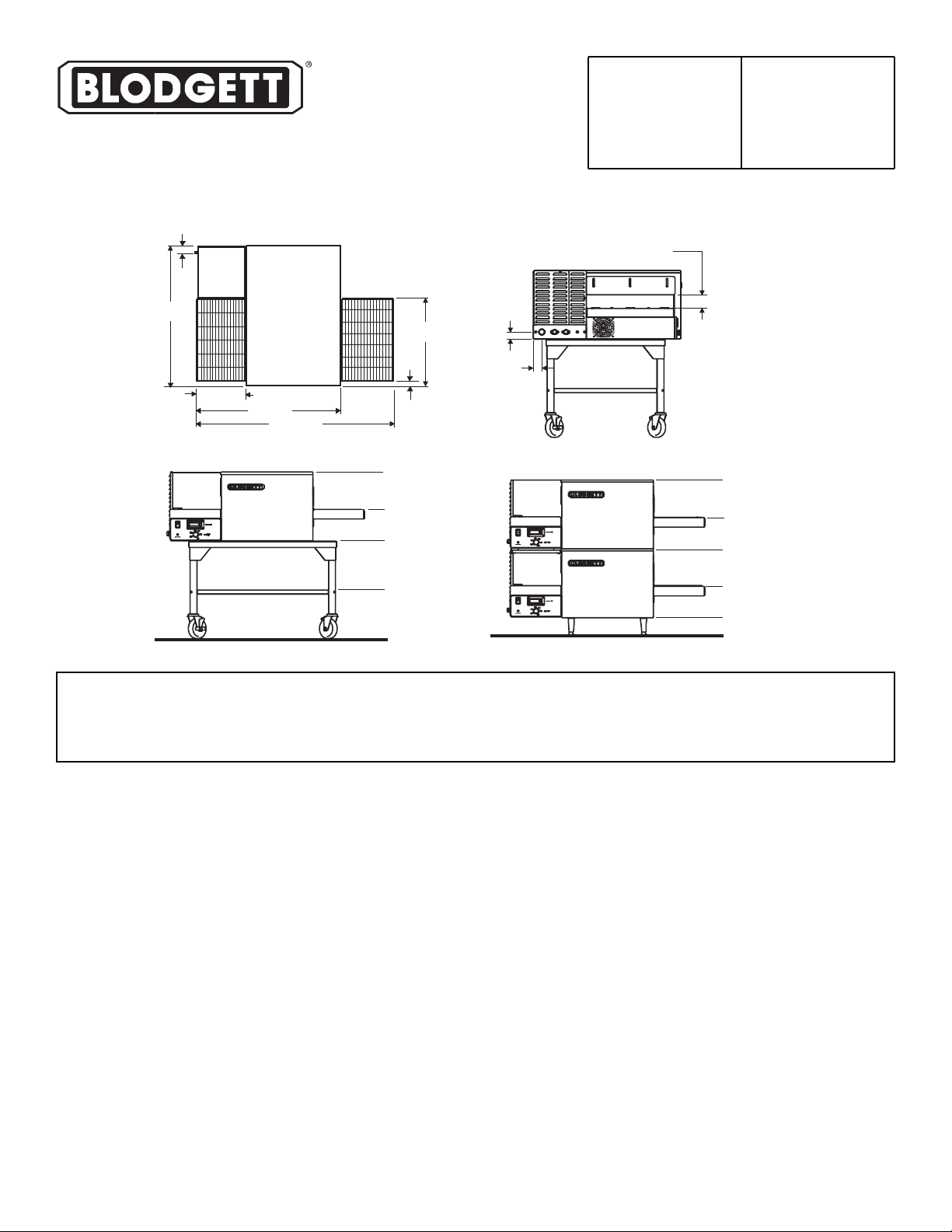

1.8” (46mm)

TOP VIEW

PRODUCT CLEARANCE

2.9” (75mm)

32”

(815mm)

11” (285mm)

31” (790mm)

42” (1075mm)

SIDE VIEW

20.5”

(520mm)

1.5”

(35mm)

38.5” (978mm)

29.8” (757mm)

24.5” (622mm)

12.25” (311mm)

0” (0mm)

ELECTRICAL

CONNECTION

1.7”

(43mm)

1.8” (46mm)

END VIEW

SIDE VIEW

36” (910mm)

27.3” (690mm)

20” (505mm)

11.3” (285mm)

4” (100mm)

0” (0mm)

Loading...

Loading...