Page 1

Biolistic®PDS-1000/He

Particle Delivery System

Catalog Numbers

165-2257 and

165-2250LEASE

to 165-2255LEASE

For Technical Service Call Your Local Bio-Rad Office or in the U.S. Call 1-800-4BIORAD (1-800-424-6723)

Page 2

Warranty and Regulatory Notices

Warranty Statement

This warranty may vary outside of the continental United States. Contact your local Bio-Rad

office for the exact terms of your warranty.

Bio-Rad Laboratories warrants that the Biolistic PDS-1000/He system (catalog numbers

165-2257 and 165-2250LEASE to 165-2255LEASE) will be free from defects in material

and workmanship, and will meet all performance specifications for the period of 1 year from

the date of shipment. This warranty covers all parts and labor.

In the event that the instrument must be returned to the factory for repair under warranty, the instrument must be packed for return in the original packaging.

Bio-Rad shall not be liable for any incidental, special, or consequential loss, damage, or

expense directly or indirectly arising from the use of the Biolistic PDS-1000/He system. BioRad makes no warranty whatsoever in regard to products or parts furnished by third parties,

such being subject to the warranty of their respective manufacturers. Service under this warranty shall be requested by contacting your nearest Bio-Rad office.

The following items are considered customer-installed consumables: fuses, microcarriers,

macrocarriers, and rupture disks. These parts are not covered by this warranty. All customerinstalled parts are warranted only to be free from defects in workmanship.

This warranty does not extend to any instruments or parts thereof that have been subject

to misuse, neglect, or accident, or that have been modified by anyone other than Bio-Rad or

that have been used in violation of Bio-Rad instructions.

The foregoing obligations are in lieu of all other obligations and liabilities including negligence

and all warranties, of merchantability, fitness for a particular purpose or otherwise, expressed or

implied in fact or by law, and state Bio-Rad’s entire and exclusive liability and buyer’s exclusive

remedy for any claims or damages in connection with the furnishing of goods or parts, their

design, suitability for use, installation, or operation. Bio-Rad will in no event be liable for

any special, incidental, or consequential damages whatsoever, and Bio-Rad’s liability under no

circumstances will exceed the contract price for the goods for which liability is claimed.

Regulatory Notices

Important: This Bio-Rad instrument is designed and certified to meet EN55011,

EN50082-1, and IEC 1010-1 requirements, which are internationally accepted electrical safety standards. Certified products are safe to use when operated in accordance with the instruction manual. This instrument should not be modified or altered in any way. Alteration of this

instrument will:

Void the manufacturer’s warranty.

Void the regulatory certifications.

Create a potential safety hazard.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Page 3

Table of Contents

Section 1 Biolistic PDS-1000/He Particle Delivery System..............................................1

1.1 Particle Delivery Technology ....................................................................................1

1.2 Overview of PDS-1000/He Particle Delivery System ..............................................1

1.3 Important Safety Information.....................................................................................3

1.4 Requirements for System Operation..........................................................................3

Section 2 Product Description .....................................................................................5

2.1 Packing List ................................................................................................................5

2.2 Identification of Unit Controls and Components ....................................................10

Section 3 Installation ..................................................................................................13

3.1 Connecting the PDS-1000/He System to a Helium Source ....................................13

3.2 Connecting the PDS-1000/He to a Vacuum Source................................................15

3.3 Power Cord/Voltage Regulator................................................................................16

Section 4 Operation of the PDS-1000/He Instrument ............................................17

4.1 Preparation of System Components Prior to Bombardment...................................17

4.2 Performing a Bombardment.....................................................................................22

4.3 Removal of Residual Helium Pressure–Shut Down ...............................................30

Section 5 Selection and Adjustment of System Bombardment Parameters........30

5.1 Overview -Matrix of Variables: Cell Types, Settings and Conditions ...................30

5.2 Vacuum Level in Bombardment Chamber..............................................................31

5.3 Helium Pressure / Rupture Disk Selection ..............................................................31

5.4 Solenoid Valve Adjustment .....................................................................................32

5.5 Vacuum Flow Rate Control Valves.........................................................................32

5.6 Distance Between Rupture Disk and Macrocarrier.................................................32

5.7 Distance Between Macrocarrier and Stopping Screen............................................32

5.8 Distance Between Stopping Screen and Target Shelf

(microcarrier flight distance)....................................................................................32

5.9 Microcarrier Selection..............................................................................................33

5.10 Preparation of Biological Material for Bombardment ............................................34

Section 6 Troubleshooting......................................................................................................37

6.1 Rupture Disk Bursts at Incorrect Pressure...............................................................37

6.2 Stopping Screen Forced Through Screen Support Ring .........................................37

6.3 Excessive Gas Usage................................................................................................38

6.4 Chamber Will Not Hold Vacuum ............................................................................38

6.5 Sample Damage From Gas Pressure Wave .............................................................38

6.6 Unit Will Not Pressurize Gas Acceleration Tube....................................................39

Section 7 Product Information..................................................................................40

7.1 Biolistic System........................................................................................................40

7.2 Spare Parts ................................................................................................................41

Section 8 Appendices ..............................................................................................................43

8.1 Cleaning the PDS-1000/He Device .........................................................................43

8.2 Metal Case Version ..................................................................................................43

8.3 Specifications ...........................................................................................................46

8.4 Performing a Bombardment—Quick Guide Tear-Out............................................47

Page 4

Section 1

Introduction to Particle Delivery

1.1 Particle Delivery Technology

Biolistic particle delivery is a method of transformation that uses helium pressure to introduce DNA-coated microcarriers into cells. Microprojectile bombardment can transform such

diverse targets as bacterial, fungal, insect, plant, and animal cells and intracellular organelles.

Particle delivery is a convenient method for transforming intact cells in culture since minimal

pre- or post-bombardment manipulation is necessary. In addition, this technique is much easier and faster to perform than the tedious task of micro-injection. Both stable and transient

transformation are possible with the Biolistic particle delivery system.

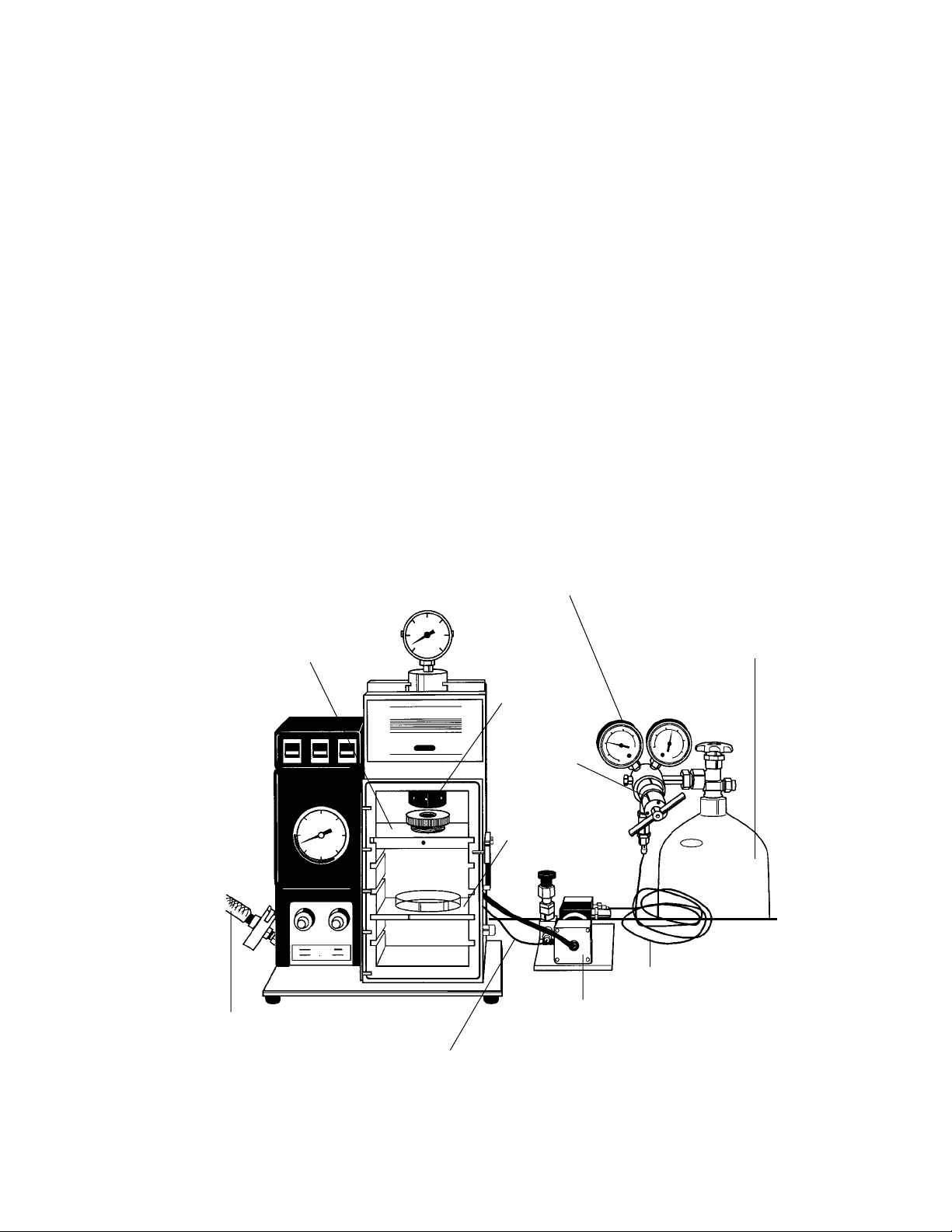

1.2 Overview of PDS-1000/He Particle Delivery System

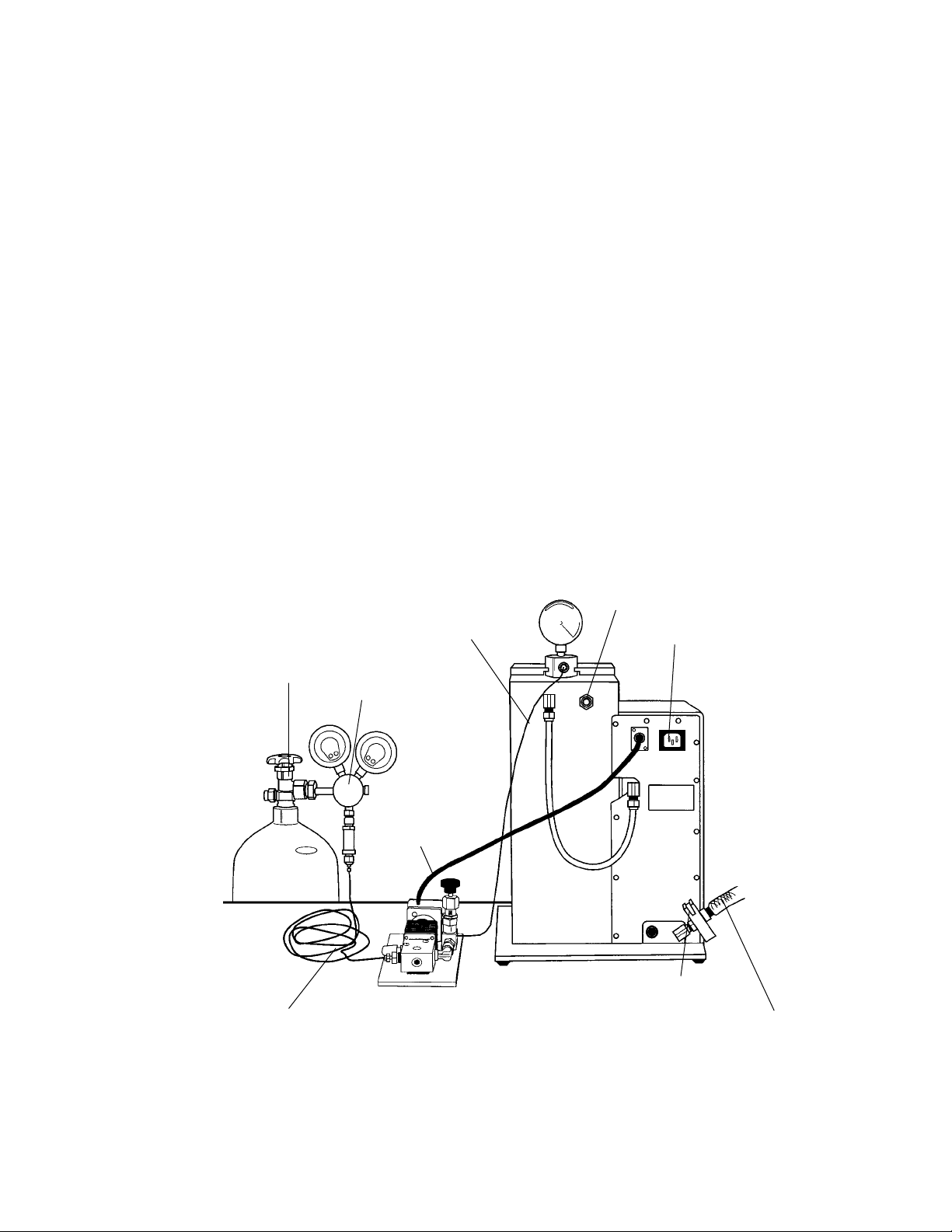

The Biolistic System

The Biolistic PDS-1000/He instrument uses pressurized helium to accelerate sub-cellular sized microprojectiles coated with DNA (or other biological material) over a range of

velocities necessary to optimally transform many different cell types. The system consists of

the bombardment chamber (main unit), connective tubing for attachment to vacuum source,

and all components necessary for attachment and delivery of high pressure helium to the main

unit (helium regulator, solenoid valve, and connective tubing).

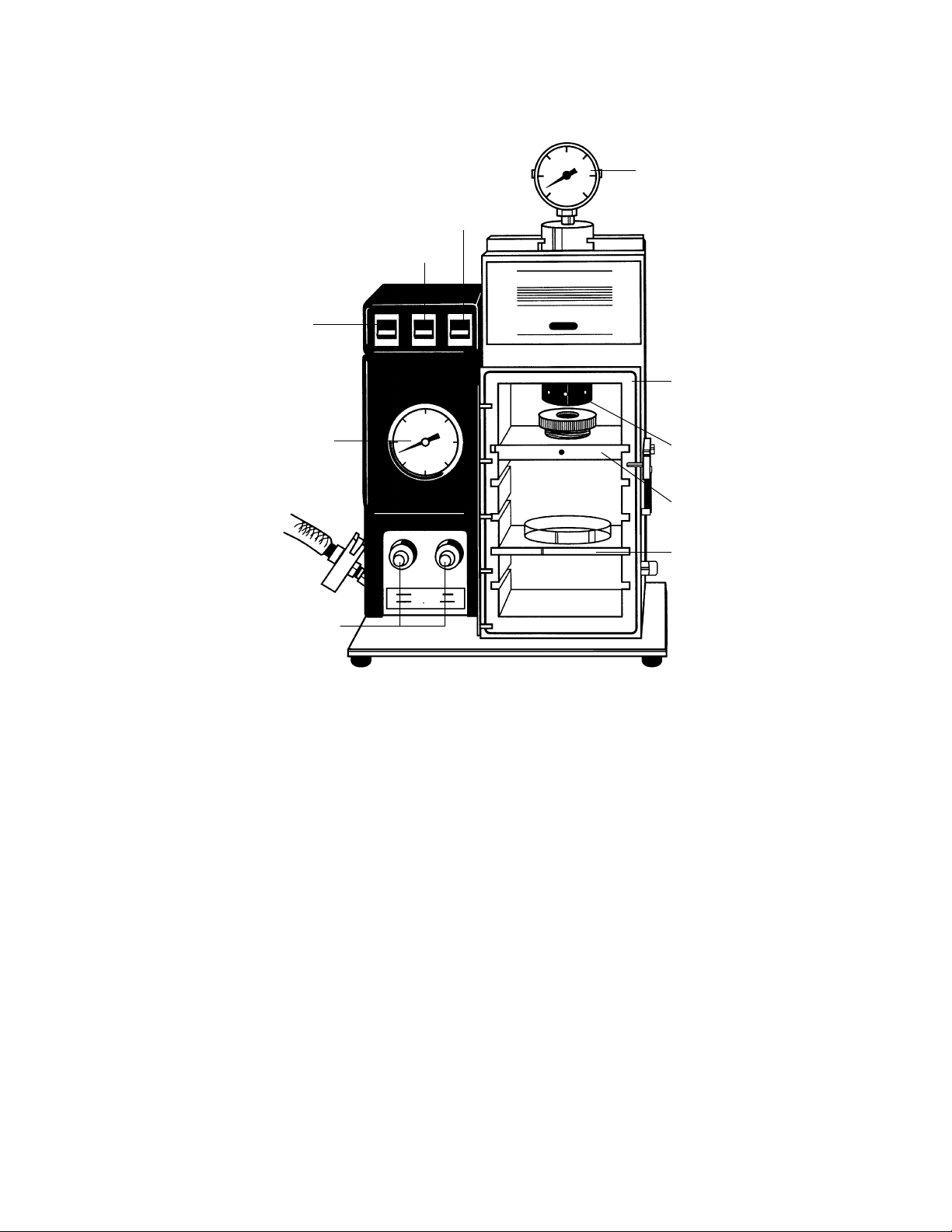

Fig. 1.1. Unit components, front view.

1

Helium

Pressure

Regulator

Vacuum (reinforced PVC)

Tygon Tubing

2.5 ft PEEK Tubing

6 ft PEEK Tubing

Tank of Pressurized Helium

(user provided)

Rupture Disk

Retaining Cap

3-Way Helium Metering

(solenoid) valve

Microcarrier Launch

Assembly

Helium Regulator

Target Plate Shelf

Page 5

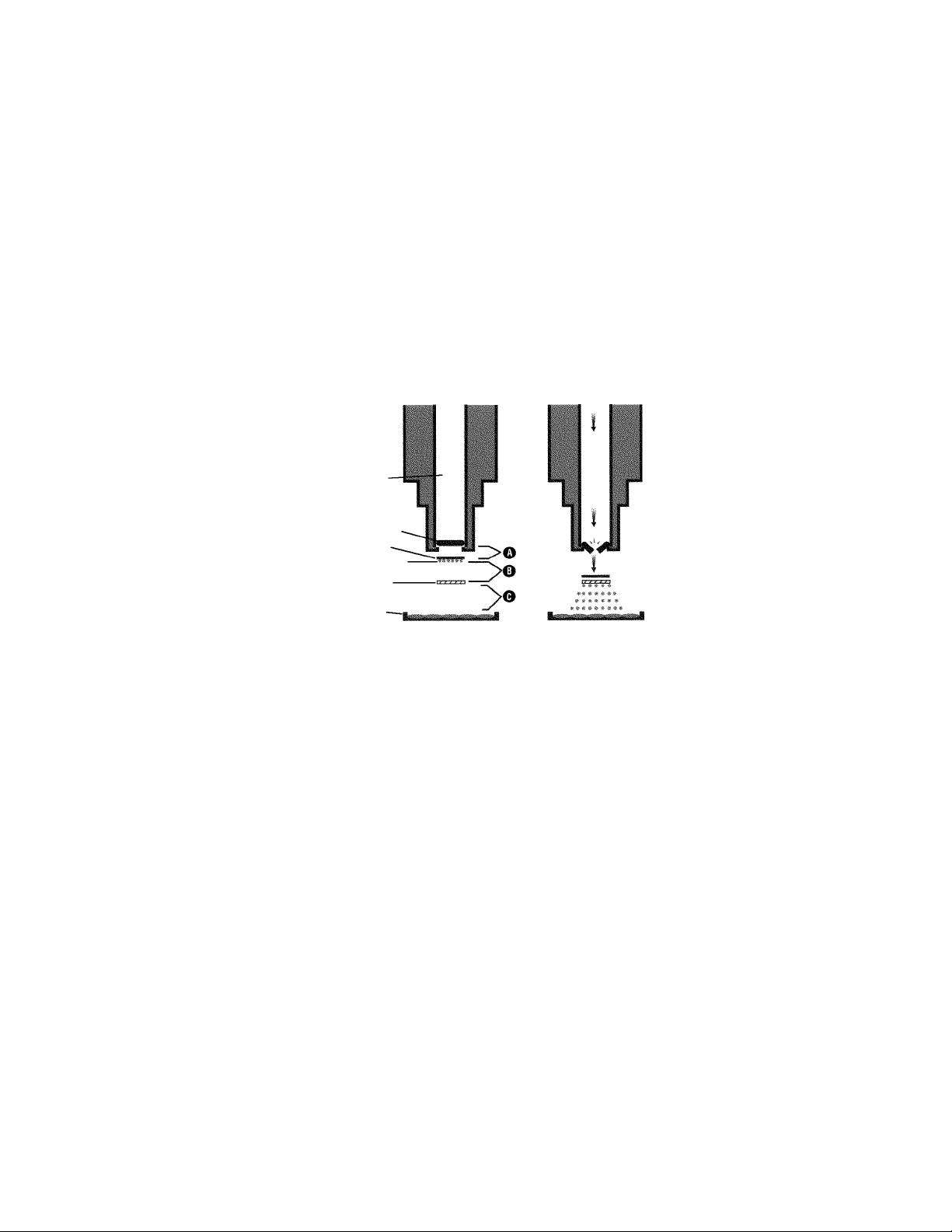

The Biolistic Process

The Biolistic PDS-1000/He system uses high pressure helium, released by a rupture disk,

and partial vacuum to propel a macrocarrier sheet loaded with millions of microscopic tungsten or gold microcarriers toward target cells at high velocity. The microcarriers are coated with

DNA or other biological material for transformation. The macrocarrier is halted after a short

distance by a stopping screen. The DNA-coated microcarriers continue traveling toward the

target to penetrate and transform the cells.

The launch velocity of microcarriers for each bombardment is dependent upon the helium pressure (rupture disk selection), the amount of vacuum in the bombardment chamber, the

distance from the rupture disk to the macrocarrier (A), the macrocarrier travel distance to the

stopping screen (B), and the distance between the stopping screen and target cells (C).

Fig. 1.2. The Biolistic bombardment process.

Design Improvements

The original Biolistic device used a gunpowder explosion to accelerate DNA-coated

microcarriers into target cells. The helium technology used in the current PDS-1000/He system has primary advantages of providing cleaner, safer, and more reproducible particle acceleration. This stems from the use of rupture disks that burst at a defined pressure. In addition,

helium inflicts less tissue damage. Bulletin 1689 offers a comparative analysis of gunpowder

and helium target patterns and transformation efficiencies.

The PDS-1000/He device was updated in March 1995 to improve the quality of key components. We removed parts originally designed to operate with the gunpowder acceleration

method. The most notable change was the conversion of the material used for the bombardment chamber from metal to a strong, lightweight plastic. This makes the instrument easier

to transport and clean, with no change in bombardment performance (identical internal chamber dimensions). An over-pressure relief valve and a particle filter on the vacuum vent supply were also added.

The actual steps for performing a particle bombardment of a biological sample are

unchanged, and the consumables are also the same with the plastic case version. Extensive testing involving the genetic transformation of yeast, plant, and animal cells by both Bio-Rad

and independent researchers demonstrated that the gene transfer results obtained with the

new plastic chamber design are equivalent to those of the previous metal chamber model.

See Appendix 8.2 for a description of parts unique to the metal-chamber design.

2

Before

Gas Acceleration Tube

Rupture Disk

Macrocarrier

Stopping Screen

Target Cells

DNA-coated Microcarriers

After

Page 6

1.3 Important Safety Information

Pressurized Helium Safety Information

Caution: Although helium is neither toxic nor flammable, all gases under pressure are potentially dangerous if used improperly. Never use a helium tank with, or attach a tank to, the

PDS-1000/He system unless the tank is properly secured. Follow the instructions provided with

the helium cylinder from the supplier and those that are applicable for your institution (site

safety officer). Bio-Rad has supplied tubing, fittings, a control valve, and a pressure regulator capable of safely handling the high pressure helium gas used in the Biolistic bombardment process. These components have been carefully selected and are the only parts to be

used with the PDS-1000/He system.

Power Safety Information

Figure 1.3 shows the serial number certification label which is found at the rear of the

Biolistic PDS-1000/He unit. This label provides the manufacturing data about the instrument,

its voltage settings, and CDRH standards for electrical safety. This instrument and its accessories conform to the IEC and CDRH standards for electrical safety.

Fig. 1.3. Instrument serial number label on the rear of the instrument.

1.4 Requirements for System Operation

Selecting Site for Operation

Prepare a space 61 cm wide x 46 cm long x 61 cm high (24 inches x 18 inches x 24 inches)

preferably in a bio-containment hood or other tissue preparation area, near a standard electrical

outlet (110 V/60 Hz in the U.S.). Also, allow for placement of the vacuum pump near the site of

operation if house vacuum is not used (see Vacuum Supply).

User Supplied Components

Helium Supply

Only helium gas is to be used with PDS-1000/He system. The low atomic weight of helium permits maximum gas expansion into the bombardment chamber. Thus, sufficient acceleration of the DNA-coated microcarriers is generated for penetration of the target cell membrane.

Obtain a high pressure (2,400 to 2,600 psi) tank of high purity helium for optimization of

bombardment conditions for the biological system of choice. This allows use of all of the rupture

disks (the highest disk has a 2,200 psi rating). Only grade 5 (99.999%) or grade 4.5 (99.995%)

helium is to be used, since helium of a lesser grade contains contaminating material which may

obstruct gas flow within the PDS-1000/He system, as well as contaminate the biological sample.

Follow all safety instructions provided by helium supplier for helium tank installation.

3

Made in U.S.A.

Model No.

Voltage

Serial No.

Page 7

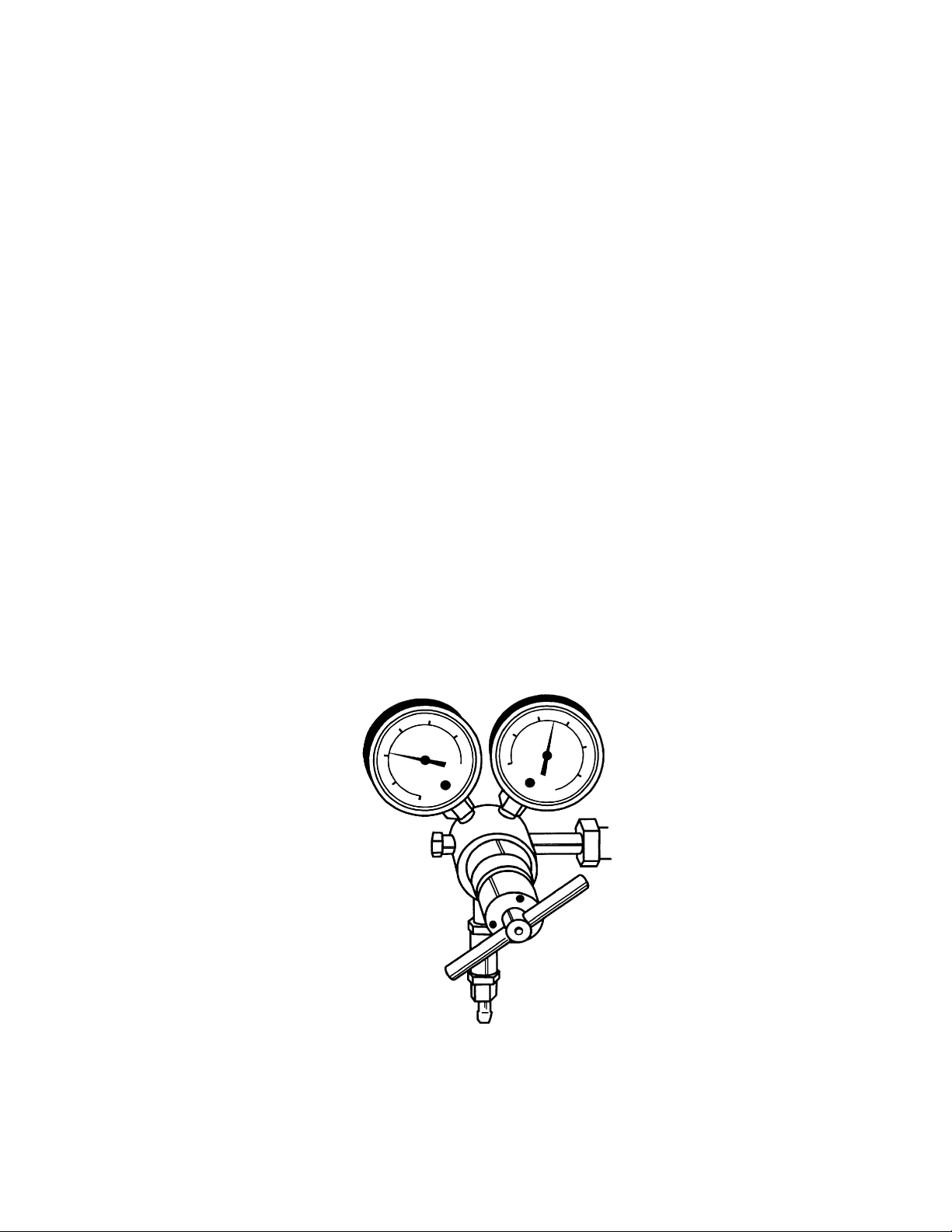

The helium pressure regulator (supplied) has a CGA 580, female fitting (standard in the

United States) for attachment to the user-supplied helium tank. An adaptor to this fitting may

be required outside the United States. Contact your local Bio-Rad office for information on

the helium pressure regulator adaptor requirements in your location.

A user-supplied, 1 inch adjustable wrench is required for attachment of the regulator to

a helium tank having a capacity of 55 cubic feet or greater.

Vacuum Source

The main unit of the PDS-1000/He system must be connected to a vacuum source capable of evacuating the bombardment chamber to a minimum of 5 inches of mercury for operation. This minimum vacuum requirement is part of the instrument safety system (the chamber

door must be sealed for helium pressure to be delivered into the main unit). Tubing is supplied

to connect the PDS-1000/He system to vacuum source.

For maximum evacuation capacity, we recommend connecting the PDS-1000/He device

to an oil-filled, rotary vane vacuum pump, either single or dual stage, with an pumping speed

of 90–150 liters/minute (3–5 cubic feet/minute). This pumping rate minimizes the time target

cells are exposed to vacuum. Oil for the vacuum pump must be supplied by the user. An

exhaust mist eliminator on the vacuum pump is also recommended.

The level of the vacuum required in the bombardment chamber depends on the biological system being targeted for transformation. Higher vacuum reduces drag forces on microcarriers during helium-driven acceleration. During the brief bombardment process (less than

1 minute), typical protocols require a vacuum level within the bombardment chamber between

15–29 inches of mercury. Some cells, tissues, and intact plant cells require a high vacuum

(up to 28 inches of mercury) for efficient transformation.

House vacuum may be sufficient for bombardment of certain cell types (mammalian

cells), but house vacuum pumping rates can fluctuate and vary greatly in overall evacuation

capacity (typically 20 inches of mercury, maximum).

Consumables

The 500 Optimization Kit (catalog number 165-2278) provides the consumables needed

for 500 bombardments. It is recommended for users who have yet to determine the optimal

conditions for the bombardment of the biological system of interest. The kit contains 0.25 g

each of 0.6 µ, 1.0 µ, and 1.6 µ gold microcarriers, 100 each of the nine different rupture disks

(ranging from 450 psi to 2,200 psi), 500 macrocarriers, and 500 stopping screens. After optimal conditions are determined, Standard Pressure Kits are available (see Section 7 or the current Bio-Rad catalog for a complete listing).

Additional Laboratory Supplies and Equipment

Vortex mixer is needed for microcarrier preparation.

Common laboratory supplies, such as 95% ethanol, pipettes, etc. are required, as cited in

standard protocols.

Additional Items Available from Bio-Rad

The Yeast Optimization Kit (catalog number 170-3100) allows first-time users to become

familiar with the Biolistic instrument. It is also helpful for experienced users wishing to

periodically standardize their bombardment conditions. This kit provides all of the biological

material needed to transform yeast. Yeast provides a system that is quickly and easily assayed.

The kit demonstrates the effect of varying the DNA concentration, rupture disk pressure, and

the target distance (from the stopping screen), and includes Saccharomyces cerevisiae strain

4

Page 8

948, YEp352 DNA, CaCl2, spermidine, culture medium, and plating medium. Enough material for 60 bombardments is provided.

Macrocarrier Holders, set of 5 (catalog number 165-2322), are included with the Biolistic

PDS-1000/He system. Additional holders are desirable to facilitate a series of bombardments

in one experiment.

The Disk-Vac (catalog number 165-2323) is a small pen-shaped device capable of generating a suction for efficient handling of rupture disks and macrocarriers. Use of the Disc-Vac

reduces static generated during manipulation and prevents contamination with glove powder

or oil from skin.

Customers outside the continental USA and Canada will require a Voltage Converter

(catalog number 165-2259). To use the system, you must locally obtain a cord set which has

an IEC/320/CEE 22 connector on one end. This connects to the Voltage Converter and is the

type commonly found on computers or televisions. The other end of the power cord will

terminate in a plug which will fit the receptacle used in your location. Contact your local

Bio-Rad office for more information on this Voltage Converter.

Section 2

Product Description

2.1 Packing List

Check the items received with your PDS-1000/He unit against the list below. If items are

missing, contact your local Bio-Rad office.

Instruction Manual

Pressure Regulator for Helium Cylinder (with in-line 0.45 µ filter)

Fig. 2.1. Helium pressure regulator.

5

Page 9

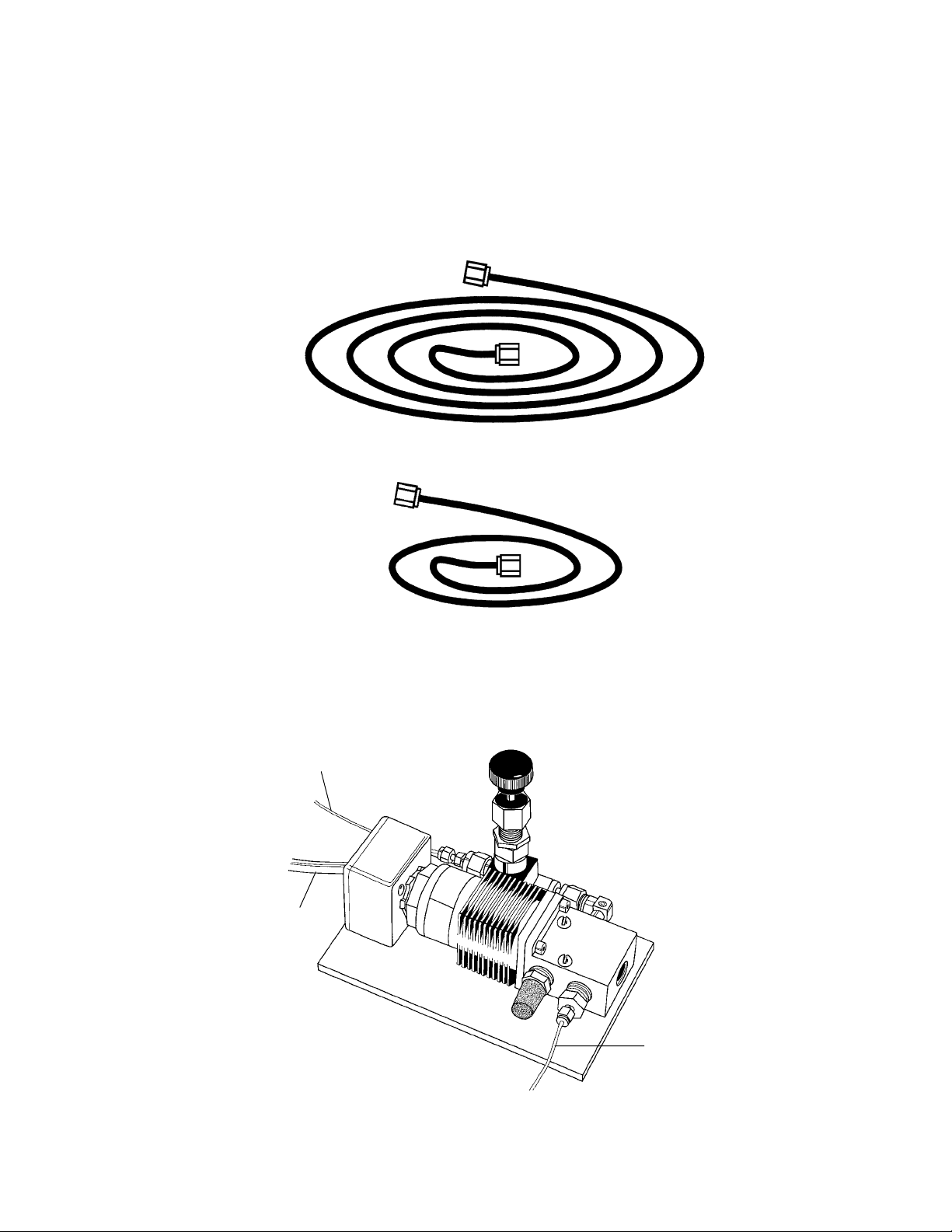

6.0 ft PEEK plastic tubing (1/16" OD x .010" ID tubing & fittings), used to connect 3-way

helium metering (solenoid) valve to helium pressure regulator

2.5 ft PEEK plastic tubing (1/16" OD x .010" ID tubing and fittings), used to connect

3-way helium metering (solenoid) valve to rear of main unit

Fig. 2.2. 6 ft and 2. 5 ft PEEK tubing.

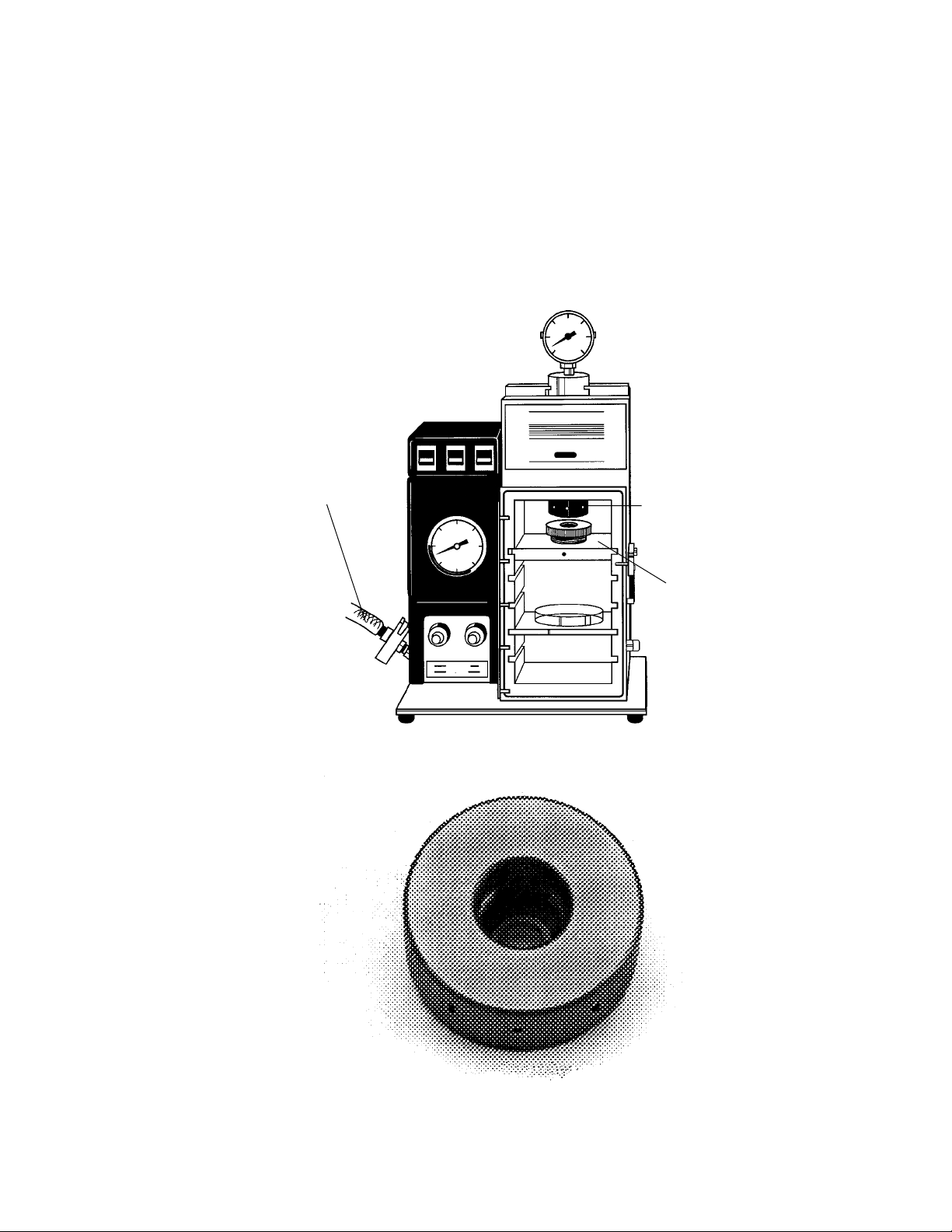

3-Way Helium Metering (solenoid) Valve, with attached cord for power connection to

main unit

Power cord (US and Canada only, 120 V three prong plug)

Fig. 2.3. 3-way helium metering (solenoid) valve.

6

Power Cord

To Unit

6 ft PEEK Tubing

To Helium Tank

2.5 ft PEEK

Tubing To Unit

Page 10

Tools

3 Hexagonal gap setting tools (1 each- 1/8", 1/4", and 3/8"), used to set gap between the

bottom of the rupture disk retaining cap and the lid of the microcarrier launch assembly

1 3/16" hex key (Allen) wrench, used for removal of gas acceleration tube (service only)

1 1/8" hex key (Allen) wrench, used for releasing set screw in microcarrier launch assembly shelf

2 1/4" x 5/16" open-end wrenches, used for connecting small Swagelock fittings of plastic

PEEK tubing to rear of instrument, external solenoid valve, and helium pressure regulator

1 torque wrench for rupture disk retaining cap

1 seating tool for macrocarriers

Fig. 2.4. PDS-1000/He tools.

7

Page 11

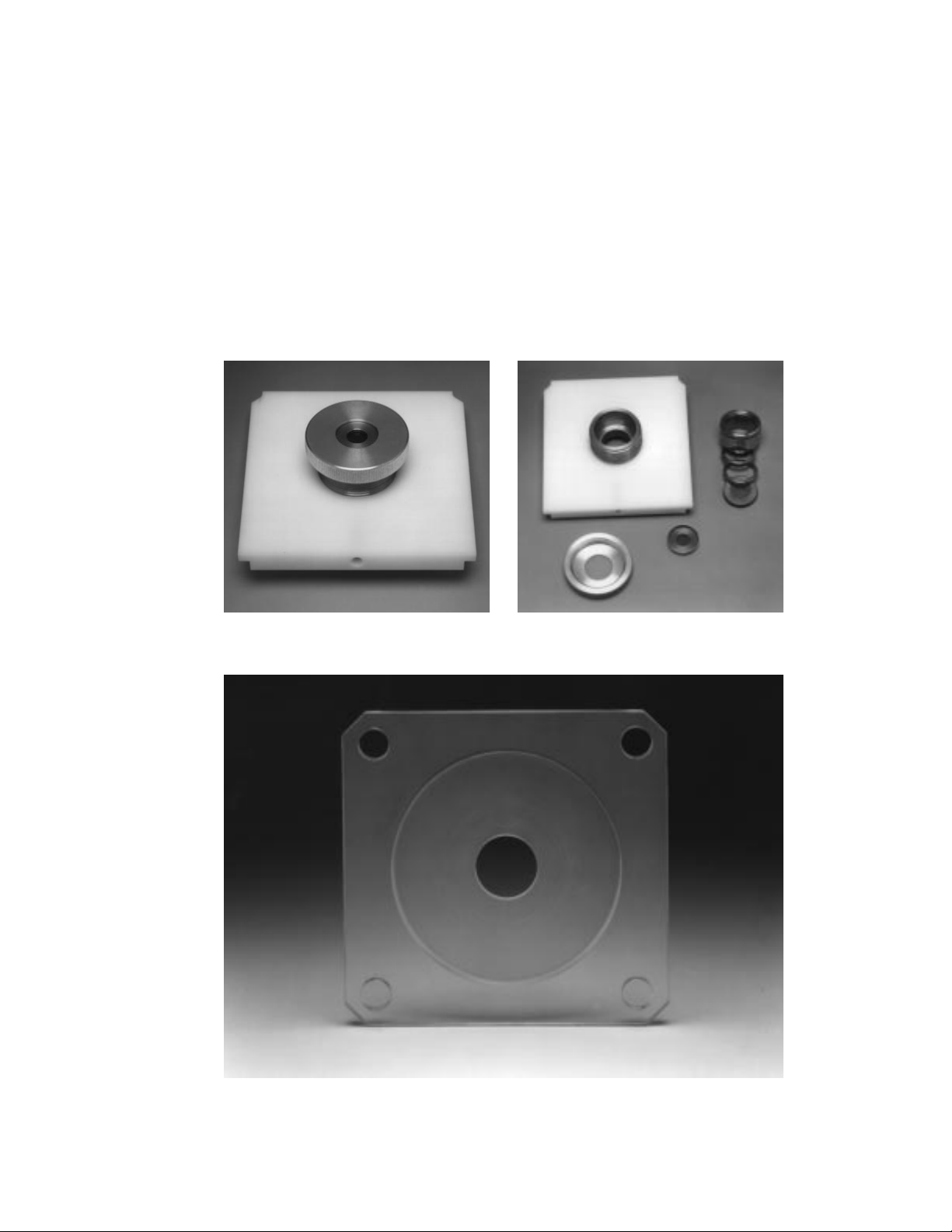

PDS-1000/He Main unit (bombardment chamber with control panel and gauges; shipped

fully assembled)

Reinforced PVC vacuum tubing (1/2" ID x 3/4" OD, 5 ft. length & fitting) attached to rear

of unit by clamp assembly (centering ring, vacuum hose clamping ring and nozzle adaptor; see Section 3.2 for individual components)

Rupture disk retaining cap (with torque wrench placement holes; Figure 10), attached to

gas acceleration tube within bombardment chamber

Fig. 2.5. PDS-1000/He main unit.

Fig. 2.6. Rupture disk retaining cap.

8

Microcarrier

Launch Assembly

Vacuum Tubing

Rupture Disk

Retaining Cap

Page 12

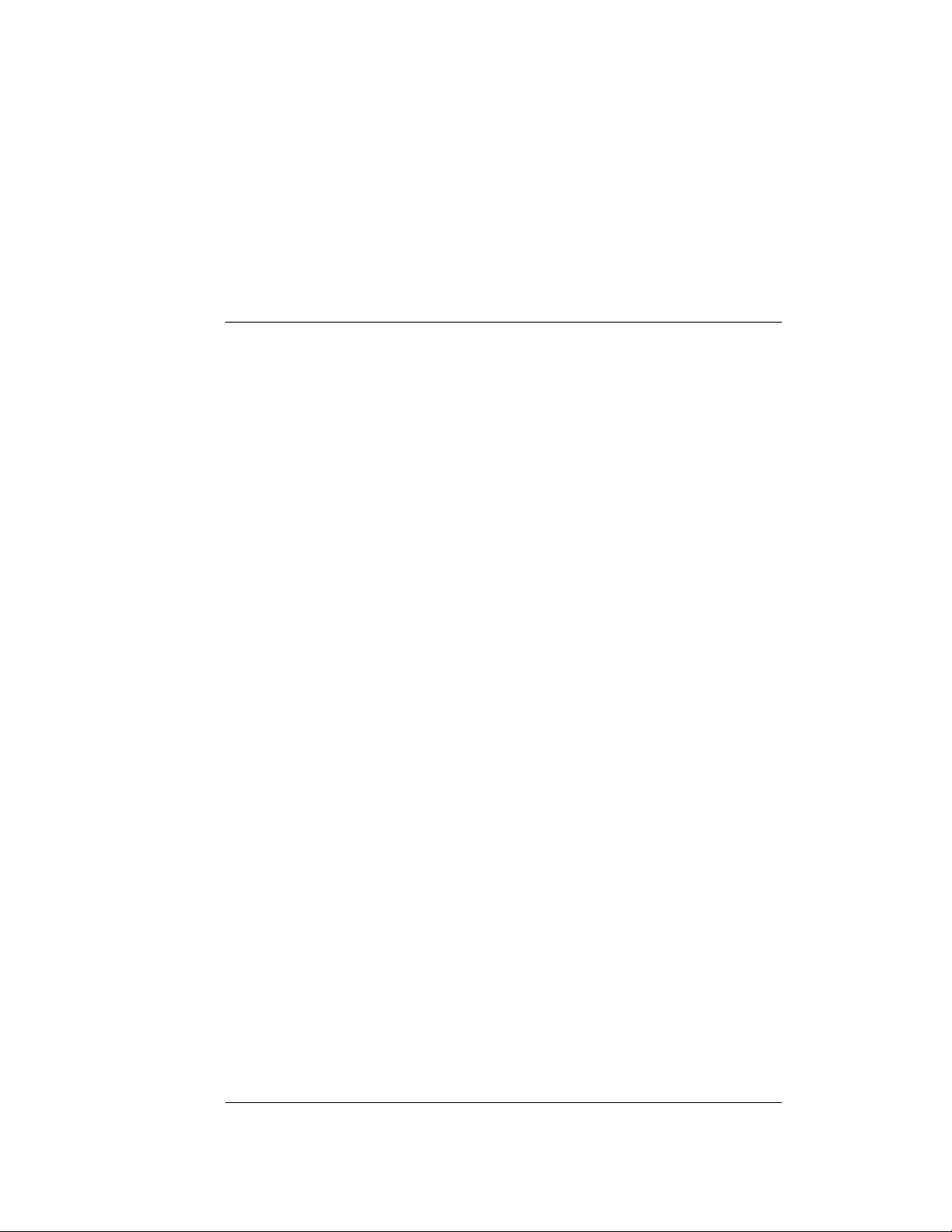

Microcarrier launch assembly (shipped fully assembled) consists of the following:

Launch Assembly Shelf with Recessed Set Screw

Macrocarrier Cover Lid

Adjustable Nest

Fixed Nest with Retaining Spring

Stopping screen Support Ring

Spacer Rings, 5 mm height, 2

Macrocarrier Holders, 5, for use within microcarrier launch assembly, after macrocarrier

is inserted using macrocarrier insertion tool

Target Plate Shelf

Fig. 2.7. Microcarrier launch assembly (A) and disassembled components (B).

Fig. 2.8. Target plate shelf.

9

A

B

Page 13

2.2 Identification of Unit Controls and Components

The following is a brief description of the operation controls for the PDS-1000/He unit

(Figure 2.9)

Table 2.1. Unit Controls and Components

Controls and

Components Description

Front View- Exterior

Power Switch, ON/OFF Controls supply of line electrical power to the

instrument.

Fire Switch Controls flow of helium into Gas Acceleration Tube by

activating Solenoid Valve. Illuminated red when

enabled, i.e. when safety interlock is satisfied that at

least 5 inches Hg. vacuum is present in chamber.

Fire Switch must be held ON continuously until

Rupture Disk bursts; then release Fire Switch to stop

flow of helium.

If the Fire Switch is released before the disk ruptures,

the helium is vented via a safety vent in the external

three-way metering (solenoid) valve.

Vac/Vent/Hold Switch Controls application of vacuum to bombardment

chamber. Vac applies vacuum from line source. Vent

releases vacuum using filtered air. Hold maintains

vacuum by isolating chamber.

Bombardments should be performed with this switch

in “Hold” position.

Vacuum Gauge Indicates level of vacuum in bombardment chamber,

in inches of mercury where zero equals ambient atmospheric pressure.

Vacuum/Vent Rate Regulate rate of application and relief of vacuum in

Control Valves bombardment chamber. Clockwise rotation closes valves.

Helium Pressure Gauge Indicates helium pressure in Gas Acceleration Tube,

in psi. When solenoid valve is activated by Fire Switch,

the needle in this oil-filled gauge rotates clockwise until

rupture disk bursts. Watch this gauge carefully during a

bombardment and note the actual rupture pressure.

Gas Acceleration Tube Helium accumulates within this tube when it is sealed

by rupture disk at chamber-end of Tube. Helium PEEK

tubing connects at top of Gas Acceleration Tube outside,

rear of chamber.

Bombardment Chamber Holds Rupture Disk, Microcarrier Launch Assembly, and

biological target under vacuum during a bombardment.

10

Page 14

Fig. 2.9. Front view of PDS-1000/He unit.

Table 2.2. Front View-Interior of Bombardment Chamber

Bombardment Chamber Closes chamber with a solid piece of polycarbon-

Door (with Brace) ate plastic. Note the single, large o-ring which

seals vacuum in the chamber, and the self-positioning brace which eliminates flex of chamber

walls during bombardment cycle.

Rupture Disk Seals Rupture Disk against chamber end of Gas

Retaining Cap Acceleration Tube. This must be tightened securely.

The Torque Wrench is used in the holes in the cap

which are visible in the photo.

Microcarrier Launch Assembly Holds the DNA/microcarrier preparation on a

Macrocarrier sheet over the Stopping Screen in

the path of the helium shock wave.

Target Shelf Holds the biological target in a Petri plate in the

path of the accelerated DNA/microcarrier preparation. Particle flight distance is determined by positioning the shelf at one of four levels using slots in

the chamber walls.

11

Microcarrier

Launch Assembly

Power Switch

ON/OFF

Helium Pressure Gauge

Target Shelf

Bombardment

Chamber Door

Vacuum Gauge

Vac/Vent/Hold Switch

Vacuum/Vent Rate

Control Valves

Fire Switch

Disk Retaining

Cap

Page 15

Table 2.3. Rear Connections

Refer to Figure 2.10 for a rear perspective view of the unit.

Helium Connection to Gas Tube Connects top of Gas Acceleration Tube to plastic

tubing from Solenoid Valve, supplying high pressure helium.

Over-Pressure Relief Valve Opens at 0.5 psi chamber pressure to relieve

accumulation of gas. A new safety feature.

Automatically resets after activation.

Vacuum Line, Chamber to Controls Supplies vacuum to chamber from control valves.

Helium Metering (Solenoid) Valve Supplies electric power to 3-way Solenoid Valve

Electrical Connection in helium line. Plug the three-pin connector from

the Solenoid Valve into this receptacle.

Line Cord Electrical Connection Supplies electric power to Biolistic unit from

house line. Plug connector from Line Cord into

this receptacle.

Vacuum Line, Connection to Source Connects unit to house vacuum supply or vacuum

pump via fittings included. Feeds into vacuum

flow controls.

Fig. 2.10. Rear view of main unit, component connection points.

12

Vacuum Port / Clamping Ring

Attachment Site

6.0 ft. PEEK Tubing

(connects to helium regulator)

2.5 ft PEEK Tubing

(connects to gas

acceleration tube)

Metering (solenoid)

Valve Power Cord

(connects to rear

of main unit)

Helium Pressure

Regulator

Adjustable

Metering Valve

Main Unit Power

Cord Socket

Over-Pressure Relief Valve

Vacuum (reinforced PVC)

Tygon®Tubing

Page 16

Section 3

Installation

3.1 Connecting the PDS-1000/He System to a Helium Source

Refer to Section 2.2, Identification of Unit Controls and Components, prior to system

installation.

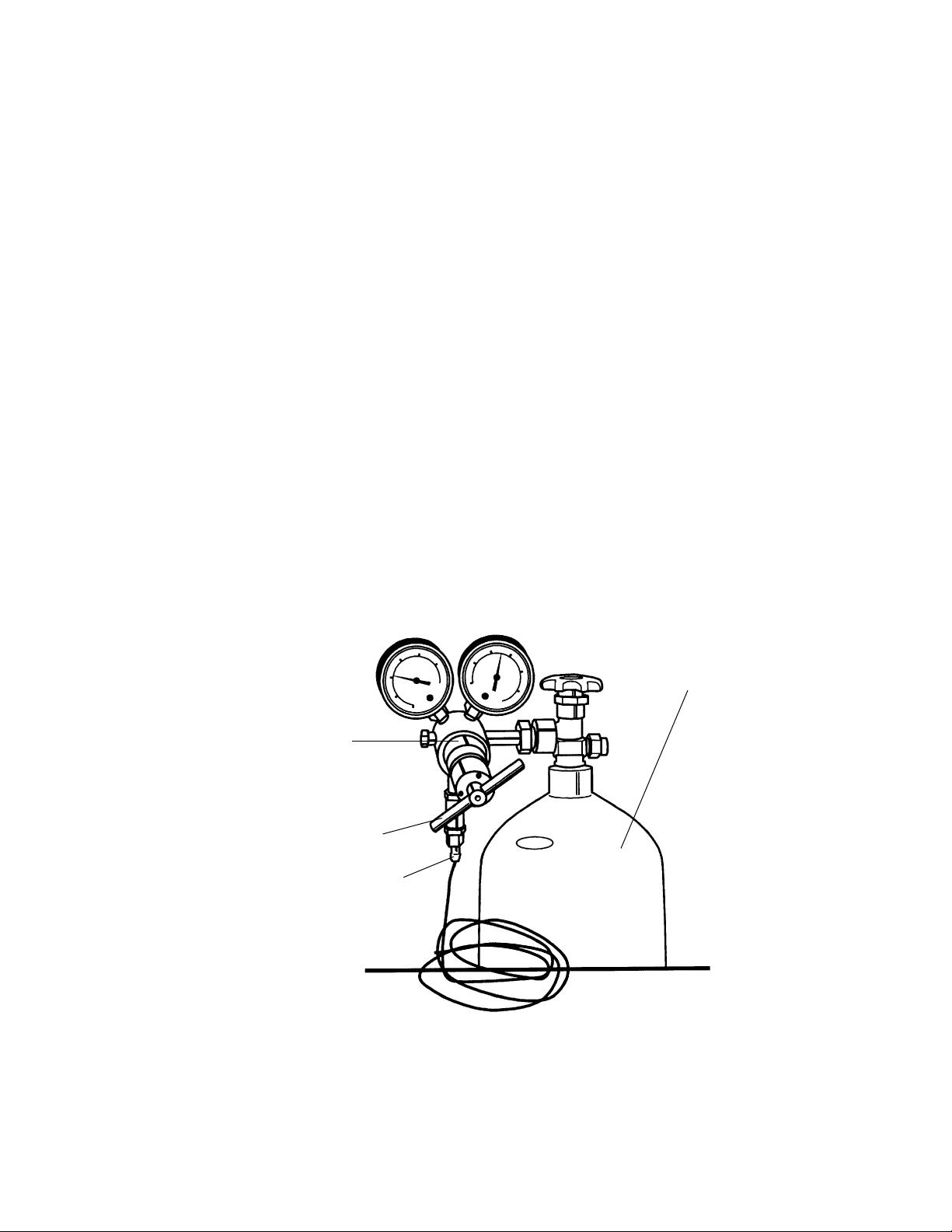

Helium Pressure Regulator Installation

Connecting the helium pressure regulator to a tank of pressurized helium.

Components needed:

• Pressure regulator for helium cylinder (with 0.45 micron in-line filter), provided with

unit (Figure 3.1).

• Cylinder of grade 4.5 to 5.0 helium (minimum 99.995% pure); maximum pressure of

2,600 psi, user supplied.

• 1 1/8" open-end wrench or a 10" or 12" adjustable wrench, user supplied.

Note: The regulator is intended for use only with helium gas under a maximum of 2,600 psi

of pressure. The outlet on pressurized helium cylinders used in the United States (maximum 2,600 psi) is compatible with the fitting supplied on the pressure regulator with the

PDS-1000/He unit (CGA 580, female fitting). Outside of the US, contact your local Bio-Rad

office for information regarding the proper cylinder/regulator fitting in your area.

Fig. 3.1. Helium regulator/tank attachment.

13

Helium Tank

Adjustment Handle

Attachment Site for

6 ft PEEK Tubing

Helium Regulator

Page 17

1. Secure the cylinder to a wall, post, or other anchored fixture so it will not tip or fall during use.

2. Inspect the cylinder valve for dirt, dust, oil, grease, or damaged threads. Remove dust

and dirt with a clean cloth. Do not attach the regulator if you determine that the valve

port is damaged or cannot be cleaned. Inform your gas supplier of this condition and

request a replacement cylinder.

3. Clear the valve port of any foreign matter by standing to the side of the cylinder and

quickly opening and closing the cylinder valve.

4. Attach the regulator to the cylinder valve and tighten securely with a 1 1/8" open-end

wrench or a 10" or 12" adjustable wrench.

Three-Way Metering Valve (Solenoid) Installation

Connecting the helium pressure regulator to the 3-way helium metering (solenoid) valve

Components needed:

• Two 5/16" open end wrenches (Figure 2.4)

• PEEK tubing, 6 feet (Figure 2.2)

• Solenoid valve (Figure 2.3)

Note: The Swagelock fittings used on the flexible tubing are easily damaged by over

tightening. Turn finger-tight, then use wrench for 1/6 additional turn (60°).

1. Connect one end of the 6 foot tubing assembly to helium pressure regulator (Figure 3.1).

Attach the tubing to the in-line, 0.45 micron filter at the end of the regulator. Use two

5/16" open end wrenches to tighten the connection.

2. Connect the other end of the 6 foot tubing assembly to the inlet port of the 3-way helium

(solenoid) valve assembly. This is the port nearest the metal exhaust filter on the 3-way metering valve. Use two 5/16" open end wrench to tighten the connection (Figures 2.3 and 2.10).

Connecting the 3-way helium metering (solenoid) valve to the PDS-1000/He main unit

Components needed:

• Two 5/16" open end wrenches (Figure 2.4)

• PEEK tubing, 2.5 feet (Figure 2.2)

• Solenoid valve (Figure 2.3)

Note: The Swagelock fittings used on the flexible tubing are easily damaged by over

tightening. Turn finger-tight, then use the wrench for 1/6 additional turn (60°).

1. Connect one end of the 2.5 foot PEEK tubing assembly to the outlet port of the 3-way helium metering (solenoid) valve assembly (Figures 2.3 and 2.10). This is the port nearest the

adjustable metering valve (black knob). Use two 5/16" open end wrenches to tighten the

connection. Do not alter the setting of the metering valve at this time.

2. Connect one end of the 2.5 foot long PEEK tubing assembly to the PDS-1000/He unit.

This port is located on the gas acceleration tube, below the helium pressure gauge (top,

rear of unit). Use a 5/16" open end wrench to tighten the connection (Figure 2.10).

3. Plug the power cord of the 3-way helium metering (solenoid) valve into the rear of the

PDS-1000/He unit (Figure 2.10).

14

Page 18

3.2 Connecting the PDS-1000/He Unit to a Vacuum Source

The main unit is shipped with the vacuum hose assembly attached to the port on the rear

of the unit, via the clamping assembly. Only the connection of the free end of the tubing to a

vacuum source is required for connecting the vacuum source to the system.

Choice of Vacuum Source

A vacuum system with a 3 cfm (cubic feet per minute) or 100 l/min pumping capacity is rec-

ommended for use with the PDS-1000/He unit. This minimizes the total time the target cells/tissue are exposed to reduced atmospheric pressure when inside the bombardment chamber. It is

also recommended that the pump have an exhaust mist eliminator.

House or shared source vacuum systems commonly have variable evacuation capacities,

from 20 inches to 23 inches Hg. When multiple users access a common vacuum system, the

actual vacuum pressure will vary, often decreasing to less than 20 inches Hg. per outlet. This

is an inadequate vacuum level for yeast and plant cell/tissue bombardment.

Most rotary vacuum pumps will achieve up to 26–28 inches of mercury (Hg) vacuum.

However, the length of time required to attain the desired vacuum depends on the pumping

capacity of the vacuum source. The higher the pumping capacity, the less time is required to

achieve the desired vacuum. Variation in evacuation time in the bombardment chamber has

an unknown effect on target cells and tissue transformation efficiency.

Table 3.2. Pumping rates of various vacuum systems with the

PDS-1000/He system

Vacuum Source Vacuum Level

Pumping Capacity (inches of Hg) Evacuation Time

†

House/Common Source 20 10–15 seconds

29 Typically not attainable

Pump - 1 cfm or 28 l/min 20 12 seconds

29 45 seconds

Pump - 3 cfm or 100 l/min 20 7 seconds

29 25 seconds

†

Vacuum Flow Rate Valve fully open.

Replacement and Re-assembly of connecting components

See Figure 3.2 for a diagram outlining component assembly. The clamp consists of an O-

ring and a vacuum hose centering ring with male nozzle fitting screwed to it.

1. Place the clamping assembly at one end of the vacuum tubing. The vacuum tubing is

PVC-reinforced Tygon tubing (1/2" ID x 3/4" OD; 5 feet length).

2. The vacuum tubing is shipped with the clamping ring assembly (Figure 3.2) attached to

the PDS-1000/He unit at the brass vacuum port located on the rear of the unit.

3. Attach the free end of the vacuum hose assembly to the vacuum source.

15

Page 19

Fig. 3.2. Components used to connect vacuum source to main unit.

3.3 Power Cord / Voltage Regulator

The power cord must be plugged directly into a 100 V-120 V outlet. Plug other end into

unit. For use with a 220 V or 240 V line voltage (users outside the US or Canada), connect a

voltage converter to the power cord prior to use (catalog number 165-2259, see Figure 3.3).

You must supply a cord set that has an IEC-320/CEE-22 connector on the end that attaches

to the voltage converter; the other end of the cord set will terminate with a plug that is compatible with the electrical outlets in your area.

Fig. 3.3. Voltage converter.

16

Clamping Ring

Centering Ring

Vacuum tubing

Male Pipe Adaptor

Quick Flange

Adaptor

Page 20

Section 4

Operation of the PDS-1000/He Instrument

4.1 Preparation of System Components Prior to Bombardment

Instrument Preparation

1. Verify that helium tank has 200 psi in excess of desired rupture disk pressure for bombardment.

2. Set gap distance between rupture disk retaining cap and microcarrier launch assembly.

When the rupture disk retaining cap is in place, insert the fully assembled microcarrier

launch assembly (with cover lid) inside the bombardment chamber on the highest possible bombardment chamber wall slot (Figure 4.1). The set screw in the white plastic shelf

should face outward. Release the set screw on the front of the microcarrier launch assembly with the smaller of the two hex key wrenches provided (Figure 2.4).

Fig. 4.1. Microcarrier launch assembly and target shelf inside bombardment chamber.

17

Page 21

Three hexagonal gap adjustment tools of 1/8", 1/4", and 3/8" have been provided to reproducibly set the gap distance (Figure 2.4). A 1/4" distance between the rupture disk retaining cap and the macrocarrier cover lid is recommended for initial optimization

bombardments.

While holding the hexagonal gap adjustment tool against the bottom of the rupture disk

retaining cap, turn the adjustable nest until the macrocarrier cover lid touches the gap

adjustment tool. The position of the adjustable nest is fixed by tightening the set screw in

the white plastic shelf with the hex key wrench.

Fig. 4.2. Microcarrier Launch Assembly adjustment.

18

Brass Adjustable Nest

Stainless Steel Fixed Nest

Spacer Rings

Stopping Screen Support

Macrocarrier Holder

Macrocarrier Cover Lid

Page 22

3. Prepare the Rupture Disk Retaining Cap. After setting the gap between cap and microcarrier launch assembly, wrap the Rupture Disk Retaining Cap in aluminum foil and sterilize by autoclaving.

4. Prepare the Microcarrier Launch Assembly.

The effect of the gas shock wave on the microcarrier velocities is determined in part by

the gap between the rupture disk and the macrocarrier.

The macrocarrier flight distance can be adjusted by varying the positions of the stopping

screen support and the spacer rings inside the fixed nest (Figure 4.2). The Stopping Screen

Support is placed in the middle position at the factory. This is the recommended position

when initially optimizing bombardment parameters.

To make this adjustment, remove the microcarrier launch assembly from the PDS-1000/He

unit. Unscrew and remove the macrocarrier cover lid. Disassemble the components of the

microcarrier launch assembly by placing the macrocarrier insertion tool into the bottom of

the assembly and pushing up. This releases the stainless steel fixed nest from the brass

adjustable nest. The two spacer rings and the stopping screen support will fall out from

within the fixed nest.

To change the factory-set position to the position for the minimum macrocarrier travel distance (6 mm), invert the fixed nest and insert the stopping screen support inside the fixed

nest so that the conical side of the stopping screen support faces down in the final orientation; then insert the two spacer rings (5 mm thickness, each). With the fixed nest still

inverted, place the macrocarrier launch assembly over the fixed nest and seat the fixed nest

within the brass adjustable nest.

If greater macrocarrier travel is desired, rearrange the spacer rings and stopping screen support accordingly. The macrocarrier travel distance can be increased in two 5 mm steps, to

a maximum of 16 mm.

Sterilize the microcarrier launch assembly by wrapping in aluminum foil and autoclaving.

Alternatively, this assembly can be sterilized by wiping with 70% ethanol, followed by

drying in a sterile environment.

5. Target Shelf

Sterilize the target shelf by wiping with 70% ethanol, followed by drying in a sterile environment just prior to use. This part may not be autoclaved.

19

Page 23

Consumable Preparation

Several consumables are available for use with the PDS-1000/He system (Figure 4.3).

Fig. 4.3. Consumables for the PDS-1000/He instrument. The 0.6 micron gold is not pictured.

1. Macrocarriers

Pre-assemble and pre-sterilize the macrocarrier set in a macrocarrier holder prior to performing sample cell/tissue bombardments. The Disk-Vac (catalog number 165-2323)

provides ease in handling rupture disks and macrocarriers.

Macrocarriers are shipped in quantities of 500/box, with paper linings between disks.

Transfer selected macrocarriers to individual Petri dishes for easier handling. Remove

the paper lining from between the macrocarriers. Place the macrocarrier into the macrocarrier holder using the seating tool (Figure 4.4). The edge of the macrocarrier should be

securely inserted under the lip of the macrocarrier holder. The macrocarrier holders, with

macrocarriers already in place, should be sterilized by autoclaving.

2. Rupture disks

Rupture disks (Figure 4.3) are packaged and shipped in quantities of 100/box. Transfer

selected rupture disks to individual Petri dishes for easier handling. Sterilize rupture disks

by briefly dipping them in 70% isopropanol just prior to insertion in the Retaining Cap.

Do not soak for more than a few seconds. Extensive soaking may delaminate the disks,

resulting in premature rupture. All disks, with the exception of those rated at 450, 650, and

1,100 psi, are laminated. Autoclaving is not recommended because of potential delamination.

20

A. Macrocarriers

B. Rupture disks

C. Stopping screens

D. Tungsten microcarriers

E. Gold microcarriers

A

C

D

E

B

Page 24

Fig. 4.4A and 4.4B. Insertion of macrocarrier into macrocarrier holder with plastic insertion tool.

3. Stopping screens

Transfer selected stopping screens (Figure 4.3) to individual Petri dishes for easier handling. Sterilization by autoclaving is recommended. Alternatively, these parts can be sterilized by soaking in 70% ethanol, followed by drying in a sterile environment.

4. Microcarriers

The following procedure prepares tungsten or gold microcarriers for 120 bombardments

using 500 µg of the microcarrier per bombardment, based on the method of Sanford, et

al. [Methods in Enzymology, 217, 482-509 (1993)].

Weigh out 30 mg of microparticles into a 1.5 ml microfuge tube.

Add 1 ml of 70% ethanol (v/v).

Vortex vigorously for 3–5 minutes (a platform vortexer is useful).

Allow the particles to soak in 70% ethanol for 15 minutes.

Pellet the microparticles by spinning for 5 seconds in a microfuge.

Remove and discard the supernatant.

Repeat the following wash steps three times:

• Add 1 ml of sterile water.

• Vortex vigorously for 1 minute.

• Allow the particles to settle for 1 minute.

• Pellet the microparticles by briefly spinning in a microfuge.

• Remove the liquid and discard.

After the third wash, add 500 µl sterile 50% glycerol to bring the microparticle concentration to 60 mg/ml (assume no loss during preparation).

The microparticles can be stored at room temperature for up to two weeks. Tungsten aliquots

should be stored at -20 °C to prevent oxidation. Gold aliquots can be stored at 4 °C or room

temperature.

Store dry tungsten and gold microcarriers in a dry, non-oxidizing environment to minimize agglomeration.

21

Macrocarrier

Insertion

Tool

Helium

Macrocarrier

Helium

Macrocarrier

Holder

Direction of Tool

Movement

Page 25

Coating Washed Microcarriers with DNA

The following procedure is sufficient for six bombardments; if fewer bombardments are

needed, adjust the quantities accordingly.

Vortex the microcarriers prepared in 50% glycerol (30 mg/ml) for 5 minutes on a platform

vortexer to resuspend and disrupt agglomerated particles.

When removing aliquots of microcarriers, it is important to continuously vortex the tube

containing the microcarriers to maximize uniform sampling. When pipetting aliquots, hold the

microcentrifuge tube firmly at the top while continually vortexing the base of the tube.

Remove 50 µl (3 mg) of microcarriers to a 1.5 ml microcentrifuge tube.

Continuous agitation of the microcarriers is needed for uniform DNA precipitation onto

microcarriers. For added convenience and/or multiple samples, use a platform attachment on

your vortex mixer for holding microcentrifuge tubes.

While vortexing vigorously, add in order:

• 5 µl DNA (1 µg/µl)

• 50 µl 2.5 M CaCl

2

• 20 µl 0.1 M spermidine (free base, tissue culture grade)

Continue vortexing for 2–3 minutes.

Allow the microcarriers to settle for 1 minute.

Pellet microcarriers by spinning for 2 seconds in a microfuge.

Remove the liquid and discard.

Add 140 µl of 70% ethanol (HPLC or spectrophotometric grade).

Remove the liquid and discard.

Add 140 µl of 100% ethanol.

Remove the liquid and discard.

Add 48 µl of 100% ethanol.

Gently resuspend the pellet by tapping the side of the tube several times, and then by vor-

texing at low speed for 2–3 seconds.

4.2 Performing a Bombardment

Quick Guide (This summary is repeated in Section 8.4 as a tear-out sheet.)

Before the Bombardment

1. Select/adjust bombardment parameters for gap distance between rupture disk retaining cap

and microcarrier launch assembly. Placement of stopping screen support in proper position inside fixed nest of microcarrier launch assembly

2. Check helium supply (200 psi in excess of desired rupture pressure).

3. Clean/sterilize:

Equipment: rupture disk retaining cap, microcarrier launch assembly

Consumables: macrocarriers/macrocarrier holders

4. Wash microcarriers and resuspend in 50% glycerol

5. Coat microcarriers with DNA and load onto sterile macrocarrier/macrocarrier holder the

day of experiment

22

Page 26

Firing the Device

1. Plug in power cord from main unit to electrical outlet.

2. Power ON.

3. Sterilize chamber walls with 70% ethanol.

4. Load sterile rupture disk into sterile retaining cap.

5. Secure retaining cap to end of gas acceleration tube (inside, top of bombardment chamber) and tighten with torque wrench.

6. Load macrocarrier and stopping screen into microcarrier launch assembly.

7. Place microcarrier launch assembly and target cells in chamber and close door.

8. Evacuate chamber, hold vacuum at desired level (minimum 5 inches of mercury).

9. Bombard sample: Fire button continuously depressed until rupture disk bursts and helium pressure gauge drops to zero.

10. Release Fire button.

After the Bombardment

1. Release vacuum from chamber.

2. Target cells removed from chamber.

3. Unload macrocarrier and stopping screen from microcarrier launch assembly.

4. Unload spent rupture disk.

5. Remove helium pressure from the system (after all experiments completed for the day).

Detailed Operation Procedure

Note: We recommend that the first bombardment each day be a “dry run” with no target

cells or microcarriers to ensure that the system is set up properly and the gas pathway is

filled with helium, not air.

1. Power On

With the unit plugged in to the appropriate electrical outlet or voltage converter, turn on the

unit by pressing the ON switch. This is the left-most red control panel switch (Figure 2.9).

2. Helium Pressure

Confirm that the helium tank pressure regulator is set to 200 psi over the selected rupture disk

burst pressure (e.g., set the regulator to 1,100 psi when working with a 900 psi rupture disk).

3. Pressurizing the System with Helium

Make certain that the helium pressure regulator is properly installed on the helium tank

(see Set-up).

Close the helium pressure regulator by turning the regulator adjustment screw counterclockwise until the adjusting spring pressure is released.

Release helium into the pressure regulator by carefully and slowly opening the cylinder

valve on the helium tank. The cylinder pressure in the tank is indicated on the high pressure gauge (the gauge closest to cylinder).

Set the desired helium delivery pressure for the rupture disk you are using (measured on

gauge on the outside, farthest from cylinder) by turning the regulator adjustment handle

clockwise. The pressure should be set to 200 psi above the rupture disk rating.

23

Page 27

4. Coating microcarriers with DNA

The day of the scheduled bombardment, coat the microcarriers with DNA. To obtain the

best results, use the DNA-coated microcarriers as soon as possible.

5. Loading DNA-coated microcarriers onto a macrocarrier/macrocarrier holder

Each macrocarrier is placed inside a macrocarrier holder and sterilized, as described

above. Prior to the application of the DNA-coated microcarriers onto a macrocarrier, prepare a small desiccating chamber for each macrocarrier/macrocarrier holder and place

away from excessive vibration.

A small desiccating chamber consists of a sterile 60 mm tissue culture Petri dish (with lid)

containing CaCl2as desiccant in the base of the dish (Figures 4.5 and 4.6). The desiccant is

covered with a small piece of filter paper to provide a stable platform for the macrocarrier/

macrocarrier holder. The sterile macrocarrier/macrocarrier holder is placed atop the filter

paper, with the macrocarrier facing up and the stainless steel holder touching the filter paper.

Fig. 4.5A and 4.5B. Loading DNA-coated microcarriers onto a macrocarrier/macrocarrier holder,

positioned in small desiccating chamber.

This environment permits rapid access to each macrocarrier and provides a low humidi-

ty environment for the ethanol to uniformly evaporate from the microcarriers. This low humidity, along with a minimum of vibration during evaporation, minimizes microcarrier

agglomeration.

For each macrocarrier, remove 6 µl aliquots (approximately 500 µg) of microcarriers and

spread evenly over the central 1 cm of the macrocarrier using a pipette tip. Pipet from a continuously vortexed tube and rapidly apply suspended microcarriers to the macrocarrier, as

microcarriers quickly settle out from the ethanol solution in the tube or even in the pipette tip.

Immediately cover the culture dish after application of the microcarrier suspension to the

macrocarrier. The ethanol should evaporate within 10 minutes to leave the DNA-coated microcarriers adhering to the macrocarrier. The loaded macrocarriers should be used within 2 hours.

6. Cleaning chamber walls

Clean the chamber of the PDS-1000/He as desired with 70% ethanol. Allow time for drying. Do not autoclave or flame sterilize the PDS-1000/He unit.

24

A

B

Page 28

7. Loading the rupture disk

Unscrew the rupture disk retaining cap from the gas acceleration tube from within the

bombardment chamber (Figure 4.6) or unwrap cap from sterile wrapping.

Fig. 4.6. Removal/mounting of rupture disk retaining cap onto end of gas acceleration tube inside

bombardment chamber.

Select rupture disk of desired burst pressure. Handle all rupture disks with sterile forceps

or Disk-Vac (catalog number 165-2323). Grease, fingerprints, or even powder from plastic

gloves on the rupture disk may prevent a tight seal from forming within the retaining cap.

Fig. 4.7. Rupture disk insertion into recess of retaining cap.

Immediately before placing a rupture disk in the retaining cap, briefly wet the rupture

disk in isopropanol (do not soak the disk for an extended period of time or the disk may

delaminate). Loading the rupture disk while wet forms a liquid gasket when the cap is screwed

onto the gas acceleration tube, and thereby reduces the failure rate of the rupture disk. Place

the rupture disk in the recess of the rupture disk retaining cap (Figure 4.7).

25

Page 29

Screw the rupture disk retaining cap onto the gas acceleration tube using a left -to-right

motion. Never tighten the rupture disk retaining cap without a rupture disk in place or scratching and deformation of the two metal surfaces will occur and cause helium to leak when a rupture disk is pressurized.

The retaining cap is tightened to a torque of 60 inch/pounds with the retaining cap torque

wrench. To use the torque wrench, insert the short end of the metal rod into an accessible hole

in the retaining cap. Push the long end of the rod to the right only until it touches the inner surface of the black tube (Figure 4.8). If the retaining cap is not tightened sufficiently, the rupture

disk may slip out of place as the gas acceleration tube fills with helium. Test fire once to fill gas

tubing with helium.

Fig. 4.8. Proper torque applied to retaining cap with torque wrench.

8. Microcarrier Launch Assembly

Unscrew the macrocarrier cover lid from the assembly. Place a sterile stopping screen on the

stopping screen support (Figure 4.9). Note: Never operate the PDS-1000/He instrument without

a stopping screen in place. The target sample will be destroyed from the uninterrupted acceleration

of the macrocarrier by the helium shock wave.

Install the macrocarrier/macrocarrier holder on the top rim of the fixed nest (Figure 4.10).

The dried microcarriers should be facing down, toward the stopping screen. Replace the

macrocarrier cover lid on the assembly and turn clockwise until snug. Do not over-tighten.

Place the microcarrier launch assembly in the top slot inside the bombardment chamber

(Figures 4.11 and 5.1).

26

➡

➥

Page 30

Fig. 4.9. Placement of stopping screen inside fixed nest with macrocarrier and cover lid removed.

Fig. 4.10. Removal / replacement of macrocarrier cover lid with assembled fixed nest.

Macrocarrier holder (with macrocarrier properly inserted) is inverted and placed atop fixed nest.

27

Page 31

9. Target cells/tissue placement in chamber

Place the Target Shelf at the desired level inside the bombardment chamber. Place the

sample (usually contained within a Petri dish) on the Target Shelf. Close and latch the sample chamber door.

10. Chamber evacuation/hold

Turn on the vacuum source. Set the vacuum switch on the PDS-1000/He (middle red

control switch, Figure 4.11) to the VAC position. Evacuate the sample chamber to the

desired level, at least 5 inches of mercury. The rightmost red control switch (the FIRE

switch) will be illuminated when the minimum vacuum is achieved.

When the desired vacuum level is reached, hold the chamber vacuum at that level by

quickly pressing the vacuum control switch through the middle VENT position to the

bottom HOLD position.

Fig. 4.11. Sample bombardment: power switch ON, vacuum switch on HOLD position, and user

continuously pressing FIRE button.

11. Bombard the sample

With the vacuum level in the bombardment chamber stabilized, press and hold the FIRE

switch to allow helium pressure to build inside the gas acceleration tube that is sealed by

a selected rupture disk (Figure 4.11).

28

Page 32

Estimate rupture disk burst pressure by observing the helium pressure gauge at the top of

the acceleration tube. A small pop will be heard when the rupture disk bursts. The rupture

disk should burst within 10% of the indicated rupture pressure and within 11–13 seconds.

Release the FIRE switch immediately after the disk ruptures to avoid wasting helium.

Releasing the FIRE switch prior to disk rupture will vent the gas acceleration tube via the

3-way helium metering (solenoid) valve.

Note: Variation in the burst pressure indicated on the helium pressure gauge (on the top

of the unit) from the rated rupture disk pressure may observed if the gas acceleration tube

fill rate is improperly set. See Section 5.4 for solenoid valve adjustment procedure.

12. Release vacuum from chamber

Release the vacuum in the sample chamber by setting the VACUUM switch to the middle VENT position.

13. Target cells removal from chamber

After vacuum is released, the vacuum gauge should read 0 inches of mercury (Hg) of

vacuum. Open the sample chamber door. Remove the sample and treat as appropriate.

14. Macrocarrier and stopping screen removal from microcarrier launch assembly

Remove the microcarrier launch assembly. Unscrew the lid and remove the macrocarrier holder. Discard the used macrocarrier and stopping screen (Figure 4.12).

Fig. 4.12. View of used macrocarrier and stopping screen within disassembled microcarrier

launch assembly after a bombardment.

15. Removal of spent rupture disk

Unscrew the rupture disk retaining cap from the gas acceleration tube. Remove the remains of

the rupture disk (Figure 4.13). The next bombardment may now be performed (from step 7).

29

Page 33

Fig. 4.13. View of spent rupture disk within the retaining cap.

4.3 Removal of Residual Helium Pressure—Shut Down

After completing all bombardment(s), remove the helium pressure from the PDS-1000/He

system and close the helium cylinder valve. Perform the following steps to remove helium

pressure from the system.

1. Close the helium cylinder valve and chamber door.

2. With at least 5 inches of Hg of vacuum in bombardment chamber, remove residual line

pressure from the regulator, solenoid and PEEK tubing by activating the FIRE button.

3. Release the FIRE button on the apparatus, and remove all tension on the pressure adjustment screw of the helium regulator, turning counter-clockwise, until it turns freely.

4. Vent any residual vacuum from the bombardment chamber by setting the vacuum switch

to the VENT position.

Section 5

Selection and Adjustment of

System Bombardment Parameters

5.1 Overview—Matrix of Variables

Factors affecting bombardment efficiency are numerous, and interact in complex ways.

All possible variables cannot be addressed in a single large factorial experiment. Instead, most

users will find it sufficient to prioritize variables by the magnitude of their effects, optimizing

them individually, and then testing their interactions on a more limited scale. Table 5.1 shows

some examples of conditions used in published protocols for a variety of target materials.

30

Page 34

Table 5.1. Cell Types, Settings, and Conditions

Target Helium

Cell Growth Cell Vacuum Distance Pressure Particle

Type Phase Density Osmoticum (inches Hg) (cm) (psi) Size

Bacteria Late log 108–109 per 0.75 M sorbitol 29 6 1,100 M5

to early 100 mm tungsten

stationary plate

Yeast Early 108–109per 0.75 M sorbitol 28 6 1,300 0.6 µ

stationary 100 mm and 0.75 M gold

plate manitol

Algae Log 108–109per 29 6 1,300 0.6 µ

100 mm gold

plate

Plant

• embryos – 10 explants None 28 6 1,300 1.0 µ

per 100 mm gold

plate

• callus or Log 0.75 ml None 28 9 1,100 1.0 µ

cell culture packed cell gold

volume

Subcellular Mid-log 5 x 10

7

per None 28 6 1,300 0.6 µ

Organelles 100 mm gold

plate

Animal

• tissue Log 50–80% None 15 3 1,100 1.6 µ

culture confluent gold

on 35 mm

plates

• tissue 1 hr–4 days400 µm None 25 9 1,100 1.6 µ

sections post- sections gold

excision

5.2 Vacuum Level in Bombardment Chamber

The vacuum in the bombardment chamber reduces the frictional drag of the microcarriers as they are accelerated toward the target cells. The unit should be connected to a vacuum

system (see previous section) that can evacuate the bombardment chamber to 28–29 inches

Hg in less than 30 seconds. This level of vacuum is useful for most plant and microbial

cells/tissues. Mammalian cells/tissue should be bombarded at approximately 15 inches Hg.

Helium gas enters the evacuated bombardment chamber once the rupture disk bursts. The

use of low molecular weight helium minimizes the deceleration of the microcarriers as they

pass through helium and also reduces the force of the gas shock wave that hits the target cells.

This reduced impact will help minimize target tissue damage.

5.3 Helium Pressure / Rupture Disk Selection

Each of the nine different rupture disks available ruptures at a specific pressure, ranging in

rating from 450 to 2,200 psi. The rupture pressure determines the power of the shock wave

entering the bombardment chamber. Increasing helium pressure will increase particle acceleration and subsequent target tissue penetration by the DNA-coated microcarriers. Since the

shock wave or resulting acoustic wave may cause damage to the target cells or tissue, use the

lowest helium pressure used that gives high transformation efficiency.

31

Page 35

Suggested starting helium pressure conditions for optimizing various biological systems are:

Cell type Rupture disk pressure

Bacteria 1,100 psi

Fungi 1,300 psi

Yeast 1,300 psi

Plant cells/tissue 1,100 psi

Mammalian cells 1,100 psi

5.4 Solenoid Valve Adjustment

A factory pre-set metering valve (black knob) on the 3-way helium metering (solenoid)

valve assembly controls the fill rate of the gas acceleration tube. The proper fill rate is set at

the factory for a 1,550 psi rupture disk to burst within 12–15 seconds. A more rapid fill rate

may result in what appears to be a lower burst pressure, due to a lag of needle movement in

the oil-filled gauge. The metering valve (black knob) may be adjusted if desired. Adjust knob

in small increments: a clockwise rotation of the black knob will lengthen the fill rate.

5.5 Vacuum Flow Rate Control Valves

Both valves are set at the factory to be fully open (counter clock-wise), for maximum

flow rates. To decrease the rates, turn the valves (knob) clockwise until the desired evacuation and/or vent rate is achieved (see Figure 2.9).

5.6 Distance Between Rupture Disk and Macrocarrier

The effect of the gas shock wave on microcarrier velocities is determined in part by the

gap between the rupture disk and the macrocarrier. The smaller the distance, the more powerful the effect of the gas shock wave on macrocarrier acceleration.

Three hexagonal gap adjustment tools of 1/8", 1/4", and 3/8" have been provided to reproducibly set the gap distance (Figure 2.4). A 1/4" distance between the rupture disk retaining cap

and the macrocarrier cover lid is recommended when initially optimizing bombardment parameters.

5.7 Distance Between Macrocarrier and Stopping Screen

Macrocarrier flight instability increases with greater travel distance, therefore, the shortest travel distance is recommended. This is achieved by having the stopping screen support placed above

both spacer rings inside the fixed nest when initially optimizing bombardment conditions. The

macrocarrier flight distance can be adjusted by varying the position of the stopping screen support,

as positioned by the spacer rings inside the fixed nest of the microcarrier launch assembly. The travel can be increased to a maximum of 16 mm in steps of 5 mm by varying spacer ring placement.

5.8 Distance Between Stopping Screen and Target Shelf (microcarrier flight distance)

One of the most important parameters to optimize is target shelf placement within the

bombardment chamber. This placement directly affects the distance that the microcarriers

travel to the target cells for microcarrier penetration and transformation.

Four target shelf levels are available in the bombardment chamber: level 1= 3 cm,

level 2 = 6 cm, level 3 = 9 cm, and level 4 =12 cm below the stopping screen (Figure 5.1).

32

Page 36

Fig. 5.1. Target shelf placement and corresponding target distances.

5.9 Microcarrier Selection

Types of Microcarrier

Two types of microcarriers are available, gold and tungsten. The density of these microcarriers is sufficient to penetrate a wide variety of cell and tissue types using the Biolistic

PDS-1000/He acceleration system.

Five tungsten particle sizes are available. The tungsten particles are less expensive, but

more irregular in shape and the size variation within a given particle size is much wider than

gold. This size variation makes optimization using a certain particle size more difficult. Also,

tungsten may be toxic to certain cell types and may oxidize to alter DNA binding.

Gold microcarriers are available in three sizes. Gold particles are more spherical and are

more uniform in size within a given sample than tungsten microcarriers. Gold is biologically inert, but the DNA coating of this type of microcarrier is subject to more variation during

precipitation than tungsten.

Microcarrier Size

The velocity of the chosen microcarrier increases with larger particle size. Increased

microcarrier velocity has a major effect on particle penetration into target cells/tissue and

thus transformation efficiency.

33

L1= 3 cm

L2= 6 cm

L3= 9 cm

L4= 12 cm

Page 37

Recommended starting particle size/type for bombardment of various cell types is

Bacteria 0.7 µm (M5) tungsten

Yeast 0.6 µm gold

Algae 0.6 µm gold

Plant cells/tissue 1.0 µm gold

Animal cell cultures 1.6 µm gold

Sub-cellular organelles 0.6 µm gold

Table 5.1 and bulletins 1688 and 2015 give a detailed discussion of optimization parameters.

5.10 Preparation of Biological Material for Bombardment

Plant Cells

Many factors contribute to optimum performance in any system for plant gene transfer.

Transformation procedures employing microcarrier bombardment are no exception, but the improved

PDS-1000/He apparatus lends itself to rapid and easy modification, to tailor its performance to a particular application. Microcarrier bombardment also allows exploitation of a very broad range of

explant tissue types. This permits optimization of a crucial aspect of the transformation system

which usually is difficult to alter when transforming by other means. The following is a discussion

of some of the critical parameters in the microcarrier transformation system, together with a brief

examination of explant characteristics which affect transformation efficiency. This is not intended

as a “how to” manual. Because of the extreme diversity of applications possible with the system, and

the various types of tissues which can be employed, it is not possible to produce a universal protocol for all applications. Rather, this discussion is intended to aid the new user to design experiments.

Note: If you are a first-time user, it is important to be certain that your PDS-1000/He

apparatus has been assembled correctly and is operating according to specifications. We

suggest that you use the Yeast Optimization Kit (catalog number 170-3100) to be sure that

microcarrier preparation has been carried out properly, and that microcarriers are being

delivered uniformly. This also provides an opportunity to examine firsthand the pattern

of particle delivery and gene expression in treated cells. This may save substantial time

as you begin to optimize the system for your own purposes.

Choice of Explant Tissue

Unlike most other procedures for DNA transfer, microcarrier bombardment places few

constraints on the types of tissues which can be treated. DNA can be delivered into essentially any cell or tissue which can be exposed sufficiently to allow particle penetration. Thus

more emphasis usually can be given to issues such as the tissue’s ability to regenerate plants,

or its physiological suitability for gene regulation studies. There are, however, several aspects

of the explant which contribute to the efficiency of the system.

An ideal tissue for microcarrier bombardment could perhaps be described as a cell monolayer, all cells of which are capable of expressing introduced genes, and all of which could, independently, divide and differentiate into functional plants. Microcarrier bombardment of such a tissue

will likely be efficient because cells can be spread over a large area, thus efficiently capturing a large

proportion of the particles delivered in each bombardment. Particles also have a high probability

of penetrating such cells because they are not covered by overlying cell layers which would very

likely intercept some of the particles delivered by each bombardment. Absolute transient expression levels are likely to be high, because of the number of cells affected. The low profile of cell clusters reduces the probability that the tissue will be moved about by the gas released in the shockwave

during treatment. Such a tissue would also lend itself well to selection with antibiotics or herbicides,

in part, at least, because it would have a favorable geometry for the establishment of a uniform

concentration of the selective agent throughout the culture.

34

Page 38

Some kinds of embryogenic suspension cultures approach this ideal. In fact, it is this type of

tissue which has allowed great success in the microcarrier-mediated transformation of recalcitrant

species such as maize [see, for example, Gordon-Kamm et al., The Plant Cell, 2, 603-618 (1990)].

Most explants, however, differ from this ideal in substantive ways. It is useful, though, to keep

these characteristics in mind when choosing and preparing tissues for bombardment, whether

taken from established cultures, or recently removed from donor plants. For example, tissue damage is typically most severe within the central area of bombardment where particle density is

greatest. Cultured materials can usually be arranged to minimize this effect by placing them in a

circle around the central area of bombardment. Even though some of the DNA-bearing particles

fail to enter cells, this will often increase the absolute number of transformation events recovered from a single bombardment by reducing tissue damage. Similarly, explants from donor

plants should be arrayed so as to capture as large a portion of particles as possible. Newly acquired

explants can be dissected so that the cell types of interest are exposed as much as possible. The

height of the tissue above the surface of its support medium can be minimized to reduce losses

during treatment, which result from tissues with high profiles being blown about during bombardment. Finally, it may be useful to reduce the size of each explant or tissue mass to more

closely approximate the geometry of suspension culture cells, in order to enhance the uniformity of selection.

Most tissues appear to vary with regard to their ability to express introduced genes following bombardment. For example, this effect is frequently observed as fluctuations in the frequency or intensity of transient expression of ß-glucuronidase (GUS) constructions among

different tissues, or even among cells in different areas of a single explant. It can be caused

in part by unevenness in particle distribution during preparation of macrocarriers, but apparently can also be caused by heterogeneity of the tissue itself. In intact explants it is not uncommon to see variation in expression associated with the physiological age of the explant.

Although the causes of these phenomena are unknown, it is important to realize that such

effects exist, and can be a source of serious confounding in experiments designed to choose

tissues for use in transformation experiments, and to optimize bombardment parameters.

Optimization of Bombardment Parameters—Transient expression vs stable transformation

The goal of many microcarrier bombardment experiments is to develop protocols for efficient production of transgenic plants. The frequency at which stable transformation events

are recovered is the ultimate criterion by which these protocols must be measured. However,

measurement of transient expression (i.e., expression of newly introduced DNA sequences

after a relatively brief period following bombardment) provides rapid feedback, and can be an

invaluable aid in the determination of effective bombardment parameters for a specific tissue.

A precise quantitative relationship between the level or frequency of transient expression

observed in a bombarded tissue, and the frequency at which stable transformation of cells occurs

within that tissue may not exist. Transient expression is, however, a very useful indicator of the

efficiency of DNA delivery, and can help to define conditions required to deliver DNA into

specific cell layers. In this way, measurement of transient expression allows rapid determination

of a set of parameters which permit delivery of DNA into tissues of interest, and provides critical information about which parameters have the greatest effect.

Choice of reporter gene and assay procedures for optimization of bombardment must be

determined by the particular question to be addressed. Histochemical assay of ß-glucuronidase

expression in bombarded cells is currently the most commonly used measurement of the

frequency of transient expression events in bombarded tissues. It is also ideal for determining which cell types in a heterogeneous tissue are capable of expressing the introduced

sequence. This procedure is not useful, however, for determining the absolute expression

levels produced by a particular set of bombardment parameters. For such measurements, it is

35

Page 39

more appropriate to use an extractive assay procedure in which expression level can be

measured, for example, as a function of enzyme activity per unit of total protein. Several

excellent markers (and associated assay procedures) are available for this type of study. These

include luciferase and ß-glucuronidase measured by a fluorometric process, and neomycin

phosphotransferase, for which a commercial ELISA assay has recently been marketed.

Yeast/Bacteria/Microbes

Cells which grow in suspension should be grown to late log to early stationary phase in

media under the appropriate conditions. Pellet the cells and resuspend in sterile water. Estimate

the cell density by determining the absorbence (for yeast, 1 O.D.

600

is approximately 2.8 x 10

9

cells/ml; for E. coli, 1 O.D.

600

is approximately 1.0 x 109cells/ml). Spread 1 x 108yeast of

2 x 10

9

E.coli on 100 mm Petri plates containing the appropriate media. In addition to the

necessary supplements, the media for growing yeast should contain 0.75 M mannitol and

0.75 M sorbitol, while media for growing bacteria should contain 0.75 M sorbitol. The plates

should be allowed to air dry briefly, but used within 1 or 2 hours. Transformation efficiency

decreases if the plates are allowed to sit even for several hours.

Mammalian Cells

Cells in culture

Both primary and established animal cell lines are transformable using particle bombardment. Because optimum bombardment conditions are usually found when mammalian

cells are placed at the top level of the bombardment chamber, the cells can be inoculated into

35 mm tissue culture plates. Only if cells are to be bombarded at Target Level 2 or farther

should larger plates be used.

Cells which grow as attached cultures should be inoculated into tissue culture plates one

day prior to bombardment so that they are in log phase and 50–80% confluent at the time of

transformation. Cells which grow as suspension cultures should be inoculated from log phase

cultures onto plates which have been asceptically coated by adsorption with Cell-Tak

(Collaborative Biomedical Products, Bedford, MA) according to the manufacturer’s instructions. The cells should be allowed to attach for 1 or 2 hours and should be approximately

75% confluent at the time of bombardment.

Immediately prior to bombardment, tissue culture media should be aspirated so that the

cells are directly exposed to air. Cells to be bombarded are placed in the bombardment chamber centered under the stopping screen, the chamber door closed, the chamber evacuated to

the proper vacuum, and the cells bombarded. After bombardment, add fresh tissue culture

media to the cells and incubate for the appropriate time.

Organ cultures

Animal organs may be transformed by particle bombardment 1 hour to several days after

preparation. Tissues should be approximately 400 µm thick sections and no more than 1 cm

square. The tissue may be grown in cell culture inserts containing a permeable membrane. The

tissue section (in the cell culture insert) is placed in a Petri plate containing 1% agar, then