Page 1

CFX Automation System II

Instruction Manual

Catalog #184-5075

Page 2

Page 3

Bio-Rad Technical Support

For help and technical advice, please contact the Bio-Rad Technical Support department. In the United

States, the Technical Support department is open Monday–Friday, 5:00 AM–5:00 PM, Pacific time.

http://www.bio-rad.com

Bio-Rad Laboratories

Life Science Research

2000 Alfred Nobel Drive

Hercules, CA 94547

Telephone: 510-741-1000

Tele x: 335-358

Toll Fre e: 1-800-4-BIORAD (1-800-424-6723)

Fax: 510-741-5800

Free Fax: 1-800-879-2289

Online technical support and worldwide contact information are available at www.consult.bio-rad.com.

Legal Notices

Windows and Microsoft Office are trademarks of Microsoft Corporation.

Bio-Rad real-time systems are covered by one or more of the following U.S. patents, their foreign

counterparts, or their foreign patents pending, owned by Eppendorf AG: US Patent Nos. 6,767,512

and 7,074,367.

Bio-Rad’s Hard-Shell PCR plates are covered by one or more of the following U.S. patents, patents pending,

or their foreign counterparts, owned by Eppendorf AG: US Patent Nos. 7,347,977, 6,340,589, 6,528,302.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopy, recording, or any information storage or retrieval system, without

permission in writing from Bio-Rad Laboratories.

Bio-Rad reserves the right to modify its products and services at any time. This instruction manual is subject

to change without notice.

Although prepared to ensure accuracy, Bio-Rad assumes no liability for errors, or for any damages resulting

from the application or use of this information.

Copyright © 2014 by Bio-Rad Laboratories, Inc. All rights reserved.

CFX Automation System II | i

Page 4

Bio-Rad Laboratories Resources

Bio-Rad provides many resources for scientists, including rich technical resources on a wide variety of methods and applications

related to PCR, real-time PCR, and gene expression. Table 1 lists available resources and how to locate what you need.

Table 1. Bio-Rad resources.

Resource How to Contact

Local Bio-Rad Laboratories Find local information and contacts on the Bio-Rad website (www.bio-rad.com) by selecting

representatives your country on the home page, and find the nearest contacts on the Contact Us page. Find the

nearest international office listed on the back of this manual

Technical support scientists Bio-Rad’s technical support scientists provide our customer with practical and expert solutions.

To find local technical support on the phone, contact your nearest Bio-Rad office. For technical

support in the United States and Canada, call 1-800-424-6723 (toll-free), and select the technical

support option

Service support engineers Maintenance and repairs should be carried out only by authorized service support engineers

For service support in the United States and Canada, call 1-800-424-6723 (toll-free), and select

the technical support option to request service support

Technical notes and literature Go to the Bio-Rad website (www.bio-rad.com). Type a term in the Search box and select

Documents tab to find links to technical notes, manuals, and other literature

Writing Conventions Used in This Manual

This manual uses the writing conventions listed in Table 2.

Table 2. Conventions used in this manual.

Convention Meaning

Tip: Provides helpful information and instructions, including information explained in further detail elsewhere in this manual

Note: Provides important information, including information explained in further detail elsewhere in this manual

WARNING! Explains very important information about something that might injure the researcher, damage the instrument, or

cause data loss

X > Y Select X and then select Y from a toolbar, menu, or sof tware window

Safety and Regulatory Compliance

For safe operation of the CFX Automation System II, we strongly recommend that you follow the safety specifications listed in this

section and throughout the manual.

Safety Warning Labels

Warning labels posted on the instrument and in this manual warn you about sources of injury or harm. Refer to Table 3 to review the

meaning of each safety warning label.

Table 3. Meaning of safety warning labels.

CAUTION: Risk of danger! This symbol identifies components that pose a risk of personal injury or damage to

the instrument if improperly handled. Wherever this symbol appears, consult the manual for further information

before proceeding

CFX Automation System IIii |ii |

Page 5

Instrument Safety Warnings

The warning labels shown in Table 4 are displayed on the instrument and refer directly to the safe use of the CFX Automation System II.

Table 4. Instrument safety warning labels.

Warning about risk of harm to body or equipment.

Risk of puncture injury. Keep clear of plate handler when in operation.

Operating the CFX Automation System II before reading this manual can constitute a personal injury hazard.

For safe use, do not operate this instrument in any manner unspecified in this manual. Only qualified laboratory

personnel trained in the safe use of electrical equipment should operate this instrument. Always handle all

components of the system with care, and with clean, dry hands

Safe Use Specifications and Compliance

Electrical Safety Information and Classification

Table 5 lists the safe use specifications for the CFX Automation System II. Shielded cables (supplied) must be used with this unit to

ensure compliance with the Class A FCC limits.

Table 5. Safe use specifications.

Safe Use Requirements Specifications

Temperature Ambient temperatures of 4–30°C. Relative humidity maximum of 85% noncondensing

WARNING! To reduce the risk of electric shock, do not remove the cover. No user serviceable parts are inside the CFX Automation

System II. Refer to qualified service personnel if help is required.

WARNING! Use this product only in the manner described in this manual. If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

FCC Warnings and Notes

n

Warning. Changes or modifications to this unit not expressly approved by Bio-Rad Laboratories could void the user’s authority to

operate the equipment

n

Note. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the

interference, at his own expense

n

Note regarding FCC compliance. Although this instrument has been tested and found to comply with Part 15, Subpar t B of the FCC

Rules for a Class A digital device, please note that this compliance is voluntary, for the instrument qualifies as an “exempted device”

under 47 CFR 15.103(c), in regard to the cited FCC regulations in effect at the time of manufacture

n

Note regarding Canadian EMC compliance: Le present appereil numerique n’emet pas de buits radioelectrique depassant les

limites applicables aux appareils numeriques de class A prescrites dans le regulement sur le brouillage radioelectrique edicte par le

Ministere des Communications du Canada

Regulatory Compliance

This instrument has been tested, and found to be in compliance with all applicable requirements of the following safety and

electromagnetic standards:

n

IEC 61010-1:2010 (3rd Ed.), EN61010-1:2010 (3rd Ed). Electrical Equipment for Measurement, Control, and Laboratory Use - Part 1:

General requirements

n

IEC 61010-2-081:2001+A1, EN61010-2-081:2002+A1. Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use. Part 2-081: Par ticular requirements for automatic and semi-automatic laboratory equipment for analysis and other

purposes (includes Amendment 1)

n

CAN/CSA-C22.2 NO. 60101-1:2012 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use,

Part 1: General Requirements

n

CAN/CSA-C22.2 NO. 60101-2-081:2004 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory

Use, Part 2-081: Particular Requirements for automatic and semi-automatic laboratory equipment for analysis and other purposes

| iiiCFX Automation System II | iii

Page 6

n

EN 61326-1:2006 (Class A) Electrical Equipment for Measurement, Control and Laboratory Use. EMC requirements,

Part 1: General requirements

n

UL 61010-1:2012 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use, Part 1:

General requirements

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

Warranty

The CFX Automation System II and associated accessories are covered by a standard Bio-Rad warranty. Contact your local Bio-Rad

Laboratories office for details of the warranty.

CFX Automation System IIiv |iv |

Page 7

Table of Contents

Chapter 1. CFX Automation System II Installation ...................... 1

CFX Automation System II Parts ............................................. 1

CFX Automation System II Compatibility....................................... 2

CFX Automation System II Hardware Installation ................................ 3

Software Installation ......................................................10

Enable Computer to Continuously Communicate with Barcode Scanner .............11

Turn Off Windows Automatic Update Feature...................................12

CFX Automation System II Configuration and Calibration ..........................12

Chapter 2. Using the CFX Automation System II ...................... 21

Introduction.............................................................21

Starting an Automation Run ............................................... 22

Adding Plates after Starting an Automation Run.................................24

Canceling an Automation Run ..............................................25

Pausing or Canceling a Single Plate Run in a CFX System.........................25

Emptying the Waste Rack..................................................25

LIMS Information.........................................................25

PrimePCR Information.................................................... 26

Create the Plate List: Additional Features ..................................... 26

Barcode Controls: Advanced Features ........................................27

Modify Settings ......................................................... 29

Statu s Tab ..............................................................31

History Tab ............................................................ 32

Chapter 3. Resources............................................ 33

Maintenance ........................................................... 33

Power Outage.......................................................... 34

Troubleshooting the CFX Automation System II ................................ 34

Frequently Asked Questions ............................................... 36

Ordering Information ............................................ 37

| vCFX Automation System II | v

Page 8

CFX Automation System IIvi |

Page 9

1

CFX Automation System II Installation

Read this chapter for information about installing the CFX Automation System II.

■n

CFX Automation System II Parts

■n

CFX Automation System II Compatibility

■n

CFX Automation System II Hardware Installation

■n

Software Installation

■n

CFX Automation System II Configuration and Calibration

CFX Automation System II Parts

Arm

Wrist

Tow er

Rear CF X System

Front CFX System

Mounting plate

Fig. 1. CFX Automation System II par ts.

Gripper assembly

Rack 1

Rack 2

Rack 3

Barcode scanner

Base

Foot assembly

Rotary axis Power LED

CFX Automation System II | 1

Page 10

Chapter 1: CFX Automation System II Installation

Table 6. CFX Automation System II part details.

Part Function

Arm Reach axis. Moves horizontally 11.25 in (28.5 cm) to 19.75 in (50.1 cm) from tower

Wrist Rotates plate to appropriate position (270° rotation)

Gripper assembly Gripper fingers open and close to grasp and release the plate

Tower Vertical axis. Moves the arm up and down

Rotary axis Rotates the arm 340° around the base of the CFX Automation System II

Barcode scanner Scans plates prior to placing them into the CFX System

Rack Holds source and waste plates. Each rack holds a maximum of 32 sealed

96-well plates or 48 sealed 384-well plates

CFX Automation System II Compatibility

Compatible CFX Systems

The CFX Automation System II is compatible with the following CFX Systems:

CFX9 6 Touc h

CFX384 Touch

CFX Connect

CFX96 Touch Deep Well

CFX96

CFX384

™

Real-Time PCR Detection System

™

Real-Time PCR Detection System

™

Real-Time PCR Detection System

™

Real-Time PCR Detection System

™

Real-Time PCR Detection System

™

Real-Time PCR Detection System

Plastics Compatibility

The CFX Automation System II is compatible with Hard-Shell® Low-Profile 96-Well Skirted PCR

Plates and Hard-Shell 384-Well Skirted PCR Plates. Table 7 lists the Bio-Rad catalog numbers

for compatible plates. The same gripper fingers are compatible with both 96- and 384-well

plates. PCR plates not listed in Table 7 may not be compatible with the gripper fingers, plate

handler, or CFX Systems.

For more information, visit www.bio-rad.com/pcrplastics.

Table 7. PCR plate compatibility with CFX Automation System II.

PCR Plate Barcode Well Color Catalog Number

Hard-Shell 384-Well Barcoded White HSP-3905

Skirted Nonbarcoded White HSP-3805

Barcoded White HSP-9955

Hard-Shell Low Clear HSP-9901

Profile 96-Well Skirted Nonbarcoded White HSP-9655

Clear HSP-9601

Seal Compatibility

Bio-Rad Hard-Shell Plates can be sealed with Microseal® 'B' Optically Clear Adhesive Seals

(catalog #MSB-1001). After the plate is sealed, remove the end tabs before loading the plates

into the racks.

Plates may also be heat sealed using Bio-Rad’s PX1

and Optically Clear Heat Seals (catalog #181-4030). This semi-automated heat sealer ensures a

reproducible seal every time, helping minimize sample evaporation during thermal cycling. For

more information, go to www.bio-rad.com/pcrplatesealer.

™

PCR Plate Sealer (catalog #181-4000)

2 | CFX Automation System II2 |

Page 11

Minimum Computer Requirements

A computer with either Windows 7 or Windows 8 operating system is required to run CFX

Automation Control Software version 2.0 or higher. The software package must be installed on

the computer by a user with administrative privileges.

™

Note: CFX Manager

CFX Automation Control Software.

Table 8 lists the computer system requirements for CFX Manager Software and CFX

Automation Control Software.

Table 8. Computer requirements.

System Minimum Recommended

Operating system Windows 7 or Windows 8 Windows 7 or Windows 8

Drive CD-ROM drive CD-RW drive

Hard drive 10 GB 20 GB

Processor speed 2.0 GHz 2.0 GHz

RAM 1 GB RAM 2 GB RAM

Screen resolution 1,024 x 768 with true-color mode 1,280 x 1,024 with true-color mode

USB USB 2.0 Hi-Speed port USB 2.0 Hi-Speed port

Software Microsoft Office Suite

Software version 3.1.1620 or higher must be installed before installing

Chapter 1: CFX Automation System II Installation

CFX Automation System II Hardware Installation

Getting Started

Determine where the automation system will be installed. Remove any objects from the bench

that will interfere with installation. Unplug and remove the CFX System(s) and computer from the

laboratory bench before installing the plate handler (note the location of any cables connected

to the instruments).

Determine the placement of the CFX System(s), plate handler, and computer on the lab bench.

If a single CFX System will be integrated, the CFX System front panel must face forward and be

located to the right of the plate handler (Figure 2A). If two CFX Systems will be integrated, the CFX

Systems must be installed with their front panels oriented toward the plate handler (Figure 2B).

A B

Fig. 2. Single and dual CFX Automation System II configurations.

| 3CFX Automation System II | 3

Page 12

Chapter 1: CFX Automation System II Installation

Space Requirements

The CFX Automation System II must be assembled on a sturdy, level lab bench. The benchtop

must be sturdy enough to support the weight of the computer, the plate handler, and the CFX

System(s) without sagging. An uneven surface will result in misalignment of the automation

system. Ensure there are sufficient electrical outlets available for the plate handler, CFX System(s)

and the computer. Table 9 illustrates the space requirements needed for the system.

Table 9. CFX Automation System II dimensions.

Operational Space

Footprint Requirements*

Single CFX Dual CFX Single CFX Dual CFX

Plate Handler System System System System

Dimensions Alone Configuration Configuration Configuration Configuration

Height, cm (in) 97 (38) 97 (38) 97 (38) 97 (38) 97 (38)

Width, cm (in) 53 (21) 91 (36) 99 (39) 91 (36) 114 (45)

Depth, cm (in) 77 (30) 77 (30) 77 (30) 86 (34) 86 (34)

* Operational space includes space for the plate handler arm travel and CFX System lid to open.

Tools required to assemble and install the CFX Automation System II include:

■n

Adjustable wrench

■n

Bubble level (provided with the system)

Unpacking the CFX Automation System II

WARNING! Use two people to lift the CFX Automation System II. The plate handler weighs

approximately 110 lb (50 kg). Lift the plate handler with care. Do not lift the plate handler by the

arm. Lift only by the base. Take precautions to avoid injury.

■n

Examine the carton for damage

■n

Remove the outer carton

■n

Remove the startup kit packaging on top of the plate handler. Make sure the startup kit is not

stuck in the top of the outer carton

■n

Retain the box and packing materials. If the unit needs to be returned for any reason, you

must use the original packing materials and box for shipping. If there has been damage to the

instrument in transit, it is particularly important to retain the packaging for inspection

Parts List

The shipping cartons should include the following items:

■n

Plate handler with attached barcode scanner

■n

Three removable racks

■n

Declaration of Conformity

■n

Startup kit containing:

- Power cord

- Communications cable [6 ft (1.8 m),

USB-B to USB-A]

- Calibration block

- Mounting plate

- Bubble level

- Eight extra gripper pads

- Two plate lifters for use with CFX384 Systems

- CFX Automation System II instruction manual

- CFX Automation Control Software

installation CD

- Ex tra fus es

- Warranty card

- Software registration card

4 | CFX Automation System II4 |

Page 13

Position the Mounting Plate and Plate Handler

Position the mounting plate on the bench such that the two holes for the plate handler feet are

on the right and the beveled edge faces up (Figure 3).

Lift the plate handler and place the two left feet inside the designated holes on the mounting

plate. The barcode scanner should be located in the front left.

WARNING! The plate handler weighs 110 lb (50 kg). Do not lift the plate handler by the arm.

Lift only by the base. Take precautions to avoid injury.

Beveled edge faces up

Back lef t foot of the plate handler will be

placed in this hole

Single CFX System configuration. Right feet of

the CFX System will be placed in these holes

Chapter 1: CFX Automation System II Installation

Dual CFX System configuration. Front feet of

the CFX Systems will be placed in these holes

Front left foot of the plate handler will be

placed in this hole

Fig. 3. Mounting plate.

Carefully cut the tie-wrap with the red sticker from the counterbalance rail and remove the

tiewrap and the black split tubing (Figure 4).

Fig. 4. Remove tie-wrap and black split tubing.

| 5CFX Automation System II | 5

Page 14

Chapter 1: CFX Automation System II Installation

Install the CFX System(s)

1. Install the CFX System(s) in the desired positions.

■n

Single CFX System. Align the right side feet of the CFX System in the mounting plate

such that the CFX System front panel is facing forward (Figure 2)

■n

Dual CFX Systems. Align the front feet of the CFX Systems in the mounting plate such

that the CFX Systems’ front panels are facing the plate handler (Figure 2)

2. Connect CFX System(s) power cord(s) and communication cable(s). For detailed

instructions on installing the CFX Systems, refer to the CFX Systems instruction manual

(bulletin #10021337).

3. Install the plate lifter (Figure 5) in all 384-well CFX Systems configured with the plate handler.

The plate lifter aids in the removal of 384-well plates by gently lifting the plate slightly out of

the reaction block when the heated lid is opened.

Note: The plate lifter is not required for 96-well CFX Systems. Save unused plate lifters for

potential future use with 384-well CFX Systems.

■n

Place the plate lifter around the outside of the 384-well block, with the lifters facing up

(Figure 5)

■n

Gently press down on the long edges of the plate lifter until the four notches on the short

side of the plate lifter push against the 384-well block

■n

Examine the plate lifter to ensure that it is properly installed

Fig. 5. Plate lifter for 384-well CFX Systems.

Level the Plate Handler

WARNING! This step requires two people. The plate handler weighs 110 lb (55 kg). When

lifting, grasp only the bottom of the plate handler. Do not lift the system by the arm.

Note: The bench top must be able to support the weight of the computer, the plate handler

and the CFX System(s) without sagging. An uneven surface will result in the misalignment of the

plate handler.

Lifters face upward

Press down here

Notches push into block

6 | CFX Automation System II6 |

Page 15

Chapter 1: CFX Automation System II Installation

Fig. 6. Bubble level in CFX System block.

1. Place bubble level in the center of the CFX System(s) block (Figure 6). Note where the

bubble is within the level.

2. Lift the plate handler arm up high enough to access the tower opening. Place the level

inside the center of the plate handler tower (Figure 7). Compare the position of the

bubble to its position when placed on the CFX System block. Because the CFX Systems

do not have leveling feet, the most important thing is to level the plate handler relative

to the CFX System(s).

■n

If the bubble position differs significantly in the plate handler tower and CFX System(s),

proceed to step 3

■n

If the bubble position does not differ significantly when placed in the plate handler tower

and CFX System(s), proceed to step 6

Fig. 7. Bubble level in tower.

| 7CFX Automation System II | 7

Page 16

Chapter 1: CFX Automation System II Installation

3. Turn the securing nut down toward the bench until it rests against the adjusting nut

(Figure 8). Repeat on all four foot assemblies.

Tip: Have one person slightly lift the corner of the instrument while another person turns

the securing nut.

WARNING! The plate handler arm may swing when the instrument is lifted. Take

precautions to avoid injury.

Base

Securing nut

Screw threads

Adjusting nut

Foot

Fig. 8. Foot assembly.

4. Turn the adjusting nut until approximately two screw threads are visible between the plate

handler base and the securing nut. This will allow for adequate travel in either direction

during the leveling process. Repeat on all four foot assemblies.

5. Begin leveling the plate handler by turning the adjusting nut as needed until the bubble

matches the position when the level is placed on the CFX System(s). You may need to raise

one foot assembly and lower another during the leveling process.

Note: Rotating the foot itself will not change the height of the foot assembly. To level the

plate handler, you must rotate the adjusting nut.

6. Push down on all four corners of the plate handler base to ensure the system is evenly

seated on all four feet. All four feet must touch the bench for the instrument to be secure.

Although the bubble in the level may appear centered, if any of the feet are not on the

bench, the instrument is not secure.

7. When the plate handler is level, use an adjustable wrench to turn each securing nut upward

until it is flush against the system base. Hold the foot and adjusting nut in place while

turning the securing nut to ensure the plate handler remains level during this step. This step

locks the plate handler into the desired level position.

Install the Racks

1. Lift a rack by the two side handles.

2. Hold the rack over the designated position with the two side handles facing toward you. The

racks and rack positions are labeled and must be paired accordingly.

3. Lean the top of the rack toward you slightly.

8 | CFX Automation System II8 |

Page 17

Chapter 1: CFX Automation System II Installation

4. Place the rack locator notch under the lip of the rack position (Figure 9).

5. Maintain the placement of the rack under the lip while you lean the rack backward and

snap it into place against the locator pin.

Locator pin

Locator

notch

Fig. 9. Rack securing position.

6. Before releasing the rack, make sure it is firmly secured under the lip by gently pulling it

toward you. Release gently in order to maintain the proper position.

Note: If the rack is not correctly placed under the lip, the rack will not be level. This will

misalign the racks and the plate handler will not function properly.

7. Verify the region of the plate handler that holds the racks is level relative to the CFX

System(s). Place the bubble level at the bottom of each empty rack. Compare the position

of the bubble when the level is placed in the racks, in the tower, and on the CFX System(s)

block(s). If the racks are not level, adjust the plate handler foot assemblies so that all regions

of the plate handler are as level as possible, relative to the CFX System(s) (see Level the

Plate Handler).

To remove a rack, reverse the steps above.

Connect the Power Cord and Communications Cable

WARNING! Before proceeding, verify the plate handler power switch is OFF and the computer

power cord is unplugged.

LIp

1. Connect one end of the USB cable to the USB connector on the back of the plate handler

(Figure 10).

2. Connect the other end of the USB cable to an available USB port on the computer.

| 9CFX Automation System II | 9

Page 18

Chapter 1: CFX Automation System II Installation

3. Connect the power cord to the receptacle on the back of the plate handler (Figure 10).

4. Plug the plate handler AC power cord into a grounded 100 V, 120 V, or 240 V outlet.

5. Plug the computer AC power cord and the computer monitor AC power cord into

appropriate power outlet.

WARNING! Plug the power cord into a properly grounded outlet only. Use only a standard

IEC 60320-style power cord appropriate for your country. Equipment is Class 1 and must be

connected to an outlet that has proper grounding to ensure safety. The power inlet is a basic

disconnect device and should be positioned for easy access.

USB connector Power switchPower cord

Fig. 10. Rear panel of the CFX Automation System II.

Software Installation

receptacle

10 | CFX Automation System II10 |

CFX Manager Software 3.1.1620 or higher must be installed first to run the CFX Automation

System II. Refer to the CFX System instruction manual (bulletin #10021337) for detailed

instructions on CFX Manager Software installation.

The CFX Automation Control Software must be installed on the computer by a user with

administrative privileges. To install CFX Automation Control Software 2.0 or higher:

1. Place the CFX Automation Control Software CD in the computer CD drive.

2. Double click setup.exe to launch the software installation.

3. Click box for Accept license agreement. Click Install.

4. Click Extract for FTDI Chip CDM Drivers.

5. Click Next on the software installation screen.

6. Click Finish to exit device driver installation wizard.

Page 19

Chapter 1: CFX Automation System II Installation

7. Click Next for the CP210X USB to UART Bridge Driver Installer.

8. Select radio button I accept this agreement. Click Next.

9. When the software installation is complete, click OK to exit the installation wizard.

10. When completed, the CFX Automation Control Software icon appears on the desktop.

Note: To uninstall CFX Automation Control Software from your computer, use the Windows

Add/Remove Programs function.

Enable Computer to Continuously Communicate with Barcode Scanner

Default power management settings for the barcode scanner must be modified to enable the

system to function properly. To modify the power management settings:

1. Find the computer device manager by typing device manager into the computer’s

search field.

2. Expand the Ports (COM & LPT) option by clicking its arrow (Figure 11A).

3. Double click Silicon Labs CP210x USB to UART Bridge.

4. Select the Power Management tab (Figure 11B).

5. Clear the checkbox next to Allow the computer to turn off the device to save power.

A B

Fig. 11. A, device manager folder. B, modify the power management options for the barcode scanner.

| 11CFX Automation System II | 11

Page 20

Chapter 1: CFX Automation System II Installation

Turn Off Windows Automatic Update Feature

When the Windows automatic updating feature is turned on, updates will be automatically

installed and the computer will automatically restart. If these Windows automatic updates occur

when an automation run is in progress, the run will be stopped and the application will close.

No error messages will be displayed. To prevent this from occurring, turn off the Windows

automatic updating feature and manually install Windows updates as needed.

CFX Automation System II Configuration and Calibration

After the CFX Automation System II, CFX System(s), CFX Manager Software, and CFX

Automation Control Software are installed, follow these steps to complete instrument setup:

■n

Configure the Automation System

■n

Calibrate the Automation System

■n

Test the Calibration

■n

Complete a Test Automation Run

Configure the Automation System

System configuration must be set during system installation, when CFX Systems are added or

removed and when optical modules are swapped on C1000™ Thermal Cycler bases.

1. Turn on the CFX System(s) and the plate handler using the power switches on the back of

the instruments.

2. Open the CFX Automation Control Software.

3. In the menu bar, select Tool s > Configuration. The platform configuration window will

appear (Figure 12).

4. Select Single CFX System or Dual CFX Systems according to your setup.

5. Under Platform Configuration:

■n

Use the dropdown menu to select the CFX System base serial number corresponding

to the configured CFX System. The base serial number can be found on the back of

the instrument base, and on the home screen display on systems with touch screens

(Figure 13). If only a single CFX System is configured, select the serial number for that

system next to the “front” CFX System. If two CFX Systems are configured, select

the appropriate CFX System base serial number for the front and rear CFX Systems

(Figure 1). Note that all CFX Systems and 1000-series thermal cyclers connected to this

computer will be displayed in the dropdown menu

■n

If you are switching just the optical modules and the thermal cycler base will remain the

same, first select NOT USED from the dropdown menu. Then select the appropriate serial

number again. This process will enable the software to recognize the new optical head

■n

Select the desired waste rack

6. Select OK to save configuration

■n

Each time the system configuration window is modified, the software will

automatically restart

12 | CFX Automation System II12 |

Page 21

Fig. 12. Platform configuration window.

Chapter 1: CFX Automation System II Installation

Serial number located on the

base of the instrument.

Fig. 13. Base serial number locations.

Calibrate the Automation System

The CFX Automation System II must be properly calibrated during installation. Recalibrate any

time the system is moved or CFX Systems are added or removed.

Default calibrations for your CFX System configuration are automatically loaded during the

system configuration step. The automation software includes a calibration wizard that aids in

making the fine adjustments required for proper calibration. To calibrate the system:

■n

Select Tool s > Calibration

■n

Select the positions to calibrate

Home screen on CFX System

touch screens. Base serial number

is located on this screen.

| 13CFX Automation System II | 13

Page 22

Chapter 1: CFX Automation System II Installation

■n

Select Calibrate

■n

The calibration wizard will walk you through the steps to calibrate, modify, and accept

each calibration position. At each step, carefully read the instructions presented and

perform the required actions. If calibration modification is required, manually adjust the

plate handler by moving the arm to the desired location

■n

Select Next. Instructions for the next calibration step will automatically appear

This manual provides additional details to supplement the information displayed in the

calibration wizard.

During calibration, refer to the following sections:

■n

Begin Calibration

■n

Calibrate the Racks

■n

Calibrate the Barcode Scanner

■n

Calibrate the CFX System(s)

After calibration is complete, test the calibration using the calibration wizard.

Lastly, confirm calibration by completing a test automation run.

Begin Calibration

During installation, factory calibration values are loaded. These values are starting points for

calibration and must be adjusted as needed. If the system requires calibration at any of the

positions, manually adjust the plate handler by moving it to the correct calibration position.

When instructed by the software, the robot arm can be moved along the vertical axis and

horizontal axis and extended in and out from the tower (Figure 14). The wrist can be rotated to

help obtain ideal calibration.

WARNING! Adjust the plate handler only when instructed. Manually adjusting the plate handler

at other times may damage the instrument.

Gently pull out or

push in the arm to

change the reach

Rotate the wrist

to obtain proper

calibration

The rotary axis

can be modified

to obtain proper

calibration

Gently push up

or pull down the

arm to adjust the

vertical position

14 | CFX Automation System II14 |

Fig. 14. Manually changing positions during calibration.

Page 23

Chapter 1: CFX Automation System II Installation

When calibrating the plate handler, always use the same brand and model of PCR plates that

will be used in experiments. See Table 7 for a list of plates compatible with the automation

system. All plates should be sealed. If both CFX96 and CFX384 Systems are being used, the

calibration instructions will indicate which positions should use 96-well and 384-well plates.

WARNING! Stand clear of the plate handler arm throughout the calibration process.

To begin calibration:

1. In the menu bar, select Tools > Calibration.

2. The main calibration screen is displayed (Figure 15).

3. Select the positions to calibrate.

■n

All positions should be calibrated during installation. After installation, specific positions

may be recalibrated

■n

If you will always or occasionally use barcoded plates, calibrate the barcode scanner

during the initial installation. This will ensure a smooth automation run when the barcode

software options are selected

4. Select Calibrate.

5. Carefully follow the instructions that appear in the calibration window and then select Next

to continue through calibration. The system will execute the appropriate calibration steps

and then display the next set of instructions.

Select all

positions to be

calibrated

Save or cancel

calibration

Exit calibration

wizard

Fig. 15. Main calibration and test window.

Calibrate the Racks

The instructions on the calibration screen will guide you through the calibration of the racks.

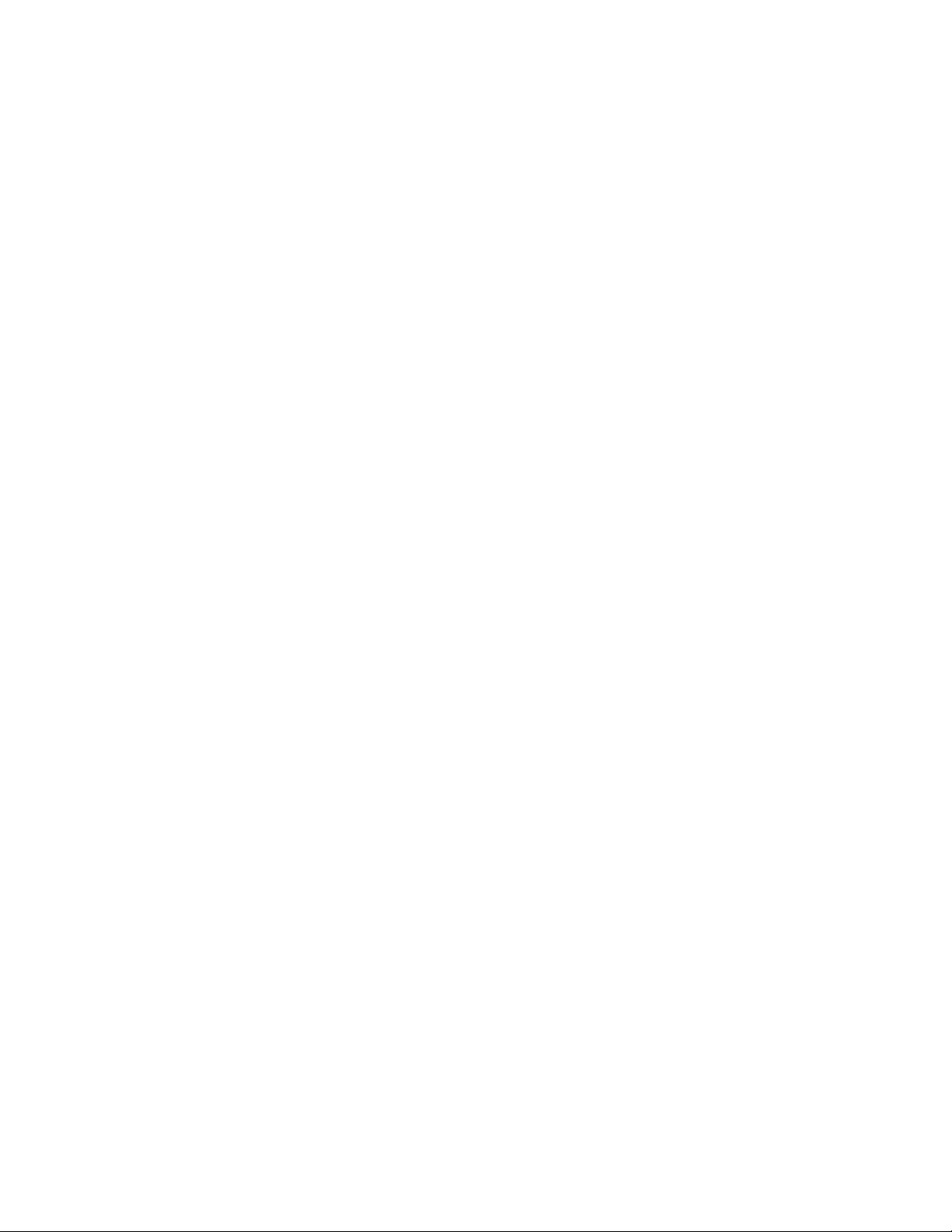

1. Place a single sealed PCR plate at the bottom of each rack. Well A1 should face out toward

the exterior of the plate handler.

Note: Use the same brand and model of the plates that will be used in actual automation

runs. If both 96-well and 384-well CFX Systems are connected to the plate handler, use a

384-well plate to calibrate the bottoms of all three racks.

Carefully read

and follow all

instructions

displayed

Provides status

information

| 15CFX Automation System II | 15

Page 24

Chapter 1: CFX Automation System II Installation

2. When instructed by the software, place the calibration block on top of the rack to be

calibrated (Figure 16). The calibration block is larger than a PCR plate and is designed to sit

on top of the rack and aid in this calibration position.

3. The top of the rack is properly calibrated when the gripper fingers are perfectly centered on

the calibration block (Figure 16).

4. If the calibration needs to be adjusted, manually adjust the plate handler only when

instructed by the software.

5. If needed, adjust the calibration by manually separating the gripper fingers from the

calibration block. Extend or retract the plate handler arm the appropriate amount so that

the gripper fingers will be centered on the calibration block. Release the gripper fingers and

inspect their location on the calibration block. Repeat as needed.

6. Follow the calibration wizard instructions to complete rack calibration.

Fig. 16. Calibrating the racks.

Calibrate the Barcode Scanner

1. Place a sealed plate in rack 1.

Note: If both 96-well and 384-well CFX Systems are configured, use a 384-well plate for

this step.

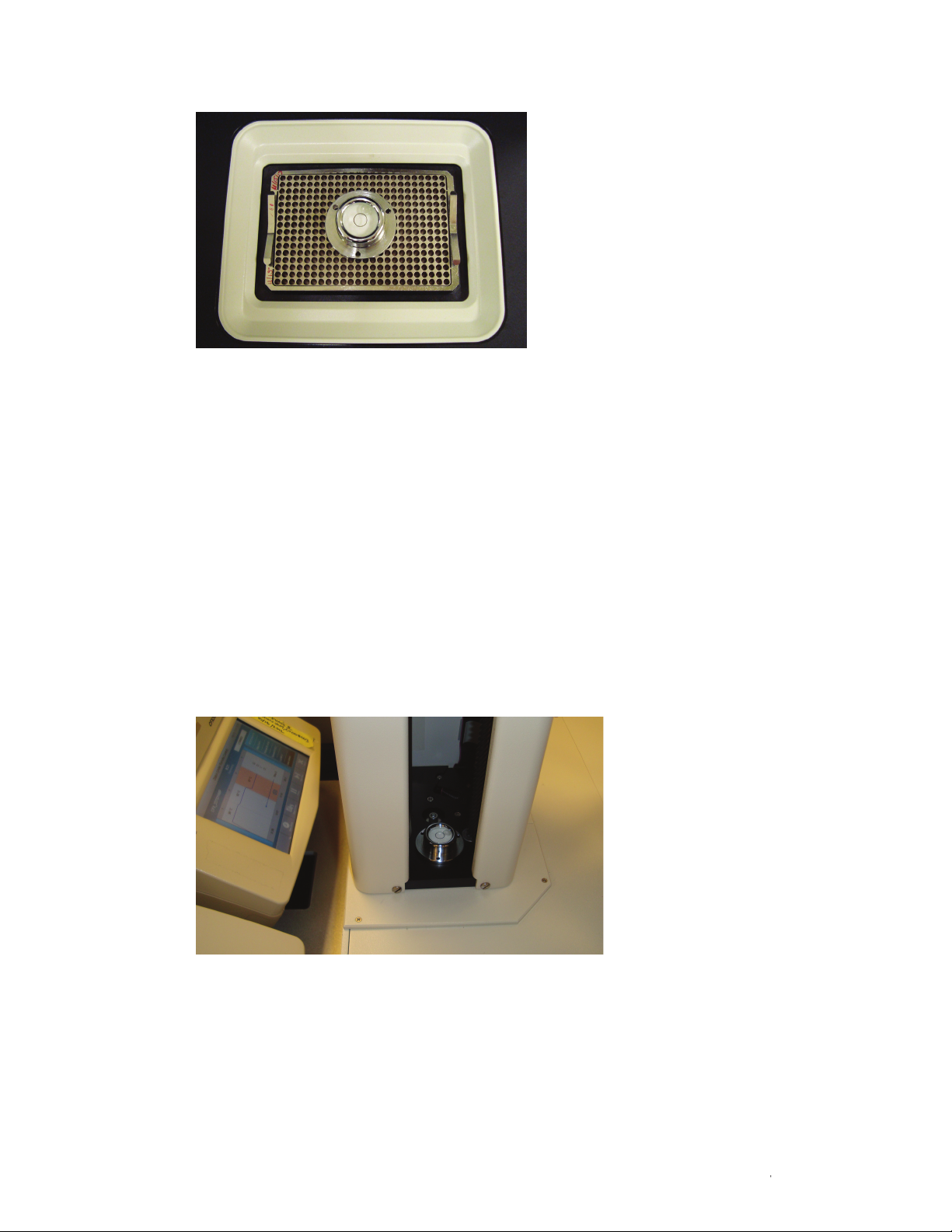

2. The plate handler will move the plate from rack 1 to the barcode scanner. Confirm that the

barcode on the short side of the plate is facing the barcode scanner.

3. To be properly calibrated, the LED light from the barcode scanner should illuminate the

region immediately above the plate barcode or at the very bottom of the gripper assembly

(Figure 17). Manually adjust the plate handler arm and gripper assembly if not properly

positioned. Ensure the plate handler arm remains fully extended.

Note: For the software to properly calibrate the barcode scanner, the LED beam must

illuminate the region above the top of the barcode sticker.

4. Select Next. The software will now calibrate the barcode scanner.

Properly calibrate the top

of the rack by making sure

the gripper fingers grasp

the calibration block with

an equal number of black

pyramids on each side.

16 | CFX Automation System II16 |

Page 25

Chapter 1: CFX Automation System II Installation

Position the plate handler arm so the beam

illuminates the region slightly above the top of the

barcode sticker. It should be illuminating the very

bottom of the gripper assembly.

Fig. 17. Calibrating the barcode scanner.

Calibrate the CFX System(s)

1. Place a sealed plate in the CFX System(s).

2. Keep the CFX System(s) lid(s) open.

3. The gripper assembly will move to the CFX System and stop approximately one inch above

the plate. At this point, confirm that the gripper assembly is approximately centered above

the plate.

■n

This step confirms the general location of the gripper assembly. Do not lower the plate

handler arm down toward the plate at this step

■n

If the gripper assembly is misaligned by a large amount, you may make manual

adjustments at this point. Fine adjustments to the calibration will be made in the next step

4. Select Next. The gripper assembly will move down and grip the plate. Confirm that the

gripper assembly is centered on the plate (Figure 18).

■n

Confirm the gripper fingers are centered, touching the plate with equal distance from the

notches on the plate

■n

Confirm that the top of the gripper assembly is squared on the plate, overhanging the

plate by equal amounts

■n

If changes need to be made, carefully spread the gripper fingers, releasing them from the

plate. Continue to hold the gripper fingers open. Move the gripper assembly as needed

so that it is centered on the plate. Gently release the gripper fingers and examine if the

gripper assembly is centered on the plate (Figure 18). Repeat until properly centered

5. Select Next.

| 17CFX Automation System II | 17

Page 26

Chapter 1: CFX Automation System II Installation

6. The plate handler will pick up the plate, place it in rack 1 and then return the plate to the

CFX System. Confirm that the plate transitions smoothly between all positions.

Once all positions are calibrated, select Save. The application will automatically restart and

load the saved calibration. Select Cancel to cancel any modifications that were made to the

calibration and restore the previously set calibration values.

Gripper fingers are equal distance from

each of the notches on the plate.

Fig. 18. Calibrate the CFX Systems.

Test the Calibration

You must test all calibration positions to verify calibration is correct.

1. Select To ols > Calibration.

2. Select all positions that will be used during the automation run.

3. Select Test . The automation system will proceed through a series of steps ensuring that all

calibration settings work together.

18 | CFX Automation System II18 |

Gripper assembly overhangs the plate

by equal amounts on both sides.

Page 27

4. Carefully observe the entire test process. Confirm the gripper assembly smoothly picks up

and releases plates, the plate is perfectly placed into the CFX System(s) and plates never

scrape against the racks.

5. If any of the calibration positions fail, a message will alert you to the failed position. You can

instruct the system to continue testing the other positions.

6. When testing is complete, recalibrate the failed positions. After calibration is complete, test

these positions.

Complete a Test Automation Run

After calibration and testing is complete, set up a plate list and run several empty plates through

an automation run before actual experimental plates are used. Plates can remain empty but

must be sealed. Use short cycling protocols in CFX Manager Software to reduce the amount of

time required for this final recommended test.

Carefully observe the entire test automation run. Confirm the gripper assembly smoothly picks

up and releases plates, the plate is perfectly placed into the CFX System(s), and plates never

scrape against the racks. If the entire test automation run completes correctly, the automation

system has been correctly installed and calibrated and is ready for use.

Chapter 1: CFX Automation System II Installation

| 19CFX Automation System II | 19

Page 28

Chapter 1: CFX Automation System II Installation

20 | CFX Automation System II20 |

Page 29

2

Using the CFX Automation System II

Read this chapter for information about using the CFX Automation System II.

■n

Introduction

■n

Starting an Automation Run

■n

Adding Plates after Starting an Automation Run

■n

Canceling an Automation Run

■n

Pausing or Canceling a Single Plate Run in a CFX System

■n

Emptying the Waste Rack

■n

LIMS Information

■n

PrimePCR™ Information

■n

Create the Plate List: Additional Features

■n

Barcode Controls: Advanced Features

■n

Modify Settings

■n

Sta tus Ta b

■n

History Tab

Introduction

CFX Automation Control Software and CFX Manager™ Software are used together to

automate CFX System(s). The automation software controls the plate handler and is the main

interface for controlling all automation processes. CFX Manager Software is used to create

plate setup files and cycling protocols, control the CFX System thermal cycling processes,

and analyze data. Refer to the CFX System instruction manual (bulletin #10021337) for

detailed information about CFX Manager Software. To use CFX Manager Software and the

automation software simultaneously, CFX Manager Software must be opened prior to

the automation software.

CFX Automation System II | 21

Page 30

Chapter 2: Using the CFX Automation System II

Open the CFX Automation Control Software by double clicking the automation system icon. The

main software tabs in the CFX Automation Control Software include:

■n

Status tab. Illustrates the status of the plate lists, the configured CFX System(s), and the

waste rack

■n

Plate list tabs. Named according to the rack on which the source plates are loaded

■n

History tab. Provides a log of plates run using the CFX Automation System II

Plate list tabs History tab

Status tab

Selection box

to highlight an

entire row

Select barcode

cell to be

modified

Plate list

controls

Fig. 19. Plate list tab.

Starting an Automation Run

The plate list is the table that contains the cycling instructions for all plates loaded into a specific

source rack (Figure 19). The plate list tabs are named according to the rack in which the source

plates are loaded (Rack 1, Rack 2, etc). View each of the plate lists by selecting either of the

plate list tabs on the main tool bar. All controls for creating, editing, saving, and running plate

lists are found on the plate list window.

CFX System selection

Import LIMS or

PrimePCR run

ID as barcode

Barcode

controls

Basic automation runs can be started by following these five steps:

1. Create the plate list.

2. Select the CFX System(s).

3. Modify the barcode controls.

4. Load the plates.

5. Select Start.

CFX Automation System II22 |

Page 31

Step 1: Create the Plate List

Use the plate list controls (Figure 19) to add plates to a plate list:

■n

Select protocol, LIMS, or PrimePCR file — use the dropdown menu or browse function

to select the desired protocol, Laboratory Information Management Systems (LIMS) file, or

PrimePCR file. Protocols must be created and saved using CFX Manager Software. Because

LIMS and PrimePCR files contain both protocol and plate information, when one of these files

is selected, the plate file dropdown box will be disabled. For additional information on LIMS,

see LIMS Information. For additional information on PrimePCR, see PrimePCR Information

■n

Select plate file — use the dropdown menu or browse function to select the desired plate

file. Plate files must be created and saved using CFX Manager Software

■n

Select Add — a new entry with the selected files will be added to the plate list. If no rows on

the plate list are selected, the new entry will be added to the bottom of the plate list. If a row

in the plate list is selected, the new row will be inserted directly below the selected row

Tip: See Create the Plate List: Additional Features for tips to quickly add files to a plate list and

information on editing and saving plate lists.

Step 2: Select the CFX System(s)

If a single CFX System is configured, all plates will automatically go to that CFX System and this

step can be skipped.

Chapter 2: Using the CFX Automation System II

If two CFX Systems are connected, designate the CFX System(s) on which the plates should be

run. Select Front CFX System and/or Rear CFX System on the desired plate list (Figure 19). If

both 96-well and 384-well CFX Systems are configured, each CFX System must be controlled

by an individual plate list and the source rack must contain only 96-well or 384-well plates.

Note: If two separate plate lists have the same CFX System(s) selected, the software will

alternate running plates from each plate list until the automation run is complete.

Step 3: Modify the Barcode Controls

Select or deselect the Scan Barcodes option in the barcode controls section of the plate list

tab (Figure 19).

Select the Match Barcodes option to match scanned barcodes to plate list barcode

information and pair the cycling and plate protocols accordingly.

For more information on barcode options, see Barcode Settings: Advanced Features.

Step 4: Load the Plates

If using Bio-Rad’s Microseal® 'B' optical seals, peel off the seal end tabs after sealing the

plates. Place the plates in the source rack. The source rack can be identified by the tab name

on the plate list page, for example Rack 1. Well A1 should face out toward the exterior of the

plate handler (Figure 20).

CFX Automation System II | 23

Page 32

Chapter 2: Using the CFX Automation System II

Fig. 20. Plate well A1 faces outward.

We ll A1

Step 5: Begin the Automation Run

Before beginning, confirm:

■n

Plates are placed in the input rack defined in the plate list window (Figure 19)

■n

Plates are placed with well A1 facing outward, away from the plate handler tower (Figure 20)

■n

If two CFX Systems are configured with the plate handler, the desired CFX System(s) is/are

selected (Figure 19)

■n

Confirm Match Barcodes is selected if scanned barcodes should be matched with

associated cycling protocols

■n

If configured CFX System(s) are also used in manual mode, confirm plates from former

experiments have been removed from the CFX System block

Select Start on the plate list tab. The automation run will begin.

Adding Plates after Starting an Automation Run

You may add additional plates after an automation run has begun. To do this:

■n

Select the plate list window to which plates will be added

■n

Highlight the row under which you would like to add additional plates

■n

Select the desired protocol and plate files (or LIMS or PrimePCR file) and select Add

■n

Add the plates to the appropriate place in the input rack

Note: If Match Barcodes is not selected, the location of the plate in the plate list must match

the physical location of the plates in the rack. Failure to correctly match orientations will lead to

the incorrect pairing of cycling protocols with the plate.

WARNING! When using this feature, the plate handler arm will move to exchange plates at

the appropriate time. Take care to ensure that you do not obstruct the movement of the plate

handler arm when adding plates.

24 | CFX Automation System II

24 |

Page 33

Chapter 2: Using the CFX Automation System II

Canceling an Automation Run

To cancel an entire automation run:

■n

Select the plate list window corresponding to the automation run to be canceled

■n

Select Cancel

Any plates being cycled in a CFX System originating from that plate list will be canceled. The

plate handler will remove the plate(s) from the CFX System(s) and place them in the waste rack.

The automation run will be completely stopped. All plates not thermal cycled will be labeled

“Not Run” in the status column.

Note: If two plate lists are running simultaneously using different CFX Systems, each plate list

must be canceled separately.

Pausing or Canceling a Single Plate Run in a CFX System

You may pause or stop a single plate either through the CFX System or CFX Manager

Software. Remember, selecting Cancel in the CFX Automation Control Software cancels the

entire automation run, not a particular plate. See Canceling an Automation Run (above) for

more detail.

Note: CFX Manager Software must be opened before CFX Automation Control Software to use

both applications simultaneously.

To stop a single plate run, select Cancel on the CFX System or Stop in CFX Manager Software.

All end-of-run processing will occur using the incomplete data generated to that point and the

plate handler will move the plate to the waste rack. The automation run will continue with the

next plate in the plate list.

To pause a single plate run, select Pause on the CFX System or in CFX Manager Software.

Resume the cycling protocol using the CFX System or CFX Manager Software. The automation

software will wait until the run is resumed or canceled to continue using that CFX System for

the automation run. If the plate list is feeding plates to two CFX Systems, the automation run will

continue using the other CFX System.

Emptying the Waste Rack

The waste rack may be emptied any time the plate handler is not actively performing an operation.

The plate handler checks the waste rack capacity immediately before removing a plate from a

CFX System and placing it in the waste rack. Plates should not be emptied from the waste rack

during this time.

You can set up automatic email notifications to alert you when the waste rack is approaching

full. See Emails and Notifications for more information.

LIMS Information

The CFX Automation System II can be integrated with Laboratory Information Management

Systems (LIMS) to facilitate automation and information flow. All LIMS integration is managed

through CFX Manager Software.

| 25CFX Automation System II

| 25

Page 34

Chapter 2: Using the CFX Automation System II

The CFX System instruction manual (bulletin #10021337) explains in detail the steps required to

set up LIMS integration. These steps include:

■n

Setting up a LIMS folder and data export options

■n

Creating a LIMS file (*.plrn) using the provided CFX96™ or CFX384™ LIMS Plate Import

Template files. Detailed definition of the LIMS Plate Import Template file content is provided

■n

Exporting data as a LIMS file

To complete LIMS integration, CFX Manager Software requires plate setup information

generated by the LIMS platform, a protocol file created using CFX Manager Software (*.prcl), a

defined data export location, and a defined export format. The LIMS file created by your internal

LIMS contains the plate setup details and the protocol file name. CFX Manager Software will

use the LIMS file to create a plate file that will be used in conjunction with the named protocol

file to start a run and generate data. Refer to the LIMS Integration Section in the CFX System

instruction manual (bulletin #10021337) for more detail.

When LIMS files are created for use with the automation system, plate barcode information

provided in column B, row 8 of the LIMS file (the Run ID field) can be directly imported into the

automation software (see Entering Barcode Information into a Plate List). Information entered in

column B, row 11 of the LIMS file (the Data File field) can be used to name data files, reports,

and export files (see File Name Format).

Once LIMS integration is complete, LIMS files may be loaded into the automation software and

LIMS data export files can be generated.

PrimePCR Information

Bio-Rad offers 96- and 384-well PrimePCR plates that contain primer pairs lyophilized in

the plate wells. You may customize the genes on the plates or choose from a wide variety of

predesigned disease- and pathway-specific panels. For more information, go to

www.bio-rad.com/primepcr.

Bio-Rad provides run files containing gene layout and cycling protocol information for all

PrimePCR plates. Run files for predesigned and custom plates can be downloaded from

www.bio-rad.com/primepcr. Run files for custom plates are saved under My PrimePCR

once configured and purchased. To obtain run files for predesigned panels, select Run File on

the Review Plate webpage.

Once the run files are downloaded, easily load PrimePCR files into any automation plate list

using the plate list controls.

Create the Plate List: Additional Features

Quickly Add Rows to the Plate List

■n

Add multiple rows with the same protocol and plate files (or same LIMS or PrimePCR

files). Enter the desired number of plates in the Rows box before selecting Add

■n

Apply identical protocol and plate files (or LIMS or PrimePCR files) to all plates in a

rack. Enter the protocol and plate file (or LIMS or PrimePCR file) into a single row and select

Repeat row 1 until rack is empty. The protocol and plate files will be applied to all plates

in the input rack. Each time a new plate is retrieved from the source rack, a new row will be

automatically added to the plate list. This option is available only when a single row is defined

in the plate list

CFX Automation System II26 |

Page 35

Chapter 2: Using the CFX Automation System II

■n

Add multiple LIMS or PrimePCR files to a plate list at once. Select Browse, select

all desired LIMS or PrimePCR files, and select Open. Each LIMS or PrimePCR file will be

automatically added as a unique row on the plate list

■n

Add multiple rows with the same protocol file but different plate files. Select the desired

protocol file using the dropdown menu or browse button. Select Browse in the plate file field

and open the folder that contains multiple plate files of interest. Select all desired plate files

and select Open. Each plate file will be paired with the protocol file and automatically added

to the plate list

■n

Add multiple rows with the same plate file but different protocol files. Select the desired

plate file using the dropdown menu or browse button. Select Browse in the protocol file field

and open the folder that contains multiple protocol files of interest. Select all desired protocol

files and select Open. Each protocol file will be paired with the plate file and automatically

added to the plate list

Note: The maximum number of rows that can be added to a plate list is 1,000.

Edit a Plate List

Select the row to be modified by clicking on the selection box for that row (Figure 19). Multiple

rows may be selected by using the shift and control keys. After selecting the desired rows,

you may:

■n

Modify the protocol, LIMS, PrimePCR, or plate file using the dropdown menu or browse options

■n

Modify the order of the selected row by selecting Move up or Move down

■n

Delete a row by selecting Delete

■n

Clear an entire plate list by selecting Clear

Enter in notes for any row by selecting the desired notes cell in the plate list. All notes typed

in the automation software will be stored in the CFX Manager Software data file.

Save a Plate List

By default, new plate lists are named “Untitled_rackX”. Save a plate list

by selecting File > Save. The default directory for saved plate lists is:

C:\Users\Public\Documents\Bio-Rad\CFXAutomationSystem\UserData. The saved

plate list file also stores the selected CFX System(s) and barcode selections. However,

the information specified under the Settings selection is not saved with the file.

You may load a previously saved plate list file by selecting File > Open and choosing the

desired plate list file. Modifications to the plate list file can be saved by selecting File > Save.

Modifications can be saved as a new plate list by selecting File > Save As and giving the

plate list file a unique name.

Note: When loading a saved plate list file, remember that although CFX System(s) and barcode

selections are stored within the file, the information stored under Settings is not associated with

the plate list file. Carefully review the Settings each time a plate list file is loaded.

Barcode Controls: Advanced Features

Define If the System Should Scan Barcodes and/or Match Barcodes

Each plate list tab contains a barcode controls section (Figure 19) that permits you to modify

how the system applies barcode information. Table 10 provides an overview of system

response for the various options selected.

| 27CFX Automation System II

| 27

Page 36

Chapter 2: Using the CFX Automation System II

Define How the System Should Respond When Unable to Scan Barcodes or

Match a Barcodes

Table 11 provides an overview of options available for how the system should respond when

unable to scan or match a barcode.

Table 10. Barcode controls and associated system response.

Plate Scanned/Barcode System Response

Information Required System Response Options When Unable

Barcode Prior to Starting When Barcode is to Scan or Match

Controls Automation Run Scanned Barcode (Table 11)

No/No N/A N /A

Yes/No Barcode recorded in the next Pause and Notify,

plate list row Skip and Notify,

Protocol and plate file (or LIMS

or PrimePCR file) in the next

available row will be applied

Yes/Yes Protocol and plate file (or LIMS or Pause and Notify,

(see Entering Barcode PrimePCR file) associated with Skip and Notify

Information into a that barcode will be applied to

Plate List) the plate placed in the CFX System

The displayed order of the plate

list will be modified so that the

currently running plate is moved up

Run Plate Anyway

Table 11. System response when unable to scan or match a barcode.

Barcode Controls Plate Handler Response Plate List Response* Email Notifications Sent**

Plate placed in source Pauses Yes

rack

Plate placed in waste rack Continues running with Yes

the next plate

Plate placed in CFX Protocol and plate file (or No

System LIMS or PrimePCR file)

associated with next row

on the plate list will be

applied to the plate

* If another automation run is executing using a different plate list, that run will continue.

** Email addresses must be properly configured in CFX Manager Software in order for these emails to be received.

28 | CFX Automation System II

28 |

Page 37

Entering Barcode Information into a Plate List

Barcode information can be entered into the software and applied in a variety of ways,

described below.

■n

Manual entry — select the barcode cell that corresponds to the plate of interest (Figure 19).

Type in barcode information and then press the Enter key. The barcode cell for the next row

will be automatically highlighted

■n

External barcode scanner — connect an external barcode scanner to the computer. Select

the barcode cell corresponding to the plate of interest. Scan the plate. The barcode information

will be entered, and the barcode cell for the next row will be automatically highlighted

■n

Import LIMS or PrimePCR Run ID as barcode — CFX Manager Software LIMS and

PrimePCR Import Template files have a cell, B8, called Run ID. When Import LIMS or

PrimePCR Run ID as barcode is selected, barcode information in cell B8 of the LIMS or

PrimePCR file will be automatically loaded into the plate list

Note: This option must be selected before the LIMS or PrimePCR file is added to the plate list.

■n

Scan barcodes — no barcode information is loaded into the plate list prior to starting the

automation run. When Scan Barcodes is selected, all plates are moved to the barcode

scanner, scanned, and then placed in the CFX System. Barcode information is entered into

the plate list

Chapter 2: Using the CFX Automation System II

Modify Settings

Settings allow you to customize the way files are named, managed, and stored, and to customize

the email notifications. Each plate list tab is associated with a separate set of software

settings. These settings are saved when the software is shut down. The settings will be applied

to all plate lists created and used with that particular source rack. To modify the settings, select

Settings. A window displaying three tabs with modifiable settings is displayed (Figure 21):

■n

Plate List Details

■n

Reports

■n

Emails and Notifications

Note: When saving a plate list, modifications made in Settings are not saved with the plate list file.

Fig. 21. Settings window.

| 29CFX Automation System II

| 29

Page 38

Chapter 2: Using the CFX Automation System II

Plate List Details

Plate List Defaults

Customize the protocol, LIMS, or PrimePCR file and plate files displayed in the dropdown menu

when the application is opened. Because LIMS and PrimePCR files contain both protocol and

plate information within the single file, when these files are selected, the Plate File dropdown

box is disabled.

Data File Destination Directory

Specify the location for data files generated by CFX Manager Software. The data file directory

information set in this window overrides directory settings set in CFX Manager Software.

File Name Format

Use the dropdown menus to define the file name format. Free form text can be entered in the

prefix and suffix boxes. The time and date field is required in all file names. A preview of the

sample name is displayed.

Alternatively, file names can be directly imported from a LIMS or PrimePCR file by selecting Use

LIMS or PrimePCR Data File as name on the main plate list tab. The information entered in

the Data File field in the LIMS import file will be used as the file name (see LIMS Information).

Selecting this option will override any naming selection chosen in the dropdown menus.

Reports

Default Plate List

This allows you to have a particular plate list loaded each time the application is opened. By

default, no plate list is displayed. To have a plate list always displayed at application startup,

select Open this Plate List at Startup and choose a plate list you have previously saved.

Generate PDF Reports

By selecting this box, a PDF report will be automatically generated when a run is completed.

There is also a Report column on the plate list screen. This column allows you to easily

determine if a report will be generated. You may also create reports for individual plates by

selecting or deselecting this column for individual plates.

Report File Destination Directory

This section allows you to specify the storage location for the reports.

Use CFX Manager Default Report Template

This section determines the template used for reports. When selected, the report template

specified in CFX Manager Software will be used. To change the default report template in

CFX Manager Software, go to User > User preferences > Custom export and select the

export items you would like included.

30 | CFX Automation System II

30 |

Page 39

Emails and Notifications

Run Completion Notification

When Send Run Completion Notifications is selected, an email containing the data file will be

automatically sent at the completion of a run. Enter the desired email address in the text box.

Multiple email addresses can be entered by separating each address with a comma.

Tip: To receive report files in addition to data files, ensure Generate PDF Report is selected in

the Reports tab.

Other Notifications

This section enables the software to automatically email recipients regarding the status of

theautomation system. Options include:

■n

Notifications regarding the waste rack capacity. Enter in the percent capacity at which email

notifications should be sent

■n

Notifications for when a plate list has completed

■n

Notifications when the automation system has encountered an error

Status Tab

The Status tab provides an overview of the status of both plate lists and the waste rack

(Figure 22). When the automation software is in successful communication with the CFX

System(s), CFX System status information is displayed. The Status tab also displays

information on ongoing plate lists as well as waste rack capacity. Detailed plate list information

can be viewed by selecting Manage.

Chapter 2: Using the CFX Automation System II

Configured

CFX System

status

Plate list

name

View plate list

Fig. 22. Status tab.

| 31CFX Automation System II

| 31

Page 40

Chapter 2: Using the CFX Automation System II

History Tab

The History tab contains details of all automation runs completed since the last time the

application was opened (Figure 23). You may sort the history information by clicking on any

column header. By default, the information is sorted by date.

Run history files for automation runs completed in the past can be located using the following

file path: C:\Users\Public\Documents\Bio-Rad\CFXAutomationSystem\UserData.

Fig. 23. Histor y tab.

32 | CFX Automation System II

32 |

Page 41

3

Resources

Read this chapter for information about maintaining and troubleshooting the

CFX Automation System II.

■n

Maintenance

■n

Power Outage

■n

Troubleshooting the CFX Automation System II

■n

Frequently Asked Questions

Maintenance

Cleaning the CFX Automation System II

Wipe up any spills immediately.

■n

Avoid direct contact with spilled liquid

■n

Wear protective gloves and safety glasses

The outside surfaces of the plate handler should be cleaned periodically. Clean only the exterior

of the unit. Never remove any instrument covers to clean the inside of the instrument.

■n

Use a cloth or sponge dampened with water, alcohol, glass cleaner, or a mild soap solution

diluted with water

■n

If using glass cleaner or mild soap, wipe with a cloth or sponge dampened with water after

cleaning to remove any residue

■n

Do not use abrasive cleaners

■n

Do not spray cleaner onto the instrument

■n

Do not allow water or other fluids to drip inside the plate handler

Clean the gripper assembly and the racks with alcohol or other residue-free solvent. The

surface beneath the plate handler racks must be clean at all times. Debris or dust under the

racks will cause the plate handler and the racks to be out of calibration.

CFX Automation System II | 33

Page 42

Chapter 3: Resources

Changing the Fuses

WARNING! Electrical shock hazard. Disconnect the power cord before changing the fuses.

WARNING! For continued fire protection and correct system functioning, replace fuses only

with exact part number.

To change the plate handler fuses:

1. Verify the plate handler power switch is OFF and the power cord is unplugged from the

instrument.

2. Using a small flat-blade screwdriver at the top of the fuse housing, gently pry the fuse

housing (Figure 24) out of the power entry port.

3. Remove the two 2.5 A fuses.

4. Replace both fuses with fuses with the same part number.

5. Confirm that the fuses are seated securely in the fuse housing.

6. Snap the fuse housing back into the power entry port.

Pry here

Fig. 24. CFX Automation System II power entry port.

Power Outage

If a power outage occurs during operation of the CFX Automation System II, the grippers

will open and the plate will drop when the power is restored. If you routinely operate the CFX

Automation System II overnight or with valuable samples, consider using a 900 W (or greater)

uninterruptable power supply (UPS) to each connected instrument to provide a backup power

source for the CFX Automation System II, the CFX System(s), and the computer.

Troubleshooting the CFX Automation System II

This section describes how to view automation system logs. It also includes a list of potential

problems that may be encountered when using the system, along with their solutions. If you

continue to experience problems after following the instructions below, contact Bio-Rad

Laboratories technical support.

CFX Automation System II34 |

Page 43

View Logs

The CFX Automation Control Software tracks information about the state of an instrument

during an automation run. Use these logs to track events that occur on instruments and in the

software, and for troubleshooting. To open the log, select Tools > View Log.

Logs are also stored in file folders. The file path to access these files is:

C:\ProgramData\Bio-Rad\CFXAutomationSystem\Logs.

Error Messages

Error messages inform the user of problems requiring immediate attention. If an error occurs

during operation, the CFX Automation System II stops and an error message is displayed on

the computer screen. Error messages along with the probable causes and possible solutions

are listed in Table 12.

Table 12. Error messages, possible causes, and solutions.

Error Message Possible Cause Possible Solution

Another instance of The automation software was To use both CFX Manager Software and

CFX Manager

already running CFX Manager Software time, open CFX Manager Software first

Plate list [xx] has paused. Unable to Incompatible plates may be The CFX Automation System II is

load plate in CFX System. Check for being used compatible with Hard-Shell

obstructions. Restart or cancel the 96-Well and 384-Well Skirted PCR

plate list after correcting the issue Plates. See Table 7 for detailed ordering

information.

Plate list [xx] has paused. Unable to The CFX Automation System II Test the calibration using the calibration