Page 1

CFX96™ and CFX384™ Real-Time

PCR Detection Systems

Instruction Manual

Catalog # 184-5384

# 185-5384

# 184-5096

# 185-5096

Page 2

Copyright ©2008 Bio-Rad Laboratories, Inc. Reproduction in any form, either print or electronic, is

prohibited without written permission of Bio-Rad Laboratories, Inc.

Excel, Microsoft, PowerPoint, Windows, and Windows Vista are trademarks of Microsoft Corporation.

Adobe and Reader are trademarks of Adobe Systems Incorporated. Cy is a trademark of GE Healthcare

group companies. Fluor and Quasar are trademarks of Biosearch Technologies, Inc. SYBR and Texas

Red are trademarks of Invitrogen Corporation. Bio-Rad Laboratories, Inc. is licensed by Invitrogen

Corporation to sell reagents containing SYBR Green I for use in real-time PCR, for research purposes

only. Other brands or product names are trademarks of their respective holders.

LICENSE NOTICE TO PURCHASER

Bio-Rad Real-time thermal cycler CFX96 or CFX384 is licensed real-time thermal cycler(s) under Applera's United

States Patent No. 6,814,934 B1 for use in research and for all other fields except the fields of human diagnostics and

veterinary diagnostics.

This CFX96 or CFX384 detection module, when combined with a C1000 thermal cycler for which the applicable realtime thermal cycler royalty fee has been paid, constitutes a real-time thermal cycler licensed under U.S. Patent No.

6,814,934 and corresponding claims in any Canadian counterpart patent thereof owned by Applera Corporation, for

use solely in research and all applied fields except human and veterinary in vitro diagnostics. These license rights

are effective only if this detection module is combined with a Bio-Rad thermal cycler for which the applicable realtime thermal cycler royalty fee has been paid and not with any other thermal cycler. No rights are conveyed

expressly, by implication or estoppel to any patents on real-time methods, including but not limited to 5' nuclease

assays, or to any patent claiming a reagent or kit. For further information on purchasing license rights, contact the

Director of Licensing at Applied Biosystems, 850 Lincoln Centre Drive, Foster City, California, 94404, USA.

This product is covered by one or more of the following U.S. patents, their foreign counterparts, or their foreign

patents pending, owned by Eppendorf AG: US Patent Nos. 6,767, 512 and 7,074,367. No rights are conveyed

expressly, by implication or estoppel to any patents on PCR methods, or to any patent claiming a reagent or kit

Bio-Rad’s Hard-Shell® plates are covered by one or more of the following U.S. patents, patents pending, or their

foreign counterparts, owned by Eppendorf AG: US Patent Nos. 7,347,977, 6,340,589, 6,528,302 and US application

2007246858, 20080084004, 20030180192 and 20060120927

Page 3

Bio-Rad Resources

Bio-Rad provides many resources for scientists. The following websites contain useful information about

running PCR and real-time PCR experiments:

• Gene Expression Gateway (www.bio-rad.com/genomics/)

This site provides rich technical resources on a wide variety of methods and applications related to

PCR, real-time PCR, and gene expression

• Life Science Research website (discover.bio-rad.com)

This site includes links to technical notes, manuals, product information, and technical support.

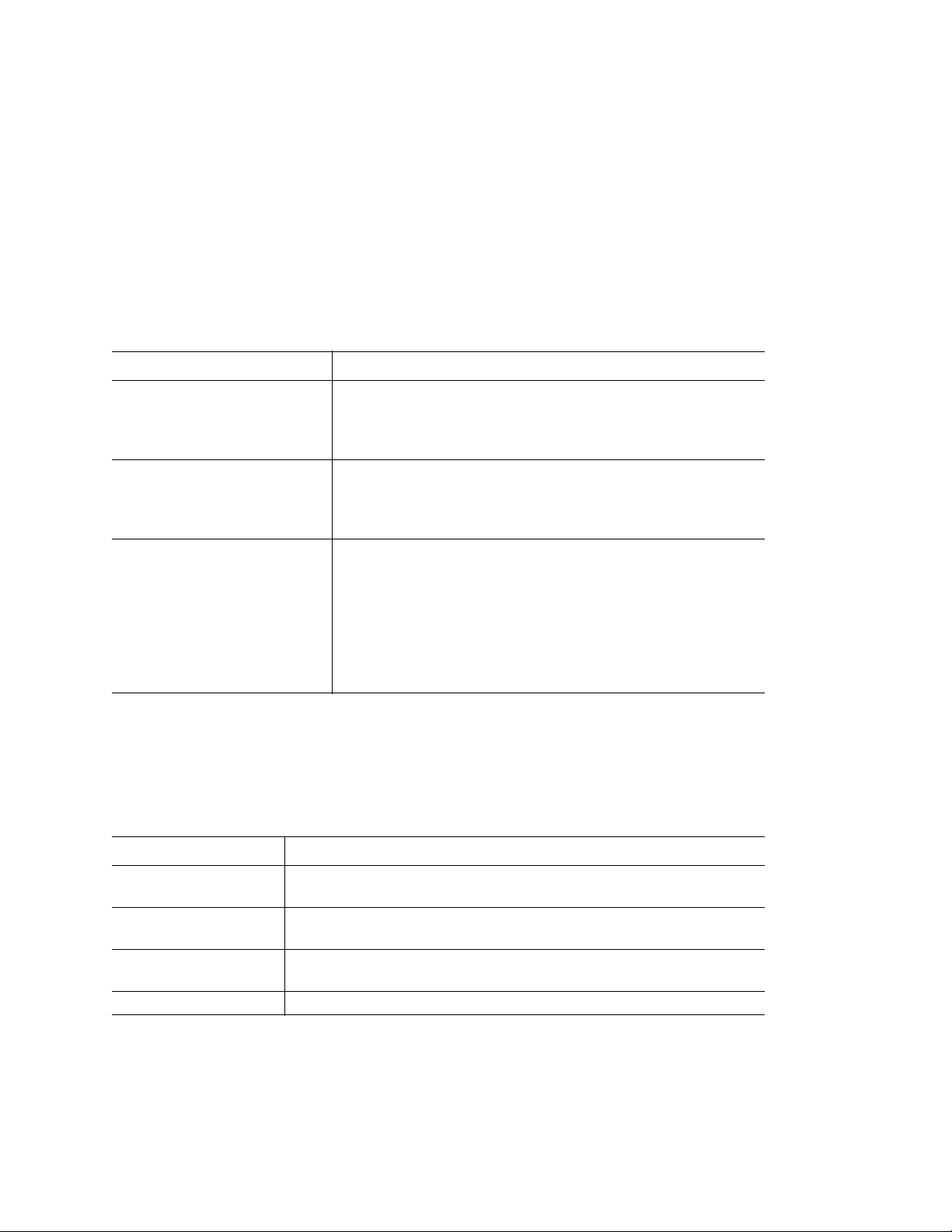

Table 1 lists other Bio-Rad resources and how to locate what you need:

Table 1. Bio-Rad resources

Resource How to Contact

Local Bio-Rad Laboratories

representatives

Technical notes and literature Go to the Bio-Rad website (www.bio-rad.com) or Gene

Technical specialists Bio-Rad’s Technical Support department is staffed with

Find local information and contacts on the Bio-Rad website

by selecting your country on the home page

(www.bio-rad.com). Find the nearest international office

listed on the back of this manual

Expression Gateway (www.bio-rad.com/genomics/). Type a

search term in the Search box and select Literature to find

links to technical notes, manuals, and other literature

experienced scientists to provide customers with practical

and expert solutions

To find local technical support on the phone, contact your

nearest Bio-Rad office. For technical support in the United

States and Canada, call 1-800-424-6723 (toll-free phone),

and select the technical support option

Writing Conventions Used in this Manual

This manual explains how to safely set up and operate the CFX96 system or the CFX384 system. The

manual uses the writing conventions listed in Table 2.

Table 2. Conventions used in this manual

Convention Meaning

TIP: Provides helpful information and instructions, including information

explained in further detail elsewhere in this manual

NOTE: Provides important information, including information explained in

further detail elsewhere in this manual

WARNING! Explains very important information about something that might

damage the researcher, damage an instrument, or cause data loss

X > Y Select X and then select Y from a toolbar, menu or software window

For information about safety labels used in this manual and on the CFX96 system or the CFX384 system,

see, “Safety and Regulatory Compliance” on page iii.

ii

Page 4

CFX96 and CFX384 Systems Manual

Safety and Regulatory Compliance

For safe operation of the CFX96 system or the CFX384 system, we strongly recommend that you follow

the safety specifications listed in this section and throughout this manual.

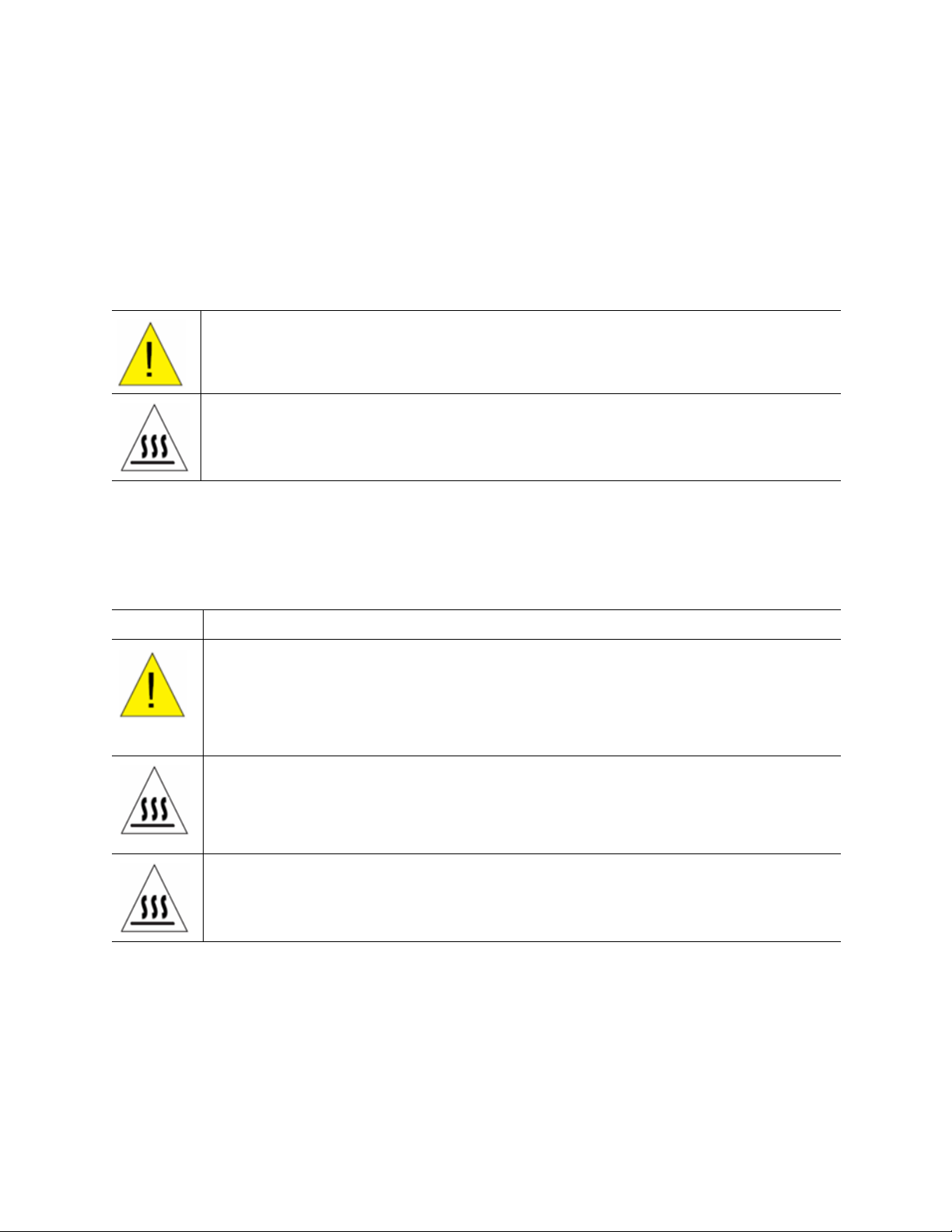

Safety Warning Labels

Warning labels posted on the instrument and in this manual warn you about sources of injury or harm.

Refer to Table 3 to review the meaning of each safety warning label.

Table 3. Meaning of safety warning labels

CAUTION: Risk of danger! This symbol identifies components that pose a risk of personal

injury or damage to the instrument if improperly handled. Wherever this symbol appears,

consult the manual for further information before proceeding

CAUTION: Hot surface! This symbol identifies components that pose a risk of personal

injury due to excessive heat if improperly handled

Instrument Safety Warnings

The warning labels shown in Table 4 also display on the instrument, and refer directly to the safe use of

the CFX96 system or the CFX384 system.

Table 4. Instrument Safety Warning Labels

Icon Meaning

Warning about risk of harm to body or equipment.

Operating the CFX96 or CFX384 real-time PCR detection system before reading this

manual can constitute a personal injury hazard. For safe use, do not operate this instrument

in any manner unspecified in this manual. Only qualified laboratory personnel trained in the

safe use of electrical equipment should operate this instrument. Always handle all

components of the system with care, and with clean, dry hands

Warning about risk of burning.

A thermal cycler generates enough heat to cause serious burns. Wear safety goggles or

other eye protection at all times during operation. Always allow the sample block to return

to idle temperature before opening the lid and removing samples. Always allow maximum

clearance to avoid accidental skin burns

Warning about risk of explosion.

The sample blocks can become hot enough during the course of normal operation to cause

liquids to boil and explode

NOTE: For information about the C1000™ thermal cycler, refer to the C1000 thermal cycler

instruction manual.

iii

Page 5

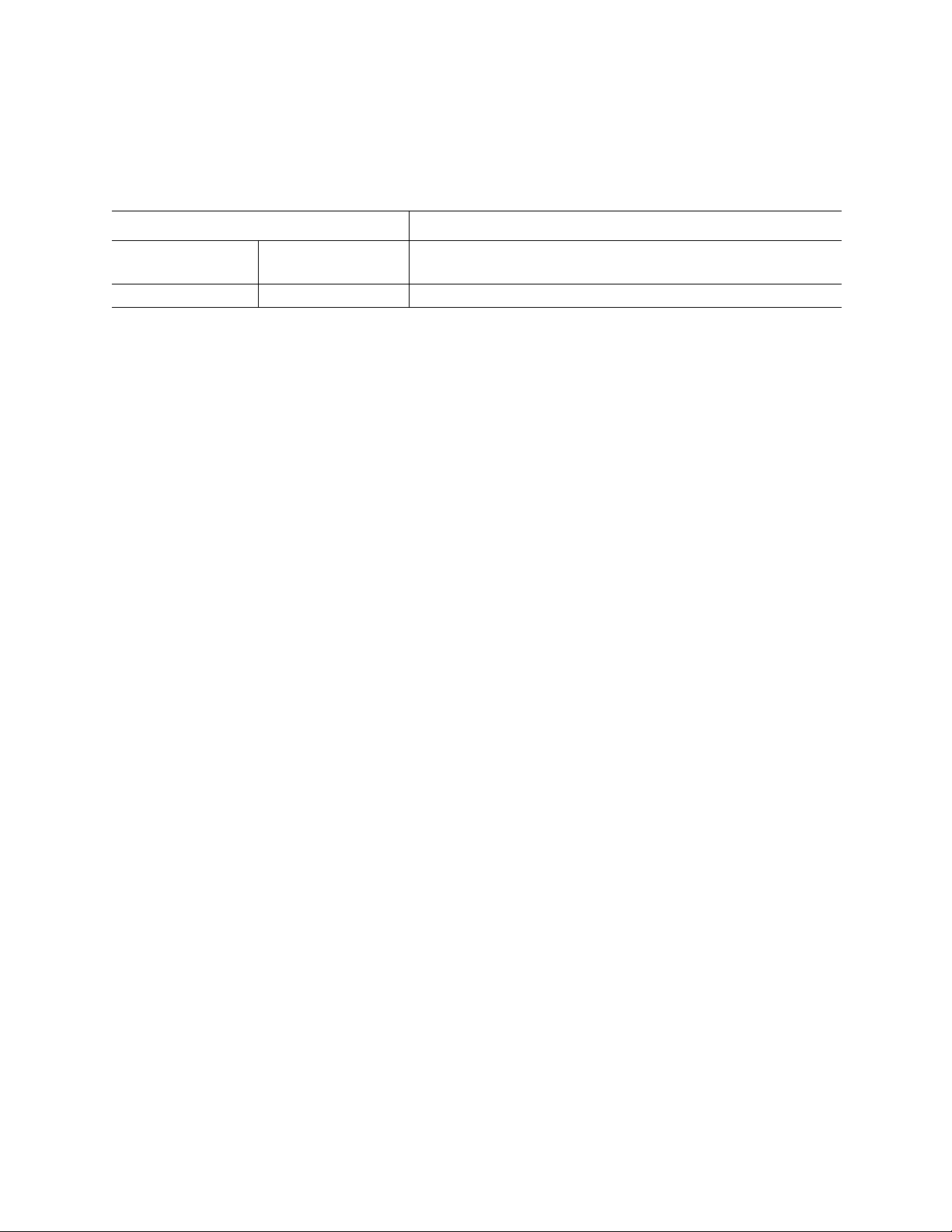

Safe Use Specifications and Compliance

Table 5 lists the safe use specifications for the CFX96 system or the CFX384 System. Shielded cables

(supplied) must be used with this unit to ensure compliance with the Class A FCC limits.

Table 5. Safe Use Specifications

Safe Use Requirements Specifications

Temperature Indoor use

Altitude Up to 2,000 meters above sea level

Ambient temperature of 15—31

maximum of 80% noncondensing

REGULATORY COMPLIANCE

This instrument has been tested, and found to be in compliance with all applicable requirements of the

following safety and electromagnetic standards:

• IEC 61010-1:2001 (2nd Ed.), EN61010-1:2001 (2nd Ed). Electrical Equipment For

Measurement, Control, and Laboratory Use - Part 1: General Requirements

• IEC 61010-2-010:2005, EN61010-2-010:2003. Safety requirements for electrical equipment

for measurement, control and laboratory use. Part 2-010: Particular requirements for

laboratory equipment for the heating of materials

• IEC 61010-2-081:2001+A1, EN61010-2-081:2002+A1. Safety requirements for electrical

equipment for measurement, control and laboratory use. Part 2-081: Particular requirements

for automatic and semi-automatic laboratory equipment for analysis and other purposes

(includes Amendment 1)

• EN 61326-1:2006 (Class A) Electrical equipment for measurement, control and laboratory

use. EMC requirements, Part 1: General requirements

o

C. Relative humidity

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

iv

Page 6

CFX96 and CFX384 Systems Manual

Table of Contents

Bio-Rad Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Writing Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety and Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1. System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking the Optical Reaction Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Setting up the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing CFX Manager Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Running Experiments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2. Introduction to CFX Manager Software . . . . . . . . . . . . . . . . . . 11

Main Software Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Startup Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Detected Instruments Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Instrument Properties Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Software Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tips and Tricks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3. Running Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Experiment Setup Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Protocol Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Plate Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Start Run Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Run Details Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Instrument Summary Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 4. Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Protocol Editor Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Protocol Editor Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Temperature Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Protocol AutoWriter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

v

Page 7

Table of Contents

Chapter 5. Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Plate Editor Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Select Fluorophores Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Experiment Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Well Groups Manager Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Plate Spreadsheet View Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 6. Stand-Alone Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Experiment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Exporting Data for Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Creating a Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Setting Up Email . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 7. Data Analysis Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Data Analysis Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Data Analysis Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Quantitation Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Data Analysis Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Well Selectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Spreadsheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Chapter 8. Data Analysis Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Quantitation Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Quantitation Data Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Melt Curve Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Melt Curve Data Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

End Point Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Allelic Discrimination Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

QC Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reports for Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 9. Gene Expression Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Gene Expression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Plate Setup for Gene Expression Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Gene Expression Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Experiment Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Gene Study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Gene Study Data Spreadsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Gene Study Report Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Gene Expression Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

vi

Page 8

CFX96 and CFX384 Systems Manual

Chapter 10. Users and Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Log in or Select User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

User Preferences Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Email Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Files Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Protocol Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Plate Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Data Analysis Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Gene Expression Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

QC Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

User Administration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Chapter 11. Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Calibration Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Instrument Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Application Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Software Help Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Instruments, Parts, and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

vii

Page 9

Table of Contents

viii

Page 10

CFX96 and CFX384 Systems Manual

1 System Installation

Read this chapter for information about setting up the CFX96 or CFX384 system:

• Unpacking the optical reaction module (below)

• System requirements (page 1)

• System overview (page 2)

• Setting up the system (page 3)

• Installing CFX Manager software (page 6)

• Running experiments (page 9)

Unpacking the Optical Reaction Module

Your CFX96 or CFX384 optical reaction module shipment includes these components:

• Optical reaction module

•USB cable

• CFX Manager

• Instruction manual

• CFX Manager software uick guides for system installation, protocol, plate, data

analysis, and gene expression analysis

Remove all packing materials and store them for future use. If any items are missing or

damaged, contact your local Bio-Rad office.

Tm

software installation CD

System Requirements

To operate the CFX96 or CFX384 system, use the following power sources and cables:

• Input power. 100—240 VAC, 50—60 Hz

• Indoor use. Ambient temperature of 15—31

(non-condensing)

• USB cable. If the CFX96 system is going to be controlled by a computer via a USB

cable, the provided cable from Bio-Rad is sufficiently shielded for use.

NOTE: For a full list of the safety and compliance requirements for this instrument,

see “Safety and Regulatory Compliance” on page iii.

o

C. Relative humidity maximum of 80%

1

Page 11

System Installation

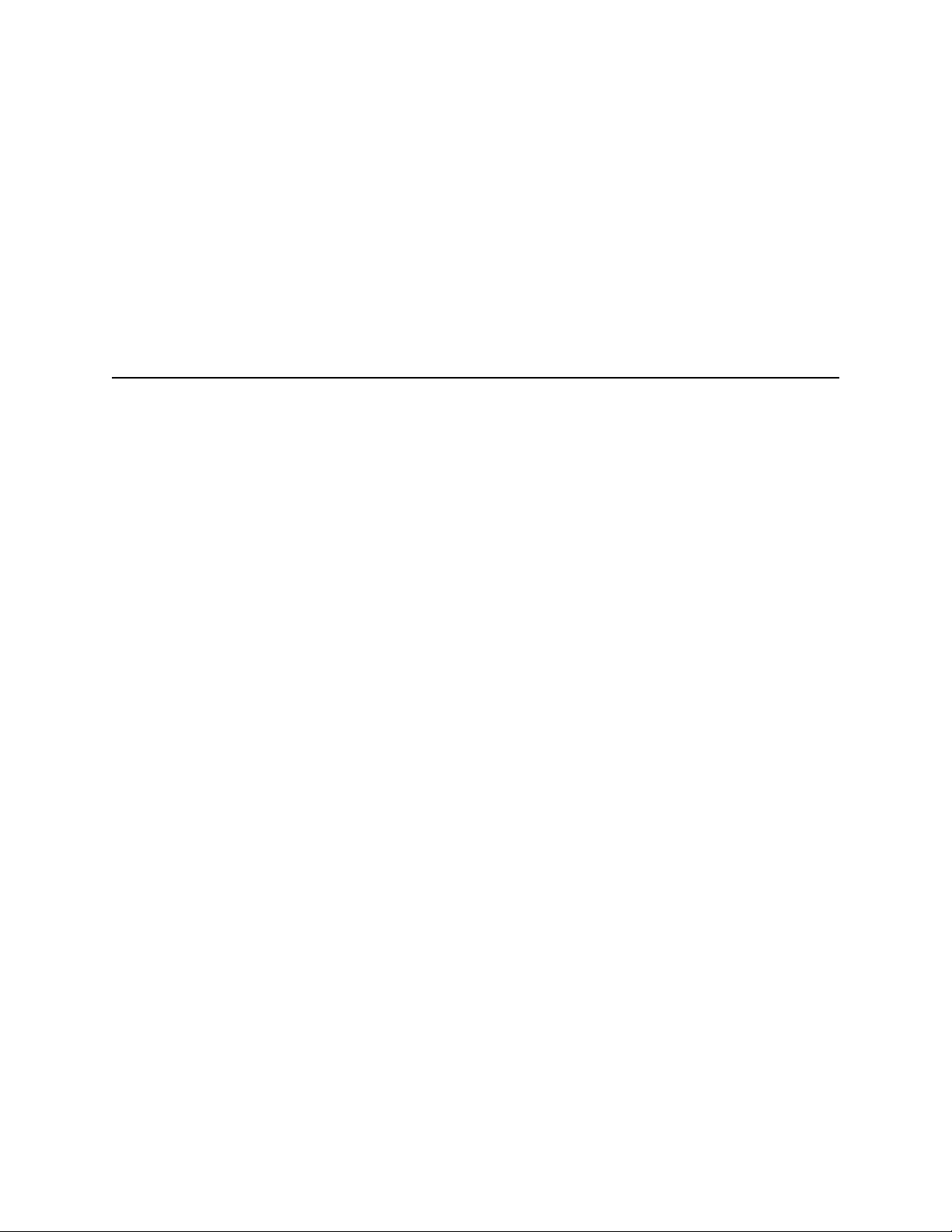

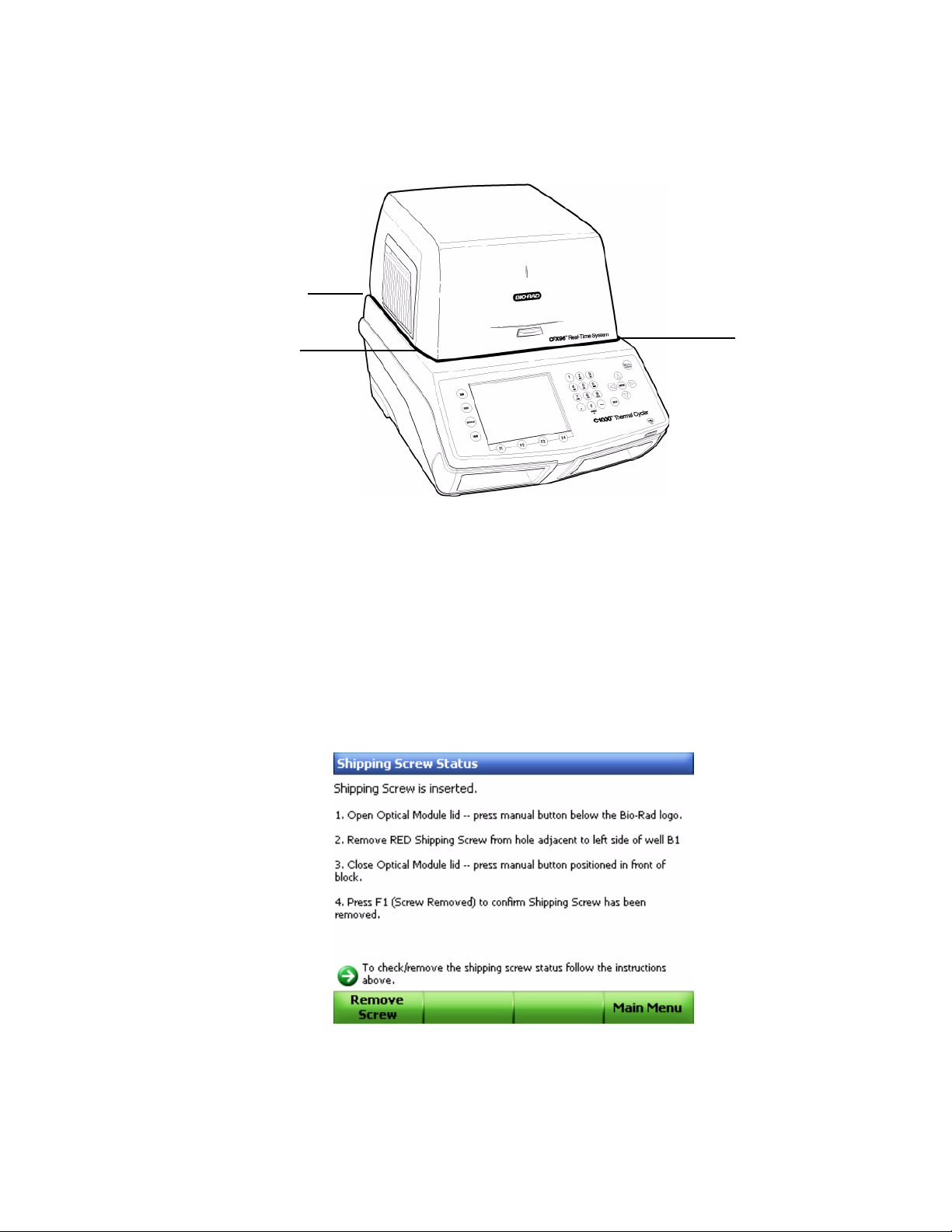

Open button

Indicator LED

Front panel

Close button

Block

Inner lid with heater plate

System Overview

The CFX96 system or CFX384 system includes two components:

• Optical reaction module. This module includes an optical system to collect fluorescent

data and a thermal cycler block

NOTE: The serial number of the CFX96 or CFX384 module is located on the back.

• C1000

Tm

thermal cycler base. The C1000 base includes a user interface to control the

system when running in stand-alone mode and the power button and ports (both on

back panel) to connect to a computer

Figure 1. Front view of the CFX96 system.

When open, the CFX96 or CFX384 system includes the features shown in Figure 2.

Figure 2. Inside view of the CFX96 system.

WARNING! Avoid touching the inner lid or block: These surfaces can be hot.

2

Page 12

CFX96 and CFX384 Systems Manual

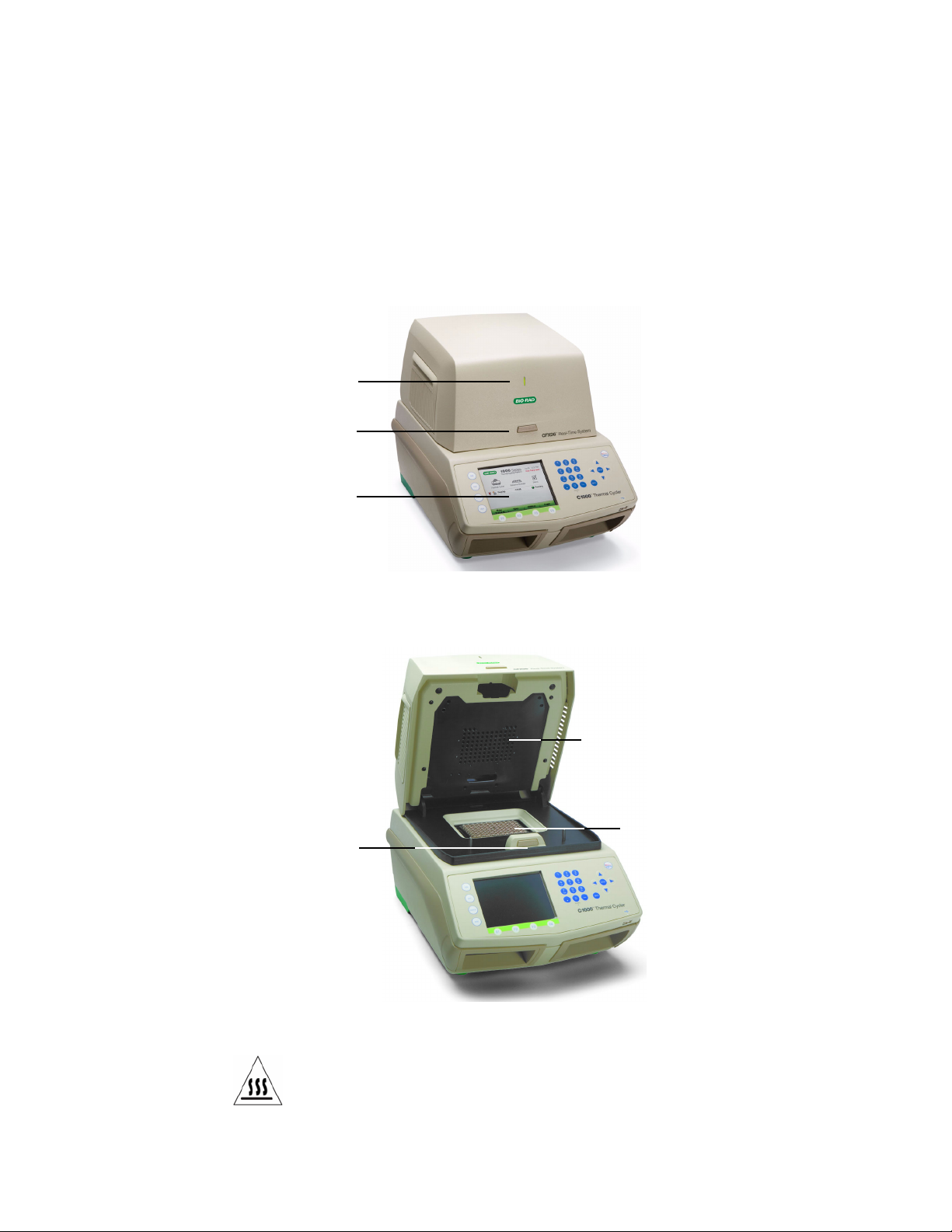

Power

Power

input

switch

USB connections

Ethernet

port

• Inner lid with heater plate. The heater lid maintains temperature on the top of the

consumable to prevent sample evaporation. Avoid touching or otherwise contaminating

the heater plate. Never poke anything through the holes; the optics shuttle system could

be damaged

•Block. Load samples in this block before the run

• Close button. Press this button on the inside of the lid to close the motorized lid

WARNING! Prevent contamination of the instrument by spills, and never run a

reaction with an open or leaking sample lid. For information about general cleaning

and maintenance of the instrument, see “Instrument Maintenance” (page 133).

The back panel of the C1000 chassis includes these features (Figure 3):

• Power switch. Press the power switch to turn on the power to the system

• Power input. Plug in the power cord here

• Ethernet port. Connect an ethernet cable to email run logs and stand-alone data files

• USB connections. Use these ports to connect the CFX96 system or CFX384 system to

a computer or to connect an S1000

Tm

thermal cycler

Figure 3. Back panel of C1000 thermal cycler.

WARNING! Avoid contact with the back panel of the C1000 during operation.

Setting up the system

The CFX96 or CFX384 real-time PCR detection system should be installed on a clean, dry,

level surface with sufficient cool airflow to run properly. The CFX96 system or CFX384 system

can be run in two modes: stand-alone or software-controlled. If you are running the system

under software-controlled mode, make sure there is sufficient space for a computer during

setup.

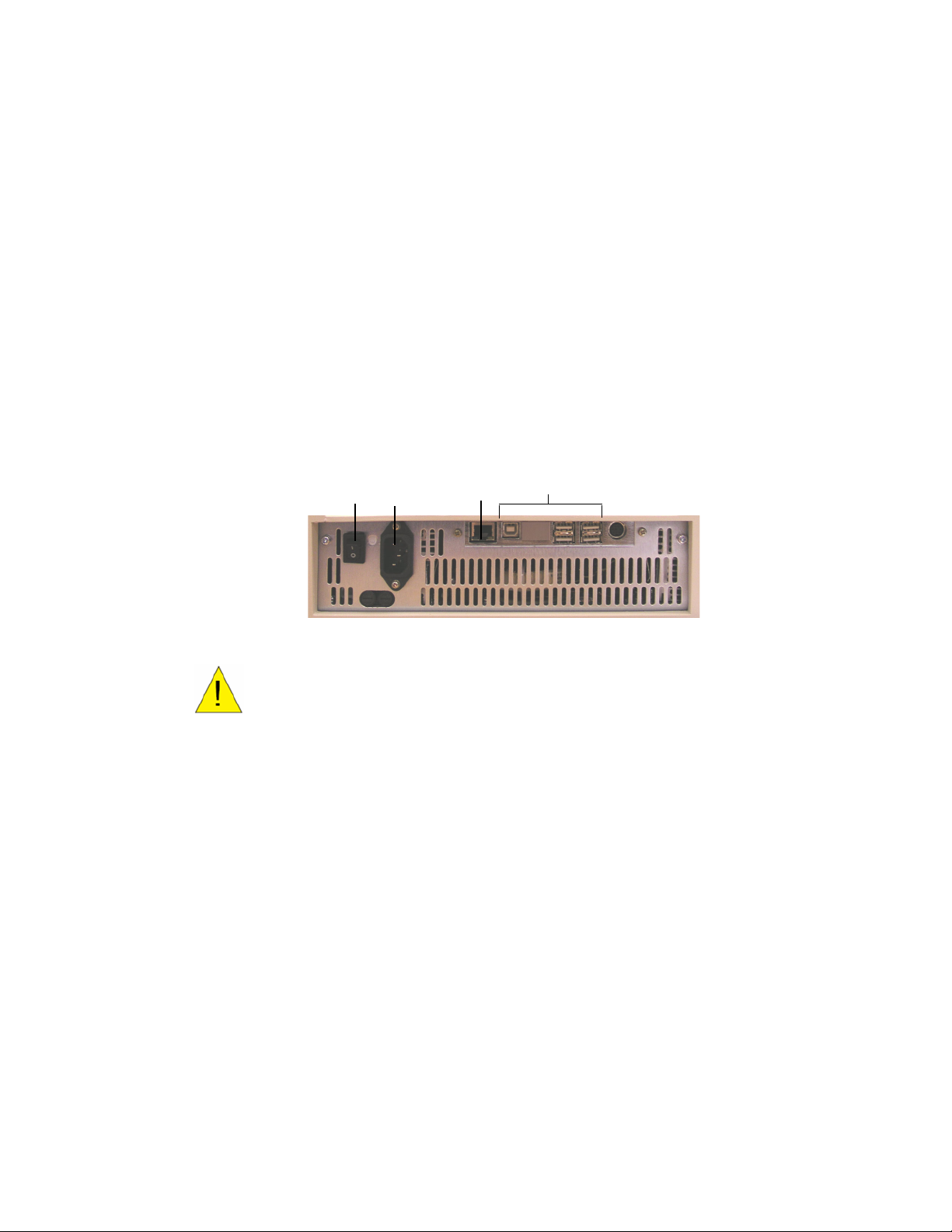

To insert the CFX96 or CFX384 optical reaction module into the reaction module bay of

the C1000 chassis, follow these instructions:

1. Place the C1000 chassis in a suitable location with the locking bar down. Remove any

previously installed reaction modules.

3

Page 13

System Installation

2. Lift the optical reaction module using the handle indents above the side air vents

(Figure 4).

Figure 4. Lifting the optical reaction module into the C1000 chassis.

3. Position the module in the reaction module bay of the C1000 chassis, leaving about 2 cm

of space in the front. When in the chassis bay, the optical module should be covering the

Bio-Rad logo in front of the bay of the C1000 chassis.

4. Reach around and pull up the locking bar of the C1000 until it is flush with the sides of

the module bay. This action moves the module forward, locking it into place (Figure 5)

Figure 5. Locking the optical module into place.

4

Page 14

CFX96 and CFX384 Systems Manual

Check

space

Check

space

Check

space

5. Check that the module is completely and evenly seated in the C1000 base. As shown in

Figure 6, check the space around the bottom of the module. There should be no extra

space between the module and the base; the space should be even.

Figure 6. Check for even space between module and base.

NOTE: If the space between the module and C1000 base is uneven, reinstall the

module starting from Step 2 (page 4).

6. Plug the power cord into the back of the C1000 base (Figure 3 on page 3), and into an

appropriate three-pronged electrical outlet.

7. Press the power switch on the back panel of the C1000 thermal cycler to start the

system.

8. Follow the instructions in the C1000 front panel to remove the red shipping screw from

the inner heater lid (Figure 7). Turn the screw counterclockwise to lift it out of the hole.

Figure 7. Instructions to remove the shipping screw.

5

Page 15

System Installation

NOTE: If the shipping screw is not removed at this step, it will be detected by CFX

Manager software. Follow the instructions in the software to remove the screw

(page 19).

TIP: The shipping screw must be in place when the module is shipped. Save this

screw in a safe place for future shipping.

9. Remove the shipping plate from the thermal cycler block to operate.

Installing CFX Manager Software

CFX Manager software is run on a PC computer with either the Windows XP or Windows Vista

operating system and is required to analyze real-time PCR data from the CFX96 system or

CFX384 system. This software can also be used to control the CFX96 system or CFX384

system in software-controlled mode. Table 6 lists the computer system requirements for the

software on Windows XP and Windows Vista.

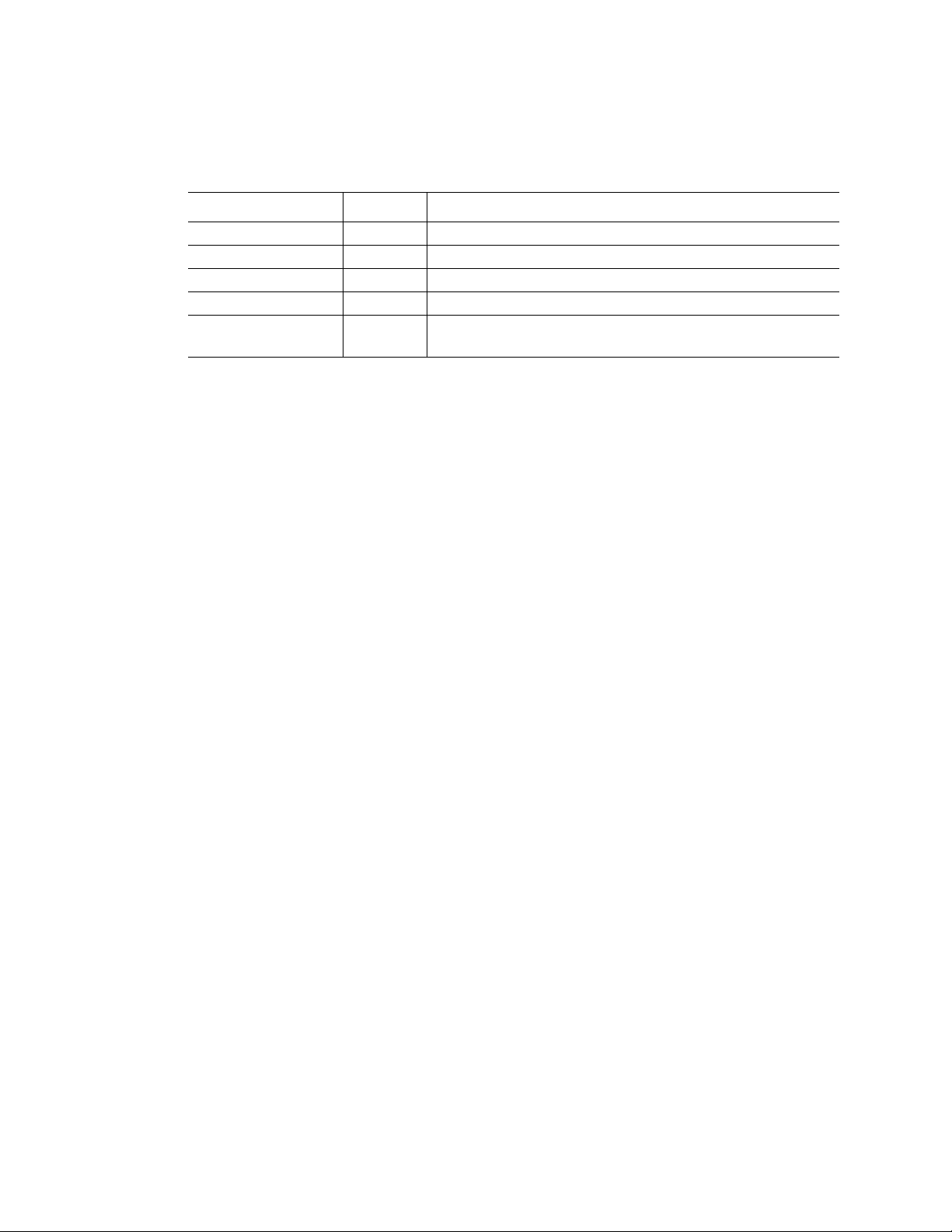

Table 6. Computer requirements for CFX Manager software

System Minimum Recommended

Operating system Windows XP Professional SP2 and

Above or Windows Vista Home

Premium and above

Drive CD-ROM drive CD-RW drive

Hard drive 10 GB 20 GB

Processor speed 2.0 GHz 2.0 GHz

RAM 1 GB RAM (2 GB for Windows

Vista)

Screen resolution 1024 x 768 with true-color mode 1280 x 1024 with true-color mode

USB USB 2.0 Hi-Speed port USB 2.0 Hi-Speed port

Internet browser Internet Explorer Internet Explorer

Software Microsoft Office Suite

Windows XP Professional SP2 and

above or Windows Vista Home

Premium and above

2 GB RAM

NOTE: Running a CFX96 or CFX384 system with CFX Manager Software on a PC

computer with a Windows 64-bit Operating Systems is not supported due to

incompatible USB Drivers. A PC computer with a 64-bit processor (like Intel) on a

32-bit Windows Operating System is supported.

To install CFX Manager software:

1. The software must be installed on the computer by a user with administrative privileges.

Make sure you are logged in with administrative privileges.

2. Place the CFX Manager software CD in the computer’s CD drive.

6

Page 16

CFX96 and CFX384 Systems Manual

3. The software launch page should appear automatically. Double-click Install Software on

the software launch page (Figure 8).

Figure 8. Software installation screen.

TIP: Click the Documentation button to find searchable PDF copies of the

instrument manuals and other documentation.

4. Follow the instructions on screen to complete installation. When completed, the Bio-Rad

CFX manager software icon will appear on the desktop of the computer.

5. If the launch page does not appear automatically, double-click on (CD drive):\Bio-Rad

CFX, then open and follow instructions in the Readme.txt file. See “Installing the

Software Manually” on page 136.

Installing the Drivers

If the CFX96 system or CFX384 system is going to be run in Software-controlled mode,

drivers must be installed on the computer. Use only the supplied USB cable, which is

sufficiently shielded to prevent data loss.

To install the system drivers:

1. Connect the C1000 chassis to the computer by plugging a USB cable into the USB 2.0 A

port located on the back of the chassis (Figure 3 on page 3), and then connecting the

cable into the USB 2.0 B port located on the computer.

2. If it is not already turned on, turn on the system using the power switch on the back of

the C1000 chassis. Follow the instructions in the Found New Hardware Wizard that

launches after the instrument is first detected by the computer.

7

Page 17

System Installation

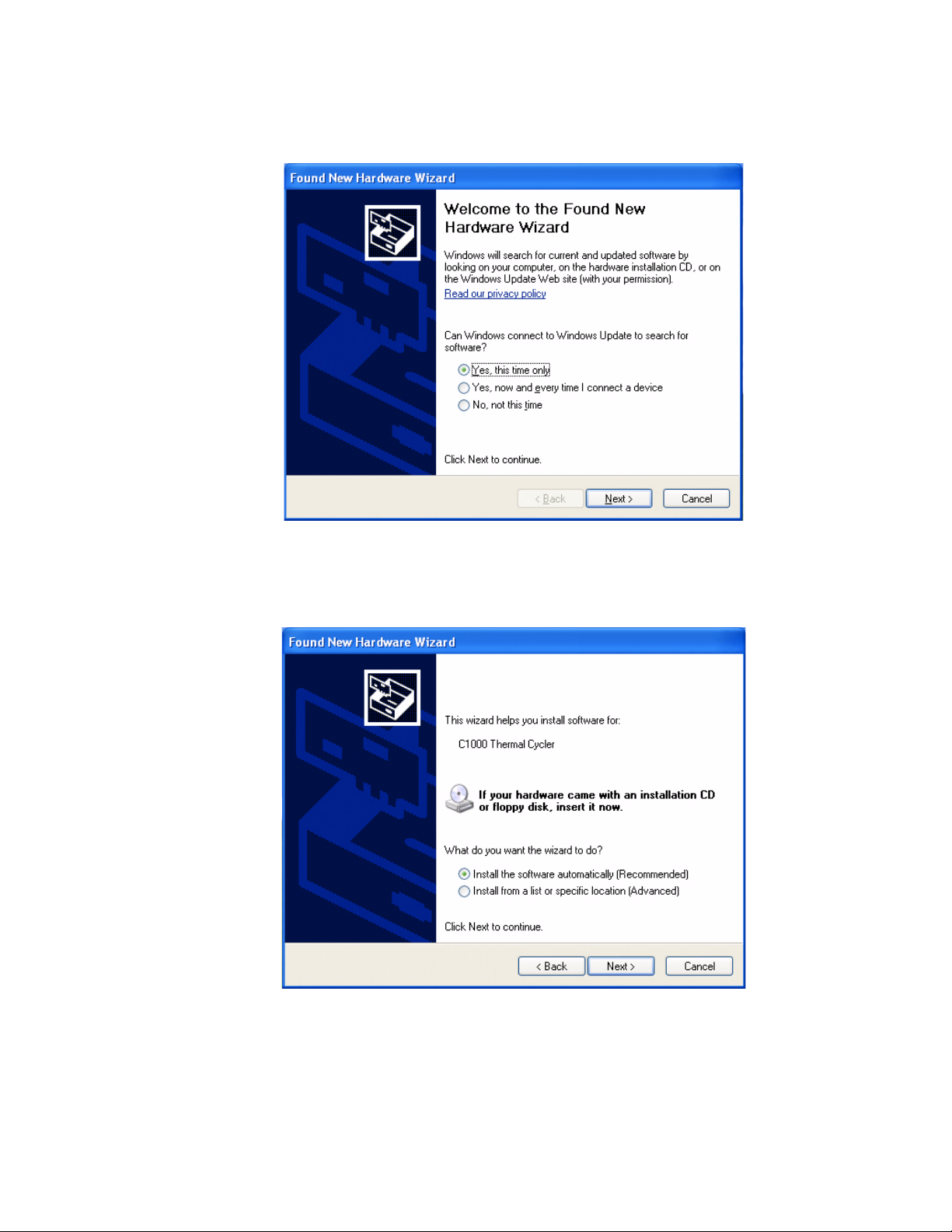

3. On the first screen, select Yes, this time only to instruct the Windows operating system

to connect to Windows Update to search for software (Figure 9). Click Next.

Figure 9. Found New Hardware Wizard.

4. Instruct the wizard to “

installing the drivers (Figure 10).

Install the software automatically

.” Click Next to continue

Figure 10. Software (Driver) installation screen.

5. Click Finish at the software installation completion screen when the drivers are installed.

8

Page 18

Running Experiments

Recommended Plastic Consumables

Run only 384-well plates in the CFX384 system. For optimal results, Bio-Rad recommends the

following consumables for the CFX384 system (catalog numbers are provided in bold):

• HSP-3805. Low-profile 384-well Hard-Shell® plates with clear shell and white wells

• HSP-3866. Low-profile 384-well Hard-Shell plates with black shell and white wells

• MSB-1001. Microseal ‘B’ adhesive seals, optically clear

The CFX96 system accepts both low profile 0.2 ml plates and tubes. For optimal results, BioRad recommends the following consumables:

• MLL-9601. Low-profile 96-well unskirted plates with clear wells

• MLL-9651. Low-profile 96-well unskirted plates with white wells

• HSP-9601. Hard-Shell 96-well skirted plates with white shell and clear wells

• HSP-9655. Hard-Shell 96-well skirted plates with white shell and white wells

• TLS-0801. Low-profile 0.2 ml 8-tube strips without caps, clear wells

• TLS-0851. Low-profile 0.2 ml 8-tube strips without caps, white wells

• TCS-0803. Optical flat 8-cap strips, for 0.2 ml tubes and plates

• MSB-1001. Microseal ‘B’ adhesive seals, optically clear

CFX96 and CFX384 Systems Manual

Loading the Block

To load your reactions in the block, follow these suggestions:

• Click the Open Lid button located on software’s Start Run tab (see “Start Run Tab”

on page 24), or press the lid button on the front of the system (Figure 1) to start

opening the motorized lid.

WARNING! The lid moves slowly at first, and then increases speed when it opens

or closes.

• Place the 0.2 ml microplate or tube strips with sealed lids in the block. Check that

the tubes are completely sealed to prevent leakage. For optimal results load sample

volumes of 10–25 μl for the CFX96 system and load sample volumes of 5–20 μl for

the CFX384 system.

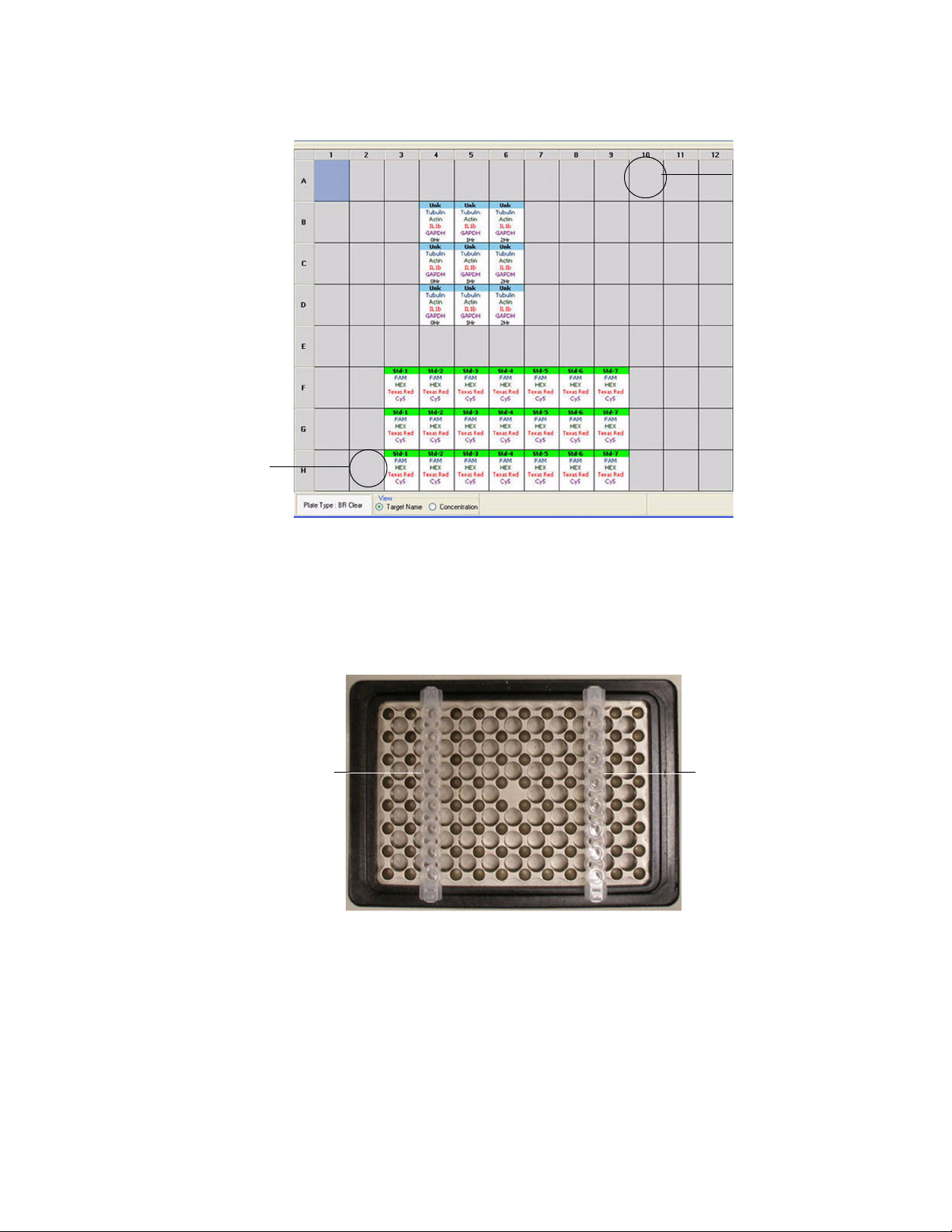

NOTE: For accurate data analysis, check that the orientation of reactions in the

block is exactly the same as the orientation of the well contents in the software

Plate tab (see “Plate Tab” on page 23). If needed, edit the well contents before,

during, or after the run. As shown in Figure 11 on page 10, rotating the microplate

by 180

well.

o

causes the software to expect the reading for well H3 to be an empty A10

9

Page 19

System Installation

Well H3

Well A10

(180

o

rotation)

(correct)

Filled tube

strip

Tube strip for

balance

Figure 11. Plate Editor window showing plate orientation.

WARNING! When running the CFX96 system, always balance the tube strips or cut

microplates in the wells (Figure 12). For example, if you run one tube strip on the

left side of the block, run an empty tube strip (with caps) on the right side of the

block to balance the pressure applied by the heated lid.

Figure 12. Balance the tube strips or cut microplates in the block.

WARNING! Be sure that nothing is blocking the lid when it closes. Although there

is a safety mechanism to prevent the lid from closing if it senses an obstruction, do

not place anything in the way of the closing lid.

10

Page 20

CFX96 and CFX384 Systems Manual

2 Introduction to CFX Manager

Software

Read this chapter for information about getting started with CFX Manager software.

• Main software window (below)

• Startup Wizard (page 15)

• Detected Instruments pane (page 16)

• Instrument Properties window (page 18)

• Software files (page 20)

• Tips and tricks (page 20)

Main Software Window

For instructions about running the system, refer to one of the CFX Manager software quick

guides that ships with the system:

• Installation quick guide

• Protocol quick guide

• Plate quick guide

• Data Analysis quick guide

• Gene Expression Analysis quick guide

TIP: See the software Help for more guides about running experiments.

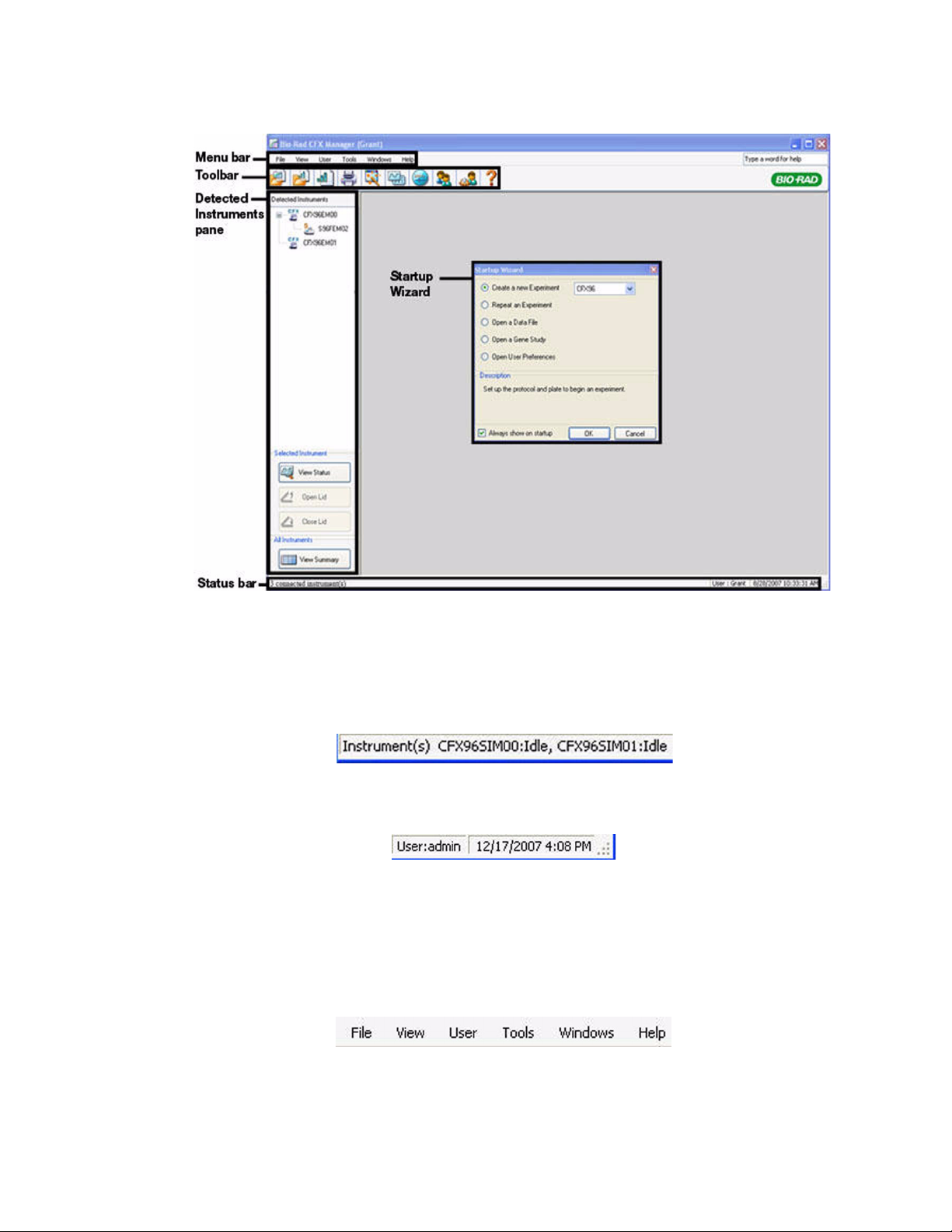

Get started in the main software window by using these features (Figure 13):

• Status bar. View the current software and instrument status (page 12)

•Menu bar. Select software commands (page 12), such as creating or opening files

• Toolbar buttons. Click these buttons (page 14) to open software files, the Startup

Wizard (page 18), the Experiment Setup window (page 21)

• Detected Instruments pane. View a list of attached instruments (page 15)

11

Page 21

Introduction to CFX Manager Software

• Startup Wizard window. Access common software commands (page 16)

Figure 13. The main software window.

Status Bar

The status bar at the bottom of the main software window shows the status of the software.

View the left side of the status bar (Figure 14) to see the current status of instruments.

Figure 14. Left side of status bar in main software window.

View the right side of the status bar (Figure 15) to see the current user name, date, and time.

Figure 15. Right side of status bar in the main software window.

Click and drag the right corner of the status bar to resize the main window.

Menu Bar

The menu bar of the main software window provides the items listed in Figure 16:

12

Figure 16. Menu bar in the main software window.

Page 22

CFX96 and CFX384 Systems Manual

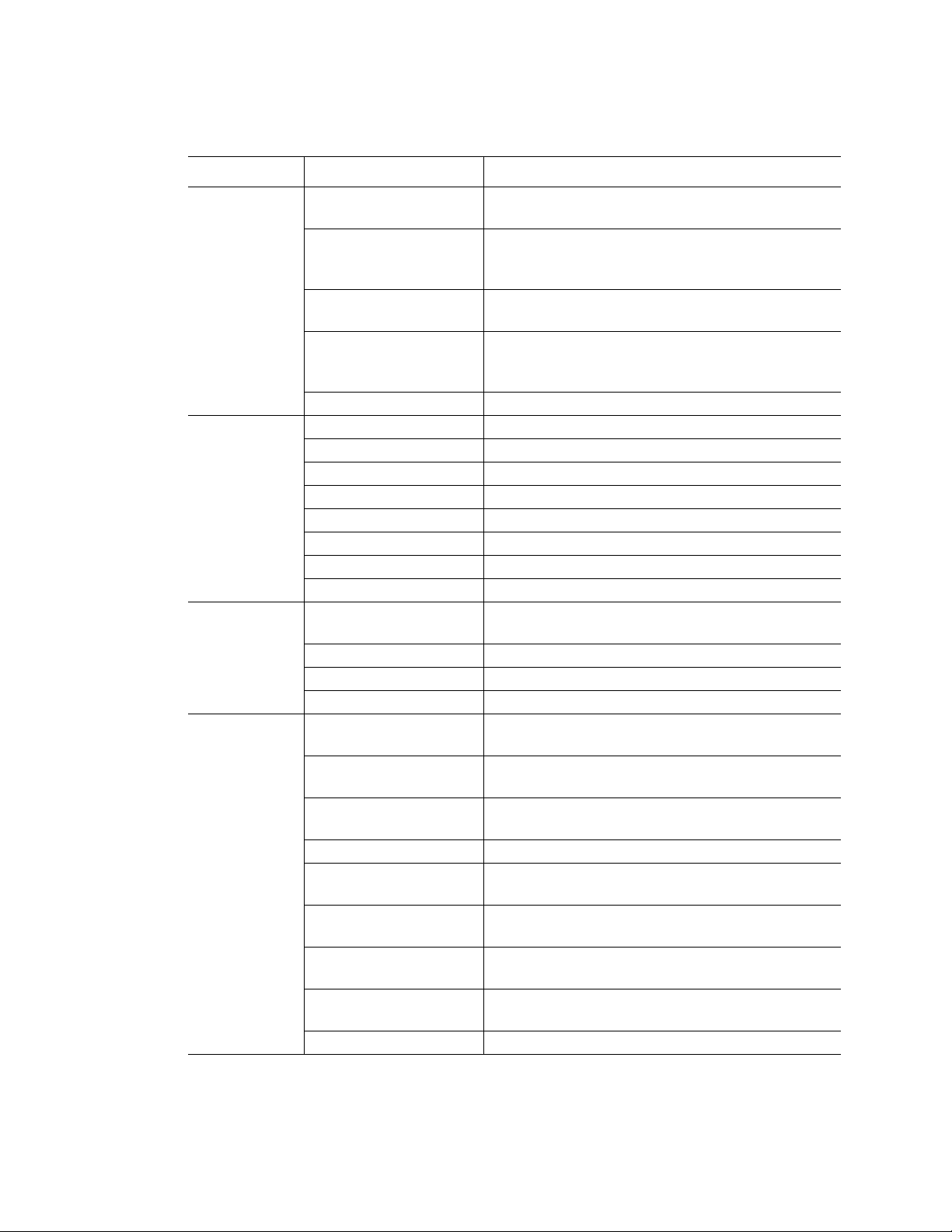

Select the commands shown in the menu bar (Table 7).

Table 7. Menu bar items in the main software window

Menu Item Command Function

File New Create a new protocol, plate, experiment, or Gene

Study

Open Open existing files, including protocol (.prcl), plate

(.pltd), data (.pcrd), and Gene Study (.mgxd) files,

stand-alone run files (.zpcr)

Recent Data Files View a list of the ten most recently viewed data

files, and select one to open in Data Analysis

Repeat an Experiment Open the Experiment Setup window with the

protocol and plate from a completed run to quickly

repeat the run

Exit Exit the software program

View Application Log Display the application log for the software

Run Reports Select a run report to review from a list

Startup Wizard Open the Startup Wizard

Experiment Setup Open the Experiment Setup window

Instrument Summary Open the Instrument Summary window

Detected Instruments Show or hide the Detected Instruments pane

Toolbar Show or hide the main software window toolbar

Status Bar Show or hide the main software window status bar

User Select User Open the Select User window to change software

users

Change Password Change your user password

User Preferences Open the User Preferences window

User Administration Manage users in the User Administration window

Tools Dye Calibration Wizard Open the Dye Calibration window to calibrate an

instrument for a new fluorophore

Protocol AutoWriter Open the Protocol AutoWriter window to create a

new protocol

Ta Calculator Open the Ta Calculator window to calculate the

annealing temperature of primers

View Block Status Log View a log of the thermal cycler block

Application Data Folder Open the Application Data folder to view software

files

User Data Folder Open the Data folder to view protocol, plate, and

data files

Properties All

Instruments

Zip Data and Log Files Choose and condense selected files in a zipped

Options Configure software email settings

View properties of all detected instruments,

including serial numbers

file for storage or to email

13

Page 23

Introduction to CFX Manager Software

Table 7. Menu bar items in the main software window (continued)

Menu Item Command Function

Windows Cascade Arrange software windows on top of each other

Tile Vertical Arrange software windows from top to bottom

Tile Horizontal Arrange software windows from right to left

Close All Close all open software windows

Help Contents Open the software Help for more information

Index View the index in the software Help

Search Search the software Help

Gene Expression

Gateway Web site

PCR Reagents Website View a website that lists Bio-Rad consumables for

PCR Plastic

Consumables Website

Software Updates Check for software updates from Bio-Rad

About Open a window to see the software version

about running PCR and real-time PCR

Open a web site to find information about running

PCR and real-time PCR experiments

PCR and real-time PCR reagents

View a website that lists Bio-Rad consumables for

PCR and real-time PCR experiments

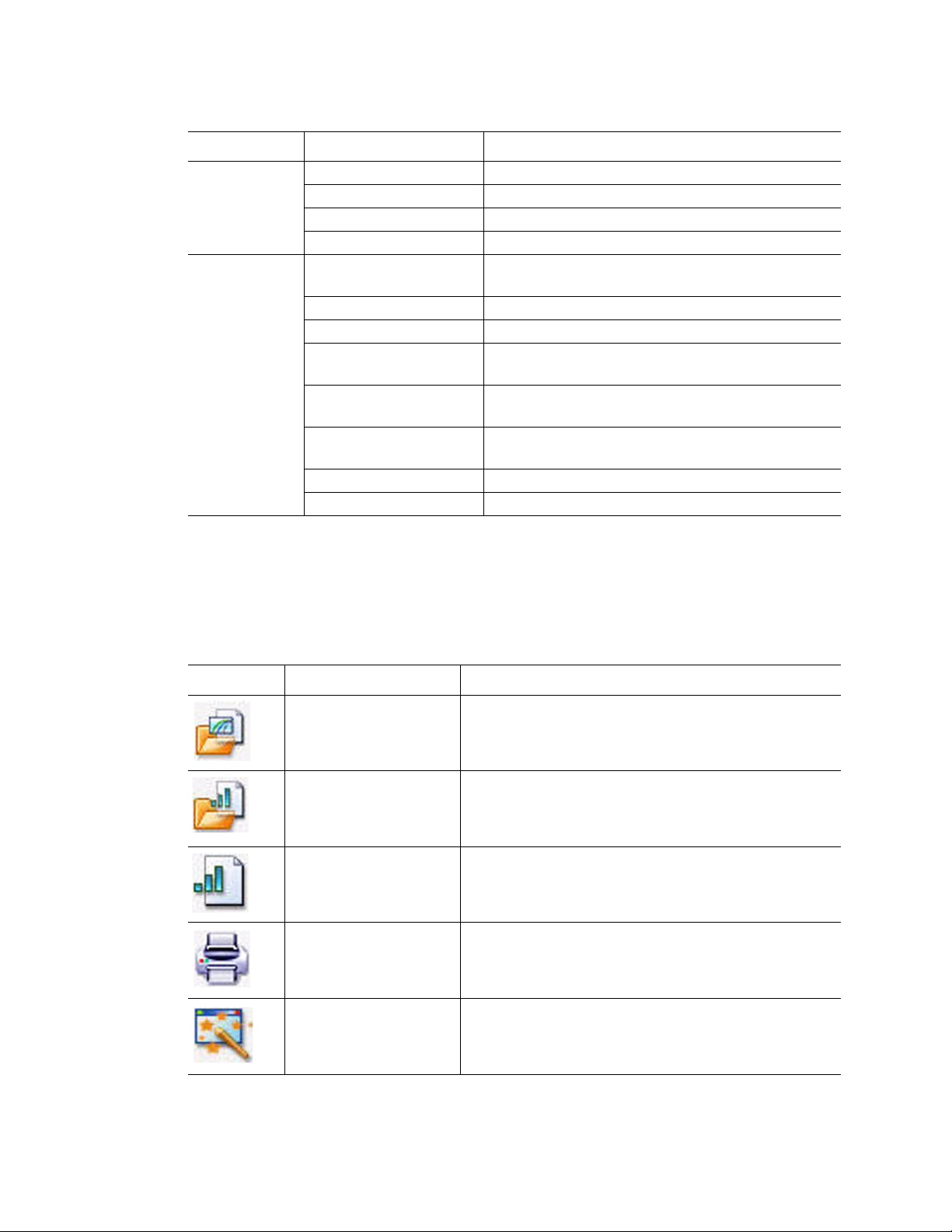

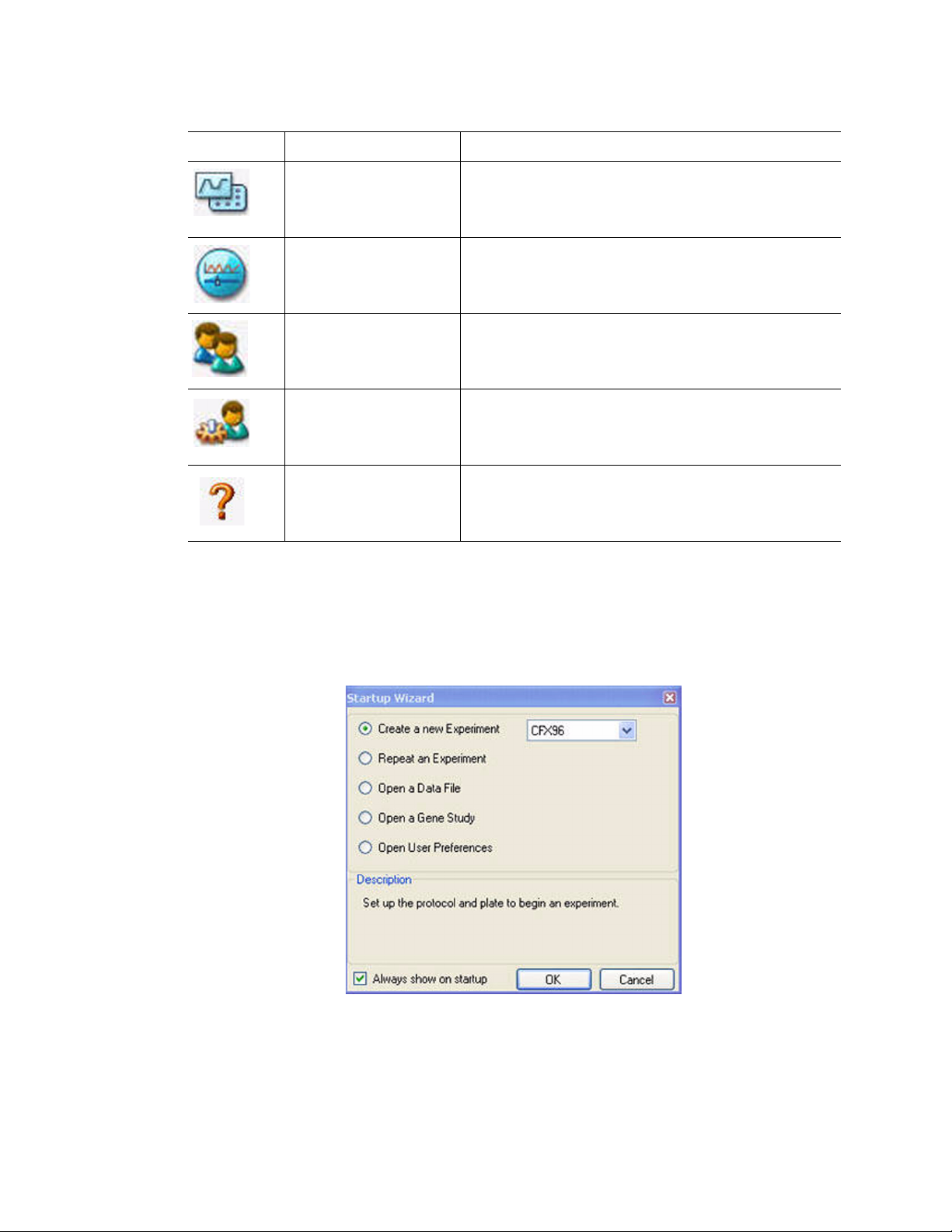

Toolbar Buttons

Click a button in the toolbar of the main software window (Table 8) for quick access to

common software commands.

NOTE: To show or hide the toolbar, select View > Toolbar in the menu bar.

Table 8. Toolbar buttons in the main software window

Button Button Name Function

Open a Data File Open a browser window to locate a data file (*.pcrd

extension) and open it in the Data Analysis window

(page 69)

Open a Gene Study Open a browser window to locate a Gene Study file

(.mgxd extension) and open it in the Gene Study

window (page 101)

Create a New Gene

Study

Print Print the current software window

Open the Gene Study window (page 101) to add files

and create a new study

14

Startup Wizard Open the Startup Wizard that links you to common

software functions (page 16)

Page 24

CFX96 and CFX384 Systems Manual

Table 8. Toolbar buttons in the main software window (continued)

Button Button Name Function

Experiment Setup Open the Experiment Setup window to run an

experiment (page 21)

Protocol AutoWriter Open the Protocol AutoWriter window to create a new

protocol (page 37)

Select User Open the Select User window to change software

users (see “Log in or Select User” on page 121)

User Preferences Open the User Preferences window (page 121)

Help Open the software Help window for more information

about running PCR and real-time PCR

Startup Wizard

The Startup Wizard automatically appears when CFX Manager software is first opened

(Figure 17). If it is not shown, click the Startup Wizard button on the main software window

toolbar.

Figure 17. Startup Wizard window.

Options in the Startup Wizard include the following:

15

Page 25

Introduction to CFX Manager Software

• Create a new Experiment (page 21). Set up the protocol and plate to begin a new

experiment.

NOTE: Select the appropriate instrument in the pull down list to make sure the

default plate settings match the instrument to be used for the experiment.

• Repeat an Experiment. Set up an experiment with the protocol and plate from a

completed run. If needed, you can edit the experiment before the run

• Open a Data File (page 69). Open a data file to analyze results

• Open a Gene Study (page 101). Open a multi-file gene expression study to analyze

results from multiple gene expression experiments

• Open User Preferences (page 121). Open the User Preferences window to customize

software settings

Detected Instruments Pane

CFX Manager software runs these 1000-series instruments:

• CFX96 and CFX384 real-time PCR systems. Systems include a C1000 thermal cycler

and an optical reaction module

• C1000 thermal cycler. The most versatile of the instruments run by CFX Manager

software. Add and remove these PCR reaction modules to the C1000 chassis in

seconds:

• 96-well fast reaction module, gradient enabled

• 384-well reaction module

• Dual 48/48 fast reaction module, gradient enabled

• S1000 thermal cycler connected to a C1000 thermal cycler. For more information,

see S1000 and C1000 thermal cycler instruction manuals

TIP: Locate PDF copies of the instruction manuals by opening the Documents

folder on the CFX Manager software installation CD.

You can simultaneously run up to four instruments with CFX Manager software, including a

combination of CFX96 system and CFX384 systems, or a mix of real-time PCR systems and

thermal cyclers.

Viewing Detected Instruments

Connected instruments appear in the Detected Instruments pane (page 17). This list shows

each instrument as an icon named with the serial number (default). The list of instruments also

shows individual blocks (Block A and Block B) for each dual block reaction module.

TIP: Right-click any instrument in the Detected Instruments pane to open the

Instrument Properties window and rename the instrument.

Figure 18 shows four detected instruments:

• One C1000 thermal cycler (C48FSIM00) with a dual 48/48 reaction module

• One S1000 thermal cycler (S96FSIM01) with a 96-well block, which is connected to

the C1000 thermal cycler called C48FSIM00

• One CFX384 system (CFX384SIM03)

16

Page 26

CFX96 and CFX384 Systems Manual

• One CFX96 system (CFX96SIM02)

Figure 18. Instruments listed at the top of the Detected Instruments pane.

Right-click on the instrument icon or block to select one of these options:

•View Status. Open the Run Details window to check the status of the selected

instrument block

• Flash Block Indicator. Flash the indicator LED on the instrument

• Open Lid. Open a motorized lid on the selected instrument block

•Close Lid. Close a motorized lid on the selected instrument block

• Rename. Change the name of the instrument

•Properties. Open the Instrument Properties window

• Collapse All. Collapse the list of instruments in the Detected Instruments pane

• Expand All. Expand the list of instruments in the Detected Instruments pane

You can also control a block by clicking an instrument block icon in the Detected Instrument

pane and then clicking a button in the Selected Instrument pane (Figure 19).

Figure 19. Buttons at the bottom of the Detected Instruments pane.

• Click View Status to open the Run Details window to check the status of the

selected instrument block

• Click Open Lid to open the motorized lids on the selected instrument

• Click Close Lid to close the motorized lids on the selected instrument

• Click View Summary to open the Instrument Summary window

17

Page 27

Introduction to CFX Manager Software

If only one instrument is detected, then the View Summary button does not appear. To view

the Instrument Summary window for a single instrument, select View > Instrument Summary.

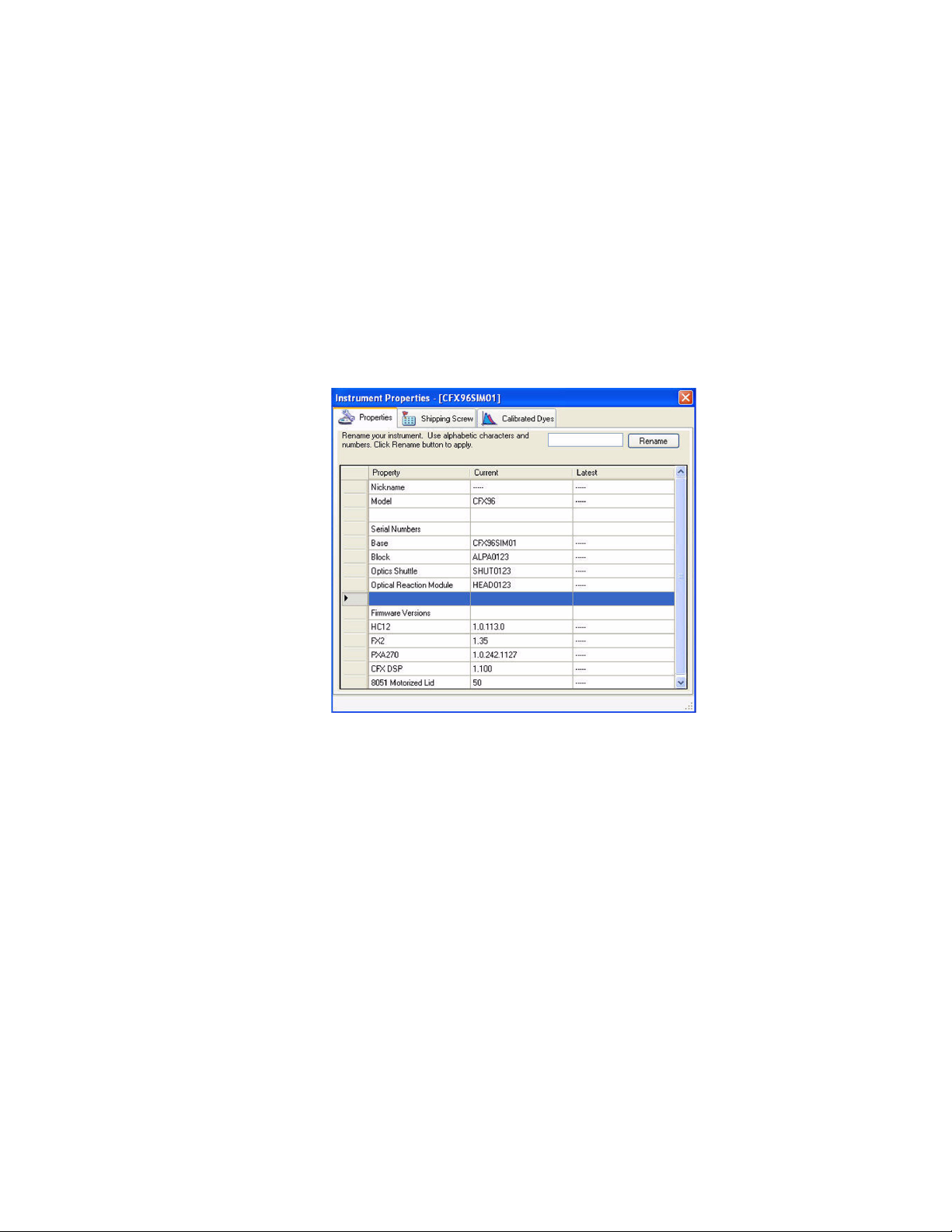

Instrument Properties Window

To open the Instrument Properties window to view information about an instrument, right-click

on the instrument icon in the Detected Instruments pane (Figure 18 on page 17). The window

includes three tabs (Figure 20):

•Properties. View serial numbers and the C1000 thermal cycler name

• Shipping Screw. Remove the shipping screw to run the instrument, or install the

shipping screw when you want to transport the instrument

• Calibrated Dyes. View the list of calibrated fluorophores

18

Figure 20. Instrument Properties window.

Properties Tab

The default name for an instrument is the C1000 thermal cycler serial number, which appears

in many locations, including the Detected Instruments pane (Figure 18).

To rename an instrument for ease of identification, follow these instructions:

• In the Instrument Properties tab, type a name in the Rename box at the top of the

Properties tab and hit the Rename button to save the new name

NOTE: In the Detected Instrument pane, right-click the instrument icon and select

Rename to open the Instrument Properties window.

The Properties tab displays important serial numbers for the connected instrument, including

the thermal cycler and reaction module. The firmware versions are also displayed.

Page 28

CFX96 and CFX384 Systems Manual

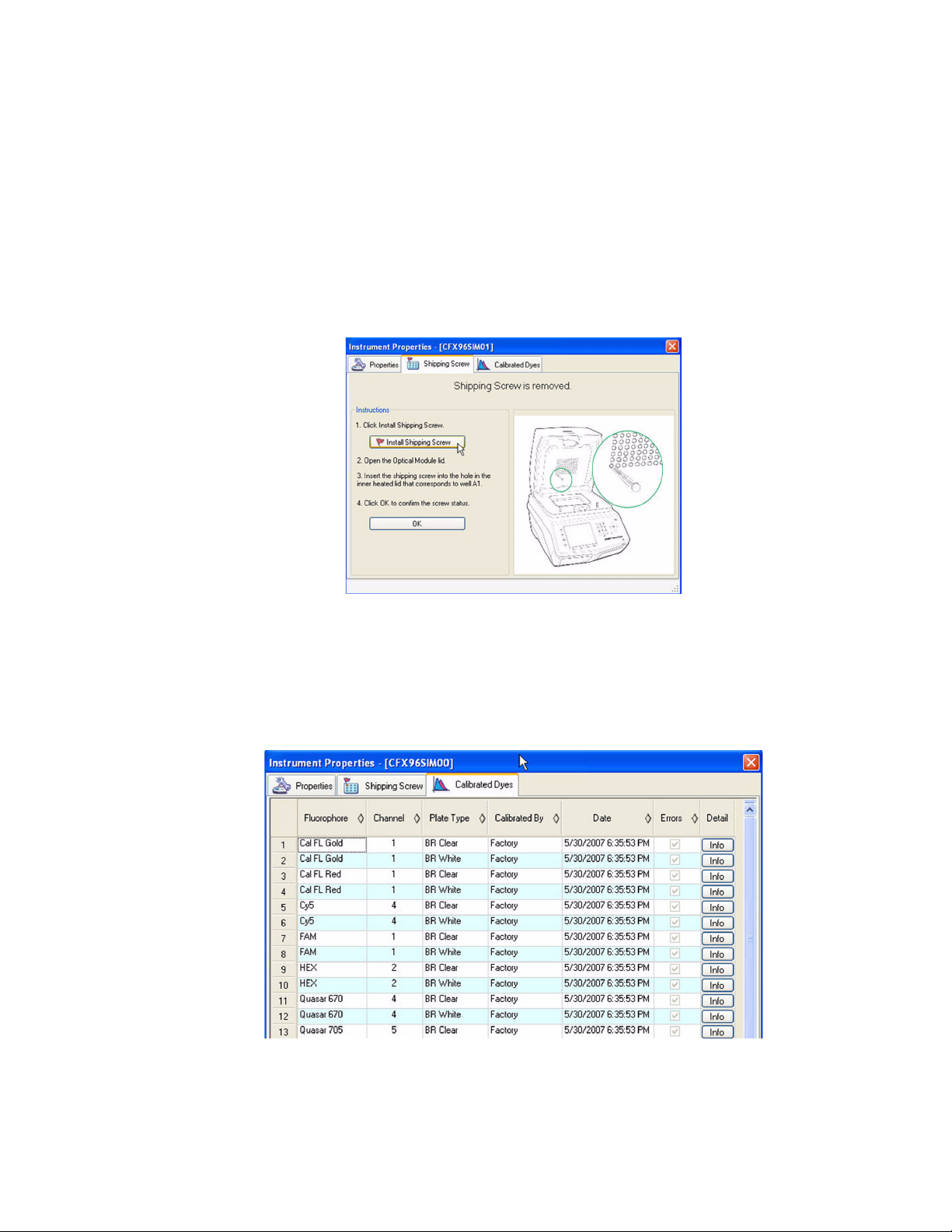

Shipping Screw Tab

The Shipping Screw tab includes instructions for installing or removing the red shipping screw.

To prevent damage to the optical reaction modules, install the shipping screw any time you

ship the CFX96 system or CFX384 system.

NOTE: If the shipping screw is detected by the software, the Instrument Properties

window automatically opens with the Shipping Screw tab in front. Follow the

instructions to remove the screw.

The information in this tab changes depending on whether the shipping screw is installed or

removed. For example, to install the shipping screw, click the Install Shipping Screw button

and follow the instructions in the tab (Figure 21).

Figure 21. Instructions for installing the shipping screw.

Calibrated Dyes Tab

Open the Calibrated Dyes tab to view the list of calibrated fluorophores and plates for the

selected instrument. Click an Info button to see detailed information about a calibration.

Figure 22. Calibrated Dyes tab in the Instrument Properties window.

19

Page 29

Introduction to CFX Manager Software

Software Files

CFX Manager software stores information about experiments in specific files (Table 9):

Table 9. Open these file types with CFX Manager software

File Type Extension How to View and Edit File

Protocol .prcl Select in Experiment Setup and edit in Protocol Editor

Plate .pltd Select in Experiment Setup and edit in Plate Editor

Data .pcrd View and analyze in Data Analysis window

Gene Study .mgxd View and analyze in Gene Study window

Stand-alone pre-data

file

.zpcr Contains fluorescence readings from stand-alone

Tips and Tricks

Tips and tricks for using CFX Manager software are listed below.

• Open any Protocol, Plate, Data, or Gene Study file by dragging it from a folder to an

open software window

• Print or export the information shown in many windows by right-clicking a chart,

spreadsheet, or well selector

• Change the size of any window by clicking and dragging the edges

• Open the User Preferences window to choose default settings that activate every

time you log in to the software

• Add data files to a Gene Study by dragging from a folder to an open Gene Study

window

• Open multiple Data Analysis and Gene Study files at the same time

• Click the Settings or Tools menus to find advanced functions

• To add or delete files from the Express Load menu, add or delete the files (.prcl

and.pltd extensions) in the ExpressLoad folder, select Tools > User Data Folder in

the menu bar of the main software window

• To view all the information loaded into one well in a plate, double-click the well to

open the Well Info window

• Right-click any graph or chart to change viewing and data analysis options

• Edit well contents before, during, or after the run

• Select a well group to view and analyze a subset of the wells in the plate. Select each

well group by name in the Well Group pull-down menu in the toolbar

operation that is converted into a data file

20

Page 30

CFX96 and CFX384 Systems Manual

3 Running Experiments

Read this chapter for information about running experiments using CFX Manager software:

• Experiment Setup window (below)

•Protocol tab (page22)

• End point only runs (page 22)

• Plate tab (page 23)

• Start Run tab (page 24)

• Run Details window (page 26)

• Instrument Summary Window (page 28)

Experiment Setup Window

The Experiment Setup window provides quick access to the files and settings needed to set

up and run an experiment. To open the Experiment Setup window, follow one of these options:

• Click Create a New Experiment option in the Startup Wizard (page 16)

• Click the Experiment Setup button in the main software toolbar (page 14)

•Select File > New > Experiment in the main software menu bar (page 12)

The Experiment Setup window includes three tabs:

•Protocol. Click the Protocol tab to select an existing protocol to run or edit, or to create

a new protocol in the Protocol Editor window (page 31)

•Plate. Click the Plate tab to select an existing plate to run or edit, or to create a new

plate in the Plate Editor window (page 41)

• Start Run. Click the Start Run tab (page 24) to check the run settings, select one or

more instrument blocks, and begin the run

NOTE: If the protocol currently selected in the Protocol tab does not include a step

with a plate read for real-time PCR analysis, then the Plate tab is hidden. To view

the Plate tab, add a “Plate Read” (page 34) in at least one step in the protocol.

NOTE: Start a new experiment from a previous run by selecting File > Repeat an

Experiment in the main software menu bar. Then select the data file (.pcrd) for the

experiment you want to repeat.

21

Page 31

Running Experiments

The Experiment Setup window opens with the Protocol tab in front (Figure 23). To open

another tab, click that tab or click Prev and Next buttons at the bottom of the window.

Figure 23. Experiment Setup window, including the Protocol, Plate, and Start Run tabs.

Protocol Tab

The Protocol tab shows a preview of the selected protocol file loaded in the Experiment Setup

(Figure 23). A protocol file contains the instructions for the instrument temperature steps, as

well as instrument options that control the ramp rate and lid temperature.

Select one of the following options to select an existing protocol, create a new protocol, or edit

the currently selected protocol:

• Create New button. Open the Protocol Editor to create a new protocol

• Select Existing button. Open a browser window to select and load an existing protocol

file (.prcl extension) into the Protocol tab

• Express Load pull-down menu. Quickly select a protocol to load it into the Protocol tab

TIP: To add or delete protocols in the Express Load menu, add or delete files (.prcl

extension) in the ExpressLoad folder. To locate this folder, select Too ls > U se r

Data Folder in the menu bar of the main software window

• Edit Selected button. Open the currently selected protocol in the Protocol Editor

End Point Only Runs

To run a protocol that contains only an end point data acquisition step, select Options > End

Point Only Run from Options in the menu bar of the Experiment Setup window. The default

end point protocol, which includes two cycles of 60.0°C for 30 seconds, is loaded into the

Protocol tab.

22

Page 32

Figure 24 shows the default end point protocol.

Figure 24. End Point Only protocol.

CFX96 and CFX384 Systems Manual

To change the step temperature or sample volume for the end point only run, click the Start

Run tab and edit the Step Temperature or Sample Volume. Figure 25 shows the step

temperature is changed to 55.0oC.

Plate Tab

The Plate tab shows a preview of the selected plate file loaded in the Experiment Setup

(Figure 26). In a real-time PCR experiment, the plate file contains a description of the contents

of each well, the scan mode, and the plate type. CFX Manager software uses these

descriptions for data collection and analysis.

Select one of the following options to select an existing plate, create a new plate, or edit the

currently selected plate:

• Create New button. Open the Plate Editor to create a new plate

• Select Existing button. Open a browser window to select and load an existing plate file

• Express Load pull-down menu. Quickly select a plate to load it into the Plate tab

Figure 25. Change the sample volume on the Start Run tab.

(.pltd extension) into the Plate tab

TIP: To add or delete plates in the Express Load menu, add or delete files (.pltd

extension) in the ExpressLoad folder. To locate this folder, select Too ls > U se r

Data Folder in the menu bar of the main software window.

23

Page 33

Running Experiments

• Edit Selected button. Open the currently selected plate in the Plate Editor

Figure 26. Plate tab window.

Start Run Tab

The Start Run tab (Figure 27) includes a section for checking information about the run that is

going to be started, including the selected protocol and plate files, and a section for selecting

the instrument block.

• Run Information pane. View the selected Protocol file, Plate file, and data acquisition

Scan Mode setting. Enter optional notes about the experiment in the Notes box

• Start Run on Selected Block(s) pane. Select one or more blocks, edit run parameters

(if necessary), and then click the Start Run button to begin the experiment

24

Figure 27. The Start Run tab.

Page 34

CFX96 and CFX384 Systems Manual

By default, the Start Run on Selected Block(s) pane shows the block name, block type and

status of each instrument detected by the software. These descriptions can not be edited.

NOTE: You can override the Sample Volume loaded in the Protocol file by selecting

the volume in the spreadsheet cell and typing a new volume.

NOTE: A run ID can be entered for each block by selecting the cell and typing an ID

or by selecting the cell and scanning with a bar code reader.

To add or remove run parameters from the spreadsheet in the Start Run on Selected Block(s)

pane, right-click on the list and select an option in the menu to display. Choose the value to

change by clicking the text inside the cell to select it and then typing in the cell, or by selecting

a new parameter from the pull-down menu. Editable parameters include:

• Lid Temperature. View the temperature of the lid. Override the lid temperature by

selecting the text and typing a new temperature

Table 10 shows additional options on the right-click menu in the Start Run on Selected

Block(s) pane:

Table 10. Start Run on Selected Block(s) right-click menu options

Right-Click Option Function

Copy Copy selected text

Copy as Image Copy an image of the Start Run on Selected Block(s) pane

Print... Print the current view of the list of selected blocks

Print Selection... Print the column that is currently selected

Export to Excel... Export the list of blocks to an Excel spreadsheet file

Export to Text... Export the list of blocks to a text file

Find... Find text in the list of blocks

Sort... Sort up to three columns in the list of blocks

Buttons for Controlling the Instrument

Click the following buttons in the Start Run tab to remotely operate the selected instruments:

• Start Run. Start the experiment on the selected instrument blocks

• Flash Block Indicator. Flash the indicator LED on the selected instrument blocks

• Open Lid. Open motorized lid on selected instrument blocks

•Close Lid. Close motorized lid on selected instrument blocks

Run Details Window

When you click the Start Run button, CFX Manager software prompts you to save the name of

the data file and then opens the Run Details window. Review the information in this window to

monitor the progress of a run.

• Run Status tab. Check the current status of the protocol, open the lid, pause a run, add

repeats, skip steps, or stop the run

• Real-Time Status tab. View the real-time PCR fluorescence data as they are collected

• Time Status tab. View a full-screen countdown timer for the protocol

25

Page 35

Running Experiments

Figure 28 shows the features of the Run Details window.

Figure 28. Run Details window.

Run Status Tab

The Run Status tab (Figure 28) shows the current status of a run in progress in the Run Details

window and provides buttons (page 26) to control the lid and change the run in progress.

• Run Status pane. Displays the current progress of the protocol, including the current

step, current GOTO repeat, block temperature, remaining hold time for the current step,

sample temperature, lid and shuttle temperature

• Run Status buttons. Click one of the buttons to remotely operate the instrument or to

interrupt the current protocol

• Run Information pane. Displays experiment details

Run Status Tab Buttons

Click one of the buttons listed in Table 11 to operate the instrument from the software, or to

change the run that is in progress.

NOTE: Changing the protocol during the run, such as adding repeats, does not change the

protocol file associated with the run. These actions are recorded in the Run Log.

Table 11. Run Status buttons and their functions

Button Function

Open the motorized lid on selected instruments

WARNING! Opening the lid during a run pauses the

run during the current step and might alter the data.

Close the motorized lid on selected instruments

26

Page 36

CFX96 and CFX384 Systems Manual

Table 11. Run Status buttons and their functions (continued)

Button Function

Add more repeats to the current GOTO step in the protocol.

This button is only available when a GOTO step is running.

Skip the current step in the protocol. If you skip a GOTO step,

the software verifies that you want to skip the entire GOTO

loop and proceed to the next step in the protocol.

Flash the LED on the selected instrument to identify the

selected blocks

Pause the protocol

NOTE: This action is recorded in the Run Log.

Resume a protocol that was paused

Stop the run before the protocols ends, which may alter your

data

Real-Time Status Tab

The Real-Time Status tab (Figure 29) shows real-time PCR data collected at each cycle during

the protocol after the first two plate reads. This tab also shows the well selector and text

describing the protocol status at the bottom of the window.

TIP: Click the View/Edit Plate button to open the Plate Editor window. During the

run, you can enter more information about the contents of each well in the plate.

Figure 29. The Real-time Status tab displays the data during a run.

27

Page 37

Running Experiments

Replacing a Plate File

During a run, replace the plate file by clicking the Replace Plate button (Figure 29) in the Realtime Status tab. Select the new plate file (.pltd) from the list in the windows browser.

NOTE: CFX Manager software checks the scan mode and plate size for the plate

file; these must match the run settings that were started during the experiment.

TIP: Replacing a plate file is especially useful if you start a run with a Quick Plate

file in the Express Load folder.

Time Status Tab

The Time Status tab shows a countdown timer for the current run (Figure 30).

Figure 30. The Time Status tab displays a count-down timer for the current run.

Instrument Summary Window

The Instrument Summary window shows a list of the detected instruments and their status.

Open the Instrument Summary by clicking the View Summary button (Figure 19 on page 17)

in the Detected Instrument pane.

Figure 31 shows the Instrument Summary window, including the Block Name list and the

current status of all detected instruments. Select one or more blocks and click the buttons in

the tool bar to change the status of each instrument.

28

Figure 31. Instrument Summary window.

Page 38

CFX96 and CFX384 Systems Manual

Instrument Summary Toolbar

The Instrument Summary toolbar includes buttons and functions listed in Table 12.

Table 12. Toolbar buttons in the Instrument Summary window

Button Button Name Function

Set Up Experiment Set up an experiment on the selected

block by opening the Experiment Setup

window

Stop Stop the current run on selected blocks

Pause Pause the current run on selected blocks

Resume Resume the run on selected blocks

Flash Block Indicator Flash the indicator LED on the lid of the

selected blocks

Open Lid Open a selected block motorized lid

Close Lid Close a selected block motorized lid

Hide Selected Blocks Hide the selected blocks in the

Instrument Summary list

Show All Blocks Show the selected blocks in the

Instrument Summary list

Show Select which blocks to show in the list.

Select one of the options to show all

detected blocks, all idle blocks, all the

blocks that are running with the current

user, or all running blocks

Right-Click Menu

Right-click in the Instrument Summary window to change the list of options that appear:

• Block Name. View the name of the block

•Type. View the size and type of the block

• Status. View the current status of the block

•User. View the current user who is logged in to the software

• Remaining. View the time remaining in the current run

29

Page 39

Running Experiments

• Copy. Copy the entire list

• Copy as Image. Copy the list as an image file

•Print. Print the list

• Print Selection. Print only the selected cells in the list

• Export to Excel. Export the list as an Excel formatted file

• Export to Text. Export the list as a text file

•Find. Find text in the list

•Sort. Sort the list by selecting up to three columns of data in the Sort window

30

Page 40

4 Protocols

Read the following chapter for information about creating and editing protocol files:

• Protocol Editor window (below)

• Protocol Editor controls (page 33)

• Temperature control mode (page 37)

• Protocol AutoWriter (page 37)

CFX96 and CFX384 Systems Manual

Protocol Editor Window

A protocol instructs the instrument to control the temperature steps, lid temperature, and other

instrument options. Open the Protocol Editor window to create a new protocol or to edit the

protocol currently selected in the Protocol tab. Once a Protocol is created or edited in the

Protocol Editor, click OK to load the protocol file into the Experiment Setup window and run it.

Opening the Protocol Editor

To open the Protocol Editor, follow one of these options:

• To create a new protocol, select File > New > Protocol or click the Create New

button in the Protocol tab (page 22)

• To open an existing protocol, select File > Open > Protocol, or click the Open

Existing button in the Protocol tab (page 22)

• To edit the current protocol in the Protocol tab, click the Edit Selected button in the

Protocol tab (page 22)

TIP: To change the default settings in the Protocol Editor window, enter the

changes in the Protocol tab in the user Preferences window (page 124)

Protocol Editor Window

The Protocol Editor window (Figure 32) includes the following features:

•Menu bar. Select settings for the protocol

• Toolbar. Select options for editing the protocol

•Protocol. View the selected protocol in a graphic (top) and text (bottom) view. Click the

temperature or dwell time in the graphic or text view of any step to enter a new value

31

Page 41

Protocols

• Protocol Editor buttons. Edit the protocol by clicking one of the buttons to the left of

the text view

Figure 32. Protocol Editor window with buttons for editing protocols.

Protocol Editor Menu Bar

The menu bar in the Protocol Editor window provides the menu items listed in Table 13

Table 13. Protocol Editor menu bar

Menu Item Command Function

File Save Save the current protocol

Save As Save the current protocol with a new name or in a new

location

Close Close the Protocol Editor

Settings Lid Settings Open the Lid Settings window to change or set the Lid

Temperature

Tools Gradient

Calculator

Run-time

Calculator

The toolbar (Figure 33) in the Protocol Editor window provide quick access for important

functions:

Select the block type for a gradient step. Choose 96 Wells

or 384 Wells

Select the instrument and scan mode to be used for

calculating the estimated run time in the Experiment Setup

window

32

Figure 33. Protocol Editor toolbar.

Page 42

CFX96 and CFX384 Systems Manual

Table 14 lists the function of the Protocol Editor toolbar buttons:

Table 14. Protocol Editor toolbar buttons

Toolbar Button and Menus Name Function

Save Save the current protocol file

Print Print the selected window

Insert Step Select After or Before to insert steps in a

position relative to the currently highlighted

step

Sample Volume Enter a sample volume in μl between 0 and

50 (for 96-well block), or between 0 and 30

(for 384-well block)

Sample volume determines the Temperature

Control mode (page 37). Enter zero (0) to

select Block mode

Run Time View an estimated run time based on the

protocol steps and ramp rate

Help Open the software Help for more

information about protocols

Protocol Editor Controls

The Protocol Editor window includes buttons for editing the protocol. First, select and highlight

a step in the protocol by left clicking it with the mouse pointer. Then click one of the Protocol

Editor buttons at the bottom left side of the Protocol Editor window to change the protocol.

The location for inserting a new step, “Before” or “After” the currently selected step is

determined by the status of the Insert Step box located in the toolbar.

Insert Step Button

To insert a temperature step before or after the currently selected step:

1. Click the Insert Step button.

2. Edit the temperature or hold time by clicking the default value in the graphic or text view,

and entering a new value.

33

Page 43

Protocols

3. (Optional) Click the Step Options button to enter an increment or extend option to the

step (page 36). Figure 34 shows the new step that was inserted after step 2.

Figure 34. Protocol with inserted step.

Add or Remove a Plate Read

To add a plate read to a step or to remove a plate read from a step:

1. Select the step by clicking the step in either the graphical or text view.

2. Click the Add Plate Read to Step button to add a plate read to the selected step. If the

step already contains a plate read, the text on the button changes, so now the same

button reads Remove Plate Read. Click to remove a plate read from the selected step.

In Figure 34, notice that the camera icon in the graphic view (top) shows that step 4 includes a

plate read.

Insert Gradient Button

To insert a gradient step before or after the currently selected step:

1. Insert a temperature gradient step by clicking the Insert Gradient button.

2. Make sure the plate size for the gradient matches the block type of the instrument, 96

well or 384 well. Select the plate size for the gradient by selecting Tools > Gradient

Calculator in the Protocol Editor menu bar.

3. Edit the gradient temperature range by clicking the default temperature in the graphic or

text view, and entering a new temperature. Alternatively, click the Step Options button to

enter the gradient range in the Step Options window (page 36)

34

4. Edit the hold time by clicking the default time in the graphic or text view, and entering a

new time.

Page 44

CFX96 and CFX384 Systems Manual

Figure 35 shows the inserted gradient step. The temperatures of each row in the gradient are

charted on the right side of the window.

Figure 35. Protocol with inserted gradient step.

Insert GOTO Button

To insert a GOTO step before or after the selected step:

1. Click the Insert GOTO button.

2. Edit the GOTO step number or number of GOTO repeats by clicking the default number

in the graphic or text view, and entering a new value.

Figure 35 shows an inserted GOTO step at the end of the protocol. Notice that the GOTO loop

includes steps 2 through 4.

Insert Melt Curve Button

To insert a melt curve step before or after the selected step:

1. Click the Insert Melt Curve button.

2. Edit the melt temperature range or increment time by clicking the default number in the

graphic or text view, and entering a new value. Alternatively, click the Step Options

button to enter the gradient range in the Step Options window (page 36).

NOTE: You cannot insert a melt curve step inside a GOTO loop.

NOTE: The melt curve step includes a 30 second hold at the beginning of the step

that is not shown in the protocol.

35

Page 45

Protocols

Figure 36 shows a melt curve step added after step 6:

Figure 36. Protocol with inserted melt curve step.

Step Options

To change a step option for the selected step:

1. Select a step by clicking on the step in the graphic or text view.

2. Click the Step Options button to open the Step Options window.

3. Add or remove options by entering a number, editing a number, or clicking a check box.

TIP: To hold a step forever (an infinite hold), enter zero (0.00) for the time.

Figure 37 shows the selected step with a gradient of 10

available in a gradient step. A gradient step cannot include an increment or ramp rate change.

Figure 37. Step option for a gradient.

o

C. Notice that some options are not

36

NOTE: A gradient runs with the lowest temperature in the front of the block (row H)

and the highest temperature in the back of the block (row A).

The Step Options window lists the following options you can add or remove from steps:

• Plate Read. Check the box to include a plate read

• Temperature. Enter a target temperature for the selected step

• Gradient. Enter a gradient range for the step

Page 46

CFX96 and CFX384 Systems Manual

• Increment. Enter a temperature to increment the selected step; the increment amount is

added to the target temperature with each cycle

• Ramp Rate. Enter a rate for the selected step; the range depends on the block size

•Time. Enter a hold time for the selected step

•Extend. Enter a time to extend the selected step. The extend amount is added to the

hold time with each cycle

•Beep. Check the box to include a beep at the end of the step

TIP: When you enter a number that is outside the option range, the software

changes the number to the closest entry within the range.

Delete Step Button

To delete a step in the protocol:

1. Select a step in the graphic or text view.

2. Click the Delete Step button to delete the selected step.

WARNING! You cannot undo this function.

Temperature Control Mode

The instrument uses one of two temperature control modes to determine when the sample

reaches the target temperature in a protocol.

TIP: The sample volume can be changed before a run by editing the Sample

Volume parameter in the Start Run tab (see “Start Run Tab” on page 24).

Enter a sample volume in the protocol editor to select a temperature control mode:

• Calculated mode. When you enter a sample volume between 1 and 50 μl (96-well block)

or between 1 and 30 μl (384-well block) the thermal cycler calculates the sample

temperature based on the sample volume. This is the standard mode

• Block mode. When you enter a sample volume of zero (0) μl, the thermal cycler records

the sample temperature as the same as the measured block temperature

Protocol AutoWriter

Open the Protocol AutoWriter to quickly write protocols for PCR and real-time PCR

experiments. To open the Protocol AutoWriter, select one of these options:

• Click the Protocol AutoWriter button in the main software window toolbar

•Select Tools > Protocol AutoWriter from the menu bar in the main software window

37

Page 47

Protocols

Figure 38 shows a protocol (bottom of window) written by the Protocol AutoWriter.

Figure 38. Protocol AutoWriter window with a new protocol.

Protocol AutoWriter Overview

The Protocol AutoWriter window uses information about your reaction to automatically

generate a protocol file. Enter the following information about your PCR experiment:

• Annealing Temperature (Ta) or primer sequence. Enter the annealing temperature for

the primers. If the annealing temperature is unknown, click the Ta Calculator button to

enter the primer sequence to calculate the annealing temperature in the Ta Calculator

window

• Amplicon Length (bp). Enter the expected length of the PCR product

• Enzyme. Select the DNA polymerase enzyme (iTaq, iProof, or Other) (iTag

Tm

Polymerase; iProof

including hot start activation time, and final extension time

• Run time and type. Enter a speed (Standard, Fast, Ultrafast) to adjust the total run time,

and select the type of PCR (Real-time PCR or PCR)

The run time for any protocol is influenced by the number of steps and cycles, the incubation

time at each step, and the time it takes to reach uniformity at the target temperature. To reduce

the overall run time, the Protocol AutoWriter makes one or more of the following changes:

• Reduces the total number of protocol steps

• Reduces the number of GOTO repeats

• Minimizes the hold time in each temperature step

• Minimizes the ramp time between steps by reducing the temperature change from

one step to the next

high fidelity DNA Polymerase); enter additional information

Tm

DNA

38

Page 48

CFX96 and CFX384 Systems Manual

For example, a typical PCR protocol includes the following three sets of steps with a total run

time of 1.5 to 2.0 hours:

1. Initial template denaturation and enzyme activation (95°C for 3-10 minutes).

2. Cycles of three temperature steps (30 to 40 cycles): Denaturation of template (94-95°C

for 15-30 seconds), annealing of primers (anneal for 15-30 seconds), and extension of

product (72°C for 15-60 seconds).

3. Final extension (72°C for 10 minutes).