Page 1

Instrument User Manual

[04]

510731-10EN1 (06/2008)

24262

bioMérieux, Inc.

Box 15969

Durham, North Carolina 27704-0969 / USA

Tel. (1) 800-682-2666

EC REP

bioMérieux

au capital de 12 029 370 €

673 620 399 RCS LYON

69280 Marcy l’Etoile / France

tél. 33 (0)4 78 87 20 00 / fax 33 (0)4 78 87 20 90

http://www.biomerieux.com

®

SA

Page 2

Argentina

bioMérieux Argentina

Av. Congreso 1745

C1428BUE

Capital Federal Buenos Aires

tel. (54) 11 5555 6800

fax (54) 11 5555 6888

Australia

bioMérieux Australia P/L

Unit 25 - Parkview Business Centre

1, Maitland Place

Baulkham Hills NSW 2153

tel. (61) 2 8852 4700

fax (61) 2 8852 4777

Austria

bioMérieux Austria GmbH

Eduard-Kittenberger-Gasse 97

Top 3

A-1230 Wien

tel. (43) 186 50 650

fax (43) 186 50 661

Belgium

bioMérieux Benelux s.a./n.v.

Media Square

18–19 Place des Carabiniers

Bruxelles 1030

tel. (32) 2 743 01 70

fax (32) 2 733 55 97

Brazil

bioMérieux Brasil SA

Estrada Do Mapuá

491 Taquara - Jacarepaguá

CEP 22710 261

Rio de Janeiro RJ

tel. (55) 21 2444 1400

fax (55) 21 2455 6025

Canada

bioMérieux Canada, Inc.

7815, Henri-Bourassa West

Saint Laurent, QC

H4S 1P7

tel. (1) 514 336 7321

fax (1) 514 807 0015

Chile

bioMérieux Chile S.A.

Seminario 131

Providencia

Santiago

tel. (56) 2634 20 92

fax (56) 2634 20 93

China

bioMérieux China Limited

Room 1601-02B & 10

Est Ocean Centre

nº 24A Jiang Guo Men Nei Street

100004 Beijing

tel. (86) 10 6515 6963

fax (86) 10 6515 6993

bioMérieux China Limited

Room 2605, South Tower,

World Trade Center

371-375 Huan Shi Dong East Road

510095 Guangzhou

tel. (86) 20 8762 7010

fax (86) 20 8762 7015

Colombia

bioMérieux Colombia Ltda

Avenida 15 No. 100-43

Piso 2

Bogotá, D.C.

tel. (57) 1 520 0080

fax (57) 1 520 0088

(57) 1 520 0831

Czech Republic

bioMérieux CZ s.r.o.

Business Park Kosice

Jinonická 80

158 00 Praha 5

tel. (420) 2 57 290 623

(420) 2 57 290 232

fax (420) 2 57 290 964

Denmark

bioMérieux Danmark Aps

Smedeholm 13C

2730 Herlev

tel. (45) 70 10 84 00

fax (45) 70 10 84 01

Finland

bioMérieux Suomi Oy

Konalantie 47 C

FI-00390 Helsinki

tel. (358) 9 8545 6000

fax (358) 9 8545 6045

France

bioMérieux SA

69280 Marcy l’Etoile

tel. (33) 0(4) 78 87 20 00

fax (33) 0(4) 78 87 20 90

http://www.biomerieux.com

Germany

bioMérieux Deutschland GmbH

Weberstrasse 8

D 72622 Nürtingen

tel. (49) 7022 30070

fax (49) 7022 36110

Greece

bioMérieux Hellas S.A.

Papanikoli 70

15232 Halandri

Athens

tel. (30) 210 81 72 400

fax (30) 210 68 00 880

Hungary

bioMérieux Hungária Kft.

Fóto út. 56 (5. emelet)

H-1047 Budapest

tel. (36) 1 231 3050

fax (36) 1 231 3059

India

bioMérieux India Pvt. Ltd

A-32, Mohan Co-Operative Ind. Estate

New Delhi 110 024

tel. (91) 11 42 09 88 00

fax (91) 11 24 64 88 30

Indonesia

Representation Office

bioMérieux Indonesia

Enseval Building

Kawasan Industri Pulo Gadung JI. Pulo - Lentut No. 10

Jakarta Timur 13920

tel. (62) 21 461 51 11

fax (62) 21 460 41 07

Italy

bioMérieux Italia S.p.A.

Via Fiume Bianco, 56

00144 Roma

tel. (39) 06 523 081

fax (39) 06 523 08240

Ivory Coast

bioMérieux Afrique Occidentale

08 BP 2634

Abidjan 08

tel. (225) 22 40 93 93/22 40 41 40

fax (225) 22 40 93 94

Japan

Sysmex bioMérieux, Ltd.

Seizan Bldg.

12-28 Kita-Aoyama 2-chome

Minato-ku, Tokyo 107-0061

tel. (81) 3 5411 87 11

fax (81) 3 5411 87 10

Korea

bioMérieux Korea Co., Ltd.

1st & 2nd Floor, Yoosung Building

# 830-67 Yeoksam-dong,

Kangnam-gu

Séoul 135-080

tel. (82) 2 2188 4700

fax (82) 2 547 6263

Mexico

bioMérieux México SA de CV

Chihuahua 88, col. Progreso

México 01080, D.F.

tel. (52) 55 5481 9550

fax (52) 55 5616 2245

Netherlands (The)

bioMérieux Benelux BV

Boseind 15

P.O. Box 23

5280 AA Boxtel

tel. (31) 411 65 48 88

fax (31) 411 65 48 73

New Zealand

bioMérieux New Zealand Ltd.

C/- Logical Freight Solutions

12C Rennie Drive, Airport Oaks

Auckland

tel. (64) 9 918 6354

fax (64) 9 918 6355

i Manual Name

702358-4EN1 REV nn/nnnn

Page 3

Norway

bioMérieux Norge AS

Økernveien 145

N-0513, Oslo

tel. (47) 23 37 55 50

fax (47) 23 37 55 51

Philippines (The)

Representation Office

bioMérieux Philippines

11th Floor, Pearlbank Centre

146 Valero Street, Salcedo Village

1227 Makati City

tel. (632) 817 7741

fax (632) 812 0896

Poland

bioMérieux Polska Sp. Z.o.o.

Ul. Zeromskiego 17

01-882 Warsaw

tel. (48) 22 569 85 00

fax (48) 22 569 85 54

Portugal

bioMérieux Portugal, Lda.

Av. 25 de Abril de 1974, nº 23-3º

2795-197 LINDA-A-VELHA

tel. (351) 21 415 23 50

fax (351) 21 418 32 67

Russia

o.o.o. bioMérieux

Derbenevskaya ul. 20, str. 11

115 114 Moscow

tel. (7) 495 221 10 79

fax (7) 495 221 10 79

Spain

bioMérieux España S.A.

Manual Tovar, 45–47

28034 Madrid

tel. (34) 91 358 11 42

fax (34) 91 358 06 29

Sweden

bioMérieux Sverige AB

Hantverksvägen 15

436 33 Askim

tel. (46) 31 68 84 90

fax (46) 31 68 48 48

Switzerland

bioMérieux Suisse s.a.

51, avenue Blanc

Case postale 2150

1211 Genève 2

tel. (41) 22 906 57 60

fax (41) 22 906 57 42

Taiwan

Representation Office

bioMérieux China Limited

Taiwan Branch

RM 608, No. 6-3 Ching Cheng Street

Taipei 105

tel. (886) 2 2545 2250

fax (886) 2 2545 0959

Thailand

bioMérieux Thailand Ltd

Regent House Bldg, 16th Floor

183 Rajdamri Road, Lumpini,

Pathumwan

Bangkok 10330

tel. (66) 2 651 98 00

fax (66) 2 651 98 01

Turkey

bioMérieux Diagnostik A.S.

ğirmen Sok. Nida Plaza Kat:6

De

34742 Kozyata

tel. (90) 216 444 00 83

fax (90) 216 373 16 63

United Kingdom

bioMérieux UK Ltd

Grafton Way, Basingstoke

Hampshire RG22 6HY

tel. (44) 1256 461881

fax (44) 1256 816863

USA

bioMérieux, Inc.

100 Rodolphe Street

Durham NC 27712

tel. (1) 919 620 2000

Vietnam

Representation Office

bioMérieux Vietnam

Room 4A, 4th Floor

Green House Building

62A Pham Ngoc Thach Street, Ward 6

District 3

Ho Chi Minh City

tel. (84) 88 209 906

ği-Istanbul

Manual Name ii

702358-4EN1 REV nn/nnnn

Page 4

Liability Disclaimer

bioMérieux, Inc. makes no express or implied warranty

regarding this manual, its quality, performance, or appropriate

use regarding any type of specific procedure.

Furthermore, this manual may be modified by bioMérieux

without notice and without implying any obligation or liability on

the part of the company.

Intellectual Property

bioMérieux, the blue logo, bioLIAISON and VITEK are used,

pending and/or registered trademarks belonging to bioMérieux

SA or one of its subsidiaries.

© 2008 by bioMérieux, Inc. All rights reserved.

No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any

language (human or computer) in any form, or by any means

whatsoever, without the prior express written permission of

bioMérieux, Inc.

Patent Information

Product covered by one or more of U.S. Patent Numbers

D377,455; 5,670,375; 5,674,454; 5,697,409; 5,736,102;

5,762,873; 5,762,874; 5,798,084; 5,798,085; 5,853,666;

5,853,667; 5,856,193; 5,869,006; 5,881,781; 5,888,455;

5,891,396; 5,897,835; 5,925,884; 5,955,736; 5,965,090;

6,024,921; 6,086,824; 6,136,270; 6,156,565; D414,272;

D437,797; 5,609,828; 5,746,980; 5,804,437; 5,869,005;

5,932,177; 5,951,952; 6,267,929; 6,309,890; 6,340,573;

D397,611; D393,592; and Foreign Counterparts.

Page 5

Warranty

Seller, bioMérieux, Inc., warrants the VITEK® 2 instrument (the

“instrument”) to the original purchaser for a period of one (1)

year after date of installation against defects in material and

workmanship and defects arising from failure to conform to

specifications applicable on the date of installation. Seller

further agrees to correct, either by repair, or, at its election, by

replacement, any such defect found on examination to have

occurred, under normal use and service, during such one (1)

year period, provided Seller is promptly notified in writing upon

discovery of such defect.

Seller shall not be liable under this Warranty for any defect

arising from abuse of the system, failure to operate and

maintain the system in accordance with the documentation

included with the Instrument, including repair service, alteration

or modification of the system by any person other than service

personnel of bioMérieux, Inc., or Seller; or use of modified,

changed, or previously used disposables.

The Warranty of Seller set forth above and the obligations

and liabilities of Seller thereunder are exclusive and in lieu

of all other remedies or warranties, express or implied,

arising by law or otherwise, with respect to the system

delivered hereunder (including without limitation any

obligation of Seller with respect to merchantability, fitness

for particular purpose, and consequential damages, and

whether or not occasioned by Seller’s negligence).

This Warranty shall not be extended or altered except by written

instrument signed by Seller.

All of the product elements in the Seller’s Instrument and the

total instrument are warranted to be new or equivalent to new

for the full product warranty period of one year. Disposables

and replacement items with a normal life expectancy of less

than one (1) year, such as batteries and bulbs, are excluded

from this warranty.

Page 6

Page 7

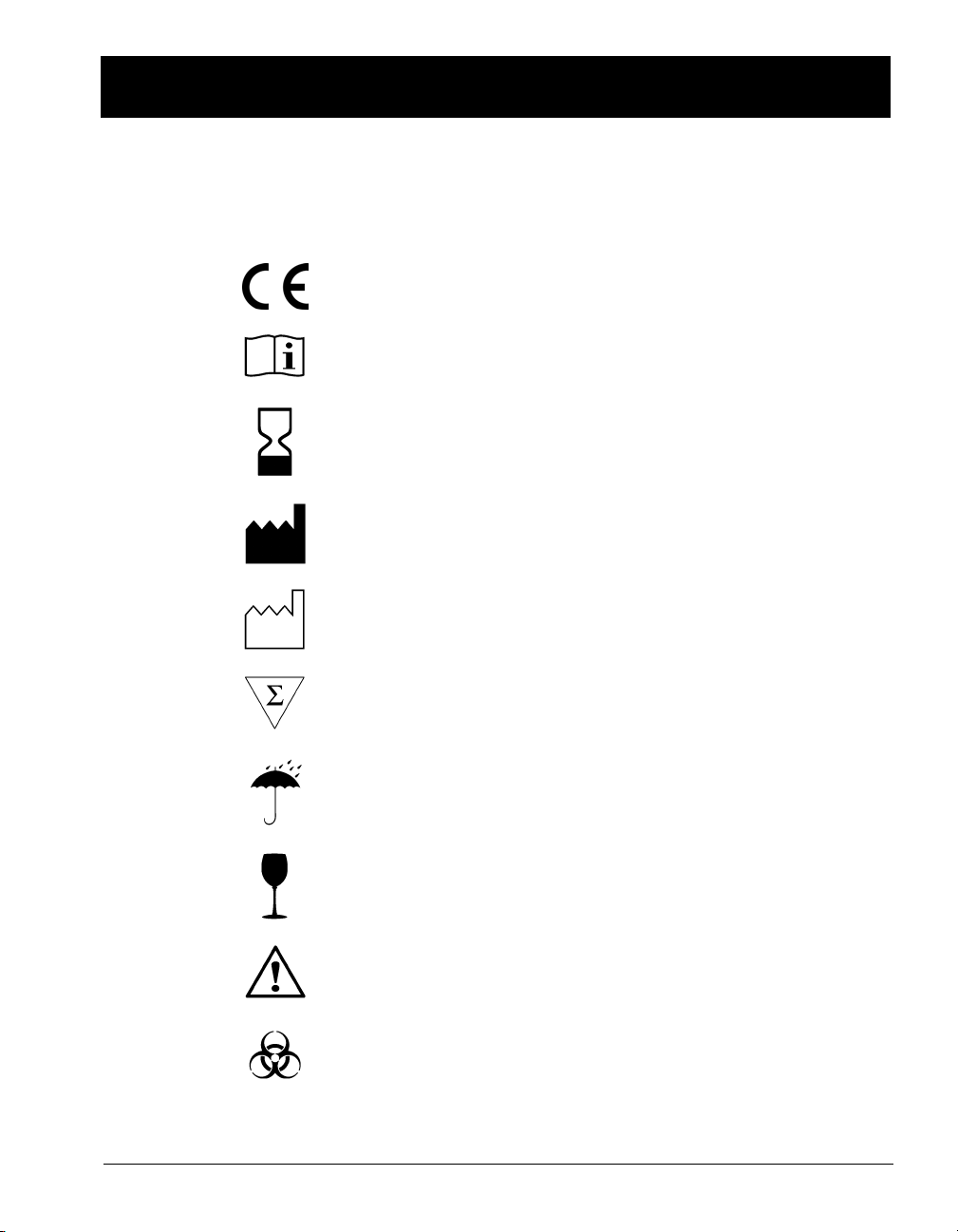

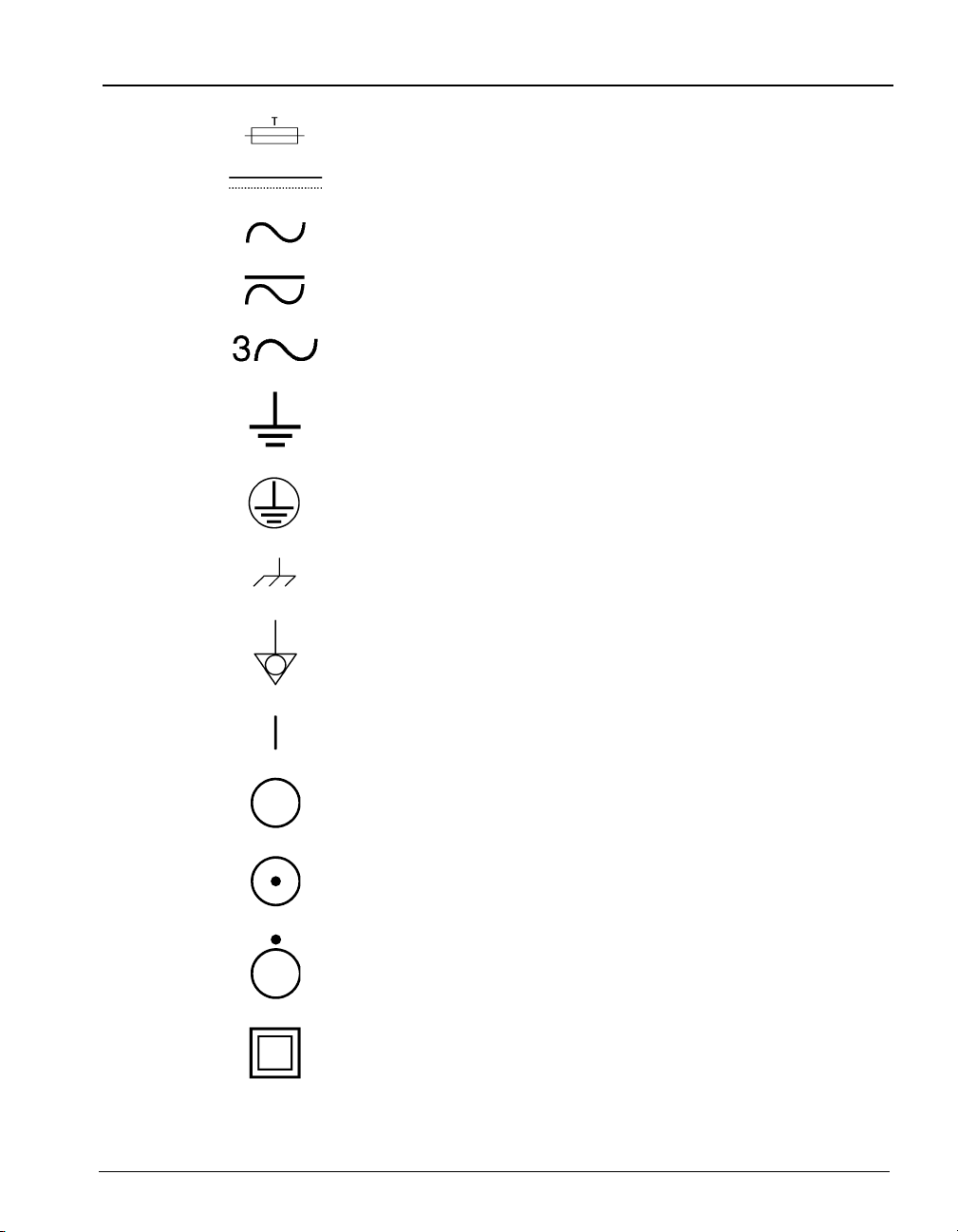

STANDARD SYMBOLS

The following table presents symbols that may appear in the instructions for

use or on the instrument, package inserts, or packaging.

CE-Marking of Conformity

Consult Instructions for Use

Use by

Manufacturer

Date of manufacture

Contains sufficient for <n> tests

Keep dry

Fragile, handle with care

Caution, consult accompanying documents

Biological risks

Manual Name i

702357-3EN1 REV nn/nnnn

Page 8

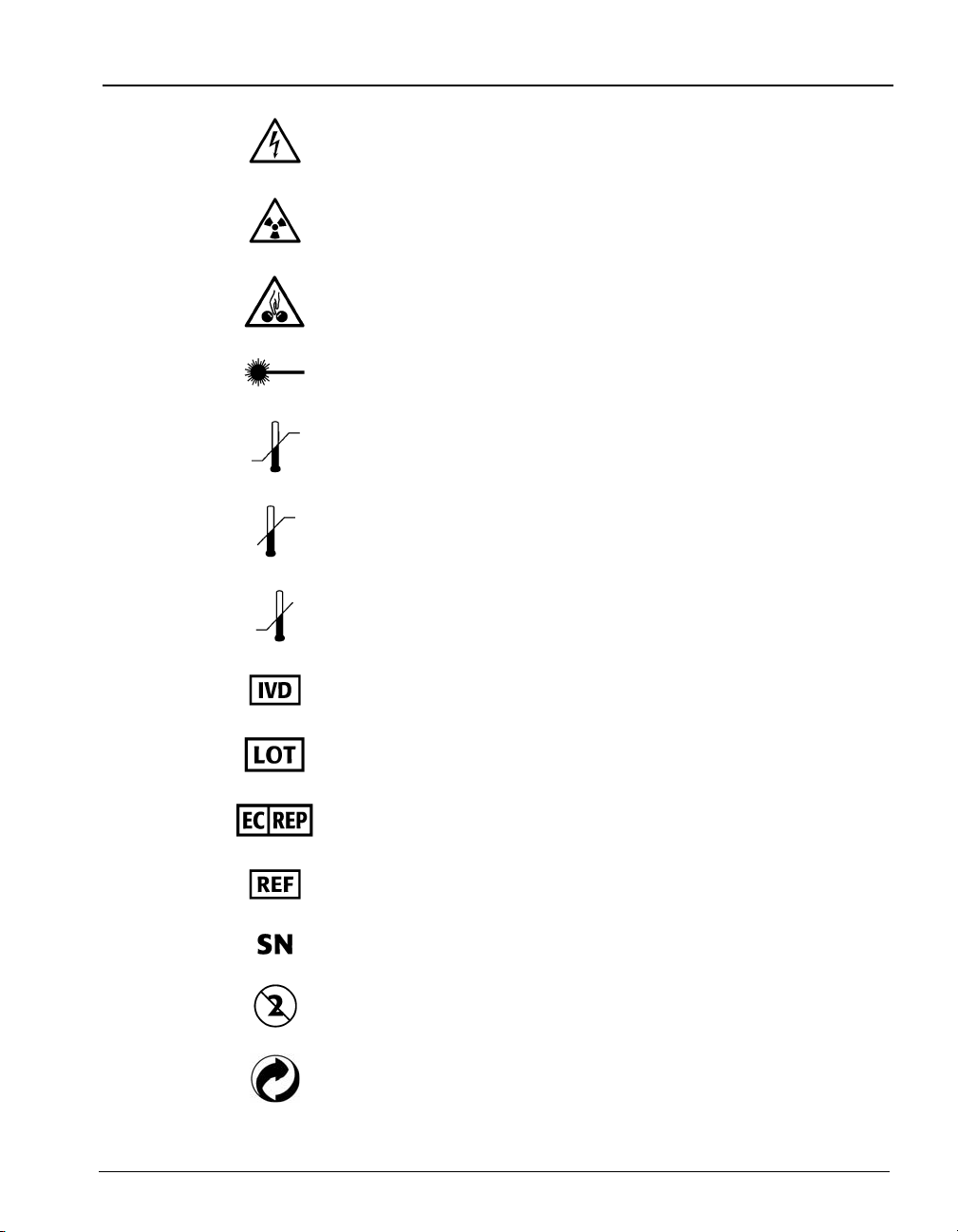

Electric shock warning

Radiation warning

Potential pinch-point warning

Laser

Temperature limitation

Upper limit of temperature

Lower limit of temperature

Standard Symbols

In Vitro Diagnostic Medical Device

Batch code

Authorized Representative in the European Community

Catalog number

Serial Number

Do not reuse

Recyclable

ii Manual Name

702357-3EN1 REV nn/nnnn

Page 9

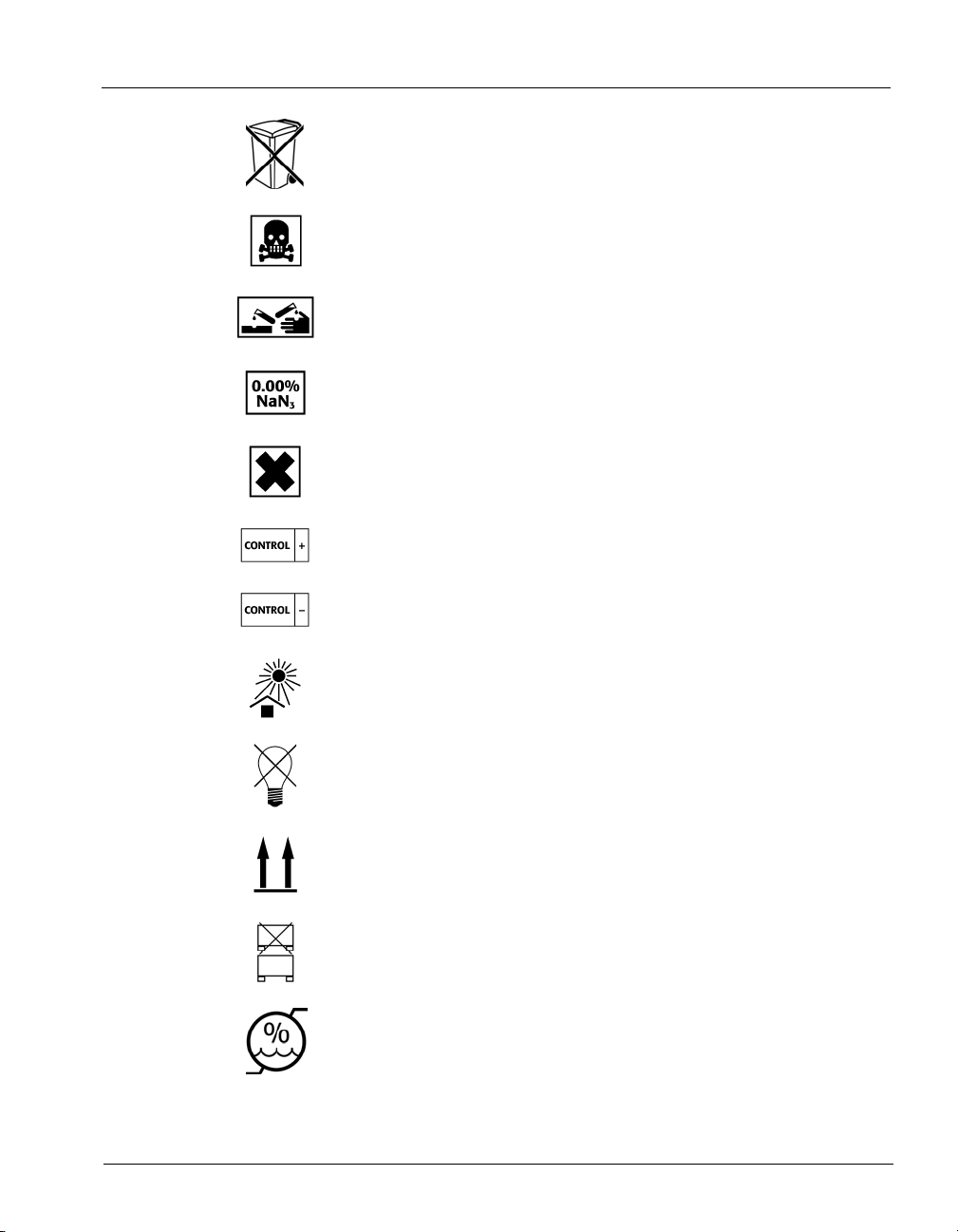

Standard Symbols

Separate collection for waste electrical and electronic

equipment

Very toxic

Corrosive

Sodium azide

Irritant

Positive control

Negative control

Keep away from sunlight

Protect from light

This way up

Do not stack

Humidity limitation

Manual Name iii

702357-3EN1 REV nn/nnnn

Page 10

Fuse

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective conductor terminal

Frame or chassis terminal

Standard Symbols

Equipotentiality

ON (supply)

OFF (supply)

ON (only for a component of the system equipment)

OFF (only for a component of the system equipment)

Equipment protected throughout by double insulation or

reinforced insulation (Equivalent to Class II of IEC 536)

iv Manual Name

702357-3EN1 REV nn/nnnn

Page 11

GENERAL WARNINGS

IMPORTANT: The user is advised to read and understand all instructions in this

manual to be able to derive the best performance from the VITEK® 2

instrument and the Smart Carrier Station.

IMPORTANT: The configuration that you have purchased is adapted to the legislation

and standards of the different countries it will be sent to. For this

reason, it may differ from the one presented in this document. However,

this will have no effect on the performance of your VITEK® 2 instrument

or the Smart Carrier Station. For further information on peripherals

(computer, printer, monitor, etc.) please refer to the relevant

manufacturers’ instruction manuals.

IMPORTANT: If either the VITEK® 2 instrument or the Smart Carrier Station does not

respond properly to keyboard inputs after an inadvertent electrostatic

discharge or electrical fast transient, turn the power off, then back on

using the power switch and resume normal operations.

VITEK® 2 Instrument User Manual i

510731-10EN1

Page 12

General Warnings

General Warnings

BIOHAZARD WARNING

This instrument may be involved with hazardous organism

suspensions. This user manual does not purport to address all

of the safety matters associated with the instrument’s use. It is

the responsibility of the user of this instrument to establish and

follow appropriate safety and health practices and to determine

the applicability of regulatory limitations prior to use.

BIOHAZARD WARNING

All organism suspensions should be considered as potentially

infectious. Qualified laboratory personnel should use

acceptable procedures for biohazardous material.

LASER WARNING

All access doors and covers must remain closed when

processing cards to avoid exposure to laser light.

AMBIENT LIGHT/DIRECT SUNLIGHT WARNING

The transmittance optics are sensitive to ambient light. Ensure

all access doors are closed when cards are processing in the

instrument. Do not place the instrument in direct sunlight.

Strong light shining onto the front of the instrument can cause

the optics to read incorrectly.

ii VITEK® 2 Instrument User Manual

510731-10EN1

Page 13

General Warnings

WARNING

This statement only applies to European countries with regard

to the waste electrical and electronic equipment European

directive:

You can play an important role in contributing to reuse,

recycling and other forms of recovery of waste electrical and

electronic equipment. Sorting this type of waste significantly

reduces potential negative effects on the environment and

human health as a result of the presence of hazardous

substances in electrical and electronic equipment.

At the end of the life cycle of this product, do not dispose of the

product as unsorted municipal waste, even if it is

decontaminated. It is imperative that you contact bioMérieux to

assure for its appropriate disposal.

VITEK® 2 Instrument User Manual iii

510731-10EN1

Page 14

General Warnings

Laser Caution

A laser caution label appears on the VITEK® 2 and VITEK® 2 XL at the

following locations:

VITEK® 2 VITEK® 2 XL

• on the front access door • on the left front access door

• on the inside panel behind the

• above the center front sliding door

front access door

• behind the waste collection door • behind the right side waste

collection door

The label appears as shown here:

CAUTION

Laser light when open.

DO NOT STARE INTO BEAM.

530520-2

iv VITEK® 2 Instrument User Manual

510731-10EN1

Page 15

TABLE OF CONTENTS

General Warnings ........................................................................................................i

General Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Laser Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

List of Tables ............................................................................................................xiii

List of Figures ...........................................................................................................xv

How To Use This Manual........................................................................................ 1-1

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How to Find Topics and Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typographic and Usage Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Graphical User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Click . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Names and Titles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Screen Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

User Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Warnings, Cautions, and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Smart Carrier Station .............................................................................................. 2-1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Preparations for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Smart Carrier Station Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SCS Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

SCS Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

System Physical and Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Setup Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

SCS Configuration .................................................................................................. 3-1

Configuration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

VITEK® 2 Instrument User Manual v

510731-10EN1

Page 16

Table of Contents

When to Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Accessing Configuration Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

SCS Main Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cassette ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting Cassette ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Setup Technologist ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Setup Technologist ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Bench Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Bench Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

SCS Workflow Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

AST Dilution Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Setting AST Dilution Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Erase Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting Cassette Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Begin Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting Begin Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

SCS Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting SCS Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Audible Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting Audible Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Host Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Changing Host Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting SCS Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

SCS Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

®

VITEK

2 Instrument ............................................................................................... 4-1

External Instrument Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Controls, Access Doors and Connections . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Turning on the VITEK

®

2 Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Instrument Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Smart Carrier Station (SCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cassette Load and Unload Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Boats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Bar Code Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Button Memory Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Dispenser/Pipettor Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

vi VITEK® 2 Instrument User Manual

510731-10EN1

Page 17

Table of Contents

Pipettor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Displacement Pump Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Filler Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Sealer Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Test Card Incubation and Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Carousel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Transmittance Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Card Ejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Waste Collection Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

User Interface System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Keypad and Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Configuring the VITEK

®

2 Instrument ................................................................... 5-1

Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cassette Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Instrument Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Schedule Instrument QC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cassette Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Dilution Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Bar Code Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Audible Alarm Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Audible Alarm Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Visual Alarm Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Audible Feedback Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Screen Contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Waste Tray Warning Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Using the Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Defining Character Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Setting Time for QC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Using Option Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Setting a Range Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

®

Processing VITEK

2 Test Cards........................................................................... 6-1

Instrument Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Displaying the Status Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Instrument Status Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Non Standard Card Reading Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Card Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Cassette Name Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

VITEK® 2 Instrument User Manual vii

510731-10EN1

Page 18

Table of Contents

Dilution Mode Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Status Screen Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Monitoring Pipette Tips and Saline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

®

VITEK

2 Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Frequently Used Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

About the Smart Carrier Station (SCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Advantages of Using SCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Cassette Edit Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Understanding the Slot Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

SCS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Option Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Organism ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Gram Positive Susceptibility Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Offline Test Result Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

ANC Identification Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Offline Test Result Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Gram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Morphology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Aerotolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Modifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Selecting an Entry Using an Option Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Bar Code Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Processing Test Cards Using the Smart Carrier Station . . . . . . . . . . . . . . . . . 6-16

Configuration Options for Smart Carrier Workflow . . . . . . . . . . . . . . . . . . 6-16

Smart Carrier Workflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Entering Test Information With SCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Correct Positioning of AST Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Loading a Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Using the Cassette Load Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Loading a Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Monitoring Card Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Tracking Cassettes and Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Processing Test Cards in Cassette Only Mode . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Configuration Options in Cassette Only Mode . . . . . . . . . . . . . . . . . . . . . 6-21

Cassette Only Mode Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Cassette Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Printing a Cassette Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Using the Cassette Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Correct Positioning of Susceptibility Test Cards. . . . . . . . . . . . . . . . . . . . . . . .6-24

Using the Cassette Setup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Loading a Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Using the Cassette Load Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Loading a Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Monitoring Test Card Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Entering Data for a Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

viii VITEK® 2 Instrument User Manual

510731-10EN1

Page 19

Table of Contents

Tracking Cassettes and Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Batch Loads (Smart Carrier or Cassette Only Mode) . . . . . . . . . . . . . . . . . . . 6-28

Selecting Batch Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Starting a Batch Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Unloading the Cassette and Removing Waste . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Unloading a Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Removing Ejected Test Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Removing the Waste Collection Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Replacing the Waste Collection Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Maintaining the VITEK® 2 Instrument.................................................................... 7-1

Maintaining Disposables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Monitoring the Disposables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Interpreting the Graphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using the Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Expiration of Disposables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

The Dispenser/Pipettor Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Installing an Accessory Kit, Part A: Saline and Tubing . . . . . . . . . . . . . . . 7-4

Installing an Accessory Kit, Part B: Pipette Tips . . . . . . . . . . . . . . . . . . . . 7-8

Cleaning the Carousel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Removing the Carousel for Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Carousel Cleaning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Replacing the Carousel After Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Cleaning the Cassettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Replacing the Button Memory Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Cleaning the Boats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Removing Boats for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Cleaning the Boats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Replacing Boats after Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Cleaning the Instrument Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Shutting Down the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Cleaning the Test Card Collection Tray . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Cleaning Optics (Normal Maintenance). . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Cleaning the Base Pan, Vacuum Seal and Vacuum Chamber . . . . . . . . 7-28

Cleaning the Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Removing the Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Cleaning the Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Replacing the Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Turning the Instrument On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Cleaning the SCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

VITEK® 2 Instrument User Manual ix

510731-10EN1

Page 20

Table of Contents

Troubleshooting the VITEK® 2 Instrument ........................................................... 8-1

Error Handling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Error Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Types of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Status Screen Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Instrument Halted Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Reviewing an Instrument Halted Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Resolving a Transport Halted Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Message Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Reviewing a Message Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Error Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Reviewing an Error Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Cassette Load Processing Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Types of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Workflow Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Bar Code Read Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Resolving Bar Code Read Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

SCS and Bar Code Reader Conflict . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Resolving SCS and Bar Code Reader Conflicts. . . . . . . . . . . . . . . . . . . . . . . .8-13

Inoculum Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Resolving an Inoculum Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-15

Card Capacity Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Resolving a Card Capacity Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

Disposables Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

How to Resolve a Disposables Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

Working Without the Bar Code Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Entering Bar Codes Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Disabling the Bar Code Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

Entering Bar Codes Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

Instrument Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Instrument Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Checking the Instrument Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-19

Dispenser/Pipettor Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

Dispenser/Pipettor Volumetric Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-21

Cleaning Optics (Cards Processing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Optical Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Boat Transport Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Displaying Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Using Error Message and Recovery Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Restarting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

x VITEK® 2 Instrument User Manual

510731-10EN1

Page 21

Table of Contents

Appendix A: Hardware Specifications ..................................................................A-1

®

VITEK

2 Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Optical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Transmittance Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Pipettor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Vacuum (Filler) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Incubator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Glossary......................................................................................................Glossary-1

Index.................................................................................................................. Index-1

Notes ................................................................................................................ Notes-1

VITEK® 2 Instrument User Manual xi

510731-10EN1

Page 22

Table of Contents

xii VITEK® 2 Instrument User Manual

510731-10EN1

Page 23

LIST OF TABLES

Table 2-1: Physical Characteristics .....................................................................................2-9

Table 2-2: Electrical Requirements .....................................................................................2-9

Table 2-3: Environmental Requirements .............................................................................2-9

Table 2-4: Bar Code Scanner Model References .............................................................2-11

Table 3-1: SCS Configuration Options ................................................................................3-2

Table 4-1: Components Involved in the Test Card Processing Cycle .................................4-5

Table 4-2: Indicator Light States .........................................................................................4-7

Table 5-1: Configuration Options that Affect Instrument Operation ....................................5-2

Table 5-2: Configuration Options that Affect Only Physical Parameters .............................5-2

Table 5-3: Types of Interfaces for Configuration Options ...................................................5-8

Table 6-1: Optical Configurations ........................................................................................6-5

Table 6-2: Summary of SCS Functions .............................................................................6-13

Table 6-3: Processing Test Cards (Using the Smart Carrier) ............................................6-17

Table 6-4: Data Entry Methods (Smart Carrier Mode) ......................................................6-18

Table 6-5: Cassette Load Parameters (Smart Carrier Mode) ...........................................6-19

Table 6-6: Card Identity Components (Smart Carrier Mode) ............................................6-21

Table 6-7: Processing Test Cards (Cassette Only Mode) .................................................6-22

Table 6-8: Cassette Load Parameters (Cassette Only Mode) ..........................................6-25

Table 6-9: Card Identity Components (Cassette Only Mode) ...........................................6-27

Table 8-1: Dispenser/Pipettor Volumetric Test .................................................................8-22

Table 8-2: Error Message and Recovery Table ................................................................8-30

VITEK® 2 Instrument User Manual xiii

510731-10EN1

Page 24

List of Tables

xiv VITEK® 2 Instrument User Manual

510731-10EN1

Page 25

LIST OF FIGURES

Figure 2-1: Smart Carrier Station .........................................................................................2-2

Figure 2-2: SCS – Cable Connections .................................................................................2-4

Figure 2-3: Initial SCS Screen ..............................................................................................2-6

Figure 2-4: The Smart Carrier Station ..................................................................................2-7

Figure 2-5: The SCS Keyboard ............................................................................................2-8

Figure 2-6: SCS Firmware Update Screen .........................................................................2-10

Figure 2-7: Bar Codes for Bar Code Scanner – A ..............................................................2-13

Figure 2-8: Bar Codes for Bar Code Scanner – B ..............................................................2-14

Figure 2-9: Bar Codes for Bar Code Scanner – C ..............................................................2-15

Figure 2-10: Bar Codes for Bar Code Scanner – D ..............................................................2-16

Figure 3-1: SCS Main Configuration Screen ........................................................................3-3

Figure 3-2: SCS Workflow Configuration Screen .................................................................3-5

Figure 3-3: SCS Utilities Screen ...........................................................................................3-7

Figure 3-4: SCS Firmware Update Screen ...........................................................................3-9

Figure 4-1: The VITEK

Figure 4-2: VITEK® 2 XL Instrument ....................................................................................4-2

Figure 4-3: Cassette Components .......................................................................................4-6

Figure 4-4: The Cassette Load/Unload Station ....................................................................4-7

Figure 4-5: Boat Components ..............................................................................................4-9

Figure 4-6: Dispenser System ............................................................................................4-11

Figure 4-7: Disposable Pipettes .........................................................................................4-12

Figure 4-8: Carousel Placement .........................................................................................4-15

Figure 4-9: Carousel Reader Head ....................................................................................4-15

Figure 4-10: Optics ...............................................................................................................4-16

Figure 4-11: Waste Collection Station ..................................................................................4-17

Figure 4-12: The VITEK

Figure 5-1: The Instrument QC Status Screen .....................................................................5-4

Figure 5-2: VITEK® 2 Main Menu .........................................................................................5-9

Figure 5-3: Cassette Names Configuration Screen ..............................................................5-9

Figure 5-4: Character Selection Screen .............................................................................5-10

Figure 5-5: Schedule QC Status Screen ............................................................................5-11

®

2 60 Instrument .............................................................................4-2

®

2 Keypad and Screen ..................................................................4-18

VITEK® 2 Instrument User Manual xv

510731-10EN1

Page 26

List of Figures

Figure 5-6: Option Box Screen .......................................................................................... 5-12

Figure 5-7: Range Value Screen ....................................................................................... 5-12

Figure 6-1: VITEK

®

2 Status Screen in Cassette Only Mode .............................................. 6-3

Figure 6-2: VITEK® 2 Status Screen in Non Standard Card Reading Mode ....................... 6-4

Figure 6-3: Pipette Tips Status ............................................................................................ 6-7

Figure 6-4: VITEK

®

2 Main Menu ........................................................................................ 6-7

Figure 6-5: Detailed Structure of the VITEK® 2 Menu System ............................................ 6-8

Figure 6-6: Previous Screen Key ......................................................................................... 6-9

Figure 6-7: Fields of the Cassette Edit Screen .................................................................. 6-11

Figure 6-8: Organism ID Options ....................................................................................... 6-14

Figure 6-9: Offline Tests Option Box ................................................................................. 6-15

Figure 6-10: Offline Test Result Screen .............................................................................. 6-15

Figure 6-11: Correct Orientation of Cassettes ..................................................................... 6-20

Figure 6-12: Cassette Worksheet ........................................................................................ 6-23

Figure 6-13: Cassette Setup Screen ................................................................................... 6-24

Figure 6-14: Correct Orientation of Cassette ....................................................................... 6-26

Figure 6-15: Batch Load Screen .......................................................................................... 6-29

Figure 6-16: Smart Carrier Mode Batch Load Screen ......................................................... 6-29

Figure 6-17: Cassette Only Mode Batch Load Screen ........................................................ 6-30

Figure 6-18: The Waste Collection Station .......................................................................... 6-32

Figure 7-1: VITEK

®

2 Status Screen ................................................................................... 7-3

Figure 7-2: Location of Saline Dispensing Chamber ........................................................... 7-5

Figure 7-3: Cannula and Tubing Assembly ......................................................................... 7-6

Figure 7-4: Saline Dispensing Chamber .............................................................................. 7-6

Figure 7-5: Saline Fill Line ................................................................................................... 7-7

Figure 7-6: Location of Pipettor Tip Container ..................................................................... 7-8

Figure 7-7: Pipette Tip Replacement ................................................................................... 7-9

Figure 7-8: VITEK

Figure 7-9: VITEK

®

2 XL Carousel Cleaning Screen ........................................................ 7-11

®

2 XL Preparing for Section Removal Screen ..................................... 7-11

Figure 7-10: Machined Incubator Access Cover ................................................................. 7-12

Figure 7-11: Molded Incubator Access Cover ..................................................................... 7-13

Figure 7-12: Carousel Cleaning Prompt .............................................................................. 7-13

Figure 7-13: Removing a Carousel Section ......................................................................... 7-14

Figure 7-14: Machined Incubator Access Cover ................................................................. 7-16

xvi VITEK® 2 Instrument User Manual

510731-10EN1

Page 27

List of Figures

Figure 7-15: Molded Incubator Access Cover ......................................................................7-16

Figure 7-16: Carousel Cleaning Replace Section Now Screen ............................................7-17

Figure 7-17: Orientation of the Carousel ..............................................................................7-17

Figure 7-18: Removing the Button Memory Module .............................................................7-20

Figure 7-19: Metal Contacts on Cassette .............................................................................7-20

Figure 7-20: Replacing the Button Memory Module .............................................................7-21

Figure 7-21: Boat Cleaning Prompt ......................................................................................7-22

Figure 7-22: Positioning of Boat ...........................................................................................7-24

Figure 7-23: Optics ...............................................................................................................7-27

Figure 7-24: Opening the Optics ..........................................................................................7-27

Figure 7-25: Vacuum Seal ....................................................................................................7-29

Figure 7-26: Drip Pan Handle ...............................................................................................7-30

Figure 7-27: SCS Base Unit Metal Contacts ........................................................................7-32

Figure 8-1: VITEK

®

2 Error Handling System ......................................................................8-3

Figure 8-2: Instrument Halted Status Screen .......................................................................8-5

Figure 8-3: Transport Halted Screen (VITEK

®

2) .................................................................8-7

Figure 8-4: Transport Halted Screen (VITEK® 2 XL) ............................................................8-7

Figure 8-5: VITEK

®

2 Status Screen ....................................................................................8-8

Figure 8-6: Message Queue .................................................................................................8-9

Figure 8-7: Bar Code Error Message .................................................................................8-12

Figure 8-8: Resolving Bar Code Errors ..............................................................................8-12

Figure 8-9: Card Type Error Message ................................................................................8-14

Figure 8-10: Inoculum Source Error Message .....................................................................8-15

Figure 8-11: Card Capacity Warning Message ....................................................................8-16

Figure 8-12: Bar Code Reader Screen .................................................................................8-18

Figure 8-13: Temperature Diagnostics Screen (VITEK

Figure 8-14: Temperature Diagnostics Screen (VITEK

®

2 XL) ............................................8-19

®

2) ..................................................8-20

Figure 8-15: Optics ...............................................................................................................8-24

Figure 8-16: Opening the Optics ..........................................................................................8-25

Figure 8-17: Boat Transport Positions ..................................................................................8-27

Figure 8-18: Version Information Screen .............................................................................8-29

VITEK® 2 Instrument User Manual xvii

510731-10EN1

Page 28

List of Figures

xviii VITEK® 2 Instrument User Manual

510731-10EN1

Page 29

HOW TO USE THIS MANUAL

Introduction

This chapter gives you important information about how to use this manual.

bioMérieux recommends that you read this chapter first.

IMPORTANT: Read this manual carefully before you attempt to operate the VITEK®2

system.

Chapter Contents

Organization • 1-2

Printed Documentation • 1-2

Intended Use • 1-2

How to Find Topics and Procedures • 1-3

Typographic and Usage Conventions • 1-3

References • 1-3

Graphical User Interface • 1-3

Warnings, Cautions, and Information • 1-5

1

VITEK® 2 Instrument User Manual 1-1

510731-10EN1

Page 30

Organization How To Use This Manual

Organization

The manual is separated into four basic parts:

• Part 1, which includes Chapter 2 and Chapter 3, covers the Smart Carrier

Station. Chapter 2 describes the hardware and Chapter 3 provides the

procedures you use to configure this station for your laboratory workflow.

• Part 2, which includes Chapter 4 and Chapter 5, covers the VITEK

Instrument. Chapter 4 describes the hardware and Chapter 5 shows you

how to configure the instrument’s user interface.

®

2

• Part 3, including only Chapter 6, is the primary part of the manual. It

• Part 4, consisting of Chapter 7 and Chapter 8, provides troubleshooting

Documentation

The documentation for the VITEK® 2 system consists of this manual and

VITEK

that the computer workstation may be in a different location than the VITEK

2 instrument and Smart Carrier Station.

• This manual covers the VITEK

•The VITEK

Intended Use

describes all of the procedures you need to follow to process VITEK

®

2 test

cards. The chapter contains two subparts, one each to describe test card

processing with, and without, a Smart Carrier Station.

and maintenance procedures for the VITEK

®

2 Systems Product Information. This division allows for the possibility

®

2 instrument and the Smart Carrier

®

2 instrument.

Station, including both the hardware and the programmed user interfaces.

®

2 Systems Product Information contains information about the

test cards, including culture techniques, analytical techniques, and

performance characteristics.

®

The VITEK® 2 and Smart Carrier Station (SCS) have applications as in vitro

diagnostic medical devices.

1-2 VITEK® 2 Instrument User Manual

510731-10EN1

Page 31

How To Use This Manual How to Find Topics and Procedures

How to Find Topics and Procedures

There are four tools to help you find a topic or procedure in the manual.

• General Table of Contents. This table is located in the front of the manual

and includes the entire document. You can use this table to locate major

headings throughout the manual. The table also includes a List of Tables

and a List of Figures.

• Chapter Table of Contents. Each of the succeeding chapters begin with

their own tables of contents. They contain the same information as the

general table for the manual, but have the advantage of addressing only

what is in that chapter.

• Page Headers. Each page in the manual has a header, which can serve as

a visual aid to help you find a topic. The inside portion of the header, the

side closest to the binding, always shows the chapter title. The outside

portion of the header shows the title of the current section.

• Index. Found at the end of the manual, the Index is the most useful device

for finding individual topics throughout the manual.

Typographic and Usage Conventions

References

References to chapter and section titles in this manual are in Proper Case.

Example: See Chapter 5, Configuring the VITEK

References to other manuals are in Proper Case and italic font.

®

Example: See the VITEK

Graphical User Interface

Click

The term “click” refers to moving a mouse pointer to choose or select a

command, window, button or option, then pressing the left, or primary, mouse

button to initiate action in the software.

Example: Click OK

Commands

Menu, keyboard and button commands are in proper case, bold.

2 Systems Product Information.

®

2 Instrument.

VITEK® 2 Instrument User Manual 1-3

510731-10EN1

Page 32

Typographic and Usage Conventions How To Use This Manual

Example: File > Quit menu command

Names and Titles

The names and titles of menus, dialog boxes, fields, icons and toolbar

buttons are in proper case, bold.

Example: Setup menu

The names of windows are in proper case, but are not bold.

Example: Configuration window

Press

The term “press” refers to holding down a key on the keyboard in order to

initiate action in the software.

Example: Press Enter

Select

The word “select” is generally used for selecting menus, menu commands

and GUI navigation.

Screen Text

User Input

Example: Select File > Quit

Text that appears on the screen will be shown in a monotype font.

Example: Saline Test in Progress

Instructions for user input begin with the word “type” or “enter.” These

instructions use bold for literal user input and italic for placeholders.

Example of literal user input: Login as micb, and password micb

In this example, type exactly what you see on the page (micb in this

example).

Example of a placeholder: Enter your password before you...

In this example, type your assigned password.

1-4 VITEK® 2 Instrument User Manual

510731-10EN1

Page 33

How To Use This Manual Typographic and Usage Conventions

Warnings, Cautions, and Information

This manual uses different types of symbols to alert you to important

information. Symbols and their associated information are labeled in text

where they occur and set off from surrounding paragraphs, as shown in the

following examples.

WARNING

Warning is a statement that alerts the user to the possibility of

injury, death, or other serious adverse reactions associated

with the use or misuse of a device.

CAUTION: Caution is a statement that alerts the user to the

possibility of a problem with the device associated with its use

or misuse. Such problems include device malfunction, device

failure, damage to the device, or damage to other property.

Where applicable, a caution statement may include a precaution

that should be taken to avoid the hazard.

IMPORTANT: Important relates to content presented in this manual. It is used to

reinforce the importance of your understanding or remembering

something.

Note: Note supplies additional information about a topic.

VITEK® 2 Instrument User Manual 1-5

510731-10EN1

Page 34

Typographic and Usage Conventions How To Use This Manual

1-6 VITEK® 2 Instrument User Manual

510731-10EN1

Page 35

SMART CARRIER STATION

Introduction

Use this chapter to familiarize yourself with the Smart Carrier hardware. It

includes an overview of each part of the unit.

Chapter Contents

Purpose • 2-2

Unpacking Instructions • 2-2

Unpacking Procedure • 2-3

Installation Procedure • 2-4

Preparations for Operation • 2-5

Smart Carrier Station Overview • 2-6

SCS Keyboard • 2-8

SCS Base Unit • 2-9

System Physical and Electrical Requirements • 2-9

Setup Bar Codes • 2-10

2

VITEK® 2 Instrument User Manual 2-1

510731-10EN1

Page 36

Purpose Smart Carrier Station

Purpose

The purpose of this chapter is to aid in the safe handling, setup, configuration

and operation of the Smart Carrier Station.

Unpacking Instructions

Figure 2-1 shows a Smart Carrier Station (SCS).

1

2

1 — Display Screen

4

3

5

Figure 2-1: Smart Carrier Station

2 — Power Supply

3 — Base Unit

4 — Bar Code Scanner

5 — Keyboard

2-2 VITEK® 2 Instrument User Manual

510731-10EN1

Page 37

Smart Carrier Station Unpacking Instructions

Inspect the shipping container for external damage. If it has been damaged,

inspect the SCS itself for damage. If the SCS has been damaged, file a claim

with the shipper and notify bioMérieux, Inc.

Check the packing list included with the VITEK

required items are included in the shipment.

Note: The packaging materials and shipping container should be retained for future

transportation needs, if necessary.

®

2 System and verify that all

WARNING

This statement only applies to European countries with regard

to the waste electrical and electronic equipment European

directive:

You can play an important role in contributing to reuse,

recycling and other forms of recovery of waste electrical and

electronic equipment. Sorting this type of waste significantly

reduces potential negative effects on the environment and

human health as a result of the presence of hazardous

substances in electric and electronic equipment.

At the end of the life cycle of this product, do not dispose of the

product as unsorted municipal waste, even if it is

decontaminated. It is imperative that you contact bioMérieux to

assure for it’s proper disposal.

Unpacking Procedure

To remove the SCS from its shipping container:

1) Open the shipping carton and remove the unit from the carton.

2) Carefully remove the unit from the packing material. Be sure to remove

all parts and literature from the carton.

3) Remove the remaining packing materials from the SCS and store with

the shipping container.

An electric shock hazard could exist if the enclosure of the SCS

or its external power supply is damaged exposing electrical

components.

WARNING

VITEK® 2 Instrument User Manual 2-3

510731-10EN1

Page 38

Unpacking Instructions Smart Carrier Station

Installation Procedure

After completing the unpacking procedure, the SCS is ready to be placed in

its permanent location. The SCS is intended for use on any normal, flat bench

top, commonly found in a microbiology lab, away from direct sunlight. Some

cables must be connected to the unit. Figure 2-2 shows the cable

connections on the back of the unit.

1

2

3

4

5

Figure 2-2: SCS – Cable Connections

The back panel of the base unit, shown in Figure 2-2, contains the on/off

switch, the power cord receptacle, and the connector ports for various cables.

1 — On/Off Switch

2 — DC Power Receptacle

3 — Receptacle for the Bar Code Scanner

4 — Circular Connector for the SCS Keyboard

5 — Service/Update Cable Connector

2-4 VITEK® 2 Instrument User Manual

510731-10EN1

Page 39

Smart Carrier Station Preparations for Operation

Preparations for Operation

Place the SCS in its permanent location.

WARNING

Do not place the SCS in a location where it could be exposed to

direct sunlight during operation.

Position the instrument to meet the minimum clearance of 5 cm (2 in.) on all

sides and 30.5 cm (12 in.) above the instrument to provide adequate space

for placing cassettes onto the unit.

Use this procedure to begin using the SCS. The unit should be located on a

bench top with room next to it for test cards and specimens. Use Figure 2-2 of

the SCS to locate and identify the various parts referred to in the procedure.

WARNING

An electric shock hazard could exist if the SCS or its external

power supply is immersed in water.

1) Connect the SCS keyboard to its receptacle (4, Figure 2-2) on the back

of the base unit.

2) Connect the bar code scanner to its receptacle (3) on the back of the

base unit.

3) Connect the external power supply cord to the back of the SCS (2) and

the main cord to an AC power outlet.

4) Push the On/Off switch (1) to turn the unit on. The computer takes a few

moments to go through its startup routine.

VITEK® 2 Instrument User Manual 2-5

510731-10EN1

Page 40

Smart Carrier Station Overview Smart Carrier Station

Figure 2-3: Initial SCS Screen

5) When the SCS is ready to be used, the screen shown in Figure 2-3 will

be displayed. If there is no display, switch the power OFF and restart at

Step 2.

Note: If you have not yet customized your configuration settings, the Configuration

screen is displayed. For information on changing the settings, see Chapter 3

in this Manual.

Smart Carrier Station Overview

The Smart Carrier Station (SCS) is a small computer dedicated to collecting

information about test cards and specimens, and for transferring that

information to the VITEK

five main components.

®

2 instrument. The SCS, shown in Figure 2-4, has

2-6 VITEK® 2 Instrument User Manual

510731-10EN1

Page 41

Smart Carrier Station Smart Carrier Station Overview

3

2

1

5

Figure 2-4: The Smart Carrier Station

1 — SCS Base Unit. The SCS base contains the microprocessor. There are

connection ports on the back of the base for the keyboard and the bar code

scanner. The top of the base is specifically shaped to accept a cassette.

Metal contacts on the base connect the unit’s computer to a button memory

chip on the cassette. Ensure that the cassette is fully seated in order to make

an electrical connection to the cassette memory. This memory chip stores the

information you entered to be transferred to the workstation.

4

2 — SCS Display Screen. The display for the SCS is a liquid crystal display

(LCD). Use the display to view and confirm the information you are entering

for the test cards and specimens.

3 — SCS Bar Code Scanner. The SCS is equipped with a bar code scanner

that allows you to enter data with a simple bar code scan rather than

repeated typing. You can scan most data fields. The data appears

automatically on the display. The scanner can be hand-held or used while

mounted in its holder.

4 — SCS Keyboard. The SCS keyboard has a standard set of alphanumeric

keys, plus several specially designed keys for SCS functions. The SCS

VITEK® 2 Instrument User Manual 2-7

510731-10EN1

Page 42

SCS Keyboard Smart Carrier Station

keyboard is smaller than a standard size keyboard, so it can be stored under

the Base Unit.

5 — External Power Supply. The SCS is powered by an external DC power

supply. This power supply accepts 120 VAC to 240 VAC mains power via a

detachable two conductor power cord.

SCS Keyboard

The SCS keyboard has a standard set of alphabetic and numeric keys. It also

has several keys that are uniquely designed for use on the SCS.

Figure 2-5: The SCS Keyboard

Help. Displays context-sensitive help screens and data field option boxes.

Previous Slot/ Next Slot. This key has two functions. When you press the

arrow on the left, the display changes to the Previous Slot. When you press

the arrow on the right, the display changes to the Next Slot.

Shift. Changes case of letter entered on keyboard.

Shift Lock. When Shift Lock is selected, the light next to the shift lock key

goes on and the keypad stays in the upper case mode. Press Shift Lock

again to cancel upper case mode.

2-8 VITEK® 2 Instrument User Manual

510731-10EN1

Page 43

Smart Carrier Station SCS Base Unit

SCS Base Unit

The base unit for the SCS contains the electronic components that make its

data entry and storage functions possible. The power switch and cable

connectors are located on the back panel of the base unit.

The base unit is actually a small computer with its own processing unit,

memory, and software program. However, the program in this computer is

limited to the task of entering and storing data for a cassette.

System Physical and Electrical Requirements