Page 1

USER MANUAL

4501-1671 - C - en

bioMérieux S.A. 69280 Marcy l'Etoile / France

Tel. 33 (0)4 78 87 20 00 - Fax 33 (0)4 78 87 20 90

RCS Lyon 673 620 399

http://www.biomerieux.com

29730

Version C

03/2009

Page 2

Page 3

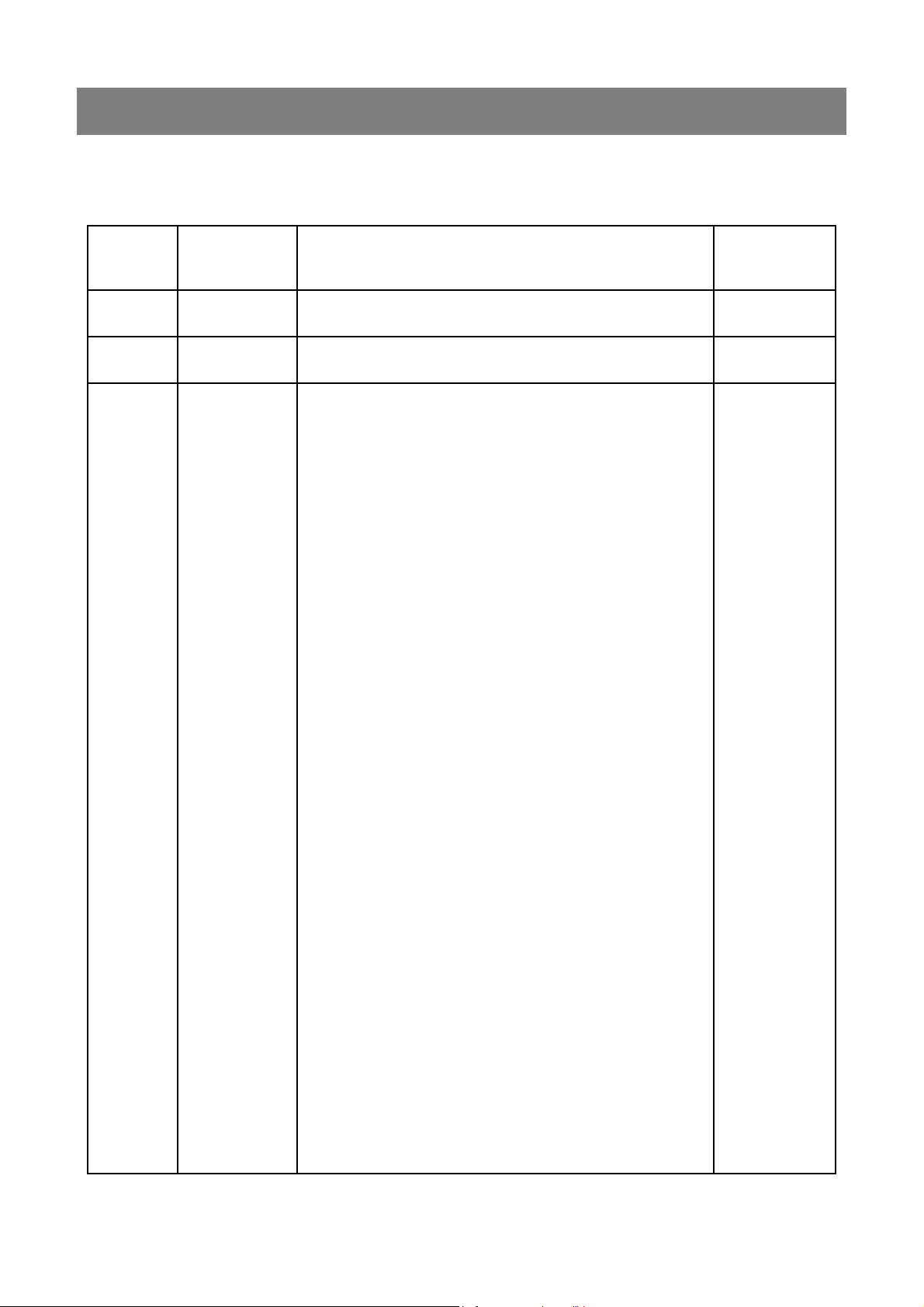

Revisions

The list of revisions below summarizes replacements or additional pages in your User

Manual.

Version Date of printing Modifications Pages modified

A 10/2008 Creation All

B Not used

C 03/2009

− New software version

− Deletion of Modify button

− Addition of information for loading labels

− Modification to Figure 4-21 : Barcode (DOB removed)

− Correction of folder name in Instrument Log Files section

− New Maintenance Menu screenshot

− New order for performing maintenance operations

− Deletion of Label roll length sensing procedure

− Deletion of severity column in List of Error Messages

− Addition of Event no. 20110 in List of Error Messages

− Addition of Event no. 35026 in List of Error Messages

− Additions to Error, Cause and Recovery table

− Updated procedure for replacing the PREVITM Isola HEPA

filter

− New procedure for pipettor decontamination

All

2-24

4-16

4-25

7-6

8-2

8-3 to 8-20

8-28

9-1 to 9-9

9-6

9-9

9-11 to 9-14

9-18 to 9-22

9-23 to 9-24

− New procedure for reinitializing the instrument after the

pipettor descends into a plate on the process station

9-25

Page 4

Page 5

4501-1618 B en

Warning

IMPORTANT! Use of the instrument and manual implies acceptance of the clauses below and the

The contents of this manual are based on the software release V 1.1.

This manual is periodically updated. The updates shall be included in the new releases of the

Software.

Information supplied in this manual may be subject to modifications before the products

described become available.

This manual may contain information or references relating to certain bioMérieux S.A.

products, software or services which are not available in the country of release; this shall not

mean that bioMérieux S.A. intends to market such products, software or services in such

country

To request copies of publications or for any technical request, contact bioMérieux S.A. or your

local distributor.

clauses set out in the regulatory booklet. Users are invited to refer to these clauses.

Trademarks

bioMérieux, the blue logo, PREVI, VITEK and DENSICHEK are used, pending and/or

registered trademarks belonging to bioMérieux S.A. or one of its subsidiaries.

Windows is a trademark belonging to Microsoft.

Monovette is a trademark of Sarstedt AG & Co.

Vacutainer is a trademark of Becton, Dickinson and Company.

ATCC is a trademark of American Type Culture Collection.

Sterilin is a trademark of Bibby Sterilin Ltd.

Microstreak is a trademark of Lab Tech.

Any other name or trademark is the property of its respective owner.

© 2008 - 2009 bioMérieux S.A.

Photos: bioMérieux / Printed in France / bioMérieux S.A. RCS Lyon 673 620 399

Page 6

Page 7

4501-1577 B en

SOFTWARE LICENSE AGREEMENT

User: No.:

Software: Release:

Computer: Brand name:

Printer: Brand name:

Disk player: Brand name:

The use of this Software is strictly governed by the following terms and conditions.

I - Purpose of this Agreement / Rights granted

bioMérieux S.A. hereby grants, to the User who, by using this manual, accepts a non-exclusive

right to use the Software. The license is personal, non transferable, non assignable and does not

comprise the right to grant sub-licenses.

The User expressly agrees, in its own name and behalf as well as in the name and on behalf of its

employees, agents and collaborators, not to make any copy of the Software-except one single

backup copy for archival purposes- display the Software on any computer other than the

Computer, reproduce, sell, rent, lease, modify, adapt, translate or otherwise dispose of, all or part

of the Software, the equipment, the user manual and its related documentation.

Specifically, the User agrees not to decompile, reverse engineer or disassemble all or part of the

Software.

II - Intellectual Property

III - Warranties

All intellectual property rights including patrimonial rights, in and to the Software are and shall

remain bioMérieux S.A. exclusive property, subject to possible third party rights. Consequently,

the User is not entitled to copy or reproduce the Software except as set forth above.

Except as expressly specified above, nothing contained herein shall be construed as conferring to

the User any right, title or interest in and to the Software.

Provided that this Agreement duly signed is received by bioMérieux S.A. within ten (10) business

days from the delivery, bioMérieux S.A. warrants that the Software is free from defect in materials

and workmanship under normal conditions of use during three (3) months from the delivery.

Should any defect occur during such period, bioMérieux S.A. or one of its authorized distributors

in the country of sale shall replace the Software provided that the User makes its request in

writing together with copy of the Software invoice and, as the case may be, the defective media.

Apart from the foregoing, the Software is provided "AS IS" and no warranty, whether express or

implied, of merchantability, safety, quality, or fitness for a particular purpose is given hereunder

nor any warranty that the Software shall not infringe upon the intellectual property rights of any

third party.

The warranty provided herein shall apply provided that Software is used under normal conditions

and to the exclusion of any replacement caused by accidental or willful damage, or misuse of the

software or accident whatsoever.

It is expressly understood that, according to this License, bioMérieux S.A. shall not perform any

service related to the training, assistance or maintenance of the Software unless otherwise

agreed upon between the parties through a separate written agreement setting forth the terms

and conditions (in particular, financial conditions) of such training, assistance or maintenance.

Page 8

IV - Liability

In no event shall bioMérieux S.A. be held liable for any consequences that may arise from any

modifications made to the Software without its intervention, or, should the software be connected

to the user’s network or system, for any malfunctions or damage to the software caused directly

or indirectly by the network or system, in particular in the event of failure of the security system, or

the consequences of installing software on the same hardware as this Software without the

intervention and/or authorisation of bioMérieux S.A.

In no event shall bioMérieux S.A. be liable for any direct, indirect, special, consequential or nonconsequential, incidental, material or immaterial damage (including loss of goodwill, profits, data

or any other economic advantage) related to, arising out of or in connection with, any use of the

Software and/or its results by the User and/or any third party, including without limitation, its

clients, customers and sub-contactors. User hereby agrees to indemnify, defend and hold

bioMérieux S.A. harmless from all claims, damages, expenses, suits, losses or liabilities relating

to, arising out of or in connection with User or such parties as well for any action of such third

parties against bioMérieux S.A.

Should this provision be held unenforceable or void, the User irrevocably agrees that

bioMérieux S.A. liability and expenses for all causes shall not exceed the total amount actually

paid by the User hereunder for the software release concerned by the claim.

V - Applicable Law and settlement of disputes

This agreement is governed and construed in accordance with French Law.

Parties shall make their best efforts to settle any dispute through amicable discussions. In the

event no amicable settlement is reached in the period of three (3) months after communication of

the claim, any litigation shall be held in the exclusive jurisdiction of the courts of Lyon, France.

Done ..............................................................................

This…….....................day of..........................................

Signature and User's stamp:

COPY TO BE RETURNED TO bioMérieux

S.A.

Page 9

4501-1577 B en

SOFTWARE LICENSE AGREEMENT

User: No.:

Software: Release:

Computer: Brand name:

Printer: Brand name:

Disk player: Brand name:

The use of this Software is strictly governed by the following terms and conditions.

I - Purpose of this Agreement / Rights granted

bioMérieux S.A. hereby grants, to the User who, by using this manual, accepts a non-exclusive

right to use the Software. The license is personal, non transferable, non assignable and does not

comprise the right to grant sub-licenses.

The User expressly agrees, in its own name and behalf as well as in the name and on behalf of its

employees, agents and collaborators, not to make any copy of the Software-except one single

backup copy for archival purposes- display the Software on any computer other than the

Computer, reproduce, sell, rent, lease, modify, adapt, translate or otherwise dispose of, all or part

of the Software, the equipment, the user manual and its related documentation.

Specifically, the User agrees not to decompile, reverse engineer or disassemble all or part of the

Software.

II - Intellectual Property

III - Warranties

All intellectual property rights including patrimonial rights, in and to the Software are and shall

remain bioMérieux S.A. exclusive property, subject to possible third party rights. Consequently,

the User is not entitled to copy or reproduce the Software except as set forth above.

Except as expressly specified above, nothing contained herein shall be construed as conferring to

the User any right, title or interest in and to the Software.

Provided that this Agreement duly signed is received by bioMérieux S.A. within ten (10) business

days from the delivery, bioMérieux S.A. warrants that the Software is free from defect in materials

and workmanship under normal conditions of use during three (3) months from the delivery.

Should any defect occur during such period, bioMérieux S.A. or one of its authorized distributors

in the country of sale shall replace the Software provided that the User makes its request in

writing together with copy of the Software invoice and, as the case may be, the defective media.

Apart from the foregoing, the Software is provided "AS IS" and no warranty, whether express or

implied, of merchantability, safety, quality, or fitness for a particular purpose is given hereunder

nor any warranty that the Software shall not infringe upon the intellectual property rights of any

third party.

The warranty provided herein shall apply provided that Software is used under normal conditions

and to the exclusion of any replacement caused by accidental or willful damage, or misuse of the

software or accident whatsoever.

It is expressly understood that, according to this License, bioMérieux S.A. shall not perform any

service related to the training, assistance or maintenance of the Software unless otherwise

agreed upon between the parties through a separate written agreement setting forth the terms

and conditions (in particular, financial conditions) of such training, assistance or maintenance.

Page 10

IV - Liability

In no event shall bioMérieux S.A. be held liable for any consequences that may arise from any

modifications made to the Software without its intervention, or, should the software be connected

to the user’s network or system, for any malfunctions or damage to the software caused directly

or indirectly by the network or system, in particular in the event of failure of the security system, or

the consequences of installing software on the same hardware as this Software without the

intervention and/or authorisation of bioMérieux S.A.

In no event shall bioMérieux S.A. be liable for any direct, indirect, special, consequential or nonconsequential, incidental, material or immaterial damage (including loss of goodwill, profits, data

or any other economic advantage) related to, arising out of or in connection with, any use of the

Software and/or its results by the User and/or any third party, including without limitation, its

clients, customers and sub-contactors. User hereby agrees to indemnify, defend and hold

bioMérieux S.A. harmless from all claims, damages, expenses, suits, losses or liabilities relating

to, arising out of or in connection with User or such parties as well for any action of such third

parties against bioMérieux S.A.

Should this provision be held unenforceable or void, the User irrevocably agrees that

bioMérieux S.A. liability and expenses for all causes shall not exceed the total amount actually

paid by the User hereunder for the software release concerned by the claim.

V - Applicable Law and settlement of disputes

This agreement is governed and construed in accordance with French Law.

Parties shall make their best efforts to settle any dispute through amicable discussions. In the

event no amicable settlement is reached in the period of three (3) months after communication of

the claim, any litigation shall be held in the exclusive jurisdiction of the courts of Lyon, France.

Done ..............................................................................

This…….....................day of..........................................

Signature and User's stamp:

COPY TO BE KEPT BY USER

Page 11

Table of Contents

1 How to use this Manual

Finding topics and procedures .................................................................................................................................. 1-1

Warnings................................................................................................................................................................... 1-1

2 Description

Intended Use............................................................................................................................................................. 2-1

System Capabilities...................................................................................................................................................2-1

Workflow Principle..................................................................................................................................................... 2-2

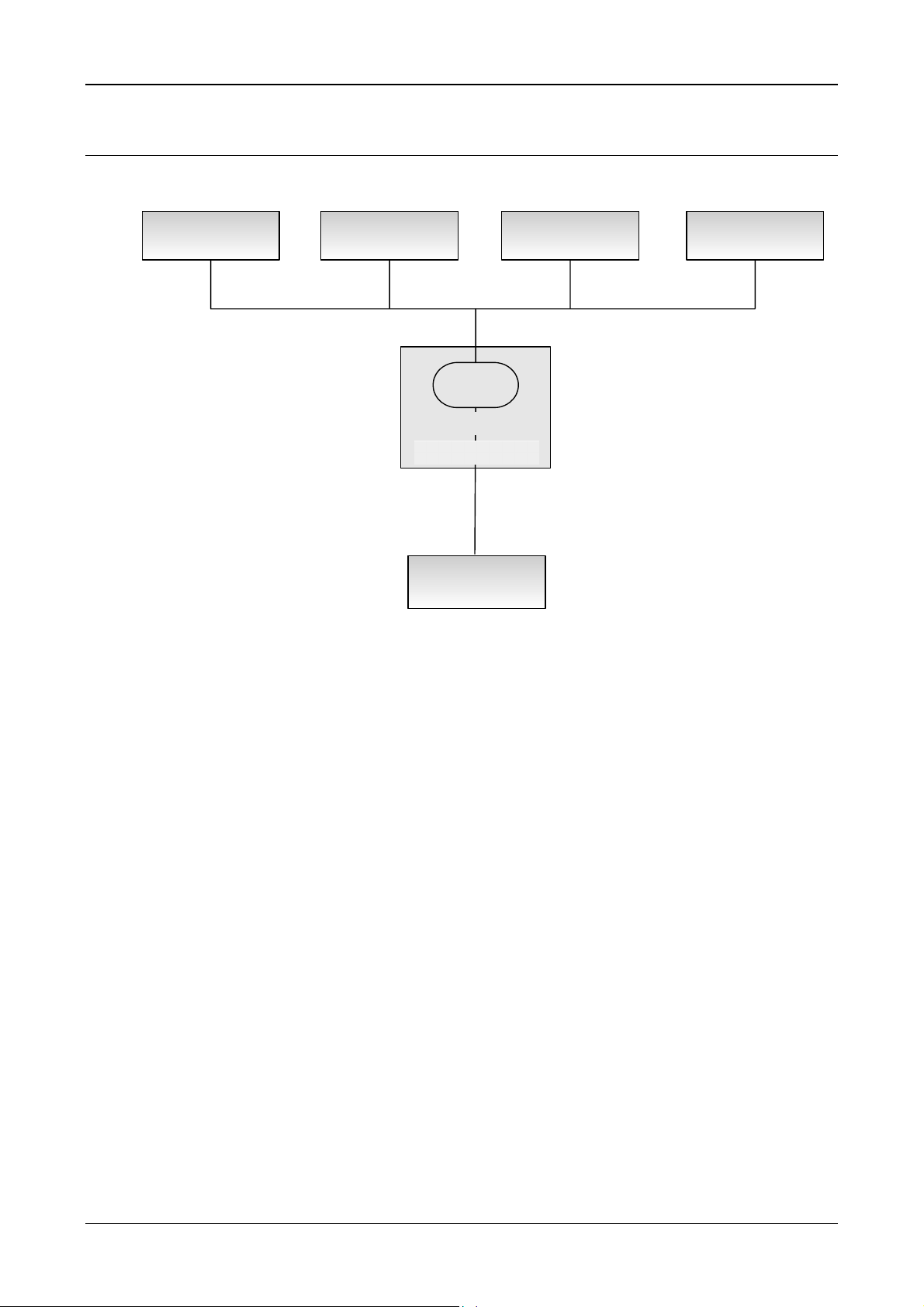

System Architecture.................................................................................................................................................. 2-3

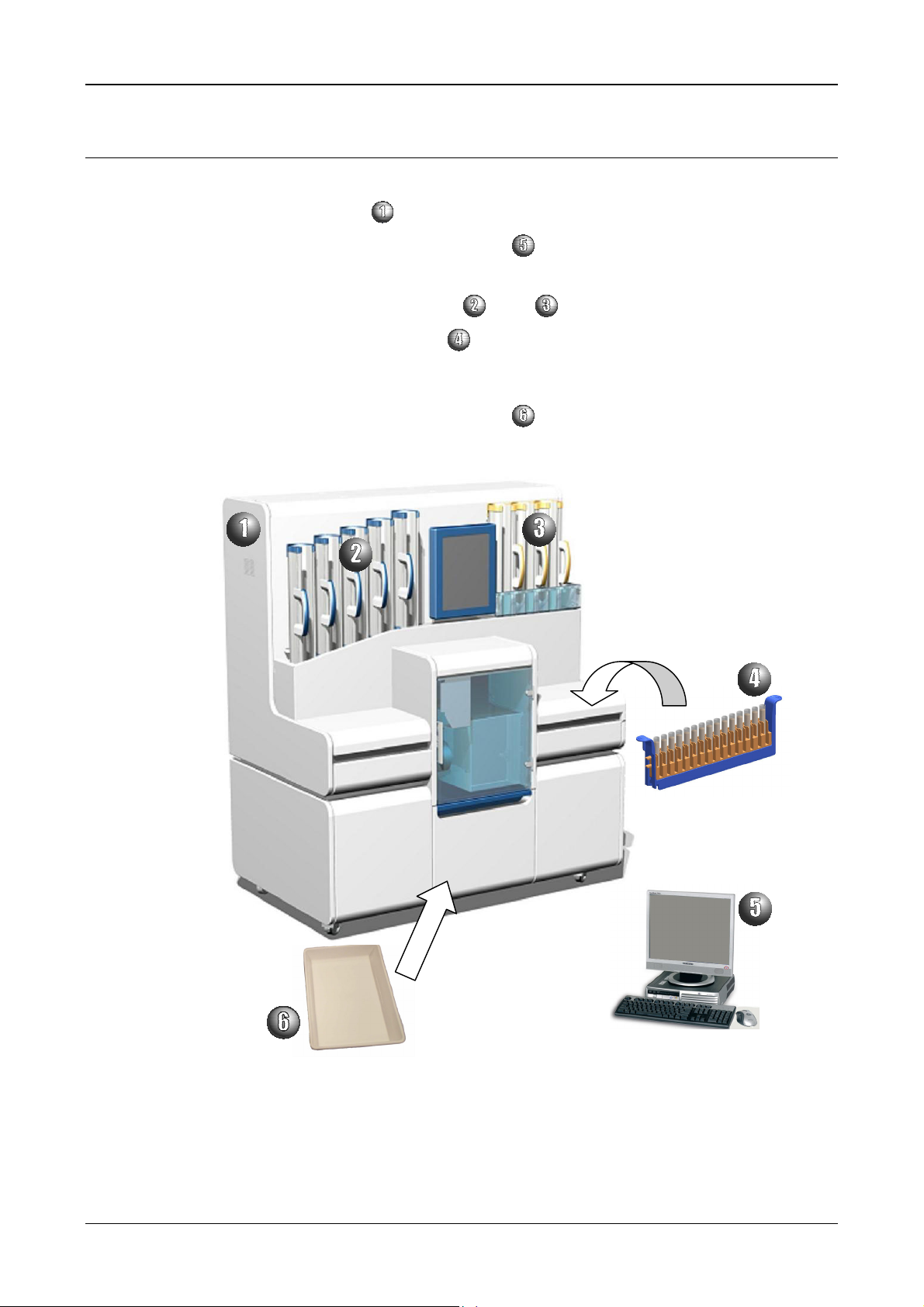

System Components................................................................................................................................................. 2-4

Workstation ............................................................................................................................................................... 2-5

Description......................................................................................................................................................... 2-5

Instrument ................................................................................................................................................................. 2-6

Sample racks ..................................................................................................................................................... 2-9

Sample tubes................................................................................................................................................... 2-10

Tubes compatible for use with the PREVI Isola .......................................................................................2-10

Fill heights.................................................................................................................................................2-10

Prepoured media (Plates) ................................................................................................................................ 2-10

Plates compatible for use with the PREVI Isola .......................................................................................2-10

Input cassettes................................................................................................................................................. 2-11

Output cassettes.............................................................................................................................................. 2-12

Touch-screen ................................................................................................................................................... 2-12

PREVI Isola Waste Paper Bin ......................................................................................................................... 2-13

Waste drawer................................................................................................................................................... 2-13

Interlocks................................................................................................................................................................. 2-14

Consumables .......................................................................................................................................................... 2-15

PREVI Isola Applicators .................................................................................................................................. 2-15

PREVI Isola Applicator cartridge ..................................................................................................................... 2-15

PREVI Isola Tips ............................................................................................................................................. 2-16

PREVI Isola Labels .........................................................................................................................................2-16

PREVI Isola biohazardous Waste Bin ............................................................................................................. 2-16

PREVI Isola HEPA filter ..................................................................................................................................2-17

Instrument Operating Principle................................................................................................................................ 2-18

Index next sample............................................................................................................................................ 2-19

Read sample barcode...................................................................................................................................... 2-19

Retrieve sample data ....................................................................................................................................... 2-20

Pick up tip ........................................................................................................................................................ 2-20

Aspirate sample ............................................................................................................................................... 2-20

Perform plate workflow ....................................................................................................................................2-21

Retrieve input plate...................................................................................................................................2-21

Transfer to plate transfer robot .................................................................................................................2-21

Transfer to process station .......................................................................................................................2-21

Measure agar height, dispense sample ....................................................................................................2-21

Pick up applicator .....................................................................................................................................2-21

Streak plate...............................................................................................................................................2-21

Discard applicator ..................................................................................................................................... 2-21

If Bi – plate................................................................................................................................................ 2-21

Transfer to transfer robot ..........................................................................................................................2-21

Label plate ................................................................................................................................................2-22

Transfer to output robot ............................................................................................................................2-22

Dispose of tip ................................................................................................................................................... 2-22

PREVI

TM

Isola User Manual I-1

Page 12

Table of Contents

Workstation Software.............................................................................................................................................. 2-23

Principle ........................................................................................................................................................... 2-23

General screen layout...................................................................................................................................... 2-23

Menu bar.......................................................................................................................................................... 2-24

Title and button bar .......................................................................................................................................... 2-24

Working area ................................................................................................................................................... 2-24

Status bar ........................................................................................................................................................ 2-24

Instrument Software................................................................................................................................................ 2-25

Main screen and general layout....................................................................................................................... 2-25

Alarm zone....................................................................................................................................................... 2-26

Title bar............................................................................................................................................................ 2-26

Status bar ........................................................................................................................................................ 2-26

Navigation/action bar ....................................................................................................................................... 2-27

Working area ................................................................................................................................................... 2-28

3 Getting Started

Assembly and Installation .........................................................................................................................................3-1

Choosing a location ...........................................................................................................................................3-1

Electrical connections ........................................................................................................................................ 3-1

Hazardous Magnetic Fields Precautions................................................................................................................... 3-1

Moving the Instrument............................................................................................................................................... 3-1

Barcode Reader Installation...................................................................................................................................... 3-1

Installation of the PREVI Isola and BCI .................................................................................................................... 3-2

Checking installation .......................................................................................................................................... 3-2

Powering up the Workstation .................................................................................................................................... 3-3

Connecting to BCI NET .....................................................................................................................................3-3

Connecting to BCI RS232.................................................................................................................................. 3-3

Starting the Workstation Software............................................................................................................................. 3-4

Entry of an incorrect user name or password ....................................................................................................3-4

Changing work sessions .................................................................................................................................... 3-5

Inactivity timeout ................................................................................................................................................ 3-5

Defining Plate Panels................................................................................................................................................ 3-6

Creating a plate panel........................................................................................................................................ 3-7

Modifying a plate panel ...................................................................................................................................... 3-9

Deleting a plate panel ........................................................................................................................................ 3-9

Printing a plate panel ....................................................................................................................................... 3-10

Defining Plate Types ............................................................................................................................................... 3-11

Creating a plate type........................................................................................................................................ 3-11

Modifying a plate type ...................................................................................................................................... 3-12

Deleting a plate type ........................................................................................................................................ 3-12

Defining Incubation Types....................................................................................................................................... 3-13

Creating an incubation type .............................................................................................................................3-13

Modifying an incubation type ........................................................................................................................... 3-14

Deleting an incubation type.............................................................................................................................. 3-14

Assigning Plate Panels to Specimen Types............................................................................................................ 3-15

Printing plate panels assigned to specimen types ...........................................................................................3-17

Automatically Assigning Plate Panels to Samples .................................................................................................. 3-18

Defining Plate Cassettes Configurations................................................................................................................. 3-19

Creating a plate cassettes configuration .......................................................................................................... 3-19

Modifying a plate cassettes configuration ........................................................................................................ 3-21

Deleting a plate cassettes configuration .......................................................................................................... 3-21

Assigning Plate Panels to Samples ........................................................................................................................ 3-22

Viewing and Printing Worklists................................................................................................................................ 3-24

General Settings ..................................................................................................................................................... 3-26

I-2 PREVI

TM

Isola User Manual

Page 13

Table of Contents

4 Using the System

Basic Workflow .........................................................................................................................................................4-1

Starting the System................................................................................................................................................... 4-2

Powering up the instrument ............................................................................................................................... 4-2

Screensaver....................................................................................................................................................... 4-2

Prerequisites for Sample Processing ........................................................................................................................ 4-4

Pre-start Checks ....................................................................................................................................................... 4-4

Selecting Plates ........................................................................................................................................................ 4-5

Loading Plates .......................................................................................................................................................... 4-7

Loading plates during processing ......................................................................................................................4-7

Loading plates without removing the input cassette........................................................................................... 4-8

Plate cassettes status ........................................................................................................................................ 4-9

Loading PREVI Isola Applicators............................................................................................................................ 4-10

Loading PREVI Isola Tips....................................................................................................................................... 4-13

Loading PREVI Isola Labels................................................................................................................................... 4-15

Monitoring Consumables and Waste Bins Status ................................................................................................... 4-17

Consumables ................................................................................................................................................... 4-17

PREVI Isola Waste Bins.................................................................................................................................. 4-18

Sample Preparation ................................................................................................................................................4-19

Recommended procedures.............................................................................................................................. 4-19

Urine .........................................................................................................................................................4-19

Feces........................................................................................................................................................4-19

Dry mono swab......................................................................................................................................... 4-19

Swab in a liquid transport medium............................................................................................................ 4-19

Swab in gel transport medium ..................................................................................................................4-19

Blood ........................................................................................................................................................4-19

Liquid respiratory samples........................................................................................................................4-19

Placing Sample Tubes in Racks ............................................................................................................................. 4-20

Loading Sample Racks ........................................................................................................................................... 4-21

Processing Samples ...............................................................................................................................................4-23

Processing hints............................................................................................................................................... 4-27

Pausing the Instrument ........................................................................................................................................... 4-28

Instrument-generated pause............................................................................................................................ 4-28

User-generated pause ..................................................................................................................................... 4-28

Stopping the Instrument .......................................................................................................................................... 4-29

Instrument-generated stop (Error case) ........................................................................................................... 4-29

Resuming operations after stopping .........................................................................................................4-29

User-generated stop ........................................................................................................................................ 4-31

Resuming operations after stopping .........................................................................................................4-31

Unloading Processed Plates ................................................................................................................................... 4-32

Unloading processed plates on completion of processing ............................................................................... 4-32

Unloading processed plates during processing ............................................................................................... 4-33

Remove a full output cassette...................................................................................................................4-33

Remove plates from the cassettes in situ .................................................................................................4-33

Unloading unprocessed plates......................................................................................................................... 4-33

Unloading Sample Tubes........................................................................................................................................ 4-34

Removing Waste..................................................................................................................................................... 4-35

PREVI Isola biohazardous Waste Bin ............................................................................................................. 4-35

PREVI Isola Waste Paper Bin ......................................................................................................................... 4-36

Powering Down the Instrument ............................................................................................................................... 4-37

Examples of Correct Streaking Patterns ................................................................................................................. 4-38

PREVI

TM

Isola User Manual I-3

Page 14

Table of Contents

5 Quality Control

Intended Use............................................................................................................................................................. 5-1

Material ..................................................................................................................................................................... 5-1

Workstation Preparation............................................................................................................................................ 5-1

Instrument Preparation.............................................................................................................................................. 5-2

Sample Tube Preparation ......................................................................................................................................... 5-2

Sample Run and Plate Incubation............................................................................................................................. 5-2

Results ...................................................................................................................................................................... 5-2

Score determination .................................................................................................................................................. 5-3

Reference Appearance ............................................................................................................................................. 5-3

Results ...................................................................................................................................................................... 5-4

6 Information Technology Security

User Management..................................................................................................................................................... 6-1

User groups ....................................................................................................................................................... 6-1

Creating a new user account ............................................................................................................................. 6-2

Assigning user permissions and rights............................................................................................................... 6-5

Disabling a user account.................................................................................................................................. 6-10

Unlocking a user account................................................................................................................................. 6-11

Changing of a password by a user................................................................................................................... 6-12

Antivirus .................................................................................................................................................................. 6-13

Windows Update..................................................................................................................................................... 6-13

IT Verification Protocol ............................................................................................................................................ 6-13

Printer Verification Protocol..................................................................................................................................... 6-14

7 Data Backup, Restore and Audit Trail

Presentation.............................................................................................................................................................. 7-1

Manual data backup.................................................................................................................................................. 7-1

Data restoration from a removable medium .............................................................................................................. 7-1

Audit trail data viewing using the event viewer.......................................................................................................... 7-2

Saving the Audit Trail ................................................................................................................................................ 7-4

Instrument and Workstation Log File Retrieval .........................................................................................................7-6

Instrument log files............................................................................................................................................. 7-6

Workstation and data server log files ................................................................................................................. 7-6

Full System Backup and Restoration ........................................................................................................................ 7-7

Full System Backup ........................................................................................................................................... 7-7

Full System Restoration..................................................................................................................................... 7-7

8 Maintenance

Introduction ............................................................................................................................................................... 8-1

Safety Precautions and Controls............................................................................................................................... 8-1

Biological safety requirements ........................................................................................................................... 8-1

Recommended maintenance product ................................................................................................................ 8-1

Presentation of the Maintenance Menu..................................................................................................................... 8-2

Maintenance Logs..................................................................................................................................................... 8-3

Daily Maintenance Procedures ................................................................................................................................. 8-4

Clean the tray under input cassettes.................................................................................................................. 8-4

Clean the waste chute top, the area around the waste chute top and the waste chute chimney ....................... 8-5

Clean the process station drip tray..................................................................................................................... 8-6

Clean the pipettor, drip tray and area under and around the drip tray................................................................ 8-7

Clean the sample racks .....................................................................................................................................8-8

Clean the sample rack tray and sample spill tray............................................................................................... 8-9

Clean the tray under output cassettes .............................................................................................................8-11

Clean the waste chute deflector....................................................................................................................... 8-12

Check, replace or empty the waste bins, and clean the deflector .................................................................... 8-13

I-4 PREVI

TM

Isola User Manual

Page 15

Table of Contents

Weekly Maintenance Procedures ........................................................................................................................... 8-14

Clean the inside of input and output cassettes ................................................................................................ 8-14

Clean the area around the applicator cartridge and the tip tray .......................................................................8-15

Clean the process station, reference block, transfer robot suction cups, and agar sensor ..............................8-15

Clean the printer and the printer platen............................................................................................................ 8-18

Clean the print head......................................................................................................................................... 8-19

Clean the touch-screen.................................................................................................................................... 8-19

Clean the external surfaces of the instrument.................................................................................................. 8-20

Clean the waste drawer ................................................................................................................................... 8-20

Maintenance Operations Performed by bioMérieux ................................................................................................ 8-21

Spill Management ...................................................................................................................................................8-21

Materials required ............................................................................................................................................ 8-21

Decontamination Procedures.................................................................................................................................. 8-21

Basic decontamination..................................................................................................................................... 8-21

Removal and Disposal of Materials and Waste....................................................................................................... 8-22

Disposal of used consumables ........................................................................................................................ 8-22

Loading PREVI Isola Label Rolls............................................................................................................................ 8-23

Replacing Fuses ..................................................................................................................................................... 8-29

Replacing the PREVI Isola HEPA Filter.................................................................................................................. 8-29

9 Troubleshooting

Introduction ............................................................................................................................................................... 9-1

List of Error Messages .............................................................................................................................................. 9-2

Event Log................................................................................................................................................................ 9-10

Error, Cause and Recovery..................................................................................................................................... 9-11

Recovery from events with “Warning” severity........................................................................................................ 9-15

Recovery from events with “Error” severity ............................................................................................................. 9-15

Recovery from Events with “Fatal” Severity ............................................................................................................ 9-16

Restarting the Instrument Software......................................................................................................................... 9-16

PREVI Isola HEPA Filter ........................................................................................................................................9-17

Replacing the PREVI Isola HEPA filter............................................................................................................ 9-18

Pipettor.................................................................................................................................................................... 9-23

Clean and decontaminate the pipettor if it descends into a sample tube ......................................................... 9-23

Material required.......................................................................................................................................9-23

Procedure .................................................................................................................................................9-23

Possible issues after cleaning...................................................................................................................9-25

Reinitialize the instrument after the pipettor descends into a plate on the process station ..............................9-25

Procedure .................................................................................................................................................9-25

Examples of Incorrect Inoculation and Streaking Patterns...................................................................................... 9-26

Back up Instrument Log Files.................................................................................................................................. 9-27

Anonymization of Patient Data................................................................................................................................ 9-27

10 General System Characteristics

Dimensions ...................................................................................................................................................... 10-1

Weight.............................................................................................................................................................. 10-1

Electrical specifications.................................................................................................................................... 10-1

Environmental considerations.......................................................................................................................... 10-1

TM

PREVI

Isola User Manual I-5

Page 16

Table of Contents

11 Appendices

Appendix A: Packing list.......................................................................................................................................... 11-1

Instrument kit ...................................................................................................................................................11-1

User Manual kit................................................................................................................................................ 11-1

Workstation PC kit ...........................................................................................................................................11-1

Appendix B: Stopping and Restarting the Data Server ...........................................................................................11-2

Stopping the data server.................................................................................................................................. 11-2

Restarting the data server................................................................................................................................ 11-4

12 Glossary

I-6 PREVI

TM

Isola User Manual

Page 17

List of Figures

2 Description

Figure 2-1 : Workflow Principle ................................................................................................................................. 2-2

Figure 2-2 : System Architecture............................................................................................................................... 2-3

Figure 2-3 : System Components .............................................................................................................................2-4

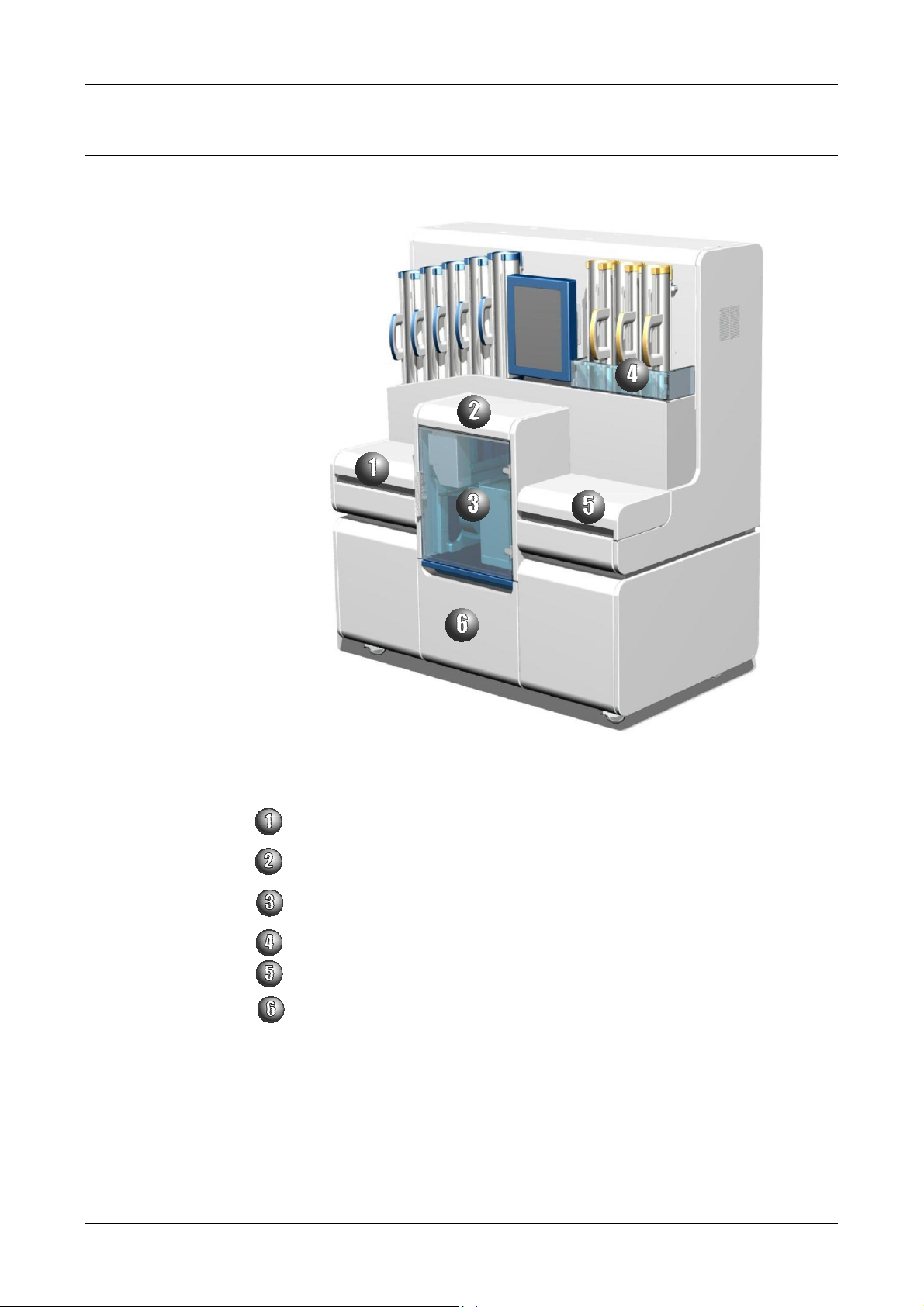

Figure 2-4 : Front view of the PREVI Isola with covers on........................................................................................ 2-6

Figure 2-5 : Front view of the PREVI Isola – front covers removed.......................................................................... 2-7

Figure 2-6 : Back view of the PREVI Isola with covers on........................................................................................ 2-8

Figure 2-7 : Sample racks ......................................................................................................................................... 2-9

Figure 2-8 : Fill heights............................................................................................................................................ 2-10

Figure 2-9 : Input cassette – front ...........................................................................................................................2-11

Figure 2-10 : Input cassette – back......................................................................................................................... 2-11

Figure 2-11 : Output cassette - front .......................................................................................................................2-12

Figure 2-12 : Output cassette - back....................................................................................................................... 2-12

Figure 2-13: Touch-screen...................................................................................................................................... 2-12

Figure 2-14 : PREVI Isola Waste Paper Bin ........................................................................................................... 2-13

Figure 2-15 : Waste Drawer .................................................................................................................................... 2-13

Figure 2-16 : PREVI Isola Applicator ...................................................................................................................... 2-15

Figure 2-17 : PREVI Isola Applicator cartridge ....................................................................................................... 2-15

Figure 2-18 : PREVI Isola Tips in tray ....................................................................................................................2-16

Figure 2-19 : Simplified sample workflow................................................................................................................ 2-18

Figure 2-20 : Positioning a barcode label on a tube ................................................................................................ 2-19

Figure 2-21 : General screen layout........................................................................................................................ 2-23

Figure 2-22 : Main screen layout............................................................................................................................. 2-25

Figure 2-23 : Working area .....................................................................................................................................2-28

3 Getting Started

Figure 3-1 : Login pop-up window............................................................................................................................. 3-4

Figure 3-2 : “Invalid user name / password” window................................................................................................. 3-4

Figure 3-3 : Workstation software shutdown window ................................................................................................3-5

Figure 3-4 : “Plate Panels” screen ............................................................................................................................ 3-6

Figure 3-5 : Create a plate panel .............................................................................................................................. 3-7

Figure 3-6 : “Plate Panel” error message .................................................................................................................. 3-8

Figure 3-7 : “Invalid entry” error message................................................................................................................. 3-8

Figure 3-8 : “Delete a plate panel” confirmation message......................................................................................... 3-9

Figure 3-9 : “Plate Panel Printing” selection window............................................................................................... 3-10

Figure 3-10 : Plate panel “Print Preview” window ...................................................................................................3-10

Figure 3-11 : “Plate Panels” plate types screen ...................................................................................................... 3-11

Figure 3-12 : Define incubation types...................................................................................................................... 3-13

Figure 3-13 : Incubation types................................................................................................................................. 3-14

Figure 3-14 : “Specimen Types” screen .................................................................................................................. 3-15

Figure 3-15 : Specimen types “Print Preview” window............................................................................................ 3-17

Figure 3-16 : “Plate Cassettes Configuration” screen .............................................................................................3-19

Figure 3-17 : New plate cassettes configuration ..................................................................................................... 3-20

Figure 3-18 : “Invalid Input” error message ............................................................................................................. 3-20

Figure 3-19 : “Delete a plate cassettes configuration” confirmation message......................................................... 3-21

Figure 3-20 : “Sample Assignment“ screen............................................................................................................. 3-22

Figure 3-21 : “Sample Assignment“ screen with sample ......................................................................................... 3-23

Figure 3-22 : “Worklist” screen................................................................................................................................ 3-24

Figure 3-23 : Worklist “Print Preview” window......................................................................................................... 3-25

Figure 3-24 : “General Settings” screen .................................................................................................................. 3-26

PREVI

TM

Isola User Manual II-1

Page 18

List of Figures

4 Using the System

Figure 4-1 : Basic workflow diagram ......................................................................................................................... 4-1

Figure 4-2 : Powering up the instrument ................................................................................................................... 4-2

Figure 4-3 : Main screen ........................................................................................................................................... 4-3

Figure 4-4 : “Select Plates” screen............................................................................................................................ 4-5

Figure 4-5 : Load plates agar-side up .......................................................................................................................4-7

Figure 4-6 : Loading plates without removing the input cassette ..............................................................................4-8

Figure 4-7 : Main screen – “Cassettes status” ..........................................................................................................4-9

Figure 4-8 : “Load Applicators and Tips” screen .....................................................................................................4-10

Figure 4-9 : Pulling the top lock............................................................................................................................... 4-11

Figure 4-10 : Inserting the cartridge ........................................................................................................................ 4-11

Figure 4-11 : “Load Applicators and Tips” screen ...................................................................................................4-13

Figure 4-12 : Inserting the PREVI Isola Tip tray .....................................................................................................4-14

Figure 4-13 : “Load Labels” screen ......................................................................................................................... 4-15

Figure 4-14 : "Main screen – consumable status"................................................................................................... 4-17

Figure 4-15 : Sample tubes in racks........................................................................................................................ 4-20

Figure 4-16 : Correct position of tubes in rack ........................................................................................................ 4-20

Figure 4-17 : “Load Samples” screen...................................................................................................................... 4-21

Figure 4-18 : Load sample racks............................................................................................................................. 4-22

Figure 4-19 : “Preparing to start processing …” screen ..........................................................................................4-23

Figure 4-20 : Processing screen ............................................................................................................................. 4-24

Figure 4-21 : Barcode ............................................................................................................................................. 4-25

Figure 4-22 : Sample processing status.................................................................................................................. 4-26

Figure 4-23 : “Processing Complete” screen........................................................................................................... 4-27

Figure 4-24 : “Fatal Error” screen............................................................................................................................ 4-29

Figure 4-25 : “Shutdown Requested” window – instrument processing .................................................................. 4-30

Figure 4-26 : Opening guard and removing output cassette ................................................................................... 4-32

Figure 4-27 : Correct streaking patterns.................................................................................................................. 4-38

5 Quality Control

Figure 5-1 : Score determination.............................................................................................................................. 5-3

Figure 5-2 : Reference appearance ......................................................................................................................... 5-3

6 Information Technology Security

Figure 6-1 : Opening the Computer Management window........................................................................................ 6-2

Figure 6-2 : "Computer Management" screen........................................................................................................... 6-2

Figure 6-3 : "New User" screen................................................................................................................................. 6-3

Figure 6-4 : "New User" creation box ........................................................................................................................ 6-3

Figure 6-5 : "New User" creation box with data entered............................................................................................ 6-4

Figure 6-6 : "User Rights Management" screen ........................................................................................................ 6-5

Figure 6-7 : User “Properties" screen........................................................................................................................ 6-5

Figure 6-8 : "User properties" – " Member Of “ tab screen........................................................................................ 6-6

Figure 6-9 : "Select Groups" screen.......................................................................................................................... 6-6

Figure 6-10 : "Select Groups" screen (cont’d)........................................................................................................... 6-7

Figure 6-11 : "Select Groups" screen (cont’d)........................................................................................................... 6-7

Figure 6-12 : "Select Groups" screen (cont’d)........................................................................................................... 6-8

Figure 6-13 : "Select Groups" screen (cont’d)........................................................................................................... 6-8

Figure 6-14 : "Properties" screen – "Member Of" tab screen .................................................................................... 6-9

Figure 6-15 : "User Rights Management" screen.................................................................................................... 6-10

Figure 6-16 : "User Properties" - "General" tab screen ........................................................................................... 6-10

Figure 6-17 : "User Rights Management" screen.................................................................................................... 6-11

Figure 6-18 : " Windows Security" window................................................................................................................ 6-12

Figure 6-19 : "Change Password" window .............................................................................................................. 6-12

II-2 PREVI

TM

Isola User Manual

Page 19

List of Figures

7 Data Backup, Restore and Audit Trail

Figure 7-1 : Event viewer shortcut ............................................................................................................................7-2

Figure 7-2 : “Event viewer” window........................................................................................................................... 7-2

Figure 7-3 : Event viewer “AS_Audit” window........................................................................................................... 7-3

Figure 7-4 : “Event Properties” window ..................................................................................................................... 7-3

Figure 7-5 : “Save Log File AS…” window ................................................................................................................ 7-4

Figure 7-6 : Save “AS_Audit” As… window............................................................................................................... 7-5

8 Maintenance

Figure 8-1 : Maintenance Menu.................................................................................................................................. 8-2

Figure 8-2 : Removing the tray under the input cassettes ............................................................................................ 8-4

Figure 8-3 : Removing the waste chute top................................................................................................................. 8-5

Figure 8-4 : Removing the process station drip tray..................................................................................................... 8-6

Figure 8-5 : Cleaning the pipettor ...............................................................................................................................8-7

Figure 8-6 : Drip tray to the right of the process station................................................................................................ 8-8

Figure 8-7 : Sample rack tray presented for cleaning................................................................................................... 8-9

Figure 8-8 : Applying cleaning solution ....................................................................................................................... 8-9

Figure 8-9 : Removing the sample spill tray .............................................................................................................. 8-10

Figure 8-10 : Lifting up the sample spill tray.............................................................................................................. 8-10

Figure 8-11 : Removing the tray under output cassettes............................................................................................ 8-11

Figure 8-12 : Removing the waste chute deflector ...................................................................................................8-12

Figure 8-13 : Waste chute deflector ........................................................................................................................ 8-12

Figure 8-14 : PREVI Isola Waste Bins in drawer....................................................................................................... 8-13

Figure 8-15 : Cleaning inside cassettes .................................................................................................................... 8-14

Figure 8-16 : Wiping inside cassettes ..................................................................................................................... 8-14

Figure 8-17 : Cleaning the process station.............................................................................................................. 8-15

Figure 8-18 : Reference block................................................................................................................................. 8-16

Figure 8-19 : Robot suction cups ............................................................................................................................8-16

Figure 8-20 : Cleaning the agar sensor................................................................................................................... 8-17

Figure 8-21 : Cleaning the platen............................................................................................................................ 8-18

Figure 8-22 : Print head ..........................................................................................................................................8-19

Figure 8-23 : Raising the roller arms ....................................................................................................................... 8-23

Figure 8-24 : Raising the release latches................................................................................................................ 8-23

Figure 8-25 : Removing the empty roll .................................................................................................................... 8-23

Figure 8-26 : Correct position of new roll ................................................................................................................ 8-24

Figure 8-27 : Using the guides ................................................................................................................................ 8-24

Figure 8-28 : Feeding label backing through the printer.......................................................................................... 8-25

Figure 8-29 : Instructions for loading labels on instrument touch-screen ................................................................ 8-25

Figure 8-30 : Pull mechanism slot (top view) .......................................................................................................... 8-26

Figure 8-31 : Label backing correctly pulled into the slot (top view)........................................................................ 8-26

Figure 8-32 : Lowering the roller arms ....................................................................................................................8-26

Figure 8-33 : Turning the label roll ..........................................................................................................................8-27

Figure 8-34 : Metal plate not to be removed ........................................................................................................... 8-27

Figure 8-35 : Label backing coming out of deflector ............................................................................................... 8-28

Figure 8-36 : Main power inlet fuses ....................................................................................................................... 8-29

9 Troubleshooting

Figure 9-1 : Event Log screen................................................................................................................................. 9-10

Figure 9-2 : Warning Message................................................................................................................................ 9-15