Page 1

Ref. 99709

Version C

11/2003

mini API

Instrument User's Manual

Tel. 33 (0)4 78 87 20 00 - Fax 33 (0)4 78 87 20 90

bioMérieux® SA 69280 Marcy l'Etoile / France

http://www.biomerieux.com

Printed in France / 673 620 399 RCS Lyon

Page 2

Page 3

V. AB 09.2003

Argentina

bioMérieux Argentina s.a.

Av. Congreso 1745

(C1428BUE) Capital Federal

Buenos Aires

tel. (54) 11 5555-6800

fax (54) 11 5555-6888

Australia

bioMérieux Australia Pty. P/L

Unit 25, Parkview Business Center

1 Maitland Place

Baulkham Hills NSW 2153

tel. (61) 2 8852 4700

fax (61) 2 8852 4777

Austria

bioMérieux Austria GmbH

Eduard-Kittenberger-Gasse 97

Top 3

A-1230 Wien

tel. (43) 186 50 650

fax (43) 186 50 661

Belgium

bioMérieux Benelux s.a./n.v.

Media Square

18-19 Place des Carabiniers

Bruxelles 1030

tel. (32) 2.743 01 70

fax (32) 2.733 55 97

Brazil

bioMérieux Brasil SA

Estrada Do Mapuá

491 Jacarepaguá

CEP 22710 261 Rio de Janeiro R.J

tel. (55) 21.2444 1400

fax (55) 21.2455 6099

Canada

bioMérieux Canada, Inc.

4535, Dobrin

Saint Laurent (Québec) H4R 2L8

tel. (1) 514 336 7321

fax (1) 514 336 6450

Chile

bioMérieux Chile S.A.

Seminario 131

Providencia

Santiago

tel. (56) 2634 20 92

fax (56) 2634 20 93

China

bioMérieux China Limited

Unit 1701-2, 17/F, Nanyang Plaza

No. 57 Hung To Road, Kwun Tong

Kowloon - Hong Kong

tel. (852) 2356 7033

fax (852) 2330 2085

Colombia

bioMérieux Colombia Ltda

Diagonal 109 # 20A - 33

Bogotá

tel. (57) 1 619 64 70

fax (57) 1 619 69 10

Denmark

bioMérieux Danmark Aps

Smedeholm 13C,

2730 Herlev

tel. (45) 70 10 84 00

fax (45) 70 10 84 01

Finland

bioMérieux Suomi Oy

Rajatorpantie 41 C

01640 Vantaa

tel. (358) 9 8545 6000

fax (358) 9 8545 6045

France

bioMérieux SA

69280 Marcy l’Etoile

tel. 33 (0)4 78 87 20 00

fax 33 (0)4 78 87 20 90

http://www.biomerieux.com

Germany

bioMérieux Deutschland GmbH

Weberstrasse 8

D 72622 Nürtingen

tel. (49) 7022 30070

fax (49) 7022 36110

Greece

bioMérieux Hellas S.A.

Papanikoli 70

15232 Halandri

Athens

tel. (30) 210 81 72 400

fax (30) 210 68 00 880

India

bioMérieux India Pvt. Ltd

D-45, Defense Colony

New Delhi 110 024

tel. (91) 11 2 464 88 40

fax (91) 11 2 464 88 30

Indonesia

bioMérieux Asean

Enseval Building

Kawasan Industri Pulo Gadung - JI. Pulo

Lentut No. 10

Djakarta Timur 13920

tel. (62) 21 461 51 11

fax (62) 21 460 41 07

Italy

bioMérieux Italia S.p.A.

Via Fiume Bianco, 56

00144 Roma

tel. (39) 06 52308.1

fax (39) 06 52308.240

Ivory Coast

bioMérieux Afrique Occidentale

08 BP 2634

Rue Joseph Blohorn - Cocody

Abidjan 08

tel. (225) 22 40 93 93

fax (225) 22 40 93 94

Japan

bioMérieux Japon, Ltd.

Seizan Bldg.,

12-28 Kita-Ayoama 2-chome

Minato-ku, Tokyo 107-0061

tel. (81) 3.5411 86 91

fax (81) 3.5411 86 90

Korea

bioMérieux Korea Co., Ltd.

7th floor Yoosung Building

# 830-67, Yoksam-dong, Kangnam ku

Séoul

tel. (82) 2.547 6262

fax (82) 2.547 6263

Mexico

bioMérieux México SA de CV

Chihuahua 88, col. Progreso

México 01080, D.F.

tel. (52) 55 5481 9550

fax (52) 55 5616 2245

Netherlands (The)

bioMérieux Benelux BV

Boseind 15

P.O. Box 23

5280 AA Boxtel

tel. (31) 411 65 48 88

fax (31) 411 65 48 73

New Zealand

bioMérieux New Zealand Ltd.

22/10 Airbourne Road

North Harbour

Auckland

tel. (64) 9 415 0601

fax (64) 9 415 0603

Norway

bioMérieux Norge AS

Ækernveien 145

N - 0513 Oslo

tel. (47) 23 37 55 50

fax (47) 23 37 55 51

Page 4

Philippines (The)

Representation office

bioMérieux Philippines

11th Floor, Pearlbank Centre

146 Valero Street, Salcedo Village

1227 Makati City

tel. (632) 817 7741

fax (632) 812 0896

Poland

bioMérieux Polska Sp. Z o.o.

ul. Zeromskiego 17

01-882 Warszawa

tel. (48) 22 569 85 00

fax (48) 22 569 8554

Portugal

bioMérieux Portugal, Lda.

Rua Alto do Montijo, Lotes 1 e 2

Portela de Carnaxide

2794-070 Carnaxide

tel. (351) 21 424 59 80

fax (351) 21 418 32 67

Russia

o.o.o. bioMérieux

Petrovsko-Razoumovskii proyezd, 29

127287 Moscow

tel. (7) 095 212 10 26

(7) 095 424 79 38

fax (7) 095 214 95 41

Spain

bioMérieux España s.a.

Manual Tovar, 36

28034 Madrid

tel. (34) 91.358 11 42

fax (34) 91.358 06 29

Sweden

bioMérieux Sverige AB

Hantverksvägen 15

436 33 Askim

tel. (46) 31 68 84 90

fax (46) 31 68 48 48

Switzerland

bioMérieux Suisse s.a.

51, avenue Blanc

Case postale 2150

1211 Genève 2

tel. (41) 22.906 57 60

fax (41) 22.906 57 42

Taiwan

Representation office

bioMérieux China Limited - Taiwan

Branch

RM 608, No. 6-3 Ching Cheng Street

Taipei 105

tel. (886) 2 2545 2250

fax (886) 2 2545 0959

Thaïland

bioMérieux Thaïland Ltd

Regent House Bldg, 16 th Floor

183 Rajdamri Road, Lumpini, Pathumwan

Bangkok 10330

tel. (66) 2 651 98 00

fax (66) 2 651 98 01

Distribution in over 130 countries

Turkey

bioMérieux Diagnostik A.S.

Yenisahra Mah.

Caliskan Sok. No. 4

34746 Kadiköy / Istanbul

tel. (90) 216 472 81 30

fax (90) 216 472 81 35

United Kingdom

bioMérieux UK Ltd

Grafton way, Basingstoke

Hampshire RG22 6HY

tel. (44) 1256.461881

fax (44) 1256.816863

USA

bioMérieux, Inc.

100 Rodolphe Street

Durham NC 27712

tel. (1) 919 620 20 00

fax (1) 919 620 22 11

Vietnam

Representation office

bioMérieux Vietnam Rep. Office

Sai Gon Center Bldg. 11

65 Le Loi District 1

Ho Chi Minh City

tel. (08) 914 1700-1

fax (08) 914 1702

th

Fl.

Page 5

V.A 09/2003

This document will be updated for each software modification or any other change.

Information supplied in this document is subject to modification before the products

described become available.

This document may contain information or references concerning certain

bioMérieux

however, shall not mean that bioMérieux

products, programs or services in such country.

To request copies of publications or for any technical request, contact

bioMérieux

Liability disclaimer

bioMérieux® SA disclaims all warranties, guarantees or liabilities, express or implied

arising by law or otherwise with respect to this manual, its quality, accuracy or

performance, including without limitation, any obligation of bioMérieux

respect to MERCHANTABILITY AND FITNESS FOR A PARTICULAR USE, noninfringement and consequential or incidental damages. IN NO EVENT SHALL

bioMérieux

REFUND OF THE AMOUNT PAID TO bioMérieux

SERVICE WHICH IS THE SUBJECT OF THE CLAIM.

In no event shall bioMérieux

have the right to modify the manual without notice.

®

SA products, programs and services not available in such country; this,

®

SA or your local distributor.

®

SA’ s LIABILITY TO CUSTOMER UNDER ANY CLAIM EXCEED A

®

SA be bound by the manual. bioMérieux® SA shall

®

SA intends to commercialize such

®

SA with

®

SA FOR THE PRODUCT OR

bioMérieux® SA Copyright

This manual, its content and graphics are copyrighted by bioMérieux® SA.

In no event does bioMérieux

reproduction, adaptation or translation, by any process and in any country

whatsoever.

All editorial content and graphics (including without limitations, all articles, text ,

images, logos, compilations, designs) are protected by French Copyright Law and

international treaties and may not be copied without the express permission of

bioMérieux

Any representation or reproduction whether partial or integral, by any process

whatsoever, would therefore be considered fraudulent and sentenced by the

applicable law.

®

SA.

®

SA concede to the manual's user any right for

Page 6

The logo is a registered and protected trademark of bioMérieux

®

SA or one of its subsidiaries.

Page 7

General warnings

DANGER ! All biological fluids should be considered as potentially infectious.

Protective gloves must be worn when manipulating blood, products

derived from blood or objects contaminated with blood.

Qualified laboratory personnel should use acceptable procedures for

biohazardous material.

IMPORTANT! The user is advised to read and understand all instructions in this manual

to be able to derive the best performance from the mini API

®

The accuracy of results obtained with this instrument depends, in

particular, on the maintenance operations described in this manual.

The user should be aware that if the maintenance operations are not

performed, are only partially performed, or are not performed as described

in this manual, bioMérieux

®

SA is in no case liable for any false test

results obtained.

The configuration that you have purchased is adapted to the legislation

and standards of the different countries it will be sent to.

For this reason, it may differ from the one presented in this document.

However it will not prevent mini API

®

from operating correctly.

WARNING! This product is an in vitro diagnostic medical device. It complies with the

directives and standards mentioned in the certificate supplied with it.

However, this instrument may cause harmful interference if not installed in

accordance with the instruction manual.

bioMérieux

®

SA recommends that you observe the different warnings

inscribed on the instrument itself and indicated in the documentation

supplied.

.

Page 8

WARNING! Changes to the equipment not expressly approved by bioMérieux® SA

could void conformity and thus the user’s authority to operate the

equipment. The user will be required to repair damage at his own expense.

bioMérieux

â

SA is in no case liable for any damage that may arise from

failure to comply with technical specifications in this manual, from the

handling of biological fluids or any operation conducted on the equipment

not in compliance with these mandatory standards.

Page 9

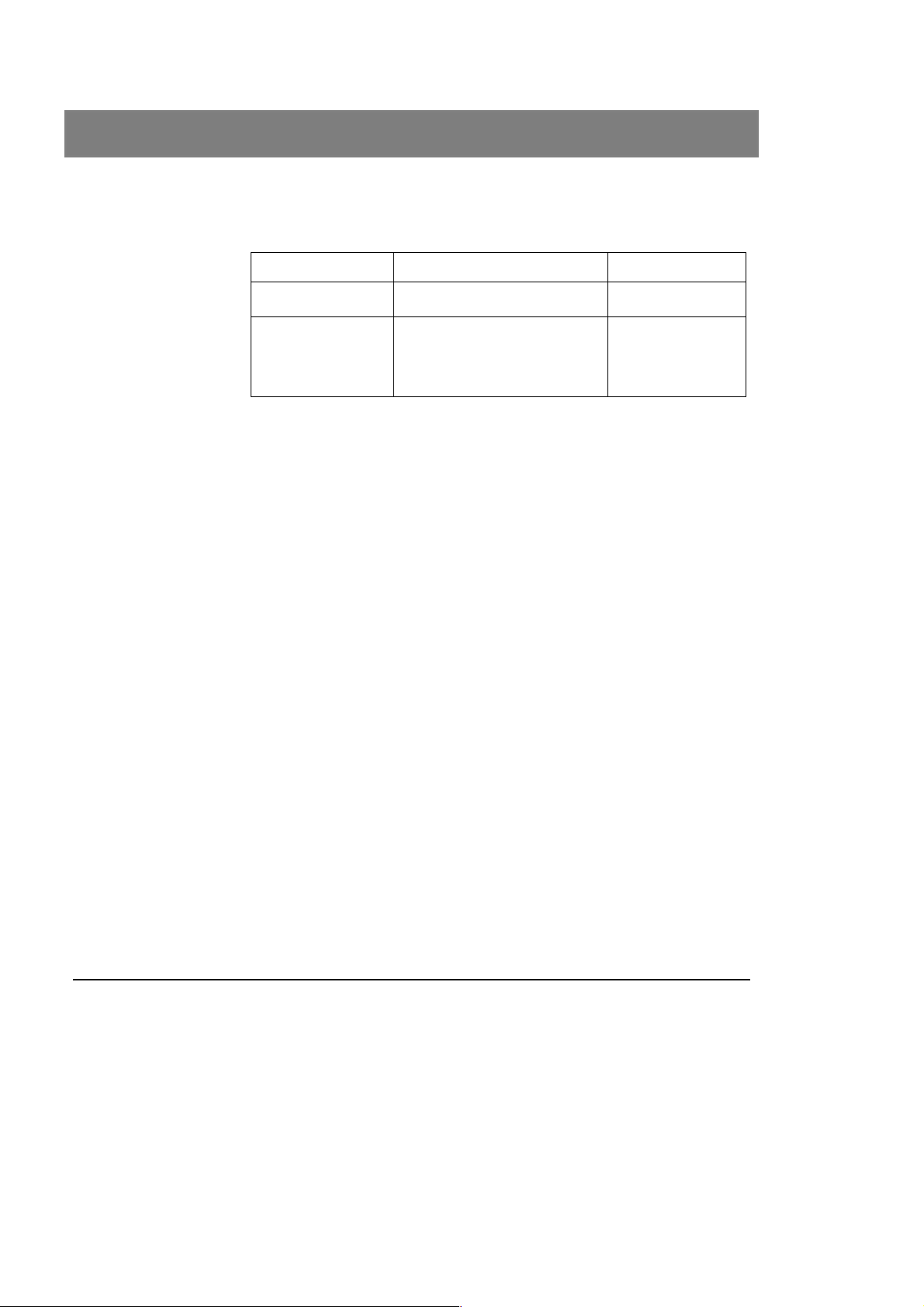

Revisions

The list of revision below summarizes replacements or additional pages in your

mini API

®

Instrument User's Manual.

Manual Reason Page(s)

V.B 04/2001 New format (7x9) All

V.C 10/2003 CE marking Cover page

Chapter 1

Chapter 6

mini API

®

Instrument User's Manual Revisions-1

Page 10

Page 11

Table of contents

List of figures VI-1

1

How to use this manual 1-1

Introduction ............................................................................................................................................... 1-1

Finding topics and procedures .................................................................................................................. 1-2

Typographic conventions.......................................................................................................................... 1-3

Graphic symbols ....................................................................................................................................... 1-4

2 Functional description of mini API® 2-1

Introduction ............................................................................................................................................... 2-1

Description / aim ....................................................................................................................................... 2-1

Configuration components........................................................................................................................ 2-2

Hardware ........................................................................................................................................... 2-2

Software............................................................................................................................................. 2-2

Consumables..................................................................................................................................... 2-2

General features and technical specifications of the analyzer .................................................................. 2-4

Environmental conditions ...................................................................................................................... 2-4

Physical features................................................................................................................................... 2-4

Electrical characteristics ........................................................................................................................ 2-5

Characteristics of optical components................................................................................................... 2-5

Principle of operation ................................................................................................................................ 2-7

Turbinephelometric reading................................................................................................................... 2-7

Colorimetric reading .............................................................................................................................. 2-8

3 Preliminary instructions 3-1

Introduction ............................................................................................................................................... 3-1

Recommendations for installation and use ............................................................................................... 3-1

Unpacking mini API®................................................................................................................................3-2

Assembly and installation.......................................................................................................................... 3-3

Choosing a location............................................................................................................................... 3-4

Setting up the strip carriage................................................................................................................... 3-5

Connections .......................................................................................................................................... 3-6

Preparing for operation.......................................................................................................................... 3-6

mini API

®

Instrument User's Manual V-1

Page 12

Table of contents

4 Set-Up 4-1

Starting mini API®..................................................................................................................................... 4-1

Adjusting the contrast and brightness of the screen.................................................................................. 4-2

Printer operation........................................................................................................................................ 4-3

Functions............................................................................................................................................... 4-4

Checking the operation of the printer (self-test) ........................................................................................ 4-5

Stopping mini API®................................................................................................................................... 4-6

5 Using mini API® 5-1

Procedure for use...................................................................................................................................... 5-1

6 Maintenance 6-1

Testing mini API®..................................................................................................................................... 6-2

Maintenance.............................................................................................................................................. 6-3

Cleaning mini API®............................................................................................................................... 6-3

Changing the ribbon.................................................................................................................................. 6-9

Changing the roll of paper....................................................................................................................... 6-11

Changing the fuse................................................................................................................................... 6-13

7 Troubleshooting 7-1

8 DENSIMAT densitometer 8-1

9 Electronic pipette 9-1

10 Appendices 10-1

Appendix A: Installing MS DOS 6.22 or later versions ............................................................................ 10-1

Appendix B: Installing the mini API® CONFIGURATION floppy disk...................................................... 10-2

Appendix C: Protecting data on floppy disks through write inhibit........................................................... 10-3

11 Glossary 11-1

12 Index 12-1

Notes Notes-1

V-2 mini API® Instrument User's Manual

Page 13

List of figures

2 Functional description of mini API

Fig. 2-1: Configuration components ........................................................................................................ 2-1

Fig. 2-1 : Using mini API®....................................................................................................................... 2-3

Fig. 2-2: Description of the spectral zone................................................................................................ 2-6

Fig. 2-3: Reading principle of the test strip reader .................................................................................. 2-6

3. Preliminary instructions

Fig. 3-1: Setting up the strip carriage...................................................................................................... 3-5

Fig. 3-2: Connections.............................................................................................................................. 3-6

4. Set-Up

®

Fig. 4-1: Back panel of mini API

Fig. 4-2: Adjusting the contrast and brightness of the screen ................................................................. 4-2

Fig. 4-3: Printer control panel.................................................................................................................. 4-3

Fig. 4-4: Print-out during the self-test...................................................................................................... 4-5

5. Using mini API®

Fig. 5-1: Position of the strip carriage and the protection rail .................................................................. 5-3

6. Maintenance

........................................................................................................... 4-1

Fig. 6-1: Strip carriage assembly. ........................................................................................................... 6-4

Fig. 6-2: Strip carriage ............................................................................................................................ 6-4

Fig. 6-3: Preparing the photodiode cleaning tool..................................................................................... 6-7

Fig. 6-4: Cleaning the photodiodes ......................................................................................................... 6-7

Fig. 6-5: Printer cover ............................................................................................................................. 6-9

Fig. 6-6: Paper cutter .............................................................................................................................. 6-9

Fig. 6-7: Changing the ribbon ............................................................................................................... 6-10

Fig. 6-8: Loading paper......................................................................................................................... 6-12

Fig. 6-9: Back panel of mini API®......................................................................................................... 6-13

mini API

®

Instrument User's Manual VI-1

Page 14

Page 15

1 How to use this manual

Introduction

The mini API® Instrument Manual deals solely with the instrument and

consumables. It includes the information you need for the installation, set-up

and maintenance of mini API

The software and the procedures for use are described in the mini API

Procedures Manual.

®

.

®

CAUTION! The user is advised to read and understand all instructions in this manual

to be able to derive the best performance from mini API

®

.

mini API® Instrument User's Manual 1-1

Page 16

How to use this manual

Finding topics and procedures

Finding topics and procedures

The information in the manual is organized in 12 chapters. The first 7 contain

the topics and procedures.

- Chapter 8 describes the DENSIMAT densitometer.

- Chapter 9 describes the electronic Pipette.

- Chapter 10 includes the Appendices.

- Chapter 11 is the glossary.

- Chapter 12 is the Index.

Table of contents

List of figures

Graphic symbols

Page headers and

page footers

Glossary

Index

The main table of contents of the manual is located on pages V-1 to V-2.

It lists each chapter and the procedures and/or topics contained in the manual.

Page VI-1 contains the list of figures found in this manual.

The standard symbols used for our instruments and their meanings can be

found in this list (Page 1-4 to 1-6).

Apart from the first page of every chapter, each page of the manual includes a

page header and a footer.

Each page header includes the chapter title and the title of a procedure or its

corresponding description.

These titles are located on the outside of the page so that you can thumb

through the pages to quickly locate a chapter or a procedure.

The footers contain the title of the manual, the name of the product and the

page number.

The glossary is located in chapter 11 at the back of the manual. It gives the

definition of the main technical terms used in the manual.

The index is located in chapter 12 at the back of the manual. It is used to locate

a particular description or procedure.

1-2 mini API® Instrument User's Manual

Page 17

How to use this manual

Typographic conventions

Typographic conventions

Following are the terms and visual cues used in this manual to aid in your

·

<Return>

<Ctrl>

E.g.:

<Esc>

<NumLock>

<>, <¯>, <¬> and

<®>

ABC 123 This typography is used for messages that appear on the screen.

understanding of the procedures.

The bullet point is used to denote an action to be performed.

Can also be <

This key is always associated with another key.

Both keys should be pressed simultaneously.

Press <Ctrl> U.

This key is sometimes used to quit the menu.

This key must be activated (light on) before you can use the numeric

keyboard.

These keys enable you to move the cursor in different directions on the

screen.

The <> key is also called <Cursor up> in the software.

> or <Enter> depending on the type of keyboard.

8

1

2

3

ABC 123

mini API® Instrument User's Manual 1-3

E.g.: C : \ >

This typography is used to represent a text to be typed through the computer

keyboard.

E.g.:

· Type: APICONF

4

5

Page 18

How to use this manual

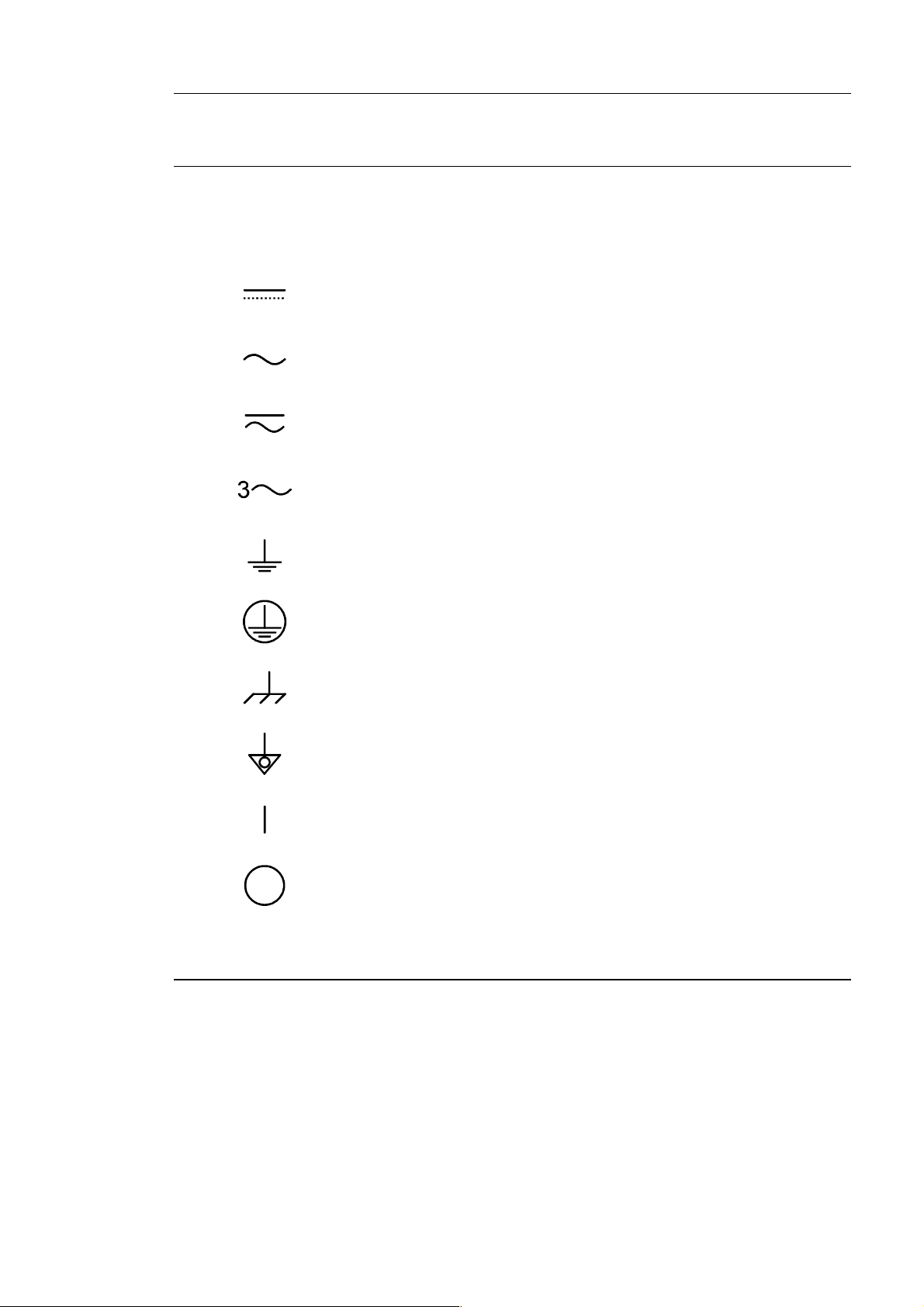

Graphic symbols

Graphic symbols

V.A 09/2003

The standard symbols used for our systems and their meanings can be found

below:

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) TERMINAL

PROTECTIVE CONDUCTOR TERMINAL

Frame or chassis TERMINAL

Equipotentiality

ON (power supply)

OFF (power supply)

1-4 mini API® Instrument User's Manual

Page 19

How to use this manual

Graphic symbols

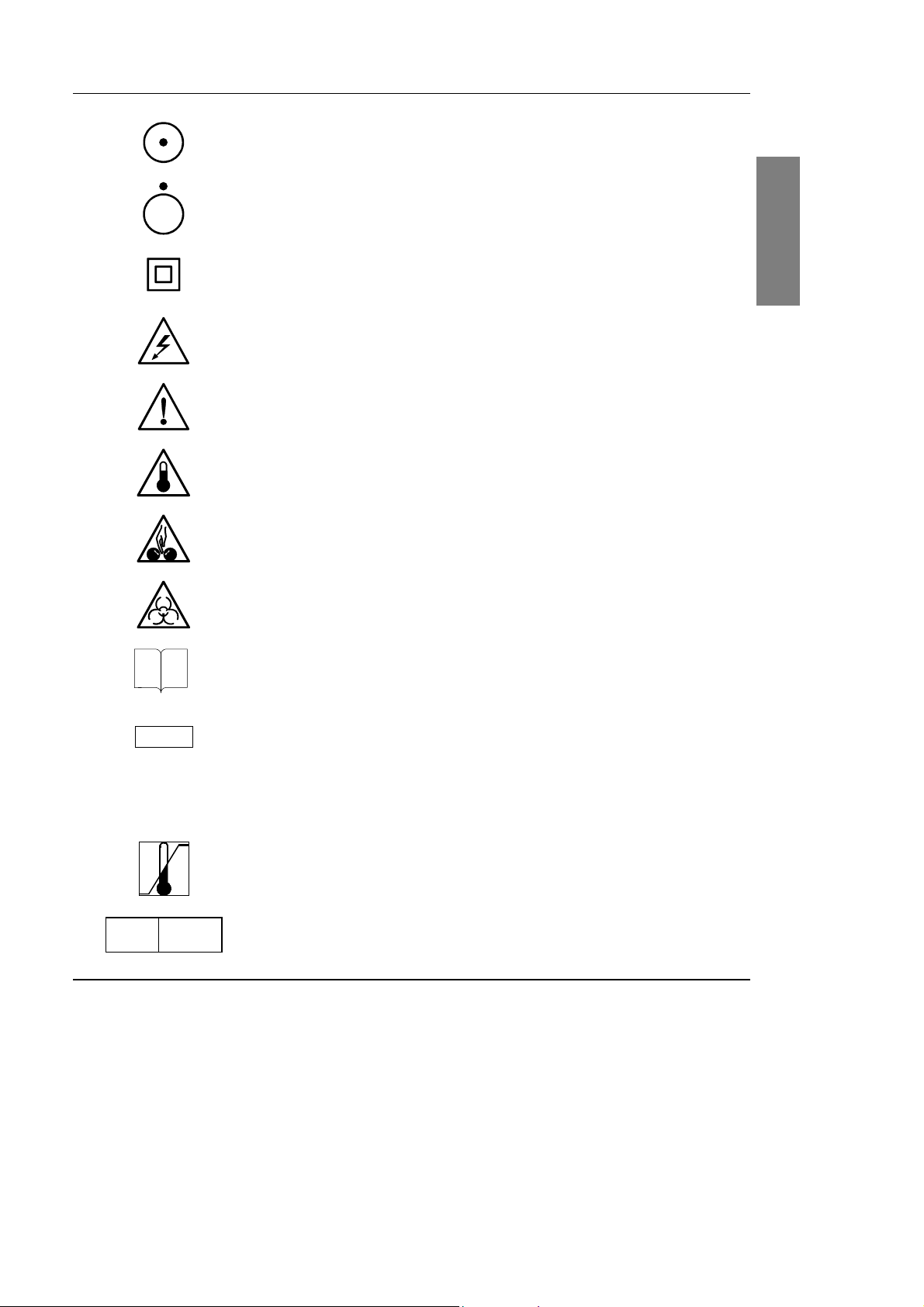

ON" (only for a component of the system equipment)

"OFF" (only for a component of the system equipment)

Equipment protected throughout by DOUBLE INSULATION or

i

REINFORCED INSULATION (equivalent to Class II of IEC 536)

Caution !: risk of electric shock

(background color: yellow, symbol and outline: black)

Caution !: see accompanying documents

(background color: yellow, symbol and outline: black)

Caution !: high temperature

Caution !: potential pinch point

Caution !: potential biohazard

Consult instructions for use

1

2

3

4

LOT

REF

EC REP

mini API® Instrument User's Manual 1-5

Batch code

Catalogue number

Temperature limitation

Authorised representative

5

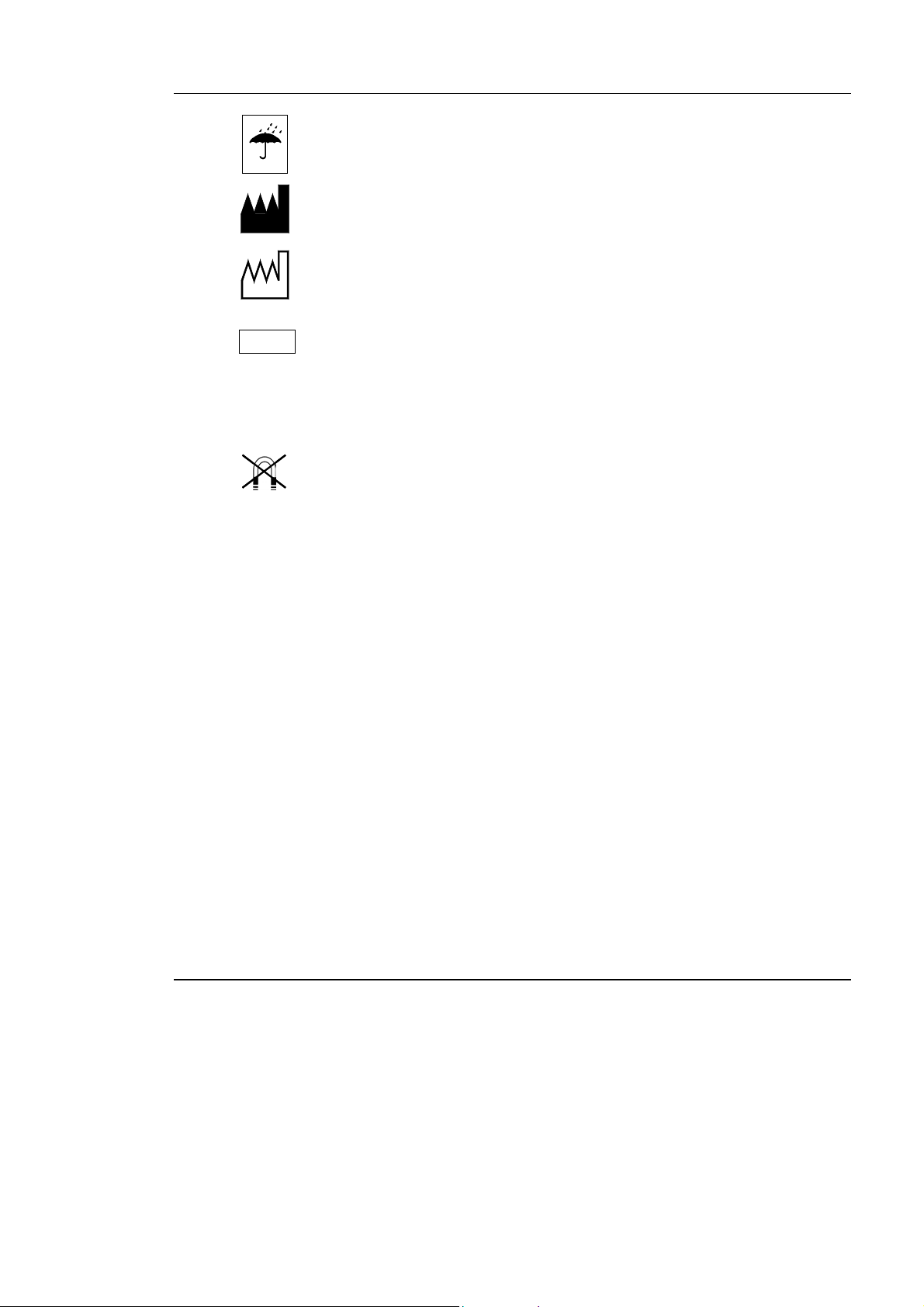

Page 20

How to use this manual

Graphic symbols

Keep dry

IVD

SN

Manufactured by

Date of manufacture

In vitro diagnostic medical device

Serial number

Keep away from magnetic field

1-6 mini API® Instrument User's Manual

Page 21

®

2 Functional description of mini API®

Introduction

This manual deals with the mini API® instruments and consumables.

The software is described in the mini API

Description / aim

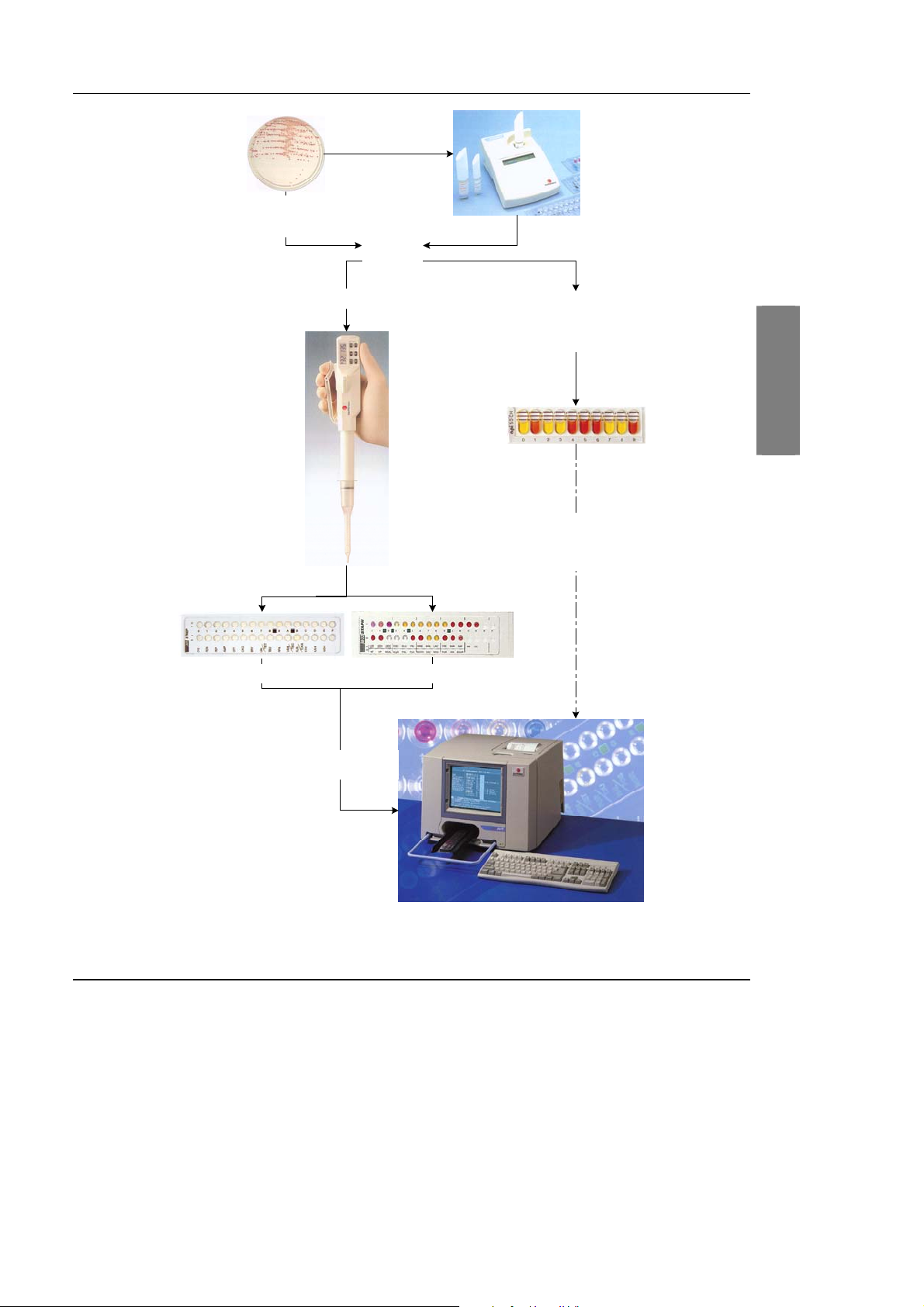

mini API® is designed for the automatic identification and susceptibility testing of

ID 32, rapid ID 32, ATB® and rapid ATB® strips.

It also enables computer assisted interpretation of API

®

Procedures Manual.

®

strips read visually.

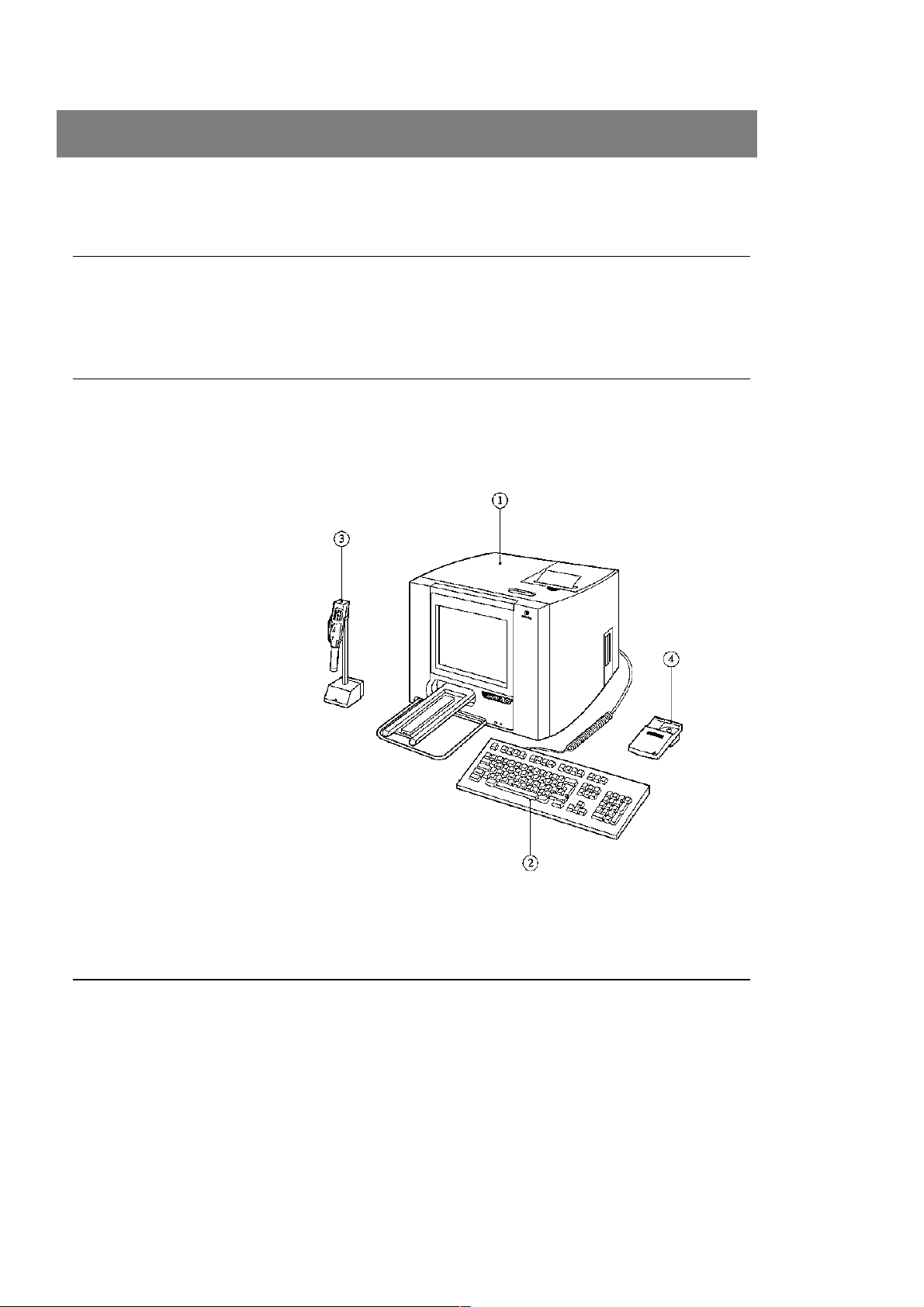

mini API

¬ -mini API

-Keyboard

® -Electronic pipette

¯ -DENSIMAT densitometer

Fig. 2-1 : Configuration components

®

Instrument User's Manual 2-1

Page 22

Functional description of mini API®

Configuration components

Configuration components

mini API® is an automated instrument for identification and susceptibility testing.

It consists of:

- the hardware,

- the software,

- the consumables.

Hardware

Software

The package includes:

®

- mini API

, a self-contained analytical module enabling:

. reading of test strips,

. management of results and data,

. printing of results obtained,

- a DENSIMAT densitometer to standardize the turbidimetry of the bacterial

suspension (please refer to the manual supplied with the densitomer).

- an electronic Pipette to dispense the required amount of bacterial

suspension into each cupule of the identification and susceptibility test strips

(55 µl or 135 µl) (please refer to the manual supplied with the pipette).

The mini API software enables:

- interpretation of data,

- interpretation of strip results (identification or susceptibility tests),

- expert analysis of susceptibility tests,

- storage of results on the hard disk,

- printing of results,

- extraction of data,

- connection with a central computer.

Consumables

The mini API® consumables include:

- strips with associated media and reagents

(see package inserts),

- ribbons and paper for the printer,

- pipette tips.

2-2 mini API® Instrument User's Manual

Page 23

Functional description of mini API®

Configuration components

Isolation

Isolation medium.

Orientation tests

Choice of

strips

Automated technique

Standardized

inoculation using the

electronic pipette

Standardization of the

inoculum using the

DENSIMAT

Manual technique

1

2

ATB or rapid ATB strips ID 32 or rapid ID 32 strips

Automatic reading

and interpretation.

Visual reading.

Entry of biochemical profiles

via keyboard.

Automatic interpretation.

3

4

5

Fig. 2-2 : Using mini API

®

mini API® Instrument User's Manual 2-3

Page 24

Functional description of mini API®

General features and technical specifications of the analyzer

General features and technical specifications of the

analyzer

Environmental conditions

- Operating Temperature: + 15° C to + 30° C (59° F to 86° F)

- Transport and storage temperature: -10°C to +50°C

- Relative humidity: 10 to 70 %, without condensation

- Type of installation: indoor, residential, commercial, and light industry.

- Maximum altitude for installation: 2000 m

- Installation category (voltage overload category): II

(in accordance with standard IEC 61010.1)

- Pollution degree: No. 2

(in accordance with standard IEC 61010.1)

Physical features

Dimensions

Instrument packed Instrument alone

Height: 50 cm (19.7 inches) 34.5 cm (13.6 inches)

Width: 60 cm (23.6 inches) 43 cm (17 inches)

Depth: 65 cm (25.6 inches) Protection rail in 46 cm (18.1 inches)

Protection rail out 63 cm (24.8 inches)

Mass

Instrument packed Instrument alone

Mass: 32 kg (70.41 lb) 25 kg (55.11 lbs)

2-4 mini API® Instrument User's Manual

Page 25

Functional description of mini API®

General features and technical specifications of the analyzer

Electrical characteristics

Class I Equipment

Power supply 100 - 240 VAC

The power supply is self-switching.

Characteristics of optical components

Consumption maximum 2 A from 90 to 120 VAC

maximum 1.1 A from 220 to 240 VAC

Frequency 50 - 60 Hz

Power maximum 240 VA

Safety fuse External (power input block)

3.15 AT - 250 VAC

- Light source: Halogen 12 V 20 W

- Central photosensor: BP W21

- Side photosensor: SD 5421

- Strip decoding: BP W34

1

2

3

4

5

mini API® Instrument User's Manual 2-5

Page 26

Functional description of mini API®

A

General features and technical specifications of the analyzer

Transmission %

Wavelength in mm

Fig. 2-3: Description of the spectral zone

Light

source

Filter support

A/D

DT Green

DT Blue

µP CARD

Multiplexer

Empty

Tray

Amplifier

K40

Strip code

Scattered light

Transmitted li ght

Lens

K60

Diaphragm

Photodiodes

Fig. 2-4: Reading principle of the test strip reader

TB Strip

2-6 mini API® Instrument User's Manual

Page 27

Functional description of mini API®

Principle of operation

Principle of operation

mini API® performs two types of readings:

Turbinephelometric reading

Turbinephelometric reading is used for test strips containing assimilation tests

Example: - ID 32 GN

1st stage

2nd stage

- ID 32 C

®

- ATB

UR

mini API® performs two types of measurements:

- Turbidimetry: measurement of the intensity of transmitted light (T) which is

inversely proportional to the amount of bacterial growth.

- Nephelometry: measurement of the intensity of light scattered (S) at 30°

directly proportional to the amount of bacterial growth.

These two measurements allow the estimation of the density of bacterial growth.

A turbinephelometric reading cycle occurs in two stages:

- Entry of the strip carriage.

- Detection of the strip code.

- Measurement without a filter.

- Exit of the strip carriage.

- At the end of the cycle, the result is processed by the software.

1

2

3

4

mini API® Instrument User's Manual 2-7

5

Page 28

Functional description of mini API®

Principle of operation

Colorimetric reading

Colorimetric reading is used for strips containing chromogenic substrates.

Example: - ID 32 STAPH

- rapid ID 32 E

- rapid ID 32 A

- rapid ID 32 STREP

mini API® measures the transmission of light for each cupule in four regions of

the visible spectrum.

A colorimetric reading cycle occurs in 4 stages:

1st stage 1st entry of the strip carriage:

- Detection of the strip code,

- Measurement under a K60 filter.

2nd stage 1st exit of the strip carriage:

- Measurement under a K40 filter.

3rd stage 2nd entry of the strip carriage:

- Measurement under a DT blue filter.

4th stage 2nd exit of the strip carriage:

- Measurement under a DT green filter.

At the end of the reading cycle, the result is transmitted to the computer.

2-8 mini API® Instrument User's Manual

Page 29

3 Preliminary instructions

Introduction

This chapter covers the very first steps you need to take before you can use

mini API

®

.

Recommendations for installation and use

In order to facilitate the assembly of mini API®, it is recommended to unpack the

components and carefully read the instructions below before starting.

CAUTION! Before unpacking the instruments, it is advisable to have previously

planned where they will be placed.

Avoid exposing the equipment to direct sunlight, excessive heat, humidity

or dust.

Only power cords and accessories supplied by bioMérieux

used to connect the instruments.

All connections should be performed with the power turned off.

Do not use sockets controlled by wall-mounted switches or power

programmers. Power cuts can destroy data in the memories of the

computer and analyzer.

The electrical power supply must be :

- direct,

- individual,

- calibrated,

- protected,

- compatible with the technical specifications of the product or

configuration.

No electrical equipment likely to cause interference (particularly

equipment not bearing the

electric line or operated in the vicinity of the mini API

Extension leads and serially-connected adapters should not be used.

If the power supply is not sufficient to guarantee proper functioning of the

instrument, an independent protective device, adapted to the instrument’s

technical characteristics should be used.

Do not use power sockets controlled by wall-mounted switches or timers.

The safety connection (grounding) should not be interrupted by an

extension lead without a protective conductor.

mark), should be connected to the same

®

®

SA should be

.

mini API

®

Instrument User's Manual 3-1

Page 30

Preliminary instructions

Unpacking mini API®

Unpacking mini API®

Before opening the boxes:

- Make sure that no damage has been caused during transportation.

If damage has occurred, make a claim to the transport company and notify

bioMérieux® or your local distributor.

When opening the boxes:

- Make sure that all the items in the packing list have been delivered.

If possible keep packaging materials in case the mini API

be moved in the future.

CAUTION! Any damage directly or indirectly resulting from the transport of the

instrument without adequate containers will not be covered by the

warranty or maintenance contract.

®

instruments have to

3-2 mini API® Instrument User's Manual

Page 31

Preliminary instructions

Assembly and installation

Assembly and installation

This manual contains information and warnings which have to be respected by

the purchaser or the leasor to ensure safe operation and to maintain the

instruments in good condition.

1

DANGER Any break in the grounding protective conductor inside or outside the

equipment or disconnection of the protective ground terminal may

render the equipment dangerous. Deliberate interruption of such

conductors is forbidden

Opening covers or removing components, except those manœuverable

by hand, may give access to parts that can be dangerous if touched

Prior to any adjustment, replacement, servicing or repair, disconnect the

instrument if it has to be opened.

After opening, if it is imperative to switch the instrument on, any

adjustment, servicing or repair must be performed by a qualified

technician, well aware of the possible risks.

The electrical plugs to which the mini API® and accessories are

connected, must be equipped with a ground terminal and plastic

shutters preventing a one-pin plug being used.

Using repaired fuses or short-circuiting fuses is prohibited.

bioMérieux® SA declines all responsibility in the event of intervention on

the equipment by unauthorized personnel and reserves the right to void

the warranty.

An improperly installed plug or poor wiring of the electrical outlet can

cause the exposed metal parts of the instrument to become dangerously

live. For your own safety, the plug of your instrument must be connected

to a power socket that is correctly wired and grounded. The user is

responsible for installing this power socket.

Before connecting or disconnecting the connecting cables, check that

the power supply leads are disconnected.

Whenever possible, use only one hand to connect or disconnect

signaling cables so as to avoid the risk of electric shock from contact

with two surfaces at different electrical potentials.

2

3

4

5

mini API® Instrument User's Manual 3-3

Page 32

Preliminary instructions

Assembly and installation

CAUTION! Never download into the computer, programs or floppy disks other than

Choosing a location

CAUTION! · Avoid exposing the equipment to direct sunlight, excessive heat, humidity

®

those provided by bioMérieux

SA. If these instructions are not complied

with, the computer could become infected with computer viruses. Any

intervention directly or indirectly resulting from the presence of such a

virus cannot be covered by the warranty or the maintenance contract.

or dust.

mini API

of your mini API

®

is equipped with adjustable feet. If you wish to adjust the height

®

, please contact the Technical Dept. at bioMérieux® or

your local distributor.

To lift the instrument, place your hands under either side of the unit. Do

not use the protection rail for this manoeuvre.

Place the equipment on a flat stable surface allowing:

- access to the ON/OFF switch,

- access to the disk drive,

- use of the protection rail,

- opening of the printer cover,

- circulation of air.

3-4 mini API® Instrument User's Manual

Page 33

Preliminary instructions

Assembly and installation

Setting up the strip carriage

· Place the strip carriage between rollers 1 and 3 and gently push it inside the

reader (Fig. 3-1).

¬ - Left-hand roller

- Optical switch for detection of the strip carriage

® - Right-hand roller

1

2

3

4

Fig. 3-1: Setting up the strip carriage

IMPORTANT! To avoid pinching your fingers, do not touch the roller while the strip

carriage is inserting.

mini API® Instrument User's Manual 3-5

5

Page 34

Preliminary instructions

Assembly and installation

Connections

·

Connect the power cord to the male outlet on the instrument.

·

Connect the keyboard cable (Fig. 3-2).

±

¬ -Keyboard cable connection

-Serial port for bi-directional interface

® -Power cord connection

¯ -Printer connection box

° -Printer "Reset" button

± -Printer

Preparing for operation

Prior to switching on mini API®, make sure that:

- The AC plug is connected to a grounded outlet.

- Spare fuses with appropriate rating and of specified type are available.

IMPORTANT ! Using repaired fuses and short-circuiting fuses is prohibited.

CAUTION! In case of intervention by unauthorized personnel, the Supplier rejects any

responsibility and reserves the right to cancel the warranty.

°

¯

¬

Fig. 3-2: Connections

®

3-6 mini API® Instrument User's Manual

Page 35

4 Set-Up

Starting mini API®

After you have assembled and installed the different mini API® components,

taking into account the safety recommendations in the "Preliminary Instructions"

chapter, proceed as follows:

Switch on mini API®: ON/OFF switch at the back of the instrument (Fig. 4-1). ·

- When mini API

- The instrument beeps twice: mini API

- The mini API

®

is switched on, the internal system configuration is

tested (identification of the microprocessor, size of the memory).

®

has successfully carried out the

internal tests.

®

software presentation page is briefly displayed on the

screen before the main menu appears.

mini API

¬

¬ - "ON/OFF" switch

Fig. 4-1: Back panel of mini API®

®

Instrument User's Manual 4-1

Page 36

Set-Up

Adjusting the contrast and brightness of the screen

Adjusting the contrast and brightness of the screen

You can adjust the contrast and the brightness of the screen to suit you

(Fig. 4-2).

¬ ® ¯

¬ -Hard disk access light (orange)

-Power indicator light (green)

® -Contrast adjustment

¯ -Brightness adjustment

Fig. 4-2: Adjusting the contrast and brightness of the screen

4-2 mini API® Instrument User's Manual

Page 37

Set-Up

G

t

Printer operation

Printer operation

The printer is used to print results.

The control panel (Fig. 4-3) consists of:

- 1 <FEED> button,

- 1 <ON LINE> button,

- 1 green ON LINE indicator light,

- 1 red ALARM indicator light.

1

2

reen ON LINE indicat or ligh

Red ALARM indicato r light

ALARM

<ON LINE> button

ON

LINE

FEED

<FEED> button

3

Fig. 4-3: Printer control panel

4

5

mini API® Instrument User's Manual 4-3

Page 38

Set-Up

Printer operation

Functions

The <ON LINE> button enables you to put the printer:

- ON LINE (the printer is waiting to print).

When the printer is ON LINE the green indicator light is on.

- OFF LINE (the printer is not available).

When the printer is OFF LINE, the green ON LINE indicator light is off.

If you press the <FEED> button once, the paper will advance by one line.

If you hold down the <FEED> button, the paper will continue advancing.

The green ON LINE indicator light automatically comes on a few seconds after

mini API

- ON

®

is switched on.

:

It indicates that the printer is waiting to print.

- OFF:

It indicates that the printer is not available.

Nota : If the red indicator light is on, the green indicator light is off.

The red ALARM indicator light:

- ON

:

There is no paper in the printer and/or the printer is down.

- OFF:

Everything is functioning properly.

4-4 mini API® Instrument User's Manual

Page 39

Set-Up

Checking the operation of the printer (self-test)

Checking the operation of the printer (self-test)

This test can be performed when mini API® is switched on.

Step 1

Step 2

Step 3

·

Hold down the <FEED> key.

·

Switch on mini API®.

When the printer starts printing, release the <FEED> button. Printing will stop

automatically.

You should obtain the following print-out:

1

2

3

Fig. 4-4: Print-out during the self-test

4

5

mini API® Instrument User's Manual 4-5

Page 40

Set-Up

Stopping mini API®

Stopping mini API®

When the main mini API® menu is displayed, to quit the application:

Press <Del>. ·

·

Switch off the instrument.

·

Push in the protection rail.

4-6 mini API® Instrument User's Manual

Page 41

5 Using mini API®

This chapter describes the preparation before using mini API®.

For further information, please refer to the Procedures Manual.

Procedure for use

Before reading the strips:

Step 1

Step 2 Preparing the strips for reading:

Step 3

·

Switch on mini API® using the ON/OFF switch at the back of the instrument.

·

Wait 15 minutes before starting to read the strips (preheating).

·

Remove the strip lids.

·

Add the reagents required for the development of certain tests (please refer

to the package inserts for the strips).

·

Pull out the protection rail.

mini API

CAUTION!

IMPORTANT ! Do not touch the strip carriage while it is moving.

®

Instrument User's Manual 5-1

You must pull out the protection rail completely to allow the strip carriage

to come out.

The protection rail delimits the area required for the strip carriage to move

freely. It should not be used as a handle to lift the instrument.

Do not place anything on the protection rail when it has been pulled out.

®

The mini API

automatic strip reading.

software automatically sends out the strip carriage at the time of

Page 42

Using mini API®

Procedure for use

Step 4

·

Place the strip on the strip carriage.

Step 5 Reading the strips:

·

Strip reading is initiated by the mini API software.

·

Processing of strips is automatic.

·

The strip code is read and the results are interpreted. This generates the type

of reading corresponding to the strip: turbinephelometric or colorimetric:

Note: For a turbinephelometric reading, the strip carriage enters and exits once

For a colorimetric reading, the strip carriage enters and exits twice.

At the end of the reading cycle the strip carriage stays out. It automatically goes in when

you quit the result entry module of the mini API® software.

If you forget to remove a strip from the strip carriage, please refer to Chapter 7

"Troubleshooting" in the mini API

The instrument is equipped with a fan which allows it to remain switched on when it is not

being used.

®

Procedures Manual.

5-2 mini API® Instrument User's Manual

Page 43

Using mini API®

Procedure for use

¬ - Strip carriage

- Protection rail

®

- Disk drive

¯

- Printer

mini API open

mini API closed

6

2

3

4

Fig. 5-1: Position of the strip carriage and the protection rail

mini API® Instrument User's Manual 5-3

5

Page 44

Page 45

6 Maintenance

DANGER! Any maintenance not described in this chapter must be performed by a

bioMérieux® technician or your local distributor.

Besides the maintenance operations described in this manual, the

instrument must undergo periodical preventive maintenance in order to

check, among other things, the accuracy of its results.

Preventive maintenance should only be performed by bioMerieux® SA

technicians or a qualified person trained by bioMerieux® SA.

The list of maintenance operations and their frequency is available from

bioMerieux® SA.

Opening covers or removing components, other than those

manoeuverable by hand, may give access to parts that can be dangerous

if touched.

Disconnect the instruments prior to any adjustment, replacement,

servicing or repair requiring them to be opened.

mini API

IMPORTANT! If the instrument has to be switched on again after opening, any

adjustment, servicing or repair should be carried out by a qualified

technician who is well aware of the possible risk.

®

Instrument User's Manual 6-1

Page 46

Maintenance

Testing mini API®

Testing mini API®

mini API® must be tested:

- when there is any doubt as to the precision of the instrument,

- when visual interpretation differs from automatic reading.

CAUTION!

The tests should be performed by a bioMérieux

®

technician.

6-2 mini API

®

Instrument User's Manual

Page 47

Maintenance

Maintenance

Maintenance

Cleaning mini API®

CAUTION!

Do not use corrosive products to clean the surface of mini API® and the

screen, as they could damage the components.

* To remove dust from the surface of the machine:

·

Wipe gently with a soft, dry cloth. If this is not sufficient, use a special plastic

casing cleaner on a soft cloth.

* To clean the disc drive:

·

Use the 3.5" disc cleaning kit (available from bioMérieux® SA, part no.

4550122A).

* To clean the printer:

6

7

·

CAUTION!

IMPORTANT! The preventive maintenance described in this chapter should be

Note: It is the responsability of the user to perform maintenance operations as described in this

Use a soft-bristled brush, taking care to remove all dust or dirt.

The printer should be cleaned several times a year to ensure proper functioning

(we recommend cleaning once a month).

Do not use alcohol or solvents to clean the printer, as they could damage

components.

Do not allow water to run into the printing mechanism or on the electronic

components.

Do not use hard-bristle brushes or abrasive materials.

Do not spray lubricants inside the printer.

Do not use compressed air to clean inside the printer.

performed every year.

During the warranty period, and then as part of the maintenance contract,

or when requested, you can obtain the intervention of a bioMérieux

technician or your local distributor.

manual.

3

4

5

®

mini API® Instrument User's Manual 6-3

Page 48

Maintenance

Maintenance

¬

®

¬ – Left-hand roller.

– Strip carriage optical switch.

® – right-hand roller.

Fig. 6-1: Strip carriage assembly. Fig. 6-2: Strip carriage

IMPORTANT! To avoid pinching your fingers, do not touch the roller while the strip

carriage is inserting.

¬ - Notch

- Hole (reading of strip test)

Hole (reading of strip code)

® -

6-4 mini API

®

Instrument User's Manual

Page 49

Maintenance

Maintenance

DANGER Prior to any decontamination procedures, the power switch must be

moved to the OFF position. Power cords must be disconnected from the

power supply.

Disposable powderless gloves should be worn. Do not allow any

disinfectant solution to spill into the instrument.

* To clean the strip carriage:

6

Remove the carriage. ·

·

Use the <¬> and <®> keys to position the cursor on "api/ATB".

·

Press <Return>.

·

Press <F2> = Identify an organism, so that the strip carriage sides out.

·

Press <Return> to perform a reading without a strip.

When the "Not recognised" message appears:

·

Remove the carriage completely from the machine.

·

Press <ESC> twice.

·

Press <Del> to quit the software.

·

Switch off mini API®.

·

Clean the strip carriage with soap and water (do not use detergents).

·

Rinse in clean water.

·

Leave to dry or dry using compressed air (RCII type or equivalent - neutral

dry gas) or use a hairdryer.

·

Put the strip carriage back into place between rollers 1 and 3 and push it

gently back into the reader (Fig. 6-1).

Maintenance should be carried out at regular intervals to ensure optimum

reading performance and correct decoding of the strip code.

7

3

4

IMPORTANT! All media should be considered as potentially infectious and be

manipulated appropriately.

* To decontaminate the strip carriage:

mini API® Instrument User's Manual 6-5

IMPORTANT! This operation should be performed by qualified laboratory personnel

only, who should take the usual precautions necessary for infectious

agents (disposable gloves etc...).

5

Page 50

Maintenance

Maintenance

IMPORTANT! Do not place the strip carriage in a bleach solution (risk of corrosion).

DANGER! All biological fluids should be considered as potentially infectious.

Should the contents of a strip accidentally spill onto the strip carriage,

decontaminate the carriage as follows:

Remove the strip carriage and place it in a disinfectant solution (e.g.

·

Bioblock BACTINYL 5M).

· Clean the strip carriage as described above.

Qualified laboratory personnel should use acceptable procedures for

biohazardous material.

6-6 mini API

®

Instrument User's Manual

Page 51

Maintenance

Maintenance

¬ -Cut the cotton swab to the required length.

-Insert the cotton swab into the special tool.

6

7

Fig. 6-3: Preparing the photodiode cleaning tool

3

4

Fig. 6-4: Cleaning the photodiodes

mini API® Instrument User's Manual 6-7

5

Page 52

Maintenance

Maintenance

* To clean the photodiodes:

Remove the strip carriage (see page 6-5). ·

·

Prepare the cleaning tool (Fig. 6-3).

·

Dampen it with 90° alcohol.

·

Clean the diodes on the lower part between the two rollers (Fig. 6-4).

·

Leave to dry or dry using compressed air (RCII type or equivalent - neutral

dry gas).

·

Put the strip carriage back into place (see Fig. 6-1 page 6-4).

Note: The photodiode cleaning tool is available from bioMérieux

no. 4550409 A.

®

SA under spare part

6-8 mini API

®

Instrument User's Manual

Page 53

Maintenance

Changing the ribbon

Changing the ribbon

DANGER! Do not touch the printing head immediately after printing as it may be

very hot.

Remove paper from the printer before changing the ribbon.

Step 1

Step 2

· Open the printer cover.

Fig. 6-5: Printer cover

· Lift the paper cutter.

Note: The ribbon is wound around two plastic spools.

¶

6

7

3

4

Ê -

Paper cutter

Fig. 6-6: Paper cutter

mini API® Instrument User's Manual 6-9

5

Page 54

Maintenance

Changing the ribbon

Step 3

* To remove the old ribbon,

Release the detection lever on the left-hand spool and pull the spool

·

upwards.

· Repeat the operation for the right-hand spool.

À Spools  Fixing pin Ä Ribbon guide Æ Drive pins

Á Detection lever à Platen Å Printing head

Fig. 6-7: Changing the ribbon

Step 4

Step 5

* To insert a new ribbon,

Unwind a few centimeters of ribbon (the drive pins Æ should be facing

·

downwards).

·

Release the detection lever Á and insert the left-hand spool.

·

Position the ribbon correctly before inserting the right-hand spool.

·

Release the detection lever Á and insert the right-hand spool.

·

Retighten the ribbon by turning the left-hand spool clockwise until the righthand spool begins to turn.

·

Put the paper into place.

Note: The life span of a ribbon is approximately 800,000 characters.

6-10 mini API

®

Instrument User's Manual

Page 55

Maintenance

Changing the roll of paper

Changing the roll of paper

Switch off mini API® before changing the roll of paper.

Step 1

Step 2

Step 3

· Open the printer cover.

· Lift the paper cutter.

· Remove the rest of the old roll of paper and take out the holder.

· Prepare the new roll.

The edge of the paper should be cut cleanly .

6

Step 4

Step 5

7

Correct Incorrect

· Insert the holder inside the roll of paper.

Roll of paper

Holder

· Position them inside the printer.

Make sure that the paper unrolls correctly, from underneath.

3

4

5

mini API® Instrument User's Manual 6-11

Page 56

Maintenance

Changing the roll of paper

Step 6

· Slide the paper into the printer, holding the leading edge down flat.

¬

¬ Ink ribbon

Paper feed

Fig. 6-8: Loading paper

Step 7

Step 8

Step 9

Step 10

* At the same time,

Press <FEED>. ·

The paper will be fed through by the printer.

Green ON LINE light

Red ALARM light

<ON LINE> k ey <FEED> key

· Feed out approximately ten centimeters of paper.

· Pass the paper through the paper cutter.

· Lower the paper cutter and the printer cover.

ON

LINE

FEED

6-12 mini API

®

Instrument User's Manual

Page 57

Maintenance

Changing the fuse

Changing the fuse

·

Switch off mini API®.

·

Disconnect the power plug.

·

Open the fuse holder located above the "On/Off" switch (insert a

screwdriver into the space provided above the power switch).

·

Replace the faulty fuses with new ones.

(3.15 AT - 250 V).

6

DANGER! Disconnect the instruments prior to any adjustment, replacement,

servicing or repair during which the instrument has to be opened.

À Fuse holder

Á

Space for screwdriver

"On/Off" switch

Â

Male power plug

Ã

Fig. 6-9: Back panel of mini API

®

7

3

4

5

DANGER! For continuous protection against fire hazard, replace used fuses with

fuses of the same type and rating, as recommended by bioMérieux® SA.

mini API® Instrument User's Manual 6-13

Fuses 3.15 AT- 250V

Page 58

Page 59

7 Troubleshooting

Please refer to chapter 7 "Troubleshooting" in the mini API® Procedures

Manual.

mini API

®

Instrument User's Manual 7-1

Page 60

Page 61

8 DENSIMAT densitometer

Please refer to the manual supplied with the DENSIMAT densitometer

(Product no. 99535).

mini API

®

Instrument User's Manual 8-1

Page 62

Page 63

9 Electronic Pipette

Please refer to the manual supplied with the electronic Pipette

(Product no. 93201).

mini API

®

Instrument User's Manual 9-1

Page 64

Page 65

10 Appendices

Appendix A: Installing MS DOS 6.22 or later versions

CAUTION! The installation of MS DOS 6.22 or later versions requires the intervention

of a qualified technician.

mini API

®

Instrument User's Manual 10-1

Page 66

Appendices

Appendix B: Installing the mini API® CONFIGURATION floppy disk

Appendix B: Installing the mini API® CONFIGURATION

floppy disk

This floppy disk contains all the files required for the configuration of your

mini API

Initialize the computer. When the: C :\ > prompt appears on the screen:

·

·

When the A:\> prompt appears on the screen:

·

®

for automated use of the mini API® software.

Insert the mini API® CONFIGURATION floppy disk in drive A. ·

Type:

A:

Press <Return>.

Type:

APICONF

·

Press <Return>.

When all the files have been installed A :\ > appears on the screen

·

Press <Ctrl>, <Alt>, <Del> simultaneously to restart the computer.

10-2 mini API® Instrument User's Manual

Page 67

Appendices

Appendix C: Protecting data on floppy disks through write inhibit

Appendix C: Protecting data on floppy disks through

write inhibit

3.5" Floppy disks To locate the write-inhibit shutter,

It is possible to accidentally format or write data on a disk.

Important data may be lost (for instance Thesauri on the backup disk).

When disks are write-inhibited, they can be read but no information can be

written on them.

·

Turn the disk over, with the label to the bottom.

To avoid writing on a disk,

·

Move the shutter downwards.

To allow writing on a disk,

·

Move the shutter upwards.

6

7

8

Not writeprotected

Label

mini API® Instrument User's Manual 10-3

Shutter

Writeprotected

9

10

Page 68

Page 69

11 Glossary

AZERTY KEYBOARD

COLORIMETRIC READING

DISK DRIVE

HARD DISK

NEPHELOMETRY

PHOTOSENSOR

QWERTY KEYBOARD

SCREEN

Keyboard with keys corresponding to French characters.

Measurement of light transmitted in four regions of the visible spectrum for

each cupule of a colorimetric test strip.

Mechanical and electronic module for reading information on a floppy disk.

Rigid magnetic support to back up data and programs.

Measurement of the intensity of light scattered (S) at 30°, directly

proportional to the bacterial growth.

Sensor enabling a light source received to be transformed into a source of

electrical current.

Keyboard with keys corresponding to English characters.

Used to display information from the mini API® software.

STRIP

TURBIDIMETRY

TURBINEPHELOMETRIC

READING

mini API

®

Instrument User's Manual 11-1

Set of standardized miniaturized tests on a plastic support.

Measurement of the intensity of transmitted light (T) which is inversely

proportional to the bacterial growth.

Reading which combines turbidimetry and nephelometry to evaluate the

bacterial density.

Page 70

Page 71

12 Index

B

Backup

~ disk...................................................................................................................................................... 10-3

C

Connection

Safety ~ .................................................................................................................................................... 3-1

D

Disk drive.................................................................................................................................... 3-4, 10-2, 11-1

F

Files............................................................................................................................................................ 10-2

I

Installation .................................................................................................................................. 3-1, 10-1, 10-2

~ category................................................................................................................................................. 2-4

recommendations for ~............................................................................................................................. 3-1

type of ~.................................................................................................................................................... 2-4

P

Printer.................................................................................................................................................... 3-4, 4-3

~ operating ............................................................................................................................................... 4-3

ribbons and paper for the ~ ...................................................................................................................... 2-2

R

Reading

colometric ~ .............................................................................................................................. 2-8, 5-2, 11-1

turbinephelometric ~................................................................................................................. 2-7, 5-2, 11-1

S

Screen ........................................................................................................................................................ 11-1

adjustment of the contrast and the brightness of the ~............................................................................. 4-2

Strip carriage ....................................................................................................................2-7, 2-8, 3-5, 5-2, 5-3

Strips ............................................................................................................................................ 5-1, 5-2, 11-1

~ results.................................................................................................................................................... 2-2

detection of the ~ code............................................................................................................................. 2-7

reading the ~ ............................................................................................................................................ 5-2

test ~......................................................................................................................................................... 2-2

mini API

®

Instrument User's Manual 12-1

Page 72

Page 73

Notes

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................

mini API

®

Instrument User's Manual Notes-1

Page 74

The logo is a registered and protected trademark of bioMérieux® SA or one of its subsidiaries.

Loading...

Loading...