Page 1

User Manual

[03]

95269

(01/2010)

EC REP

bioMérieux, Inc.

Box 15969

Durham, North Carolina 27704-0969 / USA

Tel. (1) 800-682-2666

bioMérieux

au capital de 12 029 370 €

673 620 399 RCS LYON

69280 Marcy l’Etoile / France

tél. 33 (0)4 78 87 20 00 / fax 33 (0)4 78 87 20 90

http://www.biomerieux.com

®

SA

Page 2

Algeria

bioMérieux Algérie EURL

Algéria Business Center

Les Pins Maritimes - Mohammadia

Alger

tel. (213) 21 89 14 81

fax (213) 21 89 14 82

Argentina

bioMérieux Argentina

Av. Congreso 1745

C1428BUE

Capital Federal Buenos Aires

tel. (54) 11 5555 6800

fax (54) 11 5555 6888

Australia

bioMérieux Australia P/L

Unit 25 - Parkview Business Centre

1, Maitland Place

Baulkham Hills NSW 2153

tel. (61) 2 8852 4700

fax (61) 2 8852 4777

Austria

bioMérieux Austria GmbH

Eduard-Kittenberger-Gasse 97

Top 3

A-1230 Wien

tel. (43) 186 50 650

fax (43) 186 50 661

Belgium

bioMérieux Benelux s.a./n.v.

Media Square

18–19 Place des Carabiniers

Bruxelles 1030

tel. (32) 2 743 01 70

fax (32) 2 733 55 97

Brazil

bioMérieux Brasil SA

Estrada Do Mapuá

491 Taquara - Jacarepaguá

CEP 22710 261

Rio de Janeiro RJ

tel. (55) 21 2444 1400

fax (55) 21 2445 6025

Canada

bioMérieux Canada, Inc.

7815, Henri-Bourassa West

Saint Laurent, QC

H4S 1P7

tel. (1) 514 336 7321

fax (1) 514 807 0015

Chile

bioMérieux Chile S.A.

Seminario 131

Providencia

Santiago

tel. (56) 2634 20 92

fax (56) 2634 20 93

China

bioMérieux China Limited

Room 1601-02B & 10

Est Ocean Centre

nº 24A Jiang Guo Men Nei Street

100004 Beijing

tel. (86) 10 6515 6963

fax (86) 10 6515 6993

bioMérieux China Limited

Room 2605, South Tower,

World Trade Center

371-375 Huan Shi Dong East Road

510095 Guangzhou

tel. (86) 20 8762 7010

fax (86) 20 8762 7015

Colombia

bioMérieux Colombia Ltda

Avenida 15 No. 100-43

Piso 2

Bogotá, D.C.

tel. (57) 1 520 0080

fax (57) 1 520 0088

(57) 1 520 0831

Czech Republic

bioMérieux CZ s.r.o.

Business Park Kosice

Jinonická 80

158 00 Praha 5

tel. (420) 2 57 290 623

(420) 2 57 290 232

fax (420) 2 57 290 964

Denmark

bioMérieux Danmark Aps

Smedeholm 13C

2730 Herlev

tel. (45) 70 10 84 00

fax (45) 70 10 84 01

Finland

bioMérieux Suomi Oy

Konalantie 47 C

FI-00390 Helsinki

tel. (358) 9 8545 6000

fax (358) 9 8545 6045

France

bioMérieux SA

69280 Marcy l’Etoile

tel. (33) (0)4 78 87 20 00

fax (33) (0)4 78 87 20 90

http://www.biomerieux.com

Germany

bioMérieux Deutschland GmbH

Weberstrasse 8

D 72622 Nürtingen

tel. (49) 7022 30070

fax (49) 7022 36110

Greece

bioMérieux Hellas S.A.

Papanikoli 70

15232 Halandri

Athens

tel. (30) 2 10 81 72 400

fax (30) 2 10 68 00 880

Hungary

bioMérieux Hungária Kft.

Fóto út. 56 (5. emelet)

H-1047 Budapest

tel. (36) 1 231 3050

fax (36) 1 231 3059

India

bioMérieux India Pvt. Ltd

A-32, Mohan Co-Operative Ind. Estate

New Delhi 110 024

tel. (91) 11 42 09 88 00

fax (91) 11 24 64 88 30

Indonesia

Representation Office

bioMérieux Indonesia

Enseval Building

Kawasan Industri Pulo Gadung JI. Pulo - Lentut No. 10

Jakarta Timur 13920

tel. (62) 21 461 51 11

fax (62) 21 460 41 07

Italy

bioMérieux Italia S.p.A.

Via Fiume Bianco, 56

00144 Roma

tel. (39) 06 523 081

fax (39) 06 523 08240

Ivory Coast

bioMérieux Afrique Occidentale

08 BP 2634

Avenue Joseph Blohorn

Abidjan 08

tel. (225) 22 40 93 93/22 40 41 40

fax (225) 22 40 93 94

Japan

Sysmex bioMérieux, Ltd.

Osaki Central Tower 8F

1-2-2 Osaki Shinagawa-ku

Tokyo 141-0032

tel. (81) 3 6834 2666

fax (81) 3 6834 2667

Korea

bioMérieux Korea Co., Ltd.

1st & 2nd Floor, Yoosung Building

# 830-67 Yeoksam-dong,

Kangnam-gu

Séoul 135-080

tel. (82) 2 2188 4700

fax (82) 2 547 6263

Mexico

bioMérieux México SA de CV

Chihuahua 88, col. Progreso

México 01080, D.F.

tel. (52) 55 5481 9550

fax (52) 55 5616 2245

Netherlands (The)

bioMérieux Benelux BV

Boseind 15

P.O. Box 23

5280 AA Boxtel

tel. (31) 411 65 48 88

fax (31) 411 65 48 73

i Manual Name

702358-4EN1 REV nn/nnnn

Page 3

New Zealand

bioMérieux New Zealand Ltd.

C/- Logical Freight Solutions

12C Rennie Drive, Airport Oaks

Auckland

tel. (64) 9 918 6354

fax (64) 9 918 6355

Norway

bioMérieux Norge AS

Økernveien 145

N-0513, Oslo

tel. (47) 23 37 55 50

fax (47) 23 37 55 51

Philippines (The)

Representation Office

bioMérieux Philippines

11th Floor, Pearlbank Centre

146 Valero Street, Salcedo Village

1227 Makati City

tel. (632) 817 7741

fax (632) 812 0896

Poland

bioMérieux Polska Sp. Z.o.o.

Ul. Zeromskiego 17

01-882 Warsaw

tel. (48) 22 569 85 00

fax (48) 22 569 85 54

Portugal

bioMérieux Portugal, Lda.

Av. 25 de Abril de 1974, nº 23-3º

2795-197 LINDA-A-VELHA

tel. (351) 21 415 23 50

fax (351) 21 418 32 67

Russia

o.o.o. bioMérieux

Derbenevskaya ul. 20, str. 11

115 114 Moscow

tel. (7) 495 221 10 79

fax (7) 495 221 10 79

Singapore

bioMérieux Singaporete. Ltd.

11 Biopolis Way, Helios, Block 11

#10-03 Singapore 138667

tel. (65) 6513 9554

fax (65) 6478 9501

South Africa

bioMérieux South Africa Pty

7 Malibongwe Drive

Randburg 2125

tel. (27) 11 801 91 10

fax (27) 11 791 24 19

Spain

bioMérieux España S.A.

Manual Tovar, 45–47

28034 Madrid

tel. (34) 91 358 11 42

fax (34) 91 358 06 29

Sweden

bioMérieux Sverige AB

Hantverksvägen 15

436 33 Askim

tel. (46) 31 68 84 90

fax (46) 31 68 48 48

Switzerland

bioMérieux Suisse s.a.

51, avenue Blanc

Case postale 2150

1211 Genève 2

tel. (41) 22 906 57 60

fax (41) 22 906 57 42

Taiwan

Representation Office

bioMérieux China Limited

Taiwan Branch

RM 608, No. 6-3 Ching Cheng Street

Taipei 105

tel. (886) 2 2545 2250

fax (886) 2 2545 0959

Thailand

bioMérieux Thailand Ltd

3195/9 Vibulthani Tower, 4th Floor

Rama IV Road, Klongton, Klongtoey

Bangkok 10110

tel. (66) 2 661 56 44

fax (66) 2 661 56 45

Turkey

bioMérieux Diagnostik A.S.

ğirmen Sok. Nida Plaza Kat:6

De

34742 Kozyata

tel. (90) 216 444 00 83

fax (90) 216 373 16 63

United Kingdom

bioMérieux UK Ltd

Grafton Way, Basingstoke

Hampshire RG22 6HY

tel. (44) 1256 461881

fax (44) 1256 816863

USA

bioMérieux, Inc.

100 Rodolphe Street

Durham NC 27712

tel. (1) 919 620 2000

Vietnam

Representation Office

bioMérieux Vietnam

Room 4A, 4th Floor

Green House Building

62A Pham Ngoc Thach Street, Ward 6

District 3

Ho Chi Minh City

tel. (84) 88 209 906

fax (84) 88 209 905

ği-Istanbul

Manual Name ii

702358-4EN1 REV nn/nnnn

Page 4

This product and its documentation complies with the In Vitro Diagnostic

Medical Device Directive 98/79/EC.

Liability Disclaimer

bioMérieux, Inc. makes no express or implied warranty regarding this

manual, its quality, performance, or appropriate use regarding any type of

specific procedure.

Furthermore, this manual may be modified by bioMérieux without notice and

without implying any obligation or liability on the part of the company.

Intellectual Property

bioMérieux, the blue logo, BacT/ALERT, and MB/BacT are used, pending,

and/or registered trademarks of bioMérieux in the USA and other countries.

CLSI is a registered trademark of Clinical and Laboratory Standards Institute,

Inc.

PSC and Quickscan are a registered trademarks of PSC, Inc.

Zip is a registered trademark of Iomega Corporation.

No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language (human or

computer) in any form, or by any means whatsoever, without the prior

express written permission of bioMérieux, Inc.

© 2010 bioMérieux, Inc. All rights reserved.

Page 5

Warranty

Seller, bioMérieux, Inc., warrants the BacT/ALERT® 3D 60 instrument (the

“instrument”) to the original purchaser for a period of one (1) year after date of

installation against defects in material and workmanship and defects arising

from failure to conform to specifications applicable on the date of installation.

Seller further agrees to correct, either by repair, or, at its election, by

replacement, any such defect found on examination to have occurred, under

normal use and service, during such one (1) year period, provided Seller is

promptly notified in writing upon discovery of such defect.

Seller shall not be liable under this Warranty for any defect arising from abuse

of the system, failure to operate and maintain the system in accordance with

the documentation included with the Instrument, including repair service,

alteration or modification of the system by any person other than service

personnel of bioMérieux, Inc., or Seller; or use of modified, changed, or

previously used disposables.

The Warranty of Seller set forth above and the obligations and liabilities of

Seller thereunder are exclusive and in lieu of all other remedies or warranties,

express or implied, arising by law or otherwise, with respect to the system

delivered hereunder (including without limitation any obligation of Seller with

respect to merchantability, fitness for particular purpose, and consequential

damages, and whether or not occasioned by Seller’s negligence).

This Warranty shall not be extended or altered except by written instrument

signed by Seller.

All of the product elements in the Seller’s Instrument and the total instrument

are warranted to be new or equivalent to new for the full product warranty

period of one year. Disposables and replacement items with a normal life

expectancy of less than one (1) year, such as batteries and bulbs, are

excluded from this warranty.

Page 6

Page 7

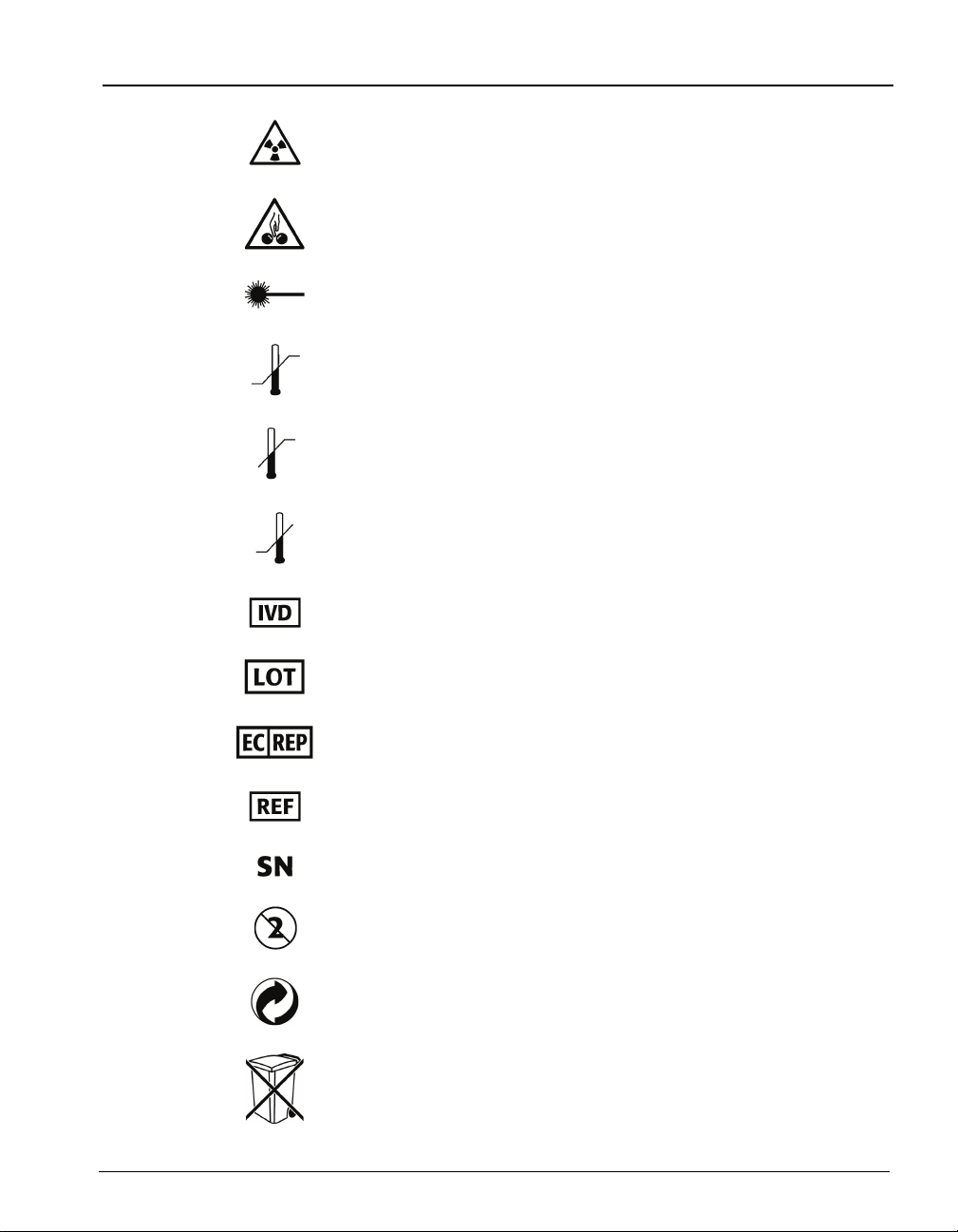

STANDARD SYMBOLS

The following table presents symbols that may appear in the instructions for

use or on the instrument, package inserts, or packaging.

CE-Marking of Conformity

Consult Instructions for Use

Use by

Manufacturer

Date of manufacture

Contains sufficient for <n> tests

Keep dry

Fragile, handle with care

Caution, consult accompanying documents

Biological risks

Electric shock warning

Page 8

Radiation warning

Potential pinch-point warning

Laser

Temperature limitation

Upper limit of temperature

Lower limit of temperature

In Vitro Diagnostic Medical Device

Standard Symbols

Batch code

Authorized Representative in the European Community

Catalog number

Serial Number

Do not reuse

Recyclable

Separate collection for waste electrical and electronic

equipment

Page 9

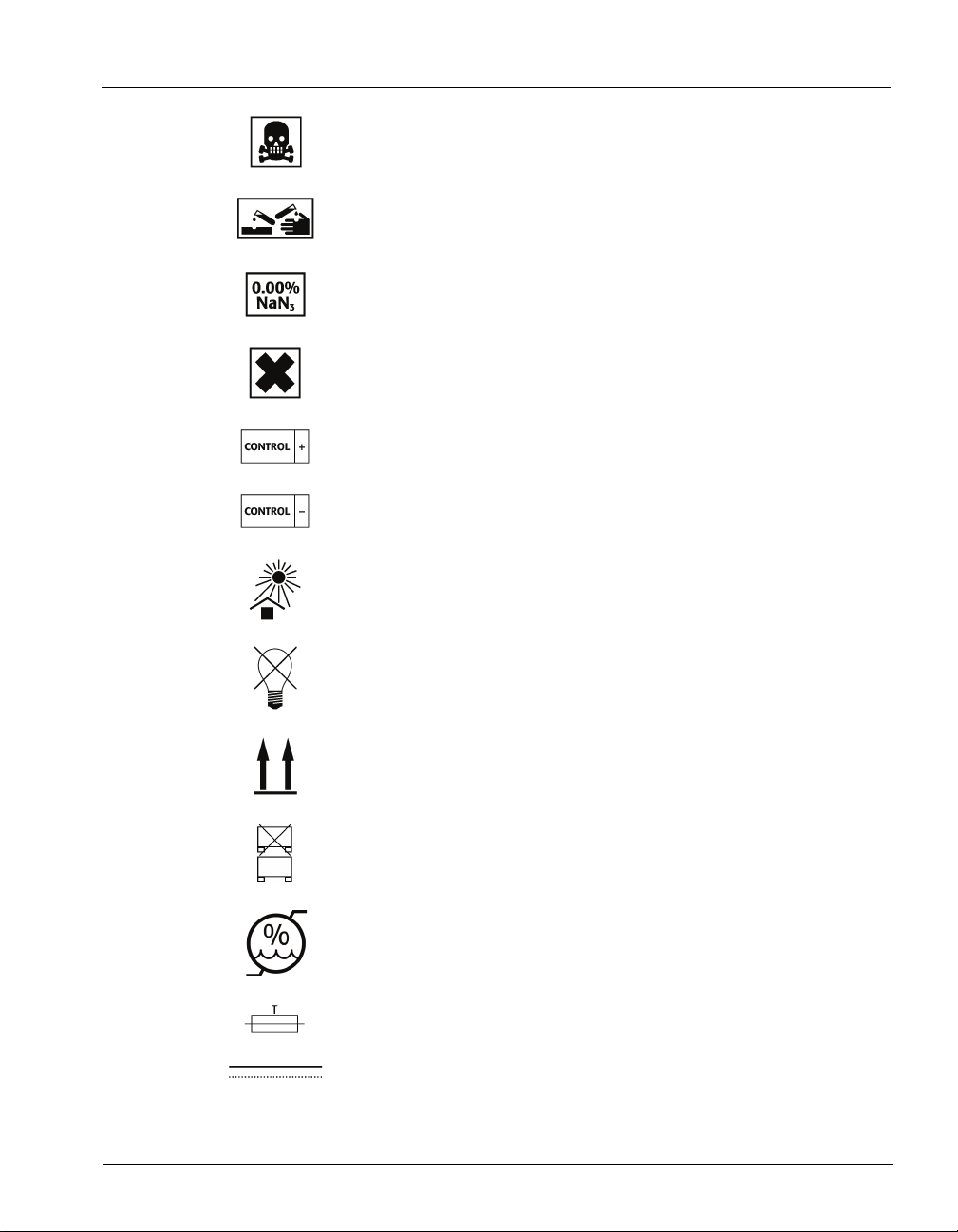

Standard Symbols

Very toxic

Corrosive

Sodium azide

Irritant

Positive control

Negative control

Keep away from sunlight

Protect from light

This way up

Do not stack

Humidity limitation

Fuse

Direct current

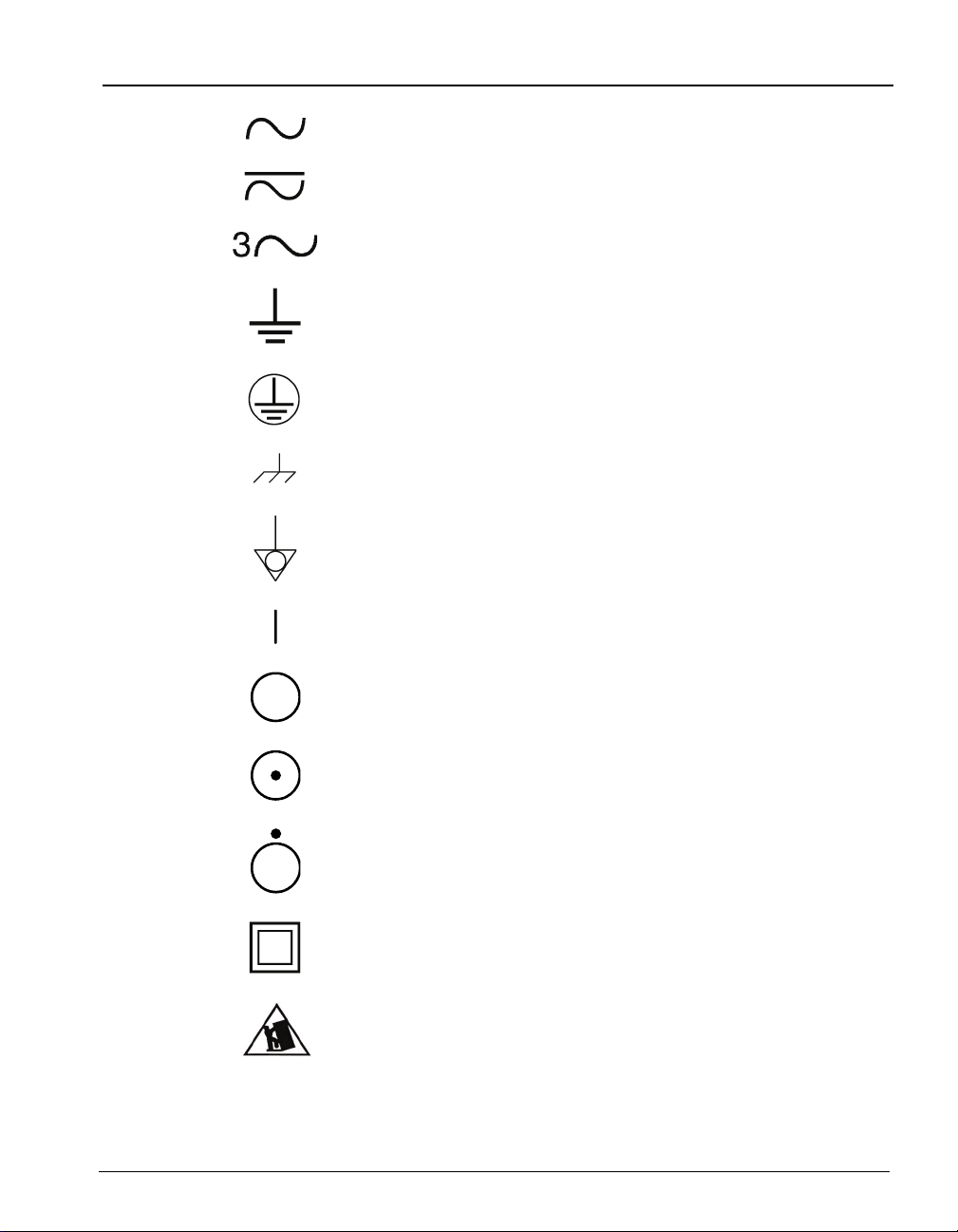

Page 10

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective conductor terminal

Frame or chassis terminal

Equipotentiality

ON (supply)

Standard Symbols

OFF (supply)

ON (only for a component of the system equipment)

OFF (only for a component of the system equipment)

Equipment protected throughout by double insulation or

reinforced insulation (Equivalent to Class II of IEC 536)

Potential tip over/crush hazard

Page 11

TABLE OF CONTENTS

Standard Symbols......................................................................................................vi

List of Figures ............................................................................................................ix

List of Tables ............................................................................................................xiii

H

OW TO USE THIS MANUAL........................................................................................ 1-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Purpose of the BacT/ALERT

Additional Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Manual Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Finding Topics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Typographic and Usage Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Name and Titles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Click . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Procedural Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

User Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Warnings, Cautions, and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

®

3D 60 System. . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

S

YSTEM OVERVIEW ..................................................................................................... 2-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hardware Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Software Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

21 CFR Part 11 and HIPAA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Principle of Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Electrical Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Electrical Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Electrical and Electronic Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

®

BacT/ALERT

BacT/ALERT® 3D 60 User Manual i

95269

3D 60 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Page 12

Table of Contents

Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Barcode Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Backup Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

UPS Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

UPS Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Monitor Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Mouse Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Keyboard Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Printer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

External Speaker Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Power Entry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Modem Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

LIS Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Comm Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Instrument Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Electrical Power Services Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Power Consumed in Watts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Heat Dissipated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Sound Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Instrument Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Instrument Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Operating Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Storage Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Operating Humidity Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Storage Humidity Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Maximum Operating and Storage Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Pollution Degree 2 in accordance with IEC 664 . . . . . . . . . . . . . . . . . . . . . . . .2-12

Overvoltage Category II per IEC 664 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Instrument Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

BacT/ALERT

®

3D 60 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Monitor Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Common Screen Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Common System Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Scroll Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Slidebar Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Anchor Display/Scroll Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Text Entry Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

SYSTEM INSTALLATION ................................................................................................ 3-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

ii BacT/ALERT® 3D 60 User Manual

95269

Page 13

Table of Contents

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Verifying Site Requirements Are Met. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Verifying Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting the AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Choosing Instrument Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Making Instrument Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Powering Up the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Configuring the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Setting the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Checking for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Functional Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Modem Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Barcode Reader Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

®

UPS Functional Test (BacT/ALERT

3D 60 Only, APC UPS 650) . . . . . 3-12

Installing the Optional Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

B

ASIC FUNCTIONS....................................................................................................... 4-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Monitoring the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Main Screen Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Background Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Instrument Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Bottle Count Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Viewing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Viewing the Cell Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Understanding the View Cell Status Screen Display . . . . . . . . . . . . . . . . . . . . .4-6

Text/Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Common Text Fields and Field Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Using the Barcode Scanner to Enter Data. . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Manually Entering Text into a Data Entry Field (Keyboard). . . . . . . . . . . . 4-9

Loading Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Loading Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Changing the Maximum Test Time (Individual Bottles) . . . . . . . . . . . . . . 4-13

Handling Anonymous Bottles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Unloading Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Unloading Bottles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Handling Unconfirmed Positive Bottles (False Positives) . . . . . . . . . . . . 4-17

BacT/ALERT® 3D 60 User Manual iii

95269

Page 14

Table of Contents

EDITING TEST DATA .................................................................................................... 5-1

Accessing the Setup Screen Function Buttons . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Accessing the Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Inactivity Timeout for all Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Setup Screen Function Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Viewing and Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Viewing Bottle Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Viewing/Printing Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Viewing/Printing Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Using the Print Screen Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Viewing and Printing Test Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Viewing and Printing Bottle Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Display Bottle Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Sending/Requesting LIS Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Sending Results to the LIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Requesting Information from the LIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Viewing/Editing Bottle Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Selecting Bottles Using the Edit Cell Contents Button . . . . . . . . . . . . . . . . 5-3

Selecting Bottles Using the Select Bottle to Edit/Graph Button . . . . . . . . . 5-4

Editing Bottle Details Using the Edit Bottle Detail Screen. . . . . . . . . . . . . . 5-5

Edit Bottle ID Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

View Accession Number Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

View Hospital ID Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

View Patient First Name Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

View Patient Last Name Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Edit Load Status Slidebar Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Edit Maximum Test Time Scroll Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Edit Bottle Type Scroll Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

View Cell Location Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

View First Loaded Time Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

View Last Unloaded Time Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

View Time of Last Bottle Reading Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

View Test Time Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

View Test Result Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Edit Test Result Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Graph Bottle Readings Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

View Algorithm/Polynomial Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

View How Determined/Positivity Index Icon . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Editing Data Relationships . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

iv BacT/ALERT® 3D 60 User Manual

95269

Page 15

Table of Contents

Initiating the Edit Data Relationships Function . . . . . . . . . . . . . . . . . . . . 5-12

Editing Bottle ID to Accession Number Relationships . . . . . . . . . . . . . . . 5-13

Attaching Bottle IDs Without an Accession Number to an Accession Number 5-14

Moving a Bottle ID Association from one Accession Number to Another . . . . .5-14

Editing Accession Number to Hospital ID Relationships . . . . . . . . . . . . . 5-15

Attaching Accession Numbers Without a Hospital ID to a Hospital ID . . . . . . .5-16

Moving an Accession Number Association from one Hospital ID to Another . .5-16

Editing Hospital ID to Patient Name Relationships . . . . . . . . . . . . . . . . . 5-17

S

OFTWARE CONFIGURATION........................................................................................ 6-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Setting the Maximum Test Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Setting the Audible Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Priority of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Terminating an Instrument Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Changing the System Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Initiating Manual Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Configuring Report Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Entering Report Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Configuring Report Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Load Report Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Status Report Configuration Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Unload Report Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Viewing and Printing Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Viewing and Printing Calibration History . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

SYSTEM MAINTENANCE ............................................................................................... 7-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Hardware Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Safety Precautions and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Spill Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Disinfection Procedure for Spills Onto the Instrument . . . . . . . . . . . . . . . . . . . .7-3

Disinfection Procedure for Spills Within the Instrument . . . . . . . . . . . . . . . . . . . 7-4

Using the Keyboard in Place of the Mouse . . . . . . . . . . . . . . . . . . . . . . . . 7-6

UPS On/Off Button Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Instrument Reboot/Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Shutdown Method 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Shutdown Method 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Shutdown Method 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

BacT/ALERT® 3D 60 User Manual v

95269

Page 16

Table of Contents

S

Shutdown Method 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Instrument Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Software Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Restarting the Incubation Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Setting and Formatting the System Date and Time . . . . . . . . . . . . . . . . . 7-11

Enabling and Disabling Racks and Cells . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Relocating Bottles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Adjusting an Instrument’s Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Checking an Instrument's Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Setting the Optimal Temperature for an Instrument . . . . . . . . . . . . . . . . . . . . .7-17

Calibrating an Instrument's Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Calibrating an Instrument Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Locating a Cell Which Failed Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Viewing a Cell's Readings and/or Calibrating a Cell. . . . . . . . . . . . . . . . . . . . .7-19

Viewing Incubation Chamber Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

YSTEM TROUBLESHOOTING .......................................................................................8-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Instrument Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Instrument Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Operator Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Bottle Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

User Output Device Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

21 CFR P

ART 11 MODE..............................................................................................9-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Log In/Out of System — 21 CFR Part 11 Mode. . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Logging In for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Logging In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Inactivity Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Login Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Change Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Change Password Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Logging Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Configuring Users — 21 CFR Part 11 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Adding a User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Deleting a User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

vi BacT/ALERT® 3D 60 User Manual

95269

Page 17

Table of Contents

Deleting More Than One User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

Clearing a User Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Clearing More Than One User Password. . . . . . . . . . . . . . . . . . . . . . . . .9-17

Audit Trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Accessing the Audit Trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

M

YCOBACTERIAL TESTING......................................................................................... 10-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

BacT/ALERT

Circulation Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Installation Procedures and Special Requirements . . . . . . . . . . . . . . . . . . . . .10-3

®

3D 60 Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

BacT/ALERT® 3D 60 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Set Maximum Test Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Positive Detection Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Bottle Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

MB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Limitations of the Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Principle of Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

Spill Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

Disinfection Procedure for Spills Within/Onto the Instrument. . . . . . . . . . . . . .10-8

UNPACKING INSTRUCTIONS..........................................................................................A-1

BacT/ALERT® 3D 60 Unpacking Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . A-1

P

ART CHECKLIST ........................................................................................................B-1

BacT/ALERT

®

3D 60 Part Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

INSTALLATION CHECKLIST ...........................................................................................C-1

BacT/ALERT® 3D 60 Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

BacT/ALERT® 3D 60 User Manual vii

95269

Page 18

Table of Contents

INTERNATIONAL CHARACTER ENTRY ............................................................................D-1

B

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

International Character Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Entering International Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

OTTLE QUALITY CONTROL.........................................................................................E-1

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

BacT/ALERT

®

Culture Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-2

Flip Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Stopper/Seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Volume Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Barcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Limitations of the Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Quality Control of Growth Performance . . . . . . . . . . . . . . . . . . . . . . . . . . .E-4

Blood Culture Bottles (SA, SN, FA, FN, and PF) . . . . . . . . . . . . . . . . . . . . . . . E-4

Mycobacteria Culture Bottles (MB and MP) . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

GLOSSARY................................................................................................... GLOSSARY-1

I

NDEX .................................................................................................................. INDEX-1

viii BacT/ALERT® 3D 60 User Manual

95269

Page 19

LIST OF FIGURES

Figure 1-1: Procedure Icon ...................................................................................................1-7

Figure 2-1: Electrical Grounding Requirements ...................................................................2-7

Figure 2-2: Instrument Front View ........................................................................................2-8

Figure 2-3: Instrument Rear View ......................................................................................2-10

Figure 2-4: Button Examples ..............................................................................................2-14

Figure 2-5: Scroll Button .....................................................................................................2-15

Figure 2-6: Slidebar Switch ................................................................................................2-15

Figure 2-7: Anchor Display/Scroll Buttons ..........................................................................2-16

Figure 3-1: Power Entry Module with Fuse Holder Removed ..............................................3-3

Figure 3-2: PEM with 115 VAC Version ...............................................................................3-4

Figure 3-3: PEM with 230 VAC Version ...............................................................................3-5

Figure 3-4: Additional Fuse Holder Views ............................................................................3-6

Figure 3-5: Installation and Setup Diagram — Port and Power Connections .......................3-9

Figure 3-6: Modem Configuration and Dip Switch Settings ................................................3-11

Figure 3-7: Countertop/Surface Mounting Diagram ...........................................................3-13

Figure 3-8: Mounting Surface Diagram ..............................................................................3-13

Figure 3-9: Mounting Surface (Drilling) Template ...............................................................3-14

Figure 4-1: Main Screen .......................................................................................................4-3

Figure 4-2: Instrument Icons ................................................................................................4-4

Figure 4-3: Bottle Count Table/Unload Buttons ....................................................................4-5

Figure 4-4: View Cell Status Screen ....................................................................................4-6

Figure 4-5: Disabled Cell ......................................................................................................4-7

Figure 4-6: Main Screen — Load Mode .............................................................................4-10

Figure 4-7: Change Maximum Test Time Screen ...............................................................4-13

Figure 4-8: Main Screen — Unload Mode ..........................................................................4-15

Figure 4-9: Setup Screen ...................................................................................................4-18

Figure 4-10: Report Selection Screen ..................................................................................4-22

Figure 4-11: Sample Report Screen .....................................................................................4-24

Figure 4-12: Find Text Screen ..............................................................................................4-27

Figure 4-13: Save to File Screen ..........................................................................................4-28

Figure 4-14: Select Bottle to Edit/Graph Screen ..................................................................4-29

Figure 4-15: Graph Bottle Readings Screen ........................................................................4-30

BacT/ALERT® 3D 60 User Manual ix

95269

Page 20

Figure 4-16: Bottle Readings Screen .................................................................................. 4-32

Figure 4-17: Find Text Screen ............................................................................................. 4-34

Figure 4-18: Save to File Screen ......................................................................................... 4-35

Figure 5-1: Edit Cell Contents Screen ................................................................................. 5-3

Figure 5-2: Select Bottle to Edit/Graph Screen ................................................................... 5-4

Figure 5-3: Edit Bottle Detail Screen ................................................................................... 5-5

Figure 5-4: Edit Test Result Screen .................................................................................... 5-9

Figure 5-5: Edit Data Relationships Screen ...................................................................... 5-12

Figure 5-6: Edit Bottle ID to Accession Number Relationships Screen ............................. 5-13

Figure 5-7: Edit Accession Number to Hospital ID Relationships Screen ......................... 5-15

Figure 5-8: Edit Hospital ID to Patient Name Relationships Screen .................................. 5-17

Figure 6-1: Set Maximum Test Time Screen ....................................................................... 6-2

Figure 6-2: Set Audible Alarm Options Screen .................................................................... 6-4

Figure 6-3: Change Password Screen ................................................................................ 6-6

Figure 6-4: Padlock Icon (Full Open Position) ..................................................................... 6-6

Figure 6-5: Padlock Icon (Half Open Position) .................................................................... 6-7

Figure 6-6: Padlock Icon (Closed Position) ......................................................................... 6-7

Figure 6-7: Backup Management Screen ............................................................................ 6-8

Figure 6-8: Backup in Progress Icon ................................................................................... 6-8

Figure 6-9: Report Selection Screen ................................................................................. 6-10

Figure 6-10: Report Label Entry Screen .............................................................................. 6-11

Figure 6-11: Report Selection Screen ................................................................................. 6-14

Figure 6-12: Load Report Configuration Screen .................................................................. 6-16

Figure 6-13: Status Report Configuration Screen ............................................................... 6-17

Figure 6-14: Unload Report Configuration Screen .............................................................. 6-18

Figure 6-15: Report Selection Screen ................................................................................. 6-19

Figure 6-16: Cell Calibration Report Screen ........................................................................ 6-20

Figure 6-17: View Window ................................................................................................... 6-21

Figure 6-18: Report Selection Screen ................................................................................. 6-22

Figure 6-19: Calibration History Screen .............................................................................. 6-23

Figure 7-1: View Cell Status Screen .................................................................................. 7-11

Figure 7-2: Set Date/Time Screen ..................................................................................... 7-12

Figure 7-3: Enable/Disable Rack or Cell Screen ............................................................... 7-13

Figure 7-4: Reference Thermometer ................................................................................. 7-15

x BacT/ALERT® 3D 60 User Manual

95269

Page 21

Figure 7-5: Calibrate Instrument Temperature Screen .......................................................7-16

Figure 7-6: Calibrate Cell Screen .......................................................................................7-19

Figure 7-7: View Incubation Chamber Information Screen ................................................7-23

Figure 8-1: Instrument Icon with Fault Codes ......................................................................8-3

Figure 8-2: Instrument Status Code 710 ............................................................................8-16

Figure 8-3: Operator Error Code 911 .................................................................................8-18

Figure 8-4: QuickScan

®

6000 Reset Barcode ....................................................................8-30

Figure 8-5: Honeywell Reset Barcode ................................................................................8-30

Figure 8-6: Informational Warning Screen .........................................................................8-31

Figure 9-1: Main Screen While Logged Out —21 CFR Part 11 Mode ..................................9-2

Figure 9-2: User Login Screen .............................................................................................9-3

Figure 9-3: User Login Screen with Change Password Fields .............................................9-4

Figure 9-4: Main Screen While Logged In — 21 CFR Part 11 Mode ...................................9-5

Figure 9-5: User Login Screen .............................................................................................9-6

Figure 9-6: User Login Screen with Wrong Password Alert .................................................9-8

Figure 9-7: User Login Screen with Change Password Fields .............................................9-9

Figure 9-8: User Login Screen with Change Password Error .............................................9-10

Figure 9-9: User Login Screen with Wrong Password Alert ...............................................9-11

Figure 9-10: User Configuration Screen ...............................................................................9-13

Figure 9-11: Add User Screen ..............................................................................................9-14

Figure 9-12: Delete User Screen ..........................................................................................9-15

Figure 9-13: Clear Password Screen ...................................................................................9-17

Figure 10-1: Instrument Icon for MB-Configured System .....................................................10-3

Figure 10-2: Bottle Count Table and Unload Buttons ...........................................................10-4

Figure 10-3: Metabolic Pathway for Mycobacterial CO2 ......................................................10-7

Figure E-1: Typical BacT/ALERT

®

Culture Bottle ................................................................ E-2

BacT/ALERT® 3D 60 User Manual xi

95269

Page 22

xii BacT/ALERT® 3D 60 User Manual

95269

Page 23

LIST OF TABLES

Table 2-1: Common System Buttons ................................................................................2-14

Table 3-1: Facility Power Rating and Conversion Chart .....................................................3-4

Table 3-2: Restraint Hardware ..........................................................................................3-12

Table 3-3: Table of Equivalent Dimensions (Inches to Centimeters) ................................3-14

Table 5-1: Bottle Specific Algorithms ................................................................................5-10

Table 5-2: Status Determination Codes ............................................................................5-10

Table 6-1: Report Field Descriptions .................................................................................6-12

Table 9-1: Audit Trail Events .............................................................................................9-18

Table D-1: International Character Table ...........................................................................D-2

BacT/ALERT® 3D 60 User Manual xiii

95269

Page 24

xiv BacT/ALERT® 3D 60 User Manual

95269

Page 25

HOW TO USE THIS MANUAL

About This Chapter

1

This chapter gives you important information about the

BacT/ALERT

that you read this chapter first.

IMPORTANT: Read this manual carefully before you attempt to operate the

BacT/ALERT® 3D 60 system.

®

3D 60 system and how to use this manual. We recommend

Chapter Contents

Intended Audience • 1-2

Purpose of the BacT/ALERT

Additional Supplies • 1-3

Purpose of This Manual • 1-3

Manual Organization • 1-4

Chapter Organization • 1-5

Finding Topics • 1-6

Typographic and Usage Conventions • 1-6

Name and Titles • 1-6

Click • 1-6

Press • 1-7

Procedural Steps • 1-7

References • 1-7

Select • 1-7

User Input • 1-8

Warnings, Cautions, and Information • 1-8

®

3D 60 System • 1-2

BacT/ALERT® 3D 60 User Manual 1-1

95269

Page 26

How To Use This Manual Intended Audience

Intended Audience

The BacT/ALERT® 3D 60 system and this manual are intended for laboratory

use by trained, professional users.

Purpose of the BacT/ALERT® 3D 60 System

The BacT/ALERT® 3D 60 Microbial Detection System is a totally automated

test system capable of incubating, agitating, and continuously monitoring

aerobic and anaerobic media inoculated with patient specimens suspected of

having bacteremia, fungemia, and/or mycobacteremia.

CAUTION: bioMérieux shall not be liable as to any defect arising

from abuse of the instrument, failure to operate and maintain the

instrument in accordance with the User Manual, operation of the

instrument by a person who has not been trained in its operation

by bioMérieux, repair, service, alteration or modification of the

instrument by any person other than service personnel of

bioMérieux, or modification, change or reuse of the disposables

supplied by bioMérieux for use in the instrument.

CAUTION: This BacT/ALERT® 3D User Manual is only intended

for use with B.30 Software or higher. The software version B.30

(or higher) is displayed at the bottom of the instrument icon on

the Main screen.

CAUTION: All figures depicting monitor screens are examples

only. Actual screens may differ to the extent they are affected by

the actual data entered by the user, or actual data transmitted to

the instrument over the LIS interface, or actual data generated

by the instrument.

1-2 BacT/ALERT® 3D 60 User Manual

95269

Page 27

Additional Supplies How To Use This Manual

CAUTION: Regarding section "Entering Report Labels," the user

is solely responsible for the choice of customized report label

text and for validating that the intended label text appears in all

associated reports. bioMérieux shall not be liable for any

consequences resulting from misinterpretation of customized

report labels.

Additional Supplies

Contact bioMérieux or your local vendor for laboratory supplies and

accessories.

Purpose of This Manual

This manual focuses on the BacT/ALERT® 3D 60 software application and

how you use it in your workflow. It contains step-by-step procedures for using

your BacT/ALERT

®

3D 60 system.

By using these procedures, you can perform all the functions required to

operate your system, including:

• accessing the BacT/ALERT® 3D 60 software

• system monitoring

• entering order information (where applicable)

• loading and unloading bottles

• viewing and printing data

• LIS interaction with the BacT/ALERT® 3D 60 SelectLink

• accessing the Setup screen

Note: Screens and figures are intended for illustrative purposes only and are not to

be construed as representations of actual test data, results, or components.

Screens and components are not shown to scale.

BacT/ALERT® 3D 60 User Manual 1-3

95269

Page 28

How To Use This Manual Manual Organization

Manual Organization

This manual is organized by chapters. Chapters are organized according to

the order of menu commands in the software application.

Chapter 1, How To Use This Manual — Provides an introduction to the

BacT/ALERT

®

3D 60 system and how to use this manual. It is recommended

that you read this chapter first.

Chapter 2, System Overview — This chapter gives you a complete

description of the different BacT/ALERT

®

3D 60 hardware and software

configurations available. Also, the monitor screens are listed along with a

description of common screen elements.

Chapter 3, System Installation — Provides detailed instructions on how to

install the instrument and perform functional tests.

Chapter 4, Basic Functions — Introduces you to the Main screen and

shows you how to perform basic functions (ex. enter data, view faults, view

the Cell Status screen, load/unload bottles, etc.). This chapter also introduces

you to the Setup screen and the associated function buttons.

Chapter 5, Editing Test Data — Explains how to access bottle data for

loaded and unloaded bottles using the Edit Bottle Detail screen. This chapter

shows you how to view and edit bottle data.

Chapter 6, Software Configuration — Explains how to configure the

software for your specific needs. This chapter shows you how to set the

maximum test time, set the audible alarms, change the system password,

initiate a manual backup, configure report screens, and view and print

calibration data.

Chapter 7, System Maintenance — This chapter provides you with

procedures on how to perform maintenance on the BacT/ALERT

®

3D 60

hardware and software.

Chapter 8, System Troubleshooting — Describes the different types of

instrument fault, instrument status and operator error codes, as well as bottle

and user output device problems, you may encounter when using the

instrument. Cause(s) and solutions(s) for each type of fault/error/problem are

also listed.

Chapter 9, 21 CFR Part 11 Mode — This chapter explains how to log in and

out of the instrument while in 21 CFR Part 11 mode, as well as instructions for

configuring users (ex. adding or deleting a user, or clearing a user password).

1-4 BacT/ALERT® 3D 60 User Manual

95269

Page 29

Chapter Organization How To Use This Manual

This chapter also describes the events recorded in the audit trail and how to

retrieve the audit trail.

Chapter 10, Mycobacterial Testing — This chapter provides you with a

complete description of the of the BacT/ALERT

configured for Mycobacterial (MB) functions.

Appendix A, BacT/ALERT

diagram illustrating how to unpack the instrument.

Appendix B, BacT/ALERT® 3D 60 Part Checklist — To use when verifying

and inspecting kit contents.

Appendix C, BacT/ALERT® 3D 60 Installation Checklist — To use when

installing the instrument.

Appendix D, International Character Entry — Explains how to enter

international characters on the BacT/ALERT

Appendix E, Bottle Quality Control — This chapter provides you with a

description of the BacT/ALERT® 3D 60 culture bottle along with a quality

control procedure.

Glossary — An alphabetized list of frequently used terms along with a

definition for each term.

Chapter Organization

®

3D 60 instrument when it is

®

3D 60 Unpacking Instructions — Contains a

®

3D 60 instrument.

All chapters include the following:

• About This Chapter — Brief description of the chapter’s content and

purpose.

• Chapter Contents — A table of contents for the chapter.

• Descriptions and/or Procedures — Chapters contain descriptions and

procedures appropriate to their subject matter. See the Manual

Organization section in this chapter for more information.

• Background Information, where applicable and useful.

BacT/ALERT® 3D 60 User Manual 1-5

95269

Page 30

How To Use This Manual Finding Topics

Finding Topics

This manual uses several methods to help you find information and keep your

bearings.

Table of Contents — Located at the front of the manual. It contains the titles

of all chapters/appendices and their sections, and the page number of each

title and section.

List of Figures — Located at the front of the manual. It contains a list of all

figures in the manual and the page number of each figure.

List of Tables — Located at the front of the manual. It contains a list of all

tables in the manual and the page number of each table.

Chapter Contents — Located at the front of each chapter. It lists all sections

in the chapter and their page numbers.

Page Headers — Located at the top of each page. There are two parts to a

header: the chapter title and the primary section title.

Page Footers — Located at the bottom of each page. There are three parts

to a footer: the manual’s title, the chapter’s part number, and the page

number.

Index — Located at the back of the manual. It contains topical entries and

their page numbers.

Typographic and Usage Conventions

Name and Titles

Button, icon and field names are in Proper Case, bold.

Example: Click the Select Maximum Test Time button.

The names of windows and screens are in Proper Case, but are not bolded.

Example: The Set Maximum Test Time screen...

Click

This manual uses the word “click” to refer to using a mouse to choose or

select a text entry field, button, or option.

Example: Click OK.

1-6 BacT/ALERT® 3D 60 User Manual

95269

Page 31

Typographic and Usage Conventions How To Use This Manual

See the Select section in this chapter for more information

Press

This manual uses the word “press” to refer to pressing a key on the keyboard

in order to initiate action in the firmware.

Keyboard entries are in Proper Case and bolded (ex. Ctrl). If two keys are to

be pressed simultaneously, they will be separated with a plus sign (ex. press

Ctrl + Alt + Delete).

Procedural Steps

Steps in procedures are sequentially numbered. A bullet list in a step

indicates options.

Sections that contain procedures are denoted by the Procedure icon in the

margin.

Figure 1-1: Procedure Icon

References

References to chapter and section titles in this manual are in Proper Case.

Example: See Chapter 7, Software Configuration.

References to other manuals are in Proper Case and italic.

®

Example: See the BacT/ALERT

3D 60 Service Manual.

Select

The word “select” is generally used for selecting user interface navigation.

Example: Select the appropriate bottle type from the Media Type scroll

button.

BacT/ALERT® 3D 60 User Manual 1-7

95269

Page 32

How To Use This Manual Warnings, Cautions, and Information

User Input

Instructions for user input begin with the word “type” or “enter.” This manual

uses bold for literal user input and italic for placeholders.

Example of a Literal User Input: Enter the Software Exit Password

24313124.

In this example, you are to type exactly what you see on the page (24313124

in this example).

Example of a Placeholder: Enter your password before you...

In this example, you are to type your assigned password.

Warnings, Cautions, and Information

This manual uses different types of symbols to alert you to important

information. Symbols and their associated information are labeled in text

where they occur and set off from surrounding paragraphs, as shown in the

following examples.

WARNING

Warning is a statement that alerts the user to the possibility of

injury, death, or other serious adverse reactions associated

with the use or misuse of a device.

CAUTION: Caution is a statement that alerts the user to the

possibility of a problem with the device associated with its use

or misuse. Such problems include device malfunction, device

failure, damage to the device, or damage to other property.

Where applicable, a caution statement may include a precaution

that should be taken to avoid the hazard.

IMPORTANT: Important relates to content presented in this manual. It is used to

reinforce the importance of your understanding or remembering

something.

Note: Note supplies additional information about a topic.

1-8 BacT/ALERT® 3D 60 User Manual

95269

Page 33

SYSTEM OVERVIEW

About This Chapter

2

This chapter gives you a complete description of the different

BacT/ALERT

the monitor screens are listed along with a description of common screen

elements.

Chapter Contents

Introduction • 2-2

Hardware Configuration • 2-2

Software Configuration Options • 2-2

21 CFR Part 11 and HIPAA • 2-3

Theory Of Operation • 2-3

Electrical Warnings • 2-4

Electrical Grounding • 2-6

Electrical and Electronic Recycling • 2-7

Fuse Replacement • 2-7

BacT/ALERT

Instrument • 2-8

Instrument Specifications • 2-11

Instrument Environmental Requirements • 2-12

Instrument Installation and Setup • 2-13

BacT/ALERT® 3D 60 Software • 2-13

Monitor Screens • 2-13

Common Screen Elements • 2-14

®

®

3D 60 hardware and software configurations available. Also,

3D 60 Hardware • 2-8

BacT/ALERT® 3D 60 User Manual 2-1

95269

Page 34

System Overview Introduction

Introduction

The BacT/ALERT® 3D 60 is the next generation of BacT/ALERT®

instrumentation with comparable sensitivity and specificity to the

BacT/ALERT

conjunction with a mouse allows for a text-free user interface to direct rapid

loading and unloading of individual test samples.

Once placed in the unit, handling of a specimen bottle is not required until a

result is obtained. Immediately upon detection, positive results are indicated

visually on the unit's monitor and, if desired, by an audible beep. If no

microbial growth is present after a specified time, a specimen is determined

to be negative. The system will also indicate the negative samples that are

ready for removal when prompted. Because the system handles bottles

individually, testing of new specimens may begin at any time. The system

also utilizes barcode technology to assist in specimen and data tracking.

The disposable culture bottles contain a liquid emulsion sensor that is

monitored continuously using solid-state photodetectors. In addition, the

bottles contain media and atmosphere which promote the recovery of a wide

variety of microorganisms without venting.

®

3D systems. The system is non-invasive. A monitor screen in

Hardware Configuration

The BacT/ALERT® 3D 60 utilizes a stand-alone instrument that has 60 cells

for bottle monitoring.

Software Configuration Options

The instrument supervises the reading of the sensors and contains decisionmaking algorithms to determine which specimens are positive or negative.

The instrument can be arranged in one of two BacT/ALERT

configurations:

• BacT/ALERT

not connected to a Laboratory Information System (LIS). Limited data

management is available through the system.

• BacT/ALERT

is connected directly to an LIS. Limited data management is available

through the system.

The software configuration is listed at the top of all screens (see Figure 4-1,

Main Screen) except for the Edit Cell Contents or View Cell Contents screen

(see Figure 5-1, Edit Cell Contents Screen). The background color will also

®

3D Select configuration —The BacT/ALERT® 3D 60 is

®

3D SelectLink configuration — The BacT/ALERT® 3D 60

®

3D 60 software

2-2 BacT/ALERT® 3D 60 User Manual

95269

Page 35

Introduction System Overview

indicate the configuration unless there is an error condition or a loaded

positive bottle (see Main Screen Introduction in Chapter 4):

• Blue — BacT/ALERT® 3D Select configuration

• Green — BacT/ALERT® 3D SelectLink configuration

21 CFR Part 11 and HIPAA

The BacT/ALERT® 3D 60 Version B.30 or higher product release provides

compatibility with 21 CFR Part 11 and Health Insurance and Portability and

Accountability Act (HIPAA) requirements.

When installed, the BacT/ALERT

operate in 21 CFR Part 11 mode. If 21 CFR Part 11 mode is enabled, you will

need to enter a user name and password to access all functions available to