Page 1

BB

T AT A LL EE RR T T 33 D D

00

TM

AA CC

66

Service Manual

bioMérieux, Inc.

Box 15969, Durham, NC 27704 -0969

http://www.biomerieux.com

© BIOMÉRIEUX 2002 Manual Part Number 48001-6 Rev A

March 2003

Page 2

BacT/ALERT® 3D 60

All Rights Reserved Worldwide

Printed in the United States of America

No part of this publication may be used or reproduced in any form, electronic or written via database or

retrieval system, without the prior written permission of bioMérieux. Documenting copies of any part of this

publication, for any purpose other than for which has been authorized in advance, is in strict violation of

United States copyright laws.

BioMérieux, Inc.

PO Box 15969

Durham, NC 27704-0969

USA

ASTM is a trademark of American Society for Testing and Materials. Bac T/ALERT, BacT/LINK, BacT/VIEW

and MB are registered trademarks of bioMérieux in the USA and other countries. MS DOS is a registered

trademark of Microsoft Corporation. Zip is a registered trademark of Iomega Corporation. The logo is a

registered and protected trademark of bioMérieux, Inc. or one of its subsidiaries.

Distribution in over 130 countries

Service Manual

Page 3

BacT/ALERT® 3D 60

This document will be updated for each software modification or any other change.

Information supplied in this document is subject to modificati on before the products described

become available.

This document may contain information or references concerning certain bioMérieux®

products, programs and services not available in certain countries; this, however, shall not

mean that bioMérieux intends to commercialize such products, programs or services in said

countries.

To request copies of publications or for any technical request, contact bioMérieux or your

local distributor.

Liability disclaimer

bioMérieux disclaims all warranties, guarantees or liabilities, express or implied arising by law

or otherwise with respect to this manual, its quality, accuracy or performance, including

without limitation, any obligation of bioMérieux with respect to MERCHANTABILITY AND

FITNESS FOR A PARTICULAR USE, non-infringement and consequential or incidental

damages. IN NO EVENT SHALL bioMérieux’ s LIABILITY TO CUSTOMER UNDER ANY

CLAIM EXCEED A REFUND OF THE AMOUNT PAID TO bioMérieux FOR THE PRODUCT

OR SERVICE WHICH IS THE SUBJECT OF THE CLAIM.

In no event shall bioMé rieux be bound by the manual. bioMérieux shall have the right to

modify the manual without notice.

bioMérieux Copyright

This manual's content and graphics are copyrighted by bioMérieux.

In no event does bioMérieux concede to the manual's users any right for reproduction,

adaptation or translation, by any process and in any country whatsoever.

All editorial content and graphics (including without limitations, all articles, text, images, logos,

compilations, designs) are protected by United States Copyright Law, French Copyright Law

and international treaties and may not be copied without the express permission of

bioMérieux.

Any representation or reproduction whether partial or integral, by any process whatsoever,

would therefore be considered fraudulent and sentenced by the applicable law.

Service Manual

Page 4

BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

Service Manual

Page 5

BacT/ALERT® 3D 60 TABLE OF CONTENTS

TABLE OF CONTENTS

0 FRONT MATTER ..................................................................................................................IX

0.1 APPENDICES.................................................................................................................IX

0.2 LIST OF TABLES...........................................................................................................XI

0.3 LIST OF ILLUSTRATIONS..........................................................................................XIII

0.4 TYPOGRAPHY AND GRAPHIC CONVENTIONS.....................................................XIX

0.4.1 Bullets..............................................................................................................xxi

0.4.2 Text Boxes ....................................................................................................... xxi

0.4.3 Bracketed Italics................................................................................................ xxi

0.4.4 Underlined Text................................................................................................. xxi

0.4.5 Bracketed Text .................................................................................................xxii

0.4.6 Text Within Quotation Marks.............................................................................xxii

0.4.7 Italicized (Whether Bold or Not) Text .................................................................xxii

0.5 SAFETY SUMMARY.................................................................................................XXIII

0.5.1 General Information to Follow ........................................................................... xxv

0.5.2 Electrical Warnings...........................................................................................xxv

0.5.3 Electrical Grounding .........................................................................................xxvi

0.5.4 Fuse Replacement Warning..............................................................................xxvi

0.5.5 Hazardous Voltages .........................................................................................xxvi

0.5.6 Cleaning Agents...............................................................................................xxvi

0.5.7 Health Risks ...................................................................................................xxvii

0.5.8 ESD Precautions.............................................................................................xxvii

0.5.9 Moving Parts ...................................................................................................xxvii

0.5.10 Heating Element ............................................................................................. xxvii

Service Manual i

Page 6

TABLE OF CONTENTS BacT/ALERT® 3D 60

1 GENERAL INFORMATION.............................................................................................. 1-1

1.1 INTRODUCTION...........................................................................................................1-1

1.2 REFERENCE DATA .....................................................................................................1-2

1.3 EQUIPMENT DESCRIPTION .......................................................................................1-3

1.4 ASSEMBLY DESCRIPTIONS......................................................................................1-4

1.4.1 Electrical Components .......................................................................................1-4

1.4.1.1 Power Panel Assembly ....................................................................1-5

1.4.1.2 Transformer Assembly.....................................................................1-5

1.4.1.3 Heater ............................................................................................1-5

1.4.1.4 Blower ............................................................................................1-5

1.4.1.5 Step-5 Motor Assembly ...................................................................1-7

1.4.1.6 Fan ................................................................................................1-7

1.4.1.7 Quick Reference Card .....................................................................1-7

1.4.2 Communications Ports (Input / Output) ...............................................................1-8

1.4.2.1 COMM Port .....................................................................................1-9

1.4.2.2 Printer Port .....................................................................................1-9

1.4.2.3 Internal Speaker w/external Speaker Jack ........................................1-9

1.4.2.4 Power Entry Module (PEM) / ON-OFF Switch ...................................1-9

1.4.2.5 Modem Port ....................................................................................1-9

1.4.2.6 LIS Port ..........................................................................................1-9

1.4.2.7 Monitor Port ....................................................................................1-9

1.4.2.8 UPS Port ........................................................................................1-9

1.4.2.9 UPS Serial Port...............................................................................1-9

1.4.2.10 Mouse Port .....................................................................................1-9

1.4.2.11 Keyboard Port.................................................................................1-9

1.4.2.12 Barcode Scanner Port .....................................................................1-9

1.4.3 Electronic Components....................................................................................1-10

1.4.3.1 CPU PCBA ...................................................................................1-11

1.4.3.2 ModSig PCBA...............................................................................1-11

1.4.3.3 Quad Serial PCBA.........................................................................1-11

1.4.3.4 Thermistor PCBA (Input/Output).....................................................1-11

1.4.3.5 CompactFlash Memory Disk ..........................................................1-13

1.4.3.6 CompactFlash Adapter PCBA........................................................1-13

1.4.3.7 Step-5 PCBA ................................................................................1-13

1.4.3.8 Incubator Chamber Components ....................................................1-15

1.4.3.8.1 Rack...........................................................................1-15

1.4.3.8.2 Cell ............................................................................1-15

1.4.3.8.3 Cell Flag .....................................................................1-15

1.4.3.8.4 Cell Indicator Lamp .....................................................1-15

ii Service Manual

Page 7

BacT/ALERT® 3D 60 TABLE OF CONTENTS

1.4.4 Input / Output Devices .....................................................................................1-16

1.4.4.1 Operator Display Monitor ...............................................................1-17

1.4.4.2 Barcode Scanner ..........................................................................1-17

1.4.4.3 Keyboard......................................................................................1-17

1.4.4.4 Zip Drive.......................................................................................1-17

1.4.4.5 56K FAX Modem (Domestic)..........................................................1-19

1.4.4.6 56K Fax Modem (International)......................................................1-19

1.4.5 Uninterruptible Power Supply “UPS” .................................................................1-20

1.4.5.1 On/Off Switch................................................................................1-21

1.4.5.2 UPS Comm Port (Computer Interface Port).....................................1-21

1.4.5.3 Overload Reset Switch..................................................................1-21

1.4.5.4 Test (Check Battery/Alarm Disable) Switch.....................................1-21

1.4.5.5 120V Backup Receptacles .............................................................1-21

1.4.5.6 Accessory Surge Rec eptacles........................................................1-21

1.4.5.7 AC Power Cord .............................................................................1-21

1.5 OPERATOR DISPLAY CONFIGURATION SCREENS............................................1-24

1.5.1 Instrument Configuration Screen ......................................................................1-25

1.5.1.1 Accessing the Configuration Screen ...............................................1-25

1.5.1.2 Instrument Con figuration Screen - Initial Entry.................................1-26

1.5.1.3 Configuration Screen [X Box] Buttons .............................................1-27

1.6 QUICK REFERENCE CARD ......................................................................................1-29

2 BACKGROUND INFORMATI ON .................................................................................... 2-1

2.1 INTRODUCTION...........................................................................................................2-1

2.2 SYSTEM CONTROL - MODSIG PCBA .......................................................................2-2

2.3 THERMISTOR PCBA (INPUT/OUTPUT)....................................................................2-6

2.4 3D 60 POWER SUPPLY ASSEMBLY.........................................................................2-8

2.5 DC POWER SUPPLY.................................................................................................2-10

2.6 CPU PCBA.................................................................................................................2-12

2.7 COMPACTFLASH ADAPTER PCBA ........................................................................2-14

2.8 QUAD SERIAL INTERFACE PCBA..........................................................................2-16

2.9 RACK CONTROLLER PCBA....................................................................................2-18

2.10 STEP-5 PCBA............................................................................................................2-24

Service Manual iii

Page 8

TABLE OF CONTENTS BacT/ALERT® 3D 60

3 INSTALLATION PROCEDU RES.................................................................................... 3-1

3.1 INTRODUCTION...........................................................................................................3-1

3.2 BACT/ALERT 3D 60 INS TALLATION PROCEDURES..............................................3-3

3.2.1 Verification of Site Requirements........................................................................3-3

3.2.2 Record Line Noise.............................................................................................3-3

3.2.3 Unpacking ........................................................................................................3-3

3.2.4 Repacking ........................................................................................................3-3

3.2.4.1 Verification of Contents....................................................................3-6

3.2.4.1.1 3D 60 Instrument Parts ..................................................3-6

3.2.5 Set AC Power...................................................................................................3-7

3.2.6 Instrument Placement........................................................................................3-9

3.2.7 Instrument UPS .................................................................................................3-9

3.2.8 Power Up .......................................................................................................3-11

3.2.9 Instrument Configuration ..................................................................................3-11

3.2.10 Temperature ...................................................................................................3-11

3.2.11 Error Check ....................................................................................................3-11

3.2.12 Modem Functional Test ...................................................................................3-12

3.2.13 Barcode Reader Functional Test......................................................................3-13

3.2.14 UPS Functional Test (3D 60 Only, APC UPS 650).............................................3-13

3.2.15 Complete the Installation Checklist ...................................................................3-13

3.3 RESTRAINT INSTALLATI ON....................................................................................3-14

3.3.1 Overview........................................................................................................3-14

3.3.2 Procedure.......................................................................................................3-14

3.4 SOFTWARE INSTALLATION....................................................................................3-17

3.5 SWITCHING ON.........................................................................................................3-17

3.5.1 Initialization.....................................................................................................3-17

iv Service Manual

Page 9

BacT/ALERT® 3D 60 TABLE OF CONTENTS

4 SERVICING.........................................................................................................................4-1

4.1 INTRODUCTION...........................................................................................................4-1

4.2 SPECIFIC TOOLS AND REQUIRED...........................................................................4-3

4.3 POWER UP/DOWN PROCEDURES...........................................................................4-3

4.3.1 Introduction .......................................................................................................4-3

4.3.2 3D 60 Power Down ...........................................................................................4-3

4.3.3 3D 60 Power Up................................................................................................4-4

4.4 MB CONVERSION PROCEDURE...............................................................................4-5

4.4.1 Overview..........................................................................................................4-5

4.4.2 Procedure.........................................................................................................4-5

4.5 DATA BACKUP/RESTORE PROCEDURES..............................................................4-9

4.5.1 BacT/ALERT 3D 60 - Data Backup Procedure ....................................................4-9

4.5.2 BacT/ALERT 3D 60 - Data Restore Procedure ....................................................4-9

4.6 PREVENTIVE MAINTENANCE.................................................................................4-11

4.6.1 Overview........................................................................................................4-11

4.6.2 Perform Data Backup......................................................................................4-11

4.6.3 Barcode Reader Functional Test......................................................................4-11

4.6.4 Printer Maintenance ........................................................................................4-11

4.6.5 Temperature Verification ..................................................................................4-11

4.6.6 Disabled Cell Check........................................................................................4-11

4.6.7 +5 DC Voltage Verification ...............................................................................4-11

4.6.8 UPS Test ........................................................................................................4-11

4.6.9 “Door Open” Test ............................................................................................4-12

4.6.10 Completing the Preventive Maintenance Card...................................................4-12

4.7 DIAGNOSTICS AND TROUBLESHOOTING............................................................4-13

4.7.1 Introduction.....................................................................................................4-13

4.7.2 Symptomatic Errors .........................................................................................4-13

Service Manual v

Page 10

TABLE OF CONTENTS BacT/ALERT® 3D 60

4.8 SOFTWARE DIAGNOSTICS.....................................................................................4-15

4.8.1 Button Legend ................................................................................................4-15

4.8.2 Purpose of the Section ....................................................................................4-16

4.8.3 Special Equipment ..........................................................................................4-16

4.8.4 Accessing the Diagnostics Screens ..................................................................4-17

4.8.5 Diagnostic Screens Overview ...........................................................................4-18

4.9 ALIGNMENTS AND CALIBRATIONS.......................................................................4-69

4.9.1 Overview........................................................................................................4-69

4.9.2 System Power Supply......................................................................................4-69

4.9.3 Temperature ...................................................................................................4-69

4.9.4 Optics.............................................................................................................4-69

4.9.5 Rack – Single Cell Calibration ..........................................................................4-69

4.9.6 System Power Supply Check and Adjustments .................................................4-74

4.9.7 Door Micro Switch 1 & 2 Checks ......................................................................4-77

4.10 REMOVE AND REPLACE PROCEDURES..............................................................4-79

4.10.1 Introduction.....................................................................................................4-79

4.10.2 CPU PCBA Assembly (P/N 750 -0070-01).........................................................4-81

4.10.3 Quad Serial Interface PCBA (P/N 750 -0066-01) ................................................4-89

4.10.4 CompactFlash Adapter PCBA (P/N 957-0004-356)............................................4-91

4.10.5 Software Installation and CompactFlash Memory Ca rd Replacement .................4-94

4.10.6 ModSig PCBA (P/N 48300 -1) (Order Spare P/N 48300-901) ..............................4-95

4.10.7 ModSig PCBA Fuses (P/N 870-0008-14, -17, -22) ...........................................4-105

4.10.8 Step-5 PCBA (P/N 48301-1) (Order Spare P/N 48301 -901)..............................4-108

4.10.9 Step-5 Motor (P/N 48104 -1) ...........................................................................4-111

4.10.10 Outlet Thermistor PCBA (P/N 32300 -1) ..........................................................4-117

4.10.11 Inlet Thermistor PCBA (P/N 32300-1) .............................................................4-119

4.10.12 Zip™ Drive (P/N 895-0004-38) .......................................................................4-120

4.10.13 System Power Panel .....................................................................................4-124

vi Service Manual

Page 11

BacT/ALERT® 3D 60 TABLE OF CONTENTS

4.10.14 Power Supply Transformer (P/N 851-0015-01) ................................................4-126

4.10.15 Power Supply MOV - Metal Oxide Varistor (P/N 43116 -2) ................................4-128

4.10.16 Power Panel Solid State Relays (P/N 845-0018-01) ........................................4-130

4.10.17 DC Power Supply (P/N 852-0010-01) ............................................................. 4-132

4.10.18 Power Entry Module (PEM) Fuses (P/N 870-0008-14, -17, -24, -25).................4-135

4.10.19 Fan (P/N 941 -0009-07).................................................................................. 4-138

4.10.20 Heater (P/N 847 -0009-01).............................................................................. 4-140

4.10.21 Blower Assembly (P/N 48411 -1).....................................................................4-142

4.10.22 Blower Motor Capacitor (P/N 601-0001-02)..................................................... 4-143

4.10.23 Digital Reference Thermometer (P /N 848 -0003-01) .........................................4-148

4.10.24 Rack Assembly (P/N 43147 -921, -922, -923)...................................................4-149

4.10.25 Step-5 Drive Agitation Linkage Assembly (P/N 48418-1)..................................4-153

4.10.26 Gas Spring Assembly (P/N 926-0037-01)........................................................ 4-156

4.10.27 Magnetic Door Switches (P/N 841 -0012-01)....................................................4-158

4.10.28 Keyboard (P/N 957 -0004-373).......................................................................4-160

4.10.29 Barcode Scanner (P/N 957 -0004-291)............................................................4-161

4.10.30 Domestic 56K Fax Modem (P/N 957-0004-342) ..............................................4-162

4.10.31 International Fax Modem (P/N 957-0004-364).................................................4-163

4.10.32 APC Back-UPS Model 650 (Domestic Model) (P/N 957 -0060-02)..................... 4-164

4.10.33 APC UPS (International Model) (P/N 957-0060-03) .........................................4-169

4.11 POST SERVICE VALIDATION ................................................................................4-175

4.11.1 Overview......................................................................................................4-175

4.11.2 Required Materials ........................................................................................4-175

4.11.3 Procedures ...................................................................................................4-175

Service Manual vii

Page 12

TABLE OF CONTENTS BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

viii Service Manual

Page 13

BacT/ALERT® 3D 60 TABLE OF CONTENTS

00 FFRROONNTT MMAATTTTEERR

00..11

INDEX .................................................................................................. Index-1

AAPPPPEENNDDIICCEESS

Appendix A GLOSSARY.......................................................................................A.1

Appendix B PARTS LIST ......................................................................................B.1

Appendix C DISINFECTION ..................................................................................C.1

Appendix D ERROR CODES .................................................................................D.1

Appendix E DIAGRAMS ........................................................................................ E.1

Alphabetical Listing.................................................................................

Introduction .......................................................................................C.1

Procedures........................................................................................C.1

Spills .............................................................................................C.1

Instrument Shipping ...........................................................................C.1

Assembly Shipping ............................................................................C.1

Service Manual ix

Page 14

TABLE OF CONTENTS BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

x Service Manual

Page 15

BacT/ALERT® 3D 60 TABLE OF CONTENTS

00..22

LLIISSTT OOFF TTAABBLLEESS

Section 1

Table 1.2.1 Reference Data ........................................................................................1-2

Section 2

Table 2.2.1 Audio Frequency Selection (JP 23 through JP26) .......................................2-4

Table 2.5.1 Power Supply Data.................................................................................2-10

Section 3

Table 3.2.1 3D 60 instrument Parts List .......................................................................3-6

Table 3.2.2 Facility Power Rating and Conversion Chart ...............................................3-8

Table 3.2.3 Setup and Connections Table....................................................................3-9

Table 3.3.3 Restraint Hardware .................................................................................3-14

Table 3.3.4 Table of Equivalent Dimensions...............................................................3-15

Section 4

Table 4.2.1 Required Tools and Equipment..................................................................4-3

Table 4.7.1 Symptomatic Problems ...........................................................................4-13

Table 4.10.18 Facility Power Rating and Fuse Conversion Chart...................................4-135

Appendices

Table C 1.2 Disinfection Equipment .............................................................................C.1

Service Manual xi

Page 16

TABLE OF CONTENTS BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

xii Service Manual

Page 17

BacT/ALERT® 3D 60 TABLE OF CONTENTS

00..33

LLIISSTT OOFF IILLLLUUSSTTRRAATTIIOONNSS

CHAPTER 0 – FRONT MATTER

Fig. 1 - Text Box ......................................................................................................................................................................... xxi

Fig. 2 - USA 115 VAC Standard............................................................................................................................................xxvi

Fig. 3 - European 230 VAC Standard..................................................................................................................................xxvi

CHAPTER 1 – GENERAL INFORMATION

Fig. 4 - BacT/ALERT 3D 60 Instrument................................................................................................................................1-3

Fig. 5 - 3D 60 Power Panel Assembly ..................................................................................................................................1-4

Fig. 6 - Transformer ..................................................................................................................................................................1-4

Fig. 7 - Blower & Heater...........................................................................................................................................................1-4

Fig. 8 - Step-5 Motor Assembly..............................................................................................................................................1-6

Fig. 9 - Fan Assembly...............................................................................................................................................................1-6

Fig. 10 - BacT/ALERT 3D 60 System Control (Rear View) w/Comm Ports.................................................................1-8

Fig. 11 - CPU PCBA................................................................................................................................................................1-10

Fig. 12 - ModSig PCBA..........................................................................................................................................................1-10

Fig. 13 - Quad Serial PCBA...................................................................................................................................................1-10

Fig. 14 - Thermistor PCBA....................................................................................................................................................1-10

Fig. 15 - CompactFlash Memory Disk ................................................................................................................................1-12

Fig. 16 - CompactFlash Adapter PCBA .............................................................................................................................1-12

Fig. 17 - Step-5 PCBA.............................................................................................................................................................1-12

Fig. 18 - BacT 3D 60 Incubator Chamber..........................................................................................................................1-14

Fig. 19 - Rack Assembly........................................................................................................................................................1-14

Fig. 20 - Operator Display Monitor .....................................................................................................................................1-16

Fig. 21 - Barcode Scanner....................................................................................................................................................1-16

Fig. 22 - Keyboard...................................................................................................................................................................1-16

Fig. 23 - Zip Drive ....................................................................................................................................................................1-16

Fig. 24 - Uninterruptible Power Supply (UPS) Domestic Model – Front and Rear Views....................................1-20

Fig. 25 - Uninterruptible Power Supply (UPS) European Model – Front and Rear Views...................................1-22

Fig. 26 - Instrument Configuration Screen.......................................................................................................................1-24

Fig. 27 - Main Screen ..............................................................................................................................................................1-25

Fig. 28 - Setup Screen w/Field Engineer Password Activation ..................................................................................1-26

Fig. 29 - Instrument Configuration Screen.......................................................................................................................1-26

Fig. 30 - [X Box ] Selection Checkbox................................................................................................................................1-27

Fig. 31 - Quick Reference Card – Front Side ...................................................................................................................1-30

Fig. 32 - Quick Reference Card – Rear Side.....................................................................................................................1-31

Service Manual xiii

Page 18

TABLE OF CONTENTS BacT/ALERT® 3D 60

CHAPTER 2 – BACKGROUND INFORMATION

Fig. 33 - ModSig PCBA Diagram...........................................................................................................................................2-2

Fig. 34 - ModSig Block Diagram............................................................................................................................................2-5

Fig. 35 - Thermistor PCBA......................................................................................................................................................2-6

Fig. 36 - Power Distribution Block Diagram.......................................................................................................................2-8

Fig. 37 - CPU PCBA Diagram...............................................................................................................................................2-12

Fig. 38 - CompactFlash Adapter PCBA .............................................................................................................................2-14

Fig. 39 - Quad Serial Interface PCBA Diagram................................................................................................................2-16

Fig. 40 - Rack Controller PCBA Diagram ..........................................................................................................................2-18

Fig. 41 - Rack Controller PCBA Block Diagram ..............................................................................................................2-20

Fig. 42 - Rack Address Concept..........................................................................................................................................2-22

Fig. 43 - Step-5 PCBA Diagram............................................................................................................................................2-24

Fig. 44 - Step-5 PCBA Block Diagram................................................................................................................................2-28

CHAPTER 3 – INSTALLATION PROCEDURES

Fig. 45 - 3D 60 Instrument Repacking Sequence .............................................................................................................3-4

Fig. 46 - 3D 60 Instrument Repack – Web Strapping Diagrams...................................................................................3-5

Fig. 47 - Power Entry Module w. Fuse Holder Removed................................................................................................3-7

Fig. 48 - Fuse Holder w/Fuse..................................................................................................................................................3-7

Fig. 49 - PEM w/115 VAC Version .........................................................................................................................................3-8

Fig. 50 - PEM w/230 VAC Version .........................................................................................................................................3-8

Fig. 51 - Installation and Setup Diagram...........................................................................................................................3-10

Fig. 52 - Communications Panel Connection Diagram .................................................................................................3-12

Fig. 53 - Modem Configuration & Dip Switch Settings Diagram................................................................................3-12

Fig. 54 - Countertop/Surface Mounting Diagram............................................................................................................3-12

Fig. 55 - Mounting Surface Diagram..................................................................................................................................3-15

Fig. 56 - Mounting Surface (Drilling) Template...............................................................................................................3-16

Fig. 57 - Installation Checklist.............................................................................................................................................3-18

CHAPTER 4 - SERVICING

Fig. 58 - 3D 60 Instrument – Power Switch........................................................................................................................4-3

Fig. 59 - Step-5 Motor PCBA Power Disconnect...............................................................................................................4-5

Fig. 60 - MB Conversion – Lock Screw Removal.............................................................................................................4-6

Fig. 61 - MB Conversion – Lock Screw Installation.........................................................................................................4-7

Fig. 62 - Backup Management Button .................................................................................................................................4-9

Fig. 63 - Cancel Button ............................................................................................................................................................4-9

Fig. 64 - ModSig PCBA LED 55 and 56 location..............................................................................................................4-12

Fig. 65 - Scanner Default Settings Barcode.....................................................................................................................4-13

Fig. 66 - Diagnostics Setup Screen Buttons....................................................................................................................4-15

Fig. 67 - Diagnostic Test Selection (Setup) Screen.......................................................................................................4-17

Fig. 68 - 1.7 Inc Module/Flag Check...................................................................................................................................4-18

Fig. 69 - 1.5 Inc Module 1/Temperature Log (Find Text String) ..................................................................................4-19

xiv Service Manual

Page 19

BacT/ALERT® 3D 60 TABLE OF CONTENTS

Fig. 70 - 1.5 Inc Module 1/Temperature Log (Text String Output)..............................................................................4-20

Fig. 71 - 1.5 Inc Module 1/Temperature Log (Save Output to Zip) .............................................................................4-20

Fig. 72 - 1.5 Inc Module 1/Temperature Log (Scroll/Anchor Buttons) ......................................................................4-21

Fig. 73 - 1.5 Inc Module 1/Temperature Log (Slide Bar) ...............................................................................................4-22

Fig. 74 - 1.1 Inc Module 1/Loopback Test Screen...........................................................................................................4-24

Fig. 75 - 1.2 Inc Module 1/Port Stats Test Screen ...........................................................................................................4-25

Fig. 76 - 1.3 Inc Module 1/Message Stats Test Screen..................................................................................................4-26

Fig. 77 - 1.4 Inc Module 1/ Message Log Test Screen....................................................................................................4-27

Fig. 78 - 1.5 Inc Module 1/Temperature Log Test Screen .............................................................................................4-28

Fig. 79 - 1.6 Inc Module 1/Reading Log Test Screen.....................................................................................................4-29

Fig. 80 - 1.7 Inc Module 1/Flag Check Screen.................................................................................................................4-30

Fig. 81 - 1.7 Inc Module 1/Flag Check Test Screen........................................................................................................4-31

Fig. 82 - 1.7 Inc Module 1/Flag Check (Calibration Screen..........................................................................................4-31

Fig. 83 - 1.8 Inc Module 1/Heater Screen..........................................................................................................................4-32

Fig. 84 - 1.9 Inc Module 1/LED Check................................................................................................................................4-33

Fig. 85 - 1.9 Inc Module 1/LED Check (Walking).............................................................................................................4-33

Fig. 86 - 7.1 Instrument Cntrl/ZIP Drive Test Screen.....................................................................................................4-35

Fig. 87 - 7.2 Instrument Cntrl/Barcode Loopback Test Screen...................................................................................4-36

Fig. 88 - 7.4 Instrument Cntrl/Power Event Log Screen...............................................................................................4-39

Fig. 89 - 7.6 Instrument Cntrl/Software Test Screen – Scan........................................................................................4-62

Fig. 90 - 7.6 Instrument Cntrl/Software Test Screen – Misc........................................................................................4-66

Fig. 91 - Diagnostic Test Selection Screen – Flag Check............................................................................................4-70

Fig. 92 - Incubator Flag Check – Cell Differences Screen...........................................................................................4-71

Fig. 93 - Flag Check – Cell Calibration Screen................................................................................................................4-72

Fig. 94 - System Power Panel and DC Supply.................................................................................................................4-74

Fig. 95 - Step-5 PCBA at Connector J4.............................................................................................................................4-75

Fig. 96 - ModSig PCBA with +5 VDC Test Points ...........................................................................................................4-75

Fig. 97 - DC Power Supply....................................................................................................................................................4-75

Fig. 98 - Door Micro Switches and Magnets....................................................................................................................4-77

Fig. 99 - Top Panel Screw Locations (Removal).............................................................................................................4-81

Fig. 100 - CPU PCBA w/Quad Serial PCBA plugged in.................................................................................................4-82

Fig. 101 - CPU PCBA - Screw Removal.............................................................................................................................4-83

Fig. 102 - CPU PCBA – J27 and J7 Cable Routing.........................................................................................................4-84

Fig. 103 - Quad Serial PCBA Removed from CPU PCBA.............................................................................................4-85

Fig. 104 - CPU PCBA Cable Connections.........................................................................................................................4-86

Fig. 105 - WinSystems

®

CPU Connector Locations.......................................................................................................4-87

Fig. 106 - Quad Serial PCBA................................................................................................................................................4-89

Fig. 107 - Quad Serial PCBA Cable Connections ...........................................................................................................4-90

Fig. 108 - EMC – CompactFlash PCBA..............................................................................................................................4-91

Fig. 109 - CompactFlash Adapter & ZIP Drive Installed...............................................................................................4-92

Fig. 110 - CompactFlash Adapter w/WinSystems Computer......................................................................................4-92

Fig. 111 - CompactFlash Card (Memory Removal) ........................................................................................................4-93

Fig. 112 - CompactFlash Adapter (Removal) ...................................................................................................................4-93

Fig. 113 - ModSig PCBA – Connector Location..............................................................................................................4-95

Fig. 114 - ModSig PCBA........................................................................................................................................................4-96

Fig. 115 - ModSig PCBA – Tie Wrap Removal.................................................................................................................4-97

Fig. 116 - ModSig PCBA – Bundled Cable Disconnection...........................................................................................4-98

Fig. 117 - ModSig PCBA – JP19 Cable Removal.............................................................................................................4-99

Fig. 118 - ModSig PCBA – JP21, MS-JP11, JP12, &JP31 Cable Removal................................................................4-99

Fig. 119 - ModSig PCBA – MS-JP1 Cable Removal....................................................................................................4-100

Service Manual xv

Page 20

TABLE OF CONTENTS BacT/ALERT® 3D 60

Fig. 120 - ModSig – Rear Panel Screw Removal..........................................................................................................4-100

Fig. 121 - ModSig PCBA – Mounting Screw Locations..............................................................................................4-101

Fig. 122 - ModSig – Step -5 MCJ4 Connection..............................................................................................................4-102

Fig. 123 - ModSig – Rear Panel Hex Nut & Knurled Nut Removal..........................................................................4-103

Fig. 124 - ModSig PCBA – JP10, JP1 and Ground Cable .......................................................................................... 4-103

Fig. 125 - ModSig PCBA Fuse Locations.......................................................................................................................4-105

Fig. 126 - ModSig PCBA – Fuse Locations 1 ................................................................................................................ 4-106

Fig. 127 - ModSig PCBA (Installed) - Fuse Locations 2.............................................................................................4-107

Fig. 128 - Step-5 PCBA Location ...................................................................................................................................... 4-108

Fig. 129 - Step-5 PCBA Connector and Wiring Locations ........................................................................................4-109

Fig. 130 - Step-5 Motor Windings ....................................................................................................................................4-111

Fig. 131 - Step-5 Motor Removal – MCJ3 Disconnection..........................................................................................4-112

Fig. 132 - Step-5 Motor Removal – Set-Screw Removal............................................................................................4-113

Fig. 133 - Step-5 Motor Removal – Mounting Screw Removal.................................................................................4-114

Fig. 134 - Step-5 Motor Removal......................................................................................................................................4-114

Fig. 135 - Step-5 Motor Removal – Reinstalling Mounting Screws........................................................................4-115

Fig. 136 - Outlet Thermistor PCBA Removal................................................................................................................4-117

Fig. 137 - Inlet Thermistor PCBA Removal....................................................................................................................4-119

Fig. 138 - Zip™ Drive Removal ......................................................................................................................................... 4-120

Fig. 139 - Zip Drive – Flash Adapter PCBA Removal ................................................................................................. 4-120

Fig. 140 - Zip Drive Screw Removal................................................................................................................................4-121

Fig. 141 - Zip Drive Removal – Cutout Hole .................................................................................................................. 4-121

Fig. 142 - Zip Drive Sled Removal (Side Screws)........................................................................................................4-122

Fig. 143 - Zip Drive Sled Removal (Bottom Screws)...................................................................................................4-122

Fig. 144 - Zip Drive – Reconnecting IDE Cable and Power Connector..................................................................4-122

Fig. 145 - Power Panel Assembly – Screw Removal..................................................................................................4-124

Fig. 146 - Power Panel Assembly....................................................................................................................................4-125

Fig. 147 - Power Panel Assembly – Installed...............................................................................................................4-125

Fig. 148 - Power Supply Transformer – Power Supply Panel Removed...............................................................4-126

Fig. 149 - Power Panel with Transformer Installed.....................................................................................................4-127

Fig. 150 - Transformer – PEM Connections .................................................................................................................. 4-127

Fig. 151 - Power Supply – Simplified Schematic.........................................................................................................4-128

Fig. 152 - Term Board 1 (TB1)...........................................................................................................................................4-128

Fig. 153 - Power Panel Solid State Relay Layout ........................................................................................................ 4-130

Fig. 154 - Power Supply Assembly w/DC Power Supply...........................................................................................4-132

Fig. 155 - DC Power Supply – J1 and J2 Disconnection ........................................................................................... 4-133

Fig. 156 - Power Panel Assembly – DC Supply Screw Removal.............................................................................4-134

Fig. 157 - Power Entry Module w/Fuse Holder Removed..........................................................................................4-135

Fig. 158 - Fuse Holder Fuse Installation ........................................................................................................................ 4-135

Fig. 159 - PEM Fuse Removal w/ Screwdriver..............................................................................................................4-136

Fig. 160 - PEM Fuse Holder Removal.............................................................................................................................4-136

Fig. 161 - PEM Fuse Holder Pulled Out..........................................................................................................................4-136

Fig. 162 - PEM w/115 VAC Version..................................................................................................................................4-137

Fig. 163 - PEM w/230 VAC Version..................................................................................................................................4-137

Fig. 164 - Fan – Inside View...............................................................................................................................................4-138

Fig. 165 - Fan Wiring Connections .................................................................................................................................. 4-138

Fig. 166 - Heater Terminal Connectors..........................................................................................................................4-140

Fig. 167 - Heater Removal..................................................................................................................................................4-141

Fig. 168 - Blower Motor ......................................................................................................................................................4-142

Fig. 169 - Blower Motor Capacitor...................................................................................................................................4-143

xvi Service Manual

Page 21

BacT/ALERT® 3D 60 TABLE OF CONTENTS

Fig. 170 - Power Supply Panel – BHP1 Connector ......................................................................................................4-144

Fig. 171 - Power Supply Panel – HBJ1/HBP1 Connector .......................................................................................... 4-144

Fig. 172 - Power Supply Panel – Mounting Screw Remo val.....................................................................................4-145

Fig. 173 - Blower Motor Capacitor – Boot and Clamp Removal .............................................................................. 4-146

Fig. 174 - Reference Thermometer..................................................................................................................................4-148

Fig. 175 - Rack Blocks Installed.......................................................................................................................................4-149

Fig. 176 - Rack Assembly w/Cable Cover Removed...................................................................................................4-150

Fig. 177 - Rack Cable Clamp Removed .......................................................................................................................... 4-150

Fig. 178 - Rack Cable Disconnection..............................................................................................................................4-150

Fig. 179 - Rack Assembly – Captive Screw Removal.................................................................................................4-151

Fig. 180 - Step-5 Drive Agitation Linkage Assembly..................................................................................................4-153

Fig. 181 - Drive Linkage and Bushings Specs.............................................................................................................4-154

Fig. 182 - Gas Spring Assembly ....................................................................................................................................... 4-156

Fig. 183 - Gas Spring Assembly Removal ..................................................................................................................... 4-157

Fig. 184 - Magnetic Door Switches..................................................................................................................................4-158

Fig. 185 - Door Switch LEDs – ModSig PCBA..............................................................................................................4-159

Fig. 186 - 3D 60 Rear Panel – Keyboard Port Connection ........................................................................................ 4-160

Fig. 187 - 3D 60 Rear Panel – Barcode Scanner Port Connection..........................................................................4-161

Fig. 188 - Fax Modem Port Connections (Domestic Model).....................................................................................4-162

Fig. 189 - Domestic 56K Fax Modem – Rear Port Connection.................................................................................4-162

Fig. 190 - Modem Port Connections (International Model).......................................................................................4-163

Fig. 191 - International 56K Fax Modem – Rear Port Connection...........................................................................4-163

Fig. 192 - APC UPS Domestic Model – BackUPS 650 (120V) (Front and Rear View).........................................4-164

Fig. 193 - 3D 60 System Rear Communications Ports (UPS Cable Connection)................................................4-164

Fig. 194 - UPS Battery Connection Preparation .......................................................................................................... 4-165

Fig. 195 - UPS Battery Cover Removal...........................................................................................................................4-165

Fig. 196 - Connecting UPS Battery Cable to Terminal............................................................................................... 4-166

Fig. 197 - Domestic UPS with Battery Cables Connected.........................................................................................4-166

Fig. 198 - Domestic UPS with Battery Cover Secured...............................................................................................4-167

Fig. 199 - Domestic UPS Peripheral Connections.......................................................................................................4-167

Fig. 200 - APC UPS International Model _BackUPS 650 (240V) (Front and Rear View) ....................................4-169

Fig. 201 - 3D 60 System Rear Communications Ports (UPS Cable Connection)................................................4-169

Fig. 202 - International UPS Battery Connection Preparation ................................................................................. 4-170

Fig. 203 - International UPS Battery Cover Removal.................................................................................................4-170

Fig. 204 - Connecting UPS Battery Cable to Terminal ............................................................................................... 4-171

Fig. 205 - International UPS with Battery Cables Connected...................................................................................4-171

Fig. 206 - International UPS with Battery Cover Secured.........................................................................................4-172

Fig. 207 - International UPS Peripheral Connections.................................................................................................4-172

Fig. 208 - Instrument Status Code 710................................................................................................................................D-9

Service Manual xvii

Page 22

TABLE OF CONTENTS BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

xviii Service Manual

Page 23

BacT/ALERT® 3D 60 TYPOGRAPHY AND GRAPHIC CONVENTIONS

00..44

TTYYPPOOGGRRAAPPHHYY AANNDD GGRRAAPPHHIICC CCOONNVVEENNTTIIOONNSS

The following is a comprehensive list of the typographical and graphic elements of this manual.

0.4 TYPOGRAPHY AND GRAPHIC CONVENTIONS.....................................................XIX

0.4.1 Bullets..............................................................................................................xxi

0.4.2 Text Boxes ....................................................................................................... xxi

0.4.3 Bracketed Italics................................................................................................ xxi

0.4.4 Underlined Text................................................................................................. xxi

0.4.5 Bracketed Text .................................................................................................xxii

0.4.6 Text Within Quotation Marks.............................................................................xxii

0.4.7 Italicized (Whether Bold or Not) Text .................................................................xxii

Service Manual xix

Page 24

TYPOGRAPHY AND GRAPHICS CONVENTIONS BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

xx Service Manual

Page 25

Important Steps

BacT/ALERT® 3D 60 TYPOGRAPHY AND GRAPHIC CONVENTIONS

00..44..11

00..44..22

BBuulllleettss

Bullets are used to designate items in a list (•, -) or steps in a procedure (1, 2, et c)

TTeexxtt BBooxxeess

Whenever text is contained within a box (Reference Figure 1) it identifies things that require

special attention. There are three different text boxes used within this manual:

• NOTES: Used to clarify or explain a particular step. These text boxes are identified by

• CAUTIONS: Used to identify actions that could cause DAMAGE to the instrument or

• WARNINGS: Used to identify actions that could result in INJURY or DEATH to

• IMAGE NOTES: Used to explain steps of a process, identify component parts,

A text box can be a NOTE, CAUTION, WARNING or Image Note.

Fig. 1 - Text Box

the word 'NOTE' (bold and all caps) centered at the top of the box and normal text

following.

test equipment. These text boxes are identified by the word 'CAUTION' (bold and all

caps) centered at the top of the box and bold text following.

personnel performing the procedure (or close by). These text boxes are identified by the

word 'WARNING ' centered at the top of the box and bold capitalized text following.

suggestions and other steps related to the functionality of the instrument. The text

boxes are not identified with any special markings. Generally they will surround photos

and drawings and will explain processes, parts or other related information.

00..44..33

00..44..44

Service Manual xxi

BBrraacckkeetteedd IIttaalliiccss

Brackets around Italics text, [Italics Text], identifies items to be clicked on the display screen.

(I.E.: Press [On Line] to continue).

UUnnddeerrlliinneedd TTeexxtt

Underlined text identifies words, groups, or characters that are to be typed on the keyboard.

(I.E.: Type <Y><E><S> to continue, or Press <ALT> + <CTRL> + <DEL> to reboot.)

Page 26

TYPOGRAPHY AND GRAPHIC CONVENTIONS BacT/ALERT® 3D 60

00..44

00..44..55

00..44..66

00..44..77

TTYYPPOOGGRRAAPPHHYY AANNDD GGRRAAPPHHIICC CCOONNVVEENNTTIIOONNSS ((CCOONNTTIINNUUEEDD))

BBrraacckkeetteedd TTeexxtt

Single text within brackets identifies single keys to be pressed on the keyboard. (I.E.: Press

<Esc> to exit the system.)

TTeexxtt WWiitthhiinn QQuuoottaattiioonn MMaarrkkss

Whenever text is displayed within quotation marks, it usually means that this a displayed

message on the screen. (I.E.: After previous step is complete, the system will display 'Press

Any Key to Continue'.)

IIttaalliicciizzeedd ((WWhheetthheerr BBoolldd oorr NNoott)) TTeexxtt

Whenever text is in Italics (or Bold Italics), it provides for emphasis, or identifies key words

or concepts. Whenever this format is seen, it is an important operative part of the meaning of

the text or added notation. Bold Italics designate STRONG emphasis and is not to be

ignored or taken lightly.

xxii Service Manual

Page 27

BacT/ALERT® 3D 60 SAFETY SUMMARY

00..55

SSAAFFEETTYY SSUUMMMMAARRYY

The following is a comprehensive list of the safety issues outlined in this chapter.

0.5 SAFETY SUMMARY.................................................................................................XXIII

0.5.1 General Information to Follow ........................................................................... xxv

0.5.2 Electrical Warnings...........................................................................................xxv

0.5.3 Electrical Grounding .........................................................................................xxvi

0.5.4 Fuse Replacement Warning..............................................................................xxvi

0.5.5 Hazardous Voltages .........................................................................................xxvi

0.5.6 Cleaning Agents...............................................................................................xxvi

0.5.7 Health Risks ...................................................................................................xxvii

0.5.8 ESD Precautions.............................................................................................xxvii

0.5.9 Moving Parts ...................................................................................................xxvii

0.5.10 Heating Element ............................................................................................. xxvii

Service Manual xxiii

Page 28

SAFETY SUMMARY BacT/ALERT® 3D 60

THIS PAGE

INTENTIONALLY

LEFT BLANK

xxiv Service Manual

Page 29

BacT/ALERT® 3D 60 SAFETY SUMMARY

00..55..11

00..55..22

GGeenneerraall IInnffoorrmmaattiioonn ttoo FFoollllooww

This manual contains WARNINGS, CAUTIONS and NOTES, specific instructions and other

information that must be followed and observed at all times. This will help ensure the safe

handling and operation of the instrument.

• NOTE: Clarifies or explains a particular step or procedure. A note box is identified with

the word NOTE in bold text and the explanatory body text is not bolded.

• CAUTION: Warns of a risk of DAMAGING equipment or components. A caution may be

identified with the word CAUTION and its explanatory body text is bolded.

• WARNING: Identifies a process step that may cause injury or DEATH to personnel. A

warning may be identified with the word WARNING and its explanatory body text is

bolded in all caps.

EElleeccttrriiccaall WWaarrnniinnggss

The BacT/ALERT 3D 60 has been designed and tested IAW IEC Publication 61010-1: Safety

Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use, UL

3101-1, CAN/CSA C22.2 No. 1010.1-92 and has been supplied in safe condition. A CB

Certificate and Construction File have been established for the instrument.

1. Before applying power, ensure that the Power Entry Module (PEM) is properly

configured for the specific facility power voltage. Also ensure that the fuse(s) is (are)

installed and of proper rating value. (See Subsection 3.2.5 – Set AC Power)

2. Any interruption of the protective conductor inside or outside of the instrument or

disconnection of the protective earth terminal is likely to make the instrument dangerous

to lab personnel and other users.

3. Any adjustment, maintenance or repair of the opened instrument while under voltage

should be avoided. If power to the instrument is necessary, repair or maintenance shall

be carried out only by a trained and qualified individual who is aware of the hazard(s)

involved with the task. In addition, a second individual will be nearby to render aid, if

necessary.

4. Make sure that only fuses with the required current rating and of the specified type are

used for a replacement. The use of makeshift fuses or the short-circuiting of any fuse

holder is extremely dangerous and prohibited. (See Subsection 3.2.5 – Set AC Power)

5. Whenever it is likely that a BacT/ALERT 3D 60 has been impaired, it will be made

inoperative by powering it down and disconnecting the power cord. If there is evidence

of moisture within the instrument, turn the facility power off at the circuit breaker junction

box before removing the power cable. The instrument is likely to be impaired if it:

• Shows visible damage

• Fails to perform an intended operation

• Has been subjected to storage or operation under unfavorable conditions. (i.e.,

above 80% humidity, dusty environment, prolonged storage. (Refer to Section 1-

2, Table 1.2.1, for tolerances.

• Has been subjected to severe transport stresses.

6. If any of the above conditions occur, a qualified service technician must check the

instrument out prior to use.

Service Manual xxv

Page 30

WARNING

SAFETY SUMMARY BacT/ALERT® 3D 60

00..55

00..55..33

SSAAFFEETTYY SSUUMMMMAARRYY ((CCOONNTTIINNUUEEDD))

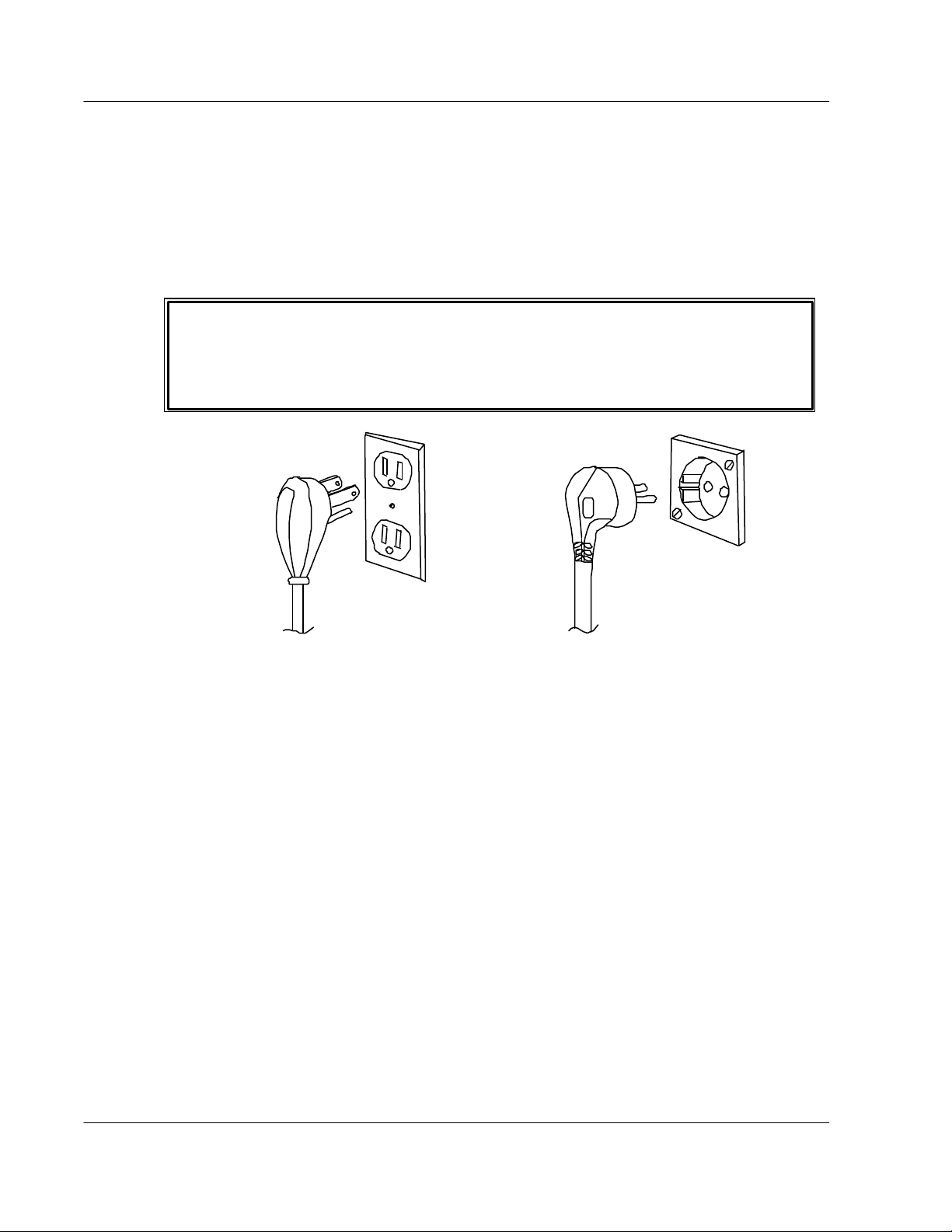

EElleeccttrriiccaall GGrroouunnddiinngg

An electrical ground is required and must be in place for this instrument.

Before installing the instrument, ensure that a grounded wall receptacle is available for each

unit. It must be plugged into a mating grounding type wall receptacle in accordance with

National Electrical Codes (US Domestic) and/or applicable local codes and ordinances

(domestic or international) for this type of installation. (Reference Figure 2, below)

UNDER NO CIRCUMSTANCES IS THE GROUND PRONG TO BE REMOVED. IF THE

GROUND PRONG, THE PL UG, OR THE CORD HAVE ANY PHYSICAL DAMAGE, THE CORD

IS TO BE REPLACED. IT IS EXTREMELY HAZARDOUS TO OPERATE THIS (OR ANY)

INSTRUMENT WITH A MISSING GROUND PRONG OR A FAULTY CABLE IN PLACE.

00..55..44

00..55..55

00..55..66

Fig. 2 - USA 115 VAC Standard Fig. 3 - European 230 VAC Standard

FFuussee RReeppllaacceemmeenntt WWaarrnniinngg

There are no user-serviceable fuses in the BacT/ALERT® 3D 60. Only trained and qualified

service technicians are to replace any fuse within the instrument. The only exception to fuse

installation will be during the initial installation of the unit. At the time of installation, the

customer does install PEM fuses according to steps outlined in the Installation section of the

BacT/ALERT 3D 60 Operator’s Manual.

HHaazzaarrddoouuss VVoollttaaggeess

DC voltages used within the instrument are low voltage and low current. They do not pose

any immediate hazard to technicians. There is, however, facility power of either 115 VAC or

230 VAC within or near the power supply assembly, which could pose an electrical hazard if

proper precautions are not observed. Note: All voltages are potentially hazardous under the

proper circumstances.

CClleeaanniinngg AAggeennttss

Follow manufactures’ instructions and MSDS (Material Safety Data Sheets) information to

prevent any possible hazards that may be present when using cleaning agents (or other

chemicals).

xxvi Service Manual

Page 31

BacT/ALERT® 3D 60 SAFETY SUMMARY

00..55

00..55..77

00..55..88

00..55..99

00..55..1100

SSAAFFEETTYY SSUUMMMMAARRYY ((CCOONNTTIINNUUEEDD))

HHeeaalltthh RRiisskkss

Specimens and inoculated culture bottles are to be assumed as though they are capable of

transmitting infectious agents. Handling of any bottles or spec imens must be done with the

utmost care. Spills must be cleaned as soon as possible, using the disinfection procedures

outlined in the BacT/ALERT® 3D 60 Operator’s Manual and Appendix C of this manual.

EESSDD PPrreeccaauuttiioonnss

The BacT/ALERT® 3D 60 contains several electrostatic sensitive devices within the modules.

Proper ESD precautions, in addition to the use of a grounding strap, are imperative whenever

working on or near any ESD components.

MMoovviinngg PPaarrttss

There are moving parts within the left side of the instrument’s chassis. At times, personnel

may be exposed to the Agitation Drive Arm, Motor Offset Round and other internal moving

parts. Care must be taken to avoid exposure of clothing, hands, fingers, arms, etc. Prior to

performing maintenance procedures around moving parts, it is advised that loose clothing

(i.e. ties, long sleeves, etc.) be secured.

HHeeaattiinngg EElleemmeenntt

The instrument contains a heater to perform the incubation process. The heater may remain

hot for a period of time after the unit is first shut down for maintenance. To prevent burns,

avoid contact with the heater until it is known that it is cool enough to touch.