Page 1

8

027908 394224

AUTOMAZIONI PER PORTE BASCULANTI E SEZIONALI

AUTOMATION FOR OVERHEAD AND SECTIONAL GARAGE DOORS

AUTOMATION POUR PORTES BASCULANTES ET SECTIONALES

GARAGENTORANTRIEB FÜR SCHWING UND SEKTIONALTORE

AUTOMATIZACIONES PARA PUERTAS BASCULANTE Y SECCIONALES

AUTOMATISERINGEN VOOR KANTEL- EN SECTIEDEUREN

D811796 00100_05 24-05-12

ISTRUZIONI D’USO E DI INSTALLAZIONE

INSTALLATION AND USER’S MANUAL

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

INSTALLATIONS-UND GEBRAUCHSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

INSTALLATIEVOORSCHRIFTEN

Attenzione! Leggere attentamente le “Avvertenze” all’interno! Caution! Read “Warnings” inside carefully! Attention! Veuillez lire attentivement les Avertissements qui se trouvent à l’intérieur! Achtung! Bitte lesen Sie

aufmerksam die „Hinweise“ im Inneren! ¡Atención¡ Leer atentamente las “Advertencias”en el interior! Let op! Lees de “Waarschuwingen” aan de binnenkant zorgvuldig!

TIZIANO B GDA 260 S01

TIZIANO B GDA 260 S01

Page 2

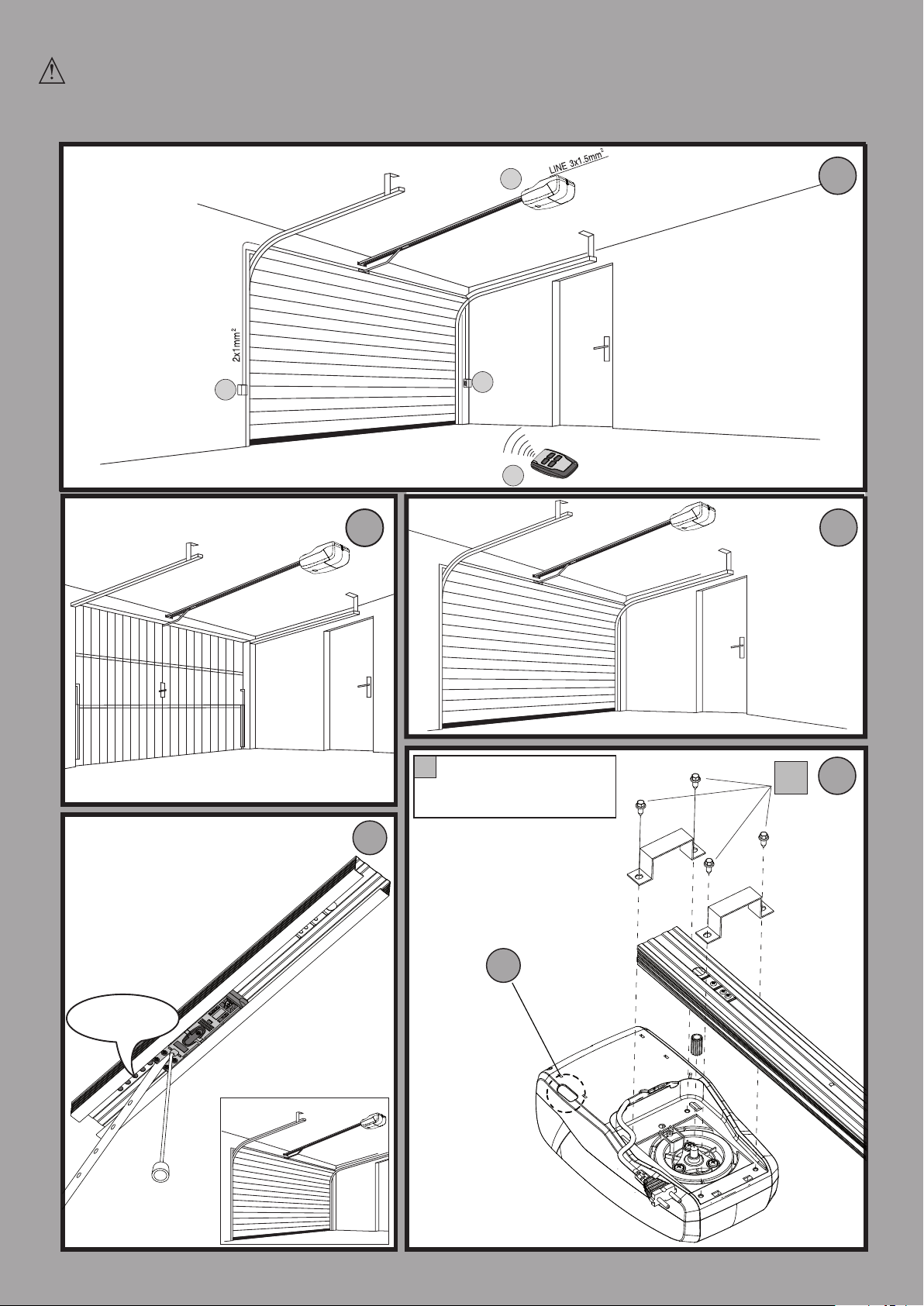

INSTALLAZIONE VELOCE-QUICK INSTALLATION-INSTALLATION RAPIDE

SCHNELLINSTALLATION-INSTALACIÓN RÁPIDA - SNELLE INSTALLATIE

a) Prima di iniziare con l’installazione bisogna leggere le avvertenze.

a) Before commencing installation, make sure you read the warnings.

a) Avant de commencer l’installation lisez les avertissements.

a) Vor der Installation müssen die Hinweise gelesen werden.

a) Antes de comenzar con la instalación es necesario leer las advertencias.

a) Voor met de installatie te beginnen moet u de waarschuwingen lezen.

b) Oltre alle gure, bisogna seguire le indicazioni date nel paragrafo corrispondente a pag.8

b) In addition to the gures, you must follow the instructions given in the relevant section on page 11

b) Suivez non seulement les gures mais aussi les indications données dans le paragraphe correspondant à

la page 14

b) Außer den Abbildungen müssen die Angaben im entsprechenden Abschnitt auf Seite 17 befolgt werden

b) Además de las guras, es necesario seguir las indicaciones dadas en el apartado correspondiente en pág. 20

b) Volg niet alleen de guren, maar ook de aanwijzingen die in de paragraaf op pag. 23 staan

D811796 00100_05

PREDISPOSIZIONE TUBI,

TUBE ARRANGEMENT,

PRÉDISPOSITION DES TUYAUX,

VORBEREITUNG DER LEITUNGEN,

DISPOSICIÓN DE TUBOS,

VOORBEREIDING LEIDINGEN.

Ft

B

2

5x1mm

Fr

M

T

A

C

LOCK

D

V1

15

E1

6,3

V1

E

2 - TIZIANO B GDA 260 S01

Page 3

FOTOCELLULE /PHOTOCELL / PHOTOCELLULES / FOTOZELLEN / FOTOCÉLULAS / FOTOCELLEN

Connection of 1 pair of non-tested photocells

D811796 00100_05

Anschluss von einem Paar nicht überprüften Fotozellen

Conexión de 1 par fotocélulas no comprobadas

Aansluiting van 1 paar fotocellen anders dan “trusted device”

JP3

310 11 6

ITALIANO ENGLISH

F

24V ~

2

DIP TEST PHOT = ON

DIP test fotocellule OFF/ Photocell test DIP OFF

DIP essai photocellules Désactivée / DIP Test Fotozellen OFF

DIP prueba fotocélulas OFF / DIP test fotocellen OFF

1

Tx 1

5

4

3

2

1

Rx 1

COM

PHOT

JP13

JP10

JP11

JP12

24VSafe MAX 180mA

24V~ MAX 180mA

ANT

SHIELD

3 1245678910111213

FRANÇAIS DEUTSCH ESPAÑOL

Luce di cortesia,Courtesy lamp,Lampe de courtoisie,

Hilfsbeleuchtung,Luz interior, Waaklicht.

Fusibile,Fuse,Fusible,

Schmelzsicherung,Fusible,

Zekering:

0,8A T

230V~

DL1 DL2

24V~

JP6

Fig.F1

FOTOCELLULE /PHOTOCELL / PHOTOCELLULES / FOTOZELLEN / FOTOCÉLULAS / FOTOCELLEN

1

1

12

2

2

13

12

13

1-PHOT

1

1

TX1 RX1

TX1 RX1

2

2

1

1

10

2

2

11

3

3

3

4

7

5

5

6

2-PHOT

12

1

1

13

2

2

T1 T2 T3

UP

DOWN

TX1 RX1

TX1 RX1

TX2 RX2

TX2 RX2

10

1

1

2

2

11

3

3

4

4

3

6

5

5

1

1

10

2

2

11

3

3

7

4

4

3

5

5

Trimmer regolazioni, Adjustment trimmer, Trimmer réglages,

Einstelltrimmer, Trimmers para las regulaciones, Instellingen Trimmer.

DIP SWITCH

NEDERLANDS

TIZIANO B GDA 260 S01 - 3

Page 4

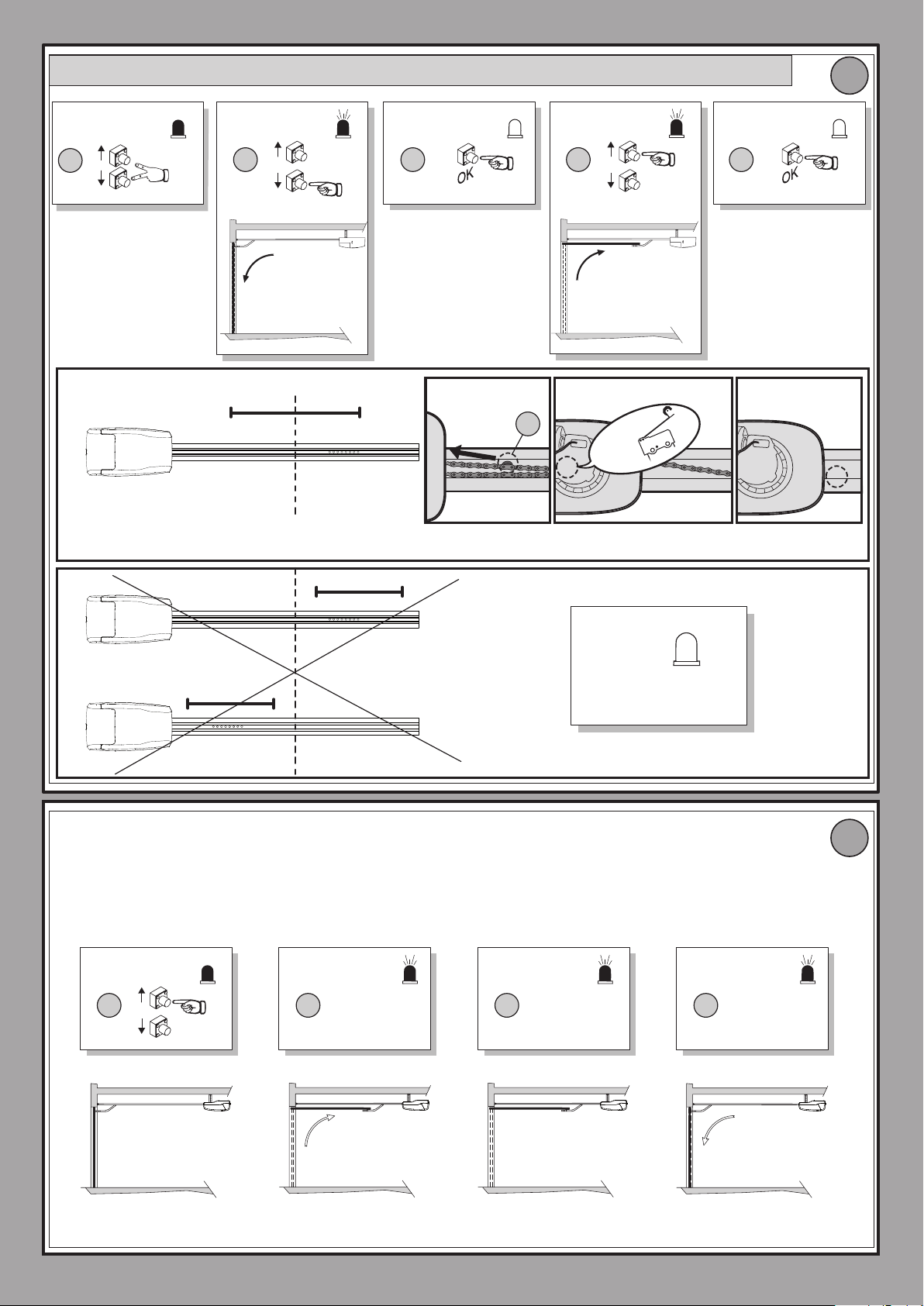

REGOLAZIONE FINECORSA, LIMIT DEVICE SETTING,ÉGLAGE FIN DE COURSE, EINSTELLUNG DER ENDSCHALTER,

REGULACION DEL GRUPO DE FIN DE CARRERA, REGELING EINDAANSLAG.

G

1

OK!

SET

5 sec.

SET

2 3

DOWN

CHIUSURA

CLOSING

FERMETURE

SCHLIESSUNG

CIERRE

SLUITING

1 sec.

SET

4a

4

UP

APERTURA

OPENING

OUVERTURE

ÖFFNUNG

APERTURA

OPENING

CLICK

SET

1 sec.

SET

D811796 00100_05

5

5 sec.

SET

ERROR!

AUTOSET COPPIA APERTURA / CHIUSURA, OPENING / CLOSING TORQUE AUTOSETTING, RÉGLAGE AUTOMATIQUE COUPLE

OUVERTURE / FERMETURE, AUTOSET DREHMOMENT ÖFFNUNG / SCHLIESSUNG, AJUSTE AUTOMATICO DEL PAR EN FASE DE

APERTURA / CIERRE, CIERRE, ZELFINSTELLING KOPPEL OPENING.

SET

1

5 sec.

2

SET

3

ERROR!

SET

4

H

SET

SWC

4 - TIZIANO B GDA 260 S01

AUTO

OPEN

SWO

AUTO

CLOSE

Page 5

D811796 00100_05

PROGRAMMAZIONE TRASMETTITORI MANUALE, MANUAL TRANSMITTER PROGRAMMING, PROGRAMMATION ÉMETTEURS MANUELLE, MANUELLE

SENDERPROGRAMMIERUNG, PROGRAMACION DE TRANSMISORES MANUAL, HANDMATIGE PROGRAMMERING ZENDERS.

I

1

RADIO RADIO RADIO

PROGRAMMAZIONE TRASMETTITORI REMOTA, REMOTE TRANSMITTER PROGRAMMING, PROGRAMMATION ÉMETTEURS A DISTANCE,

SENDER, PROGRAMACION DE TRANSMISORES REMOTA,

Radiocomando già memorizzato

Radio transmitter already memorised

1

Radiocommande déjà mémorisée

Bereits gespeicherte Funksteuerung

Radiomando ya memorizado

Reeds gememoriseerde afstandsbediening

CANCELLAZIONE TRASMETTITORI, TRANSMITTER CANCELLATION, TION ÉMETTEURS, LÖSCHEN VON SENDERN, ANNULERING ZENDERS.

Radiocomando già memorizzato

Radio transmitter already memorised

2 3 4

Radiocommande déjà mémorisée

Bereits gespeicherte Funksteuerung

Radiomando ya memorizado

Reeds gememoriseerde afstandsbediening

2

REMOTE PROGRAMMERING TRANSMITTERS.

Radiocomando da memorizzare

Radio transmitter to memorise

Radiocommande à mémoriser

Zu speichernde Funksteuerung

Radiomando que memorizar

Te memoriseren afstandsbediening

3

1 2 3

Cancellazione in corso

RADIO RADIO RADIO

10 sec.

Cancellation in progress

Annulation en cours

Löschvorgang läuft

Cancelación en curso

Bezig met wissen

Cancellazione eettuata

Cancellation completed

Annulation eectuée

Löschung ist erfolgt

Cancelación efectuada

Wissen uitgevoerd

FERNPROGRAMMIERUNG DER

Radiocomando da memorizzare

Radio transmitter to memorise

Radiocommande à mémoriser

Zu speichernde Funksteuerung

Radiomando que memorizar

Te memoriseren afstandsbediening

3

ON

OFF

4

L

1

ON

6

2

5

Fusibile/fuses/Fusibles

Sicherungen/Fusibles

Zekeringen

TIZIANO B GDA 260 S01 - 5

Page 6

M

V1

Non in dotazione /

Not supplied / Ne sont pas fournis /

Nicht im lieferumfang /

No asignadas en el equipamiento base /

Niet meegeleverd

V1

6

80

* Consigliate/advised/ Conseillées

Empfohlen/ Recomendadas

Aangeraden

:

108-166mm*

V3

V2

*

N

D811796 00100_05

M8

*

Non in dotazione /

Not supplied /

Ne sont pas fournis /

Nicht im lieferumfang /

No asignadas en el

equipamiento base /

Niet meegeleverd

*

**

*

R1

8

20

Ø8

+

V2 R1

O

V2

R1

6,3

15

V2

8

20

R2

Ø8

V3

35

M8

5

7

7

-3

75

1

3

62,5

5

5

4

3

-

5

85

2

*

*

P

1

8

0

130

0

2

3

Q

Aprire la confezione del gruppo rotaia

Open the rail assembly pack

1

Ouvrez l’emballage du groupe rail

Önen Sie die Verpackung der Baugruppe Schiene.

Abrir el embalaje del grupo carril

Open de verpakking van de rails

Posizionare la rotaia sviluppandola nella direzione della freccia

Unfold the rail in the direction of the arrow

2

Placez le rail en le déroulant dans le sens de la èche

Positionieren Sie die Schiene in Pfeilrichtung.

Posicionar el carril extendiéndolo en la dirección que indica la echa

Plaats de rail in de richting van de pijl

Muovere il connettore verso il centro della rotaia e tra le posizioni di necorsa

Move the connector to the middle of the rail and between the position limits

3

Déplacez le connecteur vers le centre du rail et entre les positions de n de course

Bewegen Sie die Steckverbindung zum Zentrum der Schiene und zwischen die Positionen der Endschalter.

Mover el conector hacia el centro del carril y entre las posiciones de nal de carrera

Verplaats de stekker naar het midden van de rail en tussen de eindpositiesl

Posizione di necorsa

Position limit

Position de n de course

Position des Endschalters

Posición de nal de carrera

Eindpositie

Serrare il dado con una boccola Ø10

Tighten the nut with s sleeve Ø10

4

Serrez l’écrou avec une douille de 10 de diamètre

Ziehen Sie die Mutter mit einer Büchse Ø10 an.

Apretar la tuerca con un casquillo Ø10

Draai de moer vast met een bus Ø10

Regolare come indicato nel disegno

Adjust as the drawing shows

5

Réglez de la façon indiquée sur le dessin

Stellen Sie sie wie auf der Zeichnung gezeigt ein.

Ajustar como se indica en el diseño

Afstellen zoals in de tekening is aangeduid

Fine

6

Finished

FIN

Ende

Final

Einde

R

39-41 mm

Connettore/Connector/ Connecteur/ Steckverbindung/ Conector/ Stekker

6 - TIZIANO B GDA 260 S01

Page 7

INSTALLER WARNINGS

WARNING! Important safety instructions. Carefully read and comply with

all the warnings and instructions that come with the product as incorrect

installation can cause injury to people and animals and damage to property.

The warnings and instructions give important information regarding safety,

installation, use and maintenance. Keep hold of instructions so that you can

attach them to the technical le and keep them handy for future reference.

GENERAL SAFETY

This product has been designed and built solely for the purpose indicated herein.

Uses other than those indicated herein might cause damage to the product and

create a hazard.

- The units making up the machine and its installation must meet the requirements

of the following European Directives, where applicable: 2004/108/EC, 2006/95/

EC, 2006/42/EC, 89/106/EC, 99/05/EC and later amendments. For all countries

outside the EEC, it is advisable to comply with the standards mentioned, in addition to any national standards in force, to achieve a good level of safety.

- The Manufacturer of this product (hereinafter referred to as the “Firm”) disclaims

all responsibility resulting from improper use or any use other than that for

which the product has been designed, as indicated herein, as well as for failure

to apply Good Practice in the construction of entry systems (doors, gates, etc.)

and for deformation that could occur during use.

- Before installing the product, make all structural changes required to produce

safety gaps and to provide protection from or isolate all crushing, shearing and

dragging hazard areas and danger zones in general in accordance with the

provisions of standards EN 12604 and 12453 or any local installation standards.

Check that the existing structure meets the necessary strength and stability

requirements.

- Before commencing installation, check the product for damage.

- The Firm is not responsible for failure to apply Good Practice in the construction

and maintenance of the doors, gates, etc. to be motorized, or for deformation

that might occur during use.

- Make sure the stated temperature range is compatible with the site in which the

automated system is due to be installed.

- Do not install this product in an explosive atmosphere: the presence of ammable

fumes or gas constitutes a serious safety hazard.

- Disconnect the electricity supply before performing any work on the system.

Also disconnect buer batteries, if any are connected.

- Before connecting the power supply, make sure the product’s ratings match the

mains ratings and that a suitable residual current circuit breaker and overcurrent

protection device have been installed upline from the electrical system. Have

the automated system’s mains power supply tted with a switch or omnipolar

thermal-magnetic circuit breaker with a contact separation that meets code

requirements.

- Make sure that upline from the mains power supply there is a residual current

circuit breaker that trips at no more than 0.03A as well as any other equipment

required by code.

- Make sure the earth system has been installed correctly: earth all the metal par ts

belonging to the entry system (doors, gates, etc.) and all parts of the system

featuring an earth terminal.

- Installation must be carried out using safety devices and controls that meet

standards EN 12978 and EN 12453.

- Impact forces can be reduced by using deformable edges.

- In the event impact forces exceed the values laid down by the relevant standards,

apply electro-sensitive or pressure-sensitive devices.

- Apply all safety devices (photocells, safety edges, etc.) required to keep the

area free of impact, crushing, dragging and shearing hazards. Bear in mind the

standards and directives in force, Good Practice criteria, intended use, the installation environment, the operating logic of the system and forces generated by

the automated system.

- Apply all signs required by current code to identify hazardous areas (residual

risks). All installations must be visibly identied in compliance with the provisions

of standard EN 13241-1.

- Once installation is complete, apply a nameplate featuring the door/gate’s data.

- This product cannot be installed on leaves incorporating doors (unless the motor

can be activated only when the door is closed).

- If the automated system is installed at a height of less than 2.5 m or is accessible,

the electrical and mechanical parts must be suitably protected.

- Install any xed controls in a position where they will not cause a hazard, away

from moving parts. More specically, hold-to-run controls must be positioned

within direct sight of the part being controlled and, unless they are key operated,

must be installed at a height of at least 1.5 m and in a place where they cannot

be reached by the public.

- Apply at least one warning light (ashing light) in a visible position, and also

attach a Warning sign to the structure.

- Attach a label near the operating device, in a permanent fashion, with information on how to operate the automated system’s manual release.

- Make sure that, during operation, mechanical risks are avoided or relevant

protective measures taken and, more specically, that nothing can be banged,

crushed, caught or cut between the part being operated and surrounding parts.

- Once installation is complete, make sure the motor automation settings are

correct and that the safety and release systems are working properly.

- Only use original spare parts for any maintenance or repair work. The Firm disclaims all responsibility for the correct operation and safety of the automated

system if parts from other manufacturers are used.

- Do not make any modications to the automated system’s components unless

explicitly authorized by the Firm.

- Instruct the system’s user on what residual risks may be encountered, on the

control systems that have been applied and on how to open the system manually in an emergency. give the user guide to the end user.

- Dispose of packaging materials (plastic, cardboard, polystyrene, etc.) in accordance with the provisions of the laws in force. Keep nylon bags and polystyrene

out of reach of children.

WIRING

WARNING! For connection to the mains power supply, use: a multicore cable with

a cross-sectional area of at least 5x1.5mm

phase power supplies or 3x1.5mm

type H05 VV-F cable can be used with a cross-sectional area of 4x1.5mm2). To connect auxiliary equipment, use wires with a cross-sectional area of at least 0.5 mm

- Only use pushbuttons with a capacity of 10A-250V or more.

- Wires must be secured with additional fastening near the terminals (for example,

using cable clamps) in order to keep live parts well separated from safety extra

low voltage parts.

- During installation, the power cable must be stripped to allow the earth wire

to be connected to the relevant terminal, while leaving the live wires as short

as possible. The earth wire must be the last to be pulled taut in the event the

cable’s fastening device comes loose.

WARNING! safety extra low voltage wires must be kept physically separate from

low voltage wires.

Only qualied personnel (professional installer) should be allowed to access

live parts.

CHECKING THE AUTOMATED SYSTEM AND MAINTENANCE

Before the automated system is nally put into operation, and during maintenance

work, perform the following checks meticulously:

- Make sure all components are fastened securely.

- Check starting and stopping operations in the case of manual control.

- Check the logic for normal or personalized operation.

- For sliding gates only: check that the rack and pinion mesh correctly with 2 mm

of play along the full length of the rack; keep the track the gate slides on clean

and free of debris at all times.

- For sliding gates and doors only: make sure the gate’s running track is straight

and horizontal and that the wheels are strong enough to take the weight of the

gate.

- For cantilever sliding gates only: make sure there is no dipping or swinging

during operation.

- For swing gates only: make sure the leaves’ axis of rotation is perfectly vertical.

- Check that all safety devices (photocells, safety edges, etc.) are working properly

and that the anti-crush safety device is set correctly, making sure that the force

of impact measured at the points provided for by standard EN 12445 is lower

than the value laid down by standard EN 12453.

- Impact forces can be reduced by using deformable edges.

- Make sure that the emergency operation works, where this feature is provided.

- Check opening and closing operations with the control devices applied.

- Check that electrical connections and cabling are intact, making extra sure that

insulating sheaths and cable glands are undamaged.

- While performing maintenance, clean the photocells’ optics.

- When the automated system is out of service for any length of time, activate the

emergency release (see “EMERGENCY OPERATION” section) so that the operated

part is made idle, thus allowing the gate to be opened and closed manually.

If the power cord is damaged, it must be replaced by the manufacturer or their

-

technical assistance department or other such qualied person to avoid any risk .

- If “D” type devices are installed (as dened by EN12453), connect in unveried

mode, foresee mandatory maintenance at least every six months

WARNING!

Remember that the drive is designed to make the gate/door easier to use and

will not solve problems as a result of defective or poorly performed installation

or lack of maintenance

SCRAPPING

Materials must be disposed of in accordance with the regulations in force. There

are no particular hazards or risks involved in scrapping the automated system. For

the purpose of recycling, it is best to separate dismantled parts into like materials

(electrical parts - copper - aluminium - plastic - etc.).

DISMANTLING

If the automated system is being dismantled in order to be reassembled at another

site, you are required to:

- Cut o the power and disconnect the whole electrical system.

- Remove the actuator from the base it is mounted on.

- Remove all the installation’s components.

- See to the replacement of any components that cannot be removed or happen

to be damaged.

2

or 4x1.5mm2 when dealing with three-

2

for single-phase supplies (by way of example,

Anything that is not explicitly provided for in the installation manual is not allowed. The operator’s proper operation can only be

guaranteed if the information given is complied with. The Firm shall

not be answerable for damage caused by failure to comply with the

instructions featured herein.

While we will not alter the product’s essential features, the Firm reserves the right, at any time, to make those changes deemed opportune to improve the product from a technical, design or commercial

point of view, and will not be required to update this publication

accordingly.

D811796 00100_05

2

.

10 - TIZIANO B GDA 260 S01

AVVERTENZE PER L’INSTALLATORE D811766_06

Page 8

INSTALLATION MANUAL

2) GENERAL OUTLINE

The TIZIANO B GDA 260 S01 system is suitable for motorising sectional doors

(g. C), protruding fully retracting spring-operated overhead doors (g. B). The

overhead door must not be higher than 3 metres. Its easy installation allows fast

D811796 00100_05

tting without needing the door to be modied. The irreversible gearmotor keeps

the door locked in the closing position.

3) TECHNICAL SPECIFICATIONS

ACTUATOR

Power supply 230V~±10%, 50/60Hz single-phase (*)

Motor voltage 24V

Max. power absorbed from

mains

Towing and pushing force 600N

Working stroke

Average speed 6.6 m/min

Impact reaction integrated torque limiter on control panel

Manoeuvres in 24 hours 20

Limit switch Electronic with ENCODER

Courtesy light 24V~ 25W max, E14 Bulb

Working temperature -20°C / +60°C

Degree of protection IPX0

Motor head weight 5 kg

Noise level <70dB(A)

Dimensions See g.P

Supply to accessories

Torque limiter setting on closing and opening

Incorporated rolling-code

radio receiver

Coding rolling-code algorithm

No. combinations 4 milliard

Max no. radio controls to be

memorised

Slow-down distance Closing/ opening: ~24 cm

Fuses see Fig. F

(*) Available in all mains voltages.

3) TUBE ARRANGEMENT Fig.A

Install the electrical system referring to the standards in force for electrical

systems CEI 64-8, IEC 364, harmonization document HD 384 and other national

standards.

4) ACTUATOR INSTALLATION

4.1) Assembly

FITTING

1) Remove the existing locking bolt from the cremone bolt of the door.

2) In order to x the track correctly, mark the mid-point of the door, position

the BIN on the ceiling and mark the holes.

3) Drill the ceiling with a 10-dia. drill bit following the previously made marks,

and insert the Fischer plugs.

4) Secure the track at the base, g.E.

5) With the help of an adequate support, lift the entire motor, screw the

screws onto the track-holding bracket without xing them to the door frame (Fig.M) or, if the height allows it, t the bracket to the masonry lintel by

means of plugs.

6) Lift the motor-driven head until everything rests against the ceiling, and in-

sert the xing screws which lock the track (including the anchoring bracket

screws).

7) In the event the motor head and track are not fastened directly to the ceiling,

check that the surface they are attached to is level and that the track runs

straight.

8) For xing to the ceiling and in case the track is not xed directly to the ceiling,

see Fig.N.

9) In the case where the track is made in two halves, see Fig.R; for the dierent

types of xing methods, see the previous gures.

10)

Release the carriage and x the anchoring brackets to the door panel

(Fig.O). The distance allowed between track and sectional door is 108 to

166 mm (Fig.O1).

4) CHAIN TIGHTENER ADJUSTMENT

The operator supplied is already calibrated and inspected. Should the chain

tension need to be adjusted, proceed as shown in g.R 4-5.

WARNING: Should it be necessary to reduce the track length and consequent

trolley run, cut the chain using a specic chain removing device.

100 W

TRACK L.=3000 corsa utile=2520 mm

TRACK L.=3600 corsa utile=3120 mm

CONTROL PANEL

24V ~ (180 mA)

24Vsafe (180mA max)

frequency 433.92 MHz

10

In re-assembling the cut chain, take care to ensure that the REFERENCE

CAM IS POSITIONED TOWARDS THE OUTSIDE (SEE FIG. G Ref. 4a) AND THAT

DURING MANOEUVRE, THE CAM INTERCEPTS THE MICRO-SWITCH AT THE

BASE OF THE MOTOR.

5) MANUAL RELEASE (See USER GUIDE -FIG.3-).

5.1 IN ORDER TO ENSURE THE DOOR WILL CLOSE, THE RUNNER MUST BE

ENGAGED WITH THE HOLES FIG.D

5.2) REMPLACEMENT DE L’AMPOULE (FIG.3)

6) ELECTRICAL INSTALLATION SET-UP (Fig.A)

M) Actuator

Ft) Transmitter photocell

Fr) Receiver photocells

T) 1-2-4 channel transmitter.

Arrange for the connection of accessories and safety and control devices to reach

the motor unit, keeping the mains voltage connections clearly separate from the

extra low safety voltage connections (24 V), using the specic window (g. E1).

Proceed to connection following the indications given in the wiring diagram.

The cables for connecting the accessories must be protected by a raceway.

7) TERMINAL BOARD CONNECTIONS Fig.F

TERMINAL DESCRIPTION

JP6 transformer wiring

JP10, JP11 motor wiring

JP12 Encoder

JP13 Micro switch

1-2

3-4 START input (N.O.)

3-5 STOP input (N.C.) If not used, leave the jumper inserted.

3-6

3-7

8-9 24 V~ output for blinking light (25 W max)

10-11

12-13

7.1) LED (Fig.F)

DL1 RADIO Incorporated radio-receiver led

DL2 SET Limit device setting led - power ON

7.2) SELEZIONE DIP-SWITCH (Fig.F)

DIP1

DIP2 TEST PHOT

7.3) TRIMMER SETTING (Fig.F)

T1 TCA 3s 120s

T2

T3

----------------------------------------------------------

Antenna input for integrated radio-receiver board

(1: BRAID. 2: SIGNAL)

PHOTOCELL input (N.C.) If not used, leave the jumper

inserted.

FAULT input (N.O.)

Input for photocells provided with checking N.O. contact

24V~ 180mA max output – power supply for photocells or

other devices

24V~ Vsafe 180mA max output – power supply for checking

photocell transmitters.

LED Description

DIP-SWITCH Description

IBL

Locks

impulses

Parameter

OPENING

TORQUE

CLOSING

TORQUE

ON: During the opening phase, does not accept

START commands.

OFF: During the opening phase, accepts START com-

mands.

ON: Enables photocell checking (5-connector pho-

tocells must be used - see Fig.F1).

OFF: Disables photocell checking.

+

min.+max.

0% 99%

0% 99%

Sets the automatic closing time, after

which the gate closes automatically. If

the trimmer is turned all the way, the

TCA is disabled.

Sets the ampere-stop sensitivity on

opening.

Sets the ampere-stop sensitivity on

closing.

Description

ENGLISH

TIZIANO B GDA 260 S01 -

11

Page 9

INSTALLATION MANUAL

NOTE: In case of obstacle detection, the Ampere-stop function halts the leaf

movement, reverses the motion for 1 sec. and stays in the STOP state.

Incorrect sensitivity setting can cause injuries to persons or animals,

or damage to things.

7.4 BUTTONS

DESCRIPTION

UP

DOWN limit device setting and closing command

OK radio programming

7.5 COURTESY LIGHT

COURTESY LIGHT DESCRIPTION NOTES

ON time starting from last

operation

Thermal overload warning

Microswitch malfunction warning

8 LIMIT DEVICE SETTING (Fig.G)

1) Simultaneously press the “UP” and “DOWN” keys for 5 seconds. The “SET” led

blinks to indicate that the limit device setting is activated.

2) Bring the leaf to the required closing position, using the “UP” and “DOWN”

buttons on the control unit, and keeping in mind that the “DOWN” button

closes the leaf, while the “UP” button opens the leaf.

3) As soon as the leaf reaches the required closing position, press the “OK” button

in order to memorise the limit device closing position. The “SET” led conrms

data storage by blinking for 1 second.

4) Bring the leaf to the required opening position, using the “UP” and “DOWN”

buttons on the control unit, and keeping in mind that the “DOWN” button

closes the leaf, while the “UP” button opens the leaf.

WARNING: in the event the track, and hence carriage travel, needs to be

shortened, cut the chain with a suitable chain link extractor.

When retting the cut chain, make sure that the REFERENCE CAM IS POSI-

TIONED ON THE OUTSIDE (SEE FIG. G Ref. 4a) AND THAT WHEN THE DEVICE

IS OPERATED, THE CAM ENGAGES THE MICROSWITCH LOCATED UNDER THE

BASE OF THE MOTOR.

5) As soon as the leaf reaches the required opening position, press the “OK”

button in order to memorise the limit device opening position. The “SET” led

conrms data storage by blinking for 1 second and then lits up again.

NOTE 1: These manoeuvres are carried out in “hold-to-run” mode at reduced

speed and with no safety devices activated.

NOTE 2: In case of errors, the “SET” led remains o on for 5 seconds.

9 OPENING / CLOSING TORQUE AUTOSETTING (Fig.H)

1)

After reaching the closing end-of-stroke position, press the “UP” button for 5 seconds.

2) The “SET” led blinks rapidly and the leaf starts to open until it reaches the

opening end-of-stroke.

3) 3 second down time.

4) The “SET” led blinks rapidly and the leaf starts to close until it reaches the

closing end-of-stroke.

5) After completing the autoset adjust the opening/closing torque trimmers so

as to obtain the desired sensitivity to the obstacle.

Any input activation (START, RADIO TRANSMITTER, STOP, PHOTOCELL) during autosetting will annul the autoset in progress.

limit device setting and opening command. An autoset operation of the torque will be performed by keeping this button

pressed for 5 seconds

90s

3 ashes at start

of operation

3 ashes at end

of operation

Allow automated device

to cool

Check Microswitch connection

memorised in standard mode by means of manual programming.

3) The courtesy lamp blinks. Press the hidden key of a transmitter to be memorised within 10s.

4) The courtesy lamp stays on permanently. Press the normal key (T1-T2-T3-T4)

of a transmitter to be memorised.

The receiver exits the programming mode within 10s., within this time new additional transmitters can be memorised.

This mode does not require access to the control panel.

10.3) TRANSMITTER CANCELLATION (Fig.I)

To cancel the control unit memory totally, press the “OK” button on the control

unit for 10 seconds (“RADIO” LED blinking). Correct memory cancellation will be

indicated by the “RADIO” LED staying on permanently. To exit the storage mode,

wait until the LED is switched o completely.

11) AUTOMATION CHECK

Before the automation device nally becomes operational, scrupulously

check the following conditions:

• Check that the door (antisquash) thrust is comprised within the limits set out

by the current standards, and anyway not too strong for the installation and

operating conditions.

• Check that the spring is not pressed all the way down during operation.

• Check the manual opening control operation.

•

Check the opening and closing operations using the control devices tted.

• Check the normal and customised operation electronic logics.

12) AUTOMATION CONTROL

The use of this control device allows the gate to be opened and closed automatically. There are dierent types of controls (manual, radio control, magnetic card

access etc.) depending on the installation requirements and characteristics. For

the various control systems, see the relevant instructions. The automation device

users must be instructed on control and operation.

13) FUSE CHANGE Fig. L

14 PULLING ARM ASSEMBLY AND ACTUATOR DIMENSIONS FIG.P

15) ACCESSORIES

SET/S External release device with retrac ting handle for sectional doors measur-

ing max 50mm (Fig.Q).

15) MAINTENANCE

Before carrying out any maintenance operation, disconnect the system power

supply.

• Periodically check the tension of the chain/belt (twice a year).

• Occasionally clean the photocell optical elements, if installed.

• Have a qualied technician (installer) check the correct setting of the electronic

clutch.

• When any operational malfunction if found, and not resolved, disconnect

the system power supply and request the assistance of a qualied technician

(installer). When the product is out of service, activate the manual release

device to allow the door to be opened and closed manually.

If the power supply cable is damaged, it must be replaced directly by our

company or our technical service department or by a technician having similar

qualication so as to avoid any risks.

D811796 00100_05

10 INTEGRATED RECEIVER

Transmitter versions which can be used:

all Rolling Code transmitters .

10.1) MANUAL TRANSMITTER PROGRAMMING (Fig.I)

1) Press the “OK” button on the control unit.

2) When the “RADIO” LED blinks, press the transmitter hidden key, and the “RADIO”

LED will stay on permanently.

3) Press the key to be memorised on the transmitter, LED “RADIO” will start

blinking again.

4) To memorise another transmitter, repeat steps 2) and 3).

5) To exit the storage mode, wait until the LED is switched o completely.

10.2) REMOTE TRANSMITTER PROGRAMMING (Fig.I)

1) Press the hidden key of a transmitter that has been already memorised in

standard mode by means of manual programming.

2) Press the normal key (T1-T2-T3-T4) of a transmitter that has been already

12 - TIZIANO B GDA 260 S01

Page 10

MANUEL D’UTILISATION: MANŒUVRE MANUELLE - BEDIENUNGSANLEITUNG: MANUELLES MANÖVER-

MANUAL DE USO: ACCIONAMIENTO MANUAL - GEBRUIKSHANDLEIDING: MANUEEL MANOEUVRE

D811796 00100_05

FIG. 2

MANUALE D’USO: MANOVRA MANUALE - USER’S MANUAL: MANUAL OPERATION-

1

+

2

ON

OFF

ON

FIG. 3

SOSTITUZIONE LAMPADINA / REPLACING THE LIGHT BULB / REMPLACEMENT D’UNE LAMPE

ERSETZUNG DER GLÜHBIRNE / SUSTITUCIÓN DE LA LÁMPARA / LAMPJE VERVANGEN

1 2

E14 24V

25W max

TIZIANO B GDA 260 S01 - 25

Page 11

AVVERTENZE PER L’UTILIZZATORE ( I )

ATTENZIONE! Importanti istruzioni di sicurezza. Leggere e seguire attentamente le

Avvertenze e le Istruzioni che accompagnano il prodotto poiché un uso improprio può

causare danni a persone, animali o cose. Conservare le istruzioni per consultazioni future

e trasmetterle ad eventuali subentranti nell’uso dell’impianto.

Questo prodotto dovrà essere destinato solo all’uso per il quale è stato espressamente

installato. Ogni altro uso è da considerarsi improprio e quindi pericoloso. Il costruttore

non può essere considerato responsabile per eventuali danni causati da usi impropri,

erronei e irragionevoli.

SICUREZZA GENERALE

Nel ringraziarVi per la preferenza accordata a questo prodotto, la Ditta è certa che da esso otterrete

le prestazioni necessarie al Vostro uso.

Questo prodotto risponde alle norme riconosciute della tecnica e della disposizioni relative

alla sicurezza se correttamente installato da personale qualicato ed esperto (installatore

professionale).

L’automazione, se installata ed utilizzata correttamente, soddisfa gli standard di sicurezza nell’uso.

Tuttavia è opportuno osservare alcune regole di comportamento per evitare inconvenienti

accidentali:

- Tenere bambini, persone e cose fuori dal raggio d’azione dell’automazione, in particolare

durante il movimento.

- Non permettere a bambini di giocare o sostare nel raggio di azione dell’automazione.

- Questa automazione non è destinata all’uso da parte di bambini o da parte di persone con ridotte

capacità mentali, siche e sensoriali, o persone che mancano di conoscenze adeguate a meno che

esse non abbiano potuto beneciare, attraverso l’intermediazione di una persona responsabile

della loro sicurezza, di una sorveglianza o di istruzioni riguardanti l’uso dell’apparecchio.

- I bambini devono essere sorvegliati per sincerarsi che non giochino con l’apparecchio. Non per-

mettere ai bambini di giocare con i controlli ssi. Tenere i telecomandi lontani dai bambini.

Evitare di operare in prossimità delle cerniere o organi meccanici in movimento.

-

-

Non contrastare il movimento dell’anta e non tentare di aprire manualmente la porta se non è

stato sbloccato l’attuatore con l’apposita manopola di sblocco.

- Non entrare nel raggio di azione della porta o cancello motorizzati durante il loro movimen-

to.

- Non lasciare radiocomandi o altri dispositivi di comando alla portata dei bambini onde evitare

azionamenti involontari.

- L’attivazione dello sblocco manuale potrebbe causare movimenti incontrollati della porta se in

presenza di guasti meccanici o di condizioni di squilibrio.

- In caso di apritapparelle: sorvegliare la tapparella in movimento e tenere lontano le persone

nché non è completamente chiusa. Porre cura quando si aziona lo sblocco se presente, poiché

una tapparella aperta potrebbe cadere rapidamente in presenza di usura o rotture.

La rottura o l’usura di organi meccanici della porta (parte guidata), quali ad esempio cavi, molle,

-

supporti, cardini, guide.. potrebbe generare pericoli. Far controllare periodicamente l’impianto

da personale qualicato ed esperto (installatore professionale) secondo quanto indicato

dall’installatore o dal costruttore della porta.

- Per ogni operazione di pulizia esterna, togliere l’alimentazione di rete.

- Tenere pulite le ottiche delle fotocellule ed i dispositivi di segnalazione luminosa. Controllare

che rami ed arbusti non disturbino i dispositivi di sicurezza.

- Non utilizzare l’automatismo se necessita di interventi di riparazione. In caso di guasto o di mal-

funzionamento dell’automazione, togliere l’alimentazione di rete sull’automazione, astenersi da

qualsiasi tentativo di riparazione o intervento diretto e rivolgersi solo a personale qualicato ed

esperto (installatore professionale) per la necessaria riparazione o manutenzione. Per consentire

l’accesso, attivare lo sblocco di emergenza (se presente).

Per qualsiasi intervento diretto sull’automazione o sull’impianto non previsto dal presente manuale,

-

avvalersi di personale qualicato ed esperto (installatore professionale).

- Con frequenza almeno annuale far verificare l’integrità e il corretto funzionamento

dell’automazione da personale qualicato ed esperto (installatore professionale), in particolare

di tutti i dispositivi di sicurezza.

- Gli interventi d’installazione, manutenzione e riparazione devono essere documentati e la

relativa documentazione tenuta a disposizione dell’utilizzatore.

- Il mancato rispetto di quanto sopra può creare situazioni di pericolo.

Tutto quello che non è espressamente previsto nel manuale d’uso, non è permesso. ll

buon funzionamento dell’operatore è garantito solo se vengono rispettate le prescrizioni

riportate in questo manuale. La Ditta non risponde dei danni causati dall’inosservanza delle

indicazioni riportate in questo manuale.

Lasciando inalterate le caratteristiche essenziali del prodotto, la Ditta si riserva di apportare

in qualunque momento le modiche che essa ritiene convenienti per migliorare tecnicamente, costruttivamente e commercialmente il prodotto, senza impegnarsi ad aggiornare

la presente pubblicazione.

USER WARNINGS (GB)

WARNING! Important safety instructions. Carefully read and comply with the Warnings

and Instructions that come with the product as improper use can cause injury to people

and animals and damage to property. Keep the instructions for future reference and hand

them on to any new users.

This product is meant to be used only for the purpose for which it was explicitly installed.

Any other use constitutes improper use and, consequently, is hazardous. The manufacturer

cannot be held liable for any damage as a result of improper, incorrect or unreasonable

use.

GENERAL SAFETY

Thank you for choosing this product. The Firm is condent that its performance will meet your

operating needs.

This product meets recognized technical standards and complies with safety provisions when installed

correctly by qualied, expert personnel (professional installer).

If installed and used correctly, the automated system will meet operating safety standards.

Nonetheless, it is advisable to observe certain rules of behaviour so that accidental problems

can be avoided:

- Keep adults, children and proper ty out of range of the automated system, especially while it is

moving.

- Do not allow children to play or stand within range of the automated system.

- This automated system is not meant for use by children or by people with impaired mental,

physical or sensory capacities, or people who do not have suitable knowledge, unless a person

who is responsible for their safety provides them with necessary supervision or instructions on

how to use the device.

- Children must be supervised to ensure they do not play with the device. Do not allow children

to play with the xed controls. Keep remote controls out of reach of children.

- Do not work near hinges or moving mechanical parts.

- Do not hinder the leaf’s movement and do not attempt to open the door manually unless the

actuator has been released with the relevant release knob.

- Keep out of range of the motorized door or gate while they are moving.

- Keep remote controls or other control devices out of reach of children in order to avoid the

automated system being operated inadvertently.

- The manual release’s activation could result in uncontrolled door movements if there are me-

chanical faults or loss of balance.

- When using roller shutter openers: keep an eye on the roller shutter while it is moving and keep

people away until it has closed completely. Exercise care when activating the release, if such a

device is tted, as an open shutter could drop quickly in the event of wear or breakage.

- The breakage or wear of any mechanical parts of the door (operated part), such as cables, springs,

supports, hinges, guides…, may generate a hazard. Have the system checked by qualied, expert

26 - TIZIANO B GDA 260 S01

AVVERTENZE PER L’UTILIZZATORE D811767_02

personnel (professional installer) at regular intervals according to the instructions issued by the

installer or manufacturer of the door.

- When cleaning the outside, always cut o mains power.

- Keep the photocells’ optics and illuminating indicator devices clean. Check that no branches or

shrubs interfere with the safety devices.

- Do not use the automated system if it is in need of repair. In the event the automated system

breaks down or malfunctions, cut o mains power to the system; do not attempt to repair or

perform any other work to rectify the fault yourself and instead call in qualied, expert personnel

(professional installer) to perform the necessary repairs or maintenance. To allow access, activate

the emergency release (where tted).

- If any part of the automated system requires direct work of any kind that is not contemplated

herein, employ the services of qualied, expert personnel (professional installer).

- At least once a year, have the automated system, and especially all safety devices, checked

by qualied, expert personnel (professional installer) to make sure that it is undamaged and

working properly.

- A record must be made of any installation, maintenance and repair work and the relevant

documentation kept and made available to the user on request.

- Failure to comply with the above may result in hazardous situations.

Anything that is not explicitly provided for in the user guide is not allowed. The operator’s

proper operation can only be guaranteed if the instructions given herein are complied

with. The Firm shall not be answerable for damage caused by failure to comply with the

instructions featured herein.

While we will not alter the product’s essential features, the Firm reserves the right, at any

time, to make those changes deemed opportune to improve the product from a technical,

design or commercial point of view, and will not be required to update this publication

accordingly.

AVERTISSEMENTS POUR L’UTILISATEUR (F)

ATTENTION ! Instructions de sécurité importantes. Veuillez lire et suivre attentivement

tous les avertissements et toutes les instructions fournis avec le produit sachant qu’un

usage incorrect peut provoquer des préjudices aux personnes, aux animaux ou aux biens.

Veuillez conserver les instructions pour d’ultérieures consultations et pour les transmettre

aux propriétaires futurs éventuels.

Cet appareil ne peut être destiné qu’à l’usage pour lequel il a été expressément installé.

Tout autre usage sera considéré comme impropre et donc dangereux. Le fabricant ne

sera en aucun cas considéré comme responsable des préjudices dus à un usage impropre,

erroné ou déraisonné.

SECURITE GÉNÉRALE

Nous vous remercions d’avoir choisi ce produit qui, nous n’en doutons pas, saura vous garantir

les performances attendues.

Ce produit, correctement installé par du personnel qualié et expérimenté (monteur professionnel)

est conforme aux normes reconnues de la technique et des prescriptions de sécurité.

Si l’automatisation est montée et utilisée correctement, elle garantit la sécurité d’utilisation

prescrite. Il est cependant nécessaire de respecter certaines règles de comportement pour éviter

tout inconvénient accidentel.

- Tenir les enfants, les personnes et les objets à l’écart du rayon d’action de l’automatisation, en

particulier pendant son fonctionnement.

- Empêcher les enfants de jouer ou de stationner dans le rayon d’action de l’automatisation.

- Cette automatisation n’est pas destinée à être utilisée par des enfants, des personnes ayant des

capacités mentales, physiques et sensorielles réduites ou des personnes ne disposant pas des

connaissances nécessaires à moins de disposer, par l’entremise d’une personne responsable de

leur sécurité, d’une surveillance ou d’instructions sur l’usage de l’appareil.

- Les enfants doivent être surveillés an de s’assurer qu’ils ne jouent pas avec l’appareil. Interdire

aux enfants de jouer avec les contrôles xes. Ranger les télécommandes hors de portée des

enfants.

Eviter d’opérer à proximité des charnières ou des organes mécaniques en mouvement.

-

- Ne pas s’opposer volontairement au mouvement du vantail et ne pas tenter d’ouvrir la por te à la

main si le déclencheur n’est pas déverrouillé avec le levier de déverrouillage prévu à cet eet.

- Ne pas entrer dans le rayon d’action du portail/de la porte motorisé/e pendant son mouvement.

- Ranger les radiocommandes ou les autres dispositifs de commande hors de portée des enfants

an d’éviter tout actionnement involontaire.

- L’activation du déverrouillage manuel risque de provoquer des mouvements incontrôlés de la

porte en présence de pannes mécaniques ou de conditions de déséquilibre.

- Avec les ouvre-stores: sur veiller le store en mouvement et veiller à ce que les personnes restent

à l’écart tant qu’il n’est pas complètement fermé. Actionner l’éventuel déverrouillage avec

prudence car si un store reste ouvert il peut tomber brutalement s’il est usé ou cassé.

- La rupture ou l’usure des organes mécaniques de la porte (partie guidée), tels que les câbles, les

ressorts, les supports et les gonds peuvent générer des risques. Faire contrôler périodiquement

l’installation par du personnel qualié et expérimenté (monteur professionnel), conformément

aux indications du monteur ou du fabricant de la porte.

- Mettre hors tension avant d’accomplir les opérations de nettoyage extérieur.

- Veiller à la propreté des lentilles des photocellules et des lampes de signalisation. Veiller à ce

que les dispositifs de sécurité ne soient pas gênés par des branches ou des arbustes.

- Ne pas utiliser l’automatisation si elle a besoin d’être réparée. En cas de panne ou de mauvais

fonctionnement de l’automatisation, mettre l’automatisation hors tension, éviter toute tentative

de réparation ou d’intervention directe et s’adresser uniquement à du personnel qualié et expérimenté (monteur professionnel) pour la réparation ou les opérations d’entretien nécessaires.

Pour permettre l’accès, activer le déverrouillage d’urgence (s’il y en a un).

- Pour toutes les interventions directes sur l’automatisation ou sur l’installation non prévues dans

le présent manuel, s’adresser uniquement à du personnel qualié et expérimenté (monteur

professionnel).

- Une fois par an au moins, faire vérier le bon état et le bon fonctionnement de l’automatisation

par du personnel qualié et expérimenté (monteur professionnel) et en particulier tous les

dispositifs de sécurité.

- Les inter ventions de montage, d’entretien et de réparation doivent être documentées et cette

documentation doit être tenue à la disposition de l’utilisateur.

- Le non respect des prescriptions ci-dessus peut être à l’origine de dangers.

Tout ce qui n’est pas expressément prévu dans le manuel de montage est interdit. Le bon

fonctionnement de l’appareil n’est garanti que si les données indiquées sont respectées.

Le Fabricant ne répond pas des dommages provoqués par l’inobservation des indications

données dans ce manuel.

En laissant inaltérées les caractéristiques essentielles de l’appareil, l’entreprise se réserve le

droit d’apporter à tout moment les modications qu’elle jugera opportunes pour améliorer

le produit du point de vue technique, commercial et de sa construction, sans s’engager à

mettre à jour la présente publication.

HINWEISE FÜR DEN BENUTZER (D)

ACHTUNG! Wichtige Hinweise zur Sicherheit. Bitte lesen und befolgen Sie aufmerksam die

Hinweise sowie die Bedienungsanleitung, die das Produkt begleiten, denn eine falsche

Benutzung des Produkts kann zu Verletzungen von Menschen und Tieren sowie zu Sachschäden führen. Bitte bewahren Sie die Anweisungen für die zukünftige Konsultation sowie

für eventuelle zukünftige Benutzer der Anlage auf.

Dieses Produkt ist ausschließlich für den Einsatz bestimmt, für den es ausdrücklich installiert worden ist. Alle sonstigen Einsatzweisen gelten als Zweckentfremdung und somit als

D811796 00100_05

Page 12

Loading...

Loading...