Page 1

Instruction Manual

Page 2

Page 3

TABLE OF CONTENTS

ESSENTIAL PARTS

Names of Parts 6

Standard Accessories 7

Dust cover 7

Sewing table 8

Accessory box 8

Free arm Sewing 8

GETTING READY TO SEW

Connecting the Power Supply 9

Controlling the Sewing Speed 9

Presser foot lever 10

Changing the Presser Foot 10

Attaching and removing the presser foot holder 10

Changing the needle 11

Fabric and Needle Chart 11

Setting Spool Pins 12

Removing or Inserting the Bobbin Case 12

Winding the Bobbin 13

Threading the Bobbin Case 13

Threading the Machine 14

Needle threader 14

Drawing Up Bobbin Thread 15

Thread tension dial 15

Stitch pattern selector knob 16

Stitch length knob 16

Stitch width knob 16

Reverse sewing lever 17

Lowering and raising the feed dog 17

UTILITY STITCHES

Zigzag 19

Overcasting 20

3-step zigzag 20

Stretch-Overlock Stitch 21

Triple straight stitch 21

Triple zigzag 22

Sewing Buttons 22

Automatic Buttonhole 23

Buttonhole with cord 25

Zipper Application 26

Blindstitch 27

Rolled Hem 28

DECORATIVE STITCHING

Vari-Overlock (scallop hem) 29

Smocking 29

Appliqué 30

Stretch Stitch Patterns 30

CARE OF YOUR MACHINE

Cleaning the Bobbin Case and the Shuttle Race 31

Dismantling Shuttle Race Unit 31

Assembling Shuttle Race Unit 31

Oiling 32

Cleaning the feed dog 32

Troubleshooting 33

STITCH PATTERN

Overview 34

BASIC SEWING

Straight stitch 18

Changing the Sewing Direction 18

Seam Guide Lines 19

Turning a Square Corner 19

3

Page 4

IMPORTANT

The following basic safety precautions must

be observed when operating an electrical

device:

Please read the instruction manual carefully

before using this machine.

Keep the instruction manual at a suitable

place with the machine and hand it over if you

give the machine to a third party.

When the machine is not in use or left

unattended, always disconnect the

machine from the power supply system.

Unplug it from the outlet.

DANGER!

To reduce the risk of electric shock:

1. Never leave the machine unattended

when it is plugged in.

2. Always unplug this machine from the

electric outlet immediately after using

and before cleaning.

3. LED RADIATION: Do not look directly at

the LED using an optical instrument.

WARNING!

To reduce the risk of burns, fire, electric shock

or injury to persons:

1. The machine mustn’t be used by children under 8 or by people with reduced

physical, sensory or mental capabilities

or if there is a lack of experience and

knowledge how to operate the machine.

Unless they have been given instruction

concerning the use of the machine and

the involved risks by a person who is

responsible for their safety.

2. Do not use this machine as a toy. Close

attention is necessary when this machine

is used by children, near children or

people with reduced sensation.

3. Use this machine only for its intended

use as described in this manual. Use

only accessories recommended by the

manufacturer.

4. Children should be supervised to ensure

that they do not play with the machine.

5. Never operate this machine if it has a

damaged cord or plug, if it is not working

4

properly, if it has been dropped or damaged, or dropped into water. Return the

machine to the nearest authorized dealer

or service centre for examination, repair,

electrical or mechanical adjustment.

6. Never operate the machine with any air

openings blocked. Keep ventilation openings of the machine and the foot control

free from accumulation of lint, dust, and

loose cloth.

7. Keep fingers away from all moving parts.

Special care is required around the

machine needle.

8. Always use the proper stitch plate. Using

the wrong stitch plate can result in needle breakage.

9. Do not use bent needles.

10. Do not pull or push the fabric while sewing. This can result in needle breakage.

11. Switch the machine off (“O”) when making any adjustments in the needle area,

such as threading or changing the needle, threading the bobbin, or changing

the presser foot, and the like.

12. Always unplug the machine when performing cleaning or maintenance worksuch as replacing the sewing light or

when making any other user maintenance adjustments mentioned in the

instruction manual (disconnect the power

plug). Cleaning and maintenance work

must not be carried out by children without supervision.

13. Never drop or insert any object into any

openings.

14. Use this machine only in dry and protected areas. Never operate the machine

in a damp or wet environment.

15. Do not operate the machine where aerosol spray products are being used or

where oxygen is being administered.

16. To disconnect, turn the power switch to

(“O”)(off), then remove the plug from the

outlet. Do not unplug by pulling the cord,

instead grasp the plug to pull it from the

outlet.

17. If the supply cord of the foot control is

damaged, it must be replaced by the

manufacturer or an appropriate service

agent or a similar qualified person in

order to avoid endangerment.

18. Never place anything on the foot control.

19. The machine may only be used in combination with a type C-1028 (100-120 V)

or KD-2902 (220-240 V) foot control.

Page 5

20. The sound pressure level during normal

operation is lower than 75dB(A).

21. This machine is provided with double

insulation (except U.S.A/Canada). Use

only identical replacement parts. See

instructions for Servicing of double-insulated products.

SERVICING OF DOUBLE-INSULATED

PRODUCTS

All rights reserved

For technical and product improvement reasons, the machine‘s features, parts and accessory are subject to unannounced changes

and alterations at any time. The accessory

included can differ from country to country.

PLEASE NOTE:

If the machine is stored in a cold room, it should

be brought to a warm room about one hour

before use.

In a double-insulated product, two systems of

insulation are provided instead of grounding.

No grounding means is provided on a doubleinsulated product nor should a means for

grounding be added to the product. Servicing

a double-insulated product requires extreme

care and knowledge of the system and should

only be done by qualified service personnel.

Replacement parts for a double-insulated

product must be identical to those parts in the

product. A double insulated product is marked

with the words «DOUBLE INSULATION» or

«DOUBLE INSULATED».

The symbol may also be marked on the

product.

WARNING:

This machine is intended for household use

only. If used intensively or commercially, regular cleaning and especially attentive care is

required.

Signs of wear and tear owing to intensive or

commercial use are not covered automatically,

even if they occur within the warranty period.

The decision on how to deal with any such

cases rests with the local authorised servicing

staf f.

Please note that on disposal, this product

must be safely recycled in accordance with

relevant National legislation relating to electrical/electronic products. If in doubt please

contact your retailer for guidance. (European

Union only)

SAVE THESE INSTRUCTIONS!

Europe only: This appliance may only be used by

children over eight and by persons with reduced

physical, sensory or mental capabilities or by persons who lack experience and knowledge of how

to operate the machine under supervision, after

instruction on how to use the equipment safely and

once they have understood the potential dangers.

Children shall not play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

Outside of Europe (except for the USA and Canada): This appliance may only be used by persons

(including children) with reduced physical, sensory

or mental capabilities or by persons who lack

experience and knowledge of how to operate the

machine under supervision and after instruction

on how to use the equipment safely by a person

responsible for their safety. Children should be

supervised to ensure that they do not play with the

appliance.

5

Page 6

ESSENTIAL PARTS

Names of Parts

Reverse sewing lever

Stitch pattern selector knob

Stitch length knob

Stitch width knob

Bobbin winder stopper

Bobbin winder spindle

Spool pin

Bobbin winder pre-tension

Thread guide

Thread take-up lever

Thread tension dial

Head cover

Thread cutter

Needle threader

Stitch plate

Sewing table (accessory box)

Presser foot holder

Needle clamp screw

Needle

Presser foot (Zigzag foot)

Carrying handle

Handwheel

Power switch

Power/Foot control connection

Free arm

Buttonhole lever

Presser foot lever

Foot control*

PLEASE NOTE:

To carry the sewing machine, hold the carrying

handle with your hand, and support the sewing

machine with the other hand.

PLEASE NOTE:

Design and specifications are subject to change

without prior notice.

* The foot control included may differ from the illustration.

6

Page 7

Standard Accessories

Bobbins (4x)

Seam ripper (buttonhole opener)

Screwdriver (large)

Screwdriver (small)

Needle assortment

Hemmer foot

Zipper foot

Satin stitch foot

Button-sew-on foot

Blindstitch foot

Buttonhole foot with slide

More information on optional accessories can be found

on our website:

http://www.mybernette.com/accessories

Dust cover

Sewing instructions for your own personalized dust

cover are available at:

www.mybernette.com/cover

7

Page 8

Sewing table

The sewing table increases the sewing area and is easy

to remove for freehand sewing.

• Removing the sewing table:

Pull the table away from the machine.

Sewing table

• Attaching the sewing table:

Slide the sewing table along the free arm and insert the

guides into the openings until the table locks into the

machine.

Free arm

Guide

Hole

Accessory box

The accessories are stored inside the sewing table.

Unfold the cover to open the accessory box.

Accessory box

Free arm Sewing

Free arm sewing is used for stitching sleeves, waistbands, pant legs or any other tubular garments. It is also

useful for darning socks or mending knees or elbows.

8

Page 9

GETTING READY TO SEW

Connecting the Power Supply

Switch off the power switch.

Insert the machine plug into the Power/Foot control

connection.

Insert the power supply plug into the wall outlet.

Turn the power switch on.

Power supply plug

Power switch

Wall outlet

Power/Foot control connection

Machine plug

CAUTION:

Before connecting to the power supply, make sure

the voltage shown on the machine conforms to

your electrical power.

WARNING:

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts

such as the thread take-up lever, handwheel or

needle.

Always turn off the power switch and unplug from

the power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the foot control, otherwise the machine will run intermittently.

Controlling the Sewing Speed

Sewing speed can be varied by the foot control.

The harder you depress the foot control, the faster the

machine runs.

9

Page 10

Presser foot lever

The presser foot lever raises and lowers the presser foot.

You can raise it about 1/4˝ (0.6 cm) higher than the normal up position for easy removal of the presser foot, or

to help you place heavy fabric under the foot.

Lowered position

Normal up position

Highest position

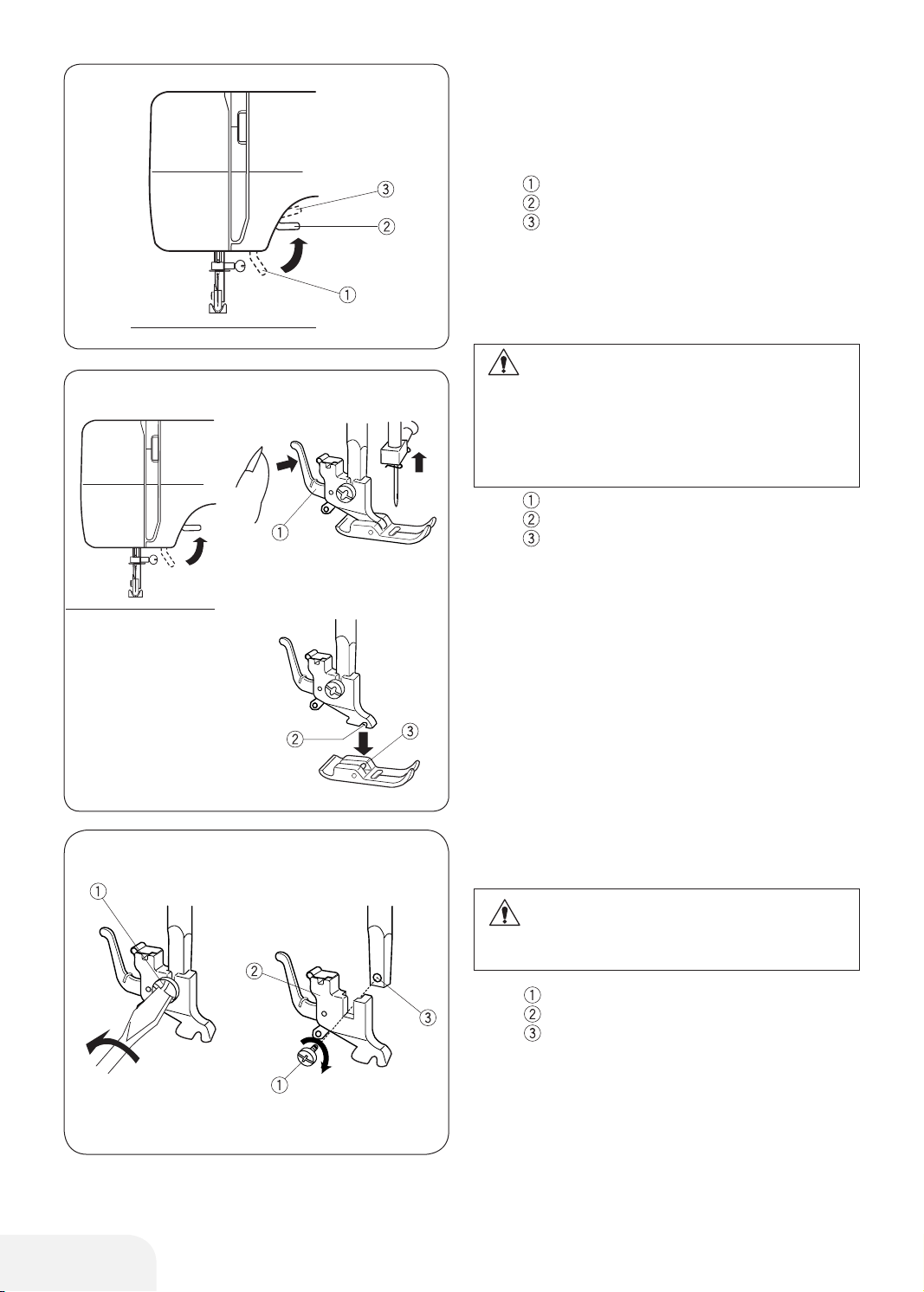

Changing the Presser Foot

CAUTION:

Turn OFF the power switch before changing the

foot. Always use the foot that corresponds to the

selected stitch. The wrong foot can cause the

needle to break.

Presser foot release lever

Groove

Pin

• To remove:

Turn the handwheel toward you to raise the needle bar

to its highest position.

Raise the presser foot.

Push the presser foot release lever to snap off the

presser foot holder.

10

• To attach:

Place the presser foot so that the pin on the foot lines up

directly below the groove of the presser foot holder.

Lower the presser foot.

Attaching and removing the presser

foot holder

CAUTION:

Turn OFF the power switch before changing the

presser foot holder.

Setscrew

Presser foot holder

Threaded hole

• To remove:

Remove the setscrew by turning it counterclockwise with

a screwdriver.

• To attach:

Match the hole in the presser foot holder with the

threaded hole in the presser bar. Fit the setscrew into

the hole. Tighten the screw by turning it clockwise with

screwdriver.

Page 11

Changing the needle

CAUTION:

Always make sure to turn the power switch off and

disconnect the machine from power supply before

changing the needle.

Raise the needle by turning the handwheel toward you

and lower the presser foot.

Switch off the power switch.

Loosen the needle clamp screw by turning it coun-

terclockwise.

Remove the needle from the clamp.

Insert a new needle into the needle clamp with the

flat side of the needle to the rear.

When inserting the needle into the needle clamp,

push it up against the stopper pin and tighten the

needle clamp screw firmly.

• To check the needle:

To check needle straightness, place the flat side of the

needle onto something flat (a stitch plate, glass etc.) The

gap between the needle and the flat surface should be

consistent.

Never use a blunt needle.

Fabric Thread Needle

Lawn

Fine

Medium

weight

Heavy

weight

Georgette

Tricot

Organza

Crepe

Sheeting

Jersey

Broadcloth

Fleece

Denim

Tweed

Coating

Quilting

Silk #80-100

Cotton #80-100

Synthetic #80-100

Silk #50

Cotton #50-80

Synthetic #50-80

Silk #30-50

Cotton #40-50

Synthetic #40-50

#9/65-11/75

#11/7514/90

#14/9016/100

PLEASE NOTE:

The needle assortment includes 1 x blue shank

needle (no. 11/75), 2 x no. 11/75 needles and 2 x

no. 14/90 needles.

For optimal sewing results, it is recommend using

Organ needles.

Fabric and Needle Chart

• Use a needle size of 11/75 or 14/90 for general

sewing work.

• A fine thread and a fine needle must be used to

sew lightweight fabric to prevent damage to the

fabric.

• Heavy fabric requires a needle large enough to

pierce the fabric without the needle thread fraying.

• Always test the needle size on a spare section of

the fabric you will be using for sewing.

• In general, use the same thread for the needle

and the bobbin.

PLEASE NOTE:

Use a blue shank needle (available separately)

when sewing flexible fabrics, very fine fabrics and

synthetic fabrics. The blue shank needle effectively prevents skipped stitches.

11

Page 12

Setting Spool Pins

The spool pins are used for holding the spool of thread

in order to feed thread to the machine.

To use, pull up the spool pin. Push down for storage.

PLEASE NOTE:

When using thread which has tendency to tangle

around spool pin, thread through the hole of spool

pin as shown. The hole should face the thread

spool.

Upper thread

Hole

Tangle

Removing or Inserting the Bobbin Case

Remove the sewing table by pulling it to the left.

Open the bobbin cover.

Bobbin cover

Raise the needle by turning the handwheel toward you.

Take out the bobbin case by holding the latch.

Latch

When inserting the bobbin case, place the horn into the

recess of the hook race.

Horn

12

Page 13

Winding the Bobbin

Pull the handwheel out.

Draw the thread from the spool.

Guide the thread around the bobbin winder pre-

tension.

Insert the thread through the hole in the bobbin

from the inside to the outside.

Put the bobbin on the bobbin winder spindle.

Push it to the right.

With the free end of the thread held in your hand,

depress the foot control.

Stop the machine when it has made a few turns,

and cut the thread close to the hole in the bobbin.

Depress the foot control again.

When the bobbin is fully wound, stop the machine.

Return the bobbin winder spindle to its original

position by moving the spindle to the left, and cut

the thread.

Push the handwheel back into the original position.

PLEASE NOTE:

When stopping the machine, push the bobbin

winder spindle to the left.

Threading the Bobbin Case

Place the bobbin into the bobbin case.

Make sure the thread unwinds in the direction of

arrow.

Pull the thread into the bobbin case slot.

Draw the thread under the tension spring and into

the delivery eye.

* Pull a thread roughly 4" (10 cm) long from the bobbin.

13

Page 14

Threading the Machine

Raise the thread take-up lever to its highest position by

turning the handwheel toward you.

Raise the presser foot.

Place a spool on the spool pin as shown, with thread

coming from back of the spool.

Draw the thread into thread guide using both hands.

While holding the thread near spool, draw thread

down into the tension area and then around the

check spring holder.

Firmly draw the thread up and through the take–up

lever from right to left.

Then pull the thread downwards and guide it into

the thread guide on the bottom of the sewing head,

moving from right to left.

Pull the thread downwards and, on the left side of

the needle bar, insert it into the thread guide.

Thread the needle eye from front to back.

Needle threader

Raise the needle to its highest position by turning

the handwheel toward you. Pull down the needle

threader as far as it will go.

Turn the needle threader away from you so the

hook comes out through the needle eye from

behind.

Pull the thread around the guide and under the

Hook. Take particular care with the point of the

needle when doing so.

Hook

Turn the needle threader toward you to pull the

thread through the needle eye. Release the needle

threader slowly while holding the thread end with

your hand. A loop of the thread is pulled up through

the needle eye.

14

Page 15

Drawing Up Bobbin Thread

Raise the presser foot and hold the needle thread

slightly with your left hand.

Use your right hand to slowly turn the handwheel

counterclockwise until the needle has been lowered. Continue turning the handwheel until the

thread take-up lever is at its highest point.

Slightly draw up the needle thread forming a loop of

the bobbin thread.

Pull 10 cm (4˝) of both threads back and under the

presser foot.

Thread tension dial

• Correct tension

The thread tension is adjusted depending on the sewing

materials, layers of fabric and sewing method.

In an ideal zigzag stitch, the bobbin thread does not

show on the right side (top) of the fabric, and the needle

thread shows slightly on the wrong side (bottom) of the

fabric.

Needle thread (Top thread)

Bobbin thread (Bottom thread)

Right side (Top side) of fabric

Wrong side (Bottom side) of fabric

Thread tension dial

Setting mark

• The needle thread tension is too tight

When the bobbin thread (bottom thread) appears on the

right side (top side) of the fabric, loosen the needle

thread tension by moving the dial to a lower number.

• The needle thread tension is too loose

When the needle thread (top thread) appears on the

wrong side (bottom side) of the fabric, tighten the needle

thread tension by moving the dial to a higher number.

15

Page 16

Stitch pattern selector knob

Turn the stitch pattern selector knob so that the symbol

with the desired stitch pattern points at the setting mark.

Setting mark

CAUTION

To avoid needle or fabric damage, make sure the

needle is up and out of the fabric while selecting a

stitch.

Stitch length knob

Turn the stitch length knob so that the symbol with the

desired stitch length points at the setting mark.

The higher the number, the longer the stitch length.

Setting mark

+ –

S

• Set the knob for sewing with a zigzag stitch

between 0.5 and 4.

• Turn the knob to "S" to sew with stretch stitch pat-

terns, which are marked on the machine in red.

• If the stretch stitch pattern is irregular, turn the

stitch length knob towards "–" to condense the

stitch or towards "+" to expand the stitch.

Stitch width knob

Set the stitch width knob so that the symbol with the

desired stitch width points at the setting mark.

The higher the number, the wider the stitch width

Setting mark

PLEASE NOTE:

Raise the needle above the fabric, when you turn

the stitch width knob.

16

Page 17

Reverse sewing lever

As long as you keep the reverse sewing lever depressed,

the machine will sew in reverse.

Lowering and raising the feed dog

Remove the sewing table by pulling it to the left.

Open the bobbin cover.

Bobbin cover

To lower the feed dog, press the lever down and

move it in the direction indicated by the arrow (see

figure)

To raise the feed dog, press the lever down, move

it in the direction indicated by the arrow (see figure)

and turn the handwheel counterclockwise.

17

Page 18

BASIC SEWING

Straight stitch

Stitch selection: A

Presser foot: Zigzag foot

Thread tension: 2 – 6

Stitch length: 1.5 – 4

Needle position: (0) or (5)

• Starting sewing

Raise the presser foot and position the fabric with its

edge lining up with a seam guide line on the stitch plate.

Lower the needle into the fabric.

Lower the presser foot and smooth the threads toward

the back. Depress the foot control.

Gently guide the fabric along the guide line letting the

fabric feed by itself.

PLEASE NOTE:

Draw the threads to the left when sewing with the

buttonhole foot with slide.

To fasten the beginning of the seam, first sew several stitches in reverse then sew forward.

• Finishing sewing

For fastening the end of seams, press the reverse sewing lever and sew several reverse stitches.

Raise the presser foot and remove the fabric. Draw the

threads towards the back as you do so.

Cut the threads with the thread cutter .

The threads are now the proper length to begin sewing

the next seam.

Thread cutter

Changing the Sewing Direction

CAUTION:

Keep fingers away from the presser foot when

guiding the fabric. Otherwise fingers may be

struck and injured by the needle clamp screw.

Stop the machine and turn the handwheel toward you to

bring the needle down into the fabric.

Raise the presser foot.

Pivot the fabric around the needle to change sewing

direction as desired. Lower the presser foot and continue

sewing in the new direction.

18

Page 19

Seam Guide Lines

The numbers on the stitch plate indicate the distance

between the center needle position and the guideline.

The numbers in front are centimeters.

The numbers in back are fractions of an inch.

Number 10 15 20 3/8 4/8 5/8 6/8

Distance (cm) 1 1.5 2 — — — —

Distance

(inch)

— — — 3/8 1/2 5/8 3/4

Center needle position

Guide lines

Numbers

Turning a Square Corner

To turn a square corner 5/8˝ (1.6 cm) from the fabric

edge.

Stop stitching and lower the needle by turning the handwheel counterclockwise.

Raise the presser foot and turn the fabric to line the

edge with the 5/8˝ (1.6 cm) seam guide.

Lower the presser foot and begin stitching in the new

direction.

Line up the fabric edge facing you with the cornering

guide shown.

Cornering guide

UTILITY STITCHES

Zigzag

Stitch selection: B

Presser foot: Zigzag foot

Thread tension: 2 – 5

Stitch length: 0.5 – 4

Stitch width: 0 – 5

Simple zigzag stitching is frequently used for overcasting, sewing on buttons, etc.

Adjust the stitch length to suit your sewing needs.

19

Page 20

Overcasting

Stitch selection: B

Presser foot: Zigzag foot

Thread tension: 1 – 4

Stitch length: 1 – 2

Stitch width: 5

Simple zigzag stitching is used to finish raw edges (overcasting) on most fabrics in order to prevent fraying. This

is the fastest way to finish an edge.

Place the fabric edge against the black guide on the foot.

Sew.

3-step zigzag

Stitch selection: C

Presser foot: Zigzag foot

Thread tension: 1 – 4

Stitch length: 0.5 – 4

Stitch width: 5

20

This stitch is used to finish the raw edge on synthetics

and other fabrics that tend to pucker.

Place your fabric to allow a 1.6 cm (5/8˝) seam.

Trim the seam allowance after sewing.

Be careful not to cut the stitches.

Page 21

Stretch-Overlock Stitch

Stitch selection: F

Presser foot: Zigzag foot

Thread tension: 1 – 4

Stitch length: S

Stitch width: 5

This knit stitch is ideal for sewing swimwear and stretch

velour because it provides the greatest amount of elasticity and strength.

Place your fabric to allow a 1.6 cm (5/8˝) seam.

Trim the seam allowance after sewing.

Be careful not to cut the stitches.

Triple straight stitch

Stitch selection: A

Presser foot: Zigzag foot

Thread tension: 2 – 6

Stitch length: S

Needle position: (0) or (5)

The stitch is sewn with two forward stitches and one

reverse stitch, creating a seam that is difficult to tear.

Use it to reinforce areas such as crotch and armhole

seams.

Also use it when constructing items such as backpacks

for extra strength.

Carefully guide the fabric while sewing as the fabric

moves back and forth.

21

Page 22

Triple zigzag

Stitch selection: B

Presser foot: Zigzag foot

Thread tension: 2 – 6

Stitch length: S

Stitch width: 2 – 5

Sew on stretch fabrics in any area that you might use a

zigzag stitch.

This stitch is also used as a decorative stitch.

Sewing Buttons

Stitch selection: B

Presser foot: Button-sew-on foot

Thread tension: 2 – 6

Stitch length: 0

Stitch width: Adjust as required

Feed dog: Lowered

22

Lower the feed dog.

Match the holes in the button with the horizontal

slot on the presser foot.

Adjust the stitch width matching the distance of the

holes in the button.

Lower the foot to hold the button in place. Check to

see if the needle enters into the holes in the button

by turning the handwheel by hand.

Sew about ten (10) stitches.

To strengthen the shank, cut the threads leaving

about 4.0˝ (10.0 cm). Bring the needle thread down

through one of the holes in the button and wind it

around the shank. Bring the needle thread to the

wrong side (bottom side) and knot.

Page 23

Automatic Buttonhole

Stitch pattern:

Presser foot: Buttonhole foot with slide

Thread tension: 1 – 5

Stitch length:

Stitch width: 5

* The size of buttonhole is automatically set by placing

the button in the rear of the buttonhole foot with slide.

* The button holder of the foot takes a button size up to

1˝ (2.5 cm) in diameter.

* Sew a test buttonhole on a stitch that matches the

fabric, the interfacing and the seams on the actual item

of clothing.

* Use interfacing on stretch fabrics.

Raise the needle by turning the handwheel toward

you.

Raise the presser foot lever.

Attach the buttonhole foot with slide.

Groove

Pin

Pull the button holder to the back A, and place the

button in it.

Push back the button holder toward you B as far as

it will go.

Button holder

* If the button is extremely thick, make a test buttonhole.

If it is difficult to fit the button through the test buttonhole,

lengthen the buttonhole by pulling the button holder back

to create a gap.

Gap

Pull the buttonhole lever downward as far as it will

go.

Buttonhole lever

Insert the fabric under the foot. Turn the handwheel

toward you one rotation and remove the fabric to

the left to draw both threads to the left. Insert the

garment under the foot, and lower the needle at the

starting point. Then lower the buttonhole foot with

slide.

Starting point

PLEASE NOTE:

Make sure there is no gap between the slider and

spring holder, otherwise the left and right length

will be different.

Slider

Spring holder

There should be no gap.

Sewing gap

23

Page 24

Depress the foot control to sew a buttonhole.

The machine automatically sews the front bartack,

the left row, the rear bartack and the right row. Stop

the machine at the ending point.

Ending point

Raise the presser foot and cut the both needle and

bobbin threads leaving 10 cm (4˝) thread ends.

Draw the needle thread to wrong side of the fabric

by pulling the bobbin thread.

Then, knot the threads.

Place a pin on both buttonhole ends directly in front

of the bartacks to prevent the bartacks being cut

open. Cut the opening with the seam ripper.

Pin

Seam ripper

• Repeating buttonhole sewing

To repeat buttonhole sewing, turn the stitch selec-

tor to , then back to again, as shown.

Now, simply step on the foot control to sew an iden-

tical buttonhole.

When the buttonhole sewing is finished, push the

buttonhole lever upward as far as it will go.

Buttonhole lever

• Adjusting stitch density for buttonholes

Turn the stitch length knob to the right for a coarser density.

Turn the stitch length knob to the left for a tighter density.

24

Page 25

Buttonhole with cord

Stitch pattern:

Presser foot: Buttonhole foot with slide

Thread tension: 1 – 5

Stitch length:

Stitch width: 5

With the buttonhole foot with slide raised, hook the

filler cord on the cord pin at the back of the buttonhole foot with slide.

Bring the ends toward you under the buttonhole

foot with slide until they clear the front end.

Hook the filler cord into the slits on the front of the

buttonhole foot with slide to hold them tight.

Pin

Slits

Lower the needle into the garment where the but-

tonhole will start and lower the foot. Depress the

foot control gently and sew the buttonhole.

Both sides of the buttonhole and the bartacks are

sewn over the filler cord.

* The sewing steps are the same as the buttonhole sewing.

Remove the fabric from the machine and cut the

sewing threads.

Pull the left end of the filler cord to tighten it. Thread

the end through a darning needle, draw to the bottom side of the fabric and cut.

25

Page 26

Zipper Application

Stitch selection: A

Presser foot: Zipper foot

Thread tension: 2 – 6

Stitch length: 1.5 – 4

Stitch width: 5

Pin or baste zipper tape to fabric and place it under the

foot.

Pull the threads towards the back and lower the foot.

To sew the left side of the zipper, guide the zipper teeth

along the edge of the foot and stitch through the garment and zipper tape.

Turn the fabric and sew the other side of the zipper in the

same way as you did the left side.

26

Page 27

Blindstitch

Stitch selection: D or E

Presser foot: Blindstitch foot

Thread tension: 2 – 4

Stitch length: 1 – 3

Stitch width: 5

[A] [B]

On heavyweight fabrics that ravel, the raw edge

should be overcast first. Then fold the hem, as illustrated, leaving 1/4˝ (0.7 cm) of the hem edge showing.

Wrong side of the fabric

1/4˝ (0.7 cm)

[A] Heavy weight fabrics

[B] Fine or medium weight fabrics

Position the fabric, so that the needle at its leftmost

position just pierces the edge of the fold

. Turn the guide screw to adjust the guide aligning

with the folded edge.

Sew along the folded edge guiding the fabric so the

needle catches the folded edge.

Guide screw

Guide

Folded edge

After hemming is completed, press together both

sides of the finished hem. The top side of the fabric

should show only the blind stitches.

27

Page 28

Rolled Hem

Stitch selection: A

Presser foot: Hemmer foot

Thread tension: 2 – 6

Stitch length: 2

Stitch width: 5

Trim off the corner of the fabric 0.5 cm (3/16˝) by

0.8 cm (5/16˝) to avoid a bulkiness of the hem at

the corner.

Fold the fabric edge twice 0.3 cm (1/8˝) wide and 6

cm (2 3/8˝) long.

Wrong side of the fabric

0.5 cm

0.8 cm

Curl of the foot

Place the fabric aligning the hem edge with the

guide on the foot. Lower the foot and sew several

stitches while pulling both threads to the back. Stop

the machine with the needle in the fabric and raise

the presser foot. Insert the folded portion of the

fabric into the curl of the foot. Lower the foot and

sew. Raise the edge in the process so that it feeds

in evenly.

28

Page 29

DECORATIVE STITCHING

Vari-Overlock (scallop hem)

Stitch selection: F

Presser foot: Zigzag foot

Thread tension: 2 – 6

Stitch length: 2 – 3

Stitch width: 5

Use a lightweight fabric such as tricot. Fold the fabric

and stitch on the bias. You may need to increase the

needle thread tension slightly. Allow the needle to just

clear the folded edge of the fabric at zigzag stitches.

When sewing Vari-Overlock stitches, the distance

between the rows should be at least 5/8" (1.5 cm). The

Vari-Overlock can also be sewn in any direction on knitted fabrics or fabrics with a soft and smooth texture.

Smocking

Stitch selection: C

Presser foot: Zigzag foot

Thread tension: 1 – 4

Stitch length: S

Stitch width: 5

With the stitch length at “4”, sew straight stitching lines 1

cm (3/8˝) apart, across the area to be smocked.

Knot the threads along one edge. Pull the bobbin

threads and distribute the gathers evenly.

Secure the threads at the other end.

Sew the decorative stitch between the gathering stitches.

Pull out the gathering stitches.

3/8˝ (1 cm)

PLEASE NOTE:

A similar effect can be achieved by using an elastic thread as the bottom thread. Wind the elastic

thread by hand onto the bobbin. Use a straight

stitch.

29

Page 30

Appliqué

Stitch selection: B

Presser foot: Satin stitch foot

Thread tension: 1 – 4

Stitch length: 0.5 – 1

Stitch width: 5

Baste (or fuse with iron-on fabric joiner) appliqué pieces

on the fabric.

Sew on the appliqué, ensuring that the needle sews

along the outer edge of the appliqué.

When sewing corners, lower the needle down into the

fabric.

Raise the presser foot and pivot the fabric to the right or

left.

Stretch Stitch Patterns

Stitch selection: A – K

Presser foot: Zigzag foot

Thread tension: 1 – 4

Stitch length: S

Stitch width: 5

The balance must be adjusted if the nature of the fabric

prevents a uniform forward and backward feed. To do so,

turn the stitch length knob as follows:

If the stitches are being condensed, turn the knob

towards "+".

If the stitches are being expanded, turn the knob

towards "–".

30

Page 31

CARE OF YOUR MACHINE

Cleaning the Bobbin Case and the

Shuttle Race

WARNING:

Always switch off the power switch and /or unplug

the machine from the power supply before disassembling or cleaning the machine.

The machine must only be disassembled as

described in this section.

CAUTION:

Do not store the machine in a high-humidity area,

near a heat radiator, or in direct sunlight.

Dismantling Shuttle Race Unit

Raise the needle to its highest position and open the

bobbin cover.

Open the hinged latch of bobbin case and take it out of

the machine.

Open the shuttle race ring holders and remove the

shuttle race ring.

Remove the shuttle.

* Clean the shuttle race with a brush and a soft dry cloth.

Bobbin case

Shuttle race ring holder

Shuttle race ring

Shuttle

Shuttle race

Assembling Shuttle Race Unit

Hold the shuttle by the center pin and fit it carefully back

into the shuttle race, forming a perfect circle with the

shuttle driver.

Attach the shuttle race ring making sure the bottom pin

fits into the notch.

Lock the shuttle race ring by turning the holders back

into position. Insert the bobbin case.

Pin

Notch

31

Page 32

Oiling

WARNING:

• Always switch off the power switch and/or unplug

the machine from the power supply before oiling

the shuttle race unit.

• Remove the shuttle race unit as described.

• If the machine will not be used for the time being,

do not apply the oil until its next use.

• Only use high-quality oil that is suitable for sewing

machines.

• 1-2 drops of oil are sufficient.

• Remove any excess oil from the stitch plate as

otherwise it may contaminate the fabric.

• Oiling the shuttle race

Open the shuttle cover.

Remove the shuttle race ring and the shuttle. Clean the

hook area with a brush and a soft dry cloth.

Oil the indicated location.

Shuttle cover

Shuttle race ring

Shuttle

Cleaning the feed dog

CAUTION:

Always switch off the power switch and /or unplug

the machine from the power supply before cleaning the feed dog.

Remove the needle and the presser foot.

Remove the stitch plate setscrew and remove the stitch

plate.

Setscrew

Remove dust and lint from the feed dog using a brush.

Reset the stitch plate.

32

Page 33

Troubleshooting

Condition Cause Remedy

The needle thread

breaks.

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The needle thread and the bobbin thread are not set properly

under the presser foot at the beginning of sewing.

6. The fabric is not drawn to the rear when the sewing has finished.

7. The thread is either too heavy or too fine for the needle.

Page 14

Page 15

Page 11

Page 11

Page 15

Page 18

Page 11

The bobbin thread

breaks.

The needle breaks.

Skipped stitches.

Seam puckering

1. The bobbin thread is not threaded properly in the bobbin

case and shuttle.

2. Lint has collected in the shuttle area.

3. The bobbin is damaged and does not turn smoothly.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle clamp screw is loose.

4. The needle thread tension is too tight.

5. The fabric is not drawn to the rear when the sewing has finished.

6. The needle is too fine for the fabric being sewn.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle and/or threads are not suitable for the work being

sewn.

4. A blue shank needle is not being used for sewing stretch,

very fine fabrics and synthetics.

5. The needle thread is not threaded properly.

6. The wrong needle is being used.

1. The needle thread tension is too tight.

2. The needle thread is not threaded properly.

3. The needle is too heavy for the fabric being sewn.

4. The stitch length is too long for the fabric.

Page 13

Page 31

Replace the bobbin

Page 11

Page 11

Page 11

Page 15

Page 18

Page 11

Page 11

Page 11

Page 11

Page 11

Page 14

Change the needle

Page 15

Page 14

Page 11

Make the stitch shorter

The fabric is not

feeding smoothly.

The machine does

not work.

Noisy operation

1. Accumulation of lint on the feed dog.

2. The stitches are too fine.

1. The machine is not plugged in.

2. A thread is jammed in the shuttle race.

3. The clutch is disengaged. The handwheel is pulled out.

1. A thread is jammed in the shuttle race.

2. Lint has built up in the shuttle or the shuttle race.

Page 31

Make the stitch longer

Page 9

Page 31

Page 13

Page 31

Page 31

33

Page 34

STITCH PATTERN

Overview

Description

Sewing together, top-stitching and sewing in zippers. Can also

be used as a basted seam. A stitch length of approx. 1/10" (2.5

mm) is ideal for normal seams, while the length should be

longer for basted seams or on firmer fabrics such as jeans.

Overcasting edges, sewing on bands, appliqué, sewing on

buttons and securing lace inserts. Reduce the stitch length to

roughly 1/50" (0.5 mm) for sewing appliqué.

Overcasting and reinforcing fabric edges, sewing on elastic

bands, decorative seams, darning tears and patching work.

For an invisible hem fastening with simultaneous edge over-

casting on elastic fabrics.

Overcasting double-knitted fabrics like tricot, jersey or other

lightweight fabrics on edges to create shell edging. Embellish-

ing any sewing projects.

Flat joining seams, visible hems, sewing on elastic bands and

decorative seams.

Thread

tension

Stitch

width

Stitch

length

Buttonhole slide 0.5 - 1.0 5 1-5 Standard button hole

One-step button-

hole

34

Stitch pattern Stitch Presser foot

A Straight stitch Zigzag foot 1.5 - 4.0 2-6

B Zigzag Zigzag foot 0.5 - 4.0 2-5 2-6

C 3-step zigzag Zigzag foot 0.5 - 4.0 5 1-4

D Elastic blindstitch Blindstitch foot 1.0 - 3.0 5 2-4

F Vari-Overlock Zigzag foot 2.0 - 3.0 5 2-6

E Blindstitch Blindstitch foot 1.0 - 3.0 5* 1-3 For an invisible hem fastening on woven fabrics.

G Universal stitch Zigzag foot 1.5 - 3.0 5 6-8

H Satin stitch Satin foot 0.5 - 1 5 3 Decorative stitch

I Satin stitch Satin foot 0.5 - 1 5 3 Decorative stitch

J Satin stitch Satin foot 0.5 - 1 5 3 Decorative stitch

K Decorative stitch Satin foot 0.5 - 1 5 3 Decorative stitch

Page 35

Description

For hard-wearing seams in firm fabrics, visible hems and visible

seams.

2-6

Thread

tension

Elastic, decorative stitch for decorative seams on flexible mate-

rials and for sewing on elastic thread and bands.

Decorative elastic stitch. For decorating knitted or woven fab-

rics. Also ideal for crazy quilting.

For sewing together and overcasting elastic fabrics in a single

operation. Also for decorating items of clothing, household tex-

tiles and handicrafts.

3 Decorative stitch

3 Decorative stitch

3 Decorative stitch

2-6 Elastic stitch for decorative hem ends and quilting seams.

1-4

1-4

1-4

1-4 Sewing together and simultaneously overcasting elastic fabrics.

1-4 Sewing together and simultaneously overcasting elastic fabrics.

3 Decorative cross stitch

5

Stitch

width

Stitch

length

2-5

5

5

5

5

5

5

5*

5

Stitch pattern Stitch Presser foot

A Triple straight stitch Zigzag foot S

B Triple zigzag Zigzag foot S

C Honeycomb stitch Zigzag foot S

D Florentine stitch Zigzag foot S

F Stretch overlock Zigzag foot S

E Reinforced overlock Zigzag foot S

G Double overlock Zigzag foot S

I Decorative stitch Satin foot S

J Decorative stitch Satin foot S

H Decorative stitch Satin foot S

K Cross stitch Satin foot S

* Stitch width max. 2 mm

35

Page 36

36

Page 37

37

Page 38

38

EN – 04/2017 – 2nd Edition

5060005.0.04 / 311801105

© BERNINA International AG

Steckborn CH, www.bernina.com

Page 39

Page 40

www.mybernette.com/blue-jeans

EN – 04/2017 – 2nd Edition

5060005.0.04 / 311801105

© BERNINA International AG

Steckborn CH, www.bernina.com

Loading...

Loading...