Page 1

See appendix for differences in the

030529.52.04_0303_a135 a145_EN

activa 135 S Patchwork Edition

Page 2

In choosing BERNINA, you are assured of years of rewarding sewing. For over 100 years my family

030529.52.04_0303_a135 a145_EN

has concentrated on providing complete satisfaction to our customers. And it is my personal wish to

continue this tradition of offering you Swiss precision engineering combined with state of the art

”Welcome to

the BERNINA

family”

H.P. Ueltschi

Owner BERNINA

Sewing Machine Company

technology and an after sales service second to none.

The new BERNINA activa 135 S and 145 S are characterized by a youthful appeal which is combined

with a range of added value features to give you, dear Customer, more sewing pleasure than ever

before.

Enjoy modern, creative sewing with BERNINA: our wide range of accessories as well as

our sewing publications brimming with imaginative ideas and practical tips all add to the joy of

sewing BERNINA style.

Any questions you have will be dealt with courteously and efficiently by our highly

trained BERNINA dealers, who will also be glad to service your sewing computer for you.

•

Fritz Gegauf Ltd.

BERNINA Sewing Machines •CH-8266 Steckborn/Switzerland

Page 3

2

030529.52.04_0303_a135 a145_EN

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical machine, basic safety precautions should

always be followed, including the following.

Read all instructions before using this sewing computer.

When the sewing computer is not in use, it should be

disconnected from the electricity supply by removing the plug

from the outlet.

DANGER

To reduce the risk of electric shock:

1. A sewing computer should never be left unattended when

plugged in.

2. Always unplug the sewing computer from the electric outlet

immediately after using and before cleaning.

3. Always unplug before replacing light bulb. Replace the bulb

with the same type rated 12 volts/5 watts.

WARNING

To reduce the risk of burns, fire, electric shock or injury

to persons:

1. Do not allow to be used as a toy.

Close attention is necessary when the sewing computer is

used by or near children and infirm persons.

2. Use this sewing computer only for its intended use as

described in this manual. Use only attachments recommended

by the manufacturer as contained in this manual.

3. Never operate this sewing computer if

•

it has a damaged cord or plug

•

it is not working properly

•

it has been dropped or damaged

•

it has fallen into water

Return the sewing computer to the nearest authorized

BERNINA dealer or service center for examination, repair,

electrical or mechanical adjustment.

4. Never operate the computer with any air openings blocked.

Keep ventilation openings of the sewing computer and foot

control free from accumulation of lint, dust and loose cloth.

5. Keep fingers away from all moving parts. Special care is

required around the sewing needle.

Page 4

3Safety instructions

030529.52.04_0303_a135 a145_EN

6. Always use the BERNINA original needle plate. The wrong plate

can cause the needle to break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deflect the

needle causing it to break.

9. Turn power switch to «0» when making any adjustments

in the needle area, such as threading or changing the needle,

threading the bobbin or changing the presser foot.

10. Always unplug the sewing computer from the electrical outlet

when removing covers, lubricating or when making any other

user servicing adjustments mentioned in this instruction manual.

11. Never drop or insert any object into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol (spray) products are being used or

where oxygen is being administered.

14. Before disconnecting, turn all controls to the off («0») position

then remove the plug from the outlet.

15. Do not unplug by pulling on the cord but grasp the plug.

16. No responsibility will be taken for any possible damage as the

result of misuse of the sewing computer.

17. This sewing computer is provided with double insulation.

Use only identical replacement parts. See instructions for

Servicing of double-insulated machines.

SERVICING DOUBLEINSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No grounding means is provided on a

double-insulated product nor should a means for grounding be

added to the product. Servicing a double-insulated product requires extreme care and knowledge of the system and should only be

done by qualified service personnel. Replacement parts for a

double-insulated product must be identical to those parts in the

product. A double insulated product is marked with the words

«DOUBLE INSULATION» or «DOUBLE INSULATED».

The symbol may also be marked on the product.

This sewing computer is intended for household use only.

SAVE THESE INSTRUCTIONS!

Page 5

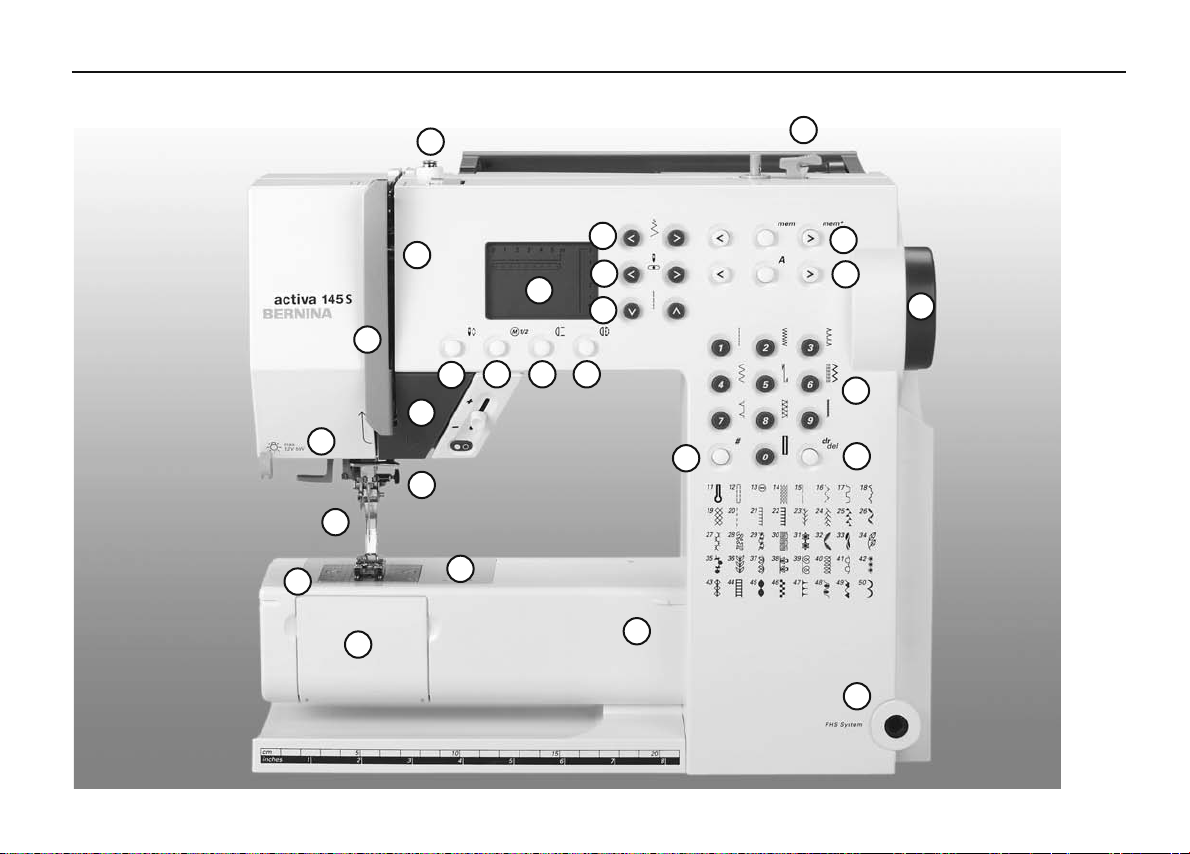

Details4

030529.52.04_0303_a135 a145_EN

Details of the sewing computer

11

14

Front view

9

13

8

19 20 21

18

12

7

6

5

2

1

3

15

16

17

25

4

22

23

27

24

26

28

Page 6

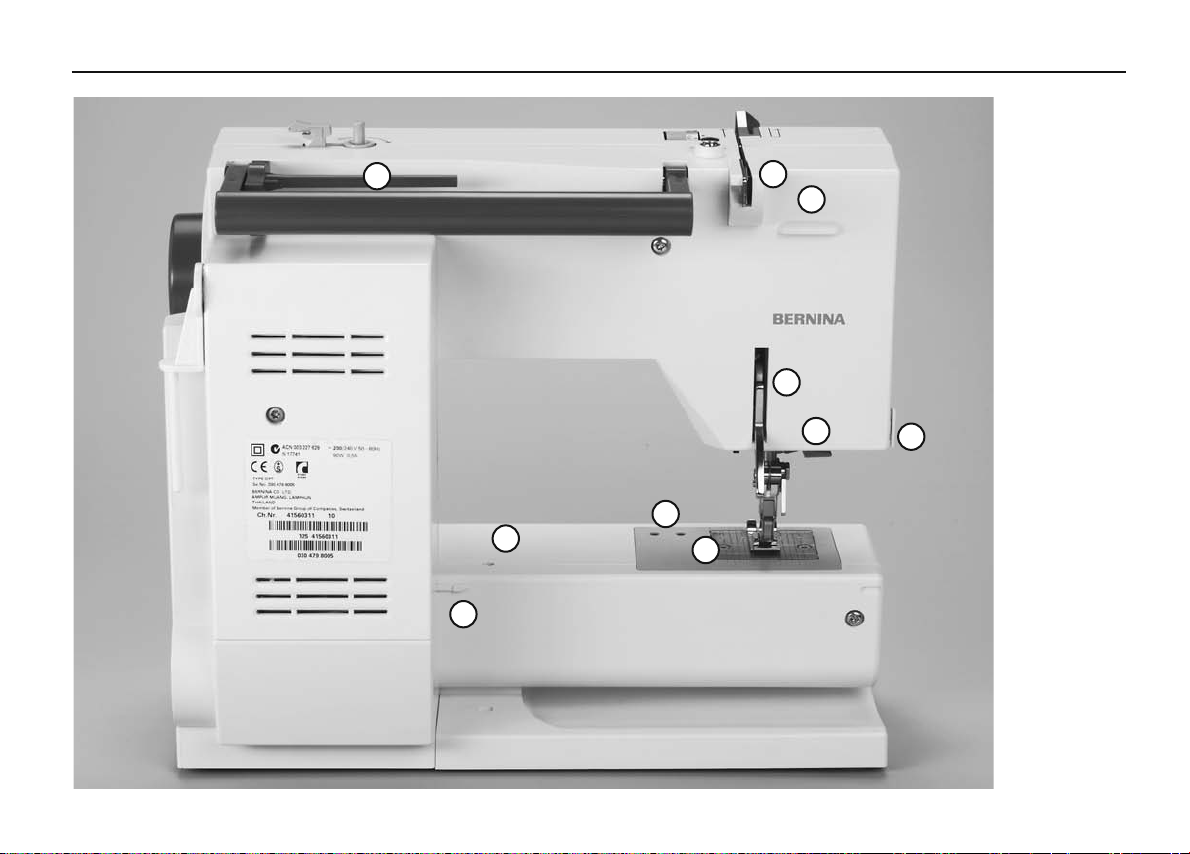

11

030529.52.04_0303_a135 a145_EN

Details

5

Right end

32

33

10

27

29

14

30

31

34

1 Bobbin cover

2 Stitch plate

3 Attachment base for

special accessories

4 Sewing table socket

5 Presser foot

6 Needle clamp with

fixation screw

7 Thread guide

8 Thread take up cover

9 Thread path

10 Thread tension

adjustment

11 Bobbin pre-tension

12 Reverse button/quick and

continuous

13 Screen

14 Bobbin winder with

on/off switch and thread

cutter

15 Stitch width button

16 Needle position button

17 Stitch length button

18 Needle stop up/down

19 1/2 speed

20 Pattern end

21 Mirror image

22 mem (memory) button

23 Alphabet buttons

24 Stitch selection buttons

25 #-button

26 clr/del-button

27 Handwheel

28 FHS connection

29 Balance adjustment knob

30 Power switch on/off

31 Power plug socket

32 Drop feed-dog

33 Foot control socket

34 Spool pin (vertical,

collapsible)

Page 7

Details6

030529.52.04_0303_a135 a145_EN

43

42

40

36

45

37

3

39

2

4

Back view

Page 8

Details

030529.52.04_0303_a135 a145_EN

7

35

36

42

37

38

46

35 Carrying handle

36 Presser foot lifter

(manual)

37 Thread cutter

38 Thread take up

39 Darning ring connection

40 Accessory box connection

41 Thread tension disc

42 Rear thread guide

43 Horizontal spool pin

44 Accessory box catch

44

41

45 Needle Threader

46 Lens holder

43

Left end

Sewing computer with Accessory box

Accessory box

Page 9

8 Setting up the sewing computer

030529.52.04_0303_a135 a145_EN

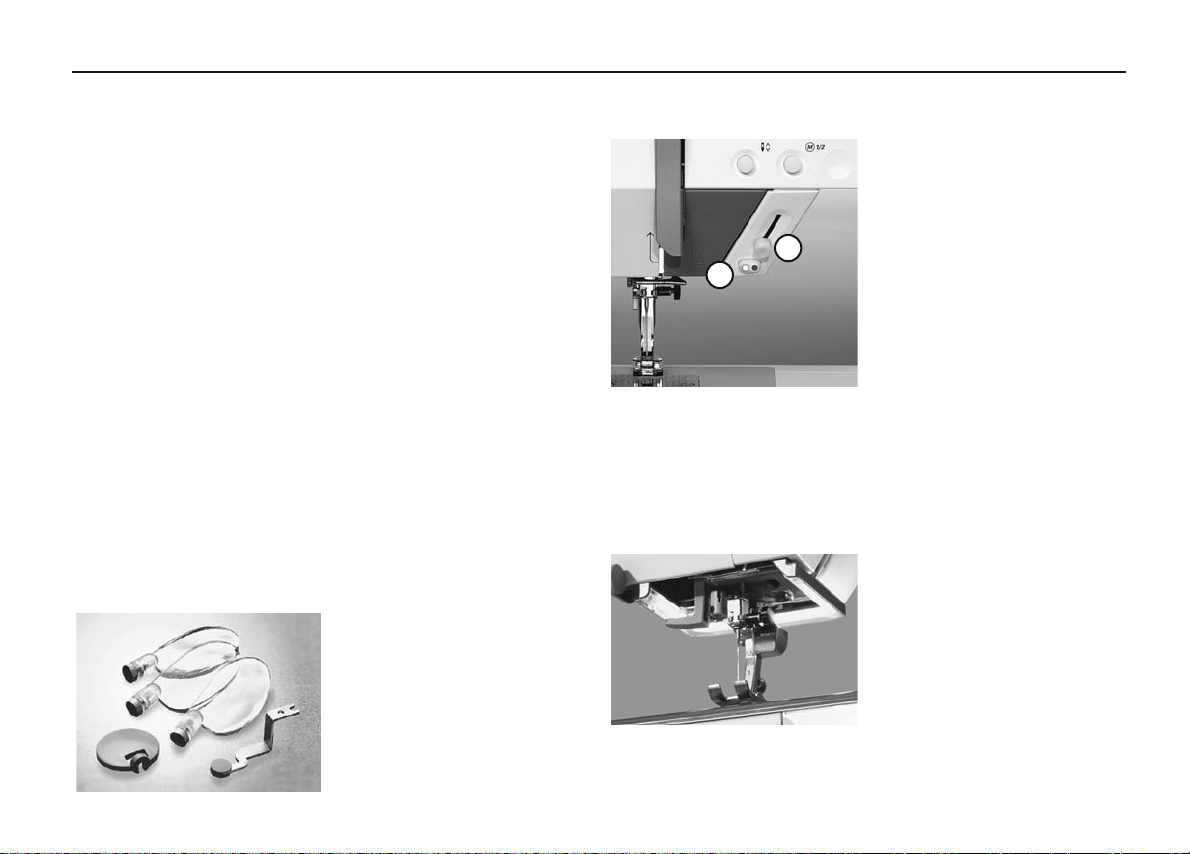

Accessories

•

foot control

•

instruction manual

•

power cable

•

warranty card

•

Accessory box

•

presser foot lifter

Standard accessories*:

4 bobbins (+ 1 in the capsule

in the sewing computer)

Selection of 130/705H needles

Seam ripper

Screwdriver

Angle key Torx

Screwdriver Torx

Lint brush

Seam guide

Compensating plate

3 spool discs

Foam pad

Oiler

Fabric cover

•

protects from dust and dirt

•

compartment for accessories

Lens Set: **

We recommend the use of the

BERNINA Lens Set for more

comfort when sewing.

Caution!

To avoid injury always attach

the protective cover of the

magnifying glass holder

when the magnifying glass is

not in use.

Start-stop-unit**

B

A

* can vary from country to country;

see presser foot selection p. 33

** available as a special accessory

Please refer to the safety

instructions!

With the Start-stop-unit (SSU)

the start-stop-function can be

controlled by hand.

•

press start-stop-button A =

stitching starts

•

with the speed regulator B

the sewing speed can be

regulated by hand

•

to interrupt or stop sewing =

press start-stop-button A

again

Note:

If the foot control is connected with the sewing machine,

the Start-stop-unit is out

functions.

CFL **

Contrary to an ordinary bulb, the CFL

sewing light has a better illumination

and a longer life.

Caution:

Please note that a defective CFL

sewing light must ONLY be replaced

by an authorized technician. The

sewing computer must be brought

to an authorized BERNINA dealer!

Page 10

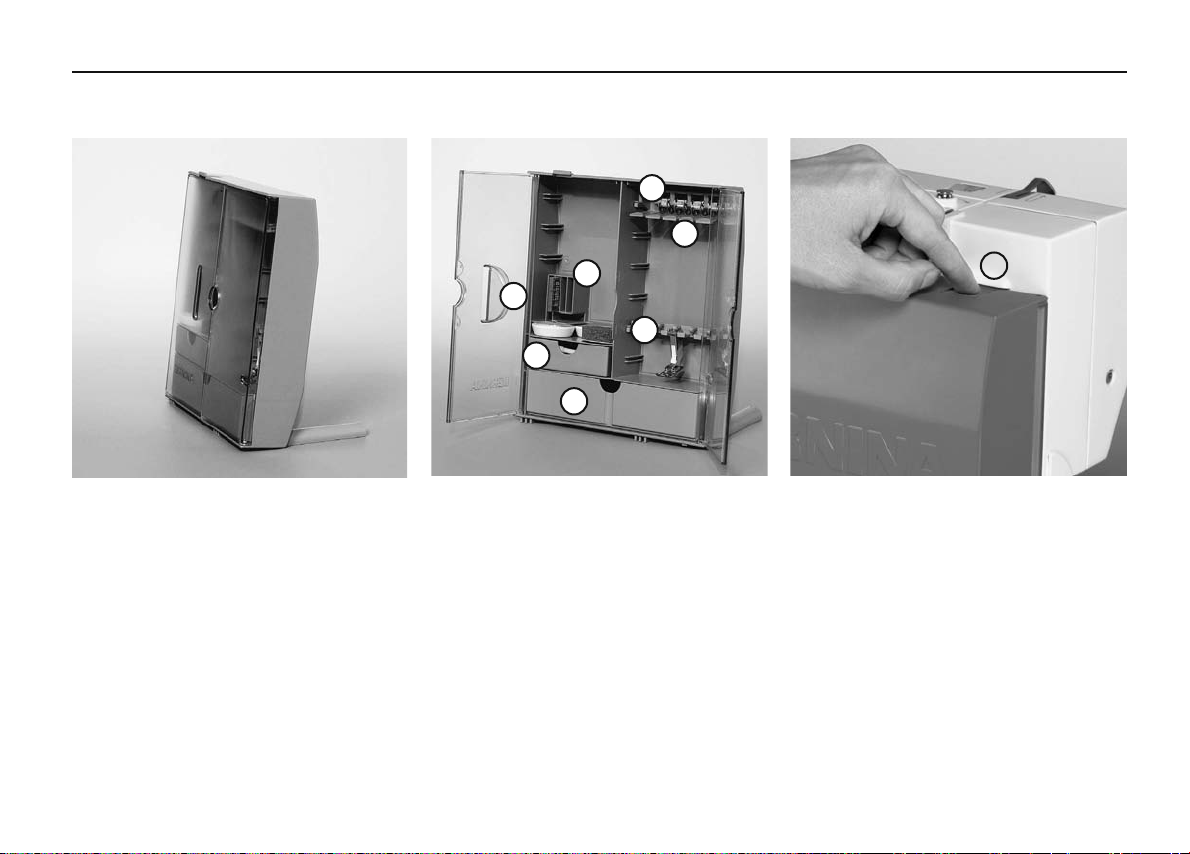

Accessory box

030529.52.04_0303_a135 a145_EN

Setting up the sewing computer 9

D

F

G

A

H

E

B

C

Free standing accessory box

•

pull both feet out until they click into

place

•

stand box in chosen position

Storing accessories

Standard accessories are supplied in a

plastic bag.

The box is equipped with one small and

one large drawer (B and C) as well as compartments for bobbin holders D and presser

feet E. (Additional compartments and

drawers are available as optional extras.)

•

push the bobbins into the compartments

provided

•

to remove a bobbin, press the compartment holder F lightly

•

insert the presser feet into the slot E

•

the needle selection box can be stored in

compartment G

Attaching the accessory box to the

sewing computer

•

close the doors

•

push feet back into position

•

attach the box to the sewing computer

(catch A must engage); inserting

the presser foot lifter into the opening H

Note: first lower the presser foot lifter!

Removing the accessory box

•

press catch A on the top of the box

•

remove box to the rear

Available as a special accessory

Page 11

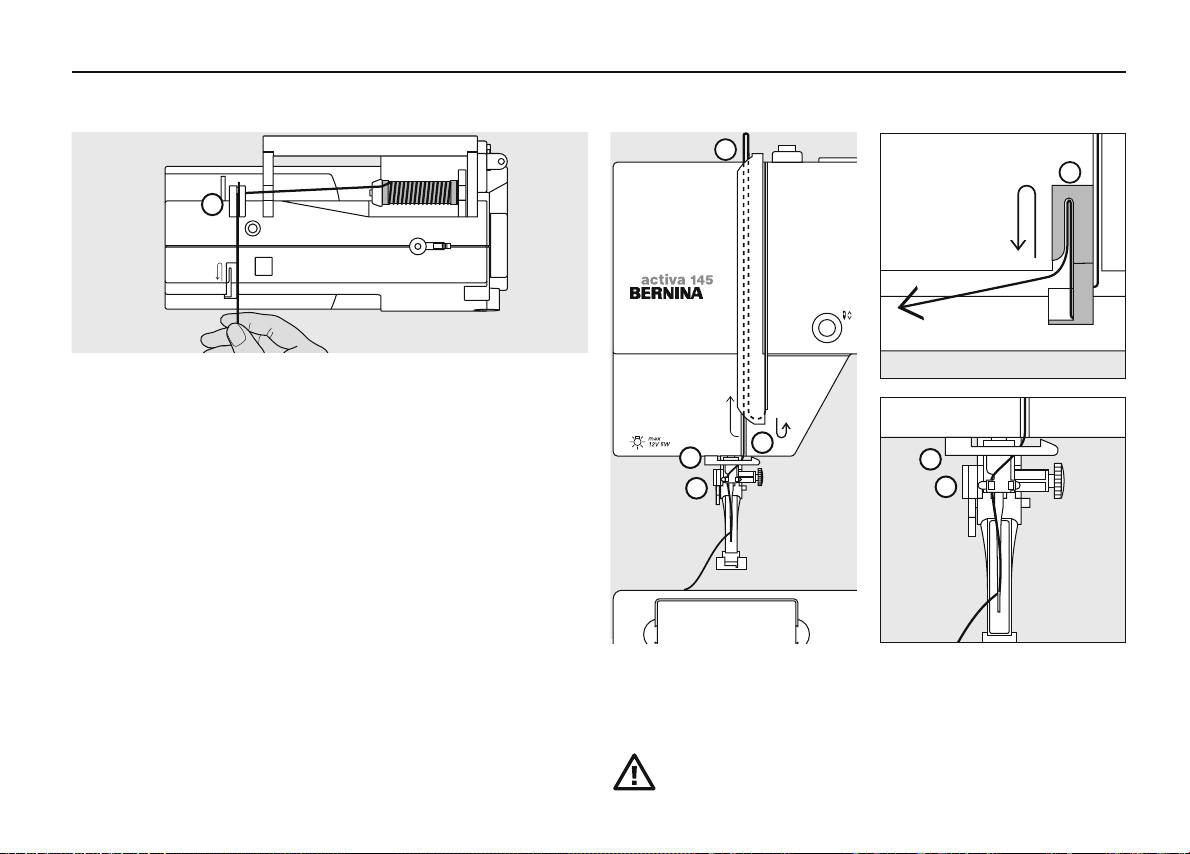

Setting up the sewing computer10

030529.52.04_0303_a135 a145_EN

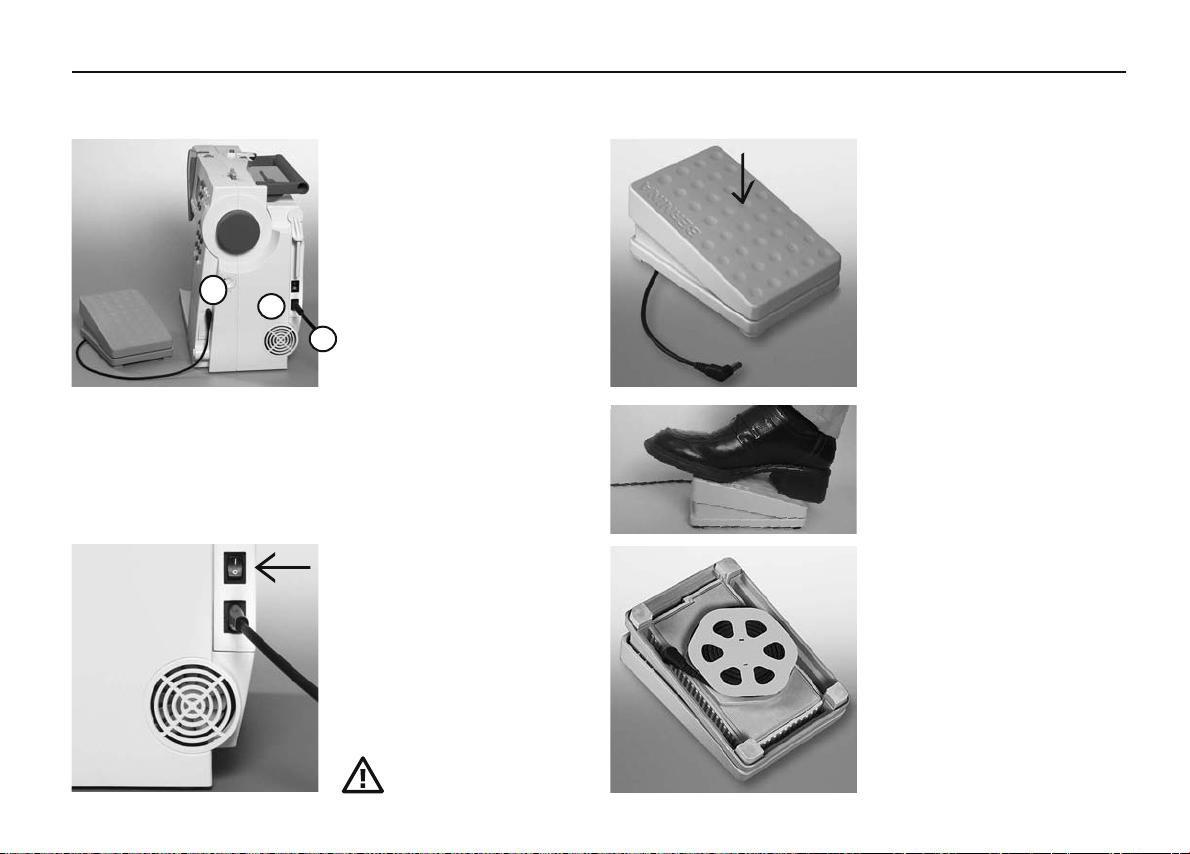

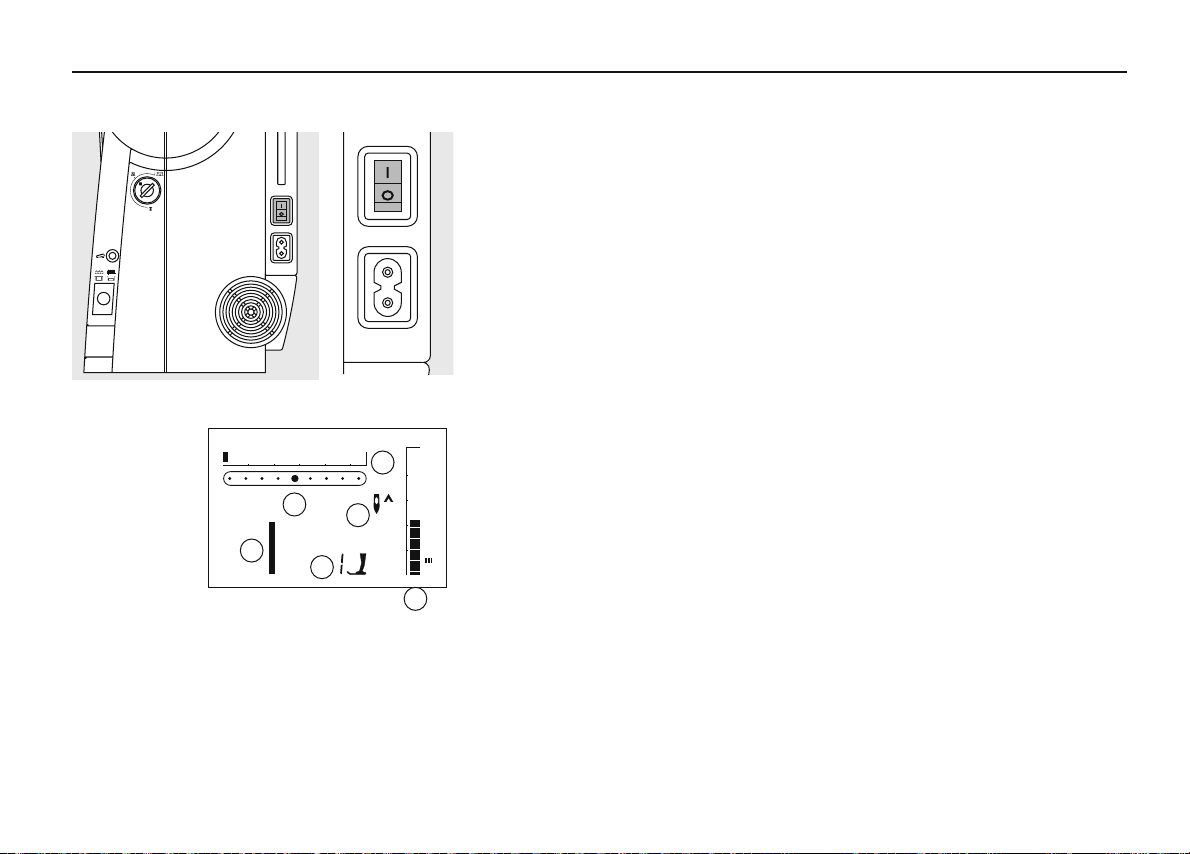

Power cable

C

Power switch

Foot control

The power cable

•

plug A into sewing computer

•

plug B into wall socket

Foot control cable

•

plug C into sewing computer

Important! (USA/Canada only)

A

This sewing computer has a

polarized plug (one blade

B

wider than the other). To reduce the risk of electric shock,

this plug is intended to fit in a

polarized outlet only one way.

If the plug does not fit fully in

the outlet, reverse the plug.

If it still does not fit, contact a

qualified electrican to install

the proper outlet. Do not

modify the plug in any way.

The switch is on the handwheel

side of the computer

1 the computer is switched on

0 the computer is switched off

The sewing light is switched on

and off with the power switch.

The foot control regulates the

sewing speed

Sewing speed is adjusted by

applying more or less pressure

to the foot control.

Important! (USA/Canada only)

Use only foot controller type

SR-1 with sewing computers

activa 135 S/145 S.

Self storing cord

•

wind the cord on the reel

•

insert the plug into the groove provided

When sewing

•

unwind the cable

Refer to the safety

instruction!

Page 12

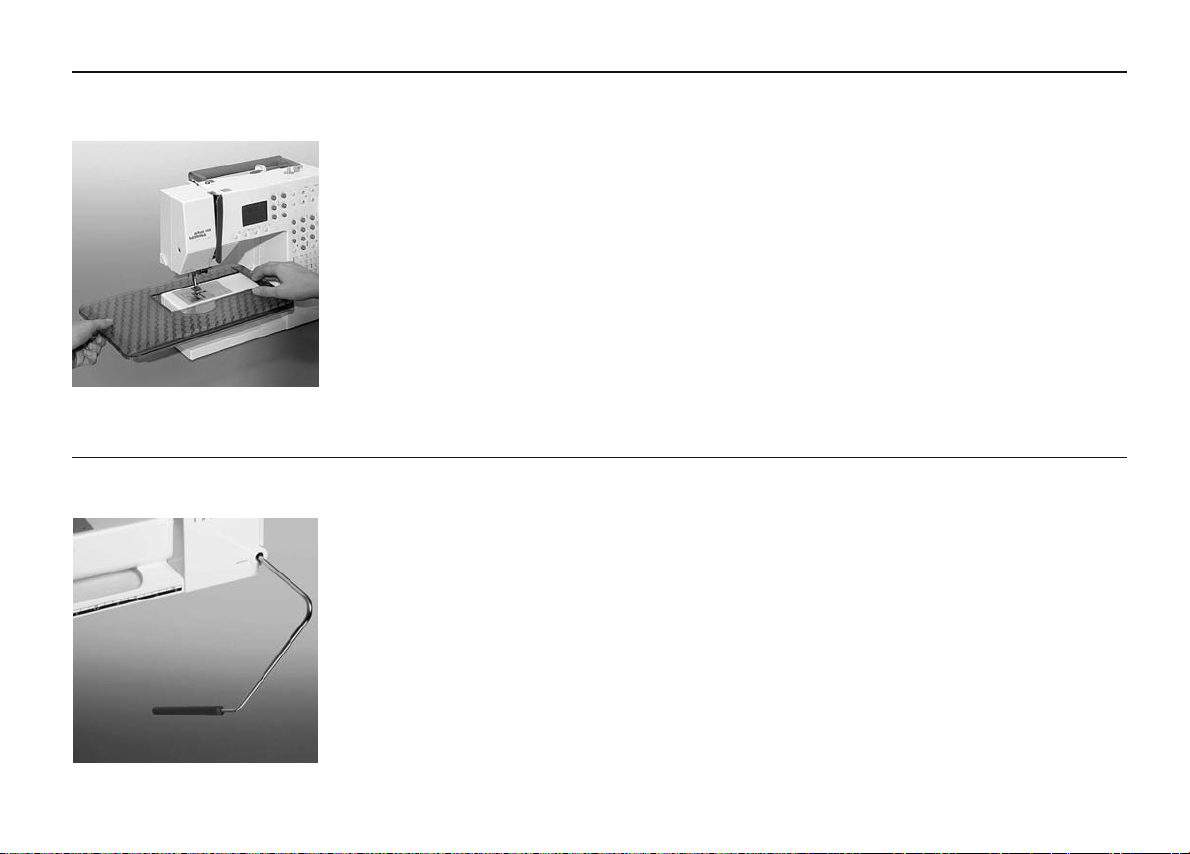

Sewing table

030529.52.04_0303_a135 a145_EN

11Setting up the sewing computer

Increases the sewing surface.

To attach

•

raise the needle and presser

foot

•

place the table over the free

arm and press firmly so that it

To remove

•

raise the needle and presser

foot

•

pull the table out of the

fixing cam

•

pull in horizontal position to

the left

Seam guide

•

•

engages on the fixing cam

Scale

•

«0» corresponds to the centre

needle position

Free-Hand-System (FHS) presser foot lifter* (knee-operated)

Attaching the presser foot

lifter

Insert into the opening in the

base plate: you should be able

to operate the lifter with your

knee in your normal sitting

position.

Note:

Your dealer can adjust it if

necessary.

The presser foot lifter raises

and lowers the presser foot

•

push to the right

•

the presser foot is raised

•

the feed-dog is lowered

simultaneously

•

the feed-dog is raised as soon

as the first stitch is sewn

* Special accessory can vary from

insert into the groove (underside of table) from the right or

left

it can be freely adjusted over

the whole width of the table

Note: Remove the presser

foot when attaching the seam

guide!

country to country

Page 13

Setting up the sewing computer12

030529.52.04_0303_a135 a145_EN

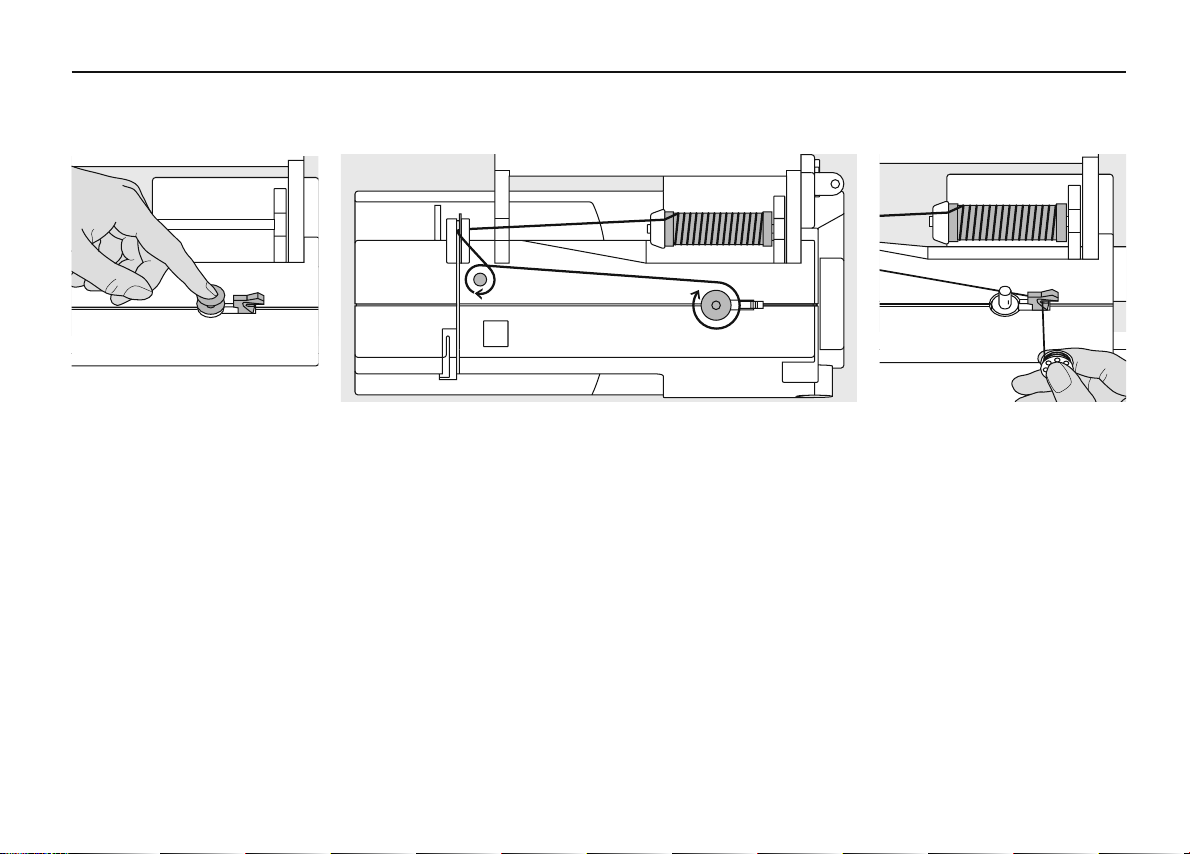

Winding the bobbin

Winding the bobbin

•

turn power switch on

•

place empty bobbin on

spindle

Note:

When winding the bobbin

on the vertical spool holder

(p. 15), it may be necessary to

adjust the speed.

•

following the direction of the arrow take thread through the rear

guide and round the pre-tension stud

•

wind it several times round the empty bobbin

•

press the engaging lever against the bobbin

•

press the foot control

•

the motor will stop automatically when the bobbin is full

•

remove the bobbin

Thread cutter

•

cut the thread on the thread

cutter

Page 14

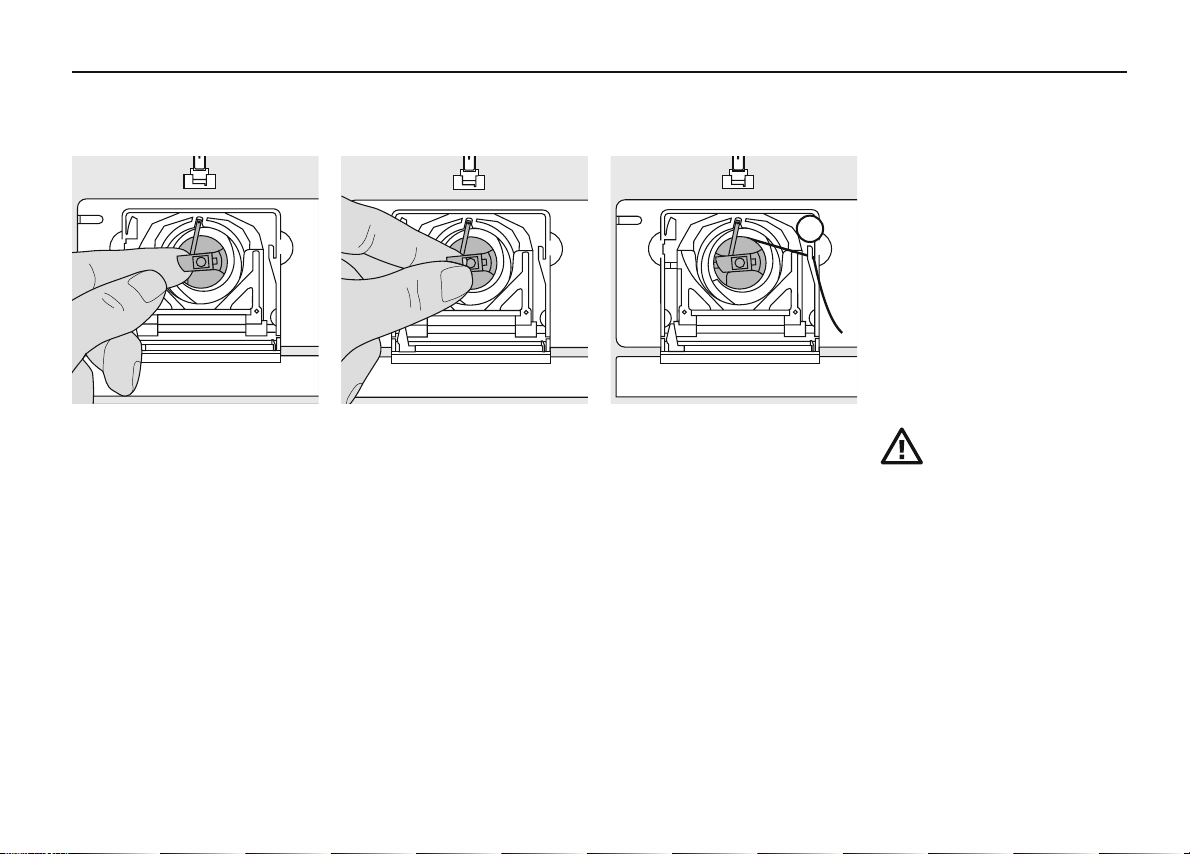

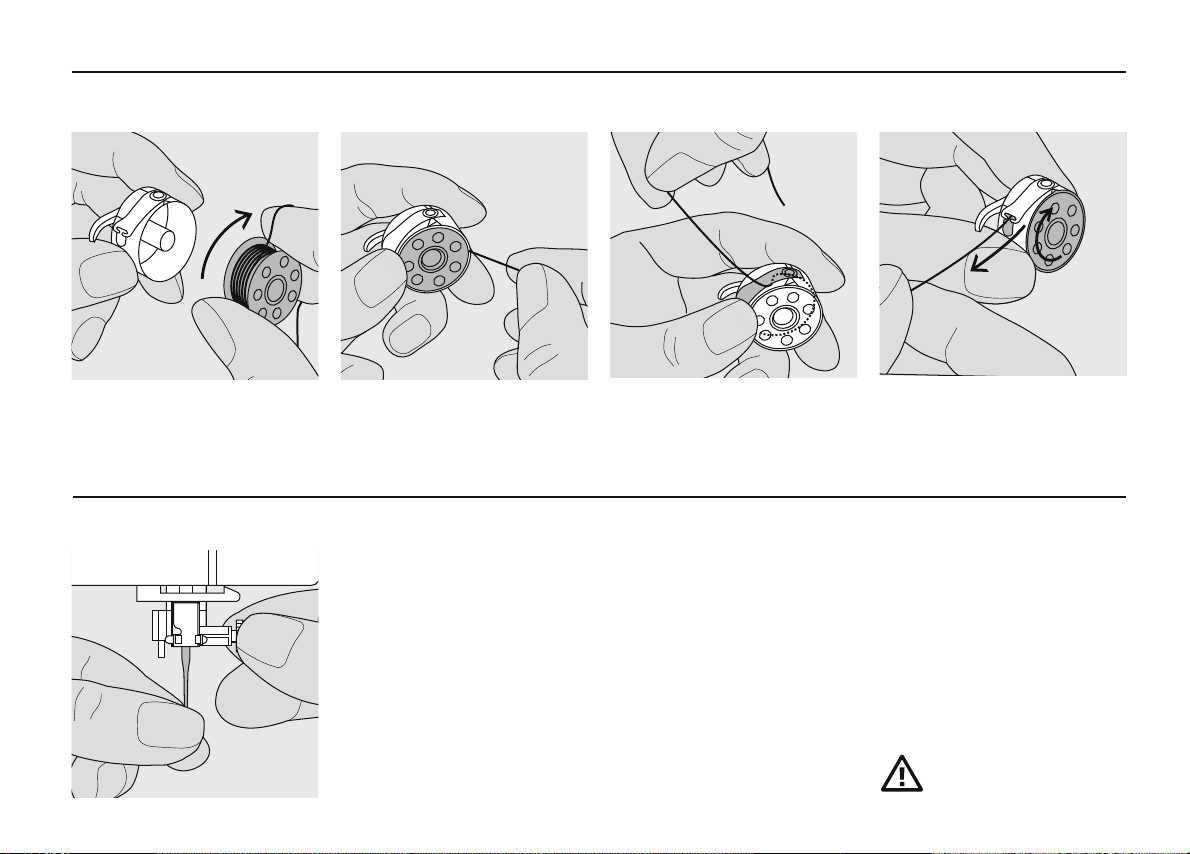

Bobbin case

030529.52.04_0303_a135 a145_EN

13Setting up the sewing computer

A

To remove the bobbin case

•

raise the needle

•

turn power switch to «0»

•

open the bobbin cover

•

grasp the latch of the bobbin

case

•

remove case

To insert the bobbin case

•

hold the bobbin case latch

•

the finger on the case should

point upwards

•

insert so that it clicks into

place

Bobbin thread cutter

•

insert the bobbin case

•

take the thread over cutter A

•

thread is cut

•

close the bobbin cover

Note:

The bobbin thread does not

have to be brought up as

the loose end is just the right

length to start sewing.

Refer to the safety

instruction!

Page 15

Setting up the sewing computer14

030529.52.04_0303_a135 a145_EN

Inserting the bobbin

Insert the bobbin

Insert the bobbin so that the

thread runs clockwise.

Changing the needle

Pull the thread counter clockwise into the slot.

Removing the needle

•

raise the needle

•

turn power switch to «0»

•

lower the presser foot

•

loosen the needle clamp screw

•

pull the needle down to remove

Inserting the needle

•

flat side of needle to the back

•

insert the needle as far as it will go

•

tighten the needle clamp screw

Pull the thread to the left

under the spring until ...

... it lies in the T-shaped slit at

the end of the spring.

The bobbin must turn clockwise when thread is pulled.

Refer to the safety

instruction!

Page 16

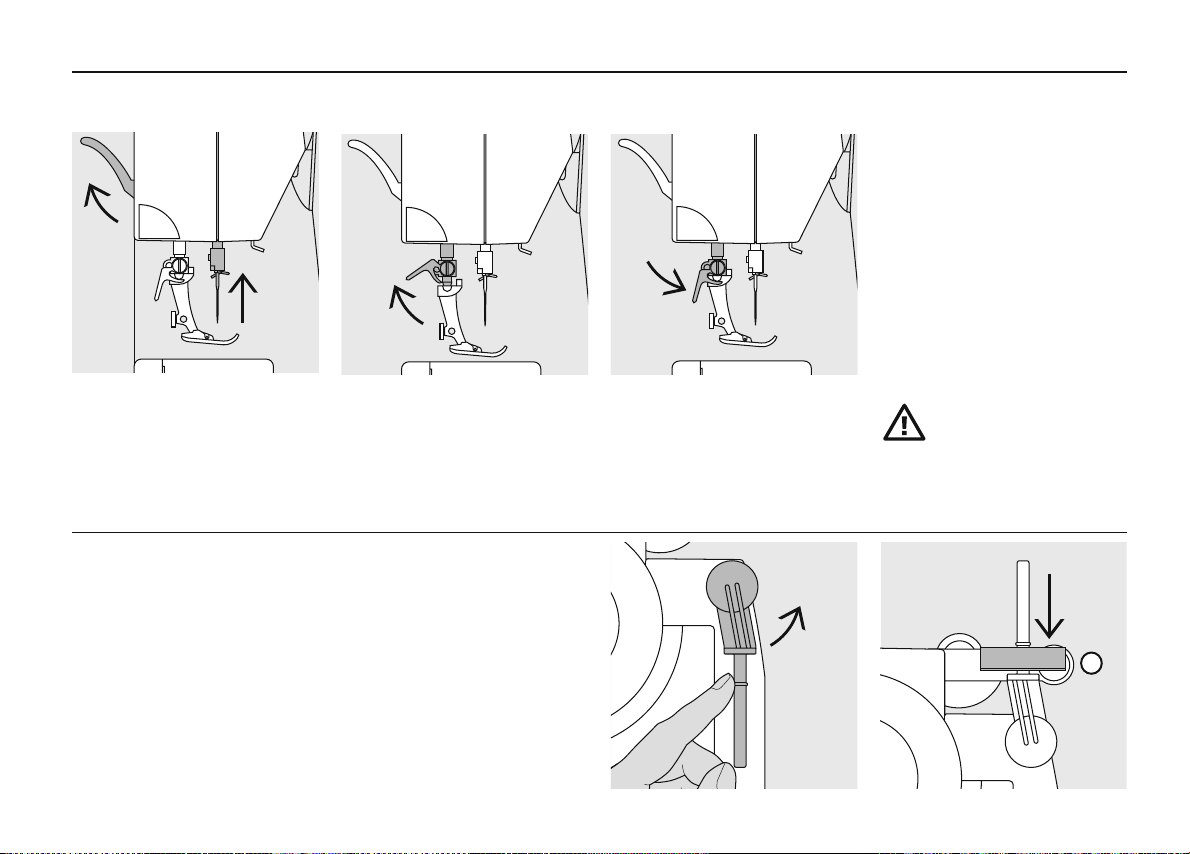

Changing the presser foot

030529.52.04_0303_a135 a145_EN

15Setting up the sewing computer

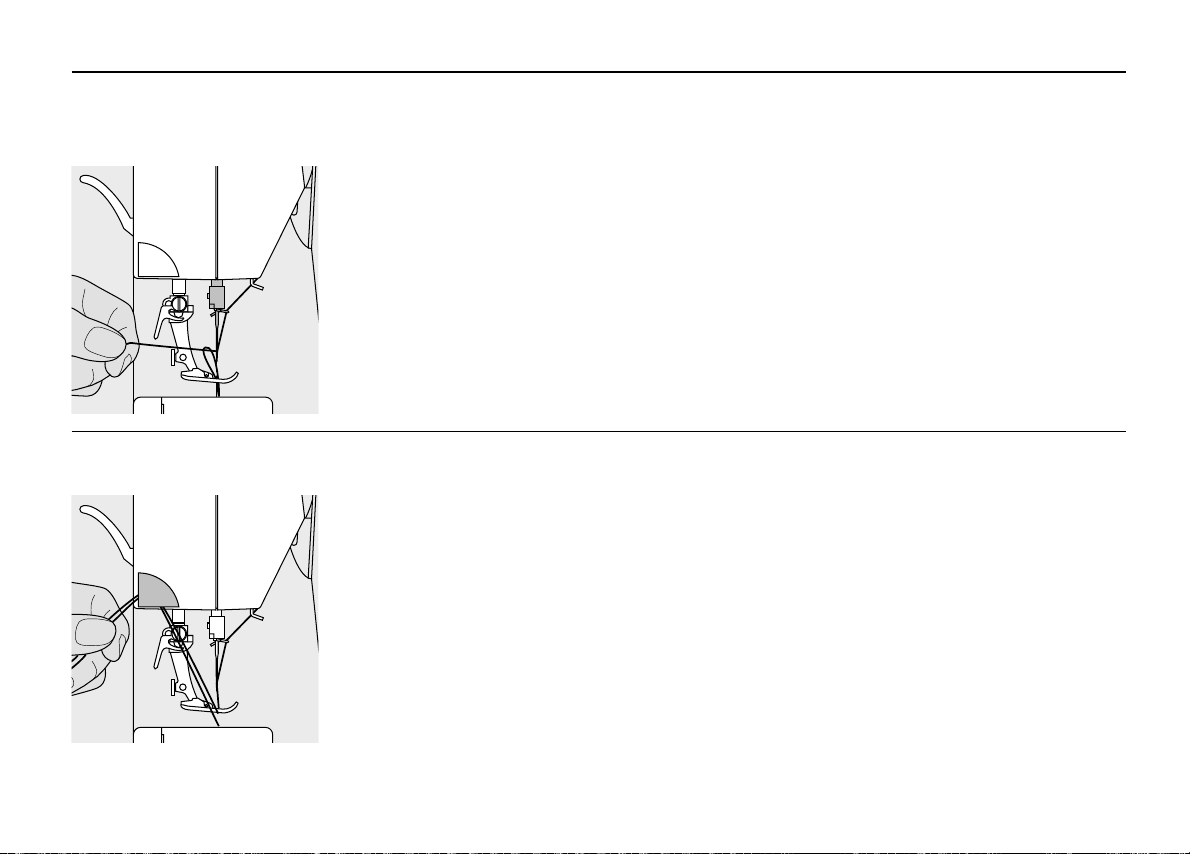

Presser foot with shank

•

raise the needle and

•

presser foot

•

turn power switch to «0»

Supplementary spool pin

Collapsible vertical spool pin

•

found on the back of the sewing computer

behind the handwheel

•

essential aid for sewing with more than one thread, i.e. double

needle work

•

raise the pin until it clicks into its vertical position

•

when using large reels, add the foam pad A for stability

•

raise the clamping lever

•

remove the presser foot

Attaching the presser foot

•

guide the foot upwards

•

over the cone

•

press the clamping lever

down

Refer to the safety

instruction!

A

Page 17

Setting up the sewing computer16

030529.52.04_0303_a135 a145_EN

Threading the upper thread

A

•

raise the needle and presser foot

•

turn the power switch to «0»

•

place spool on pin and attach the appropriate

spool disc – diameter of spool = disc size

•

take thread through rear guide A

•

then into slit of upper thread tension

•

pull thread down to the right of the take-up cover to B

•

then up to the left of the cover to C

•

and down through guides D and E

C

C

C

S

D

E

B

D

E

Refer to the safety

instruction!

Page 18

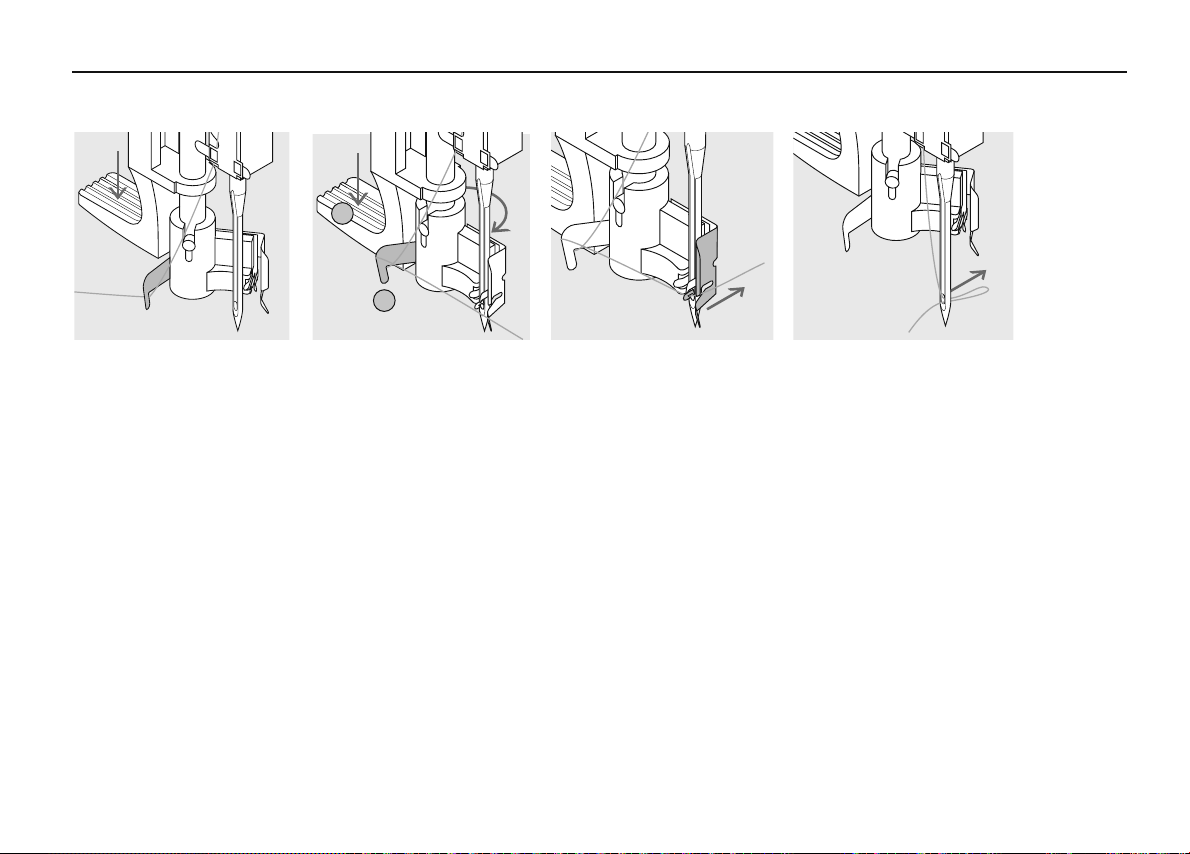

Needle Threader

030529.52.04_0303_a135 a145_EN

17Needle Threader

A

B

Thread in hook

· lower the presser foot

· lay the thread behind

hook B and hold lightly

Lever down

· press lever A down and

simultaneously guide the

thread around hook B to

the right to the needle

Thread in front of needle

· put the thread from the

front into the guide until

it catches in the hook

Release the lever and thread

· let go of lever A and

thread

Page 19

Setting up the sewing computer18

030529.52.04_0303_a135 a145_EN

Bringing up the lower thread

•

hold the upper thread

•

sew one stitch

•

pull the upper thread until the bobbin thread appears

in the stitch plate hole

•

pull bobbin thread out of the hole and insert both

threads through the slit in the presser foot towards the back

•

pull threads over the cutter

Thread cutter

•

pull both threads from front to back over the

cutter

•

the threads release as soon as the first stitch is

sewn

Note:

The bobbin thread must be

brought up through the stitch

plate for certain types of

work. The length of thread

is sufficient for most normal

work if the lower thread

cutter has been used.

Page 20

Stitch plate

030529.52.04_0303_a135 a145_EN

1

15/

1

/

8

4

Feed-dog

19Setting up the sewing computer

Stitch plate markings

•

5

/

4

1

/

8

the stitch plate is marked with seam guide lines in mm and inches

•

the millimetre markings are at the front

•

the inch markings are at the back

•

the measurements show the distance (with needle position centre) from

needle to line

•

10 201020

lines are provided to the right and left of the needle

•

they are very useful guide lines for precise seaming

•

the horizontal lines are useful for sewing corners, etc.

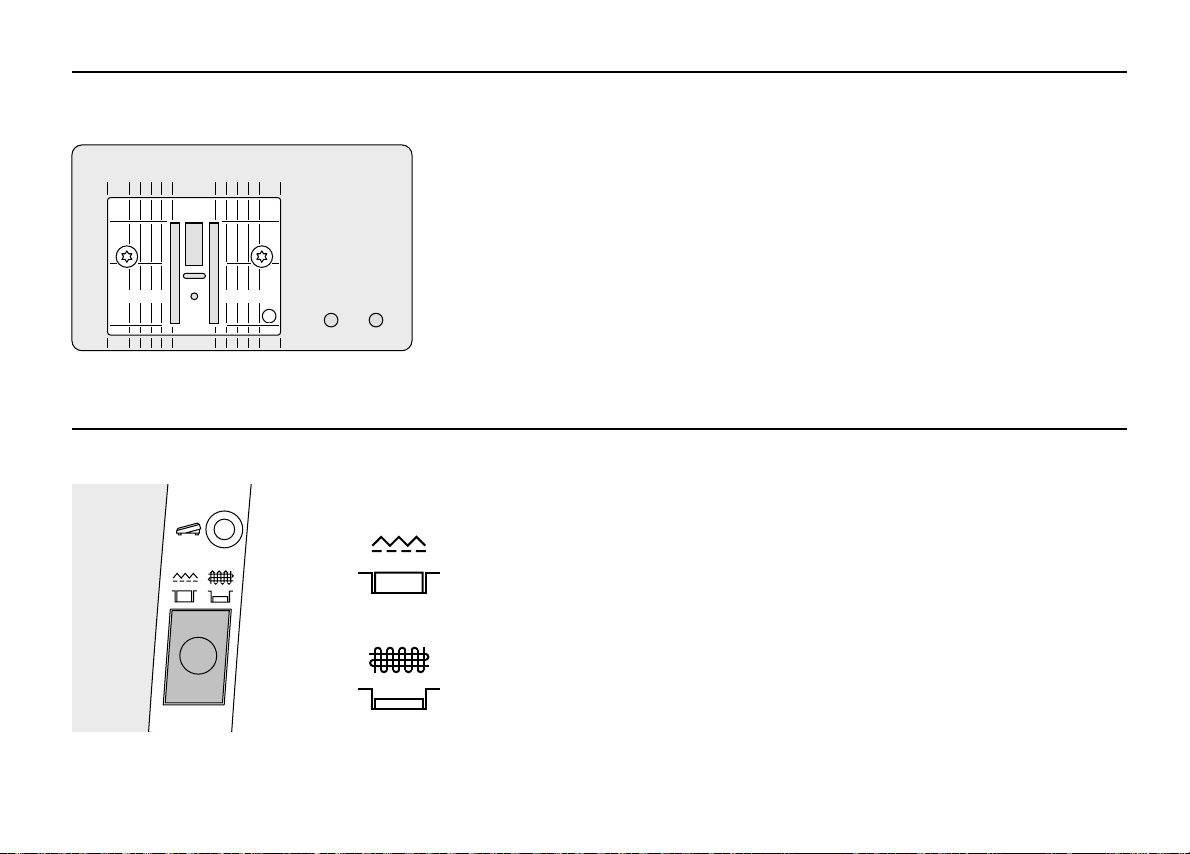

Button below the handwheel

Button flush with housing =

sewing position

Button depressed = feed-dog is lowered

•

for free-hand sewing (darning, embroidery, etc.)

Page 21

Setting up the sewing computer20

3

5

030529.52.04_0303_a135 a145_EN

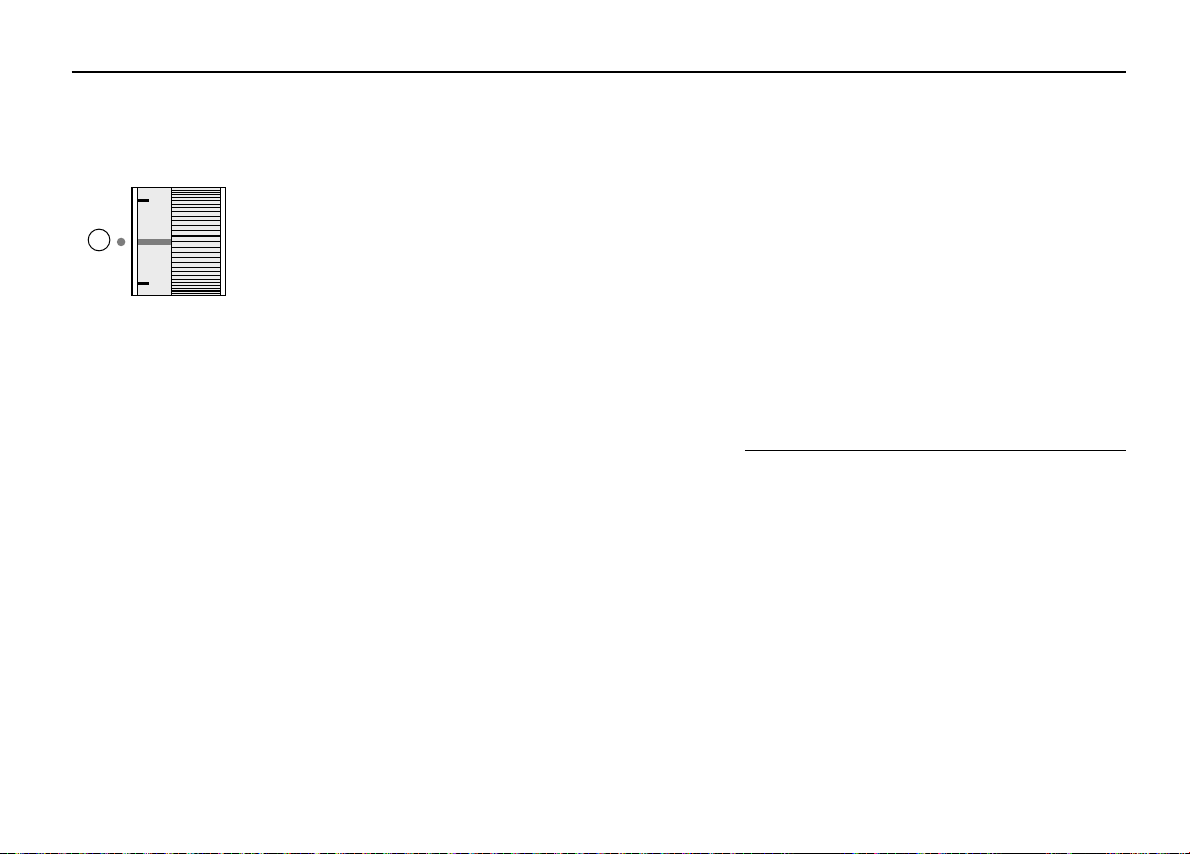

Thread tension

The basic setting

•

is indicated when the red line on the tension

adjustment wheel is in line with the marking A

•

A

the tension does not need adjusting for normal

The tension is factory set for the best results.

Metrosene 100/2 (Arova Mettler, Switzerland)

is used to set both the upper and lower thread

tension.

sewing work

•

for special sewing work, the tension can be

adjusted to suit the fabric

If other sewing or embroidery threads are used,

the tension may need adjusting to suit the fabric

and chosen stitch.

For example:

To reduce the tension

turn to between 3 and 1

To increase the tension

Metallic thread approx. 3 90

Tension Needle

turn to between 5 and 10

Monofilament approx. 2– 4 80

Page 22

0

23451

5.5

1

2

3

4

5

0

General instructions

030529.52.04_0303_a135 a145_EN

3

5

6

21Operating instructions

Main switch to 1

•

the sewing sewing computer is ready to sew

The screen shows

1

1 stitch width basic setting blinks constantly

2 stitch length basic setting blinks constantly

4

3 needle position (9 positions)

4 needle stop up/down (generally up)

5 stitch number 1 (straight stitch)

6 presser foot number 1 indicator (recommended foot

2

for selected stitch)

Page 23

Operating instructions22

030529.52.04_0303_a135 a145_EN

Stitch* selection

•

stitches 1–10:

touch the number of your choice; stitch number and basic width and

length settings appear

Note: touch «0» to select stitch number 10 (standard buttonhole)

•

to select stitches 11–30 (activa 135 S) or 11–50 (activa 145 S):

touch #-button and the appropriate number

* see p. 30 for the complete stitch selection; for activa 135 S PE see appendix A1

Stitch width

•

left button = narrow the stitch width

•

right button = widen the stitch width

•

the basic settings of the chosen stitch blink constantly

Needle position

•

left button = needle to the left

•

right button = needle to the right

Stitch length

•

left button = shorten the stitch length

•

right button = increase the stitch length

Page 24

Functions

030529.52.04_0303_a135 a145_EN

Functions are ...

activated when the symbol appears on the screen.

deactivated when the symbols no longer appear on the screen.

23Operating instructions

Reverse sewing

quick reverse:

•

press button

•

Sewing computer sews reverse until button

is released (max. stitch length 3 mm)

Applications:

•

programming buttonholes

•

programming darning program

•

switch to straight stitch securing program

(stitch No. 5)

•

manual securing (seam begin and end)

continous reverse:

•

press button quickly twice

•

the sewing computer sews the chosen stitch

in reverse

•

press button once to cancel

1/2 speed

•

press the button and the sewing speed will be

halved

•

press the button again to revert to full speed

Needle stop

•

basic setting needle stop up

•

press button

•

arrow points down = sewing computer stops

with needle down

•

press button again

•

arrow points up = sewing computer stops

with needle up

Note:

Press key a bit longer = the needle will go automatically up or down.

Stitch end

•

press button

•

sewing computer stops at the end of a single

stitch or stitch combination (in Memory)

Mirror image*

•

press button

•

mirror image of selected stitch will be sewn

*activa 145 S only

Page 25

Operating instructions24

030529.52.04_0303_a135 a145_EN

#-button

Stitch selection button (see p. 22)

clr/del (clear/delete)

•

press button = reverts to basic settings

•

other selected functions are cleared

Exceptions:

•

needle stop down

•

1/2 speed

•

altered basic settings for buttonholes =

press «clr/del»-button twice

Letters, numbers and punctuation marks

(only activa 145 S)

•

press the alphabet button

•

letters appear on the screen

•

press the right button to scroll letters and

numbers forwards (A B C ...)

•

press the left button to scroll letters and

numbers backwards (9 8 7 ...)

Alphabet contents

ABCEFGHIJKLMNOPQRSTUVXYZ

_-.’! ? % ( ) [ ] Д Ц Ь Е ЖŒШСИЙКАВ

0123456789

mem (Memory)

•

press the centre button to open memory

(capacity of 30)

•

use the left and «mem+»-buttons to scroll and

programme stitches, letters and numbers

Altered Stitch Memory

•

any stitch length or width alterations will be

saved automatically

For example:

•

sew altered stitch, e.g. zig-zag

•

select another stitch, e.g. straight stitch

•

return to zig-zag, your alterations are still

active

Return to basic settings

•

basic settings can be restored manually for

individual stitches

•

all altered settings are lost when the

«clr/del»-button is pressed or when the

sewing computer is turned off

Application

•

for all stitches and fabrics

•

particularly useful for switching between

:

different applications

Page 26

Memory

mem

0

23451

5.5

1

2

3

4

5

0

mem

0

23451

5.5

1

2

3

4

5

0

030529.52.04_0303_a135 a145_EN

25Operating instructions

Any combination of 30 stitches, letters or numbers can be saved

in Memory, which is long term. They remain saved until deleted

by the user. Power failures or disconnection from the electricity

23451

0

5.5

mem

Memory buttons

•

press left button (<) to scroll

contents backwards

•

press centre button (mem) to

open and close Memory

•

press right button (mem+)

to scroll contents forwards

Open Memory

5

•

press «mem»-button to open

4

Memory

3

• if the Memory is empty, the

2

cursor and number 30 (=

empty memories) blink

1

• if the Memory is not empty,

0

the saved stitches, letters or

numbers appear on the

screen; scroll forwards until

the cursor and number of

empty memories blink

supply do not affect the Memory. Alterations to the stitch length,

width or needle position can be made at any time. Individual

stitches, letters or numbers can be deleted or overwritten.

Example: saved stitch

•

saved stitch (28) is shown

To program stitches see p. 25

Example: saved letter

•

saved letter (E) is shown

To program letters and numbers

see p. 27

Page 27

Operating instructions26

mem

0

23451

5.5

1

2

3

4

5

0

mem

0

23451

5.5

1

2

3

4

5

0

030529.52.04_0303_a135 a145_EN

Delete complete Memory

•

press «clr/del» and «mem»button at the same time

•

release both buttons

•

leave Memory by pressing the

mem button

•

Memory is now completely

deleted

Programming practical and

decorative stitches

•

open Memory (p. 25)

•

select stitch (p. 22)

•

stitch number appears on the

screen (here 21)

•

press «mem+» to program

(save)

•

the number of remaining

empty memories (here 29)

and the cursor blink

•

select next stitch, press

+

«mem

» and continue in

this manner

Scroll backwards

press left button = the programmed stitch numbers scroll

backwards

Scroll forwards

press «mem

+

»-button = the

programmed stitch numbers

scroll forwards

Begin sewing

• press the foot control = the

sewing computer starts automatically at the beginning of

a stitch sequence

• select Pattern End ( ) as well

= the sewing computer stops

automatically at the end of a

stitch sequence

Note:

The following special programs

cannot be saved in Memory:

No. 5, Securing program

Nos. 10–12, Buttonholes

No.13, Button sewing-on

program

No. 14, Darning program

No. 15, Basting stitch

Page 28

27Operating instructions

mem

0

23451

5.5

1

2

3

4

5

0

030529.52.04_0303_a135 a145_EN

Programming letters, numbers

and punctuation marks

(activa 145 S only)

•

open Memory (p. 25)

•

press Alphabet button

•

select letter or number (p. 24)

•

press «mem+» to program

(save)

•

the number of remaining

empty memories (here 29)

and the cursor blink

•

select next letter/number,

press «mem

+

» and continue

in this manner

•

programme single words or

sentences/numbers

•

select (_) to program spacing

Note:

If the stitch length and/or

width of letters or numbers

have been altered, the alterations will affect all of them.

If you only want to alter

single letters or numbers, this

must be done individually.

Corrections in Memory

Changing individual stitches,

letters and numbers

•

scroll with the right or left

button to find the stitch you

want to change or correct

•

then correct or change:

stitch

letter

number

stitch length or width

needle position

etc.

•

press «mem+» to save the

change(s)

Delete single stitch, letter or

number

•

scroll to find the stitch

•

press «clr/del» to delete

• stitch/letter/number is deleted

Page 29

Operating instructions28

0

23451

5.5

1

2

3

4

5

0

030529.52.04_0303_a135 a145_EN

Leave Memory

•

press «mem»-button =

contents are saved

•

Memory is closed

«mem»-symbol disappears from

the screen

The contents of the memory

remain saved even when the

sewing computer is disconnected from the electricity

supply. They can be recalled

at any time.

The contents of the memory

will be lost if the sewing computer is switched off without

pressing the mem button

before closing the memory.

Page 30

Balance

030529.52.04_0303_a135 a145_EN

29Operating instructions

Note:

If the balance has been

adjusted, return it to the

normal setting once sewing

is completed.

Your sewing computer has

been tested and factory set

using a double layer of

cretonne fabric and Metrosene

100/2 threads (Arova Mettler,

Switzerland).

Normal position Denser stitch formation

Different fabrics, threads and

stabilisers can naturally affect

the stitch balance so that they

are sewn too close together or

not close enough.

This can be remedied with

Balance to suit the fabric and

produce perfect results.

(shorter stitch length)

Applications:

Practical stitches, e.g.

Honeycomb stitch on jersey,

decorative stitches, fantasy stitches, letters, buttonholes, etc.

Finer stitch formation

(longer stitch length)

Page 31

Stitches30

030529.52.04_0303_a135 a145_EN

Stitches

Practical and decorative

1 Straight stitch

2 Zig-zag

3 Vari-overlock

4 Running stitch

5 Securing stitch

6 Triple straight and zig-zag

7 Blind stitch

8 Double overlock

9 Super stretch stitch

10 Standard buttonhole

11 Keyhole buttonhole

12 Straight stitch buttonhole

13 Button sewing-on program

14 Darning program

15 Basting stitch

16 Sewn-out zig-zag

17 Universal stitch

18 Gathering stitch

19 Honeycomb stitch

activa 135 S

20–22 Quilting stitches

23–30 Decorative stitches

*

activa 135 S

activa 145 S

activa 145 S

20–28 Quilting stitches

29–50 Decorative stitches

*activa 135 S PE see appendix A1

Page 32

Stitch selection*

030529.52.04_0303_a135 a145_EN

31Stitches

1 Straight stitch

1

4

7

2

5

8

3

2 Zig-zag

3 Vari-overlock

4 Running stitch

6

5 Securing stitch

6 Triple straight and

triple zig-zag

7 Blind stitch

8 Double overlock

9 Super stretch

All non-stretch fabrics. All straight stitch work

Most fabric types; all simple zig-zag such as oversewing fine

fabrics. Sewing on elastic and lace

Primarily for fine jerseys, stretch overlock seams and hems

Most types of fabric. Mending, patching, reinforcing seams

All types of fabric. Secures the beginning and end of seams sewn

with straight stitch

Reinforced seams in tough, heavy fabrics

Most types of fabric; blind hems, shell edging on soft jerseys and

fine fabrics, decorative seams

All types of knit; Overlock = sew and neaten in one operation

Open seam for all super-stretch fabrics

*activa 135 S PE see appendix A

Page 33

Stitches32

030529.52.04_0303_a135 a145_EN

10

14

19

11

20

12

14 Darning program

19 Honeycomb stitch

20 Quilt/hand stitching

10 Standard buttonhole

11 Keyhole buttonhole

12 Straigth stitch buttonhole

Automatic darning for fine and medium weight fabrics

Most types of interlock and smooth fabrics; visible seams

and hems

Hand stitched effect: only the one stitch (lower thread) is visible;

the other stitch (upper thread = monofilament) is invisible; increase

upper thread tension to suit the fabric (6–9)

Fine to medium weight woven fabrics; blouses, shirts, trousers,

bedlinens, etc.

Heavy weight, non stretch fabrics. Jackets, coats, trousers,

leisure wear, etc.

Pre-stitch program for bound buttonholes (Foot No. 3A) or pocket

openings (Foot No. 3, special accessory)

Page 34

2

Standard foot selection

1

5

3A

37

9

20

030529.52.04_0303_a135 a145_EN

33Presser feet

1

Reverse pattern foot

Practical and decorative stitches

5

Blind stitch foot

Blind hems, edge stitching

activa 135 S = 6 feet (1, 2, 3A, 4, 5, 9)

activa 135 S PE = 7 feet (1, 3A, 4, 5, 9, 20, 37)

activa 145 S = 7 feet (1, 2, 3A, 4, 5, 9, 37)

2

Overlock foot

Overlock seam, hems, oversewing

edges, narrow satin stitch

9

Darning foot

Freehand quilting for light to

medium weight quilts; darning

3A

Buttonhole foot with slide

Buttonhole on smooth fabrics,

darning

20

Open Embroidery foot

4

Zipper foot

Sewing in zips

37

Patchwork foot

Patchwork with seam allowance

1/4” or 1/8” (≈ 6 or 3 mm)

Page 35

Selected practical stitches: Straight stitch with securing program34

030529.52.04_0303_a135 a145_EN

Securing program

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Securing program No. 5*

size and type suitable for the fabric selected (see p. 57)

cotton/polyester

raised (sewing position)

Reverse pattern foot No. 1

Securing program

•

for all fabrics

•

secures seam begin and end

•

sews exactly over the previous stitches

Seam begin

•

sewing computer secures automatically (5 stitches forwards,

5 reverse)

•

continues sewing straight stitch forwards

Seam end

•

press the reverse button = sewing computer secures

automatically (5 stitches reverse, 5 forwards)

•

stops automatically when securing is complete

* 135 S PE see appendix A2

Page 36

Basting stitch

030529.52.04_0303_a135 a145_EN

35Selected practical stitches: Basting stitch

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

TIP

Basting stitch No. 15 (activa 135 S PE No. 14)

size and type suitable for the fabric selected (see p. 57)

cotton/polyester

lowered (darning position)

No. 9

Basting stitch

•

for all work which requires a very long stitch

•

for basting seams, hems, quilts, etc.

•

easy to remove

Preparation:

•

pin work horizontally to basting direction to prevent the

layers slipping

Basting

•

lower the feed-dog

•

position work under the presser foot and sew one stitch;

hold threads when starting to sew

•

pull work from behind to the required length of the stitch

•

sew one stitch and repeat the procedure

Securing/fixing the thread

•

sew a few basting stitches at the beginning and end of a seam

Basting

•

use a fine darning thread for basting as it is easier to remove

Page 37

Selected practical stitches: Blind hem36

5

030529.52.04_0303_a135 a145_EN

Blind hem

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Sewing

•

the needle should just pierce

the edge of the fold (same as

hand sewing)

•

adjust the stitch width to suit

the fabric

•

after sewing about 10 cm

(4"), check both sides of

fabric and adjust width again

if necessary

Blind stitch No. 7

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Blind stitch foot No. 5

Blind hem

for «invisible» hems in medium to heavy cotton, wool

and blended fabrics

Preparation

•

neaten raw edges

•

prepare seam as for sewing by hand

•

place work under the presser foot (see drawing)

Wrong side of

fabric

Wrong side of

fabric

Right side of fabric

TIP

Fine stitch width adjustment

Guide the folded edge evenly

along the metal guide on the

foot = even depth

Page 38

Darning program

030529.52.04_0303_a135 a145_EN

37Selected practical stitches: Darning

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Darning Program No.14 (activa 135 S PE No. 13)

size and type suitable for the fabric selected (see p. 57)

darning thread

up (sewing position)

Reverse pattern foot No. 1

Buttonhole foot No. 3A

Quick darning of holes or worn areas

Replacement of damaged fibres/threads

Darning with Reverse pattern foot No. 1 (auto stitch counter)

•

insert needle in top left of damaged area

•

sew the first length and stop the sewing computer

•

press the securing button: length is programmed

•

complete the darn; the sewing computer stops automatically

Large areas:

•

the darning area can be extended by moving the work

under the foot

•

clear the programme by pressing the «clr/del»-button

Darning with Buttonhole foot with slide No. 3A

•

use for small tears and damaged areas, not more than

1

3 cm (1

•

use same method as with foot No. 1

/4”) long

TIP

Reinforcement

use fine fabric or interlining as

a backing

Preparation

stretch fabric into darning

ring* prevents puckering

*The darning ring is available as a

special accessory

Page 39

Selected practical stitches: Zippers38

030529.52.04_0303_a135 a145_EN

Zippers

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Needle position:

4

TIP

Straight stitch No. 1

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Zipper foot No. 4

far right or far left

Preparation:

•

baste in zipper

•

fabric edges should meet over the center of the zipper

Sewing

•

sew in the zipper, each side from bottom to top

•

once with needle position far right and once with

needle position far left

•

the edge of the foot runs along the teeth of the zip

•

the needle inserts close to the teeth

To sew around zipper pull

•

close zipper and sew up to

about 5 cm (2") away from

the pull

•

insert needle, raise the

Seam begin

hold thread firmly when

starting to sew = pull fabric

slightly to the back (fewer

stitches)

presser foot, open the zipper,

lower the foot and continue

to sew

Zipper or fabric is thick or

densely woven

use a 90–100 needle for even

stitch formation

Page 40

Everything you need to know about buttonholes

1

2

3

4

0

5

0

23451

5.5

030529.52.04_0303_a135 a145_EN

Thread tension

•

thread the bobbin thread through the finger of the bobbin case = the bobbin tension is

a little tighter

•

this gives the beads on the right side of the fabric a slightly rounded appearance

•

the buttonhole looks more attractive

· gimp reinforces buttonholes and enhances their appearance (pages 47, 48)

Buttonholes are not only

practical closures, they can

also be used to decorative

effect

Select the buttonhole of your

choice (No. 10 or 11);

the following appears on the

screen:

39Selected practical stitches: Buttonholes

1

3

1 Buttonhole number

2 Buttonhole symbol

3 Presser foot number

Mark the length of

automatic buttonholes

•

mark the length of just

one buttonhole

•

after sewing the first

2

buttonhole, the length for all

subsequent buttonholes is

automatically programmed

•

mark only the beginning of

all subsequent buttonholes

Mark the length of manual

buttonholes

•

mark the buttonhole length

in the appropriate position

•

stitch using buttonhole foot

No. 3 (optional accessory)

Mark the length of keyhole

buttonholes

•

mark the bead length only

•

the correct length eye will be

added when the buttonhole

is sewn

Page 41

Selected practical stitches: Buttonholes40

030529.52.04_0303_a135 a145_EN

Note:

When all buttonholes have

been sewn, return balance to

the normal setting!

Test sewing

•

always test sew on the fabric and stabilizer you intend to use

•

select the buttonhole type you intend to use

•

sew the buttonhole in the same direction on the fabric (with or

against the grain)

•

cut the buttonhole open

•

push the button through and adjust the buttonhole length if

necessary

Corrections

To adjust the bead width:

•

alter the stitch width

•

altered stitch widths can be deleted by pressing the «clr/del»button

Altering the stitch length:

•

any alterations to the stitch length affect both beads (denser or

less dense)

•

altered stitch length can be deleted by pressing the «clr/del»button

Balance for automatic/manual buttonholes

•

any balance alterations to the 6-step manual and auto length

buttonholes affects both beads identically because they are sewn

in the same direction

TIP

If a buttonhole is to be sewn at

right angles to a seam, we

recommend the use of the buttonhole leveler. Insert the plate

from behind between the

fabric and the foot up to and

over the thicker area.

Page 42

Automatic standard buttonhole with auto length

3A

030529.52.04_0303_a135 a145_EN

Both beads are sewn in the same direction.

Note:

The automatic buttonhole foot No. 3A must lie perfectly flat on

the fabric. If the foot lies on a seam, the length cannot be measured accurately.

41Selected practical stitches: Buttonholes

Feed-dog:

Presser foot:

Stitch:

Needle:

Thread:

Standard buttonhole No. 10

size and type suitable for fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Automatic buttonhole foot No. 3A

Automatic standard buttonhole

•

insert the lower thread in the finger of the bobbin case (p. 39)

•

when using Buttonhole foot No. 3A, the length of the buttonhole is automatically registered by the lens on the foot = exact

duplication and automatic sequence change when the maximum

length has been sewn

•

each step of the sewing sequence blinks on the screen

Note:

When any automatic buttonhole is selected,

presser foot No. 3 is indicated on the screen.

Page 43

Selected practical stitches: Buttonholes42

030529.52.04_0303_a135 a145_EN

1

Note:

When all buttonholes have

been sewn, return balance to

the normal setting!

Programme the standard buttonhole

1 sew the first bead forwards, stop the sewing computer

•

press the reverse button

•

«auto» and presser foot No. 3A are indicated on the screen =

the buttonhole length is programmed

2 the sewing computer sews reverse straight stitch automatically

3 the first bar tack

4 the second bead forwards

5 the second bar tack and securing stitches

5432

•

sewing computer stops and returns automatically to buttonhole

begin

Auto buttonhole

•

all subsequent buttonholes will be sewn to exactly the same

length (no need to press the reverse button)

•

press the «clr/del»-button to delete the programme

•

the programmed buttonhole can be saved in the long term

memory (see p. 49)

Corrections see p. 40

Balance

•

any changes to the balance affect both beads of auto length

buttonholes, because both beads are sewn in the same direction

TIP

Exact duplicates

the auto function ensures that

each buttonhole will be exactly

the same length as the previous one

Marking

mark only the beginning of the

buttonholes – a real time

saver!

Sewing speed

•

sew at moderate speed for

best results

•

sew all buttonholes at the

same speed for a consistent

bead density

Compensating plates for

buttonholes (special accessory)

If a buttonhole is to be sewn

horizontally to the edge of the

garment, it is worth using the

compensating plates.

This accessory provides an even

surface for the buttonhole foot

with slide which results in a perfect buttonhole (see tips p. 40).

Page 44

3A

Automatic keyhole buttonhole with auto length

030529.52.04_0303_a135 a145_EN

Both beads are sewn in the same direction.

43Selected practical stitches: Buttonholes

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Keyhole buttonhole No. 11

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Automatic buttonhole foot No. 3A

Automatic keyhole buttonhole

•

insert the lower thread in the finger of the bobbin case (p. 37)

•

when using Buttonhole foot No. 3A, the length of the buttonhole is automatically registered by the lens on the foot = exact

duplication and automatic sequence change when the maximum

length has been sewn

Marking the keyhole buttonhole

•

mark the bead length only. The correct eye length will be added

when the buttonhole is sewn.

•

each step of the sewing sequence blinks on the screen

Page 45

Selected practical stitches: Buttonholes44

030529.52.04_0303_a135 a145_EN

Programming the buttonhole

1 sew the straight stitch forward, stop the sewing

computer,

•

press the reverse button

•

auto and presser foot No. 3A are displayed on

1

the screen = buttonhole length is programmed

2 the sewing computer automatically sews the eye

3 the first bead in reverse

Exact duplicates

the auto function ensures

that each buttonhole will be

exactly the same length as

the previous one

TIP

4 sews second straight stitch

5 sews second bead in reverse

2

3

54

6

6 sews bartack and securing stitches

•

the sewing computer stops and returns automatically

to buttonhole begin

Marking

mark only the beginning of

the buttonholes – a real time

saver!

Note:

When all buttonholes have

been sewn, return balance to

the normal setting!

Auto buttonhole

•

all subsequent buttonholes will be sewn automatically

to the same length (without pressing the reverse button)

•

Press the «clr/del»-button to delete the programme

•

the programmed buttonhole can be saved in the long

term memory (see p. 49)

Corrections see p. 40

Balance

•

any changes to the balance affect both beads of auto

length buttonholes, because both beads are sewn in the

same direction

•

any distortions to keyhole buttonholes can be corrected

with balance

Double sewn keyhole

buttonholes

•

keyhole buttonholes can be

sewn twice on thick fabrics

•

after sewing the first buttonhole, do not move the work

•

simply tap the foot control

once to begin sewing again

Page 46

Manual buttonhole (all types)

030529.52.04_0303_a135 a145_EN

Manual buttonholes are particularly suitable for single buttonholes or for repairing

existing buttonholes.

Individual steps can be eliminated or repeated. The number of steps

corresponds to the buttonhole type. Manual buttonholes cannot be saved.

45Selected practical stitches: Buttonholes

Feed-dog:

Presser foot:

Stitch:

Needle:

Thread:

any buttonhole

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Buttonhole foot No. 3 (optional accessory)

Preparation

•

select the desired buttonhole

•

screen shows:

buttonhole number (10 or 11)

presser foot No. 3

the buttonhole symbol (the first step blinks on the

screen)

•

insert the lower thread in the finger of the bobbin

case

Always test sew buttonholes

•

test on the fabric and stabilizer you intend to use

•

sew buttonholes in the same grain direction

(with or against)

Note: Corrections see p. 40

Page 47

Selected practical stitches: Buttonholes46

030529.52.04_0303_a135 a145_EN

Sewing a manual standard buttonhole

Both beads are sewn in the same direction.

The individual steps blink on the screen.

1 sew the first bead forward, stop the sewing computer

•

press the reverse button

2 sew reverse straight stitch, stop the sewing computer at the first

1

2

stitch (buttonhole begin)

•

press the reverse button

3 sew the bartack and the second bead, stop the sewing computer

•

press the reverse button

4 sew the bartack and the securing stitches

3

4

Manual keyhole buttonhole

Sew both forward and reverse beads at the same speed.

The individual steps blink on the screen.

1 sew straight stitch forwards, stop the sewing computer, press the reverse button

2 sew the eye and the first bead in reverse, stop the sewing computer at the first

stitch (buttonhole begin), press the reverse button

21

3 sew straight stitch forwards and stop at the keyhole, press the quick

reverse button

4 sew the second bead in reverse, stop the sewing computer at the first stitch

(buttonhole begin), press the reverse button

345

5 sew bartack and securing stitches

Page 48

Buttonhole with gimp

3A

3A

030529.52.04_0303_a135 a145_EN

Gimp

•

gimp cord reinforces buttonholes and enhances their

appearance

•

the loop of the cord should

be at the end of the buttonhole most subject to wear

cord loop = where button is

sewn on

•

position the work accordingly

•

gimp cord is particularly

recommended for standard

and stretch buttonholes

Ideal cords

•

Perle yarn No. 8

•

strong hand sewing thread

•

fine crochet yarn

Hooking the cord in the buttonhole foot with slide No. 3A

•

insert the needle at the

beginning of the buttonhole

•

raise the presser foot

•

guide the cord under the foot

to the right

•

hook the cord over the pin at

the back of the foot

•

bring the cords to the front of

the foot

•

pull them into the slit

•

sew the buttonhole

Sewing

•

sew the buttonhole in the

usual manner

•

do not hold the cord tightly

•

the buttonhole will form over

the cord, covering it

47Selected practical stitches: Buttonholes

Hooking the cord onto presser

foot No. 3

•

insert the needle at the

beginning of the buttonhole

•

raise the presser foot

•

hook the cord over the centre

pin on the front of the foot

Page 49

Selected practical stitches: Buttonholes48

030529.52.04_0303_a135 a145_EN

•

place both ends of the cord

in the grooves on the sole of

the foot and pull them to the

back

•

lower the presser foot

Sewing

•

sew the buttonhole in the

usual manner

•

do not hold the cord tightly

•

the buttonhole will form over

the cord, covering it

Securing the cord

•

pull the cord through the

buttonhole

•

pull cords through to back of

fabric

•

knot or secure with stitches

Cutting buttonholes open

with the seam ripper

•

use the back of the seam

ripper to nick the stitches

•

cut from both ends towards

the middle

Buttonhole cutter and block

(special accessory)

•

place the fabric on the wood

•

place the cutter in the centre

of the buttonhole

•

press down on the cutter

with your hand or a hammer

Page 50

Programmed buttonholes

030529.52.04_0303_a135 a145_EN

Saving programmed buttonholes in long term memory

•

after programming press the «mem+»-button

•

the buttonhole is now saved in long term memory

Opening saved buttonholes

Programmed saved buttonholes can be opened for re-use even after the sewing computer

has been disconnected.

•

select the buttonhole

•

press the «mem»-button

•

sew the programmed buttonhole

•

only one of any style buttonhole can be saved, if a new length is saved

with «mem

+

», it overwrites the previously saved buttonhole

49Selected practical stitches: Buttonholes

Page 51

Selected practical stitches: Button sewing-on program50

030529.52.04_0303_a135 a145_EN

Button sewing-on program

Stitch:

Stitch width

Needle:

Thread:

Feed-dog:

Presser foot:

Button sewing-on program No. 13 (activa 135 S PE No. 12)

depends on distance between the holes

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

down (darning position)

Foot No. 9

Button sew-on foot No. 18 (optional accessory)

Sewing on buttons

•

sews buttons with 2 or 4 holes

•

buttons being sewn on for decorative purposes only

can be stitched without forming a thread shank

•

the length of the shank (= thread between button and fabric)

can be made shorter or longer as required with foot No.18

Sewing on buttons with foot No. 9

•

select Button Sew-on program

•

sew the securing stitches; hold the threads when starting to sew

•

check distances between holes with the handwheel and adjust

stitch width if necessary

•

sew

•

sewing computer stops automatically when program is

completed and is ready for the next button

Beginning and ending threads

•

the threads are secured and can be trimmed

For added security

•

after sewing on the button, pull the upper thread ends

through to the wrong side and knot

Page 52

Sewing on buttons with foot No.18

030529.52.04_0303_a135 a145_EN

•

set the shank length with the screw on the foot

•

select Button sewing-on program and continue as

with foot No. 9 (p. 50)

Beginning and ending threads

•

the threads are secured and can be trimmed

For added security

•

after sewing on the button, pull the upper thread ends

through to the wrong side and knot or

•

using the upper thread ends to sew a «shank» by hand

TIP

4-hole button

•

sew the front holes

•

carefully move the button

forward

•

sew the back holes

•

cut the diagonal joining

thread

51Selected practical stitches: Button sewing-on program

Page 53

Selected practical stitches: Overlock seams52

030529.52.04_0303_a135 a145_EN

Vari-overlock seam

Feed-dog:

Presser foot:

2

Stitch:

Needle:

Thread:

Vari-overlock No. 3

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Overlock foot No. 2 or

Reverse pattern foot No. 1

Overlock foot No. 2 is specially designed for overlock stitches.

The pin on the foot produces more thread in each stitch so that

the elasticity of the seam is maintained.

Closed seam

Stretchy seam in fine, soft knits such as silk jersey and interlock.

Sewing

•

guide the raw edge along the pin on the overlock foot

•

the stitch will form over the pin and over the edge of the fabric

TIP

Knits and jersey

use a new needle to prevent

damaging the loops

Sewing stretch fabrics

if necessary use a stretch

needle (130/705H-S) = needle

point slides between the fibers

Page 54

Double overlock seam

030529.52.04_0303_a135 a145_EN

53Selected practical stitches: Overlock seams

Feed-dog:

Presser foot:

2

Stitch:

Needle:

Thread:

Double overlock No. 8

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Overlock foot No. 2 or

Reverse pattern foot No. 1

Overlock foot No. 2 is specially designed for overlock stitches.

The pin on the foot produces more thread in each stitch so that

the elasticity of the seam is maintained.

Closed seam

overlock seam in loose knits and cross seams in knits and jerseys

Sewing

•

guide the raw edge along the pin on the overlock foot

•

the stitch will form over the pin and over the edge of the fabric

TIP

Knits and jersey

use a new needle to prevent

damaging the loops

Sewing stretch fabrics

if necessary use a stretch

needle (130/705H-S) = needle

point slides between the fibers

Page 55

Selected practical stitches: Overlock seams54

030529.52.04_0303_a135 a145_EN

Ribbing with overlock seam

Feed-dog:

Presser foot:

2

Stitch:

Needle:

Thread:

Vari-overlock No. 3

size and type suitable for the fabric selected (see p. 57)

cotton or polyester

up (sewing position)

Overlock foot No. 2 or

Reverse pattern foot No. 1

Overlock foot No. 2 is specially designed for overlock stitches.

The pin on the foot produces more thread in each stitch so that

the elasticity of the seam is maintained.

Ribbing with overlock seam

for all fine cotton, synthetic and mixed fiber jersey

Preparation

•

fold ribbing in half

•

pin and baste to opening, right side outside

Sewing

•

sew Vari-overlock over the raw edge

•

guide the edge along the pin on the foot

Back view

Front view

TIP

Needle stop down

needle stays in fabric when

you stop to adjust the ribbing

Page 56

Self-facing with Honeycomb stitch

030529.52.04_0303_a135 a145_EN

55Selected practical stitches: Honeycomb stitch

Stitch:

Needle:

Thread:

Feed-dog:

Presser foot:

Note:

After sewing return balance

to the normal setting!

Honeycomb No. 19 (activa 135 S PE No. 15)

universal, ballpoint or stretch as needed

cotton or polyester

up (sewing position)

Presser foot: Reverse pattern foot No.1

Ribbing with visible seam

for all cotton, wool, synthetic and mixed fiber jersey

Preparation

press 1 cm (3/8") to wrong side

Sewing

•

sew from the right at a foot's width from the edge

•

trim surplus fabric (wrong side)

Balance/corrections

bring stitch together

open out stitch

TIP

Needle stop down

needle stays in fabric when

you stop to adjust the ribbing

Page 57

Needles, Threads56

030529.52.04_0303_a135 a145_EN

Important facts about sewing computer needles

Sewing computer, needle and thread

Your BERNINA uses needle system 130/705H.

Needle and thread

The most commonly sold needles are nos. 70 –120.

The finer the needle, the lower the number. The table

shows which needle is suitable for which threads.

Needle appropriate

for thread

When sewing, the thread

runs in the long groove on

the needle.

Needle inappropriate

for thread

If the needle is too fine, the

groove will be too narrow for

the thread and faulty stitching

or thread breakage can occur.

Needle and fabric

Condition of needle

The needle must be in perfect

condition. Problems can occur

with damaged needles.

Needle 70 80 90 100 110–120

Darning thread

Embroidery thread

Mercerised

cotton thread

Synthetic thread

Thick threads,

synthetic mercerised

thread

Buttonhole thread

for decorative

seams (cordonnet)

••

•

••

••

••

••

bent needle

blunt needle

hooked needle

Page 58

Special materials are easier to sew if the appropriate needle is used.

030529.52.04_0303_a135 a145_EN

Special needles are available at your BERNINA dealer.

57Needles

Needle table

Standard

needle

Special

needles

Double needle

Triple needle

Description

130/705 H

130/705-SES

130/705 H-SUK

130/705 H-S

130/705 H-J

130/705

H-LR + H-LL

130/705 H

ZWI

130/705 H

DRI

Needle point

Normal point,

slightly

rounded

Fine ball point

Medium ball

point

Medium ball

point

Extra fine point

Cutting point

Widths:

1,6 / 2,0 / 2,5

3,0 / 4,0

Widths:

2,5 / 3,0

Suitable for

Universal needle for woven, needle synthetic and

natural fibers, e.g. linen, chiffon, batiste, organdie,

wool, satin, decorative stitching, embroidery

Fine knits, especially for synthetic fibers

Heavier knits in synthetic or natural fibers

Special needle for delicate or difficult stretch fabrics

Overalls, heavy linen, denim, canvas.

Pierces dense fabrics easily

Natural and synthetic leather, plastic, coated

and waxed fabric

Visible hems in stretch fabrics, pintucks,

decorative sewing

Decorative sewing

Hemstitch

needle

130/705 H

HO

Width:

2,0

Hemstitch in loose weaves

Page 59

Needle, thread, fabric feed58

030529.52.04_0303_a135 a145_EN

Feed-dog and fabric feed

Feed-dog and stitch length

With each stitch the feed-dog moves forward by one step.

The length of this step is determined by the stitch length selected.

With an extremely short stitch length, the steps are also short.

The fabric moves under the foot quite slowly, even at full sewing

speed. Buttonholes, satin stitch and decorative stitches are all

sewn with a very short stitch length.

Important

Let the fabric feed evenly! Holding back will result in

Pulling or pushing will result in

gaps.

knots.

Page 60

Feed-dog and fabric feed with compensating plates

1

030529.52.04_0303_a135 a145_EN

59Needle, thread, fabric feed

1

The feed-dog can work

normally when the foot is level.

Thick fabrics: feed-dog and sewing corners

If the foot is at an angle, e.g.

when sewing over thick to thin

or vice-versa, the feed-dog

cannot grip and feed the fabric

and the fabric hangs up.

The gap between the two rows

of teeth is relatively large due

to the width of the stitch plate

hole.

When sewing corners only a

small section of the fabric is

actually on the feed-dog so

that it cannot grip the fabric

well.

Uneven layers

To solve this problem, place

one, two or three compensating plates as required behind

the needle under the presser

foot.

To correct the height in front of

the foot, place one or more

plates to the right of the foot

close to the needle. Sew until the

foot is level again and remove

the plates.

Correct this by placing one

or more compensating

plates as close as possible

to the edge of the fabric.

Page 61

Cleaning and maintenance60

030529.52.04_0303_a135 a145_EN

Cleaning

If the sewing computer is stored in a cold room, it should be brought to a

warm room about one hour before use.

Cleaning

Clean the sewing computer after every use

•

turn power switch to «0»

•

remove presser foot and needle

•

open the free-arm cover

•

unscrew the stitch plate (with screwdriver

TORX)

•

lift and remove it

•

clean the area with the brush

•

replace the stitch plate

Cleaning the hook

•

turn power switch to «0»

•

remove the bobbin case

•

push the release lever to the left

•

push the locking lever to the left and fold

down the hook race cover

•

remove the hook

•

clean the hook race with a cloth or brush,

never use a sharp instrument

•

replace the hook, turning the handwheel if

necessary so that the hook driver is on the left

•

close the hook race cover and secure with the

locking lever, the locking pin must engage

•

check by turning the handwheel

•

insert the bobbin case

Cleaning the screen and the sewing computer

•

wipe with a damp cloth

CAUTION

Disconnect plug

from the socket

before cleaning

and servicing

Lubricating

•

squeeze 2–3 drops of oil into the hook race

•

run the machine for a short time without

thread to prevent oil soiling your work

Important!

Never use alcohol, petrol, white spirit or any

type of solvent to clean the sewing computer!

Refer to the safety instruction!

Page 62

Sewing light

030529.52.04_0303_a135 a145_EN

Replacing the bulb

•

turn power switch to «0»

•

loosen the screw

•

remove the cover by lifting it

slightliy and detaching from

the top

Replacing the Sewing Light**

•

remove the bulb

•

insert the new bulb

•

replace cover and tighten

screw

61Cleaning and maintenance

CAUTION

Disconnect plug

from the socket

before cleaning

and servicing

Note:

Use bulb type

12 V 5 W.

W 2.1 x 9.5 d.

Light bulbs get hot.

Allow to cool down before

removal.

Refer to the safety

instruction!

Please refer to the safety instructions!

Contrary to an ordinary bulb,

the CFL sewing light has

a better illumination and a

longer life.

Caution:

Please note that a defective

CFL sewing light must ONLY

be replaced by an authorized

technician. The sewing computer must be brought to an

authorized BERNINA dealer!

** Available as a special accessory

Page 63

Faults62

030529.52.04_0303_a135 a145_EN

Trouble shooting

In most cases you will be able to identify and remedy faults

by checking the following.

Check whether:

•

the upper and lower threads are threaded correctly

•

the needle is inserted correctly

•

the needle size is correct – check the needle/thread table p. 57

•

the sewing computer is clean – brush out any thread fluff

•

the hook race is clean

•

any threads are trapped between the tension discs or under the

bobbin case spring

•

the bobbin runs smoothly in the case or if remnants or lint need

removing

Upper thread breaks

•

The upper thread tension

is too tight.

•

The needles are of a poor

quality. Ideally needles should

be purchased from your

BERNINA dealer.

•

The needle is bent or blunt.

•

Poor quality, knotted or dried

out thread has been used.

•

Use the correct spool disc.

•

Stitch plate or hook tip

Lower thread breaks

•

The lower thread tension is

too tight.

•

The bobbin is jamming in

the bobbin case. Remove and

replace the bobbin.

•

The hole in the stitch plate

has been damaged by the

needle. This must be

repolished by an expert.

•

The needle is blunt or bent.

damaged. Take your sewing

computer to your BERNINA

dealer.

Skipped stitches

•

Wrong needles used.

Use only 130/705H system.

•

The needle is blunt, bent or

incorrectly inserted.

•

Push right to the top when

inserting.

•

Needle inserted all the way

to the top.

•

The needle point does not

suit the fabric being sewn.

If necessary use a ball point

for knitted fabrics and

cutting point for hard leather.

Needle breaks

•

Needle clamp screw loose.

•

Fabric taken out in front

instead of behind presser foot.

•

When sewing over thick area,

the fabric was pushed with

the needle still in the fabric.

•

Poor quality thread, unevenly

wound or knotted.

•

See pages 56 and 57 for

information about needles

Faulty stitching

•

Remnants of thread between

the tension discs.

•

Remnants of thread under

the bobbin case spring.

•

Lower thread still threaded in

the bobbin case finger.

•

Sewing computer threaded

with foot down.

•

Incorrect threading. Check

upper and lower threads.

•

Use the correct spool disc.

Sewing computer fails to run

or runs slowly

•

Plug not properly inserted.

•

Power switch in off position.

•

Sewing computer has been

standing in a cold room.

•

Bobbin winder still switched

on.

Page 64

Index

030529.52.04_0303_a135 a145_EN

63

A

Accessory box 8, 9

B

Balance 29, 49, 55

Basting stitch 35

Blanket stitch A3

Blind hem 36

Bobbin 12

Bobbin case 13

Bobbin thread cutter 13

Bringing up the lower thread 18

Button sewing-on program 50

Buttonholes 39–49

•

Altering buttonholes 49

•

Automatic keyhole buttonhole 43

•

Automatic standard buttonhole 41

•

Buttonhole with gimp 47

•

Manual buttonhole 45

•

Programmed buttonholes 49

C

Changing the needle 14

Changing the presser foot 15

CFL 8, 61

Cleaning 60

Compensating plates 59

D

Darning program 37

Details of the sewing computer 4–7

Double blanket stitch A3

Double overlock seam 53

F

Fabric cover 8

Fabric feed, Needles, Threads 56–59

Feather stitch A6

Feed-dog 18, 58

Foot control 10

Functions 23

•

#-button 24

•

1/2 speed 23

•

clr/del (clear/delete) 24

•

Letters 24

•

mem (Memory) 24

•

Mirror image 23

•

Needle stop 23

•

Reverse sewing 23

•

Stitch end 23

H

Handlook quilt stitch A5

Honeycomb stitch 55

I

Inserting the bobbin 14

K

Keyhole buttonhole 43

Knits and jersey 52, 53

L

Letters programming 27

Lower thread 18

Lens Set 8

M

Maintenance 60, 61

Memory 25

•

Balance 29

•

Corrections in Memory 27

•

Leave Memory 28

•

Memory buttons 25

•

Open Memory 25

Page 65

Index64

030529.52.04_0303_a135 a145_EN

•

Programming letters, numbers and

punctuation marks 27

•

Programming practical and decorative

stitches 26

•

Scroll backwards/forwards 26

•

Stitches 30, 31, 32

N

Needle position 22

Needles, Threads, Fabric feed 56–59

Needle Threader 17

O

Overlock seam 54

P

Power cable 10

Presser feet 33

Presser foot lifter 11

Q

Quilters securing program A2

Quilt stitch (Handlook quilt stitch) A5

R

Ribbing with overlock seam 54

Reverse sewing 23

S

Screen shows 21

Seam guide 11

Securing program 34

Self-facing with Honeycomb stitch 55

Sewing light 61, 8

Sewing table 11

Single blanket stitch A3

Spool pin 15

Standard accessories 8

Standard buttonhole 41