Bently Nevada 3500/22M Data sheet

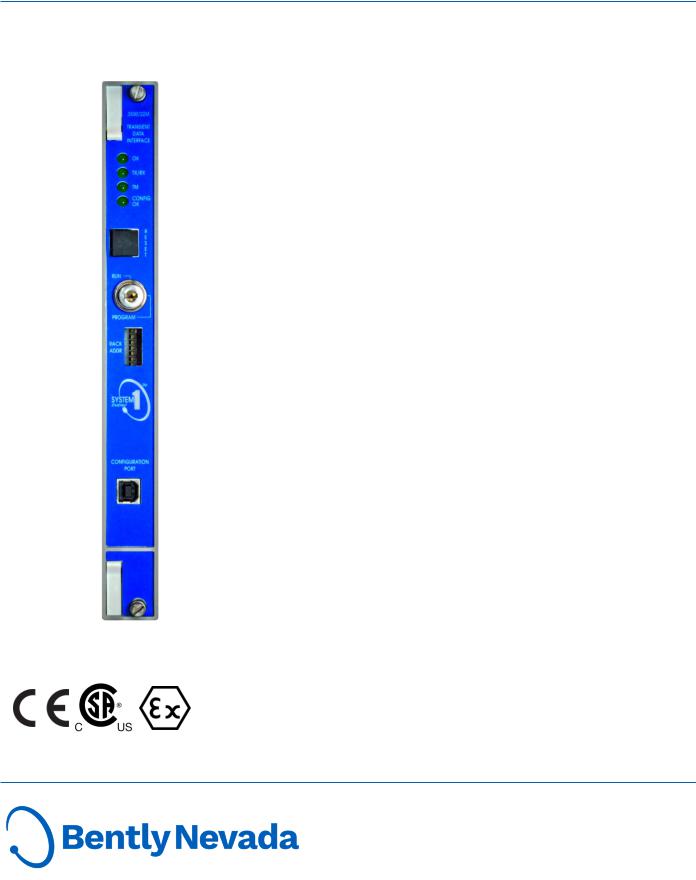

3500/22M Transient Data Interface Module

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

The 3500/22M Transient Data Interface (TDI) is the interface between the 3500 monitoring system and compatible software (System 1 Condition Monitoring and Diagnostic software and 3500 System Configuration software). The TDI combines the function of a 3500/20 Rack Interface Module (RIM) with the data collection capability of a communication processor such as TDXnet.

The TDI resides in the slot adjacent to the power supplies of a 3500 rack. It interfaces with M series monitors (3500/40M, 3500/42M, etc.) to continuously collect steady state and transient dynamic (waveform) data and pass this data through an Ethernet link to the host software. Refer to the Compatibility section at the end of this document for more information.

Static data capture capability is standard with the TDI. However, using an optional Channel Enabling Disk will allow the TDI to capture dynamic and high-resolution transient data as well. The TDI incorporates the communication processor function within the 3500 rack.

Although the TDI provides certain functions common to the entire rack, it is not part of the critical monitoring path and has no effect on the proper, normal operation of the overall monitor system for automatic machinery protection. Every 3500 rack requires one TDI or RIM, which always occupies Slot 1 (next to the power supplies).

Document: 161581

Rev. T

3500/22M Transient Data Interface Module

Datasheet

Specifications

Inputs

|

|

Power |

|

Consumption |

|

10.5 Watts |

|

|

|

Data |

|

Front Panel |

|

USB-B |

|

10Base-T/ |

|

10Base-T or 100Base-TX |

|

100Base-TX I/O |

Ethernet, autosensing |

||

100Base-FX I/O |

100Base-FX Fiber-Optic |

||

Ethernet |

|||

|

|

||

Outputs |

|

|

|

|

|

||

|

Front Panel LEDs |

||

OK LED |

Indicates when the 3500/22M is |

||

operating properly |

|||

|

|||

TX/RX LED |

Indicates when the 3500/22M is |

||

communicating with the other |

|||

|

modules in the rack |

||

TM LED |

Indicates when the 3500 rack is in |

||

Trip Multiply mode |

|||

|

|||

CONFIG OK |

Indicates that the 3500 rack has a |

||

LED |

valid configuration |

||

I/O Module OK Relay

Indicates when the 3500 rack is operating normally or when a fault has been detected within

Function

the rack. User can select either an “OPEN” or “CLOSED” contact to annunciate a NOT OK condition. This relay always operates as “Normally Energized”.

Standard OK Relay is rated to 5A @ 24 Vdc/120 Vac, 120 Watts/600 VA Switched Power

Ratings (maximum)

OK Relay with gold-plated contacts is rated down to 1 mA @ 1 Vdc (minimum)

Arc

Arc suppressors are provided.

Protection

Controls

|

Front Panel |

Rack reset |

Clears latched alarms and Timed |

OK Channel Defeat in the rack. |

|

button |

Performs same function as “Rack |

|

Reset” contact on I/O module |

Address |

Used to set the rack address: |

switch |

127 possible addresses |

Used to place 3500 rack in either “RUN” mode or “PROGRAM” mode. RUN mode allows for normal operation of the rack and locks out configuration changes. PROGRAM mode allows for normal operation of the rack and also allows for local or

Configuration remote rack configuration. The key can be removed from the

Keylock

rack in either position, allowing the switch to remain in either the RUN or PROGRAM position. Locking the switch in the RUN position allows you to restrict unauthorized rack reconfiguration. Locking the switch in PROGRAM position allows remote reconfiguration of a rack at any time.

2/10 |

161581 Rev. T |

3500/22M Transient Data Interface Module

Datasheet

I/O Module System Contacts |

• Supports multiple events per revolution |

speed inputs up to 20 kHz |

|

|

|

Trip Multiply |

Startup/Coastdown Data |

|

Description |

Used to place 3500 rack in Trip |

Multiply |

|

Maximum |

<1 mAdc, Dry Contact to |

Current |

Common |

|

Alarm Inhibit |

Description |

Used to inhibit all alarms in the |

3500 rack |

|

Maximum |

<1 mAdc, Dry Contact to |

Current |

Common |

|

Rack Reset |

Description |

Used to clear latched alarms and |

Timed OK Channel Defeat |

|

Maximum |

<1 mAdc, Dry Contact to |

Current |

Common |

I/O Module Signal Common Terminal

Both versions of the TDI I/O Module now include a 2-pin connector for connecting Signal Common to a single point Instrument Ground for the rack. When this is done, the selector switch on the side of the Power Input Module (PIM) must be slid in the direction of the arrow marked "HP" to isolate Signal Common from chassis (safety) ground.

•Data collected at selected increments of speed and time

•Increasing and decreasing speed intervals are independently programmable

•Initiation of transient data collection based on detecting the machine speed within one of two programmable windows

•The number of transient events that can be collected is only limited by the available memory in the module

Alarm Data Collection

•Preand post-alarm data

•Static values collected at one second intervals for 10 minutes before the event and 1 minute after the event

•Static values collected at 100 ms intervals for 20 seconds before the event and 10 seconds after the event

•2.5 minutes of waveform data collected at

10-second intervals before the alarm and

1 minute of waveform data collected at

10-second intervals after the alarm

Static Values Data

Data Collection

Keyphasor Inputs

•Supports the four 3500 system Keyphasor signals. The speed range support is based on the number of dynamic channels enabled:

Number of |

Minimum |

Maximum |

Channels |

Speed |

Speed |

1 to 16 |

1 rpm |

100,000 rpm |

17 to 24 |

1 rpm |

60,000 rpm |

25 to 48 |

1 rpm |

30,000 rpm |

•TDI will collect the static values including the values measured by the monitors.

•TDI provides four nX static values for each point. Amplitude and phase are returned for each of the values.

Waveform Sampling

•Collection of waveforms for 48 channels.

•DC-coupled waveforms

•Simultaneous Synchronous and Asynchronous data sampled during all operational modes

•User-configurable Synchronous waveform sampling rates:

3/10 |

161581 Rev. T |

Loading...

Loading...