Bently Nevada 3300 XL NSv Specifications

3300 XL NSv Proximity Transducer System

Datasheet

BentlyNevadaMachineryCondition Monitoring |

147385Rev. K |

Description

The3300XL NSvProximity Transducer system is intended for usewith centrifugalair compressors, refrigeration compressors, process gas compressors and other machines with tight installation requirements. The3300XL NSvProximity Transducer System consists of:

•a 3300NSvprobe

•a 3300NSvextension cable

•a 3300XL NSvProximitor Sensor(1)

Theprimary uses for the3300XL NSvTransducer System are for areas wherecounter bore, sideview or rearview restrictions limit theuseofstandard Bently Nevada 3300and 3300XL 5 and 8mm Transducer Systems. It is also idealfor smalltarget applications, such as measuring radialvibration on shafts smaller than 51mm (2 in) or axialposition on flat targets smaller than 15mm (0.6in). It is primarily used in the following applications on fluid-filmed bearing machines wherea smallshaft or reduced side-view is present:

•Radialvibration and radialposition measurements

•Axial(thrust) position measurements

•Tachometer and zero speed measurements

•Phasereference(Keyphasor signals)

The3300XL NSvTransducer System design allows it to replace both the3300RAMTransducer Systems and the3000-series or 7000-series 190Transducer System. Upgrades from the 3300RAMsystem to the3300XL NSvsystem may usethe existing probe, extension cable, and monitoring system with 3300XL NSvProximitor Sensor. Upgrades from the3000-series or 7000-series Transducer System must replacetheprobe, extension cableand Proximitor Sensor with NSvcomponents.

3300XL NSv Proximity TransducerSystem |

|

Datasheet |

147385Rev. K |

The3300XL NSvTransducer System has an AverageScaleFactor of7.87V/mm (200 mV/mil), which is themost common output for eddy current transducers. Its enhanced sideview and smalltarget characteristics giveit a shorter linear rangethan theBently Nevada 3300XL-series 5and 8mm Transducer System. With The1.5mm (60mils) oflinear range exceeds thelinear rangeofthe3000-series 190 Transducer System.

Although theterminals and connector on theProximitor Sensor have protection against electrostatic discharge, takereasonableprecautions to avoid electrostatic dischargeduring handling.

Proximitor Sensor

The3300XL NSvProximitor Sensor has similar features to thosefound in the3300XL 8mm Proximitor Sensor. Its thin design allows the user to mount it in either a high-density DIN-rail installation or a moretraditionalpanelmount configuration. Improved RFI/EMIimmunity allows the3300XL NSvProximitor Sensor to achieveEuropean CE mark approvals without any specialmounting considerations. This RFI immunity also prevents nearby high frequency radio signals from adversely affecting the transducer system. SpringLoc terminalstrips on theProximitor Sensor requireno special installation tools and facilitatefaster, highly robust field wiring connections.

Proximity Probe and Extension Cable

The3300NSvprobeand extension cableare mechanically and electrically compatibleand interchangeablewith Bently Nevada’s previous 3300RAMproximity probeand extension cable. TheNSvprobehas increased chemical resistancecompared to the3300RAMprobe, which allows its usein many process compressor applications. Theside-view characteristics ofthe3300NSvprobearealso superior to thoseofthe3000-series 190probe when gapping the3300NSvprobeat thesame distancefrom theprobetarget.

The3300NSvprobecomes in varying probe caseconfigurations, including armored and unarmored ¼ -28, 3⁄8-24, M8X1and M10X1 probethreads. Thereversemount 3300NSv probecomes standard with either 3⁄8-24or M10X1threads. Allcomponents ofthe transducer system havegold-plated brass ClickLocconnectors. ClickLoc connectors lock into placeand prevent theconnection from loosening. Thepatented TipLocmolding method provides a robust bond between the probetip and theprobebody. Bently Nevada’s patented CableLocdesign provides 220N(50 lb) ofpullstrength and securely attaches the probecableto theprobetip. Connector protectors arerecommended for useon the probe-to-extension cableconnection, as well as on thecable-to-Proximitor Sensor connection. Connector protectors prevent most liquids from entering into theClickLoc connectors and adversely affecting the electricalsignal(2).

Notes:

(1)ProximitorSensors aresupplied by default from thefactory calibrated to AISI4140steel. Calibration to other target materials is available upon request.

(2)Siliconetapeis also provided with each 3300NSvextension cableand can beused instead ofconnector protectors. Siliconetape is not recommended in applications wherethe probe-to-extension cableconnection willbe exposed to turbineoil.

2/30

3300XL NSv Proximity TransducerSystem |

|

|

|

Datasheet |

|

147385Rev. K |

|

|

|

|

|

|

|

(1,000 feet)between the3300 XL |

|

Specifications |

|

NSv ProximitorSensorand the |

|

|

monitor. Seethefrequency |

||

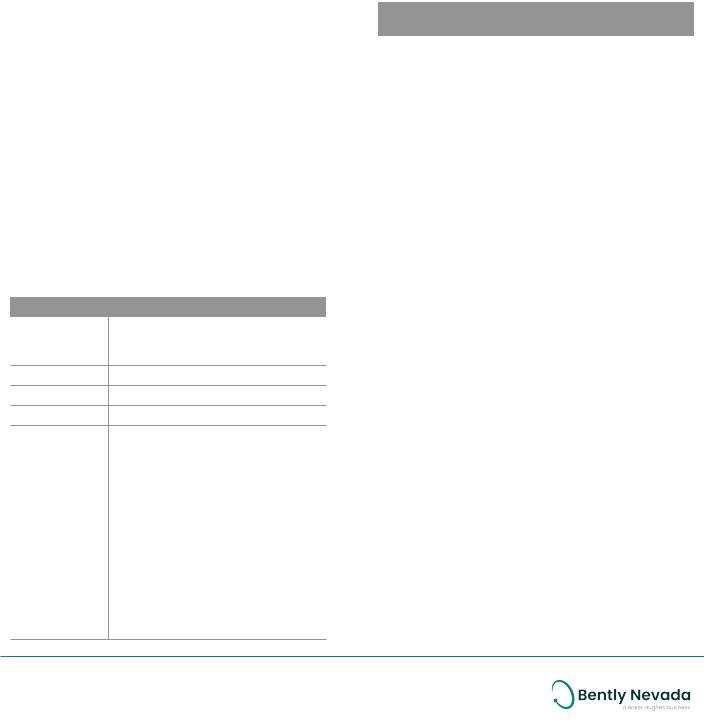

Unless otherwisenoted, thefollowing |

|

responsegraphs Figure16 and |

|

|

Figure17 forsignal rolloff at high |

||

specifications arefor a 3300XL NSvProximitor |

|

frequencies when using longerfield |

|

Sensor, extension cableand probebetween 0°C |

|

wiring lengths. |

|

and +45°C(+32°F to +113°F), with a -24Vdc |

|

1.5 mm (60 mils). Linearrange |

|

power supply, a 10kΩload, a Bently Nevada |

|

begins at approximately 0.25 mm |

|

supplied AISI4140steeltarget that is 31mm (1.2 |

LinearRange |

(10 mils)from target and is from |

|

in) diameter or larger, and a probegap of1.0 |

|

0.25 to 1.75 mm (10 to 70 mils) |

|

mm (40mils). Thesystem accuracy and |

|

(approximately -1 to -13 Vdc). |

|

interchangeability specifications do not apply |

Recommended |

1.0 mm (40 mils) |

|

when using a transducer system calibrated to |

Gap Setting |

|

|

any target other than a Bently Nevada AISI4140 |

System performance over ambient temperature |

||

steeltarget. |

range (0°C to 45°C) |

||

Electrical

Proximitor |

Accepts onenon-contacting 3300 |

|

RAM or3300 NSv Proximity Probe |

||

SensorInput |

||

and Extension Cable. |

||

|

||

|

Requires -17.5 Vdc to -26 Vdc |

|

|

without barriers at 12 mA maximum |

|

Power |

consumption, -23 Vdc to -26 Vdc |

|

with barriers. Operation at a more |

||

|

positivevoltagethan -23.5 Vdc can |

|

|

result in reduced linearrange. |

|

Supply |

Less than 2 mV changein output |

|

voltagepervolt changein input |

||

Sensitivity |

||

voltage. |

||

|

||

Output |

50 Ω |

|

resistance |

||

|

||

Probe dc Resistance |

||

ProbeLength |

Resistancefrom theCenter |

Conductorto theOuterConductor |

|

(m) |

(RPROBE)(ohms) |

|

0.54.0 ± 0.5

1.04.2 ± 0.5

5.05.3 ± 0.7

7.05.9 ± 0.9

Extension |

Centerconductor: 0.220 Ω/m |

|

(0.067 Ω/ft) |

||

cabledc |

||

resistance |

Shield:0.066 Ω/m (0.020 Ω/ft) |

|

|

||

Extension |

69.9 pF/m (21.3 pF/ft)typical |

|

cable |

||

capacitance |

|

|

|

2 |

|

|

0.2 to 1.5 mm (16 to 24 AWG) [0.25 |

|

|

2 |

|

|

to 0.75 mm (18 to 23 AWG)with |

|

Field Wiring |

ferrules]. Recommend using three- |

|

|

conductorshielded triad cable. |

|

|

Maximum length of 305 metres |

Incremental |

7.87 V/mm (200 mV/mil)+12.5%/- |

|

20% including interchangeability |

||

ScaleFactor |

errorwhen measured in increments |

|

(ISF) |

of 0.25 mm (10 mils)overthe1.5 |

|

|

mm (60 mil)linearrange. |

|

Deviation from |

Less than ±0.06 mm (±2.3 mils). |

|

best fit straight |

||

line(DSL) |

|

|

Frequency |

0 to 10 kHz: +0, -3 dB typical, with up |

|

to 305 metres (1000 feet)of field |

||

Response |

||

wiring. |

||

|

||

|

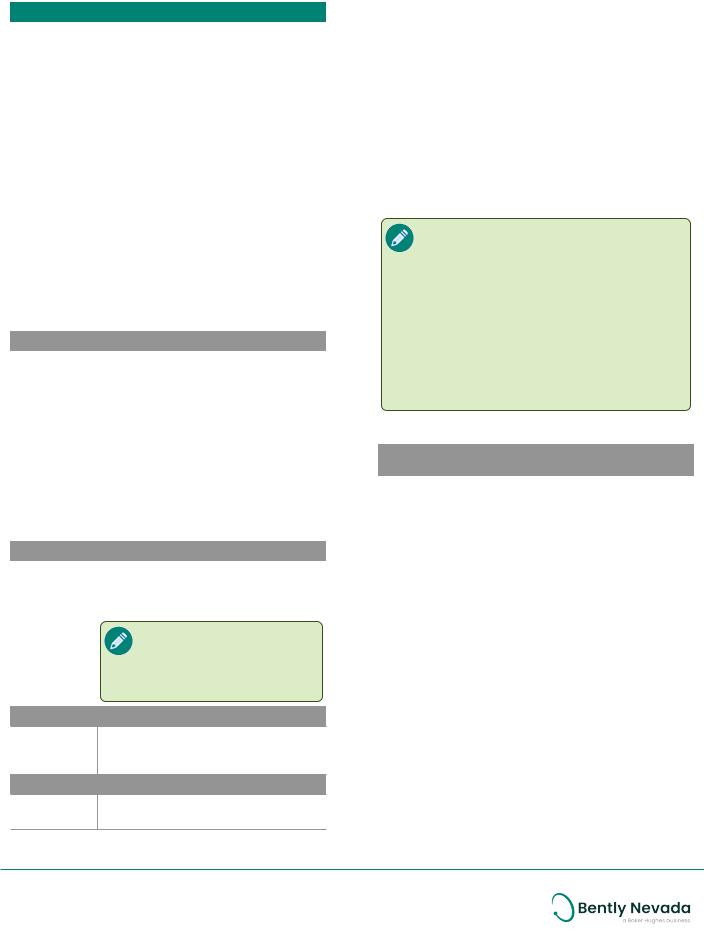

Minimum: 8.9 mm (0.35 in) |

|

|

diameter |

|

|

Recommended minimum: 13 mm |

|

|

(0.5 in)diameter |

|

Target Size(flat |

Axial position measurements on |

|

target) |

shaft diameters smallerthan 13mm |

|

|

(0.5 in)will generally result in a |

|

|

changein scalefactor. Reducing |

|

|

thegap between theprobeand |

|

|

target will help limit thechangein |

|

|

scalefactor. SeeFigure12 for |

|

|

additional information. |

|

|

Minimum (standard X-Y probe |

|

|

configuration): 30 mm (1.2 in) |

|

|

Minimum (X-Y proximity probes |

|

|

offset axially by 23 mm (0.9 in)): 20 |

|

|

mm (0.8 in) |

|

Shaft Diameter |

Measurements on shaft diameters |

|

|

smallerthan 30 mm (1.2 in)usually |

|

|

requireclosespacing of radial |

|

|

vibration oraxial position |

|

|

transducers. This creates the |

|

|

potential fortheirelectromagnetic |

|

|

emitted fields to interact with one |

|

|

|

3/30

|

3300XL NSv Proximity TransducerSystem |

|

|

|

|

|

|

|

|

||||||

|

Datasheet |

|

|

|

|

|

|

|

|

|

|

147385Rev. K |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

another(cross-talk), resulting in |

|

Extension |

75 Ωcoaxial, fluoroethylene |

|||||||

|

|

|

|

|

erroneous readings. To prevent |

|

Cable |

||||||||

|

|

|

|

|

|

propylene(FEP)insulated. |

|||||||||

|

|

|

|

|

cross-talk, maintain minimum |

|

Material |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

separation of m transducertips of |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Proximitor |

|

|

|

|

|

||||

|

|

|

|

|

at least 25 mm (1.0 in)foraxial |

|

|

|

|

|

|

||||

|

|

|

|

|

|

Sensor |

A380 aluminum |

|

|

|

|||||

|

|

|

|

|

position measurements or23 mm |

|

|

|

|

||||||

|

|

|

|

|

|

Material |

|

|

|

|

|

||||

|

|

|

|

|

(0.9 in)forradial vibration |

|

|

|

|

|

|

||||

|

|

|

|

|

|

System |

5 or7 metres including extension |

||||||||

|

|

|

|

|

measurements. ProbeCross-talk |

|

|||||||||

|

|

|

|

|

with Probes Mounted in Parallel and |

|

Length |

cable |

|

|

|

||||

|

|

|

|

|

ProbeCross-talk with Probes |

|

Extension |

FlexibleAISI 302 SSTwith/without FEP |

|||||||

|

|

|

|

|

Mounted in X-Y Configuration |

|

CableArmor |

||||||||

|

|

|

|

|

Radial vibration orradial position |

|

(optional) |

outerjacket. |

|

|

|

||||

|

|

|

|

|

measurements on shaft diameters |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

220 N(50 lb)probecaseto probe |

||||||||

|

|

|

|

|

smallerthan 20 mm (0.8 in)will |

|

Tensile |

||||||||

|

|

|

|

|

|

lead. 220 N(50 lb)at probelead to |

|||||||||

|

|

|

|

|

generally result in greaterthan a |

|

Strength |

||||||||

|

|

|

|

|

|

extension cableconnectors. 220 N |

|||||||||

|

|

|

|

|

10% changein AverageScaleFactor |

|

(maximum |

||||||||

|

|

|

|

|

|

(50 lb)probecaseto stainless steel |

|||||||||

|

|

|

|

|

(ASF). SeeFigure13 foradditional |

|

rated) |

||||||||

|

|

|

|

|

|

armor. |

|

|

|

||||||

|

|

|

|

|

information. |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Connector |

|

|

|

|

|

|

|

|

|

|

Minimum: 9.5 mm (0.375 in) |

Gold-plated brass |

|

|

|

||||||

|

|

|

|

|

|

material |

|

|

|

||||||

|

|

|

|

|

Recommended minimum: 13 mm |

|

|

|

|

|

|

||||

|

|

|

|

|

|

Recommended |

|

case hole and tap size for 1/4-28 |

|

||||||

|

|

|

|

|

(0.5 in) |

|

|

|

|

case |

|

|

|

|

|

|

|

|

|

|

Counterbores smallerthan 13 mm |

|

Drill Size |

0.213 in |

|

|

|

||||

|

|

Counterbore |

|

|

(0.5 in)generally result in a change |

|

HoleSize |

0.218 to 0.222 in |

|

|

|

||||

|

|

|

|

in scalefactorat fargaps. |

|

|

|

|

|

|

|

||||

|

|

|

|

|

HoleDepth |

0.376 to 0.750 in |

|

|

|

||||||

|

|

|

|

|

Reducing thegap between the |

|

|

|

|

||||||

|

|

|

|

|

|

Tap Drill Size |

#3 |

|

|

|

|||||

|

|

|

|

|

probeand thetarget will allow the |

|

|

|

|

||||||

|

|

|

|

|

transducersystem to maintain its |

|

Recommended |

|

case hole and tap size for M8x1 |

|

|||||

|

|

|

|

|

AverageScaleFactor(ASF)overa |

|

case |

|

|

|

|

|

|||

|

|

|

|

|

reduced linearrange. SeeFigure9 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Drill Size |

7.4mm |

|

|

|

|||||

|

|

|

|

|

foradditional information. |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

HoleSize |

7.511 to 7.622 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Effects of 60 Hz Magnetic Fields Up to 300 Gauss |

|

|

|

|

|

|

|

||||||

|

|

|

HoleDepth |

12 to 24 mm |

|

|

|

||||||||

|

|

|

|

|

(5 metre system) |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Tap Drill Size |

L |

|

|

|

||||

|

|

Output voltagein mil pp/gauss |

|

|

|

|

|

||||||||

|

|

|

|

Recommended case hole and tap size for 3/8-24 |

|||||||||||

|

|

Gap |

Proximitor |

Probe |

|

Ext. Cable |

|

case |

|

|

|

|

|

||

|

|

|

Sensor |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Drill Size |

0.332 in |

|

|

|

||||

|

|

0.25 mm |

0.006 |

0.001 |

|

0.001 |

|

|

|

|

|||||

|

|

|

|

HoleSize |

0.338 to 0.343 in |

|

|

|

|||||||

|

|

(10 mils) |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

HoleDepth |

0.562 to 0.xxx1.125 in |

|

|||

|

|

1.0 mm (40 |

0.007 |

0.002 |

|

0.001 |

|||||||||

|

|

|

|

Tap Drill Size |

Q |

|

|

|

|||||||

|

|

mils) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

1.75 mm (70 |

|

|

|

|

|

|

|

|

|

||||

|

|

0.008 |

0.002 |

|

0.003 |

|

Recommended |

|

case hole and tap size for M10x1 |

|

|||||

|

|

mils) |

|

|

|

|

|

|

|

case |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mechanical |

|

|

|

|

Drill Size |

9.4mm |

|

|

|

||||

|

|

|

|

|

|

HoleSize |

9.541 to 9.662 mm |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

ProbeTip |

|

Polyphenylenesulfide(PPS). |

|

HoleDepth |

15 to 30 mm |

|

|

|

|||||

|

|

Material |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Tap Drill Size |

U |

|

|

|

||

|

|

ProbeCase |

|

AISI 304 stainless steel (SST). |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Material |

|

|

Connector-to-connector Torque |

||||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

75 Ωcoaxial, fluoroethylene |

|

|

|

|

|

|

|

||||

|

|

|

|

|

ProbeCase |

|

Maximum Rated |

Recommended |

|||||||

|

|

ProbeCable |

|

propylene(FEP)insulated probe |

|

|

|||||||||

|

|

|

|

Torque |

|

||||||||||

|

|

Specifications |

cablein thefollowing total probe |

|

|

|

|

|

|

||||||

|

|

|

¼ -28 orM8x1 |

|

|

|

|

|

|||||||

|

|

|

|

lengths: 0.5, 1, 5, or7 metres. |

|

|

7.3 N•m |

5.1 N•m |

|||||||

|

|

|

|

|

|

|

|

|

|

probecases |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4/30

3300XL NSv Proximity TransducerSystem |

|

|

|

|

|

|

|

|

|

|

|||||

Datasheet |

|

|

|

|

|

|

|

|

|

|

147385Rev. K |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Connector-to-connector Torque |

|

Storage |

|

-52°C to +105°C (-62°F to +221°F) |

||||||||||

|

|

|

|

|

|

|

Temperature |

||||||||

|

|

|

|

(65 in•lb) |

(45 in•lb) |

||||||||||

|

|

|

|

|

|

|

|

|

100% condensing, non-submersible |

|

|||||

|

3/8-24 orM10x1 |

33.9 N•m |

11.3 N•m |

|

Relative |

||||||||||

|

|

|

when connectors areprotected. |

||||||||||||

|

probecases |

|

|

(300 in•lb) |

(100 in•lb) |

|

Humidity |

|

Tested to IEC 68-2-3 damp heat. |

||||||

|

|

|

|

|

|

|

|

|

3300 NSv probes aredesigned to seal |

|

|||||

|

3/8-24 orM10x1 |

22.6 N•m |

7.5 N•m |

|

|

||||||||||

|

probecases – |

|

|

|

|

|

differential pressurebetween the |

||||||||

|

first three |

|

|

(200 in•lb) |

(66 in•lb) |

|

|

|

probetip and case. Theprobe |

||||||

|

threads |

|

|

|

|

|

Probe |

|

sealing material consists of a Viton |

||||||

|

|

|

|

|

|

|

|

O-ring. Probes arenot pressure |

|||||||

|

Reversemount |

22.6 N•m |

7.5 N•m |

|

Pressure |

|

|||||||||

|

|

|

tested priorto shipment. Contact our |

||||||||||||

|

probes |

|

|

(200 in•lb) |

(66 in•lb) |

|

|

|

custom design department if you |

||||||

|

|

|

|

|

|

|

|

|

requirea test of thepressureseal for |

||||||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

yourapplication |

|

|

|

|

||

|

Recommended |

|

Fingertight |

|

|

|

|

|

|

|

|||||

|

|

|

|

It is theresponsibility of thecustomeroruser |

|||||||||||

|

torque |

|

|

|

|

|

|||||||||

|

Maximum |

|

|

0.56 N• m (5 in• lb) |

|

to ensurethat all liquids and gases are |

|||||||||

|

torque |

|

|

|

contained and safely controlled should |

||||||||||

|

|

|

|

|

|

|

leakageoccurfrom a proximity probe. In |

||||||||

|

Minimum Bend |

|

|

|

|||||||||||

|

|

|

|

|

addition, solutions with high orlow pH |

||||||||||

|

Radius (with or |

|

25.4 mm (1.0 in) |

|

|

||||||||||

|

|

|

|

values may erodethetip assembly of the |

|||||||||||

|

without sst |

|

|

|

|

|

probecausing media leakageinto |

|

|

||||||

|

armor) |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

surrounding areas. Bently Nevada will not |

|||||||||

|

System Weight (typical) |

|

|

beheld responsibleforany damages |

|

|

|||||||||

|

Probe |

|

|

Approximately 14 to 150 g (0.5 to |

|

resulting from leaking 3300 NSv Proximity |

|||||||||

|

|

|

5.3 oz) |

|

|

Probes. In addition, 3300 NSv Proximity |

|||||||||

|

|

|

|

|

|

|

Probes will not bereplaced undertheservice |

||||||||

|

Extension |

|

|

|

|

||||||||||

|

|

|

45 g/m (0.5 oz/ft) |

|

|

plan dueto probeleakage. |

|

|

|||||||

|

Cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Armored |

|

|

|

|

|

Field Wiring Limitations |

|

|

|

|

||||

|

Extension |

|

|

64 g/m (0.7 oz/ft) |

|

|

|

|

|

|

|

|

|

|

|

|

Cable |

|

|

|

|

|

Type |

Gas |

Capicitance |

|

Inductance |

|

L/R Ratio |

||

|

|

|

|

|

|

|

Approval |

Group |

(μF) |

|

(mH) |

|

(μH/Ω) |

||

|

Proximitor |

|

|

255 g (9 oz) |

|

||||||||||

|

|

|

|

|

|

IIC |

0.078 |

|

0.99 |

|

29.2 |

|

|||

|

Sensor |

|

|

|

|

ATEX and |

|

|

|

||||||

|

|

|

|

|

|

|

IEC Zone |

IIB |

0.645 |

|

7.41 |

|

117.0 |

|

|

|

Environmental Limits |

|

|||||||||||||

|

|

0/1 |

|

|

|

|

|

|

|

||||||

|

|

IIA |

2.144 |

|

15.6 |

|

234.0 |

|

|||||||

|

|

|

|

|

|

|

|

A & B |

0.070 |

|

1.0 |

|

29.2 |

|

|

|

ProbeTemperatureRange |

|

|

|

|||||||||||

|

|

|

CSA Div 1 |

C |

0.600 |

|

5.0 |

|

117.0 |

|

|||||

|

Operating |

-52°C to +177°C (-62°F to +351°F) |

|

|

|

|

|||||||||

|

|

|

D |

2.09 |

|

11.0 |

|

234.0 |

|

||||||

|

Temperature |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

CSA Div 2 |

All |

0.460 |

|

100.0 |

|

N/A |

||

|

|

-52°C to +177°C (-62°F to +351°F) |

|||||||||||||

|

Storage |

|

|

Exposing theprobeto |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

temperatures below -34°C (- |

|

|

|

|

|

|

|

|

|

|

||

|

Temperature |

|

|

30°F)fora sustained period |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of timemay causepremature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

failureof thepressureseal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extension Cable Temperature Range

Operating

and Storage -52°C to +177°C (-62°F to +351°F) Temperature

Proximitor Sensor Temperature Range

Operating |

-52°C to +100°C (-62°F to +212°F) |

Temperature |

5/30

3300XL NSv Proximity TransducerSystem |

|

Datasheet |

147385Rev. K |

Compliance and

Certifications

FCC

This devicecomplies with part 15ofthe FCCRules. Operation is subject to the following two conditions:

•This devicemay not causeharmful interference.

•This devicemust accept any interferencereceived, including interferencethat may cause undesired operation.

EMC

EN61000-6-2

EN61000-6-4

EMCDirective2014/30/EU

RoHS

RoHS Directive2011/65/EU

Maritime

ABS 2009SteelVessels Rules 1-1-4/7.7,4-8-3/1.11.1,4-9-7/13

Hazardous Area Approvals

Forthedetailed listing of country and product specific approvals, referto theApprovals Quick ReferenceGuide(108M1756)availablefrom Bently.com.

CSA/NRTL/C

3300 XL Proximitor Sensor

ia |

Class I, Zone0: AEx/Ex ia IIC T4/T5 |

|

When installed |

Ga; |

|

Class I, Groups A, B, C, and D, |

||

with |

Class II, Groups E, F and G, |

|

intrinsically |

Class III; |

|

safezener |

T5 |

@ Ta= -55°˚C to + 40°˚C. |

barriers per |

||

drawing 141092 |

T4 |

@ Ta= -55°˚C to + 80°C. |

|

|

|

|

|

|

|

Class I, Zone2: AEx/Ex nA IIC T4/T5 |

|

|

Gc; |

|

nA, ec |

Class I, Division 2, Groups A, B, C, |

|

and D; |

||

When installed |

Class I, Zone2: AEx/Ex ec llC T4/T5 |

|

without |

Gc; |

|

barriers per |

Class I, Division 2, Groups A, B, C, |

|

and D; |

||

drawing |

||

140979. |

T5 @ Ta= -55°C to + 40°C |

|

|

||

|

T4 @ Ta= -55°C to + 80°C |

|

3300 XL Probe |

||

|

|

|

ia |

|

|

When installed |

Class I, Zone0: AEx/Ex ia IIC T5...T1 |

|

with |

Ga; |

|

intrinsically |

Class 1, Groups A, B. C, and D, |

|

safezener |

Class II, Groups E, F, and G, |

|

barriers per |

Class III; |

|

drawing 141092 |

(seeTemperatureScheduletableto |

|

orwhen |

||

installed with |

follow) |

|

galvanic |

|

|

isolators. |

|

|

nA, ec |

Class I, Zone2: AEx/Ex nA IIC T5…T1 |

|

Gc; |

||

When installed |

Class 1, Division 2, Groups A, B, C, D; |

|

Class 1, Zone2: AEx/Ex ec llC T5…T1 |

||

without |

Gc; Class I, Division 2, Groups A, B, C, |

|

barriers per |

and D; |

|

drawing |

(seeTemperatureScheduletableto |

|

140979. |

||

|

follow) |

|

6/30

3300XL NSv Proximity TransducerSystem |

|

Datasheet |

147385Rev. K |

ATEX/IECEx

3300 XL Proximitor Sensor

|

|

II 1 G |

|

|

|

|

|

Ex ia IIC T4/T5 Ga |

|

||

|

|

Ex ia IIIC T90C/T105C Dc |

|

||

|

|

ForEPL Dc: |

|

|

|

|

|

T105C @ Ta = -55°C to 100°C |

|

||

ia |

|

T90C @ Ta = -55°C to +85°C |

|

||

|

Ui= -28V |

Uo= -28V |

|

||

|

|

Ii= 140mA |

Io= 140mA |

|

|

|

|

|

|

|

|

|

|

Pi= 0.91W |

Po= 0.742W |

|

|

|

|

|

|

|

|

|

|

Ci47nF |

Co= 1.5nF |

|

|

|

|

|

|

|

|

|

|

Li= 1460µH |

Lo= 610µH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

II 3 G |

|

|

|

|

|

Ex nA IIC T4/T5 Gc |

|

||

nA,ec |

|

Ex ec llC T4/T5 Gc |

|

||

|

|

|

|

|

|

|

|

Ui= -28V |

|

li= 140 mA |

|

|

|

|

|

|

|

|

|

T5 @ Ta= -55˚ C to + 40˚C |

|

||

|

|

T4 @ Ta= -55 ˚C to + 80˚C |

|

||

3300 XL Probe

Probeentity parameters aremet when used with BNextension cables and connected to BNProx.

|

|

II 1 G |

|

|

|

|

|

Ex ia IIC T5…T1 Ga, |

|

|

|

|

|

(seeTemperatureSchedule |

|

||

|

|

tableto follow) |

|

|

|

ia |

|

Ex ia IIIC T90°C ... T280°C Dc |

|

||

|

ForEPL Dc: |

|

|

||

|

|

|

|

|

|

|

|

Ui= -28V |

|

Ci = 1.5 nF |

|

|

|

|

|

|

|

|

|

Ii = 140 mA |

|

Li =610 μH |

|

|

|

|

|

|

|

|

|

Pi = 0.91 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

nA,ec |

|

II 3 G |

|

|

|

|

Ex nA IIC T5…T1 Gc, |

|

|||

|

|

Ex ec llC T5…T1 Gc, |

|

|

|

|

|

(seeTemperatureSchedule |

|

||

|

|

tableto follow) |

|

|

|

|

|

|

|

|

|

|

Ui= -28V |

li= 140 mA |

|

|

|

|

|

|

|

|

|

|

|

Temperature Schedule

Temperature |

Ambient Temperature |

Classification |

(Probe Only) |

For EPL Ga and Gc |

|

|

|

|

|

T1 |

-55°C to +232°C |

|

|

T2 |

-55°C to +177°C |

|

|

T3 |

-55°C to +120°C |

|

|

T4 |

-55°C to +80°C |

|

|

T5 |

-55°C to +40°C |

|

|

For EPL Dc |

|

|

|

T280°C @ Ta |

-55°C to +232°C |

|

|

T225°C @ Ta |

-55°C to +177°C |

|

|

T170°C @ Ta |

-55C to +120°C |

|

|

T130°C @ Ta |

-55°C to +80°C |

|

|

T105°C @ Ta |

-55°C to +100°C |

|

|

T90°C @ Ta |

-55°C to +40°C |

|

|

7/30

3300XL NSv Proximity TransducerSystem |

|

Datasheet |

147385Rev. K |

Hazardous Area Conditions of Safe Use

CSA/NRTL/C:

ia

Installper Bently Nevada drawing 141092. nA, ec

Installper Bently Nevada drawing 140979.

ATEX/IECEx:

ia

Installper Bently Nevada drawing 141092. nA, ec

TheProxmust beinstalled so as to providethe terminals with a degreeofprotection ofat least IP54.

Field Wiring Limitations

Type |

Gas |

Capicitance |

Inductance |

L/R |

|

Ratio |

|||||

Approval |

Group |

(μF) |

(mH) |

(μH/Ω) |

|

|

|

|

|

||

ATEXand |

IIC |

0.078 |

0.99 |

29.2 |

|

IEC Zone |

IIB |

0.645 |

7.41 |

117.0 |

|

0/1 |

|

|

|

|

|

IIA |

2.144 |

15.6 |

234.0 |

||

|

|||||

|

A & B |

0.070 |

1.0 |

29.2 |

|

CSA Div 1 |

C |

0.600 |

5.0 |

117.0 |

|

|

D |

2.09 |

11.0 |

234.0 |

|

CSA Div 2 |

All |

0.460 |

100.0 |

N/A |

8/30

3300XL NSv Proximity TransducerSystem |

|

|

|

|

Datasheet |

|

147385Rev. K |

||

|

|

|

|

|

|

1 2 |

Miniaturecoaxial ClickLoc connector, |

|

|

Ordering Information |

FluidLoc cable |

|

||

|

||||

E: Agency Approval Option |

||||

Forthedetailed listing of country and product |

0 0 |

Not required |

|

|

specific approvals, referto theApprovals Quick |

|

|

|

|

0 5 |

MultipleApprovals |

|||

ReferenceGuide(108M1756)availablefrom |

||||

Bently.com. |

|

|

|

|

3300 NSv Proximity Probes

330901 3300 NSv Probe, 1/4-28 UNF thread, without armor

330902 3300 NSv Probe, 1/4-28 UNF thread, with armor

330908 3300 NSv Probe, 3/8-24 UNF thread, without armor

330909 3300 NSv Probe, 3/8-24 UNF thread, with armor

Part Number-AA-BB-CC-DD-EE

A: Unthreaded Length Option

Unthreaded length must beat least 0.7 inch less than thecaselength.

Orderin increments of 0.1 in

Length configurations:

Maximum unthreaded length: 9.2 in

Minimum unthreaded length: 0.0 in

Example: 0 4 = 0.4 in

B: Overall Case Length Option

Orderin increments of 0.1 in

Threaded length configurations:

Maximum caselength: 9.9 in

Minimum caselength: 0.8 in

Example: 2 4 = 2.4 in

C:Total Length Option 0 5 0.5 metre(20 in) 1 0 1.0 metre(39 in)

5 0 5.0 metres (16.4 feet)

7 0 7.0 metres (23.0 feet)

D:Connector and Cable-Type Option

0 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

connectorprotector, standard cable |

||

|

||

0 2 |

Miniaturecoaxial ClickLoc connector, |

|

standard cable |

||

|

||

1 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

connectorprotector, FluidLoc cable |

||

|

3300 NSv Proximity Probes, Metric

330903 3300 NSv Probe, M8 x 1 thread, without armor

330904 3300 NSv Probe, M8 x 1 thread, with armor

330905 3300 NSv Probe, M10 x 1 thread, without armor

330910 3300 NSv Probe, M10 x 1 thread, with armor

Part Number-AA-BB-CC-DD-EE

A: Unthreaded Length Option

Unthreaded length must beat least 20 mm less than thecaselength.

Orderin increments of 10 mm. Length configuration: Maximum unthreaded length: 230 mm

Minimum unthreaded length: 0 mm

Example:

0 6 = 60 mm

B: Overall Case Length Option

Orderin increments of 10 mm.

Metric thread configurations:

Maximum length: 250 mm

Minimum length: 20 mm

Example: 0 6 = 60 mm

C:Total Length Option 0 5 0.5 metre(20 in) 1 0 1.0 metre(39 in)

5 0 5.0 metres (16.4 feet)

7 0 7.0 metres (23.0 feet)

D:Connector and Cable-Type Option

0 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

connectorprotector, standard cable |

||

|

9/30

Loading...

Loading...