Page 1

®

Bendix® SV-1™ Synchro Valve SV-3™ & SV-4™ Trailer Release Valve

SD-03-4020

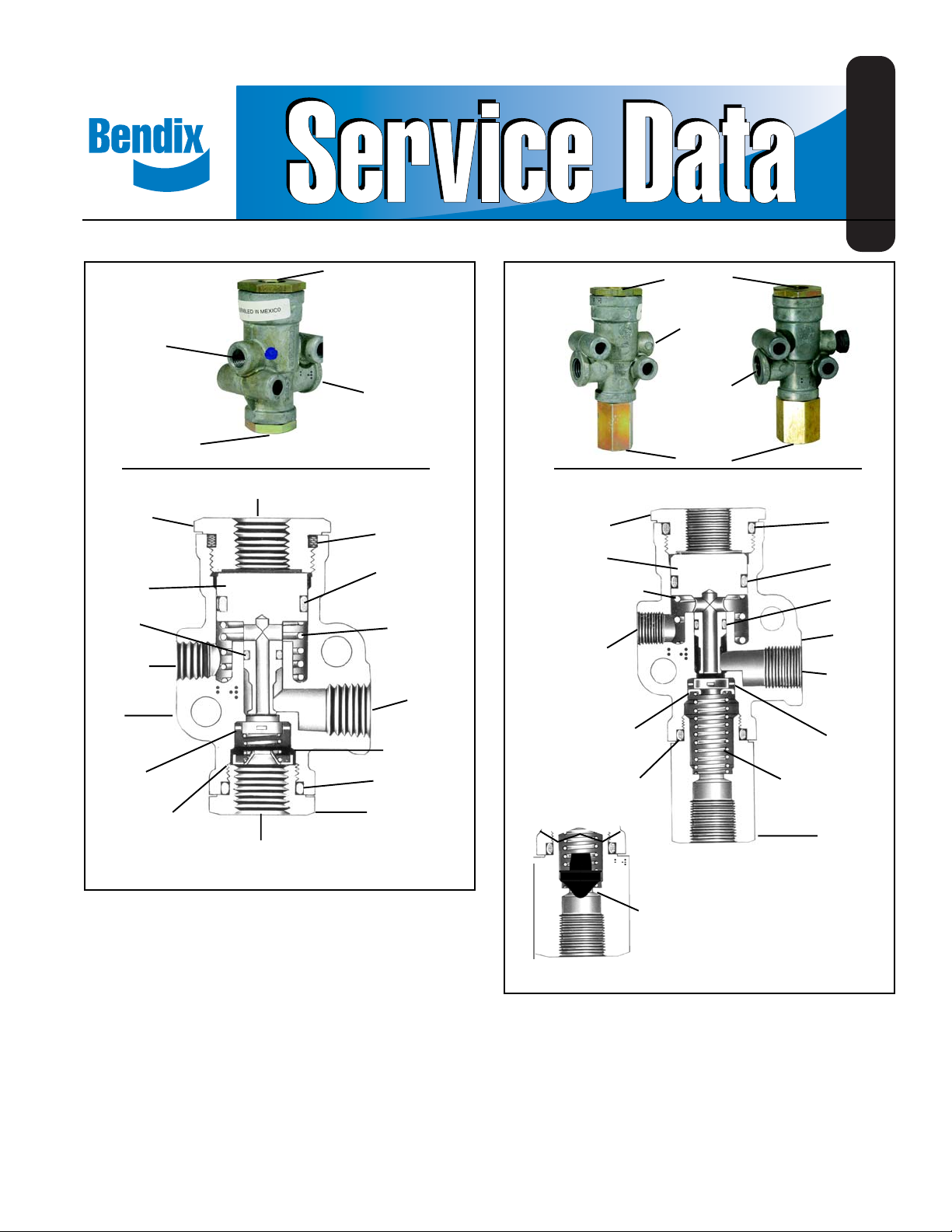

EXHAUST

CAP NUT

PISTON

O-RING

1/8" P.T.

EXHAUST

BODY

VALVE

SUPPLY

1/4" P.T.

CONTROL

CONTROL

DELIVERY

O-RING

O-RING

PISTON

SPRING

1/4" P.T.

DELIVERY

VALVE

SPRING

O-RING

™

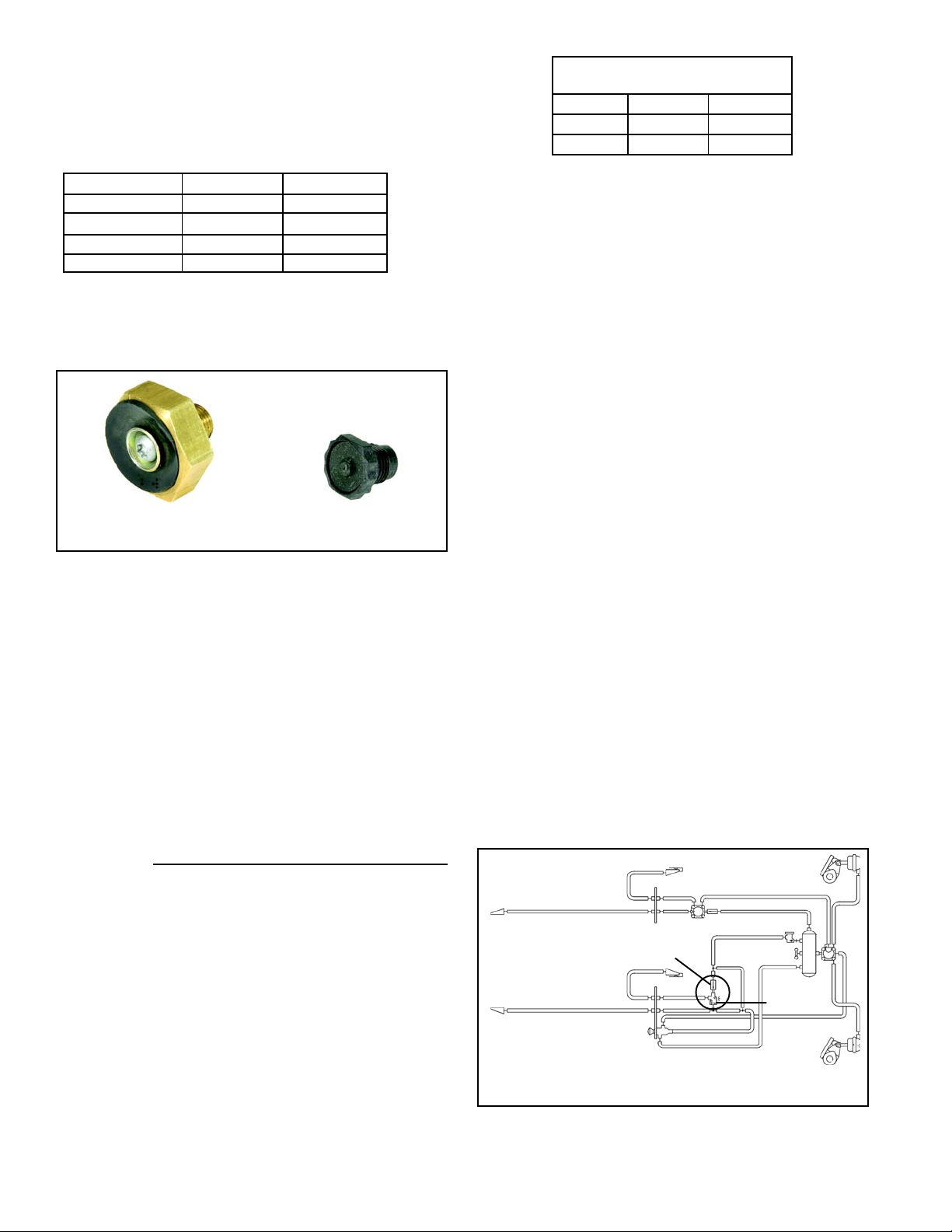

SV-3

VALVE

CAP NUT

PISTON

PISTON SPRING

1/8" P.T.

EXHAUST

SPRING

GUIDE

O-RING

CONTROL

EXHAUST

DELIVERY

SUPPLY

1/4" P.T.

CONTROL

VALVE

SPRING

™

SV-4

VALVE

O-RING

O-RING

O-RING

BODY

1/4" P.T.

DELIVERY

VALVE

SPRING

GUIDE

FIGURE 1 - SV-1™ SYNCHRO VALVE

1/4" P.T.

SUPPLY

CAP NUT

DESCRIPTION

The SV-1™ synchro valve and the SV-3™ trailer release valve

are pilot operated, non-graduating pneumatic control valves.

These valves are used to control air from a remote supply,

have set opening and closing pressures and can be used to

delay or sequence the action of other pneumatic devices.

GENERAL

The SV-1™ synchro valve (figure 1) and SV-3™ & SV-4™ trailer

release valves (figure 2) are air controlled, “On-Off” (nongraduating) control valves that are primarily used to delay or

CAP NUT

1/4" P.T.

SUPPLY

CHECK VALVE

DETAIL OF SV-4

VALVE

FIGURE 2 - SV-3™ & SV-4™ TRAILER RELEASE VALVE

™

DETAIL OF SV-3

VALVE

™

sequence various devices and events in the air brake system.

These valves can be operated either in an automatic or

manual mode using different air connection methods.

Two .28 inch mounting holes are provided in the die cast

aluminum body for panel or frame mounting. Two hex cap

nuts at the ends of the cylindrical valve body retain the internal

1

Page 2

components. The air connection ports for SV-1™, SV-3™ &

SV-4™ valves are the same and are located in relatively the

same position on each model. All connections are pipe thread.

Lettering embossed in the valve body identifies two of the

four connection ports in these valves. Refer to the chart below

and figure one.

Air Connection Body Ident. Thread Size

Air Supply SUP 1/4" PT

Delivery DEL 1/4" PT

Control None 1/4" PT

Exhaust None 1/8" PT

IMPORTANT: An exhaust check valve should be installed in

the threaded exhaust port of these valves when they are

mounted outside the cab in unprotected environments.

™

SV-1

Synchro Valve

SV-3™/SV-4™ Valve Comparison

Supply Cap Nut Dimensions

Diameter Length

SV-3 .8125" 1.162"

SV-4 .94" 1.062"

OPERATION

GENERAL

™

The SV-1

fashion. All can be connected in the air system so that other

valves control them. When connected in this non-automatic

mode the valve serves as a remote mounted, On-Off control.

They can also be installed so that they function automatically

or self actuate at a preset pressure. Automatic operation is

the most common application. Regardless of how they are

connected the internal valve operation is the same.

, SV-3™, & SV-4™ valves all operate in a similar

1/8" PIPE THREAD

1/8" PIPE THREAD

Note: Either style may be installed in the

SV-1™, SV-3™ or SV-4™ valves

FIGURE 3 - EXHAUST CHECK VALVE STYLES

The SV-1™ valve is a general purpose valve used in a variety

of applications on trucks, buses, tractors, trailers and

converter dollies. The SV-1™ valve is the base valve from

which both the SV-3™ and SV-4™ valves are derived. It is

offered in a variety of pressure settings to accommodate

applications where automatic operation is required. It is easily

distinguished from the SV-3™ and SV-4™ valve by its smaller

size.

SV-3™ Trailer Release Valve

While originally designed for automatic operation to

accomplish brake release on trailers without spring brakes,

the SV-3™ valve can be used in any installation where its

single automatic pressure setting is advantageous. The

SV-3™ valve is very similar in appearance to the SV-4™ valve

but can be distinguished by measuring the length and

diameter of the supply hex cap nut (1/4" PT supply port).

See the comparison chart for the dimensions.

NON-AUTOMATIC (valve controlled remotely by another

valve)

With no air pressure present at the control port, supply port

air pressure and the inlet/exhaust valve spring hold the inlet

valve on its seat in the body. The piston is held away from

the inlet/exhaust valve by the piston spring, and the delivery

line is vented to atmosphere through the hollow exhaust

stem of the piston.

When sufficient air pressure is applied to the control port,

the control piston moves against the resistance of its return

spring. As the control piston moves, it contacts the exhaust

valve portion of the inlet and exhaust valve which seals the

hollow exhaust passage in the piston stem. Continued piston

movement drives the inlet valve from its seat and allows

supply air to flow through the body and out the delivery port.

When air pressure is removed from the control port, the

piston return spring and delivery port air pressure move the

piston away from the inlet/exhaust valve. As the piston moves,

the inlet valve re-seats itself preventing air flow to the delivery

port. Continued movement unseats the hollow exhaust

passage in the piston stem allowing delivery air to flow

through the stem and out the exhaust check valve.

SV-4™ Trailer Release Valve

The SV-4™ valve was designed primarily for use on trailer

converter dollies to minimize the possibility of false charging.

Like the SV-3™ valve it can be used in other applications.

The SV-4™ valve is the combination of two valves; an SV-3

valve and a single check valve. A typical installation is

illustrated in figure 4. The SV-4™ valve can be distinguished

from the SV-3™ valve using the dimensions given in the

comparison chart. In addition, the tip of the check valve

contained in the SV-4™ valve is visible at the bottom of the

¼" PT supply port.

2

SINGLE CHECK VALVE

™

Note: An SV-4™ valve can be used in place of the

SV-1™ valve and single check valve shown here.

FIGURE 4 - TRAILER CONVERTER DOLLY

™

SV-1

SYNCHRO

Page 3

AUTOMATIC (self actuating at a pre-set pressure)

There are two methods for accomplishing automatic operation

of an SV valve.

1. One method for affecting automatic operation is to

connect the SV valve control port to its supply port using

a pipe or tubing tee. This is referred to as “common

control and supply” since the pressure at the supply

and control port is the same.

With common control and supply, the valve opens

(delivers air) on ascending supply air pressure and closes

and exhausts on descending pressure. The pressure at

which delivery and exhaust occurs differs for various part

numbers. Opening and exhaust pressure is specified

for the various part numbers.

2. SV valves can be made to operate automatically even

when the supply port and control ports are separate (not

connected as described in #1 above).

The SV valve will open (deliver air) and close (and

exhaust) when control port pressure is increased or

decreased. Consult Bendix Engineering for specific

control port pressure for valve opening and closing when

this type of automatic operation is used. When using

the SV-1™ synchro valve in this manner, the control signal

ramp rate should be limited by orificing or other methods.

Please contact Bendix Engineering with specific

application requirements.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the SV

valves should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

the SV valves not meet the elements of the operational tests

noted in this document, further investigation and service of

the valve may be required.

If the SV-1™, SV-3™, or SV-4™ valve fails to function as

described or leakage is excessive, it should be repaired or

replaced with a genuine Bendix unit, available at any

authorized parts outlet.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

EXTREME CAUTION should

ANY work on the

™

3

Page 4

OPERATING AND LEAKAGE TESTS

OPERATING TEST

Two accurate air gauges are necessary to perform these

tests. Depending upon installation, it may be necessary to

remove valve to properly test it. Correct opening pressures

of the valve should be known before beginning tests; consult

vehicle manual.

1. Install an accurate gauge in the common control and

supply line; install another gauge in the delivery port.

2. Gradually apply air pressure to the common supply and

control line. As common supply and control pressure

increases, note at what pressure delivery of air through

valve is made and compare with specifications in vehicle

manual.

3. Slowly decrease pressure in the common supply and

note at what pressure delivery line pressure is vented;

compare with vehicle manual.

4. Pay particular attention to the exhaust check valve in

the exhaust port if so equipped (note figure 3). Make

certain it is free of contamination and the rubber valve is

free to function. Replace this item as necessary.

LEAKAGE TEST

1. With 120 psi air pressure present in supply, control and

delivery ports:

- Apply a soap solution around control port cap nut and

supply port cap nut. No leakage is permitted.

- Apply soap solution to the exhaust port; leakage must

not exceed a 1" bubble in less than 5 seconds (100

sccm).

Excessive leakage would indicate a faulty o-ring, inlet/

exhaust valve or piston exhaust seat.

2. Plug the delivery port and apply 10 psi to the supply port

only. Apply soap solution to the exhaust port:

-For the SV-1™ valve - leakage must not exceed a 1"

bubble in less than 5 seconds (100 sccm).

-For the SV-3™ & SV-4™ valve - leakage must not exceed

a 1" bubble in less than 10 seconds (50 sccm).

Excessive leakage would indicate a faulty inlet valve or

inlet valve seat.

If the valve does not function as described or if leakage is

excessive, it is recommended that it be replaced with a new

unit, or repaired with genuine Bendix parts available at Bendix

outlets.

INSTALLING

1. Mount the valve securely.

2. Check and clean air lines; identify air lines and connect

to valve.

DISASSEMBLY

1. Remove the control port cap nut and its o-ring. Remove

the o-ring from the cap nut.

2. Remove the piston from the valve body. Remove the large

and small piston o-rings from the piston.

3. Remove the piston return spring from the body.

4. Remove the supply port cap nut and its o-ring. Remove

the o-ring from the cap nut.

5. Remove the inlet/exhaust valve stop (SV-1™ valve) or the

spring guide (SV-3™ & SV-4™ valve), then the inlet/

exhaust valve spring.

Note: The SV-4™ valve contains a check valve which is

installed in the opposite end of the inlet/exhaust

valve return spring.

6. Remove the inlet/exhaust valve.

7. Remove the exhaust check valve if so equipped.

CLEANING AND INSPECTION

1. Using good commercial grade of solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superficial corrosion and/or pitting on the exterior portion

of the body and cap nuts is acceptable. Replace the

entire valve if the interior of the body or cap nuts exhibit

signs of corrosion or pitting.

3. Inspect the body bore and the check valve seat in the

supply port cap nut of the SV-4™ valve for deep scuffing

or gouges. Replace the entire valve if either are found.

4. Inspect the pipe threads in the body and cap nuts. Make

certain they are clean and free of thread sealant.

5. Inspect all springs for signs of corrosion, pitting and

cracks. Replace as necessary.

6. Inspect all air line fittings for corrosion and replace as

necessary. Make certain to remove all old thread sealant

before reuse.

7. Inspect the exhaust check valve making certain all

passages are clear and open.

REMOVING AND INSTALLING

REMOVING

1. Block and hold vehicle by means other than air brakes.

2. Drain air brake system.

3. Identify the air lines to facilitate reinstallation, disconnect

the lines, remove the mounting bolts, and then the valve.

4

Page 5

ASSEMBLY

Prior to assembly, lubricate the piston, o-rings and body

bores with Dow-Corning 55-M pneumatic grease (Bendix

Pc. No. 291126).

1. Install the inlet/exhaust valve in the body.

™

2. Install the inlet valve spring and valve stop (SV-1

or spring guide (SV-3™ & SV-4™ valve). NOTE: Install

the check valve in the small diameter end of the inletexhaust valve return spring of the SV-4™ valve before

installing in the body.

3. Install the o-ring on the supply cap nut then install and

tighten the cap nut. Torque to approximately 100 inch

pounds.

4. Install piston return spring in body.

5. Install the small and large diameter o-rings on the piston.

Insert the piston into body. (Piston should now rest on

top of spring.)

6. Install the control port cap nut o-ring on the cap nut then

install and tighten the cap nut in body. Torque to

approximately 275 inch pounds.

7. Install the exhaust check valve if the valve assembly

was so equipped.

8. Perform tests as outlined in the “Operating and Leakage

Tests” section.

valve)

5

Page 6

6

BW1574 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 10/2004 Printed in U.S.A.

Loading...

Loading...