Page 1

®

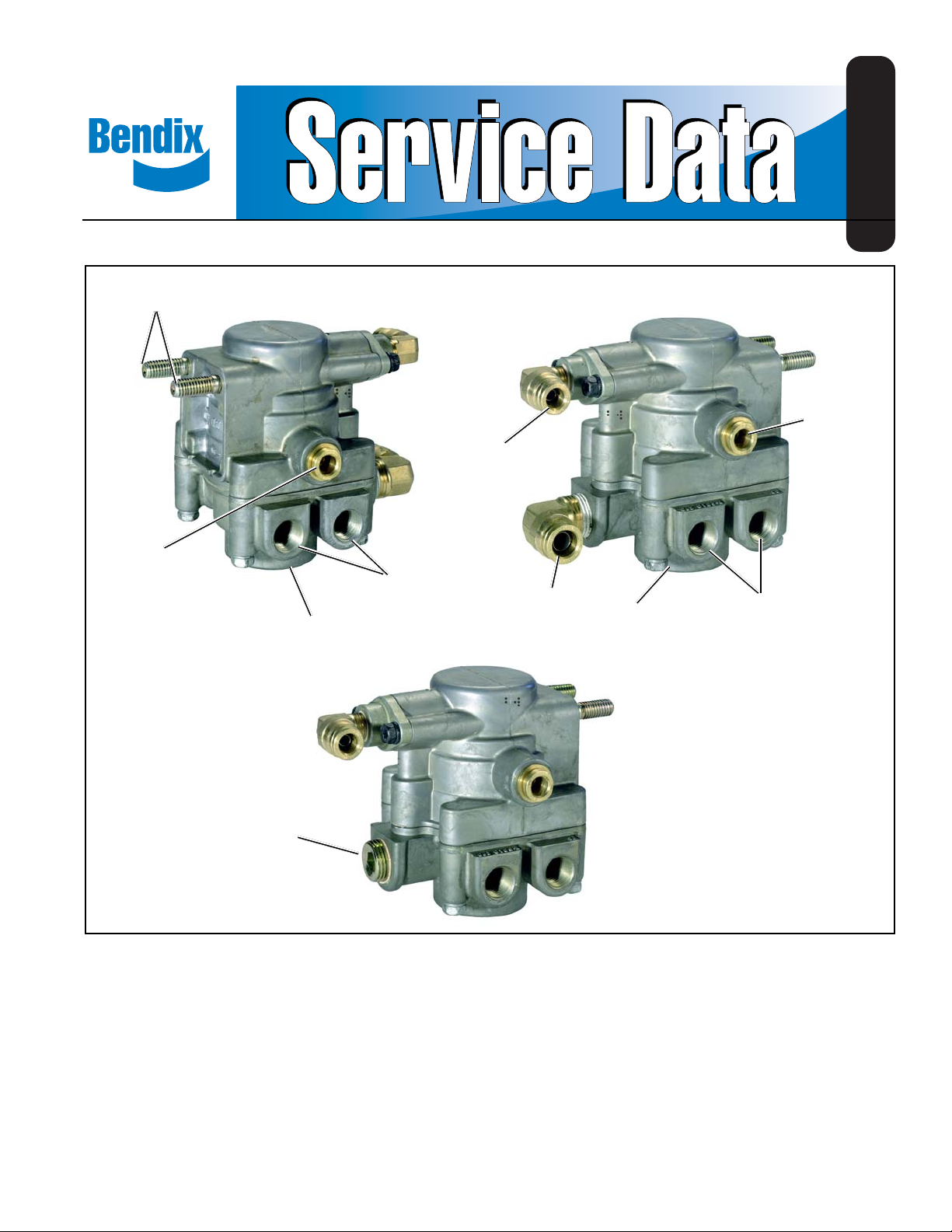

Bendix® SR-7™ Spring Brake Modulating Valve

MOUNTING

STUDS (2)

4-1

PARK CONTROL

(FROM DASH

VALVE)

42

CONTROL

PORT

EXHAUST

2

DELIVERY

1

SUPPLY

PORT

3

EXHAUST

SD-03-9043

41

BALANCE

PORT

2

DELIVERY

PIPE PLUG

(INCLUDED IN

QUICK RELEASE

VALVE

APPLICATIONS)

FIGURE 1 - EXTERIOR VIEW

DESCRIPTION

The Bendix® SR-7™ spring brake modulating valve is used in

conjunction with a dual air brake system and spring brake

actuator and performs the following functions:

1. Provides a rapid application of the spring brake actuator

when parking.

2. Modulates the spring brake actuator application using

the dual brake valve should a primary failure occur in

the service brake system.

3. Prevents compounding of service and spring forces.

The valve has one park control, one service control, one

supply, one balance, four delivery NPTF ports, and an

exhaust port protected by an exhaust diaphragm. The valve

incorporates two mounting studs for mounting the valve to

the frame rail or cross member (where applicable).

1

Page 2

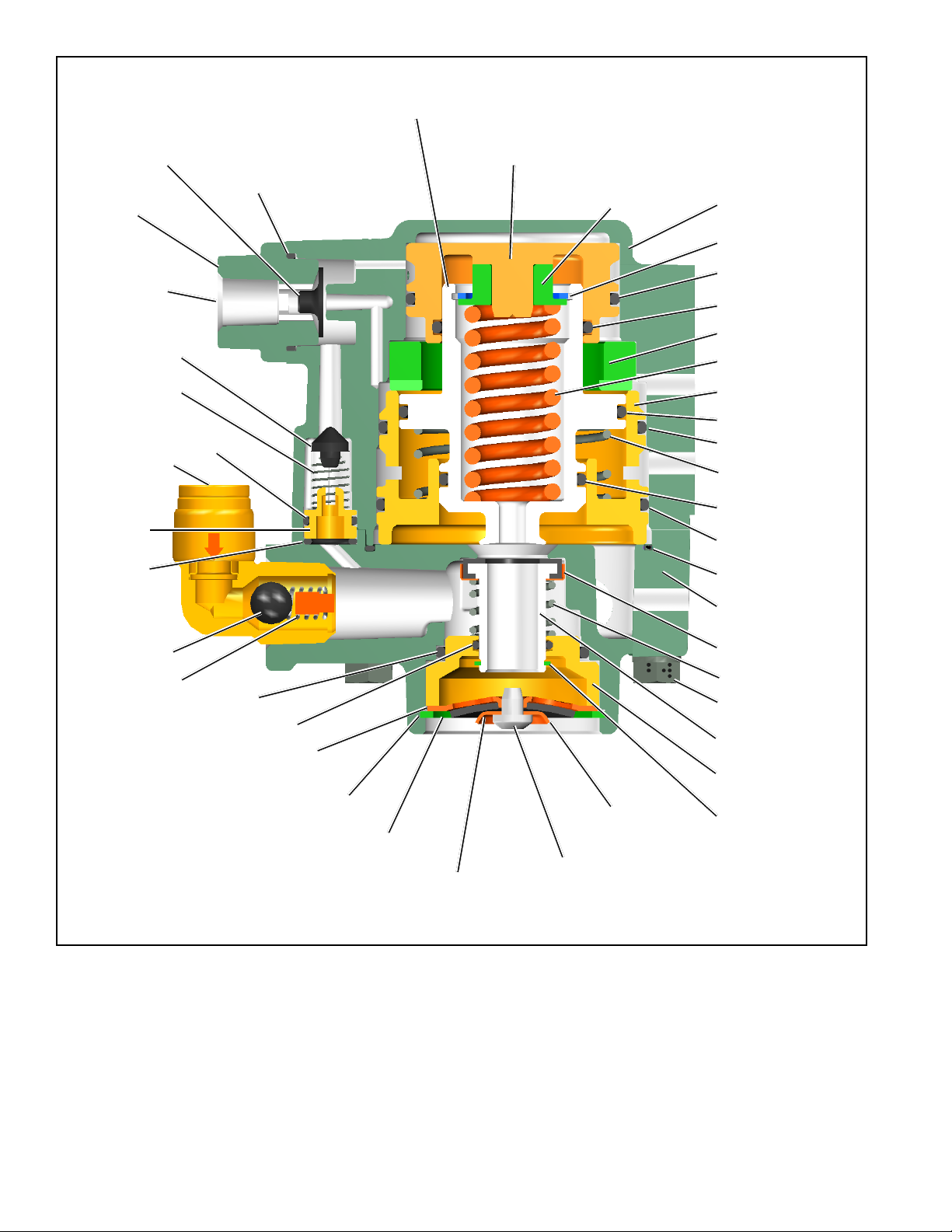

MAIN PISTON

DOUBLE CHECK

VALVE

CHECK VALVE

COVER

PARK CONTROL

PORT

IN-LINE SINGLE

CHECK VALVE

SPRING

SUPPLY PORT

CHECK VALVE

GUIDE

O-RING

O-RING

O-RING

CONTROL PISTON

SPRING GUIDE

UPPER BODY

RETAINING RING

O-RING

O-RING

SPACER

MAIN PISTON SPRING

STATIC PISTON

O-RING

O-RING

STATIC PISTON

SPRING

O-RING

O-RING

O-RING

LOWER BODY

BALL CHECK

VALVE

SPRING

FIGURE 2 - SECTIONAL VIEW OF SR-7™ SPRING BRAKE MODULA TING VAL VE USED IN RELA Y V A LVE APPLICA TIONS

O-RING

O-RING

VALVE SEAT

RETAINING RING

DIAPHRAGM

DIAPHRAGM WASHER

EXHAUST

PORT

#10 TORX HEAD SCREW

VALVE RETAINER

SPRING

1/4-20 MACHINE

SCREWS

INLET / EXHAUST

VALVE

LOWER VALVE

GUIDE

RETAINING RING

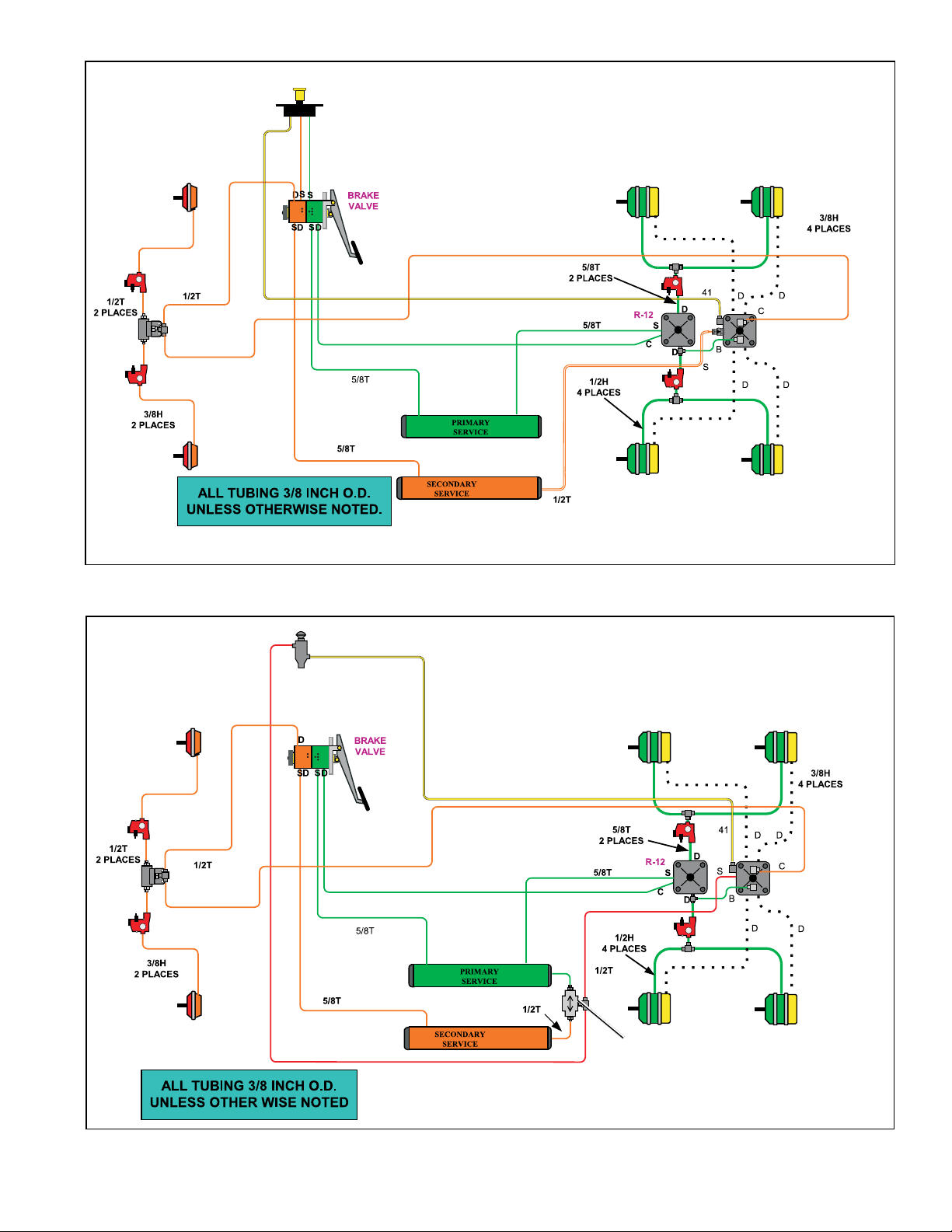

OPERATION

The operation guidelines shown in this manual represent

the relay valve based SR-7™ (refer to system schematic

shown in figure 3). A quick release based valve functions

similarly to the relay valve based version with the exception

that all air delivered to spring brakes passes through the

park control port through the in-line single check valve. The

SR-7™ quick release style can be easily identified by the

pipe plug in the supply port of the valve.

2

Page 3

PP-DC

VALV E

™

SYSTEM FOR A 4X2 OR 6X4

STRAIGHT TRUCK WITH

PP-DC PARKING CONTROL

™

™

SR-7 Valve w/single check

Ref: 5010914

FIGURE 3 - SYSTEM SCHEMATIC WITH PP-DC™ PARK CONTROL

™

PP-1

VALV E

SYSTEM FOR A 4X2 OR 6X4

STRAIGHT TRUCK WITH

™

PP-1 PARKING CONTROL

SR-7 valve

w/o single check

™

FIGURE 4 - SYSTEM SCHEMATIC WITH PP-1

™

DC-4

VALVE

™

P ARK CONTROL AND DC-4™ DOUBLE CHECK VALVE

3

Page 4

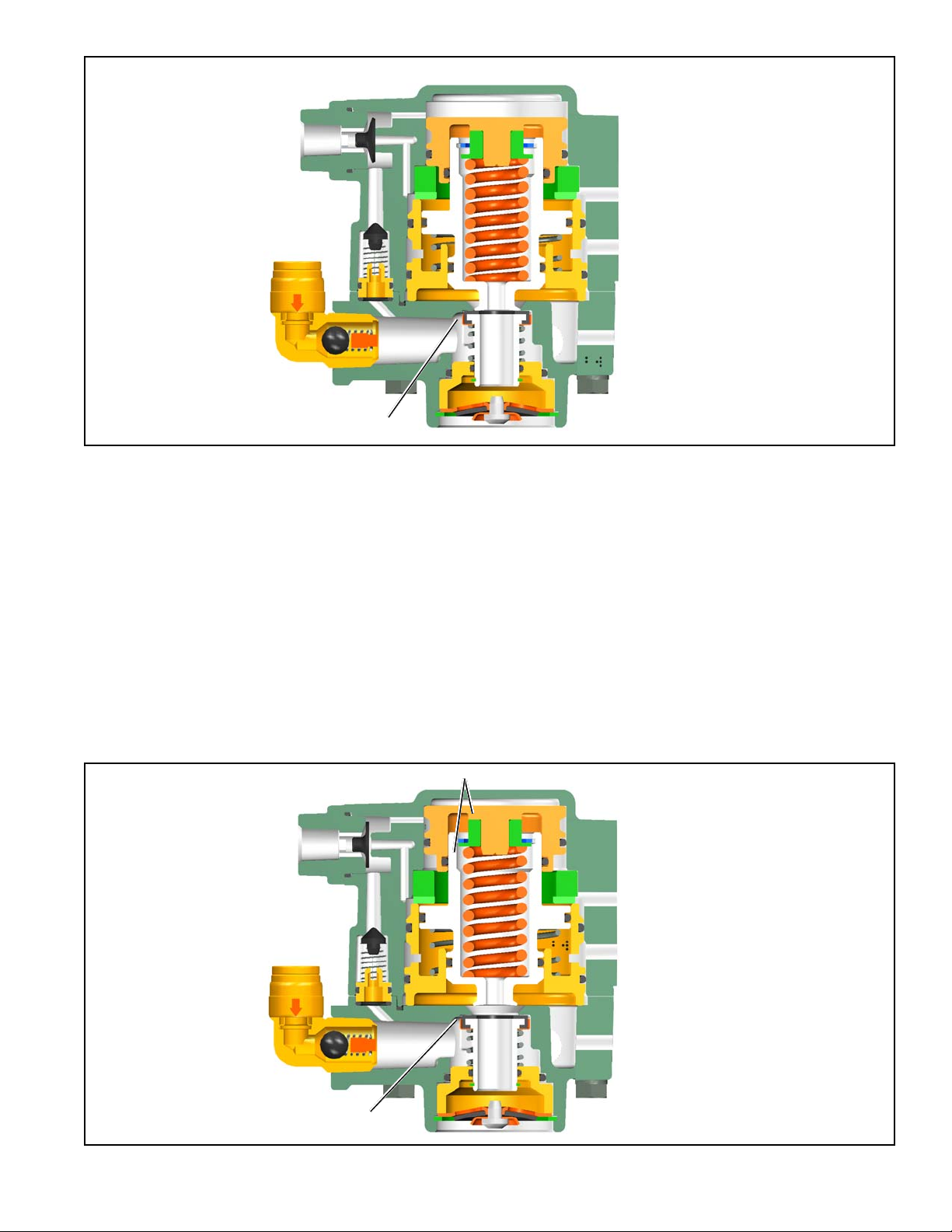

CONTROL LINE PRESSURE

à

à

à

à

à

à

BALANCE PORT

SECONDARY RESERVOIR

CONSTANT PRESSURE

INLET / EXHAUST VALVE OPEN

FIGURE 5 - CHARGING LESS THAN 107 PSI

à

à

à

CHARGING SPRING BRAKE ACTUATORS

BELOW 107 PSI (FIGURE 5)

With the air brake system charged and the parking brakes

released (by pushing the dash valve button in), air enters

the park control port. This opens the SR-7™ valve to supply

air pressure to the spring brake chambers. As illustrated,

air pressure in the chambers is below 107 psi (nominally).

CONTROL PORT

à

DELIVERY TO SPRING BRAKES

à

CHARGING SPRING BRAKE ACTUA TORS ABOVE

107 PSI (FIGURE 6)

Once the SR-7™ valve delivery pressure reaches 107 psi

(nominal), the inlet and exhaust are closed (valve lap

position). This maintains the spring brake hold-off pressure

at 107 psi (nominal).

CONTROL LINE PRESSURE

à

SECONDARY RESERVOIR

CONSTANT PRESSURE

INLET / EXHAUST VALVE SEATED

FIGURE 6 - CHARGING GREA TER THAN 107 PSI

4

à

à

à

àà

à

BALANCE PORT

CONTROL PORT

DELIVERY TO SPRING BRAKES

à

Page 5

CONTROL LINE PRESSURE

à

à

à

à

à

à

BALANCE PORT - PRIMARY

à

CIRCUIT PRESSURE

SECONDARY RESERVOIR

CONSTANT PRESSURE

INLET / EXHAUST VALVE SEATED

FIGURE 7 - NORMAL SERVICE APPLICA TION

NORMAL SERVICE APPLICATION (FIGURE 7)

During a service brake application, the valve remains in the

lap position. The SR-7™ valve monitors the presence of air

pressure in both primary and secondary delivery circuits.

à

CONTROL PORT - SECONDARY

à

CIRCUIT PRESSURE

DELIVERY TO SPRING BRAKES

à

PARKING (FIGURE 8)

Actuating the park brakes (by pulling the dash valve button

out) exhausts spring brake air pressure through the SR-7

valve exhaust port.

™

CONTROL LINE PRESSURE

SECONDARY RESERVOIR

CONSTANT PRESSURE

FIGURE 8 - PARKING

MAIN AND CONTROL PISTONS MOVE UP

à

à

INLET V AL VE SEA TED

à

à

à

à

à

à

à

BALANCE PORT

CONTROL PORT

AIR EXHAUSTS FROM

à

SPRING BRAKES

5

Page 6

CONTROL LINE PRESSURE

à

MAIN PISTON MOVES UP

à

à

à

à

SECONDARY RESERVOIR

CONSTANT PRESSURE

à

à

à

à

à

INLET VALVE SEATED

FIGURE 9 - SERVICE APPLICA TION LOSS OF PRIMAR Y CIRCUIT

SERVICE APPLICATION WITH LOSS OF AIR IN

PRIMARY CIRCUIT (FIGURE 9)

With the parking brakes released (dash valve button in) and

the absence of air in the primary circuit delivery, a service

brake application from the secondary circuit causes the

pressure in the spring brakes to be exhausted proportionally

to this application. This is known as spring brake modulation.

A 30 psi service brake application will exhaust the spring

brake pressure to approximately 60 psi.

LOSS OF

à

à

BALANCE PORT -

PRIMARY CIRCUIT PRESSURE

CONTROL PORT - SECONDARY

à

CIRCUIT PRESSURE

à

à

AIR EXHAUSTS FROM

à

SPRING BRAKES

à

SERVICE APPLICATION WITH LOSS OF AIR IN

SECONDARY CIRCUIT (FIGURE 10)

With the parking brakes released (dash valve button in) and

the absence of air in the secondary circuit reservoir, the

external single check valve in the supply port seals to prevent

air leakage to atmosphere from the SR-7™ valve. The dash

valve delivery air flows through the in-line single check valve

and becomes SR-7™ valve supply air. This air is delivered to

maintain at least 107 psi (nominal) in the spring brake

chambers.

à

à

à

CONTROL LINE PRESSURE

à

à

à

IN-LINE SINGLE

CHECK VALVE

SECONDARY RESERVOIR

NO PRESSURE

FIGURE 10 - SERVICE APPLICATION LOSS OF SECONDARY CIRCUIT

6

à

à

à

à

à

à

BALANCE PORT - PRIMARY

à

CIRCUIT PRESSURE

CONTROL PORT - LOSS OF

SECONDARY CIRCUIT PRESSURE

DELIVERY TO

SPRING BRAKES

à

Page 7

NO CONTROL LINE

PRESSURE

SECONDARY RESERVOIR

CONSTANT PRESSURE

à

à

à

à

à

à

à

à

à

à

à

à

à

BALANCE PORT -

PRIMARY CIRCUIT PRESSURE

à

SECONDARY CIRCUIT PRESSURE

CONTROL PORT -

à

à

INLET / EXHAUST VALVE OPEN

FIGURE 11 - ANTI-COMPOUNDING

ANTI COMPOUNDING (FIGURE 11)

The SR-7™ valve provides anti-compounding of the service and

spring brake forces. When the park brakes are actuated

(by pulling the dash valve button out), a service brake

application will cause the SR-7™ valve to deliver air pressure

to the spring brake chambers. Thus the vehicle is held

stationary using a service brake application. When the

service brake application is released, the delivery pressure

is exhausted from the spring brake chambers and the vehicle

remains parked using the spring brake actuators.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions; as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the SR-7

valve should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

the SR-7™ valve not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

DELIVERY TO SPRING BRAKES

à

OPERATING TEST

Block vehicle and hold by means other than vehicle brakes.

Charge air brake system to governor cut-out pressure.

1. Place parking control valve in “park” position. Observe

that spring brake actuators apply promptly. Remove

one line from delivery port of the SR-7™ valve and install

test gauge known to be accurate. Place parking control

valve in “release” position. Observe that spring brake

actuators release fully .

2. With parking control valve in “release” position, note

gauge pressure reading. (Correct spring brake actuator

hold-off pressure is 107 psi nominally .)

3. Place parking control valve in “park” position - gauge

reading should drop to zero promptly . A lag (more than

3 seconds) in drop of pressure would indicate faulty

operation.

4. With the parking control valve in the “park” position,

gradually apply foot brake valve and note a pressure

reading increase on the gauge installed in the SR-7

™

valve delivery port.

5. Place parking control valve in “release” position.

6. Drain the reservoir, which supplies the rear service brake

circuit, apply the foot brake valve several times and note

that pressure reading on gauge decreases each time

foot brake valve is applied (spring brake modulation).

After the foot brake valve has been applied several times,

pressure on gauge will drop to the point where release

of the spring brake actuators will no longer occur.

™

7

Page 8

LEAKAGE TEST

Place the park control valve in the “release” position; using

a soap solution, coat all ports including the exhaust port. A

1" bubble in 3 seconds is permitted (175 SCCM).

If the valve does not function as described, or if leakage is

excessive, it is recommended that it be replaced with a new

or remanufactured unit available from a Bendix parts outlet.

DO NOT ATTEMPT TO DISASSEMBLE THE SR-7

V AL VE. THE VAL VE CONT AINS HIGH SPRING FORCES

THAT COULD RESULT IN PERSONAL INJURY IF

DISASSEMBL Y IS A TTEMPTED!

SERVICING THE SR-7™ VA LV E

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

™

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

V AL VE REMOVAL

1. Prior to removing the SR-7™ valve, apply the parking

brakes and drain all the vehicle reservoirs.

2. Identify all air lines before disconnecting.

3. Remove the two mounting nuts that secure the valve to

the frame rail and remove the valve.

V AL VE INST ALLA TION

1. Align the mounting studs with the mounting holes on

the vehicle frame rail. Tighten the mounting nuts to

180-220 in. lbs.

2. Install the valve onto the vehicle ensuring all ports are

connected as marked during disassembly .

TESTING THE REPLACEMENT SR-7™ SPRING

BRAKE MODULA TING VALVE

Perform operating and leakage tests as outlined in “Operating

™

Tests” section.

8

BW2271 © 2004 Bendix Commercial Vehicle Systems LLC 3/2004. Printed in U.S.A. All rights reserved.

Loading...

Loading...