Page 1

®

The Bendix® ESP® EC-80™ Controller

SD-13-4986

INTRODUCTION

The Bendix® ESP® EC‑80™ Electronic Control Unit (ECU)

is a member of a family of three Bendix®‑brand electronic

Antilock Braking System (ABS) devices used to help

improve the braking characterist ics of air‑braked heavy‑

and medium‑duty trucks, tractors, and buses:

1. The Bendix® ABS ESP® ECU uses wheel speed sensors

to monitor four wheel‑ends to detect wheel‑slip or wheel

lock‑up during braking. The system inter venes when

needed — using Pressure Modulator Valves (PMVs)

to adjust and/or pulse the brake pressure — in order

to optimize the contact bet ween the t ires and t he road

surface.

2. The Bendix® Automatic T raction Control (ATC ) EC‑80

ECU provides standard ABS; improves vehicle traction

during acceleration; and aid lateral stability while driving

through curves. The Bendix® A TC E CU communicates

with the engine’s Controller to provide Engine Torque

Limiting (ETL), and/or use Differential Braking (DB) to

make brake applications at individual wheels.

3. The Bendix ESP EC‑80 Controller provides — in

addition to the ABS and ATC functions described

above — advanced braking features referred to as the

Bendix® ESP® Electronic Stability Program. The Bendix

ESP EC‑80 Controller analyzes the vehicle's motion

compared to the driver 's intended path and provides

Yaw Control (YC) and Roll Stability Program (RSP)

capabilities. When necessary, the s ystem will intervene

to reduce the engine throt tle, and/or apply the brakes

at one or more of the wheel ends — to help the vehicle

return to the intended direction.

™

Label Shows ECU

Designation

FIGURE 1 - THE BENDIX® ESP® EC‑80™ CONTROLLER

The driver is always responsible for the control

and safe ope rat io n of th e vehicl e at a ll ti me s. The

Bendix® ABS system does not replace the need

for a skilled, alert professional driver, reacting

appropriately and in a timely manner, and using

safe driving practices.

TABLE OF CONTENTS Page

Components . . . . . . . . . . . . . . . . . . . . . 3‑4

Indicator Lamps and Power‑Up Sequence . . . . . 8‑9

ABS Operation. . . . . . . . . . . . . . . . . . . . 9‑10

ATC Operation. . . . . . . . . . . . . . . . . . . . 11‑12

ESP ABS With Stability Control . . . . . . . . . . . 12‑13

Important Safety Information About

The ESP Stability System . . . . . . . . . . . . . 13‑14

Troubleshooting . . . . . . . . . . . . . . . . . . . 17‑62

See page 63 for the full Table of Contents

®

Bendix

™

EC‑80

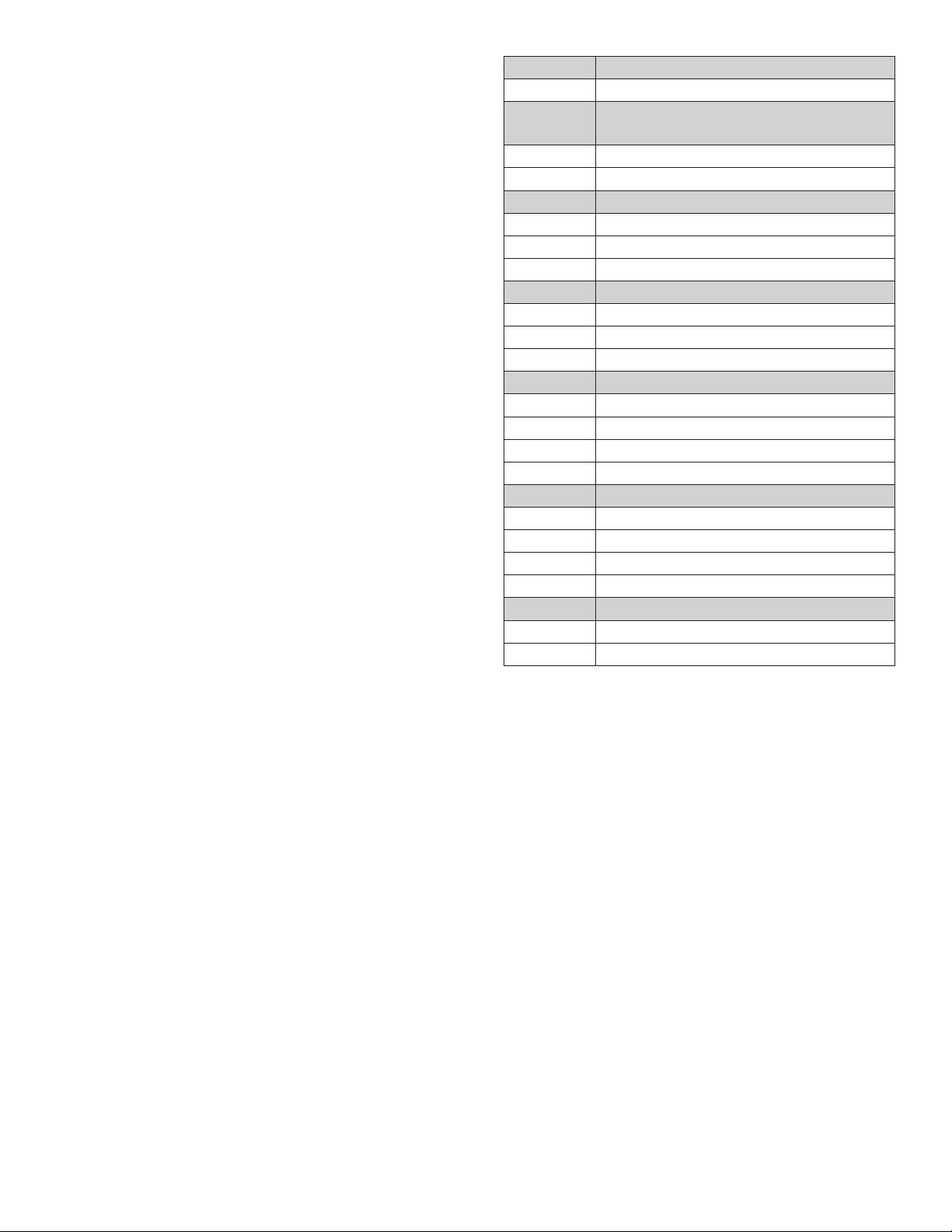

System Name

ABS “Standard”

ATC “Premium”

ESP

®

EC‑60™ ECU)

Designations

“Advanced”

Previous

(Bendix

®

ECU; Pressure Modulator Valves (PMVs);

Four Wheel Speed Sensors.

Items above, plus: Automatic Traction

Control (ATC) Valve; Option of two more

Wheel Speed Sensors and PMVs.

All items above, plus: Yaw Rate Sensor;

Steering Angle Sensor; Load Sensor;

Steer‑axle ATC valve; Brake Demand

Sensor; and an Additional PMV

Key Components

ESP® is a registered trademark of DaimlerChrysler and is used by BCVS under license.

Key System Features

(ECU Designation Shown

on the ECU Label)

ABS [Antilock Braking]

(EC‑80 ABS)

ABS plus ATC [Traction Control]

(EC‑80 ATC)

ABS plus ATC plus ESP

[Yaw Control (YC) and

Roll Stability Program (RSP

(EC‑80 ESP)

®

ECU

Connector

Locations

Provided

Two SD‑13‑4983

Three SD‑13‑4983

Four

)].

See

Service Data

Sheet

SD‑13‑4986

(This

Document)

1

Page 2

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following guidelines should be observed AT ALL TIMES:

▲ Park the vehicle on a level surface, apply the

parking brakes and always block the wheels.

Always wear personal protection equipment.

▲ Stop the engine and remove the ignition key

when working under or around the vehicle.

When working in the engine compartment,

the engine sho uld be shut off and the ig nition

key should be removed. Where circumst ances

require that the engine be in operation, EXTREME

CAUTION should be used to prevent personal

injury resulting from contact with moving,

rotating, leaking, heated or electrically-charged

components.

▲ Do not att empt to install, remove, dis assemble

or assemb le a component until you have re ad,

and thoroughly understand, the recommended

procedures. Use only the proper tools and

observe all precautions pertaining to use of those

tools.

▲ If the wor k is being per formed on th e vehicle’s

air brake system, or any auxiliary pressurized air

systems, make ce rta in to drain th e air pressur e

from all rese rvoirs before be ginning ANY work

on the vehicle. I f th e vehicle i s equip ped wi th a

Bendix® AD-IS® air dryer system, a Bendix® DRM™

dryer re se rvoir modul e, o r a B en di x® AD-9si™ air

dryer, be sure to drain the purge reservoir.

▲ Following the vehicle manufacturer’s

recommended procedures, deactivate the

electrical system in a manner that safely removes

all electrical power from the vehicle.

▲ Never exceed manufacturer’s recommended

pressures.

▲ Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a compone nt or plug unless you ar e certai n all

system pressure has been depleted.

▲ Use only genuine Bendix

parts, components and kits. Replacement

hardware, tubing, hose, ttings, etc. must be of

equivalent size, type and strength as original

equipment and be designed speci cally for such

applications and systems.

▲ Component s with st rippe d threads o r damaged

part s should be replaced ra ther than repaired.

Do not attempt repairs requiring machining or

welding unless speci cally stated and approved

by the vehicle and component manufacturer.

▲ Prior to retur ning the vehicle to ser vice, make

certain all components and systems are restored

to their proper operating condition.

▲ For vehicles with Automatic Traction Control

(ATC), the ATC function m ust be disabled (ATC

indicator lamp should be ON) prior to performing

any vehicle maintenance where one or more

wheels on a d rive axle ar e lifted of f the groun d

and moving.

▲ The power MUST be t emporarily disco nnected

from the radar sensor whenever any tests USING

A DYNAMOMETER are conducted on a Bendix

Wingman® Advanced™-equipped vehicle.

®

brand replacement

®

▲ You should consult the vehicle manufacturer's operating and service manuals, and any related literature,

in conjunction with the Gu ideli nes above.

Even with the Bendix® ESP® system with the EC-80™

Controller, the driver remains responsible for ensuring

vehicle stability during operation. The braking system

can only function within the limits of physics. The

system helps mitigate potential vehicle stability

incidents, but cannot prevent them in all cases.

Other factors such as driving too fast for road, trafc

or weather conditions, oversteering, an excessively

high vehicle Center of Gravity (CG), or poor road

conditions can cause vehicle instability that is beyond

the capability of any stability system to mitigate. In

addition, the effectiveness of Bendix ESP system

with the EC-80 Controller can be greatly reduced on

vehicles towing multiple trailer combinations.

2

The Bendix ESP system with the EC-80 Controller

(see page 12) may only be used on vehicles tested and

approved by Bendix engineering. The tests produce

a validated parameter data set for use by the vehicle’s

Bendix ESP EC-80 Electronic Control Unit (ECU).

When replacing an ECU, only specic Controllers —

with the correct parameter set — may be used. See

“Obtaining a N ew Bendix ES P EC‑ 80 C ontroller ” on

page 17 for further details.

Bendix ESP system with the EC-80 Controller-equipped

ve hi c les should not be dr i v e n on hi g h -ba n k e d ro a d s —

such as those found on high-speed test or race tracks.

Test per sonnel must have the Be ndix ESP system's

stability features disabled prior to operating a vehicle

on such tracks.

Page 3

For vehicles with the (optional) Hill Start Aid (HSA) system

(sometimes referred to as a “Hill Start Assist”, or simply “Hill

Start ”), this feature interfac es between the transmis sion

and the braking system. HSA helps the driver prevent

the vehicle from rolling downhill w hen m oving up a steep

incline from a stationar y position. See page 6 for more

information.

YAW CONTROL (YC)

A Bendix® EC‑80™ ESP® Controller includes Yaw Control

(YC) functionality. Yaw Control has the ability to apply

brakes to individual wheel ends, as well as applying the

trailer brakes, to counteract trailer “pus h” that — during

cert ain maneuvers — could lead to a loss‑ of‑control or

a jackknife incident. See " Yaw Stability" on page 13 for

further details.

ROLL STABILITY PROGRAM (RSP)

®

The Bendix

ABS solution that helps decrease vehicle speed by

reducing the engine's throttle and applying all vehicle

brakes as needed, mitigating the vehicle's tendency to

roll over. RSP focuses on reducin g the vehicle’s speed

below the critical ro ll thre sho ld dur in g direc ti on‑changing

maneuvers — such as driving on curved highway exit

ramps or obstacle avoidance maneuvers on dry, high

friction sur faces. See " ESP ABS with Stabilit y Control"

on page 12 for further details.

Roll Stability Program (RSP), is an all‑a xle

The Bendix ESP EC‑80 Controller 's ESP/RSP function

utilizes the following additional components:

• A Steer Axle T raction Control V alve (may be integral

to the service brake Relay Valve or a stand‑alone

device)

Sensor

Clamping

Sleeve

Straight Speed

90° Speed

Sensors

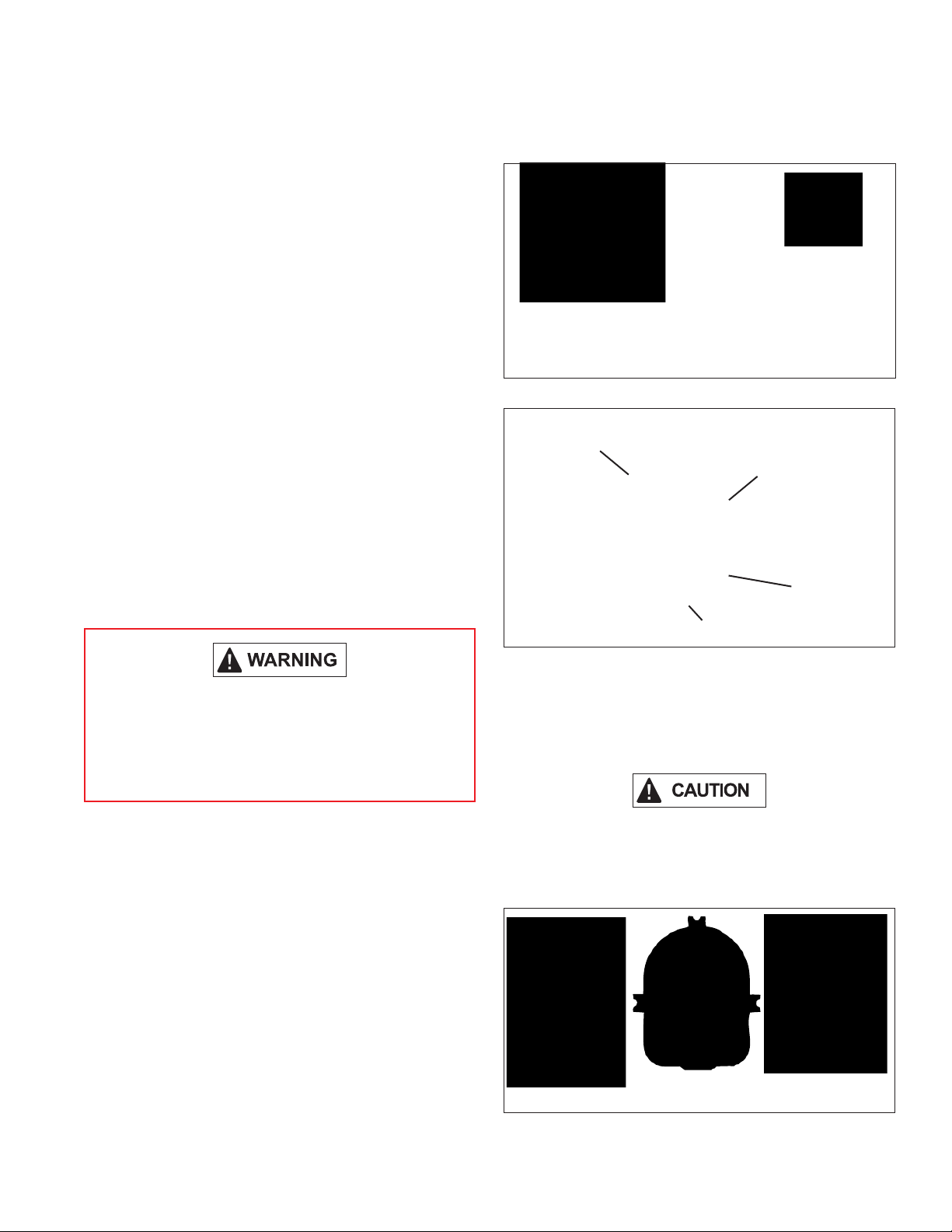

FIGURE 2 - BENDIX® WS‑24™ WHEEL SPEED SENSORS

Delivery

(Port 2)

™

M-40X

Modulator

Exhaust (Port 3)

Sensors

Supply

(Port 1)

Electrical

Connector

During an RSP syste m intervent ion, the vehicle

automatically decelerates. RSP can slow the

vehicle with or without the operator applying

the brake p edal, and even when the o perator is

applying the throttle.

COMPONENTS

The Bendix ESP EC‑80 Controller’s ABS function utilizes

the following components:

• Bendix® WS‑24™ Wheel Speed Sensors (four or

six, depending on the conguration), each with a

clamping sleeve. [Refer to SD-13-4860]

• Bendix® M‑40QR™ or M‑40‑HF™ Pressure Modulator

Valves (four, ve, or six may be present) [refer to

SD-13-4958]. For legacy systems where a Bendix®

M‑32™ or M‑32QR™ Pressure Modulator Valve is

used, refer to SD-13-4870.

• A dash‑mounted tractor ABS Indicator Lamp

• A service brake Relay Valve

• A dash‑mounted trailer ABS Indicator Lamp

• An optional blink code Activation Switch

• An optional ABS Off‑road Switch

FIGURE 3 - EXAMPLE OF A BENDIX M‑40X™ MODULATOR

• A dash‑mounted ESP Status/Indicator Lamp (also

serves as the ATC Status/Indicator Lamp)

• A Bendix® SAS‑60™ Steering Angle Sensor

(mounted to the steering column ‑ See Figure 4)

When replacing a steering wheel, take care not to

damage the Steering Angle Sensor or interfere with

its operation, and the Steering Angle Sensor must be

recalibrated (see Troubleshooting section.)

Straight

Connector

FIGURE 4 - EXAMPLES OF STEERING ANGLE SENSORS

90° Connectors

3

Page 4

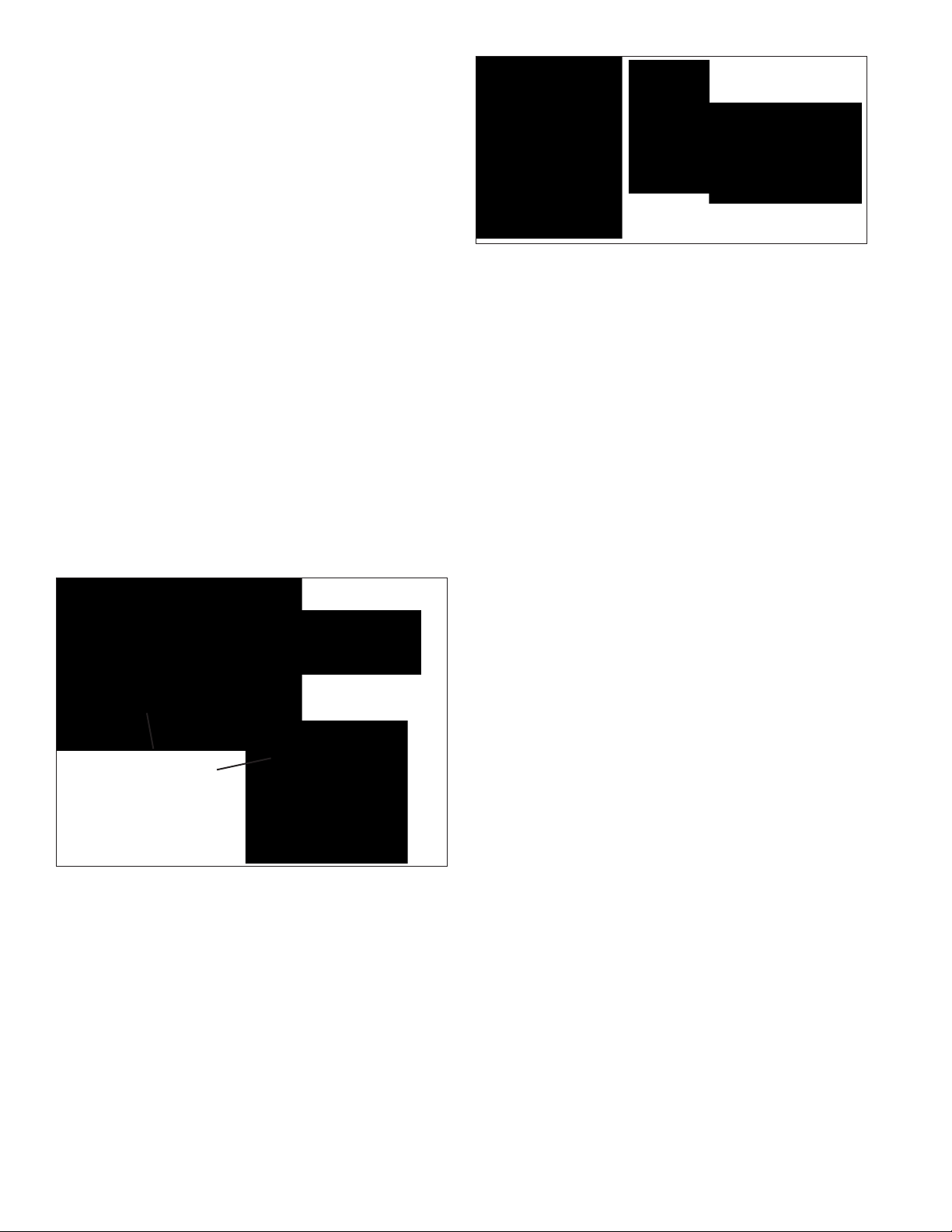

• Bendix® YAS‑60™ or YAS‑70X™ Yaw Rate/Lateral

Acceleration Sensors (typically mounted to a cross‑

member near the back of the vehicle cab). See

Figure 5.

• Brake Demand Sensors (installed in the primary

and secondary delivery circuits)

• A Load Sensor (typically installed in the suspension

air bag)

• An additional Modulator Valve (Bendix® M‑40QR™ or

M‑40HF™ Pressure Modulator Valve) that controls

the pressure applied to the trailer brakes during a

system intervention

The Bendix® ESP® EC‑ 80™ Controller's ATC function

utilizes the following additional components:

• A drive axle Traction Control V alve (may be integral

to the service brake relay valve or a stand‑alone

device)

• A dash‑mounted ATC Status/Indicator Lamp

• A J1939 serial communication Control Module

• A J1939‑ or ECU hardware‑provided Stop Lamp

Switch Input

• An optional ATC Mud/Snow Switch (sometimes

referred to as an ATC off‑road switch)

Brake Demand/

Load Sensor

®

Bendix® RV-3

Pressure

Reducing Valve

FIGURE 6 - ADDITIONAL VALVES NECESSARY FOR THE

HILL START AID FEATURE

™

Bendix® AT-3

Traction Control

Valve

™

Bendix

Double Check

Valve

DC-4

®

BENDIX® ETRAC™ AUTOMA TED AIR

SUSPENSION TRANSFER SYSTEM

The Bendix® eTrac™ automated air pressure transfer system

is used on 6 x 2 semi‑trac tors that feature Bendix® ATC

and ESP Antilock Brake Systems (ABS). This system

complements the Bendix® S MART AT C™ traction control

feature of our ABS system to provide improved traction at

low speeds (e.g. pulling away on an inclined ramp, or in

slippery conditions such as mud or snow‑covered surfaces,

etc.) When active, the Bendix eTrac system vents — or

“dumps” — the air pressure of the tag axle susp ension

air bags, and increases the air pressure in t he drive a xle

suspension air bags to a pre‑determined maximum. This

action helps the drive axle to gain more traction.

See SD-13-21021 for more information about the Bendix®

eTrac™ Automated Air Suspension Transfer System.

Yaw/Lateral

Accelerator Sensors

(Two examples

shown.)

FIGURE 5 - YAW AND BRAKE DEMAND/LOAD SENSORS

The Bendix ESP EC‑80 Controller's Hill Start Aid function

utilizes the following additional components:

• A Bendix® AT‑3™ Traction Control Valve

• A dash‑mounted Hill Start Status/Indicator Lamp

• A dash‑mounted Enable/Disable Switch

• A Bendix® RV‑3™ Pressure Reducing Valve

• A Bendix® DC‑4® Double Check Valve

ECU MOUNTING

The Bendix ESP EC‑80 Controller is not protected against

moisture, and must be mounted in an environmentally

protected area.

All wire harness connectors must be properly seated. The

use of secondary locks is strongly recommended.

The Bendix ESP EC‑80 Controller utilizes connectors from

the AMP MCP 2.8 product family.

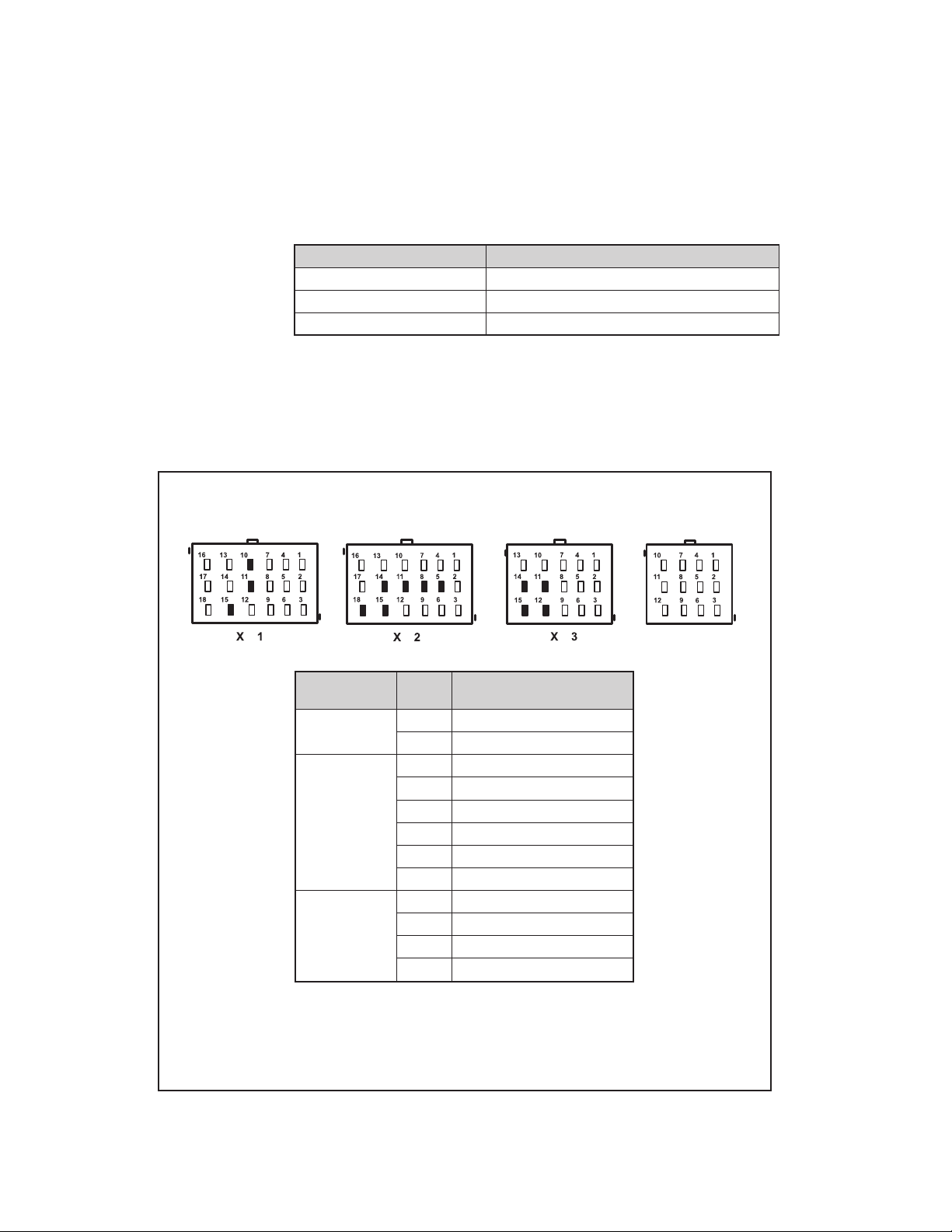

HARDWARE CONFIGURATIONS

Bendix ESP EC‑80 Controllers support applications up to

six sensor/six modulator (6S/6M) installations with ATC

and drag torque control. They can also support Hill Start

functions. All 12 volt models suppor t Power Line Carr ie r

(PLC). 24 volt models do not support PLC. See Figure 7

for more details.

4

Page 5

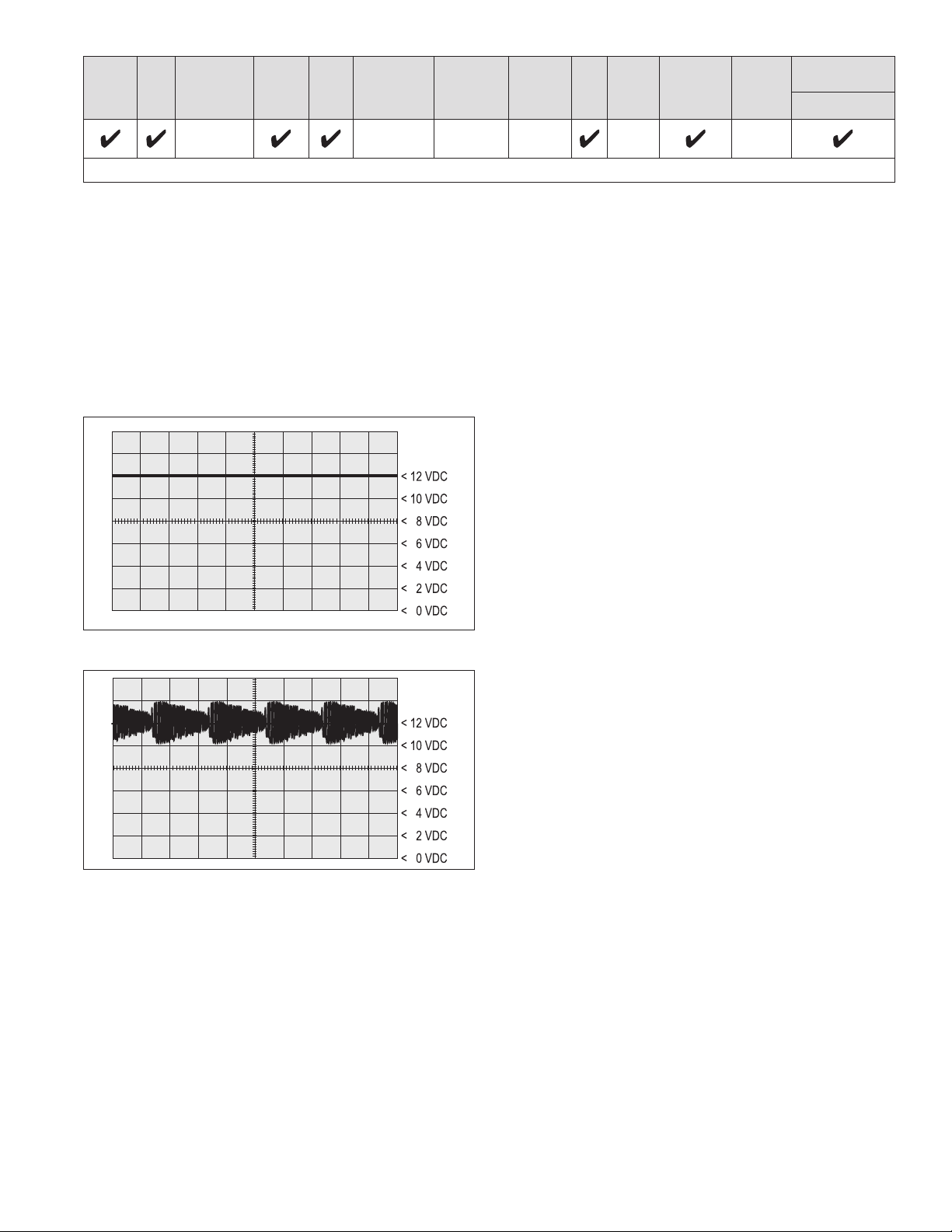

ABS

Off-

Road

ATC

ATC

Mud/Snow

Blink

Codes

ESP/

RSP

HSA

Hill Start

Aid Feature

Bendix

eTrac

system*

Optional Optional Optional 12/24 4/5/6 4/6

For information about the Bendix® eTrac™ automated air suspension transfer system, see SD‑13‑21021

*

FIGURE 7 - BENDIX® ESP® EC‑80™ CONTROLLER FEATURES

BENDIX® ESP® EC-80™ CONTROLLERS USE

POWER LINE CARRIER (PLC)

All new towing vehicles built since March 1, 2001 , have had

an in‑cab trailer ABS Indicator Lamp installed.

Trailers built since Marc h 1, 2001, transmit the status of

the trailer ABS over the power line (the blue wire of the

J560 connector) to the tractor using a Power Line Carrier

(PLC ) signal. See Figures 8 and 9. Typically the signal is

broadcast by the trailer ABS Electronic Control Unit (ECU).

®

™

Voltage

Input

PLC

Modu-

lators

(PMVs)

Retarder

Relay

Sensors

Serial

Communication

J1939

Suggested oscilloscope settings are AC coupling, with one

volt/div, 100 µsec /div. The signal should be measured at

the ignition power input of the Bendix EC‑80 Controller.

Note: An ABS trailer equipped with PLC, or a PLC

diagnostic tool, must be connected to the vehicle in order

to generate a PLC signal on the power line.

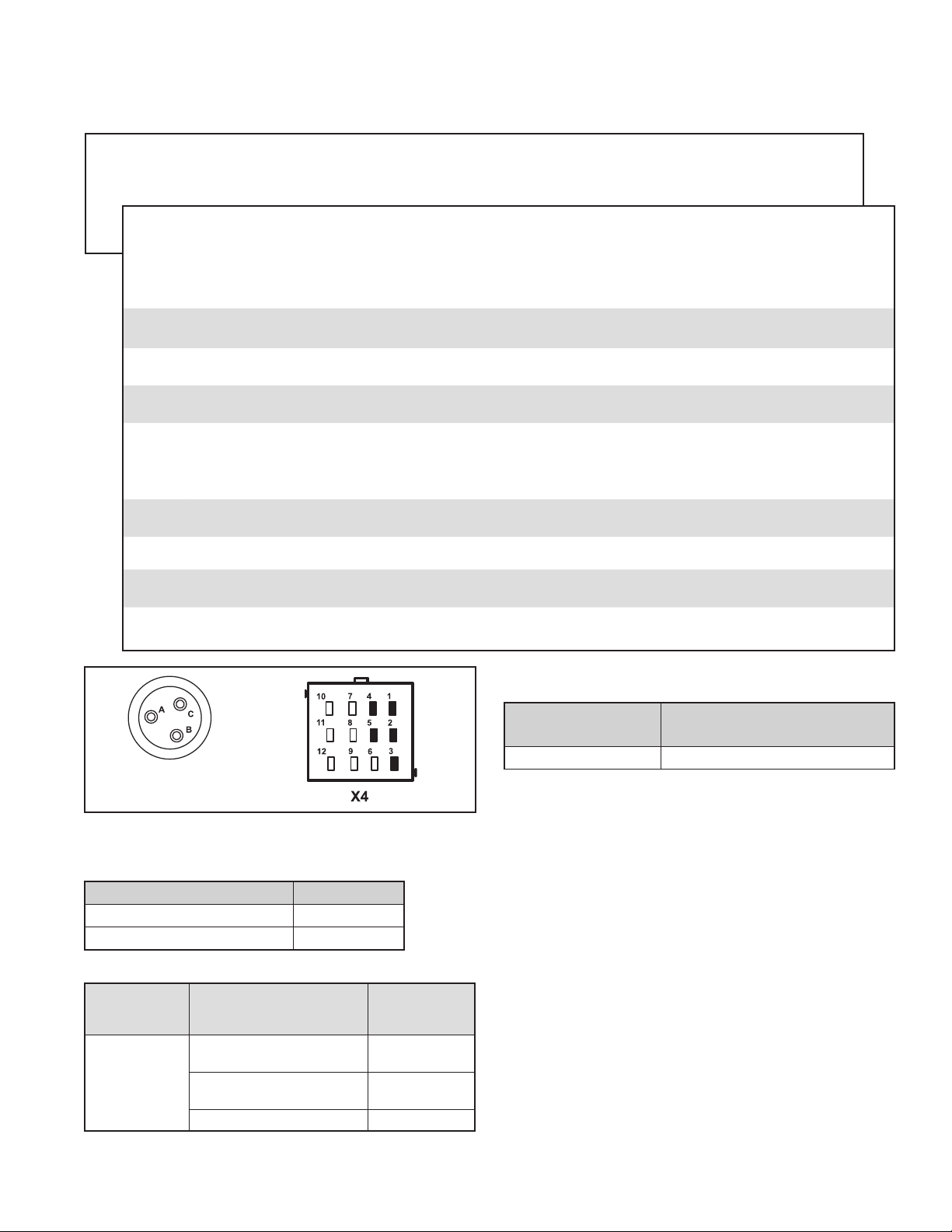

BENDIX ESP EC-80 CONTROLLER INPUTS

Battery and Ignition Inputs

The Bendix ESP EC‑ 80 Controller oper ates at a nominal

supply voltage of 12 or 24 volts, depending on the ECU.

The battery input is connected through a 3 0 amp fuse

directly to the battery.

The ignition input is applied by the ignit ion switch circuit

through a 5 amp fuse.

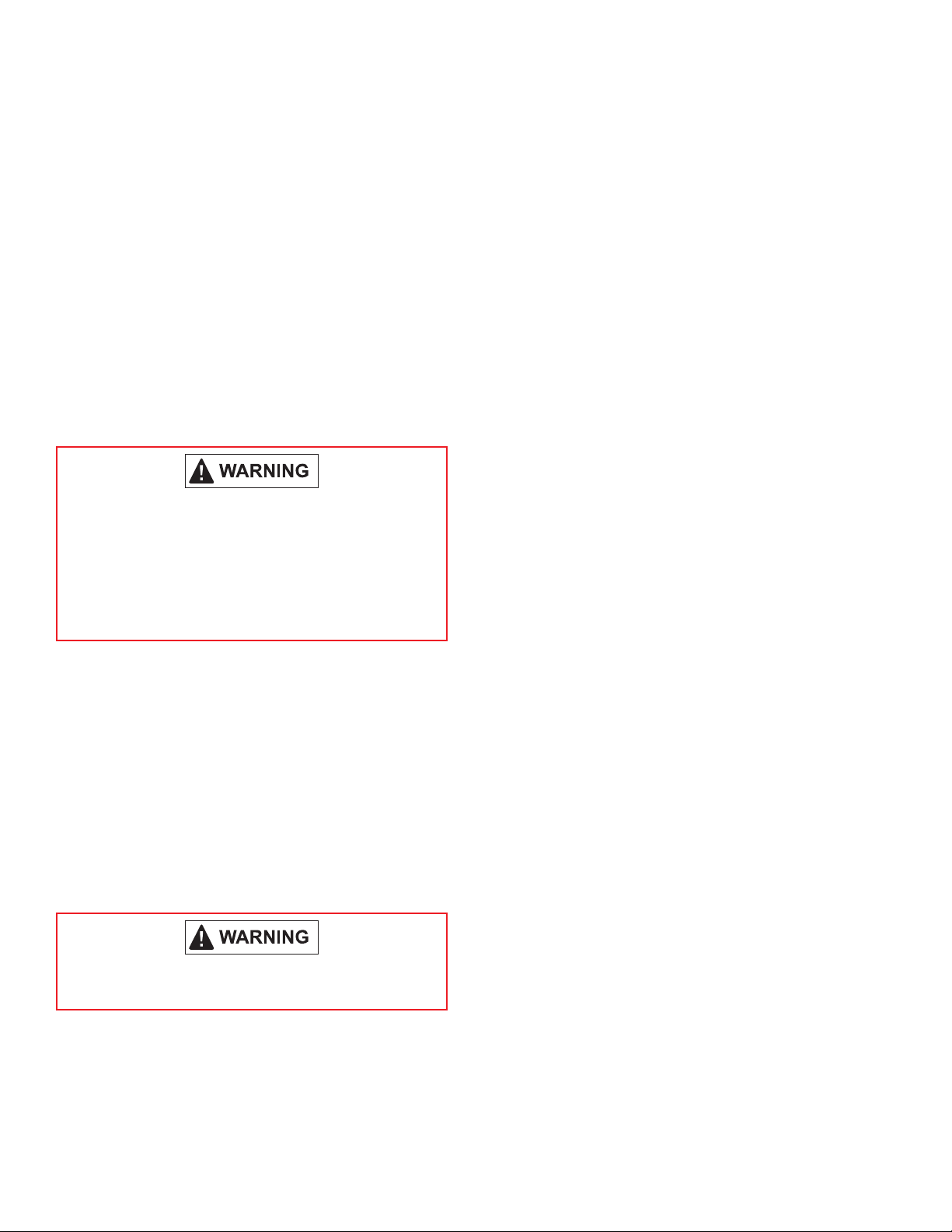

FIGURE 8 - POWER LINE WITHOUT PLC SIGNAL

FIGURE 9 - POWER LINE WITH PLC SIGNAL

The application of PLC technology fo r the heavy vehicle

industry in North America is known as “PLC4Trucks.”

The Bendix® ESP® EC‑ 80™ Controller supports PLC

communications in accordance with SAE J2497.

PLC SIGNAL

An oscillosc ope can be used to measure or identif y the

presence of a PLC signal on the power line. The PLC

signal is an amplitude and frequency‑modulated signal.

Depending on the ltering and load on the power line,

the PLC signal amplitude can range from 5.0 mVp‑p to

7.05 Vp‑p.

Ground Input

The Bendix ESP EC‑ 80 Controller supp orts one gr ound

input. See pages 52 and 53 for wiring system schematics.

ABS Indicator Lamp Ground Input

The Bendix ESP EC‑80 Controller requires a second

ground input (X1‑12) for the ABS indicator lamp. The X1

wire harness co nnector contains an AB S indicator lamp

interlock (X1‑15), which shorts the ABS indicator lamp

circuit (X1‑18) to ground if the connector is removed from

the ECU.

Bendix® WS-24™ Wheel Speed Sensors

Wheel speed data is provided to the B endix ESP EC‑ 8 0

Controller from the Bendix® WS‑24™ wheel speed sensor

(see Figure 2). Vehic les have an exciter ring (or “tone

ring”) as part of the wheel assembly. As the wheel

turns, the teeth of the exciter ring pass the whee l speed

sensor, generating an AC signal. The Bendix ESP EC‑80

Controller receives the AC signal, which varies in voltage

and frequency as the wheel speed changes.

Vehicle axle configurations determine the number of

Bendix WS‑24 wheel speed se nsors that must be used.

A vehicle with a single rear axle requires four wheel speed

sensors. Vehicles with two rear axles can utilize six wheel

speed sensors for optimal performance.

5

Page 6

Diagnostic Blink Code Switch

A momentary switch that grounds the ABS Indicator Lamp

output is used to place the ECU into the diagnostic blink code

mode and is typically located on the vehicle’s dash panel.

Optional ABS Off-Road Switch and Indicator

Lamp Operation

Vehicle operators use an optional dash‑mounted switch to

place the Bendix® ESP® EC‑ 8 0™ Controller into the ABS

off‑road m ode. See "Optional A BS Off- Road Mode" on

page 10 for further details. In some c ases, ECUs may

also be put into the ABS off‑road mode by one of the other

vehicle control module s, using a J193 9 message to the

Bendix ESP EC‑80 Controller.

(If you need to know if a specic Bendix ESP EC‑80

Controller uses a J1939 message to operate the lamp,

contact the Bendix Tech Team. E‑mail the Tech Team

at ABS@bendix.com (be sure to specify the ECU par t

number), or call 1‑800‑AIR‑BRAKE (1‑800‑245‑2725).

The ABS off-road mode should not be used on

normal, paved road surfaces because vehicle

stability and steerability may be adversely affected.

When the ECU is placed in the ABS off-road mode,

the ABS Indicator Lamp will ash constantly (at a

rate of onc e per 2 .5 secon ds) to notif y th e vehicle

operator that the off-road mode is active.

Optional ATC Mud/Snow (Off-Road) Switch and

Indicator Lamp Operation (also see page 8.)

The Bendix ESP system uses a dash‑mounted switch for the

operator to place the ECU into the ATC Mud/Snow mode.

Optional Hill Start/Hill Start Assist Feature

Switch and Lamp Operation (see also page 8.)

ESP Controllers use a dash‑mounted switch for the

operator to place the ECU into the hill star t mode. This

feature interfaces between the transmission and the

braking system to help the driver prevent the vehicle from

rolling downhill when moving up a steep incline fro m a

stationary position.

With Hill Start Aid Feature option you lose the ABS

off-road function and the retarder relay output.

When the ECU is placed in the Hill Start Aid (HSA) feature

mode, the HSA Indicator Lamp will ash constantly (at a

rate of once per 2.5 seconds) to notify the vehicle operator

that the HSA mode is active. The ECU receives J1939

messages from the t ransmissi on to engage the H S/HSA

components. When engaged, the system applies 44 psi to

the rear brakes for three (3) seconds then releases. This

function is totally controlled by the automatic transmission.

6

Stop Lamp Switch (SLS)

The Bendix ESP EC‑ 80 Controller monitors the vehic le

stop lamp status. Certain vehicle functions, such as

ATC and All‑Wheel Drive (AWD), use the status of the

stop lamp to determine when the driver makes a brake

application. This c an be provided to the ECU via J1939

communications, or hardware input.

Brake Demand Sensors

The brake demand sensors provide the Controller with an

indication of driver‑applied brake pressure. One is installed

in the primary air brake circuit, and another is installed in

the secondary air brake circuit.

Load Sensor

The load sensor provides the Controller with an indication

of the vehicle load. It is typic ally installed in one of the

suspension air bags.

Bendix® SAS-70X™ Steering Angle Sensor

Bendix® brand Steering Angle Sensors (SAS) are used to

report the steering wheel position to the Controller, utilizing

a dedicated serial communications link that is shared with

the Y a w Rat e Sensor. The Controller supplies the power

and ground inputs to the Bendix® SAS‑70X™ sensor.

The Bendix SAS‑70X sensor is available with two different

styles of wire harness connectors. (See Figure 4.)

Bendix® YAS-60™ or Y AS-70X™ Yaw Rate/Lateral

Acceleration Sensors

Bendix® brand yaw rate/lateral acceler ation sensors are

used to provide the Controller an indication of vehicle

lateral acceleration an d rotati on around t he ver ti c al ax is.

This information is provided to t he Controller, utilizing a

dedicated serial c ommunications link that is sha red with

the Bendix® SAS‑60™ sensor. The Controller supplies the

power and ground inputs to the yaw rate sensor.

BENDIX® ESP® EC-80™ CONTROLLER

OUTPUTS

Bendix® M-40QR™ and M-40HF™ Pressure

Modulator Valves (PMVs)

The Bendix ESP EC‑80 Controller operates Bendix®

M‑40QR™ and M‑40HF™ Pressure Modulator Valves

(PMVs) to modify the dr iver‑applied air pressure to the

servic e brakes during ABS, ATC, RSP or YC activation

(see pages 9-13). The PMV is an electropneumatic

control valve and is the last valve that air passes through

on its way to the brake chamber. The modulator hold and

release solenoids are activated to "modulate" or "control"

the brake pressure during an antilock braking event. The

hold solenoid is normally open and the release solenoid is

normally closed, such that the PMV nominally allows air to

ow through. This design allows for air delivery to brake

chambers in the event of electrical trouble.

Page 7

The Bendix® ESP® EC‑ 80™ Controller also utilizes an

additional Pressure Modulator Valve (PMV) for control

of the trailer service brakes during stability interventions.

Traction Control Valve (TCV)

Bendix ESP EC‑80 Controllers use two TCVs, one on the

steer axle and one on the dr i ve a x l e. The TCV may be a

separate valve or integrated into the rear axle relay valve.

The Controller will activate the drive axle TCV during

differential braking ATC events.

During stabilit y interventions, the Controller will act ivate

both the steer axle and drive axle TCVs as required.

Stop Lamp Output

The Controller provides an output to control a relay

that illuminates the vehicle stop lamps during stability

interventions. This information is also available using the

J1939 serial communications link.

ABS Indicator Lamp Control with Optional

Diagnostic Blink Code Switch

The Bendix ESP EC‑80 Controller has internal circuitry to

control the ABS Indicator Lamp on the dash panel.

The ABS Lamp Illuminates:

1. During power up (e.g. when the vehicle is started) for

approximately three (3) seconds and turns off after the

self‑test is completed, providing no Diagnostic Trouble

Codes (DTCs) are present on the ECU;

2. When full ABS operation is not available due to the

presence of a DTC on the ECU;

3. If the ECU is unplugged or has no power;

4. When the ECU is placed into the ABS off‑road

mode (the lamp ashes steadily at a rate of once per

2.5 sec.); or

5. To display blink codes for diagnostic purposes after the

external diagnostic switch is activated.

The Bendix ESP EC‑80 Controller may communicate

with other vehicle control modules to operate the ABS

Indicator Lamp using serial communications. (If you

need to know if this Bendix ESP EC‑ 80 Controll er uses

serial communications to operate the lamp; e‑mail ABS@

bendix.com, (be sure to specify the ECU part number), or

call 1‑800‑AIR‑BRAKE/1‑800‑247‑2725 and speak to the

Bendix Tech Team.)

Indicator Lamp Control Using Serial

Communications Links

As mentioned above, depending on the vehicle

manufacturer, the dash indicator lamps (ABS, ATC,

ESP, and trailer ABS) may be controlled using serial

communications links. In the se cases, the Bendix ESP

EC‑80 Controller will send a serial communications

message over the J1939 link, indicating the required status

of the lamp(s). Another vehicle contro l module receives

the message and controls the indicator lamp(s).

Dynamometer Mode Indicator Lamp Operation

When the Bendix ESP EC‑ 80 Controller is put into the

Dynamometer mode for testing purposes, the ATC

Indicator Lamp will be illuminated.

Retarder Relay Disable Output

The retarder relay disable output may be used to control a

retarder disable relay. When congured to use this output,

the ECU will energize the retarder disable relay and inhibit

the use of the retarder as needed.

If the ECU is congured for the Hill Start/ Hill Start Assist

feature (HS/HSA), the retarder relay output pin is used to

control the Hill St art status lamp. As a result, the vehic l e

loses the retarder relay function when it has the Hill Start

feature.

SAE J1939 Serial Communications

A Controller Area Network (CAN) data link (SAE J1939 ) is

provided for communication. This link is used for various

functions, such as:

• Diagnostic purposes.

• To disable retarding devices during ABS operation.

• To request that the torque converter disable lock‑up

during ABS operation

• To share information such as wheel speed and ECU

status with other vehicle control modules.

Bendix ESP EC‑80 Controllers utilize the J1939 data link

for:

• ATC and drag torque control functions.

• Vehicle stability functions.

Trailer ABS Indicator Lamp Control

The Bendix ESP EC‑80 Controller will activate a trailer ABS

Indicator Lamp (located on the dash panel) that indicates

the status of the trailer ABS unit on one, or more trailers, or

dollies that are equipped with PLC functionality. T ypically ,

the Bendix ESP EC‑80 Controller directly controls the

trailer ABS Indicator Lamp based on the information it

receives from the trailer ABS, via PLC.

Alternatively, some vehicles require the Bendix ESP EC‑80

Controller to activate the trailer A BS Indicator Lamp by

communicating with other vehicle Controllers using serial

communications.

(If you need to know if this Bendix ESP EC‑ 80 Controller

uses a serial communications message to operate the

lamp, e‑mail ABS@bendix.com (be sure to specify the ECU

part number), or call 1‑800‑AIR‑BRAKE (1‑800‑245‑2725)

and speak to the Bendix Tech Team.)

Interaxle Differential Lock Control

(AWD Transfer Case)

Bendix ESP EC‑ 80 Controllers c an control the intera xle

differential lock (AWD transfer case) . This is recommended

on AWD vehicles, but the ECU must be specially congured

to provide this feature. E‑mail ABS@bendix.com for more

details.

7

Page 8

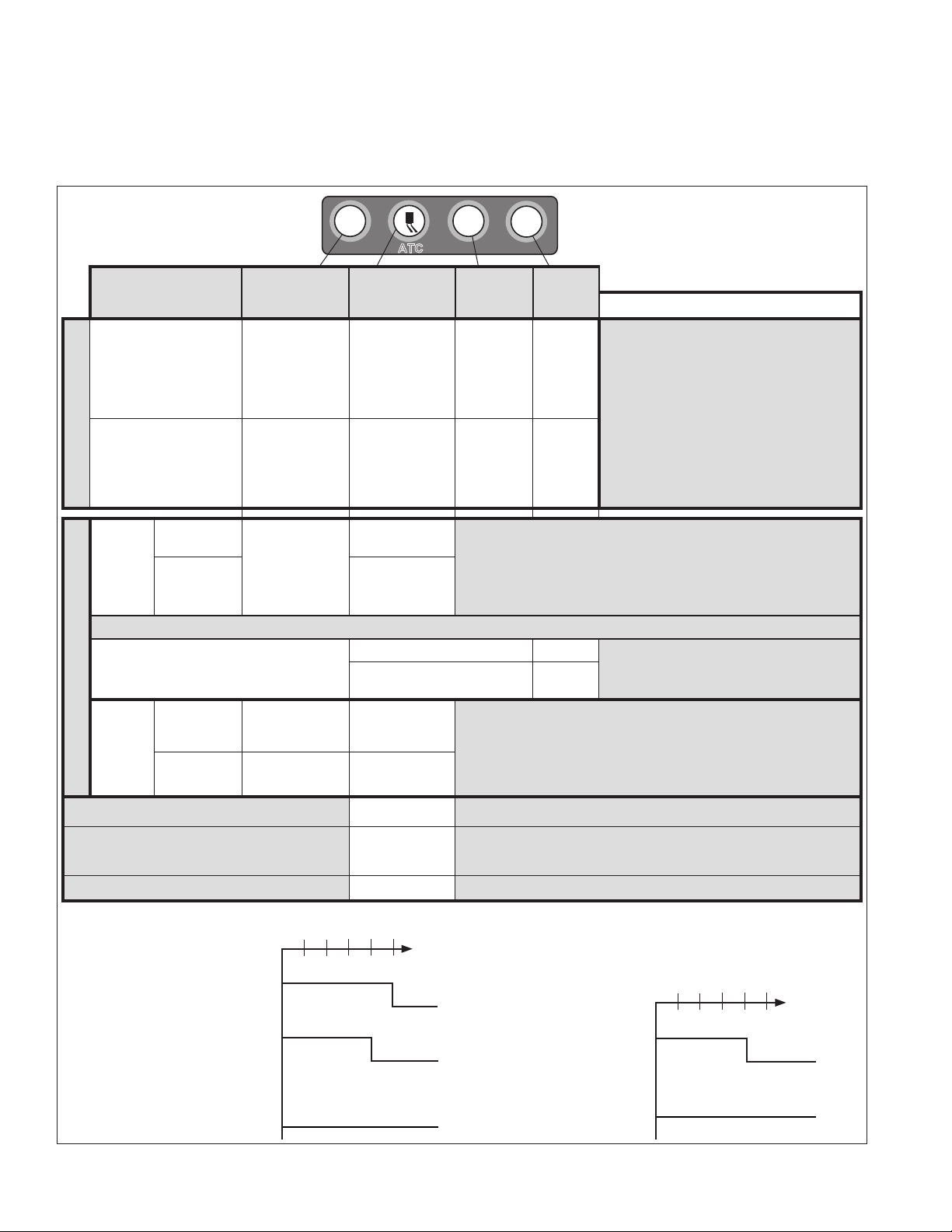

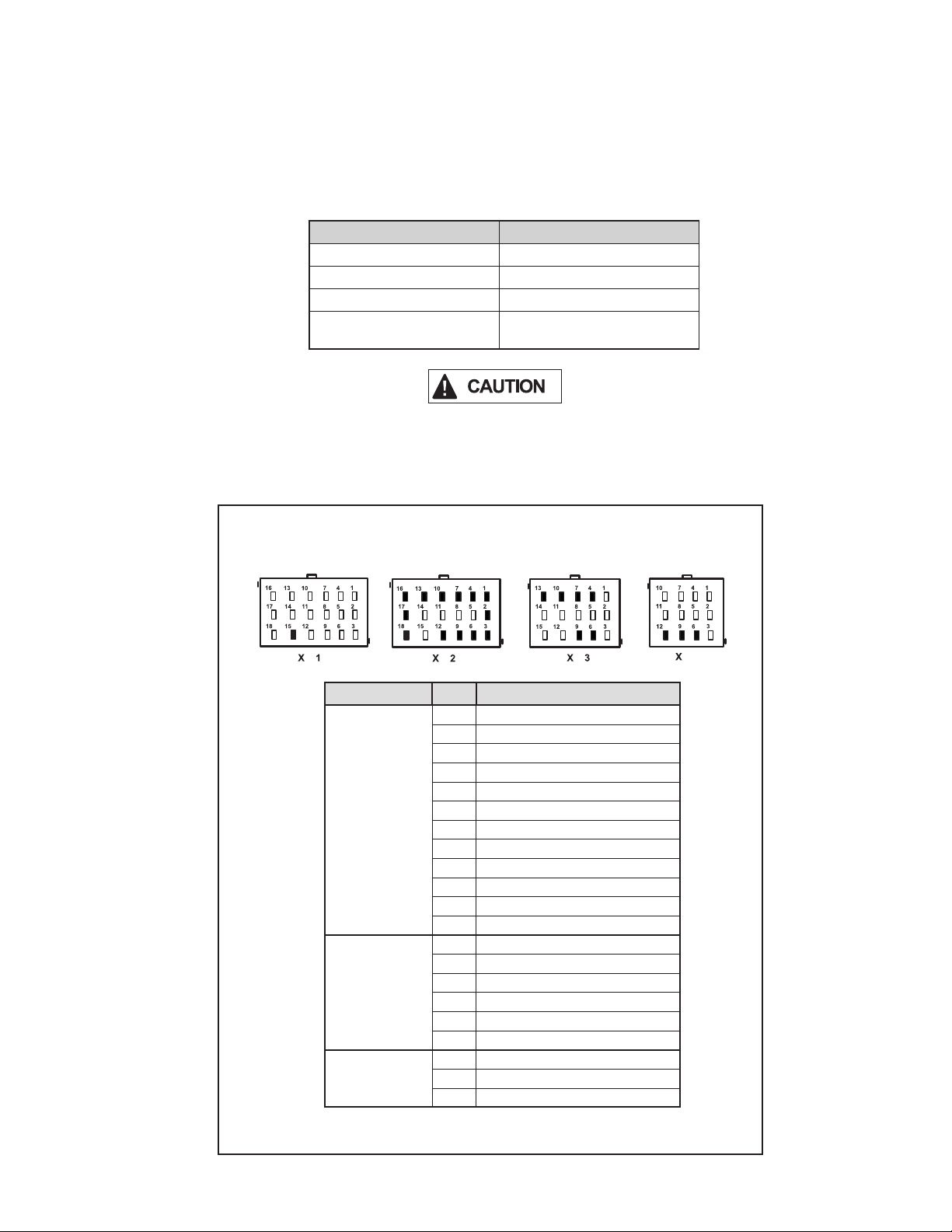

INDICATOR LAMPS AND POWER-UP

ATC

SEQUENCE

NOTICE: The vehicle operator should Verif y the proper

operation of all installed indicator lamps (ABS, ATC/ESP,

and trailer ABS) when applying ignition power and during

vehicle operation. See Figure 10.

Lamps that do not illuminate as expected when ignitio n

power is applied, or remain illuminated, indicate the need

for maintenance.

Dash Lamp Behavior for the

ABS

Bendix® ESP® EC-80™ Controller

Mode

Ignition on ‑ start up

[trailer with Power Line

Carrier (PLC)]

3 seconds after ignition

At Vehicle Startup

[with no Diagnostic

Trouble Codes (DTCs)]

ABS

Off-Road

Mode

Vehicles with Hill Start Aid (HSA):

Special Mode Operation

Deep

Mud/

Snow/

Mode

During an Automatic Traction Control (ATC) Event Flashes quickly • Reduces wheel slip during acceleration at low speeds

During Dynamometer Mode

Normal

During an ATC

Event

‑— OR, depending on vehicle options (a vehicle can have either ABS off‑road or HSA) —

During HSA Mode

(“Hill Start” / “Hill Start Assist”)

Normal OFF

During an

ATC/ESP

Event

During an ESP Event Flashes quickly •

ABS

Lamp

ON for

three (3)

seconds*

Lamp OFF* Lamp OFF* Lamp OFF**

Lamp ashes

slowly (every 2.5

seconds)

OFF Flashes quickly

ATC/ESP Lamp

ON for 2.5

seconds*

Lamp OFF

Flashes quickly

During HSA Event Lamp OFF

HSA Manually Disabled

Flashes slowly

(every 2.5

seconds)

Lamp ON

(ATC

Disabled)

TRLR

ABS Lamp

seconds**

• Uses dash switch

• Not for rm road surfaces

• Allows more wheel lock‑up (less ABS intervention)

• Mode only applies under 25 mph (Over 25 mph, the system reverts to

• Disables ATC monitoring functions

• When not in Dynamometer Mode, an illuminated lamp indicates an

ATC DTC is present

HSA

Trailer

ON for

three (3)

full ABS ‑ including ATC/ESP — and upon exiting off‑road mode, the

ATC lamp extinguishes.)

• Uses dash switch

• Increases allowable wheel slip during ATC interventions

• Not for rm road surfaces

System intervenes to reduce the risk of rollovers, loss‑of‑control, etc.

HSA

Lamp

ON for

three (3)

seconds*

Lamp

OFF*

Flashes

slowly

Comments

If any of the described lamp behaviors

*

do not occur — or if the lamp remains

on during operation — have the vehicle

serviced by a qualied mechanic as

soon as possible to restore full system

functionality.

Some vehicle manufacturers may

**

illuminate the trailer ABS indicator lamp

at power‑up regardless of whether a

PLC signal is detected from the trailer or

not. Consult the vehicle manufacturer’s

documentation for more details.

• The HSA lamp is illuminated only at power‑

up, or if an HSA DTC is present

0.5 2.0 2.5 3.0 (sec.)1.5

Power

Application

ATC/ESP System

Status Indicator

at Start-Up

ATC/ESP

enabled

No ESP

or ATC

ABS System

Status Indicators

at Start-Up

Powered Vehicle ABS

Indicator Lamp

Trailer ABS

Indicator Lamp

(PLC Detected)**

Trailer ABS

Indicator Lamp**

(PLC Not Detected)

ON

OFF

ON

OFF

ON

OFF

FIGURE 10 - BENDIX® ESP® EC‑80™ CONTROLLER INDICATOR LAMP BEHAVIOR

8

ON

OFF

ON

OFF

0.5 2.0 2.5 3.0 (sec.)1.5

Power

Application

Page 9

ABS Indicator Lamp Operation (Bulb Check)

The Bendix® ESP® EC‑80™ Controller will illuminate the

ABS Indicator Lamp for approximately three seconds when

ignition power is applied, after which the lamp will extinguish

if no Diagnostic Trouble Codes (DTCs) are detected.

The Controller will illuminate the ABS Indicator Lamp

whenever full ABS operation is not available due to a DTC.

In most cases, partial ABS is still available.

ATC/ESP Status/Indicator Lamp Operation

The Bendix ESP EC‑80 Controller will illuminate the A TC/

ESP lamp for approximately 2.5 seconds when i gnition

power is applied, after which t he lamp will extinguish if

no DTCs are detected. The Controller will continuously

illuminate the AT C/ESP Indicator Lamp whenever ESP or

ATC is disabled due to a DTC.

During an ESP or ATC intervention, the lamp will ash

rapidly (2.5 times per second). When the C ontroller is

placed in the ATC Mud/Snow (off‑ road) mode, the lamp

will ash slowly at a rate of once every 2.5 seconds.

Trailer ABS Indicator Lamp Operation

The Controller will control the Trailer ABS Indicator Lamp

when a PLC signal (SAE J2497) from a trailer ABS ECU

is detected.

Hill Start Assist (HSA) Indicator Lamp Operation

Vehicles with HSA enabled, will illuminate the HSA

Indicator Lamp when ignition power is applied. The lamp

will extinguish if there are no issues with the HSA system.

This test is performed only when the vehicle is stationary

(if the vehicle moves, the Chuff Test will not be performed).

The Bendix ESP EC‑80 Controller will per form a PMV

Chuff Test on all installed modulators in the following order:

• Steer Axle Right PMV;

• Steer Axle Left PMV;

• Drive Axle Right PMV;

• Drive Axle Left PMV;

• Additional Axle Right PMV;

• Additional Axle Left PMV; then

• Drive Axle TCV

The pattern will then repeat itself. See Figure 11.

Vehicles with a Bendix ESP EC‑80 Controller — following

the completion of the second round of PMV & TCV Chuff

Tests — the Controller (if congured to do so) will perform

a test to cross‑ check the trailer PMV o peration with the

vehicle stop lamps. If the trailer PMV c irc uit i s mis‑wired

(including the steer axle TCV), the PMV will exhaust a large

amount of air, or none at all.

NOTICE: If there are any active DTCs, the stop lamp

cross‑check portion of the Chuff Test will not be carried out

until all DTCs are fully diagnosed and the corresp onding

repairs are succes sfully conduc ted. The ESP/ATC dash

indicator will also illuminate when there are ac tive ABS,

ATC or ESP DTCs.

The ECU will not perform the PMV Chuff T est when wheel

speed sensors show that the vehicle is in motion.

Pressure Modulator Valve (PMV) and Traction

Control Valve (TCV) Chuff Test

Right Steer

Driver

Left Steer

FIGURE 11 - VEHICLE ORIENTATION (TYPICAL)

After the performance of the conguration test, the Bendix

ESP EC‑80 Controller will perform a Bendix‑patented PMV

and TCV Chuff Test. The Chuff Te st is an elect ric al and

pneumatic PMV test that can assist maintenance personnel

in verifying proper PMV wiring and installation.

When ignition power is applied, eac h m odulator so le noi d

is briey energized. If the air system is fully charged and

the servic e brake pedal is depres sed during i gnition, the

modulator creates a single, sharp audible “chuf f” of air

pressure. The modulators are energized in a certain

pattern: right front; left front; right rear; then left rear.

Right Drive

Left Drive

Right

Additional

Left

Additional

ABS OPERATION

Bendix® ABS uses wheel speed s ensors, ABS pres sure

modulator valves, and an ECU to control either four or six

wheels of a vehicle. The Bendix ESP EC‑ 80 Controlle r

monitors individual wheel tur ning motion during brak ing,

and adjusts or modulates the brake pressure at the wheel

end. When excessive wheel slip — or wheel lock‑up — is

detected, the Bendix ESP EC‑ 80 Controller will act ivate

the pressure modulator valves to automatically reduce

the brake pressure at one or more of the wheel ends.

By these actions, the A BS system helps to maintain the

vehicle's lateral stability and steerability during heavy brake

applications and during braking on slippery surfaces.

Steer Axle Control

Although both wheels of the steer axle have their own

wheel speed sensor and pres sure modulator valve, the

Bendix ESP EC‑ 80 Controller blends the applied braking

force between the two steering axle brakes. This Bendix

patented brake application control, called Modified

Individual Regulation (MIR), is designed to help reduce

steering wheel pull during an ABS event on road surfaces

with poor tracti on, or areas of poor tracti on (e.g. asphalt

road surfaces with patches of ice).

9

Page 10

Single Drive Axle Control (4x2 Vehicle)

For vehicles with a single rear drive axle (4x2) , the brakes

are operated independently by the Bendix® ESP® EC‑80™

Controller, based on the individual wheel behavior.

Dual Drive Axle Control (4S/4M Conguration)

For vehicles with dual drive axles (6x4) using a 4S/4M

conguration, one ABS modulator controls both of the

right‑side rear whe els; the other modulator c ontrols both

of the left‑side r ear wheels. Both wheels on each side

receive equal brake pressure during an A BS stop. The

rear wheel speed sensors must b e installed on the axle

with the lightest load.

Dual Rear Axle Control (6S/6M Conguration)

For vehicles with dual rear axles (6x4, 6x2) using a 6S/6M

conguration, the rear wheels are controlled independently.

Therefore, brake application pressure at each wheel is

adjusted according to the individual wheel behavior on

the road surface.

6x2 Vehicles with 6S/5M Conguration

6x2 vehicles can utilize a 6S/5M conguration, with the

additional axle (a non‑driven rear axle) having two sensors,

but only one Pressure Modulator Valve (PMV). In this case,

the PMV controls both wheels on the additional axle. The

additional axle wheels would receive equal brake pressure,

based on the wheel that is currently experiencing the most

wheel slip.

Normal Braking

During normal braking, brake pressure is delivered through

the ABS PMV and into the brake chamber. If the ECU

does not detect excessive wheel slip, it will not activate

ABS control, and normal vehicle service braking is applied.

Retarder Brake System Control

On surfac es with low trac tion, applic ation of the retar der

can lead to high levels of wheel slip at the drive axle wheels,

which can adversely affect vehicle stability.

T o prevent this, the Bendix ESP EC‑80 Controller switches

off the retarder as soon as a lock‑up is detected at one (or

more) of the drive axle wheels.

When the ECU is placed in the A BS off‑road mode (on

vehicles equipped with this optional feature), it will switch

off the retarder only w hen ABS is active on a steer a xle

wheel and a drive axle wheel.

Optional ABS Off-Road Mode

On some road conditi ons, particularly when the drivin g

surface is s oft, the stopping distance with conventional

ABS may be longer than witho ut ABS. This can occur

when a locked wheel on soft ground or loose gravel plows

up the road surface in front of the tire, changing the rolling

friction value. Alt hough vehicle stopping dist ance with a

locked wheel (in the absence of ABS) may be shorter than

corresponding stopping distanc e with conventional ABS

control, vehicle steerability and stability would be reduced.

Bendix ESP EC‑80 Controllers have an optional dash

switch that initiates a modied ABS control mode (known

as "off‑road A BS") that more effectively ac commodates

these soft road c onditions to shorten stopping distanc e

while maintaining optimal vehicle steerability and stability.

Note: Off‑road mode is not available if the vehicle is

equipped with Hill Start / Hill Start Assist (HS or HSA).

The ABS off-road mode should not be used on

normal, paved road surfaces because vehicle

stability and steerability may be reduced. The ABS

Indicator Lamp will ash slowly to indicate to the

driver that the ABS off-road mode is engaged.

When ABS off-road mode is engaged, stability

functions are disabled at speeds below approximately

25 mph/40 kph. The A TC/ESP dash lamp will illuminate

to indicat e to the driver that t he stability syst em is

disabled.

The vehicle manufacturer should provide the optional ABS

off‑road function only for vehicles that operate on unpaved

surfaces — or that are used in off‑road applications — and

is responsible for ensuring that vehicles equipped with the

ABS off‑road function meet all FMVSS‑121 requirements

and have adequate operator indicators and instructions.

The vehicle operator activates the off‑road function with a

switch on the dash panel. A ashing ABS Indicator Lamp

indicates to the driver that the A BS off‑road function is

engaged. To exit the ABS of f‑road mode, depress and

release the switch. A new ignition cycle w ill also cause

the ECU to exit the ABS off‑road mode.

All-Wheel Drive (AWD) Vehicles

AWD vehicles with an engaged interaxle differential (steer

axle to rear axle) / AWD transfer case, may have negative

effects on ABS performance. Optimum ABS performance

is achieved when the lockable differentials are disengaged,

allowing individual wheel control.

Bendix ESP EC‑80 Controllers can be programmed

specically for this conguration to control the differential

lock/unlock solenoid in the AWD transfer case. When

programmed to do so, the ECU will disengage the locked

interaxle/AWD transfer case during an ABS event and

reengage it once the ABS event has ended.

10

Page 11

ATC OPERATION

ATC Functional Overview

Just as ABS improves vehicle stabilit y during braking,

Automatic T raction Control (A TC ) improves vehicle stability

and traction during vehicle acceleration. The Bendix®

ESP® EC‑ 80™ Controller's ATC function uses the same

wheel speed information and modulator control as the

ABS function. The Bendix ESP EC‑80 Controller detects

excessive drive wheel speed; compares the speed to the

front, non‑driven wheels; and reacts to help bring the wheel

spin under control. The Controller can be congured to use

engine torque limiting and/or differential braking to control

wheel spin. For optimal AT C performance, both methods

are recommended.

ATC/ESP Lamp Output/ATC Mud/Snow Switch

Input

Bendix ESP EC‑80 Controllers operate the AT C/ESP dash

lamp as follows.

The ATC/ESP dash lamp illuminates:

1. During power up (e.g. when the vehicle is started) for

approximately 2.5 seconds and turns off after the self

test is completed, providing no Diagnostic Trouble

Codes (DTCs) are present.

2. When ESP or ATC is disabled for any reason.

3. During an ESP or ATC event (the lamp will ash rapidly

at a rate of 2.5 times per second).

4. When the ECU is placed in the ATC off‑road mode

(the lamp will ash steadily at a rate of once every 2.5

seconds). This noties the vehicle operator that the

ATC Mud/Snow mode is active.

5. When the ECU is placed in the ABS off‑road mode.

When in this mode, ESP will be disabled below 25 mph

and its inactive status will be indicated by a steadily

illuminated A TC/ESP lamp.

Differential Braking

Differential br aking within ATC is automatically activated

when drive wheel(s) on one side of the vehicle are spinning

excessively. This typically occurs on road sur faces

with patches of ice. The tract ion system will then lightly

apply the brake to the drive wheel(s) that are spinning

excessively. The vehicle differential will then drive the

wheels on the other side of the vehicle.

Differential braking (as part of A TC functionality) is available

at vehicle speeds up to 25 mph/40 kph.

Disabling ATC Differential Braking

ATC differential braking is disabled under the following

conditions:

1. During power up (e.g. when the vehicle is started), until

the ECU detects a service brake application.

2. If the ECU receives a J1939 message indicating that

the vehicle is parked.

3. When the dynamometer test mode is active. The

Dynamometer test mode is entered using the diagnostic

Blink Code Switch or by using a diagnostic tool (such

as Bendix® ACom® Diagnostics).

4. In response to a serial communications request from

a diagnostic tool.

5. If ATC Differential Braking function is activated for a

long time period to avoid overheating of the brakes. It

would take approximately three (3) continuous minutes

of activation for the time‑out to occur. Once timed‑out,

approximately two (2) minutes of "cool off" time would

be required before A TC Dif ferential Braking can be used

again.

6. When certain DTC conditions are detected.

Traction Control with Engine Torque Limiting

The Bendix ESP EC‑ 80 Controller uses Engine Torque

Limiting to control drive ‑ axl e wheel slip. This is c ommu ‑

nicated to the engine contro l module (using J19 39), and

is available at all vehicle speeds.

Bendix® SMART ATC™ System

The Bendix ESP EC‑80 Controller has an additional feature

known as the Bendix® SMART ATC™ system. This system

monitors the accelerator pedal position (using J1939)

to help provide optimum traction and vehicle stability.

By determining the driver’s throttle input and adapting the

target slip of the drive wheels to the dr iving s ituation, th e

Bendix SMART ATC system allows higher wheel slip when

the accelerator pedal is applied above a preset level.

The wheel slip allowed by the Bendix SMART AT C system

is decreased when dri ving through a cur ve for improved

stability.

Disabling ATC Engine Control and the Bendix

SMART A TC System

A TC Engine Control and the Bendix SMART AT C system

will be disabled under the following conditions:

1. In response to a serial communications request from

an off‑board tool;

2. At power‑up until the ECU detects a service brake

application;

3. If the ECU receives a J1939 message indicating that

the vehicle is parked;

4. If the dynamometer test mode is active. This may be

accomplished via an off‑board tool or the diagnostic

Blink Code Switch; or

5. When certain DTC conditions are detected.

11

Page 12

Optional ATC Mud/Snow (Off-Road) Mode

In some road conditions, the vehicle operator may desire

additional drive wheel slip when ATC is active. The Bendix®

ESP® EC‑8 0™ Controller has an optional c o ntro l m od e to

permit this desired performance.

The vehicle operator can activate the Mud/Snow function

with a switch on the dash panel. Alter nately, a J1939

message may be used to place the vehicl e in this mo de.

The ATC/ESP Indicator Lamp will ash steadily at a rate

of once every 2.5 seconds to conrm that the ATC mud/

snow mode is engaged.

T o exit the A TC Mud/Snow mode, depress and release the

ATC Mud/Snow switch.

BENDIX ESP EC-80 ABS WITH STABILITY

CONTROL

Overview

The Bendix ESP system with the EC‑80 Controller reduces

the risk of rollovers, jackkning and other loss‑of‑control

events. Bendix ESP EC‑80 Controllers include Roll

Stability Program (RSP®) and Y aw Control (YC) functions.

During operation, the Bendix ESP EC‑80 Controller

constantly compares performance models to the vehicle’s

Drag Torque Control Functional Overview

Bendix ESP EC‑80 Controllers have a feature referred to

as drag torque control which reduces wheel slip on a driven

axle due to driveline iner t ia. This c on dition i s address ed

by increasing the engine torque to overcome the inertia.

Drag torque control increases vehicle stabilit y on low‑

traction road sur faces during down‑shifting or retarder

braking.

actual movement, using wheel speed sensor s; a lateral

acceleration sensor, a yaw rate sensor, and a steering

angle sensor. If the vehicle shows a tendency to leave an

appropriate travel path, or if criti cal threshold values are

approached, the system will intervene to assist the driver.

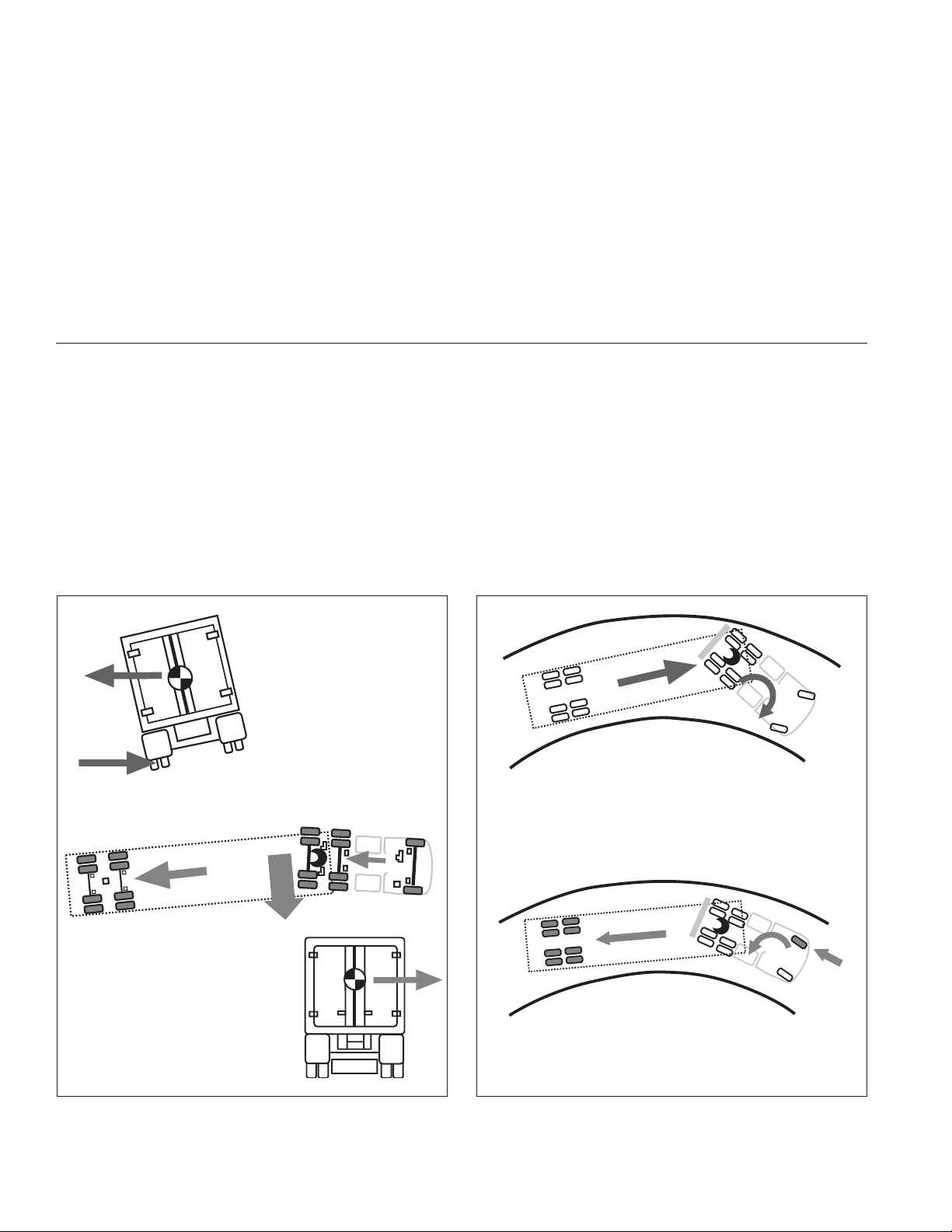

A Real World Example

Of How The RSP

System Operates:

Excessive speed for road

conditions creates forces

that exceed the threshold

at which a vehicle is likely

to rollover on a higher‑

friction surface.

The system automatically reduces

engine torque and applies the

service brakes (based on the

projected rollover risk) to reduce

the vehicle speed, thereby

reducing the tendency to roll over.

A Real World Example Of How Yaw Control

Operates:

Excessive speed exceeds the threshold, creating a

situation where a vehicle is likely to spin and jackknife.

®

The Bendix

and selectively applies brakes to reduce the tendency

to jackknife.

Y aw Control system reduces engine throttle

FIGURE 12 - RSP EXAMPLE

12

FIGURE 13 - YAW CONTROL EXAMPLE

Page 13

Bendix® Roll Stability Program (RSP®)

Bendix RSP — an element of the overall Bendix® ESP®

system with the EC‑8 0™ Controller — addresses r ollover

conditions. In the c ase of a potential roll event, the ECU

will override the throttle and quickly apply brake pressure

at all wheel ends to slow the vehicle co mbination. The

level of braking application during an RS P event will be

proportional to roll risk. See Figure 12.

Yaw Stability

Y aw stability counteracts the tendency of a vehicle to spin

about its vertic al axis. Dur ing operation — if t he frict ion

between the road surface and the tires is not sufcient

to oppose lateral (side) forces — one or more of the tires

can slide, causing the truck/tractor to spin. These events

are referred to as either an "under‑steer" situation (where

there is a lack of vehicle response to steering input due to

tire slide on the steer axle), or an "over‑steer" (where the

tractor's rear end slides out due to tire slide on the rear axle)

situation. Generally, shorter wheelbase vehicles (tractors,

for instance) have less natural yaw stability, while longer

wheelbase vehicles (straight trucks, for instance) have

greater natural yaw stability. Factors that inuence yaw

stability are: wheelbase, suspension, steering g eometry,

weight distribution front to rear, and vehicle track width.

Yaw Control

Yaw control responds to a wide range of low‑ to high‑

friction sur face scenarios including rollover, jackknife

and loss‑of‑control. It is the recommended system for all

power vehicles and especially cr itical for trac tors pulling

trailers. In the case of vehic le slide (over‑steer or under‑

steer situations), the system will reduce the throttle and

then brake one or more of the “four corners” of the vehicle

(in addition to potentially applying the trailer brakes) , thus

applying a counter‑force to better align the vehicle with an

appropriate path of travel.

For example, in an over ‑steer situation, the system applies

the “outside” front brake; while in an under‑steer condition,

the “inside” rear brake is applied. (See Figure 13)

IMPORTANT SAFETY INFORMATION

ABOUT THE BENDIX® ESP® SYSTEM

The Bendix ESP EC-80 Controller may reduce

the vehicle speed automatically.

The Bendix® ESP® system can make the

vehicle decelerate automatically and can

slow the vehicle w ith or wit h o ut the operator

applying the brake — and even when the

throttle is being applied.

T o minimize une xpected deceleration and reduce the

risk of a collision, the operator must:

• Avoid aggressive driving maneuvers, such as sharp

turns or abrupt lane changes at high speeds, which

might trigger the stability system; and

• Always operate the vehicle safely, drive defensively ,

anticipate obstacles and pay attention to road,

weather and trafc conditions. Bendix ABS, ATC

and ESP systems are no substitute for prudent,

careful driving.

Towing Doubles Or Triples May Reduce The

Effectiveness Of Stability Systems

The Bendix ESP syst em wi t h th e EC-80 Con t roll er i s

designed and optimized for trucks and for tractors that

tow single trailers. If a tractor equipped with Bendix

ESP is used to powe r multiple trail er combination s

(known as “doubl es” or “trip les”) the eff ectiveness

of the Bendi x ESP system may be greatly r educed.

Extremely careful driving is always required when

towing doubles or triples. Excessive speed and

aggres s i v e ma n e uv e r s — such as sha r p tu r ns , su d den

steering inputs, or abrupt lane changes — should be

avoided.

Limitations Of Stability Systems

The effectiveness of the Bendix ESP system with the

EC‑80 Controller may be greatly reduced if:

• The load shifts due to improper retention, accident

damage, or the inherently mobile nature of some loads

(for example, hanging meat, live animals or partially

laden tankers),

• The vehicle has an unusually high — or off‑set — center

of gravity (CG),

• One side of the vehicle drops off the pavement at an

angle that is too large to be counteracted by a reduction

in speed,

• The vehicle is used to haul double or triple trailer

combinations,

• If very rapid steering changes are attempted at high

speeds,

• There are mechanical problems with suspension

leveling of the tractor or trailer resulting in uneven loads,

• The vehicle is maneuvering on a high banked road

creating either additional side forces due to the weight

(mass) of the vehicle, or a deviation between expected

& actual yaw rates,

• Gusty winds are strong enough to cause signicant

side forces on the vehicle and any towed vehicles.

13

Page 14

To Maximize The Effectiveness Of The Bendix®

®

System with the EC-80™ Controller:

ESP

• Loads must be properly secured at all times.

• Drivers need to exercise extreme caution at all times,

plus avoid sharp turns, sudden steering adjustments

or abrupt lane changes at high speeds, particularly if:

› the vehicle hauls loads that could shift;

› the vehicle or load has a high or off‑set center of

gravity (CG) when loaded; or

› the vehicle tows doubles or triples.

Truck Chassis Modications

If the vehicle’s chassis components are altered (for

example, a wheel base extension or reduction; tag

axle addition or rem oval; a major body change suc h as

conversion of a tractor into a truck; or an axle, suspension,

or steering system component modication) the Bendix

®

ESP

system must be disabled. Have a qualied mechanic

®

replace the Bendix ESP EC‑80 Co ntr o lle r w it h a B e ndi x®

®

ESP

ATC EC‑80™ Controller and secure the X4 connector

(which will no longer be used). The ATC/ESP indicator

lamp would continue to function as an A TC indicator lamp,

and should be designated as ATC only.

If a modied vehicle does not have the Bendix

®

ESP® system disabled, serious vehicle braking

and performance issues could result, including

unnecess ary ESP syst em inter vention s. This can

lead to a loss-of-control of the vehicle.

In addition, remove all cab signage (e.g. visor

labels, etc.) that were used to show that the Bendix

ESP system was installed. Make any necessar y

notations in the vehicle manual(s), so that drivers do

not misunderstand which ABS options are installed

on the vehicle.

Sensor Location Modications

The location and orientation of the Steering Angle Sensor

and Y aw Rate Sensor must not be altered. When servicing,

an identical component must be used in the same

orientation (using OEM brackets & torque requirements).

During installation follow the OEM leveling guidelines.

Steering Angle Sensor Re-Calibration

Whenever maintenance or repair work is performed to the

steering mechanism, linkage, steering gear, adjustment of

the wheel track, or if the steering angle sensor is replaced,

a recalibration of the Steering Angle Sensor must be

performed.

If the Steering Angle Sensor is not recalibrated, the

yaw control system ma y not function properly, which

can result in incidents leading to loss of vehicle

control. See page 19 of this document for more

details on this procedure.

DYNAMOMETER TEST MODE

Bendix ATC and ESP systems must be disabled prior

to conducting any dynamometer testing. When the

Dynamometer Test Mode is engaged, the Bendix ATC

EC‑80 Controller's brake control and engine control —

along with drag torque contr ol and Bendix ESP system

functions — are disabled. This test mode is used to avoid

torque reduction or torque increase and brake control

activation when the vehicle is operated on a dynamometer

for testing purposes.

The Dynamometer Test Mode may be activated by pressing

and releasing the diagnostic Blink Code Switch ve times

or by using a hand‑held or PC‑based diagnostic tool.

During Dynamometer Test Mode the AT C lamp remains ON.

Bendix ESP EC‑80 Controllers will remain engaged in

the Dynamometer Test Mode even if power to the ECU

is removed and re‑applied. To exit the test mode, press

and release the Blink Code S witch three time s, or use a

hand‑held or PC‑based diagnostic tool.

AUTOMATIC TIRE SIZE CALIBRATION

The ECU requires a precise rolling circ umference ratio

between steer axle and dr ive axle tires in order for the

Bendix ABS, ATC, and ESP systems to perform in an

optimal manner. For this reason, a continuously monitoring

process takes place in which the precise ratio is calculated.

This calculated value is stored in the ECU memory

provided the following conditions are met:

1. Rolling‑circumference ratio is within the permissible

range;

2. Vehicle speed is greater than approximately

12 mph/19 kph;

3. No acceleration or deceleration is taking place; and

4. There are no active speed sensor Diagnostic Trouble

Codes (DTCs).

The ECU is provided with a ratio value of 1.00 as a default

setting. If the automatic tire size alignment c alculates a

different value, this is used to overwrite the original gure

in the memor y. This process adapts t he ABS and ATC

function to the vehicle.

14

Page 15

Acceptable Tire Sizes

The speed calculatio n for an exciter ring with 100 teeth

is based on a default tire size of 510 revolutions per mile.

This gure is based on the actual rolling circumference of

the tires, which varies with tire size, tire wear, tire pressure,

vehicle loading, etc.

The ABS response sensitivity is reduced when the actual

rolling circumference is excessive on all wheels. For a 100

tooth exciter ring, the minimum number of tire revolutions

per mile is 376, and the maximum is 665. T he ECU will

set a Diagnostic Trouble Code (DTC) if the number of

revolutions is out of this range.

In addition, the size of the steer axle tire s compared to

the drive axle tires als o has to be within t he A BS system

design. To avoid DTCs, the ratio of the effective rolling

circumference of the steer a xle, divided by the effective

rolling circumference of th e drive axle, must be bet ween

0.85 to 1.15.

Drive Axle/Additional Axle Wheel Speed Sensor

DTC

The Bendix ATC and E SP systems are disabled. In a four

sensor system, ABS on the affected wheel is disabled, but

ABS on all other wheels remains active.

In a six sensor system, ABS remains active by using input

from the remaining rear wheel speed sensor on the same

side.

ATC Modulator DTC

The Bendix ATC and ESP systems are disabled. ABS

remains active.

J1939 Communication DTC

The Bendix ATC and ESP systems are disabled. ABS

remains active.

ECU DTC

The Bendix ABS, ATC, and ESP systems are disabled.

The system reverts to normal braking.

The Bendix® ESP® system with t he EC- 80 Cont roller

effectiveness relies on the accuracy of vehicle speed.

If a major ch a n g e on the tire siz e s is ma d e — su c h that

the odometer setting needs to be changed to correct

for the new tires — the Bendix ESP EC-80 Controller's

setting o f tire sizes must al so be reprogramme d to

revised values.

SYSTEM IMPACT DURING ACTIVE

DIAGNOSTIC TROUBLE CODES (DTCs)

ABS PARTIAL SHUTDOWN

Depending on which component the DTC is detected,

the Bendix ABS, ATC, and ESP system functions may

be fully or partially disabled. Even with the ABS indicator

lamp illuminated, the Bendix ESP EC‑ 80 Controller m ay

still provide ABS function on wheels that are not affected.

The ABS system Controller shoul d be servic ed as soon

as possible.

Steer Axle ABS Modulator DTC

ABS on the affected wheel is disabled. ABS and ATC on

all other wheels remains active. The Bendix ESP system

with the EC‑80 Controller is disabled.

Drive Axle/Additional Axle ABS Modulator DTC

ATC is disabled. ABS on the af fec ted wheel i s disabled.

ABS on all other wheels remains active. The Bendix ESP

EC‑80 system is disabled.

Steer Axle Wheel Speed Sensor DTC

The wheel with the DTC is still controlled by using input

from the remaining wheel speed sensor on the steer axle.

ABS remains active on the rear wheels. The Bendix ATC

and ESP systems are disabled.

Voltage DTC

While voltage is out of range, Bendix ABS, A TC, and E SP

systems are disabled. The system reverts to normal

braking. When the co rrect voltage level is restored, full

ABS and ATC function is available. The operating voltage

range is 9.0 to 17.0 VDC for 12 volt systems, and 20 to 33.5

volts for 24 volt systems.

Steering Angle Sensor DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

Yaw Rate/Lateral Acceleration Sensor DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

Brake Demand Pressure Sensor DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

Load Sensor DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

Steer Axle Traction Control Valve (TCV) DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

Trailer Pressure Modulator Valve (PMV) DTC

The Bendix ESP system is disabled. Bendix ABS and ATC

systems remain active.

15

Page 16

SYSTEM RECONFIGURATION

The Bendix® ESP® EC‑ 80™ Controller is designed to

allow the technician to change the default system settings

(chosen by the vehicle OEM) to provide additional or

customized features.

Depending on the model, the customizable features include

ABS control settings, engine module c ommunication etc.

Many of these settings can be recongured using a hand‑

held or PC‑ based sof t ware, such as t he Bendix® ACom®

Diagnostic software.

ECU RECONFIGURATION

Reconguring a Bendix ESP EC‑80 Controller may be

carried out by using the B link Code S witch or by using a

hand‑held or PC‑based diagnostic tool.

Note: During the reconfiguration process — and

independently from any reconguration being carried out

by the technician — the Electronic Control Unit (ECU) will

automatically check the J1939 serial link and communicate

with other vehicle modules. In particular, if the serial link

shows that the vehicle has a retarder device present, the

ECU will congure itself to communicate with the retarder

device for improved ABS per formance. For example, if

the ECU detects the presence of a retarde r disable r elay

during a reconguration, it will congure itself to control the

relay to disable the retarding device as needed.

DATA STORAGE

Depending on the product type and version, Bendix®

brand ECUs may store data related to troubleshooting,

diagnostics, service needs, vehicle system operating

status, and vehicle operator inputs. No personally

identifying data (e.g. name, gender or age) is recorded.

Bendix will not acces s stored ECU data or share it with

others except: with the consent of the vehicl e owner; in

response to an ofcial request by law enforcement or

other governmental agency; as par t of Bendix’s defense

of litigation; or, as otherwise required by law. Data that

Bendix receives may also be used for research purposes

or made available to others for research purposes, where

a need is shown and the data is not linked to a specic

vehicle or owner.

Bendix brand antilock ECUs are not designed to store

data for purposes of acc ident rec onstruc tion and Bendi x

ACom Diagnostic Software is not intended to retrieve data

for purposes of accident reconstruction. Bendix makes no

representations as to the acc uracy of data retrieved and

interpreted from Bendix ECUs for purpose s of accident

reconstruction.

Reconguration Using the Blink Code Switch

With ignition power removed from the Bendix ESP EC‑80

Controller, depress the Blink Code Switch. After the

ignition power is activated, depress and release the switch

seven (7) times to initiate a reconguration event.

Diagnostic Tool

A reconguration event may be initiated using a hand‑held

or PC‑based diagnostic tool to communicate with the ECU

over the SAE J1939 diagnostic link.

6S/5M Conguration

A Bendix ESP EC‑80 Controller will congure for 6S/5M

operation when a reconguration event is initiated, and the

ECU detects that an additional‑axle Pressure Modulating

Valve (PMV) is wired as follows:

PMV Connector ECU Connector

Hold Right Additional Axle Hold

Release Left Additional Axle Release

Common Right Additional Axle Common

16

Page 17

Troubleshooting: General

GENERAL SAFETY GUIDELINES

Read and follow the General Safety Guidelines shown on

page two (2) of this document.

REMOVAL OF THE BENDIX® ESP® EC-80™

CONTROLLER ASSEMBL Y

1. Turn vehicle ignition off.

2. Remove as much contamination as possible prior to

disconnecting electrical connections.

3. Note the Bendix ESP EC‑80 Controller assembly

mounting position on the vehicle.

4. Disconnect the electrical connectors from the Controller.

5. Remove and retain the mounting bolts that secure the

Controller.

The VIN of th e vehicle is stored in the Be ndix ESP

EC-80 Controller's internal memor y, and is crosschecked by the E lectronic Co ntrol Unit (ECU) using

information obtained from other vehicle Controller( s).

If the VI N stored i n the ECU doe s not match t he VI N

obtained from the other vehicle Controller(s), the ECU

will generate an ECU Internal VIN Mismatch Diagnostic

Trouble Code (DTC).

Accordingl y, d o not attempt to move a Bend ix ESP

EC-80 Controller from one vehicle to another.

OBTAINING A NEW BENDIX® ESP® EC-80™

CONTROLLER

Should the Bendix ESP EC‑80 Controller require

replacement, certain steps must be followed:

1. Record the vehicle model, VIN, year and date of

manufacture from the vehicle.

2. Record the part number of the Bendix ESP EC‑80

Controller.

3. Provide this information to your local OEM vehicle

service department to obtain a new Bendix ESP EC‑80

ECU. The OEM service department will install the same

parameter set in the new Controller that was loaded into

the original ECU at the vehicle OEM assembly facility .

INSTALLING A NEW BENDIX ESP EC-80

CONTROLLER

When replacing the Bendix ESP EC-80 Controller,

verif y with the OEM service depart ment that the unit

you are installing has the correct parameter set.

Failure to do so could re sult in a loss of f eature s or

degraded ESP performance.

For further information, contact either the vehicle

manufacturer, Bendix, or your local authorized Bendix

distributor.

1. Position and secure the Bendix ESP EC‑80 Controller

in the original mounting orientation using the mounting

bolts retained during removal. Use no more torque than

is necessary to rmly secure the ECU into position.

Over‑tightening the mounting hardware can cause

damage to the Bendix ESP EC‑80 Controller.

2. Reconnect the electrical connectors to the Bendix

EC‑80 Controller.

3. Apply power and monitor the Bendix ESP EC‑80

Controller power‑up sequence to Verify the proper

system operation.

See Troubleshooting: Wiring section beginning on page 45

for more information on wire harnesses.

The Bendix ESP system with the EC-80 Controller is

validated with specic Bendix

Always use Bendix brand replacement parts to

prevent compromising system performance.

Bendix is not a ble t o validat e th e safe an d relia ble

use of substitute or alternate components that

may be available f rom other ma nufactu rers, since

supplier s of a non-Ben dix brand ABS com ponent

may implement design changes in their component

(without the knowledge or approval of Bendix) which

could negatively af fect antilock system reliabilit y

and braking performance issues.

®

brand components.

17

Page 18

STEERING ANGLE SENSOR MAINTENANCE

Service Checks:

1. Check all wiring and connectors. Some installations

also include an intermediate connector from the

steering angle sensor to the main vehicle wire harness.

Make sure all connections are free from visible damage.

2. Examine the sensor. Make sure the sensor, its

mounting screws, and the interface between the hub

and the steering column are not damaged.

Diagnostics:

®

The Bendix

in conjunction with a Bendix® ESP® EC‑80™ Controller. No

independent diagnostics can be performed on the sensor.

See pages 38-39 for Diagnostic Trouble Codes (DTCs)

associated with this device.

Removal:

1. Remove steering column sheathing.

2. Depending upon manufacturer, the steering angle

sensor could be located either near the steering wheel,

necessitating the removal of the steering wheel, or

near the joint to the vehicle steering mechanism,

necessitating the disconnection of this linkage.

3. Unplug sensor cable assembly from body of sensor.

Squeeze the mounting tabs and pull gently on the

connector until it disengages.

4. Unscrew all three of the mounting screws that hold the

body of the sensor to the steering column body.

5. Slide the sensor over the column to remove. Take note

if the sensor label is facing upward or downward.

Installation:

1. Obt ain a new senso r. The sensor is not repairable in

the eld.

2. Slide the sensor over the column. The center hub of the

sensor must be aligned with the c o r re sp onding n otch

in the column. Dif ferent column manufacturers may

implement this hub alignment in dif ferent ways. The

sensor label should be facing in the same direction as

the removed sensor.

brand steering angle sensor is only operational

3. Assemble to column non‑moving plate with three self‑

locking screws.

4. Tighten screws to steering column manufacturer's

recommended torque specication.

5. Reconnect the connector. Ensure that there will be no

force applied to the sensor be cause the c onnec tor is

pulling on the sensor body.

6. If the wire harness leading to the sensor is being

replaced, ensure that it is adequately tie wrapped

so that the full motion of the steer ing column can b e

achieved without pulling apart the connectors.

7. Reinstall the column sheathing. The sensor is not

protected against dirt or water intrusion, so care

must be taken not to introduce these elements during

installation.

STEERING ANGLE SENSOR CALIBRATION

The steering angle sensor calibration can only be achieved

when the sensor is powered by the Bendix ESP EC‑ 80

Controller. No stand‑alone sensor calibration can be

carried out. The calibration procedure is performed

using Bendix® ACom® Diagnostic software V6.7. 2.5 or

higher. See “Troubleshooting Diagnostic Trouble Codes:

Steering Angle Sensor (Bendix® SAS-60™)” for the

calibration procedure using this tool. The sensor must be

recalibrated using ACom Diagnostic Software after any of

these situations:

• Replacement of the steering angle sensor;

• Any opening of the connector hub from the steering angle

sensor to the column;

• Any maintenance or repair work on the steering linkage,

steering gear or other related mechanism;

• Adjustment of the wheel alignment or wheel track; or

• Af ter an accident that may have led to damage of the

steering angle sensor or assembly

If the steering angle sensor is not properly

recalibrated as needed, the yaw control system may

not funct io n p roperly, which can re sul t in a l o ss o f

vehicle control.

18

Page 19

Y AW RA TE/LATERAL ACCELERA TION

SENSOR MAINTENANCE

Different generations of yaw rate/lateral acceleration

sensors are not compatible. Only replace these

sensors with exactly the same device.

Service Checks:

1. Check all wiring and connectors. Make sure all

connections are free from visible damage.

2. Examine the sensor. Make sure the sensor, its

mounting bolts, and the mounting bracket are not

damaged.

3. Check t he vent hole in under body of sens or housing.