Page 1

welcome

Dear customer

Congratulations on your choice of a Beko quality washing machine

which has been designed to give you lasting service.

Please read these instructions thoroughly before installing or using

- and keep for handy reference. Make sure you understand the

controls prior to using your appliance. The washer must only be used

for its intended purpose, ie the washing of clothes in the home.

Failure to observe these instructions may invalidate your right to free

service during the guarantee period.

If you have any questions, or if you are not sure about any

information contained in this booklet please contact us - details are

on the back cover.

Beko Customer Service

Due to the quality control processes during production, there

may be some water left in your machine. This does not cause

any damage.

Note that temperatures in this book are for guidance only. Always

check the clothing labels before selecting your wash program

Notes

Page 2

contents

Introduction

Welcome 2

Installation

Know your washing machine/specification 4

Location 5

Installation 5

Electrical connection 7

Operating

How to use 8

Programme descriptions 10

Function buttons 11

ITCL fabric care symbols 11

Machine care

Care & maintenance 12

Before calling service/trouble shooting 14

Guarantee 15

Service 15

Page 3

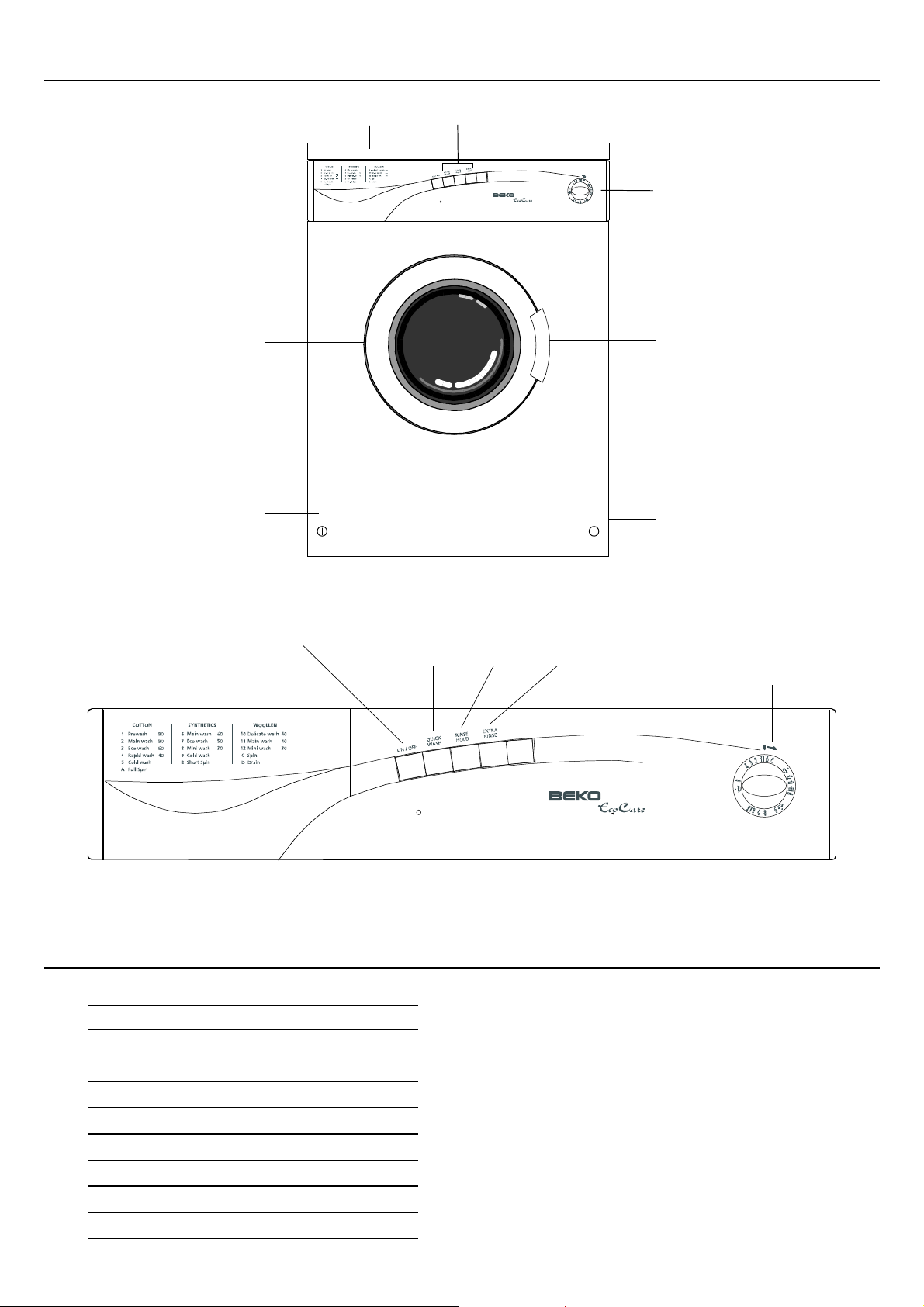

Capacity (dry fabric) 5 kg

Dimensions width x depth x height

60cm x 54cm x 85cm

Net weight 62kg

Supply voltage 230V~ 50Hz

Nominal current 10A

Motor power 350 watts

Heater power 2100 watts

Washing speed 52 rpm

Because we continually strive to improve

our products, we may change our specifications

and designs without prior notice.

Rating plate behind kick plate

Front door

Adjustable feet for levelling

Kick plate

Kick plate opening screw

Top lid Function buttons

Control panel

Door Handle

know your washing machine

specification

Quick

wash

button

Detergent and softener drawer

Programme

selection

knob

On/Off button

Indicator light

Rinse

hold

button

Extra

rinse

button

Page 4

Removing transport safety bolts

The transport safety bolts must be removed

before any operation of the machine.

1

Turn the bolt heads C anti-clockwise until

the bolt can be partially withdrawn.

2

Remove them and the rubber bushes by

pulling outwards. An up/down action and

a small squirt of washing up liquid will ease

removal.

3

Plastic plugs, supplied inside the protective

bag, designated P, should be placed in the

safety bolt holes as shown.

Attention!

Keep the safety bolts for future

transportation and reinstate them before

transporting your machine. Never transport

your machine without the transport bolts in

position. Any resultant damage is not covered

by the warranty.

location

installation

You can locate the washing machine

anywhere (except bathrooms, showers and

away from rain, damp places and water) as

long as you have hot and cold water supply,

drainage and electrical connection alongside.

Ensure there is clearance each side of the

machine to allow slight side ways movement

during washing and spin drying.

Attention!

Never place your machine on a carpet. This

prevents air circulation. The electrical

components of the machine may overheat and

may cause damage.

Please ensure the power, water supplies

and waste are suitable, if in doubt, consult a

qualified plumber or electrician.

C

P

C

5

Feet adjustment

To ensure quiet and stable operation, the

machine should be positioned correctly and

on the level. If the machine is unstable, adjust

one of the front feet by loosening the plastic

lock nut and screwing or unscrewing the foot

until the machine is level. After positioning,

tighten the lock nut.

5

Page 5

Water inlet connections

Your machine comes with both cold and

hot water connections.

Connect the cold water using the hose with

blue printing and connect the hot water using

the hose with red printing. If you have only a

cold water feed a Y adaptor will be required

(available from most D.I.Y. stores).

Cold water supply

For proper operation, the pressure of cold

water should be between 1 and 10 bars. (1

bar corresponds to more than 8 litres per minute

flow rate with a fully open tap.)

Hot water supply

Pressure: 1-10 bar Temperature: 60°C max.

A hot water supply fed from a separate cold

water tank will normally be suitable. Open

outlet gas or electric water heaters must not

be used. Multipoint water heaters or

combination boilers may be suitable if they are

designed to supply washing machines. (Check

your boilers operation instructions or supplier.)

If the hot water supply is unsuitable, connect

both hoses to the cold water supply using a Y

connection. The only disadvantage of this is

the machine will use more electricity to heat

the water and take longer to wash on some

programs.

To prevent water leaks,

four sealing washers are

supplied with the water

inlet hoses inside the

machine. Place these on

each of the hose ends and tighten both ends

fully.

In order to prevent any water leakage and

damage, turn off the water taps when not in

use. Connect the cornered end of the hose to

the machine water inlet.

Drain hose

The drain hose should be placed and secured

either at the side of the sink A, directly to the

drain B or directly to the waste water

inlet C.

• The hose should not be bent.

• Using method A, the drain hose should be

secured with the elbow so that it can not

be dislodged.

• The waste pipe must only be connected

into the foul drains and not surface water

drainage system.

• The hose should be placed between 20 and

80cm from the floor level and must not be

extended otherwise the machine may not

empty the waste water.

HOT COLD

Y adaptor

A

B

C

Page 6

electrical connection

Electrical requirements

Before you insert the plug into the wall

socket make sure that the voltage and the

frequency shown in the rating label corresponds

to your electricity supply.

We recommend that this appliance be

connected to the mains supply via a suitable

switched and fused socket in a readily accessible

position.

Should the mains lead of the appliance

become damaged or need replacing at any

time, it must be replaced by a special purpose

made mains lead which can only be obtained

from a Beko Authorised Service Agent.

Warning

This appliance must be earthed

If the fitted moulded plug is not suitable for

your socket, then the plug should be cut off

and an appropriate plug fitted.

Destroy the old plug, which is cut off as a

plug with a bared cord could cause a shock

hazard if inserted into a socket elsewhere in

the house.

The moulded plug on this appliance

incorporates a 13A fuse. Should the fuse need

to be replaced an ASTA approved BS1362 fuse

of the same rating must be used. Do not forget

to refit the fuse cover. In the event of losing

the fuse cover, the plug must not be used until

a replacement fuse cover has been fitted.

Colour of the replacement fuse cover must be

the same colour as that visible on the pin face

of the plug. Fuse covers are available from any

good electrical store.

Important

Fitting a different plug

As the colours of the wires in the mains

lead of this appliance may not correspond with

the coloured markings identifying the terminals

on your plug, proceed as follows:

1 Connect the green - yellow or green (earth)

wire to the terminal in the plug marked ‘E’

or with the symbol f or coloured green

and yellow or green.

2 Connect the blue (neutral) wire to the

terminal in the plug marked ‘N’ or coloured

black.

3 Connect the brown (live) wire to the terminal

in the plug marked ‘L’ or coloured red.

With the alternative plugs a 13A fuse must

be fitted either in the plug or adaptor or in the

main fuse box. If in doubt contact a qualified

electrician.

Green and yellow

or green

f

Make sure that you have an earthed power

outlet socket rated at 13 amps (minimum).

Attention!

If you use your machine as built-in, the

socket must be reachable after installation, or

a separate switch (which can disconnect the

two poles) must be used in the installation.

Connect the power cord to the appropriate

electrical socket with an equivalent current

rating indicated on the rating plate at the front

of the machine behind the kick plate.

After removing the plug from its transit

position, please insert the plug seal to prevent

water spillage entering the machine.

L

Brown or red

N

Blue or

black

Page 7

Programme selection indicator

how to use

Sorting laundry

Sort the laundry according to the following

groups and wash them separately:

• White and colour fast fabrics

• Non-fast, coloured fabrics

• Delicate fabrics (silk, rayon etc.)

• Woollens

• Hand knits should be placed inside out in

the machine.

Be sure to empty pockets and remove any

belts, buckles, pins, etc. from the clothing.

Loading the machine

Make sure power button is off.

1 Pull the door open handle.

2 Place the fabrics uniformly inside the

machine. Make sure that there is no clothing

obstructing the door.

3 Close the door by pushing lightly.

If the door does not close completely, the

machine will not start. This is a safety

precaution. The front door is locked until

the end of the washing programme and it

cannot be opened for about 2 minutes

following the end of the programme.

Programme selection

Select the programme after referring to the

programme descriptions and table on

page 10.

Warning! Always switch off the machine

before selecting your wash programme.

1 Press in the middle of the knob to release

the child safe programme selection knob.

2 Turn the programme selection knob

clockwise and bring the programme number

required in line with the programme

selection indicator. You have selected both

the washing programme and the washing

temperature at the same time.

3 Push in to prevent children tampering with

it.

Function selection

Quick wash function button can be selected

now if needed, see page 11, for suitable

programmes.

Page 8

To start the programme, press the On/Off

button. The indicator will light and the closed

door will be locked in a few seconds. The

programmer knob will rotate and advance

to the correct point to commence washing.

This is a normal function of the

programmer.

Programme operation

During the machine’s operation, the

programme selection knob turns clockwise and

follows the programme steps.

1, 2, 3, 4, 5 and A programmes end on the

line after A.

6, 7, 8, 9 and B programmes, if rinse hold

button is not pressed, end on the line after B.

10, 11,12 and C programmes, if rinse hold

button is not pressed, end on the line after C.

If fabric softener is added in the softener

compartment, it will be used in the last rinse

cycle.

If rinse hold is selected, by re-pressing this

button, you can continue the program. If no

spin is desired, you should leave the rinse hold

button pressed in. Turn off the machine, select

the letter D on the programme selection knob

and turn on the machine. During this operation,

water in the machine will be discharged.

Unloading

The machine stops automatically after

programmes are completed.

1 Press the On/Off knob to turn off your

machine.

2 The door can be opened by gently

pulling the door open handle 1-2

minutes after the washing cycle is

completed. Turn off the taps.

Detergent and softener dispenser

1 Open the drawer.

2 Put powder detergent and the fabric

softener in the compartments as shown.

3 Close the detergent and softener drawer.

Powders and liquids

The performance of the washing machine

depends on the effectiveness of the detergent.

Stains can remain if low quality detergents are

used.

• Only use powders specific for automatic

washers, otherwise over foaming and poor

washing performance will be experienced.

• Do not use liquid detergent in your detergent

drawer. Only use liquid detergents with a

dosing ball.

• Do not attempt to use detergents and

bleaching agents that contain chlorine and

sulphur.

• Concentrated softener may clog the syphon,

in this case add some water to the softener

liquid.

Amounts

Follow the manufacturer’s recommended

amount of detergent given on the packaging.

Adjust the amount according to the dirt

level, the amount of fabric and the softness of

the water. For example, if a small amount of

clothing is washed, put in half the amount of

detergent normally required.

• Do not fill the fabric softener above the max

mark as any excess amount will mix into

the wash water and you will have to re-fill

the compartment.

B

40°

11110

Woollens

2 3984 5

76

Cold

Cold

90°

Cold

60°

50°

90°

40°

60° 40°

Detergent compartment I

for prewash cycle

Syphon

Detergent compartment II

for wash cyclefor fabric softener

Starting

Attention!

Before any operation of the machine check

the following:

• Have you closed the front door?

• Are the taps open?

• Is the drain hose placed and secured

properly?

• Is power connected?

Page 9

programme descriptions

*:Energy Labelling program acc. to EN 60456:1999 ve IEC 60456 Ed.4 2001

Rinse Hold: Only select rinse hold if the clothing label states suitability or do not spin dry.

Depending on water, textile and ambient conditions the actual values given on or with the machine can deviate from the declared standard values, as they are tested according to

the laboratory conditions.

Fabric TypeNo.

1

2

3

4

5

A

6

7

8

9

B

10

11

12

C

D

Wash

Temperture

90

90

60*

40

cold

-

60

50

30

cold

-

40

40

30

-

-

Detergent

Compartment

Heavy soiled fabrics made from

cotton or linen, heat resistant

Heavy soiled fabrics made from

cotton or linen, heat resistant

Normal soiled fabrics made from

cotton or linen, heat resistant

Lightly soiled fabrics made from

cotton linen non-colour fast

Lightly soiled fabrics made from

cotton linen non-colour fast

Final Spin

Normal Soiled Easy care fabrics

made from cotton, synthetics or

blended fabrics

Lightly Soiled Easy care fabrics

made from cotton, synthetics or

blended fabrics (non-colour fast)

Lightly Soiled Easy care fabrics

made from cotton, synthetics or

blended fabrics (non-colour fast)

Lightly Soiled Easy care fabrics

made from cotton, synthetics or

blended fabrics (non-colour fast)

Final Spin

Sensitive, easy care fabrics made

from cotton, synthetics or blended

fabrics

Washable wool and wool

mixtures

Washable wool and wool

mixtures

Spin

Discharging

Max.

Load

(kg)

5

5

5

5

5

5

2.5

2.5

2.5

2.5

2.5

2

1.5

1.5

-

-

Programme

Description

Pre-wash / Main wash /3 rinses

/3 intermediate spins / Final Spin

Main wash /3 rinses /3

intermediate spins / Final Spin

Main wash /3 rinses /3

intermediate spins / Final Spin

Main wash /3 rinses /3

intermediate spins / Final Spin

Main wash /3 rinses /3

intermediate spins / Final Spin

Final spin profile for cotton

Main wash /3 rinses /3

intermediate spins/ Final Spin

Main wash /3 rinses /3

intermediate spins/ Final Spin

Main wash /3 rinses /3

intermediate spins/ Final Spin

Main wash /3 rinses /3

intermediate spins/ Final Spin

Final spin profile for easy care

Main wash /3 rinses / Final Spin

(no intermediate spin)

Main wash /3 rinses / Final Spin

(sensitive wash action / no

intermediate spin)

Main wash /3 rinses / Final Spin

(sensitive wash action / no

intermediate spin)

Final spin profile for Delicate

Drainage

I+II

II

II

II

II

-

II

II

II

II

-I

II

II

II

-

-

Programme

Duration

(~min)

140

130

130

120

90

10

110

100

95

70

10

55

45

35

2.5

-

Water

Consumption

(l)

65

56

56

60

56

-

50

50

50

50

-

50

45

45

-

-

Energy

Consumption

(kWh)

2.10

1.90

0.95

0.52

0.15

-

0.85

0.73

0.45

0.10

-

0.30

0.55

0.30

-

-

Page 10

ITCL fabric care symbols

Do not use

bleach

No spin

60°

Do not wash

Dry clean

A

Chemicals can

be used

No dry cleaning

Can be washed in

centrifugal

Do not wash in

centrifugal

Dry on

horizontal

surface

Iron permitted

Warm iron

Bleach

Do not

machine

wash

Line dry Do not iron

Descriptions of the international textile care label (ITCL) symbols.

Washing

temperature

P

Quick wash

This function should be used for lightly

soiled fabrics. If you press this button, the

washing time will be reduced. You can use

this function only on cotton (program 1,2,3,4

and 5) and synthetic (program 6,7,8 and 9).

Rinse hold

Select rinse hold to minimise your synthetic

fabrics becoming wrinkled after the wash

program. To continue the programme, you

can either press the Rinse hold button again

or select D on the programme selection knob

to drain the water. If there is a power failure

or if for any reason the machine is disconnected

from the mains supply, the programme must

be advanced to pump out the water as the

drum will be full of water and unless the water

is emptied, water spillage could occur.

You can use this function only on synthetic

(program 6,7,8 and 9) and woollen (program

10,11 and 12).

Extra rinse

Using this function, you can have 4 rinse

cycles instead of 3 in cottons programmes. The

additional rinse will extract more detergent for

sensitive skin.

You can use this function only on cotton

(program 1,2,3,4 and 5) and synthetic (program

6,7,8 and 9).

function buttons

Page 11

Detergent dispenser

It is necessary to remove the detergent

dispenser drawer from time to time to clean

away residue and ensure correct operation.

To remove

Pull out the drawer and press down on the

coloured insert to release it fully from its

housing. Wash the drawer in warm water to

remove detergent residue and before replacing

wipe out the housing.

Syphon

The syphon (coloured insert in the dispenser)

must be cleaned every 30-40 washes. Remove

the dispenser drawer and lift out the syphon

and wash in warm water to remove any

softener residue. Refit ensuring that the syphon

is correctly fitted before use.

Maintenance wash

If you regularly use low temperature

programs, certain detergents cause build up

of greasy deposits over time. We recommend

a hot maintenance wash once every 6 months

to clear such accumulation of residue.

Simply run the wash programme “2”

without laundry using the usual amount of

detergent.

Water intake filter

At the end of the water intake connection

and water inlet hose-tap side there are filters.

These filters prevent any dirt and objects

passing into the machine. It is advisable that

these filters should be cleaned every 30-40

washes. To clean these filters, first turn the tap

off. Then, disconnect the hose and clean the

filter with a thin brush. If the filter is very dirty,

you may clean it by pulling out with pliers. To

clean the filter at the tap side of the hose, pull

it out by hand and clean the filter under tap

water. Ensure that the sealing rings are in place

before reassembly.

care and maintenance

HOT COLD

Page 12

Pump filter warning

When the appliance is in use and depending

on the programme selected there can be hot

water in the filter. Never remove the filter

during a wash cycle, always wait until the

appliance has finished the cycle, and is empty.

When replacing the filter, ensure it is securely

retightened so as to stop leaks and young

children being able to remove it.

Hoses

To prevent any leakage, check the hoses

every two years. If the machine is placed in

cold ambient temperatures, the water

remaining inside the pump and hoses should

be drained to prevent freezing, empty the

water intake hoses by disconnecting from taps.

Drum

Do not leave any metal objects (pins, needles,

etc.) inside the drum. These objects may cause

rust on the drum surface and stain clothing.

Do not clean the drum with abrasive materials.

Cleaning the pump filter

Warning

When the appliance is in use and depending

on the programme selected there can be hot

water in the filter. Never remove the filter

during a wash cycle, always wait until the

appliance has finished the cycle, and is empty.

When replacing the filter, ensure it is securely

retightened so as to stop leaks and young

children being able to remove it.

To prevent objects entering the pump and

causing damage, your machine employs a filter

system that extends the pump life. It is advisable

to clean the filter every 30-40 washes. Before

opening the filter door, disconnect the power.

Turn the opening of kick plate screws 90° with

the help of a screw driver or a coin. Place a

little pan in front of the filter door to catch the

small amount of water spilling from the

machine. Remove the filter by turning in an

anti clockwise direction. After cleaning the

filter, replace it by turning clockwise making

sure that it is closed firmly. Replace the kick

plate and secure it by the locking screws.

Attention!

Ensure the machine is empty of water

before removing the filter. If the filter has

not been replaced correctly water will leak

Page 13

before calling service/trouble shooting

You turned the machine on, but the indicator

light is not lit

Have you plugged in and switched on at

the socket? Check the power cable, or for a

blown fuse. Check the front door is properly

closed.

Machine does not take in water

• Check the door for proper closure. Either

taps are closed or water inlet filters are

clogged.

• Turn the program selector clockwise until

a clicking action is present. Set to the

program required.

Water is syphoned / discharged

Check if the discharge hose is positioned

as described on page 6.

If the machine vibrates or is too noisy

• Have all the transit bolts and packing been

removed?

• Is the machine touching something?

• Are all the feet resting firmly on the ground?

• H ave the lock nuts been secure d?

• Has the recommended wash load been

exceeded? (Ma x 5 kg dry w eight)

Water coming from beneath the machine

Check the water inlet and drain hoses.

Tighten the connections. The washers of the

hoses may be worn out or the pump filter may

not be closed properly.

Foam coming out of the detergent dispenser

Check whether your detergent is suitable

for automatic machines. Next time use less

detergent.

Pump does not drain water

Check Rinse Hold button has not been

selected in error. Clean the pump filter. Do not

attempt to remove the filter if the machine is

full of water. Check whether the drain hose is

bent or not. If there is a need to clean the

pump filter, refer to the pump filter cleaning

section on page 13.

Loading...

Loading...