Page 1

Documentation | EN

IL230x-B110

Fieldbus Box for EtherCAT

2017-05-29 | Version: 1.0.3

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

1.4 Bus Coupler as a general term..........................................................................................................7

2 Basics .........................................................................................................................................................8

2.1 System Properties .............................................................................................................................8

2.2 CoE Interface...................................................................................................................................11

2.3 EtherCAT State Machine.................................................................................................................13

3 Product overview.....................................................................................................................................15

3.1 The Fieldbus Box System................................................................................................................15

3.2 Fieldbus Box - Naming conventions ................................................................................................17

3.3 Firmware and hardware issue status...............................................................................................19

3.4 Technical data .................................................................................................................................20

4 Mounting and wiring................................................................................................................................21

4.1 Dimensions......................................................................................................................................21

4.2 EtherCAT connection ......................................................................................................................23

5 Parameterizning and commissioning....................................................................................................25

5.1 Start-up behavior of the Fieldbus Box .............................................................................................25

6 Configuration ...........................................................................................................................................26

6.1 TwinCAT System Manager..............................................................................................................26

6.1.1 Configuration overview .................................................................................................... 26

6.2 Objects ............................................................................................................................................36

6.2.1 Object description ............................................................................................................ 36

6.3 Configuration of the complex modules ............................................................................................51

6.3.1 General Register Description........................................................................................... 51

6.3.2 Example for Register Communication ............................................................................. 54

6.4 ADS communication ........................................................................................................................57

6.4.1 Parameterization example with KS2000.......................................................................... 57

7 Error handling and diagnosis.................................................................................................................61

7.1 Diagnostic LEDs - Overview............................................................................................................61

7.2 Diagnostic LEDs ..............................................................................................................................62

7.3 Diagnostic LEDs for local errors ......................................................................................................65

7.4 Check of the IP-Link connection......................................................................................................67

8 Accessories .............................................................................................................................................70

8.1 Fieldbus Box accessories................................................................................................................70

8.2 Power cables ...................................................................................................................................71

9 Appendix ..................................................................................................................................................72

9.1 General operating conditions...........................................................................................................72

9.2 Approvals.........................................................................................................................................73

9.3 Test standards for device testing.....................................................................................................73

9.4 Support and Service ........................................................................................................................74

IL230x-B110 3Version: 1.0.3

Page 4

Table of contents

IL230x-B1104 Version: 1.0.3

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

IL230x-B110 5Version: 1.0.3

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

IL230x-B1106 Version: 1.0.3

Page 7

Foreword

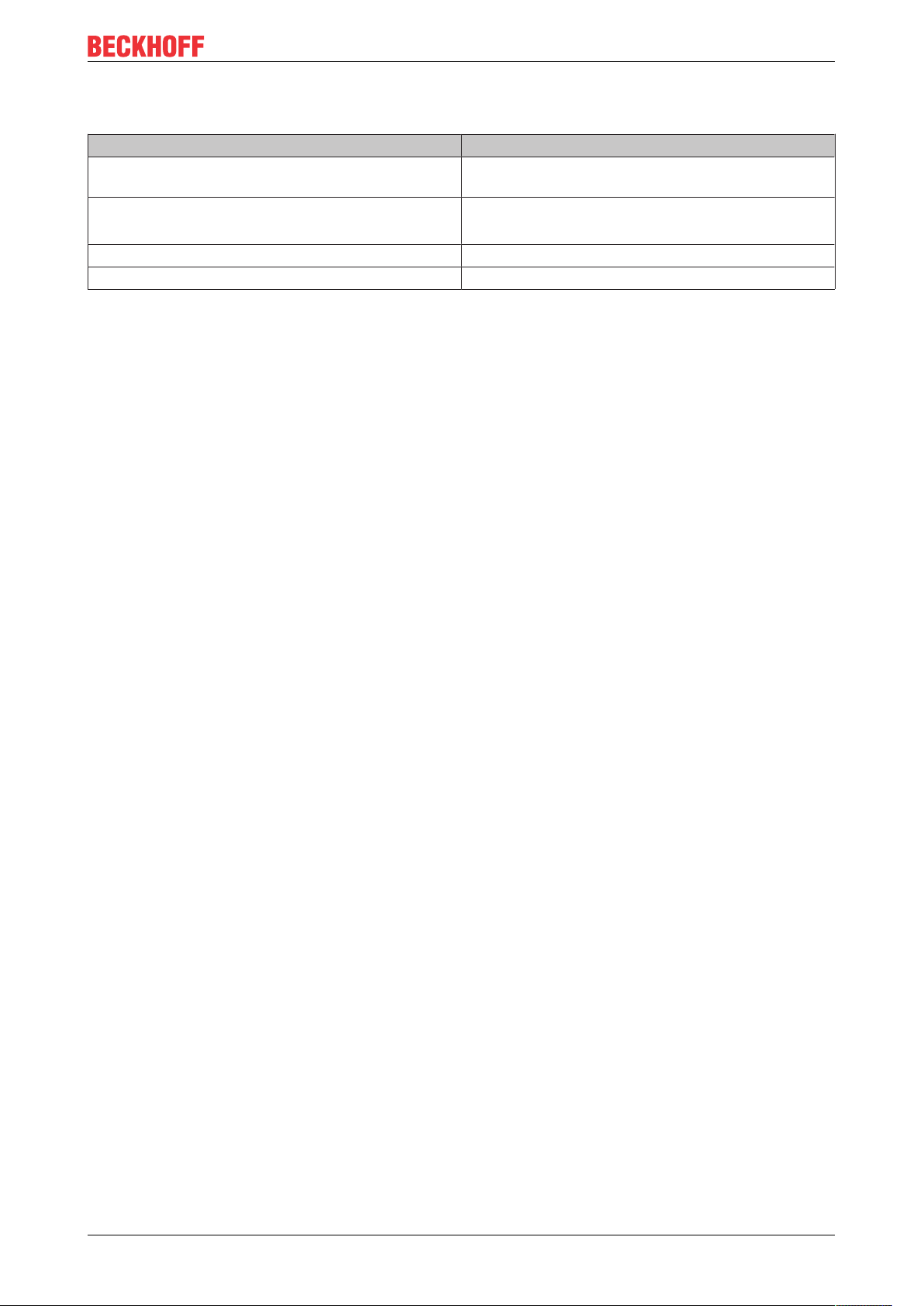

1.3 Documentation issue status

Version Comment

1.0.3 • Translation of chapter Diagnostic LEDs for

EtherCAT corrected

1.0.2 • System overview updated

• Description of CoE Interface updated

1.0.1 • EtherCAT connection updated

1.0 • First release

1.4 Bus Coupler as a general term

Parts of this manual give general information about Ethernet implementation in Beckhoff products.

Thus in the following often the term Bus Coupler is used, that describes not only the IP20 products, but also

means the IP67 modules.

IL230x-B110 7Version: 1.0.3

Page 8

Basics

2 Basics

2.1 System Properties

Protocol

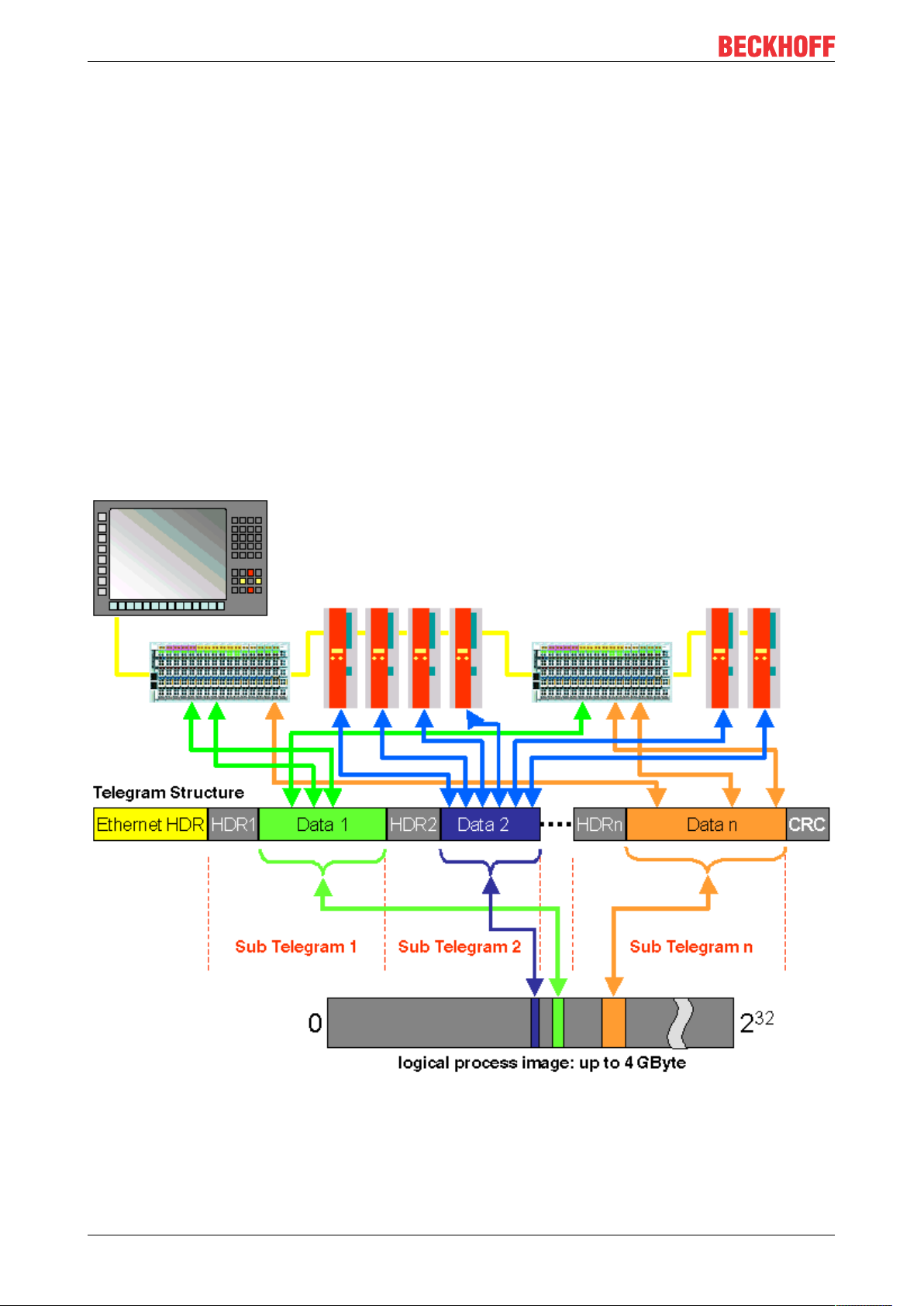

The EtherCAT protocol is optimized for process data and is transported directly within the Ethernet frame

thanks to a special Ether-type. It may consist of several sub-telegrams, each serving a particular memory

area of the logical process images that can be up to 4 gigabytes in size. The data sequence is independent

of the physical order of the Ethernet terminals in the network; addressing can be in any order. Broadcast,

Multicast and communication between slaves are possible. Transfer directly in the Ethernet frame is used in

cases where EtherCAT components are operated in the same subnet as the control computer.

However, EtherCAT applications are not limited to a subnet: EtherCAT UDP packs the EtherCAT protocol

into UDP/IP datagrams. This enables any control with Ethernet protocol stack to address EtherCAT systems.

Even communication across routers into other subnets is possible. In this variant, system performance

obviously depends on the real-time characteristics of the control and its Ethernet protocol implementation.

The response times of the EtherCAT network itself are hardly restricted at all: the UDP datagram only has to

be unpacked in the first station.

Protocol structure: The process image allocation is freely configurable. Data are copied directly in the I/O

terminal to the desired location within the process image: no additional mapping is required. The available

logical address space is with very large (4 GB).

IL230x-B1108 Version: 1.0.3

Page 9

Basics

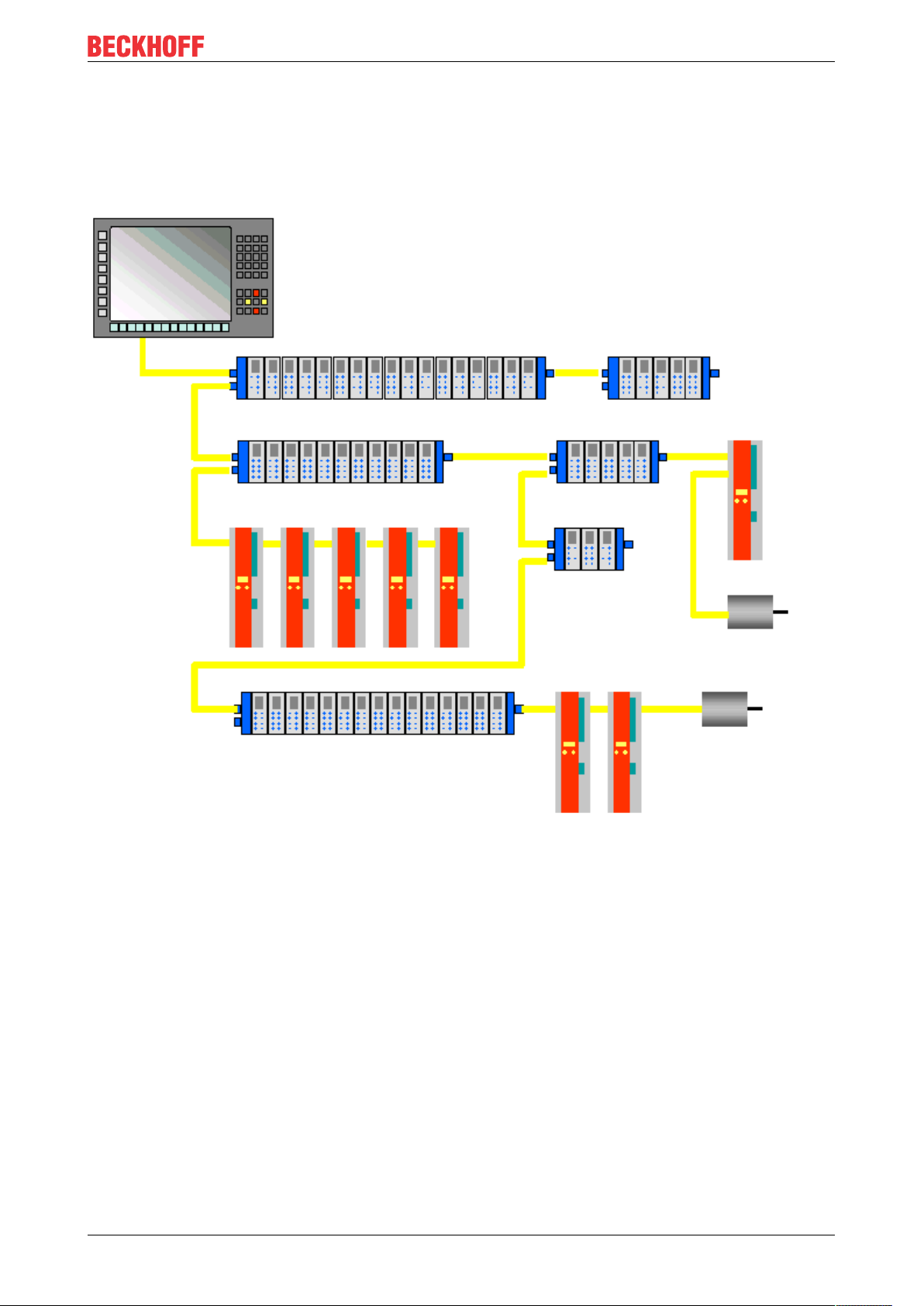

Topology

Line, tree or star: EtherCAT supports almost any topology. The bus or line structure known from the

fieldbusses thus also becomes available for Ethernet. Particularly useful for system wiring is the combination

of line and branches or stubs. The required interfaces exist on the couplers; no additional switches are

required. Naturally, the classic switch-based Ethernet star topology can also be used.

Maximum wiring flexibility:

with or without switch, line or tree topologies, can be freely selected and combined. The complete bandwidth

of the Ethernet network - such as different optical fibers and copper cables - can be used in combination with

switches or media converters.

Distributed Clocks

Accurate synchronization is particularly important in cases where spatially distributed processes require

simultaneous actions. This may be the case, for example, in applications where several servo axes carry out

coordinated movements simultaneously.

The most powerful approach for synchronization is the accurate alignment of distributed clocks, as described

in the new IEEE 1588 standard. In contrast to fully synchronous communication, where synchronization

quality suffers immediately in the event of a communication fault, distributed aligned clocks have a high

degree of tolerance vis-à-vis possible fault-related delays within the communication system.

With EtherCAT, the data exchange is fully based on a pure hardware machine. Since the communication

utilizes a logical (and thanks to full-duplex Fast Ethernet also physical) ring structure, the mother clock can

determine the run-time offset to the individual daughter clocks simply and accurately - and vice versa. The

distributed clocks are adjusted based on this value, which means that a very precise network-wide timebase

with a jitter of significantly less then 1 microsecond is available.

IL230x-B110 9Version: 1.0.3

Page 10

Basics

However, high-resolution distributed clocks are not only used for synchronization, but can also provide

accurate information about the local timing of the data acquisition. For example, controls frequently calculate

velocities from sequentially measured positions. Particularly with very short sampling times, even a small

temporal jitter in the displacement measurement leads to large step changes in velocity. With EtherCAT new,

extended data types are introduced as a logical extension (time stamp and oversampling data type). The

local time is linked to the measured value with a resolution of up to 10 ns, which is made possible by the

large bandwidth offered by Ethernet. The accuracy of a velocity calculation then no longer depends on the

jitter of the communication system. It is orders of magnitude better than that of measuring techniques based

on jitter-free communication.

Performance

EtherCAT reaches new dimensions in network performance. Protocol processing is purely hardware-based

through an FMMU chip in the terminal and DMA access to the network card of the master. It is thus

independent of protocol stack run-times, CPU performance and software implementation. The update time

for 1000 I/Os is only 30 µs - including terminal cycle time. Up to 1486 bytes of process data can be

exchanged with a single Ethernet frame - this is equivalent to almost 12000 digital inputs and outputs. The

transfer of this data quantity only takes 300 µs.

The communication with 100 servo axes only takes 100 µs. During this time, all axes are provided with set

values and control data and report their actual position and status. Distributed clocks enable the axes to be

synchronised with a deviation of significantly less than 1 microsecond.

The extremely high performance of the EtherCAT technology enables control concepts that could not be

realized with classic fieldbus systems. For example, the Ethernet system can now not only deal with velocity

control, but also with the current control of distributed drives. The tremendous bandwidth enables status

information to be transferred with each data item. With EtherCAT, a communication technology is available

that matches the superior computing capacity of modern Industrial PCs. The bus system is no longer the

bottleneck of the control concept. Distributed I/Os are recorded faster than is possible with most local I/O

interfaces. The EtherCAT technology principle is scalable and not bound to the baud rate of 100 MBaud –

extension to GBit Ethernet is possible.

Diagnostics

Experience with fieldbus systems shows that availability and commissioning times crucially depend on the

diagnostic capability. Only faults that are detected quickly and accurately and which can be precisely located

can be corrected quickly. Therefore, special attention was paid to exemplary diagnostic features during the

development of EtherCAT.

During commissioning, the actual configuration of the I/O terminals should be checked for consistency with

the specified configuration. The topology should also match the saved configuration. Due to the built-in

topology recognition down to the individual terminals, this verification can not only take place during system

start-up, automatic reading in of the network is also possible (configuration upload).

Bit faults during the transfer are reliably detected through evaluation of the CRC checksum: The 32 bit CRC

polynomial has a minimum hamming distance of 4. Apart from breaking point detection and localization, the

protocol, physical transfer behavior and topology of the EtherCAT system enable individual quality

monitoring of each individual transmission segment. The automatic evaluation of the associated error

counters enables precise localization of critical network sections. Gradual or changing sources of error such

as EMC influences, defective push-in connectors or cable damage are detected and located, even if they do

not yet overstrain the self-healing capacity of the network.

Integration of standard Bus Terminals from Beckhoff

In addition to the new Bus Terminals with E-Bus connection (ELxxxx), all Bus Terminals from the familiar

standard range with K-Bus connection (KLxxxx) can be connected via the BK1120 or BK1250 Bus Coupler.

This ensures compatibility and continuity with the existing Beckhoff Bus Terminal systems. Existing

investments are protected.

IL230x-B11010 Version: 1.0.3

Page 11

Basics

2.2 CoE Interface

Object directory

All EtherCAT slaves supporting the CoE interface have an object directory containing all parameter,

diagnostic, process or other data that can be read or written via EtherCAT.

The object directory can be read via the SDO information service. It is included in the device description file.

All EtherCAT slaves should support the SDO information service at least to such an extent that the compact

object description of each object can be read (from index 0x1000). This object description contains the data

type, the length, the access rights and information as to whether the object can be mapped in a PDO (and

therefore can be used as process data).

Start-Up list

The Start-up list describes the interrelationship between EtherCAT state machine, process data mapping

and device parameter settings during start-up of EtherCAT network.

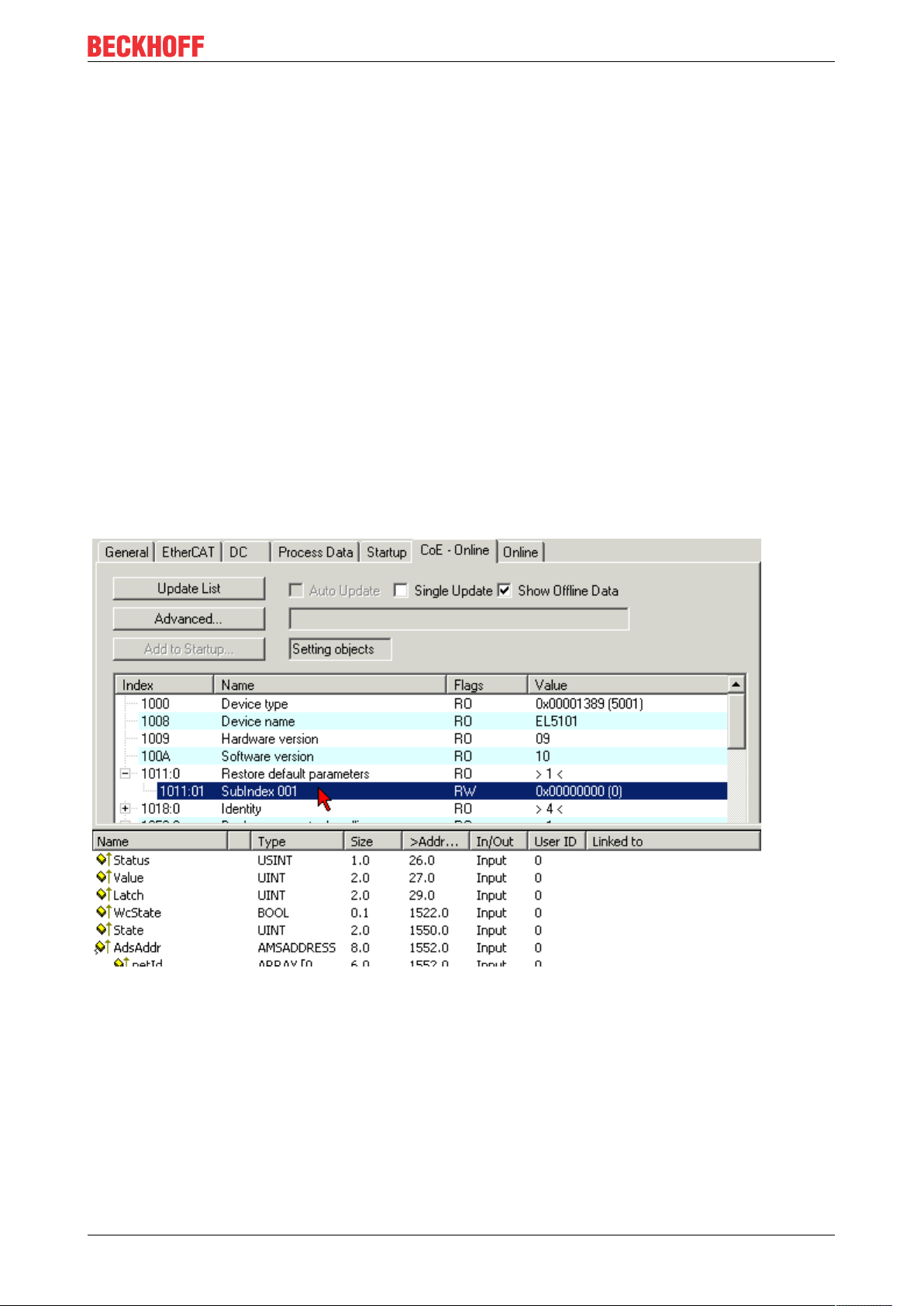

Restoring the delivery state

Restoring the delivery state To restore the delivery state for backup objects in ELxxxx terminals, the CoE

object "Restore default parameters", SubIndex001 can be selected in the TwinCAT System Manager

(Config mode) (see Fig. 1)

Fig. 1 Selecting the "Restore default parameters" PDO

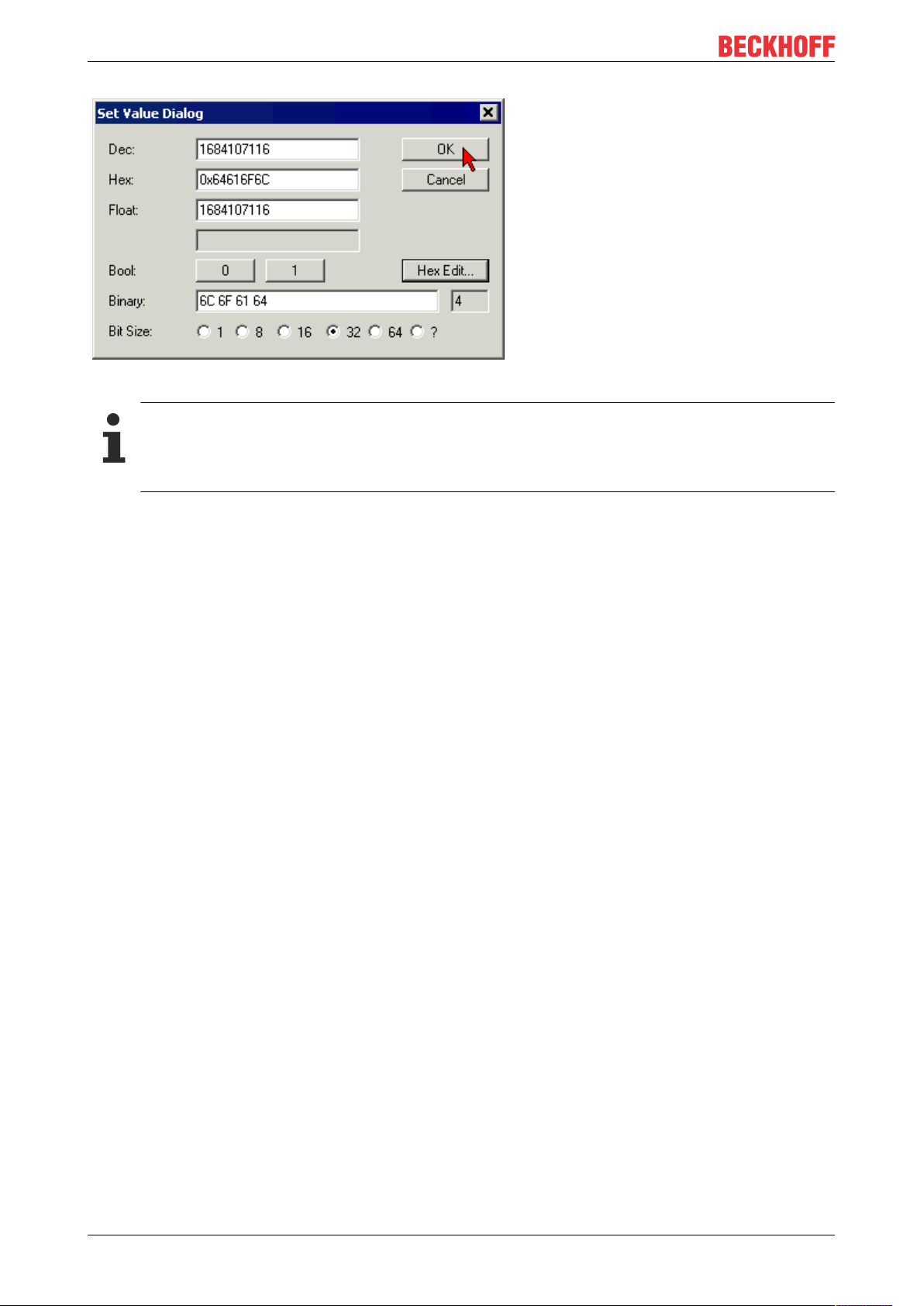

Double-click on SubIndex 001 to enter the Set Value dialog. Enter the value 1684107116 in field "Dec" or the

value 0x64616F6C in field "Hex" and confirm with OK (Fig. 2).

All backup objects are reset to the delivery state.

IL230x-B110 11Version: 1.0.3

Page 12

Basics

Fig. 2 Entering a restore value in the Set Value dialog

Alternative restore value

In some older terminals the backup objects can be switched with an alternative restore value: Decimal value: "1819238756" Hexadecimal value: "0x6C6F6164" An incorrect entry for the restore value

has no effect.

IL230x-B11012 Version: 1.0.3

Page 13

Basics

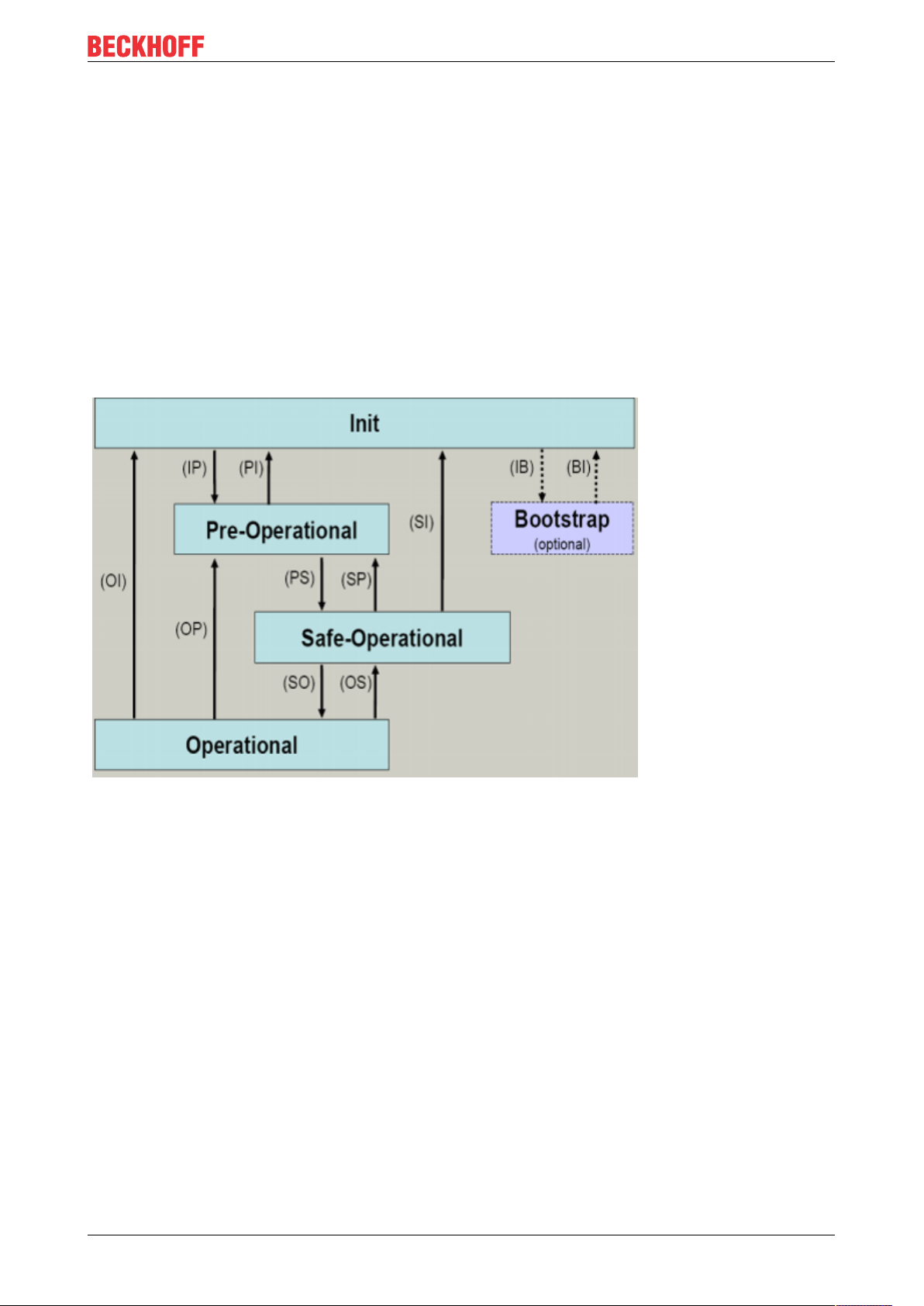

2.3 EtherCAT State Machine

The state of the EtherCAT slave is controlled via the EtherCAT State Machine (ESM). Depending upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the bootup of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Boot

The regular state of each EtherCAT slave after bootup is the OP state.

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before

it acknowledges the change of state, the EtherCAT slave copies current input data into the associated DPRAM areas of the EtherCAT slave controller (ECSC).

IL230x-B110 13Version: 1.0.3

Page 14

Basics

In Safe-Op state mailbox and process data communication is possible, although the slave keeps its outputs

in a safe state, while the input data are updated cyclically.

Outputs in SAFEOP state

The default set watchdog monitoringremoved link: watchdog monitoring sets the outputs of the

module in a safe state - depending on the settings in SAFEOP and OP - e.g. in OFF state. If this is

prevented by deactivation of the watchdog monitoring in the module, the outputs can be switched or

set also in the SAFEOP state.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

Boot

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

IL230x-B11014 Version: 1.0.3

Page 15

Product overview

3 Product overview

3.1 The Fieldbus Box System

Fieldbus box modules are robust fieldbus stations for a large number of different fieldbus systems. They offer

a wide range of I/O functionality. All relevant industrial signals are supported. As well as digital and analog

inputs and outputs including thermocouple and RTD inputs, there are also incremental encoder interfaces

available for displacement and angle measurement as well as serial interfaces to solve a large number of

communications tasks.

Three varieties of signal connection

The digital inputs and outputs can be connected with snap-on 8mm diameter plugs, screw-in M8

connectors, or with screw-in M12 pendants. The M12 version is provided for analog signals.

All important signal types

Special input and output channels on the combination I/O modules can be used for either input or output. It is

not necessary to configure them, since the fieldbus interface is available for every combination channel as

well as for input and output data. The combination modules give the user all of the advantages of fine signal

granularity.

The processor logic, the input circuitry and the power supply for the sensor are all fed from the control

voltage. The load voltage for the outputs can be supplied separately. In those Fieldbus Boxes in which only

inputs are available, the load power supply, UP, can optionally be connected in order to pass it on

downstream.

The states of the Fieldbus Box, the fieldbus connection, the power supplies and of the signals are indicated

by LEDs.

The label strips can be machine printed elsewhere, and then inserted.

Fieldbus Boxes can be combined for greater flexibility

In addition to the Compact Box, the Fieldbus Box series also includes extendable devices, namely the

Coupler Box and the Extension Box, as well as intelligent devices, the PLC Boxes.

Compact Box

The Compact Box makes the I/O data from the connected digital and analog sensors and actuators available

to the fieldbus.

Coupler Box

The Coupler Box also collects I/O data from the Extension Boxes via an interference-proof optical fiber

connection (IP-Link). Up to 120 Extension Boxes can be connected to a Coupler Box. In this way a

distributed IP67 I/O network is formed with only one fieldbus interface.

The Coupler Box is capable of automatically recognizing the extension modules connected to it during startup, and maps the I/O data automatically into the fieldbus process image – a configuration is not necessary.

The Coupler Box appears, from the fieldbus point of view, along with all of the networked Extension Boxes,

as a single participating bus device with a corresponding number of I/O signals.

The Coupler Box corresponds to the Bus Coupler in the BECKHOFF Bus Terminal system. BECKHOFF

fieldbus devices made to protection class IP 20 (Bus Terminals) and IP 67 (Fieldbus Box) can be combined

without difficulty – the data is handled in the same way in either case.

IL230x-B110 15Version: 1.0.3

Page 16

Product overview

IP-Link

The IP-Link is an optical fiber connection with a transmission rate of 2 MBits/s which is capable of

transmitting 1000 items of binary I/O data in approx. 1 ms, rapidly and securely. Smaller configurations are

correspondingly faster. Because of the high usable data rate, the coupling via IP-Link does not reduce the

performance of the fieldbus at all.

Low-priced plug connectors made according to Protection Class IP67 can be used for the rapid and simple

preparation of the IP-Link cable, in situ. The connection does not require special tools, and can be performed

quickly and simply. The IP-Link cables can also be obtained with prepared plugs if required.

The separate supply of the output voltage allows output groups to be switched off individually. Differing

potentials can also be created within an extension ring without difficulty, since the IP-Link naturally has

optimum electrical isolation.

Extension box

Like the Compact Boxes, the Extension Boxes cover the full spectrum of I/O signals, and may be up to 15m

apart. They are remarkably small in size, and lead to particularly economical I/O solutions with high levels of

protection. Here again, the digital inputs and outputs may optionally be connected via snap-on 8 mm

connectors, or via screw-in connectors (M8 and M12). Analog signal types are provided with the M12

version. The snap-on connectors lock in place positively, forming a shake-proof connection, while the screwin connectors offer the advantage of high resistance to being pulled out.

PLC Box

The PLC Box is an intelligent Fieldbus Box with PLC functionality for distributed pre-processing of the I/O

signals. This allows parts of the application to be farmed out from the central controller. This reduces the

load on the CPU and the fieldbus. Distributed counting, controlling and switching are typical applications for

the PLC Box. The reaction times are independent of the bus communication and of the higher-level

controller.

In the event of a bus or controller failure, maintenance of function (e.g. bringing the process to a safe state in

an orderly manner) is possible.

Programming is carried out with TwinCAT in accordance with IEC 61131-3. Five different programming

languages are available:

• Instruction List (IL)

• Function Block Diagram (FBD)

• Ladder Diagram (LD)

• Sequential Function Chart (SFC)

• Structured Text (ST)

The program download occurs either via the fieldbus or via the programming interface.

Extensive debugging functions (breakpoint, single step, monitoring, etc) are also available. The PLC Box

contains a powerful 16 bit controller, 32/96 kByte program memory and 32/64 kByte data memory. A further

512 bytes of non-volatile memory are available for remanent flags.

PLC Box with IP-Link

The programmable PLC Box with IP-Link provides almost unlimited I/O possibilities. Up to 120 extension

modules, with more than 2000 I/Os, can be directly addressed from the PLC program. The PLC Box is thus

also suitable for use as a small, autonomous controller for the operation of parts of equipment or small

machines.

IL230x-B11016 Version: 1.0.3

Page 17

3.2 Fieldbus Box - Naming conventions

The identifications of the Fieldbus Box modules are to be understood as follows:

IXxxxy-zyyy

IX describes the design:

"IP" stands for the CompactBox design [}18]

"IL" stands for the CouplerBox design (with IP-Link) [}18]

"IE" stands for the ExtensionBox design [}18]

xxxy describes the I/O connection:

xxx describes the I/O property:

"10x" - 8 x digital inputs

"15x" - counter module

"20x" - 8 x digital outputs

"25x" - PWM module

"23x" - 4 x digital inputs and 4 x digital outputs

"24x" - 8 x digital inputs and 8 x digital outputs

"3xx" - 4 x analog inputs

"4xx" - 4 x analog outputs

"5xx" - incremental encoder or SSI transducer

"6xx" - Gateway module for RS232, RS422, RS485, TTY

Product overview

y represents the mechanical connection:

"0" stands for 8mm snap-on connection,

"1" stands for M8 bolted connection

"2" stands for M12 bolted connection and

"9" stands for M23 bolted connection

zyyy describes the programmability and the fieldbus system

z distinguishes whether the device is a slave or is a programmable slave:

"B" - not programmable

"C" - programmable (PLC Box)

"yyy" stands for the fieldbus system and the bus connection:

"110" - EtherCAT

"200" - Lightbus

"310" - PROFIBUS

"318" - PROFIBUS with integrated tee-connector

"400" - Interbus

"510" - CANopen

"518" - CANopen with integrated tee-connector

"520" - DeviceNet

"528" - DeviceNet with integrated tee-connector

"730" - Modbus

"800" - RS485

"810" - RS232

"900" - Ethernet TCP/IP with RJ45 for the bus connection

"901" - Ethernet TCP/IP with M12 for the bus connection

"903" - PROFINET

"905" - EtherNet/IP

IL230x-B110 17Version: 1.0.3

Page 18

Product overview

Compact Box

Compact Box

The Compact Box modules offer a wide range of I/O functionality. All relevant industrial signals are

supported. The digital inputs and outputs can be connected either with snap-on 8mm diameter plugs, screwin M8 connectors, or screw-in M12 connectors. The M12 version is made available for analog signals.

Depending on the module, the I/O section and the power supply section can differ.

Coupler Box

Coupler Box

There are three versions of the coupler box named IL230x-Bxxx. It differs from the compact box in that this

module offers an interface to what are known as extension boxes. This interface is a subsidiary bus system

based on the optical fiber what is known as IPLink. This powerful subsidiary bus system can handle up to

120 extension boxes at one coupler box.

Extension Box

Extension Box

Extension Modules, that are independent of the fieldbus and that can only be operated together with a

coupler box via IPLink.

PLC Box

PLC Box

A PLC Box differ from the Coupler Box in that this module can be programmed in IEC 61131-3. This means

that this slave is also capable of working autonomously, without a master, for instance for control or

regulation tasks.

Also see about this

2 Fieldbus Box - Naming conventions [}18]

IL230x-B11018 Version: 1.0.3

Page 19

Product overview

3.3 Firmware and hardware issue status

The documentation refers to the hardware and software status that was valid at the time it was prepared.

The properties are subject to continuous development and improvement. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. Existing properties, however,

are always retained and are not changed, so that these modules can always be replaced by new ones.

The number beginning with a D allows you to recognize the firmware and hardware status of a module.

Syntax:

D.wwyyxyzu

ww - calendar week

yy - year

x - bus board firmware status

y - bus board hardware status

z - I/O board firmware status

u - I/O board hardware status

Example:

D.22081501

- Calendar week 22

- in the year 2008

- bus board firmware status: 1

- bus board firmware hardware status: 5

- I/O board firmware status: 0 (no firmware is necessary for this board)

- I/O board hardware status: 1

IL230x-B110 19Version: 1.0.3

Page 20

Product overview

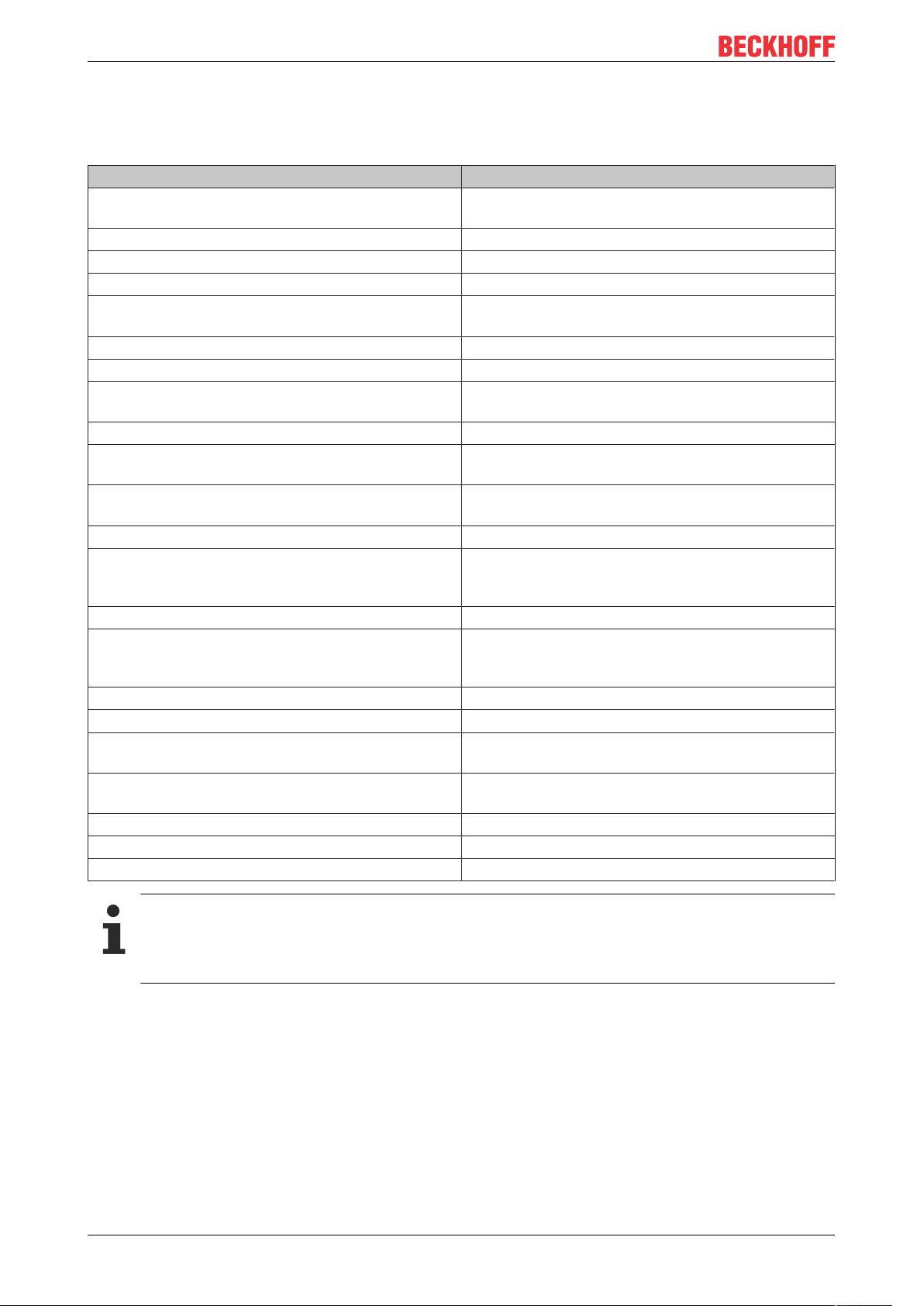

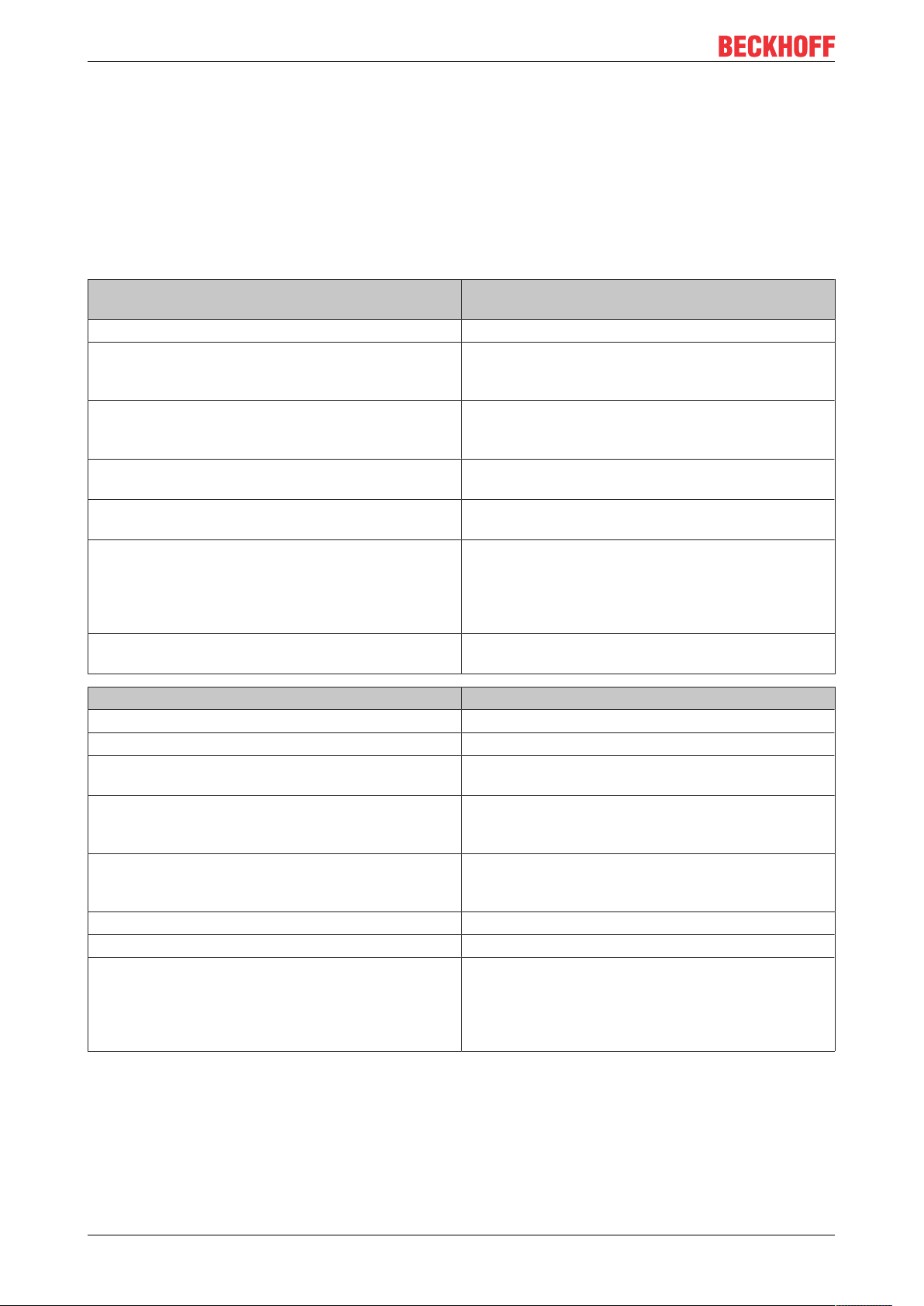

3.4 Technical data

Technical data IL230x-B110

Extension modules (IL....) max. 32 (until firmware version B0)

max. 78 (from firmware version B1)

Number of bytes, fieldbus max. 512bytes Input and max. 512bytes output

Digital peripheral signals (IL....) max. 624inputs and max. 624outputs

Analog peripheral signals (IL....) max. 128inputs and max. 128outputs

Data transfer medium 4 x 2 twisted pair copper cable; category 5 (100

Mbaud)

Baud rate 100 Mbaud

Distance between modules 100 m

Configuration KS2000 configuration software, TwinCAT System

Manager or via EtherCAT (ADS)

Protocols EtherCAT (Direct Mode)

Power supply Control voltage: 24VDC (-15%/+20%); load voltage:

According to I/O type

Control voltage current consumption According to I/O type + current consumption of

sensors, max. 0.5 A

Load voltage current consumption According to I/O type

Power supply connection Feed: 1 x M8 plug, 4-pin

Onward connection: 1 x M8 socket, 4-pin (except IP/

IE204x)

Fieldbus connection 2 x M12 d-coded, socket

Electrical isolation Channels/control voltage: no

between the channels: no

Control voltage/fieldbus: yes

Operating temperature 0°C... +55°C

Storage temperature -25°C... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27,

EN60068-2-29

EMC resistance burst / ESD conforms to EN61000-6-2 (EN50082)/

EN61000-6-4 (EN50081)

Protection class IP 65/66/67 (conforms to EN 60529)

Installation position any

Approvals CE, UL E172151

Further documentation

Detailed technical data for all available I/O variants can be found under Signal variants, Installation,

I/O module configuration on Products & Solutions CD from Beckhoff or on the Internet (http://

www.beckhoff.com) under Download/Fieldbus Box.

IL230x-B11020 Version: 1.0.3

Page 21

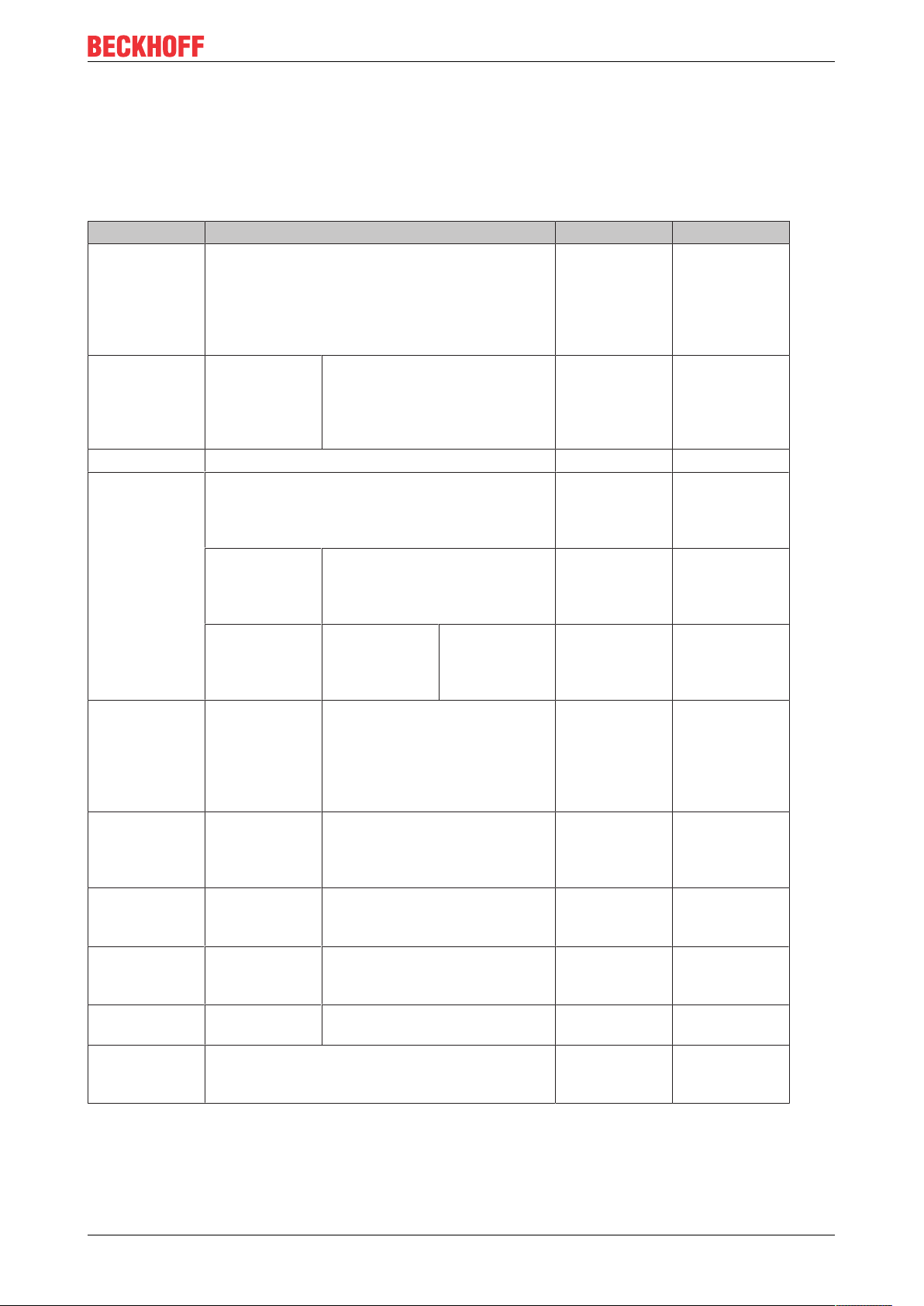

4 Mounting and wiring

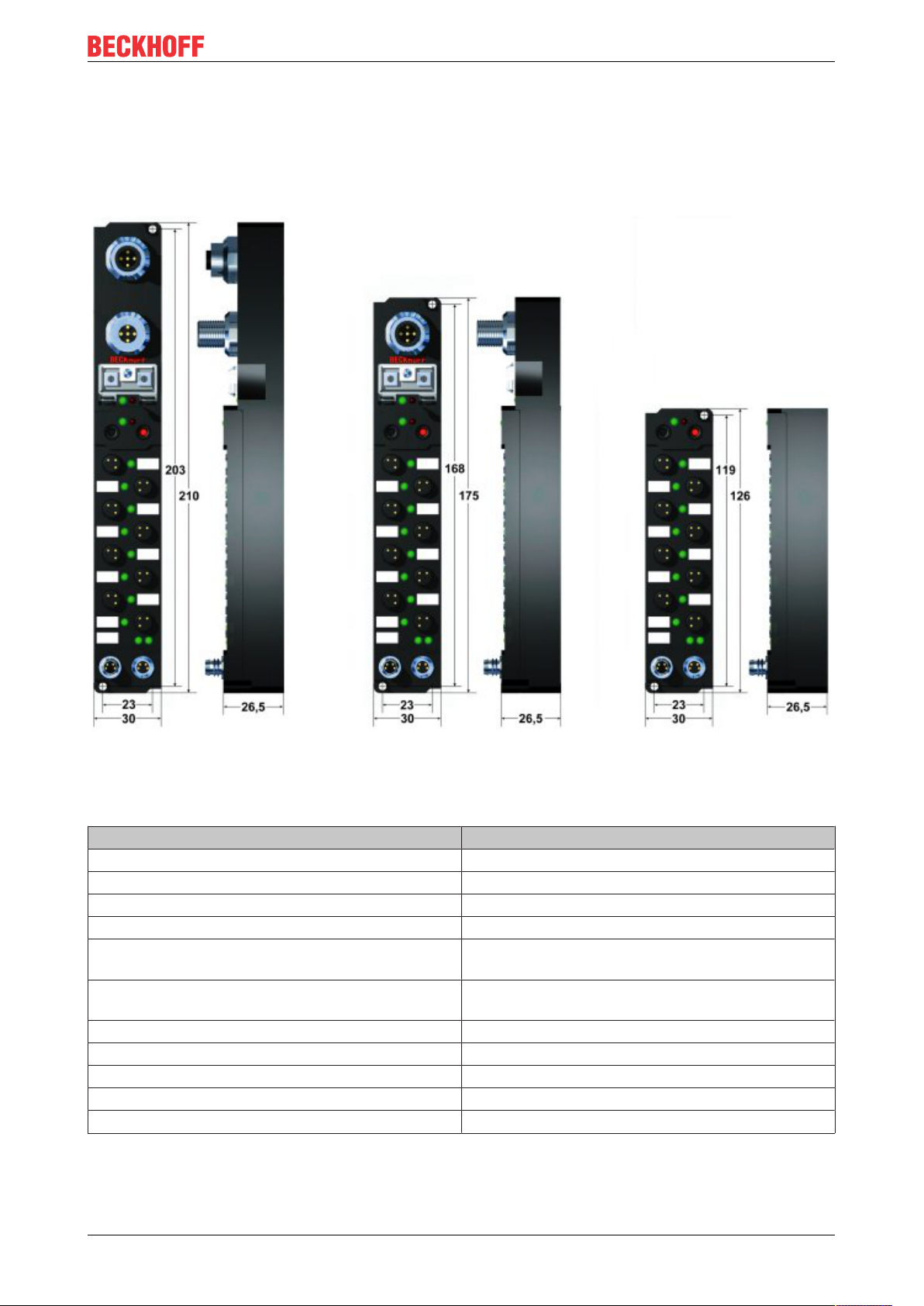

4.1 Dimensions

Mounting and wiring

All dimensions are given in millimeters.

General

Technical data Fieldbus Box

Material PA6 (polyamide), casting compound: polyurethane

Assembly 2 x fixing holes for M3

Metal parts Brass, nickel-plated

Contacts CuZn, gold-plated

Vibration / shock resistance according to EN60068-2-6/ EN60068-2-27,

EN60068-2-29

EMC resistance burst / ESD according to EN61000-6-2 (EN50082)/

EN61000-6-4 (EN50081)

Permissible ambient temperature during operation 0... 55°C

Permissible ambient temperature during storage -25 ... + 85°C

Installation position any

Type of protection IP65/66/67 when screwed together

Approvals CE, UL E172151

IL230x-B110 21Version: 1.0.3

Page 22

Mounting and wiring

IPxxxx-Bxx8, IL230x-Bxx8, IL230x-B110, IXxxxx-B400, IXxxxx-B90x, IXxxxx-C900

Technical data Compact and Coupler Box with integrated tee

connector

Dimensions (Hx WxD) ca. 210 x30x26,5mm (height to upper edge of

fieldbus socket: 30 mm)

Weight ca. 260g-290g, depending on module type

IPxxxx-Bxx0, IL230x-Bxx0, IL230x-Cxx0

Technical data Compact and Coupler Box

Dimensions (Hx WxD) Approx. 175 x 30 x 26.5 mm (height to upper edge of

fieldbus socket: 30 mm, with T- connector

ZS1031-2600 height approx. 65 mm)

Weight Approx. 250 g - 280 g, depending on module type

IExxxx

Technical data Extension box

Dimensions (Hx WxD) Approx. 126 x 30 x 26.5 mm

Weight Approx. 120 g - 200 g, depending on module type

IL230x-B11022 Version: 1.0.3

Page 23

Mounting and wiring

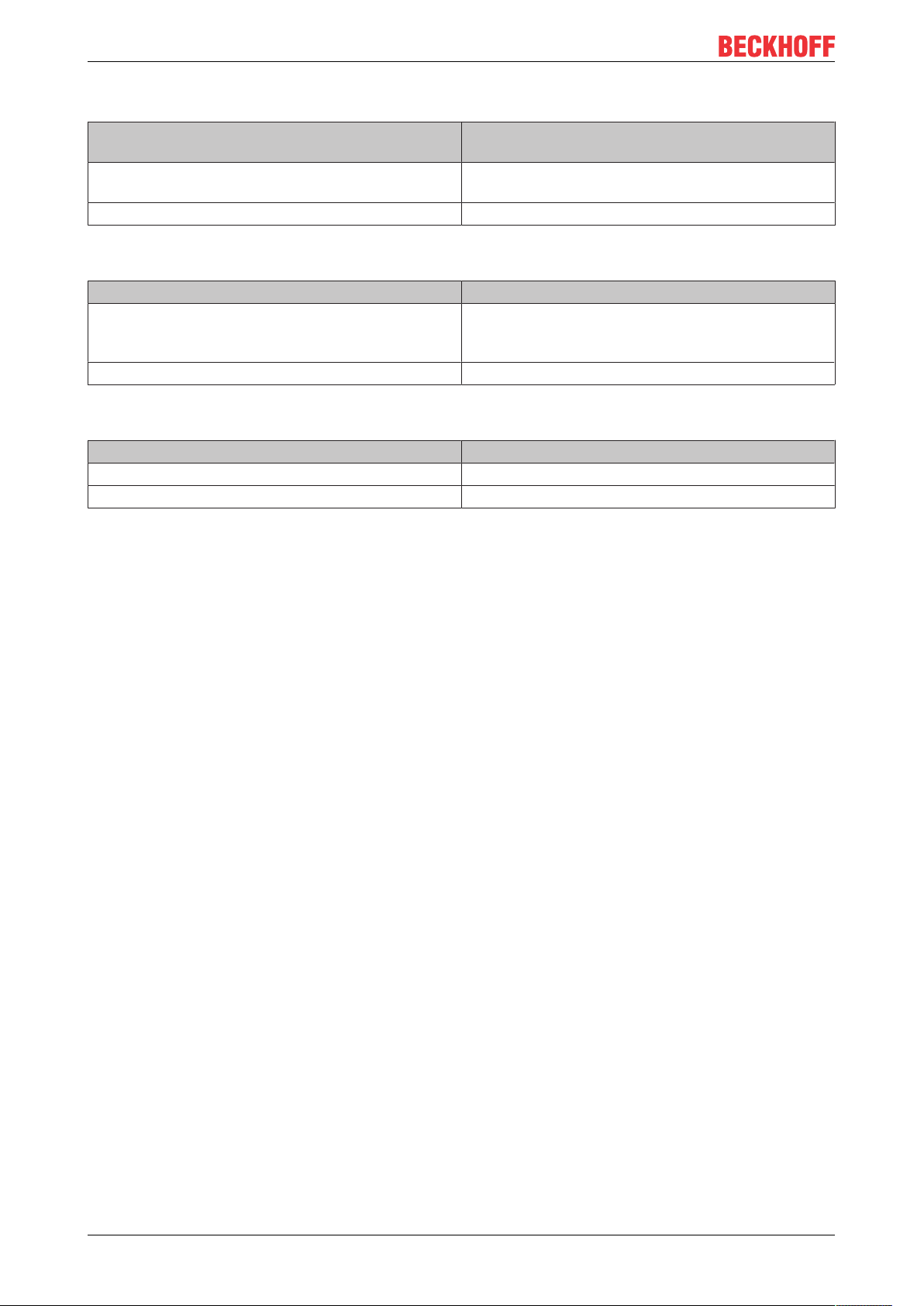

4.2 EtherCAT connection

The EtherCAT connection is established via two d-coded M12 sockets (one for the EtherCAT input, one for

the output).

The cable length between two EtherCAT devices must not exceed 100 m.

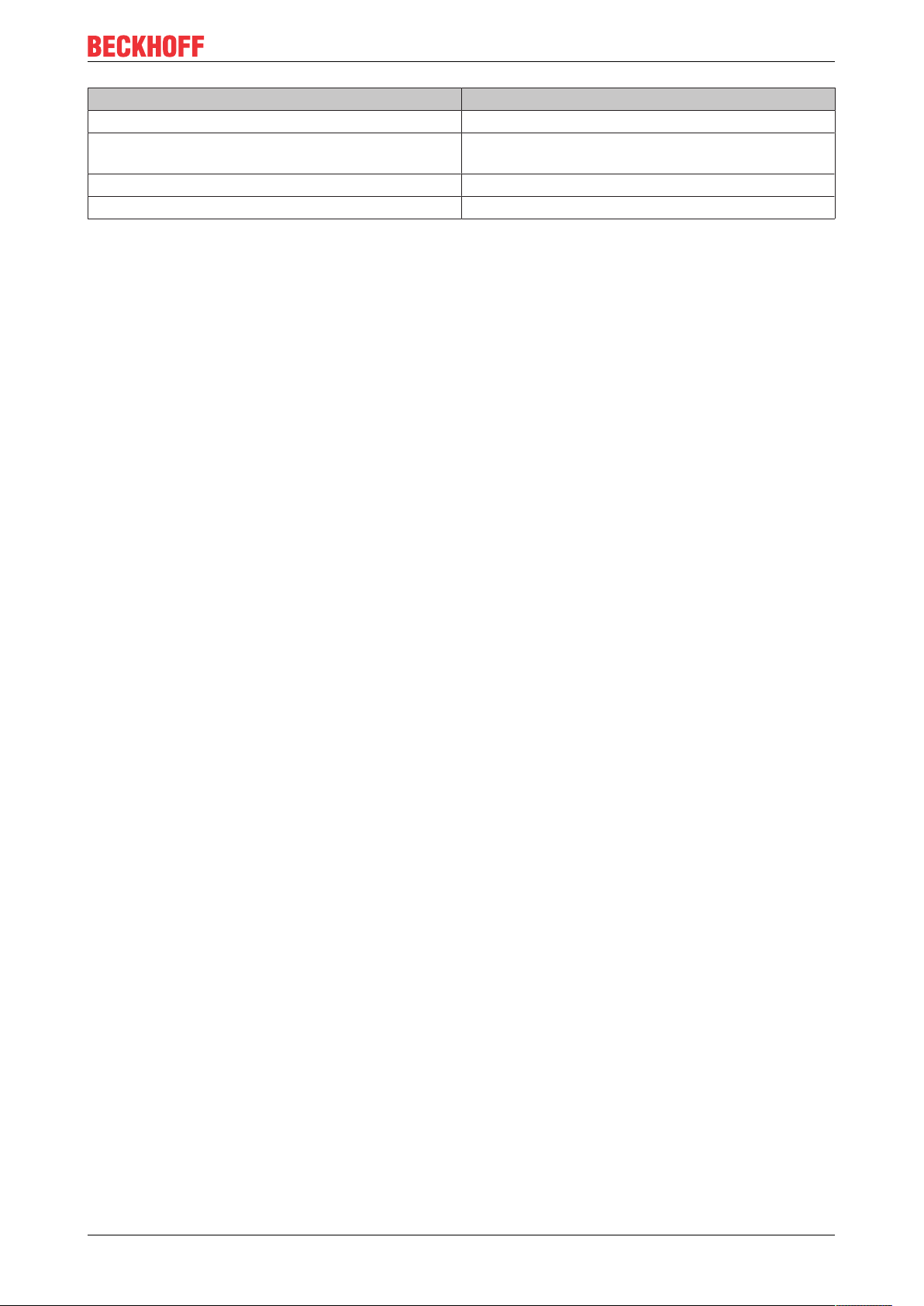

Cables and connectors

For connecting EtherCAT devices only Ethernet cables that meet the requirements of at least category 5

(CAt5) according to EN 50173 or ISO/IEC 11801 should be used. EtherCAT uses 4 wires for signal transfer.

The following cables and connectors are suitable for application in EtherCAT systems:

Name Comment

ZB9010 EtherCAT cable, fixed installation, CAT 5e, 4-core

ZB9020 EtherCAT cable, suitable for drag chain applications

CAT 5e, 4-core

ZS1090-0004 M12 connector, 4-pin, IP67, field-configurable

ZK1090-6161-0005 EtherCAT cable, ready-made, M12 connector - M12

connector, 0.5 m length

ZK1090-6161-0010 EtherCAT cable, ready-made, M12 connector - M12

connector, 1.0m length

ZK1090-6161-0020 EtherCAT cable, ready-made, M12 connector - M12

connector, 2.0m length

ZK1090-6161-0025 EtherCAT cable, ready-made, M12 connector - M12

connector, 2.5m length

ZK1090-6161-0050 EtherCAT cable, ready-made, M12 connector - M12

connector, 5.0m length

ZK1090-6161-0100 EtherCAT cable, ready-made, M12 connector - M12

connector, 10m length

ZK1090-6292-0005 EtherCAT cable, female M12 connector - RJ45, 0.5

m length

ZK1090-6292-0020 EtherCAT cable, female M12 connector - RJ45, 2.0

m length

Data sheets

There are different standards for assignment and colors at plugs and cables for Ethernet/EtherCAT.

Please take assignment and colors of Beckhoff cables from the according data sheets.

Pin assignment of the M12 plug (d-coded)

IL230x-B110 23Version: 1.0.3

Page 24

Mounting and wiring

PIN Signal Description

1 Tx + Transmit Data+

2 Rx + Receive Data+

3 Tx- Transmit Data4 Rx- Receive Data-

Pin assignment of the RJ45 plug

PIN Signal Description

1 TD + Transmit Data+

2 TD - Transmit Data3 RD + Receive Data+

4 - reserved

5 - reserved

6 RD - Receive Data7 - reserved

8 - reserved

IL230x-B11024 Version: 1.0.3

Page 25

Parameterizning and commissioning

5 Parameterizning and commissioning

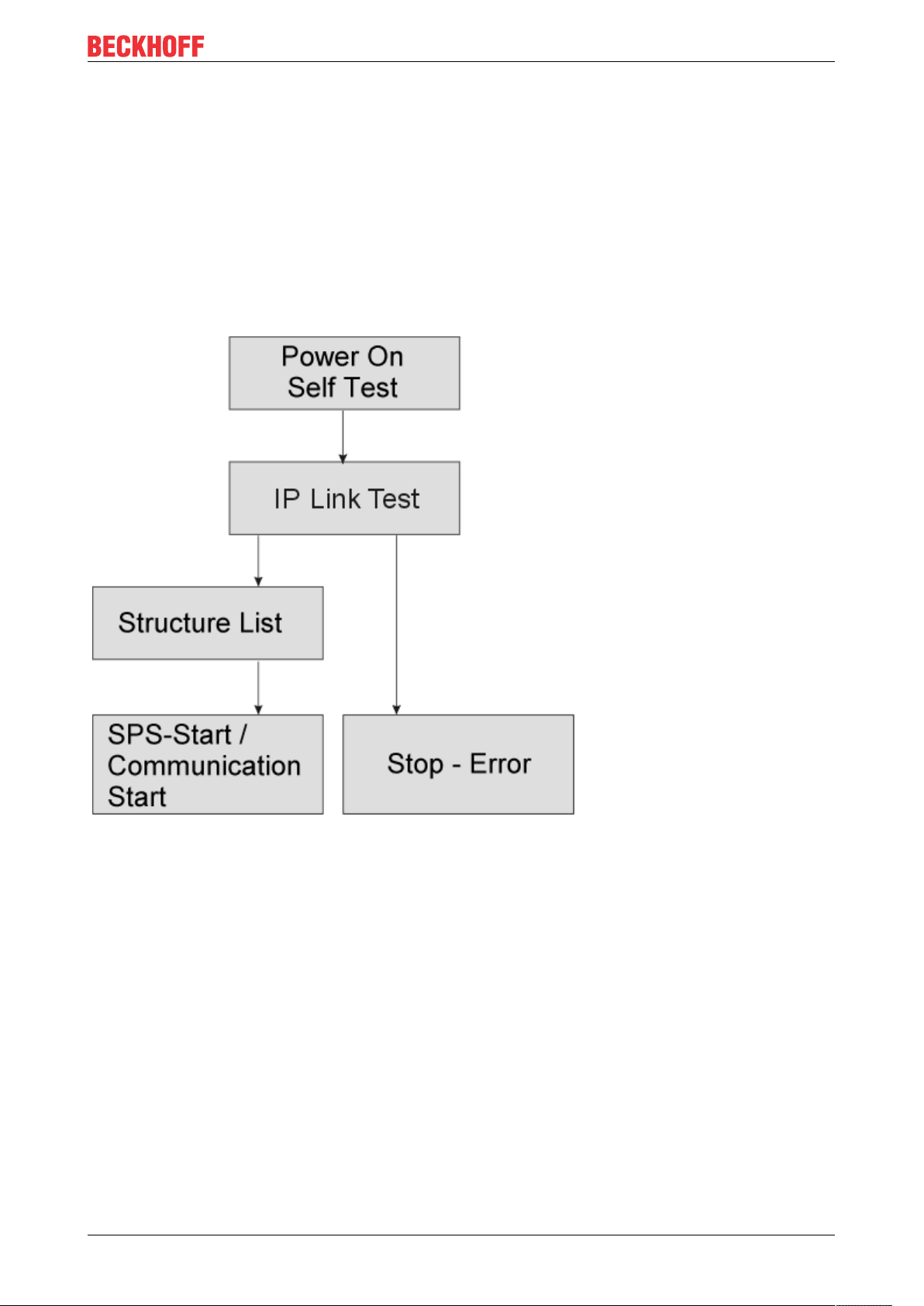

5.1 Start-up behavior of the Fieldbus Box

After power up, the Fieldbus Box checks its state, configures the IP-Link (if present) and refers to the

extension modules to create a structure list. If the Fieldbus Box contains a decentralized controller (IL230xC310) the local PLC is started once the structure list has successfully been created.

The I/O LEDs illuminate and flash as the module starts up. If there are no errors, the I/O LEDs should stop

flashing within about 2-3 seconds. If there is an error, then the LED that flashes will depend on the type of

that error (see Diagnostic LEDs).

IL230x-B110 25Version: 1.0.3

Page 26

Configuration

6 Configuration

6.1 TwinCAT System Manager

6.1.1 Configuration overview

IL230x-B110 [}26] Inputs [}27] Outputs [}28] Working counter status (WcState) [}29] Online status

(Info Data) [}30] ADS address (ADSAddr) [}31] EtherCAT cycle time [}32]

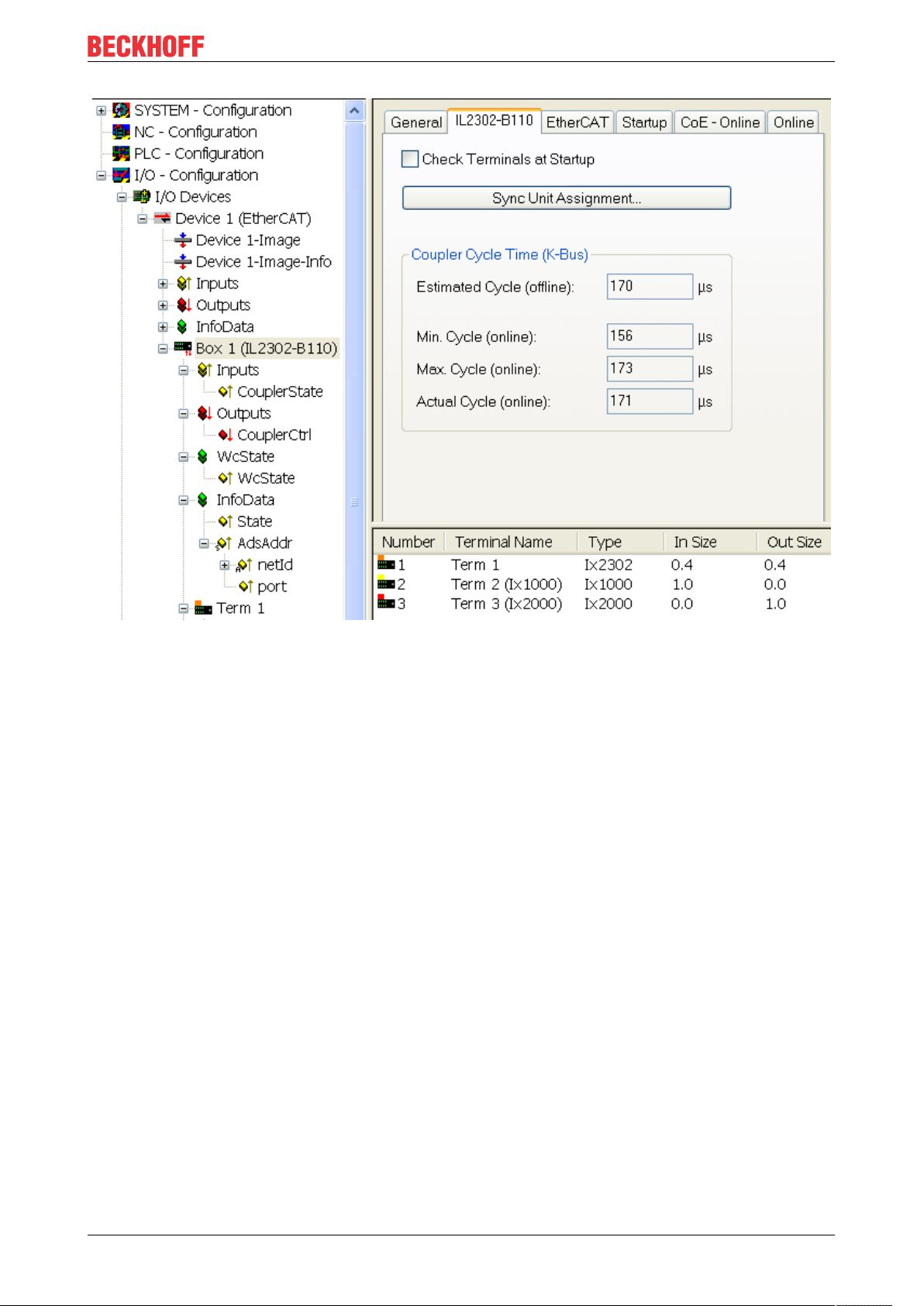

IL230x-B110 (IL2300-B110, IL2301-B110, IL2302-B110)

IL230x-B110 (IL2300-B110, IL2301-B110, IL2302-B110)

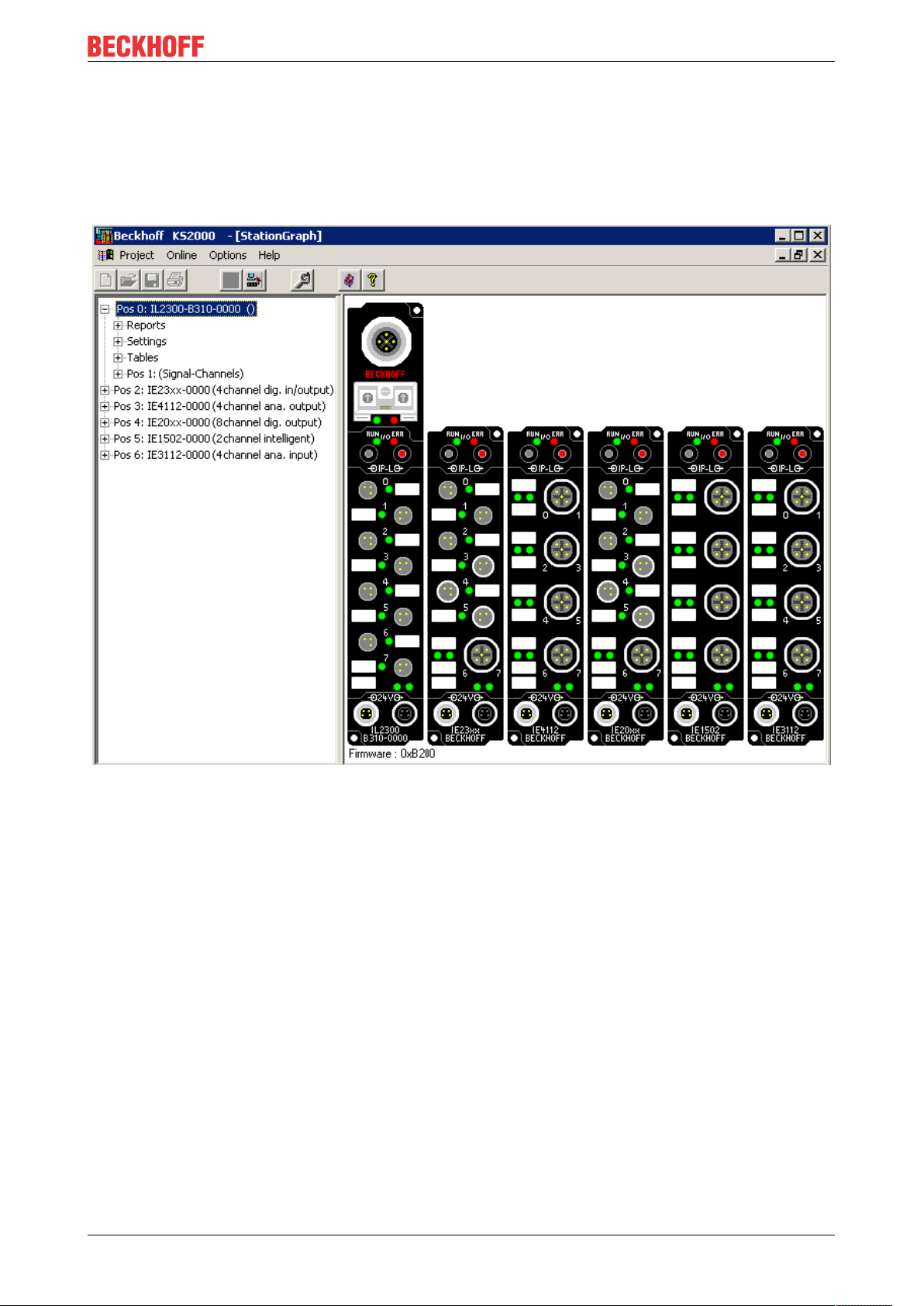

In TwinCAT System Manager Config mode enter the IL230x-B110 as an EtherCAT (Direct Mode) device

under Devices (Fig. 1). Any Fieldbus Box modules already connected to the network can also be read. All

boxes with extensions and configurations are uploaded automatically. You can then adapt these to meet

your requirements. FreeRun status must be set in TwinCAT.

Note regarding the screenshots: IP-Link values are displayed as K-Bus values in TwinCAT.

IL230x-B11026 Version: 1.0.3

Page 27

Configuration

Fig.1: Fbb_B110_TCAT_Sysman1

Fig. 1 TwinCAT tree IL2302-B110

Inputs

Inputs

CouplerState, "Online" tab

Display of general Fieldbus Box errors.

IL230x-B110 27Version: 1.0.3

Page 28

Configuration

Fig. 3 CouplerState, "Online" tab

Outputs

Outputs

CouplerCtrl, "Online" tab

Display of IP-Link/K-Bus errors or deactivation of outputs.

IL230x-B11028 Version: 1.0.3

Page 29

Configuration

Fig. 4 CouplerCrtl, "Online" tab

Working counter status (WcState)

Working counter status (WcState)

WCstate, "Online" tab

Boolean variable indicating the working counter status of the Fieldbus Box. An invalid working counter

(value: 1) is displayed if invalid data were transferred by the EtherCAT slave controller.

IL230x-B110 29Version: 1.0.3

Page 30

Configuration

Fig. 5 WCstate, "Online" tab

Online status (Info Data)

Online status (Info Data)

State, "Online" tab

Indicates the online status of the Fieldbus Box.

IL230x-B11030 Version: 1.0.3

Page 31

Configuration

Fig. 6 State, "Online" tab

Value Description

0x___1 Slave in 'INIT' state

0x___2 Slave in 'PREOP' state

0x___3 Slave in 'BOOT' state

0x___4 Slave in 'SAFEOP' state

0x___8 Slave in 'OP' state

0x001_ Slave signals error

0x002_ Invalid vendorId, productCode... read

0x004_ Initialization error occurred

0x010_ Slave not present

0x020_ Slave signals link error

0x040_ Slave signals missing link

0x080_ Slave signals unexpected link

0x100_ Communication port A

0x200_ Communication port B

0x400_ Communication port C

0x800_ Communication port D

ADS address (ADSAddr)

ADS address (ADSAddr)

IL230x-B110 31Version: 1.0.3

Page 32

Configuration

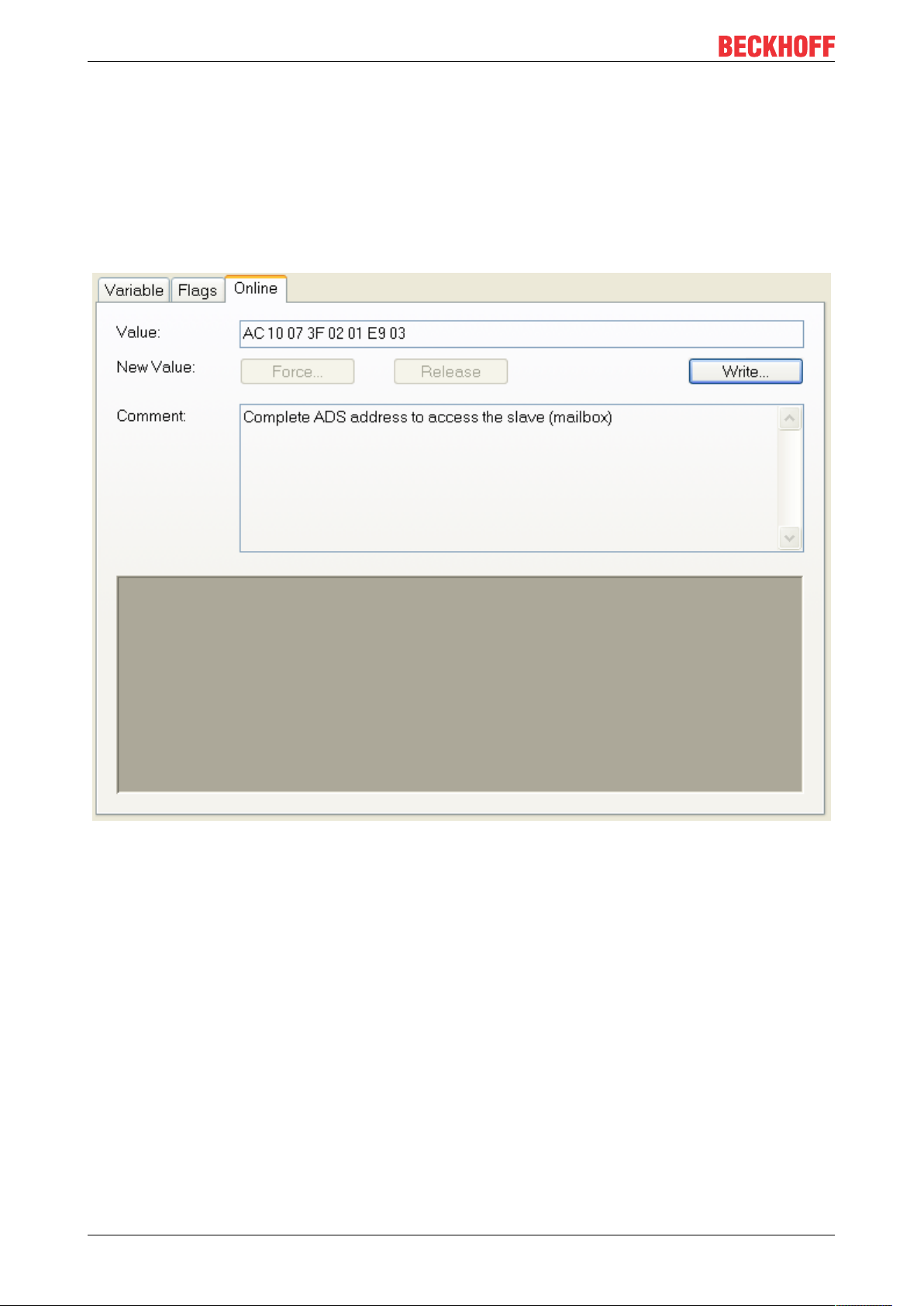

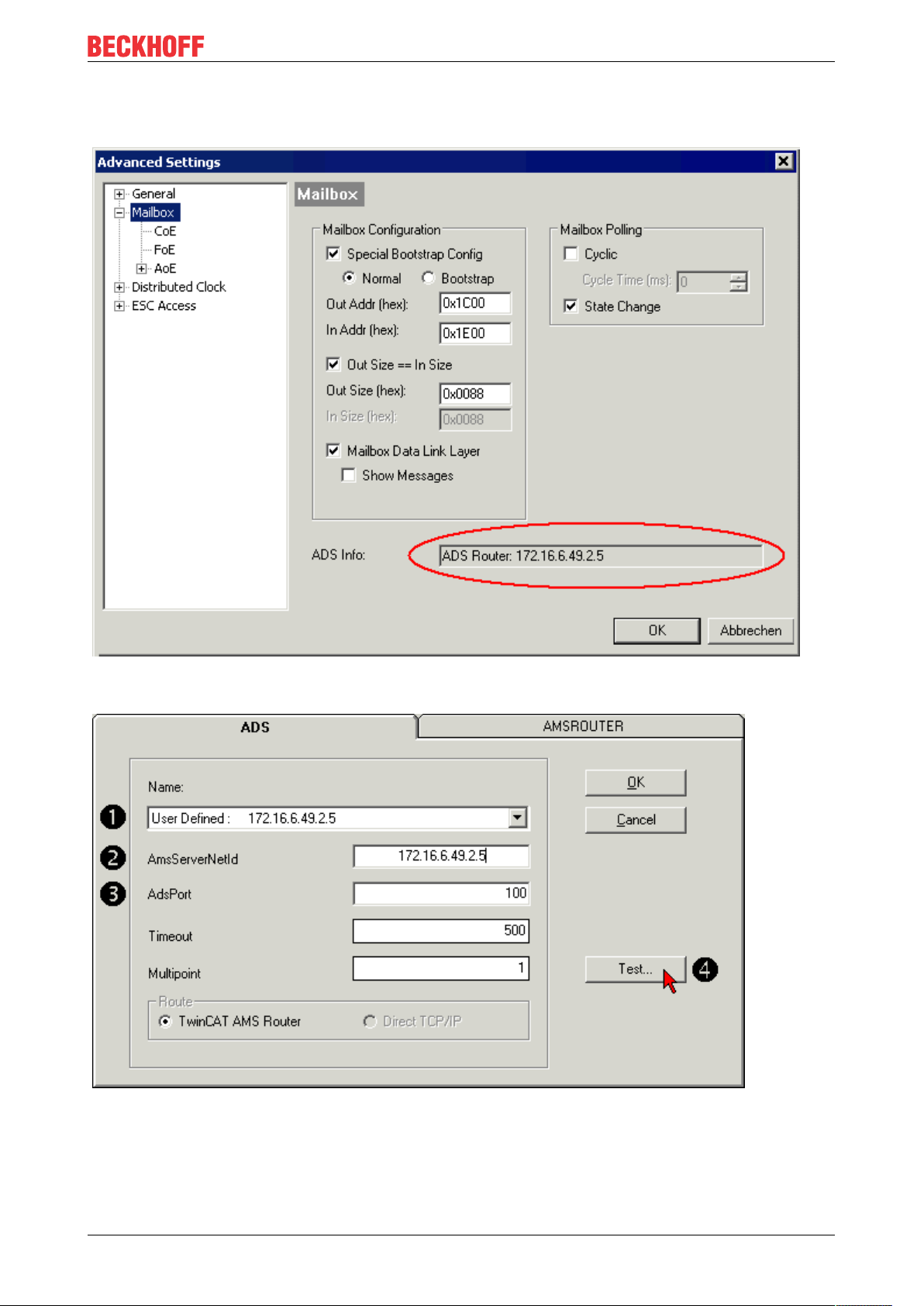

ADSAddr, Online tab

Single line indicating the AMS netID and the AMS port of the Fieldbus Box using the hexadecimal system.

This information is required for mailbox communication via ADS.

Example

AC 10 07 3F 02 01 (AMS netID) = 172.16.7.63.2.1

03 E9 (port) = 1001

dec

Fig. 7 ADSAddr, "Online" tab

EtherCAT / IP-Link cycle time

EtherCAT / IP-Link cycle time

The IP-Link cycle time resulting from the station configuration with extension box modules is directly

displayed in ConfigMode.

IL230x-B11032 Version: 1.0.3

Page 33

Configuration

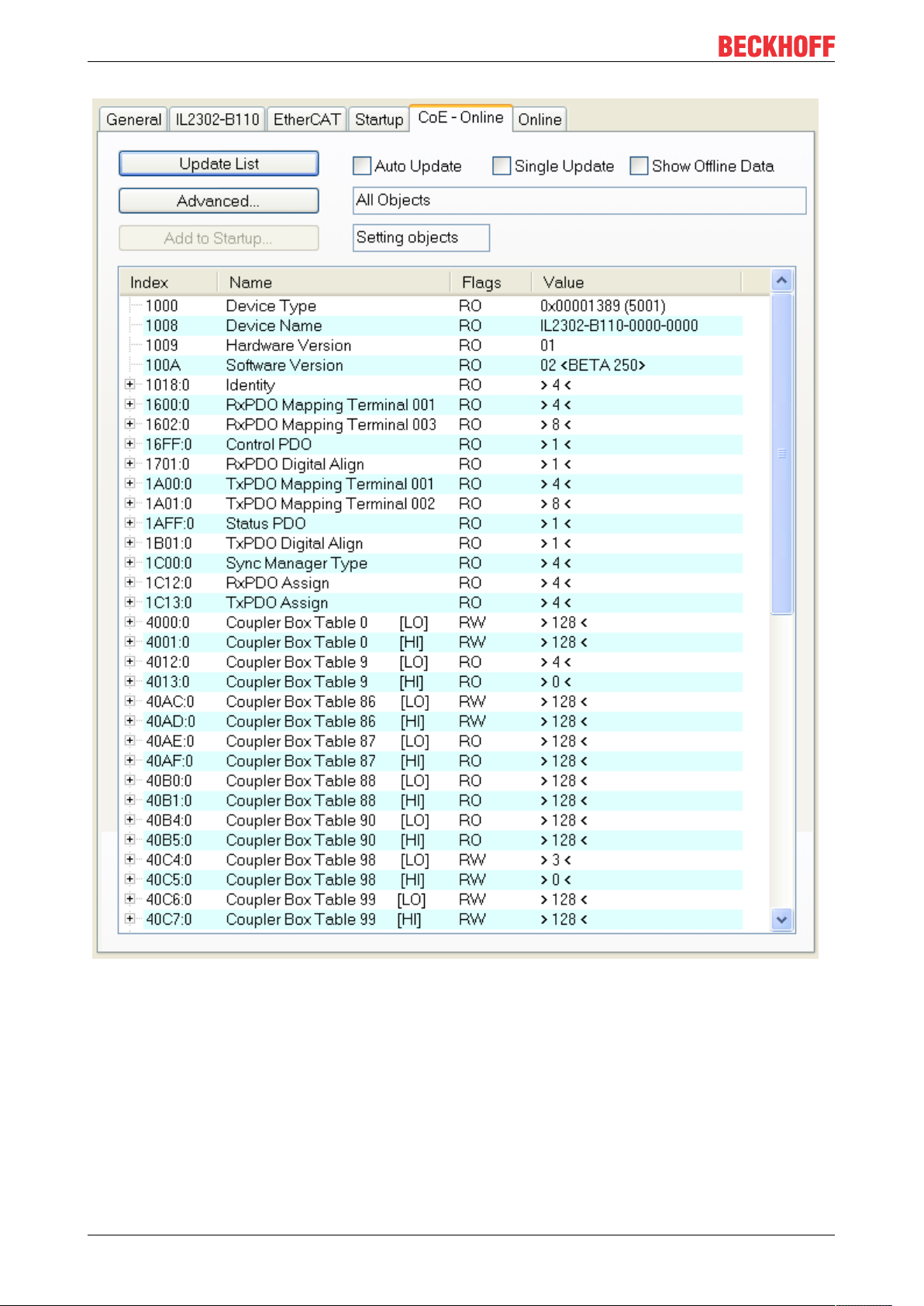

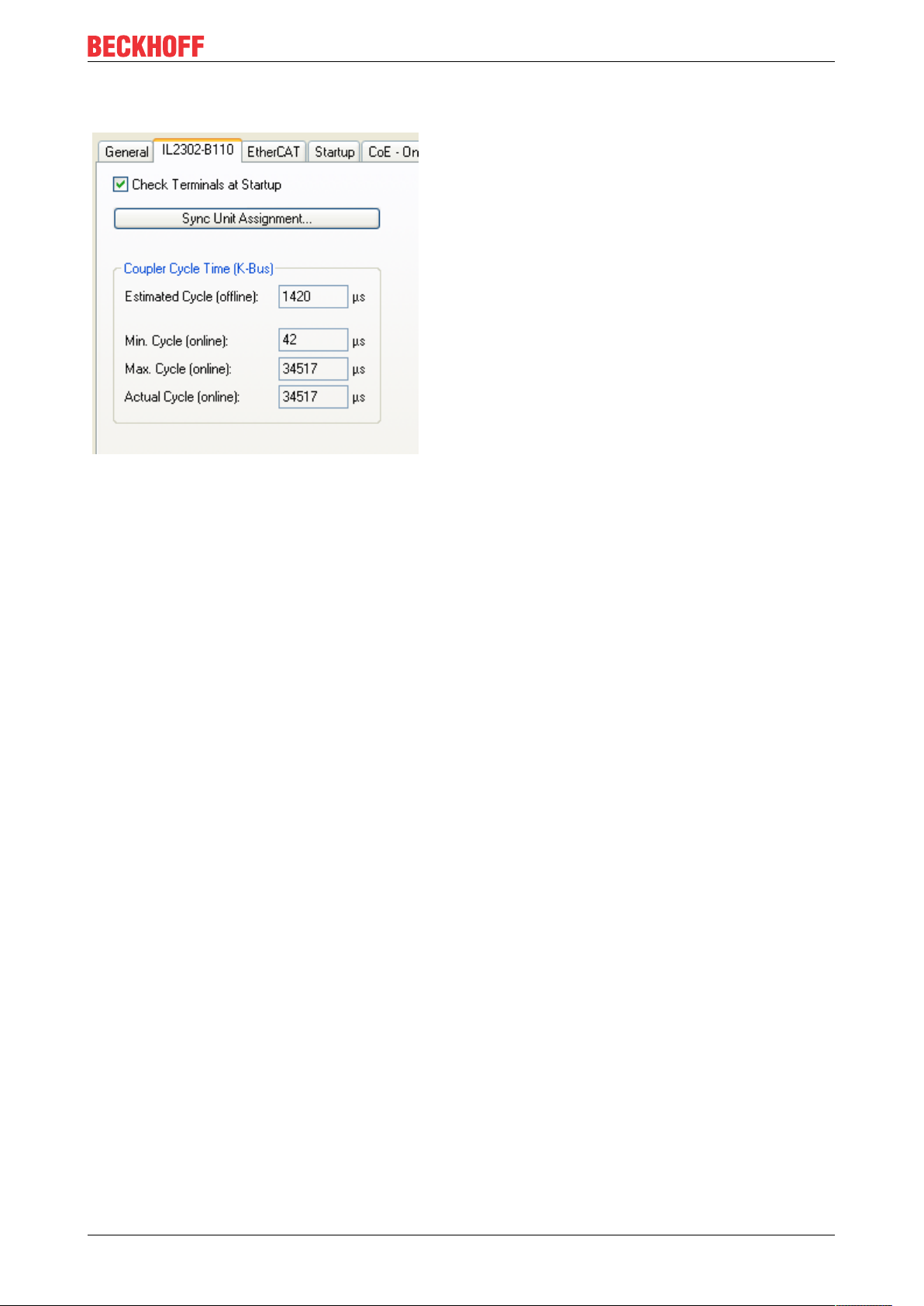

Fig. 8 CycleTime

If the EtherCAT cycle time exceeds the IP-Link cycle time both systems operate in synchronous mode. The

IP link is started after an EtherCAT telegram and copies its inputs into the memory. They are retrieved with

the next EtherCAT telegram, i.e. the inputs are always exactly one cycle old.

If the EtherCAT cycle is shorter than the IP link cycle, the K-Bus operates asynchronous relative to

EtherCAT. Faster polling than "Estimated Cycle (offline)" is therefore possible but may lead to outdated input

data or outputs not being set in time via the IP link.

The EtherCAT cycle applied to the IL230x-B110 Fieldbus Box modules should therefore be significantly

greater than the "Estimated Cycle (offline)" (min. 250 µs, depending on the configuration). Online control in

the system through "Max. Cycle (online)" or "CouplerState" is recommended.

The cycle time can also be read via CoE Online from Table 98 [LO].

IL230x-B110 33Version: 1.0.3

Page 34

Configuration

Fig. 9 CycleTime via Table98[LO]

IL230x-B11034 Version: 1.0.3

Page 35

Configuration

Check of the connected boxes

If you activate "Check Terminals at Startup", at startup is checked if the connected boxes fit to the configured

boxes.

IL230x-B110 35Version: 1.0.3

Page 36

Configuration

6.2 Objects

6.2.1 Object description

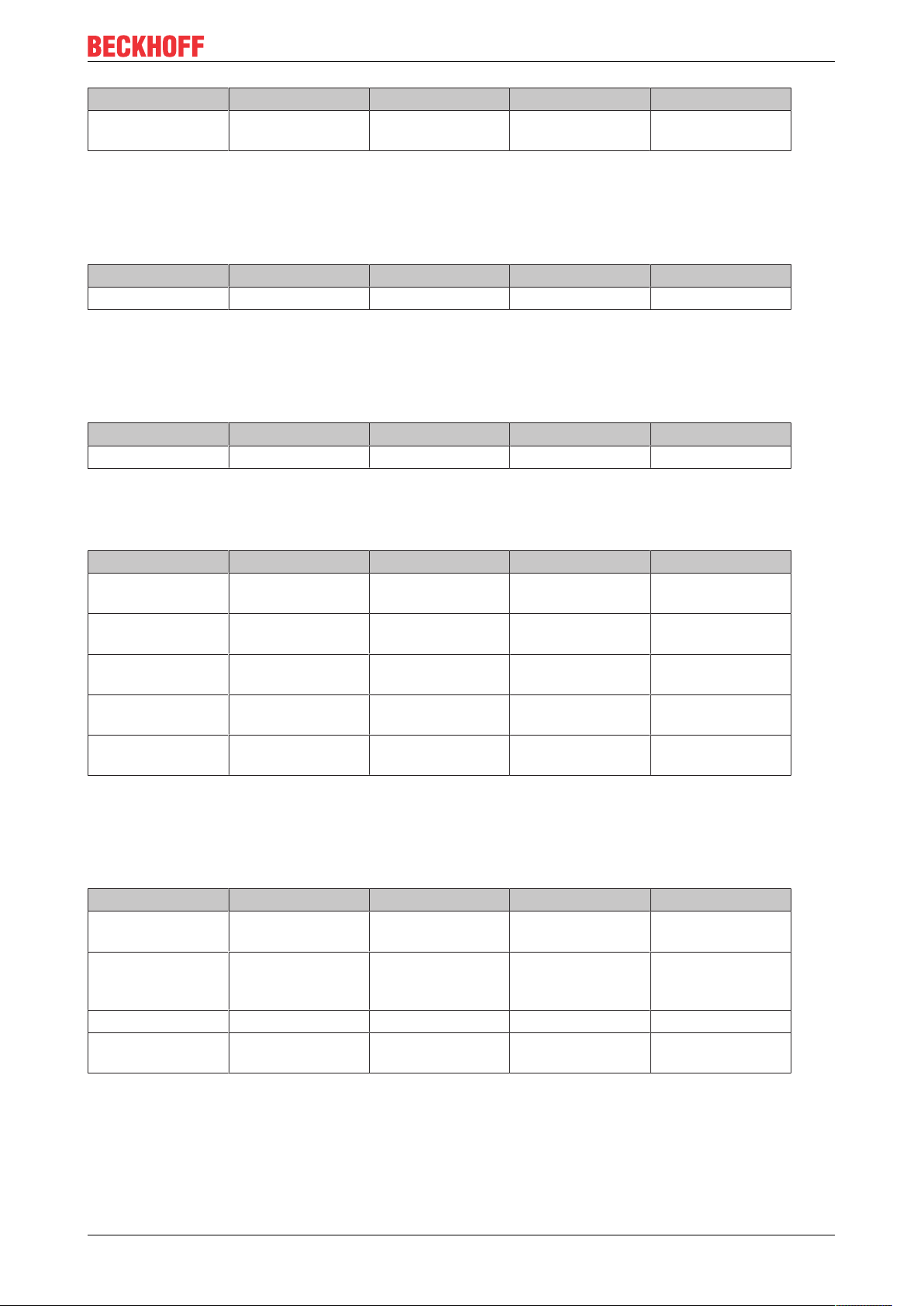

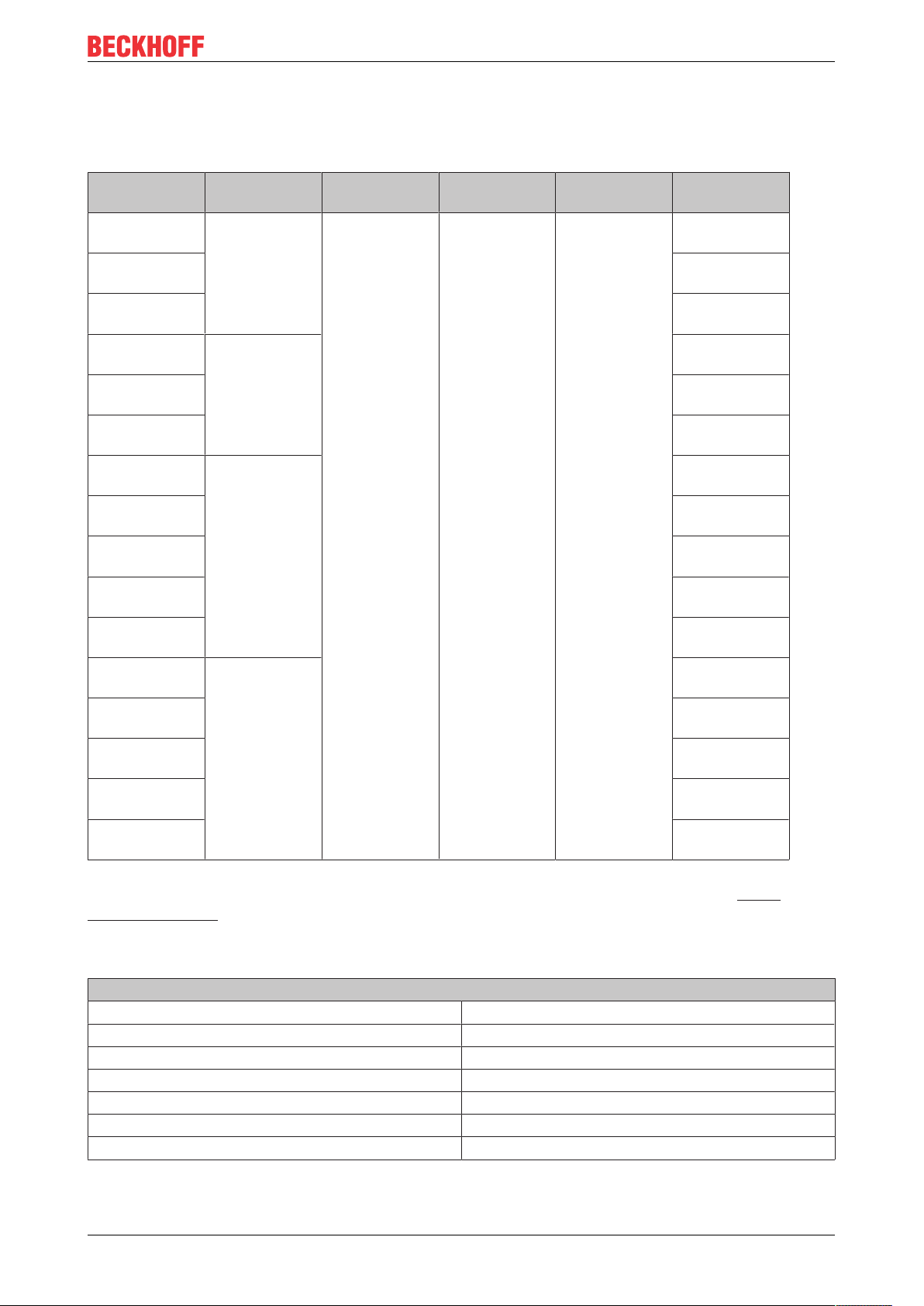

Table1: Extracted nested table 0

IL230x-B11036 Version: 1.0.3

Page 37

Index Name Meaning

6000:0 IE23xx IE2301, max .

Subindex (4)

6000:01 Channel 1 1. Channel, IE2301

6000:02 Channel 2 2. Channel, IE2301

6000:03 Channel 3 3. Channel, IE2301

6000:04 Channel 4 4. Channel, IE2301

6010:0 IE10xx IE1001, max.

Subindex (8)

6010:01 Channel 1 1. Channel, IE1001

6010:02 Channel 2 2. Channel, IE1001

6010:03 Channel 3 3. Channel, IE1001

6010:04 Channel 4 4. Channel, IE1001

6010:05 Channel 5 5. Channel, IE1001

6010:06 Channel 6 6. Channel, IE1001

6010:07 Channel 7 7. Channel, IE1001

6010:08 Channel 8 8. Channel, IE1001

6030:0 IE3102 IE3102, max.

Subindex (12)

6030:01 Channel 1 Status 1. Channel, Status,

IE3102

6030:03 Channel 1 Data 1. Channel, Data

IE3102

6030:04 Channel 2 Status 2. Channel, Status,

IE3102

6030:06 Channel 2 Data 2. Channel, Data,

IE3102

6030:07 Channel 3 Status 3. Channel, Status,

IE3102

6030:09 Channel 3 Data 3. Channel, Data,

IE3102

6030:0A Channel 4 Status 4. Channel, Status,

IE3102

6030:0C Channel 4 Data 4. Channel, Status,

IE3102

Signals in Coupler

Box: IE2301

Position 1 behind

Coupler Box:

IE1001

Position 3 behind

Coupler Box:

IE3102

Configuration

Input data

IL230x-B110 37Version: 1.0.3

Page 38

Configuration

Index Name Meaning

7000:0 IE23xx IE2301, max .

Subindex (4)

7000:01 Channel 1 1. Channel, IE2301

7000:02 Channel 2 2. Channel, IE2301

7000:03 Channel 3 3. Channel, IE2301

7000:04 Channel 4 4. Channel, IE2301

7020:0 IE20xx IE2001, max .

Subindex (8)

7020:01 Channel 1 1. Channel, IE2001

7020:02 Channel 2 2. Channel, IE2001

7020:03 Channel 3 3. Channel, IE2001

7020:04 Channel 4 4. Channel, IE2001

7020:05 Channel 5 5. Channel, IE2001

7020:06 Channel 6 6. Channel, IE2001

7020:07 Channel 7 7. Channel, IE2001

7020:08 Channel 8 8. Channel, IE2001

7030:0 IE3102 IE3102, max.

Subindex (12)

7030:01 Channel 1 Control 1. Channel,

Control, IE3102

7030:03 Channel 1 Data 1. Channel, Data

IE3102

7030:04 Channel 2Control 2. Channel,

Control, IE3102

7030:06 Channel 2 Data 2. Channel, Data

IE3102

7030:07 Channel 3 Control 3. Channel,

Control, IE3102

7030:09 Channel 3 Data 3. Channel, Data

IE3102

7030:0A Channel 4 Control 4. Channel,

Control, IE3102

7030:0C Channel 4Data 4. Channel, Data

IE3102

Signals in Coupler

Box: IE2301

Position 2 behind

Coupler Box:

IE3102

Position 3 behind

Coupler Box:

IE3102

Output data

Standard objects

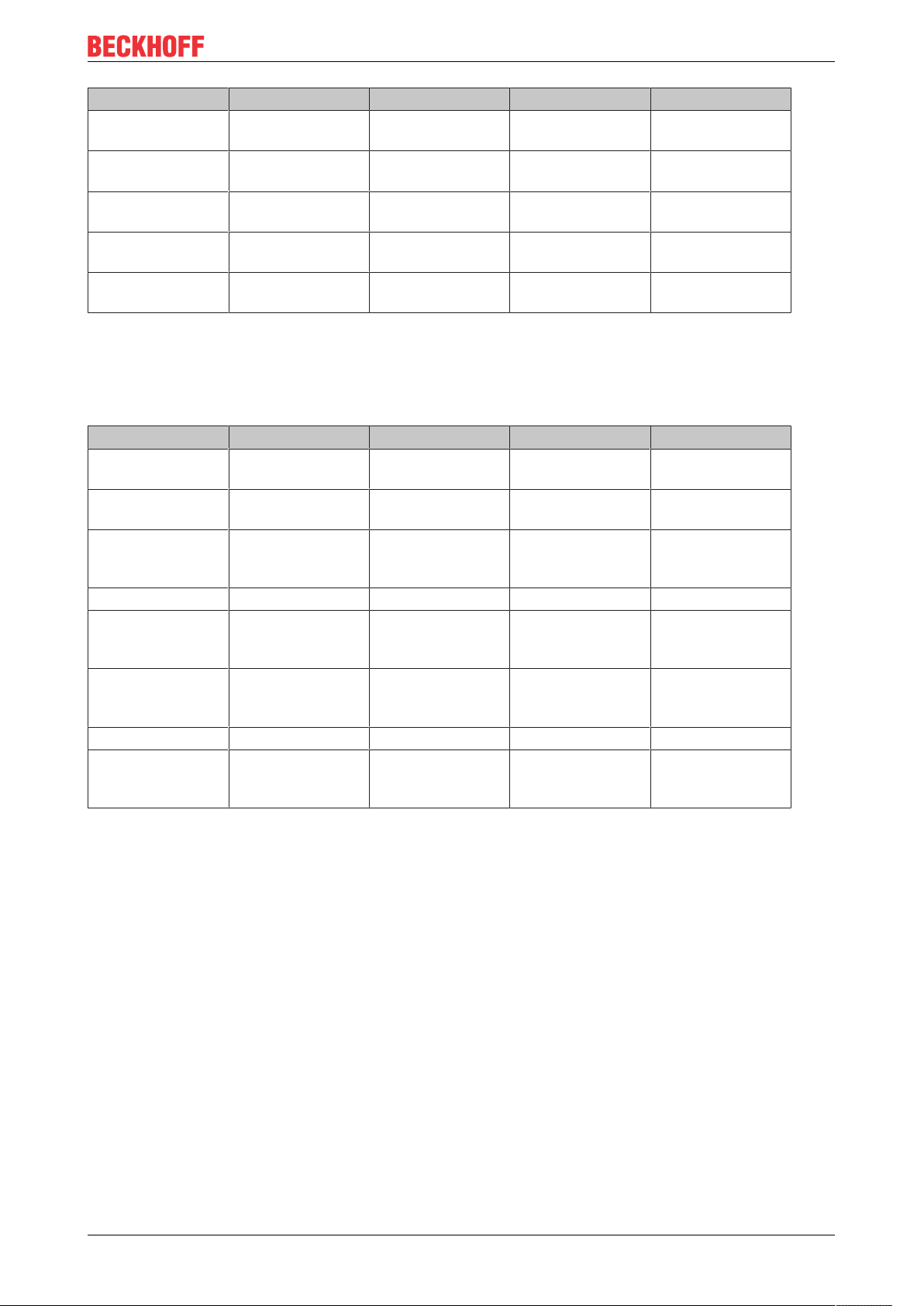

Standard objects

Index 1000 Device type

Index 1000

Device type (read only) of the EtherCAT slave.

Index Name Meaning Flags Default

1000 DeviceType Device type RO 0x00001389

(5001

dec

)

Index 1008 Device name

Index 1008

Device name (read only, Value: z. B. IL2302-B110-0000-0000) of the EtherCAT slave.

IL230x-B11038 Version: 1.0.3

Page 39

Configuration

Index Name Meaning Flags Default

1008 DeviceName Device name RO e.g. IL2302-

B110-0000-0000

Index 1009 Hardware version

Index 1009

Hardware-Version (read only) of the EtherCAT slave.

Index Name Meaning Flags Default

1009 Hardware Version Hardware version RO e.g. 01

Index 100A Software version

Index 100A

Version (read only, Value: z. B. 01) of the Firmware (processing of the I/O signals) of the EtherCAT slave.

Index Name Meaning Flags Default

100A Software version Software version RO e.g. 01

Index 1018 Identity object

Index 1018

Index Name Meaning Flags Default

1018:0 Identity object Length of this

RO -

object

1018:01 Vendor id Vendor id of the

RO 0x00000002 (2

EtherCAT slave

1018:02 Product code Product code of the

EtherCAT slave

1018:03 Revision number Revision number of

RO 0x04602C22

(73411618

RO 0x00000000 (0

the EtherCAT slave

1018:04 Serial number Serial number of

RO 0x00000000 (0

the EtherCAT slave

Index 16kk RxPDO Mapping Terminal

Index 16kk

Value range: (kk = 00...FE)

, [(hh = 01...FF)

hex

, (ddd = 001...255)]

hex

dec

Index Name Meaning Flags Default

16kk:0 RxPDO Mapping

Terminal

16kk:01 Output Mapping

Area 001

Length of this

object

1. output variable

of this box

RW -

RW z. B. 0x7kk0:01, 1

(Subindex 001)

... ... ... ... ...

16kk:hh Output Mapping

Area ddd

last output variable

(Subindex ddd)

RW e.g. 0x7kk0:hh, 1

dec

)

dec

)

)

dec

)

dec

Index 16FF Control PDO

Index 16FF

IL230x-B110 39Version: 1.0.3

Page 40

Configuration

Index Name Meaning Flags Default

16FF:0 Control PDO Length of this

RW -

object

16FF:01 Output Mapping

Control-word RW 0xF200:01, 16

Area

Index 1701 RxPDO Digital Align

Index 1701

Index Name Meaning Flags Default

1701:0 RxPDO Digital

Align

1701:01 PDO Align Word Alignment

Length of this

object

RW -

RW 0x0000:00, 12

Dummy for Digital

RxPDOs

Index 1Akk TxPDO Mapping Terminal

Index 1Akk

Value range: (kk = 00

hex

...FE

), [(hh = 01

hex

hex

...FF

), (ddd = 001

hex

dec

...255

dec

)]

Index Name Meaning Flags Default

1Akk:0 TxPDO Mapping

Terminal

1Akk:01 Input Mapping Area

001

Length of this

object

1. input variable of

this Box (Subindex

RW -

RW z. B. 0x6kk0:01, 1

001)

... ... ... ... ...

1Akk:hh Input Mapping Area

ddd

last input variable

of this Box

RW z. B. 0x6kk0:hh, 1

(Subindex ddd)

Index 1AFF Status PDO

Index 1AFF

Index Name Meaning Flags Default

16FF:0 Status PDO Length of this

RW object

16FF:01 Input Mapping Area Status-word RW 0xF100:01, 16

Index 1B01 TxPDO Digital Align

Index 1B01

Index Name Meaning Flags Default

1B01:0 TxPDO Digital

Align

1B01:01 PDO Align Word Alignment

Length of this

object

RW -

RW 0x0000:00, 12

Dummy for Digital

TxPDOs

Index 1C00 SM type

Index 1C00

IL230x-B11040 Version: 1.0.3

Page 41

Index Name Meaning Flags Default

1C00:0 Sync Manager

Type

1C00:01 Subindex 001 sync manager,

Length of this

object

RO 4

RO 0x01 (1

parameter 1

1C00:02 Subindex 002 sync manager,

RO 0x02 (2

parameter 2

1C00:03 Subindex 003 sync manager,

RO 0x03 (3

parameter 3

1C00:04 Subindex 004 sync manager,

RO 0x04 (4

parameter 4

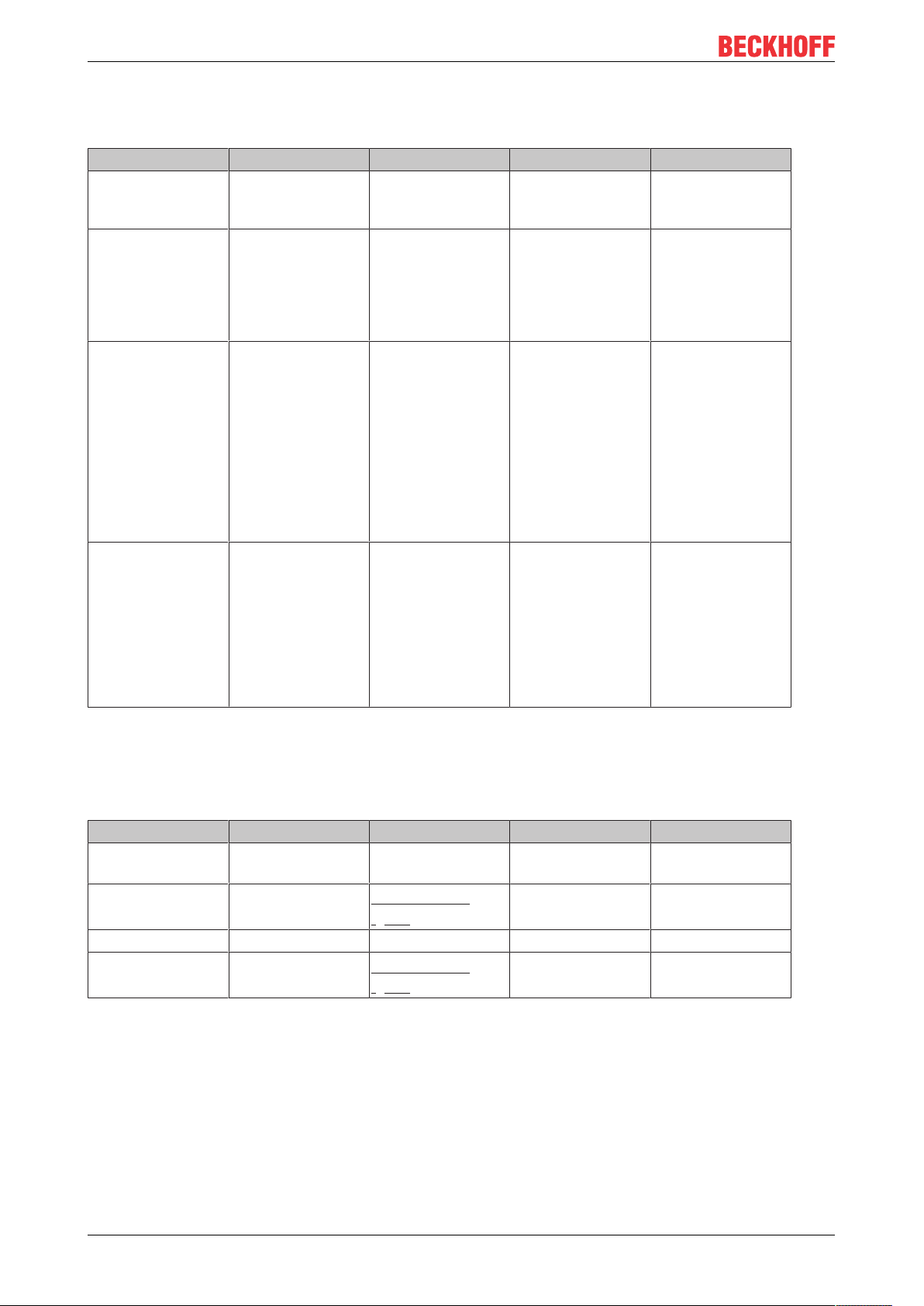

Index 1C12 RxPDO Assign

Index 1C12

Configuration

)

dec

)

dec

)

dec

)

dec

Value range: [(hh = 01

hex

...FF

), (ddd = 001

hex

dec

...255

dec

)]

Index Name Meaning Flags Default

1C12:0 RxPDO Assign Length of this

RW object

1C12:01 Subindex 001 assignment of the

RW 0x16FF(5887

Control PDO

1C12:02 Subindex 002 assignment 1.

RxPDO analog

RW z. B. 0x1603

(5635

boxes

... ... ... ... ...

1C12:nn Subindex nnn assignment n.

RxPDO analog

RW z. B. 0x1605

(5637

boxes

1C12:(nn+1) Subindex (nnn+1) assignment (n+1).

RxPDO digital

RW z. B. 0x1600

(5632

boxes

... ... ... ... .....

1C12:hh Subindex ddd assignment Word

RW 0x1701(5889

Alignment Dummy

for Digital RxPDOs

Index 1C13 TxPDO Assign

dec

dec

dec

)

dec

)

)

)

)

dec

Index 1C13

Value range: [(hh = 01

hex

...FF

), (ddd = 001

hex

dec

...255

dec

)]

IL230x-B110 41Version: 1.0.3

Page 42

Configuration

Index Name Meaning Flags Default

1C13:0 TxPDO Assign Length of this

RW object

1C13:01 Subindex 001 assignment of the

RW 0x1AFF(6911

Control PDO

1C13:02 Subindex 002 assignment 1.

TxPDO analog

RW z. B. 0x1A03

(6659

boxes

... ... ... ... ...

1C13:nn Subindex nnn assignment n.

TxPDO analog

RW z. B. 0x1A05

(6661

boxes

1C13:(nn+1) Subindex (nnn+1) assignment (n+1).

TxPDO digital

RW z. B. 0x1A01

(6657

boxes

... ... ... ... .....

1C13:hh Subindex ddd assignment Word

RW 0x1B01(6913

Alignment Dummy

for Digital TxPDOs

dec

dec

dec

)

dec

)

)

)

)

dec

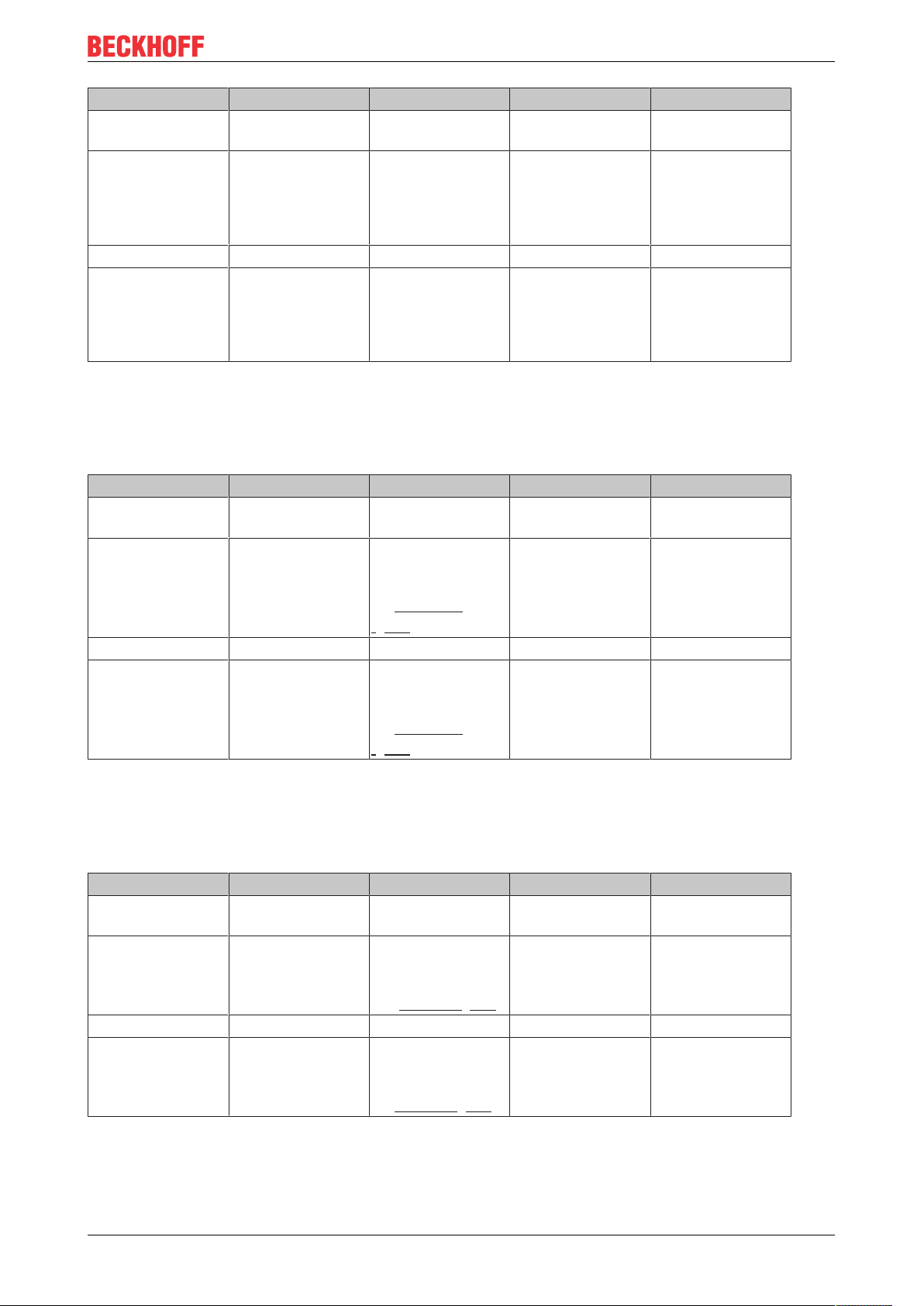

Device specific objeks

Index 4000 Coupler Box Table 0 [LO]: general configuration of the Fieldbus Box

Index 4000

Index Name Meaning Flags Default

4000:0 Coupler Box Table

0 [LO]

Length of this

object

RW 128

4000:01 Subindex 001 Register 0 RW

4000:02 Subindex 002 Register 1 RW

... ... ... ...

4000:80 Subindex 128 Register 127 RW

Index 4001 Coupler Box Table 0 [HI]: general configuration of the Fieldbus Box (continuation)

Index Name Meaning Flags Default

4001:0 Coupler Box Table

0 [HI]

Length of this

object

RW 128

4001:01 Subindex 001 Register 128 RW

4001:02 Subindex 002 Register 129 RW

... ... ... ... ...

4001:80 Subindex 128 Register 255 RW

Index 4012 Coupler Box Table 9 [LO]: Subordinate Extension Box Modules

IL230x-B11042 Version: 1.0.3

Page 43

Index Name Meaning Flags Default

4012:0 Coupler Box Table

9 [LO]

4012:01 Subindex 001 Register 0:

Length of this

object

RO max. 128

RO 0x006E (110

identification of the

Fieldbus Box

4012:02 Subindex 002 Register 1:

identification of the

RO e.g.: 0x000A

(10

dec

1. extension

4012:03 Subindex 003 Register 2:

identification of the

RO e.g.: 0x000A

(10

dec

2. extension

4012:04 Subindex 004 Register 3:

identification of the

RO e.g. 0x0C82

(3202

3. extension

... ... ... ... ...

4012:80 Subindex 121 Register 120:

RO

identification of the

120. extension

1

) For the Fieldbus Box and intelligent (e.g. analog) extensions the module name

is given decimal in clear text e.g. 0x0C82 (3202

2

) For simple (digital) Extension Box Modules the following coding is given:

) means IE3202.

dec

Configuration

1

)

dec

2

)

2

)

)

dec

Wert Meaning

0x000A (10) 4 digital inputs and 4 digital outputs

0x0015 (21) 8 digital inputs and 8 digital outputs

0x0035 (53) 8 digital inputs and 8 digital outputs (physical on the

same address)

0x0011 (17) 8 digital outputs

0x0014 (20) 8 digital inputs

Index 40AE Coupler Box Table 87 [LO]: IP-Link error place

Index Name Meaning Flags Default

40AE:0 Coupler Box Table

87 [LO]

Length of this

object

RO 128

dec

40AE:01 Subindex 001 RO

40AE:02 Subindex 002 RO

40AE:03 Subindex 003 number of faulty

RO

telegrams at the 1.

Extension Box

40AE:04 Subindex 004 number of faulty

RO

telegrams at the 2.

Extension Box

... ... ... ...

40AE:0127 Subindex 127 Register 127:

RO

reserved

Index 40B4 Coupler Box Table 90 [LO]: internal diagnostic information of the Fieldbus Box

IL230x-B110 43Version: 1.0.3

Page 44

Configuration

Index Name Meaning Flags Default

40B4:0 Coupler Box Table

90 [LO]

Length of this

object

RO 128

dec

40B4:01 Subindex 001 reserved RO

40B4:02 Subindex 002 reserved RO

40B4:03 Subindex 003 error Code RO

40B4:04 Subindex 004 error Argument RO

... ... ... ... ...

40B4:04 Subindex 128 reserved RO

The error code and the argument are similar to the meaning of the Blink-Codes of the Feldbus LEDs [}65].

Index 40C4 Coupler Table 98 [LO]: IP-Link cycle time (µs)

Index Name Meaning Flags Default

40C4:0 Coupler Table 98

IP-Link Cycle Time

Length of this

object

RW 3

(µs)

40C4:01 Min IPL time minimum update

RW time on the IP-Link

40C4:02 Max IPL time maximum update

RW time on the IP-Link

40C4:03 Curr IPL time current update time

RW on the IP-Link

Index 427F Extension Box No

Index Name Meaning Flags Default

427F:0 ExtensionBoxNo To communicate

RW 0

with the intelligent

extension boxes in

this object the

number of the box

has to be inserted.

Now the box can

be paremeterized

by the four

following tables

(object 4280 -

4287).

Count like: the

Coupler Box has

got Nor. 0. The first

extension Box has

got no. 1 and so

on.

Only intelligent

boxes (with register

set) can be

paremeterized!

Index 4280 - 4287Terminal Table 0 [LO]: for parameterizing of the box specified by object 427F

Index 4280 - 4287

IL230x-B11044 Version: 1.0.3

Page 45

Configuration

Index Name Meaning Flags Default

428x:0 ExtensionBox

Channel 0 ... 3

428x:01 Subindex 001 Register 0 RW 0x0000 (0

428x:02 Subindex 002 Register 1 RW 0x0000 (0

Length of this

object

RW 64

dec

dec

)

)

... ... ... ... ...

428x:40 Subindex 064 Register 63 RW 0x0000 (0

dec

)

Index 6xxx and 7xxx Process Data

Index 6xxx and 7xxx

At index 6xxx and 7xxx the process data of the Extension Boxes is displayed. The sequence is equal to the

physical sequence within the IP-Ling ring. The indices are counted in steps by 10, that means e.g. 6000,

6010, 7020, 7030, 6040... if the dedicated module has only inputs or outputs. If it has inputs and outputs like

e.g. an IE2301 (on the Coupler Box) the index 6000 as also the index 7000 exists.

Dynamic generation of the input and output objects

The vValue range of the "kk", "hh", and "ddd" variables from the input and output indices are

showed below. The dynamic generation of the input and output objects depends on the sequence of

the Extension Box Modules within the whole Fieldbus Box station.Example of a Fieldbus Box StationIL2301-B110 - IE1001- IE2001- IE3102; EtherCAT respectively the Coupler Box doesn't differ

the digital Boxes from their different connection types, so e.g. an IE2301 is displayed as

IE23xx.Mapping of the assigned PDOs (from Index 6000):see "Extracted nested table 0"

Index 6kk0 Process Input Data

Index 6kk0

Digital Extension Boxes:

Value range:

(kk = 00

[(hh = 01

hex

...FF

hex

hex

...FF

),

), (ddd = 001

hex

dec

...255

dec

)]

Index Name Meaning Flags Default

6kk0:0 Process Input Data [Module

RO P -

identification]

6kk0:01 Channel 001 Channel 001 RO P -

... ... ... ... ...

6kk0:hh Channel ddd Channel ddd RO P -

Not Digital Extension Boxes (for hh ≥ 03; ddd ≥ 003):

Value range:

(kk = 00

[(hh = 01

hex

...FF

hex

hex

...FF

),

), (ddd = 001

hex

dec

...255

)] for integer by 3 divisible values hh respectively ddd

dec

IL230x-B110 45Version: 1.0.3

Page 46

Configuration

Index Name Meaning Flags Default

6kk0:0 Process Input Data [Module name] RO P 6kk0:01 Channel 001

Status

6kk0:02 Channel 001 Word-

Alignment

Channel 001:

Status

Channel 001:

Word-Alignment

RO P -

RO P -

6kk0:03 Channel 001 Data Channel 001: Data RO P -

... ... ... ... ...

6kk0:hh-2 Channel ddd/3 Channel ddd/3:

RO P -

Status

6kk0:hh-1 Channel ddd/3 Channel ddd/3:

RO P -

Word-Alignment

6kk0:hh Channel ddd/3 Channel ddd/3:

RO P -

Data

Index 7kk0 Process Output Data

Digital Extension Boxes:

Value range:

(kk = 00

[(hh = 01

hex

...FF

hex

hex

...FF

),

), (ddd = 001

hex

dec

...255

dec

)]

Index Name Meaning Flags Default

7kk0:0 Process Output

Data

[Module

identification]

RO P -

7kk0:01 Channel 001 Channel 001 RO P -

... ... ... ... ...

7kk0:hh Channel ddd Channel ddd RO P -

Not Digital Extension Boxes (for hh ≥ 03; ddd ≥ 003):

Value range:

(kk = 00

[(hh = 01

hex

...FF

hex

hex

...FF

),

), (ddd = 001

hex

dec

...255

)] for integer by 3 divisible values hh respectively ddd

dec

Index Name Meaning Flags Default

7kk0:0 Process Input Data [Module name] RO P 7kk0:01 Channel 001 Ctrl Channel 001:

RO P -

Control

7kk0:02 Channel 001 Word-

Alignment

Channel 001:

Word-Alignment

RO P -

7kk0:03 Channel 001 Data Channel 001: Data RO P -

... ... ... ... ...

7kk0:hh-2 Channel ddd/3 Ctrl Channel ddd/3:

RO P -

Control

7kk0:hh-1 Channel ddd/3

Word-Alignment

7kk0:hh Channel ddd/3

Data

Channel ddd/3:

Word-Alignment

Channel ddd/3:

Data

RO P -

RO P -

Index 9kk0 Slave Info Data

Index 9kk0

IL230x-B11046 Version: 1.0.3

Page 47

Configuration

Value range: (kk = 00

hex

...FF

hex

)

Index Name Meaning Flags Default

9kk0:0 Slave Info Data [Module name] RO 9kk0:01 Position Module position

RO -

within combination

9kk0:09 Module PDO

Group

Module PDO group

• not-Digital

RO -

Extension Boxes:

group 1

• Digital Extension

Boxes: group 2

9kk0:0A Module Ident

Module

RO -

identification [}42]

Index F000 Modular Device Profile

Index F000

Index Name Meaning Flags Default

F000:0 Modular Device

Profile

F000:01 Module Index

Distance

F000:02 Maximum Number

of Modules

F000:03 Standard Entries in

Object 0x8yy0

F000:04 Standard Entries in

Object 0x9yy0

F000:04 Module PDO

Group

Length of this

object

distance module

index

Max. number of IP-

Link Modules

possible entries in

object 0x8kk0

possible entries in

object 0x9kk0

Module PDO group

of the device = 0,

RO 5

RO 0x0010 (16

RO 0x0079 (121

RO 0x0000000 (0

RO 0x0000000 (0

RO 0x00 (0

(Control and status

data is mapped in

front of the process

data

dec

)

dec

)

dec

)

dec

)

dec

)

Index F00E Group Alignment PDO

Index F00E

Index Name Meaning Flags Default

F00E:0 Group Alignment

PDO

Length of this

object (3 PDO box

RO 3

groups)

F00E:01 Subindex 001 group 0:

RO 0x0000 (0

no alignment

necessary

F00E:02 Subindex 002 group 1:

RO 0x0100 (256

Alignment PDO

(PDO 257) for PDO

group 1 (not-digital

Extension Boxes)

F00E:03 Subindex 003 group 2:

RO 0x0101 (257

Alignment PDO

(PDO 258) for PDO

group 2 (digital

Extension Boxes)

IL230x-B110 47Version: 1.0.3

dec

)

)

dec

)

dec

Page 48

Configuration

Index F00F Module Group Mapping Alignment

Index F00F

Index Name Meaning Flags Default

F00F:0 Module Group

Mapping Alignment

Length of this

object (3 PDO

RO 3

module groups)

F00F:01 Subindex 001 group 0:

RO 0x0000 (0

no alignment for

PDO group 0

necessary, Controland status data is

fix

F00F:02 Subindex 002 group 1:

RO 0x0002 (2

word-Alignment for

PDO group 1 (notdigital Extension

Boxes).

The following

process data of the

extension boxes is

always mapped to

an even byte

address

F00F:03 Subindex 003 group 2:

RO 0x0002 (2

word-Alignment for

PDO Gruppe 2

(digital Extension

Boxes).

The process data

size of digital

extension boxes is

always even.

dec

dec

dec

)

)

)

Index F010 Module List

Index F010

Value range: (hh = 01

hex

...FF

hex

), (ddd = 001

dec

...255

dec

)

Index Name Meaning Flags Default

F010:0 Module List Length of this

RO object

F010:01 Subindex 001

Name Module

RO [}42] 001

... ... ... ... ...

F010:hh Subindex ddd

Name Module

RO [}42] ddd

Index F030 Configured Module List

Index F030

Value range: (hh = 01

hex

...FF

hex

), (ddd = 001

dec

...255

dec

)

IL230x-B11048 Version: 1.0.3

Page 49

Index Name Meaning Flags Default

F030:0 Module List Length of this

RW object

F030:01 Subindex 001 Box name of

RW theconfigured

extension box at

position 1 (value

like 0x8kk0:0A)

... ... ... ... ...

F030:hh Subindex ddd Box name of

RW theconfigured

extension box at

last position (value

like 0x8kk0:0A)

Index F040 Detected Address List

Index F040

Configuration

Value range: (hh = 01

hex

...FF

hex

), (ddd = 001

dec

...255

dec

)

Index Name Meaning Flags Default

F040:0 Module List Length of this

RO object

F040:01 Subindex 001 Position oft he first

RO 0x0001 (1

extension box

(value

like0x9kk0:01

[}46])

... ... ... ... ...

F040:hh Subindex ddd Position of the last

RO 0x00hh (ddd

extension box

(value

like0x9kk0:01

[}46])

Index F050 Detected Module List

Index F050

Value range: (hh = 01

hex

...FF

hex

), (ddd = 001

dec

...255

dec

)

Index Name Meaning Flags Default

F050:0 Module List Length of this

RO object

F050:01 Subindex 001 identification of the

RO extension box an

position 1 (value

like 9kk0:0A [}46])

... ... ... ... ...

F050:hh Subindex ddd identification of the

RO extension box at

last position (value

like9kk0:0A [}46])

dec

)

)

dec

Index F100 Status PDO

Index F100

IL230x-B110 49Version: 1.0.3

Page 50

Configuration

Index Name Meaning Flags Default

F100:0 Status PDO Length of this

RO 1

object

F100:01 CouplerState Coupler Status-

RO P 0x0000 (0

Word

Index F200 Control PDO

Index F200

Index Name Meaning Flags Default

F100:0 ControlPDO Length of this

RO 1

object

F100:01 CouplerCtrl Coupler Control-

RO P 0x0000 (0

Word

Also see about this

2 Object description [}45]

dec

dec

)

)

IL230x-B11050 Version: 1.0.3

Page 51

Configuration

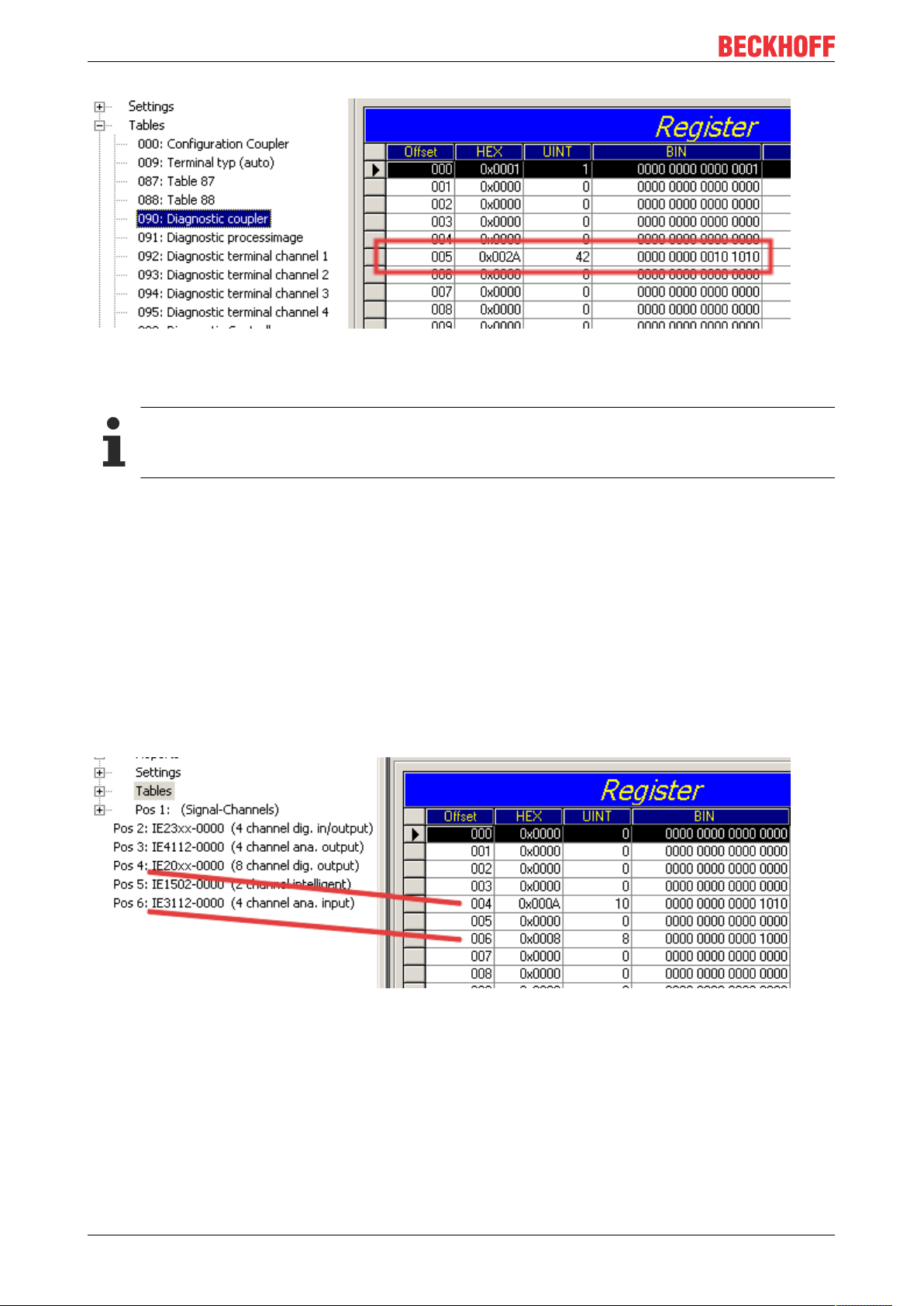

6.3 Configuration of the complex modules

6.3.1 General Register Description

Different operating modes or functionalities may be set for the complex modules. The General Description of

Registers explains those register contents that are the same for all complex modules. The module-specific

registers are explained in the following section.

Access to the module's internal registers is described in the section on Register Communication.

General Description of Registers

Complex modules that possess a processor are able to exchange data bi-directionally with the higher-level

controller. These modules are referred to below as intelligent modules. These include the analog inputs

(0-10 V, -10-10 V, 0-20 mA, 4-20 mA), the analog outputs (0-10 V, -10-10 V, 0-20 mA, 4-20 mA), the serial

interface terminals (RS485, RS232, TTY, data exchange terminals), counter terminals, encoder interface and

SSI interface terminals, PWM terminals and all the modules that can be parameterized.

The main features of the internal data structure are the same for all the intelligent modules. This data area is

organized as words, and includes 64 memory locations. The important data and the parameters of the

module can be read and set through this structure. It is also possible for functions to be called by means of

corresponding parameters. Each logical channel in an intelligent module has such a structure (so a 4channel analog module has 4 sets of registers).

This structure is divided into the following areas:

Range Address

Process variables 0-7

Type register 8-15

Manufacturer parameters 16-30

User parameters 31-47

Extended user region 48-63

Registers R0-R7 (in the terminal's internal RAM)

The process variables can be used in addition to the actual process image. Their function is specific to the

terminal.

R0-R5

The function of these registers depends on the type of terminal.

R6

Diagnostic register. The diagnostic register can contain additional diagnostic information. Parity errors, for

instance, that occur in serial interface terminals during data transmission are indicated here.

R7

Command register

- High-Byte_Write = function parameter

- Low-Byte_Write = function number

- High-Byte_Read = function result

- Low-Byte_Read = function number

Registers R8-R15 (in the terminal's internal ROM)

The type and system parameters are hard programmed by the manufacturer, and the user can read them

but cannot change them.

IL230x-B110 51Version: 1.0.3

Page 52

Configuration

R8

Fieldbus Box type: The Fieldbus Box type in register R8 is needed to identify the Fieldbus Box.

R9

Software version x.y.: The software version can be read as a string of ASCII characters.

R10

Data length: R10 contains the number of multiplexed shift registers and their length in bits. The Bus Coupler

sees this structure.

R11

Signal channels: Related to R10, this contains the number of channels that are logically present. Thus for

example a shift register that is physically present can perfectly well consist of several signal channels.

R12

Minimum data length: The particular byte contains the minimum data length for a channel that is to be

transferred. If the MSB is set, the control/status byte is not absolutely necessary for the terminal's function,

and if the Bus Coupler is appropriately configured it is not transferred to the controller. The information is

located

- in the high byte of an output module

- in the low byte of an input module

R13

Data type register

Data type register Description

0x00 Terminal with no valid data type

0x01 Byte array

0x02 Structure 1 byte n bytes

0x03 Word array

0x04 Structure 1 byte n words

0x05 Double word array

0x06 Structure 1 byte n double words

0x07 Structure 1 byte 1 word

0x08 Structure 1 byte 1 double word

0x11 Byte array with variable logical channel length

0x12 Structure 1 byte n bytes with variable logical channel

length (e.g. 60xx)

0x13 Word array with variable logical channel length

0x14 Structure 1 byte n words with variable logical channel

length

0x15 Double word array with variable logical channel

length

0x16 Structure 1 byte n double words with variable logical

channel length

R14

reserved

IL230x-B11052 Version: 1.0.3

Page 53

Configuration

R15

Alignment bits (RAM): The analog terminal is placed on a byte boundary in the K-Bus with the alignment bits.

Registers R16-R30 (manufacturer's parameters, serial EEPROM)

The manufacturer parameters are specific for each type of terminal. They are programmed by the

manufacturer, but can also be modified by the controller. The manufacturer parameters are stored in a serial

EEPROM in the terminal, and are retained in the event of voltage drop-out. These registers can only be

altered after a code-word has been set in R31.

Registers R31-R47 (application parameters, serial EEPROM)

The application parameters are specific for each type of terminal. They can be modified by the programmer.

The application parameters are stored in a serial EEPROM in the terminal, and are retained in the event of

voltage drop-out. The application region is write-protected by a code-word.

R31

Code-word register in RAM: The code-word 0x1235 must be entered here so that parameters in the user

area can be modified. If any other value is entered into this register, the write-protection is active. If write

protection is inactive, the code-word is returned when the register is read, but if write protection is active,

then the register contains a null value.

R32

Feature register: This register specifies the terminal's operating modes. Thus, for instance, a user-specific

scaling can be activated for the analog I/O modules.

R33-R47

Terminal-specific Registers: These registers depend on the type of terminal.

Registers R47-R63 (Register extension for additional functions)

These registers are provided for additional functions.

IL230x-B110 53Version: 1.0.3

Page 54

Configuration

6.3.2 Example for Register Communication

Control Byte

The Control Byteis located in the output image, and can be read or written.

Bit 7 6 5 4 3 2 1 0

Name REG R/W register number