Page 1

Documentation | EN

Fieldbus Box for PROFIBUS

2009-10-29 | Version: 1.2.1

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 Product Overview ......................................................................................................................................8

2.1 The Fieldbus Box System..................................................................................................................8

2.2 Fieldbus Box - Naming conventions ................................................................................................10

2.3 Firmware and hardware issue status...............................................................................................12

2.4 Technical Data.................................................................................................................................13

2.4.1 Modules - Technical Data ................................................................................................ 13

2.4.2 Controller - Technical Data .............................................................................................. 13

2.4.3 Current Consumption....................................................................................................... 14

3 Profibus ....................................................................................................................................................18

3.1 Fieldbus Overview ...........................................................................................................................18

3.2 Topology..........................................................................................................................................22

3.3 Application .......................................................................................................................................23

3.4 PROFIBUS Cabling .........................................................................................................................24

3.4.1 PROFIBUS Cabling ......................................................................................................... 24

3.4.2 PROFIBUS Connection ................................................................................................... 27

3.5 Protocol Description ........................................................................................................................29

3.5.1 Process Data ................................................................................................................... 29

3.5.2 Configuration Data (Cfg Data) ......................................................................................... 30

3.5.3 Activating the DPV1 Functions ........................................................................................ 31

3.6 Description of the Parameter Data ..................................................................................................33

3.6.1 General ............................................................................................................................ 33

3.6.2 Parameter Data ............................................................................................................... 41

4 Parameterization and commissioning...................................................................................................44

4.1 Start-up behavior of the Fieldbus Box .............................................................................................44

4.2 Addressing.......................................................................................................................................45

4.3 Baud Rate........................................................................................................................................46

4.4 Configuration ...................................................................................................................................47

4.4.1 Configuration Data (Cfg Data) ......................................................................................... 47

4.4.2 Configuration of the complex Modules ............................................................................ 56

5 Diagnostic LEDs ......................................................................................................................................62

5.1 Diagnostic LEDs for PROFIBUS .....................................................................................................62

5.2 Diagnostic LEDs for local errors ......................................................................................................65

5.3 Check of the IP-Link connection......................................................................................................67

5.4 Trouble Shooting .............................................................................................................................70

5.5 Diagnostic Telegrams......................................................................................................................71

5.5.1 Diagnostic Telegrams Overview ...................................................................................... 71

5.5.2 Diagnostic Telegrams for the Compact Box (IPxxx-B3xx)............................................... 71

5.5.3 Diagnostic Telegrams for the Coupler Box (IL230x-B3xx)............................................... 73

5.5.4 TwinCAT - Example for Diagnostics with the FC310x Fieldbus Card.............................. 76

3Version: 1.2.1

Page 4

Table of contents

6 Accessories .............................................................................................................................................78

6.1 PROFIBUS Accessories..................................................................................................................78

6.2 Fieldbus Box accessories................................................................................................................83

7 Appendix ..................................................................................................................................................84

7.1 General operating conditions...........................................................................................................84

7.2 Approvals.........................................................................................................................................86

7.3 Test standards for device testing.....................................................................................................87

7.4 Support and Service ........................................................................................................................88

4 Version: 1.2.1

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

5Version: 1.2.1

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

6 Version: 1.2.1

Page 7

Foreword

1.3 Documentation issue status

Version Modifications

1.2.1 • System overview updated

1.2 • Check of the IP-Link connection added

1.1 • Expanding of the specification for IP-Link up to 15

meters

1.0 • PROFIBUS-specific contents completed.

• Signal types and the signals' connection

assignments have been placed in the fieldbusneutral documentation covering Signal types

(Fieldbus Box I/O Modules). You can find this on

the internet in the Download area at http://

www.beckhoff.com.

0.7 Further Fieldbus Box Modules for special functions

added.

0.6 Fieldbus Box Modules for analog signals and special

functions added.

0.4 Fieldbus Box Modules added.

0.3 First published version.

7Version: 1.2.1

Page 8

Product Overview

2 Product Overview

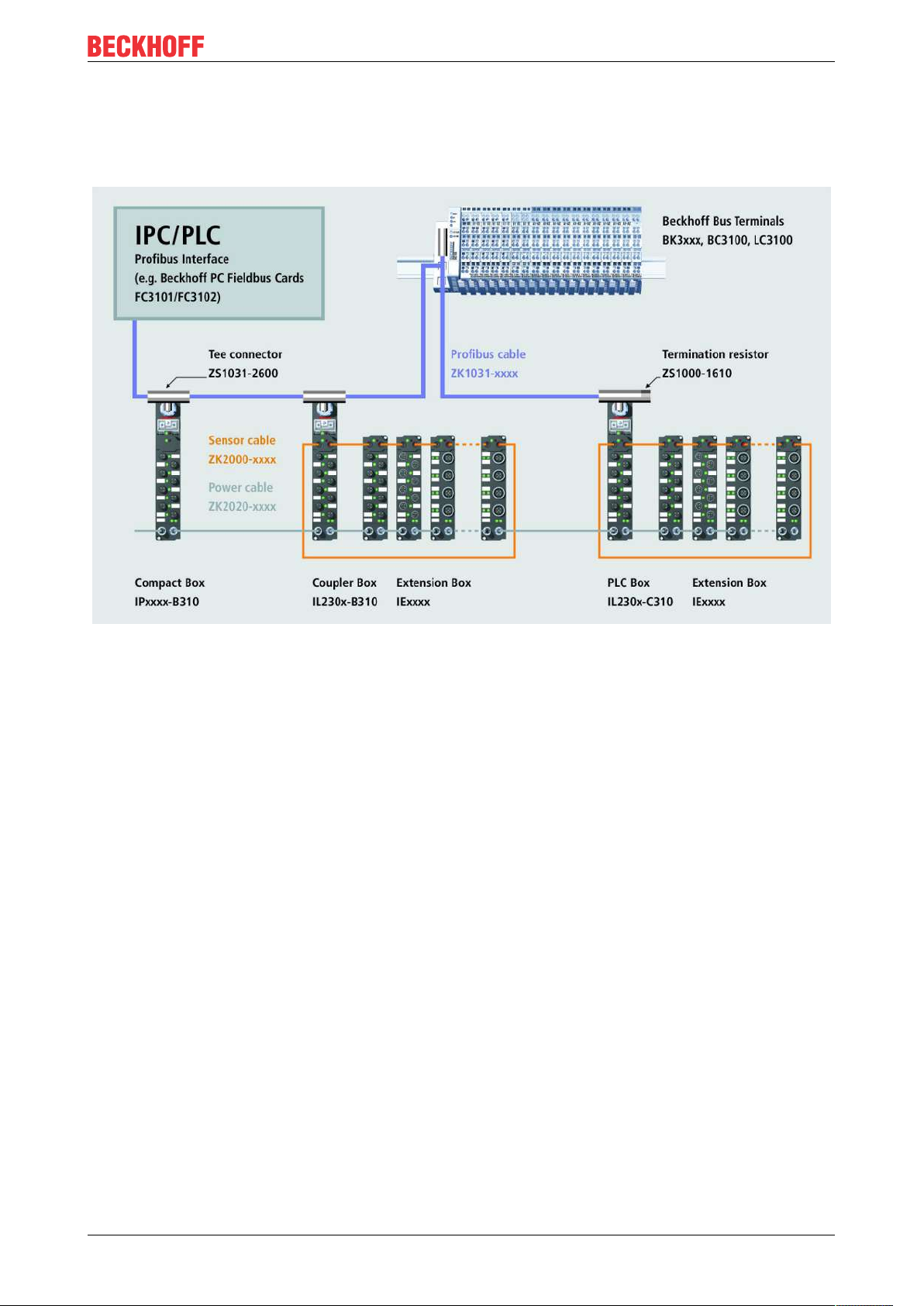

2.1 The Fieldbus Box System

Fieldbus box modules are robust fieldbus stations for a large number of different fieldbus systems. They offer

a wide range of I/O functionality. All relevant industrial signals are supported. As well as digital and analog

inputs and outputs including thermocouple and RTD inputs, there are also incremental encoder interfaces

available for displacement and angle measurement as well as serial interfaces to solve a large number of

communications tasks.

Three varieties of signal connection

The digital inputs and outputs can be connected with snap-on 8mm diameter plugs, screw-in M8

connectors, or with screw-in M12 pendants. The M12 version is provided for analog signals.

All important signal types

Special input and output channels on the combination I/O modules can be used for either input or output. It is

not necessary to configure them, since the fieldbus interface is available for every combination channel as

well as for input and output data. The combination modules give the user all of the advantages of fine signal

granularity.

The processor logic, the input circuitry and the power supply for the sensor are all fed from the control

voltage. The load voltage for the outputs can be supplied separately. In those Fieldbus Boxes in which only

inputs are available, the load power supply, UP, can optionally be connected in order to pass it on

downstream.

The states of the Fieldbus Box, the fieldbus connection, the power supplies and of the signals are indicated

by LEDs.

The label strips can be machine printed elsewhere, and then inserted.

Fieldbus Boxes can be combined for greater flexibility

In addition to the Compact Box, the Fieldbus Box series also includes extendable devices, namely the

Coupler Box and the Extension Box, as well as intelligent devices, the PLC Boxes.

Compact Box

The Compact Box makes the I/O data from the connected digital and analog sensors and actuators available

to the fieldbus.

Coupler Box

The Coupler Box also collects I/O data from the Extension Boxes via an interference-proof optical fiber

connection (IP-Link). Up to 120 Extension Boxes can be connected to a Coupler Box. In this way a

distributed IP67 I/O network is formed with only one fieldbus interface.

The Coupler Box is capable of automatically recognizing the extension modules connected to it during startup, and maps the I/O data automatically into the fieldbus process image – a configuration is not necessary.

The Coupler Box appears, from the fieldbus point of view, along with all of the networked Extension Boxes,

as a single participating bus device with a corresponding number of I/O signals.

The Coupler Box corresponds to the Bus Coupler in the BECKHOFF Bus Terminal system. BECKHOFF

fieldbus devices made to protection class IP 20 (Bus Terminals) and IP 67 (Fieldbus Box) can be combined

without difficulty – the data is handled in the same way in either case.

8 Version: 1.2.1

Page 9

Product Overview

IP-Link

The IP-Link is an optical fiber connection with a transmission rate of 2 MBits/s which is capable of

transmitting 1000 items of binary I/O data in approx. 1 ms, rapidly and securely. Smaller configurations are

correspondingly faster. Because of the high usable data rate, the coupling via IP-Link does not reduce the

performance of the fieldbus at all.

Low-priced plug connectors made according to Protection Class IP67 can be used for the rapid and simple

preparation of the IP-Link cable, in situ. The connection does not require special tools, and can be performed

quickly and simply. The IP-Link cables can also be obtained with prepared plugs if required.

The separate supply of the output voltage allows output groups to be switched off individually. Differing

potentials can also be created within an extension ring without difficulty, since the IP-Link naturally has

optimum electrical isolation.

Extension box

Like the Compact Boxes, the Extension Boxes cover the full spectrum of I/O signals, and may be up to 15m

apart. They are remarkably small in size, and lead to particularly economical I/O solutions with high levels of

protection. Here again, the digital inputs and outputs may optionally be connected via snap-on 8 mm

connectors, or via screw-in connectors (M8 and M12). Analog signal types are provided with the M12

version. The snap-on connectors lock in place positively, forming a shake-proof connection, while the screwin connectors offer the advantage of high resistance to being pulled out.

PLC Box

The PLC Box is an intelligent Fieldbus Box with PLC functionality for distributed pre-processing of the I/O

signals. This allows parts of the application to be farmed out from the central controller. This reduces the

load on the CPU and the fieldbus. Distributed counting, controlling and switching are typical applications for

the PLC Box. The reaction times are independent of the bus communication and of the higher-level

controller.

In the event of a bus or controller failure, maintenance of function (e.g. bringing the process to a safe state in

an orderly manner) is possible.

Programming is carried out with TwinCAT in accordance with IEC 61131-3. Five different programming

languages are available:

• Instruction List (IL)

• Function Block Diagram (FBD)

• Ladder Diagram (LD)

• Sequential Function Chart (SFC)

• Structured Text (ST)

The program download occurs either via the fieldbus or via the programming interface.

Extensive debugging functions (breakpoint, single step, monitoring, etc) are also available. The PLC Box

contains a powerful 16 bit controller, 32/96 kByte program memory and 32/64 kByte data memory. A further

512 bytes of non-volatile memory are available for remanent flags.

PLC Box with IP-Link

The programmable PLC Box with IP-Link provides almost unlimited I/O possibilities. Up to 120 extension

modules, with more than 2000 I/Os, can be directly addressed from the PLC program. The PLC Box is thus

also suitable for use as a small, autonomous controller for the operation of parts of equipment or small

machines.

9Version: 1.2.1

Page 10

Product Overview

2.2 Fieldbus Box - Naming conventions

The identifications of the Fieldbus Box modules are to be understood as follows:

IXxxxy-zyyy

IX describes the design:

"IP" stands for the CompactBox design [}11]

"IL" stands for the CouplerBox design (with IP-Link) [}11]

"IE" stands for the ExtensionBox design [}11]

xxxy describes the I/O connection:

xxx describes the I/O property:

"10x" - 8 x digital inputs

"15x" - counter module

"20x" - 8 x digital outputs

"25x" - PWM module

"23x" - 4 x digital inputs and 4 x digital outputs

"24x" - 8 x digital inputs and 8 x digital outputs

"3xx" - 4 x analog inputs

"4xx" - 4 x analog outputs

"5xx" - incremental encoder or SSI transducer

"6xx" - Gateway module for RS232, RS422, RS485, TTY

y represents the mechanical connection:

"0" stands for 8mm snap-on connection,

"1" stands for M8 bolted connection

"2" stands for M12 bolted connection and

"9" stands for M23 bolted connection

zyyy describes the programmability and the fieldbus system

z distinguishes whether the device is a slave or is a programmable slave:

"B" - not programmable

"C" - programmable (PLC Box)

"yyy" stands for the fieldbus system and the bus connection:

"110" - EtherCAT

"200" - Lightbus

"310" - PROFIBUS

"318" - PROFIBUS with integrated tee-connector

"400" - Interbus

"510" - CANopen

"518" - CANopen with integrated tee-connector

"520" - DeviceNet

"528" - DeviceNet with integrated tee-connector

"730" - Modbus

"800" - RS485

"810" - RS232

"900" - Ethernet TCP/IP with RJ45 for the bus connection

"901" - Ethernet TCP/IP with M12 for the bus connection

"903" - PROFINET

"905" - EtherNet/IP

10 Version: 1.2.1

Page 11

Product Overview

Compact Box

Compact Box

The Compact Box modules offer a wide range of I/O functionality. All relevant industrial signals are

supported. The digital inputs and outputs can be connected either with snap-on 8mm diameter plugs, screwin M8 connectors, or screw-in M12 connectors. The M12 version is made available for analog signals.

Depending on the module, the I/O section and the power supply section can differ.

Coupler Box

Coupler Box

There are three versions of the coupler box named IL230x-Bxxx. It differs from the compact box in that this

module offers an interface to what are known as extension boxes. This interface is a subsidiary bus system

based on the optical fiber what is known as IPLink. This powerful subsidiary bus system can handle up to

120 extension boxes at one coupler box.

Extension Box

Extension Box

Extension Modules, that are independent of the fieldbus and that can only be operated together with a

coupler box via IPLink.

PLC Box

PLC Box

A PLC Box differ from the Coupler Box in that this module can be programmed in IEC 61131-3. This means

that this slave is also capable of working autonomously, without a master, for instance for control or

regulation tasks.

Also see about this

2 Fieldbus Box - Naming conventions [}11]

11Version: 1.2.1

Page 12

Product Overview

2.3 Firmware and hardware issue status

The documentation refers to the hardware and software status that was valid at the time it was prepared.

The properties are subject to continuous development and improvement. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. Existing properties, however,

are always retained and are not changed, so that these modules can always be replaced by new ones.

The number beginning with a D allows you to recognize the firmware and hardware status of a module.

Syntax:

D.wwyyxyzu

ww - calendar week

yy - year

x - bus board firmware status

y - bus board hardware status

z - I/O board firmware status

u - I/O board hardware status

Example:

D.22081501

- Calendar week 22

- in the year 2008

- bus board firmware status: 1

- bus board firmware hardware status: 5

- I/O board firmware status: 0 (no firmware is necessary for this board)

- I/O board hardware status: 1

12 Version: 1.2.1

Page 13

Product Overview

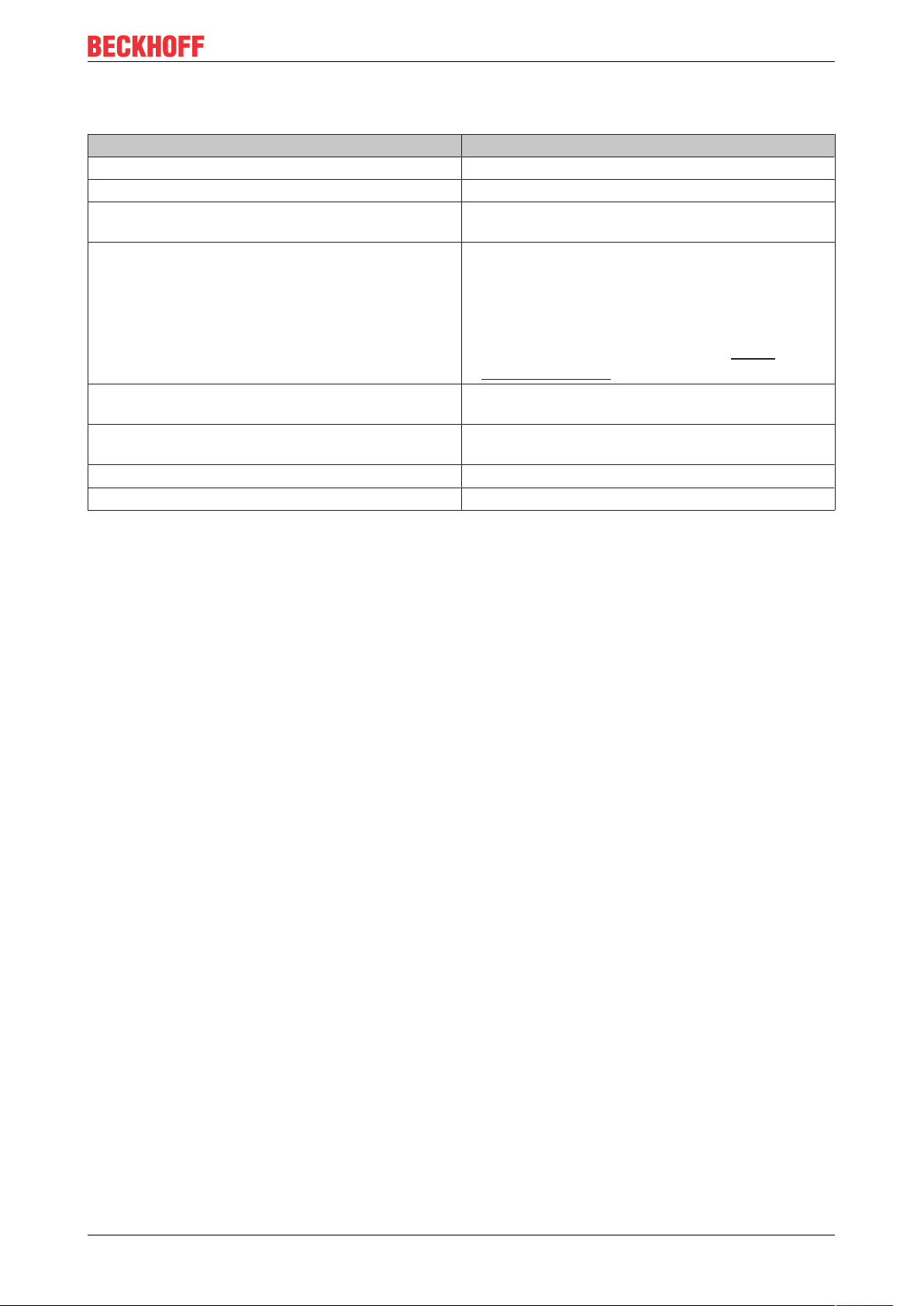

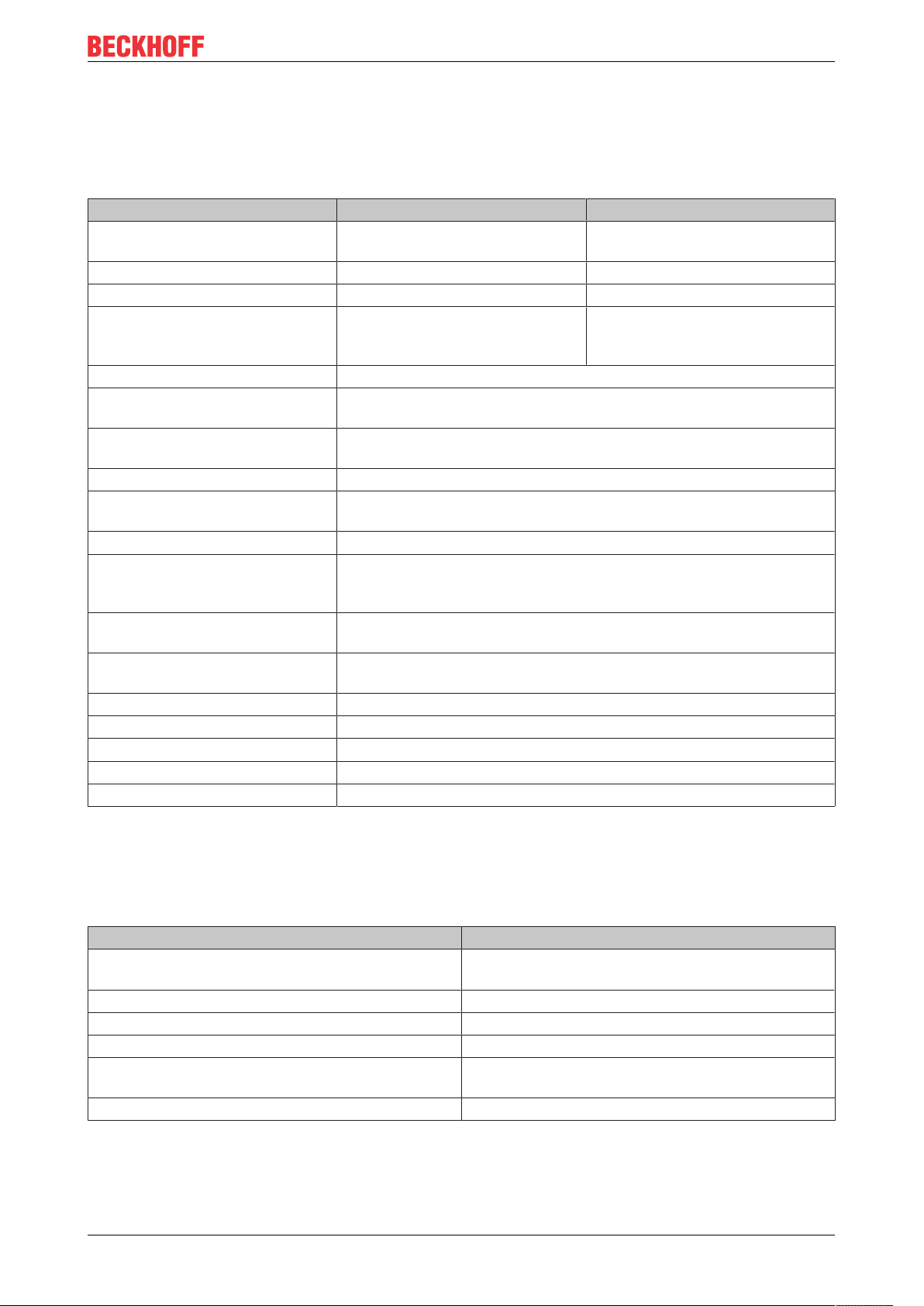

2.4 Technical Data

2.4.1 Modules - Technical Data

Technical data IPxxxx-B31x IL230x-B310, IL230x-C310

Extension modules - Max. 120 with altogether 128 bytes

input and 128 bytes output

Digital peripheral signals according to I/O type max. 960 inputs and outputs

Analog peripheral signals according to I/O type max. 60 inputs and outputs

Configuration facilities Using KS2000, via the controller

(register communication, DPV1, or

parameter data)

Baud Rate automatic detection up to max. 12 Mbaud

Power supply connection Control voltage: 24V DC (-15%/+20%); load voltage: according to I/O

type

Control voltage current

consumption

Load voltage current consumption according to I/O type

Power supply connection Feed: 1 x M8 connector, 4-pin

Fieldbus connection 1 x M12 socket, 5-pin, (inverse coding)

Electrical isolation Channels/control voltage: no

Permissible ambient temperature

during operation

Permissible ambient temperature

during storage

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27, EN60068-2-29

EMC resistance burst / ESD conforms to EN61000-6-2 / EN61000-6-4

Protection class IP 65/66/67 (according to EN 60529)

Installation position variable

Approval CE, UL E172151

according to I/O type + current consumption of sensors, max. 0.5 A

downstream connection: 1 x M8 socket, 4-pin (except IP/IE204x)

between the channels: no

control voltage/fieldbus: yes

0°C ... +55°C

-25 °C ... +85°C

Using KS2000, via the controller

(register communication or DPV1)

2.4.2 Controller - Technical Data

Requirements

PLC data IL230x-C31x

Programmability Via the programming interface (TwinCAT) or via

PROFIBUS (TwinCAT with FC310x)

Program memory 32/96 kbyte

Data memory 32/64 kbyte

Remanent flags 512 bytes

PLC cycle time approx. 3 ms for 1000 IL commands (without I/O

cycle)

Programming languages IEC 6-3 (IL, LD, FBD, ST, SFC)

13Version: 1.2.1

Page 14

Product Overview

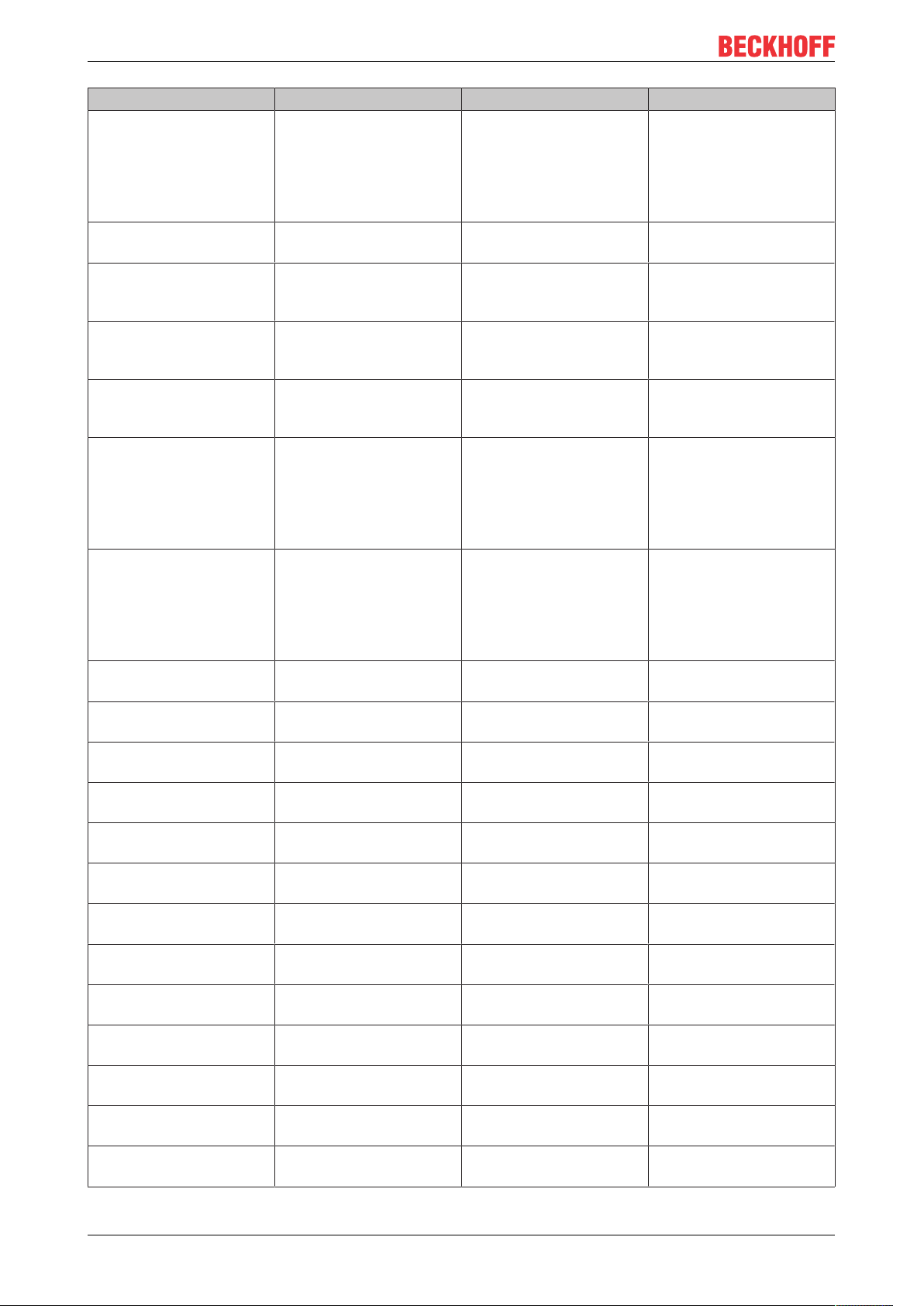

2.4.3 Current Consumption

It is important to know the current consumption of the individual modules in order to know how much current

is available, and for fusing the modules as well as considering the voltage drop in the power lead supply. The

following table contains the current consumption at 24 VDC. Current for supplying the sensors and that

eventually required for the outputs must be added on to these figures.

14 Version: 1.2.1

Page 15

Table1: I/O type Compact Box

Product Overview

15Version: 1.2.1

Page 16

Product Overview

Modules −B310 −B510, −B520 −B730, −B800, −B810

IP1000−Bxxx,

IP1001−Bxxx,

IP1002−Bxxx,

IP1010−Bxxx,

IP1011−Bxxx,

IP1012−Bxxx

IP1502-Bxxx Is = 85mA

IP2000−Bxxx,

IP2001−Bxxx,

IP2002−Bxxx

IP2020−Bxxx,

IP2021−Bxxx,

IP2022−Bxxx

IP2040−Bxxx,

IP2041−Bxxx,

IP2042−Bxxx

IP2300−Bxxx,

IP2301−Bxxx,

IP2302−Bxxx,

IP2310−Bxxx,

IP2311−Bxxx,

IP2312−Bxxx

IP2320−Bxxx,

IP2321−Bxxx,

IP2322−Bxxx,

IP2330−Bxxx,

IP2331−Bxxx,

IP2332−Bxxx

IP2400−Bxxx,

IP2401−Bxxx

IP2512−Bxxx Is = 85mA

IP3102−Bxxx Is = 140mA

IP3112−Bxxx Is = 140mA

IP3202−Bxxx Is = 110mA

IP3312−Bxxx Is = 110mA

IP4112−Bxxx Is = 115mA

IP4132−Bxxx Is = 140mA

IP5009−Bxxx Is = 140mA

IP5109−Bxxx Is = 140mA

IP5209−Bxxx Is = 110mA

IP6002−Bxxx Is = 115mA

IP6012−Bxxx Is = 115mA

Is = 85mA

Ip = 5mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Is = 90mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 35mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 35mA

Ip = 35mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 85mA

Ip = 35mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 50mA

Ip = 5mA

Is = 45mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 105mA

Ip = 5mA

Is = 70mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 85mA

Ip = 35mA

16 Version: 1.2.1

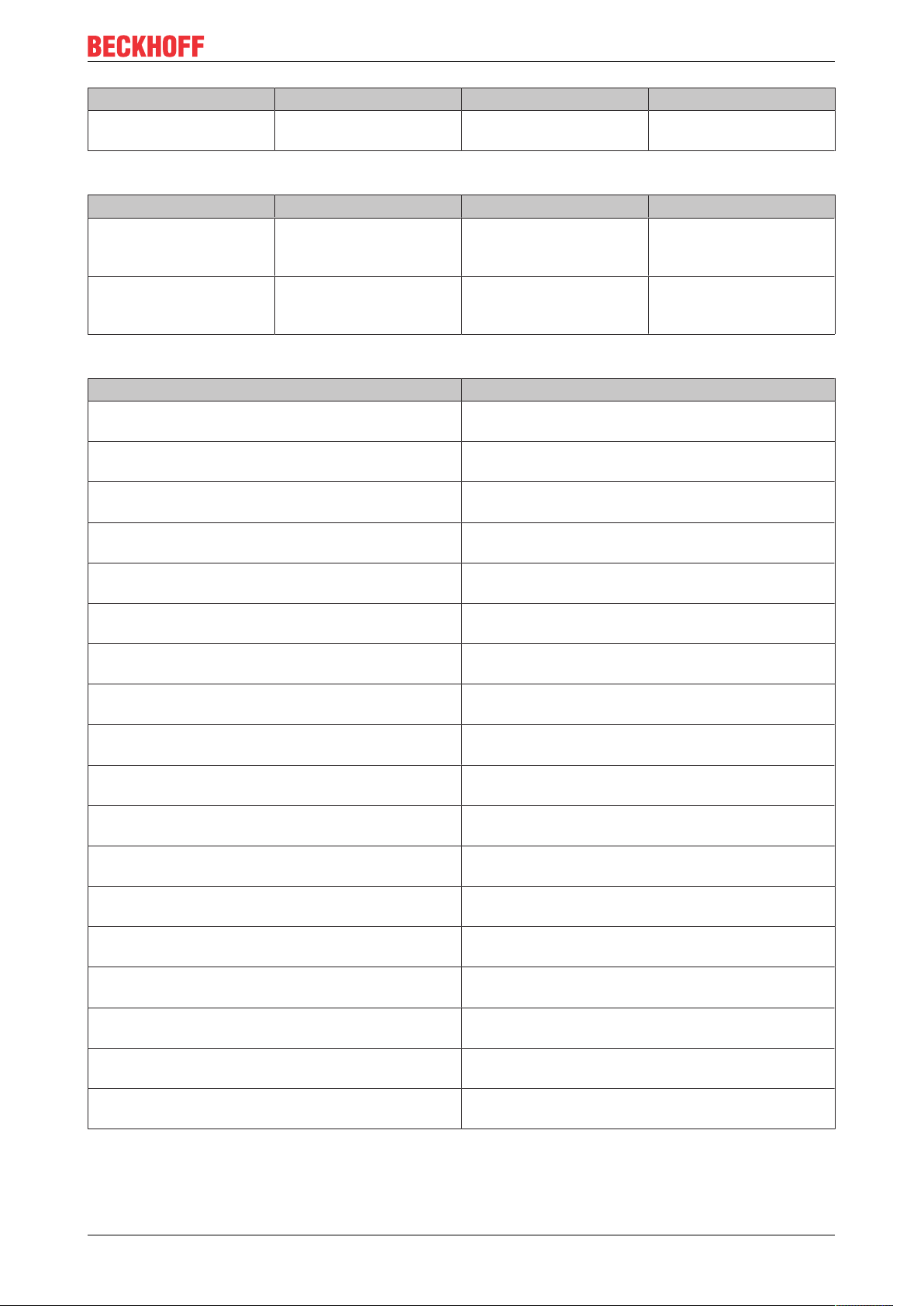

Page 17

Product Overview

Modules −B310 −B510, −B520 −B730, −B800, −B810

IP6022−Bxxx Is = 115mA

Ip = 35mA

Table2: I/O type Coupler Box

Modules −B310 −B510, −B520 −B730, −B800, −B810

IL2300−Bxxx,

IL2301−Bxxx,

IL2302−Bxxx

IL2300−Cxxx,

IL2301−Cxxx,

IL2302−Cxxx

Table3: I/O type Extension Box

Modules

IE1000, IE1001, IE1002, IE1010, IE1011, IE1012 Is = 25mA

IE1502 Is = 25mA

IE2000, IE2001, IE2002 Is = 25mA

IE2020, IE2021, IE2022 Is = 25mA

IE23xx, IE240x Is = 25mA

IE2512 Is = 25mA

IE2808 Is = 40mA

IE3102 Is = 55mA

IE3112 Is = 55mA

IE3202 Is = 40mA

IE3312 Is = 40mA

IE4112 Is = 40mA

IE4132 Is = 40mA

IE5009 Is = 55mA

IE5109 Is = 55mA

IE6002 Is = 40mA

IE6012 Is = 40mA

IE6022 Is = 40mA

Is = 100mA

Ip = 5mA

Is = 100mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 60mA

Ip = 5mA

− −

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Ip = 5mA

Is = 85mA

Ip = 35mA

Is = 60mA

Ip = 5mA

17Version: 1.2.1

Page 18

Profibus

3 Profibus

3.1 Fieldbus Overview

PROFIBUS is a manufacturer - independent, open fieldbus standard with a wide range of applications in

manufacturing and process automation. Manufacturer-independence and openness are guaranteed by the

International standards EN 50170 and EN 50254. PROFIBUS allows devices from different manufacturers to

communicate without the need for specially adapted interfaces. PROFIBUS is suitable both for fast, timecritical applications and for complex communication tasks.

PROFIBUS offers communication protocols of different functional levels: DP and FMS. According to the

application, RS-485, IEC 1158-2 or optical fiber are available as transmission techniques.

PROFIBUS specifies the technical features of a serial fieldbus system with which distributed digital

automation devices can be networked together, from the field level up to the cell level. PROFIBUS is a multimaster system, and therefore permits common operation of a number of automation, engineering or

visualization systems with their distributed peripheral devices on one bus.

PROFIBUS device types

PROFIBUS distinguishes the following device types:

Master devices determine the data traffic on the bus. A master may transmit messages without having

received an external request when it is in possession of the bus access authorization (token). Masters are

also referred to as active devices.

Slave devices are peripheral devices such as input/output devices, valves, drives, measuring transducers

and the Beckhoff PROFIBUS slaves from the BK3xx0, BC3xx0, IPxxxx-B310, IL230x-B310 and IL230x-C310

series. They do not receive any bus access authorization, so that they are only allowed to acknowledge

messages that have been received, or to send messages in response to a request from master. Slaves are

referred to as passive devices. They only require a small proportion of the bus protocol, which means that

they can be implemented with little effort.

PROFIBUS DP

PROFIBUS DP is designed for efficient data exchange at the field level. The central automation devices

such as PLC/PCs or process control systems communicate here over a fast serial link with distributed field

devices such as I/O, drives, valves etc.. Data is primarily exchanged with these distributed devices cyclically.

The communication functions required for this are specified by the basic DP functions in accordance with EN

50170.

In addition to these basic functions, PROFIBUS DP also offers extended acyclic communication services for

such purposes as parameterization and other operations. These are also supported by the Beckhoff

PROFIBUS slaves of the IPxxxx-B310, IL230x-B310 and IL230x-C310 series. A central controller (master)

cyclically reads the input information from the slaves, and writes the output information cyclically to the

slaves. The bus cycle time here should be shorter than the central automation system's program cycle time,

which lies around 10 ms in many applications.

A high data throughput is not in itself sufficient for successful use of a bus system. Ease of handling, good

diagnostic facilities and secure transmission technology are also of the utmost importance if the user’s

demands are to be satisfied. These properties are ideally combined in PROFIBUS DP.

System configuration and device types

PROFIBUS DP allows single master or multi-master systems to be implemented. This permits a high level

of flexibility in system configuration. A maximum of 126 devices (master or slaves) can be connected to one

bus. A station address between 0 and 99 can be chosen for the Beckhoff PROFIBUS slaves from the

IPxxxx-B310, IL230x- B310 and IL230x-C310 series. The specifications for the system configuration contain

the number of stations, the assignment of the station addresses to the I/O addresses, data consistency of

the I/O data and the format of the diagnostics messages and the bus parameters being used. Every

PROFIBUS DP system consists of different device types. Three types of device are distinguished:

18 Version: 1.2.1

Page 19

Profibus

Type Description

DP master class 1 (DPM1)

e.g. Beckhoff PC master card FC310x

DP master class 2 (DPM2) Devices of this type are engineering, project design

DP slave

e.g. Beckhoff Bus Coupler IPxxxx-B310

In single master systems only one master is active on the bus in the operating phase of the bus system.

The PLC controller is the central control element. The distributed slaves are coupled to the PLC controller via

the transmission medium. The shortest bus cycle time is achieved with this system configuration.

This involves a central controller that exchanges

information cyclically with the distributed stations

(slaves) in a specified message cycle. Typical

devices include, for instance, programmable logic

controllers (PLCs) or PCs.

or operating devices. They are used for

commissioning, for servicing and diagnosis in order

to configure the connected devices, to evaluate

measured values and parameters and to interrogate

the status of devices.

A PROFIBUS DP slave is a peripheral device (I/O,

drive, measuring transducer etc.) that reads input

information and passes output information on to the

peripherals. It is also possible to have devices that

only handle either input or output information. The

quantity of input and output information is device-

dependent, and may not exceed 246 bytes of input

data and 246 bytes of output data.

In a multi-master mode there is more than one master on the bus. They either form sub-systems that are

independent of one another, each consisting of one DPM1 and the associated slaves, or additional project

design and diagnostic devices. All the DP masters can read the input and output images of the slaves.

Writing the outputs is only possible for one DP master (the one assigned as DPM1 during the project

design). Multi-master systems achieve a medium bus cycle time. In time-critical applications, the increase in

bus cycle time should be observed by adding a diagnostic tool.

Basic device files (GSD)

In PROFIBUS DP, the performance characteristics of devices are documented by the manufacturers and

made available to users in the form of a device data sheet and of a basic device file. The structure, content

and coding of these basic device files (GSD) is standardized. They make it easy to plan a project with any

PROFIBUS DP slaves using project planning devices from a various manufacturers. The PROFIBUS User

Organization (PROFIBUS Nutzer Organization - PNO) archives this information for all manufacturers, and

will provide information about the GSD from any manufacturer on request. The GSD files are read by a

PROFIBUS master configuration software, and appropriate adjustments are transferred to the PROFIBUS

master. Please see the appropriate software manual from the master manufacturer for a description.

The Beckhoff GSD files may be obtained from the internet under www.beckhoff.com.

Diagnostic functions

The extensive diagnostic functions of PROFIBUS DP allow rapid fault localization. Diagnosis of the Beckhoff

Bus Coupler is not activated in the default setting of the type file or the GSD file. The diagnostic messages

are transmitted over the bus and collated by the master.

They are divided into three levels:

Diagnosis type Description

Related to the station Messages relating to the general readiness of a

device for operation such as over-temperature or

under-voltage

Related to the module These messages indicate that diagnostic signals are

pending within a specific I/O sub range of the device

(e.g. an 8 bit output module)

Related to the channel Here the cause of an error is related to a single input/

output bit (channel), such as a short circuit on output

2

19Version: 1.2.1

Page 20

Profibus

The Beckhoff PROFIBUS slaves from the IPxxxx-B310, IL230x-B310 and IL230x-C310 series support the

PROFIBUS DP diagnostic functions. Assessment of the diagnostic data by means of the controller depends

on the support for the PROFIBUS master. Please refer to the device manuals for the master interfaces for

details of how to handle the diagnosis.

Sync and Freeze Mode

In addition to the user data traffic related to the device, which is automatically dealt with by DPM1, a DP

master has the option of sending control commands to one DP slave, to a group of them or to all of them at

the same time. These control commands are transmitted as multicasts. These control commands can be

used to specify the sync and freeze operating modes, in order to synchronize the DP slave. They permit

event-controlled synchronization of the DP slaves.

The DP slaves start sync mode when they receive a sync control command from the assigned DP master.

In this operating mode, the outputs of all the addressed DP slaves are frozen at their current values. In the

following user data transmissions, the DP slaves store the output data, but the output states themselves

nevertheless remain unchanged. Only when the next sync control command is received from the master the

stored output data is switched through to the outputs. Sync operation is ended with an unsync control

command.

A freeze control command similarly causes the addressed DP slaves to enter freeze mode. In this operating

mode the states of the inputs are frozen at their current value. The input data is only updated again when the

DP master has sent the next freeze control command to the devices concerned. Freeze operation is ended

with an unfreeze command.

System behavior

The system behavior is also standardized in PROFIBUS DP, so that devices can to a large extent be

interchanged. It is largely determined by the operating condition of the DPM1. This can either be controlled

locally, or over the bus by the project design device.

The following three principal conditions are distinguished:

Operation mode Description

Stop There is no data traffic between the DPM1 and the

DP slaves. The Bus Coupler only addresses the Bus

Terminals once after the power has been switched on

(none of the I/O LEDs are lit).

Clear The DPM1 reads the input information from the DP

slaves, and maintains the outputs of the DP slaves in

a safe state (depending on the reaction to fieldbus

errors, the green I/O LED is lit and the outputs are

set).

Operate The DPM1 is in a data transfer phase. In the course

of cyclic data traffic the inputs of the DP slaves are

read and the output information is transmitted to the

DP slaves (the green I/O LED is lit).

The DPM1 sends its local status at a configurable time interval using a multicast command cyclically to all

the DP slaves that have been assigned to it. The reaction that the system has to the occurrence of an error

during the DPM1's data transfer phase, such as the failure of a DP slave, is specified in the Auto-Clear

operating parameter. If this parameter is set to True, then the DPM1 switches the outputs of all the

associated DP slaves into a safe state as soon as one DP slave is no longer ready for the transfer of user

data. The DPM1 then switches into the Clear state. If the parameter is False then the DPM1 remains in the

operating state even after a fault, and the user can himself specify the system's reaction.

Data traffic between the DPM1 and the DP slaves

The data traffic between the DPM1 and the DP slaves that have been assigned to it is automatically

executed by the DPM1 in a specified, continuously repeated sequence. The user specifies the assignment of

a DP slave to the DPM1 when the bus system's project is being planned. Those DP slaves that are included

in or excluded from the cyclic user data traffic are also defined.

20 Version: 1.2.1

Page 21

Profibus

The data traffic between the DPM1 and the DP slaves is divided into the parameterization, configuration and

data transfer phases.

Before a DP slave is included in the data transfer phase, the DPM1 checks, in the parameterization and

configuration phase, whether the theoretical configuration that has been planned agrees with the actual

configuration of devices. The check requires the device type, the format and length information, as well as

the number of inputs and outputs, to be in agreement. The user is thus provided with reliable protection

against errors in parameterization. In addition to the transfer of user data, which is automatically carried out

by the DPM1, it is possible to send new parameterization data to the DP slaves at the user's request.

Protection mechanisms

In the context of distributed peripherals it is necessary, for reasons of safety and reliability, for the system to

be given extremely effective functions to protect against incorrect parameterization or the failure of the

transmission mechanisms. PROFIBUS DP uses monitoring mechanisms in the DP Master and in the DP

Slaves. They are implemented in the form of time monitors. The monitoring interval is specified in when the

DP system project is planned.

Protection mechanisms Description

At the DP Master The DPM1 monitors the slave's transfer of user data

with the Data_Control_Timer. An individual

monitoring timer is used for each assigned slave. The

time monitor triggers if a proper transfer of user data

does not take place within the monitoring interval. In

this case the user is informed. If automatic error

reaction is enabled (Auto_Clear = True) then the

DPM1 leaves the Operate state, switches the outputs

of the assigned slaves into a safe state, and then

goes into the Clear operating mode.

At the DP Slave The slave uses communication monitoring in order to

detect errors of the master or in the transmission

segment. If data is not transferred with the assigned

master within the communication monitoring interval

the slave switches the outputs into the safe state

itself. The slave inputs and outputs further require

access protection in multi-master systems, to ensure

that direct access is only made from the authorized

master. The slaves will make an image of the inputs

and outputs available to other masters, and this can

be read by any other master even if it does not have

access authorization.

Ident number

Every DP slave and every DPM1 must have an individual identification number. This is required so that a DP

master can identify the types of the connected devices without any significant protocol overhead. The master

compares the identification numbers of the connected DP devices with the identification numbers in the

project planning data specified by DPM2. The transfer of user data only starts if the correct device types are

connected to the bus at the correct station addresses. This provides protection from project planning errors.

Manufacturer-specific identification numbers are issued by the PROFIBUS User Organization (PNO). The

PNO administers the identification numbers along with the basic device data (GSD).

21Version: 1.2.1

Page 22

Profibus

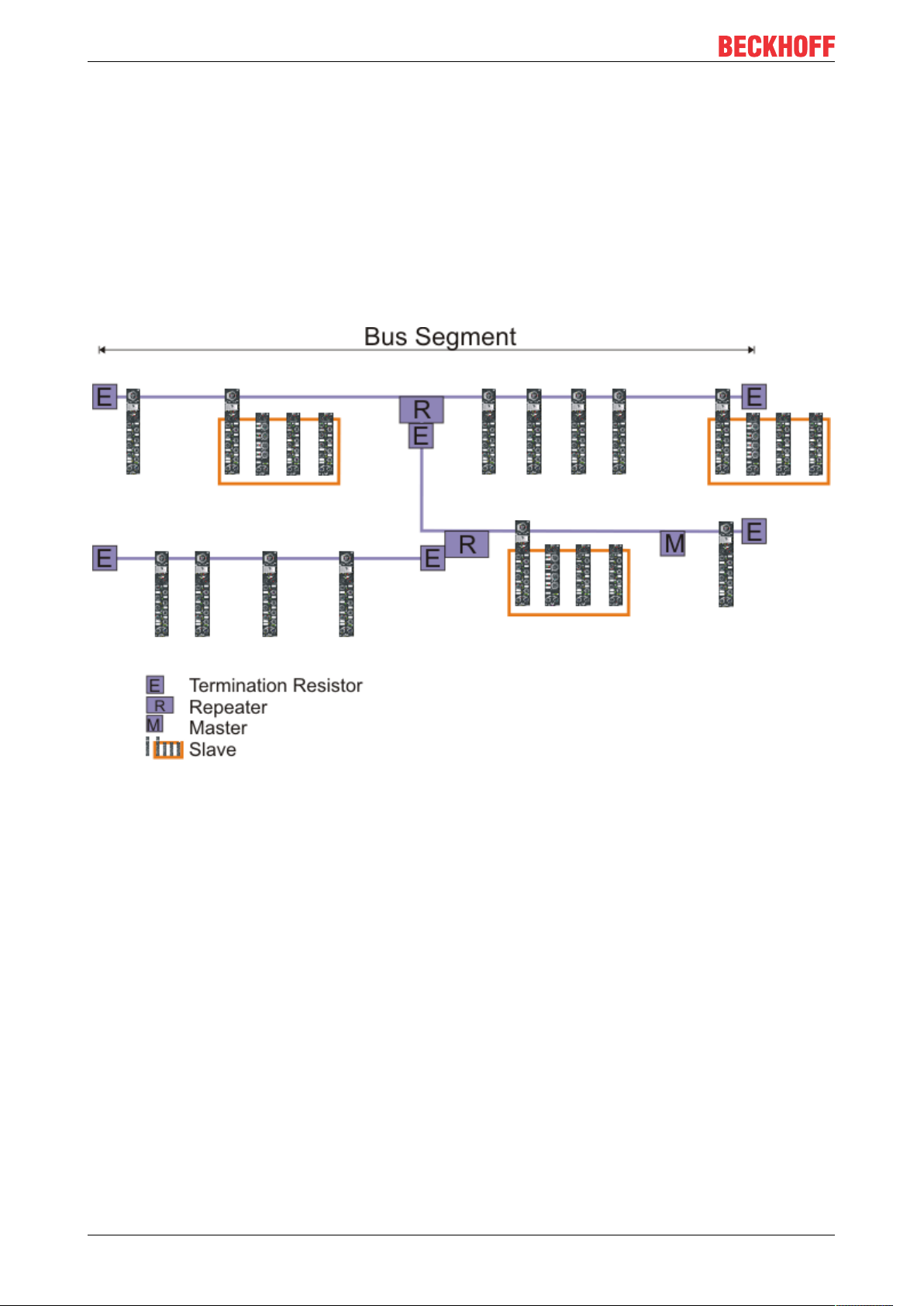

3.2 Topology

• A bus segment may consist of a maximum of 32 devices (including the repeaters).

• The maximum conductor length of a segment depends on the transmission speed in use and on the

quality of the bus cables being used.

• No more than 9 repeaters may be installed between two devices.

• Stubs are to be avoided, and are not permitted above 1.5 Mbaud.

• The maximum number of devices is 127

• Interrupting the supply voltage from cable ends by switching off the repeater/slave, or by pulling out the

plug, is not permitted.

Fig. 1: RS485 topology with 3 segments and 2 repeaters.

22 Version: 1.2.1

Page 23

3.3 Application

Example of an PROFIBUS Application

Profibus

23Version: 1.2.1

Page 24

Profibus

3.4 PROFIBUS Cabling

3.4.1 PROFIBUS Cabling

Physical aspects of the data transmission are defined in the PROFIBUS standard (see PROFIBUS layer 1:

Physical Layer).

The types of area where a fieldbus system can be used is largely determined by the choice of the

transmission medium and the physical bus interface. In addition to the requirements for transmission

security, the expense and work involved in acquiring and installing the bus cable is of crucial significance.

The PROFIBUS standard therefore allows for a variety of implementations of the transmission technology

while retaining a uniform bus protocol.

Cable-based transmission

This version, which accords with the American EIA RS-485 standard, was specified as a basic version for

applications in production engineering, building management and drive technology. A twisted copper cable

with one pair of conductors is used. Depending on the intended application area (EMC aspects should be

considered) the screening may be omitted.

Two types of conductor are available, with differing maximum conductor lengths (see the RS-485 table).

Table4: RS485 - Fundamental properties

RS-485 transmission according to the Profibus standard

Network topology Linear bus, active bus terminator at both ends, stubs

are possible.

Medium Screened twisted cable, screening may be omitted,

depending upon the environmental conditions (EMC).

Number of stations 32 stations in each segment with no repeater. Can be

extended to 127 stations with repeater

Max. bus length without repeater 100 m at 12 MBit/s

200 m at 1500 KBit/s, up to 1.2 km at 93.75 KBit/s

Max. bus length with repeater Line amplifiers, or repeaters, can increase the bus

length up to 10 km. The number of repeaters possible

is at least 3, and, depending on the manufacturer,

may be up to 10.

Transmission speed (adjustable in steps) 9.6 kBit/s; 19.2 kBit/s; 93.75 kBit/s; 187.5 kBit/s; 500

kBit/s; 1500 kBit/s; 12 MBit/s

Plug connector 9-pin D-Sub connector for IP20

M12 round connector for IP65/67

Cabling for PROFIBUS DP and PROFIBUS FMS

Note the special requirements on the data cable for baud rates greater than 1.5 MBaud. The correct cable is

a basic requirement for correct operation of the bus system. If a simple 1.5 Mbaud cable is used, reflections

and excessive attenuation can lead to some surprising phenomena. It is possible, for instance, for a

connected PROFIBUS station not to achieve a connection, but for it to be included again when the

neighboring station is disconnected. Or there may be transmission errors when a specific bit pattern is

transmitted. The result of this can be that when the equipment is not operating, PROFIBUS works without

faults, but that there are apparently random bus errors after start-up. Reducing the baud rate (< 93,75

kBaud) corrects this faulty behavior.

If reducing the baud rate does not correct the error, then in many cases this can indicate a wiring fault. The

two data lines maybe crossed over at one or more connectors, or the termination resistors may not be active,

or they may be active at the wrong locations.

24 Version: 1.2.1

Page 25

Profibus

Pre-assembled cables from Beckhoff

Installation is made a great deal more straightforward if pre-assembled cables from Beckhoff are

used! Wiring errors are avoided, and commissioning is more rapidly completed. The Beckhoff range

includes fieldbus cables, power supply cables, sensor cables and accessories such as terminating

resistors and T-pieces. Connectors and cables for field assembly are nevertheless also available.

Termination resistors

In systems with more than two stations all devices are wired in parallel. It is essential that the bus

cables are terminated with resistors at the conductor ends in order to avoid reflections and associated transmission problems.

Distances

The bus cable is specified in EN 50170. This yields the following lengths for a bus segment.

Baud rate

in kbits/

sec

Cable

length in m

Stubs up to 1500 kbaud <6.6 m; at 12 Mbaud stub segments should not be used.

Bus segments

A bus segment consists of at most 32 devices. 126 devices are permitted in a PROFIBUS network.

Repeaters are required to refresh the signal in order to achieve this number. Each repeater is counted as

one device.

IP-Link is the subsidiary bus system for Fieldbus Boxes, whose topology is a ring structure. There is an IP

master in the coupler modules (IP230x-Bxxx or IP230x-Cxxx) to which up to 120 extension modules (IExxxx)

may be connected. The distance between two modules may not exceed 5 m. When planning and installing

the modules, remember that because of the ring structure the IP-Link master must be connected again to the

last module.

Installation guidelines

9.6 19.2 93.75 187.5 500 1500 12000

1200 1200 1200 1000 400 200 100

When assembling the modules and laying the cables, observe the technical guidelines provided by the

PROFIBUS User Organization (PROFIBUS Nutzerorganisation e.V.) for PROFIBUS DP/FMS

(seewww.profibus.com).

Checking the PROFIBUS wiring

A PROFIBUS cable (or a cable segment when using repeaters) can be checked with a few simple resistance

measurements. The cable should meanwhile be removed from all stations:

25Version: 1.2.1

Page 26

Profibus

1. Resistance between A and B at the start of the lead: approx. 110 Ohm

2. Resistance between A and B at the end of the lead: approx. 110 Ohm

3. Resistance between A at the start and A at the end of the lead: approx. 0 Ohm

4. Resistance between B at the start and B at the end of the lead: approx. 0 Ohm

5. Resistance between screen at the start and screen at the end of the lead: approx. 0 Ohm

If these measurements are successful, the cable is okay. If, in spite of this, bus malfunctions still occur, this

is usually a result of EMC interference. Observe the installation notes from the PROFIBUS User

Organization (www.profibus.com).

26 Version: 1.2.1

Page 27

Profibus

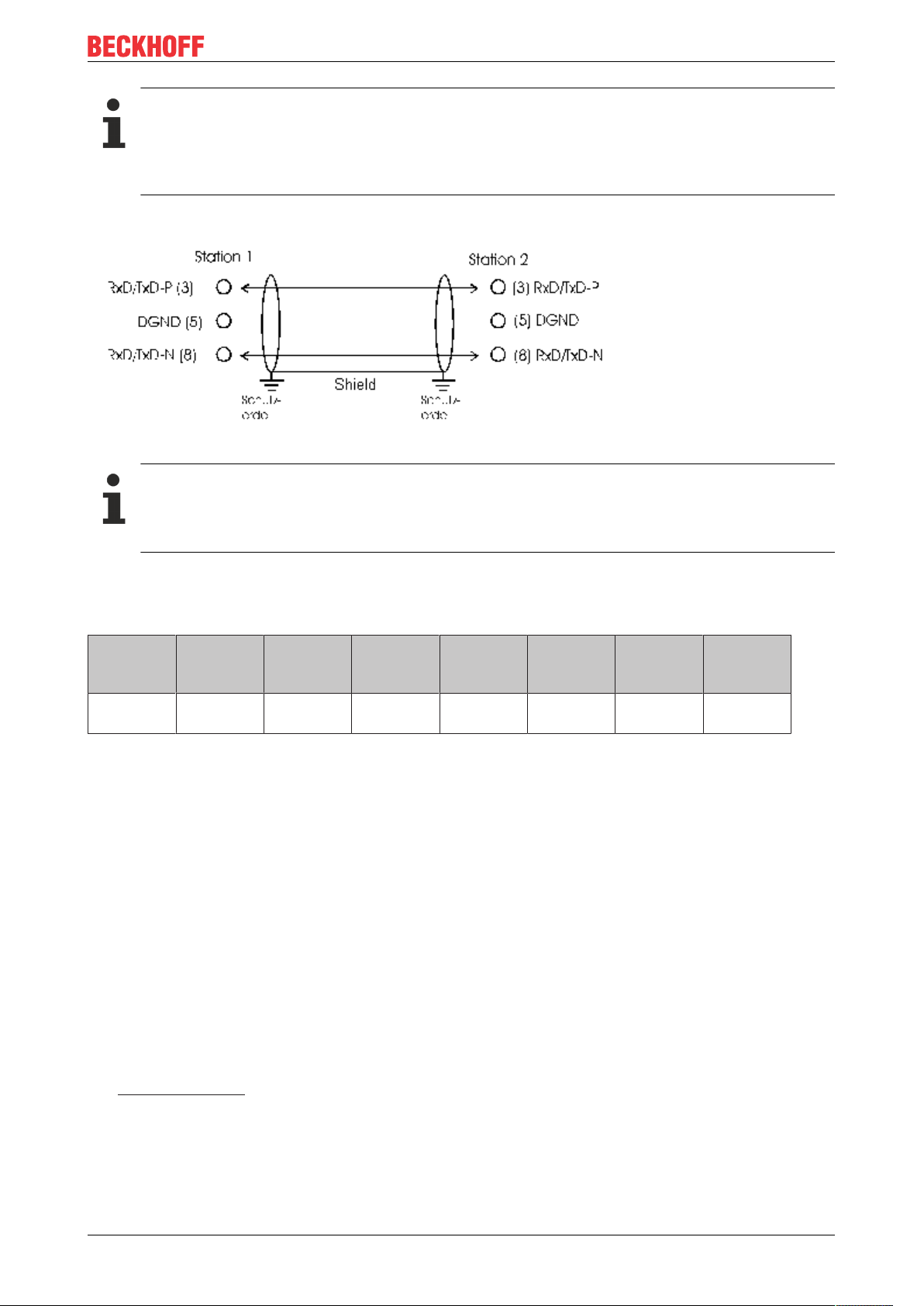

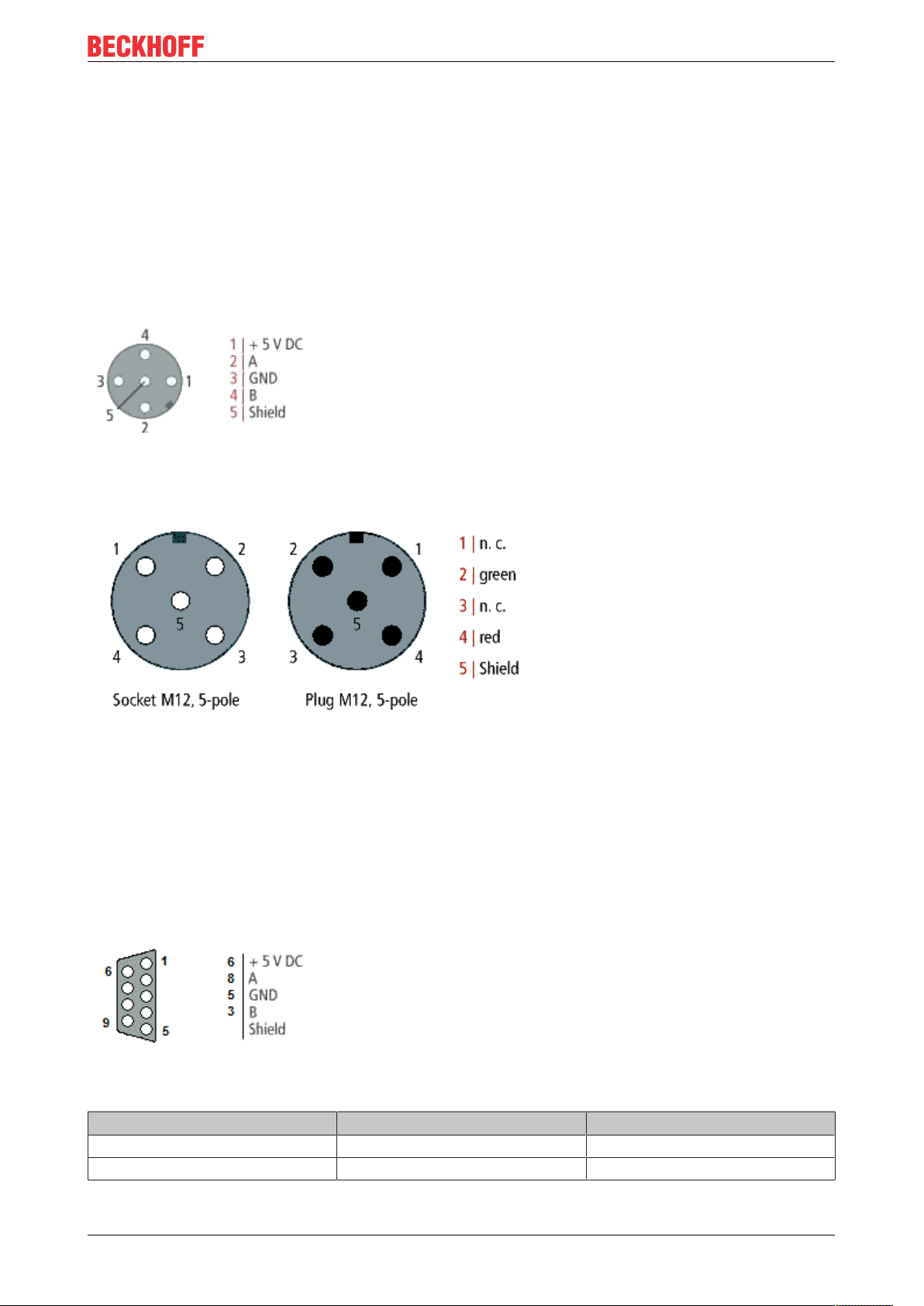

3.4.2 PROFIBUS Connection

M12 circular connector

The M12 socket is inverse coded, and has five pins. Pin 1 is 5 VDC and 3 is GND for the active termination

resistor. These must never be misused for other functions, as this can lead to destruction of the device.

Pin2 and pin4 are the PROFIBUS signals. These must never be swapped over, as this will prevent

communication. Pin5 is the shield, and this is capacitatively coupled to the Fieldbus Box chassis.

M12 socket pin assignment (-B310)

M12 socket/plug pin assignment (-B318)

Nine pole D-Sub

Pin 6 is 5 VDC und Pin 5 is GND for the active termination resistor. These must never be misused for other

functions, as this can lead to destruction of the device.

Pin3 and pin8 are the PROFIBUS signals. These must never be swapped over, as this will prevent

communication.

D-Sub socket pin assignment

PROFIBUS conductor colors

PROFIBUS conductors M12 D-Sub

B red Pin 4 Pin 3

A green Pin 2 Pin 8

27Version: 1.2.1

Page 28

Profibus

Connection of Fieldbus Box modules

The connection of the Fieldbus Box modules is done direct or via a T-piece (or Y-piece).

The B318 series does have a male and female connector, that means no external T-piece is required. The

supply voltage (+5VDC) for the termination resistor is only supplied via the female M12 connector. The

termination resistor ZS1000-1610 is only available with male connector.

Therefore the incoming PROFIBUS line should end in a female connector.

Two T-pieces are available:

• ZS1031-2600 with +5VDC on male and female connector for the termination resistor

• ZS1031-2610 with +5VDC only on the female connector

28 Version: 1.2.1

Page 29

Profibus

3.5 Protocol Description

3.5.1 Process Data

Once the parameter data and the configuration data has been correctly received and confirmed, the slave

goes into the Data_Exch state, which means that it exchanges data with the master. The master sends the

output data and the slave replies with the input data.

29Version: 1.2.1

Page 30

Profibus

3.5.2 Configuration Data (Cfg Data)

Following parameterization, the master sends a configuration telegram to the slave. The configuration

telegram causes the slave to check the configuration that has been sent by the master.

Structure of configuration byte:

Bit 0..3 Length of the data

00 = 1 byte/Word

15 = 16 byte/Word

Bit 4..5 Input/Output

00 = special identification format

01 = input

10 = output

11 = input/output

Bit 6 Byte/Word

0 = byte

1 = Word

Bit 7 Consistency

0 = consistency over byte/word

1 = consistency over the entire length

30 Version: 1.2.1

Page 31

Profibus

3.5.3 Activating the DPV1 Functions

The DPV1 functions can be activated in the parameter data (GSD, GSE). These functions are deactivated in

the default setting. (Prm. byte 0 bit 15=1 activated, bit 15 =0 [default] deactivated)

DPV1 Functions

The IP/IL modules and the EconomyPlusBus Coupler (BK3120) support the following functions in the DPV1

services. The maximum length of the DP-V1 services is 48 bytes.

IP/IL configuration (IP-Link only)

The configuration of the extension modules can be read from the IP-Link coupler module. A word (of 16 bits)

is transferred for each connected extension module (IExxxx). This contains the type of the module in the

case of the analog modules, and the size and type of the digital extension modules.

Bit Value: description of the digital module

0-1 If bit 4 = 0: number of 2-bit outputs, if bit 4 = 1:

number of 8-bit outputs

2-3 If bit 4 = 0: number of 2-bit inputs, if bit 4 = 1: number

of 8-bit inputs

4 0: Bit size 2, 1: bit size 8

5-6 0: Standard: Inputs and outputs do not have the

same starting address

1: Combined I/O: Inputs and outputs to have the

same starting address

2: Reserved

3: Outputs with diagnostics

7-15 always 0

The module configuration can be read with the following DPV1 parameters: (KS2000 Table 9) The modules

are entered in the sequence in which they are connected at the IP-Link.

Slot number Index Byte Description

0 9 0-1 Bus Coupler/module

identifier

0 9 2-3 Module -1

0 9 ... ...

0 9 46-47 Module 23

0 10 0-1 Module 24

0 10 ... ...

0 10 46-47 Module 47

0 11 0-1 Module 48

0 ... ... ...

0 13 46-47 Module 95

0 14 0-1 Module 96

0 14 ... ...

0 14 30-31 Module 119

This information can also be written by DPV1. If the written configuration does not agree with the

configuration contained in the table, a DPV1 error message is received.

Module Register

The register of extension modules can be read or written:

31Version: 1.2.1

Page 32

Profibus

Slot number Index Description

1 0 Register 0 of module 1, channel 1

1 ... ...

1 63 Register 63 of module 1, channel 1

1 64 Register 0 of module 1, channel 2

1 ... ...

1 255 Register 63 of module 1, channel 4

2 0 Register 0 of module 2, channel 1

(from here only for IP-Link)

... ... ...

255 255 Register 63 of module 255,

channel 4

IP-Link Reset

The IP-Link reset can be activated with the following DPV1 parameters: (Following an interruption of the IPLink and its correction, the IP-Link can be started again)

Slot number Index Byte Value

0 99 0 2

0 99 1 1

0 99 2 0

0 99 3 0

Measuring the IP-Link cycle time

Starting and stopping the IP-Link cycle time is set by the following DPV1 parameters:

Slot number Index Byte Value

0 99 0 4

0 99 1 1

0 99 2-3 0: Stop, >0: Start

The cycle time can be read, and to reset the values it can also be written with the following DPV1 parameter:

Slot number Index Byte Description

0 98 0-1 Minimum IP-Link cycle

time (in µs)

0 98 2-3 Maximum IP-Link cycle

time (in µs)

0 98 4-5 Current IP-Link cycle time

(in µs)

0 98 6-7 Mean IP-Link cycle time

(in µs)

Manufacturer’s setting

The following DPV1 parameters must be written in order to adopt the manufacturer's settings:

Slot number Index Byte Value

0 99 0 1

0 99 1 4

0 99 2 0

0 99 3 0

32 Version: 1.2.1

Page 33

Profibus

3.6 Description of the Parameter Data

3.6.1 General

3.6.1.1 Parameterisation Telegram

The Set_Prm service can be used to transfer not only the parameters described in the Profibus DP standard,

but also manufacturer-specific operating parameters (User_Prm_Data). This is transmitted once from the

master to the slave while the connection is being established. Generally speaking, the configuration tool for

the DP master can read those operating parameters for the Fieldbus Box that can be set out of the GSD file,

and can display them in plain text. The following manufacturer-specific operating parameters can be set for

the Fieldbus Box:

Standard functionality Modules that support the functions

DPV1 Services IPxxxx-B310, IL230x-B310, IL230x-C310

Reset in the event of an IP-Link error IL230x-B310, IL230x-C310

Process data format [}37]

Synchronisation of the DP-/IP-Link cycle [}33]

Reaction to Profibus errors [}39]

Reaction to IP-Link errors IL230x-B310, IL230x-C310

IPxxxx-B310, IL230x-B310, IL230x-C310

IL230x-B310, IL230x-C310

IPxxxx-B310, IL230x-B310, IL230x-C310

Expert functionality

2 byte PLC interface

IP-Link-Cycle-Counter

Also see about this

2 Reaction to IP-Link Errors [}40]

3.6.1.2 Updating the Process Image

Function

The K-Bus cycle (IP-Link) can be started cyclically (process image updating: free running ) or synchronously,

with receipt of the DP-Data_Exchange telegram (process image updating: synchronous with cycles). If

updating the process image is set to be synchronous with cycles, then the K-Bus cycle is started after receipt

of the Data_Exchange telegram; otherwise the K-Bus cycle (IP-Link) is started independently of the

Data_Exchange telegrams. The free running and synchronous procedures for updating of the process image

are represented schematically below.

33Version: 1.2.1

Page 34

Profibus

Free Run

Figure: Free-Run-Mode

Synchronous

Figure: The principle of updating the process image

Byte Bit Description

9 6 Updating of the process image

Note

Special attention must be paid to the running and reaction times of the whole system when parameterising the process image update function.

Fast- Free- Run

In fast-free-run mode, the priority of the K-Bus/IP-Link is set higher. This activates the internal bus more

frequently. This implies that the interfaces (such as KS2000 or DPV-1) are not dealt with so quickly. Fastfree-run mode is only permitted in asynchronous operation.

34 Version: 1.2.1

Page 35

Figure: Fast-Free-Mode

Byte Bit Description

9 4 Fast-Free-Run-Mode

Profibus

A certain running time is required to transmit the signals from the inputs to the controller and from the

controller to the outputs. It is composed of a number of elements:

• Transmission from the controller to the Profibus master

• Transmission via Profibus (see Profibus reaction time [}35]) and

• Transmission from the Profibus box to the outputs (see K-Bus reaction time [}36]) / (see IP-Link cycle

time [}37])

The opposite sequence applies to the return journey.

Please see the data provided by the Profibus master manufacturer for the reaction time from the controller to

the Profibus master. The times a comparatively short, and do not usually have to be taken into account.

Profibus reaction time

Profibus reaction time

The reaction time tDP on the Profibus is made up as follows. The constants A, B and

depend on the

TBYTE

baud rate.

t =

DP

Constant A

+ (constant B + (number of I/O

bytes x T

BYTE

))

+ (constant B + (number of I/O

bytes x T

BYTE

))

+ (constant B + (number of I/O

bytes x T

BYTE

))

+ (constant B + (number of I/O

bytes x T

BYTE

))

[Slave 1]

[Slave 2]

[Slave 3]

[Slave n]

35Version: 1.2.1

Page 36

Profibus

Baud Rate Constant A (in ms) Constant B (in ms) TBYTE (in ms)

9.6 kBaud 64.5 25.6 1.15

19.2 kBaud 32.3 12.8 0.573

93.75 kBaud 6.6 2.62 0.118

187.5 kBaud 3.3 1.31 0.059

500 kBaud 1.6 0.49 0.022

1.5 MBaud 0.67 0.164 0.00733

3 MBaud 0.436 0.085 0.00367

6 MBaud 0.27 0.044 0.00183

12 MBaud 0.191 0.024 0.00092

K-Bus reaction time (K-Bus)

K-Bus reaction time (K-Bus)

The reaction time on the K-Bus (internal bus of the Compact Box) is determined by the shifting and saving of

the data. The following table contains measured values for typical structures. It is possible to scale the

calculation up for larger numbers.

Compact Box (numbers are for channels) Running time on the K-

bus

Digital OUT Digital IN Analog IN/OUT T_cycle (µs)

4 0 0 150

8 0 0 170

12 0 0 170

16 0 0 200

20 0 0 200

24 0 0 220

28 0 0 220

32 0 0 245

0 4 0 150

0 8 0 180

0 12 0 180

0 16 0 200

0 20 0 200

0 24 0 230

0 28 0 230

0 32 0 250

4 4 0 170

8 8 0 195

12 12 0 220

16 16 0 250

20 20 0 275

24 24 0 300

28 28 0 325

32 32 0 350

4 4 1 630

4 4 2 700

36 Version: 1.2.1

Page 37

Profibus

Note

For physical reasons, the K-Bus cycle is always at least about 90 µs. This means that the running or

cycle time of the whole system, and in particular the cycle time for the PLC task, must be greater

than the running time of the K-Bus cycle. If this is not the case, unstable conditions can arise in the

input and output terminals of the PROFIBUS slave.

IP-Link reaction time

IP-Link reaction time

The reaction time on the IP-Link is determined by the shifting and saving of the data. The following table

contains measured values for typical structures. It is possible to scale the calculation up for larger numbers.

Extension Boxes added to Coupler Boxes Running time on the IP-

Link

Digital OUT (bits) Digital IN (bits) Analog IN/OUT (chan-

nels)

24 16 0 420

48 16 0 450

24 16 4 1500

48 16 16 2360

48 16 28 3500

48 16 40 4000

T_cycle (µs)

The settings for the Process image updating function are found in byte 9 of the User_Prm_Data (default

settings are printed bold):

Bit no. Description is supported by

Bit 6 Updating of the process image

0: synchronous with cycle

1: free running

In TwinCAT the settings for the PROFIBUS synchronisation DP/K-Bus cycle can be transferred with

ADSRead and ADSWrite (ADS: Automation Device Specification). For this purpose they should be activated

in the User_Prm_Data.

The settings for the Process updating function are found in the TwinCAT System Manager on the PrmData

tab for the corresponding Busbox.

IP10xx, IP15xx; IP20xx, IP23xx,

IP25xx, IP31xx, IP41xx, IP50xx,

IP51xx, IP60xx

3.6.1.3 Auto-configuration data format

This parameter sets the representation format for the complex terminals. You may choose between Intel

[}38] and Motorola [}38] formats:

37Version: 1.2.1

Page 38

Profibus

• Under the Intel format, the less significant byte (low byte) of a data word is located at the lowest

address offset of the memory location.

• Under the Motorola format, the more significant byte (high byte) of a data word is located at the lowest

address offset of the memory location.

If you choose the Motorola format for digital terminals, then the two bytes transmitted, for instance, for 16

sequential digital channels, the high byte and the low byte will be swapped.

Representation in Intel format

Intel format

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Word 0 Word 2 Word 4

Word 1 Word 3

In terms of bit addresses, the result is:

High byte Low byte

1.7 1.6 1.5 1.4 1.3 1.2 1.1 1.0 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0

Byte 1 Byte 0

Representation in Motorola format

Motorola format

Byte 1 Byte 0 Byte 3 Byte 2 Byte 5 Byte 4

Word 0 Word 2 Word 4

In terms of bit addresses, the result is:

High byte Low byte

0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 1.7 1.6 1.5 1.4 1.3 1.2 1.1 1.0

Byte 0 Byte 1

Settings

The settings for the Data format auto-configuration function are found in byte 9 of the User_Prm_Data

(default settings are printed bold):

Bit no. Description is supported by

Bit 3 Auto-configuration data format

0: Intel

1: Motorola

IP15xx, IP25xx, IP31xx, IP41xx,

IP50xx, IP51xx, IP60xx

In TwinCAT the settings for the Data format auto-configuration can be transferred with ADSRead and

ADSWrite (ADS: Automation Device Specification). For this purpose they should be activated in the

User_Prm_Data.

The settings for the Data format auto-configuration function are found in the TwinCAT System Manager on

the PrmData tab for the corresponding Busbox.

38 Version: 1.2.1

Page 39

Profibus

3.6.1.4 Reaction to PROFIBUS errors

The reaction to a PROFIBUS error (e.g. the plug is pulled out, STOP of the DP master, etc.) can be set. The

possible reactions are:

• Stopping the K-Bus

• Resetting the outputs to 0

• Retaining the current output states

Note

In the Cycle is stopped setting, the signal states of the output terminals are identical to those under

the Outputs become 0 setting.

The settings for the Reaction to Profibus error function are found in byte 10 of the User_Prm_Data (default

settings are printed bold):

Bit no. Description is supported by

Bits 0/1 Reaction to Profibus errors

0: Cycle is stopped

1: Outputs become 0

2: Outputs remain the same

In TwinCAT the settings for the Reaction to PROFIBUSerror can be transferred with ADSRead and

ADSWrite (ADS: Automation Device Specification). For this purpose they should be activated in the

User_Prm_Data.

The settings for the Reaction to PROFIBUSerror function are found in the TwinCAT System Manager on the

"PrmData" tab for the corresponding Bus Coupler.

IP10xx, IP15xx, IP20xx, IP23xx,

IP25xx, IP31xx, IP41xx, IP50xx,

IP51xx, IP60xx

39Version: 1.2.1

Page 40

Profibus

3.6.1.5 Reaction to IP-Link Errors

The error reaction can be set for an IP-Link error (such as pulling out the plug). The possible reactions are:

• Data exchange is stopped.

• Profibus inputs become 0

• Profibus inputs are retained unchanged

The settings for the reaction to Profibus error function are found in byte 10 of the User_Prm_Data (default

settings are printed bold):

Byte Bit Description is supported by

10 2, 3 Reaction to Profibus

errors

0: Data exchange is

aborted

1: Inputs become 0

2: Inputs remain

unchanged

In TwinCAT the settings for the Reaction to IP-Link error can be transferred with ADSRead and ADSWrite

(ADS: Automation Device Specification). For this purpose they should be activated in the

User_Prm_Data.

IL230x-B3xx

The settings for the Reaction to IP-Link error function are found in the TwinCAT System Manager on the

"PrmData" tab for the corresponding Bus Coupler.

40 Version: 1.2.1

Page 41

Profibus

3.6.2 Parameter Data

3.6.2.1 IPxxxx-B31x - User Parameters

Data format

Data format [}37]

Auto configuration (only applies to all complex devices, not necessary for digital devices)

Complex terminal data can be represented in either Intel or Motorola format, although controllers generally

expect the data to be in Motorola format.

Example:

In Motorola format, an analog value from an IP3312-Bxxx is shown as 0x0016. In Intel format, the high and

low bytes are exchanged, yielding 0x1600.

Updating of the process image

Updating of the process image [}33]

• Synchronous with the cycle means that the data are triggered in synchronism with the PROFIBUS

image. If a PROFIBUS telegram reaches the slave, the slave copies the data into the ASIC after the

answer telegram has been sent. The outputs are written immediately.

• Free running means that the data is fetched and copied into the ASIC, and that this is repeated

continuously.

Free running can be used when it is necessary to transfer the input data as fast as possible to the controller.

The disadvantage of this is that the data is not free from jitter. If fast outputs are needed, or if it is necessary

for the inputs to be jitter-free (e.g. for fast controllers) then cyclic transmission should be selected.

Reaction to PROFIBUS errors

Reaction to PROFIBUS errors [}39]

• Cycle is stopped. The internal data process is stopped, and the watchdog (WD) for the channels

(usually 100 ms) triggers.

• Outputs become 0. Zero is written to all the outputs in a defined manner.

• Outputs remain the same. The most recently received PROFIBUS telegram and its output data is

retained. A switched output, e.g. at a IP4112 with 12 ms, is retained as long as it takes to reconstruct

the PROFIBUS cycle and a new value is transmitted via the process data.

3.6.2.2 User parameters for the Coupler Box Modules (IL230x-B31x)

DPV1 Services

The DPV1 services can be activated or deactivated here. Default: Not active (see DPV1 services [}31]).

Behavior in the event of an IP-Link error

The IP-Link can start up again of its own accord once an IP-Link error (such as a cable break) has been

corrected. Warning: PROFIBUS data communication begins once more, and outputs are written again. The

user must ensure that undesirable outputs are not written in such a case. Default: Manual reset.

41Version: 1.2.1

Page 42

Profibus

Fieldbus Box Diagnostics

The diagnostic data can be activated here. Default: Not active (see Diagnostics for the Compact Box or

Diagnostics for the Coupler Box).

Byte 7, bit 1:

- True activated

- False deactivated

Data format

Data that is 2 bytes in size can be transmitted either in Intel or in Motorola format. The high byte and the low

byte are swapped. Default: Motorola.

Updating process data

The IP-Link can be triggered in synchronism with PROFIBUS , or can be allowed to run free. Default: Free

running (see Updating process data [}33]).

Reaction to PROFIBUS errors

This describes the behavior of the slave in the presence of a PROFIBUS error (such as a faulty cable).

Default: The IP-Link cycle is abandoned

• The IP-Link cycle is abandoned, which means that the extension module's watchdog will trigger after

100 ms, and the outputs will be switched into a safe condition

• The IP-Link master writes a 0 to the outputs

• The outputs remain frozen in their last state

Reaction to IP-Link errors

This describes the behavior of the slave in the presence of an IP-Link error (such as a faulty cable). Default:

DataExchange is abandoned

• DataExchange is abandoned, which means that the slave halts the PROFIBUS communication.

• DP inputs become 0 - A zero is written to the inputs

• DP inputs are retained - The inputs retain their most recent valid state

IL/IE Byte Alignment )

1

This allows all the IL/IE23xx modules with 4 bit input/outputs to be rounded to a byte.

Byte 10 bit 5 Default "0"

1 All the IE23xx modules are mapped with eight bits. In fact the inputs from 0..3 are sufficient (4..7 are not

used), as are the outputs from bits 4..7 (0..3 are not used).

0 All IE23xx modules are mapped with four inputs and four outputs (default)

)1Firmware update is possible for the IL modules from software version 1 D:xxxx1xxx.

3.6.2.3 IL230x-C3xx - User Parameters

Copy the fieldbus and IP-Link status into the allocated flags area

Byte 13, bit 5

1 is copied into the region %MB408-411 (default)

0 is not copied into the region %MB408-411

Saving the modules when creating the boot project

Byte 13, bit 6

1 is checked (default)

0 is not checked

42 Version: 1.2.1

Page 43

Profibus

Copy the cycle tick counter into the allocated flags area

Byte 12, bit 0

1 is copied into the region %MB404-407 (default)

0 is not copied into the region %MB404-407

Reaction to Breakpoints

Byte 12, bit 1

1 Outputs are written as zero

0 Outputs remain unchanged (default)

3.6.2.4 Module-specific Parameter Data

User parameters for Compact Box Modules (IP3xxx-B310)

The module-specific parameter data can be used as from version D.xxxx3xxx.

Your software can be updated if the hardware version is D.xxxxx8xx or above. Please contact Support for

this purpose.

IP3102-B310

- Overflow offset (can be set individually for each channel)

- Set and activate limit values (can be set individually for each channel)

IP3112-B310

- Overflow offset (can be set individually for each channel)

- Set and activate limit values(can be set individually for each channel)

- Input current range(can be set individually for each channel): 0...20mAor4...20mA

IP3202-B310

- Set PT elements(can be set individually for each channel)

- Two/three/four wire connection(can be set individually for each channel)

- Over-range protection(can be set individually for each channel)

IP3312-B310

- Adjust thermocouple (can be set individually for each channel)

- Cold junction compensation(can be set individually for each channel):

- Over-range protection(can be set individually for each channel)

User parameters for Compact Box Modules IP4xxx-B310

The module-specific parameter data can be used as from version D.xxxx3xxx.

Your software can be updated if the hardware version is D.xxxxx8xx or above. Please contact Support for

this purpose.

IP4112-B310

- Output current range (can only be set jointly for all channels): 0...20mAor4...20mA

- Watchdog(can be set individually for each channel)

IP4132-B310