Page 1

Documentation | EN

Fieldbus Box I/O-Modules

Signal Types, Installation and Configuration

2013-11-28 | Version: 2.0.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................7

1.1 Notes on the documentation..............................................................................................................7

1.2 Safety instructions .............................................................................................................................8

1.3 Documentation Issue Status..............................................................................................................9

2 System Overview.....................................................................................................................................11

2.1 The Fieldbus Box System................................................................................................................11

2.2 Fieldbus Box - Naming conventions ................................................................................................13

2.3 Firmware and hardware issue status...............................................................................................15

3 I/O-Modules ..............................................................................................................................................16

3.1 Module Descriptions ........................................................................................................................16

3.1.1 Digital Input Modules ....................................................................................................... 16

3.1.2 Digital Output Modules .................................................................................................... 20

3.1.3 Digital Combi Modules..................................................................................................... 28

3.1.4 Analog Input Modules ...................................................................................................... 40

3.1.5 Analog Output Modules ................................................................................................... 48

3.1.6 Modules for Special Functions......................................................................................... 52

3.1.7 Gateway Modules ............................................................................................................ 62

3.2 Mounting..........................................................................................................................................68

3.2.1 Dimensions ...................................................................................................................... 68

3.2.2 Fixing ............................................................................................................................... 69

3.3 Cabling ............................................................................................................................................72

3.3.1 Nut torque for connectors ................................................................................................ 72

3.3.2 Power Supply................................................................................................................... 73

3.3.3 IP-Link.............................................................................................................................. 81

3.3.4 Signal Connection............................................................................................................ 96

3.3.5 ZS2001 KM connectors ................................................................................................. 125

3.4 Block Diagrams .............................................................................................................................127

3.4.1 Overview of the Block Diagrams.................................................................................... 127

3.4.2 IP/IE1xxx Block Diagram ............................................................................................... 128

3.4.3 IP/IE1502 Block Diagram............................................................................................... 129

3.4.4 IP/IE20xx Block Diagram ............................................................................................... 130

3.4.5 IP/IE23xx Block Diagram ............................................................................................... 131

3.4.6 IP/IE2400, IP/IE2401 Block Diagram............................................................................. 132

3.4.7 IE2403 Block Diagram ................................................................................................... 133

3.4.8 IP/IE2512 Block Diagram............................................................................................... 134

3.4.9 IE2808 Block Diagram ................................................................................................... 135

3.4.10 IP/IE3102 Block Diagram............................................................................................... 137

3.4.11 IP/IE3112 Block Diagram............................................................................................... 138

3.4.12 IP/IE3202 Block Diagram............................................................................................... 139

3.4.13 IP/IE3312 Block Diagram............................................................................................... 140

3.4.14 IP/IE4112 Block Diagram............................................................................................... 141

3.4.15 IP/IE4132 Block Diagram............................................................................................... 142

3.4.16 IP/IE5009 Block Diagram............................................................................................... 143

3.4.17 IP/IE5109 Block Diagram............................................................................................... 144

Fieldbus Box I/O-Modules 3Version: 2.0.0

Page 4

Table of contents

3.4.18 IP/IE5209 Block Diagram............................................................................................... 145

3.4.19 IP/IE6002 Block Diagram............................................................................................... 146

3.4.20 IP/IE6012 Block Diagram............................................................................................... 147

3.4.21 IP/IE6022 Block Diagram............................................................................................... 148

3.5 Mapping of the Fieldbus Box Modules ..........................................................................................149

3.5.1 IP/IE10xx Mapping......................................................................................................... 150

3.5.2 IP/IE1502 Mapping ........................................................................................................ 151

3.5.3 IP/IE20xx Mapping......................................................................................................... 153

3.5.4 IP/IE23xx Mapping......................................................................................................... 154

3.5.5 IP/IE240x Mapping ........................................................................................................ 155

3.5.6 IP/IE2512 Mapping ........................................................................................................ 156

3.5.7 IE2808 Mapping............................................................................................................. 158

3.5.8 IP/IE3102 Mapping ........................................................................................................ 159

3.5.9 IP/IE3112 Mapping ........................................................................................................ 161

3.5.10 IP/IE3202, KL3204 Mapping.......................................................................................... 163

3.5.11 IP/IE3312, KL3314 Mapping.......................................................................................... 165

3.5.12 IP/IE4112 Mapping ........................................................................................................ 167

3.5.13 IP/IE4132, KL4132 Mapping.......................................................................................... 169

3.5.14 IP/IE5009 Mapping ........................................................................................................ 171

3.5.15 IP/IE5109 Mapping ........................................................................................................ 173

3.5.16 IP5209 Mapping............................................................................................................. 175

3.5.17 IP/IE60x2 Mapping ........................................................................................................ 177

3.6 Set-Up the intelligent Modules.......................................................................................................178

3.6.1 Register Communication ............................................................................................... 178

3.6.2 IP/IE1502 ....................................................................................................................... 183

3.6.3 IP/IE2512 ....................................................................................................................... 191

3.6.4 IE2808 ........................................................................................................................... 200

3.6.5 IP/IE3102 ....................................................................................................................... 206

3.6.6 IP/IE3112 ....................................................................................................................... 213

3.6.7 IP/IE3202 ....................................................................................................................... 219

3.6.8 IP/IE3312 ....................................................................................................................... 228

3.6.9 IP/IE4112 ....................................................................................................................... 236

3.6.10 IP/IE4132 ....................................................................................................................... 241

3.6.11 IP/IE5009 ....................................................................................................................... 246

3.6.12 IP/IE5109 ....................................................................................................................... 251

3.6.13 IP5209 ........................................................................................................................... 257

3.6.14 IP/IE60x2 ....................................................................................................................... 264

4 Diagnostics ............................................................................................................................................278

4.1 Signal behavior at Bus Error..........................................................................................................278

4.2 Diagnostic LEDs ............................................................................................................................279

4.3 Diagnostic LEDs for local errors ....................................................................................................280

5 Fieldbus Box accessories ....................................................................................................................282

5.1 Accessories ...................................................................................................................................282

5.2 Power cables .................................................................................................................................284

5.3 Third-party Products ......................................................................................................................285

Fieldbus Box I/O-Modules4 Version: 2.0.0

Page 5

Table of contents

6 Appendix ................................................................................................................................................288

6.1 Custom Scaling .............................................................................................................................288

6.2 General operating conditions.........................................................................................................289

6.3 Approvals.......................................................................................................................................291

6.4 UL Requirements...........................................................................................................................292

6.5 Test standards for device testing...................................................................................................293

6.6 Support and Service ......................................................................................................................294

Fieldbus Box I/O-Modules 5Version: 2.0.0

Page 6

Table of contents

Fieldbus Box I/O-Modules6 Version: 2.0.0

Page 7

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

Fieldbus Box I/O-Modules 7Version: 2.0.0

Page 8

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

Fieldbus Box I/O-Modules8 Version: 2.0.0

Page 9

1.3 Documentation Issue Status

Requirements

Foreword

Fieldbus Box I/O-Modules 9Version: 2.0.0

Page 10

Foreword

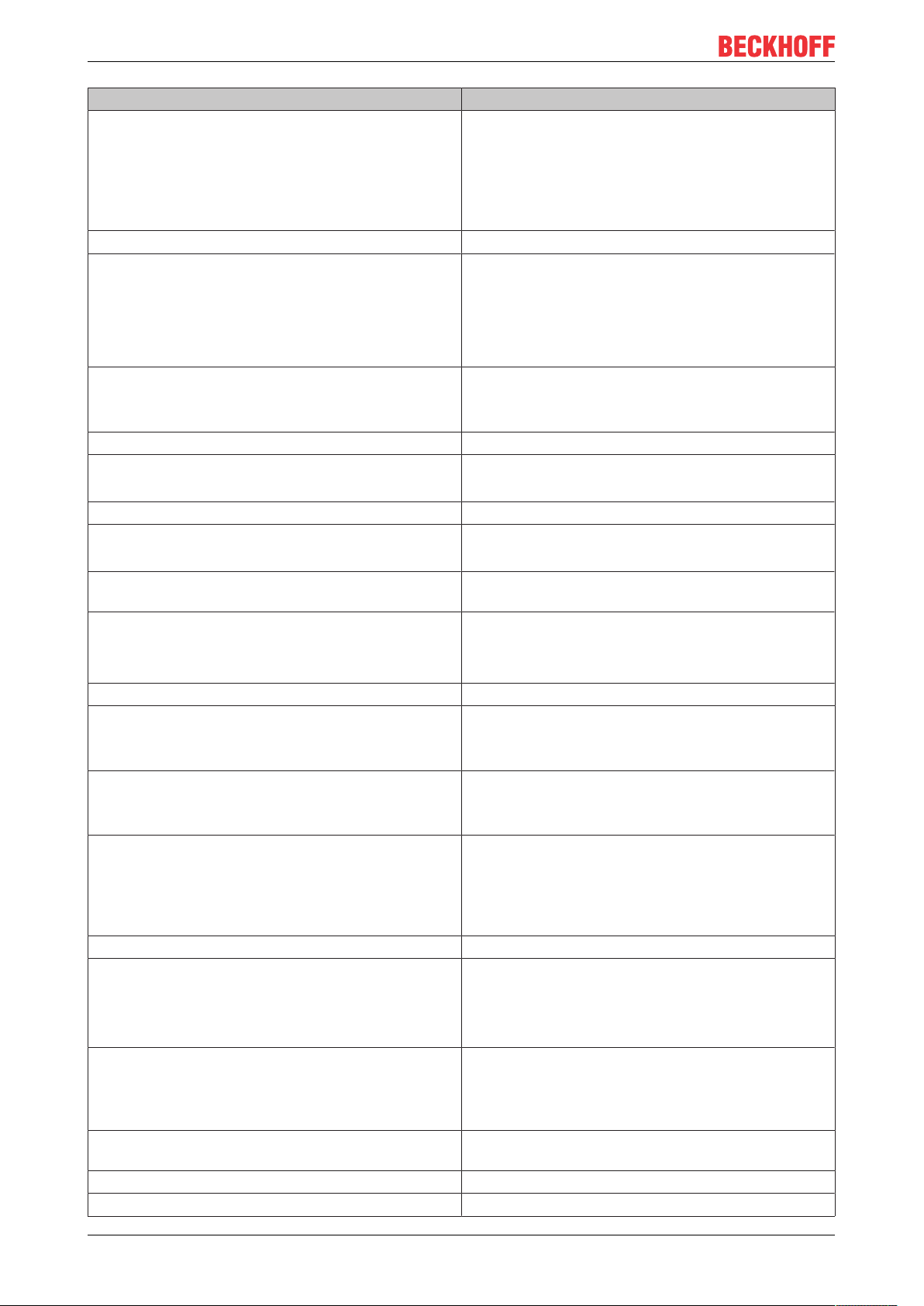

Version Comment

2.0.0 • UL notes extended

• Nut torque for connectors added

• Accessories extended

• Technical data updated

• IP-Link LED diagnostic display updated

1.9.1 • System overview updated

1.9.0 • Introduction and signal Connection of IE2808

updated

• Special type IE2808-0001 added

• Block diagram of IP/IE5109 updated

• Mounting instructions for ZS1022 added

1.8.1 • Mapping of IP5209 corrected

• Description of feature registers for IP/IE3312

updated

1.8.0 • Extension Box IE2403added

1.7.4 • IL230x-B110 added at the dimensions chapter

• Third party products chapter updated

1.7.3 • Mapping of IE2808 corrected

1.7.2 • Technical Data of IE2808 updated

• Block diagram of IE2808 corrected

1.7.1 • IP/IE1502, Gate-Input is mapped to the StatusByte

1.7.0 • Extension Box IE2808 added

• Mounting Rail ZS5300-0001 added

• IP-Link Direct Connector added

1.6.2 • Diagnostic Chapter enhanced

1.6.1 • Technical Data of Fieldbus Box Modules updated

• Minor routine corrections (typing errors,

orthography etc.)

1.6.0 • Register settings IP/IE5009 corrected

• Minor routine corrections (typing errors,

orthography etc.)

1.5 • Numbering of channels at the mapping

descriptions adapted to display in TwinCAT and

KS2000

• Minor routine corrections (typing errors,

orthography etc.)

1.4 • Description of the mappings extended for Ethernet

1.3 • Expanding of the specification for IP-Link up to 15

meters

• Chapter about IP-Link completed and over-worked

• Description of IP/IE3202 register settings corrected

1.2 • Description of control und status bytes for all

modules over-worked

• Description of mappings and configuration for the

IP/IE2512 and IP/IE5009 modules updated

1.1 • Description of the mappings adapted to the view of

the registers in KS2000 Configuration Software

1.0 • more Fieldbus Box Modules added

0.8 • first preliminary Version

Fieldbus Box I/O-Modules10 Version: 2.0.0

Page 11

System Overview

2 System Overview

2.1 The Fieldbus Box System

Fieldbus box modules are robust fieldbus stations for a large number of different fieldbus systems. They offer

a wide range of I/O functionality. All relevant industrial signals are supported. As well as digital and analog

inputs and outputs including thermocouple and RTD inputs, there are also incremental encoder interfaces

available for displacement and angle measurement as well as serial interfaces to solve a large number of

communications tasks.

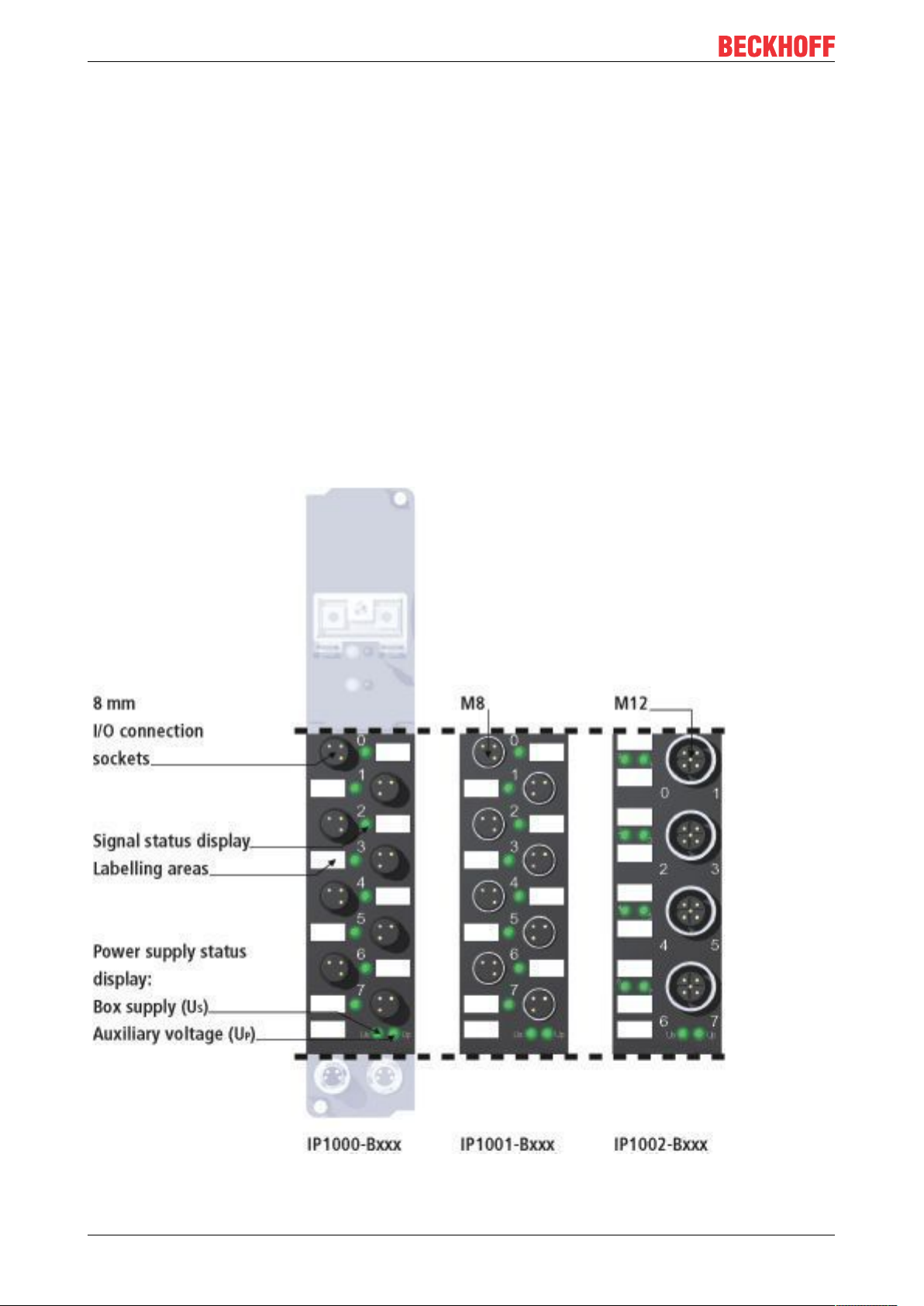

Three varieties of signal connection

The digital inputs and outputs can be connected with snap-on 8mm diameter plugs, screw-in M8

connectors, or with screw-in M12 pendants. The M12 version is provided for analog signals.

All important signal types

Special input and output channels on the combination I/O modules can be used for either input or output. It is

not necessary to configure them, since the fieldbus interface is available for every combination channel as

well as for input and output data. The combination modules give the user all of the advantages of fine signal

granularity.

The processor logic, the input circuitry and the power supply for the sensor are all fed from the control

voltage. The load voltage for the outputs can be supplied separately. In those Fieldbus Boxes in which only

inputs are available, the load power supply, UP, can optionally be connected in order to pass it on

downstream.

The states of the Fieldbus Box, the fieldbus connection, the power supplies and of the signals are indicated

by LEDs.

The label strips can be machine printed elsewhere, and then inserted.

Fieldbus Boxes can be combined for greater flexibility

In addition to the Compact Box, the Fieldbus Box series also includes extendable devices, namely the

Coupler Box and the Extension Box, as well as intelligent devices, the PLC Boxes.

Compact Box

The Compact Box makes the I/O data from the connected digital and analog sensors and actuators available

to the fieldbus.

Coupler Box

The Coupler Box also collects I/O data from the Extension Boxes via an interference-proof optical fiber

connection (IP-Link). Up to 120 Extension Boxes can be connected to a Coupler Box. In this way a

distributed IP67 I/O network is formed with only one fieldbus interface.

The Coupler Box is capable of automatically recognizing the extension modules connected to it during startup, and maps the I/O data automatically into the fieldbus process image – a configuration is not necessary.

The Coupler Box appears, from the fieldbus point of view, along with all of the networked Extension Boxes,

as a single participating bus device with a corresponding number of I/O signals.

The Coupler Box corresponds to the Bus Coupler in the BECKHOFF Bus Terminal system. BECKHOFF

fieldbus devices made to protection class IP 20 (Bus Terminals) and IP 67 (Fieldbus Box) can be combined

without difficulty – the data is handled in the same way in either case.

Fieldbus Box I/O-Modules 11Version: 2.0.0

Page 12

System Overview

IP-Link

The IP-Link is an optical fiber connection with a transmission rate of 2 MBits/s which is capable of

transmitting 1000 items of binary I/O data in approx. 1 ms, rapidly and securely. Smaller configurations are

correspondingly faster. Because of the high usable data rate, the coupling via IP-Link does not reduce the

performance of the fieldbus at all.

Low-priced plug connectors made according to Protection Class IP67 can be used for the rapid and simple

preparation of the IP-Link cable, in situ. The connection does not require special tools, and can be performed

quickly and simply. The IP-Link cables can also be obtained with prepared plugs if required.

The separate supply of the output voltage allows output groups to be switched off individually. Differing

potentials can also be created within an extension ring without difficulty, since the IP-Link naturally has

optimum electrical isolation.

Extension box

Like the Compact Boxes, the Extension Boxes cover the full spectrum of I/O signals, and may be up to 15m

apart. They are remarkably small in size, and lead to particularly economical I/O solutions with high levels of

protection. Here again, the digital inputs and outputs may optionally be connected via snap-on 8 mm

connectors, or via screw-in connectors (M8 and M12). Analog signal types are provided with the M12

version. The snap-on connectors lock in place positively, forming a shake-proof connection, while the screwin connectors offer the advantage of high resistance to being pulled out.

PLC Box

The PLC Box is an intelligent Fieldbus Box with PLC functionality for distributed pre-processing of the I/O

signals. This allows parts of the application to be farmed out from the central controller. This reduces the

load on the CPU and the fieldbus. Distributed counting, controlling and switching are typical applications for

the PLC Box. The reaction times are independent of the bus communication and of the higher-level

controller.

In the event of a bus or controller failure, maintenance of function (e.g. bringing the process to a safe state in

an orderly manner) is possible.

Programming is carried out with TwinCAT in accordance with IEC 61131-3. Five different programming

languages are available:

• Instruction List (IL)

• Function Block Diagram (FBD)

• Ladder Diagram (LD)

• Sequential Function Chart (SFC)

• Structured Text (ST)

The program download occurs either via the fieldbus or via the programming interface.

Extensive debugging functions (breakpoint, single step, monitoring, etc) are also available. The PLC Box

contains a powerful 16 bit controller, 32/96 kByte program memory and 32/64 kByte data memory. A further

512 bytes of non-volatile memory are available for remanent flags.

PLC Box with IP-Link

The programmable PLC Box with IP-Link provides almost unlimited I/O possibilities. Up to 120 extension

modules, with more than 2000 I/Os, can be directly addressed from the PLC program. The PLC Box is thus

also suitable for use as a small, autonomous controller for the operation of parts of equipment or small

machines.

Fieldbus Box I/O-Modules12 Version: 2.0.0

Page 13

2.2 Fieldbus Box - Naming conventions

The identifications of the Fieldbus Box modules are to be understood as follows:

IXxxxy-zyyy

IX describes the design:

"IP" stands for the CompactBox design [}14]

"IL" stands for the CouplerBox design (with IP-Link) [}14]

"IE" stands for the ExtensionBox design [}14]

xxxy describes the I/O connection:

xxx describes the I/O property:

"10x" - 8 x digital inputs

"15x" - counter module

"20x" - 8 x digital outputs

"25x" - PWM module

"23x" - 4 x digital inputs and 4 x digital outputs

"24x" - 8 x digital inputs and 8 x digital outputs

"3xx" - 4 x analog inputs

"4xx" - 4 x analog outputs

"5xx" - incremental encoder or SSI transducer

"6xx" - Gateway module for RS232, RS422, RS485, TTY

System Overview

y represents the mechanical connection:

"0" stands for 8mm snap-on connection,

"1" stands for M8 bolted connection

"2" stands for M12 bolted connection and

"9" stands for M23 bolted connection

zyyy describes the programmability and the fieldbus system

z distinguishes whether the device is a slave or is a programmable slave:

"B" - not programmable

"C" - programmable (PLC Box)

"yyy" stands for the fieldbus system and the bus connection:

"110" - EtherCAT

"200" - Lightbus

"310" - PROFIBUS

"318" - PROFIBUS with integrated tee-connector

"400" - Interbus

"510" - CANopen

"518" - CANopen with integrated tee-connector

"520" - DeviceNet

"528" - DeviceNet with integrated tee-connector

"730" - Modbus

"800" - RS485

"810" - RS232

"900" - Ethernet TCP/IP with RJ45 for the bus connection

"901" - Ethernet TCP/IP with M12 for the bus connection

"903" - PROFINET

"905" - EtherNet/IP

Fieldbus Box I/O-Modules 13Version: 2.0.0

Page 14

System Overview

Compact Box

Compact Box

The Compact Box modules offer a wide range of I/O functionality. All relevant industrial signals are

supported. The digital inputs and outputs can be connected either with snap-on 8mm diameter plugs, screwin M8 connectors, or screw-in M12 connectors. The M12 version is made available for analog signals.

Depending on the module, the I/O section and the power supply section can differ.

Coupler Box

Coupler Box

There are three versions of the coupler box named IL230x-Bxxx. It differs from the compact box in that this

module offers an interface to what are known as extension boxes. This interface is a subsidiary bus system

based on the optical fiber what is known as IPLink. This powerful subsidiary bus system can handle up to

120 extension boxes at one coupler box.

Extension Box

Extension Box

Extension Modules, that are independent of the fieldbus and that can only be operated together with a

coupler box via IPLink.

PLC Box

PLC Box

A PLC Box differ from the Coupler Box in that this module can be programmed in IEC 61131-3. This means

that this slave is also capable of working autonomously, without a master, for instance for control or

regulation tasks.

Also see about this

2 Fieldbus Box - Naming conventions [}14]

Fieldbus Box I/O-Modules14 Version: 2.0.0

Page 15

System Overview

2.3 Firmware and hardware issue status

The documentation refers to the hardware and software status that was valid at the time it was prepared.

The properties are subject to continuous development and improvement. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. Existing properties, however,

are always retained and are not changed, so that these modules can always be replaced by new ones.

The number beginning with a D allows you to recognize the firmware and hardware status of a module.

Syntax:

D.wwyyxyzu

ww - calendar week

yy - year

x - bus board firmware status

y - bus board hardware status

z - I/O board firmware status

u - I/O board hardware status

Example:

D.22081501

- Calendar week 22

- in the year 2008

- bus board firmware status: 1

- bus board firmware hardware status: 5

- I/O board firmware status: 0 (no firmware is necessary for this board)

- I/O board hardware status: 1

Fieldbus Box I/O-Modules 15Version: 2.0.0

Page 16

I/O-Modules

3 I/O-Modules

3.1 Module Descriptions

3.1.1 Digital Input Modules

3.1.1.1 IP100x-Bxxx, IE100x

8 Channel Digital Input (Filter 3.0 ms) 24 V

The IP100x digital input modules acquire the binary control signals from the process level and transmit them

to the higher-level automation unit. The state of the signals is indicated by light emitting diodes. The signals

are optionally connected via 8mm snap-in plugs (IP1000), screw-in M8 connectors (IP1001) or screw-in M12

connectors (IP1002). The sensors are supplied from the control voltage US. The load voltage UP is not used

in the input module, but may be connected in order to be relayed downstream.

DC

Fieldbus Box I/O-Modules16 Version: 2.0.0

Page 17

I/O-Modules

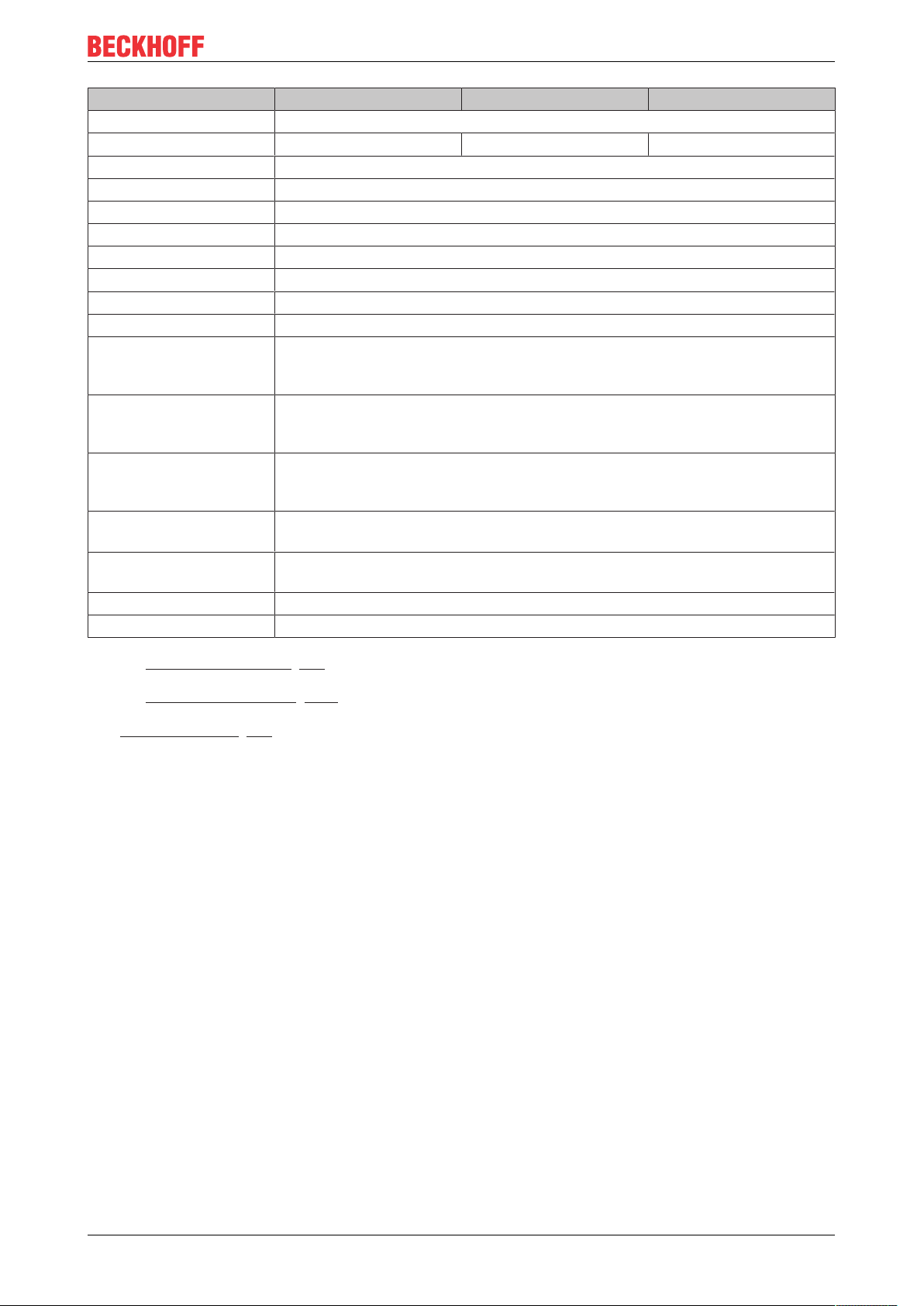

Technical data IP1000-Bxxx, IE1000 IP1001-Bxxx, IE1001 IP1002-Bxxx, IE1002

Number of inputs 8

Input connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 3.0 ms

Nominal input voltage 24 VDC (20 V... 29 V)

Signal voltage '0' -3 V... 5 V (EN61131-2, type 2)

Signal voltage '1' 11 V... 30 V (EN61131-2, type 2)

Input current typical 6 mA (EN61131-2, type 2)

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 8 bits input

Electrical isolation control voltage / fieldbus: yes

channels / control voltage: no

between the channels: no

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}96] for the connector pin assignment.

See the mapping description [}150] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 17Version: 2.0.0

Page 18

I/O-Modules

3.1.1.2 IP101x-Bxxx, IE101x

8 Channel Digital Input 24 VDC, Filter 0.2 ms

The IP101x digital input modules acquire the binary control signals from the process level and transmit them

to the higher-level automation unit. The state of the signals is indicated by light emitting diodes. The signals

are optionally connected via 8mm snap-in plugs (IP1010), screw-in M8 connectors (IP1011) or screw-in M12

connectors (IP1012). The sensors are supplied from the control voltage US. The load voltage UP is not used

in the input module, but may be connected in order to be relayed downstream.

Fieldbus Box I/O-Modules18 Version: 2.0.0

Page 19

I/O-Modules

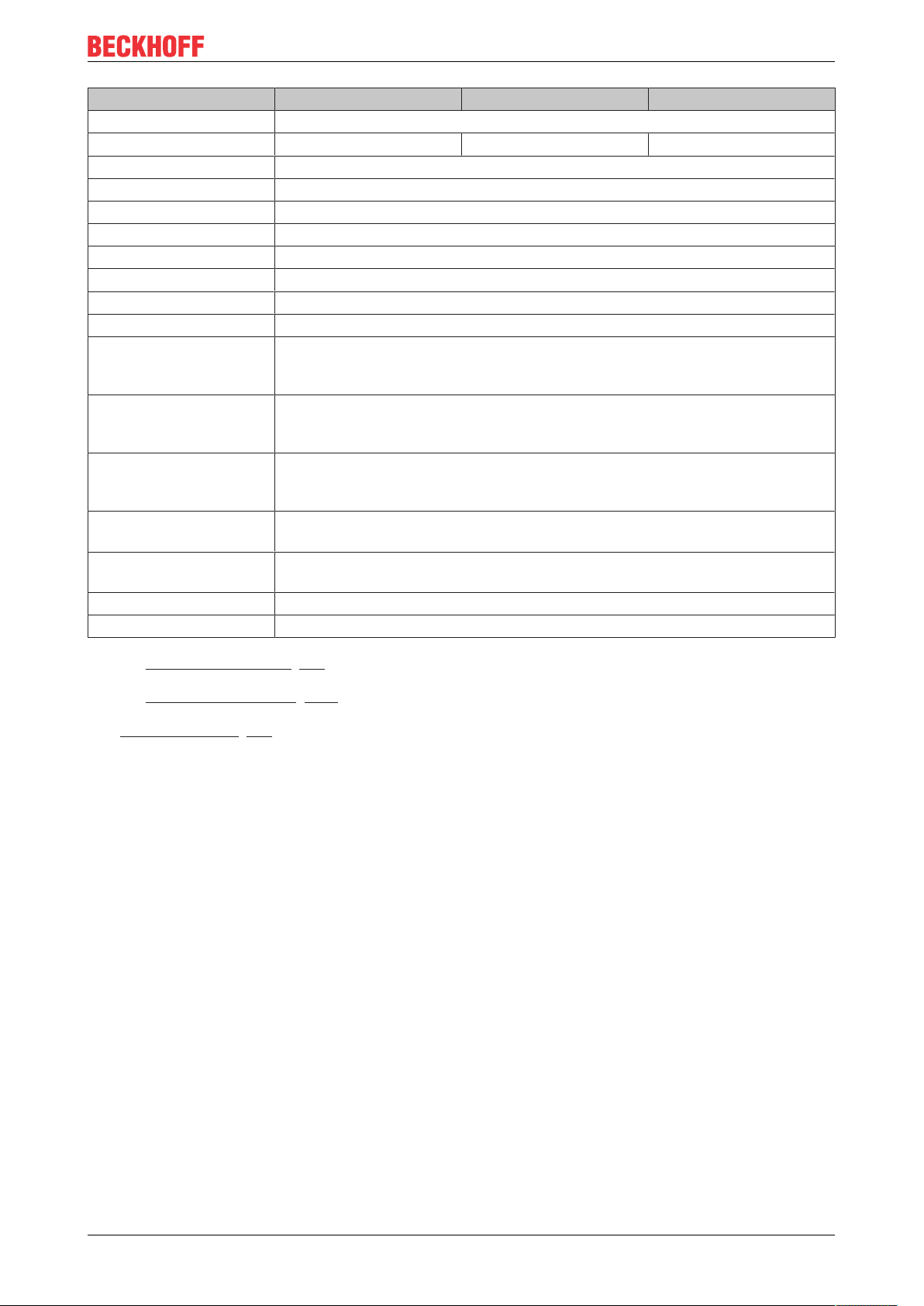

Technical data IP1010-Bxxx / IE1010 IP1011-Bxxx / IE1011 IP1012-Bxxx / IE1012

Number of inputs 8

Input connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 0.2 ms

Nominal input voltage 24 VDC (20 V... 29 V)

Signal voltage '0' -3 V... 5 V (EN61131-2, type 2)

Signal voltage '1' 11 V... 30 V (EN61131-2, type 2)

Input current typical 6 mA (EN61131-2, type 2)

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 8 bits input

Electrical isolation control voltage / fieldbus: yes

channels / control voltage: no

between the channels: no

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}97] for the connector pin assignment.

See the mapping description [}150] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 19Version: 2.0.0

Page 20

I/O-Modules

3.1.2 Digital Output Modules

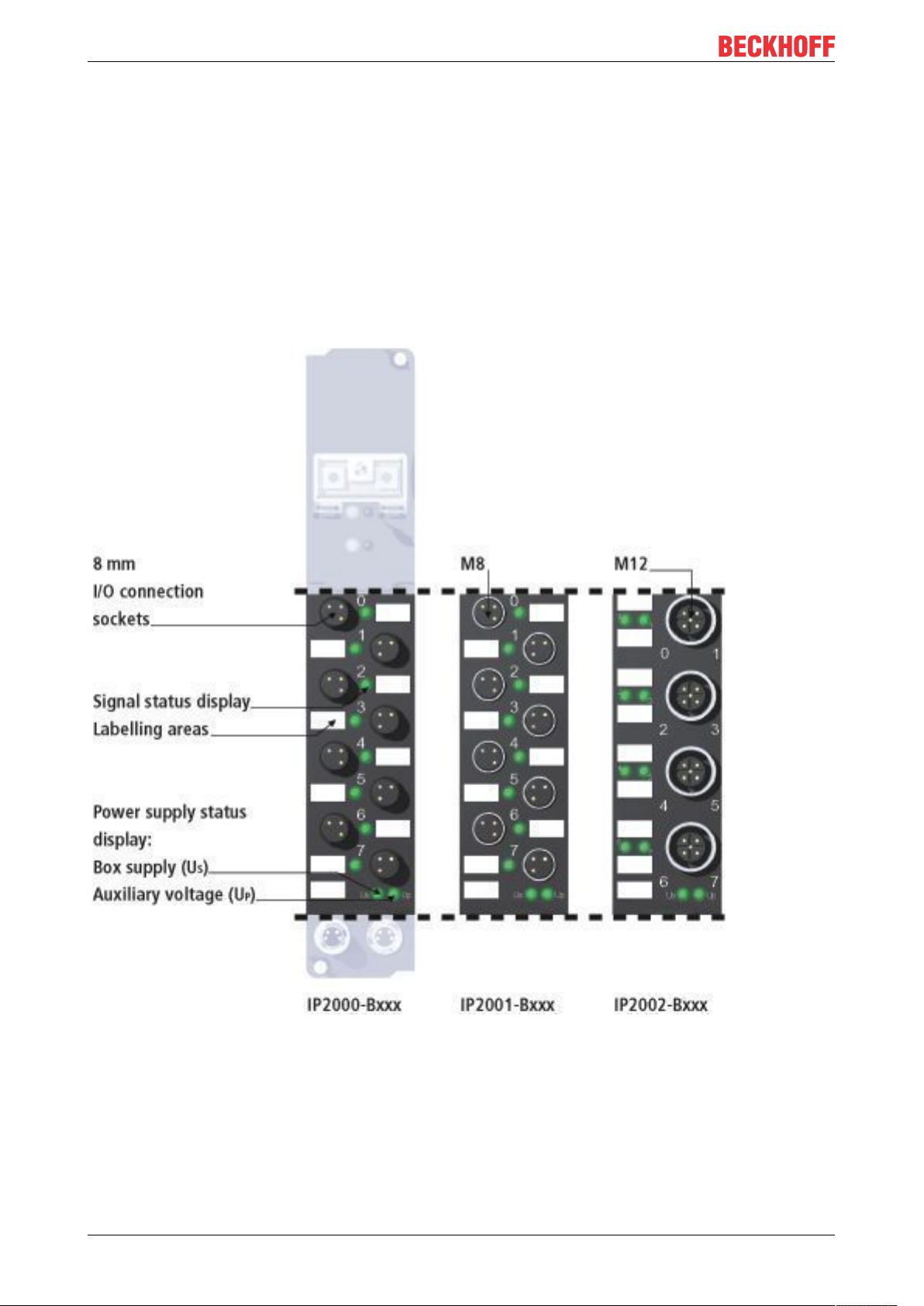

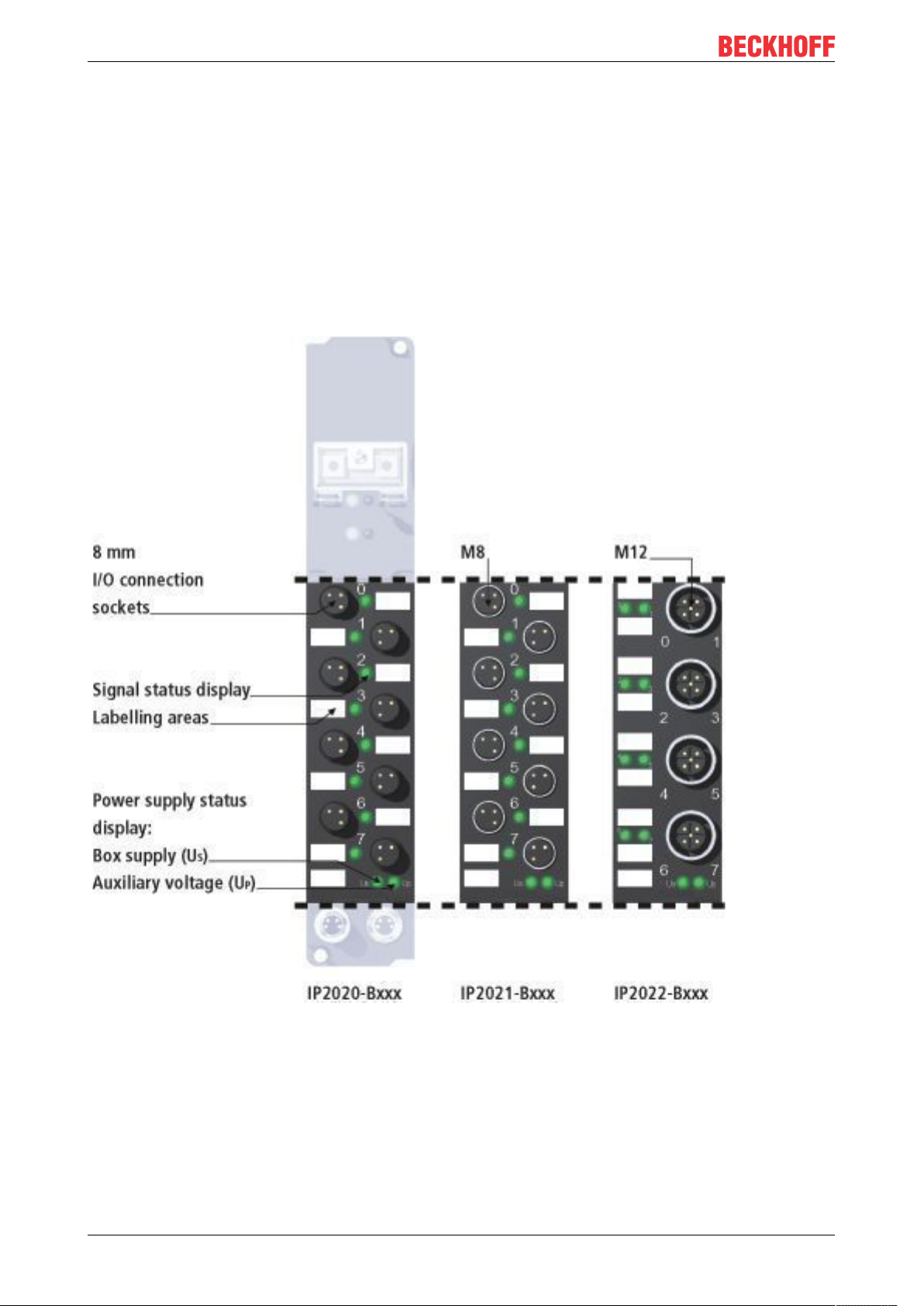

3.1.2.1 IP200x-Bxxx, IE200x

8 Channel Digital Output 24VDC, I

The IP200x digital output modules connect the binary control signals from the automation unit on to the

actuators at the process level. The 8 outputs handle load currents of up to 0.5A, and indicate their status

through light emitting diodes. The signals are optionally connected via 8mm snap-in plugs (IP2000), screwin M8 connectors (IP2001) or screw-in M12 connectors (IP2002). The outputs are short-circuit proof and

protected against inverse connection.

=0.5A

max

Fieldbus Box I/O-Modules20 Version: 2.0.0

Page 21

I/O-Modules

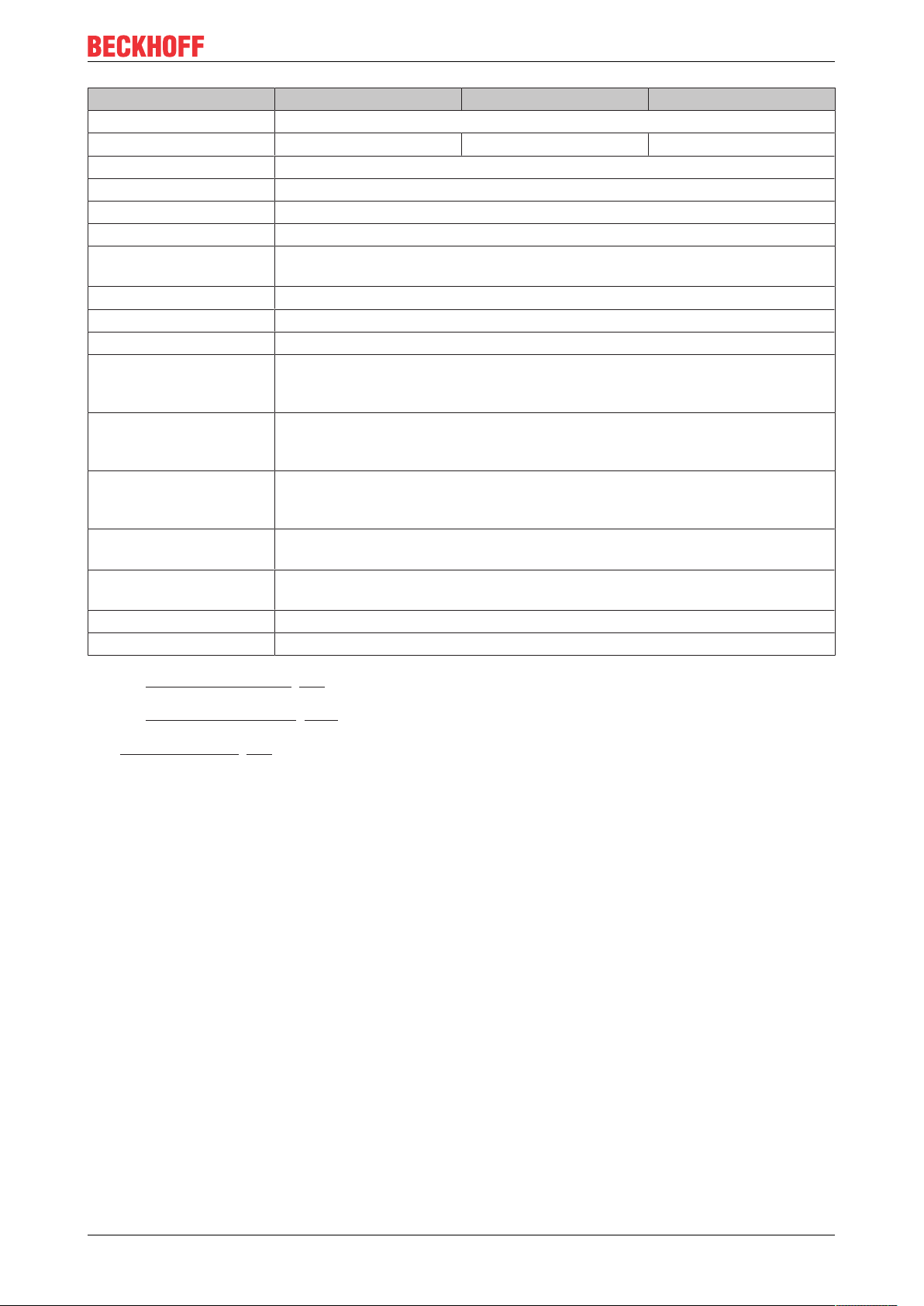

Technical data IP2000-Bxxx / IE2000 IP2001-Bxxx / IE2001 IP2002-Bxxx / IE2002

Number of outputs 8

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Load type ohmic, inductive, lamp load

Nominal voltage 24 VDC (20 V ... 29 V)

Output current max. 0.5 A on each channel, individually short-circuit proof

Short circuit current typical 1.5 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 8 bits output

Electrical isolation control voltage/ fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 20mA per channel

channels / control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}99] for details of the connection.

See the mapping description [}153] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 21Version: 2.0.0

Page 22

I/O-Modules

3.1.2.2 IP202x-Bxxx, IE202x

8 Channel Digital Output 24VDC, I

=2.0 A (total current max. 4 A)

max

The IP202x digital output modules connect the binary control signals from the automation unit on to the

actuators at the process level. The 8 outputs handle load currents of up to 2 A each, although the total

current is limited to 4A. This makes these modules particularly suitable for applications in which not all of the

outputs are active at the same time, or in which not all of the actuators draw 2A signal current. The signal

state is indicated by means of light emitting diodes.

The signals are optionally connected via 8mm snap-in plugs (IP2020), screw-in M8 connectors (IP2021) or

screw-in M12 connectors (IP2022). The outputs are short-circuit proof and protected against inverse

connection.

Fieldbus Box I/O-Modules22 Version: 2.0.0

Page 23

I/O-Modules

Technical data IP2020-Bxxx / IE2020 IP2021-Bxxx / IE2021 IP2022-Bxxx / IE2022

Number of outputs 8

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Load type ohmic, inductive, lamp load

Nominal voltage 24 VDC (20 V... 29 V)

Output current max. 2.0 A each channel, individually short-circuit proof, total current max. 4 A

Short circuit current typical 4.0 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 8 bits output

Electrical isolation control voltage / fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 30 mA per channel

channels / control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}100] for details of the connection.

See the mapping description [}153] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 23Version: 2.0.0

Page 24

I/O-Modules

3.1.2.3 IP204x-Bxxx, IE204x

8 Channel Digital Output 24 VDC, I

= 2.0 A (total current max. 12 A)

max

The IP204x digital output modules connect the binary control signals from the automation unit on to the

actuators at the process level. The 8 outputs handle load currents of up to 2A each, although the total

current is limited to 12 A. The outputs are supplied by three load circuits; for this reason these modules do

not relay the supply voltage. The signal state is indicated by means of light emitting diodes. The signals are

optionally connected via 8 mm snap-on plugs (IP2040), screw-in M8 connectors (IP2041) or screw-in M12

connectors (IP2042). The outputs are short-circuit proof and protected against inverse connection.

Fieldbus Box I/O-Modules24 Version: 2.0.0

Page 25

I/O-Modules

Technical data IP2040-Bxxx / IE2040 IP2041-Bxxx / IE2041 IP2042-Bxxx / IE2042

Number of outputs 8

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Load type ohmic, inductive, lamp load

Nominal voltage 24 VDC (20 V ... 29 V)

Output current max. 2.0 A per channel, individually short-circuit proof, total current 12A:

- channels 0...3:S 4A

- channels 4...5:S4 A

- channels 6...7:S 4A

Short circuit current typical 4.0 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 2 x M8 connector, 4-pin; no downstream connection

Bits in process image 8 bits output

Electrical isolation control voltage/ fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 50 mA per channel

channels/ control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}101] for details of the connection.

See the mapping description [}153] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 25Version: 2.0.0

Page 26

I/O-Modules

3.1.2.4 IE2808

16 Channel Digital Output 24 VDC, I

= 2,0 A (total current max. 4A)

max

The IE2808 digital output module connects the binary control signals from the automation unit on to the

actuators at the process level. The 16 outputs handle load currents of up to 0.5 A each, although the total

current is limited to 4 A. This makes these modules particularly suitable for applications in which not all of the

outputs are active at the same time, or in which not all of the actuators draw 0.5 A current. An output shortcircuit is recognized and passed on to the controller. The signal state is indicated by means of light emitting

diodes. The signal connection is realized by the 25-pin D-sub socket. The outputs are short-circuit safe and

protected against inverse connection.

Via register R32 and R33 default values can be activated, this means these values are set when

communication is lost.

With R32 this error handling can be activated. In register R33 the value (On or OFF) is specified for every

output.

Fieldbus Box I/O-Modules26 Version: 2.0.0

Page 27

I/O-Modules

Technical data IE2808-0000 IE2808-0001

Number of outputs 8

Output connection D-sub socket, 25-pin, UNC tread

Load type resistance, inductive, lamp load

Rated load voltage 24 VDC (20V...29V)

Output current max. 0,5 A per channel, individually short-circuit safe, total current max.

4 A

Short circuit current maximal 1,5A

Load voltage current consumption typical 5mA per channel

Power supply Feed: 1 x M8 male socket, 4-pole

downstream connection: 1 x M8 female socket, 4-pole

Bits in process image 16 bit output, 16 bit input (diagnostic), optional: control/status byte

Reset of error display [}200]

Electrical isolation control voltage/ fieldbus: yes, via IP-Link

Permissible ambient temperature

during operation

Permissible ambient temperature

during storage

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN61000-6-2/ EN61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

manually automatically

channels / control voltage: no

between the channels: no

0°C ... +55°C

-25°C ... +85°C

See the connection diagramm [}110] for details of connection.

See the mapping description [}158] for details on the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 27Version: 2.0.0

Page 28

I/O-Modules

3.1.3 Digital Combi Modules

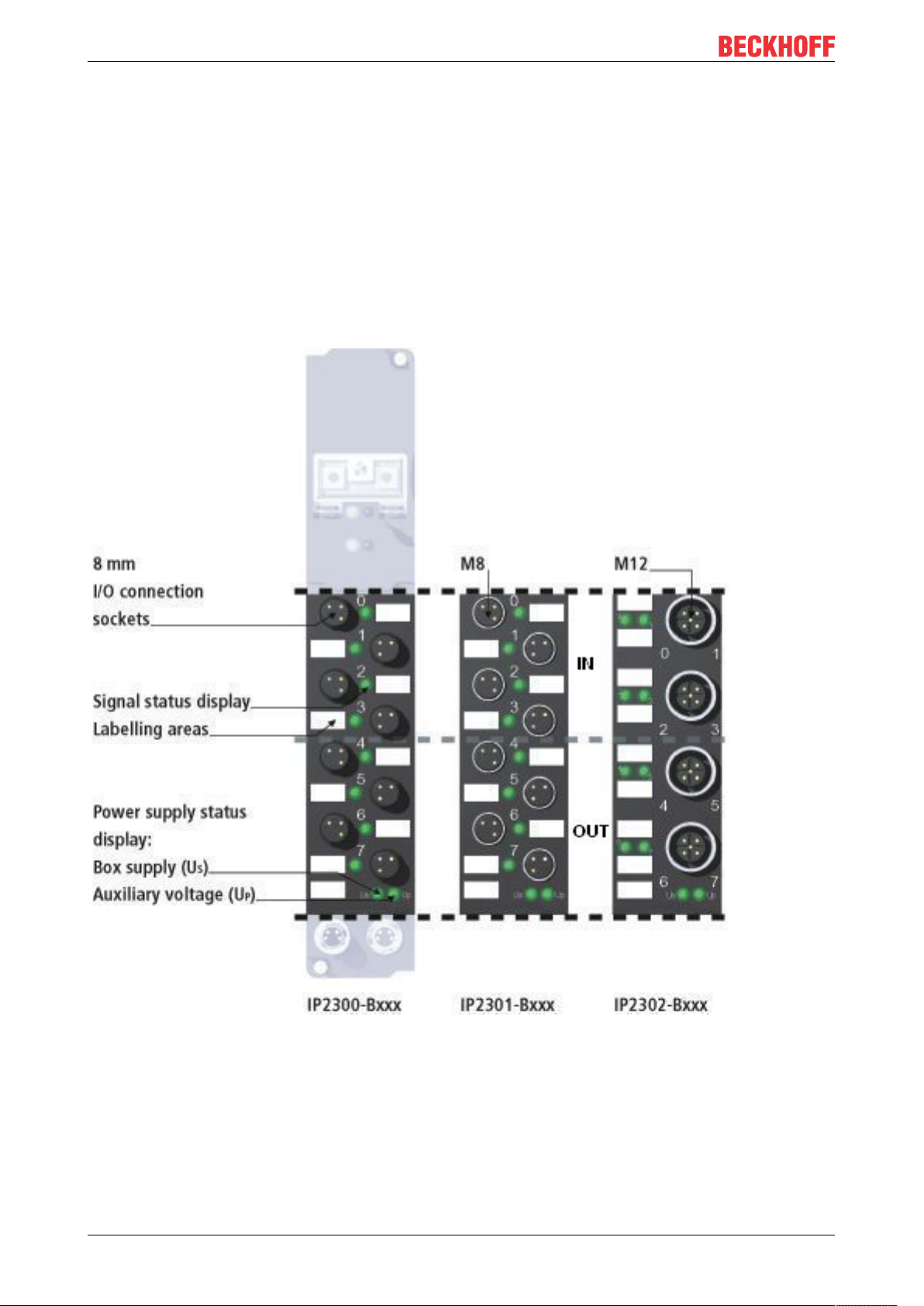

3.1.3.1 IP230x-Bxxx, IE230x

4 digital inputs (3.0 ms input filter) and 4 digital outputs, 24 VDC, I

The IP230x digital I/O modules combine 4 digital inputs with a 3 ms input filter and four digital outputs in one

device. The outputs handle load currents of up to 0.5A, are short-circuit proof and protected against inverse

polarity. The state of each signal is indicated by means of light emitting diodes. The signals are connected

optionally via 8mm snap-on plugs (IP2300), screw-in M8 connectors (IP2301) or screw-in M12 connectors

(IP2302).

=0.5 A

max

Fieldbus Box I/O-Modules28 Version: 2.0.0

Page 29

I/O-Modules

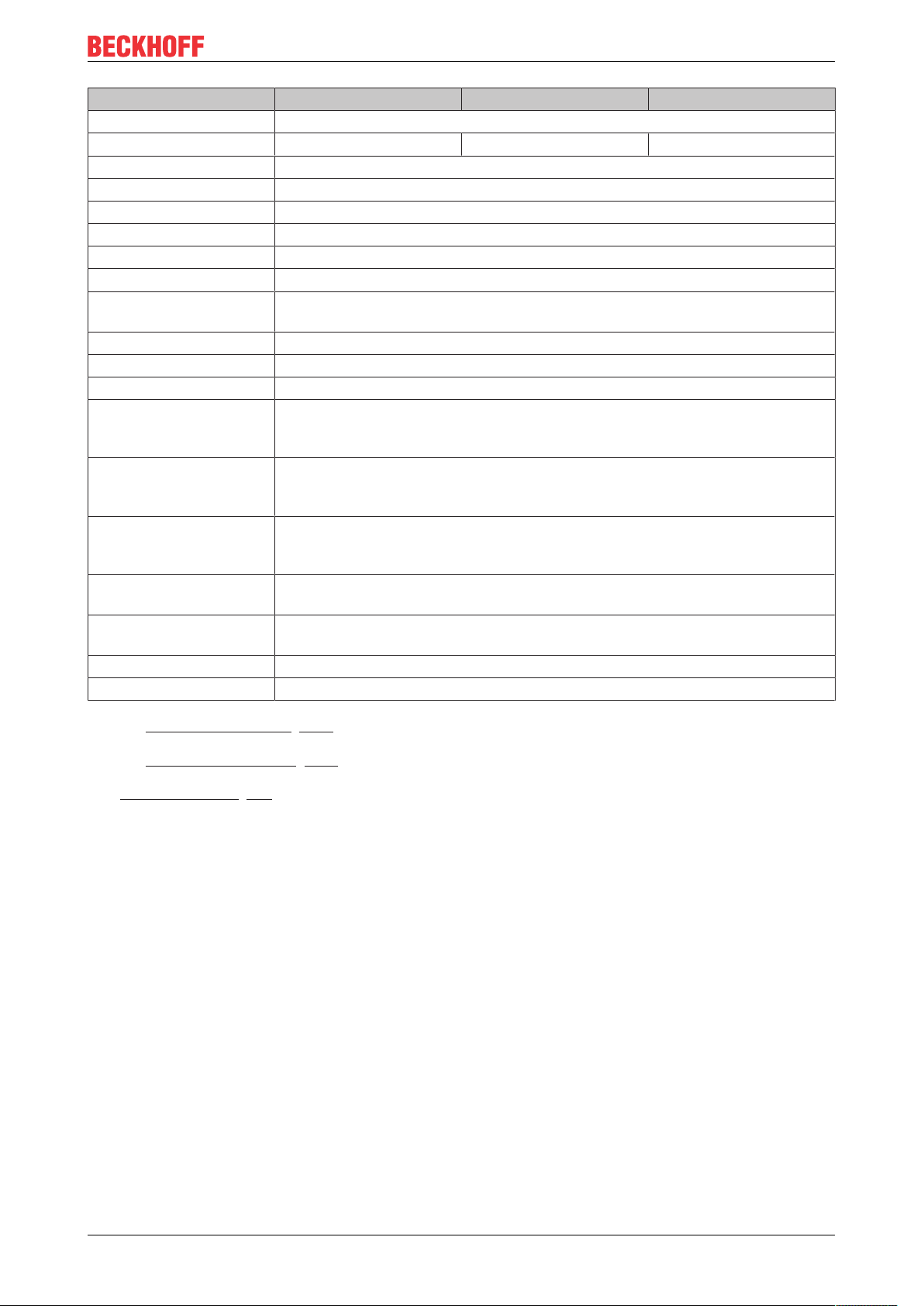

Technical data IP2300-Bxxx / IE2300 IP2301-Bxxx / IE2301 IP2302-Bxxx / IE2302

Number of outputs 4 inputs and 4 outputs

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 3.0 ms

Signals „0“ / „1“ -3 ... 5 V / 11 ... 30 V, 6 mA input current (EN61131-2, type 2)

Load type ohmic, inductive, lamp load

Rated load voltage 24 VDC (20 V ... 29 V)

Output current max. 0.5 A on each channel, individually short-circuit proof

Short circuit current typical 1.5 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 4 bits input and 4 bits output

Electrical isolation control voltage/ fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 20 mA per channel

channels/ control voltage: no,

between the channels: no,

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}102] for details of the connection.

See the mapping description [}154] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 29Version: 2.0.0

Page 30

I/O-Modules

3.1.3.2 IP231x-Bxxx, IE231x

4 digital inputs (0.2 ms input filter) and 4 digital outputs, 24 VDC, I

=0.5 A

max

The IP231x digital I/O modules combine 4 digital inputs with a 0.2 ms input filter and four digital outputs in

one device. The outputs handle load currents of up to 0.5 A, are short-circuit proof and protected against

inverse polarity. The state of each signal is indicated by means of light emitting diodes. The signals are

connected optionally via 8 mm snap-on plugs (IP2310), screw-in M8 connectors (IP2311) or screw-in M12

connectors (IP2312).

Fieldbus Box I/O-Modules30 Version: 2.0.0

Page 31

I/O-Modules

Technical data IP2310-Bxxx / IE2310 IP2311-Bxxx / IE2311 IP2312-Bxxx / IE2312

Number of outputs 4 inputs and 4 outputs

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 0.2 ms

Signals „0“ / „1“ -3... 5 V / 11 ... 30 V, 6 mA input current (EN61131-2, type 2)

Load type ohmic, inductive, lamp load

Rated load voltage 24 VDC (20 V ... 9 V)

Output current max. 0.5 A on each channel, individually short-circuit proof

Short circuit current typical 1.5 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 4 bits input and 4 bits output

Electrical isolation control voltage / fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 20 mA per channel

channels / control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram for details of the connection.

See the mapping description [}154] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Also see about this

2 IP231x-Bxxx, IE231x Signal Connection [}103]

Fieldbus Box I/O-Modules 31Version: 2.0.0

Page 32

I/O-Modules

3.1.3.3 IP232x-Bxxx, IE232x

4 digital inputs (3.0 ms input filter) and 4 digital outputs, 24 VDC, I

=2.0 A, total current 4 A

max

The IP232x digital I/O modules combine 4 digital inputs with a 3ms input filter and four digital outputs in one

device. The outputs handle load currents of up to 2.0A, are short-circuit proof and protected against inverse

polarity. The state of each signal is indicated by means of light emitting diodes. The signals are connected

optionally via 8mm snap-on plugs (IP2320), screw-in M8 connectors (IP2321) or screw-in M12 connectors

(IP2322).

Fieldbus Box I/O-Modules32 Version: 2.0.0

Page 33

I/O-Modules

Technical data IP2320-Bxxx / IE2320 IP2321-Bxxx / IE2321 IP2322-Bxxx / IE2322

Number of outputs 4 inputs and 4 outputs

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 3.0 ms

Signals „0“ / „1“ -3 ... 5 V / 11 ... 30 V, 6 mA input current (EN61131-2, type 2)

Load type ohmic, inductive, lamp load

Rated load voltage 24 VDC (20 V ... 29 V)

Output current max. 2.0 A each channel, individually short-circuit proof, total current 4 A

Short circuit current typical 4.0 A

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 4 bits input and 4 bits output

Electrical isolation control voltage/ fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 30 mA per channel

channels / control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram [}104] for details of the connection.

See the mapping description [}154] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 33Version: 2.0.0

Page 34

I/O-Modules

3.1.3.4 IP233x-Bxxx, IE233x

4 digital inputs (0.2 ms input filter) and 4 digital outputs 24 VDC, I

=2.0 A, total current 4 A

max

The IP233x digital I/O modules combine 4 digital inputs with a 0.2 ms input filter and four digital outputs in

one device. The outputs handle load currents of up to 2.0A, are short-circuit proof and protected against

inverse polarity. The state of each signal is indicated by means of light emitting diodes. The signals are

connected optionally via 8mm snap-on plugs (IP2330), screw-in M8 connectors (IP2331) or screw-in M12

connectors (IP2332).

Fieldbus Box I/O-Modules34 Version: 2.0.0

Page 35

I/O-Modules

Technical data IP2330-Bxxx / IE2330 IP2331-Bxxx / IE2331 IP2332-Bxxx / IE2332

Number of outputs 4 inputs and 4 outputs

Output connections Ø 8 snap on M8 screw-in M12 screw-in

Input filter 0.2 ms

Signals „0“ / „1“ -3... 5 V / 11 ... 30 V, 6 mA input current (EN61131-2, type 2)

Load type ohmic, inductive, lamp load

Rated load voltage 24 VDC (20 V ... 29 V)

Output current max. 2.0 A each channel, individually short-circuit proof, total current 4 A

Short circuit current typical 4.0 A per channel

Load voltage current

consumption

Sensor supply derived from the control voltage, max. 2.0 A per channel, fully short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket, 4-pin

Bits in process image 4 bits input and 4 bits output

Electrical isolation control voltage/ fieldbus: yes

Permissible ambient

temperature during

operation

Permissible ambient

temperature during

storage

Vibration / shock

resistance

EMC resistance burst /

ESD

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

typical 30 mA

channels/ control voltage: no

between the channels: no

0°C ... +55°C

-25 °C ... +85°C

conforms to EN60068-2-6/ EN60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

See the connection diagram for details of the connection.

See the mapping description [}154] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Also see about this

2 IP233x-Bxxx, IE233x Signal Connection [}105]

Fieldbus Box I/O-Modules 35Version: 2.0.0

Page 36

I/O-Modules

3.1.3.5 IP240x-Bxxx, IE240x

8 digital inputs (3.0 ms input filter) and 8 digital outputs 24 VDC, I

=0.5 A

max

The IP240x digital I/O modules have 8 channels that can be used either as inputs or as outputs. The device

can therefore be flexibly adapted to the requirements of the application. The signals are connected optionally

through snap-on 8 mm connectors (IP2400) or through screw-in M8 connectors (IP2401), both of which have

4 pins (with separate input and output pins). This makes it possible to connect antivalent sensors. Adapter

cables are available for use in input-only or output-only cases, as well as connectors for field assembly. It is

also possible to use the power supply cable directly as the sensor cable. The outputs handle load currents of

up to 0.5A, are short-circuit proof and protected against inverse polarity. The state of each signal is

indicated by means of light emitting diodes.

Fieldbus Box I/O-Modules36 Version: 2.0.0

Page 37

I/O-Modules

Technical data IP2400-Bxxx / IE2400 IP2401-Bxxx / IE2401

Number of outputs 8 inputs and 8 outputs

Output connections Ø 8 snap on M8 screw-in

Input filter 3.0 ms

Signals „0“ / „1“ -3 ... 5 V / 11 ... 30 V, 6 mA input current (EN61131-2, type 2)

Load type ohmic, inductive, lamp load

Rated load voltage 24 VDC (20 V ... 29 V)

Output current max. 0.5 A on each channel, individually short-circuit proof

Short circuit current typical 1.5 A

Load voltage current consumption typical 20 mA per channel

Sensor supply derived from the control voltage, max. 0.5 A per channel, fully short-

circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream connection: 1 x M8 socket,

4-pin

Bits in process image 8 bits input and 8 bits output

Electrical isolation control voltage/ fieldbus: yes

channels/ control voltage: no

between the channels: no

Permissible ambient temperature

during operation

Permissible ambient temperature

during storage

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

0°C ... +55°C

-25 °C ... +85°C

See the connection diagram for details of the connection.

See the mapping description [}155] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Also see about this

2 IP240x-Bxxx, IE240x Signal Connection [}106]

Fieldbus Box I/O-Modules 37Version: 2.0.0

Page 38

I/O-Modules

3.1.3.6 IE2403

8 digital inputs (3.0 ms input filter) and 8 digital outputs 24 VDC, Imax=0.5 A

The digital IE2403 combi module has 16 channels with 8 inputs and 8 outputs. The device can therefore be

flexibly adapted to the requirements of the application. The outputs handle load currents of up to 0.5 A. They

are short-circuit-proof and protected against inverse polarity. KM-connectors with a spring-loaded system are

used for the signal connection. These connectors are optionally available with 1 or 3 pins. The module is

supplied without KM-connectors.

NOTE

Attention

The IE2403 combi module conforms to protection class IP20. It is intended to be used within switch boards,

control panels or switch cabinets to integrate their signals into IP link.The IE2403 combi module conforms

not to protection classes IP65/IP67!

Fieldbus Box I/O-Modules38 Version: 2.0.0

Page 39

I/O-Modules

Technical data IE2403

Number of channels 16 (8 inputs and 8 outputs)

Input connections Via KM connector ZS2001 (not included in delivery of

IE2403).

Please order the desired type for single- or tree-wire

technique (see ordering information [}125] and

technical data [}126]).

Input filter 3.0ms

Signals „0“ / „1“ -3 ... 5 V / 11 ... 30 V, 6mA input current

(EN61131-2, type 2)

Sensor supply derived from the control voltage, max. 0.5 A per

channel, fully short-circuit proof

Output connections Via KM connector ZS2001 (not included in delivery of

IE2403).

Please order the desired type for single- or tree-wire

technique (see ordering information [}125] and

technical data [}126]).

Rated load voltage 24 VDC (20 V ... 29 V)

Load type ohmic, inductive, lamp load

Output current max. 0.5 A on each channel, individually short-circuit

proof

Short circuit current typical 1.5 A

Load voltage current consumption typical 20mA per channel

Power supply Feed: 1 x M8 connector, 4-pin

downstream connection: 1 x M8 socket, 4-pin

Bits in process image 8 bits input and 8 bits output

Electrical isolation control voltage/ fieldbus: yes, via IP-Link

channels/ control voltage: no

between the channels: no

Permissible ambient temperature during operation 0°C ... +55°C

Permissible ambient temperature during storage -25°C ... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN61000-6-2/ EN61000-6-4

Protection class IP20

Mounting position any

See the connection description [}107] for details of the connection.

See themapping description [}155] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 39Version: 2.0.0

Page 40

I/O-Modules

3.1.4 Analog Input Modules

3.1.4.1 IP3102-Bxxx, IE3102

4 Channel Analog Input ± 10 V

The IP3102 analog input module handles signals in the range from -10 V to +10 V. The voltage is digitized to

a resolution of 16 bits, and is transmitted, electrically isolated, to the higher-level automation device. The

input channels have differential inputs and possess a common, internal ground potential. The applied load

voltage (which can be any value up to 30 VDC) is fed through to supply the sensor. It is thus possible, for

instance, to supply a measuring potentiometer with 10 VDC from an external voltage source. The module is

quite versatile, but default settings have been selected in such a way that in most cases it is not necessary to

perform configuration. The input filter and associated conversion times can be set within a wide range, and

several data output formats may be chosen. The inputs can, if required, be scaled differently, and automatic

limit monitoring is also available. Parameterization may be carried out either via the fieldbus or using the

KS2000 software tool.

Fieldbus Box I/O-Modules40 Version: 2.0.0

Page 41

I/O-Modules

Technical data IP3102-Bxxx / IE3102

Number of channels 4 analog inputs

Output connections M12 screw-in

Nominal input range -10 V ... +10 V

Input resistance > 100 kΩ

Common mode voltage 35 V max.

Conversion time 250 ms (default), configurable to 5 ms

Resolution 15 bits + arithmetic sign

Relative measurement error < ± 0,3% of the full scale value

Input filter 10 variations inc. averaging, configurable

Sensor supply from load supply voltage UP, DC, any value up to 30

V

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image I: 4 x 16 bits, optional I/O: 4 x 8 bits control/state + 4

x 16 bits

Electrical isolation control voltage/ fieldbus: yes

channels/ control voltage: 500 V

between the channels: no

Permissible ambient temperature during operation 0°C ... +55°C

Permissible ambient temperature during storage -25 °C ... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See the Connection diagram [}111] for details of the connection.

See the Parameterization description [}206] for details of the parameterization.

See the Mapping description [}159] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 41Version: 2.0.0

Page 42

I/O-Modules

3.1.4.2 IP3112-Bxxx, IE3112

4 Channel Analog Input, from 0 to 20 mA

The IP3112 analog input module handles signals in the range from 0 to 20 mA. The input current is digitized

to a resolution of 16 bits (the default is 15 bits), and is transmitted, electrically isolated, to the higher-level

automation device. The input channels have differential inputs and possess a common, internal ground

potential. The applied load voltage (which can be any value up to 30 VDC) is fed through to supply the sensor.

The module is quite versatile, but default settings have been selected in such a way that in most cases it is

not necessary to perform configuration. The input filter and associated conversion times can be set within a

wide range, and several data output formats may be chosen. The inputs can, if required, be scaled

differently, and automatic limit monitoring is also available. Parameterization may be carried out either via

the fieldbus or, using the KS2000 software tool, through the configuration interface. The parameters are

stored in the module.

Fieldbus Box I/O-Modules42 Version: 2.0.0

Page 43

I/O-Modules

Technical data IP3112-Bxxx / IE3112

Number of channels 4 analog inputs

Output connections M12 screw-in

Nominal input range 0 ... 20 mA

Input resistance 80 Ω measuring resistance

Common mode voltage max. 35 V

Conversion time 140 ms

Resolution 15 bits + arithmetic sign

Relative measurement error < ± 0,3% of the full scale value

Input filter 10 variations inc. averaging, configurable

Sensor supply from load supply voltage Up, DC, any value up to 30

V

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image I: 4 x 16 bits, optional I/O: 4 x 8 bits control/state + 4

x 16 bits

Electrical isolation control voltage/ fieldbus: yes

channels/ control voltage: 500V

between the channels: no

Permissible ambient temperature during operation 0°C ... +55°C

Permissible ambient temperature during storage -25 °C ... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See the connection diagram [}112] for details of the connection.

See the parameterization description [}213] for details of the parameterization.

See the mapping description [}161] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 43Version: 2.0.0

Page 44

I/O-Modules

3.1.4.3 IP3202-Bxxx, IE3202

4 Channel Analog Input PT100 (RTD)

The IP3202 analog input module allows resistance sensors to be connected directly. The module's circuitry

can operate the sensors using 2-wire or 4-wire connection techniques. Linearization over the full temperature

range is realized with the aid of a microprocessor. The temperature range can be selected freely. The

module can also be used for resistance measurement, with the output in ohms. The module's standard

settings are: Resolution 0.1 °C in the temperature range of PT100 sensors in 4-wire connection. Sensor

malfunctions such as broken wires are indicated by error LEDs. The module is quite versatile, but default

settings have been selected in such a way that in most cases it is not necessary to perform configuration.

The input filter and associated conversion times can be set within a wide range, and several data output

formats may be chosen. The inputs can, if required, be scaled differently, and automatic limit monitoring is

also available. Parameterization may be carried out either via the fieldbus or using the KS2000 software tool.

Fieldbus Box I/O-Modules44 Version: 2.0.0

Page 45

I/O-Modules

Technical data IP3202-Bxxx / IE3202

Number of channels 4 analog inputs

Output connections M12 screw-in

Nominal input range PT100, PT200, PT500, PT1000, Ni100, Ni120,

Ni1000, resistance measurement (e.g. potentiometer)

Resolution 0.1°C per digit

Measuring current typical 0.5 A

Conversion time 260 ms

Measurement error < +/-1°C

Input filter 4 versions

Sensor supply From the load voltage, U

S

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image I: 4 x 16 bits, optional I/O: 4 x 8 bits control/state + 4

x 16 bits

Electrical isolation control voltage/ fieldbus: yes

channels/ control voltage: 500V

between the channels: no

Permissible ambient temperature during operation 0°C ... +55°C

Permissible ambient temperature during storage -25 °C ... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See the connection diagram [}113] for details of the connection.

See the parameterization description [}219] for details of the parameterization.

See the mapping description for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 45Version: 2.0.0

Page 46

I/O-Modules

3.1.4.4 IP3312-Bxxx, IE3312

4 Channel Analog Input Thermocouple

The IP3312 analog input module permits four thermocouples to be directly connected. The module's circuit

can operate thermocouple sensors using the 2-wire technique. Linearization over the full temperature range

is realized with the aid of a microprocessor. The temperature range can be selected freely. The module can

also be used for voltage measurements in the mV range. The module's standard settings are: Resolution 0.1

°C over the temperature range of type K sensors. Sensor malfunctions such as broken wires are indicated by

error LEDs. Compensation for the cold junction is made through a temperature measurement in the

connecting plug. This means that standard extension leads can be connected.

The module is quite versatile, but default settings have been selected in such a way that in most cases it is

not necessary to perform configuration. The input filter and associated conversion times can be set within a

wide range, and several data output formats may be chosen. The inputs can, if required, be scaled

differently, and automatic limit monitoring is also available. Parameterization may be carried out either via

the fieldbus or using the KS2000 software tool.

Fieldbus Box I/O-Modules46 Version: 2.0.0

Page 47

I/O-Modules

Technical data IP3312-Bxxx / IE3312

Number of channels 4 analog inputs

Output connections M12 screw-in

Nominal input range Types J, K, L, B, E, N, R, S, T, U (default setting type

K), mV measurement

Resolution 0.1°C per digit

Conversion time 260 ms

Measurement error < +/- 0.5 % (of the full scale value)

Input filter 4 versions

Cold junction compensation via ZS2000-3712

Sensor supply From the load voltage, U

S

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image I: 4 x 16 bits, optional I/O: 4 x 8 bits control/state + 4

x 16 bits

Electrical isolation control voltage/ fieldbus: yes

channels/ control voltage: 500 V

between the channels: no

Permissible ambient temperature during operation 0°C ... +55°C

Permissible ambient temperature during storage -25 °C ... +85°C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See the connection diagram [}115] for details of the connection.

See the parameterization description [}228] for details of the parameterization.

See the mapping description for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 47Version: 2.0.0

Page 48

I/O-Modules

3.1.5 Analog Output Modules

3.1.5.1 IP4112-Bxxx, IE4112

4 Channel Analog Output, from 0 to 20 mA

The IP/IE4112 analog output module generates analog output signals in the range from 0 to 20mA. The

power is supplied to the process level with a resolution of 15bits (default), and is electrically isolated. If the

input is transmitted without an arithmetical sign, 16 bit resolution may also be selected. If necessary, the

output scaling can be altered.

Ground potential for the four output channels is common with the 24VDC supply. The output drivers are

powered by the control voltage. The applied load voltage (which can be any value up to 30VDC) is fed

through to supply the actuators.

Fieldbus Box I/O-Modules48 Version: 2.0.0

Page 49

I/O-Modules

Technical data IP4112-Bxxx, IE4112

Number of channels 4

Output connections M12 screw-in

Output range 0 ... 20 mA

Load impedance < 500 Ω

Resolution 15 bit, configurable to 16 bit

Conversion time < 4 ms

Accuracy < ± 0.1% of the full scale value

Actuator power supply from the load voltage, U

P

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image O: 4 x 16 bits data, optional: 4 x 8 bits control/status

Electrical isolation control voltage/ fieldbus: depends on the bus system

channels/ control voltage: yes

between the channels: no

Permissible ambient temperature during operation 0 °C ... 55 °C

Permissible ambient temperature during storage -25 °C ... + 85 °C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See connections [}116] for connection details.

See the parameterization description [}236] for details of the parameterization.

See the mapping description [}167] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 49Version: 2.0.0

Page 50

I/O-Modules

3.1.5.2 IP4132-Bxxx, IE4132

4 Channel Analog Output, from -10V to +10V

The IP/IE4132 analog output module generates analog output signals in the range from -10V to + 10V. The

voltage is supplied to the process level with a resolution of 16bits, and is electrically isolated. If necessary,

the output scaling can be altered.

Ground potential for the four output channels is common with the 24VDC supply. The output drivers are

powered by the control voltage. The applied load voltage (which can be any value up to 30VDC) is available

for supply of the actuators.

Fieldbus Box I/O-Modules50 Version: 2.0.0

Page 51

I/O-Modules

Technical data IP4132-Bxxx

Number of channels 4

Output connections M12 screw-in

Output range -10 V/ 0 ... 10 V

Load impedance > 5 kΩ

Resolution 16 bit

Conversion time < 4 ms

Accuracy < ± 0.1% of the full scale value

Actuator power supply from the load voltage, U

P

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin

Bits in process image O: 4 x 16 bits data, optional: 4 x 8 bits control/status

Electrical isolation control voltage/ fieldbus: depends on the bus system

channels/ control voltage: yes

between the channels: no

Permissible ambient temperature during operation 0 °C ... 55 °C

Permissible ambient temperature during storage -25 °C ... + 85 °C

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IIP65, IP66, IP67 (conforms to EN 60529)

Installation position variable

See the connection diagram [}117] for details of the connection.

See the parameterization description [}241] for details of the parameterization.

See the mapping description [}244] for details of the mapping.

See dimension page [}68] for weight and dimensions.

Fieldbus Box I/O-Modules 51Version: 2.0.0

Page 52

I/O-Modules

3.1.6 Modules for Special Functions

3.1.6.1 IP1502-Bxxx, IE1502

Counter module

The counter module has two fast counters running at up to 100 kHz. It counts binary pulses, and transmits

the counter state to the higher-level automation unit. The Up/Down input allows the counters to be switched

between upwards and downwards counting (in 32 bits). The gate signals (gate inputs) allow the counters to

be triggered: depending on the level at the gate input, the counting function is halted or enabled. The outputs

can be switched or pulsed depending on the counter state, and can therefore be used as fast control signals

for field devices. From the controller it is possible to set the counter state, to start or halt the counter

functions, and to set the outputs. The module shows the states of the input and output signals by means of

light emitting diodes.

Fieldbus Box I/O-Modules52 Version: 2.0.0

Page 53

I/O-Modules

Technical data IP1502-Bxxx / IE1502

Number of counters 2, each with a depth of 32 bits

Switching frequency 100 kHz (2 kHz when switching between up and

down)

Signal connection M12 screw-in

Number of inputs 2 counter inputs, 2 gate inputs, 2 up/down

changeovers

Nominal input voltage 24 VDC (20V...29V)

Signal voltage "0" -3V...5V (EN61131-2, type 2)

Signal voltage "1" 11V...30V (EN61131-2, type 2)

Number of outputs one output per counter, max. 0.5A, short circuit proof

Sensor supply derived from control voltage, max. 0.5A over all,

short-circuit proof

Power supply Feed: 1 x M8 connector, 4-pin; downstream

connection: 1 x M8 socket, 4-pin